Page 1

CATALOG

NO.

Adjusting

instructions

and

WH5OM

Fn

st

Edit

CLASSES

513

514

515

517

519

527

528

on

illustrated

parts

list

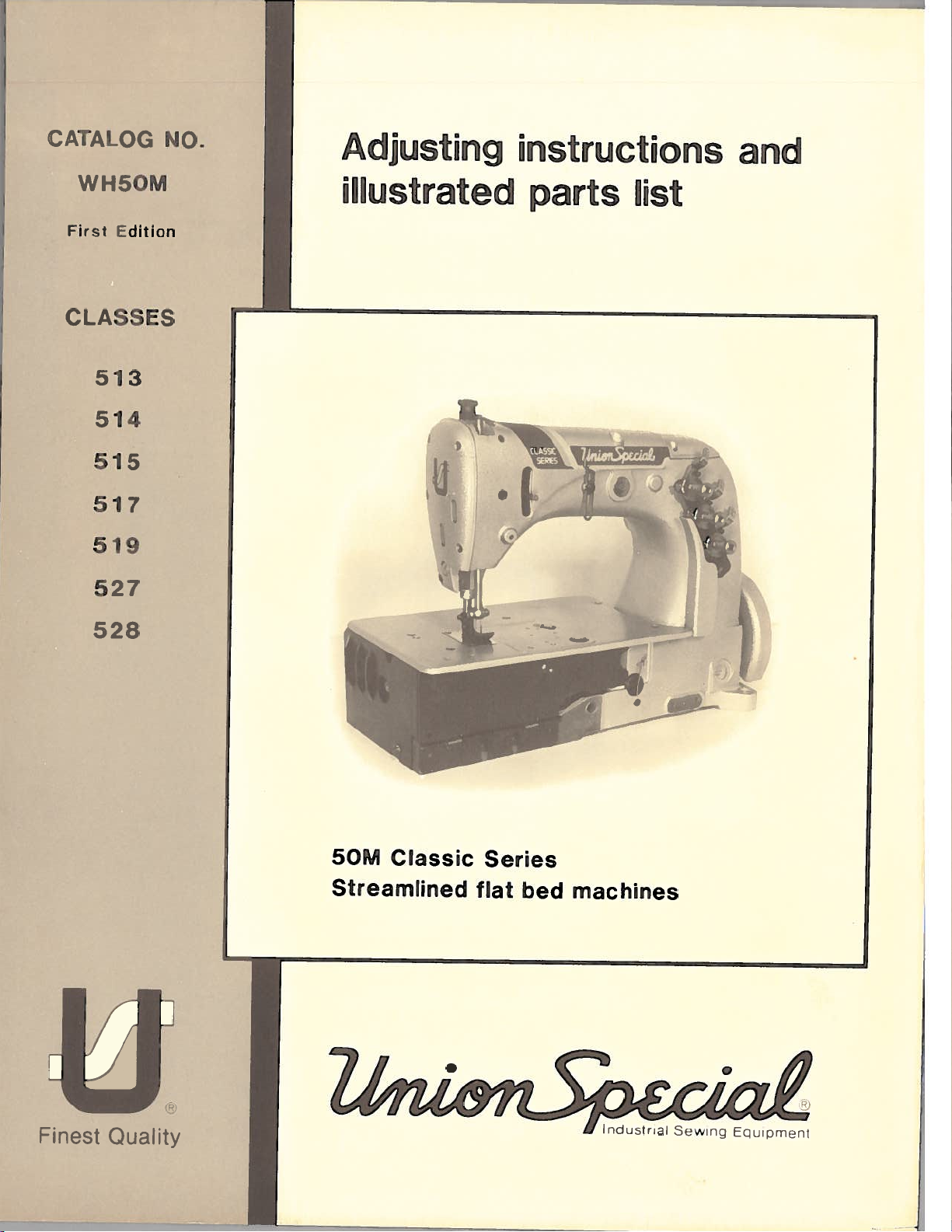

50M

Streamlined

Finest

Quality

Classic

.

Series

flat

bed

machines

ndustnal

S€wing

.

Equipment

Page 2

CATALOG

NO.

WH5O1

ADJUSTING

ILLUSTRATED

CLASSIC

50M

513—11

513—12

513-13

514—21

514-22

515-21

INSTRUCTIONS

PARTS

SERIES

BED

FLAT

STYLES

515-22

517—21

519—31

527—21

527—22

First

Copyright

LIST

STREAMLINED

-

MACHINES

Edition

1982

By

AND

FOR

527—23

527—24

528—21

528—22

528—31

528-32

Corporation

All

in

U.S.A.

in

1982

Countries

Riohts

Union

Reserved

Special

Printed

June,

2

Page 3

is

stamped

of

machine.

is

represented

presents

of

64/64

Each

The

The

UNION

in

serial

distance

a

distance

or

1

SPECIAL

the

number

between

by

a

inch.

style

gauge

of

machine

plate

is

stamped

the

number

12/64

IDENTIFICATION

located

rows

or

carries

in

of

measured

3/16

a

to

the

stitches

inch.

the

extension

OF

style

right

in

1/64ths

Similarly,

MACHINES

number,

front

of

casting

on

machines

of

64

which

of

in

an

inch.

gauge

on

the

at

all

represents

this

machine.

the

right

Classes

Thus,

class

12

machine

rear

except

gaucie

distance

a

base

513

re

Streamlined

Needle

matic

mum

513-11

513-12

513-13

Streamlined

Weight

Medium

Oil

8

Work

Maximum

Return

1/4

Lubricating

SSa-1.

sewing

BSa-1.

Presser

Duty,

Inches.

Bar

Space

Flat

Drive

to

Medium

Type

Same

Heavy

as

parts.

duty,

Type

recommended

Flat

Bar

Single

Pump,

Bed,

One

Mechanism,

System,

Right

duty,

513-11

126

Bed,

Lateral

for

128

GAS

for

GS

Two

Mechanism,

Reservoir

STYLES

Needle,

Filter

of

Needle

seaming

needle.

except

binding

needle.

speed

STYLES

Needle,

Looper

Medium

equipped

Uses

5500

Light

Enclosed

Travel,

OF

MACHINES

Light

and

Type

Oil

Bar

8

trousers,

Maximum

mattress

selvage

R.P.M.

OF

MACHINES

Left

Weight

Weight

Heavy

Return

Inches.

1/4

recommended

with

ticks

Needle

Needle

Automatic

Maximum

IN

Presser

Duty,

coats

feeding

edge

IN

in

Front,

Lubricating

Work

CLASS

Single

Pump,

and

and

similar

binding,

CLASS

Bar

Space

513

Bar

Mechanism,

Reservoir

Lateral

similar

speed

presser

514

Independent

Drive

to

Looper

aarments;

5500

R.P.M.

foot

and

operations;

standard

Mechanism,

System,

Right

Light

Enclosed

Travel,

comparable

width

Row,

Light

Filter

of

Needle

seam

seam

3/4

Light

Weight

Auto

Maxi

Type

Type

inch.

and

Type

Bar

514-21

514-22

Streamlined

anism,

matic

mum

515—21

515-22

(12

ga.)

(16

ga.)

sleeves

Type

LSc-2.

Light

Lubricating

Work

Space

(16

ga.)

(18

ga.)

ments,

recommended

left

of

Flat

Weight

to

Light

ordinary

Type

Bed,

Needle

System,

Right

For

felling

needle

speed

duty,

108

Two

of

in

5300

quality

GHS

STYLES

Needle,

Bar

Filter

Needle

overalls,

front;

when

for

needle.

Drive

piecing

light

OF

MACHINES

Independent

Mechanism,

Type

sewina

Bar

seam

Oil

8

coats,

Type

sleeves,

weight

Maximum

Return

Inches.

1/4

LSc-2.

S.P.I.;

7

3

joining

shirts

recommended

IN

Row,

Heavy

combination

and

CLASS

Light

Pump,

Type

5500

515

Weight

Duty,

Lateral

128

when

shoulders

similar

speed

Single

suits

GAS

sewing

garments;

5500

Presser

Looper

and

needle.

10-14

and

setting

R.P.M.

Bar

Reservoir

Travel,

similar

S.P.I.

seam

Mech

Auto

Maxi

gar

Maximum

Page 4

STYLES

MACHINES

OF

IN

CLASS

517

Streamlined

Presser

Duty,

Lateral

517-21

Streamlined

Weight

Heavy

Pump,

519-31

Streamlined

Disc

and

System,

Lateral

Single

(64

center

Starts

beyond

recommended

Presser

Duty,

Lateral

(9

and

ed

Take-up,

Needle

Flat

Bar

Mechanism,

Looper

qa.)

operation

ga.)

similar

speed

Bar

Filter

Looper

Bed,

Reservoir

Travel,

plait

rows

the

speed

Bed,

Flat

Bar

Single

Looper

5000

Flat

One

Driving

Type

Travel,

Two

Light

Automatic

Maximum

Light

interlininci

and

at

of

5500

Three

Mechanism,

Reservoir

Travel,

Heavy

garments;

R.P.M.

Medium

Bed,

Looper,

Mechanism,

Oil

Work

Needle,

Weight

duty,

neck.

stitching;

R.P.M.

STYLES

Needle,

Automatic

Maximum

duty,

seam Type

STYLESOFMACHINES

Throw

Needle

Return

Space

Independent

Needle

Lubricating

Work

Light

Space

for

one

strips

Plaits

for

Bearing

Pump,

used

seam

OF

MACHINES

Left

Weight

Work

seaming

LSh-3.

Machines,

Single Reservoir

Oil

to

Right

Lubricating

Bar

System,

Right

to

operation

fronts

to

in garment

Type

LSm-2.

Needle

Needle

Space

windbreakers,

Type

Two

Needle

Pump

of

Row,

Driving

IN

CLASS

in

to

147

CLASS

IN

and

Bar

Base

Needle

Needles

Mechanism,

Filter

of

Needle

folding

of

shirts

lengths

Type

519

Front,

Bar

Drive

System,

Right

Enclosed

Plate

of

needle.

GKS

527

Three Needles

Drive, Light

and

Bar

7

Abreast,

Oil

Type

Bar

8

attaching

and

similar

and

and

GKS

108

Independent

Mechanism,

Filter

Needle

mackinaws,

Maximum

Weight

Automatic

Siphon Assembly.

Oil

Inches.

3/4

Light

Light

Return

1/4

extend

needle.

Type

Bar

lumber

Abreast,

Weight

Heavy

and

Pump,

Inches.

“set-on”

garments.

1/4

Maximum

Row,

Light

Light

Oil

8

Lubricating

and

Return

1/4

jackets

recommend

Double

Presser

inch

Inches.

Bar

527-21

527—22

527-23

527-24

Streamlined

er,

Driving

Type

Travel,

(16

Maximum

(16

trousers,

heavy

inch

128

(8

(12

long

nylon

on

holder

Maximum

Four

Oil

ga.)

recommended

qa.)

overalls,

weight

wider

GAS

needle.

ga.)

ga.)

lengths,

and

wool,

light

and

Mechanism,

Return

Work

to

for

recommended

Flat

Five

Space

materials.

than

garment

medium

elastic.

Bed,

Thread

Single

Pump

to

Same

as

527-22

speed

Needle,

Two

bathrobes,

Strips

needle spacing

Maximum

Needle,

Two

lengths,

flat,

and

weight

Seam

speed

Medium

Interlock

Reservoir

Oil

Riciht

warp

STYLES

Throw

Siphon

of

except

2000

R.P.M.

Plain

recommended

Plain

and

material.

specification

5000

Needle

Feed

and

used

machine.

of

Feed

or

with

ribbed

R.P.M.

OF

MACHINES

Machines,

Stitch,

Enclosed

Assembly,

Bar

prepared

Machine,

for

similar

in

speed

Machine,

ends

knit

Automatic

Light

7

3/4

for

short

406-LSb-1

IN

Two

Automatic

Oil

lengths.

