INSTRUCTIONS

FOR

FLAT

CLASSES

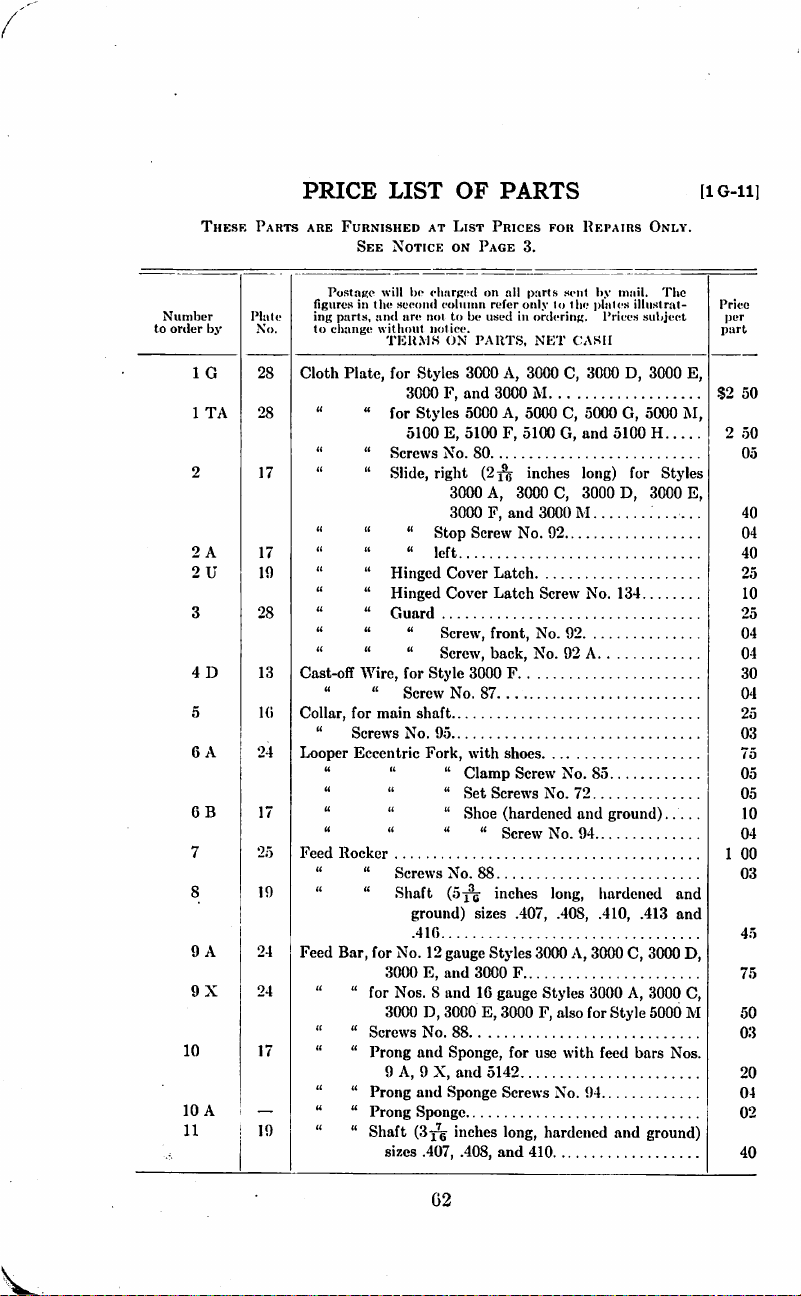

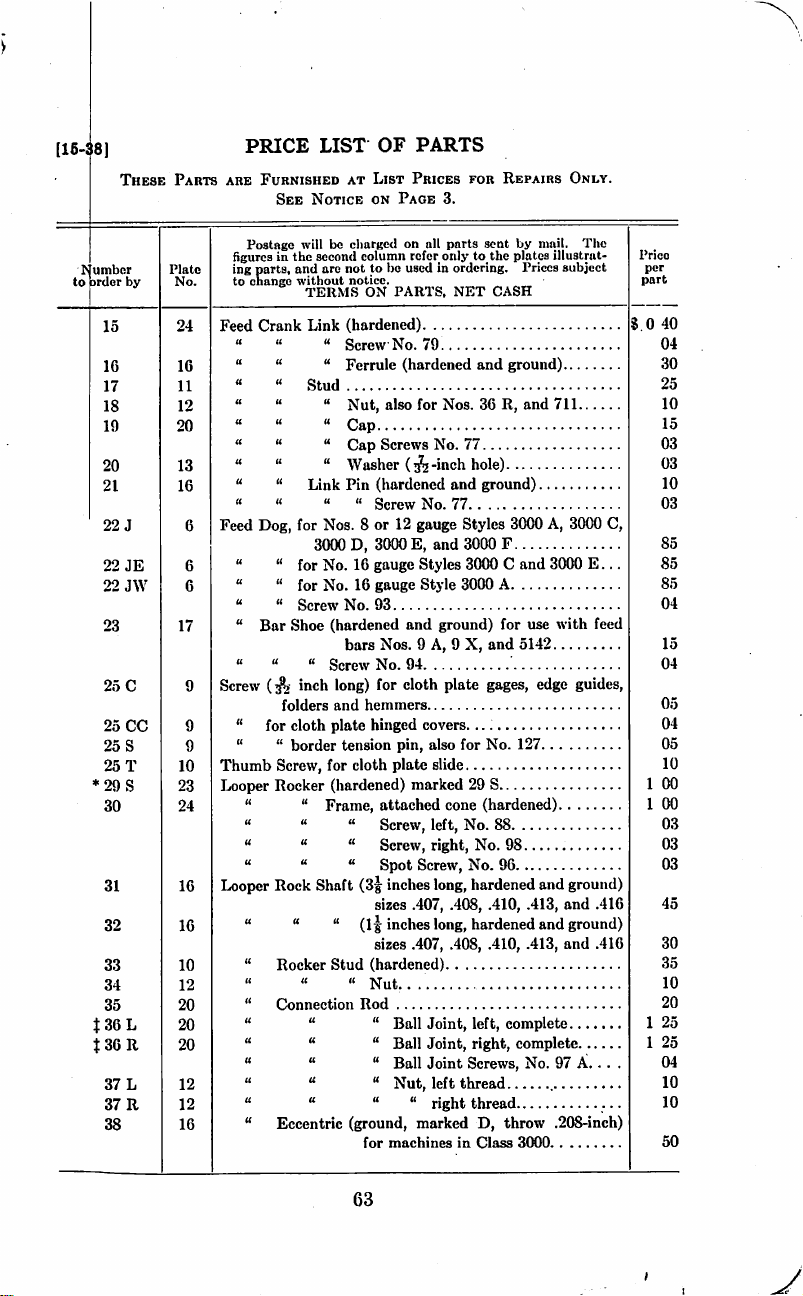

PRICE

BED

3000,

MACHINES

5000

with

ILLUSTRATIONS

and

LIST

REPAIRS

CATALOG

OF

PARTS

ONLY

No.

37

and

5100

FOR

NEW

COHOES.

UNION

YORK

ST.

LOUIS

N.

Y.

SPECIAL

CHICAGO,

BRANCH

PHILADELPHIA

ROCHESTER.

MINNEAPOLIS

TORONTO

MACHINE

ILLINOIS

OFFICES:

JOHNSON

N,

Y.

UTICA.

BOSTON

CITY.

N.

Y.

MONTREAL

COMPANY

N.Y.

AMSTERDAM,

SAN

FRANCISCO

CINCINNATI

N.Y

Union

Copyrighted

Special

Machine

Chicago,

1916

Company

Illinois

at

The

list

IMPORTANT

CUSTOMERS

parts

listed

prices

for

NOTICE

in

this

catalog

repairs

only.

TO

are

furnished

Attention

many

or

enter

that

in

we

only

machines

condition.

Notice

such

parts

of

for

to

another,

repair

which

prosecution.

is

of

said

into

furnishing

license

of

our

is

by

changing

or

purposes,

the

seller

hereby

parts

are

patented

those

their

own

hereby

the

given

purchaser,

over

machines

for

any

is

or

user

called

to

the

subjects

of

combinations,

parts

at

list

use

for

make,

in

their

that

or

the

the

from

other

than

an

infringement,

will

be

fact

that

patents,

and

prices

repairing

original

sale

of

use

there

one

style

bona fide

for

liable

to

The

3000,

matter

5000

and

of

this

5100,

CONTENTS

catalog

and

cannot

relates

only

be

applied

to

machines

to

machines

in

Classes

in

other

classes.

