Page 1

®

INDUSTRIAL

SEWING

FINEST

CLASSES

QUALITY

51200

51300

51400

51500

51700

51900

L -E W I S • C 0 L U M 8 I A

;

MACHINES

\ I I

·~---

. I

)

STYLE

51400BP

.

CATALOG

No.

104

SECOND

L

EDITION

FIFTY

·

sTREAMLINED

TH0USA-

MACHINE

ND

""·

SERIES

.

COMPANY

Page 2

1

51200

51200

51200

51200

Classes

BG

BK

51200

51200

51200

51200

BL

BM

BP

BR

51200

51200

51300

51300

51200,

BS

BT

BW

BX

51300

51300

BG

BH

BJ

BL

Catalog

LIST

51300,

No.

104

OF

PARTS

51400, 51500,

S

TYLE

S

51300

51400

51400

51400

51400

51400

51400

51400

51400

51400

51400

51400

51400

BM

BA

BB

BO

BP

BQ

BR

BS

BT

BU

BY

BW

BX

L

51700, 51900

51700

51700

51700

51900

51900

51900

51500

51500

51500

51700

BR

BG

Bll

BJ

51400

51500

51500

51500

BR

BJ

BK

BQ

BY

BJ

BK

BM

BN

BP

The

furnished

Rights

parts

Union

listed

at

list

Copyright

Special

Reserved

prices

Second

in

this

Edition

By

Machine

in

for

1Q56

All

catalog

repairs

Co.

Countries

MACHINE COMPANY

INDUSTRIAL

SEWING

CHICAGO

MACHINES

are

only

.

February,

Printed

1968

~n

3

U.

S . A.

Page 3

The

catalog

bed

line.

and

light

utmost

a

pump

made

methods

information

possible

following

all

maintenance

It

of

50000

represent

Light

weight

in

speed

for

returning

insuring

is

our

advantages

pages

the

machines

that

series

the

weight

presser

and

simple.

complete

constant

will

illustrate

FOREWORD

streamlined

latest

needle

bars

production.

filtered

All

interchangeability.

aim

enable

from

covered

the

to

and

by

design

bars

make

oil

parts

furnish

the

use

describe

this

machines

of

Union

and

it

possible

Automatic

to

the

are

carefully

customer

of

Union

catalog.

covered

driving

lubrication,

main

made

to

Specials

the

parts

Special's

mechanisms

to

attain

reservoir

by

precision

prepared

secure

by

all

.

used

this

The

flat

with

,

1n

the

has

Additional

these

listed

representatives

planning

machines,

below:

Catalog

Form

In

all

No.

357

Adjusting

of

machine

instructions

manufacturing

and

estimating

catalogs,

and

45N

, who

containing

which

Instructions

for

will

will

which

are

centers

co-operate

their

be

the

required

requirements

~

information

furnished

Needle

Engineering

.

will

Manual

Specify

adjusting

.

be

wi~h

Engineering

on

request,

Department

the

style

found

those

.

MACHINECOMPANY

relative

Union

who

des

Department

to

are

Special

ir

e

in

4

Page 4

IDFNTIFICATION

OF

~~CHINES

Each Union

machine.

have one

Style

or

numbers

in a standard

Fxample:

"51400

Styles

differs

The

from

distance

51700, 51900

gauge

distance

represents a distance

of

This

can

also

be

Style

more

containing

machine a

of

machines

the

is

64/64

catalog

applied

Special

numbers

carries a style

are

letters

"Z"

BPZ".

similar

style

number

between

represented

or 1 inch.

applies

with

suffixed,

the

discretion

51400, 51500, 51700, 51900 .

Strearrliined

Bar

Drive

L

ubricating

Space

Flat

Bed,

~~chanism,

System and

to

Right

of

One

Light

Filter

Needle Bar 8

number which

classified

letter

is

merely

in

in

the

rows

by

a gauge number measured

of

12/64

APPLICATI

only

to

STYLES

Needle,Light

and

~~dium

Type

1/4

as

but

never

''Z"'are

suffixed

construction

that

it

contains

of

stitches

or

3/16

the

standard

to

the

OF

~~CHINES

Weight

Duty,

Oil

Return

Inches.

standard

ON

special

contain

special

are

on

inch.

OF

styles

Presser

Single

Pump,

is

stamped

and

special.

the

letter

.

~hen

only

to

the

respective

grouped under a

no

letters

maclcines

in

in

l/64ths

Similarly,

CATALOG

of

machines

machines

IN CLASS

in

51200

Bar Mechanism,

Reservoir

Lateral

in

the

name

plate

Those which

Z. Example: "51400

minor chang

standard

class

. Example:

Classes

of

an

64 gauge

as

listed

Classes

Light

es

style

number which

"51400".

51400, 51500,

inch

. Thus, 12

represents

herein. It

51200, 51300,

Weight Needle

Enclosed Automatic

Looper

Travel,

Maximum Work

are

are

on

the

standard

BP"

made

number.

a

51200

J)G

seam Type

51200 B K

Type 106 GL

1 1/ 4

51200 B L

BSa-1.

3/ 4

51200

BM

51200 BP

301 G

51200

BR

operation;

51200 BS

shirt

51200 BT

fronts

used

inch

51200

BW

Seam

51200

BX

Knee

Light

SSa-1.

Light

inch

Medium

Type 126 G

inch

Medium

Light

needle

Light

Light

fronts;

Medium

ond

in

either

Medium

Type S Sa

Medium

lifter

duty,

for

Type 106 GL

duty,

for

needle.

duty,

duty,

duty,

duty,

sea

duty,

for

for

m Type

for

seam Type S

duty,

sleeves

garment

duty,

-1.

duty, for

.

Seam

seaming

binding

Uses

cut

for

binding

needle.

for

seaming

stitching

joining

LSe-1.

miscellaneous

Sa-l.

for

facing

of

woven

lengths

for

seanting

Type 110 G

seaming

Type

SSa-1.

light

to

needle

aprons,

edge

dresses

strips,

mattress

Uses

selvage

mattress

side

stays

shoulders

Type 106 G L

operations

Type 101 G

sleeves

shirts;

or

canton

and

seam Type

long

flannel

needle.

light

weight

Type 109 G

medium

weight

and

standard

ticks

and

edge binding,

ticks;

on

seam Type S

to

shoe

shirts

needle

on

needle

attaching

BSc-1.

lengths,

or

canton

needles

trousers

similar

widths

similar

linings;

and

similar

kni t

ted

one

Type 106 GL

standard

leather

flannel

and

similar

garments; seam Type

3/4,

7/8,

1, 1 1/8,

operations;

standard

Sa-l.

seam Type

garments

seam Type

widths

5/8,

Type 128

LSa-1.

in

drawer bands and

piece

button

stays

needle.

widths

palm

and

gloves

jersey

1/ 2 , 3/ 4, 7/

. Knee

cloth

operations;

BSc-1.

7/8,

GA

needle

Type

one

knitted

to

Strips

8,

1

lifter

gloves

.

.

5

Page 5

STYLES

OF

MACHINES

IN

CLASS

51300

Streamlined

Bar

Drive

Lubricatin

Space

51300

BG

S Sa-

51300

BH

to

51300

BJ

L

Sb-1.

51300 B L Heavy

seam Type

51300

BM

BSa-1.

3/4

Streamlined

Presser

Single

Lateral

Flat

Mechanism,

g System,

to

Right

Medium

1.

Type 128 G A

Heavy

left

of needle

Medium

Type 128 G A

lleavy

Type 126 G

inch

Flat

Bar

Mechanism,

Reservoir

Looper

Bed,

Medium

Filter

of

Needle Bar 8

duty,

duty,

duty,

duty,

SSa-1.

duty,

Bed,

Two

Enclosed

Travel,

One

Needle, Light

and Heavy Duty,

Type

Oil

Return

l/4

Inches.

for

seam

ing

trousers,

needle

for seaming couch

, seam

for

for

Type 143 G

for

Light

Maximum

type S Sk-1.

welt

seaming

needle

seaming heavy

needles

binding

needles.

STYLES

Needle,

Automatic

mattress

Uses

OF

Left

Weight Needle Bar

Work

MACHINES

Lubri

Space

Weight

Single

Pump,

covers

Type 143 G

trousers,

weight

ticks

selvage

Needle

cating

to

Right

Presser

coats

with

auto

edge

IN

in

Drive

System,

Reservoir

Lateral

and

or

needle

coats

cushions

and

similar

binding,

CLASS

Front,

Mechanism,

of

Needle Bar 8

Bar Mechanism,

Enclosed

Looper

similar

without

and

51400

Ind

Filter

Travel,

garments; seam Type

rope

similar

and

similar

operations;

standard

ependent

Light

Type

Row,

Oil

1/4

Light

Automatic

welt

garments;

widths

and

Weight Needle

Maximum

. Welt guided

operations;

seam Type

Light

Medium

Return

inches.

Work

seam Type

5/8,

7/8,

Weight

Duty,

Pump,

51400 B A

and

lengths.

51400 B B

at

51400 BD

of

attachments;

and

51400

BP

ordinary

Type 106

51400

BQ

interlining

seam Type

have

lengths.

51400 B R

strip. No.

106

51400

BS

to

Seam

lengths

Nos.

Light

similar

neck;

knitted

16.

GH

shirts

duty,

garments

Type 106 G

Light

Light

Light

Light

1/4

Light

Light

produced

32,

duty,

~t

itching

duty,

undergarments.

stitching

duty,

quality

GH

needle. Standard

duty,

strip

LSj

-2.

inch

Type 106 Gli

duty,

body

needle. Standard

duty,

and

and

guided

48

for

for

Type

for

for

light

for

and

Starts

margins

for

guide

for

similar

with

1/16

next

folding

in

needle. Standard

11

herrming and

piecing

one

facing

on each

folding

one

garments;

and

attaching

one

operation;

cut

on"

button

EFb-2.

