Page 1

®

INDUSTRIAL

SEWING

FI

NEST

CLASS

1400

5

5 1 6 0 0

QUALITY

E S

LEWIS

•

COLUMBIA

MACHINES

CATALOG

STYLE

51600

NO.

T12

8 L

LIST

OF

51400

PARTS

BC

FOR

51600

MACHINE COMPANY

CHICAGO

BA

STYLES

BA

Page 2

Catalog

No.

T128

L

51400

LIST

First

For

BC

OF

Styles

Edition

PARTS

51600

BA

Copyright

Union

Rights

Reserved

MACHINE

INDUSTRIAL

Printed

by

Special

COMPANY

SEWING

CHICAGO

Machine

in

in

1964

All

MACHINES

U.S.

Countries

A.

Co.

May.

1969

Page 3

IDENTIFICATION

OF

MACIDNES

Each Union

in

to

the

name plate on

st

andard

but

never

numbers

machine,

51600

which

"51600".

herein.

C

lass

e

tc. , are

direction

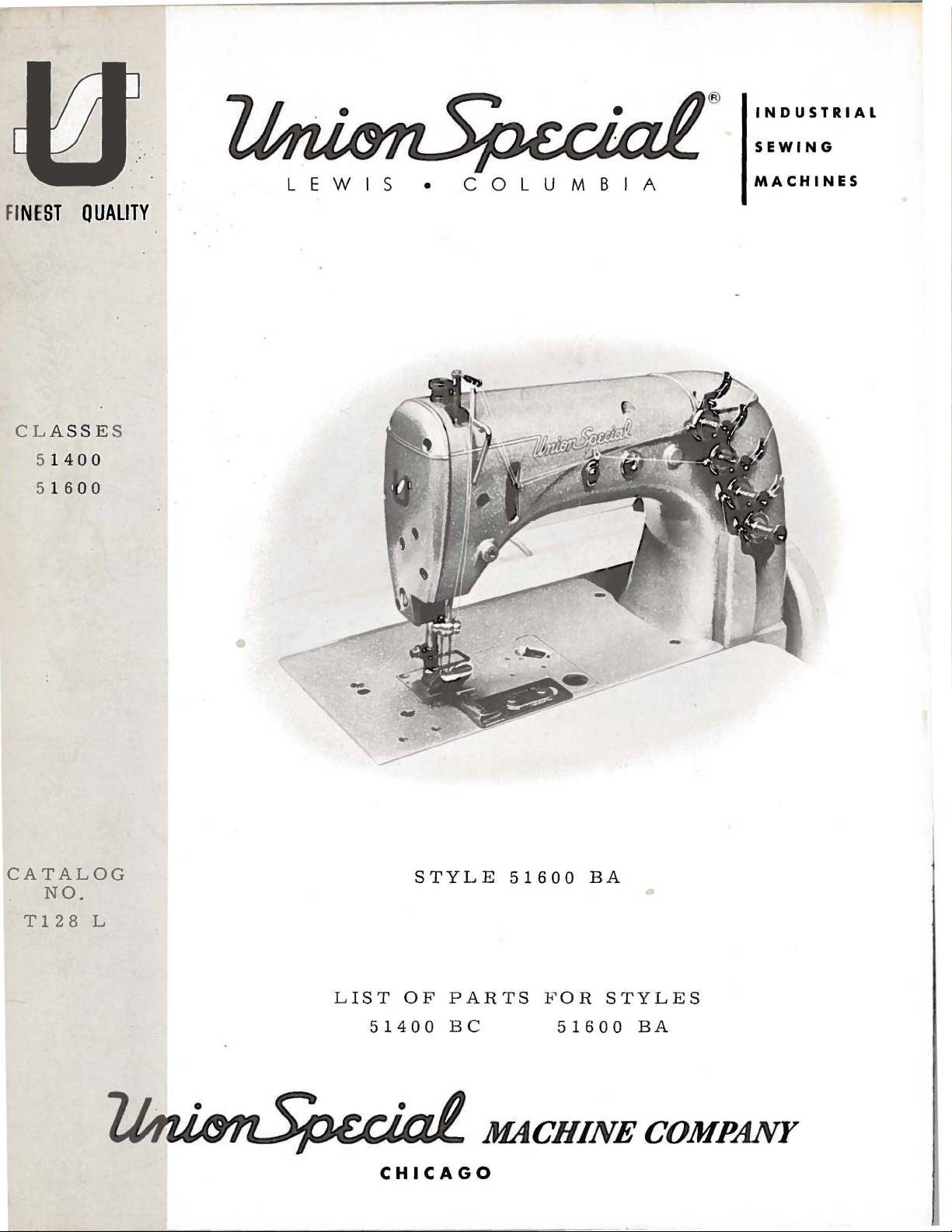

Streamlined

Treadle

Needle

System,

Looper

BAZ".

Styles

differs

This

It

es

51400

Controlled

Bar

Travel,

contain

Special

and spe

contain

a

of

catalog applies

can also

given

of

the

Driving

Filter

cial.

the

the

"Z"

Flat

is

machin

from

be

and

51600.

from

handwheel

Bed

Type

Maximum

letter

suffixed

es

the

applied

the

Intermittent

Mechanism,

Oil

machine

the

front

Standard

letter

of

Style

"Z".

"z".

to

similar

style

APPLICATION

specifically

Reference

operator's

is

Machines,

Return

Work

in

number

with

toward

STYLES

Differential

Space

is

identified

the

machine.

numbers

Example:

When

the

discretion

Single

Pump

only

standard

construction

in

to

the

to

direction,

position

the

operator.

OF

Low

Throw,

Reservoir

and

to

by a Style

Style

have

"Style

minor

Style

are

that

it

OF

CATALOG

Standard

to

some

while

MACHINES

Right

Feed,

Head

of

seated

Two

Enclosed

Needle

numbers

one

51600

changes

number.

grouped

contains

Styles

Special

such

Needles,

Light

Oil

as

at

Siphon

number

are

or

more

BA".

are

made

under a class

no

letters.

of

machines

Styles

right,

the

machine.

