Page 1

®

INDUSTRIAL

SEWING

FINEST

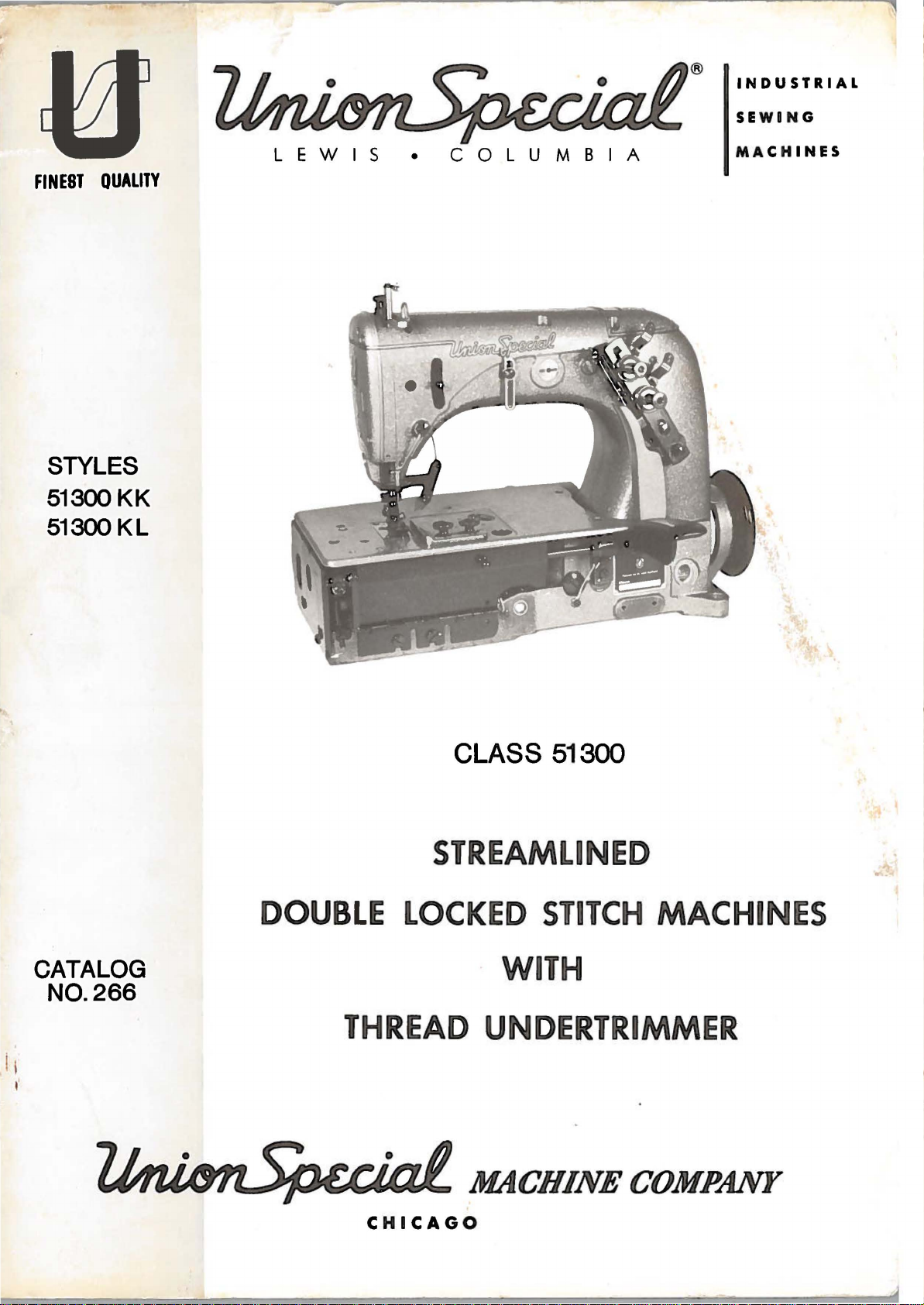

STYLES

51300KK

51300

QUALITY

KL

LEWIS

•

COLUMBIA

MACHINES

CATALOG

N0.266

DOUBLE

THREAD

CLASS 51300

STREAMLINED

LOCKED

STITCH

WITH

UNDERTRIMMER

MACHINES

CHICAGO

Page 2

Page 3

( S

Catalog

up

p 1 e m e n t t o C a t a 1 o g

INSTRUCTIONS

No.

FOR

266

No • 249

)

ADJUSTING

LIST

Streamlined

51300

KK

CLASS

Styles

First

AND

OF

Edition

OPERATING

PARTS

51300

Lockstitch

51300

KL

Rights

Union

Copyright

by

Special

Reserved

1970

Machine

in

All

Co.

Countries

MACHINE COMPANY

INDUSTRIAL

SEWING

CHICAGO

MACHINES

Jp.nuary

1970

Page 4

,-------------

Page 5

IDENTIFICATION

OF

MACHINES

Each

the

name

Standard

"Z".

only

Style

which

junction

not

clarity.

and

Example:

minor

number.

Styles

differs

This

used

KL

Union

plate

Style

changes

catalog

therewith.

on

certain51300

parts.

on

numbers

"Style

Example:

of

machines

from

Styles

Special

the

51300

machine

machine.

have

51300

are

made

"Style

similar

the

style

is a supplement

Only

those

CC,CD

CC,CD

Style

one

KK".

in a standard

51300

number,

APPLICATION

parts

areillustratedandlistedat

parts

is

identified

numbers

or

more

SpecialStylenumberscontaintheletter"Z".

KKZ".

in

construction

in

that

to

Catalog

which

are

showninphantomto

by a Style

are

letters

machine.

it

contains

OF

CATALOG

No.

are

used

number

classified

suffixed,

a "z"

are

grouped

no

249

on

as

but

is

letters.

and

Styles

the

help

which

standard

never

suffixed

under a class

should

51300

back

locatethe

is

stamped

and

contain

to

the

Example:

be

used

KK

of

this

special.

the

Standard

number

"51300".

in

and

KL

book.

51300

into

letter

When

con-

but

For

KK

NOTE:

column.

description,

those

included

are

herein.

in

given

of

When

Opposite

Adjusting

in

Catalog

in

additional

The

catalog

It

this

class.

from

handwheel

ordering

the

and

and

No. 249

this

catalog

instructions

can

also

Reference

the

operator's

is

toward

repair

illustration

amount

operating

applies

be

required.

are

specifically

applied

the

parts

page.

instructions

for

Styles

the

ones

that

pertain

with

to

direction.

position

operator.

always

parts

51300

that

specifically

to

discretion

while

use

are

identified

for

CC.CD

are

the

such

seated

the

part

Styles

respectively.

different

Standard

to

some

as

right,

at

the

number

by

detail

51300

from

to

Styles

Styles

left,

machine.

number.

KK

and

Styles

51300

of

Special

front.

listed

KL

are

The

only

51300

KK

machines

Styles

back,

Operating

in

the

second

part

number.

similar

instructions

cc,

CD

and

KL.

as

listed

of

machines

etc

.•

direction

to

or

are

3

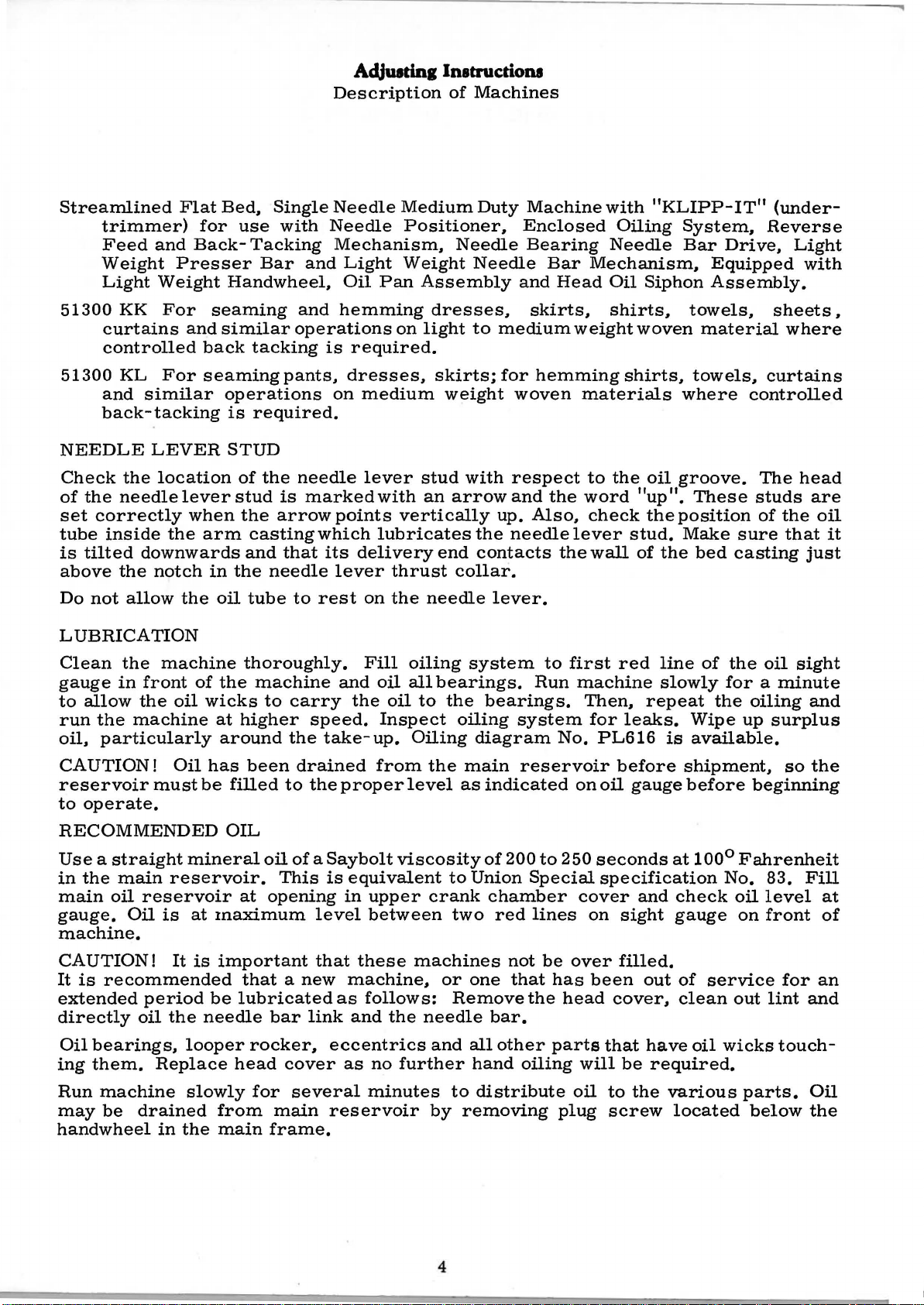

Page 6

Adjuttinl Instructions

Description

of

Machines

Streamlined

Flat

trimmer)

Feed

Weight

Light

51300

curtains

KK

and

Presser

Weight

For

and

controlled

51300

KL

and

For

similar

back-tacking

NEEDLE

Check

of

the

set

correctly

tube

is

tilted

above

Do

not

LEVER

the

needle

inside

downwards

the

notch

allow

location

lever

the

the

LUBRICATION

Bed.

for

use

Back-

Handwheel,

seaming

similar

back

seaming

operations

is

STUD

of

stud

when

arm

in

the

oil

Single

with

Tacking

Bar

operations

tacking

pants,

required.

the

is

the

arrow

casting

and

that

needle

tube

to

Needle

Needle

Mechanism.

and

Light

Oil

and

hemming

is

required.

dresses,

on

needle

marked

points

which

its

lever

rest

Medium

Positioner.

Weight

Pan

on

medium

lever

with

vertically

lubricates

delivery

thrust

on

the

Duty

Needle

Needle

Assembly

dresses,

light

to

skirts;

weight

stud

with

an

arrow

the

end

contacts

collar.

needle

lever.

Machine

Enclosed

Bearing

Bar

and

skirts.

medium

for

hemming

woven

respect

and

the

up.

Also,

needle

with

Needle

Mechanism,

Head

Oil

shirts,

weight

materials

to

the

word 11up

check

lever

the

wall

"KLIPP-

Oiling

Siphon

woven

shirts,

oil

the

stud.

of

the

System.

Bar

Equipped

Assembly.

towels,

material

towels,

where

groove.