Seam

5000

joined,

garments,

CLASS

and

Weight

Pan

Inches.

with

use

for

making

operations

Belt

specification

R.P.M.

for attaching

to

rayon,

and

stretching

inverted.

528

Three

Base

Needles

Presser

Lubricating

Plate,

Gal

belt

on

for

device

Type

Bar

kin

undertrimmer.

loops

medium

loops

elastic

similar

Abreast,One

System,

Lateral

are

4O6—EFh-1.

silk,

and

121

Needle

and

for

to

medium

3/32

bands

cotton,

operations

spool

GS

needle.

Filter

Looper

Type

in

Loop

Bar

Page 5

STYLES

OF

MACHINES

IN

CLASS

528

(Continued)

528-21

528-22

528-31

528-32

(8

ga.)

(12

ga.)

ettes

to

weight

at

right

differential

Type

speed

(16

121

5000

ga.)

crotch

material.

605-FSa-1.

(16

ga.)

ettes

to

weight

to

the

feed.

needle.

knitted

material.

angle

GS

needle.

R.P.M.

seaming,

Wrench

Type

knitted

material.

wale

or

Constant

Standard

Two

needle

undergarments,

For

to

the

feed.

Three

and

adjusted

121

Three

needle

undergarments,

For

parallel

strip

finished

four

use

wale

Constant

Standard

needle

for

similar

OBS

needle.

use

with

tension,

with

or

five

tandem

five

with

width

thread

and

lona

parallel

strip

finished

thread

operations

thread

and

long

the

Seam

interlock

for

length

tension.

differential

Maximum

for

length

wale.

specification,

1

inch.

NEEDLES

similar

flat

with

the

Seam

width

1/2

interlock

on

recommended

interlock

similar

ribbed

Wrench

Maximum

machine,

operations

knit

wale.

specification,

inch.

machine,

medium

feed.

machine,

operations

knit

adjusted

recommended

for

on

or

ribbed

Wrench

Maximum

for

to

medium

Seam

specification,

speed

for

on

strip

offset

605-BSa-1.

attaching

light

knit

adjusted

602-BSb-1.

recommended

single

heavy

5000

R.P.M.

attaching

light

cut

at

differential

Type

speed

collar

to

medium

strip

offset

operation

weight

collar

to

medium

right

121

5000

cut

angle

GBS

R.P.M.

of

shank,

on

the

shank

which

sample

packages.

080/032”.

The

by

this

able,

results.

tion,

Type

No.

108

OHS

108

GKS

Each

needle

and

is

To

needle,

but

and

needle

point,

eye.

given

have

A

type

catalog

the

The

the

Round

eye,

080/032,

Round

oversize

100/040.

has

length,

shank,

Collectively,

on

the

orders

or

the

complete

numbers

are

ones

type

sizes

shank,

spotted,

090/036,

shank,

ball

both

denotes

label

promptly

type

order

of

olven

indicated

numbers

available

round

ball

round

eye,

a

type

groove,

of

and

would

the

needles

in

the

are

of

point,

point,

100/040,

point,

spotted,

and

finish

the

largest

type

all

and

accurately

size

read

machine

those

the

recommended

are

listed

size

number.

and

diameter

and

size

needles

number

as

follows:

recommended

style

recommended

below:

Description

extra

short,

chromium

110/044,

extra

short,

chromium

other

number

packaged

filled,

should

description.

needles,

double

plated

125/049.

double

plated

The

details.

of

represent

and

forward

be

“1000

for

to

-

type

blade,

sold

given.

each

produce

together

groove,

sizes

groove,

-

sizes

number

The

measured

the

by

the

See

Needles,

style

Other

the

070/027,

080/032,

denotes

size

complete

Union

empty

description

Type

of

machine

needles

most

with

struck

075/029,

struck

number,

midway

symbol,

Special.

package,

121

are

satisfactory

their

groove,

groove,

090/036,

the

kind

stamped

between

a

on

OS,

covered

avail

descrip

ball

Size

121

OS

Round

plated

100/040,

shank,

-

available

110/044,

round

point,

in

sizes

125/049,

short,

065/025,

140/054.

double

groove,

070/027,

struck

075/029,

groove,

080/032,

chromium

090/036,

Page 6

NEEDLES

Description

(Continued)

121

GBS

Round

ball

080/032,

126

GS

Round

chromium

128

GAS

Round

spotted,

110/044,

147

GKS

Round

eye,

sizes

Selection

used.

Thread

formation.

ILLUSTRATIONS

This

Exploded

be

may

tration

the

and

catalog

views

seen

will

number

in

shank,

point,

shank,

shank,

shank,

spotted,

090/036,

of

should

of

their

be

of

090/036,

plated

chromium

125/049,

the

has

the

found

pieces

round

chromium

round

-

round

round

short

100/040,

proper

freely

pass

been

various

actual

listing

the

required

point,

plated

100/040.

point,

available

point,

plated

140/054,

point,

point,

needle

ORDERING

arranged

so

sections

position

short,

-

short,

in

short,

available

-

150/060,

long

standard

110/044,

size

through

in

the

of

the

in

single

available

double

sizes

double

double

125/049,

should

needle

REPAIR

to

as

the

of

machine.

the

parts

particular

groove,

in

groove,

080/032,

groove,

sizes

in

170/067.

groove,

and

eye

determined

be

eye

PARTS

simplify

mechanism

with

sizes

100/040,

080/032,

struck

grooves,

140/054.

order

in

the

are

the

On

their

view

being

struck

065/025,

struck

struck

by

to

ordering

shown

page

part

groove,

070/027,

groove,

054.

aroove,

090/036,

groove,

chromium

size

the

produce

of

so

opposite

numbers,

shown.

spotted,

ball

ball

100/040,

oversize

plated

of

good

a

repair

the

that

descriptions

075/029,

eye,

eye,

-

thread

stitch

parts.

parts

illus

the

ball

The

position

in

ordering

Those

indicated

the

main

65

66

67

68

69

29105

22559

22559

22894

22894

It

not

are

individually

In

catalog,

in

for

the

parts

ed

tration.

numbers

that

of

parts.

component

the

by

sub-assembly.

Z

A

B

C

D

noted

will

be

listed.

not

is

no

the

cases

specific

various

those

descriptions

in

the

part

in

Always

parts

fact

that

Looper

in

reason

The

recommended

where

usage

machines

first

the

use

of

their

Example:

Drive

Bearing

Bearing

Eccentric

Eccentric

the

for

part

a

will

if

and,

column

are

illustration.

part

the

sub-assemblies

descriptions

Eccentric

Screw,

Cap

Screw,

Cap

Set

Spot

this

and

is

be

are

example

is

the

common

mentioned

not

above

necessary,

reference

number

Assembly,

Screw

Screw

that

that

complete

to

same,

the

the

reference

The

shown

which

are

lower

upper

the

the

all

in

difference

numbers

the

in

be

can

indented

for

eccentric,

replacement

sub-assembly

the

of

description.

the

specific

the

only

number

second

furnished

under

Class

of

should

machines

usage

will

be

and

should

the

513

ball

any

shown

indicate

never

column.

repairs

for

description

stud

these

of

be

ordered.

covered

However,

will

in

and

by

when

be

the

the

used

be

are

of

bearing

parts

this

the

mention

illus

1

2

2

4

1

6

Page 7

in

tion

At

the

illustrations,

when

the

back

only

the

of

the

part

book

which

number

ORDERING

will

will

be

facilitate

is

known.

REPAIR

found

PARTS

a

numerical

locating

(Continued)

index

the

of

illustration

all

the

and

parts

descrip

shown

Where

some

smaller

cation

All

they

appear.

Success

genuine

subsidiaries

approved

efficiency

Prices

ments

are

are

insured

surance.

the

letter

part

UNION

scientific

and

forwarded

construction

parts

is

numbers

in

the

SPECIAL

and

durability

are

strictly

unless

and

on

stamped

represent

operation

Repair

authorized

principles

at

the

otherwise

permits

those

to

distinguish

Parts

distributors.

are

net

cash

buyer’s

directed.

OILING

IDENTIFYING

where

the

USE

GENUINE

of

these

as

and

made

assured.

and

risk

AND

each

same

part

the

construction

the

part,

REPAIR

part

machines

furnished

They

with

TERMS

the

subject

f.o.b.

A

charge

THREADING

PARTS

is

stamped

with

does

from

similar

regardless

PARTS

can

be

secured

by

the

Union

are

designed

utmost

to

change

shipping

is

made

precision.

without

point.

to

INSTRUCTIONS

not

of

the

Special

according

cover

its

permit,

ones.

only

notice.

Parcel

part

catalog

by

the

Corporation,its

to

The

post

the

postage

number.

an

identifi

in

which

use

the

maximum

All

ship

shipments

of

most

and

On

in

The

must

be

bolt

viscosity

Oil

the

sight

between

The

main

reservoir

A

ed.

Oil

main

reservoir

reservoir

handwheel.

