Page 1

INDUSTRIAL

FINEST

OUAUTY

LEWIS

.

COLUMBIA

INSTRUCTIONS

FOR

INSTALLING

AND

STREAMLINED,

FLAT

BED

OPERATING

HIGH

MACHINES

MACHINES

SPEED

CATALOG

No.

89

Second

Edition

VmlonxSp^jcuaZ.

1

1

\

51200

51300

51400

51500

51600

51700

CHICAGO

CLASSES

51800

51900

52100

52400

52700

52800

52900

machine

53100

53500

53700

53800

54200

54400

COMPANY

Page 2

CATALOG

No.

89

Rights

Union

Reserved

INDUSTRIAL

MACHINE

Printed

Second

Copyri

Special

CHICAGO

Edition

ght19

by

in

SE

W'l

COMPANY

in

5 5

Machine

All

NG

MACHINES

U.

S.

Co.

Countries

A.

Page 3

FOREWORD

Union

Flat

equipment.

Maximum

possible

mechanisms,

simplified

returning

Special's

Bed

Machines

speed

with

by

filtered

interchangeability

of

all

parts.

Our

information

advantages

contain

50000

Additional

are

constant

valuable

machines.

available

Catalog

51200,

Catalog

Catalog

Catalog

Catalog

53700,

Catalog

54200, 54400,

Catalog

Form

Instructions,

Adjusting

so

from

catalogs,

upon

No,

No,

No, 97

No, T97

No. 100 L

No, 102 L

No,

357

50000

is

the

and

light

and

automatic

purpose

presser

oil

is

assured

customers

their

installing

containing

your

104

51300,

111Lfor

Nfor

53800,

45

Engineering

Instructions

Series

latest

lowest

weight

to

is

Union

request.

L

51400,

Pfor

(Second

(Second

Needle

Please

of

Streamlined

design

cost

needle

bars.

lubrication,

main

by

to

reservoir.

precision

supply

can

Specials.

and

operating

specialized

Please

(Second

Class

Class

Class

Edition)

51500, 51700, 51900,

52900.

52900,

Edition)

Edition)

Manual.

Department

specify

are

in

industrial

production

bars,

Maintenance

with

manufacturing

carefully

secure

data

ask

52800.

(FrontDisposal)

(RearDisposal)

Style

required.

Highspeed

sewing

are

made

driving

a

pump

Complete

prepared

all

possible

These

for

pages

Class

information,

for:

for

Classes

for

Classes

for

Classes

Adjusting

for

which

is

for

Union

Special

manufacturing

plan

and

estimate

representatives

centers,

requirements.

anxious

lJ/rUOnSp€Cicl£.

will

to

be

cooperate

machine

Engineering

found

with

company

Department

in

you

all

to

Page 4

Page 5

1

Page 6

Page 7

INSTALLING

GENERAL

Fig.

merged

Drive."

