Page 1

INDUSTRIAL

SEWING

FINEST

CLAS

515

0

S

C 0 L U M B I A®

MACHINES

CATALOG

NO.

T107

M

UNION SPECIAL

LIST

STYLE

CHICAGO

OF

PARTS

FOR

51500

CORPORATION

BT

Page 2

Catalog

No.

T107

M

LIST

CLASS

First

OF

Style

51500

PARTS

51500

BT

Edition

Rights

Union

Copyri

Special

Reserved

g

ht

1961

by

Corporation

in

All

Countries

UNION SPECIAL CORPORATION

INDUSTRIAL

Printed

SE

WING

CHICAGO

in

MACHINES

U.S.

A.

March,

1978

Page 3

IDENTIFICATION

OF

MACHINE

Each

into

special.

the

letter

11 Z 11

•

to

the

UNION

the

name

Standard

When

standard

Styles

which

in.

class.

the

is

differs

This

It

can

Reference

operator's

toward

catalog

Streamlined

out

Knife,

Independent

Bearing

System,

Lateral

Driving

Filter

Looper

11

Z

only

of

also

the

Flat

With

Row,

".

SPECIAL

plate

Style

Example:

minor

Style

machines

from

the

applies

be

applied

to

position

operator.

Bed,

Front

Two

Mechanism,

Type

Travel,

machine

on

the

machine.

numbers

"Style

changes

number.

similar

style

APPLICATION

specifically

with

direction,

while

High

Disposal

Loopers,

Oil

Return

3/16

have

51500

are

Example:

in

number,

discretion

such

seated

STYLE ·oF

Throw,

of

Light

Single

Inch

is

identified

Style

one

made

numbers

or

BT

".

in a standard

"Style

construction

in

that

it

OF

to

the

Standard

to

as

right,

at

the

machine.

MACHINE

Top

Feed

Trimmings,

Weight

Reservoir

Pump

With

Spacing

by a Style

more

letters

Special

51500

are

contains

CATALOG

some

left,

Special

front,

Machine

Two

Presser

Enclosed

Base

Between

number

are

classified

suffixed,

Style

numbers

machine,

BTZ".

grouped

no

letters.

Style

of

Styles

back,

Operating

With

Needles,

Bar

Plate,

Needles

which

as

but

contain

11

a

Z

under a class

Example: 1151500

machine

etc.,

as

of

machines

are

direction

Spring

Left

and

Pressed

Needle

Needle

Automatic

Oil

Siphon

in

Line

is

stamped

standard

never

11

the

is

suffixed

contain

letter

number

listed

here-

in

given

of

handwheel

Throw-

in

Front,

Bar,

Needle

Lubricating

Assembly,

With

Feed.

and

11

this

from

•

51500

BT

sack

For

and

Standard

Each

number

The

blade

UNION

denotes

size

number,

measured

Collectively,

Standard

round

point,

iumJ>lated170/067.

To

have

sample

on

needle,

label. A complete

Selection

Thread

should pas s

formation.

seaming

sport

gauge

the

needle

short,

sizes

needle

or

of the

coats

No.

SPECIAL

the

kind

stamped

in

thousandths

type

number

for

double

080/032,

orders

the

type

order

proper

freely

and

10

binding

and

and

similar

standard

women's

NEEDLES

needle

of

shank,

on

Style

groove,

090/036,

promptly

and

would

has

both a type

point,

the

needle

of

an

inch,

and

the

size

51500

BT

struck

100/040,

size

numb

read: 111000

and

needle size should

through

ne

edl

quilted

garments.

width

of

length,

shank,

midway

number

is

Type

groove,

110/044,

accurately

er

should

Needles,

be de

e e ye

robes,

Seam

specification

binding 1 1/4

number

groove,

denotes

and

finish

the

between

is

the

complete

128

GAS.

ball

eye,

125/049, 140/0

filled,

be

forwarded.

Type

128

termined

in

order

to

housecoats,

jackets,

401-BSe-2.

inches.

size

number.

and

oth

lar

gest di

the shank

The type

er de ta

ame ter

and the e

symbol.

It

has a round shank,

is

spott

ed

and

54,

150/060,

an

empty

package, a

Use description

GAS,

by size of

produc

Size 090/036

thread use

e a g

ood stitch

ils.

ye

chrom-

of

11

d.

•

•

For bes

these

ba

cked

quarter

m achines. They

by

s

of

t results,

a r e

putation

a ce

ntury

use

are

•

only genuin

packaged

for

producing highes

e UNION SPECIAL

und

er

our brand name,

t q

ual

ity

needles

•

needles

~,

for

in

the oper a

more than

tion of

which

three-

is

Page 4

IDENTIFYING

PARTS

Where

some

identification

appear.

OF

shipments

unless

must

Saybolt

sight

the

of

the

Part

IMPORTANT!

MACHINE

Prices

The

Oil

red

numbers

otherwise

oil

be

filled

viscosity

is

gauge

lines

construction

smaller

letter

represent

ON

FOR

are

are

has

filled

on

the

on

WHICH

strictly

forwarded

directed.

been

before

of

90

at

the

front

the

gauge.

permits,

parts,

is

stamped

ALL

net

f.

drained

beginning

to

125

spring

of

the

each

and

on

in

the

same

ORDERS,

PART

o.

The

IS

cash

b.

shipping

A

charge

from

to

seconds

cap

machine.

capacity

part

those

to

PLEASE

ORDERED.