Type E Fg-2. Type 106 G

weight

operation

operation

needle.

or

gauge

operation

inch

to

Type 106

simuhaneously

Prepared

sleeves,

shirts

gauges Nos.

strip

side. Facing

Standard

and

attaching

lower

strip

No.

seam Type

margin on each

feed

dog. Type 106 G H

seam Type

gauge

stay

for

joining

and

folding

to

fronts

at

neck .

folder

48

folding

single

GH

use

similar

6,

and

gauge No. 48

set-on

and

LSk-2.

piece

BSc-2.

No.

48

operation

needle. Standard

inserting

with

Galkin

needle.

shoulders,and

garments; seam Type

8.

10,

attaching

of

shirts and

Plaits

and

interlining

center

required;

attaching

Starts

side.

Facing

needle.

fm:ing

on

shirts

close

Standard

12,

16,

used

seam Type LSm-2. Type

to

sleeves

Facing used

.

Starts

gauge No. 48

elastic

setting

18

extension

similar

in

garment

strips

plait

inside

operation

strip

Standard

in

coupled

gauges Nos. 12

and

button

used

in

tops

puller. No

sleeves

LSc-2

center

garments;

len

used

interlinin

at

neck.

in

gauges

of

shirts

garment

operation

and

of

.

plait,

gths

and

in

long

g

facing

long

legs

6

I

Page 6

STYLES OF

51400

BT Light

weight

needl e.

51400 BU Li

neck;

51400 B V L

duty,

extra

for piecing

fine

Standard

ght

duty, for "cut-on"

stitching

ight

Type E Fb-2

duty, for

seam Type LSd-2. Type 101 G

51400 B W

tions

Light

on

duty, for

woven

shorts,

seam Type LSc-2 . Type

51400

BX

Light

duty, for qui

51400

SSa-2.

BY

shirts

inch

presser

Type 106 GH

Light

duty,

and

similar

margin on

foot;

for

both

seam Type LSk-2. Type 106 GH.

~~CHINES

sleeves,

quality

gauges

shirts

Nos

. 8, 10,

inverted

uni

ting

the

needle. Standard

piecing

where

106

GH

lting

sleeves

the

collar

needle. Standard

folding

garments.

and

Starts

sides. Stays

IN

CLASS

joining

and

similar

12,

button stay

51400

and

garments; seam Type LSc-2. Type 1

16

operat

. Type 106 GH

lower edge

of

majority

of

shirts

of

the

needle. Standard

bands

attach

of

shirts

gauges

ing

Nos

"set-on" button

operation

used

in

garment

Standard

(Cont"d.)

setting

ions

needle. Standard

french

gauges No.

and pajamas, and

work

sleeves

on

shirts. Starts

drawer bands

12

and 16

for

consists

of

of

light

gauge

to

joining

straight

gauges Nos. 8, 10, 12, 16

and

similar

. 24,

26

at

neck . Seam produced

lengths

and

gauge No.

garments; seam Type

stays

to

guided

fronts

next

32

and

operation

No.

body fab'ri

opera-

seams;

of

with

1/32

to

medium

06

GH

at

32

c;

work

STYLES

Streamlined

Light

Weight Needle Bar

System,

Needle Bar 8

51500

BJ

needle

Filter

For

Flat

Type

1/4

felling

in

Bed

Inches

front;

Two

Drive

Oil

Return Pump,

.

overalls, coats,

seam Type

18

51500 BK.

in

for

front;

seaming

seam Type

trousers

gauge No. 1

51500

BM

For

long

Type 128 G A

51500

BN

in

facing

lengths

For seaming

front;

bibs

and guided n

needle. Standard

trousers

seam Type S Sa-2. Type 130 G needle. 7

gauge No. 1

51500 B P For seaming wind

heavy weight melton and

Type 128

51500 BR For

LSc-2

GA

needles. Standard

fell

ing

overalls

Type 128

GA

Of

MAC

HINES

Needle, Independent

Mechanism, Heavy Duty,

Lateral

combination

LSc-2

. Type 128

SSa-2

of

overalls.

ext

and simi

. Type 130 G

to

feed dog.

lar

Facing

gauge No. 18

and

similar

breakers

similar

and mackinaws,

fabrics,

gauge No. 18

and simi

needle.

lar

Standard

IN

CLASS

Row,

Light

Weight

Single

Looper

Travel,

suits,

GA

needle. Standard

garmen~s.

needle

strip

Left

garments.

. 10

cut

needle

Tandem

stitches

parallel

Tandem

stitches

coats

left

needle

garments ,

gauge No.

left

18

51500

Presser

Reservoir

Maximum

and

similar

needle

in

front;

needle

per

and

simi!

in

front; seam T

needle

Bar Mechanism,

Automatic

Work

Space t o

garments,

gauges

seat. Right

per

inch.

with

selvage,

seam Type LSk-2.

seat. Right

inch. Standard

ar

garments

ype

1.n

front;

seam Type

Lubricating

Right

left

Nos

. 16,

needle

Standard

used

needle

made from

LSb-2.

of

in

Streamlined

Flat

Bar Mechanism,

Reservoir

T

ravel, Maximum

51700

Automatic

BJ

and

interlining

at

neck.

Light

stitching;

STYLES OF

Bed,

Two

Needle, Independent

Light

Weight Needle Bar

Lubricating

Work

Space

duty,

strips

Plaits

to

Right

for

one

operation

to

used in garment

seam Type LSm-2 Type 106

System,

fronts

MACHINES

Driving

Filter

of

Needle Bar 8

folding

of

shirts

lengths

GK

7

I N

Row,

CLASS

Needles

51700

Abreast, Light

Mechanism, L

Type

Oil

Return

1/4

Inches

and

attaching

and

similar

and

extend

1/4

needle. Standard

Weight :->resser

ight

and lleavy Duty, Sint;;le

Pump,

"set-on''

garmemts .

inch

Lateral

beyond

gauges

center

Starts

the

Nos. 56

Looper

plait

operation

rows

of

, 64

Page 7

51700

BK

interlining

operation

of

51700

51700 8 R

BQ

fronts

plaits

Type

medium

strip

has 1/

Light

at

stitching;

Light

of

medium weight

used

LSk-2.

Light

weight army

cut

from body

16

inch

STYLES

duty,

strip,

neck.

seam Type

duty,

in

garment

Type 106

duty,

margins; seam Type

for

for

for

OF

one

and

Plaits

one

GK

one

shirts

fabric,

facing

LSj

army

lengths

MACHINES

operation

strips

used

in

-2.

Type 106

operation

shirts

and

needle.

operation

and

similar

used

in

LSk-2.

IN

CLASS

folding

garment

folding

and

extend

Standard

fold:ii.ng and

long

and

to

fronts

lengths

GK

and

similar

1/4

garments.

lengths,

Type 106

51700

attaching

of

needle.

attaching

garments.

inch

gauge

attaching

Starts

(Cont'd.)

extension

shirts

No.

and guided

GK

and

and

extend

Standard

"set-on"

beyond rows

64

inside

operation

needle.

similar

1/ 4

gauge

Starts

of

next

Standard

center

garments.

inch

No.

center

operation

stitching;

button

at

neck .

to

feed

plait,

Starts

beyond

facings

gauge No. 64

the

64

plaits

at

neck .

seam

to

Facing

dog. Seam

rows

to

Streamlined

Presser

Single

Travel,

51900

51900

51900

TYPE

shank,

largest

shank and

size

Bar

Reservoir

Maximum

BG

Light

and

medium wei

Standard

BH

Heavy

similar

BJ

Heavy

garments; seam Type

NUMBERS

Each

needle

point,

diameter

the

number

Flat

Bed,

Mechanism,

Automatic

Work

duty,

ght

gauges 5,

duty,

garments;

duty,

AND

has a

length,

of

the

eye, and

is

the

complete symbol.

Three

Light

Space

for

shirts

6,

for

seam Type

for

SIZES

type

groove,

blade,

is

STYLES

Needle,

Weight Needle

Lubricating

to

Right

piecing

and

7

seaming

LSc-3.

seaming

LSb-3.

stamped

Type 147 G

number and

finish

measured

OF

MACHINES

Left

Needle

Bar

System,

of

Needle Bar 8

sleeves,

similar

overalls,

windbreakers,

and

in

the

joining

garments;

dungarees,

Type 128

needle.

NEEDLES

size

number. The type number

other

in

thousandths

needle

IN

CLASS

in

Front,

Drive

details.

Mechanism,

Filter

1/4

shoulders,

seam Type

GA

mackinaws, lumber

Standard

shank.

51900

Independent

Type

Oil

Inches.

coats,

needle. Standard

The

size

of

an

inch,

Collectively,

Row, Light

Light

Return

and

LSc

combination

gauge No. 9

and Heavy Duty,

Pump,

setting

-3 . Type 106

jacks

denotes

number

midway between

the

Weight

Lateral

sleeves

GKneedle.

suits

and

gauges No.

and

similar

the

denotes

type

number and

of

7,

kind

the

the

Looper

light

8, 9

of

To have

the

type

would

The type numbers

Type

101 G

106

106

read

The

this

catalog

but

the

s~zes

available

No

.

G Round shank, round

GH

orders

and

size

as

type

numbers

are

ones

indicated

Round

025, 027, 029, 032, 034, 036, 038, 040, 042, 044, 049, 054

plated-

Round

chromium

promptly and

number

follows. "1000

given

of

are

shank, round

shank, round

should

of

the

in

the

are

those

the

recommended

listed

below:

sizes

plated -sizes

027, 029, 032, 034, 036, 038, 040, 042, 044, 049

accurately

be

given. See

Needles Type 1'06

needles

machine

point,

point,

point,

recommended

style

recommended

needles

Description

extra

extra

extra

short,

short,

short,

032, 036, 040, 044

filled,

description

to

together

the

empty package, a sample needl

marks on packages .