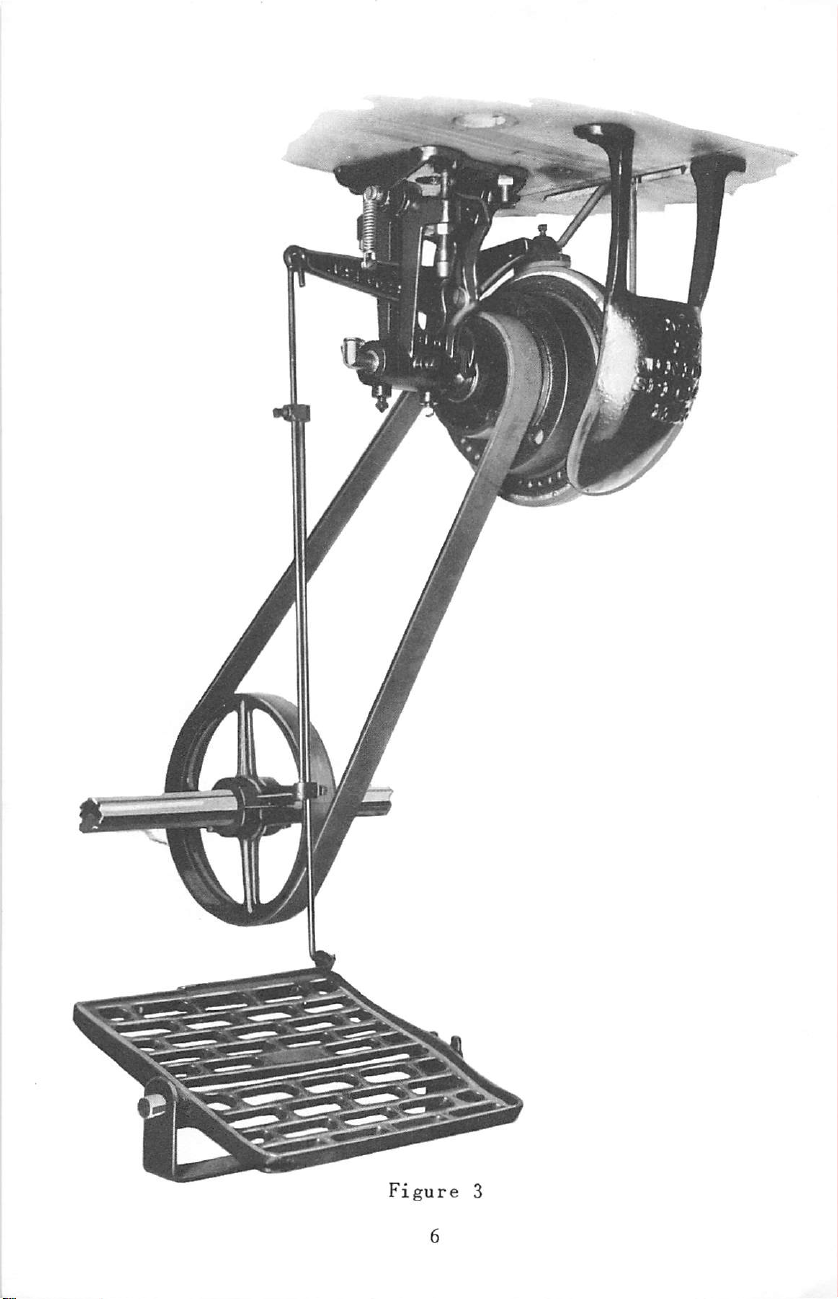

Fig.

merged

Direction

Fig.

No.

MACHINE READY TO

Before

run

sewn

fully

CAUTION!

When

the

these

threads

is

long

1,

2,

3,

28636

in,

sample

packed,

removing

threads.

loose

safe

as

PLAN

page

4,

individual

Direction

page

5|

pedestal

machine

page

6,

AA.

shipment

accurately

in

ends

thru

machine,

to

turn

it

is

your

machine

Operator

turned

shows

power

machine

shows

installation

rotates

shows

OPERATE

each

Union

adjusted,

machine

Union

to

the

machine

in

the

table

the

the

is

from

can

new

and

pulley

proper

general

rotates

general

with

is

indicated

Union

Special

carefully

evidence

Special

its

use

threads

they

plan

installation

is

plan

"Electro

Special

machine

of

arrives

shipping

this

threading.

to

are

ready

one

or

direction.

of

a

semisub-

with

indicated

of

a

semisub-

Drive."

by

arrow.

Transmitter

is

inspected.

this

work.

ready

box,

be

used.

for

two

revolutions,

"Electro

by

thoroughly

Test

Skill

to

operate.

do

not

Merely

Draw

sewing.

arrow.

remove

tie

It

as

Page 8

TABLE

For

Union

TOPS

either

Special

properly

The

following

vidual

immediate

Dimensions

Designs

bored.

power

shipment:

group

has

finished

table

INSTALLING

or

individual

prepared

installations

-

Lengths,

and

20

-

For

nonsubmerged,

table,

For

nonsubmerged,

table,

with

For

semisubmerged,

table,

For

semisubmerged,

table,

with

For

fully

table,

For

nonsubmerged,

installations

For

nonsubmerged,

installations,

For

semisubmerged,

installations

For

semisubmerged,

installations,

For

fully

installations

For

fully

installations,

wood

inches;

"Electro

"Electro

Class

"Electro

"Electro

Class

"Electro

power

table

tops,

table

are

48

and

thickness,

21700

21700

submerged,

with

with

submerged,

submerged,

with

table

with

tops

for

available

60

inches;

individual

Drive"

individual

Drive"

puller

individual

Drive"

individual

Drive"

puller

individual

Drive"

group,

group,

Class

group,

group,

Class

group,

Class

installations,

all

group

widths,

1-3/4

installations

installations,

installations

installations,

installations

transmitter

transmitter

21700

transmitter

transmitter

21700

group,

transmitter

21700

holes

or

indi

for

16

inches.

power

power

power

power

power

puller.

puller

transmitter

puller.