TERMS

and

OILING

the

operate.

at

in

where

distinguish

part,

are

point.

is

machine

100°

the

top

The

of

is

stamped

construction

regardless

INCLUDE

subject

made

Fahrenheit.

cover

oil

the

to

Parcel

to

before

Use a straight

level

oil

reservoir

with

the

PART

change

Post

cover

shipping,

and

the

should

its

part

of

catalog

without

shipments

postage

level

be

is

part

number.

does

from

not

similar

in

NAME

and

mineral

maintained

12

AND

notice.

and

the

is

checked

ounces.

are

permit,

ones.

which

insurance.

reservoir

oil

they

STYLE

All

insured

with

at

the

between

On

an

a

The

machine

main

Oil

reservoir,

reservoir

handwheel.

reservoir

A

daily

which

check

has

making

may

is

filled,

before

gone

be

automatically

is

necessary.

the

morning

through

too

drained

the

frequent

at

machine

oilings

the

plug

lubricated

start

should

is

unnecessary.

screw

and

be

filtered

in

the

no

made

and

main

oiling,

and

pumped

Excessive

frame

other

oil

back

than

added

into

oil

in

directly

keeping

if

required.

the

the

under

the

main

main

the

Page 5

2

3

4

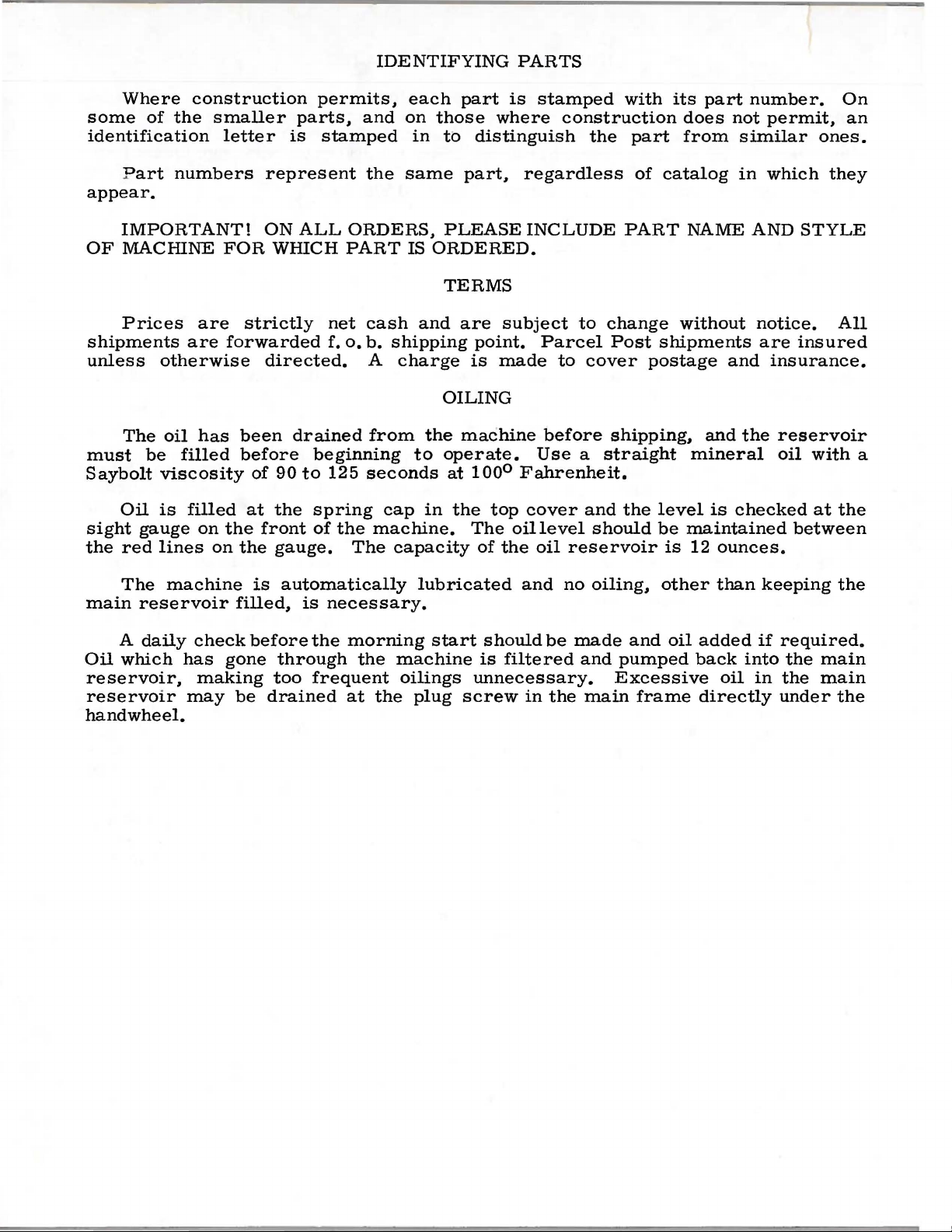

CAUTION!

FILL

BEFORE

MACffiNE

BEFORE

Thread

Use a straight

Fill

Maintain

Drain

handwheel.

oil

excess

as

indicated.

cup

"A"

oil

THREADING

The

mineral

until

level

oil

oil

between

from

AND

looper

oil

of a Saybolt

level

the

lines

the

machine

OILING

threading

is

visible

viscosity

of

gauge

by

removing

DIAGRAM

has

been

between

"B".

enlarged

of

90

lines

the

FOR

to

of

plug

OIL

STYLE

for

125

seconds

gauge

screw

RESERVOIR

STARTING

HAS

BEEN

SHIPPING

51500

clarity.

at

"B".

located

KEEP OIL

LEVEL

BETWEEN

LINES

DRAINED

BT

1 ooo

Fahrenheit.

directly

beneath

Page 6

'l'h

t: foli

Following thf' pnrts list nre

1\mt .

o\\ ing is a

Pa

rt No.