11

•

These

position

Make

bed

IT"

(under-

Reverse

Drive,

sheets.

curtains

controlled

The

studs

of

sure

casting

Light

with

where

head

are

the

oil

that

just

it

Clean

gauge

to

run

oil,

CAUTION!

reservoir

to

the

in

front

allow

the

the

machine

particularly

must

operate.

machine

of

oil

Oil

be

RECOMMENDED

Use a straight

in

the

main

main

gauge.

oil

Oil

mineral

reservoir.

reservoir

is

at

machine.

CAUTION!

It

is

recommended

extended

directly

Oil

bearings,

ing

them.

Run

machine

may

be

handwheel

It

period

oil

the

looper

Replace

slowly

drained

in

the

is

needle

thoroughly.

the

machine

wicks

at

to

higher

around

has

been

filled

OIL

oil

at

opening

maximum

important

that a new

be

lubricated

rocker,

head

for

from

main

carry

speed.

the

take-up.

drained

to

the

of a Saybolt

This

is

level

that

bar

link

eccentrics

cover

several

main

reservoir

frame.

Fill

and

oil

the

oil

Inspect

from

proper

viscosity

equivalent

in

upper

between

these

machine,

as

follows:

and

the

as

no

further

minutes

oiling

all

to

system

bearings.

the

oiling

Oiling

the

main

level

as

to

crank

two

machines

or

one

Remove

needle

and

all

to

by

removing

Run

bearings.

system

diagram

reservoir

indicated

of

200

Union

Special

chamber

red

lines

not

that

the

bar.

other

hand

oiling

distribute

to

No.

to

be

has

parts

plug

250

head

first

red

machine

Then,

for

leaks.

PL616

before

on

oil

gauge

seconds

specification

cover

on

over

and

sight

filled.

been

cover,

that

will

be

oil

to

the

screw

line

of

slowly

repeat

Wipe

is

available.

shipment,

before

at

100°

check

gauge

out

of

clean

have

oil

required.

various

located

the

oil

for a minute

the

oiling

up

surplus

so

beginning

Fahrenheit

No.

83.

oil

level

on

front

service

out

wicks

for

lint

touch-

parts.

below

sight

and

the

Fill

at

of

an

and

Oil

the

4

Page 7

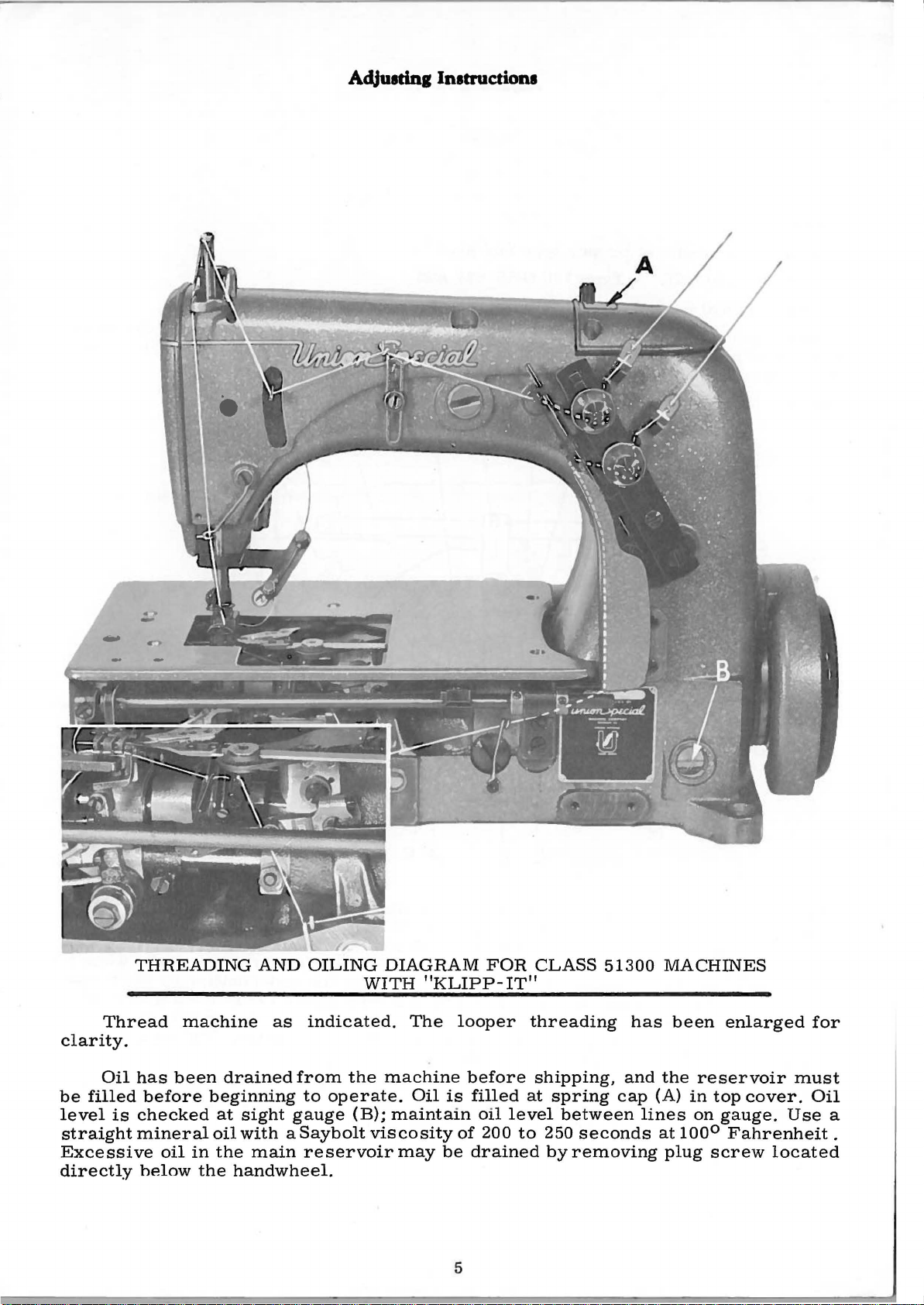

Adjuadn1Inetructions

Thread

clarity.

Oil

be

filled

level

straight

Excessive

directly

is

THREADING

machine

has

been

before

checked

mineral

oil

helow

beginning

in

the

AND

as

drained

at

sight

oil

with a Saybolt

the

handwheel.

from

gauge

main

OILING

indicated.

to

operate.

reservoirmay

DIAGRAM

WITH

the

machine

(B);

maintain

viscosity

"KLIPP-

The

Oil

is

be

FOR

looper

before

filled

oil

of

200

drained

5

CLASS

IT"

threading

shipping,

at

spring

level

to

250

byremoving

between

51300

has

and

cap

seconds

MACHINES

been

the

reservoir

(A)

in

lines

at

100°

plug

on

screw

enlarged

top

cover.

gauge.

Fahrenheit.

located

must

Oil

Use

for

a

Page 8

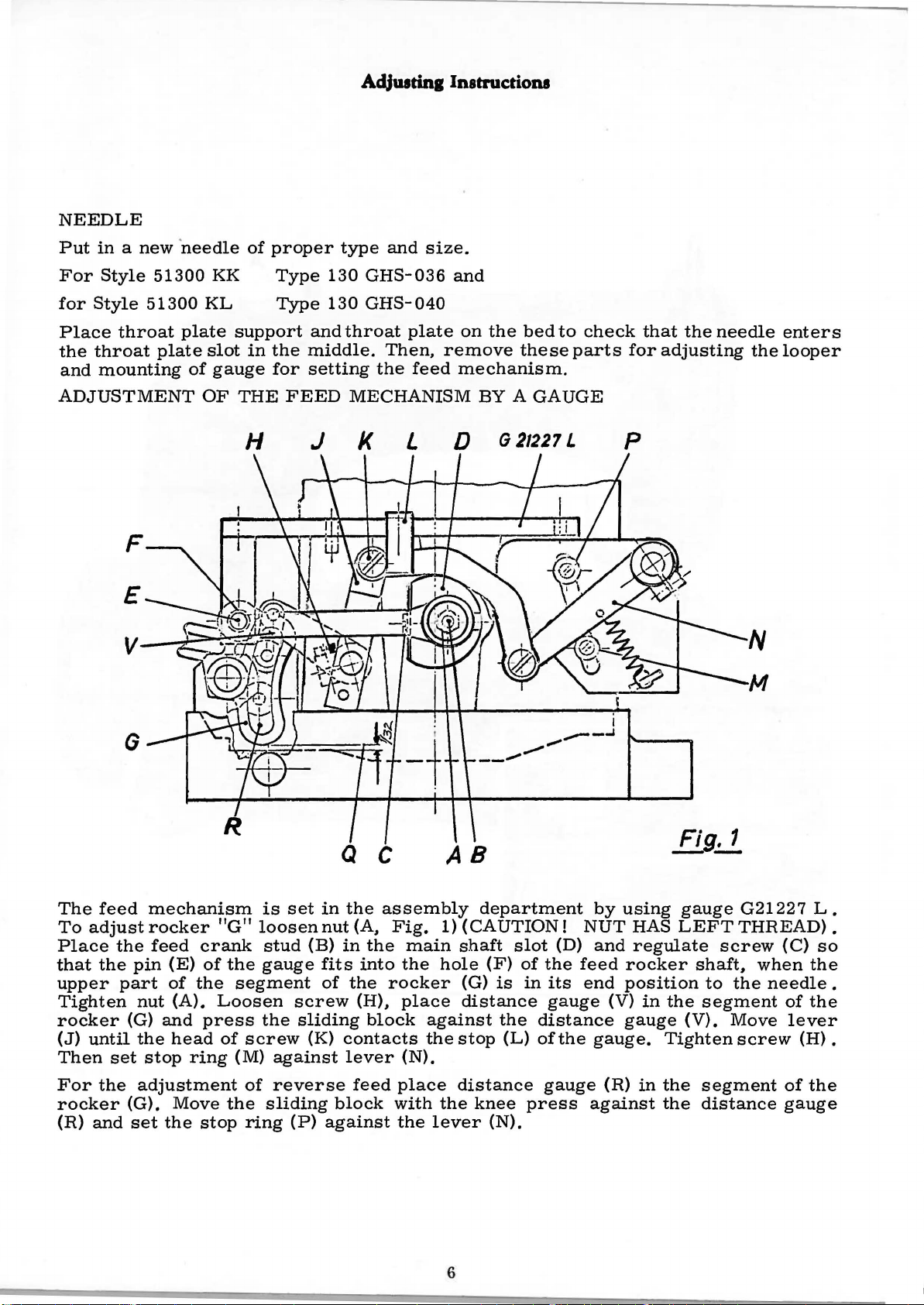

NEEDLE

Put

in a new 'needle

For

Style

for

Style

51300

51300

KK

KL

of

proper

Type

Type

Adjuatin1 Instructions

type

and

size.

130

130

GHS-036

GHS-040

and

Place

the

and

ADJUSTMENT

throat

throat

mounting

plate

F

E

G

plate

slot

of

gauge

OF

support

in

the

for

THE

FEED

H

and

throat

middle.

setting

MECHANISM

J

K

plate

Then,

the

L

on

remove

feed

mechanism.

BY A GAUGE

D G21227 L

__

the

.,.,

bed

these

_,.,.,

to

check

parts

----'

I

that

for

p

the

needle

adjusting

the

N

M

enters

looper

The

feed

To

adjust

Place

that

the

upper

Tighten

rocker

(J)

until

Then

For

rocker

(R)

set

the

and

mechanism

rocker

the

feed

pin

(E)

part

of

nut

(A).

(G)

and

the

head

stop

adjustment

(G).

Move

set

the

crank

of

the

press

ring

stop

is

"G"

loosen

stud

the

gauge

segment

Loosen

the

of

screw

(M)

of

the

sliding

ring

set

in

nut

(B)

fits

of

screw

sliding

(K)

against

reverse

(P)

Q c

the

(A.

in

the

into

the

(H).

block

contacts

lever

feed

block

against

assembly

Fig.

rocker

place

with

the

main

the

place

against

the

(N).

lever

AB

department

1)

(CAUTION!

shaft

hole

(F)

(G)

is

distance

the

stop

(L)

distance

the

knee

(N).

6

slot

of

the

in

its

gauge

distance

of

gauge

press

(D)

the

by

NUT

and

feed

end

(V)

gauge.

(R)

against

Fig. 1

--

using

HAS

LEFT

regulate

rocker

position

in

the

gauge

Tighten

in

the

the

gauge

screw

shaft.

to

segment

(V).

segment

distance

G21227

THREAD).