It

is

better

submerged

For

the

prepared

or

E1400

two

Semisubmerged

Dimensions

For

group

ordinary

installations,

construction

to

install

fully

pedestal

table

or

fully

-

submerged

installation.

tops,

submerged

Length,

thickness,

can

new

with

any

prepared

installation.

all

42

inches;

1-1/4

sewing

be

used.

8

holes

table

inches.

table

Union

properly

tops

width,

machine

tops

Spe-cial

are

20

inches;

table

for

semi-

has

bored.

available.

of

Page 9

INSTALLING

INDIVIDUAL

Individual

closed

assembly

Fig.

No.

plete

are

lifter

DIRECTIONS:

treadle

Assemble

this

to

top

curely

ready

PEDESTALS

with

1, page

21371

individual

shown;

point

holes

support

for

o£

treadle

support

isolators

provided.

fasten

POWER

power

each

stand

4,

NK

is

such

First

invert

members.

sewing

TABLES

tables

stand

and

sho>»s

for

power

as

No.

tube,

table

braces.

machine.

are

No.

table

an

stand

table

table

29480

assemble

cross

in

table

top

Assemble

Square

Attach

shipped

21371

top

(PL277).

assembled

only.

installation,

top,

drawer

AA.

table

braces,

top

support

and

table

legs

drawer.

NK

is

power

To

top

attach

top

with

"knocked

a

sketch

table.

illustrate

No.

21371

support

according

members.

"Electro

to

isolators

table

Now

down."

other

top;

table

showing

Symbol

a com

items

Q,

foot

members,

to

PL277.

At

Drive"

se

is

En

in

Union

Special

pedestals

page 5, shows an assembled

is

also

D1400,

for

circular

BELTS

Machines

endless

made

"Electro

reasonable

For

mended

belt

another

which

a

shorter

No.

in

specified

group

for

is

recommended

style

is

identical

machine

operations.

with

1

Drive"

variations

"Electro

"V"

has

installations,

driving

of

support

Drive"

belt.

circumferences.

a

belt

in

transmitter,

for

are

pedestal.

Union

with

No.

belt

a 1

driving

shipped

Special

the

arm

which

are

equipped

21261

take-up

circumferences.

inch

flat

anda9/32

machine.

assembled.

Fig.

No. E1400. There

pedestal.

illustration

facilitates

M.

These

Hanger

to

compensate

belt

supporting

to

belts

is

inch

except

run

recom

round

2,

No.

an

are

for

Page 10

SPEEDS

The

speed

ciently

tors

are

material

operation

at

is

affected

length

to

needle

performed.

INSTALLING

which-your

by many

of

run,

penetration,

machines

variable

kind

of

can

be

factors.

material,

skill

operated

of

operator,

Such

resistance

effi

fac

of

and

Please

Instructions,

PULLEY

Speed

"Electro

Safety

will

variations

Table

give

Working

"Electro

sizes

"

sizes

ranging

Electro

ranging

American

inch

Machine

diameter.

sizes

refer

DIAMETERS

to

Form

Drive"

Transmitter

a

speed

diameters

Drive"

from

Drive"

from

Safety

ranging

pulley

our

are

pulleys,

closest

of

"V*

round

Table

for

Engineering

357,

for

secured

line

pulleys.

various

belt

2-1/8

through

belt

1-3/4

through

Transmitter

from 6

No. 1

'"V"

your

by

shaft

to

that

pulleys

pulleys

pulleys

through

or

Department

particular

using

varying

pulleys,

Select

required.

are:

are

made

4-1/2

inches

are

6-1/2

inches

pulleys

10-1/2

round

belt,

Adjusting

a

made

are

inches

machine.

sizes

or

American

size

in

1/8

diameters.

in

1/4

diameters.

made

diameters.

2-1/2

that

inch

in

inches

of

inch

1/2

Machine

pulley

Transmitter

Transmitter

diameter.

Transmitter

diameter.

Flat

8,

13-1/2,

9,

belt

9-1/2,

14,

driving

driven

driven

line

14-1/2,

10,

for

No.2"V"belt,

pulley,

pulley,

pulley,

shaft

pulleys.

10-1/2,

and

15

11,

7

inches

small

large

No.