1

:J

~

~

2

1

2

I

1

1

~

1

1

:J

:J

2

1

1

~

6

2

1

2

2

1

1

~

2

~

)

1

2

1

1

2

1

1

1

1

1

:J 98 A

1

B

J

1

1

1

1

1

2

2

1

2

1

1

1

1

18

~7-4:

50 .1-

11

:'\05

109

158 B

256

256

258 A

258 A

258 A

26

402

531

531

53 8 F e

539

604

6

num

en c a l

D

c

J:i

16

!l

k.

B Sc

-\

-127

k.

F e e d Hocke r S

N

ut

55

241 N, 5

Was

:i

l:!36

Sc

r ew

N<>ed

Washe r

Sc r e w

Ne

e dl e Stop

Pin

Pw f

I .uc i

O

il Cap

Sc

r ew fo r

Sc

r "

le ve r link

upp

Screw

rew

Screw

plate

crew

(12982)

Scre

Sc

rew

plate

Sc

rew

Screw

Screw

rE-w

Screw for 51034

Screw

Sc r e w

S

crew for

2J322

Screw for 52882

crew for 52882

S

5

2894

Screw

Screw for

Screw for

feed dog

Plug Screw

Screw

Screw for

Adjusting Screw

for

Screw

Spot

5

1523

Screw for

Screw

Screw

Tension

Thread Eyelet

(98

Nut

Nut

Nut

Lock

Nut

Nut

512

Scr

ew f

78

53

Screw for

S

crew for 5149

ed Dog Height 1

Ad

ju st ing Scr

Fr

am e Thr e ad E yelet 1

:

2o, 2284 8, 22889 A l 1

Screw f

Oil

Pump

e

20

~ 5

1311~.

28

ii

0-216

B

lk.

50- 4 ;i

Bl

50- 64 8

Blk.

:i

0- 78!)

Hlk.

73

77

77

17 Sc

BO

80 S

Bl Screw

82

Ui

BB

BH

8B

BB

B B

!HJ

!JO

!JO

fl

O

0

!

Jl

n:J

o:1 .

fl

!i

!)

5

fl

::i

96

96

98

98 A

9

43

Bl

for 5124 0 E,

he r f

for 52357 A

for 51134

for 51280

for

for

for

4 0 E

list

of

photographs

escription

G, 5

for

le

for 51504 D

or 51241

te Oil

for

r

for

for

for

for

for 51242

w f

for

for

for

for 52894

for

for

for

AL-l

AB

for

for 51147

511 34 N

for 51244

Screw for

fo r 158 B

for 51291

A)

Nut

3 A 2

parts

of

haft

5244

or 539,

Bar Eyelet

Ilin

or

Disc

660

52 694 AM 1

51 23 6 G,

or

or 5143

G

1758

23223

T

Pin

K

Gauge

ge P in

looper

needle

pin,

51 054

51236

A

cloth

52980

A

Y

51236

G

throat

14649

154 65 F

AK

needle

A

514

18

F

666-138

1/4

AA

Y,

13430

B

1321375

fo r 5

All

upper

51270

B

5124

4

A 1

HA

E

-13 6 1

174

5

51283 H, 3

51257 M 1

3 BQ 6

ew

0 L 1

Ga s

ket

in this mac

some

of

Part

Amt.

1

1

1

1

1

2

2

2

2

2

1

3

1

1

2

1

1

1

2

2

2

1

2

1

1

12536

1

12982

1

13430

1

13430

1

14649

3

1

15

21212

1

1321

21657-4

1

216

1

216

1

21657

216

2

22 5

22519

22524

22528

22528

22537

225

22539

1

22

3

hin

e .

major

No.

Blk.

- 65

11

-201

B-

10

A

A

B

D

F

AI-l

57 E

57 w

X

57 y

13

17

H

39 H

R Plug

Quantities,

S

Feed

Needle

"O"Hing for

Oil Seal

Oil Seal

Oil

Oil Wick

Oil Wick

Oil Wick

Lubricat

Oil

Oil Wick

Wed

F

Felt

Dowel

Screw for

Stop

Washer

Washer

Nut

Nut

Loclr Nut

Presser

Yielding

Colla

Looper

O

Belt

Tension

Washer for 523

Tension

Tension

Tension Release

S

S

Screw for 51244

Screw for 5128

Screw

S

Screw f

P

Screw for

the

643-263

660-136

660-169

660-202

660-207

660-212

666

666-1

666-114

666-118

666-138 Felt

666-149

666-170

666-170

666-179

666

666-209 Felt

666-214

667

668-25 Eyelet

719

1740

6042

6042

7947

465

375

25

541 B

parts

iphon

0 1l T

51236

foot

bush

511 50,

(22586

1244

5

main shaft bear

main

(90)

for

lever

5

1134

666-11

elt

Dis

51273

5635 0 A

51 5

for 51520

1

Spring for

51 5

(22760

for

il Sipho

Connection

Rin

Separato

Leve

Lever Shaf

Leve

(225

cre

crew for 5127

fe

e d dog

crew for

lu

part

Description

Cr a

nk

Link

ube

(258

Bearing

E

pull

Ring for

lift

e r

lever

ing

Ring for

5

12

0 E 1

R)

