Union Special 51500BV-16 User Manual

CATALOG

104 BV

First Edition

STYLE

NO.

51500 B\l16

ADJUSTING

LIST

OF

INSTRUCTIONS

AND

PARTS

Finest Quality

STREAMLINED

TWO

MACHINE

NEEDLE

WITH

..

-

....

--

FIFTY

"DOUBLE·LOCK"

TOP

~

THOUSAND

COVER

THREAD

SERIES

STITCH

Catalog No.

INSTRUCTIONS

FOR

104

BV

ADJUSTING

AND

AND

LIST

OF

PARTS

CLASS 51500

Style

51500

First Edition

Copyright

Union Special Corporation

Rights Reserved

Printed in

U.S.A.

BV-16

By

in

November,

OPERATING

1980

All Countries

1980

2

INTRODUCTION

This technical manual has been prepared

UNION SPECIAL sewing machine. Careful attention

justing these machines will enable you to maintain the superior performance and reliability

designed and built into every UNION SPECIAL machine.

to

guide you in the maintenance

to

the instructions for operating and

of

your new

ad-

The Adjusting

each

of

the components related to forming the stitch and completing the functions

machine. Figures

the specific

The adjustments are presented in a sequence so that a logical progression is accomplish-

ed.

Some adjustments performed out

of

other related parts.

Implementation

provements in operator productivity by avoiding costly equipment breakdowns. Whenever it

becomes necessary

nuine UNION SPECIAL Repair Parts. These parts are designed specifically for your machine

and manufactured with utmost precision

To

simplify identification

stamped with its part number. Part numbers represent the same part, regardless of catalog in

which they appear.

IDENTIFICATION OF MACHINE

Each

UNION

Style number

numbers

dard Style numbers

but

BV". Special Style numbers contain the letter "Z".

When

machine, a

number. Example:

are

never

only minor changes

SPECIAL

on a name

classified

contain the letter "Z". Example: "Style

"Z"

is suffixed to the standard Style

Instructions portion

are

used

to

Items discussed.

of

preventative maintenance procedures can bring about significant im-

to

make repairs or replace parts on your machine, be sure to insist on

of

machine

plate on the machine. Style

as

standard

have

one or more letters suffixed,

are

"Style

51500

Is

and

made

BVZ".

identified

illustrate the adjustments using reference letters

in

of

this manual explains in detail the proper setting for

of

sequence may have

to

repair parts, where the construction permits, each part is

by

special.

Stan-

51500

a standard

of

to

point out

an

adverse effect on the function

assure long lasting service.

NEEDLES

a

Each

UNION

size number.

shank,

The

denotes the largest diameter of blade, measured in

thousandths of

eye.

complete symbol, which is given

needles packaged

point, length,

size number, stamped

Collectively, type

SPECIAL

The

type number denotes the kind of

an

and

needle

groove,

inch, midway between shank

and

sold

has

both a type

finish

and

on

the needle

size

number represent

on

the label of all

by

Union Special.

other details.

the

ge-

and

shank,

and

the

STYLE OF MACHINE

Streamlined Flat

Needles, Two Loopers,

Looper Thread

Weight Presser Bar and Needle Bar Driving

Mechanism,

Lubricating System

Maximum Work Space to Right of Needle Bar 7

ches

(196.8

mm).

51500

BV-16

Medium throw high speed machine for

taching facing material to the pocket lining of

trousers, jeans

medium weight materials. Produces two rows of

stitches with cover thread interlocking

Presser foot equipped with a guide.

408-SSaa-1.

tion

No.

16

only. Maximum recommended speed

R.P.M.

Bed,

Plain

Feed

Machine, Two

One

Spreader

Takeup,

Single Reservoir Enclosed Automatic

and

Type

Lateral Looper

and

Filter

Type

similar operations

147

GS

needle. Standard gauge

and

Single Disc

Travel,

Oil Return

on

on

Seam

specifica-

Light

Pump.

3/4

In-

at-

light to

401

the top.