Independent

Weight

Automatic

Assembly,

Bar 7 3/4

which

letters

Example:

left,

Presser

is

classified

Special

in a standard

of

machines

front,

Lubricating

Inches.

stamped

as

suffixed,

Style

"Style

number

Example:

as

listed

in

back,

Operating

Row,

Bar

and

Lateral

51400

51600

number

The

blade,

Collectively,

BC

For

setting

operations

of

the

a

small

Upper

differential

Type

attaching

similar

or

for

passes

ing

Standard

Each

size

106

BA

continuously

an

mechanism.

Union

denotes

number,

measured

Left

needle

puff

sleeves

on

light

work

ply

Same

intermittently

calls

percent

of

fabric

feed

GHS n

as

ruffles

operations

to

the

left

gauges

Special

the

stamped

in

type

number

calls

gathering

eedles.

Style

to

gathered

Seam

Nos.

kind

thousandths

in

front

to

for

intermittently

for

passes

51400

body

where a large

or

of

needles.

needle

of

and

in

medium

intermittently

mechanism.

Standard

BC

of

garments

straight

continuously

specification

8,

10,

has

shank,

on

the

of

and

size

1/8

inch

house

to

dresses,

weight

the

right

gauges

except

percent

seam

Treadle

12

and

NEEDLES

both a type

point,

needle

an

inch,

number

space

woven

or

continuously

or

of

Seam

right

made

gathered

controlled 3 to 1 differential

401-LSc-2

16.

length,

shank,

midway

represents

between

waists,

materials,

continuously

needles.

specification

Nos.

of

and a small

number

12

needle

from

light

the

work

curved

modified.

groove,

denotes

between

and

in

and a size

the

needles

pajamas,

where a large

gathered

gathered

Treadle

401-

16.

front.

weight

calls

percent

seam.

Type

finish,

the

largest

the

complete

for

inline

and

curved

straight

controlled 3 to

LSc-2 modified.

For

woven

an

of

Upper

106

number.

and

diameter

shank

with

for

similar

percent

seams

gathering

fabrics

intermittently

the

work

ply

of

feed

gather-

GS

needles.

The

other

symbol.

and

details.

the

feed.

and

seams.

and

and

calls

fabric

type

of

the

eye.

1

Page 4

The

type

by

this

catalog

able,

factory

but

results.

the

descriptions,

numbers

are

given

ones

indicated

The type

and

the

of

the

in

sizes

NEEDLES

needles

the

machine

are

numbers

available

(Continued)

recommended

style

those

of

recommended

the

recommended

are

listed

for

each

description.

below:

style

Other

to

produce

needles,

of

machine

needles

the

together

are

most

with

covered

avail-

satis-

their

Type

106

106

No.

GS

GHS

To

needle,

A

complete

or

Selection

Thread

formation.

Where

On

some

an

identification

Part

appear.

have

the

order

should

the

of

the

numbers

Round

ball

Round

struck

shank,

eye,

shank,

groove,

orders

type

and

would

of

the

proper

pass

construction

smaller

letter

represent

round

chromium

promptly

size

read:

freely

parts,

is

stamped

Description

point,

plated-

round

ball

number

needle

through

point,

eye,

and

"1000

accurately

should

Needles,

size

needle

IDENTIFYING

permits,

and

on

in

the

same

extra

short,

sizes

extra

chromium

be

forwarded.

is

determined

eye

PARTS

each

to

part

those

where

distinguish

part,

and

Sizes

double

027, 029,

short,

ball

plated -sizes

filled,

Type

an

106 GS,

by

in

order

is

stamped

construction

the

regardless

groove,

032,

036,

point,

double

032,

empty

Use

the

to

package,

description

Size

036

size

of

produce a good

with

its

does

part

of

from

catalog

struck

040,

036,

11

•

thread

part

not

similar

in

which

groove,

044,

049

groove,

040,

044

a

sample

on

label.

used.

stitch

number.

permit,

ones.

they

IMPORTANT!

STYLE

Success

Union

Special

Company,

ing

to

the

Maximum

Genuine

parts

are

guarantee

Prices

forwarded

wise

directed.

OF

MACIDNE

in

Needles

its

subsidiaries

most

efficiency

needles

stamped

of

the

are

f. o.

USE

the

operation

approved

and

with

highest

net

cash

b.

shipping

A

charge

ON

ALL

FOR

GENUINE

and

scientific

durability

are

packaged

the

quality

and

point.

is

ORDERS,

WHICH

of

these

Repair

and

authorized

Union

in

subject ·to

made

PART

NEEDLES

machines

Parts

as

distributors.

principles,

are

assured.

with

labels

Special

materials

TERMS

change

Parcel

to

Post

cover

PLEASE

IS

ORDERED.

AND

can

furnished

and

marked

trademark.

and

workmanship.

without

shipments

postage

INCLUDE

REPAIR

be

by

are

made

~.

notice.

and

insurance.

PARTS

secured

the

Union

They

are

with

Each

are

insured

PART

only

NAME AND

with

Special

designed

utmost

Genuine

trademark

All

shipments are

unless

genuine

Machine

accord-

precision.