11-1/2,

inches

10

2-3/4

diameter.

cone,

cone,

28601,

12,

diameters.

inches

3-3/4

5-3/4

are

12-1/2,

diameter.

inches

inches

made

in

13,

6,

Page 11

INSTALLING

ELECTRO

PROBLEM:

DRIVE

required

pulley

no

RULE:

of

driving

and

allowance

Diameter

machine, times

pulley

EXAMPLE:

ELECTRO

The

except

(3%

driving

DRIVE

rule

for

allowance

pulley

WITH

To

find

speed

on

diameter

for

of

R.P.M.

4600

R.P.M.

2-1/2

3500

R.P.M.

Then

required

4600X2-1/2^

WITH

is

the

the

addition

for

for

"V"

diameter

sewing

of

belt

driving

diameter

inches

3500

ROUND

same

slippage).

"Electro

BELT

machine

machine

slippage.

equals

equals

equals

diameter

BELT

as

"Electro

ofa97%

of

driving

pulley

pulley

of

machine

required

diameter

speed

equals

Required

Drive"

when

equals

of

3-1/4

Drive"

belt

with

pulley

R.P.M.

are

pulley,

speed

of

of

driving

driving

inches.

with

efficiency

diameter

round

to

of

known,

required

of

machine

pulley

"V"

produce

driving

with

speed

divided

machine

pulley

pulley

is:

belt,

factor

of

belt

is:

by^

AMERICAN

Rule

is

4600X2-1/2

3500

SAFETY

the

same

X

TABLE

as

.97

DRIVE

"Electro

equals

Drive"

11

3-1/2

with

inches.

round

belt.

Page 12

INSTALLING

UNION

RULE:

speed

diameter

eter

shaft,

SPECIAL

Diameter

of

of

times

EXAMPLE:

INDIVIDUAL

TRANSMITTER

machine,

of

transmitter

transmitter

94%.

4600

R.P.M.

2-1/2

pulley

3-3/4

mitter

7

inches

pulley

500

R.P.M.

94%

equals

slippage)

Required

POWER

of

times

inches

inches

7 X

TABLES

line

shaft

diameter

driven

driving

equals

equals

equals

pulley

equals

equals

belt

diameter

500

X

AND MACHINE

DRIVE

pulley

pulley,

pulley,

required

diameter

diameter

diameter

speed

efficiency

for

.94

of

line

machine

times

of

of

equals

equals

divided

speed

of

of

driving

line

(6%

shaft

required

pulley,

by

R«P.M.

of

machine

driven

driven

transmitter

shaft

allowance

pulley

13

inches.

times

diam

of

line

machine

trans

for

is:

Because

bored,

Merely

top;

PEDESTALS

assembly

assemble

then

Assembly

individual

Union

of

Special

mount

AND MACHINE

machines

power

of

machines

isolators

machine

tables.

table

to

tops

to

in

their

on

isolators.

pedestals

12

have

table

proper

is

all

tops

the

necessary

is

very

places

same

as

holes

simple.

in

table

for

Page 13

INSTALLING

UNION

These

with

Insert

front

securely.

SPECIAL

instructions

all

1/4

right

Transmitter

tension

rear

frame

lock

Now

bind.

both

1-1/4

ing

about

No.

cone

hand

ride

and

1/2

nuts

place

Measure

line

inch

transmitter

ends

21350,

and

to

crowns

transmitter

pulley.

mitter

to

tighten

holes

inch

hole

This

is

on

the

tighten

inch

to

retain

pulley

shaft

short

on

making

that

check

evenly,

and

When

table

lineshaft

TRANSMITTER

assume

bored.

bolt

of

is

sufficient

from

transmitter

equipped

flat

belt.

front

out

on

length

belt

of

vertical,

adjustment.

line

of

pulley

to

allow

frame.

cone;

drive

sure

teeth

whether

set

are

error

at

the

correctly;

by

placing

belt

pulley.