Wi ck

for

K

for

for rig

for

shaft

bearin

for 52934

ing F

510

4

Wick

for needle

for

v

ge

Pin

for

1 1

Plu

g

Siphon

c

30

for 51294

for 51241

1/4

20BT-10-l

g

w f

g Screw

Cup

Lint

Filter

Pin

for

A

for

51292

511 5 0,

Pin

for

H

for 51135

for

52894

for

Foot

BT-10-

(91)

Section

A)

r f

or 8 (88)

Rocker

29192 D (88)

n

Lock

Guard

(93)

Release

r

Releas

r S

haft

Release

t B

r C

onnection

96)

or 35731

for

lower

52 357 A

or 53783

Scre

w

52882

numbers,

A)

for

ey

8

ht

ing

left

g

A

elt

0

P

AM

R 1

K

81

Shank

1/4

Cone

ing

57 A

e

ushm

g

A

3 A

B

2 AF

N

AD

Amt.

1

2

4

1

2

2

2

2

1

1

3

5

3

1

1

!.i

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

2

1

1

1

2

1

1

1

1

2

2

1

9

1

1

1

1

1

2

1

3

2

1

2

2

2

1

2

2

1

1

and

descriptions

Part

No.

22547

c

22548

22548

22557

B

22559

A

22559

B

22559

G

22560

B

22560

B

22564

22568

22569

13

22569

B

22569

B

22570

B

22

571 A

22

571 B

22580

D

22585

A

2258

5 B

22586

R

22588

A

22596

22711

22729

22729

22729

A

22729

B

22729

c

22730

22733

B

227

58 c

22760

A

22768

22768

22768

22768

22798

22799

F

22801

22811

B

22829

22834

22839

2283

9 c S

22

84 8

22848

228

52 S

228

52 A S

2286

3 F

22883

A Plug Screw

22889

A Adap

22889

c

22689

0

2289

4 c

22894

c S

22

894 c Se

2289

4 0 Eccentri

22894

D

2289

4 F

22894

H

22894

J

22

894 T S

2

32

23

T

23

322 M Washer for

are giv

Screw

(5

Screw

Screw

Screw

Bearing Cap Screw,

lower,

Bearing Cap Screw,

upper,

Screw

Screw

SetScrew

Screw

link

Screw

Screw

housin

Screw

Screw for

Screw

Plug Screw

Plug Screw

Set Scr

Screw

Screw

Screw

Screw

Screw for

Screw

Screw

Screw

Screw

Screw

Screw for

Scre

Plug Screw

52 882 L

Screw for 53783

Screw

Screw for 51236

S

crew

S

crew for

S

crew for 56458

S

crew for 51472

Hi

51 5

S

crew

Screw for 51242

L

f

Needle

Adjusting Screw

Screw for

crew for

S

crew for 539, 51758

Screw for

crew

(5

crew

A

539

Plug S

Plug Sc

Eccentr

for 291 05 Q

cr

fo r

S

pot

5

Screw for pulley

Sc

Screw for 5

et Scre

5

Strip Gui

23322

n.

Description

for 5147

1250

C)

for

23437

for 52882 AI!:

for

537

for

for

for 51216

for

51493

for

for

needle lev

pin,

lower

for

514

for

bearin

g

for 51282

51493

for

51278

ew

for 5152

for 51282

for

5142

for

660-212

for

52350

216

for 52372

for 51243

for 514

for 51294

for 51294

55241 N

w f

or

51278

(41394

for

13430

for 51244

564

nge S

crew for

20BT-10-l

fo r 5

ock

Nut Screw

or 5174

eed Dog H

1142

1406, 5237

5

Guard

52980

cloth

52882

for 5

1216

N)

for

51242

djusting S

tor Scr

, 51758

crew

r ew

ic

Set

ew for 5127

tS

crewfor52372

c Sp ot Sc

2910

5 Q

Sc r

ew for

52375

c.

rew

for 512

w for

de

AL-l

6

83

29105

2 91

05

52934

50

5 E

57 Y

72

for

58

142

5 E

2934

older

crew

ew

Screw

3 B

42

1247

5

(2 5

1 / 4

V

L

K

BP

g

Y

All

D

AF

A

A

C

B

U

U

A)

A

D

B

B

A

A

1/4

W

A

plate

L

D

Y

for

rew

W

C)

Q

Q

e r

3

A

Page 7

Amt.

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

1

1

1

1

2

1

2

1

2

1

1

1 5

1

1

1

1

1

4

1

1

1

2

Part

23322

1

1/4

23437

23437

23437

29066

20105

29192

29

348

20476

29476

29476

29476

29476

351780

35178

35731

35766

39158

39158

39582

41394

43139

43266

51034

51054

51054

51134

11

34

51134

11

34

5

51134

51135

51142

511

45

51147

5

115

0

51193

512

16 G

No.

AL -

u

v

w

H

Q

D

y

DR

JN

KS

KT

KU

D

A

G

u

L

A

A

A

c

J

N

v

HA

p

c

A

X

De

s c r i

ption

Bind

'r

(00,

23322

Bind

e r

Bra

ck t 1

(23437

Binder

(22548)

Lock

23437

Needle

Connecting Rod

Ball Joi

Assembly (225

Looper

Eccentric

Assembly (225

22559

22894

Looper Roc

Assembl

Needle

As

sembly

F e

ed

As

sembl

•

080

Looper

Eccentric

Assembly, • 062

inch

Knife

Eccentric

Assembly, • 158

inch

Feed

Assembly,

•

158

Crankshaft

Assembl

throw

Spring

Spring for

Presser

Connection Gui

Plate ( 22513)