repair

is

your

other-

Page 5

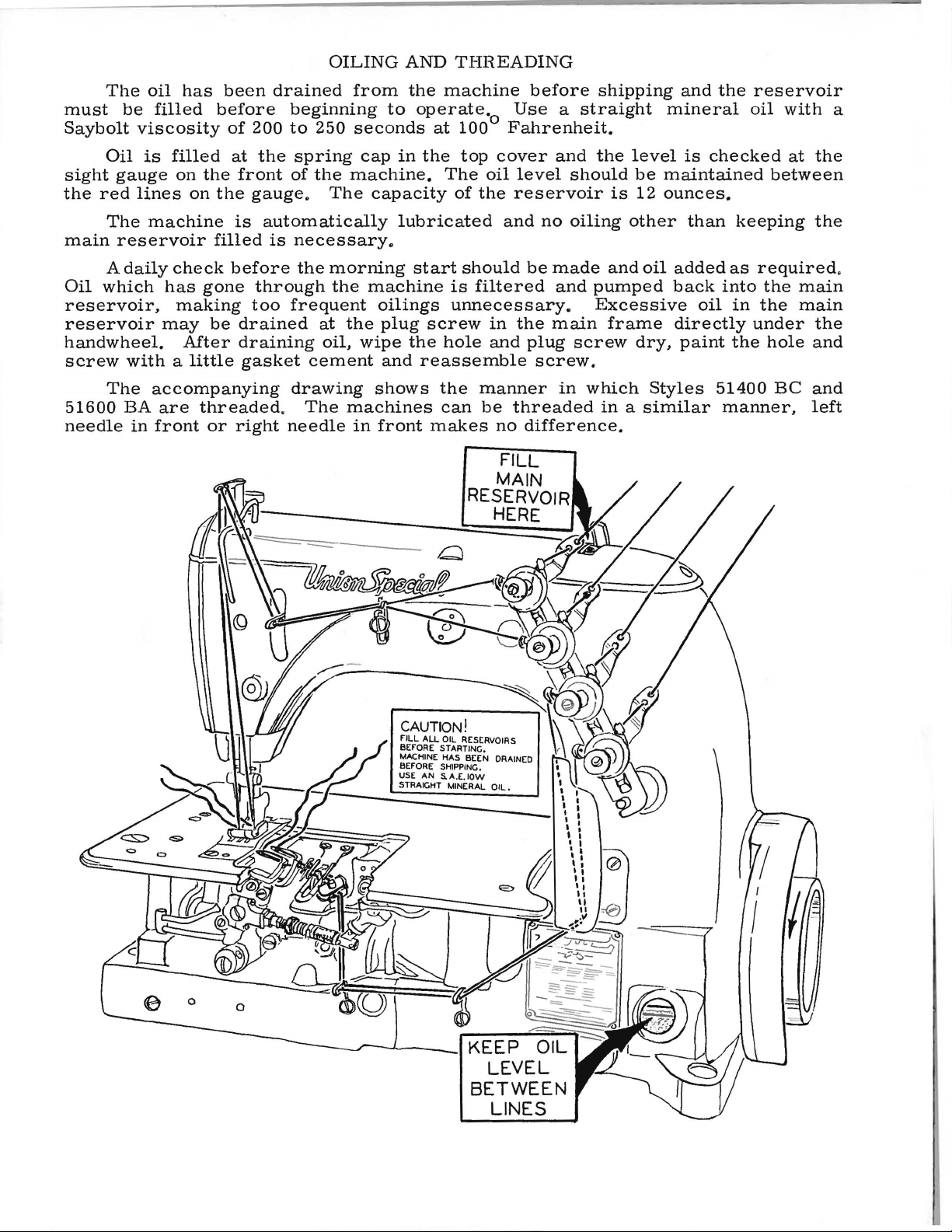

The

must

Saybolt

sight

the

be

Oil

gauge

red

viscosity

is

lines

The

main

Oil

reservoir

A

daily

which

reservoir,

reservoir

handwheel.

screw

with a little

The

51600

needle

BA

in

oil

has

been

filled

machine

filled

on

the

on

before

of

200

at

front

the

gauge.

is

filled

check

has

making

may

After

before

gone

be

too

drained

draining

gasket

accompanying

are

threaded,

front

or

right

OILING

drained

beginning

to

250

the

spring

of

the

machine.

The

automatically

is

necessary.

the

morning

through

the

frequent

at

the

oil,

cement

drawing

The

machines

needle

AND

from

the

to

seconds

cap

in

capacity

lubricated

machine

oilings

plug

wipe

the

and

shows

in

front

THREADING

machine

operate.

at

100°

the

top

The

oil

of

the

start

should

is

filtered

unnecessary.

screw

hole

reassemble

the

manner

can

be

makes

before

Use a straight

Fahrenheit.

cover

level

and

should

reservoir

and

no

oiling

be

made

and

in

the

main

and

plug

screw

screw.

in

threaded

no

difference.

shipping

the

level

be

maintained

is

12

ounces.

other

and

oil

pumped

Excessive

frame

dry,

which

Styles

in a similar

and

the

mineral

is

checked

than

added

back

into

oil

directly

paint

51400

manner,

reservoir

oil

between

keeping

as

required

the

in

the

under

the

hole

BC

with

at

main

main

and

left

a

the

the

.

the

and

CAUTION!

KEEP OIL

LEVEL

BETWEEN

LINES

Page 6

SELF-PRIMING

HEAD

OIL

SIPHON

Styles

When

the

the

the

felts,

prime

operates

per

minute,

51294

Screw

7947

Nut

51294

Clamp

22513

Screw

(In

Machine)

51400

machine

and

is

established,

twenty-

which

R----..

p

BC

and

is

trickles

four

of

51600

started,

down

it

BA

oil

the

is

maintained,

hours a day,

course,

far

35731

Guide

(In

Machine)

are

splashes

vertical

removing

exceeds

A

Plate

equipped

on

oil

tube,

unless

the

Re

with a self-priming

the

oil

rate

move

priming

thus,

the

felts

at

the

at

which

priming

rate

Cover

cup

are

of

oil

For

head

felts,

filters

the

removed.

six

to

collects

Access

Tens.

Lever

oil

siphon.

The

twelve

in

the

To

5

1294

Oil

Siphon

21212

Collar

Screw

Release

Bushing

(In

Bed)

siphon.

through

Once

siphon

drops

head.

Siphon

u

A

newly

machine

removed

distinct

The

felts

666-209,

the

entrance

the

metering

and

prevents

condition,

air

to

be

However,

the

siphon

a

precaution,

between

and

replace

soft

felt

precaution

starting

If

you

in

operation,

Before

doing

explained

action

will

is

operating.

from

drop

is

thin

the

trapped

may

the

fingers,

it

down

prevents

the

siphon.

want

this,

for

the

begin,

INSTALLING

installed

siphon

However,

the

line

and

in

oil

in

the

and

of

air.

felt.

the

felts

if

for

fail

remove

level

priming

This

entrance

of

between

some

because

in

relatively

Thesoftertopfelt,

felt,

the

siphon

the

reason

the

saturate

with

oil.

Then,

into

to

be

doubly

cup

the

so

trapping

sure

apply a certain

be

certain

soft

felt

in

and

the

oil

AND

MAINTENANCE

starts

it

maybe

the

siphon

the

head

cup

are

designed

dense,

at

the

intake

of

air

at

should

felts

air

soft

is

it

the

felt

well

or

priming

trapped

completely fill

that

it

of

that

the

amount

that

this

the

top

of

will

be

its

action

twenty

is

in

full

sump.

to

meter

666-201,

of

the

that

point.

be

dry.

in

the

between

from

with

the

oil.

definitely

air,

and

siphon

of

oil

felt

has

the

siphon

removed

OF

OIL

within

three

minutes

operation.

for a specific

the

siphon,

top

soft

cup

felts

cup.