GK

Size

036".

for

each

.

produce

double

double

double

the

with

groove, chromium

groove,

groove ,

8

style

Other

most

their

An

intelligent

of

machine covered by

needles

satisfactory

descriptions,

ball

ball

are

available

and

plated -sizes

eye, chromium

eye,

ball poi

order

results

the

nt,

e,

.

or

Page 8

NEEDLES

TYPE

Type

No.

106

106

109 G

110

126 G

128

130 G

143 G

147 G

301

NUMBER

GK

Round

GL

G

GA

G

Round

Round

Round

Round

Round

Round

Round

Round

Round

AND

SIZES

shank, round

plated -sizes

shank, round

point,

shank, round

c

hromium

shank, round

ment

point,

shank, round

sizes

032, 036, 040, 044, 049,

shank, round

plated -sizes

shank, round

point,

shank, round

sizes

054, 067, 073, 080,

shank, round

undersize eye

049, 054,

shank,

032, 034, 036, 038, 040, 042, 044, 049,

(Cont'd

point,

032,

point, extra

chromium

plated -sizes

chromium

plated -sizes

point, extra

point,

chromium

point,

point,

032, 036, 040, 044, 049, 054, 060,

point,

plated -sizes

point,

point

and

060

stay

point,

. )

Description

extra

036

extra

plated

short,

short,

short

No.

, long, double groove,

grooves,

extra

short,

, 040,

032, 036, 040, 044,

044

short,

029, 032, 036, 040, 044,

short,

short,

- sizes 036, 040, 044,

double groove,

054

double groove,

, double groove,

036, 040, 044, 049, 054,

2 bag, double groove,

090

one

step

short

, double groove,

double groove,

double groove,

double groove,

double groove,

reduction,

054

oversize

oversue

ball

049

ball

049

hall

eye,

chromium

ball

eye,

spotted,

067

ball

eye,

spotted

spotted, chromium

ball

eye,

spotted

chromium

chromium

ball

eye,

chromium

ball

eye,

ball

049

eye, government

eye, spotted , govern-

plated

chromium

, government

060, 067

, sho

plated -sizes

plated -sizes

plated

rt

point,

point,

-

-

044,

ILLUSTRATIONS

This

catalog

Exploded views

in

seen

be found

pieces required in the

of

parts.

indicated

ma~n

their

the

The

numbers

that

part

Always use

Those

sub-assembly. Example:

component

by

3

4

5

6

7

has been so

of

the

actual

listing

in

in

the

the

fact

29105

22559

22559

22894

22894

the

illustration

the

ORDERING

arran

ged as

various

position

of

particular

part

parts

that

z

A Bearing

B

c

D

sectio

ns

in

the machine.

the

parts

with

view being

first

column

.

The

number

of

thei r

Looper Drive

shown

sub-assemblies which

descriptions

Classes

BT,

BW,

Bearing

Eccentric

Eccentric

are

REPAIR

to

of

the

their

reference

reference

in the second

Eccentric

51300,

51900

BX;

Cap

Screw, lower

Cap

Screw, upper

Set

Spot Screw 1

PARTS

simplify the

mechanism

On

the page opposite the

part

numbers,

shown

.

numbers only and ind

number

can

are

indented under the

Assembly,

51500;

BH,

Screw 4

ordering

are

shown

descriptions,

should never

column

be

furnished

Styles

BJ

51200

.

for

of

repair

so

that

be

for

description

Styles

BL,

BM,

the

illustra

and the

icate

used

repairs

in

parts

parts

tion

number

the

position

in

ordering

are

of

1

2

2

.

may

will

the

be

of

It

will

be

not

is

listed.

not

reco11111ended

noted

The

reason

and

in

the above

for

t-he

this

is

complete

examp

le

that

the

that

the

replacement

sub-assembly should

9

eccentric,

of

be

ball

any

of

ordered.

stud

these

and bearing

parts

individually

are

Page 9

ORDERING

REPAIR

PARTS

ILLUSTRATIO

In

no

specific

NS

those cases where a

usage

various machines

tions

and,

if

At

the back

the

illustrations,

only the

part

IDENTIFYING

Where

smaller

letter

All

the

part

s and

is

s~amped

part

appear.

USF

GENUINE

Su

ccess

in

Union

Special

i

ts subsidiarie

approved

and

sc

ientific principles

durability

(Cont'd.)

part

will

be

mentioned

are

not

the same, the

necessary, the

of

the

which

number

is

book

will

known.

difference

will

facilitate

PARTS

construction

on

those where the

to

distinguish

numbers

NEEDLES

the operation

permits each

represent

AND

REPAIR

of

Needles and Repair

s and authorized

are

assured.

is

coll11l0n

in

be found a numerical index

the

the

same

to

all

the

description.

specific

will

be

locating

part

is stamped

construction

part

from

sim

part,

regardless

of

the machines covered

usage

shown

the

does

ilar

PARTS

these

machines can be

Parts as

distributors.

and

made

furnished

They

by

are

with the utmost precision. The

liowever,

will

be

in

the

illustration

with

not

permit,

when

mentioned

illustration

of

all

the

and

its

part

an

ones.

of

the

catalog

sec

ured only

the

Union

by

Special

designed according

by

this

catalog,

the

parts

for the

in

the

descrip-

.

parts

show

description

number.

On

identification

in

which they

the use

maximum

Machine

to

the most

of

Company,

efficiency

in

when

some

genuine

are

Genuine needles

mark".

Special

and

Genuine

padlocks . Each trade

workmanship.

repair

put

parts

TERMS

Pr1ces

are

forewarded

insured unless otherwise

are strictly

at

the

buyer's

net

directed.

OILING

The

oil has been drained

be

filled

vi

scos

sight

the red

reservoir

O

il

ity

Oil

gauge

The

daily

A

lines on

before beg

of

200 to 250 seconds

is

filled

on

machine 1s

fillea

check before the morning s

innin

at

the

the

front

the gauge.

automatically

1s necessary.

g

spring

of

which has gone through the machine

rP.servoir making too frequent

may

be

drained

at

the plug screw

up

in packages marked

at

the top

are stamped with a reproduction

mark

is

cash

risk

from

to

operate.

your guarantee

and

su~i

ect

to

F.O.B. shipping

A charge

AND

THREAD

is

INS

the machine before shippin g

Use a st

at

100°

Fahrenheit.

of

the

change without

point.

made

to

cover the postage and insurance .

TRUCTIONS

rai

ght

mineral

cap in the top cover and the

the machine. The

The

capacity

lubricated

tart

is

oilings

unnecessary. Fxcessive

in

the main frame

of

should

filt

oil

the

and

ered

level

oil

no

oiling

be

and

directly

reservoir

made

pumped

"trade

of

highest

'UNION

the

familiar Union

quality

notice.

Par

cel

post

shipments

and

the

reservoir

oil

with a Saybolt

level

is

checked

should

i s

other

and

oil

back

oil

be

maintained between

12

ounces.

than keeping

added

into

the

in

the

under the handwheel.

in

All

shipments

if

required.

main

main

SPECIAL'