(C)

when

the

needle

of

Move

screw

lever

(H).

of

gauge

L.

so

the

.

the

the

Page 9

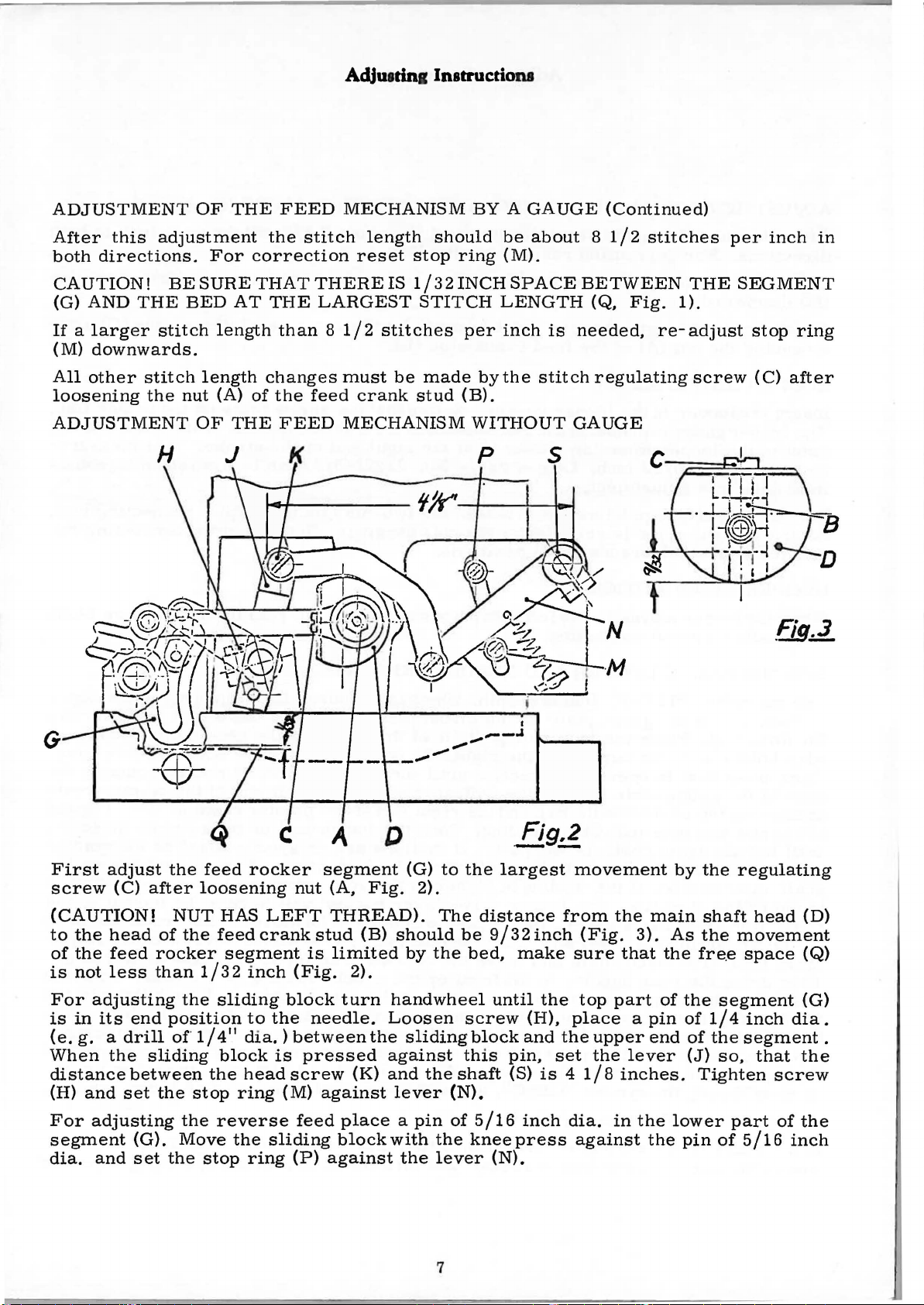

AdJutrinl Instructions

ADJUSTMENT

After

both

CAUTION!

(G)

If

(M)

All

loosening

ADJUSTMENT

this

directions.

AND

a

other

THE

larger

downwards.

stitch

adjustment

BE

stitch

the

H J

OF

SURE

BED

length

nut

OF

THE

For

AT

length

(A)

THE

FEED

the

stitch

correction

THAT

changes

of

THE

than

the

FEED

THERE

LARGEST

8 1 I 2

feed

MECHANISM

length

reset

stitches

must

crank

MECHANISM

IS

be

stop

1132

stud

should

STITCH

made

BY A GAUGE

be

about

ring

(M).

INCH

per

(B).

SPACE

LENGTH

inch

is

by

the

stitch

WITHOUT

s

(Continued)

8 1 I 2

BETWEEN

(Q,

needed,

regulating

GAUGE

stitches

Fig.

THE

1).

re-adjust

screw

per

inch

SEGMENT

stop

ring

(C)

after

in

G

First

screw

(CAUTION!

to

of

is

For

is

(e.

When

distance

(H)

For

segment

dia.

adjust

(C)

the

head

the

feed

not

less

adjusting

in

its

g. a drill

the

and

set

adjusting

and

the

after

NUT

of

the

rocker

than

the

end

position

of

sliding

between

the

the

(G).

Move

set

the

feed

rocker

loosening

HAS

feed

segment

1 I 3 2

114

stop

sliding

11

block

the

ring

reverse

the

stop

inch

to

dia.)

head

ring

nut

LEFT

crank

(Fig.

block

the

between

is

screw

(M)

feed

sliding

(P)

segment

(A,

THREAD).

stud

is

limited

2).

turn

needle.

pressed

(K)

against

place a pin

blockwith

against

_,

(G)

Fig.

(B)

should

by

handwheel

Loosen

the

sliding

against

and

lever

the

......

2).

the

......

to

The

be

the

shaft

(N).

of

the

lever

the

screw

this

I

--.&

-

Fig,2

·--

largest

distance

9l32inch

bed,

kneepress

until

block

5 I

16

(N).

make

(H),

and

pin,

(S)

inch

movement

from

(Fig.

sure

the

top

place a pin

the

upper

set

the

is 4 118

dia.

against

the

main

3).

that

part

end

lever

inches.

in

the

the

by

As

the

of

the

of

lower

pin

the

shaft

the

fre.e

segment

114

of

the

(J)

so,

Tighten

of

regulating

head

movement

space

inch

dia.

segment.

that

the

screw

part

of

the

5116

inch

(D)

(Q)

(G)

7

Page 10

AcUuttintE

Instructions

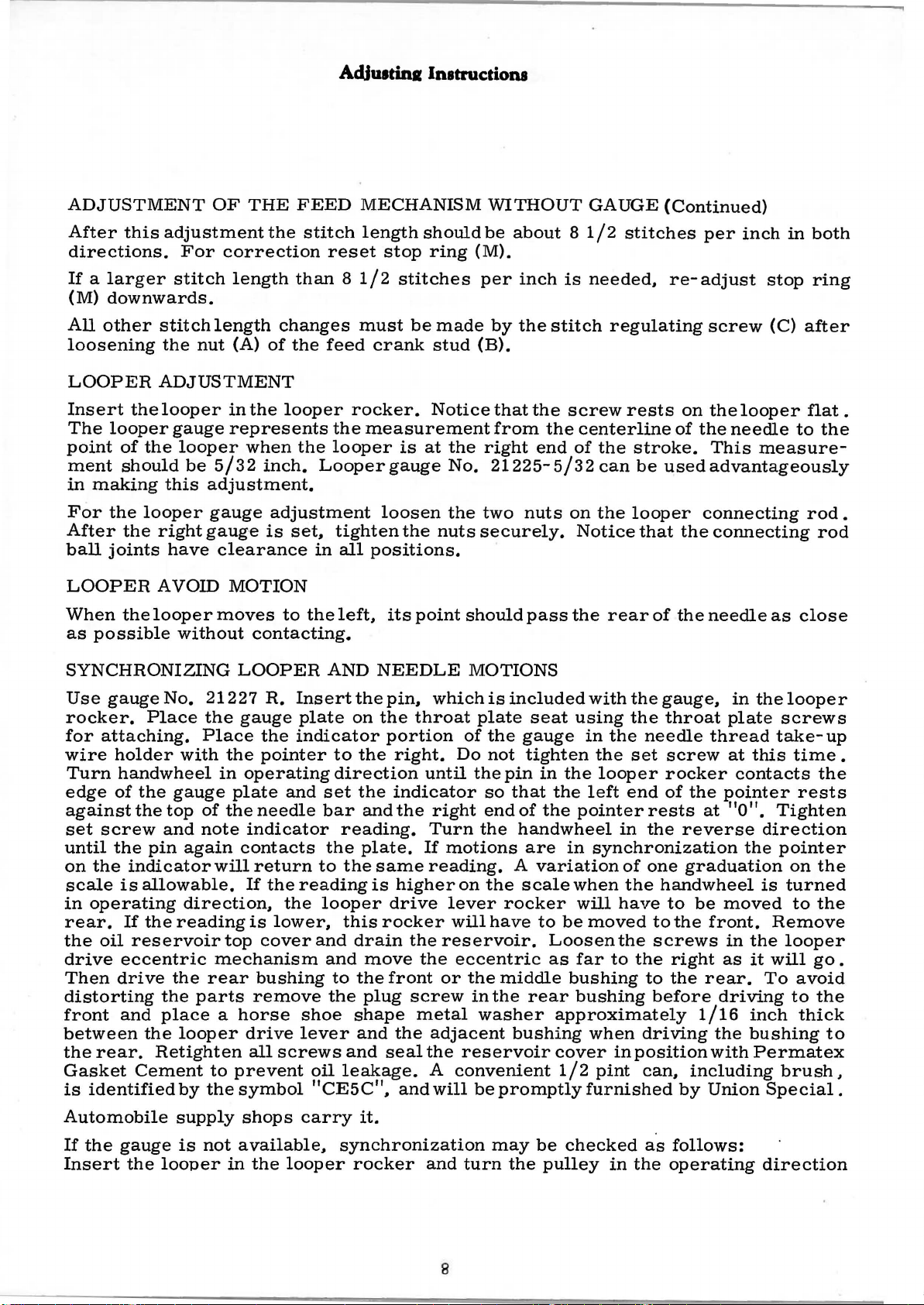

ADJUSTMENT

After

directions.

If

(M)

All

loosening

LOOPER

Insert

The

point

ment

in

For

After

ball

LOOPER

When

as

this

a

larger

downwards.

other

looper

making

the

joints

possible

stitch

ADJUSTMENT

the

looper

of

the

should

looper

the

right

A VOID

the

looper

adjustment

For

stitch

the

gauge

looper

be

this

have

without

OF

THE

the

correction

length

length

nut

(A)

of

in

the

represents

when

5/32

adjustment.

gauge

gauge

inch.

adjustment

is

clearance

MOTION

moves

contacting.

FEED

stitch

reset

than 8 1/2

changes

the

feed

looper

the

the

looper

Looper

set.

tighten

in

all

to

the

left.

MECHANISM

length

must

crank

rocker.

measurement

positions.

should

stop

stitches

be

is

at

gauge

loosen

the

its

point

ring

made

stud

Notice

the

No.

the

nuts

WITHOUT

be

about 8 1/2

(M).

per

inch

by

the

(B).

that

from

right

21225-5/32

two

nuts

securely.

should

pass

stitch

the

the

end

GAUGE

stitches

is

needed.

regulating

screw

centerline

of

the

can

on

the

Notice

the

rear

(Continued)

re-adjust

rests

stroke.

looper

be

that

of

on

of

used

the

the

per

inch

in

stop

screw

the

the

This

advantageously

connecting

connecting

needle

(C)

looper

needle

measure-

as

after

flat.

to

rod.

close

both

ring

the

rod

SYNCHRONIZING

Use

gauge

rocker.

for

attaching.

wire

Turn

edge

against

set

until

on

scale

in

rear.

the

drive

Then

distorting

front

between

the

Gasket

is

Automobile

holder

of

screw

the

the

operating

oil

rear.

identified

No.

Place

with

handwheel

the

gauge

the

top

and

pin

again

indicator

is

allowable.

direction.

If

the

reading

reservoir

eccentric

drive

and

the

the

parts

place a horse

the

looper

Retighten

Cement

by

supply

21227

the

Place

of

note

will

mechanism

rear

to

the

LOOPER

R.

gauge

the

the

pointer

in

operating

plate

the

needle

indicator

contacts

return

If

the

is

top

cover

bushing

remove

drive

all

prevent

symbol

shops

Insert

plate

indicator

and

to

reading

the

lower.

and

shoe

lever

screws

oil

"CE5C".

carry

AND

the

on

to

the

direction

set

the

bar

and

reading.

the

plate.

the

is

looper

this

drain

and

move

to

the

the

plug

shape

and

and

leakage.

it.

