Page 1

.

,,.,..

SECOND

EDITION

CATALOG

104L

STYLES

51200

51300

51400

51500

NO.

51700

51900

STREAMLINED

FIFTY

THOUSAND

SERIES

Page 2

Page 3

Catalog

No.

104

L

51200

51200

51200

BG

51200

51200

51200

51200,

BK

BL

BM

51200

51200

51200

512

BP

BR

BS

0 0

51300

51300

51300

LIST

51300, 51400,

BT

BW

BX

BG

BH

BJ

51300

BL

OF

PARTS

CLASSES

51500,

STYLES

51300

51400

51400

51400

51400

5i400

51400

51400

51400

51400

51400

51400

51400

BM

BA

BB

BD

BP

BQ

BR

BS

BT

BU

BV

BW

BX

51700,

51900

51900

51900

51700

51700

51700

BJ

51900

51500

51500

51700

BR

BG

BH

51500

51500

51500

BJ

BK

BQ

51400

51500

BN

BP

BR

BY

BJ

BK

BM

April,

1979

Second

Copyright

By

Union

Rights

Special

Reserved

UlVION SPECIAL

INDUSTRIAL

Printed

SEWING

Edition

1956

Corporation

in

All

Countries

CORPORATION

MACHINES

in

U.S.A.

3

Page 4

The

50000

latest

mechanisms

speed

oil

precision

the

machines.

machines

design

and

to

the

It

is

our

customer

series

of

the

and

light

production.

main

methods

covered

constant

to

The

following

reservoir,

secure

by

streamlined

Union

weight

Automatic

insuring

aim

all

pages

this

Special

presser

has

complete

to

furnish

possible

catalog.

FOREWORD

machines

flatbed

bars

lubrication,

made

illustrate

maintenance

interchangeability.

carefully

advantages

line.

make

and

covered

Light

with a pump

prepared

describe

weight

it

possible

simple.

from

by

the

this

catalog

needle

to

attain

for

All

parts

information

use

of

the

parts

represent

bars

returning

UNION

used

the

that

and

are

will

in

the

driving

utmost

filtered

made

SPECIAL

all

by

ehable

of

the

in

Additional

which

In

will

ments.

NOTE:

will

be

Catalog

Form

all

manufacturing

co-operate

Machine

component

catalogs.

furnished

No.

357

with

Styles

parts

on

45

centers

those

listed

can

containing

request.

N

will

who

desire

in

this

be

ordered

information

are

listed

Needle

Engineering

Instructions.

machine

instructions

be

catalog

found

in

planning

for

Manual

customer

relative

below:

Department

Specify

for

which

are

Union

and

are

discontinued.

required.

Special

estimating

repair.

UNION SPECIAL

to

these

Adjusting

the

the

adjusting

representatives,

style

In

most

machines,

of

their

require-

instances,

CORPORATION

and

who

4

Page 5

IDENTIFICATION

OF

MACIDNES

Each

name

Those

letter

special.

suffixed

Styles

which

The

51700,

12

gauge

a

diStance

This

can

also

UNION

plate

which

11

11

Z

•

When

to

the

of

differs

distance

51900

represents

of

catalog

be

on

applied

51400, 51500,

the

are

SPECIAL

machine.

standard

machine

Style

have

Example: 1151400

only

minor

respective

machines

fromthe

between

standard

similar

style

the

changes

numberin

isrepresentedby

adistance

64/64

or 1 inch.

APPLICATION

applies

with

51700

only

discretion

and

51900.

STYLES

carries

numbers

one

or

more

11

BP

•

Style

are

made

style

in

construction

thatit

rows

to

ofstitches

a

gau~enumbermeasuredin

of12j64

the

OF

or

standard

to

the

MACHINES

a

style

are

classified

letters

numbers

in a standard

number.

are

contains

on

3/16

inch.

OF

CATALOG

styles

special

machines

IN

number

suffixed,

which

as

standard

but

containing

machine,

Example: 1151400

grouped

no

machines

under a class

letters.

in

Classes

1/64ths

Similarly,

of

machines

in

Classes

CLASS

51200

is

the

stamped

never

letter

11

a

BPZ

and

contain

11

Z

11

special.

11 Z 11

is

merely

•

in

number

Example: 1151400"

64

as

51400,

ofan

gauge

listed

51200,

51500,

inch.

Thus,

represents

herein.

51300,

the

the

are

It

Streamlined

Weight

closed

Looper

51200

Needle

Automatic

Travel,

BG

operations;

51200

BK

T:ype

7j8,

51200

BL

T:ype

5/8,

51200

51200

BM

128

BP

GAS

Type

51200

BR

operation;

51200

BS

knitted

51200

BT

fronts

Strips

7/ 8 and 1 inch.

51200

BW

lifter.

51200

BX

gloves.

Flat

BarDrive

Maximum

Light

seam

Light

BSc-1.

1, 1 1/8

Medium

BSa-1.

7/8

and

Medium

needle.

Light

301 GS

Light

seam

Light

shirt

Medium

and

sleeves

used

in

Medium

Seam

Medium

Knee

Bed,

One

Lubricating

duty,

for

Type

duty,

Type

for

106

and 1 1/4

duty,

T:ype

3j

4

inch.

126

duty,

duty,

for

needle.

duty,

for

Type

duty,

for

fronts;

duty,

either

duty,

Type

SSa-1.

duty,

lifter.

Needle,

Mechanism,

System

Work

Space

seaming

SSa-1.

binding

GLS

needle.

inch.

for

binding

GS

needle.

for

seaming

stitching

joining

LSe-1.

miscellaneous

seam

for

of

Type

facing

woven

garment

for

seaming

Type

for

seaming

Seam

Type

Light

Light

and

to

Right

light

Type

106

aprons,

Uses

mattress

Uses

mattress

side

shoulders

Type

106

SSa-1.

sleeves

shirts;

lengths

seam

or

canton

110

GAS

light

SSa-1.

Weight

and

Medium

Filter

of

to

medium

GLS

dresses

cut

ticks

selvage

stays

on

GLS

to

shirts

needle.

operations

Type

and

attaching

Type

long

flannel

needle.

weight

Type

Presser

Type

Needle

weight

needle.

and

edge

strips,

and

edge

ticks;

shoe

and

on

101 GS

BSc-1.

lengths,

or

canton

109

GS

Bar

Duty,

Oil

Single

Return

Bar 8 1/4

trousers

similar

standard

similar

binding,

seam

linings;

similar

knitted

needle.

one

piece

Type

standard

.

leather

flannel

needle.

Mechanism,

Reservoir

Pump,

Inches.

and

garments;

widths

operations;

standard

Type

seam

SSa-1.

Type

garments

drawer

button

106

GLS

widths

palm

and

gloves.

jersey

Lateral

similar

widths

LSa-1.

in

bands

stays

needle.

1/2,

Light

En-

seam

3/4,

seam

Type

one

and

to

3/4,

Knee

cloth

5

Page 6

STYLES

OF

MACHINES

IN

CLASS

51300

Streamlined

Weight

Needle

Enclosed

Looper

51300

Travel,

BG

Type

51300

BH

guided

51300

BJ

seam

51300

BL

tions;

51300

BM

BSa-1.

718

and

Streamlined

Weight

and

Type

Needle

Presser

Medium

Oil

Bar

Flat

Bar

Automatic

Maximum

Medium

SSa-1.

Heavy

to

left

Medium

Type

LSb-1.

Heavy

seam

Type

Heavy

Type

3/4

inch.

Flat

Bar

Duty,

Return

Pump,

8 1 I 4

Bed,

One

Drive

Lubricating

duty,

Type

duty,

of

128

for

needle,

duty,

Type

duty,

for

SSa-1.

duty,

126

for

GS

STYLES

Bed,

Two

Mechanism,

Single

Inches.

Needle,

Mechanism,

Work

for

seaming

GAS

seaming

seam

for

welt

128

seaming

Type

binding

needle.

OF

Needle,

Reservoir

Lateral

Light

System,

Space

to

trousers,

needle.

couch

Type

seaming

GAS

needle.

heavy

143

GS

mattress

Uses

MACHINES

Left

Light

Weight

Enclosed

Looper

Weight

Medium

Filter

Right

covers

SSk-1.

trousers,

weight

needle.

ticks

selvage

Needle

Travel,

Presser

and

Heavy

Type

of

Needle

coats

with

Type

143

auto

and

similar

edge

IN

binding,

CLASS

in

Front,

Needle

Automatic

Maximum

Bar

Duty,

Oil

Bar 8 114

and

similar

or

without

GS

needle.

coats

and

cushions

51400

Independent

Bar

Drive

Lubricating

Work

Mechanism,

Single

Return

Pump,

Inches.

garments;

rope

similar

and

similar

operations;

standard

Mechanism,

System,

Space

Light

Reservoir

Lateral

seam

welt.

garments;

opera-

seam

widths

Row,

Light

Light

Filter

to

Right

Welt

Ty,Pe

5f8,

of

51400

shirts

in

51400

at

51400

legs

puller.

gauge

51400

ordinary

Type

51400

interlining

Type

1 I 4

Type

51400

strip.

106

51400

to

Seam

lengths

Nos.

BA

Light

and

garment

BB

Light

neck;

BD

Light

of

Nos.

BP

Light

106

BQ

Light

LSj-2.

inch

106

BR

Light

No

GHS

BS

Light

shirts

produced

32

duty,

similar

lengths.

duty,

stitching

duty,

knitted

No

attachments;

12

duty,

quality

GHS

duty,

strip

Starts

margins

GHS

duty,

body

needle.

duty,

and

similar

and

guided

and

48.

for

folding

garments

TjYPe

for

'cut-on"

Type

for

EFb-2.

hemming

undergarments.

stitching

and

16.

for

piecing

light

needle.

for

weight

Standard

one

andfacing

operation

on

each

side.

needle.

guide

for

Standard

folding

or

lower

Standard

for

one

15arments;

with

1j16

next

and

in

one

106

GS

button

Type

and

Prepared

sleeves,

shirts

gauge

operation

strip

at

to

neck.

Facing

gauge

and

strip

gauge

No.

operation

inch

to

margin

feed

attaching

operation;

needle.

stay

106

Standard

operation

GHS

simultaneously

for

Type

EFg-2.

joining

and

similar

Nos.

folding

fronts

and

ofshirts

Plaits

and

interlining

No.