name

a

separate

Important

IllvLstration

Description

Installation

Thread

Operating

Oiling

Oiling

Threading

Threading

Adjustment,

Adjustment

Making

Needles

Needle

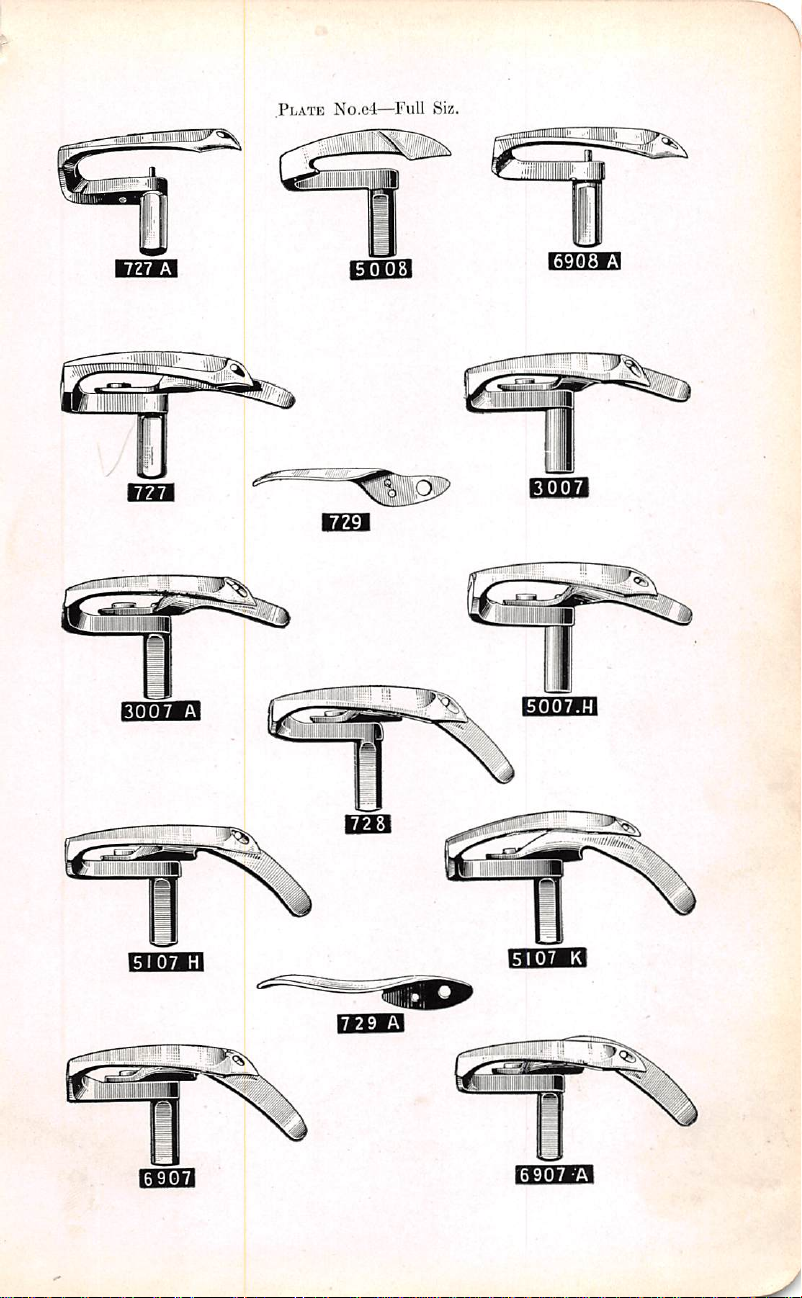

Illustrations

Plates

Price

The

plate

on

catalog.

Notice

of

of

Stands

Diagram,

Diagram,

Diagram,

Diagram,

Introductory

Repairs

Prices

and

List

of

Parts

class

the

Machine

Machines

number

machine.

to

Customers

Class

3000

Class

5100

Class

Class

Price

List

can

Power

Showing

3000

5100

of

Parts,

be

ascertained

transmitter

Installation

Explanation

by

reference

parts

are

of

to

listed

Page

;