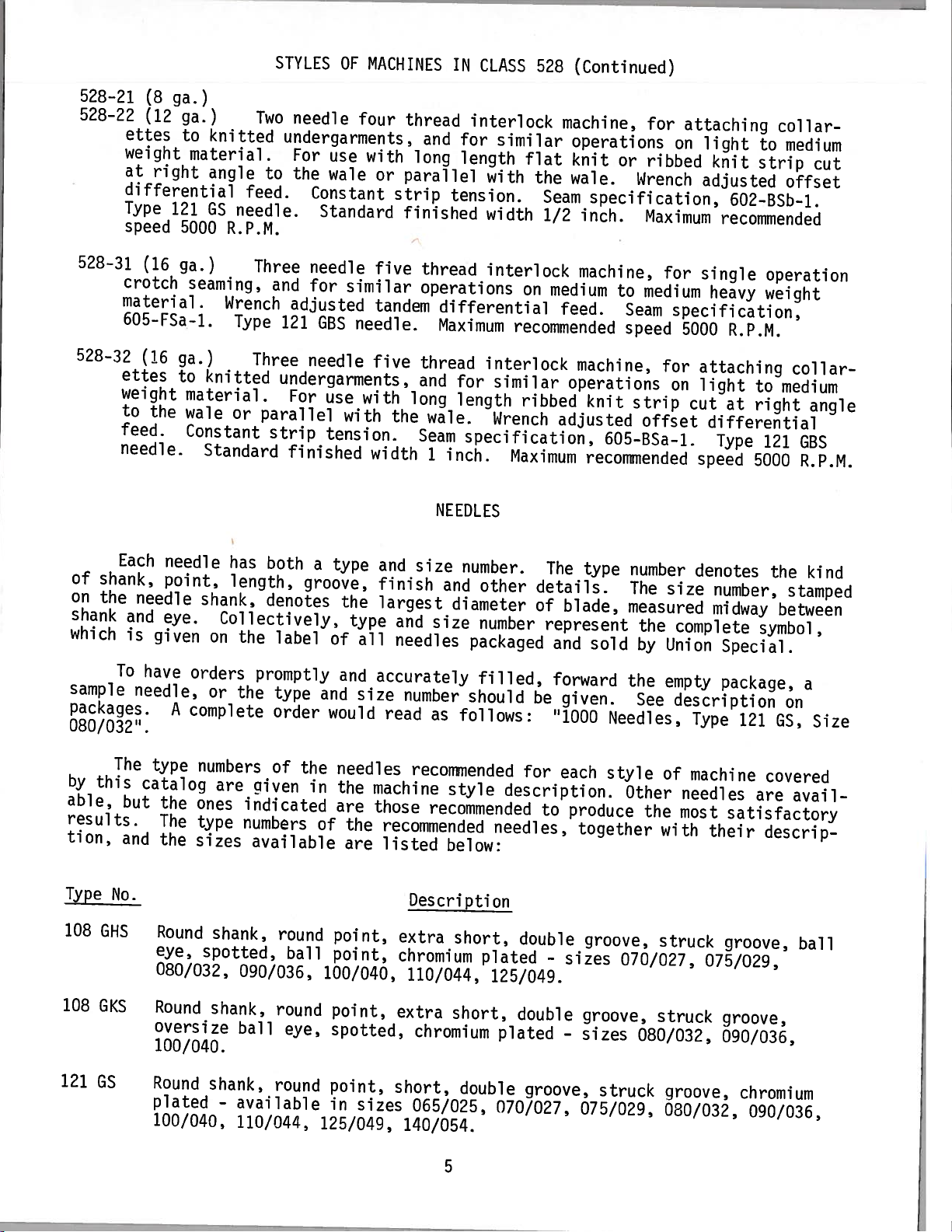

Figure

and

three

er

threading

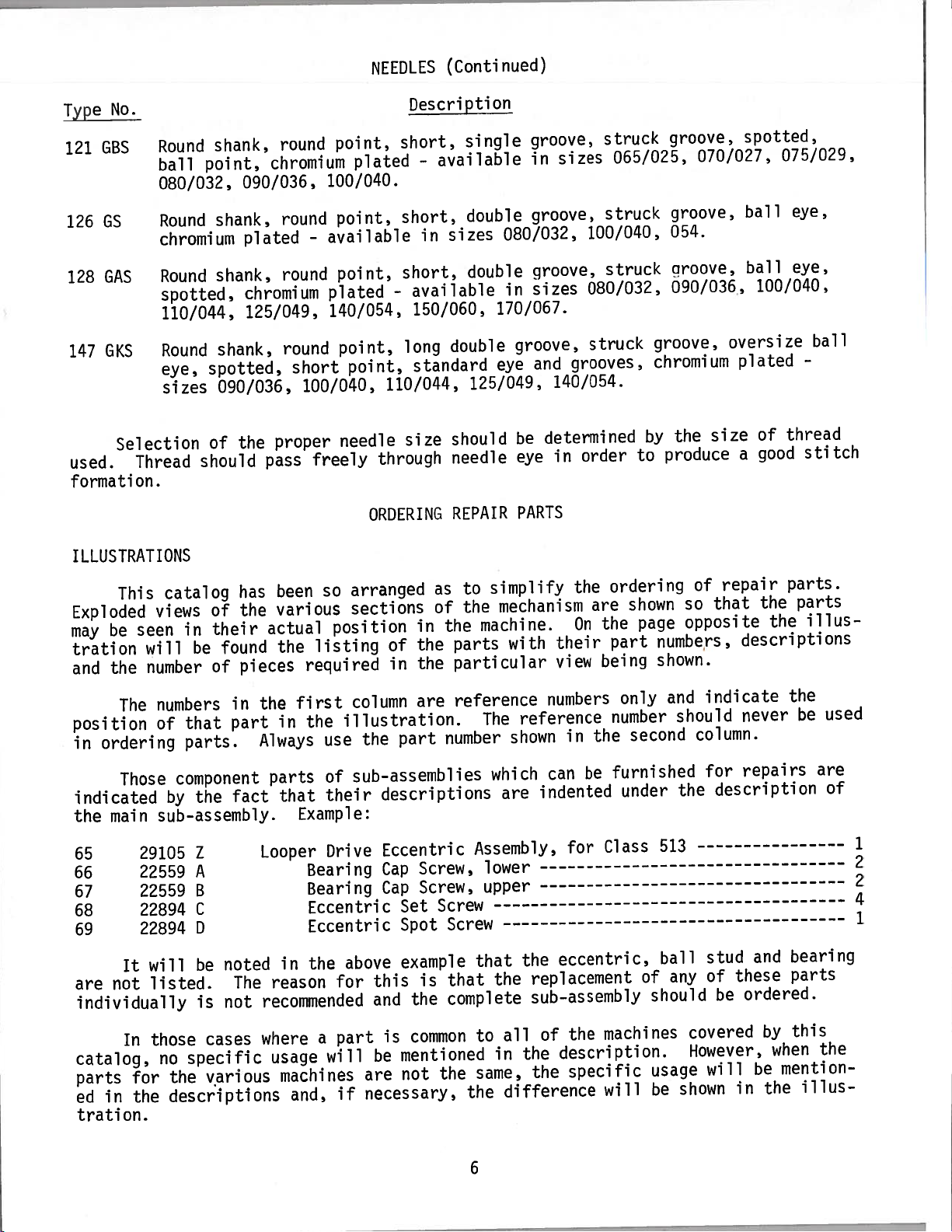

Figure

Three

ines

needle

are

oil

filled

i

gauge

the

machine

daily

which

may

needle

basically

has

before

of

filled

on

red

lines

filled

check

has

making

be

shows

1

machines

of

the

2

shows

machines

been

drained

beginning

90

to

at

the

the

on

is

automatically

is

before

gone

too

drained

the

various

the

are

threaded

125

spring

front

the

necessary.

the

through

frequent

at

the

manner

are

classes

manner

threaded

in

from

to

seconds

of

the

gauge.

morning

the

plug

in

threaded

in

the

the

operate.

at

cap

in

machine.

The

lubricated

start

machine

oilings

screw

which

in

is

indicated

which

in

substantially

same

machine

1000

the

Fahrenheit.

top

capacity

and

should

is

unnecessary.

in

a

two

substantially

two

a

manner

before

Use

cover

The

no

filtered

the

needle

in

needle

without

a

straight

oil

of

be

main

the

the

shipping

and

level

the

oiling

made

and

frame

machine

the

inserts.

Class

same

a

spreader

mineral

the

level

should

oil

reservoir

other

and

oil

pumped

Excessive

directly

is

same

528

machine

manner.

and

the

oil

is

be

than

added

back

oil

threaded.

manner.

Class

thread.

reservoir

with

checked

maintained

is

12

keeping

if

requir

into

in

the

under

the

Single

The

loop

is

threaded.

527

a

Say-

at

ounces.

the

the

main

mach

7

Page 8

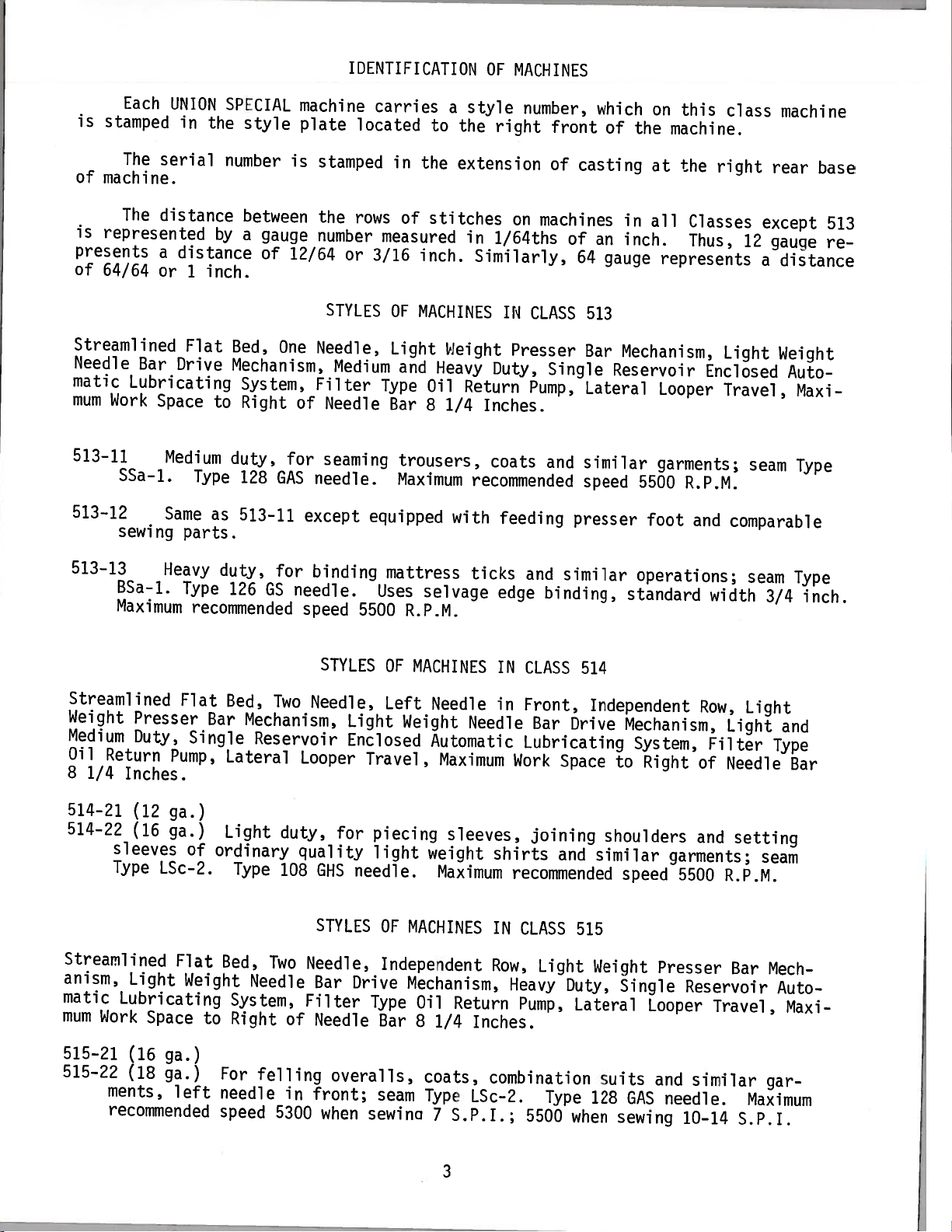

CAUTION!

FILL

BEFORE

MACHINE

BEFORE

ALL

OIL

STARTING.

HAS

SHIPPING.

RESERVOIRS

BEEN

DRAINED

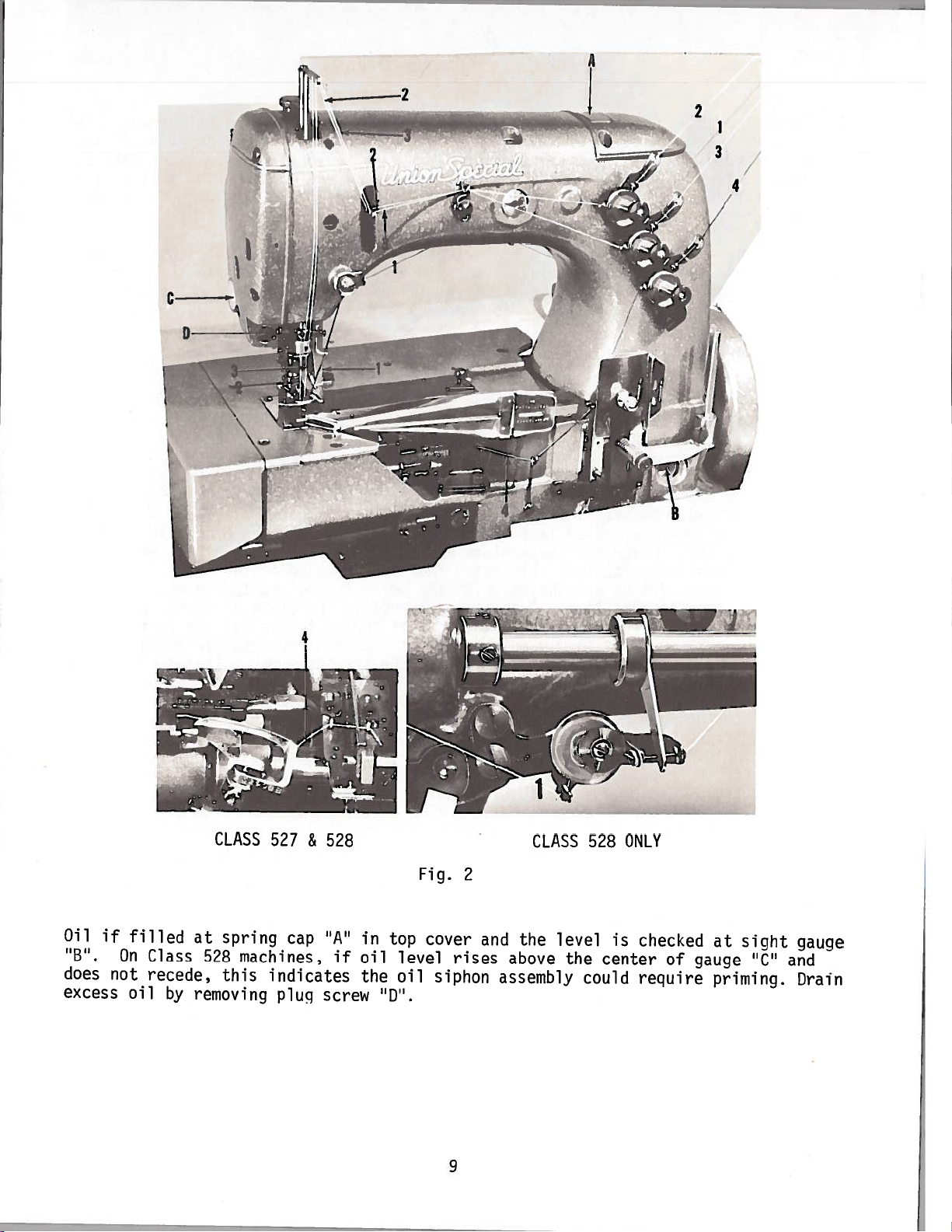

Fig.