5000

The

standard recommended needle for Style

BV-16

point, long, double

spotted, short point, undersize

step reduction, chromium plated

sizes

140/054,

filled,

and

on

Type

the

through needle

formation.

Is

Type

080/032,

150/060, 170/067.

To

have

needle orders promptly

an

empty package, a sample

size

number should

label. A complete order would

147

GS,

Size

Selection of the proper needle size

size

of thread

3

147

GS.

It

has

a round shank,

groove,

090/036,

100/040".

used.

eye

in

order to produce a good stitch

struck

100/040, 110/044,

be

forwarded.

Thread

groove,

eye

and

and

needle,

read:

is

should pass freely

and

Use

51500

round

ball

grooves,

is available

1251049,

accurately

or the type

description

"1000

needles,

determined

eye,

one

In

by

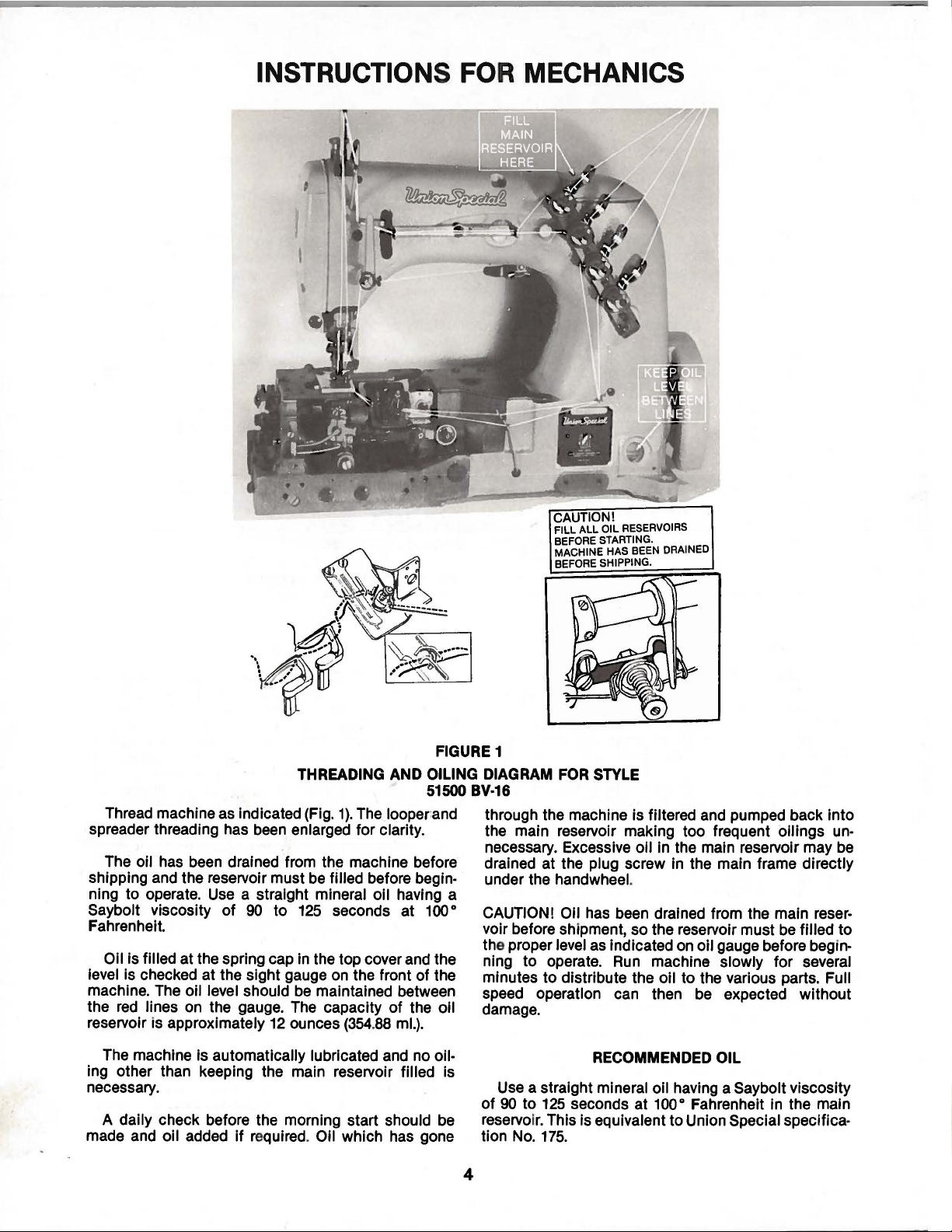

INSTRUCTIONS FOR MECHANICS

FIGURE

THREADING

AND

OILING

51500

Thread machine

spreader threading has

The oil has

shipping and the reservoir must

ning to operate.

Saybolt viscosity of

Fahrenheit.

Oil is filled at the spring cap in the top cover and the

level is checked at the sight gauge

machine.

the

reservoir is approximately

The machine is automatically lubricated and no oil·

ing other than keeping the main reservoir filled is

necessary.

A

made and oil added

The

red

lines

daily check before the morning start should