the

in

3

5

6-7

8

11

12

13

14

15

16

21

22

30

32

32

33

34

62

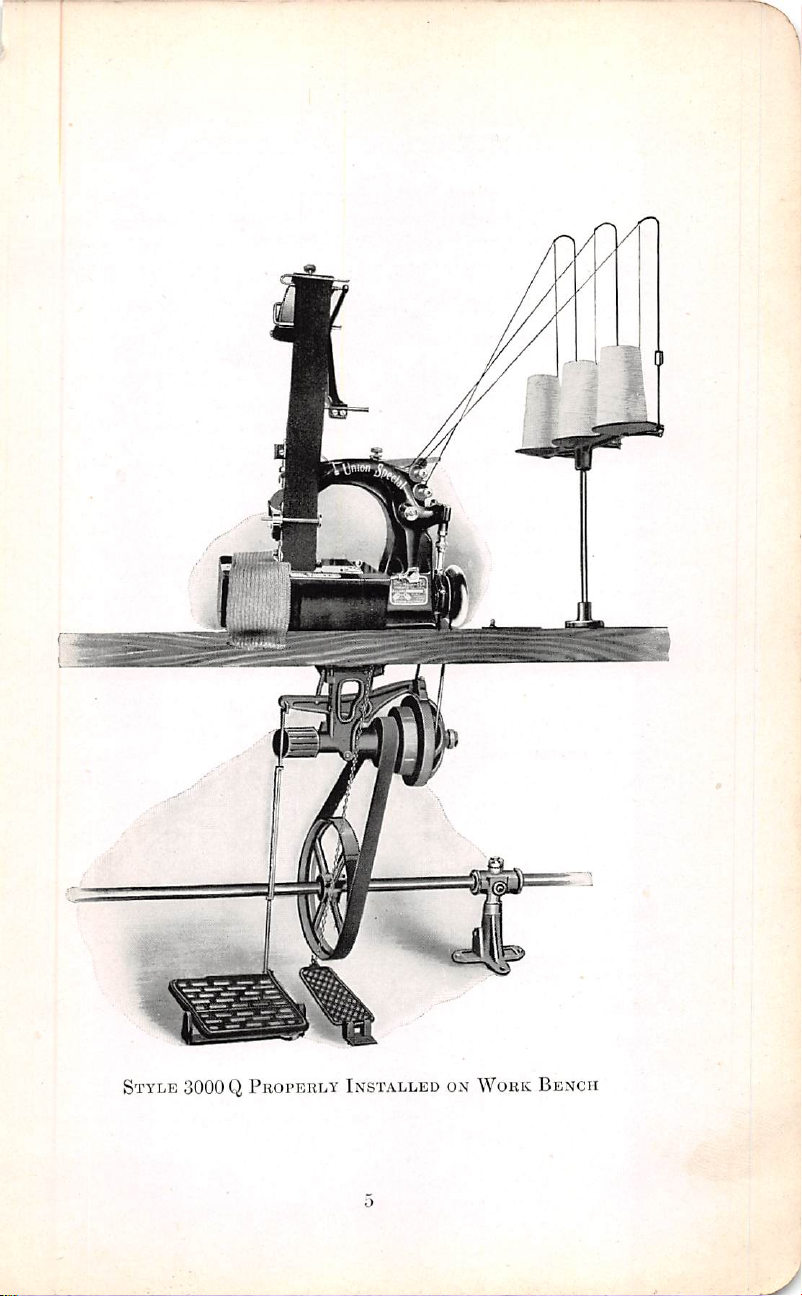

Style

3000 Q Properly

Installed

on

Work

Bench

Our

machines

the

trade-mark

Styles

which

in

the

catalog.

The

Gauge

The

spacing

Gauge

8

12

DESCRIPTION

are

separated

plate

attached

are

indicated

It

Number

of

No

by a letter

designates

represents

gauges

into

to

each

a

machine

the

Nos. 8 to

Space

K-inch

^f-inch

OF

Classes,

used

20,

the

machine.

having

space

inclusive,

The

with

the

certain

between

Gauge

10

20

MACHINES

number

of

which

Classes

Class

number

fittings

for a particular

needles.

is

as

follows:

No.

are

divided

and

will

be

found

into

is

referred

operation.

Space

]4-mch

^-inch

upon

different

to

only

Machines

otherwise

Small

Style

3000 A For

3000 C For

3000

3000

3000

3000

3000 P For

specified.

Arm

ornamental

seam

(specify

D—For

seam

sides

E—For

sewing

F—For

of

M—For

feed

tandem

collarette).

hemming

machine).

sewing

seaming

in

Class

5100

STYLES

Flat

OF

Bed

Needle

stitching,

covering,

gauge

of

covering,

(specify

gauge

lace

edging

bedspreads;

lace

edging

(specify

gauge

collarettes

differential

are

spaced

MACHINES

Two.

Needle

Stitch,

knitted

knitted

goods,

machine).

knitted

goods,

of

machine).

to

knitted

presser

to

knitted

of

machine).

to

knitted

feed

(specify

No.

16

gauge

between

IN

CLASS

Machines,

Short

underwear,

etc.;

etc.;

underwear,

foot

Needles

etc.

(specify

presser

foot

presser

foot

etc.

(specify

with

hinged flat

underwear,

undershirts

gauge

etc.;

of

machine

and

outside

needles

3000

One

Looper,

gauge

of

machine).

with

hinged

grooved

with

independently

gauge

of

machine).

bottom

(specify

with

tandem

other

and finished

differential

garments;

width

unless

Twin

bottom

yielding

gauge

with

of

3000

Q—For

foot,

border).

3000

Z—Special'.

seaming a tubular

no

folding

knitted

border

attachment

(specify

to

sweaters,

gauge

of

machine

etc.;

border

ne.\t

and

submit

to

presser

roli

of

STYLES

Flat

Style

5000

A—For finishing

differential

Bed

OF

MACHINES

Double

cut

feed

Interlock

edges,

(specify

Machines,

knitted

underwear,

gauge

of

machine).