In

the

contacts

no

trouble

is

functioning

in

the

been

cup.

as

flow

is

For

In

the

other

cup

sump

saturated

explained.

of

afilterto

keeps

the

this

felt

had

felts

Then,

with

the

should

When

SIPHON

to

five

or

so

before

Within

purpose.

priming

prevent

the

best

condition,

itself.

been

or

oiled

in

the

while

words,

oil,

and

harder

be

correctly,

around

this

in

the

the

is

minutes

an

hour,

The

oil

and

the

siphon

initial

it

is

before

soft

squeezing

squeeze

push

thin

experienc

on a machine

felt

same

done,

the

all

the

there

bottom

to

after

the

air

is

felt,

prevent

clogging

clear

of

lint,

self-priming

difficult

for

installing,

top

out

or

felt.

in

felt.

twist

ed

the

the

the

head.

As

felt

air

the

This

when

manner

siphoning

is

a

of

as

Page 7

The

follow

are given.

of

some

Amt.

1

3

Pl

2

3

2

2

2

2

2

1

2

2

1

1

1

1

2

3

1

1

2

2

1

1

2

2

2

3

1

2

1

2

1

1

1

2

1

1

:l

1

8

3

2

1

1

1

1

1

ing

of

the

Pat

·t N

8

18

18

20

25 c

25 c

25 c

25

2

7-4

Blk

21.1

:w

43

0-216

5

Bl

5

0-4

Bl

5

0-64

Bl

54

73

77

77

77

78

80

80

81

82

87

88

89

90

90

90

DO

DO

91

93

95

!J

5

95

96

96

!)8

9

1l

98

98

!JliA

109

151.1

187 A

258

258

258

269

269

:i57

is a num

Unless

major

o.

cc

35

.

c

k.

58

k.

8

k.

A

B

A

A

A

er i

cal

list

otherwi

s e

specified,

of

parts.

Description

F e

ed Hocker Shaft

Nut

for 51240

55241

N,

(right

thread) 1

P

in

for

Washer

51435,

Screw

for 232

Screw

for

Screw

for

Screw

for· 4:Jl:l9 A

(8372

A) 1

eedle

N

\\'

asher

Sc r

ew

for 52804

A

djustin

1.1344

L

oopct· Avo

t

l'ic for

(22894

Feed

Lift

for

2[)4 76 J

(22894

D)

Pin

for 51457 A

Sprin

g P

Lucitc

O

Ne

ed

le

Ba r

29348

p 1

Scr

ew fo r looper

Sere\\

fo r 3

Scr

ew

for 51054

293

48

P, upper

Scr

ew fo r 5

Scr

ew fo r 5

29348

P, lO\\er

Screw

for cloth

Scr

ew

for

Scr

ew for 5

(12982)

Stitch

Hegula

Screw

Scr

ew

for

on

51600

Sere\\

for 15465

Screw

for

Screw

for

feed dog

Sere\\

for

Screw

for

Screw

for 52882

Screw for

Clamp Screw

D,

55244 G

666-1.12 1

for 51236

517 8

33 A 1

23 25:l

23253 Z 1

Bar Eyelet

g Screw

id Ecce

294

76

BJ

D) 2

Eccc

nlt·

\H

in for

51241

il

Gauge 2

Link

1054

1236

1054

plat

1480

1242

ting

throat

BA

51418-16

differential

51282

52882

528

94

for

51600 n presser

feet

Screw

for

lug Scr

Screw for

Scr

Sere\\

Spot

Needle

Scr

Screw

Screw for 158

Screw

T ns i

Looper

Ey

Screw for

Nut

Lock

on

Nut

Nut for

N

ut for 51240

(left

Screw

ll21375

ew

for bed

ew

ew for 482 1

elet

1147

for

51270

for 51244

Screw for

for

on

51423

Set Scre

for 51244

Thr

(98 A) 2

51291 A

Disc

ad

w

13

8344 1

for

660-1

A

528

51236

36

22829

[)4 Al\1

G

D 1

Nut for

29192

for

thread)

for

380

parts

used

the

Amt.

G, 2

F'

A 1

for

n-

ic

I<

on

on

A

on

e 1

C 1

Y 1

plate

F

AE

Y

AA

AB 1

.AH

B 1

B 1

parts

1

2

1

1

2

2

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

in

Styles

listed

Part

380

402

40 2

482

31

531

643-127

Blk.

660-1

660-16

660-202

660-

660-212

666-6

666666-111

666-114

666-111.1

666-170

666-179

666-201

666-209

666-214

71!)

719

71!)

907

6042

7!)47

830

8305

8305

8

324

8324

8324

4 1/ 2

8326

8326

8326 G

8328 C-3

83

44

83 72 A

9420

9420 C-3

9420

9420

4

1/2

51400

BC

arc

No.

36

9

207

5

82

A

L

N

s

L-2

L-4

L-

A

C-2

C-4

C-

and 51600

for

both

De

scription

Latch

Spring for

1402

on 51400

(357)

Sc r ew for 216 57 Y 1

Sc r ew fo

l"

C

Sc r ew for 5

Scr

Gasket for 5

Oil

c

N

5

"0"

O

sc

Oil

ne

Oil Wic

ro

O

(PI 11.1

Oil

rocker

Oil

shaft

(35178

O

shaft

Oil

\\'ed

Felt

51294

Siphon

for

Felt

51294

Screw

Screw

Sere\\

Nut

\\asher

Nut

~lain

16

(22

l\

12 gaug e 5

(22 5

r· 53783

eed H

ocker

oll

ar (9

ew fo r

Tub

e for

ra

nk link

eedle

Bca

12

36 E

lUn

g for

il

Se

al Hin r for

r foot

lift

Se

al

Hing for

ed

le

leve r

k for·

cke

r s

haft(35178

1

il

\

ick for

) 1

Wick

shaft

Wicl<

bush

D)

il

\\'i

ck

bush

\\

icl<

ge

Pin

Plug,

u 1

Cup

51294

Lint Fil

~I

for

for

for

for

22868

for

for

51294

Feed

gauge

593

) 2

lain

Feed

93)

i\lain Feed Dog for 5

10 gau

ge 51600

(22593)

Throat

Throat

Throat Pla

D

Diff. Feed Dog for

Diff. Feed Dog

Throat

Stripper

W

Presser Foot

Presser

Presser

Presser Foot

Plate for

8 gauge 5

Plate for

12

gau

ge5

16gau

ge

if

f. Feed Dog

16 gau

ge

auge51600

12 g

10 gau

ge

Plate for

10gauge5

5

1600

BA(28

asher

for

au

ge

8 g

10 gau

ge

12 gau

ge

auge 51600

16 g

51600

BA.

machines.