as

indicated (Fig.

been

enlarged for clarity.

been

drained from the machine before

Use

a straight mineral oil having a

90

to

oil level should

on

the gauge.

if

The

12

ounces

required. Oil which has gone

1).

The

be

filled before begin·

125

seconds at 100°

on

the front of the

be

maintained between

capacity of the oil

(354.88

looper:and

mi.).

be

1

DIAGRAM

FOR

STYLE

BV·16

through the machine is filtered and pumped back into

the main reservoir making too frequent

necessary. Excessive oil in the main reservoir may

drained at the plug screw in the main frame directly

under the handwheel.

CAUTION! Oil

voir before shipment, so the reservoir must

the proper

ning to operate.

minutes to distribute the oil to the various parts. Full

speed operation can then

damage.

Use

a straight mineral oil having a Saybolt viscosity

90

to

of

reservoi

tion

r.

No.

has been drained from the main

level

as

indicated

Run

RECOMMENDED

125

seconds at 100° Fahrenheit in the main

This is equivalent to Union Special specifica-

175.

on

oil gauge before begin·

machine slowly for several

be

expected without

OIL

oilings un·

be

filled to

4

be

reser-

ALIGNING THE NEEDLE

BAR

turned in the operating direction, move the looper drive

shaft synchronizing stud

the opposite direction acts the

(C)

to the

reverse.

rear.