48.

attaching

folder

48.

folding

seam

dog.

Type

on

each

Type

single

seam

gauge

needle.

use

Type

shoulders

garments;

6,

8,

10,

attaching

used

set-on

required;

and

attaching

LSk-2.

side.

106

GHS

piece

Type

No.

on

shirts.

Standard

inserting

with

106

12,

extension

and

similar

in

garment

strips

center

seam

Starts

Facing

needle.

facing

BSc-2.

48.

elastic

Galkin

GS

needle.

and

setting

seam

16

and

used

plait

Type

inside

operation

strip

Standard

to

sleeves

Facing

Starts

gauge

operation

No.

in

close

sleeves

Type

18.

center

garments;

lengths

in

long

and

interlining

LSm-2.

button

used

used

48.

tops

and

coupled

Standard

LSc-2.

plait,

seam

and

have

lengths.

Type

facing

at

neck.

in

long

gauge

of

of

6

Page 7

STYLES

OF

MACHINES

IN

CLASS

51400

(Cont'd.)

51400

51400

51400

51400

51400

51400

Streamlined

Mechanism,

servoir

Looper

BT

medium

Type

BU

at

neck;

32.

BV

fabric;

BW

tions

seams;

12

and

BX

seam

BY

work

with

next

Automatic

Travel,

Light

106

Light

Light

seam

Light

on

16.

Light

Type

Light

shirts

1/32

to

presser

duty,

weight

GHS

stitchingTypeEFb-2

woven

seam

inch

Flat

Light

extrafine

needle.

duty,

duty,

Type

duty,

shorts,

Type

duty,

SSa-2.

duty,

and

margin

foot;

Bed,

Weight

Lubricating

Maximum

for

piecing

Standard

for

"cut-on"

for

uniting

LSd-2.

for

piecing

LSc-2.

for

quilting

Type

for

folding

similar

on

seam

STYLES

Two

Needle

Work

sleeves,

qualityshirts

gauge

button

inverted.

the

Type

where

106

garments.

both

Type

OF

Needle,

101

sleeves

the

Type

collar

GHS

and

sides.

LSk-2.

MACHINES

Bar

System,

Space

joining

andsimilargarments;

Nos.

stay

operations

Type106

lower

106

needle.

attaching

Independent

Drive

to

edge

GS

needle.

of

shirts

majority

GHS

bands

Standard

Starts

Stays

Type

IN

Mechanism,

Filter

Right

of

and

8,

10,

GHSneedle.

of

French

Standard

and

pajamas

of

the

needle.

of

shirts

"set-on"

operation

used

in

106

CLASS

Row,

Type

Needle

setting

12

and

on

work

Standard

gauge

button

at

garment

GHS.

51500

Light

Heavy

Oil

Bar 8 1/4

sleeves

seam

16.

shirts,

StandardgaugeNo.

drawer

gauge

and

for

consists

gauge

and

similar

Nos.

stays

neck.

lengths

Standard

Weight

Duty,

Return

Type

Starts

bands

Nos.

joining

24

and

Seam

gauge

Presser

Pump,

Inches.

of

light

LSc-2.

operation

to

12

and

opera-

of

straight

Nos.

to

Single

8,

garments;

26.

fronts

produced

and

guided

No.

Lateral

and

body

16.

10,

of

32.

Bar

Re-

51500

51500

51500

51500

51500

51500

StreamlinedFlat

Presser

Heavy

Pump,

Inches.

BJ

For

left

needle

Nos.

needle

Standard

in

LSk-2.

needle

Standard

made

Type

Type

16

BK

BM

long

BN

BP

from

LSb-2.

BR

LSc-2.

Bar

Duty,

Lateral

For

For

For

For

in

For

lengths

Type

in

Single

felling

in

front;seam

and

18.

seaming

front,

gauge

facing

seaming

front;

gauge

seaming

heavy

felling

Mechanism,

Looper

seam

No.

and

128

GAS

seam

No.

Type

Type

Bed,

Reservoir

overalls,

Type

trousers

Type

1.

bibs

weight

Two

of

overalls.

guided

needle.

trousers

Type

1.

windbreakers

melton

128

GAS

overalls

128

GAS

STYLES

Needle,

Light

Automatic

Travel,

coats,

LSc-2.

and

similar

SSa-2.

next

needle.

and

needle.

OF

Weight

Maximum

to

Standard

and

similar

SSa-2.

and

similar

MACHINES

Independent

combination

Type

garments.

Type

Facing

feed

Type

and

similar

Standard

Standard

Needle

Lubricating

dog.

gauge

garments.

mackinaws,

garments,

Work

128

130

strip

130

fabrics,

gauge

gauge

IN

Row,

Bar

Space

suits

GAS

GS

needle.

cut

Left

No.

18.

GS

needle.

CLASS

Needles

Driving

System,

to

and

needle.

Tandem

parallel

needle

Tandem

coats

left

No.

18.

left

No.

18.

51700

Right

similar

Standard

needle

10

stitches

with

selvage,

in

front;

needle

7

stitches

and

similar

needle

needle

Abreast,

Mechanism,

Filter

of

in

in

Type

Needle

garments,

seat.

per

seam

seat.

per

garments

front;

front;

Light

Light

Oil

Bar 8 1/4

gauge

Right

inch.

used

Type

Right

inch.

seam

seam

Weight

and

Return

51700

BJ

Light

and

interlining

at

neck.

stitching;

and

64.

duty,

Plaits

seam

for

strips

used

Type

one

to

in

garment

LSm-2.

operation

fronts

of

shirts

lengths

Type

folding

and

and

108

GKS

7

and

similar

extend

needle.

attaching

garments.

1/4

Standard

"set-on"

inch

Starts

beyond

gauge

center

operation.

the

rows

Nos.

plait

of

56

Page 8

STYLES

OF

MACHINES

IN

CLASS

51700

(Cont'd.)

51700

BK

interlining

Starts

beyond

gauge

51700

to

at

BQ

fronts

neck.

stitching;

51700

BR

medium

Facing

dog.

Standard

Streamlined

Weight

and

Return

8

1/4

51900

Presser

Heavy

Pump,

Inches.

BG

light

108

GKS

51900

BH

and

similar

gauge

51900

BJ

similar

9.

Light

operation

the

No.

Light

of

Plaits

seam

Light

weight

strip

Seam

gauge

Flat

Duty,

Lateral

Light

and

medium

needle.

Heavy

Nos.

Heavy

garments;

duty,

strip

rows

64.

duty,

medium

duty,

cut

has

No.

Bed,

Bar

Single

duty,

duty,

garments;

7, 8

duty,

for

one

and

facing

at

neck.

of

stitching;

for

one

weight

used

Type

army

1/16

for

from

in

garments

LSk-2.

one

shirts

body

inch

64.

STYLES

Three

Mechanism,

Reservoir

Looper

for

piecing

weight

shirts

Standard

for

seaming

and

9.

for

seaming

seam

operation

strips

Plaits

seam

operation

army

Type

operation

and

fabric,

margins;

OF

MACHINES

Needle,

Light

Automatic

Travel,

sleeves,

and

gauge

seam

Type

windbreakers,

Type

LSb-3.

folding

to

used

Type

folding

shirts

lengths

108

folding

similar

used

seam

Left

Needle

Weight

Maximum

similar

Nos.

5, 6

overalls,

LSc-3.

Type

and

fronts

in

garment

LSj-2.

and

and

similar

and

GKS

needle.

and

garments.

in

long

Type

IN

CLASS

Needle

Lubricating

WorkSpace

joining

garments;

and

dungarees,

147

attaching

of

shirts

lengths

Type

108

attaching

garments.

extend

Standard

attaching

Starts

lengths

LSk-2.

51900

in

Front,

Bar

shoulders

7.

Type

128

mackinaws,

GS

needle.

extension

and

similar

and

GKS

"set-on"

1/4

inch

gauge

inside

operation

and

guided

Type

Independent

Drive

Mechanism,

System,

to-Right

and

setting

seam

coats,

GAS

Type

combination

needle.

lumber

Standard

center

extend

needle.

center

Starts

beyond

No.

button

next

108

GKS

Filter

of

LSc-3.

jackets

plait,

garments.

1/4

Standard

plaits

operation

rows

64.

facings

at

neck.

to

needle.

Row,

Light

Light

Type

Needle

sleeves

Type

suits

Standard

gauge

inch

of

to

feed

Oil

Bar

of

and

No.

TYPE

NUMBERS

Each

kind

of

denotes

way

between

the

type

To

have

needle,

intelligent

The

by

this

catalog

able

but

results.

ions

and

Type

101

106

106

No.

GS

GS

GHS

needle

shank,

the

largest

the

number

orders

or

the

order

type

the

ones

The

type

the

sizes

Round

chromium

Round

ball

Round

eye,

AND

has a type

point,

diameter

shank

and

type

would

numbers

are

given

indicated

numbers

available

shank,

shank,

eye,

shank,

ballpoint,

SIZES

number

length,

and

the

size

number

promptly

and

size

read

as

of

the

needle

in

the

are

of

are

round

plated-

round

chromium

round

chromiumplated-

NEEDLES

and

size

groove,

of

the

eye

is

and

number

and

finish

blade,

is

the

complete

accurately

should

follows: 111000

recommended

machine

those

the

recommended

listed

style

recommended

below:

Description

point,

sizes

point,

extra

022,

extra

plated -sizes

point,

extra

number.

and

measured

stamped

other

in

The

type

details.

in

thousandths

the

needle

number

The

of

shank.

size

an

Collectively,

symbol.

filled,

be

given.

Needles,

description.

needles

short,

025, 027,

short,

the

Type

for

each

to

produce

double

080/032,

double

empty

See

style

Other

package,

remarks

108

GKS

of

needles

the

togetherwith

groove,

049,

groove,

on

Size

machine

most

satisfactory

their

struck

054.

struck

090/036.

short,

double

groove,

struck

sizes070/027,075/029,080/032,090/036.

denotes

number

:inch,

a

sample

labels.

090/03

covered

are

avail-

descript-

groove,

groove,

groove,

the

mid-

An

6

ball

11

•

8

Page 9

TYPE

NUMBER

AND

SIZES

(Continued)

Type

106

108

109

110

126

128

130

143

147

301

306

No.