Screw

Hin

ge

Spr

ing f

Oil

Cap

Gasket for

Lock

Nut

for

Feed Bar

(88

B)

Li

nk

ev

er

l

F

eed

Pin

Feed Bar

Feed Dog

Washer

Spr

ing (HA9 5)

T

aper

Feed Dog Ho

or

f

(258, 51134 J)

Fee

d Rocker Ar

(60

42

5

5235

E cc entric for

294

76 DR (

Eccentr

Assembly

29476 DR, JN,

KS,

Ma in Sha

95

) 1 51254 c

(

Need

St op Collar

O

il Tube

upp

er f

pin

N

eedle Lever

Co

nnect

M)

Mounting

W,

43139A)

Slide Blo

Scr

ew

for

U(43139

Lev

er

nt

Dt·ivc

B,

22894

D)

ker

y 1

Leve r

LiftEccentric

y,

lower,

inch

throw

Avo

id 1

throw

Drive

throw

LiftEccentric

upper,

inch

throw

y, •

990 inch

for

666-65

666-114

Bar

for

51450

for

51278

or

51278

22733

Nut for

234

51292

Shaft

P in

for

needle

(77,

22564)

Cr a

nk

(77) 1

529 34

le Leve

L i

Shaft

Holder

P in

lde

A, 55235

E )

228

ic B ea rin g 1

for 1

KT

ft

Colla

r Sha ft

( 71 9} 1

for

eed

ba r

R

od

in

g

ck

A)

59 G)

50

A,

C,

de

B

37 W 1

G

nk

r

m

D, 1

94

D)

r

Amt.

28

3

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

Part

No.

51216

51216

51216

51221

5

1225

51236

1236

5

51236

51236

51 236 D

51236

51236

51236

51240

5

1241

51242

51242

51242

51242

51242

51242

51242

51242

51242

51243

51244

51244

51244

51244

51

24

4 N

512

46

51

247

51250

51250

51250

5

125

4 D

512 54 J

5

1256

M

Needle

Roller

Washer

N

p

c

w

A

A

A

B

E Feed

F

G

E

I

L

M

M

p

R

s

w

y

z

c

B

K

L

c

D

c

55244

Nut

Pulley ( 22894

Was

Fe

ed

Link

Looper A void

Ec

centr

Pin

Link

51273

Feed

Cap

l"eed

for

Assembly

Feed

for

Fe

ed

(20,

Looper

Rod

Looper

Rod

r i

ght ( 12538)

Looper Drive

Rocker

Washer

Washer

Washer

Looper

Lever

Looper

Shaft

middle

Looper

Shaft

rea

Loop

(22811

Looper Dri

Rocker

22852A, 51242M)

Looper Drive Lever

Shaft

f

ront

Ball Stud

(22729)

Loop

F

rame (96, 98)

Loop

Sha

(22519

oop

L

Loop

Thru

Loop

Cl

amp Colla

(18 ,

Loo

Nu

t

Ma

in

weig

Nut

Wa

sher for 22586 R

Gasketf

Ne

edl e

Bu

shin

Needle Ba

Bus h

Ne

edle

Co

nne

P

res

Description

Bearin

for

20476

fo

22852,

G,

56315

for

51215

her

for

22 5

Lift Ecc

(77)

Pin

Crank

(22768)

Crank

51236

Cran

Crank

51236

Crank

82,

(18,

and

r

er Dri

er Rocker 1 5

er Ro

ft

er Rocke

er Rocker

st W

er Rocke

20,

pe r Roc ker Stud

Sha

ht

for 225

in

se r BarS

Pin

( 77)

ic

Link

for

( 77)

Stud

Link

E

k Li

Ferrul

E

Stud

269)

Connecting

269)

Connectin

Ball Joi

Thrust

for

22852

for

52841

Drive

Shaft

Drive

Bushin

g,

Dr1v

e Le

Bushin

g,

ve

B, 228

ve

(81,

Bus

hin

g,

Fork

cke

Ar m

H,

22768)

ashe

r

552

44 G)

ft

Counter-

(2289 4

47

or 22586 R

Bar

g, upper

r

g,

low

Ba r

ch on

entric

Lever

94

Leve

r

rSh

r Shaft

er

pr m g

Amt.

g 1

KU

1

.T

F)

85

nk

Lever

Lever

Sha

r

J)

C

1

B

l

1

1

1

1 5

1

1

1

1

1

1

g

nt,

2

1

1

1

A

G

1

1

1

ver

1

4

H)

4 51292 c T

r

4

2

2

4

1

1

1

aft

1

ft (22

1

1

1 51

1

1

1

1 5141

1

1 51

1 5

1

1

1

1

Pat·t

No.

512 57 K

51257

M

51257

AA

5

1270

B

51272

c

51272

D

51273

A

1273

B

51273

D

51278

51278

A C hip

51278

D

51278

G

51280

E

51280

J

51282

y

51282

z

512

82

AE

51282

AF

51283

H

51290

T

51291A

51292

A

512

92

D T ensi

512

92 F

-4

51292 F

51292

5

5129

51294

51294

51294

5129

51405 S- 8

51406

51408

51418

51425

51426

51430 L K

514

-8

G

1294

K

129

4 M

4 p

R

u

w

4 z O

382

A

D-

10

7C

-

12

F

422

E Main Shaft

14

24

S-

10

E X

s

30

Z-

10

Description

Presser

Presser

Connection

Guide

Presser

Bush

Needle Thread

Tak -up

Blo

Shaft

Blo

Shaft

Upper

Bracket

Upper Knife

Bearm

(22894

Upper

Rocker

Chip

Assembly (22730

51278

Sprin

Hin

Throat

Support Pin

Dowel

5

Head

Head

Needle

Bearing Oil

Oil Reservo

Cover

Pres

and

Re

Main Shaft Bush

middl

Looper Threa d

(98 A)