AND

the

top

with

shaft;

flat

and

ample

Place

in

lacing

well

can

same

MACHINE

use

of

side

over

for

holding

a

pivot

To

use

adjusting

toward

tighten

belt

transmitter

tension

belt

malleable

conforms

clinched.

runs

be

time

true.

corrected

laterally

permanently

screws

a new

of

bolt;

frame

this

needed

around

in

remaining

table.

temporarily.

feature,

screws.

line

only

to

pulley;

without

line

iron

to

curvature

Turn

If

pulley

secure

table

Place

tighten

for

Then

shaft.

enough

go

belt

pulleys

by

turning

moving

top

regulating

loosen

swing

Fasten

to

around

cut

belt

readjust

shaft

and

lacing

of

by

fails

line

trans

holes;

to

shaft

Assemble

Measure

transmitter

short;

necessary

direction

Oil

was

necessary

cup

at

But

first

escape

is

held

through

retain

isolators

length

fasten

to

of

drained

to

left

remove

during

loosely

cup

oil

pulley

cross

sewing

refill

end

at

in

of

with

from

of

plug

filling.

over

left

shaft.

in

table

round

and

machine

belt

round

machine.

transmitter

transmitter

transmitter

at

right

end.

belt

hook

belt

right

Entire

opening

Quickly

top;

needed

pulley.

No.

to

shaft

end

shaft

13

mount

21351.

acquire

before

before

of

while

replace

to

is

shaft

can

machine

go

around

Cut

belt

It

may

correct

shipment,

applying

for

this

to

be

filled

oil

right

is

on

isolators.

both

1

be

rotation

so

power.

purpose.

allow

put

end

inch

it

air

if

in

plug

is

Oil

to

thumb

to

Page 14

INSTALLING

UNION

Remove

SPECIAL

tape

assembly

Assembly.

Fasten

transmitter

For

pulley

average

directly

give

a

comfortable

for

operator

pitman

Next,

mitter

than

AMERICAN

rod

fasten

treadle,

transmitter

Installation

stantially

set

of

pulleys.

leading

shaft.

in

size

under

need

SAFETY

the

lifter

TRANSMITTER

from

oil

position

guard

pulleys,

operators,

needles.

slope

;

treadle

not

hang

lifter

treadle

having

treadle.

TABLES

of

machines

same

as

No.

660-159,

treadle

AND

drain

shown

to

with

hole;

on

under

about

Adjust

to

can

be

vertically.

chain

AND MACHINE

on

for

Union

chain

MACHINE

assemble

PL336,

side

of

1

inch

center

length

treadle.

placed

assembly

attachment

American

Special

is

available

away

from

(Cont'd)

oilj

Oil

Return

table

clearance

transmitter

of

pitman

If

more

farther

at

right

end

Safety

Transmitter.

as

transmitter

filter

in

front

convenient

back,

of

3/4

Tables

an

Pump

between.