1

8

Page 9

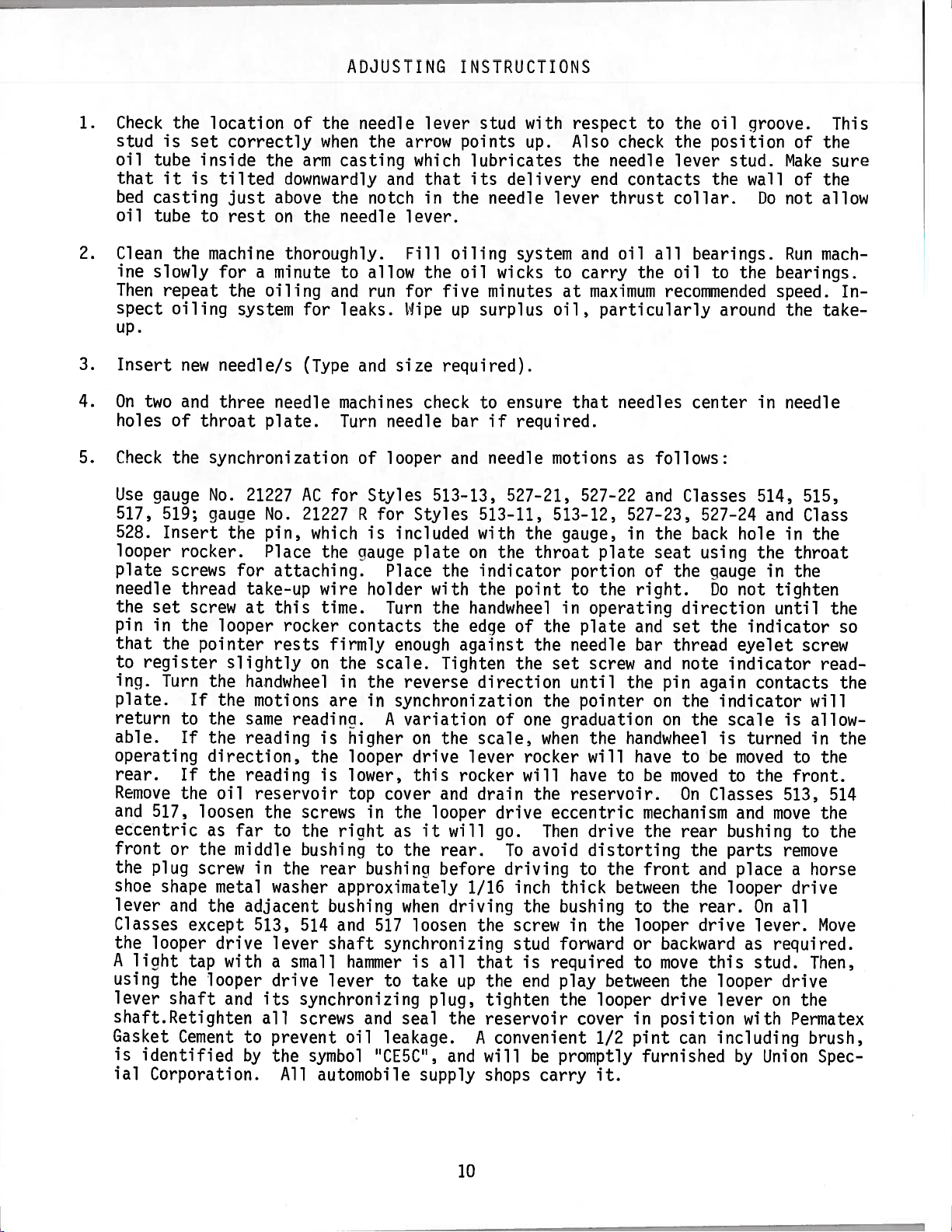

2

-—

3

ill

I

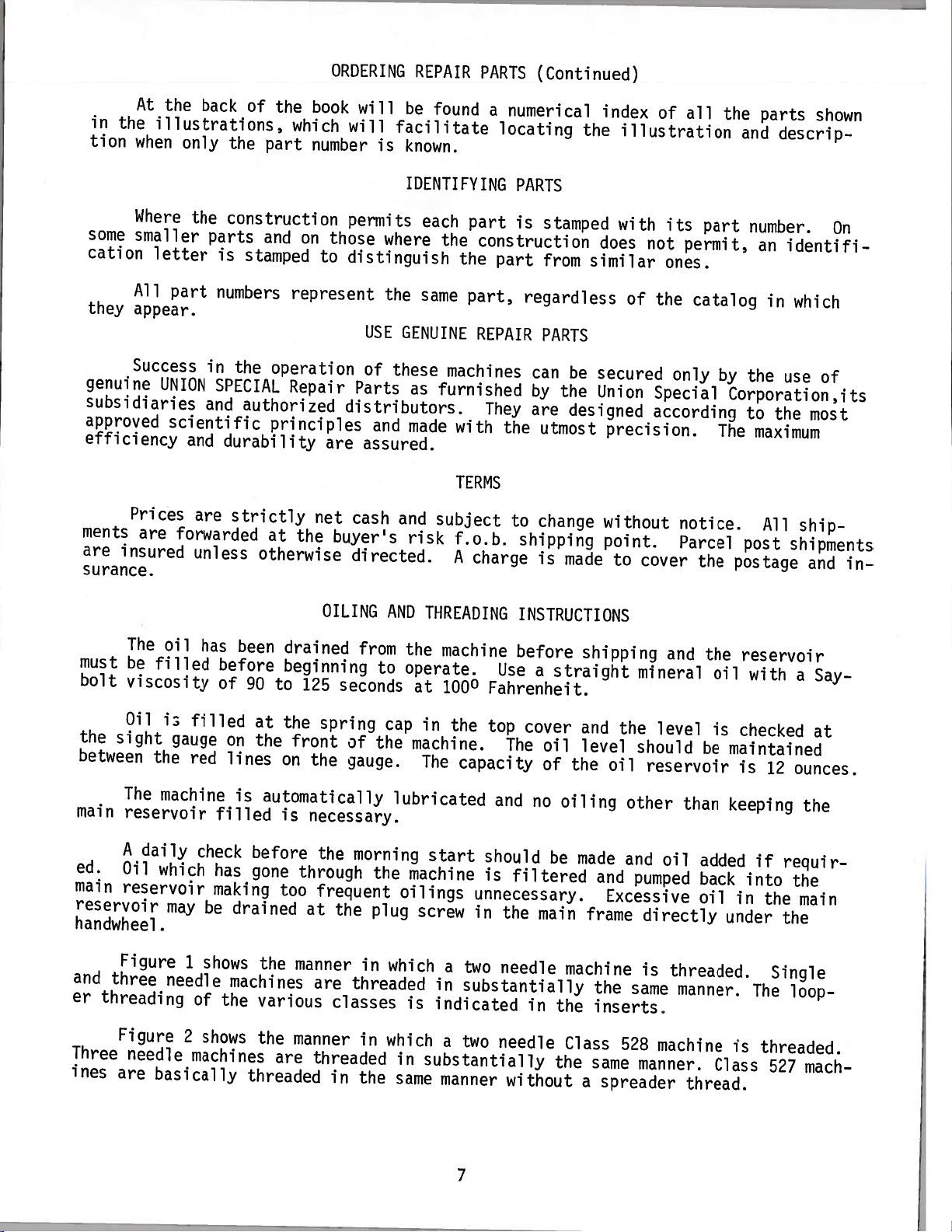

Oil

“B”.

does

excess

if

On

not

filled

Class

recede,

oil

by

CLASS

at

spring

528

this

removing

527

cap

machines,

indicates

plug

&

528

‘A”

if

screw

in

oil

the

top

level

oil

“D”.

Fig.

cover

siphon

2

rises

9

and

above

assembly

CLASS

the

level

the

528

center

could

ONLY

is

checked

of

require

at

gauqe

priming.

sicht

“C”

qauce

and

Drain

Page 10

-

—

1.

Check

stud

oil

that

bed

oil

2.

Clean

ine

Then

spect

up.

3.

Insert

4.

On

holes of

5.

Check

Use

517,

528.

looper

plate

needle

the

pin

that

to

ing.

plate.

return

able.

operating

rear.

Remove

and

eccentric

front

the

shoe

lever

Classes

the

A

lioht

using

lever

shaft.Retighten

Gasket

is

ial

the

location

is

set

tube

inside

it

is

casting

the

to

machine

tube

slowly

repeat

oiling

new

two

and

throat

synchronization

the

cauge

519;

No.

qauae

Insert

rocker.

screws

thread

set

screw

in

the

the

pointer

register

Turn

the

If

the

to

If

the

direction,

If

the reading

the

517,

loosen

as

or

the

plug

screw

shape

and

the

except

looper

tap

the

looper

shaft

Cement

identified

Corporation.

correctly

tilted

just

rest

for

a

the

system

needle/s

three

21227

the

for

take-up

at

looper

slightly

handwheel

the

motions

same

reading

oil

reservoir

far

middle

in

metal

adjacent

513,

drive

with

and

to

by

of

arm

the

downwardly

above

on

the

thoroughly.

minute

oiling

for

(Type

needle

plate.

AC

No.

21227

pin,

which

Place

attaching.

this

rocker

rests

on

readino.

the

the

screws

to

the

bushing

the

washer

514

lever

a

small

drive

its

synchronizing

all

screws

prevent

the

symbol

All

automobile

ADJUSTING

needle

the

when

the

casting

and

the

notch

needle

to

allow

and

run

leaks.

and

machines

Turn

needle

of

looper

for

Styles

R

for

is

aauqe

the

Place

wire

time.

holder

Turn

contacts

firmly

the

scale.

in

the

are

in

A

is

higher

looper

is

lower,

top

cover

in

ric,ht

to

rear

bushino

approximately

bushing

and

517

shaft

synchronizing

hammer

lever

to

and

oil

leakage.

“CE5C”,

INSTRUCTIONS

lever

arrow

which

that

in

stud

points

lubricates

its

the

needle

lever.