GLS

GKS

GS

GAS

GS

GAS

GS

GS

GS

G

GS

Round

oversize

Round

oversize

100/040.

Round

ball

100/040,

Round

ball

100/040, 110/044,

Round

chromium

Round

spotted,

125/049, 140/054, 150/060,

Round

spotted,

100/040,

Round

chromium

Round

spotted,

iumplated150/060,

Round

sizes

Round

eye,chromium

shank,

ball

shank,

ball

shank,

eye,

government

110/044,

shank,

eye,long

shank,

plated-

shank,

chromium

shank,

government

110/044, 125/049,

shank,

plated-

shank,

short

170/067.

shank,

085/034,

shank,

round

eye,

round

eye,

round

round

spot,

round

round

round

round

round

point,

sizes

stay

100}040.

stay

plated -sizes

point,

ball

point,

spotted,

point,

point,

125/049,

point,

government

125/049.

point,

sizes

point,

plated-

point,

point,

point,

sizes

point,

undersize

080/032,090/036,100/040,110/044,125/049,140/054,

point.

point,

ORDERING

point,

short,

080/032,

short,

No. 2 bag.

140/054, 150/060,

extra

extra

Description

extra

extra

chromium

extra

chromium

extra

short,

sizes

170/067.

chromium

140/054,

long,

090/036,100/040,110/044,125/049,140/054.

REPAIR

short,

chromium

short,

short,

140/054.

short,

point,

double

100/040,

double

080/032,

double

double

double

eye

in

short,

short,

double

plated -sizes

double·

plated-

double

plated -sizes

double

chromium

groove,

054.

groove,

090/036,

groove,

plated-

150/060.

groove,

170/067.

groove,

grooves.

double

double

PARTS

one

groove,

groove.

groove,

groove,

sizes

groove,

groove,

plated -sizes

struck

struck

struck

sizes

struck

struck

step

struck

036,

struck

080/032,

struck

070/027,

struck

groove,

groove,

100/040,

groove,

080/032,

groove,

groove,

reduction,

chromium

struck

040.

groove,

groove,

groove,

090/036,

groove,

090/036,

groove,

090/036,

ball

eye,

ball

eye,

110/044,

ball

eye.

090/036,

spotted,

ball

eye,

chrom-

plated

ball

-

ILLUSTRATIONS

This

Exploded

may

be

tion

will

the

number

The

position

in

ordering

Those

indicated

main

3

29105

22559

4

22559

5

6

22894

22894

7

It

are

not

dividually

catalog

views

seen

sub-assembly.

in

their

be

found

of

pieces

numbers

of

that

parts.

component

by

the

Z

A

B

part

c

D

will

be

noted

listed.

is

The

not

has

been

of

the

various

actual

the

listing

required

in

the

first

in

the

Always

parts

fact

that

their

Example:

Looper

51300,

recommended

Drive

51500;

Bearing

Bearing

Eccentric

Eccentric

in

the

reason

so

arranged

sections

position

of

illustration.

use

of

sub-assemblies

Cap

Cap

above

for

in

the

parts

in

the

column

the

part

descriptions

Eccentric

Styles

Screw.

Screw.

Set

Screw

Spot

example

this

is

and

the

as

to

of

the

the

machine.

with

particular

are

reference

The

number

Assembly.

51200

lower

upper

------------------------------------4

Screw

that

-----------------------------------1

that

the

complete

simplify

mechanism

their

view

reference

shown

which

are

indented

BL,

------------------------------2

------------------------------2

the

replacement

the

ordering

are

On

the

page

part

numbers.

being

numbers

number

in

can

for

BM,

BT,

eccentric,

sub-assembly

shown.

the

be

furnished

under

Styles

BW,

of

shown

second

any

of

so

opposite

descriptions

only

and

should

the

description

in

Classes

BX;

51900

ball

stud

of

these

should

repair

that

the

the

illustra-

indicate

never

column.

for

repairs

BH,

and

parts

be

ordered.

parts.

parts

and

the

be

used

are

of

the

BJ--1

bearing

in-

9

Page 10

ORDERING

REPAIR

PARTS

ILLUSTRATIONS

In

those.

catalog.

parts

in

the

only

for

the

descriptions

At

the

illustrations.

the

Where

some

smaller

fication

All

they

appear.

Success

genuine

UNION

Corporation.

ing

to

the

The

maximum

no

specific

the

back

part

the

letter

part

most

cases

various

number

construction

parts

is

numbers

in

SPECIAL

its

efficiency

(Continued)

where a part

usage

machines

and.

if

of

the

book

which

is

and

will

known.

on

stamped

represent

USE

GENUINE

the

operation

Needles

subsidiaries

approved

is

will

be

are

necessary.

will

be

facilitate

IDENTIFYING

permits

those

to

where

distinguish

the

NEEDLES

of

these

and

and

authorized

scientific

and

durability

common

mentioned

not

the

the

to

all

in

the

same.

the

difference

found a numerical

locating

the

PARTS

each

Repair

part

the

the

same

machines

is

construction

part

from

part.

AND

regardless

REPAIR

can

Parts

distributors.

principles

are

and

assured.

of

the

machines

description.

specific

will

be

index

illustration

stamped

does

similar

PARTS

be

secured

as

furnished

They

made

with

usage

shown

of

all

and

with

not

ones.

of

are

the

covered

However.

will

in

the

the

parts

description

its

part

permit.

the

catalog

only

by

the

designed

utmost

by

when

be

mentioned

illustration.

shown

when

·

number.

an

identi-

in

which

by

the

use

Union

Special

accord-

precision.

this

the

in

On

of

Genuine

pair

parts

mark

is

Prices

are

forwarded

insured

ance.

The

must

be

viscosity

Oil

sight

the

gauge

red

The

main

Oil

reservoir

A

daily

which

reservoir

servoir

wheel.

are

your

are

unless

oil

filled

of

90

is

filled

on

lines

machine

check

has

making

may

be

needles

stamped

guarantee

strictly

at

the

otherwise

has

been

before

to

125

at

the

front

on

the

is

filled

before

gone

too

drained

are

packaged

with

of

net

the

the

cash

buyer's

directed.

OILING

AND

drained

beginning

seconds

the

_spring

of

the

gauge.

The

automatically

is

necessary.

the

morning

through

the

frequent

at

the

with

Union

Special

highest

TERMS

and

subject

risk

f.

o.

A

charge

THREADING

from

at

cap

to

operate.

100°

the

in

machine.

capacity

lubricated

start

machine

oilings

plug

screw

labels

trademark.

quality

b.

in

to

change

shipping

is

made

INSTRUCTIONS

machine

Use a straight

Fahrenheit.

the

top

cover

The

oil

of

the

and

should

is

filtered

unnecessary.

in

the

marked~.

US

Emblem.

materials

without

point.

to

before

and

notice.

Parcel

cover

the

shipping

mineral

and

the

level

level

oil

should

reservoir

no

oiling

be

made

and

be

is

other

and

pumped

oil

Excessive

main

frame

directly

Genuine

Each

workmanship.

AU

shipments

post

shipments

postage

and

oil

is

and

the

reservoir

with a Saybolt

checked

maintained

12

ounces.

than

keeping

added

back

oil

into

in

the

under

if

required.

the

main

the

re-

trade-

are

insur-

at

the

between

the

main

re-

hand-

The

is

threaded.

manner.

accompanying

Single

The

looper

drawing

and

three

threading

also

needle

of

shows

machinE's

the

various

the

manner

are

threaded

classes

10

in

which a two

in

substantially

is

indicated

needle

in

the

machine

the

same

inserts.