Te nsi

ension Nut

Eyelet

Tensi

loope r

Tension

needle

Tensi

Upper Cl

O

il

Oil

(7947,

Scr

(7947)

Oil

Oil Tube for

il

Ga

Lower Fee

(

225

Eccentric for

29476 J I'\

Looper

i.\"eedle Bar

Ne e

88

(

Th r oat

eed

(225 85 B ,

Upp

nife Guar

515

(60

Presser Foo

Bottom for

5

Bar

Bar

and

( 31)

Bar

ing,

lower

Wire

ck

Guide

Collar

ck

Guide

Colla

Sprin

g

l<nife

Rocker

g S

tud

C)

Knife

Holder

Arm

Guard

Guard

for

g ( 22570 B)

ge

Pin

for

Plate

P in

2980

ew

sk

1520 BT-10-1 1/

for

A

Cov r (22560

Cove

r G

Lev

er

er (90)

ir

( 225 24)

se r Foot L ifte r

Tension

lea

se

L eve r

e

on

P o

st Ferrule

on Thre

on

Sp r ing,

Sp r ing,

on Post

amp

Si phon Tube

Tube Cl

Si p

729

Si p

dle Clamp Coll

er F e

20 BT-10-1 1 / 4

4)

51294 R )

for 51294

hon

A,

hon

et f

or

28)

(22

, front

B, 89)

Pla

le

Guar

ed

am p

As s em

22729 B)

Tube Conn.

51282 AF

d Dog

te (87}

d

2280

Dog (

d for

t

(95)

r

Holder

)

5127

8

(258)

asket

Top

Disc

(402)

ing,

Guard

ad

P

bly

51273 D

894 T)

ar

1)

93A

4

B)

)

Page 8

Amt

1

1

1

1

1

1

4

1

2

1

1

1

1

1

1

I

1

1

1

1

1

1

Part

No

51449

51450

51470

51472

51472

51478

51491

51493

51493

5

1493

51493

51493

51493

51493

51494

51501

51504

51513

51520

10-1 1/4

51523

51530

51745

Low

Low

Block(22568,

Upp

A

Upper

(22798)

B

Upper

(22729)

Front

Chip

(22547

Lead-in

c

Eyel

D

Oil

Shaft

E

Driving Shaft

AG

Oil

(22569

AH

Oil

Cover

BK

Lint Fil

BP

Pump

(22560

BQ

Pump

(531)

E

Oil

and

lift

A

Cloth

22839

Cast-off

D

Looper

29192

BT-

Presser

Take-up

22580

H

Yielding Section

51520

Looper

Stud

(258

51246)

De

scription

er

Knife

er

Knife Holder

35766)

e r

Knif

e 22528)

Knife Shield

Knife Clamp

Cover

and

Guard

Latch

C,

51250

Thread

et

Pwnp

Driving

Pump

Pump

Driving Gear

Driven

Tube

lower

eccentric

Plate

Gear

Housing

B)

Housing

(225

69

ter Screen

B)

Gear

for

upper

feed

(80,

C)

Plate

Rocker

B)

(28)

D 1

Foot

(96,

D)

BT-10-1

for

A,

Rocker

Cone

29192

22829,

Amt

C)

for

for

1/4

D 1

Part

No

1

51758

51909

1

52350 A

1

1 52357 A

1

52372

1

52372

2

52373

I 52841 G

1

5284I

1

52882

52882

1

52882

1

1

52882

52882

1

1

52882

52882

1

52882

1

52882

1

52883

1

52883

2

52890 c

52891 B

c

A

A

J

L

M

p

u

y

AA

AC

AD

AE

R

s

Description

Frame Thread

(20,

22848,

Looper, back

Knife Hold

(22588

Cast-off

Plate

Upper

Block

Upper

Block

(22711,

Bushing

Locking Stud

51242 y (52841

Nut

Oil

Cover

22848,

Gasket

Ga

sket

Gasket

Baffle

Oil

Spring

Chamber

(22

Crank

Cover

Presser

Lever

Presser

Lifter

Crank

Ma

in Sha

left

Crankshaft

i

ncludes

(22569

er

A)

Support

(21657

Knife

Knife

Guide

22894

for

for

5284

Reservoir

(22733

41394

for

for

for

Plat

Drip

Plate

for

Cover

541 B)

Chamber

(22

548)

Foot

Bushin

Foo

Lever

Sprin

ft

and rig

bushing

B)

52882

52882AD

52882AE

e (90)

52882

Bushing,

ht

Housing,

Eyelet

22889A)

Plate

E,

Hold

er

Hold

er

Coll

ar

C)

51273A

for

J)

1 G

Back

B,

A)

L

AD

Lifter

g

t

Bell

g

Amt

3

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

Part

No

52894

52894

52894

52934

52934

52934

5

2934

52934

5

2934

2934

5

5293 5

5

2936

2944

5

52944

52980

53783

53783

53783

53783

55

235

23

5 E

55

55241 N

55244

5631 5

56341

563

50 A

56354 A

56356

56382

56390

6458

5

56458

92127

O

AB

AK 0

AM

Oil

Main

A

Upper

B

Upper

c

Upper

D

Top

E

Lubricat

F

T

u

A

A Li

L

M

N

D

Screw

G

Looper

G

Spring for

Presser Spring

X

E

A

Needle

Set

Description

il

Tube

Tube

Tube

Feed

fter

for

Screw

joint

joint

A)