materials

are

must

at

the

the

main

reservoir

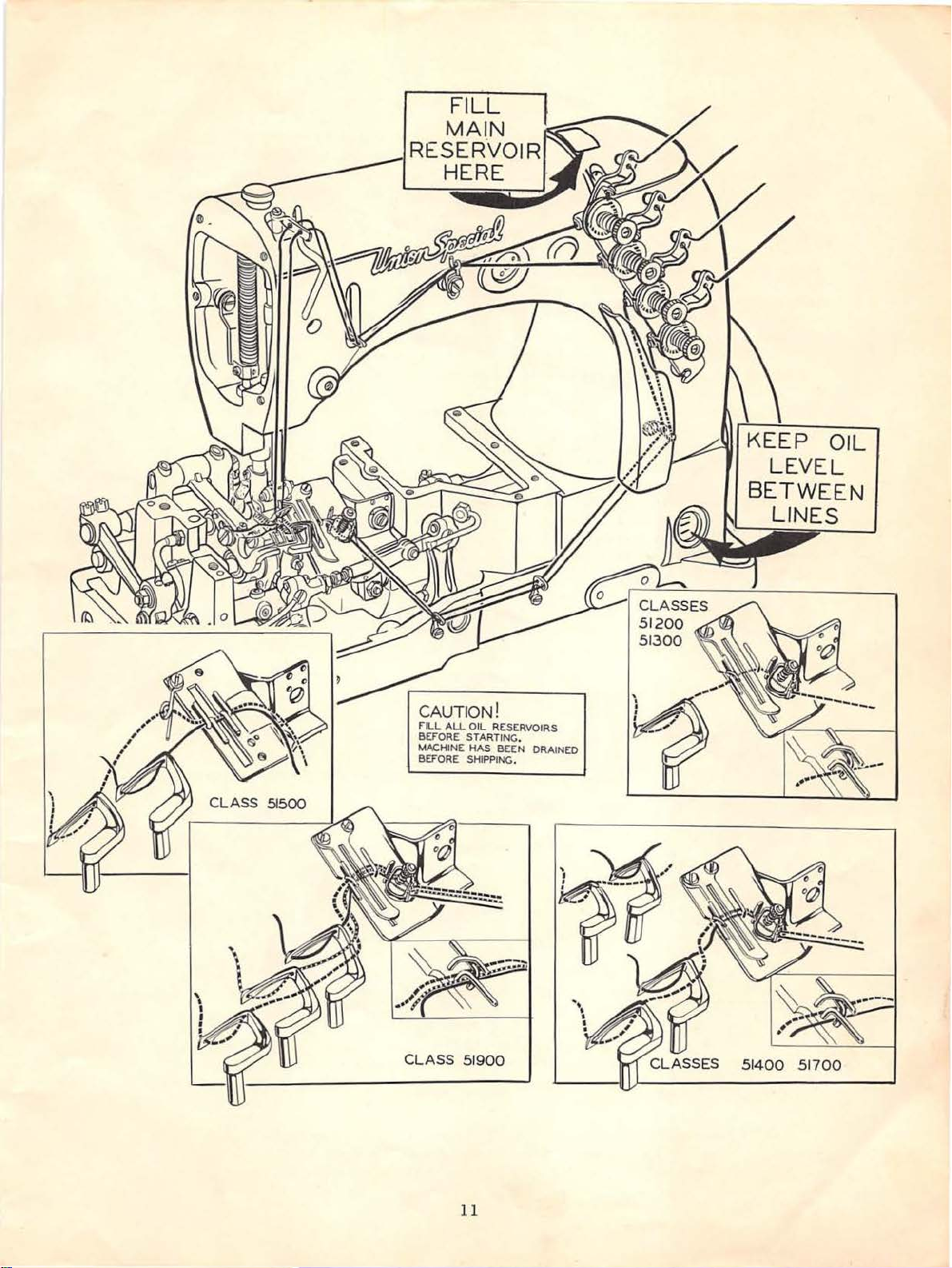

11te

accompanying drawing

threaded . Single

manner.

Tlte

looper threading

and

three

also

shows

needle mac

of

the various

the

hines

manner

are

threaded

classes

in

which a

i s

indicated

in sub

10

two

needle machine

stant

ially

in

the

the

inserts.

is

same

Page 10

FILL

MA

IN

RESERVOIR

HERE

CAUTION!

F

ILL ALL

BEFORE STARTI

MAC

BEFORE

CLASS 51900

OIL R

HINE HAS BEEN DRAINED

SHIPPING.

ESE

NG

RVOIRS

.

51400

51700

11

Page 11

12

Page 12

l:tef

No

.

.

1

2

3

4

5

P::trt

No

93

821375

98A

158

52

6 158 A

8 51282

9 22542

10

11

12

52882 w

51

282

51282

13 22569 B

14 51782 A

15

16

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

52882 w

22542

21396

666-

61394 v

11638

660660-

22569 c

21396

21396

22513

35731 A

51270 B

95

43296

57

605 A

22798 A

34 15438

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

57

22889 A

51758

20

22848

539

51958 B

51291

52882 y

90

52882 p

52882

90

52882

39582 L

52882

50-789

22541 B

51

282

52882 u

52082

22548

52882 M

58 52882

59

GO

61

62

63

64

65

66

67

68

69

70

22848

41394 A

22733 B

52882 K

53782 B

22524

22585 A

51480

51

280

51280 K

22839

22570

87

71

72 51280 A

73

80

AH

B

A

y

AC

z

BJ

79

1\1

74

75

BK

BP

WB

c

wo

A

AD

AA

AC

AE

AE

L

J

,

!\lAIN

FRA1\IIE

.

Screw

----------------------------------------------------------------------BeltGuard

Screw

----------------------------------------------------------------------Thread

Thread

Thread

Head

Eyelet

Eyelet, for

Eyelet, for

Cover, for

BB, BD, BP, BS

BR;

51700

Scre1v

Gasket

FeltLiner

Gasket

Screw

Head Cov

---------------------------------------------------------------------·

-----------------------------------------------------------------------

Gasket

Screw

Oil

Thread

Cup

Needle

Adapter

Nut

----------------------------------------------------------------------

Connection Sleeve

Coupling

Screw

---------------Needle

Needle

Screw

Thread

Thread

------------------Presser

Needle

Screw

Nipper

Nipper

Scr

Screw: for

Nipper

Nipper

Adapter Screw

Frame

\Vasher

Screw

Frame

Frame

Thread

--------------------------------------

Spring

Spd.ng

ew

for

Spring,

Spring Stud, for Styles 51200 BG, BW,

Needle

----------------------------------------------------------------------

----------------------------------------------------------------------Needle

Needle

LooperThreadGuard

Bafile

Plate

Screw

------------------------

Gasket

Crank

----------------------------------------------------------------------

Cbamber

Screw

Oil

Drip

Oil

Cap

Blk.

Spring

Pin----------------------------------------------------------------------

Screw

-----------------------------------------------------------------------

Needle

Gasket

Crank

Screw

Gasket

Oil

Sc

Gasket ---

Plug

Gasket

Oil

Screw

Screw

Throat

Lever

-------------------------------

Cbamber

----------------------

-------------------------------

Reservoir

rew

- -

Screw

----------------------------------------------------------------------

Reservoir

---------------------------------------------

-------------------------------Plate

51200 BG, BK, BL, BW,

BQ

, BR,

Dowel

Dowel

Screw

-----------------------------------------------------------------------

Throat

Throat

Throat

Throat

Screw---

Plate

Plate

Plate

Plate

BJ

, BL; 51400

, MISCELLANEOUS COVERS

AND

PLATES

Description

-------------, for two needle machines

Styles

, BT, BU,

BR

--------------------------------------------------------------

-----------------

------------------

- ----------------------------------------------------

---------------------------------------one needle machines

three

needle machines

in

Classes

BV

,

--

--------------------------------

-

------------------------------------------------

----------------------------------------

--------------------------------------51200, 51300, 51900;

BW

, BX, BY; 51

500 BJ, BK, BM, BN,

Styles

----------------------------------------------------------------

er, for

-----------------------------------

Styles 51400 BQ, BR; 51

---------

- --

-------------------------------------------------------

Lubricator

Oil

---------------

500

BP; 51700 BJ, BK, BQ--------------

---

Reservoir, for

-

--------------------------------------------------

---------------------------

Style 51500 BP----------------------

------------------------------------------------------------------

---------------------------------------------------------

----------------------------------------Lubricator

Lubricator, for

Bar

Connection Guide Plate

Take- up \Vire

Base

Plate, for

Styles

Styles

for

-

-----------------------------------------------------Oil

Reservoir

Bracket, for

Styles 51500 BP, 51900

-

-------------------------------

--------------------------------------------

--------------------------

, for

Styles

51200 BG, BW, BX; 51300 BG,

Styles 51

51200

BW

51200 BG;' 51300 BG, BJ

Styles 51200 BG, BW,

200 BG, BW, BX; 51300 BG,

BX

-----------------------------------------------

--------------------------------------

BX;

-

--------------------------------

51300 BG,

-

-----------------------

Style 51500

BJ

(felt No. 21396

--

----------------------

BJ

---------------------

BX; 51300 BG,

--------------------------------------------------------------Thread

Thread

Thread

Eyelet,

Eyelet,

Eyelet

, for Styles in

for

Styles in

for

Styles in

Classes 51200

Class

51300

Class

51900

, 51400, 51500, 51700

--------------------------

--------------------------

---------------------------------------------------------

------------------------------------------------------------------

-

Cover, upper

-------

--------------------------------------------------

---------

------------------------------

---------------------------------------------------------------Plate

----------

------------------------------------------------------------------

--

--------------

--------

--------------------------

-------------------------------------------------------------------

Bearing

Back

-----

---

----------

-----------------------------------------------------------------Top

Support, for Styles

BS, BT, BU, BW, BX,

Pin lower ---

Pin

:

Screw,

Screw, countersunk head

(See Pages 33, 35, 37, 39, 41,

Support,

----------

Oiler

---------------------------------------------------

Cover, lower

Cover

-------------------------------------------------

--------------

-----------------

Cover

- --

for

---------------------------------

Throat

fillister

-----------------------

----------

---

------------

in

BX;

51300 BH,

Plate

------------------------------------------------

head

-----------------------------------

- -----------

---

---

--------

---------

----

--------------

----------

--

--------------

-

----

Classes

BY-

--------------------------- ----

----

51500, 51700, 51900;

BM;

51400 BA, BB, BD, BP,

---------------

43)

Cor

Styles

BV

----------------------------------------------------------

----------

51200 BM, BN, BP, BR, BS, BT; 51300 BG,

----------- -

---------------------------------

------------------------------------

----------

-

-----------

----------------------

------------------------------

--------------------------

------------------------------

--

---------------------

-

-------------------------

------------------------------

-

--

-------------------------

51400 BA,

-

----------------

BP

-------------AG)

-

--------

BJ

BJ

BJ

- ----------

----------------

----------------

-----------------

-----------------

---------

Styles

----------

--------------------

-

----------

Amt.