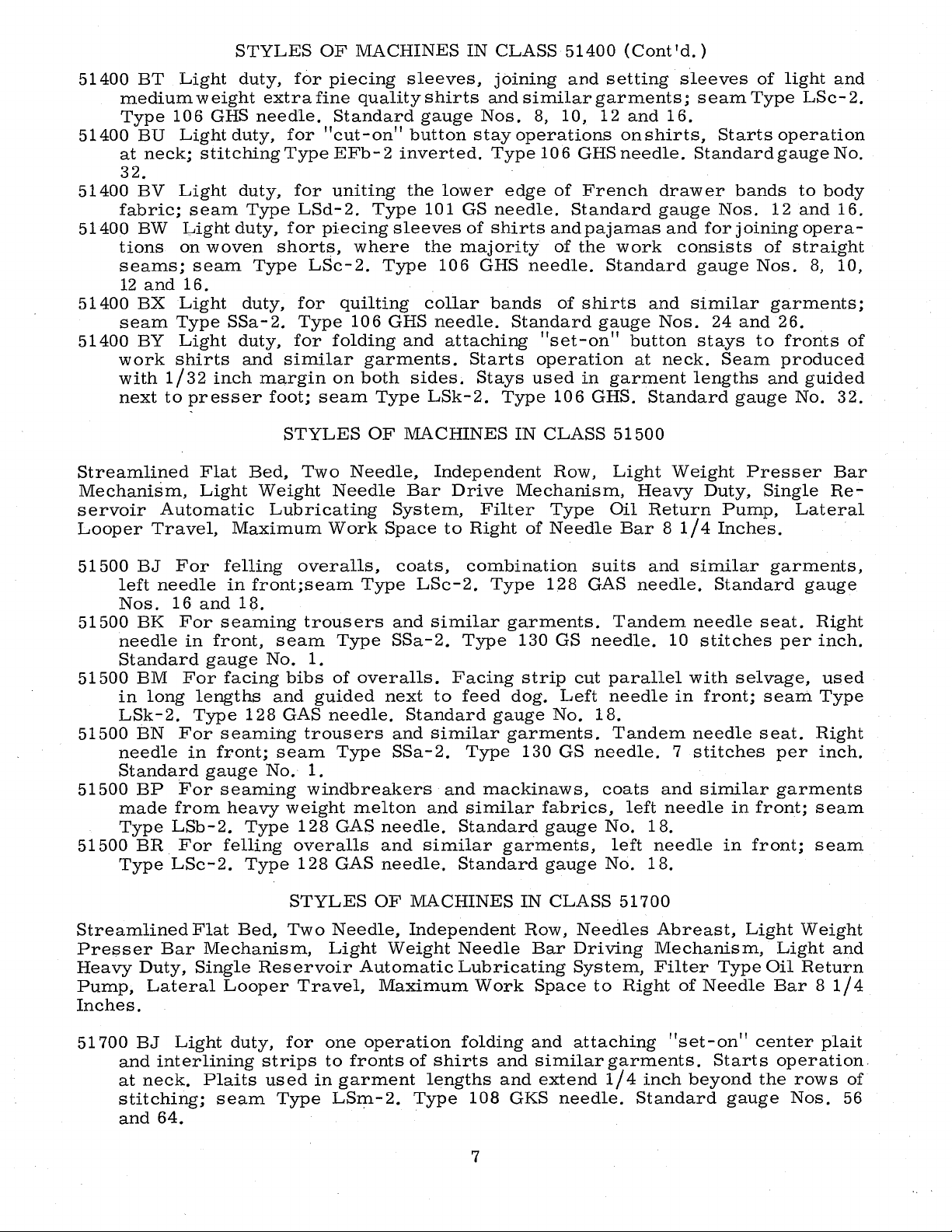

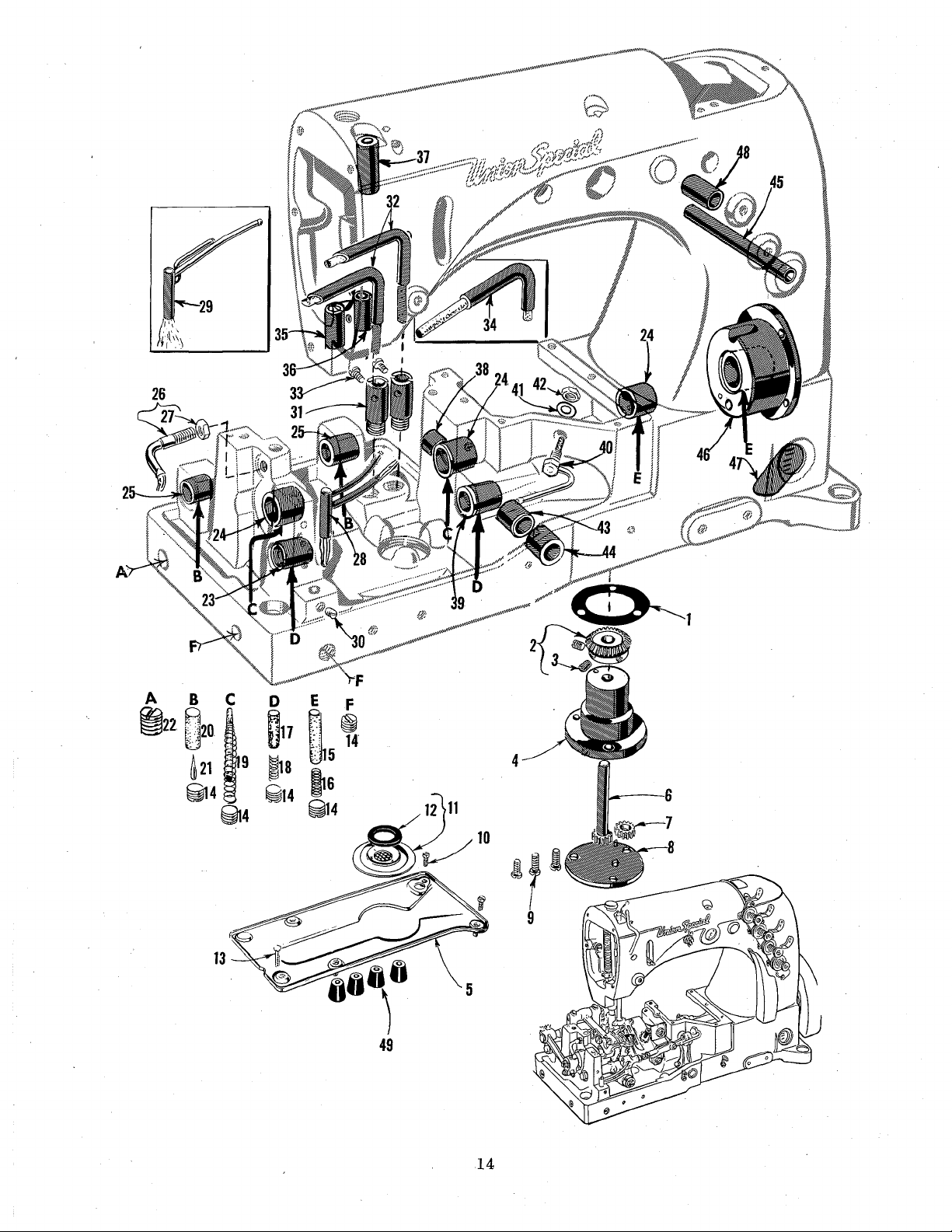

Page 11

FILL

MAIN

RESERVOIR

HERE

CAUTION!

FILL

ALL

BEFORE STARTING.

MACHINE HAS

BEFORE SHIPPING.