treadle

rod

as

trans

inch

is

extra

or

of

to

higher

sub

A

for

line

THREAD

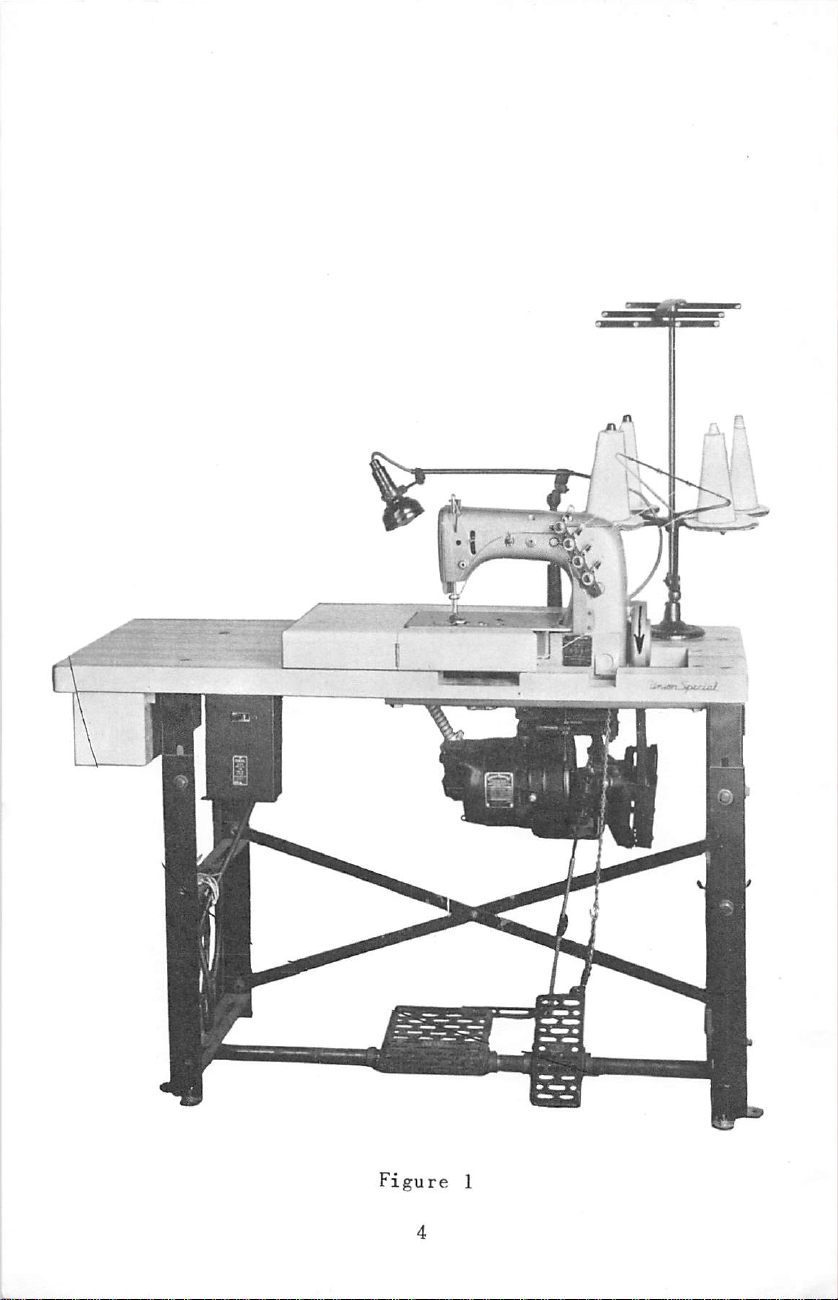

All

STANDS

machines

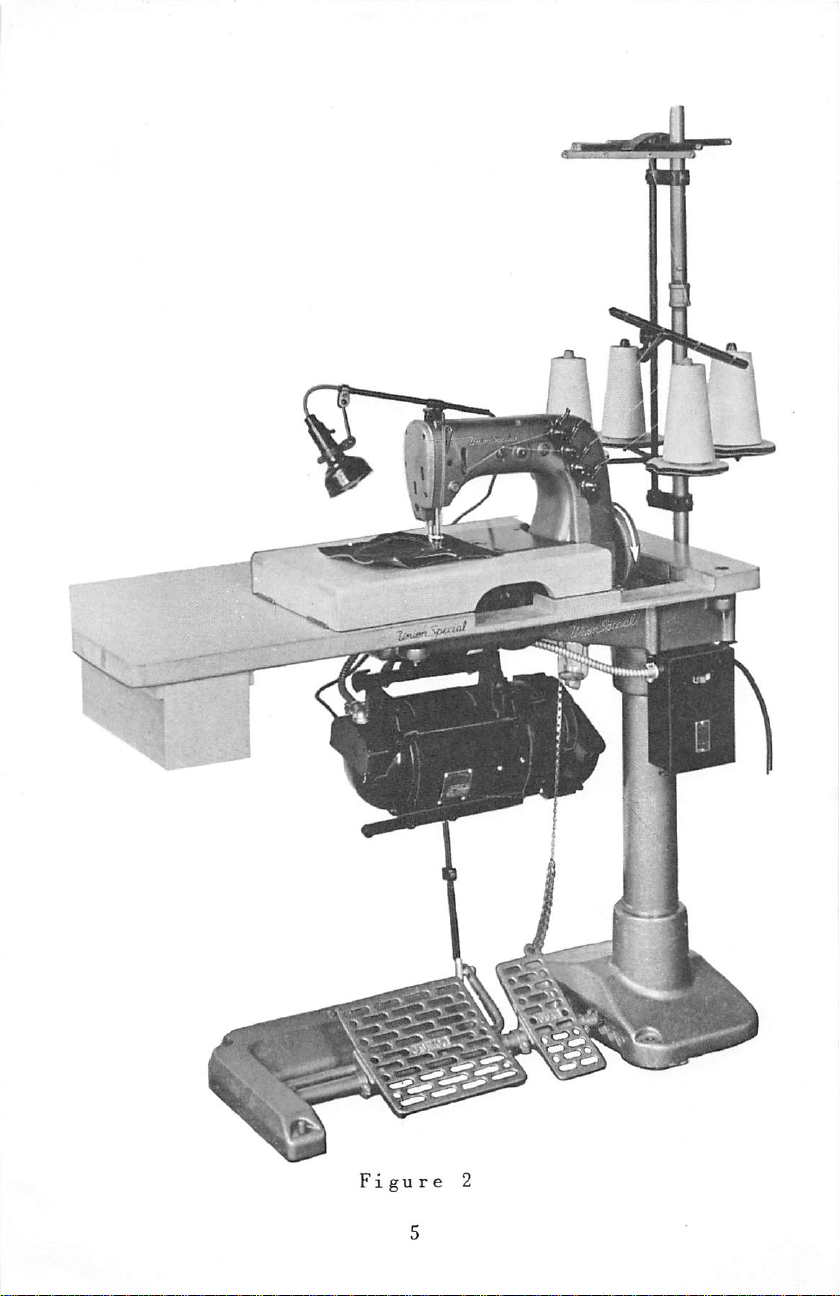

2 show

Thread

stands

machine

Exception:

accessories

pedestals:

"M"

type

available

location

for

more

with

an

thread

on

are

and

with

*'H"

adaptor

additional

equipped

assembly

fewer

favorable

type

thread

all

50000

is

stands

with

seats

delivery

Series

available

for

order.

thread

of

a

should

stands,

pedestal

14

stands.

typical

be

of

thread.

which

machines,

on

additional

installations

thread

located

are

do

Figs.

stand.

closer

standard

not

fit

order.

are

1 and

to

Page 15

USE

GENUINE

NEEDLES

OPERATING

AND

REPAIR

PARTS

Success

only

with

as

furnished

sidiaries

parts

fic

principles,

Maximum

Genuine

"

Trade

parts

Both

materials

OILING

trade

Caution:

reservoir

Oil

capacity

mineral

at

100°

Machine

Oil

level

and

should

in

are

efficiency

needles

UNION

are

oil

Fahrenheit

is

the

operation

genuine

by

and

authorized

designed

SPECIAL

stamped

marks

and

workmanship.

Oil

was

must

of

with

filled

is

checked

be

maintained

Union

and

are

are

be

the

a

Union

Special

according

are

and

put

Mark"

with

your

drained

filled

50000

Saybolt

should

with

at

of

this

Special

distributors.

made

durability

up

only

at

the

familiar

guarantee

from

before

Series

viscosity

be

oil

at

sight

between

machine

Needles

Machine

to

the

with

in

the

machine

beginning

is

used.

spring

gauge

red

Company,

most

utmost

are

assured.

packages

top.

Union

of

when

12

of

cap

on

lines

can

and

These

advanced

precision.

Genuine

Special

highest

to

ounces.

200

in

front

of

be

secured

Repair

its

needles

marked

quality