~

-

--

------

----

----

- ----- 1

---

--

--

2

1

4

3

3

3

1

1

1

1

1

5

1

1

1

1

1

1

1

1

1

2

1

1

4

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

1

1

1

3

1

1

4

1

1

9

2

1

1

1

7

2

1

2

2

3

2

2

1

1

3

13

Page 13

14

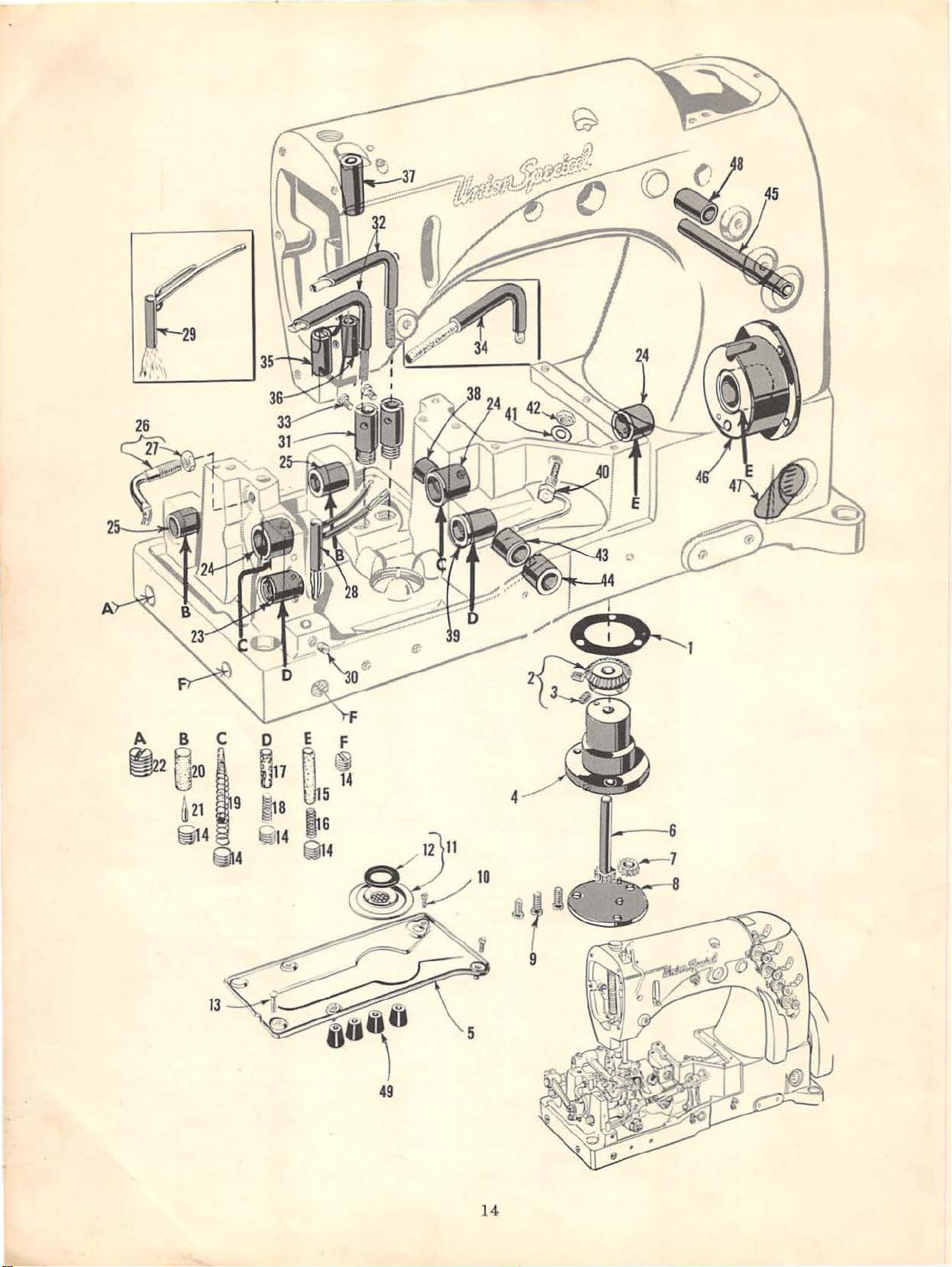

Page 14

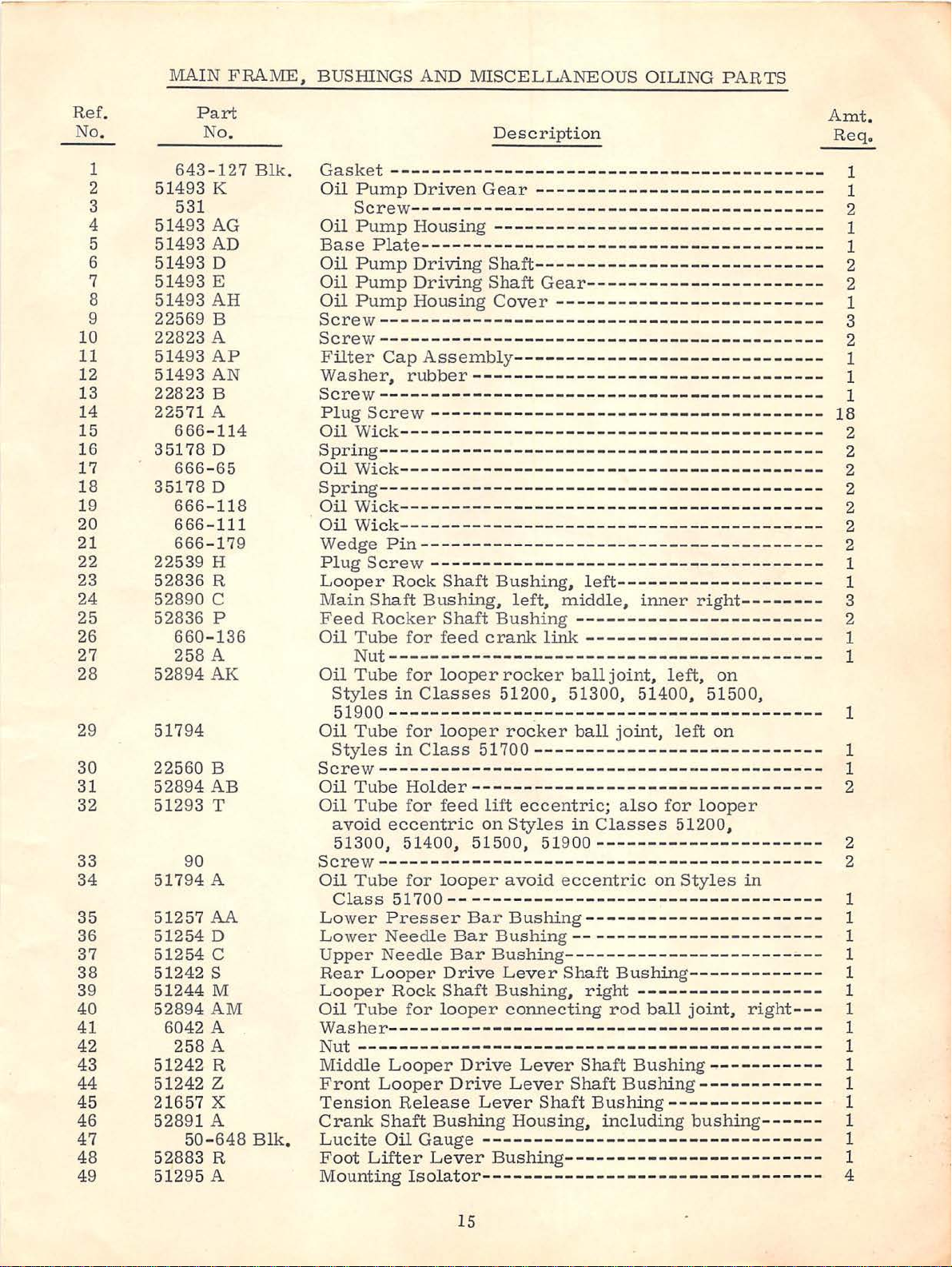

Ref

No

MAIN

.

.

FRAME,

Part

No

.

BUSH

INGS AND

MISCELLANEOUS

cription

Des

OILING

PARTS

Amt

Req.

.

1

2

3 531

4

5

6

7

8

9

10

11

12

13

14

15

16

17 666- 65

18

19

20

21 666

22

23

24

25

26 660 27

28

29 51794

30

31

32

33

34

35

36

37

38

39

40

41 604 2 A

42

43 51242 R

44

45 2

46 5

47

48

49 5

51493

51493

51493

51493 D

51493

51493

22569

22823

51493

51493

22823

22571

35178 D

35178

22539

52836 R

52890

52836

52894

22560

52894

51293

51794

51257

51254

51254

5124

51244

52894

51242

165

2891

5288 3 R

129

127

643 -

K

AG

AD

E

AH

B

A

AP

AN

B

A

-11

666

D

666-118

666

-11

-1

H

c

p

136

258

A

AK

B

AB

T

90

A

AA

D

c

2 s

M

AM

258 A

z

7 X

A

50-

648

5 A

4

79

1

Blk.

Blk

Gasket

O

il

Oil

Base Plate

Oil

Oil

Oil

Screw

Screw

Filter

VVasher,

Screw

Plug

Oil

Spring

Oil

Spring---

Oil

Oil VVick----------------------------------------VVedge

Plug

Looper

Main

Feed

Oil

Oil

Styles

51900

Oil

Styles

Screw

Oil

Oil

avo

51

Screw

Oil

Class

Lower

Lower

Upper

Rear

Looper

Oil

VVasher

Nut

Middle

Front

Tension Rel

Crank

.