CLASS

OIL RESERVOIRS

51900

BEEN DRAINED

·~

\

I

•

51400

51700

11

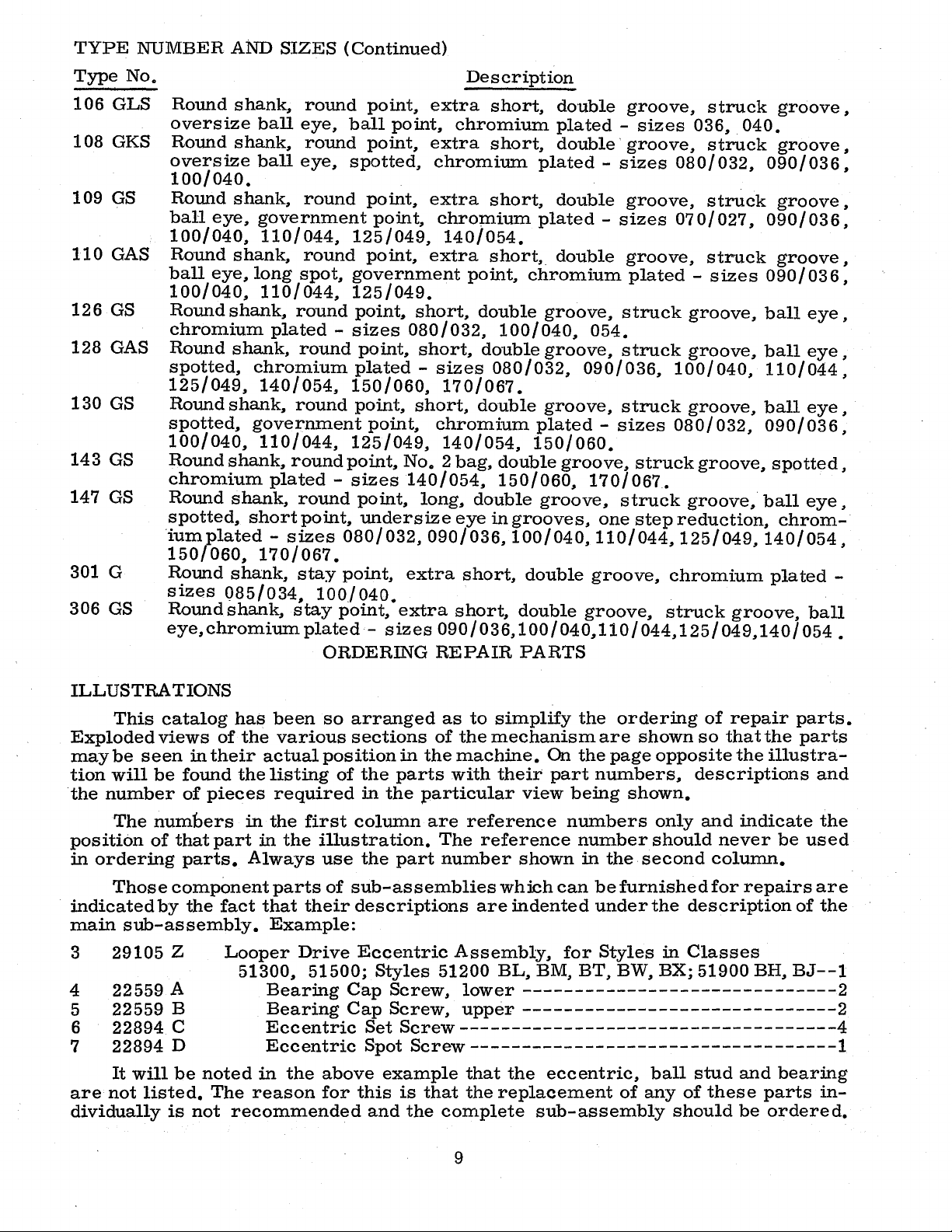

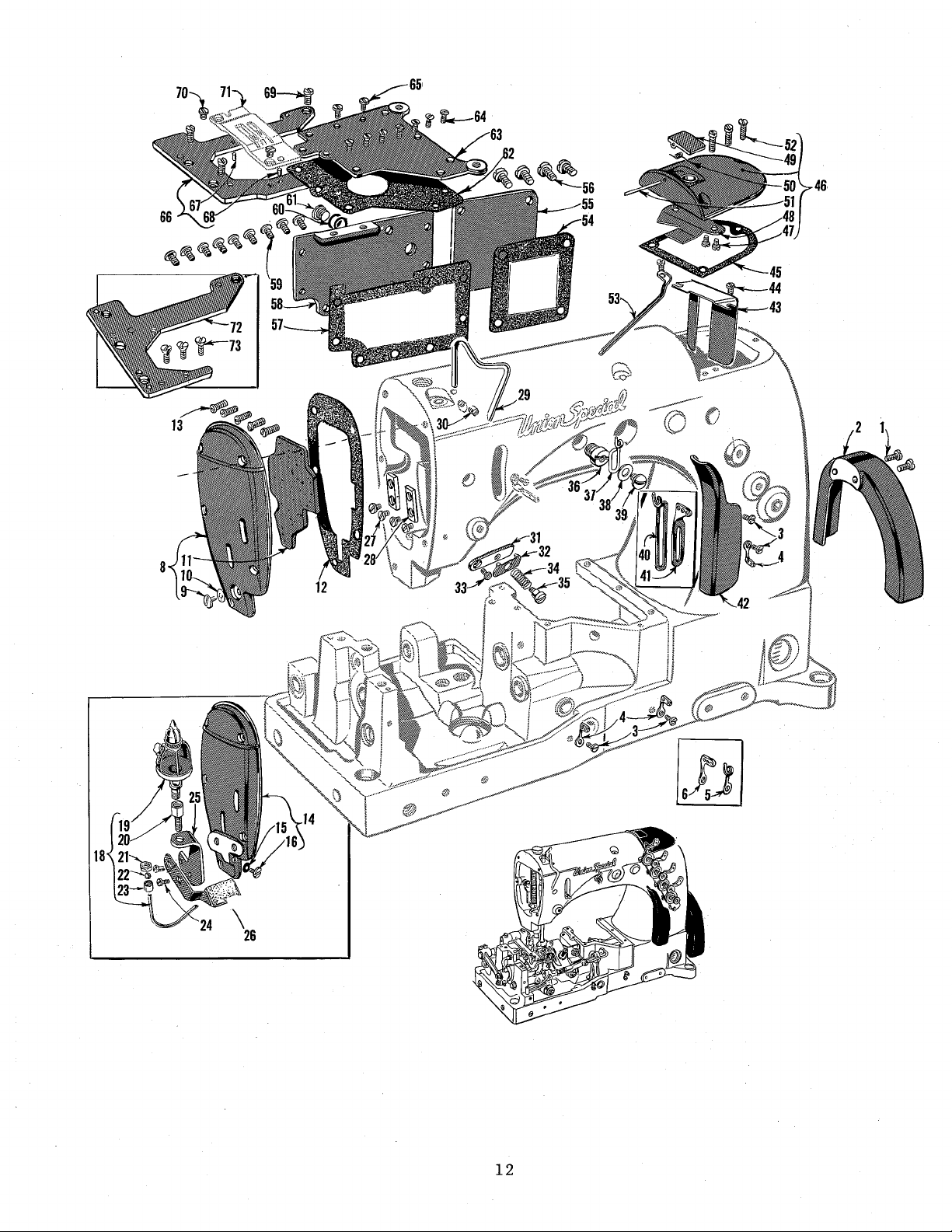

Page 12

12

Page 13

B21375

98A

158

158

22542

52882

51282AC

51282

51782

52882

22542

21396

666-79

61394

11638

660-74

660-75

21396

22513

35731

51270

95

43296

605

22798

15438

22889

51758

20

22848

51858

51291A

52882

90

52882

52882

90

52882

39582

52882

50-789

22541

51282

52882

52882

22548

52882

52882

22848

41394A

22733B

53782

22524

22585

51480

51280

51280

87

51280 A

80

Use

No.

Use

No.

Part

No.

Ref.

No.

1 93

2

3

4

5 52 A

6

8 51282 Y

9

10

11

12

13 22569 B

14

15

16

18

19

20

21

22

23

24 22569

25

26 21396

27

28

29

30

31

32 57 WB

33

34

35 57

36

37

38

39

40 539

41

42

43

44

45

46

47

48

49

50

51

52

53

54

*55

56

57

58

59

60

61

62 51382 A

63

64

65

66

67

68

69 22839

70 22570

71

72

t73

*

NOTE:

t

NOTE:

AH

B

A

W

Z

A

W

BJ

V

M

C

BK

BP

A

B

A

A

C

WD

A

Y

P

AD

AA

L

AC

B

AE

U

AE

M

L

B

A

J

K

52882

22839

Blk.

MAIN

FRAME,

Screw----------------------------------------··------------------------------

Belt

Guard------------------------------------------------------------------Screw·----------------------------------------------------------------------Thread

Thread

Thread

Head

Gasket

Screw-------------------------------------------~---------------------------

Head

Needle

Screw-----------------------------------------------------------------,------

Needle

Needle

Screw-----------------------------------------------------------------------

Presser

Needle

Screw-----------------------------------------------------------------------

Nipper

Nipper

Screw,

Screw,

Nipper

Nipper

Adapter

Frame

Washer----------------------------------------------------------------------

Screw-----------------------------------------------------------------------

Frame

Frame

Looper

Baffle

Screw----------------------------------------------------------------------Gasket

Crank

Screw-----------------------------------------------------------------------

Needle

Gasket

Crank

Screw-----------------------------------------------------------------------

Gasket

Oil

Screw----------------------------------------------------------------------Gasket----------------------------------------------------------------------

Plug

Gasket

Oil

Screw----------------------------------------------------------------------Screw-----------------------------------------------------------------------

Throat

Screw-----------------------------------------------------------------------

Throat

Throat

Throat

Throat

Screw-------------------------------------------------------------------'----

AF

on

counter

Eyelet,

Eyelet,

Eyelet,

Cover,

BB,

BD,

BR;

51700

Screw-------------------------------------------------------------------Gasket-------------------------------------------------------------------

FeltLiner----------------------------------------------------------------

----------------------------------------------------------------------

Cover,

Gasket-------------------------'-----------------------------------------Screw--------------------------------------------------------------------

Thread

OilCup-----------------------------------------------------------------Adapter------------------------------------------------------------------

Nut----------------------------------------------------------------------

Connection

Coupling

Thread

Thread

Bar

Thread

Spring

Spring

for

for

Spring,

Spring

Screw---------------------------------------------------------------

Needle

Needle

Needle

Thread

Plate------------------------------------------------------------------

----------------------------------------------------------------------

Chamber

Screw--------~-----------------------------------------------------------

Oil

Drip

Oil

Cap------------------------------------------------------------------

Spring

Pin----------------------------------------------------------------------

Lever

----------------------------------------------------------------------

Chamber

----------------------------------------------------------------------

Reservoir

Screw------------------------------------------------------------------

----------------------------------------------------------------------

Reservoir

Plate

51200

BG, BK,

BQ,

BR,

Dowel

Dowel

Pin,

Plate

Plate

Plate

Plate

BJ,

BL;

late

model

bore

head

MISCELLANEOUS

for

two

for

for

for

BP,

BS,

BR

for

Lubricator

Sleeve---------------------------------------------------------

----------------------------------------------------------------Lubricator

Lubricator,

Connection

Take-up

Base,

Plate,

Styles

Styles

for

Stud,

Thread

Thread

Thread

Guard---------------------------------------------------------

Cover,

Plate

-------------------------------------------------------------------

Bearing

Cover,

Back

Top

Support,

BS,

BT,

Pin,

lower

for

Screw,

Screw,

(See

Support,

51400

machines.

screw

needle

one

needle

three

Styles

--------------------------------------------------------------

Styles

BL,

Pages

BV

needle

in

Classes

BT,

BU,

51400

Oil

Oil

for

Guide

Wire

for

Styles

for

Styles

51200

BW,

51200

BG; 51300

Styles

51200

for

Styles

Eyelet,

Eyelet,

Eyelet,

upper--------------------------------------------------

------------------------------------------------------------

Oiler

---------------------------------------------------

lower----------------------------------'----------------

Cover-----------------------------------------------------

Cover------------------------------------------------'------

for

Styles

BW,

BX; 51300

BU,

BW,

---------------------------------------------------------

Throat

Plate------------------------------------------------

fillister

countersunk

33, 35, 37, 39,

for

Styles

----------------------------------------------------------

for

late

model

COVERS

Description

machines

machines

machines---------------------------------------

51200,

BV,

BW,

BQ,

BR;

Reservoir,

Reservoir

Styles

51500

Plate--------------------------------------------

-------------------------------------------------51200

BG,

51200

BX

for

for

BX,

head----------------------------------------------

BG,

----------------------------------------------BG,

BG,

BW,

51200

BG,

Styles

Styles

for

Styles

in

Classes

BY------------------------------------------

head------------------------------------------

51200

No.

AND

PLATES

----------------------------------------

---------------------------------------51300,

BX,

51500

for

Bracket,

BJ

BX; 51300

BW,

in

in

in

BH,

41,

BM,

51280

51900;

BY;

51500

BP;

Style

BP,

51900

BW,

BX;

BW,

BX;

-------------------------------------BX;

Classes

Class

Class

51500, 51700,

BM; 51400

43)

---------------------------------

BN,

BP,

A.

Styles

BJ,

51700

BJ,

51500

BP----------------------

for

Style

BJ

51300

51300

BG,

51300

51200, 51400,

51300

--------------------------

51900

--------------------------

BA;

BR,

51400

BK,

BM,

BK,

BQ

51500

(felt

BJ

BG,

BS,

BP

No.

21396

BG,

BJ

BG,

51900;

----------------

BJ

----------------

--------------------BJ

----------------51500,

Styles

BB,

BD,

BT;

51300

BA,

BN,

-------------

-------------AG)

51700

BP,

BG,

------

_;,.__

Amt.

Req.