Feed

52,

Rocker

22839)

37)

Ball

(18)

(18,

Holder

for

looper

and

left

(88)

for

right

(258 A,

Bar

B)

Feed

Bar

Feed

Bar

Feed

Bar

Holder

51216

ing

Felt

(92127)

ker

Shaft

g

ker

g,

right

Rocker

g,

middle

Plate

Suppor

Lever

Link

C)

Foot

Lifter

Bell

Crank

B)

Foot

Lifter

Connectin

Foot

Lifter

internal

for

51135

51135

P

Connectin

Joint,

Shaft

Collar

51216

Lever

51241 K

Lever

Stud

Lever Link

Post

Bear

Threa

(22768)

Bar

Thread

for

52935

11

rocker

ball

ball

6042

(22560

Arm

Stop

(228

Lubricating Felt

Guard

Feed

F

eed Roc

Bushin

Looper Roc

Bushin

left

Looper

Bushin

Throat

(80,

(402, 227 58

Presser

Lever

(22557

Presser

Lever

Rod

Presser

Lever,

(22 5

Nut

Looper

Rod

left

Stud

Needle

Needle

(719)

Needle

Regulator

Tension

Support

Crankshaft

Housing Gasket

Needle Lever

Eyelet

Eyelet

(90)

N)

Shaft

and

Shaft

g

P

g

N)

ng

d

NOTE:

Numbers

parts.

in

parentheses

following

parts

description

indica

te

the

screws,

nuts,

etc.,

used

to

attach

or

hold

these

Page 9

IIIII

22528

51405 S-8

51426

22585 B

s

93 A

...

51225 w

0

51425 E

51

22580 D

lk

.

r-

·-·-.

13430 B

...

•

51430 Z-10 !

51424

S-10

9

/ 22760 A

13430 D

4

-

--v,..·--

51408 D-10

j

•

H

...

28

-

51909

.&

c

52357 A

51523

22528 21657E 2

,---

~

88

B

51418 F

........

/

--

51520 BT-10-1

1/4

Page 10

(2)

(

2)

22548

f • •

/"\

80

l

52980

A

(2)

~-'-'-'"

v

23437 v

(

2)

25 c

(

2)

90

23322

M

23437 u

0

43139

A

(

2)

22730

23223

T

Page 11

51273

D

Page 12

56458

2§!_.,.,

l..5n

51278

ZQ

22889A,

51282

z

Page 13

51236E

~

512360

51236F

660-169

(2)55235E

(2)552350

22852

52934C

(BRASS)

51134N

666-47

666-138

IL

Screw

29476DR

52934B

228940

29476KT

51145A

51236A

77

Page 14

Union Special is

redu

ce

your

system to

and a part s inve

Machine Maintenance Records

up your

Union Special suggests two variations

record keeping system using cards provided by Union Specia

(Form

required, the card is

and the ir cost are entered in the s

help spot machines requiring abnormally high maintenance,

Repair-prone

maintenance dollars in short order. To help spot these problems,

The first system utilizes a

237) for

.....

The second system is

on repair costs is desired. Two record cards are used; a

Request Card

233). When a machine requi

out the

top

fills in the time the repair

off

sewing machine maintenan

............

ering two practic

ntory

system to speed rout ine repairs.

ma

chines

or

inexperi enced competent operators

..

ea

ch sewing machine in a plant. When a repair is

pulled

...

...

·~-·

Machine Maintenance Record

from

MACHIN K MAINT.NANCl RE

• n

LI

I

·

..

~

~

fO

"""'

•·

'"

normally

..

(Form

234), and a

of a ..

Repair Request Card

re

work

al

systems to he

ce

costs: a record keeping

of

a simple maintenan

the file and the repair date, parts used,

pa

ces provided and the card is refiled.

CORD

. IRIAl.

"

...

.......

11:

-

Lb

l.

31-

~t'\

~

80

te0

tf\&\0

·

oe

.

~

··

~

f=

used when more detailed i

..

Machine Repair Record

s servicf', the forelady

..

is started, the parts used and their cost,

and gives it to a mechanic. He

HO

...

~e

-.

---

lp

. J

or

pinpoint and

..

I:I

Uif'

~

-·

~

nformation

..

Repa

..

foreman fills

and the c

..

to reduce needless maintenance costs .

can

eat

abnormally high maintenance, it does

ce

l.

card

-

-

caused by routin e repairs. To alleviate this situation, Union Special

recommends that manufacturers establish a formal parts inventory

system for

be eliminated with an orderly in-plant inventory

needed parts. There is

for

downtime is kept to a

when the overall savings are considered.

--

ir

(Form

inventory

local Union Special Representative

ompl

Machine Repair Record

Whichev er system is used, management now

Repair

While record keeping tells management which machines require

Excessive machine downtime and wasted hours by mechanics can

spare parts.

For

etion time. This data is then transferred to the permanent

Part

Inventories

ea

ch type

Long

MACHINE REPAIR A&:C

~o~•a•

• •

M•u

.r

_,.

-.:s•

=-

fO~t'\

- .

-

tf\8~"'"

=-

- ·

free sample copies

lists

for

..

kept in the office.

little to help reduce the

of

sewing mach ine they operate.

no

longer a need to cannibalize other machines

waits for deliveries are avoided and machine

minimum

OAO

~"'I"

~'3'3-

it

e~el'a

a variety

. The cost

CARD

:::M...

·

0UK

J

...........