Fill

oiling

oil

the

for

five

minutes

Wipe

size

check

surplus

up

required).

to

bar

if

and

needle

513-13,

Styles

included

plate

with

enough

513-11, 513-12,

with

on

indicator

the

the

the

handwheel

the

edge

against

Tighten

reverse

direction

synchronization

variation

on

the

scale,

drive

this

the

as

the

and

looper

it

will

rear.

lever

rocker

drain

before

1/16

loosen

is

all

take

plug,

driving

the

that

up

the

reservoir

the

tighten

when

seal

A

and

will

supply

shops

with

up.

delivery

lever

system

wicks

to

oil,

ensure

required.

motions

527-21,

the

the

throat

point

of the

the

the

set

the

of

one

when

rocker

will

the

drive

go.

To

eccentric

Then

avoid

driving

thick

inch

bushing

the

screw

stud

forward

is

required

end

play

the

convenient

be

promptly

carry

respect

check

Also

needle

the

end

thrust

oil

and

carry

maximum

at

particularly

needles

that

527—22

gauge,

plate

portion

the

to

in

operating

plate

needle

screw

until

pointer

graduation

the

will

have

to

reservoir.

drive

distortina

the

to

between

the

in

between

looper

cover

1/2

it.

to

the

the

lever

contacts

collar.

all

the

oil

recommended

center

as

follows:

and

Classes

527-23,

in

the

back

seat

of

the

right.

direction

and

set

bar

thread

and

note

the

pin

on

the

on

the

handwheel

have

be

to

moved

On

mechanism

the

rear

the

front

the

to

the

looper

backward

or

to

move

the

drive

position

in

pint

can

furnished

oil

position

stud.

wall

the

bearings.

to

the

around

527—24

hole

using

gauge

Do

not

the

eyelet

indicator

again

indicator

scale

is

turned

be moved

to

Classes

and

bushing

parts

and

place

looper

rear.

drive

as

this

looper

lever

with

including

by

groove.

of

Make

of

Do

not

Run

bearings.

speed.

the

in

needle

514,

and

in

the

throat

in

the

tighten

until

indicator

contacts

is

to

the

front.

513,

move

remove

a

drive

On

all

lever.

required.

stud.

drive

on

Permatex

Union

the

the

allow

mach

take-

515,

Class

the

screw

read

will

allow

in

the

the

to

horse

Move

Then,

the

brush,

Spec

This

sure

In

the

so

the

the

514

the

10

Page 11

6.

If

the

qauqe

is

not

available,

synchronization

may

be

checked

as

follows:

8.

9.

7.

Insert

the

direction

needle/s.

er

point/s.

point/s

synchronize,

point/s

tance

when

rocker

NOTE:

from

the

to

The

to

separate

Set

the

the

shield.

With

center

When

5/32

Set

514;

looper/s

inch

the

5/32

needle

the

needle/s

looper/s

unkil

Note

again

will

the

pulley

the

remainder

machines

left

from

point

inch

looper/s

as

close

then

move

the

be

eye

rear.

main

The

at

center

of

for

5/32

in

the

looper

the

height

turn

the

the

to

height

same.

the

of

the

is

turned

Moving

of

in

all

section.

shaft

space

should

EXTREME

line

rear

looper

Class

inch

move

as

to

possible

the

pulley

left

of

needle/s

in

this

Classes

so

RIGHT

515.

for

the

looper

point/s

of

the

the

A

variation

operating

it

section

that

be

of

needle/s

to

Class

left,

without

and

eye

in

the

from

end

center

Set

rocker

move

eye

in

are

of

to

the

except

take-up

of

the

519.

their

and

to

of

the

the

reverse

even

the

of

the

direction,

opposite

reflects

527

.008

travel

for

line

point

point/s

contacting.

turn

the

needle/s

with

needle/s

.005

point

adjusting

and

has

to

.010

,

the

Class

of

rear

of

the

left

and

direction

the

with

inch

is

of

the

move

direction

528.

equal

inch.

looper

513;

needle

center

should

pulley

are

with

until

needle/s.

respect

allowable.

looper/s

the

acts

instructions

They

clearance

point/s

inch

1/8

looper

pass

in

even

respect

looper

the

will

for

inch

1/8

to

the

the

with

the

If

to

is

drive

reverse.

follow

on

should

center

rear

operating

the

to

the

looper

the

motions

looper

the

If

the

longest

applicable

each

Class

for

of

ioop

dis

lever

in

side

be

517.

Class

line

the

a

of

set

of

10.

11.

12.

13.

14.

15.

Set

the

the

looper/s

side

Set

the

above

under

Space

least

presser

feed

For

all

when

.011

shield

Draw

of

fabric.

On

Class

thread

ial.

the

looper

the

retainer

thread

stitches.

the

looper

needle

of

the

feed

the

the

the

1/64

foot.

rocker

Classes

there

to

.016

to

looper

is

The

may

needle/s.

throat

feed

feed

inch

arm

is

provide

and

Refer

515

cast

height

moves

be

This

moves

bar

when

dog

point/s

so

plate

dog,

dog

at

This

to

in

equal

inch.

clearance

needle

to

machines,

off

just

of

to

is

raised.

wiped

can

to

so

that

that

at

to

maintain

in

the

all

points

is

accomplished

the

feed

this

section

clearance

There

threads

applicable

set

after

the

retainer

the

left.

under

be

checked

the

left.

the

of

looper/s

tips

the

high

throat

and

rocker

on

should

for

into

the

looper

the

More

However,

the

looper

by

top/s

of

point

this

plate

the

by

and

except

each

be

a

the

looper

the

threading

eye

affects

looper

it

observing

of

the

moving

the

of

travel.

setting.

slots

rear

loosening

movina

515,

side

space

machine

thread

of

the

the

the

retainer

causing

needle

to

teeth

so

teeth

the

cast-off

of

take-up

of

thread.

diagram.

retainer

needle

control

thread

triangle

the

the

are

Adjust

that

pass

the

1/32

and

is

action

eye/s

left

parallel

there

screws

rocker.

plate

inch

start

comes

of

is

given

raised

are

are

the

beyond

and

between

finger

the

skips

of

1/64

even

with

supporting

is

a

the

which

set

is

the

space

operating

so

out

up

looper

to

the

too

or

pulled

the

looper

inch

with

and

clearance

rear

clamp

correctly

is

it

and

on

that

of

the

the

thread

stitch

high

the

thrad

below

left

3/64

screw,

of

from

a

mater

down

inch

of

the

the

the

piece

looper

as

when

looper

at

as

11

Page 12

16.

tension

The

strengLh

and

on

avoid

the

needle

puckering

threads

the

should

fabric.

be

as

tight

as

consistent

is

with

their

17.

18.

19.

20.

21.

On

all

looper

the

threads

front

by

the

by

the

should

See

that

ment

Check

stitch

of

end

lock

Set

the

when

yet

have

of

the

Regulate

ssure

behind

Classes

of

looper

looper

equal

with

the

is

the

nut

at

on

thread

-

just

the

the

the

stitch

altered

cloth

has

needle

its

its

loopers

the

the

the

needle

this

in

take-ups

sufficient

machine

thread

nipper

approximately

presser

dog.

feed

range

by

plate.

a

left

rear

most

forward

vertical

moving

presser

presser

bar

section

should

nipper.

and

foot

and

turning

thread.

guard

faces

to the

spring

foot

in

except

should

steady

to

apply

The

looper

one-fourth

hinges

the

set

the

Turning

horizontally

point

of

remain

left

regulating

feed

to

head

the

apply

a

combined

thread

freely

stitch

stitch

the

travel.

in

are

the

of

515

a

them.

slightly

tension

that

and

adjusting

screw

so

contact

even

screw

work

the

the

looper

barely

The

greater

tension

applied

that

length

clockwise

that

should

It

with

with

so

uniformly.

machine.

noticeable

looper

applied

the

on

to

its

as

screw

barely

it

the

that

thread

thread

tension

front

each

under

required.

shortens

be

needles

the

needles.

it

This

to

needle

surface

located

contacts

set

exerts

nipper,

tension

tension

than

each

of

the

The

the

as

low

until

only

is

located

that

thread.

under

stitches.

the

adjacent

the

on

on

applied

looper

machine

in

is

length

the

needles

possible,

as

the

enough

directly

the

thread

align

of

left

points

to

the

The

pre

22.

tension

The

foot

entirely

has

release

been

released

raised

should

when

to

within

the

be

foot

set

1/8

reaches

so

inch

that

of

its

it

the

high

begins

end

to

its

of

position.

function

travel

when

and

the

should

presser

be

12

Page 13

NOTE:

1.

Set

the

This

niach

the

shield.

section

i

nes

left

reflects

main

The

shaft

space

adjusting

so

that

should

be

the

from

instructions

take-up

.008

has

to

applicable

equal

.010

inch.

to

clearance

Class

on

527

each

and

side

523

of

2.

3.

4.

5.

6.

7.

8.

In

Class

point

7/32

ension

Set

the

the

looper,

side

When

the

right

er.

If

Recheck

machine

moves

deflect

Set

the

above

under

On

Class

there

pass

beyond

screws

On

Class

stroke

possible.

clearance

the

screws

feed

and

dog.

the

should

inch

should

needle

of

this

needle,

to

the

feed

the

the

is

which

by

rear

627

from

when

looper

is

the

left

throat

feed

527

a

clearance

the

528

moving

Space

at

which

A

machines,

be

set

No.

be

7/32

bar

the

needle.

moves

there

the

position

fitted

left

and

needle

doq

so

plate

dog,

machines,

rear

clamp

machines,

the

the

both

ends

clamp

clearance

teeth

must

1/4

12

so

should

with

that

to

of

of

the

stud

feed

with

inch

gauge

inch

that

point

to

the

barely

toward

the

at

maintain

space

at

the

feed

set

of

the

of

pass

for

the

of

be

of

a

high

least

presser

rocker

the

in

dogs

the

feed

at

looper

from

and

3/16

all

top

looper,

left,

a

space

the

looper

touches

the

tips

point

this

the

feed

1/64

differential

the

feed

in

feed

rocker

least

the

rear

at

center

inch

Styles

of

and

needles

needle

the

rear,

of

the

of

setting.

foot.

arm

the

throat

stroke,

1/64

of

EXTREME

line

for

and

the

left

movina

its

point

of

.005

with

guard

front

keeping

teeth

travel.

dog

in

inch

at

This

to

the

feed

rocker

This

arm

to

inch

the

should

presser

RIGHT

of

right

No.

gauges

needle

to

the

is

inch

respect

it

of

it

are

Adjust

the

throat

all

is

feed

control

segment

plate

is

the

feed

end

of

needle

16

gauge

in

Class

eye

left,

even

with

between

to

the

is

set

the

riqht

close

parallel

the

plate

points

and

accomplished

rocker

and

to

slot

slots

plate

so

accomplished

rocker

be

allowed

foot.

travel,

for

machines.

528.

is

3/64

is

even

the

the

needle

back

correctly

needle.

to

looper

with

supporting

slots

the

movino

secure

there

and

at

No.

inch

with

center

of

and

rear

by

the

as

high

is

by

moving

all

the

looper

8

qauge,

This

below

the

and

the

when

It

will

point.

3/64

screw,

so

that

teeth

loosening

the

rocker.

maximum

as

equal

loosening

the

points,

dim

left

of

the

loop

looper.

it

then

inch

the

9.

10.