2

1

4

3

3

3

1

1

1

1

1

5

1

1

1

1

1

1

1

1

1

2

1

1

4

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

1

1

1

3

1

1

1

4

1

1

9

2

1

1

1

7

2

1

2

2

3

2

2

1

1

3

13

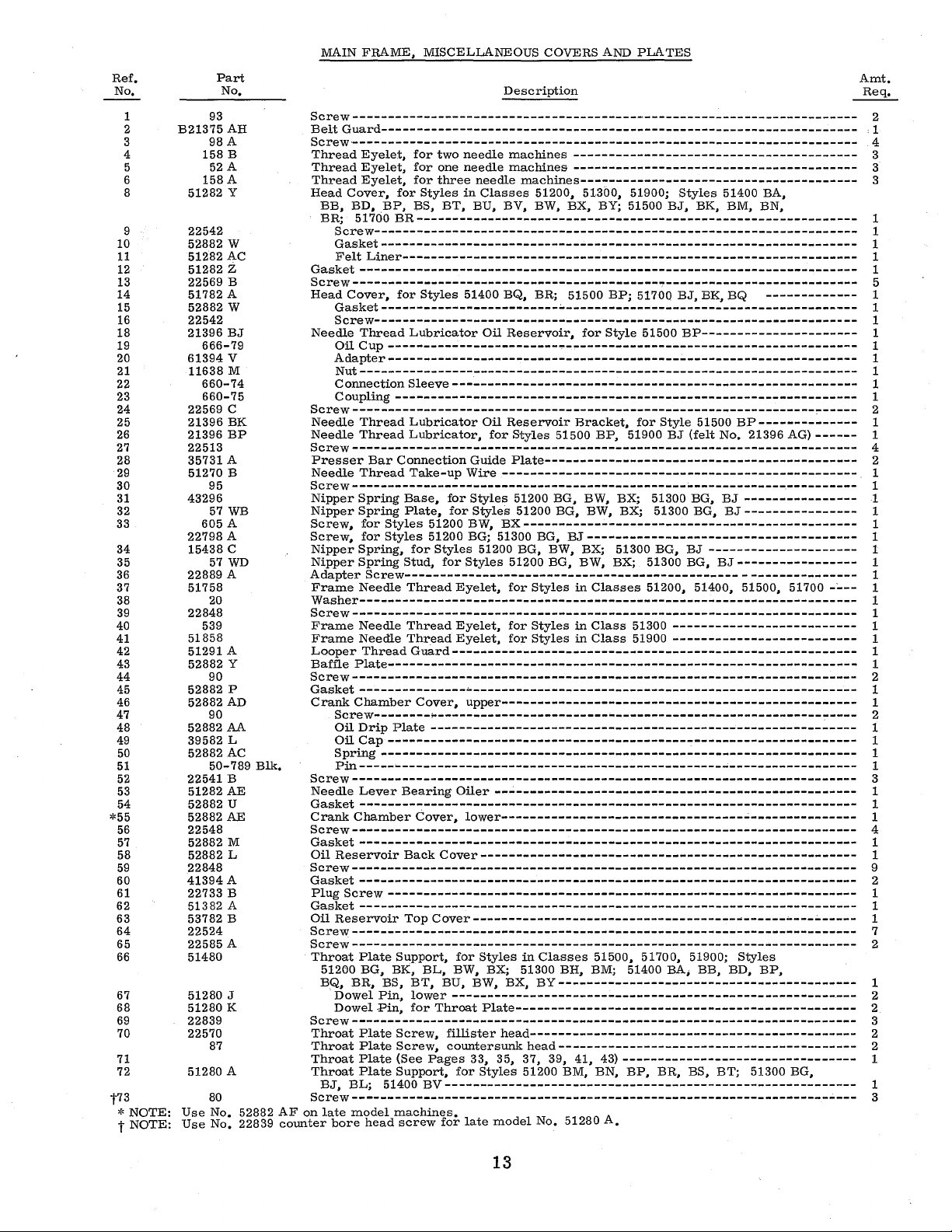

Page 14

14

Page 15

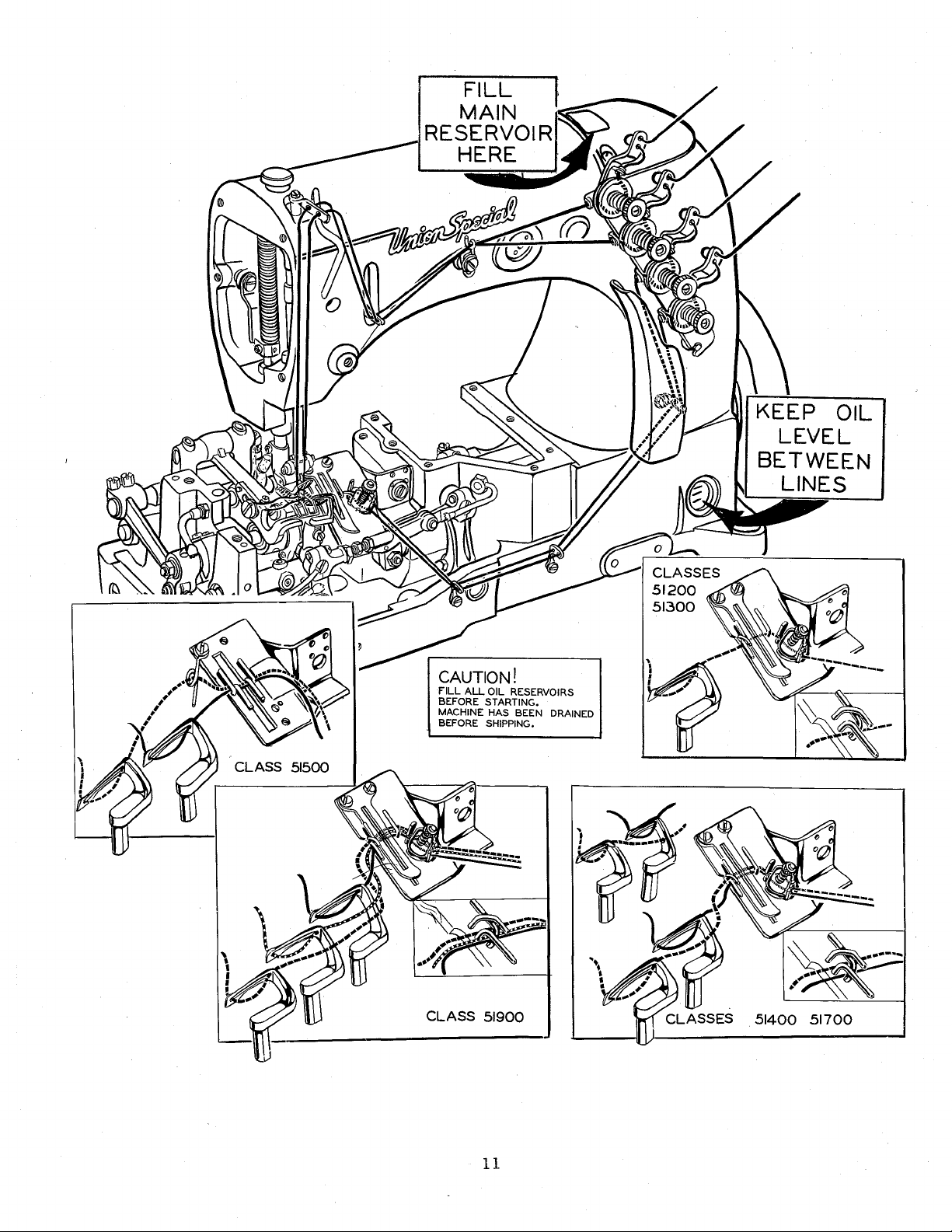

MAIN

FRAME,

BUSHINGS AND

MISCELLANEOUS

OILING

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

t11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

*32

33

34

35 51257

36

37

38

39

40

41

42

43

44

45

46 52891 B

47

48

49

t

Use

No.

*Two

No.

Part

643-127

51493 K

531

51493 AG

51493

51493 D

51493

51493

22569 B

22823 A

51493

51493

22823

22571 A

666-114

35178

666-65

35178

666-118

666-111

666-179

22539 H

52944

52890

52936

660-136

258 A

52894

51794

22560 B

52894

51293 T

90

51794

51254

51254

51242

52944

52894

6042 A

258

51242

51242

21657 X

50-648

52883

51295

51493

51293 T replaced

No.

BA

E

AH

BH

BJ

B

D

D

T

c

AK

c

AB

A

AA

D

C

S

U

AM

A

R

Z

R

A

Blk.

Blk.

BG

Amt.

Description

Gasket

Oil

Oil

Base

Oil

Oil

Oil

Screw-------------------------------------------

Screw------------------------------------------Filter

VVasher,

Screw------------------------------------------Plug

Oil

Spring-------------------------------------------

Oil

Spring---------------------------~---------------

Oil

Oil

VVedge

Plug

Looper

Main

Feed

Oil

Oil

Styles

51900------------------------------------------

Oil

Styles

Screw------------------------------------------Oil

Oil

avoid

51300,

Screw------------------------------------------Oil

Class

Lower

Lower

Upper

Rear

Looper

Oil

VVasher-------------------------------------------

Nut

Middle

Front

Tension

Crank

Lucite

Foot

Mounting

base

plate

------------------------------------------

Pump

Screw----------------------------------------

Pump

Pump

Pump

Pump

VVick----------------------------------------VVick----------------------------------------VVick-----------------------------------------

VVick-----------------------------------------

Tube

Nut------------------------------------------

Tube

Tube

Tube

Tube

Tube

Tube

---------------------------------------------

by

Driven

Housing

Plate---------------------------------------

Driving

Driving

Housing

Cap

Assembly------------------------------

rubber----------------------------------

Screw--------------------------------------

Pin---•-----------------------------------

Screw--------------------------------------

Rock

Shaft

Rocker

Looper

Lifter

oil

Bushing,

for

for

in

Classes

for

in

Class

Holder---------------------------------for

eccentric

51400, 51500,

for

51700-----------------------------------Presser

Needle

Needle

Rock

for

Looper

Looper

Release

Shaft

Oil

Gauge

Isolator---------------------------------

pad

one

each

Gear

Shaft---------------------------Shaft

Shaft

Shaft

feed

crank

looper

looper

51700

feed

lift

on

looper

Bar

Bar

Bar

Drive

Shaft

looper

Drive

Drive

Lever

Bushing

Lever

---------------------------------

with

No.

Nos.

----------------------------

--------------------------------

Gear-----------------------

Cover

Bushing,

Bushing

rocker

51200,

Bushing------------------------

Bushing-------------------------

Lever

Bushing,

Bushing-------------------------

--------------------------

left--------------------

left,

middle,

------------------------

link

-----------------------

ball

51300, 51400, 51500,

rocker

eccentric;

Styles

avoid

Bushing-----------------------

connecting

Lever

Lever

Housing,

22571

ball

----------------------------

in

51900

eccentric

Shaft

right

Shaft

Shaft

Shaft

51493

BH

B,

inner

joint,

joint,

also

for

Classes

---------------------on

Bushing-------------

------------------

rod

ball

Bushing-----------

Bushing------------

Bushing---------------

including

filter.

52794

G.

right--------

left,

on

left

on

looper

51200,

Styles

joint,

bushing------

in

right---

Req.