Moving It

In

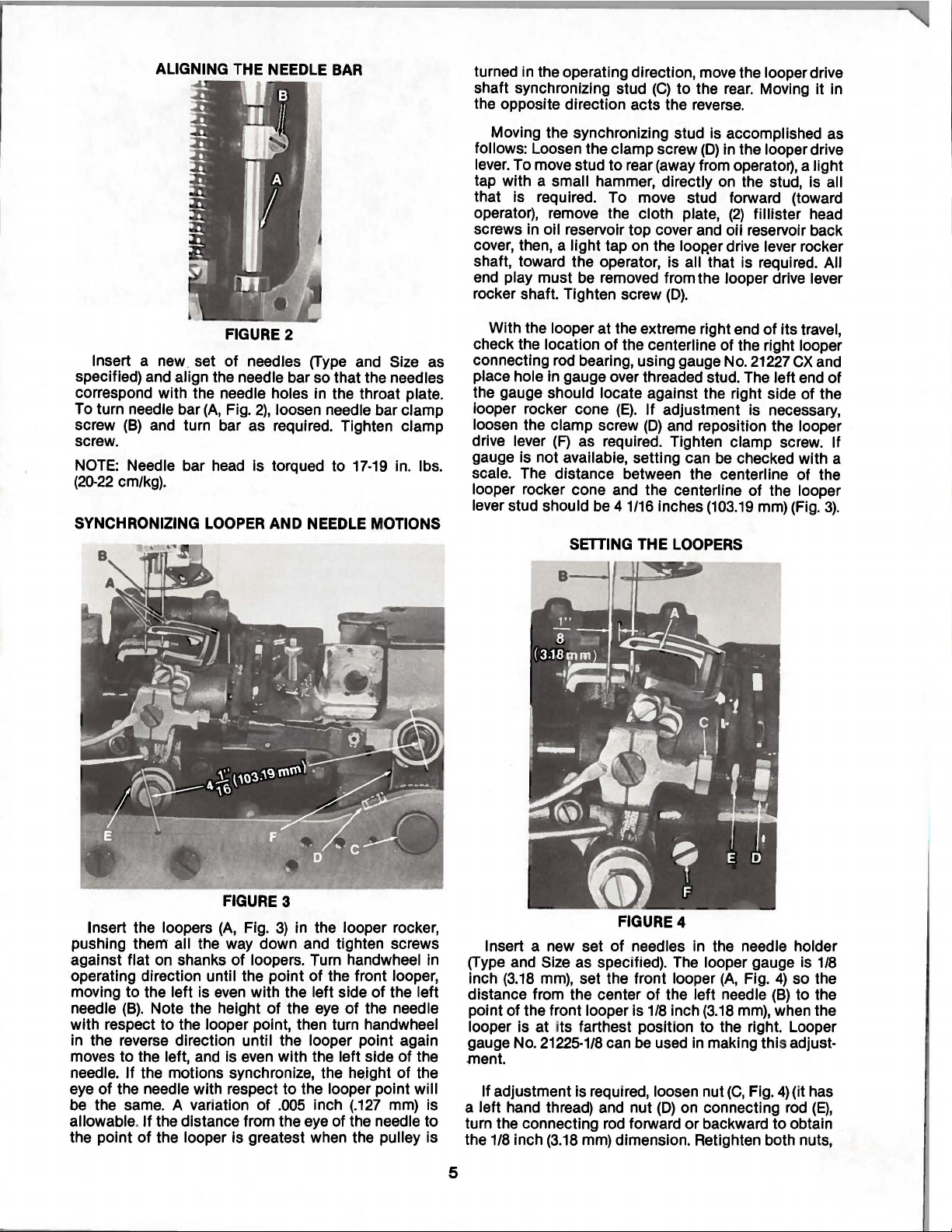

FIGURE2

Insert a

new

. set of needles

(Type

and Size

as

specified) and align the needle bar so that the needles

correspond with the needle holes in the throat plate.

To

turn needle bar

screw

(B)

and turn bar

(A,

Fig.

2),

loosen needle bar clamp

as

required. Tighten clamp

screw.

NOTE:

(20-22

SYNCHRONIZING LOOPER AND NEEDLE MOTIONS

Needle bar

em/kg).

head

is torqued to

17-19

in. lbs.

Moving the synchronizing stud is accomplished

follows: Loosen the clamp screw

lever.

To

move stud to rear (away from operator), a light

tap with a small hammer, directly

(D)

in the looper drive

on

the stud, is all

as

that is required. To move stud forward (toward

operator), remove the

cloth plate,

(2)

fillister

head

screws in oil reservoir top cover and oil reservoir back

cover, then, a

shaft, toward the operator, is

end

play must

rocker shaft. Tighten screw

light tap on the

IOORer

drive lever rocker

all that is required. All

be

removed from the looper drive lever

(D).

With the looper at the extreme right end of its travel,

check the location of the centerline of the right looper

connecting

place hole in gauge over threaded stud.

the gauge

looper rocker cone

loosen the clamp screw

drive lever (F)

gauge is not available, setting can

rod

bearing, using gauge

No.

21227

The

left

CX

end

and

of

should locate against the right side of the

(E).

If adjustment is necessary,

(D)

and reposition the looper

as

required. Tighten clamp screw. If

be

checked with a

scale. The distance between the centerline of the

looper rocker cone and the centerline of the looper

lever

stud should

be 4 1/16

SETTING

inches

THE

(103.19

LOOPERS

mm)

(Fig.

3).