Lucite

Foot Lifter Lever Bushing

Mounting

------------------------------------------

Pump

Screw

Pump

Pump

Pump

Pump

VVick

VVick

VVick-----------------------------------------

Tube

Nut

Tube

Tube

Tube

Tube

id

300, 51400,

Tube

Tube

---------------------------------------------

Driven

---------------------------------------Housing

--------------------------------------Driving

Driving

Housing

-------------------------------------------

----------Cap

Assembly

rubber

-------------------------------------------

Screw

----------------------------

Screw

Shaft

Rocker

-------------------------------------------

-------------------------------------------

Needle

Looper Dri

Looper Dri

Shaft Bushing

--------------------------------------

-----------------------------------------

-----------------

----------

Pin

-----------------

-----------

Rock

Bushing,

for

---

---

for

in

Classes

--------------~---------------------------

for

in

Class

Holder

for

eccentric

for

51700 --------------------

Presser

Needle

Rock

for

-----------------------------------------Looper

ease

Oil

Gauge

Isolator---------------------------------

Gear ----------------------------

--------------------------------

Shaft

Shaft

----------------------------------

Shaft

Shaft

feed

crank

-----------

looper

looper

51700

---------------------

feed

lift

on

51500

looper

Bar

Bar

Bar

ve Lev

Shaft

looper

Drive

ve

Lever

---------------------------------

---------------------------Gear

-------

Cover

-

-------------------------------

Bushing, left

Bushing

rocker

51200, 51300

rocker

avoid

Bushing

Bushing

Bushing, right

connecting

----

---

---------

-

----------------------

-

---------

--

-

-----------

left,

Styles

Bushing

Lever

Housing,

middle,

-----------------

link ---

-

------------------------

ball

ball

----------------------------

eccentric;

in

Classes

, 51900

er

Lever

Shaft Bushing

----------------------

eccentric

---------------

------------------------

-----------

Shaft

Shaft

Shaft

including

-------------------------

-

---------------

- -

-----------------

-

--------------------

-

--------------

-

-------------------

- -

------------------

-

--------------

-------------------inner

--------------------

joint, left, on

, 51400, 51

joint, left

also

Bushing

-----------

rod

ball

Bushing

Bushing

right-

500,

on

-

------------

for

looper

51200

on

-

---------------

----

-------------

,

Styles

----------

------------joint,

-----------

------------

bushing---

in

-----

right

18

- 2

-------

- - ---- - 2

1

1

1

1

1

2

2

2

1

-

---

-----

---

---

1

1

1

1

- 1

1

1

1

1

1

- - 1

1

1

1

4

1

1

2

1

1

2

2

1

3

2

1

1

1

2

2

2

2

2

2

1

1

3

15

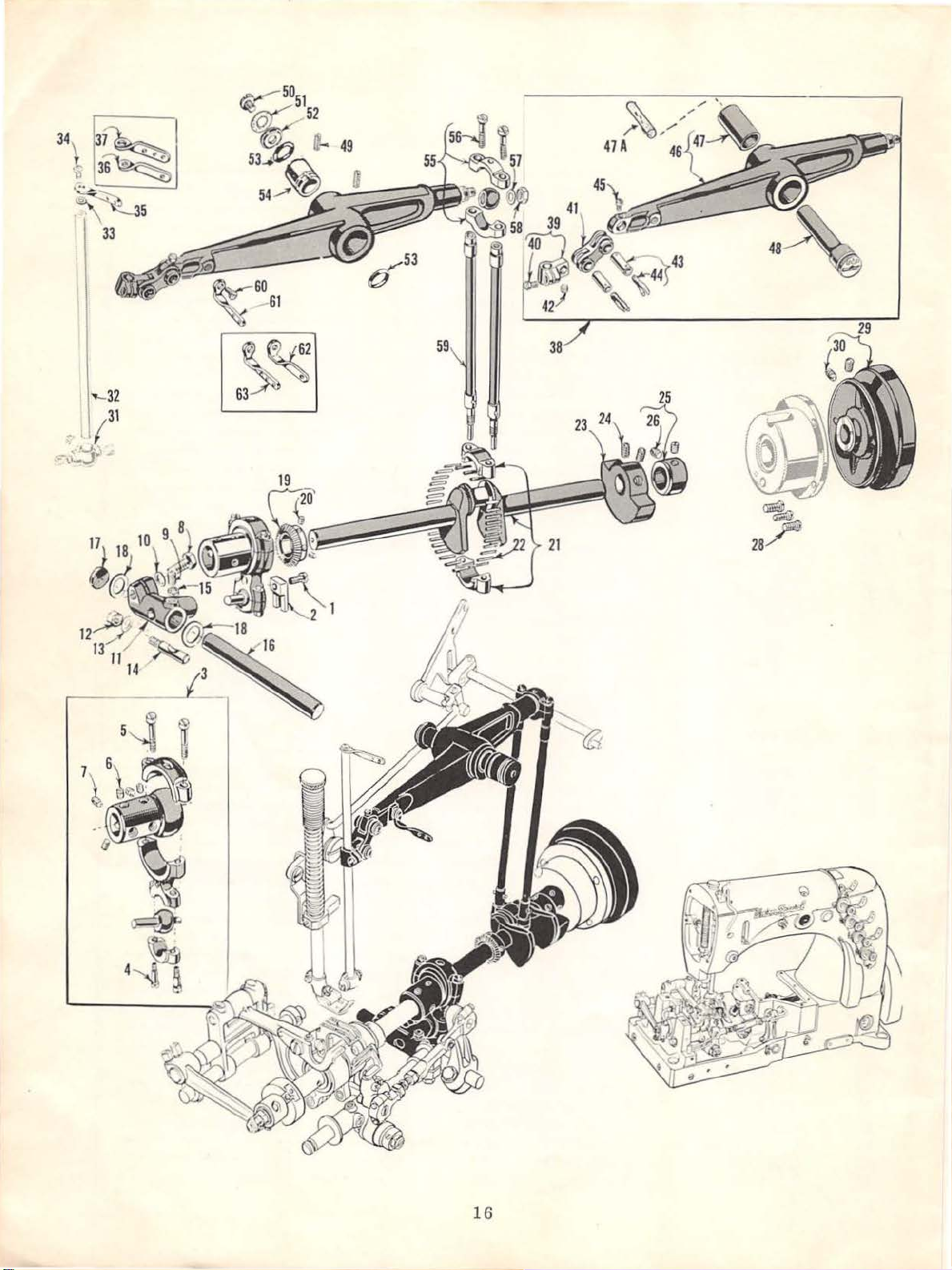

Page 15

34

~

~

'""'--

~~

3

~1

I

~

1

33

5

f:§r-

60

"\)

61

~

16

Page 16

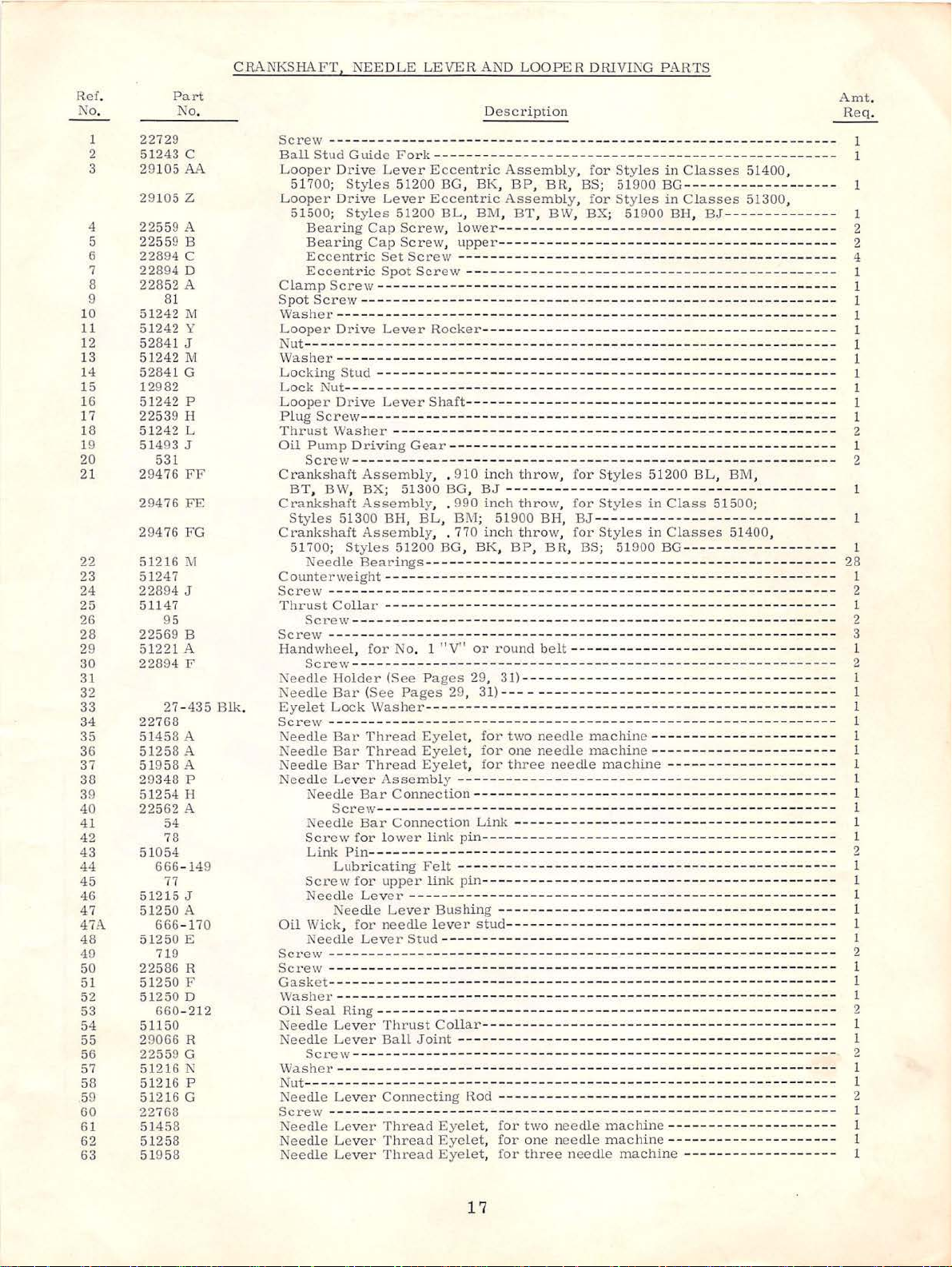

CR

ANKSHAFT, NEE

Dl..E

l..EVERAN

D l..OOPER DRIVING

PARTS

Ref.

~o

1

2

3

4

5

G

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

4-!

45

46

47

47A

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

.

Part

No.