1

1

2

1

1

2

2

1

3

2

1

1

1

18

2

2

2

·2

2

2

2

1

1

3

2

1

1

1

1

1

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

15

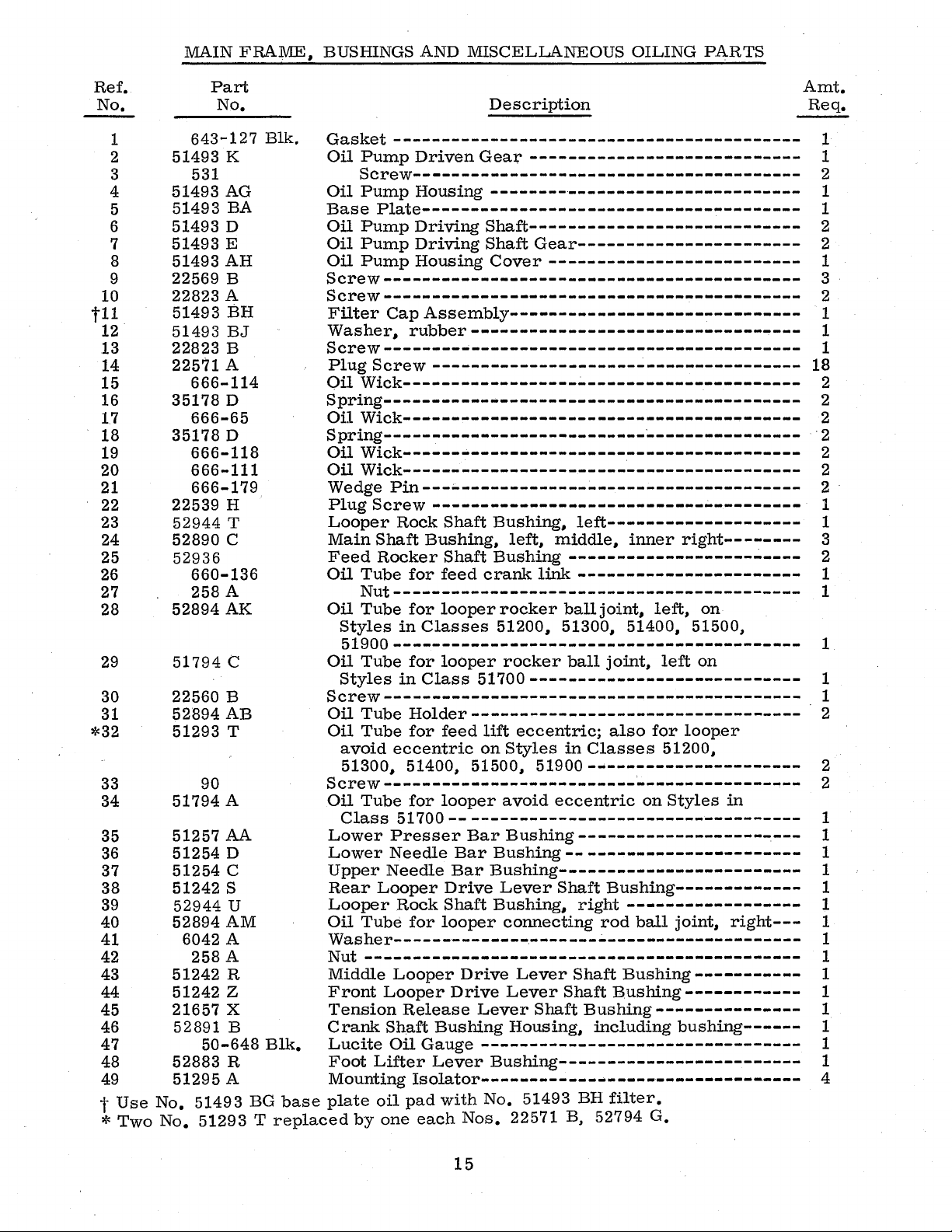

Page 16

16

Page 17

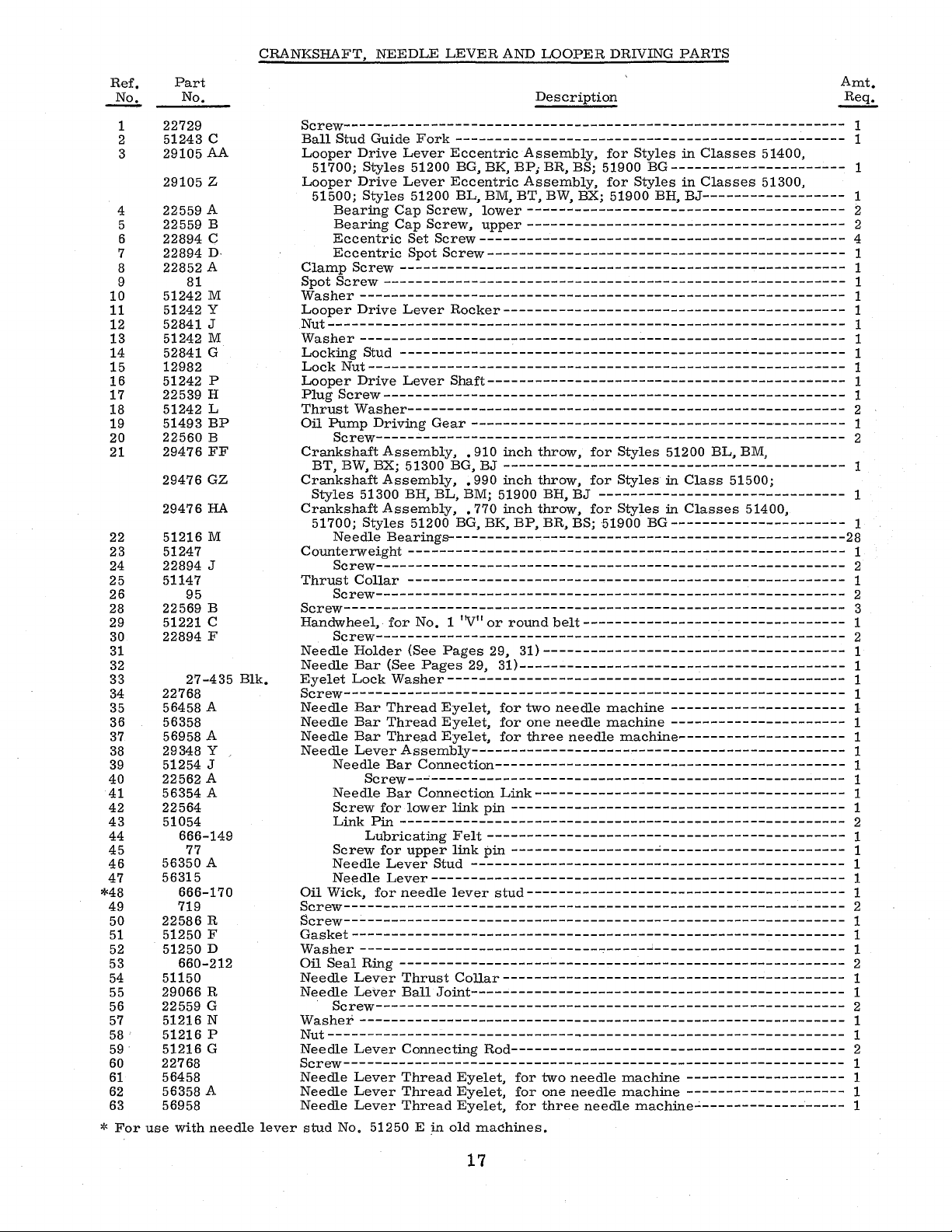

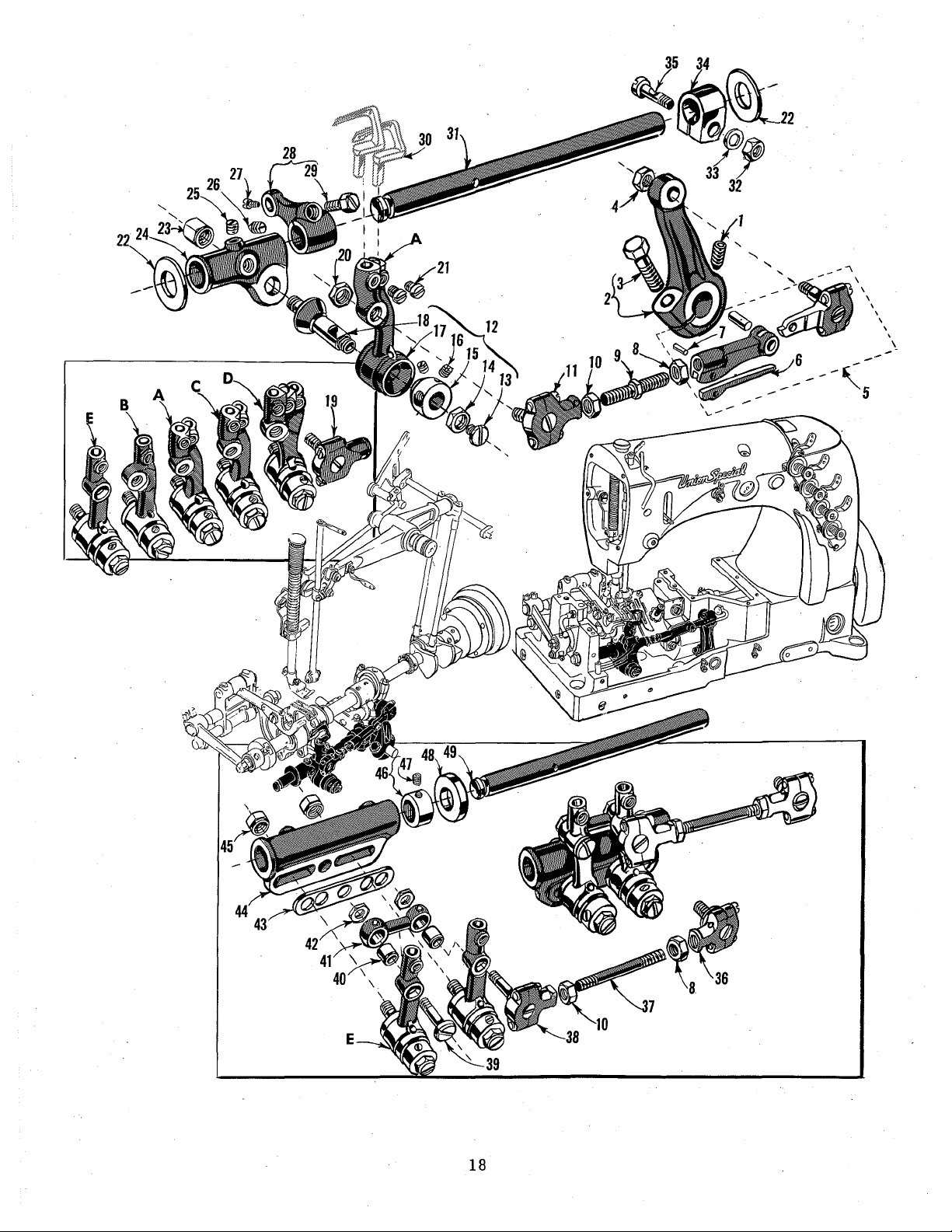

CRANKSHAFT,

NEEDLE

LEVER

AND

LOOPER

DRIVING

PARTS

Ref,

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

*48

49

50

51

52

53

54

55

56

57

58'