shipped,

operate.

A

to

250

top

cover.

of

machine,

gauge.

Parts

sub

and

scienti

repair

padlocks.

so

straight

seconds

Machine

sary,

Check

other

oil

quired.

pumped

unnecessary.

at

Please

Class

back

plug

see

21700

Transmitter

at

left

once

a

week.

is

automatically

than

daily

Oil

which

into

screw

Catalog

pullers.

has

end

of

keeping

before

has

main

Excessive

directly

No. 32

a

one-shot

the

shaft.

lubricated.

main

the

morning

gone

reservoir,

oil

under

for

oiling

This

reservoir

thru

machine

making

in

main

handwheel

oiling

system

15

start;

reservoir

diagram

system

No

oiling

filled.

is

frequent

in

through

should

add

filtered

main

is

oil

as

oilings

is

drained

frame.

covering

an

be

filled

neces

re

and

oil

cup

Page 16

CLEANING

It

is

cause

cloth

week.

between

necessary

accumulated

plate

Be

sure

feed

and

dog

OPERATING

to

keep

lint

thoroughly

to

remove

prongs.

machines

and

dust

clean

lint

quickly

from

as

clean

machine

oil

absorb

at

holes

as

least

possible,

oil.

once

and

from

be

Remove

a

slots

SETTING

Needles

tending

ending

side

On

line

in

a

machines

of

possible,

are

in

On

machines

the

line

spiral

keeping

thru

needle

THREADING

Figures

spools

threads

shown,

of

but

machine

THE

NEEDLES

have

from

a

milled

long

groove

equipped

feed;

keeping

line

with

equipped

of

feed

grooved

spot

eyes

1

and

thread

led

into

the

is

substantially

two

shank

insert

needles

above

2,

manner

grooves:

to

about

spot

extending

with

needles

long

stitch

with

(Styles

needle

from

right

pages

are

positioned

machines.

fewer

on

just

loopers

grooves

direction.

loopers

in

into

eye

4

and

the

one

1/8

inch

above

from

into

to

Classes

needle

to

to

left.