22729

51

243

c

29105

1\A

29105

z

22559

A

22559

B

22894

c

22894

D

22852

A

81

51242

51242

5284

1 J

5

124

2

Iv1

5284

1 G

12982

51242

22539

H

51242

51

493

J

531

29476

29476

FE

29476

FG

51216

:\1

51247

22894

J

51147

95

22569

B

51221

A

22894

F

27 -

22768

51458

A

51258

.-\.

51058

A

29348

p

51254

II

22562

A

54

78

51054

666

- 149

77

51215

J

51250

A

666-170

51250

E

71!)

22586

51250

51250

D

G60 -

51150

29066 R

22559

G

51216

N

51216

51216

G

22768

51458

51258

51958

lVl

y

p

r...

FF

435

R

F

212

p

Blk

Screw

Ball

Clamp

Sp

Washer

Looper

Nut

\Vasher

PlugScrew

Thrust

011

---------------------------

Stud

Looper

517

Looper

51500;

Drive

00;

Styl

Drive

Styles

Bearing

Bearing

Guide

Cap

Cap

Eccentric

Eccentric

Screw

ot

Screw

-----------------------------------------------------------

-------------------------------Drive

----------

-----------------

l..o

ckingStud

Lock

Nut

l..ooper

----------------------------------------------

Drive Lever

---------------

Washer

Pump

Driving

Screw

------------------------------------------------------------

Fork

Le

ver

es

51200

Lever

51200 BL, BM,

Screw, lower

Screw, upper

Set

Spot

-------------

Lever

----------

----------------------------------------

-------------------------------------------------------

Crankshaft Assemb

BT

BW BX· 5

Cra~shaft

Styles

Crankshaft

51700;

Needle

Counterweight

Screw

Thrust Collar ---------------

Screw

Screw

Handwheel, for No. 1

Screw

Xeedle Hold

i'\eeclle

Eyelet

.

Scre1v

t\eedle

1\eedle

Keedle

Need

Needle

7\cedle

Screw

Link

As~embl

51300

BH

Asse~b

Styles

-----------------

--------------------------------------------------------

Bar (See

Lock

--------------------------------------------------------------Bar

Bar

Bar

le

Lever

Sc

Pin

51200

Bearings

----

---------------------

-------er

(See

Pages

\Vasher

Thread

Thread

Tl11·ead

Assembly

Bar

Connection

rew--- -

Bar

Connection

for lower

---------------------------

Lubricating

Screw

for

upper

NeecUe

011

Wick, for

1\eedle

Screlv

Screw

Gasket------

\Vasher

Oil

Seal

Needle

Needle

Screw

Washer

Nut

--------------------------

Needle

Screw

Needle

Needle

Needle

Lever

Needle

Lever

needle

Lever

--------

-----------------------------------------------

-----

-----------------------------

----------Ring---------

Lever

Lever

Thr·ust Collar-----------------------------------------Ball

----------------

-------

Lever

--------------------------l..ever

Lever

Lever

------

Connecting

Thread

Thread Eyelet, for

Thread

D

escri

pti

on

--

-------------

Eccentric

Assembly, for

BG, BK, BP, Bl't, BS;

Eccentric

Assembly, for

BT

-------------

------------

Screw

--------------------------------

Screw

----------------------------------------------

-

-------

----------------------------------

-

----------------------------------Styles

51900

in

BG

Styles

, BW, BX; 51

---

--------------------------

900

-------

-

-----------------------

----------------------

---------

Shaft

Gear

ly, .

13

00

y

Bl..

ly,

Rocker

,

----------------------------------------

-----------------

-

-------------------

---

----------------------------

-

------

----------

910

in

BG

BJ

.

99

'0

inch

Bl\'1

· 5

'.

77o

'

inch

---

---

ch

thr

ow, for St

----------------------------------------throw, for

1900

BH

thro

w,'

-

----------------------------------

-----------------------------------

Styles

BJ

------------------------------

for

Styles

BG, BK, BP, BR, BS;

--------------------

--

-----------------------

yles

51200

in

in

51

900

BG

---------------------------------------------------

--------------------

----

------------

----

--------------

"V"

or

- -

---

Pages

round

-----------------------------------------------

29,

31)

29, 31)

---------------------------------

----

---------------------------

Eyelet, for

Eyelet, for

Eyelet, for

---

two

one

three

---

----------------------

------------

--------

Fell

-----

Stud

---

-----------------------------------

l..ink

link

pin

----------------

----------

----------------------------------------

link

pin

--------------------------------------------

-----------

Bushing

lever

-----

------------

stud

----

---

-----------

-------

- -

-------------

belt

---------------------------------

---

------------

-------------------------

- - -

------------

-----------

-------------------------

-------------------

-----

needle

needle

machine-------machine

needle

machine

-----------------------

---------------------------------

-----

- -

--------------------------------

-

-----------------------------

-----------------------------------

---

-

------

----

------------------------------

--

---

----------------------------

--------------------------------------

-

---

--------------------------------

---------------------------

-------------------------------------------

Joint

------------

--

--------------------------------------

--------------------

------------------------------

-

---------------------------------------

Rod

------------------------------------------

Eyelet, for

Eyelet, for

-

----------------------------------two

one

three

needle

needle

needle

machine

machine

machi

ne

Classes

-----------

in

Classes

51

400

51300

-

----

BH, BJ--------------

-

--------------

---

---------------------

-

-------

----

- -

-----------

---

------------

-

--------------

BL

, BM,

Class

5

1500;

Classes

51400,

-------------------

- - -

------------

-----------

-----

----------

-----

---

-------

---

-----

----------

----

---

------------

-----

-------------------

-------

--------

--

- -

---------

----

--------

------------

------------

---

------------

-

---------

----

-----------------

------

---------------------

---------

----------

,

,

-

-----

--

------

--

---

----

----

---

---

---

---

----

---

-

---

---

Amt

Req

-

28

--

- 1

- 1

- - 1

--

-

- -

--

.

.