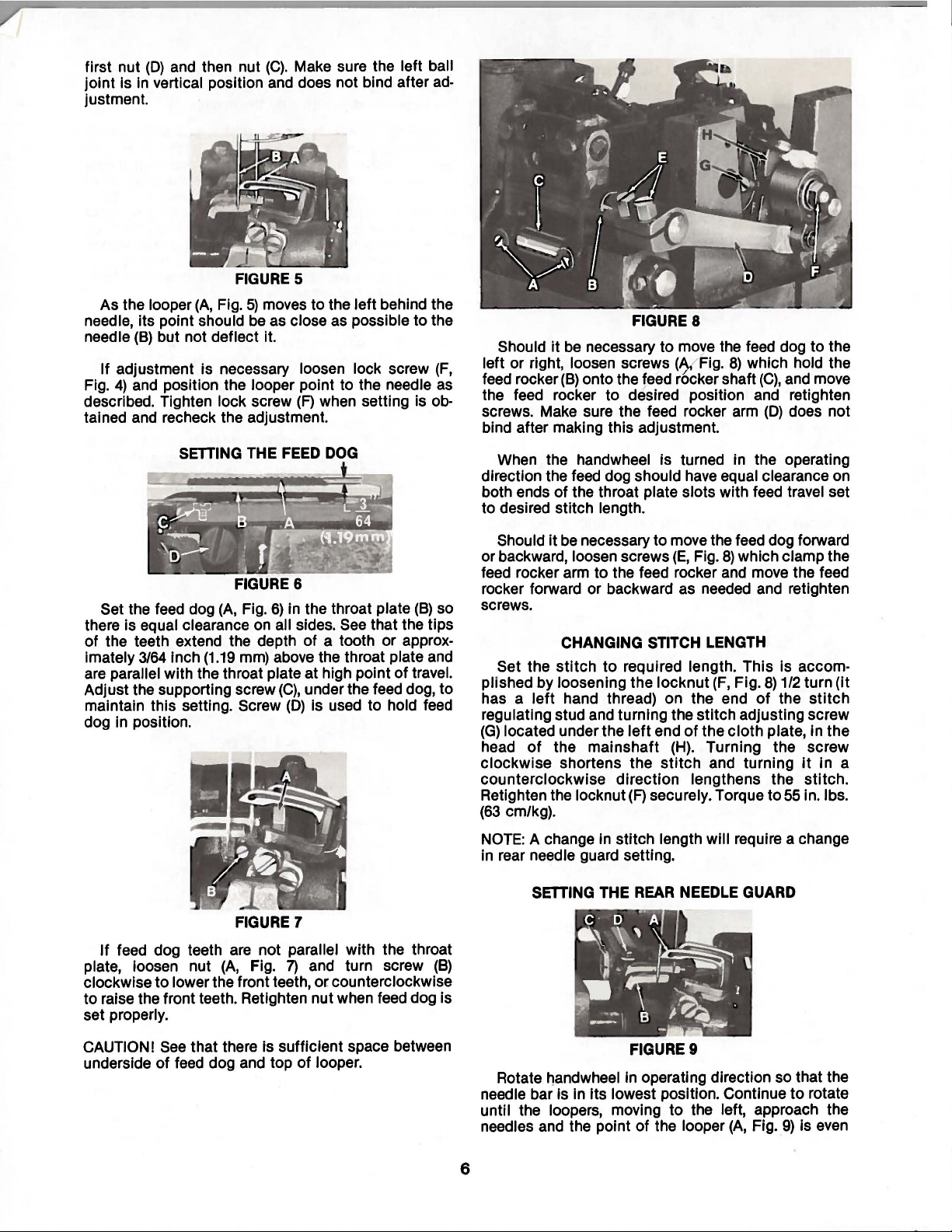

FIGURE

Insert the loopers

pushing them

against

flat

on

operating direction

moving to the left

needle

(B).

Note the height of the

(A,

all the way down and tighten screws

shanks of loopers. Turn handwheel in

until the point of the front looper,

Is

even

with respect to the looper point, then turn handwheel

in the reverse direction until the looper point again

left,

and

moves to the

is

3

Fig.