IN

CLASS

Short

etc.;

solid

5000

Needles

presser

foot,

tandem

5000 C For

5000 G For finishing

5000

5000

5000

Style

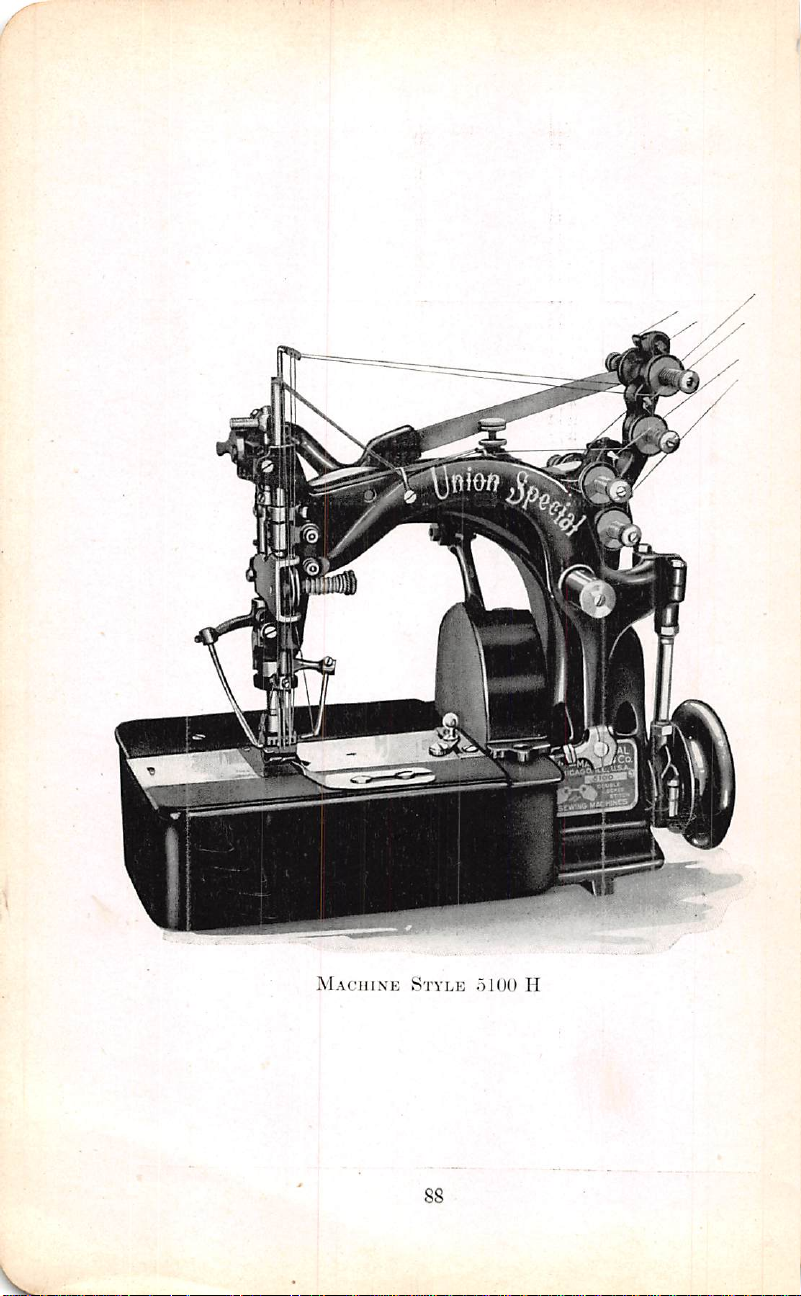

5100

5100

seaming

yielding

knitted

sides,

cut

yielding

sides,

L—For

seaming

differential

M—For

looper

Z—Special.

Flat

E—For

seaming

bottom,

F—For finishing

yielding

collarettes

feed

sewing

lace

thread

STYLES

Bed

Triple

knitted

tandem

cut

sides,

tandem

tandem

edging

(specify

edges,

tandem

underwear,

differential

edges,

knitted

differential

to

knitted

(specify

to

gauge

OF

MACHINES

gauge

knitted

Interlock

underwear,

differential

feed.

knitted

differential

etc.;

lap

seam,

feed

(specify

underwear,

undershirts

of

etc.;

feed

(specify

and

machine

and finished

undenvear,

of

machine).

