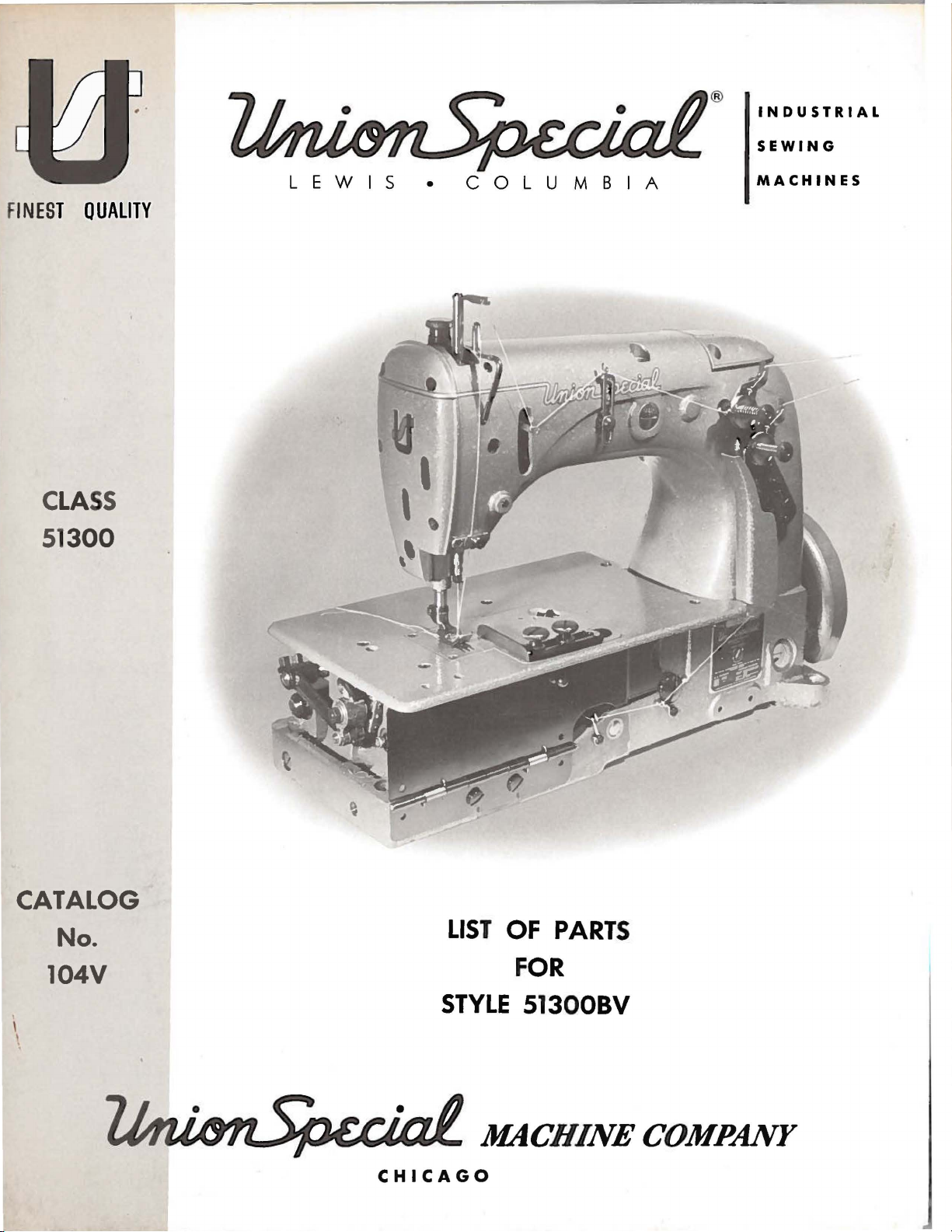

Union Special 51300BV User Manual

®

INDUSTRIAL

SEWING

F

INEST QUALITY

CLASS

51300

LEWIS

•

COLUMBIA

MACHINES

CATALOG

'

\

'

No.

104V

LIST

STYLE

OF

PARTS

FOR

51300BV

MACHINE

CHICAGO

COMPANY

INDUSTRIAL

SEWING

MACHINES

.

• •

Job

variety

why

for

requirements vary - that's why Union Special builds a wide

of

Union Special field representatives make a careful study

E

very

P

urpose!

specially designed sewing machines.

It

is

also the reason

requirements before giving you detailed recommendations

of

kind

speed

machines are built

equipment to install. Plants equipped with modern, high

Union Specials have an important advantage. Union Special

to

do the job faster

...

better

...

cheaper,

they stay on the job with minimum time out for repairs.

ahead when you use Union Special.

of

on

the

and

You're

50000

The

thousands

SERIES

models to be invaluable aids

boosting production

many machines in the improved

to do a specific job efficiently, quickly, and economically!

of

machines are finding these ultra-modern, streamlined

THE

Never before has a general purpose Lockstitch machine been so

thoroughly engineered for handling modern industrial sewing

requirements! And never has a machine offered more than the new

Union Special SIXTY-ONE-FOUR - a superior machine for light

or

heavy weight work . . . for short runs

tacking

Latest improvements in engineering, manufacturing methods,

materials have been comb ined

Class 62200 needle feed Lockstitch machines providing operators

with smooth, streamlined, light-running machines

fatigue and strain.

throughout the countr y are praising the superior performance

these ultra-modern machines!

and

back stitching . . . for curved seams

NEEDLE

FEED

SERIES

manufacturers using Union Special's new 50000

of

a wide variety

61400

LOCKSTITCH

It'

s no wonder

MACHINES

in

cutting costs

of

50000 SERIES

of

operations

products. Each

is

specially designed

LOCKSTITCH

as

well as long

and

MACHINES

in

Union Special Class 61800

that

manufacturers in plants

and

of

the

...

for

straight runs.

and

and

th

at reduce

of

THE

This new development antiquates eyery machine presentl y on

market for use where a curved needle machine is recommended.