Quantities,

l"ollowing

Amt

BC

A 1

Shaft

1.1)

1257

M 1

51493

BQ

1493

AG

feed

(258

A)

l'ing for

pulley

pres-

er

lever

stud

looper

D)

51145

for fee

d

for main 2

ing, r ig

for

ing,

for 512

for

upper,

U 3

51150

512

528

51600

ht

main

left

50 E 1

666-111

for 7

Disc

Felt

ter for 4

50 E

35 U 2

A

52894

A~l

H 2

Dog

for

BA

Dog

for

1600

BA 1

DA 3

1600 DA(87)

for

for

for

BA

BA

BA

18

0)

0)

A ) 1

1600BA(87)

te

for

51600

DA(87)

51600

BA(!JO)

BA(9

51600

BA (9

1600BA(87)

Bl a

de

C,

187

25

CC

for

BA 1

Foot for

51600

Foot for

51600

for

2

1

2

1

1

1

1

1

1

1

3

3

2

1

1

1

2

2

1

1

2

2

3

2

1

1

2

1

1

1

2

2

1

1

2

1

1

2

part

the

Part

9937

12538

12934

12982

15105

15226

1546

21210

21212

1321375

21657-4

216

57 E

216

57

21657

21657

22513

22513

22516

22519

22519

2251[) J

22524

22528

22539

22541

22548

225

57

225

59

22559

22559

22560

22

560

22560

22561

22561

22562

65

225

225

69

22

569

2

2:>

69

22570

22571

225

80

22585 A

22586 R

22593

22593

96

225

2

259

97

225

22704

2270

2272

2272

2272

2272

227

33 B

22747

227

58

227

58

No.

5 F

7 A

4

9

9 A

9 B

9 c

numbers

parts

list

Nut

Nut

Nut

A

Nut

Main

B

B

A

ll

gauge 5

(2 2

Diff. Feed Dog

8 gauge 5

Looper

for

Looper

1609

Lock

5

All

\\

X

y

1294

Belt

Tension Release

Separator

\\'asher

Tension

Lever

T ns

Shaft

Tension

Li

Connection(402,

Screw for

Screw

Scr ew

c

Screw for

II

Screw

Screw

g

uard

Screw

Screw

H

Plug

B

Screw

Screw

Screw

B

A

Cap

B

G

B

B

B

A

c

B

B

J\

D

29105

Cap

2!1105 AA,

Screw

Screw

Scr

Screw

Scr

Scr

Screw for

Scr

Scr

Screw fo

Scr

Scr

on

Plu

Set Scr

Scre

Scr

(512 50

Screw for

do

Screw

Scr

Screw for 51435

Scr

A

Screw for 51444

Screw for

Scre

Screw for 512!J

Screw

Screw

P lug

52882

F

eed

AdJusting

52834

Sc r ew for 52835 G

Scre

B

(12

and

description

are

photographs

Description

for

5143 5

for 51241

for

22758

for

81

Feed

Dog

1600

59

3)

1600

Rock

29192 A (88)

er

Collar

A

ing

Ring for

N

Guard

(93)

for

514

Release

Shaft

ion

Hele

ase

Bush

ing

Release

fter

Lever

23233

for

35731

for 52836

52836

for 51244

for needle

and

52853

for 53782

for 51457

Screw

for

for

52882

for

52882

for

53 7 83 L

Screw

for

AA,

small

Scr

ew

for

large

for

29066

for 51493

ew

for

52834

for 528

ew

for 2:12

ew

for 23253

512

ew f

or 39237

ew

for 51282 Y

r 51493

ew

for

5289 1 B

ew

for thr oat plate

514

00

BC

g S

crew

for

ew for 51423 B

w f

or

ew

:n 82 B

for 660-21

0,

51250 F )

mai

g

for :J9237 D

ew f

or

2165 7 Y

ew fo r 528

w for 51 243 C

Scre

Dog

35

51444

for 51

294

for 55241 N

w for

L (41

394

Height

Screw for

w for 52835 Q

934

A)

K

B

for

BA

for

BA(90)

Cone

for

57 A

and

Shaft

22596)

C

A

ll

C

B

B

A

bed

AD

AE

end

end

R

BP

94

Al<

53

B

Y

54

II

AH

be d

2

n feed

B

U

-12

- 16

4 U

U

A)

s

Page 8

Part

Amt,

22

1

22760

:i

1

22765

2

22768

1

22768

1

22768

1

22768

1

22799

22811

1

1

22829

22839

3

22839

2

22845

1

22848

1

22848

2

22848

9

228

1

1

22868

22883

1

1

22889

4

22894

22894

1

22894

1

22894

1

22894

2

22894

1

2

2

23233

1

23233

1

23233

1

23253

1

23253

1

23253

1

2325:J z

1

29066

1

20105

1

20192

1

20348

1

29476

1

29476

1

29476

1

35178D

4

357:ll

2

3 :!5772

30236

1

:J92:

2

392

1

758

22894

22894

i6

36 T

No,

Screw

c

Screw

A

Shank

51420

Screw

Screw

Screw

Screw

l

lin

E

press r foot

5

1420

Clamp

13

51242

Screw

(258

Scre11

Screw

c

B

Sere\

Screw

Screw

Screw

Screw

2 A

(5

Screw

A

(907,

Plug Screw

A

Adaptor

A

for

Set

c

Screw

D

Screw for

D

Spot

D

29105

Screw

F

Screw

H

Screw

J

Screw

p

Attachment

A

51400

Lower

B

Base

Upper

c

23233

Attachment,

B

for

51600

At

tachment,

F

for

51600

Attachment,

y

for

(22561)