59

60

61

62

63

*

For

No,

1

2

3

4

5

6

7

8

9

22729

51243

29105

29105

22559

22559

22894

22894

22852

51242

51242

52841

51242

52841

12982

51242

22539

51242

51493

22560

29476

29476

29476

51216

51247

22894

51147

22569

51221

22894

22768

56458

56358

56958

29348

51254

22562A

56354

22564

51054

56350

56315

22586

51250

51250

51150

29066

22559

51216

51216

51216

22768

56458

56358

56958

use

Part

No,

c

AA

z

A

B

c

D·

A

81

M

y

J

M

G

p

H

L

BP

B

FF

GZ

HA

M

J

95

B

C

F

27-435

A

A

Y

J

A

666-149

77

A

666-170

719

R

F

D

660-212

R

G

N

P

G

A

with

needle

Blk,

Description

Screw--------------------------------------------------------------Ball

Stud

Looper

51700;

Looper

51500;

Clamp

Spot

Washer

Looper

Nut-----------------------------------------------------------------

Washer

Locking

Lock

Looper

Plug

Thrust

Oil

Crankshaft

BT,

Crankshaft

Styles

Crankshaft

51700;

Counterweight

Thrust

Screw--------------------------------------------------------------Handwheel,

Needle

Needle

Eyelet

Screw--------------------------------------------------------------Needle

Needle

Needle

Needle

Oil

Screw--------------------------------------------------------------Screw--------------------------------------------------------------Gasket--------------------------------------------------------------

Washer

Oil

Needle

Needle

Washer-------------------------------------------------------------

Nut----------------------------------------------------------------Needle

Screw---------------------------------------------------------------

Needle

Needle

Needle

lever

stud

Guide

Drive

Styles

Drive

Styles

Bearing

Bearing

Eccentric

Eccentric

Screw

Screw

-------------------------------------------------------------

Drive

------------------------------------------------------------Stud

Nut------------------------------------------------------------

Drive

Screw----------------------------------------------------------

Washer-------------------------------------------------------

Pump

Screw-----------------------------------------------------------

BW,

51300

Styles

Needle

Screw-----------------------------------------------------------

Collar

Screw-----------------------------------------------------------

Screw-----------------------------------------------------------

Holder

Bar

Lock

Bar

Bar

Bar

LeverAssembly-----------------------------------------------

Needle

Screw--~----------------------------------------------------

Needle

Screw

Link

Lubricating

Screw

Needle

Needle

Wick,

------------------------------~-----~------------------------

Seal

Ring

Lever

Lever

Screw-----------------------------------------------------------

Lever

Lever

Lever

Lever

No,

51250 E in

Fork

Lever

Lever

Cap

Cap

Set

Spot

--------------------------------------------------------

---------------------------------------------------------Lever

-------------------------------------------------------Lever

Driving

Assembly,

BX;

51300

Assembly, , 990

BH

Asse~bly,'

Bearings--------------------------------------------------28

-------------------------------------------------------

-------------------------------------------------------

for

(See

(See

Washer--------------------------------------------------

Thread

Thread

Thread

Bar

Bar

for

lower

Pin

--------------------------------------------------------

for

upper

Lever

Lever----------------------------------------------------

for

needle

--------------------------------------------------------

Thrust

Ball

Connecting

Thread

Thread

Thread

-------------------------------------------------

Eccentric

51200

BG,

Eccentric

51200

BL,

Screw,

Screw,

Screw----------------------------------------------

Screw---------------------------------------------

Rocker-------------------------------------------

Shaft---------------------------------------------

Gear

-----------------------------------------------

• 910

BG,

BL

BM·

51200

No,

Connection--------------------------------------------

Connection

• 77'0

BG, BK,

1

''V"

Pages

Pages

29,

Eyelet,

Eyelet,

Eyelet,

link

Felt

link

Stud

-----------------------------------------------

lever

Collar-------------------------------------------

Joint-----------------------------------------------

Eyelet,

Eyelet,

Eyelet,

old

machines.

Assembly,

BK,

BP;

BR,

Assembly,

BM,

BT,

lower

----------------------------------------

upper

----------------------------------------

inch

BJ

------------------------------------------inch

51900

inch

BP,

or

round

29,

31)

31)-----------------------------------------

for

two

for

one

for

three

Link---------------------------------------

pin

------------------------------------------

---------------------------------------------

pin------------------...:-----------------------

stud----------------------------------------

Rod------------------------------------------

for

for

for

BS;

BW,

BX;

throw,

throw,

BH

BJ

thr~w,

BR,

BS;

belt---------------------------------

--------------------------------------

needle

needle

needle

two

needle

one

needle

three

for

Styles

51900

for

Styles

51900

for

Styles

for

Styles

-------------------------------

for

Styles

51900

machine

machine

machine---------------------

machine

machine

needle

machine-------------------

in

BG

BG

Classes

---------------------in

BH,

Classes

BJ------------------

51200

BL,

in

Class

in

Classes

----------------------

----------------------

----------------------

--------------------

--------------------

51400,

51300,

BM,

51500;

51400,

Amt,

Req,

1

1

1

1

2

2

4

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

2

1

2

3

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

2

1

1

2

1

1

2

1

1

1

1

17

Page 18

&)5

34

~~--

~~~2

33

~

32

\

\

\

\

\

\

\

'-

18

Page 19

LOOPER

ROCKER

AND

CONNECTING

ROD

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Assembly

29192

A

29192

B

29192 D

c

29192 B

D

29192

E

22894

51242

22811 B

12538

51241 K

56341 G

51240

51240 E

55241 N

22829

15465

51745

51241 D

51244

51246

51244

51244

22519 H

51144

51244

55244

51741

41047

39141

55641

22835

51771

51770-56

51770-64

51770-72

51770-80

51770-88

51770-96

51700-112

51770-128

14077

51772-56

51772-64

51772-72

51772-80

51772-88

51744

51773

54244

51244

Ref.12

Part

No,

H

w

50-458

18

269

258A

88

18

73

98

96

77

18

20

Blk.

D

F

L

B

N

G

c

4761

A

1280

88

B

L

A

Ref.

Assembly

A 51413

51213

51513

51913

c 51713

Description

Spot

Screw--------------------------------------------------------------------

Looper

Nut--------------------------------------------------------------------------Looper

Nut,

Looper

Looper

Nut,

Looper

Looper

Looper

Nut,

Looper

Thrust

Looper

Looper

Set

Spot

Screw-------------------------------------------------------------------------

Looper

Looper(See

Looper

Nut---------------------------------------------------------------------------

Washer

Looper

LockingStud-------------------------------------------------------------------

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Nut--------------------------------------------------------------------------Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Thrust

Looper

Identification

17

Drive

Lever------------------------------------------------------------

Screw

---------------------------------------------------------------------

Connecting

51400,

51200

51400,

51500,

51500,

Spring

Spring

Screw

Screw---------------------------------------------------------------------

Screw---------------------------------------------------------------------

Mark

"c"

"B"

"D"

"F"

"E"

----------------•----------------------------------------------··----Pin

rightthread---------------------------------------------------------------

Connecting

BL,

Connecting

left

thread----------------------------------------------------------------

Connecting

51500-----------------------------------------------------------------

Rocker

LockNut

LockNut------------------------------------------------------------------Looper

Looper

Looper

Rocker

SetScrew--------------------------------------------------------------

Rocker

Rocker

Connecting

for

Styles

Set

Screw

Washer-----------------------------------------------------------------

Rocker

Rocker

---------------------------------------------------------------------

Screw--------------------------------------------------------------------

Rocker

Rocker

-----------------------------------------------------------------------

Rocker

51900-----------------------------------------------------------------

Connecting

Connecting

Connecting

Connecting

Connecting

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Rocker

Washer,

Rocker

.Rod

and

Ball

Joint,

right,

for

51900

----------------------------------------------------------

----------------------------------------------------------------Rod,

for

Styles

in

Class

BM,

BT,

BW,

BX

Rod,

for

Rod

Ball

Assembly

Screw-------------------------------------------------------------

Cone-------------------------------------------------------(See

Chart

Cone

Stud----------------------------------------------------

Rod

in

Stud

Frame,

Shaft

Page

Rock

Rock

Link

Link

Link,

Link,

Link,

Link,

Link,

Link,

Link,

Link,

Spacing

Spacing

Spacing

Spacing

Spacing

Frame,

Stud

Frame

Rock

51400

51200

51500

51500

51700

for

Ball

Classes

----------------------------------------------------------Nut,

for

Arm-------------------------------------------------------

45)-----------------------------------------------------------

Shaft,

Shaft

Rod

l3all

Rod,

for

Rod,

for

Rod,

for

Rod

Ball

Stud,

Ferrule,

for

for

for

for

for

for

for

for

Plate,

Plate,

Plate,

Plate,

Plate,

for

Nut,

Spacing

Styles

Shaft,

BA,

BB,

BG, BK,

BJ,

BK,

BP,

BJ,

BK,

-----------------------------------------------·--

Styles

51200

Joint,

left,

(See

Chart

Below)---------------------------------------

Below)---------------------------------------------

Joint,

Styles

Styles

Joint,

No,

No.

No,

Joint,

Styles

for

56

64

72

80

88

96

112

128

for

for

for

for

for

Styles

Collar,

Class

Styles

BP,

BM,

BN,

BG,

BR

left,

in

in

Classes

for

right,

64

to

56

gauge,

112

and

left,

in

Styles

gauge,

gauge

gauge

gauge

gauge

gauge

gauge

gauge

No. 56

No.

No.

No,

No,

.in

Class

in

51700-----------------------------------------

BQ,

BP,

BR

BH,

51200, 51300,