·-

I

-

~

m

~e~otd

of

the machine record cards and spare part

of

the most popular machines, contact

Oooo

l'-

1 "

i'llf

~

d '

=--

~at

-

·

-

=l

fi

T-COM"'•uo

-c.MAMIC:

or

write direct

ha

s an invaluable tool

of

the most

of

a parts inventory is small

..

...

Rllf"AIR RllQU

···-···

......

•••

·

fO~t'\

~el'~

iii.TAII11 D

EST

.

....

...

.

..

· -

PAAT

8 USI D

-·

~'3A-

·

t~eque

I ..o

__

-

--

to

CARD

t

"

OM

----

Union Special.

·-

ca

td

- , -

----

--

downtime

commonly

~

1-

=

·

,-

I=

11-

-

i=

I=

1-

I=

I=

I=

your

Part

Number

51520BT-10

1 114

51405

22528

51426

93

51424

87

128

51408 D-10

S-8

s

A

S-1 0

GAS

Description

Presser

Lower

Upper

Throat

Needles

Looper, fr.ont

feed

Screw

feed

Screw

Screw

foot

for

for

plat~

for

(specify

dog

lower

dog

upper

throat

feed

dog 2

feed

dog

plate

size)

Minimum

Per 5

Quantity

Machines

1

1

1

2

1

4

200

1

•

Style

Part

Number

51909

51449

51470

73

88

B

22564

22729

22588

2122

29484

c

A

5-1/ 8

51500

Suggeated

Minimum

Description

Looper, rear

Knife,

lower

Knife,

upper

Looper

set

Need

le clamp

Needle

bar clamp

Upper kni

Lower

Looper

Screw

fe

knife

gauge

assortment

Spare

screw

screw

screw

clamp

scr

clamp screw

BT

Parts

Minimum

ew

-10-1

Uat•

Per 5 Machines

Quantity

1

4

4

6

6

2

2

2

1

1

\

• The parts and quantities listed above are intended to assist you in

setting up the

can

only be established according to actual usage. The nature

sewing operation

initial inventory

wi

ll

determine actual usage.

of

spare parts. An efficient inventory

of

the

Page 15

Helpful,

cient

machine sewed

ales

esting,

obligation

authoritative

types of

Promotion

illustrated

are the

information

equipment

article

is

Department.

bulletins

following

for

available

Among

that

:

on

the

making

from

are available wi

virtually

Union

the

many

most

Special

effi-

any

inter·

thout

HERE

ARE

HELPFUL

No.

240,

"Men's,

No.

249,

"Rainwear"

No.

250,

"Men's

No.

251,

"Service

No.

252,

"Men's

No.

253,

"Overalls, Coveralls, and Dungarees"

No.

254,

"Men's

No.

256,

"Knit

Outerwear"

No.

259,

"Men's

No.

260,

"Work

No.

262,

"Cotton,

Bags"

No.

263,

"Men's

No.

264,

"Men's

No.

265, "Women's Wear"

No.

266,

"Women's

No.

26

7, "Corsets,

No.

268,

"Children'

No.

269,

"Mattresses,

Upholstery"

No.

271,

"Awnings, Can

No.

273,

"Curt

ains &

No.

610,

"Kiipp-it"

No.

710,

"MCS

ForMation

No.

730,

"MCS

Automatic Dual

Hemmer"

No.

740,

"MCS

Automatic Rib-Knit

No.

750,

"Fusing

No.

1100,

"Lew

is

s

titch

, Machine

No.

1105,

"Butto

"Columbia

i

ng

Machin

No.

Blindstitch,

es" '

1500, "Alteration

Women's,

Dress

Shirts

Shorts

Knit

Sports

Gloves"

Burlap,

Clothing"

Women's,

Wear

Girdle

s Wear"

Presses"

Blindstitch,

n Sewers-Tick

Children's

Shirts"

and

and Pajamas"

Underwear"

Shirts"

Jute,

Children's Jackets"

And

s, Brassiere

Slip

Covers, F

opies,

Drapes"

Unit"

s"

Saddle

Department

Footwear"

Pants"

and

Multiwall

High Fashion"

s"

urniture

Tent

s, Ta

rps"

Underfront

Cuff

Chains

titch,

et

Tackers"

Stitch, and

Mach ine

Shirt

Machi

Lock·

Tie

s"

Paper

ne"

Clo

BULLETINS

TO

HELP

SEWING

s-

and

YOU

CATALOGS

SOLVE

PROBLEMS

UNION SPECIAL

fiNlST

OUAUTV

CORPORATION

Page 16

,..o

...

~

...

Q

WORLD'S

".

l f

FIIEIT

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains sales

and

facilities throughout the world. These offices

aid

you

in

the selection of the right sewing

equipment for your particular operation. Union

and

Special representatives

and

is

Check with

ILL.

Y.

PA.

and

a Union Special Representative to

tory trained

promptly

tion, there

serve you.

ATLANTA, GA.

BOSTON, MASS.

CHICAGO,

DALLAS, TEXAS

LOS ANGELES, CAL.

NEW

YORK, N.

PHILADELPHIA,

are

efficiently. Whatever your loca-

service men

able

to serve your needs

him

today.

MONTREAL,

TORONTO, CANADA

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS, FRANCE

STUnGART,

service

will

are

fac-

CANADA

ENGLAND

ENGLAND

GERMANY

Representatives

industrial

UNION SPECIAL

.400

N.

FRANKLIN

r

and

cities

dlatrlbuton

throughout

ST.,

In

all

Important

the

world.

CORPORATION

CHICAGO,

ILL.

60610

Loading...

Loading...