Attachment,

for

(25

Needle

H

ncct

Joint

upper

Looper Drive

AA

Eccentr

Looper Rocker

A

Assembly

p

Needle Leve

Asse

Feed

AR

•

080

Loo

BJ

Ass

throw

Crankshaft

FG

•

770

Spr

666-114

Presser Bar Con-

A

ne

(2251 3 )

Washer for 512

I-I

Regulating Scre

Sliding Block

;\

Diffe

Re

Washer

Di

ff, F

L

ink

Description

for

53

7 83 A

for

51281

Screw

AC-12, -16

for

for

for

for

gc

Screw

AC-12,

Screw

\V

for

A)

for 51480

for

for 51281 J\C 1

for

for

for 52882

for

1242

M)

for

39236

Plug Screw

51758

Screw

for

Screw

AA

for

for

for

for 52836

BC

Scro

for 232

Scroll

A (2251:i)

10, 12,

BA

10, 12,

BA

8 gauge 5

8 gauge

C)

Lev

ing Hod B

Assem

(22

i c

mbly

Lift Asse

inch throw

pe r

Avo

embly, • 062 inc

inch thr

ing f

or

ct

ion Gui

rential Feed Bar 1

gul a

ting St

eed Driving

(22 868 A)

AC

for

51236

B

51244

B

51458

A

fj6458

for

-16

for

15465

F

A 1

cloth

plate

5175 8

52835

N 1

L

51242

Y

39236

T 1 51150

A)

for

29105

C

for

for

C)

and

33

A 1

for

upper,

16 gau

lower,

16 gau

C)

upp e

1600

lower,

51600

Con-

all

bly,

G)

Lever

r

mbly,

ow

666-65,

de

P l

81 AC

w 1

ud

AA

C

\V 1

ge

ge

r,

BA

BA

ate

43

43

51221

51242

51247

(25

ll

(22561)

(25

er

50

Assembly

id

Assembly

Amt,

1

2

2

1

2

2

2

1

2

1

1

1

2

28

1

1

1

2 51

2

1

1

1

1 5

1

1

2

l

1

1

1

1

1

1

t 1

1

1 5

1

2

1

1 51247

Part

No,

39237

39237

D

39237

G

39582

L

41394

A

43139

A

43266

51054

5105

4

51134

c

51144

51145

1145

5

51147

51215

J

1216

G

5

51216

M

5

1216

;\/

5

1216

N

5

1216

p

12

21 c

5

235

G

12

36 A

5

12

36

B

5

5

1236

D

12

36 E

5

F

512 36

123

6 G

51 2

40

D

1241

K

5

51242 L

51242 l\1

51242 i\

1

51242

p

512

42 H

5

12

42 s

242

w

51

5

12

42 y

42

z

512

24

3 c

51

1244

51244 B

51244 L Th ru st W

:\

-f

51244

5

12

44

N

5

12

46

Description

Diff,

Feed

(22565

Diff.

Feed

Plate

(22593)

Bush

ing

Oil

Cap

Gasket

Segment

25

cc

Nut

for

Feed

Cranl< Link

(77)

Link

Pin

(77,

78)

Feed

Bar

Looper

(51244

Feed

Lift

Link for

Looper

tric Link

29476

DJ 1

l\1ain

Shaft

Needle

Collar

Needle

29348 P (51216

51216

p

eedle

N

nectin

g Hod 1

N

eedle Bearin

Hollerfor29476

W

asher for 51215

Washer

Nut

for

Il

l V

cc Belt

(22

804

W

asher for

Li

nk

Pw

and

looper avoid (77) 4

F

eed Crank Stud

(22

768)

Fe

ed Crank Li

51236

E 4 5

F

eed

Cran

F

eed

Cra

F

errule for 51236

Fe

ed Crank Stud

(20,

82,

Looper Conne

Hod

(18,

Loop

er

Rod and Ball Join

r ight (12

Thrust Wash

51242

p

\\asher for

\\'ashe

r for 5 2841 G

Loo

per Dr ive

S

haft

(5124 2

Loo

per Drive

Shaft Bushing,

Looper Drive

Sh

af

t B

Loop

er

(22811 B,

Loo

per Dri ve

Rocker

Loope

r Drive

Shaft B

B

all

Stu

20105 AA (22729) 291

Loo

per Roc

Frame (9 6, 98)

ooper Hocker Shaft

L

Ar

m (2 251 9 H )

5114

4

Looper

Bu sh

ing

Looper

Clamp Co

Nu

t for 51745

Main

Shaf

we

ig

ht (

Bar

Guide

)

Bar

Guide

for

52834

for

52882

for

Stop

51292

for

Hocker

L)

29476

Avo

Lever

(719)

Lever

Lever

for 55244

:>1215 J

F )

for feed

nk Link

269 )

Connect

538

ushing,

Dri

(81 , 2

ush

d F o

ashe

Ro ck er Sh

, right

Rocke r Shaf

t C

22894 J)

AD

22n3

13

Nut

for

G

Pin

29348

Shaft

Shaft

Eccentr

269 )

ic

AH

id

Ecccn-

for

Collar

(95)

Thrust

on

N,

Cong

FG

Pulley

52836

lift

Cap

nk

for

k L ink 1

ctin

g 1

ing

)

er

for

228

52 A

Lever

L)

Lever

middle

Lever

rear

ve

Lever

22804

H)

Lever

2852

Lever

ing, f

ront

rk for

ker

r f

or

aft

lla

r 1

ounter-

P

J

G

C

E 1

t,

A)

t

Amt.