Draw

piece

spreader

The

be

er

the

thread

setting

to

ward

thread

The

set

the

the

of

looper

set

to

thread

needles

eyelets

the

rear

causes

just

retaining

correctly

blade

needle

fabric.

should

thread

compensate

is

just

are

determines

causes

less

becomes

finger

when

of

the

and

Refer

sew

take-up

cast

clearly

located

the

more

thread

it

looper

looper

to

perfectly

for

off

visible

on

amount

thread

to

taut

controls

prevents

when

threads

applicable

is

not

varying

the

the

be

as

the

the

without

spotted

conditions.

highest

below

take-up

of

thread

to

be

pulled.

looper

the

amount

the

looper

into

the

cast

pulled

looper

13

the

machine

threading

spreader

on

the

lobe

of

under

off

pulled

from

They

are

reaches

of

slack

thread

moves

diagram.

thread.

main

It

the

side

plate

off

set

its

from

is

the

thread

triangle

right

and

shaft

set

take—up

of

are

by

the

cones

correctly

extreme

start

Machine

and

correctly

when

the

looper.

adjustable

take-up.

and

when

position

in

the

from

to

left.

operating

equipped

consequently

when

the

points

The

and

Moving

moving

them

the

to

system

being

wiped

on

the

looper

their

looper

the

and

a

with

can

loop

of

them

for

left.

it

under

is

Page 14

11.

12.

tensions

The

stitches

The

looper

the under

on

thread

on

the

tension

needle

surface

threads

should

of

the

be

should

fabric.

just

only

be

sufficient

sufficient

steady

to

to

the

produce

thread.

uniform

13.

14.

15.

16.

Check

stitch

of

end

nut

lock

change

Class

On

contacts

set

be

right

the

needle.

this

On

Class

the

right

height

the

point

needle

the

its

guarding

NOTE:

Regulate

in

bar

foot

to

the

the

is

is

in

as

Any

the

feed

stitch

altered

cloth

has

needle

527

the

low

needle

528

needle

of

below

guard

change

the

head

range

by

plate.

left

a

guard

machines,

the

the

of

needle

possible,

until

as

guard

top

there

in

work

right

as

machines,

surface.

presser

the

turning

thread.

the

stitch

spring

the

uniformly

set

and

Turning

setting.

the

set

when

yet

point

the

the

set

looper

this

at

of

the

will

This

machine

the

stitch

the

the

change

Any

needle

its

at

have

of

feed

point

point

needle

be

is

length

regulating

slight

a

desirable

a

that

so

when

stitch

adjustment

screw

in

rear

most

its

vertical

the looper

needle

bar

reaches

so

that

guarding

clearance

will

necessitate

screw

it

a

slight

length

clockwise

stitch

guard

forward

moving

guard

the

1/16

surface.

condition.

located

exerts

tension

required.

as

screw

shortens

length

horizontally

point

face

right

only

remain

to

so

inch

between

re-setting

directly

enough

is

that

side

of

Due

located

will

of

travel.

the

of

the

to

the

placed

length

The

under

the

stitch.

necessitate

so

that

contact

in

is

left

it

just

the

needle.

right

design

the

left

needle

the

needle

behind

pressure

on

the

of

the

a

barely

it

should

It

with

with

even

contacts

needle

of

and

guard.

needle

the

presser

on

fabric.

left

The

Set

17.

18.

19.

tension

The

foot

entirely

NOTE:

of

of

Use

21227

gauges

er holder.

reaches

holder

and

equals

vertically.

has

Check

clearance.

the

holder

the

that

the

machine.

the

spreader

C-12

barely

segment

spreader

the

The

are

and

the

been

released

distance

rock

its

is

set

spreader

release

raised

remainder

The

measurement

clearance

This

shaft.

gauge

for

No.

adjusting

for

Turn

the

extreme

set

the

contacts

lever

space

from

correctly

gauge

should

to

when

of

between

No.

12

pulley

right

spreader

the

the

on

is

holder

within

the

this

21227

gauge

the

position.

center

rock

its

left

when

directly

is

be

set

1/8

foot

section

centers

should

obtained

is

C-8

or

No.

travel

the

in

gauge

of

shaft

end

the

in

in

position

so

inch

reaches

of

be

for

21227

of

operating

and

the

so

to

needles

front

it

that

of

its

applies

spreader

the

2

5/32

swinging

by

adjusting

C-16

the

Place

its

holder

left

that

line

the

are

of

to

begins

end

the

high

to

inch.

No.

for

spreader

direction

spreader

the

needle

the

on

at

center

the

prevent

to

of

position.

Class

connecting

the

8

No.

and

so

that

shank.

travel

the

high

the

function

its

528

that

See

lever

gauge

16

gauge

location

until

gauge

it

of

spreader

position

the

of

spreader

travel

Only.

rod

it

on

machines,

machines.

the

in

point

the

Set

spreader

the

gauge.

and

left

when

and

at

has

the

of

spreader

the

is

ball

the

needle.

from

the

should

left

sufficient

left

No.

the

spread

spreader

even

stud

gauge

The

line

moving

presser

be

end

end

These

with

in

on

See

14

Page 15

20.

21.

22.

23.

NOTE:

Replace

under

the

of

the

and

21225-7/32

Set

the

with

so

that

low

position.

Set

the

right

the

spreader

Set

the

Type

the

under

52844

the

machine

the

moving

of

the

If

ball

9/16

gauge

arc

of

needle

21225-7/32

spreader

surface

spreader

left

thread

the

rock

the

stationary

so

that

moving

GS

121

at

A

front

the

stud

inch

is

of

the

when

and

so

needle

shaft.

front

it

is

needle

side

their

so

spreader

end

spreader

in

tor

imparted

the

spreader

spreader

can

gauge

the

that

for

guide,

edge

will

at

extreme

spreader

of

the

closest

that

of

qauqes

the

8

gauge

passes

the

spreader

be

with

upper

its

when

at

making

cooperating

Set

of

spreader

guide

thread

shank,

moving

eyelet

the

thread

slot

seqment

and

the

to

travel.

usH

spreader

surface

short

its

these

the

the

arm

thread

the

right

which

eyelet

approach.

eyelet

in

the

not

are

lever

5/8

available,

on

inch

spreader

Adjust

inch

7/32

is

advantaqeously

prong

at

of

its

and

the

passes

farthest

adjustments.

with

pull-off

just

the

in

touches

guide

spreader

position.

eyelet,

is

.080

and

attached

top

Turn

does

not

cover

so

that

stationary

the

for

without

the

to

the

extreme

set

throat

left

spreader

the

No.

thread

inch

the

its

spreader

rock

12

holder

left

in

makinq

it

so

7/32

position.

center

the

52844

into

to

diameter,

of

the

eyelet

the

thread

the

use

shaft

gauge

taking

of

left

that

plate

inch

thread

of

thread

barely

A

the

the

stationary

holder

right

eye

thread

spreader

so

or

into

so

that

the

position.

this

the

is

to

the

Use

the

when

spreader

needle

will

needle

is

that

a

11/16

consideration

the

center

adjustment.

space

21/64

left

gauge

pull—off,

thread

needles

far

enough

bar,

barely

thread

toward

set

directly

eyelet.

and

moti

inch

short

of

Gauge

between

inch.

of

Nos.

guide

notch

so

pass

the

screw.

set

on

for

prong

the

No.

Swing

the

21227

parallel

are

to

when

that

between

guide

front

in

front

the

of

No.

the

left

its

center

and

at

the

a

No.

of

Turn

16

V

24.

25.

26.

27.

28.

Draw

the

and

associated

The

spreader

eccentric

the

right

looper.

Two

separate

the

rear,

to

each

length

set

should

combined

stitches

Adjust

the

wale

Set

the

higher

of

the

should

spreader

on

needle

and

set.

of

the

always

tension

on

the

motion

of

collar

than

presser

be

3/16

timing

the

sets

the

There

spring.

upper

the

the

thread

parts.

lower

point,

of

other

apply

on

surface

of

fabric

on

the

moving

foot

inch.

should

tension

is

no

This

both

the

without

presser

parts

at

high

Use

into

be

crank

its

in

the

at

adjustment

set

a

slightly

sets

of

fabric.

differential

will

position

gauge

the

adjusted,

shaft,

downward

discs

front

should

should

stretching

bar

No.

machine

so

are

of

for

greater

be

feed

to

prevent

permit.

and

21227

and

positioning

by

that

travel,

applied

the

the

apply

tension

only

so

it.

The

the

V

check

the

spreader

is

on

machine.

front

only

sufficient

that

the

presser

space

upper

making

for

the

even

the

Check

set,

slight

a

than

the

between

surface

action

the

spreader

sheds

with

spreader

the

except

tension.

the

to

produce

machine

foot

of

this

of

the

its

thread

the

top

thread

tension

to

alter

front

set.

uniform

will

being

from

the

under

the

throat

adjustment.