IN

CLASS

Machines,

etc.;

lap

seam;

presser

underwear,

etc.;

feed.

presser

foot

gaugv

of

machine).

presser

foot

gauge

of

machine)

other

garments;

width

etc.;

four

thread

5100

Short

Needles

foot

with

presser

foot

with

independently

with

independently

with

tandem

of

collarette).

interlock,

hinged

grooved

with

independently

no

5100

G—For

5100

H—For

5100

5100

seaming

yielding

seaming

(specify

J—For

seaming

folding

Z—Special.

knitted

underwear,

sides,

tandem

ribbed

knitted

gauge

of

machine).

short

collarettes

attachment.

etc.,

lap

differential

cuffs

to

sleeves,

to

knitted

feed.

undershirts

seam;

presser

etc.;

foot

with

auxiliary

and

other

with

independently

differential

garments;

feed

without

INSTALLATION

c •

ScWtng

Special

tration,

transmitter,

Tables

to

accommodate

thoroughly

should

should

height

suited

„

Speed

tion

on

■■

A/l

MactllTlC

Alachines

page

o,

gives a good

and

foot

Any

sewing

used.

another

seasoned

be

made,

re-enforced

be

free

from

of

twenty-nine

for

operators

j The

pages 6 and

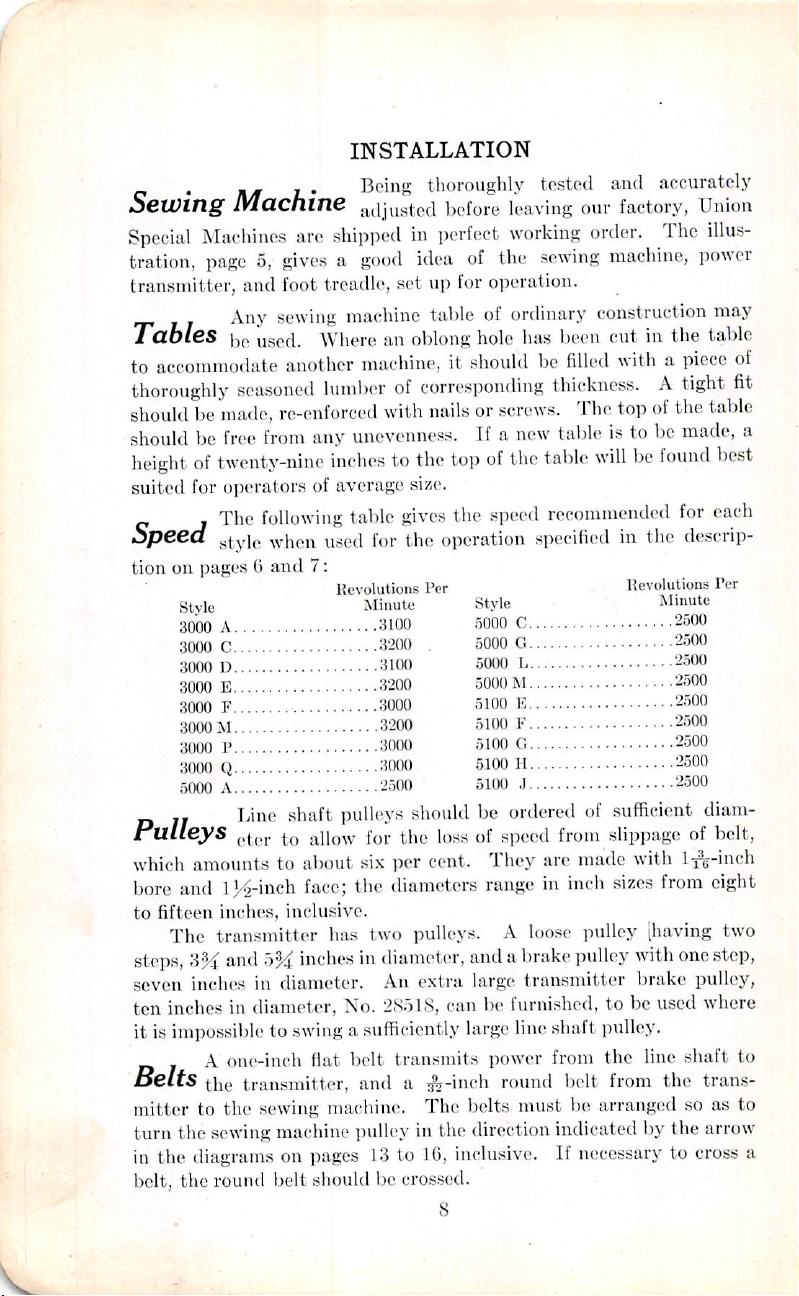

Style

3000

3000

3000

3000

3000

3000

3000

3000

5000

following

gtyle

when

A

C

D

E

r

M

P

Q

A

Line

shaft

PulleyS

which

bore

to

steps,

seven

ten

it

„

Belts

mitter

turn

in

amounts

and

fifteen

The

transmitter

8^

inches

inches

is

impossibh;

to

I>^-inch

inches,

and

in

in

diameter,

to

- A one-inch

the

transmitter,

to

the

sewing

the

the

diagrams

belt,

the

sewing

round

machine

belt

inclusive.