From its handsome, dynamically function al, modern design to its

innermost mechanism, the

duced

smoothly and quietly .

greater profit than any other like equipment available to users

today.

35700-35800

Union Special's popular feed-off-the-arm felling machines are lig

runn

ing, smooth operating machines that offer great advantages:

sewing head

eliminates feed marking,

lightest touch. Faster felling is certain with

35700-35800 feed-off-the-a

NEW

to

accelerate quicker . . .

CLASS

..

FEED-OFF-THE-ARM

of

the latest type, new presser bar which practically

and

rm

with less maintenance .

39500

THIRTY-NINE-FIVE

run

OVEREDGER

has been pro-

faster . . . operate more

..

MACH

presser foot which will lift

Union Special Class

machines.

and

the

yield a

I NES

ht

at

the

Catalog

(Supplement

No.

to

Catalog

104

No.

V

104

L)

LIST

CLASS

First

OF

Style

51300

PARTS

51300

BV

Edition

April#

1971

Copyright

1961

by

Union

Rights

Special

Reserved

Machine

in

All

MACHINE COMPANY

INDUSTRIAL

Printed

SEWING

CHICAGO

in

3

MACHINES

U.S.A.

Co.

Countries

IDENTIFICATION

OF

MACHINES

Each

the

special.

contain

the

letter"

is s uffix

Styles

which

This

conjunction

are

illustrated.

part

are

shown

This

It

can also

Union

name

Standard

the

ed

differs

catalog

number,

catalog

Special

plate on

letter "Z".

Z".

of

When

to

the

machines

from the

is a

therewith.

Opposite

description

in

phantom

applies

be

applied

the

Style

standard

style

to

References to direction,

operator's

is

toward

position

the

operator.

while

machine

is

machine.

numbers

Example:

only

minor

Style number.

similar

number,

APPLICATION

supplement

Only

parts

the

illustrated

and

amount

help

locate

specifically

with

such

discretion

as

seated

STYLE

identified

Style

have

"Style

changes

in

construction

in

that

to

Catalog

found

on

required.

51300

to

the

right,

at

the

OF

by a Style

numbers

one

or

51300

are

Example:

it

contains

OF

CATALOG

Style

page,

BV

parts

parts.

Standard

to

some

left,

front,

machine.

MACHINE

are

more

BV".

made

are

No.

51300

F

or

style

Special

Operating

number

classified

letters

Special

in a standard

"Style

grouped

no

letters.

104

L,

and

BV,

but

are

identified

clarity,

of

machine

certain

machines

back,

etc.,

direction

which

Style

is

as

standard

suffixed,

numbers

stamped

but

machine,

51300

BVZ".

under a class

Example: 1151300

not

should

on

by

as

are

be used

Style

51300

detail

51300

BG

listed

in

this

given from

of

hand

into

and

never

contain

a

"Z"

number

BG

number,

parts

herein.

Class.

the

wheel

11

in

•

Streamlined

Light

Me

Weight

chanism,

Lubricating

Assembly,

Work

51300

Space

BV

required.

Each

number

Th

e s

blade

Union

denotes

ize

number, stamped

measured

Collectively,

Standard

round poi

short

tep

s

To

sample

on

label.

nt, short,

blade

reduction,

have

needle,

A

Flat

Bed,

Presser

Needle

System,

Lateral

to

Right

For

s e

Seam

Special

the

in

the

type

needle for

1/8

inch

ball

needle

or

complete

Medium

Bar,

Bearing

Needle

Filter

Looper

of

aming

Travel,

Needle

light

Specification

needle has

kind

of

thousandths

number

Style

double groove,

less

point,

orders

the

order

type

than

chromium

promptly

and

would

Throw,

Light

Type

Bar 7 3/4

to

medium

both a type

shank,

on

the

of

and

the

51300

standard,

size

Weight

Bar

Oil

Light

Single

Drive,

Return

Needle,

Needle

Weight

Inches.

weight

401-SSa-1.

NEEDLES

number

point,

needle

an

BV

struck

inch,

size

is

length,

shank,

midway

numb

Type

groove,

width

plated -sizes

and

accurately

number

should

read: 111000

Single

Pump

Pulley,

materials

Stitch

groove,

denotes

er

is

130

of

be

Needles,

With

Back

Bar

and

Reservoir

With

Prepared

range

and a size

between

the

complete

GHS.

ball

eye,

eye

and

032,

036, 040,

filled,

forwarded.

Type

Tacking

Base

where

10

finish

the

largest

the

It

has

spotted,

groove

an

130

Needle

Enclosed

Plate,

for

back

to

16

number.

and

other

shank

symbol.

a

round sha

undersize,

044,

empty

Use

GHS,

Mechanism,

Bar

Driving

Automatic

Oil

Siphon

Oil

Shields,

tacking

is

per inch

The

type

details.

diameter

and the

of

eye.

nk,

government,

on

049,

package,

description

Size

054.

036

a

11

.

e

•

Selection

Thread

of

should

the

pa

proper

ss

freely

needle

through

size

should

needle

be

determined

eye

in

formation.

4

order

by

to

produce

size

of

a

thread

good

used.

stitch

Loading...

Loading...