NEEDLE

pin.

the

portion

same

rocker

seal

which

throat

right.

until

indicator

the

right

Turn

If

reading.

higher

drive

the

reservoir.

the

front

screw

metal

the

and

or

adjacent

the

A

will

MOTIONS

is

included

plate

of

the

Do

not

the

pin

so

that

end

of

the

handwheel

motions

A

on

the

lever

will

eccentric

convenient

rocker

have

the

middle

in

the

washer

bushing

reservoir

be

promptly

with

seat

using

gauge

tighten

are

variation

scale

to

rear

in

the

in

the

looper

the

left

the

pointer

in

synchronization

when

will

be

moved

Loosen

as

far

bushing

bushing

approximately

when

cover

1/2

pint

furnished

the

the

the

needle

set

end

in

of

the

have

the

to

the

driving

in

position

can.

gauge.

throat

thread

screw

rocker

of

the

rests

the

one

to

screws

to

before

at

reverse

graduation

handwheel

to

be

the

front.

right

the

rear.

1/16

with

including

by

Union

in

the

plate

at

this

contacts

pointer

"O".

direction

the

is

moved

in

the

as

it

driving

inch

the

bushing

Permatex

looper

screws

take-

time.

the

rests

Tighten

pointer

on

the

turned

to

the

Remove

looper

will

go.

To

avoid

to

the

thick

brush.

Special.

up

to

If

the

Insert

gauge

the

is

not

looper

available.

in

the

looper

synchronization

rocker

and

B

turn

may

the

be

pulley

checked

in

as

the

operating

follows:

direction

Page 11

Aclluatinllnatructiona

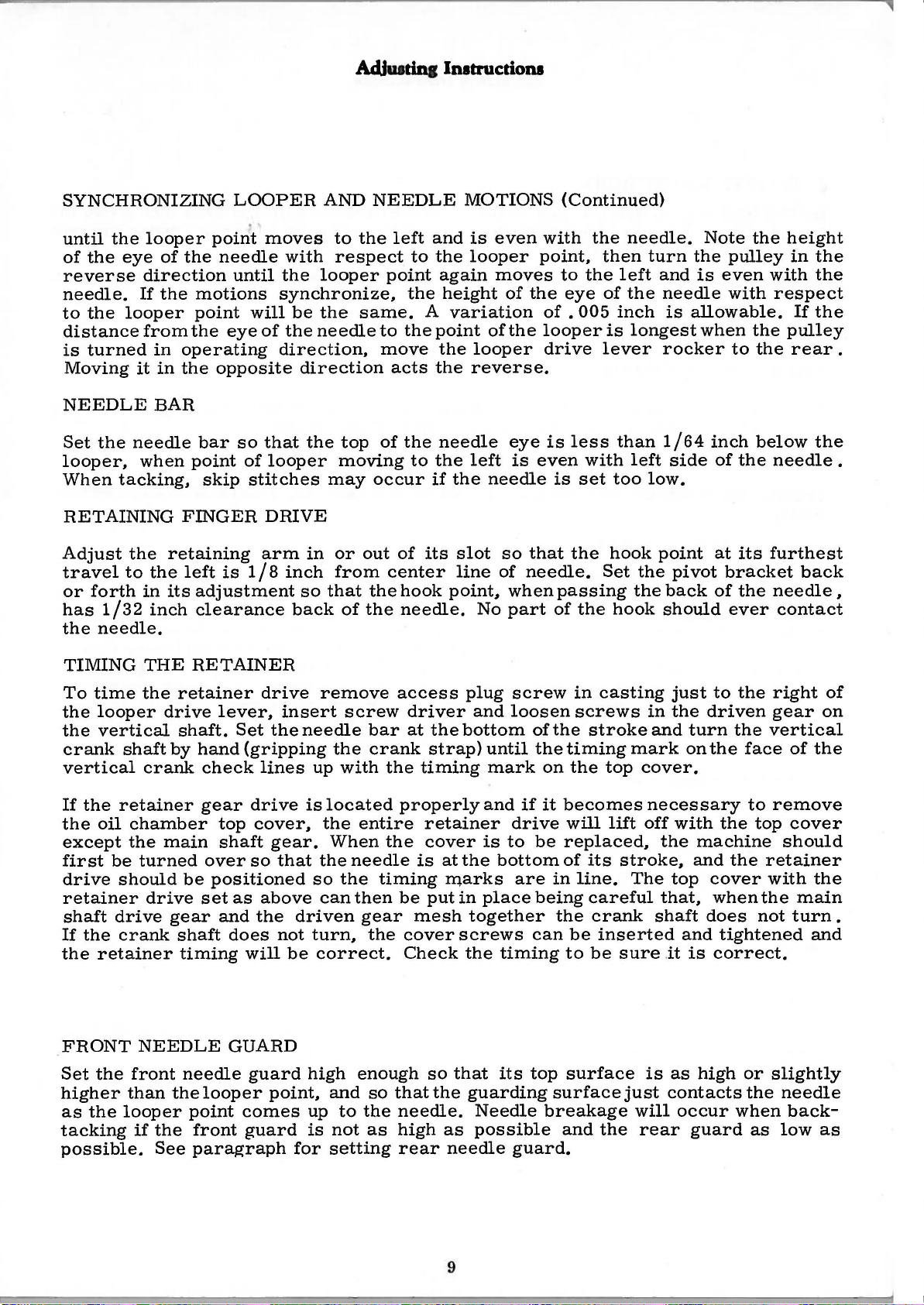

SYNCHRONIZING

until

of

reverse

needle.

to

distance

is

NEEDLE

Set

looper,

When

RETAINING

Adjust

travel

or

has

the

the

the

the

turned

Moving

the

tacking,

forth

1/32

needle.

looper

eye

of

direction

If

the

looper

from

in

it

in

BAR

needle

when

the

to

the

in

its

inch

point

the

motions

point

the

operating

the

opposite

bar

point

skip

FINGER

retaining

left

adjustment

clearance

LOOPER

moves

needle

until

will

eye

of

so

that

of

looper

stitches

DRIVE

arm

is

1/8

AND

with

the

looper

synchronize,

be

the

the

needle

direction,

direction

the

in

inch

so

that

back

to

the

respect

same.

top

moving

may

or

out

from

the

of

the

NEEDLE

occur

left

to

point

the

to

the

move

acts

of

the

to

of

center

hook

needle.

MOTIONS

and

the

again

height

A

variation

point

the

the

needle

the

if

the

its

slot

line

point,

is

even

looper

moves

of

of

the

looper

reverse.

eye

left

is

needle

so

of

when

No

part

(Continued)

with

point,

to

the

eye

of.

005

looper

drive

is

less

even

is

set

that

the

needle.

passing

of

the

the

then

the

of

is

lever

with

too

hook

Set

hook

needle.

turn

left

the

inch

longest

than

left

low.

the

the

the

and

is

needle

is

allowable.

when

rocker

1/64

side

point

pivot

back

should

Note

pulley

even

with

to

inch

of

at

bracket

of

ever

the

the

the

below

the

its

the

height

in

the

with

the

respect

If

the

pulley

rear.

the

needle

furthest

back

needle,

contact

.

TIMING

To

time

the

looper

the

vertical

crank

vertical

If

the

except

first

drive

retainer

shaft

If

the

FRONT

Set

higher

as

tacking

possible.

shaft

the

retainer

oil

be

should

drive

the

crank

retainer

the

the

looper

THE

the

retainer

drive

shaft.

by

crank

chamber

the

main

turned

be

drive

gear

shaft

timing

NEEDLE

front

than

if

needle

the

the

See

RETAINER

drive

lever,

Set

the

hand

point

front

paragraph

(gripping

check

gear

over

positioned

set

looper

lines

drive

top

cover,

shaft

so

as

above

and

the

does

will

GUARD

guard

point,

comes

guard

gear.

insert

needle

is

that

driven

not

turn,

be

high

up

is

for

remove

screw

the

up

with

located

the

entire

When

the

needle

so

the

can

then

gear

the

correct.

enough

and

to

the

not

as

setting

access

bar

crank

the

properly

the

timing

be

cover

Check

so

that

needle.

high

rear

driver

at

the

strap)

timing

retainer

cover

is

at

rnarks

put

mesh

so

the

as

needle

plug

and

bottom

until

mark

and

is

the

bottom

in

place

together

screws

the

timing

that

its

guarding

Needle

possible

screw

loosen

of

the

on

if

it

drive

to

be

are

being

can

top

breakage

guard.

in

casting

screws

the

stroke

timing

the

top

becomes

will

lift

replaced,

of

its

in

line.

careful

the

crank

be

inserted

to

be

surface

surface

and

the

just

in

the

and

mark

cover.

necessary

off

the

stroke,

The

top

that,

shaft

sure .it

is

as

just

contacts

will

rear

driven

turn

on

the

with

machine

and

cover

does

and

is

high

occur

guard

to

the

right

gear

the

vertical

face

to

remove

the

top

the

retainer

with

when

correct.

the

not

tightened

or

slightly

the

when

as

on

of

the

cover

should

the

main

turn.

and

needle

back-

low

as

of

9

Page 12

AdJUJrinl

Instruction~

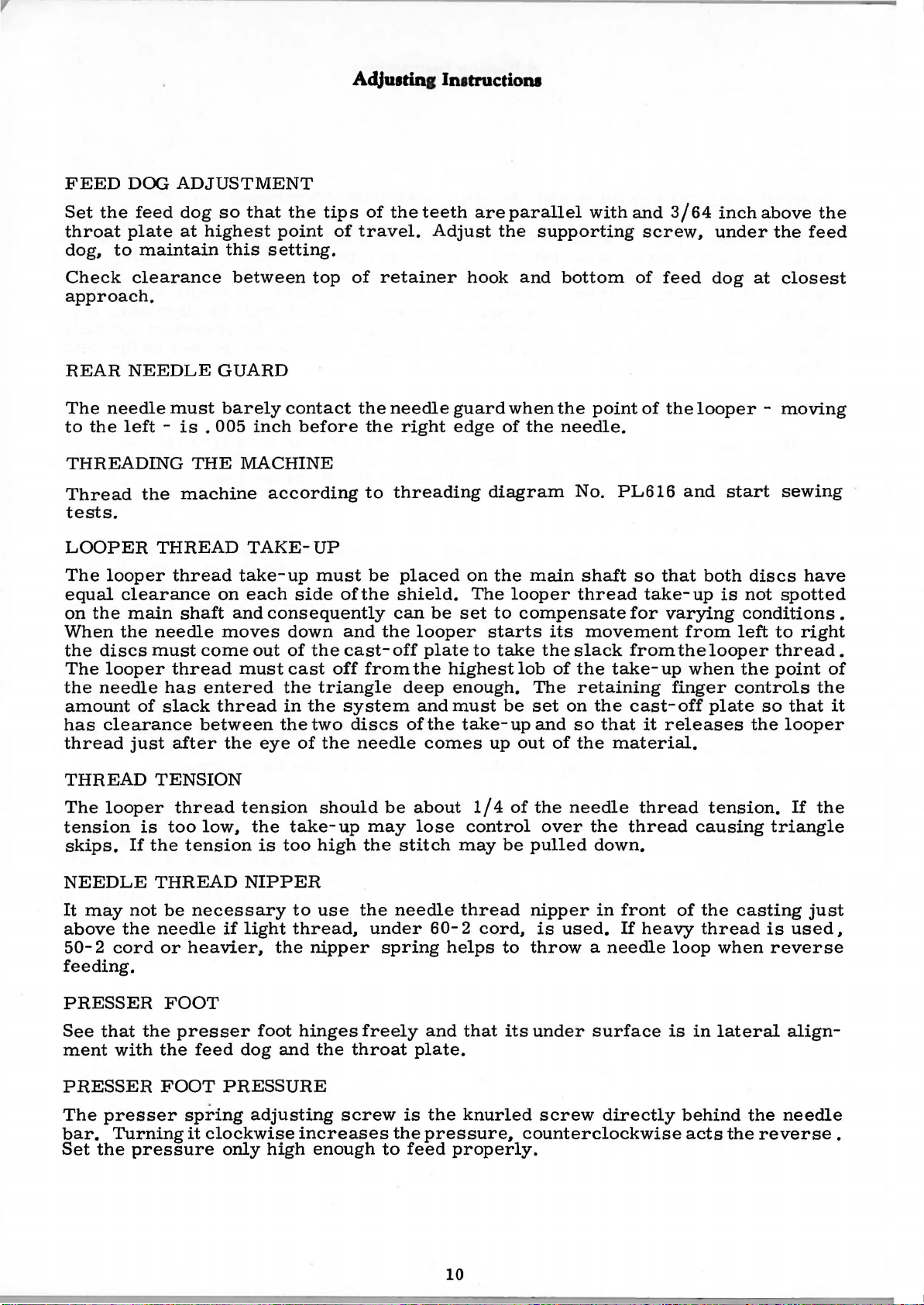

FEED

Set

throat

dog,

Check

approach.