1

1

1

1

1

1

1

1

1

1 5

1

1

1

1

1

1

1

1

1 5

4

4

2

2 5

1 5

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Part

No,

51250

A

51250

D

51250

E

51250

F

51254

c

51254

D

51254

H

51256

c

51256

N

1257

I<

1257

lV1

5

51257

AA

51270

B

1281

T-219

5

51281

AC

51282

y

1282

z

5

1282

AE

51283

H

51290

T

1201

A

51292

A

51292

c

5

1202

D

51202 F-2

1202

F-

1292

G

5

1294

K

!i1204 i\1 O

1204

N

51204

p

512

U4 H

51294

u

51301

D

51382

A

5

1401

i\[

51402

51405

AC-12

51408-12

51408-16

51409

51413

1417

C-8

5

1417

C-12

5

1417

C-16

5

1418-16

5

5

142

0

i\C-12

1420 AC-16 Presse

5

1422

5

51423 B

Bushin

Washer

Needle

(666-170,

Gasket

Needle

upper

Needle

lower

Needle

tion

(22562

Presser

Presser

Hegulator

Presser

Presser

tion

Presser

lower

Pull-off

Cloth

for

Cloth

Spring for 51600

(22760

:i5772

Head

Gasket

Needle

Oiler

Presser

and

Release Lever

middle

Looper

(98 A)

Tension Post

Tension Nut

Tension

Tension Spr ing,

Tension

Tension Post

Clamp,

5

il Siphon

Oil

(21212)

O

il

Screw

Oil

(22729

Cloth

51600 BA(80, 22839

Gas.,c

Cloth

51400 BC(80,

Cloth Plate Slid e for

51400

Ma

51400

Looper, fro

12 gaug e 514

(73)

Looper, front,

16 gauge

(73)

Looper, bac

51 4

Loo

Needle Bar

gauge 5

Need

g

Need

gauge

Ne

Presse r F

gauge 514

gauge 514

:\1a in Sh

Take-up (06, 2258

Description

for

for

22586

Lever

719)

for

22586

Bar

Bushin

Bar

Bush

Bar

on

29348

A)

Bar

Sprin

·

Bar

Bar

and Gui

Ba r

Wire

Plate

51600

BA

Plate

A,

22845

H)

Cove

r (225

for 51282

Lever

(90)

Foot

Tension

ain

Shaft Bushin

Thread

P ost

Spr i ng,

upper,

1294

u

Tube

Tube C

onnection

Tube

Clam

for 51294 P(7047

Siphon

Asse

A,

2272

Pla

te f

t for 53 782 R

P la t e

for

BC

in F

eed

Dog for

BC (2

51400

00

BC (73)

per Roc

au

ge 514

edl e Holde

ker

92

A

for

1600

le Bar for 12

00

le Bar for 16

514

00

oot

00

F

oot

00

aft

51215

H

Stud

R

ing,

Connec-

P

Spr

ing

g

Conncc-

de

(531)

Bushin

(95)

Cover

Cover

BA

B,

69

Y

Bearin

Lifter

Disc

(402)

g,

Guard

Ferrule

Eyelet

looper

needl

(43266)

for

p

mbly

9 B )

or

22 8:l0 C )

2503

)

nt,

fo

r

00

BC

f

or

BC

k, for

for

10

BA

BC

BC

r (89, 08)

for 12

BC

for 16

BC

0 D)

J

g,

g,

B)

g

e

C)

Page 9

Part

Amt,

51424

1

12

51424

1

16

51425

1

51426

1

51430

1

12

514~0

1

51430

1

51435

1

51435

1

51444-12

1

51444-16

1

51457

1

1

51458

51459

1

51480

1

51480

1

4 514!l1 c

514!)2

1

1

51493

51493

2

514!l3 AG

1

514!l3

1

514!l3 BK

1

514!l3

1

51403

1

51608

1

No,

AC-

Throat

faugc

AC-

Throat Plate

f:augc 5

Needle

AC

AC

AC-

AD

AE

B

A

A

A

J\

c

D

E

All

BP

BQ

A-8

51400

Diff,

51400

Bottom,

fool

Plunger

presser

5

Plunger

presser

5

Diff,

Lever,

9937)

Control L ver

ing (22597

Stripper

12

(22704)

Stripper

16

(22704)

Cast-off

Support

21657

Needle

Eyelet

22768)

Looper

Tension

Thread

Throat

for

Throat

for

Lead-in

Eyelet

Looper

Tension

Oil Pump

Sha

O

Shaft

Oil Pump Housing

Oil

Cover

Li

Oil

Gear

O

Gear

Looper,

8

Description

Plate

51400

22570)

225

70)

Guard

BC(22519

l"cd

BC

51420

1420

AC-12,

1420

AC-12,

F e

gauge

gauge

E,

Bar

(27-435

Plate

51400

Plate

51600

ft

il Pump

Gear

Pump

(2256!)

nt

Filter

Pump

(22560

il

Pump

(531)

gau

ge

1400

Dog

(DO)

for

presser

AC-12

Spring

foot

Pin

foot

ed

Control

rear

A)

Blade

51400

Blade

51400

\\ire

(50-216

22528)

Thread

Thread

Post

Guide

BC

BA (80)

Thread

Thread

Post

Driving

Driving

Housing

Driving

Driven

front,

51600

for

12

BC

for

16

BC

for

J)

for

for

-16

for

-16

(20,

Bush-

for

BC

for

BC

Blk,,

Blk,,

Support

(22839)

Support

B)

ere

en

B)

for

BA(73)

Amt,

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

. 1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

Part

51608

51608

51609

51617

51617

51617

51625

51745

51758

51959

51959

51959

52804

52834

52834

52835

52835

52835

52835

52835

52B:{5 S

52835

52836

52836

52836

52836

52836

52841

52841

52853

52882

52882

52882

52882

No,

A-12

A-16

A

B-8

B-12

B-16

B

D

I(

A

H

G

K

N

Q

u

c

H

p

n

G

J

L

M

p

u

Description

Looper,

gauge

Looper,

gauge

Looper,

51600

21210

Needle

gauge

Needle

gauge 51600

Needle

gauge

Needle

51600

Looper

Stud

(51246)

Frame

Thread

(20,

Looper

Nipper

Looper

Nipper

Looper

Nipper

Cast-off\\

Main

(22560

Diff,

Diff,

Lever

Control

(22758

Diff.

Spring

Control

Plate

Intermediate

Feed

Diff.

Pivot

(71!1,

Feed

Feed

(2251!l

Feed

Slot

Feed

Bushing

Looper

Bushing,

Looper

Locking

(51242

Nut

Feed

(22519

Oil

Cover

22848)

Gasket

Gasket

Gasket

front,

51600

front,

51600

back

BA

A)

Bar

51600

Bar

Bar

51600

Guard

BA

Hocker

for

29192

Needle

Eyelet

22B48, 22ll89

Thread

Disc

Thread

Nul

Thread

Spring

Feed

B,

Feed

Feed

Lever

B)

Control

(61267

Lever

(2284

Fork

Feed

Stud

22597

Hocker

Hocker

C,

Rocker

Plate

Hocker

Rocker

Lever

Stud

M,

for

52841 G

Dog

J)

Heservoir

(22733

for

for

for

BA(73)

BJ\(73)

for

(73,

for

BA

for

Bi\

for

BA

for

(22519

ire

(28)

Bar

227 4

Bar

Control

Link

Lever

G)

Stop

8)

Diff,

(2275HB)

Fork

Insert

A)

(22894

Arm

51235

Segment

(22516)

Shaft

Shaft

left

52841

Holder

Back

B,

52882

52882

528112

for

for

8

12

16

J)

Cone

A

A)

7)

Block

G)

G)

L

AD

A:E

12

16

P)

Amt.