5,

illustrate

on

Four

or

more

same.

side

above

the

the

traveling

needle

the

traveling

54200,

bar

the

left

thread

cones

threads

a

short

eye;

shank

front

as

of

the

on

to

across

bar

so

parallel

54400);

far

so

how

stands,

thread

are

groove

eye,

opposite

the

as

far

needle

as

possible,

threads

cones

are

led

eye.

the

insert

and

ex

or

as

eyes

with

pass

or

the

into

A

diagram

correct

"PL"

threading

is

threading.

numbers.

errors.

furnished

Studying

These

with

this

each

diagrams

diagram

16

machine

are

will

showing

identified

prevent

its

by

Page 17

OPERATING

THREADING

GENERAL

through

left

in

longer

CAUTIQS:

discs

never

TO

BEGIN

About

yond

the

rear.

machine.

treadle

heel

TO

In

pressure

REMOVE MATERIAL•

order

material,

are

at

a

scissors

thread;

remove

material

of

material

(Cont'd)

DIRECTIONS:

thread

machine;

in

machine,

Each

and

kept

be wound

SEWING

two

and

eyes

Place

Machine

is

to

turn

their

then

work;

draws

stand

thread

drawn

or

one

of

material

released.

is

remove

pulley

highest

under

cut

cut

cut

and

ties

Position

eyelets.

draw

rethread

against

twisted

half

needles

will

applied

work

position.

presser

needle

looper

ends

them.

in

new

must

be

completely

inches

and

to

be

stop

Machine

to

from

in

operating

foot;

threads

threads.

of

needle

cones

Tie

thread.

or

new

according

passed

tension

between

post.

around

of

thread

loopers.

sewn

under

automatically

will

stop

near

edge

machine

without

direction

Raise

draw

off

close

This

threads

spools;

threads

If

thread

to

"PL"

should

Carry

presser

instantly

of

treadle.

presser

3

to

material.

method

Thread

tension

when

or

to

pass

to

is

diagram.

its

tension

extend

threads

foot;

pressure

running

until

foot.

4

inches

of

removing

the

under

thread

thread

no

should

post.

start

when

off

needles

Pass

Now

ends

be

to

on

of

side

17

Page 18

SUGGESTIONS

OPERATING

When a

factorily,

might

(1)

(2)

(3)

(4)

(5)

(6)

machine

be

saved

Check

Remove

Check

Remove

Try

Clean

some

on

and

best

points

a new

to

in

proper

minor

by

following

threading.

"PL"

all

diagram.

lint.

needles.

inserted

needles.

test

should

set

machine

grooves

adjustment

troubles

these

Be

Be

sure

into

Be

sure

is

to

roll

roll

of

needles.

thoroughly.

in

looper

could

sure

they

needle

them

true.

and

does

suggestions:

it

be

not

the

is

the

are

bar

as

they

are

onaflat

Give

special

feed

work

cause.

same

set

correctly,

far

straight.

dog.

satis

Time

as

as

possible,

surface;

attention

shown

The

18

Page 19

WORLD'S FINEST QUALITY

★

'a/ce

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains

sales

and

facilities throughout the world. These offices will

aid you in the selection of the right sewing

equipment for your particular operation.

Special representatives and service men are fac

tory trained and are able to serve your needs

promptly

tion, there is a

and

efficiently. Whatever

Union

Special Representative to

serve you. Checkwithhimtoday.

ATLANTA,

BOSTON,

CHICAGO,

DALLAS,

LOS

NEW

PHILADELPHIA,

GA.

MASS.

ILL.

TEXAS

ANGELES,

YORK,

N.

CAL.

Y.

PA.

MONTREAL,

BRUSSELS,

LEICESTER,

LONDON,

PARIS,

STUTTGART,

FRANCE

service

Union

youT

QUEBEC

BELGIUM

ENGLAND

ENGLAND

GERMANY

loca

404

Representatives

MACHINE

N.

FRANKLIN

industrial

and

distributorsinall

cities

throughout

ST.,

the

COMPANY

CHICAGO

important

world.

10,

ILL.

Loading...

Loading...