3)

in the looper rocker,

with the left side of the left

eye

of the needle

even

with the left side of the

Insert a new set of needles in the needle holder

(Type

and Size

inch

(3.18

mm),

distance from the center of the

point of the front

looper is at its farthest position to the right. Looper

No.

gauge

21225·1/8

ment.

needle. If the motions synchronize, the he_ight of the

eye of the

be

the same. A variation of

allowable. If the distance from the

the point of the

needle with respect to the looper point will

.005

inch

(.127

mm)

is

eye

of the needle to

looper is greatest when the pulley is

If adjustment is required, loosen nut

a

left hand thread)

turn the connecting

1/8

inch

the

(3.18

5

FIGURE4

as

specified).

set the front looper

The

looper gauge is

(A,

left needle

looper is

can

be

1/8

used

inch

(3.18

mm),

in

making this adjust-

(C,

and

nut

(D)

on

connecting

rod

forward or backward to obtain

mm)

dimension. Retighten both nuts,

Fig.

Fig.

1/8

4)

so the

(B)

to the

when the

4)

(it has

rod

(E),

first nut

joint is

justment.

in

(D)

and then nut

vertical position

(C).

Make sure the left ball

and

does not bind after

ad-

FIGURE

As the looper

needle, its point should

needle

Fig.

described. Tighten lock screw

tained and recheck the adjustment.

there is

of the teeth extend the depth of a tooth or

imately

are

Adjust the supporting screw

maintain this setting.

dog in position.

(B)

If adjustment is necessary loosen lock screw

4)

and position the looper point to the needle

Set the feed dog

equal clearance

3/64

parallel with the throat plate at high point of travel.

(A,

Fig.

5)

but not deflect it.

SETTING

inch

(A,

(1.19

THE

FIGURE

Fig.

mm)

Screw

5

moves to the left behind the

be

as

close

as

possible to the

(F)

when setting is

FEED

DOG

6

6)

in the throat plate

on

all sides.

above the throat plate and

(C),

(D)

See

that the tips

under the feed dog, to

is used to hold

(F,

as

ob-

(B)

so

approx-

feed

FIGURES

Should it

left or right, loosen screws

feed rocker

the feed rocker to desired position and retighten

screws. Make sure the feed rocker

bind after making this adjustment.

When

direction the

both ends of the throat

to desired stitch

Should

or backward,

feed rocker

rocker forward or backward

screws.

Set the stitch to required length. This is accom-

plished

has a

regulating stud and turning the stitch adjusting screw

(G)

located under the

head

clockwise shortens the stitch and turning

counterclockwise direction

Retighten the

(63

em/kg).

be

necessary to move the feed dog to the

(~

Fig.

8)

which hold the

(B)

onto the feed rocker shaft

the handwheel is turned in the operating

feed

dog should

length.

it

be

necessary to move the feed dog forward

loosen screws

arm

to the feed rocker and move the feed

CHANGING

by loosening the locknut

left hand thread) on the end

left

of

the mainshaft

locknut

(F)

have

plate slots with feed travel set

(E,

Fig.

as

needed and retighten

STITCH

end

securely. Torque to

LENGTH

(F,

of

the cloth plate, in the

(H).

Turning the screw

lengthens the stitch.

(C),

and move

arm

(D)

does not

equal clearance on

8)

which clamp the

Fig.

8)

1/2

of

the

it

55

turn (it

stitch

in a

in. lbs.

FIGURE

If

feed dog teeth

plate, loosen nut

clockwise to lower the front teeth, or counterclockwise

to raise the front teeth. Retighten nut when feed dog is

set

properly.

CAUTION!

underside of

See

feed

are

(A,

that there is sufficient space between

dog and top of looper.

7

not parallel with the throat

Fig.

7)

and turn screw

(B)

NOTE:

in rear

needle bar is in its lowest position. Continue to rotate

until the loopers, moving to the left, approach the

needles and the point of the looper

6

A change in stitch length will require a change

needle guard setting.

SETTING

Rotate l')andwheel in operating direction so that the

THE

REAR

NEEDLE

.i\

.

~

-

'A~

J

..

- -

-·

•

'\

;

....:=

·~

s

_i,

1

FIGURE9

·

....

l

.

(A,

GUARD

\

Fig.

9)

is

even

Loading...

Loading...