1

1

1

1

1

1

1

2

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Part

52ll82 y

52!382 AA

52882

52882

52882

52883

52883

52890

52891

52894

52894

52894

52894

52894

52894

52925

535!)2

53782

53783

53783

53783

53783

55241

55244

56341

563!l0 E

56458

K56823

61267

No.

AC

AD

AE

H

s

c

B

AB

AC

AD

AE

AK

AM

D

B

A

L

M

N

N

G

G

G

Description

Baffle

Plate

Drip

Plate

52ll82 AD

Torsion

52882

AD

Crank

Chamber

Cover

Crank

(22548)

Presser

Presser

Oil

Presser

Gasket

(22541

Chamber

Cover,

Lever

Bushing

Lever

Bell

Spring

Main

Shaft

left

and

Crankshaft

Housing,

bushing

Tube

Oil

Tube

and

looper

eccentric

Oil

Tube

bar

shaft

Oil

Tube

bar

guide

Oil

Tube

rocker

joint

(22560

Oil

Tube

rocker

right

(258

Needle

Tension

Oil

Lifter

Presser

Presser

Looper

Looper

Spring

Needle

Looper,

Spring

Reservoir

Cover

22585

(402,

Lever

(22557

Lever

Hod

Lever,

Hod

(18)

Shaft

(18,

Eyelet

10

gauge

51600

52835

Guard

(22524,

A)

Lever

22758

Bell

Connecting

Ball

Collar

51216

for

for

Lever

BA

Pin

K

(90)

for

(DO)

Spring

for

B)

lower

Foot

Lifter

Foot

Lifter

Crank

Bush

ing,

inner

r i

Hushin

includin

(22569

B)

Holder

for

feed

avoid

for

diff.

for

diff,

for

looper

and

left

ball

B)

for

looper

ball

joint,

A,

6042

Holder

Post

Support

Top

Link

c)

Foot

Lifter

Crank

B)

Foot

Lifter

Foot

Lifter

internal

Connecting

Joint,

Hocker

(22768)

N)

51241

528!l1 B

front,

Style

(73)

for

Rock

Stud

Thread

for

ght

g

g

(90)

lift

feed

feed

A)

left

I<

NOTE:

Numbers

in

parenthesis

following

parts'

description

indicate

the

screws,

nuts,

etc,,

used

to

attach

these

parts,

Page 10

0

8~2CL4t

l

~.lif

~

8324

15105

r,

L-2

B

8324

8305

L-4

N

~

8324

T T

87

~--

'

L-4

8305

1/2

L

8328

8305

- I

C-3

s

5142 4 A

I

I

22593

C-1

2

-

22570

51405

H•l>

51424

.,

·~

AC-12

l"-A

C

:.E

Q

AC-16

<!

15226

B

8326

A

8326

832

6 G

90

5

1426

AC

Page 11

22765

(Incl. ) --

23253

23253

9420 c-·2

B

y

28 C (Adj.

9420

C-3

Screw

9420 C-4

for

22561

8344)

9420 C-4

1/2

••

187

A

8344

•

51420

AC-12

514

51420

09

AC-16

51609

A

0

21210

51608A-8

K56823

A

51608A-12

51608A-16

52853

52

"-

925

D

51425

51408-

AC 5

12

1625

51408-16

22519

J

Page 12

..

22768

1 r

22839

5130~

D

c

yy

25 c

23425

v

51281

I

22845

B

22760

T-219

:J

& 0

A

5

1281

35772

'.

-o

00

AC

H

27-435

89

0

51458

Blk.

51417

51617

51617

51617

50 J

A

C-

8

B-

8

B-12

B-16

-16

Ill

80

51

480

c

23235

F

23235

z

98(2)

~

=--),

•

5

1418-16

Page 13

II

80

22839 c

'

380

•

357

22768

'

~0

-...._"'

27-435

514 58 A

Bl k .

51401

51480 A

I

22839

y T

25

23425 v

as&IS.OW

23233 A

c

iiW

227041

•

51444-

12

51402

5

1444-16

98

(2)

7

5141 8-

51417

51417

•

89

I

16

50

•

C-1

C-16

J - 16

2

Page 14

,

28

..

IIIII

22569

51256

51282

B

N

y

--

I

51256

c

51270

..

22848

22768

•

(Q)

20

--

B

I

95

56458

d

51

758

..

'

, 51959 D

2

2889

A

5

149

='u

2 - l

I

52804

51959

r

...,

-

n

~

51457

2

1657

A

K

.,

n

I

~

1

.J

A

\

E

51282

z

I

40

2

51257

K-

•

531

51257

M

22

528

~

CQ)

..

98

A

;

i

158

B

51459

A

Page 15

39237

D (2)

22516

39236

A (2

(3)

~_,

52835

N

22848

52835

Page 16

WORLD'S

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains sales

and

facilities throughout the world. These offices

aid

you

in

the selection of the right sewing

equipment for your particular operation. Union

and

Special representatives

tory trained

promptly

tion, there

serve you.

ATLANTA,

BOSTON,

CHICAGO,

DALLAS, TEXAS

LOS ANGELES, CAL.

NEW

PHILADELPHIA,

GA.

MASS.

YORK,

and

and

is

a Union Special Representative to

Check with

ILL.

N.

Y. PARIS, FRANCE

PA.

are

efficiently. Whatever your loca-

service men

able

to serve your needs

him

today.

MONTREAL, CANADA

TORONTO,

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

sTunG

ART, GERMANY

service

will

are

fac-

CANADA

ENGLAND

ENGLAND

400

Representatives

MACHINE

N.

FRANKLIN

Industrial

and

cities

distributors

throughout

COMPANY

ST.,

CHICAGO,

In

the

oil

Important

world.

ILL.

60610

Loading...

Loading...