diameter.

on

W

are

swing a sufficiently

Being

adjusted

shipped

in

idea

treadle,

set

machine

Where

an

oldong

machine,

lumber

of

with

any

unevenness.

inches

of

used

7:

allow

about

face;

has

inches

fiat

to

the

average

table

Revolutions

pulleys

No.

size.

gives

for

the

iNIinute

3100

3200 . 5000

3100

3200

3000

3200

3000

3000

2500

should

for

the

six

per

the

diameters

two

pulleys. A loose

in

diameter,

An

extra

2S.")18,

belt

transmits

and a ^^-inch

machine.

pulley

jiages

should

in

13

to

bo

crossctd.

thoroughly

before

perfect

up

talkie

it

leaving

working

of

the

for

operation.

of

ordinary

hole

has

should

corresponding

nails

or

screws.

If a new

top

of

the

the

speed

ojieration

Per

Style

5000

C

G

5000

L

5000

M

5100

E

5100

F

5100

G

5100

II

5100

J

be

loss

cent.

can

The

the

16,

ordered

of

speed

They

range

and a brake

large

transmitter

be

furnished,

large

line

power

round

belts

must

direction

inclusive.

tested

sewing

be

thickness.

table

recommended

specified

are

in

shaft

from

and

our

order.

accurately

factory,

The

machine,

construction

been

cut

in

the

filled

with a piece

A

tight

Tiie

top

of

the

table

is

to

be

made,

will

be

found

for

in

tiie

descrip

Revolutions

Minute

2500

2500

2500

2500

2500

2500

2500

2500

2500

of

sufficient

from

slippage

made

with

l-j^-inch

inch

sizes

from

pulley

pulley

belt

be

indicated

If

necessary

[having

with

one

brake

to

be

used

pulley.