REAR

The

to

THREADING

Thread

tests.

LOOPER

The

equal

on

When

the

The

the

amount

has

thread

DOG

the

feed

plate

to

maintain

clearance

NEEDLE

needle

the

left -is . 005

the

THREAD

looper

clearance

the

main

the

needle

discs

needle

clearance

looper

of

just

must

has

slack

must

ADJUSTMENT

dog

so

that

the

at

highest

GUARD

barely

THE

machine

thread

on

shaft

moves

come

thread

entered

thread

between

after

this

the

point

setting.

between

contact

inch

MACHINE

according

TAKE-UP

take-up

each

and

consequently

down

out

of

must

cast

the

in

the

eye

tips

of

top

before

must

side

the

off

triangle

the

two

of

the

of

travel.

of

retainer

the

the

to

be

of

the

and

the

cast-

from

system

discs

needle

the

teeth

Adjust

needle

right

threading

placed

shield.

can

off

deep

of

be

looper

plate

the

highest

enough.

and

must

the

comes

guard

edge

are

parallel

the

hook

when

of

diagram

on

the

The

looper

set

to

starts

to

take

be

take-up

up

with

supporting

and

bottom

the

point

the

needle.

No.

main

compensate

lob

The

set

out

its

the

of

and

of

shaft

thread

movement

slack

the

retaining

on

the

so

that

the

and

3 I

screw,

of

feed

of

the

PL616

so

that

take-

for

varying

from

take-

cast-

material.

the

up

finger

off

it

releases

64

inch

above

under

dog

looper -moving

and

start

both

up

is

from

looper

when

plate

the

at

closest

sewing

discs

not

conditions

left

the

controls

the

spotted

to

thread

point

so

that

looper

have

right

the

feed

•

.

of

the

it

THREAD

The

looper

tension

skips.

NEEDLE

It

above

50-2 cord

feeding.

PRESSER

See

ment

PRESSER

The

bar.

Set

may

that

with

presser

Turning

the

If

not

the

pressure

TENSION

thread

is

too

low,

the

tension

THREAD

be

necessary

needle

or

heavier,

FOOT

the

presser

the

feed

FOOT

spring

it

tension

the

is

NIPPER

if

light

the

foot

dog

PRESSURE

adjusting

clockwise

only

high

should

take-

too

high

to

use

thread,

nipper

hinges

and

the

increases

enough

up

may

the

the

under

freely

throat

screw

be

about

lose

stitch

needle

spring

plate.

is

the

pressure,

to

feed

1 I 4

control

may

be

thread

60-2 cord,

helps

and

the

properly.

to

that

knurled

of

the

needle

over

pulled

nipper

is

throw a needle

its

under

screw

counterclockwise

the

down.

in

used.

surface

front

If

directly

thread

thread

heavy

loop

is

tension.

causing

of

the

thread

when

in

lateral

behind

acts

casting

is

the

the

reverse.

If

the

triangle

just

used,

reverse

align-

needle

10

Page 13

Adj111tiq lnatructiona

NEEDLE

Set

the

as

low

Raise

NEEDLE

Set

the

studis

necessary

frame

lowering a smaller

SEAM

Check

a

triangular

too

sharp.

Check

worse

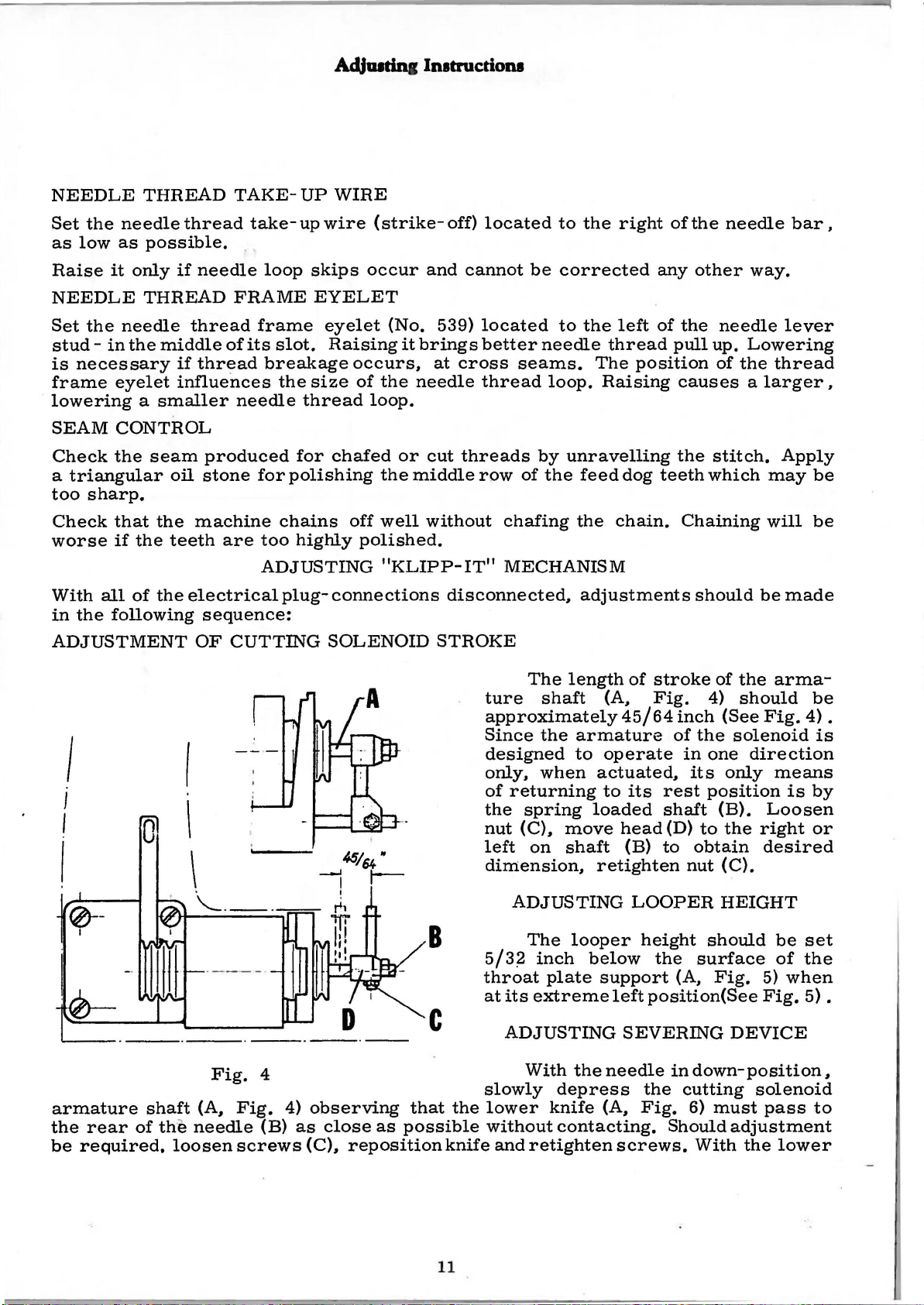

With

in

the

ADJUSTMENT

THREAD

needle

as

possible.

it

only

THREAD

needle

in

the

middle

eyelet

CONTROL

the

seam

oil

that

the

if

the

teeth

all

of

the

following

thread

if

needle

thread

if

thread

influences

produced

stone

machine

electrical

sequence:

OF

TAKE-UP

take-

loop

FRAME

frame

of

its

slot.

breakage

the

needle

for

polishing

chains

are

too

ADJUSTING

plug-connections

CUTTING

WIRE

up

wire

skips

EYELET

eyelet

Raising

occurs,

size

thread

for

chafed

off

highly

SOLENOID

(strike-

occur

(No.

it

brings

of

the

needle

loop.

or

the

middle

well

polished.

"KLIPP-IT"

off)

located

and

cannot

539)

located

better

at

cross

thread

cut

threads

row

without

disconnected,

STROKE

chafing

MECHANISM

to

be

corrected

to

needle

seams.

loop.

by

of

the

the

right

the

left

thread

The

position

Raising

unravelling

feed

dog

the

chain.

adjustments

of

the

needle

any

other

of

the

pull

causes a larger,

the

teeth

Chaining

should

needle

up.

Lowering

of

the

stitch.

which

way.

be

bar

lever

thread

Apply

may

will

made

,

be

be

I

1

I

(

armature

the

rear

be

required.

shaft

of th·e

loosen

Fig.

(A,

Fig.

needle

screws

4

(B)

4)

observing

as

close

(C),

that

as

possible

reposition

B

c

knife

The

ture

approximately

Since

designed

only,

of

returning

the

spring

nut

(C),

left

on

dimension,

ADJUSTING

The

5 I 3

~

throat

at

its

ADJUSTING

With

slowly

the

lower

without

and

retighten

length

shaft

the

armature

to

when

move

shaft

looper

inch

extreme

below

plate

theneedle

depress

knife

contacting.

of

stroke

(A,

operate

actuated,

to

loaded

retighten

support

(A,

Fig.

4 5 I 6 4

its

head

(B)

LOOPER

height

left

position(See

SEVERING

the

Fig.

screws.

of

the

4)

should

inch

(See

Fig.

of

the

solenoid

in

one

direction

its

only

rest

position

shaft

(D)

to

the

indown-position,

Should

(B).

to

obtain

nut

should

surface

(A,

Fig.

cutting

6)

must

With

Loosen

the

right

desired

(C).

HEIGHT

5)

Fig.

DEVICE

solenoid

pass

adjustment

the

arma-

be

4) .

is

means

is

by

or

be

set

of

the

when

5).

to

lower

11

Page 14

AdJUJtiaa

lrutructioru

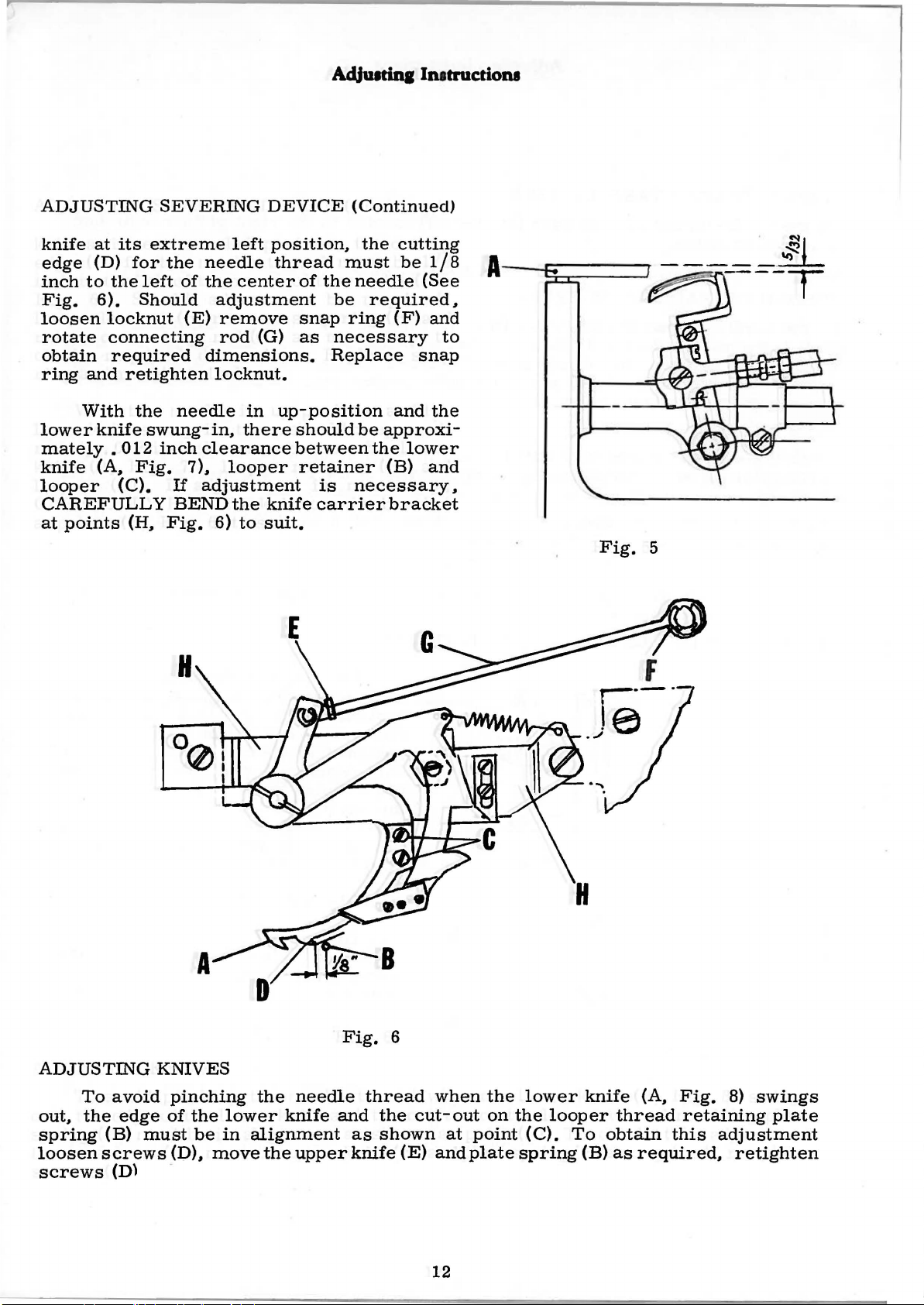

ADJUSTING

knife

edge

inch

Fig.