1

1

1

1

2

2

4

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

2

1

2

3

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

2

1

1

1

2

1

1

2

1

1

2

1

1

1

1

17

Page 17

18

Page 18

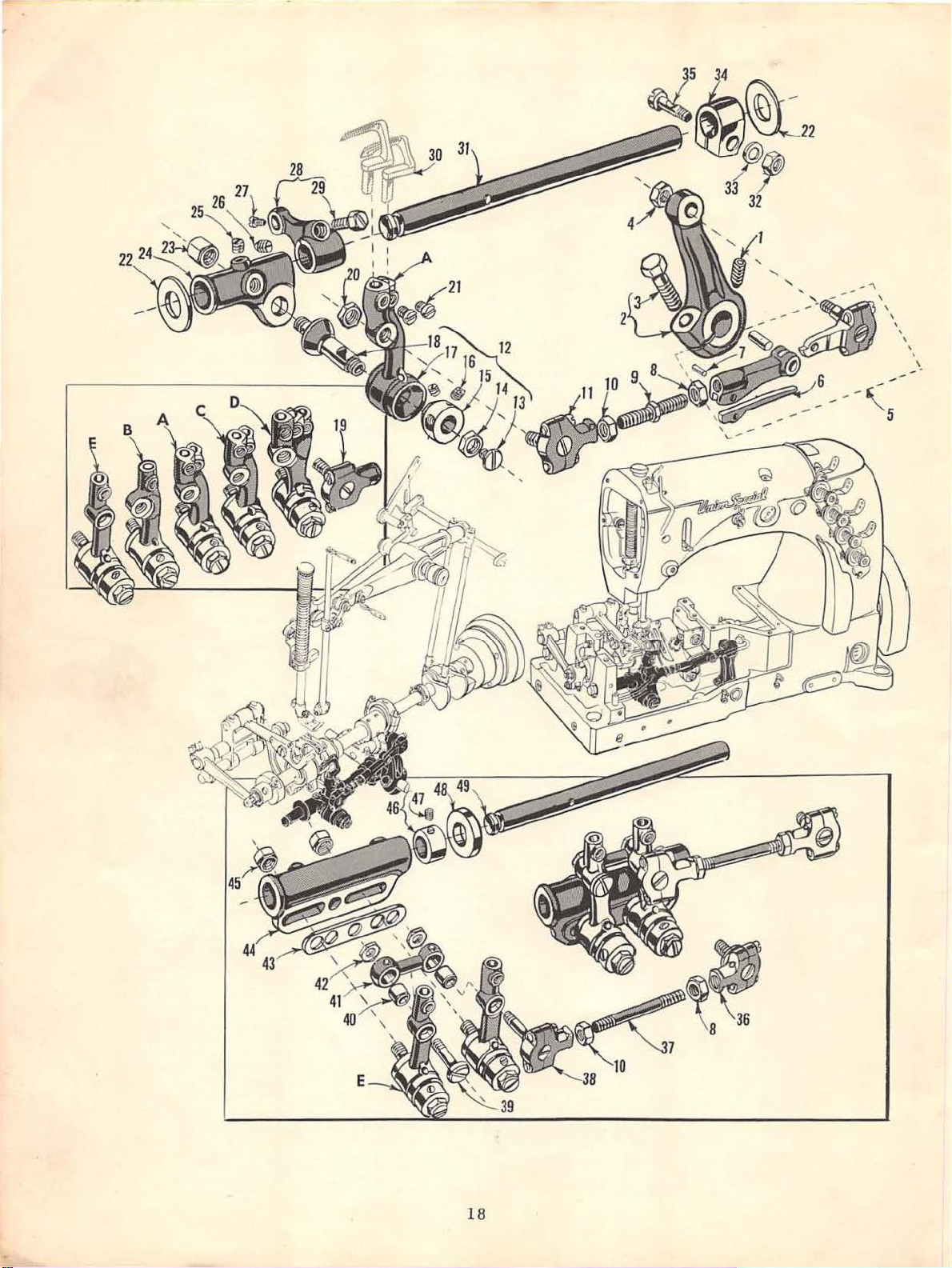

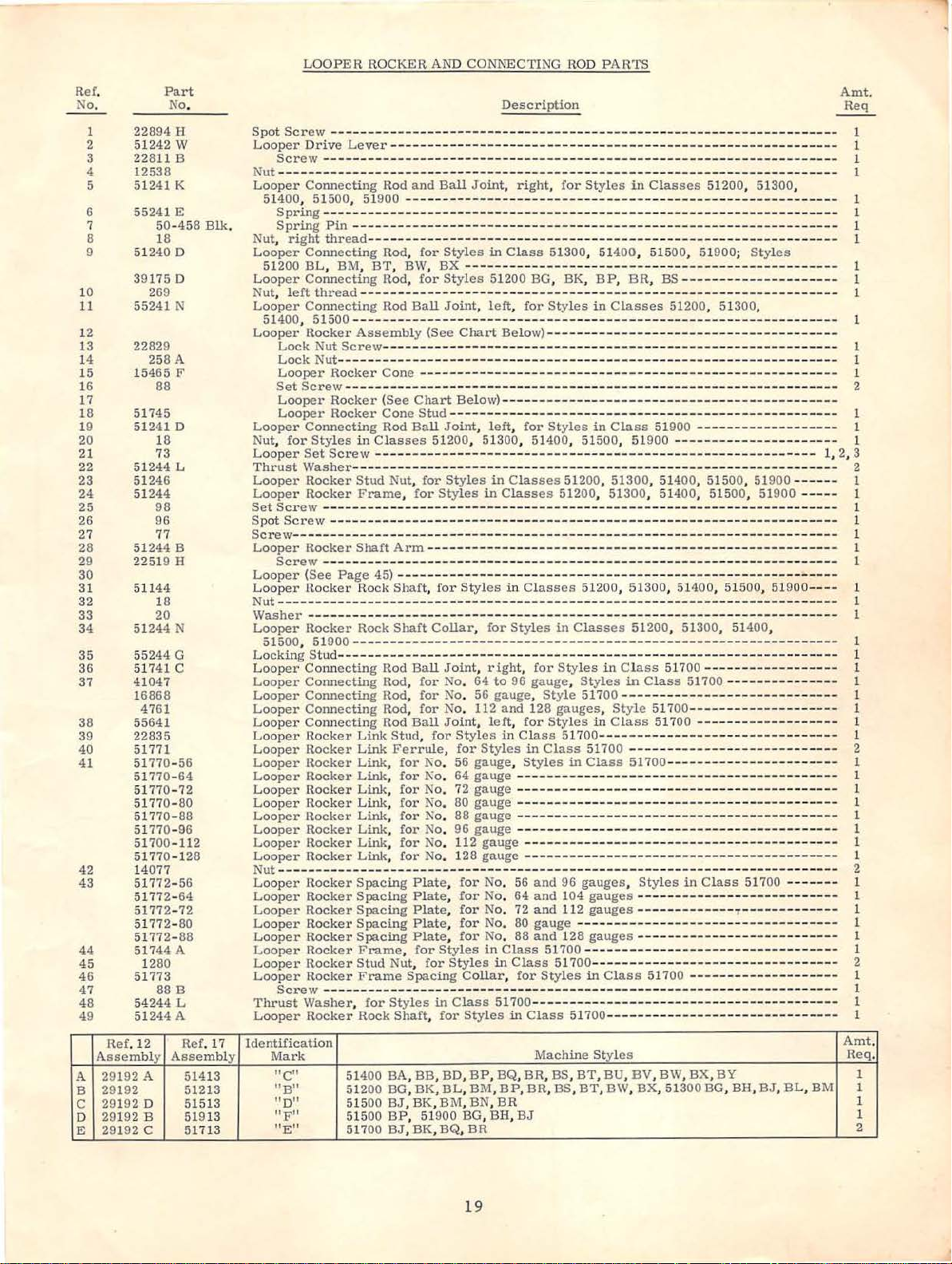

Ref.

No.

22894

1

2

51242

22811

3

4

12538

51241

5

55241

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Ref

50-

18

51240 D

391750

269

55241

22829

258

15

465

88

51745

51241 0

18

73

51244

51246

51244

98

96

77

51244

22519

51144

18

20

51244

55244

51741 c

41047

16868

4761

55641

22835

51771

51770

51770-64

51770-72

5177

51770-88

51770-96

51700

51770-128

14077

51772-56

51772

51772

5177

51772-88

51744

1280

51773

88

54244

51244

. 12 Ref. 17

Assembly

29 192 A 514

A

29 192 51213

B

29192

c

D

E

0 51513

2919

2 B 51913

29192

c 5

Part

No

.

H

w

B

K

E

458

Blk

N

A

F'

L

B

B

N

G

- 56

0- 80

- 112

- 64

- 72

2- 80

A

B

L

A

Assembly

13

1713

LOOPER

Sp~Screw

Looper Drive Lever---------------

Screw

Nut

----

Looper

.

Nut, right

Looper

Looper

Nut, left

Looper

Looper

----

Connecting

51400

, 51500, 51900

Spring

Spring

Connecting

51200

BL

Connecting

thread

Connecting

51400,

51500

Rocker

LockNut

LockNut

Looper

SetScrew

Looper

Looper

Looper

Nut, for

Looper

Thrust

Looper

Looper

Set

Spot

Screw

Looper

Connecting

Styles

Set

\Vasher

Rocker

Rocker

Screw

Screw

-----------------------------------------Rocker

Screw

Looper

Looper

Nut

\Vasher

Looper

(See

Rocker

-------------------------------------------------------------------

-----------------------------------------------------------------------

Rocker

51500

, 51900

LockingStud

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Nut

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Thrust

Looper

Connecting

Connecting

Connecting

Connecting

Connecting

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

-------------------------Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Screw ---

Washer, for

Rocker

ROCKER AND CONNECTING ROD

--------------------------------------------

-------------------------------------------------------------

------------------Rod

and

----------------------------------------------------------Pin

--------------------------------

thread

------------------------------------------

------------Rod,

, BM , BT,

B\~

Rod, for

------------------------Rod

------------------------------

Ball

Assembly

Screw

---------------------

------------------------

Rocker

Cone

---------------------------------------------

Rocker

Rocker

Screw

(See

Cone

Rod

in

------------

Stud

Ball

Classes

--------------------------------------------------Nut, for

Frame, for

-------------------

-----------------Shaft

Arm

--------------Page

45) - -

Rock

Rock

----------------------------------------------------------

---------

----------------------------------

Shaf

Shaft

- --

Rod

Ball

Rod,

Rod, for

Rod,

Rod

Link

Link

Link,

Ball

Stud, for

Ferrule, for

for

Link, for

Link, for

Link, for

Link, for

Link, for

Link, for

Linl<,

for

Spacing

Spacing

Spacing

Spacing

Spacing

Frame, for

Stud

Frame

----------------Rock

Plate, for

Plate, for

Plate, for

Plate, for

Plate, for

Nut, for

Spacing

Styles

Shaft, for

Identification

Mark

"C"

"

B"

uD''

"F"

ttE"

51400 BA,

51200

BG

51500

BJ

51500

BP

51700

BJ

, BK, BL, BM,

, BK, BM, BN, B R

, 51900 BG, BH,

, BK,BQ, BR

PARTS

Description

-

-

----------------

-----

--------

Joint, right, for

-----------in

Class

-----------------------------------------------

51200 BG, BK,

left, for

Below)-

51300, 51400, 51500,

---

---------------

Styles

--------------------------------------

-

------------------

--

----

- -

for

' .

(See

Ball

---

Styles

BX ---

Styles

Joint,

Chart

-----------------------------

--

------------------

Styles

-

--------------------------------

-

----------------------------------

BP, BR

in

Classes

- --

-----------

----------------------------

--------------

-

--------------------

in

Cl

asses

, BS

---------------------

---

51200, 51

----------

-----

-

--------------------------

--

Chart

Below)

--------

Joint, left, for

51200, 51300,

-

- -

Styles

Styles

-- -

----------------------------------------Styles

in

51400, 51500, 51900

Class

-------------------------

in

Classes

in

Classe

--

------------------------

--

------------------------------------------------

s

51200

51200,

, 51300,

51300, 51400,

--

------------------------

Stud

-----------------------

---

51900 - -

----------------------

-

---------

51400,

-

------------------

-------------------------------------------------------

-

--------------------------------------

t,

for

Styles

Collar, for

in Classes

Styles

in

51200,

Classe

s

-

-------

51300

, 51400 , 51

51200, 51300, 51400,

---------------------------------------Joint, right, for

for

No.

64

for

No.

No.

Joint,

56

112

Styles

left, for

to

gauge, Style

and

in

Styles

Ko. 56

1.\o

No. 72

No. 80

1\'o

No.

No.

No.

gauge, Styles

.

64

gauge

gauge

gauge

. 88

gauge

96

gauge

112

gauge

12

8

gauge

-

-----------------------No. 56

No.

No. 72

No. 80

No.

Styles

in

Styles

Class

in

Collar, for

-

-------------

in

Class

51700

Styles

in

BB

, BD, BP, BQ, BR, BS, BT, BU,

BP, BR, BS, BT,

Styles

in

Class

96

gauge, Styles

128

gauges, Style

Styles

Class

51700--------------------------------

in

Class

in

51700-

in

51700

Class

Class

51700

irl

Class

---------------------------51700--

51700

---------

51700

---

-------------------------------------------

---------------

---

-------------------

----------------------------

---

- - -

-------------------------------------

------------------

--