spreader

drive

of

-

The

sew

when

the

one

applied

the

rear

The

across

raised

surface

plate

at

15

Page 16

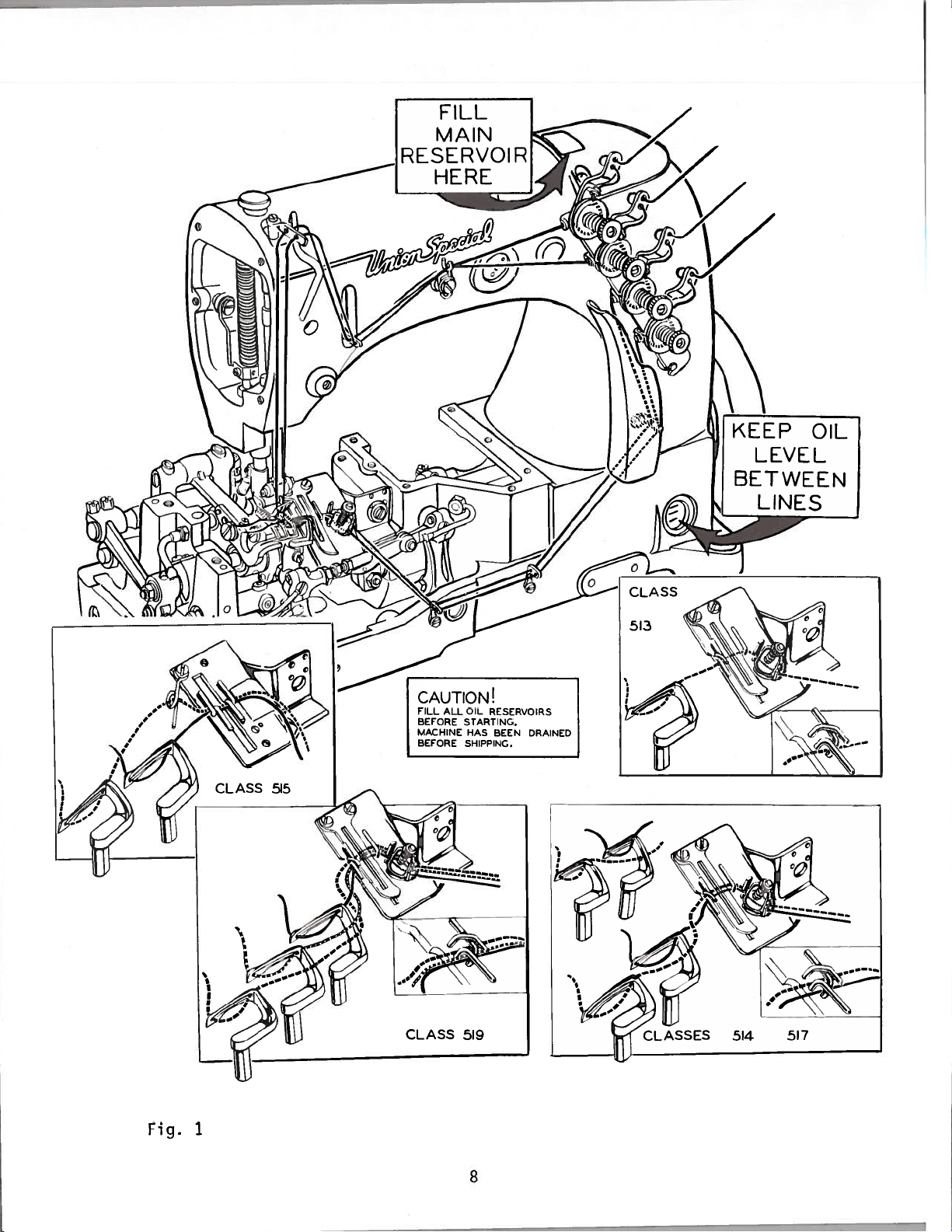

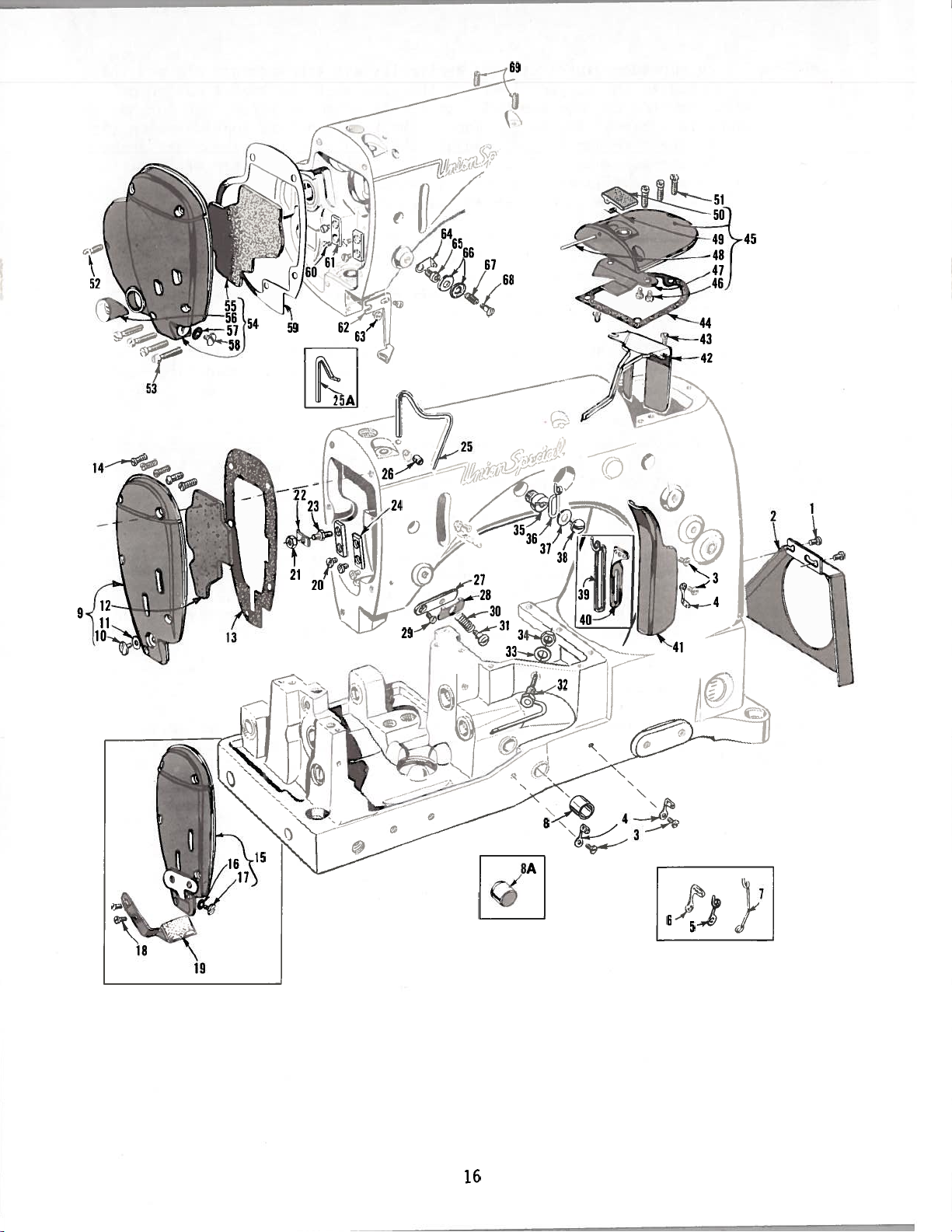

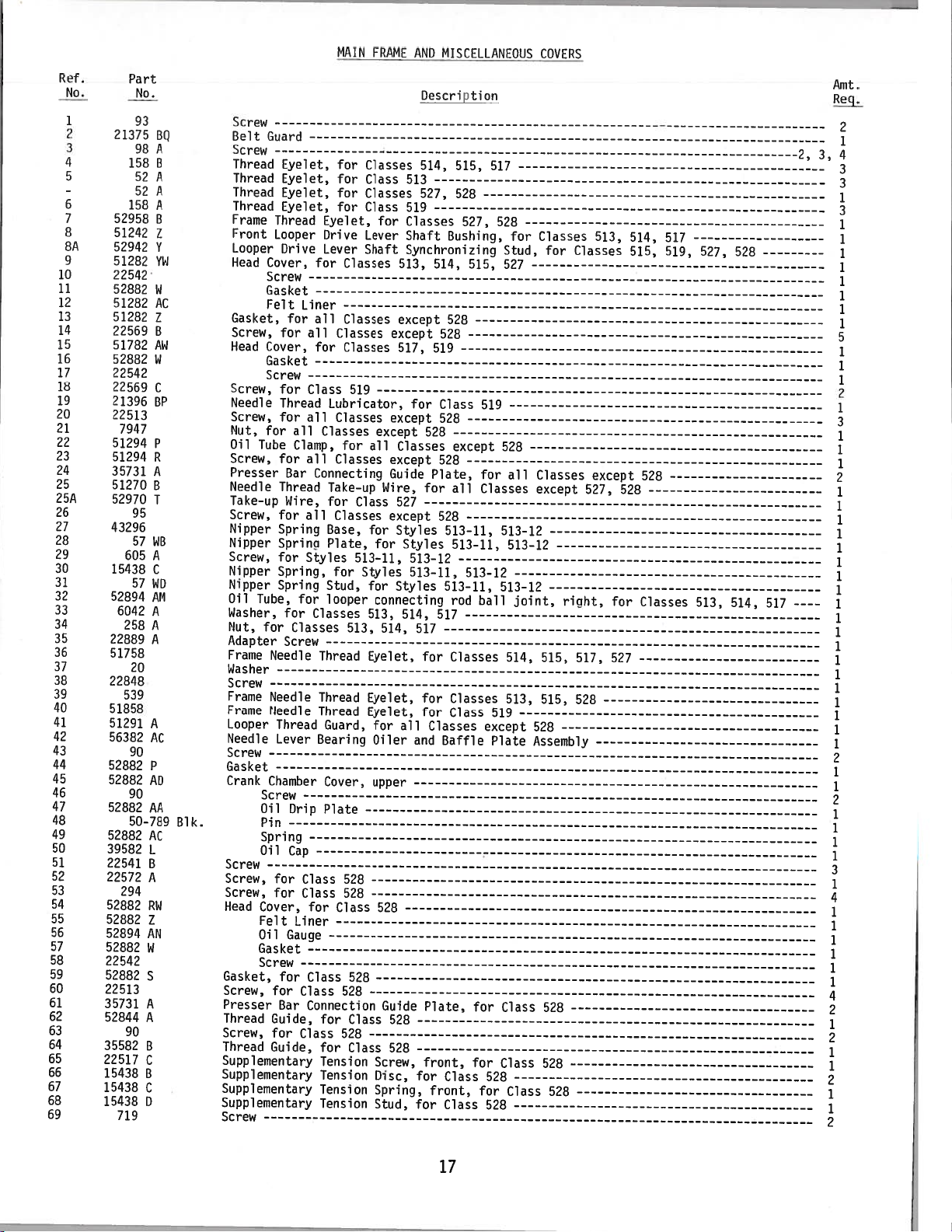

Page 17

60

61

62

63

64

65

66

67

68

69

36

37

38

39

40

41

42

43

44

45

46

47

48

49

SO

51

52

53

54

55

56

57

58

59

Ref.

8

GA

9

18

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

25A

26

27

28

29

30

31

32

33

34

35

No.

1

2

3

4

5

—

6

7

21375

52958

51242

52942

51282

22542

52882

51282

51282

22569

51782

52882

22542

22569

21396

22513

7947

51294

51294

35731

51270

52970

43296

15438

52894

6042

22889

51758

22848

539

51858

51291

56382

52882

52882

52882

52882

39582

22541

22572

294

52882

52882

52894

52882

22542

52882

22513

35731

52844

35582

22517

15438

15438

15438

719

Part

93

98

158

52

52

158

95

57

605

57

258

20

90

90

50-789

90

A

RN

7

AN

N

S

A

A

B

C

B

C

B

V

N

AC

7

B

AN

N

C

BP

P

B

A

B

T

NB

A

C

MD

AM

A

A

A

A

AC

P

AD

AA

AC

L

B

BQ

A

B

A

A

A

8

7

YW

Bl

k.

Screw

Belt

Guard

Screw

Thread

Thread

Thread

Thread

Frame

Front

Looper

Read

Eyelet,

Eyelet,

Eyelet,

Eyelet,

Thread

Leoper

Drive

Cover,

Screw

Gasket

Felt

Gasket,

Screw,

Read

for

Cover,

Gasket

Screw

Screw,

Needle

Screw,

Nut,

Oil

Screw,

Presser

Needle

Take-up

Screw,

Nipper

Nipper

Screw,

Nipper

Nippor

Oil

Washer,

Not,

Adapter

Frame

for

Thread

for

for

Tube

for

Bar

Thread

Wire,

for

Spring

Sprinu

for

Sprine,

Spring

Tube,

for

for

Screw

Needle

Washer

Screw

Frame

Needle

Frame

Needle

Looper

Needle

Thread

Lever

Screw

Gasket

Crank

Chamber

Screw

Oil

Pin

Spring

Oil

Screw

Screw,

Screw,

Wead

for

for

Cover,

Felt

Oil

Gasket

Screw

Gasket,

Screw,

Presser

Thread

Screw,

Thread

for

for

Bar

Guide,

for

Guide,

Supplementary

Supplementary

Supplementary

Supplementary

Screw

Liner

for

all

Class

all

all

Clamp,

all

Connecting

all

Styles

for

Classes

Classes

Drip

Cap

Class

Class

for

Liner

Gauge

Class

Class

Connection

Class

MAIN

for

for

for

for

Eyelet,

Drive

Lever

for

Classes

Classes

all

Classes

for

Classes

Lubricator,

Classes

Classes

for

Classes

Take—up

for

Classes

Base,

Plate,

for

Stud,

looper

Thread

Thread

Thread

Guard,

Bearing

Cover,

Plate

528

528

Class

528

for

528

for

Tension

Tension

Tension

Tension

Classes

Class

Classes

Class

Lever

Shaft

519

Class

513-11,

Styles

513,

528

Class

Class

——

FRAME

for

513,

except

except

517,

except

except

all

Classes

except

Guide

Mire,

527

except

for

Styles

for

for

Styles

connecting

513,

514,

Eyelet,

Fyelet,

Eyelet,

all

for

Oiler

upper

528

Guide

528

528

Screw,

Disc,

Spring,

Stud,

—.

.

MISCELLANEOUS

AND

IIzcrirJdpji

514,

515,

513

527,

528

519

Classes

Shaft

Rushing,

Synchronizing

514,

528

528

519

for

Class

528

520

except

528

Plate,

for

all

528

513-11,

Styles

513-11,

513-12

513—11,

513—11,

rod

514,

517

517

for

Classes

for

Classes

for

Class

Classes

and

Baffle

Plate,

front,

for

Class

front,

for

Class

—.

527,

515,

for

Classes

513-12

ball

for

for

for

—

517

528

519

513-12

519

except

Plate

Class

528

528

t:

for

Stud,

527

528

all

513—12

513-12

joint,

514,

513,

528

Assembly

Class

Class

-

COVERS

Classes

for

Classes

except

right,

515,

515,

528

528

528

513,

Classes

except

527,

517,

528

-

-

for

527

528

514,

515,

528

Classes

517

519,

527,

513,

528

514,

517

--

a

Anti.