loosen

rotate

obtain

ring

lower

mately • 012

knife

looper

CAREFULLY

at

at

(D)

to

6).

locknut

and

With

knife

(A,

points

its

extreme

for

the

left

Should

connecting

required

retighten

the

swung-in,

Fig.

(C).

(H,

SEVERING

left

the

needle

of

the

center

adjustment

(E)

remove

rod

dimensions.

locknut.

needle

inch

7),

If

BEND

Fig.

in

there

clearance

looper

adjustment

the

6)

to

DEVICE

position,

thread

of

the

snap

(G)

as

up-position

should

between

retainer

is

knife

suit.

carrier

(Continued)

the

cutting

must

be

ring

necessary

Replace

be

needle

required,

(F)

and

be

approxi-

the

(B)

necessary,

bracket

1/8

(See

and

to

snap

the

lower

and

. N

~I

A---..~c.-----..,.

Fig.

----

5

---

-·~

T

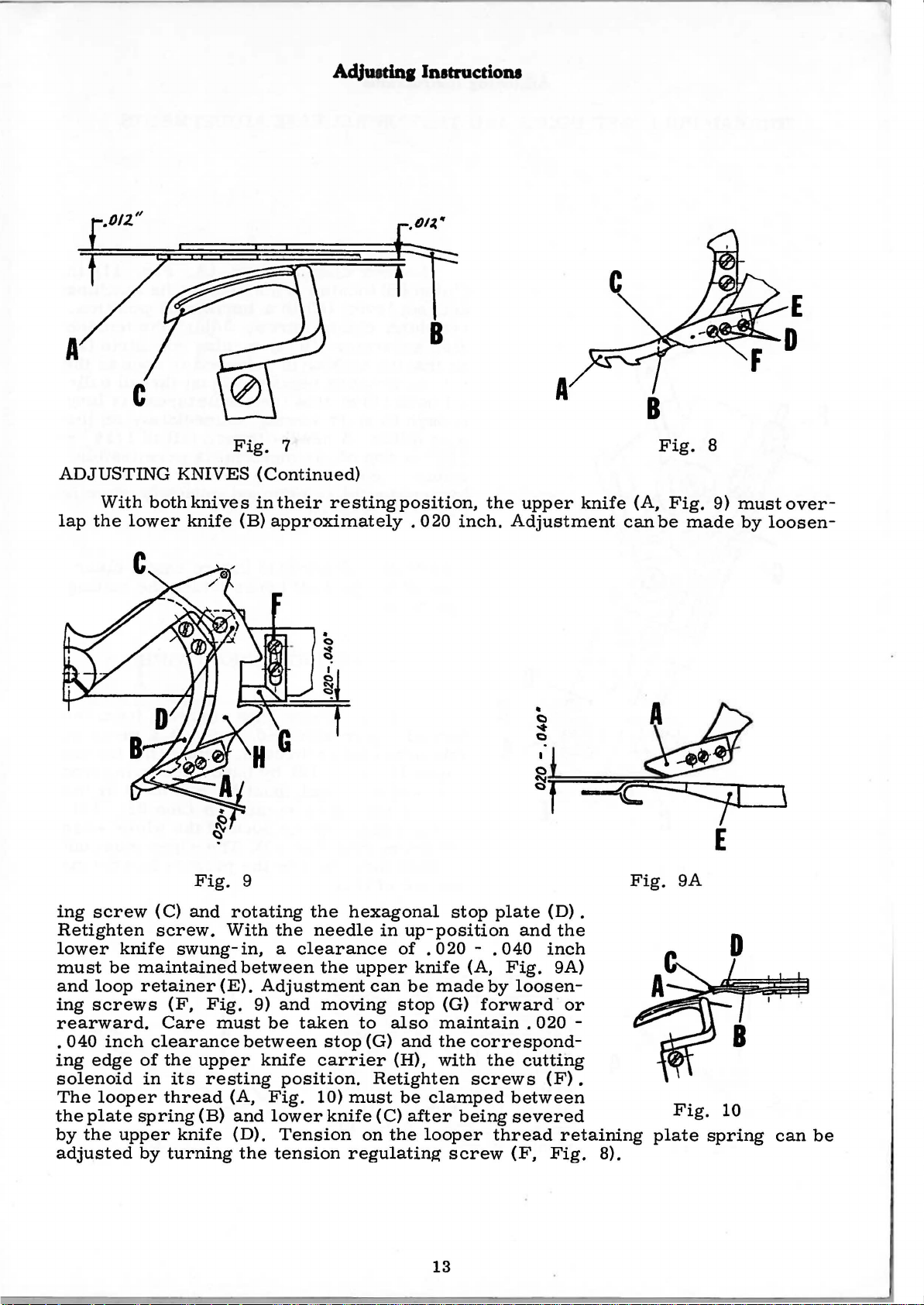

ADJUSTING

To

avoid

out,

the

edge

spring

loosen

screws

(B)

screws

(D) -

H

KNIVES

pinching

of

the

must

(D),

be

move

the

lower

in

alignment

the

needle

knife

upper

Fig.

and

as

knife

6

thread

the

shown

(E)

when

cut-out

at

and

the

on

point

plate

lower

the

looper

(C).

spring

r-·-·

te

·""

knife

To

(B)

F

(A,

thread

obtain

as

required,

Fig.

retaining

this

adjustment

8)

swings

plate

retighten

12

Page 15

A

Ac:IJUitinainatructiona

A

B

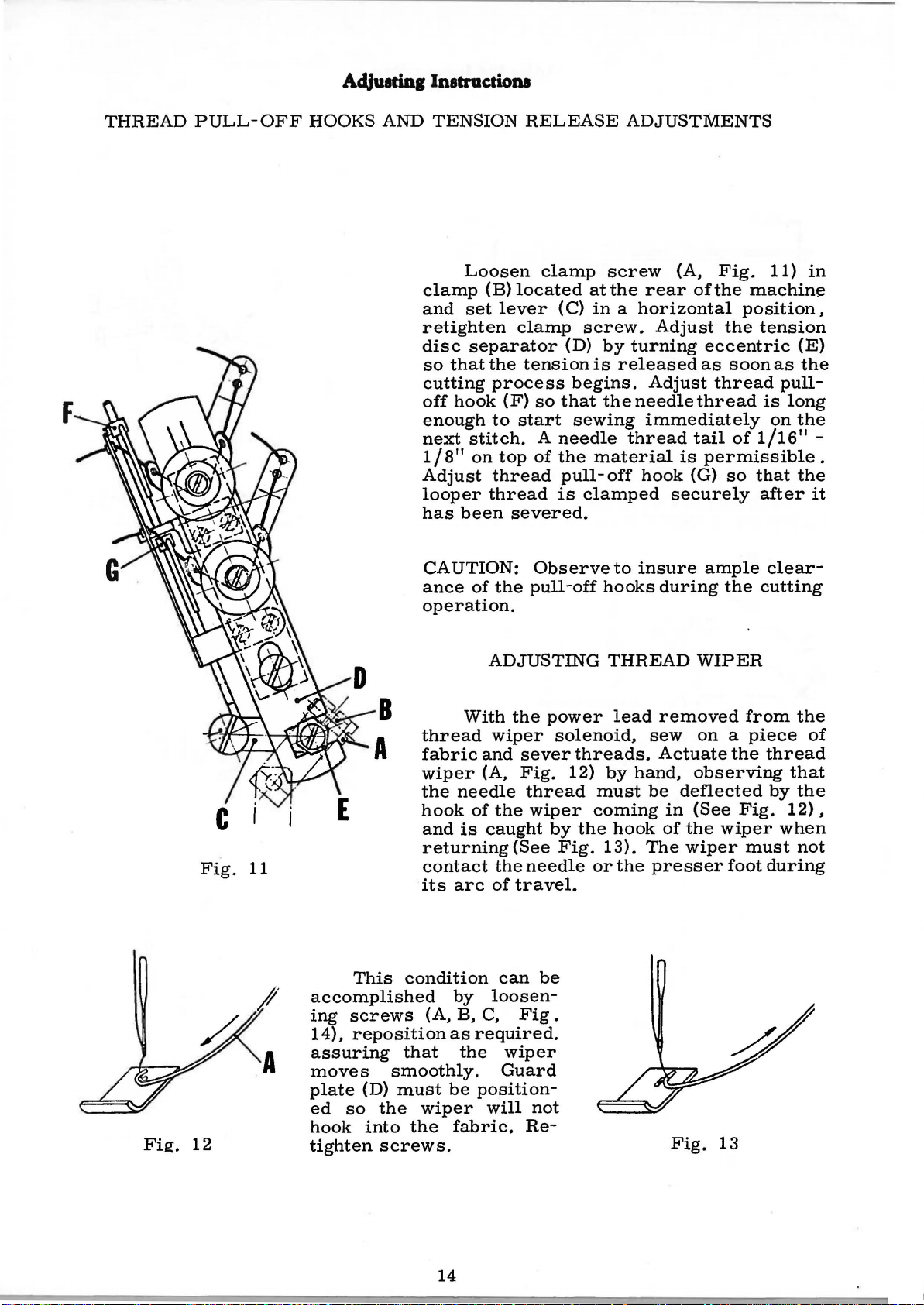

ADJUSTING

lap

With

the

both

lower

Fig.

KNIVES

knives

knife

Fig.

(B)

9

7

(Continued)

in

their

approximately . 020

resting

position,

the

inch.

upper

Adjustment

knife

•

C)

....

C)

I

()

~*=t

=~~:::;:.._

(A,

can

Fig.

Fig.

Fig.

be

9A

8

9)

made

__

must

by

loosen-

over-

,

ing

screw

Retighten

lower

must

and

ing

rearward.

.

ing

solenoid

The

the

by

adjusted

040

plate

the

be

loop

screws

inch

edge

looper

(C)

screw.

knife

upper

swung-in,

maintained

retainer

(F,

Care

clearance

of

the

in

its

thread

spring

knife

by

turning

and

(E).

Fig.

must

upper

resting

(B)

rotating

With

the

a

between

Adjustment

9)

and

be

between

knife

(A,

Fig.

and

lower

(D).

the

Tension

tension

the

needle

clearance

the

moving

taken

stop

carrier

position.

10)

knife

hexagonal

in

up-position

of . 020

upper

to

(G)

must

on

regulating

knife

can

be

stop

also

and

(H),

Retighten

be

(C)

after

the

stop

plate

and

- .

040

(A,

Fig.

made

maintain . 020

the

with

clamped

looper

13

by

(G)

forward

correspond-

the

screws

being

thread

screw

loosen-

cutting

between

severed

(F,

(D) .

the

inch

9A)

(F).

retaining

Fig.

or

-

8).

Fig.

plate

10

spring

can

be

Page 16

AdjUitinglnatructiona

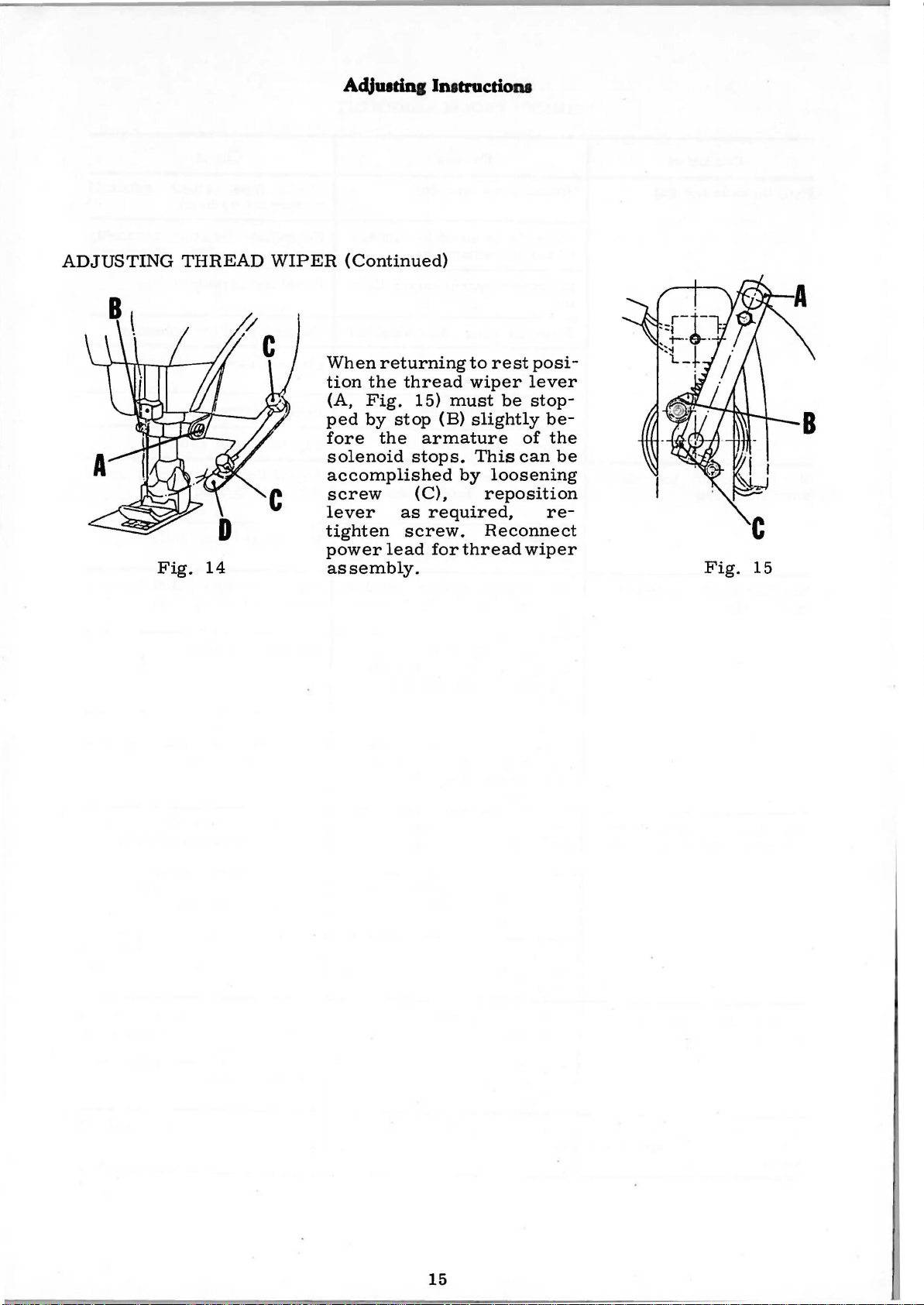

F

THREAD

PULL-

OFF

HOOKS

AND

clamp

and

retighten

disc

so

cutting

off

enough

next

1/8"

Adjust

looper

has

CAUTION:

ance

operation.

TENSION

Loosen

(B)

set

lever

separator

that

the

process

hook

to

stitch.

on

thread

thread

been

of

the

(F)

top

RELEASE

clamp

located

(C)

clamp

(D)

tension

begins.

so

that

start

severed.

sewing

A

needle

of

the

pull-

is

Observeto

pull-off

ADJUSTMENTS

screw

at

the

in a horizontal

screw.

by

is

released

the

thread

material

off

clamped

hooks

(A,

rear

turning

needle

immediately

hook

insure

ofthe

Adjust

Adjust

tail

is

(G)

securely

during

Fig.

eccentric

as

thread

thread

permissible.

ample

machine

position,

the

tension

soon

is

of

1/16"

so

that

after

clear-

the

cutting

11)

as

on

in

(E)

the

pull-

long

the

-

the

it

Fie:.

Fig.

12

11

This

accomplished

ing

screws

14),

reposition

assuring

moves

plate

ed

so

hook

tighten

condition

that

smoothly.

(D)

must

the

into

screws.

With

thread

fabric

wiper

the

needle

hook

and

is

returning

contact

its

arc

by

(A,

B,

as

the

be

wiper

the

fabric.

ADJUSTING

the

power

wiper

and

sever

(A,

Fig.

thread

of

the

wiper

caught

the

of

can

loosen-

C,

required.

Guard

position-

will

by

(See

needle

travel.

be

Fig

wiper

not

Re-

THREAD

lead

solenoid,

threads.

12)

by

must

coming

the

hook

Fig.

13).

or

the

.

removed

sew

Actuate

hand,

be

in

of

The

presser

Fig.

WIPER

from

on a piece

the

observing

deflected

(See

Fig.

the

wiper

wiper

must

foot

13

the

of

thread

that

by

the

12),

when

not

during

14

Page 17

AdJUidnilnatructiona

ADJUSTING

Fig.

THREAD

14

WIPER

(Continued)

When

tion

(A,

ped

fore

solenoid

accomplished

screw

lever

tighten

power

assembly.

returning

the

thread

Fig.

by

15)

stop

the

stops.

(C),

as

screw.

lead

armature

to

rest

wiper

must

(B)

slightly

This

by

loosening

reposition

required,

Reconnect

for

thread

be

posi-

lever

stop-

be-

of

the

can

re-

wiper

be

Fig.

15

15

Page 18

TRIMMER

TROUBLESHOOTING

Both

threads

Needle

after

Needle

trim

cycle

Condition

thread

trimming

thread

not

cut

too

pinched

short

after

Solenoid

Solenoid

of

tension

Improper

ing

Solenoid

Power

connected

Bent

relay

Loose

Needle

too

bly

Lower

of

Not

between

knife

lower

high

knife

needle

enough

Causes

not

working

jammed

assembly

synchronizer

plug

lead

thread

on

loop

disconnected

to

contacts

knife

tension

trims

around

spring

upper

by

motor

pull-

both

and

linkage

tim-

not

off

set

assem-

sides

looper

tension

lower

Check

movement

Re-adjust

linkage

Reset

Connect

Connect

Reshape

Tighten

Adjust

for

Re-adjust

Adjust

upper

fuse,

synchronizer

thread

more

spring

and

Cures

by

tension

for

plug

motor

relay

lower

needle

lower

lower

check

hand

free

for

solenoid

power

contacts

knife

strike-

thread

knife

tension

knife

solenoid

assembly

movement

lead

off

lower

between

Machine

ing

after

Needle

th~ead

thread

not

does

not

trimming

cut

caught

start

but

sew-

looper

Lower

cut

in

ing

spring

perly

Dull

kirlfe

Upper

not

overlap

shearing

Thread

pull-

offs

Looper

and

properly

Looper

spring

thread

Lower

far

Lower

adjusted

tension

enough

knife

looper

and

tail

set

thread

thread

does

knife

to

knife

and

thread

not

aligned

lower

enough

too

short,

too

control

not

not

retain

does

the

not

clearance

retain-

knives

for

proper

thread

high

adjusted

retaining

looper

not

left

properly

pro-

do

cam,

move

Re-adjust

Replace

Re-adjust

Re-adjust

ficient

er

Re-adjust

trol

Remove

knives

Re-adjust

connecting

instructions)

Adjust

knives

needle

thread

cam,

lint

and

lower

knives

knives

pull-offs

thread

looper

and

tension

from

re-adjust

knife

rod

(see

knife

for

and

thread

between

knives

assembly

adjusting

suf-

loop-

con-

and

Too

much

side

top

starting

needle

of

to

sew

thread

garment

on

when

Needle

too

low

thread

pull-

off

set

16

Raise

needle

thread

pull-off

Page 19

INSTRUCTIONS

FOR

QUICK

NEEDLE

POSITIONER

17

Page 20

1-'

00

~~

J.Z4 MIJK

!

2l~S

~A«

O.c-KtT"2!/460

~

£11ZS

PM!"

s lii8Lif"

6

SEcn oH

""

C.C

11-<C

-e

65~-?4

Jr.I

JJI

ER

S/,F,Pt~

ED

H/T

RO

H

SM

...:,

..,....I

~

-

/1

~

1-

tt

1/

...

~

'-""'""-

1-

= = = = =

"'""""

"

rr

c-

47e

·=

,;::::::-

&:;t:;.0-410

-=.

!If'

=--=

,y

,,

I

I.

===~

~

,,

C.

I"

""""'

l)

,,

" "

3 .

II

I!

~

;v

.SYNCHRONIZ£12

NS7;QLUI77DV

IN

S7.llli.L "n-1£ t:;!UI

A

UXI

LJAI?Y

Pt.AC£

AFTlZR

ACCCieOING

STRU:'T/ONS

MA

TO 7/-1£

ACCaE'OIN4

SliPU':TKJNS.

£L£C7J?ICAL

I'?ACHI/IC

KVS771LUN4

Cf-1/N£.

ArTER

S£CUI?t.N4

HANOWH£EL

a)

7:41:"£

7J4CHCO

CH.t:ON!ZER

77-IE

FOUE'

/"'CJll:JtE'RilNEL.

h)

RUN

THROV6H

A::L/6

TI-t£

AUX.

C)

RUN

FRI:lM

TO

THE

,11/110

CONN

FOLLOWS:

GROUND,

ro

THC

~CAD

CAunON

OF

AS

TIONS

CONTROL

TO

.FURNISH£0 WITH

TO 71-1£

MilK£

CONNECTIONS:

THE:

TO

77-IE

IN

THE

TI-t£

TO

S

YNCRRONIZ£R

P£R

.

hi'Va:a.t,a:"

CK-S70P

IN

77-;C

77-1£

FOURPRON4Pl.U6AT-

77-1£

J./IE'E"

HOLE:

SOL..E:NO'O~L£

THE

"TO

THE

CONTROL PANE.L.

THRCC:

AUX.

POWER

ECT

THC:

YCLll)4f;HzNL£AO

,&OWER

THC

Ft:)

NOTE::

A0JLISTIN6

MOn:>R

BOY

,o<~S

INOICATEO.

77-;£

V4BL£Boq.e£)

"n-1£

ACCCSSQE'I£S

AOVU.STING

THE:

SYNCH.eONIZ~

ANO

TIM

OF

THE

ANO

PLU6

Pt..LI6

WIRe

OFiJ.J£

t.EAOS

INLET~

£./2

INLET.

CI-I£CK

SLIP/?IN4S

1NS71?t.IC-

IN 4

CABLE:

AO.:TUSTIN6

RXLOHIN6

£NO

E'ECEPTIC!.E

l./Na;c:'O'O'WO

FEI+'U.E

CONT1?0L

INL£T

&.ACK

J,.t

IN-

TI-l£:

n<o

SYN-

IN 77-IE

Pl.U6

PAN£L

AS

TO

L£AO

eLL

S£TTI

AND

IT

IN-

1T !N

.tWO

l7iVM

HOllJR

•C

N6

lV

99B·e.so

MA

IN CON

TROL

A'f

,

INCI-I/

N6

CONN£C~TOP

0£1/IC£

TO

INS

B£

748

998

VICE

(EX

·

.39543R

·e70

IS

TRA

~I

INCH

AVAI

.SE

N D

CHA26£)

Ill

oio

IN4 ~ •

LABLE:.

AND

I

IFUS£

I I

AUXILIARY OR/

1/£

THIS

S];QI.L.ATIONS

PARTS

POS/TIOIV£R.

C/RCuiTR'Y

A

Pt.AN06RAPH

ON

()LitCk'"-

51300KKOI?KL.

NS!

SHOWS

o.r

COHR:JNENT

S7l:JP

~

Kt.IPP•!T

800

NEECJL£

:ST·36Z.