2

1

2,

3,

4

3

3

1

3

1

1

1

1

1

1

1

1

5

1

1

1

2

1

3

1

1

1

2

1

1

1

1

1

1

1

1

--——

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

1

1

1

3

1

4

1

1

1

1

1

1

4

2

1

2

1

1

2

1

1

2

17

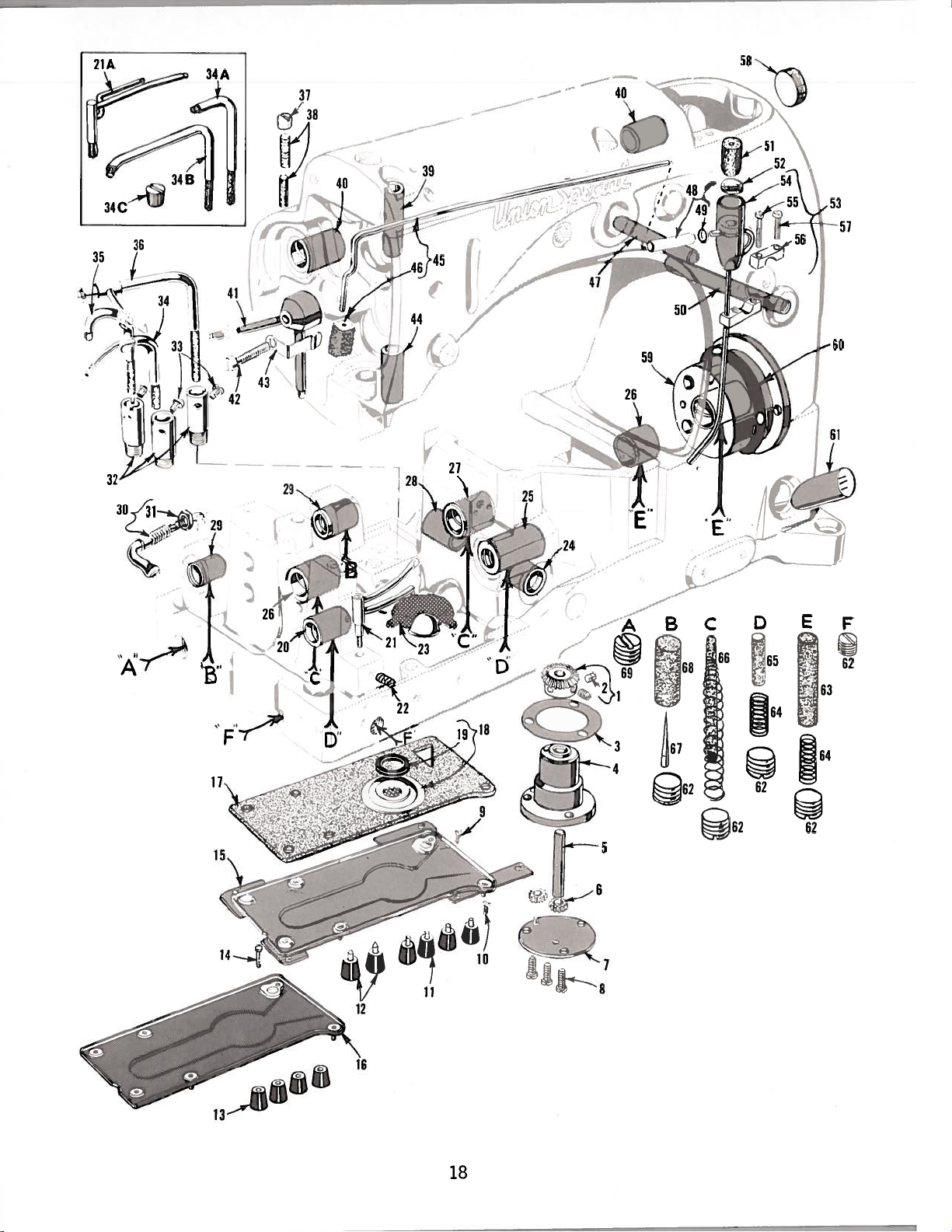

Page 18

>

n

co

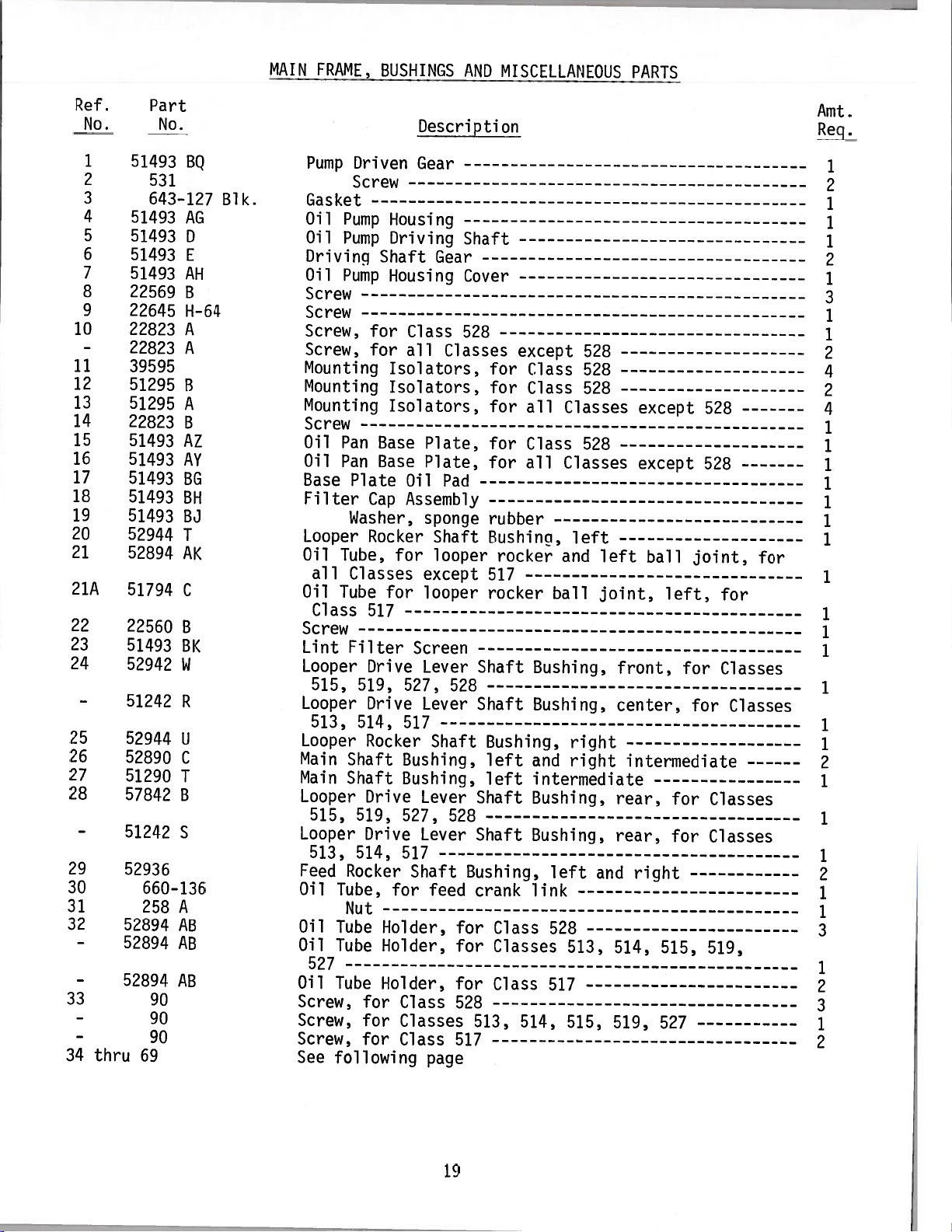

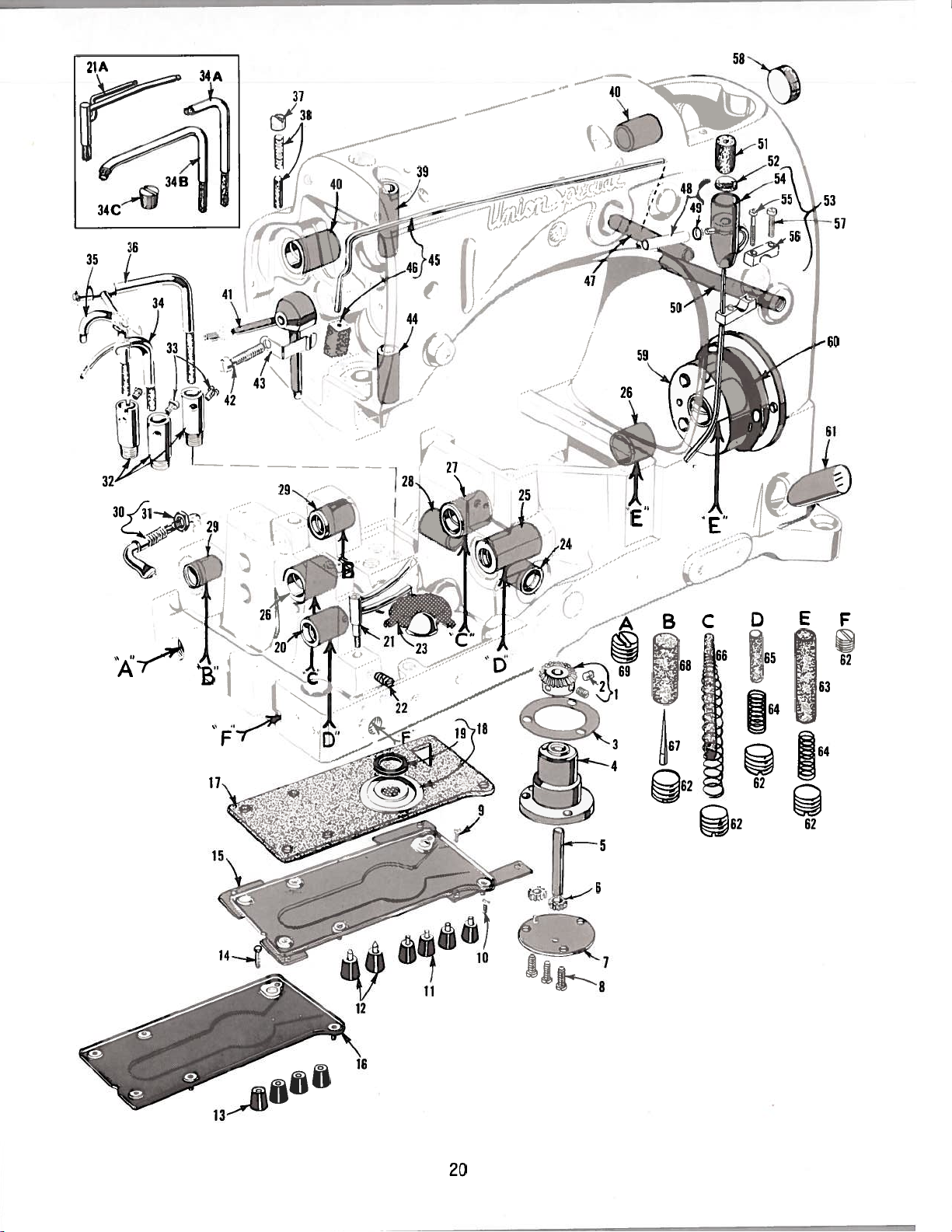

Page 19

MAIN

FRAME,

BUSHINGS

-r

--

AND

MISCELLANEOUS

PARTS

Ref.

10

11

12

13

14

15

16

17

18

19

20

21