IN·

RAe

Page 21

Adjusting Instructions

The

for

ions

Before

terminal

380

volts

are

included

SCHEMATIC

starting

strip

or

Delta

MOTOR

to

operate,

of

the

connection

on

the

AND

motor

wiring

CLUTCH

check

is

for

the

complished

on

quired,

switch

arm,

made

the

designed

220

volts

diagram

The

pitman

the

motor

located

which

as

a)

retighten

follows:

Turn

switch

switch

starts

ARM

main

to

three

furnished

clutch

rod,

by

plate,

actuates

ADJUSTMENTS

supply

accommodate

arm

loosening

on

the

in a clockwise

closes

running.

voltage

phase

when

screws.

the

set

A.

with

should

reposition

right

the

screw

C.

the

possible.

the

Adjustment

magnetic

and

with

either

Details

motor

point

three

the

hand

located

direction

the

the

motor

Star

of

both

(See

in

the

This

socket

clutch

of

side

auxiliary

of

clutch

below

wiring

connection

connect-

Fig.

direction

can

be

head

screws

arm

as re-

the

micro

the

clutch

should

the

micro

until

control

16).

of

ac

be

the

.

-

-

-

380V

c)

Now,

obtain

The

synchronizer,

into

the

corresponding

The

QUICK-STOP

the

auxiliary

iary

must

two

screws

Remove

Replacement

belt

to

can

and

purpose.

drive

be

maintained

To

replace

screws

from

the

guard.

Clutch

assure

be

accomplished

the

clutch.

that

Fig.

is

securing the

three

fan

free

16

make

correct

drive

belt

driven

the

the

carbon

screws

of

round

cover

play

the

Two . 012

should

to

round

clutch

one

setting

clutch

marked

motor

off

avoid

brush

belt

and

should

is

by

removing

more

arm

should

be

removed,

the

excesssive

belt,

belt

guard

holders

which

can

carbon

normally

never

and

b)

complete

of

the

switch.

and

sockets

be

main

remove

will

now

one . 020

motor.

and

of

allow

be

accomplished.

brushes.

engaged

spacers

Turn

direction

control

turn

auxiliary

on

the

cleaned

cleaned

Correct

wear

the

fan

pivot

the

magnetic

removal

be . 020

at

as

inch

the

set

to

stops

on

the

control

control

about

and

refilled

on

the

cover

it

to

the

of

- .

028

any

time

required,

spacers

screw

the

position

running.

set

screw

plugs

panel.

every

alignment

belt.

from

brake

the

Reassemble

inch

have

two

with

the

side. Remove

complete

but

with

the

located

been

in a counterclockwise

where

counterclockwise

may

years.

grease.

of

motor.

and

withdraw

care

brake.

between

provided

the

now

be

At this

The

the

idler

Loosen

the

magnetic

magnetic

must

Adjustment

the

auxiliary

inserted

time

auxil-

rollers

two

cap-

brushes.

brake

brake,

be

taken

motor

for

this

to

the

.

If

the

firmly.

rotated

arm

is

which

When

freely

lifted

is

clearly

clutch

arm

lifting

without

in

excess

recognizable

is

the

the

of . 020

in

braking position,

clutch

arm, a position

clutch

or

inch,

when

turning

the

brake

clutch

the

"V"

at

which

engaging must

disc

should

the

"V"

belt

19

belt

the

be

engage

pulley.

pulley

"V"

belt

obtained.

the

must

be

pulley

If

flywheel

the

braked

can

be

clutch

disc,

Page 22

Adjusting Instructions

The

carbon

In

auxiliary

Remove

remove

hood

On

suppressor

for

the

contact

circuit

ELECTRICAL

Before

ments

synchronizer

dust.

case

control.

and

the

auxiliary

or

disposes

and

should

MOTOR

of

trouble

The

the

two

the

three

the

round

rear

capacitor

one

the

of

control.

for

SYSTEM

synchronizer

be

made:

AND

caps

the

of

closing

CLUTCH

should

at

following items

screws

belt.

control

and a tuning

two

REPLACE

be

the

auxiliary

of

the

securing the

When

change-

the

SYNCHRONIZER

is

ARM

cleaned

carbon

plate

capacitor;

the

contactor

over

brake

THE

installed

ADJUSTMENTS

periodically

control

require

brush

are

contacts,

coil circuit.

CONTROL

on

it

will

removal:

holder

magnetic

installed:

the

fails

ADJUSTMENTS

the

machine,

with a clean

be

useful

and

remove

casin

the

control

to

function,

one

for

IN

CASE

PLATE.

(Continued)

to

replace

the

g,

the

belt

rectifier,

plate

the

also

check

closing the

OF

TROUBLE

following basic

cloth

carbon

contactor,

to

remove

the

entire

brushes.

guard,

contains a fuse

the

magnet

the

fuse.

IN

adjust-

The

coil

THE

fan

arc

NOTE:

Synchronizer

Supporting

~-1

Bands

Part

-·-~L

are

to

be

rotated

'-------,7"'---

..__

_ _,_ _

......._+----+----

'----=='=-'----Cutting-

__

in

the

operating

Needle

Needle

Permanent

down

up

C

ontact

-

Contact

direction

of

the

Distance

lators

as

measured

shown

machine.

of

iso-

above

Fi

g.

17

1.

2.

3.

Loosen

insulated

While

insulated

Retighten

urements

screw

area

retaining

area

screw

(See

(A,

Fig.

15/64

this

1 3 I 3 2

(A)

Fig.

17)

inch

position,

inch

noting

17).

and

from

from

that

rotate

the

end

rotate

the

these

band

of

the

band

end

of

the

dimensions

20

(B)

to

insulated

(D)

to

insulated

position

area

position

are

to

area

be

the

of

the

of

set

beginning

band

beginning

band

by

(C).

(B).

cord

of

its

of

its

meas-

Page 23

Adjusting Instructions

With

the

pulley.

Push

within • 012

the

set

screws

the

aforementioned

The

needle

travel.

(B)

If

constant

adjustment

DESCRIPTION

START

SEWING

Treadle

switch

tioner

it

is

lever

drive

closes

by

slipping -see

cutting

the

button

inch

after

on

the

bar

rotate

band

OF

is

pushed

ZSH

118.

and

engages

actuating

instruction).

SYNCHRONIZER

solenoid

switch

its

disconnected,

for

extreme

uppermost

synchronizer

condition.

should

is

required,

{D)

WIRING

down

Retighten

stop

about . 020

slightly,

DIAGRAM

forwardly

Relay 1 is

solenoid

the

switch

lever

ADJUSTMENTS

assemble

needle

up-position.

travel

unit

and

advance

set

screws.

inch

loosen

to

energized.

clutch.

screw

attain

FOR

and

{Micro

ZSH

desired

QUICK-STOP-MOTOR

thereby

Contact

118

(Continued)

the

in

the

or

before

(A,

Fig. 1 7)

conditions,

micro

R11

switch

before

synchronizer

If

the

needle

operating

retard

reaching

and

switch

disengages

Mh

must

the

mechanical

bar

direction,

as

required

its

lowest

while

retighten

FK

Mh

be

adjusted

to

the

does

holding

screw

2/UNION

is

brake

motor

machine

not

loosen

to

obtain

point

band

closed

of

posi-

so

clutch

stop

of

{A).

by

that

END

OF

Treadle

kept

until

energized

the

resistor

ring

"needle

Machine

NEEDLE

Treadle

closed.

1)

2)

SEAM

in

rest

by

circuit

and

capacitor

down"

stops

UP

AND

is

pushed

Relays

Way

12 -

R2

of

current:

contact

switch

slipring

energized

Energizing

clutch

Way

is

of

current:

contact

Mp -

plug

gized).

(starting)

its

self-

is

broken

prevents

until

with

CUTTING

and

R4

R13

Mp

-

plug

'needle

until

relay

engaged

R13

{relay

connection

position.

holding

by

slipring

de-energizing

about

needle

down

200

in

rearwardly

are

energized.

down

Synchronizer

(relay

connection

up" -contact

the

circuit

R2

changes

{for

1/2

Synchronizer

R1

de-energized)

0 -

contact

"needle

RPM

position.

R1

de-energized)

is

opened

over

rotation

plug

Micro

R12

switch

and

down

of

are

reached).

and

thereby

slipring

0 -

relay

R13 -are

by

contact

from

slipring

-

connection

Mh

will

sr,nchronizer

'.

{The

relay 1 when

micro

for

"needle

-

plug

R2.

Relay

connected

slipring

"needle

"needle

plug

"needle

R21.

Brake

down"

up" -plug

connection

6 -

relay

be

flow

switch

opened.

ring

of

current

circuit

Relay 1 is

"needle

is

broken

Mp

in

down"

through

ZSH

up" -plug connection

connection

R2

is

energized.

in

series

1

0

relay

-

micro

up".

is

disengaged

to

"needle

up").

connection

1

0

-

micro

R4 -{relay

switch

is

ener-

R2

12

by

is

As

is

and

-

21

Page 24

Adjusting Instructions

NEEDLE

3)

Wiper:

Capacitor

Relay

R3

capacitor

Way

contact

de-

energized

RAISING

By

the

severing

to

relay

UP

AND

During

Way

("needle

R3

is

noid

is

gized.

by

capacitor

turelythrough

When

K2

is

is

de-energized

CUTTING

raising

of

current:

up"

without

energized,

energized.

In

turn

K3

the

needle

charged

a

K2.

of

current:

Capacitor

R42 -R32 -plug

and

relay

NEEDLE

pressing

impulse

R4.

The

WITHOUT

the

push

is

broken.

needle

(Continued)

the

needle

Slipring

severing) -R22 -plug connection

R33

is

When

R22

is

relay

resistor

raises

through

delayed

connection

R4

is

still

SEVERING

button

Relay

raises.

slipring

closed

the

opened

R3

is

W6

relay

R23.

and

K2 -

8.

energized.

micro

"severing"

11

severing"

and

-

through

plug

needlereachesthe

and

the

severing

de-

energized.

to

guarantee

R2,

Relay

closes

plug

Wiper

switch

R2

is

connection

energized.

energizing

relay

R2

is

R32.

only

Mp

is

can

gives

connection

plu~

connection

1

up"

positionR2

circuit

Relay

R3

also

R3

and

relay

de-energized

Wiper

bridged

is

8 -

R23 -plug connection

be

actuated

over

A

diode

is

an

impulse.

15 -push

4 -

relay

is

broken.

is

energized

for

R4

and

actuated

when

and

blocking

button

R3.

Relay

severing

is

sole-

de-ener-

Delayed

prema-

short

are

R23

by

relay

impulses.

energized.

changes.

current

R3

simultaneously

the

current

of

7 -

is

Pressing

without

severing

BLOCKING

As

relay

ing

slow

speed,

the

THE

R2

push

but

the

button

wiper

CONTROL

only

is

energizeable

severing

and

is

IMPULSE

at high

simultaneously

actuated.

after

speed

This

FOR

SEVERING

de-energizing

is

impossible.

heeling the

should

be

relay

treadle

prevented.

Rl,

i.e.

raises

when

needle

reach-

22

Page 25

Push

button

Nt!~dle

up

without cu.ft/

~

ng

I

I

Pull

lfh

/'fp

lfd

switch

m1cro

micro

micro

l~ver:

~"'J(ch

:.witch

au.J(i/iary

n~~~~

~w1lch

pr~aSt:r

drire

t:JQ3itlon

foot

Li

fll.lflf/

F1/U

----'---......

I

I

..

I

\!)

U)

I

I

I

I

I

I

I

I

R

21

RZ2

R23

-

~o;-+-+-----'

o-

~

o-

~"

I

I

L

______________________

v*v~

I R11

-

R12

_

R

13

_..-f.--.r

'--------+--~----------~

~

~.,...

__

_,

.SGz

_j

Motor

R1 • Relay

Rz·

G, •

Ty

•

SGa

•

v •

K1 •

11'1

•

lt'z •

control

( 1

c

it -

Zch~

Vorietor

r:han~

Z+

I',

secondary

103 I

f:

1 •

~2

so A

Rt!lay

Rrclifirr

Tran3form~r

Oiod~ l ~y

Ocrt

Cooocitor

Re~i3tor

R~si:Jtor

onr

1."A

3,3

23

panel

fir,,.

contact,

eontad.1tl~ing

.UF r '.!VI

K

Q./

qzs W

F'ZU

1clruing contact.

30V,

3SVA

contact

fGDMing

I

I:IHtlladl

Page 26

I

lEt