the

line

the

by

the

to

shaft

so

from

arranged

Union

illus

power

may

table

table

best

each

Per

diam-

of

bolt,

eight

two

step,

pulley,

where

trans

as

arrow

cross

of

fit

a

to

to

a

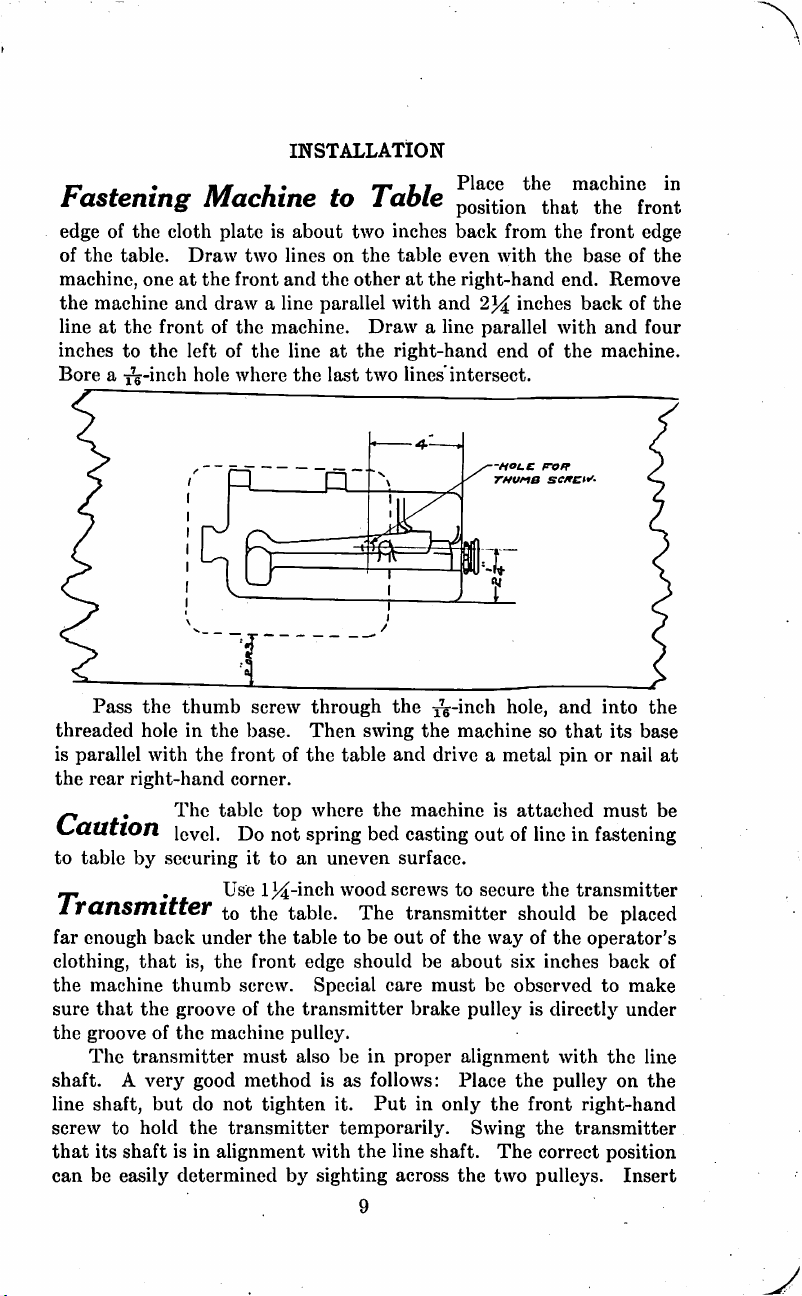

Fastening

edge

of

the

of

the

table.

machine,

the

line

inches

Bore a j^-inch

threaded

is

parallel

the

^

^ClUttOn

to

table

„

I

TansmitteiT

far

clothing,

the

sure

the

shaft. A very

line

screw

that

can

one

machine

at

the

to

Pass

the

hole

rear

right-hand

. The

by

enough

that

machine

that

the

groove

The

transmitter

shaft,

to

hold

its

shaft

be

easily

Machine

cloth

Draw

at

the

and

front

the

left

hole

thumb

in

with

the

level.

securing

,

back

under

is,

thumb

groove

of

the

good

but

do

the

is

in

determined

INSTALLATION

plate

is

about

two

lines

front

and

draw a line

of

the

machine.

of

the

line

where

the

PL

r\-

screw

through

the

base.

front

corner.

table

Do

it

Use

the

screw.

of

machine

must

method

not

transmitter

alignment

Then

of

the

top

where

not

spring

to

an

134-inch

the

table.

the

table

front

edge

the

transmitter

pulley.

also

tighten

with

by

to

Table

two

inches

on

the

table

the

other

at

parallel

at

last

with

Draw a line

the

right-hand

two

lines

jPL

the

swing

the

table

and

the

machine

bed

casting

uneven

Special

is

it.

sighting

surface.

wood

screws

The

transmitter

to

be

out

should

care

brake

be

in

proper

as

follows;

Put

in

temporarily.

the

line

across

9

Place

position

back

even

the

right-hand

and

the

from

with

2)4,

inches

parallel

end

of

intersect.

—Houc

TRUMB

^-inch

hole,

machine

drive a metal

is

attached

out

of

line

to

secure

should

of

the

way

of

be

about

six

must

be

observed

pulley

alignment

Place

only

shaft.

the

the

the

Swing

The

two

is

front

the

pulleys.

machine

that

the

front

the

front

the

base

of

end.

Remove

back

of

with

and

the

machine.

roR

SCRCf-

and

into

so

that

its

pin

or

nail

must

in

fastening

the

transmitter

be

placed

the

operator's

inches

correct

back

to

make

directlj*^

with

pulley

under

the

on

right-hand

transmitter

position

Insert

in

edge

the

the

four

the

base

at

be

of

line

the

a

second

transmitter

shaft,

front

securely.

line

the flat

Drive

so

that

into

of

the

by

alignment.

upon

of

the

hand

some

with

between

table.

and

secured

screw

of

might

Tighten

pointed

of

meet

tained

it

to

of

used

exceed

adjustment

table

protection

under

from

screw

frame

by

loosening

one,

use

Measure

shaft

pulley

belt

by a malleable

the

lacing

the

ends

the

opposite

pulley

hand

to

and

note

To

the

pulleys

transmitter

rear

screw

instances,

the

underside

either

Being

the

sewing

to

the

has

been

the

transmitter,

have a tendency

the

line

To

locate

rod

can

the

machine

the

groove

drive

the

act

as a guide

the

hole

through

for

the

34

inch.

can

A

guard

is

in

front

for

The

transmitter

the

needles.

the

front

diagonally

slightly

the

rear

wrench,

the

length

and

the

into

one

meet

on

end.

See

that

the

if

the

belt

direct

the

and

to

with

and

slightly

owing

the

now

to

of

the

right

placed

machine,

table

by

inserting

removed

it

should

shaft

pulley

the

holes

be

used

to

pulley

in

at

the

transmitter

point

of

in

the

the

same

purpose.

If

the

holes

be

obtained

provided

of

the

transmitter.

the

operator

treadle

The

edge

of

INSTALLATION

opposite

out

belt

No.

213SS

transmitter

iron

end

of

the

transmitter

that

teeth

runs

belt

compensate

respect

the

line

table,

or

left

in

proper

the

for

the

to

draw

.securely

in

the

advantage

the

the

rod

drilling

table. A carpenter's

are

for

to

be

from

should

front

the

table,

the

one

of

the

vertical

adjusting

B,

and

of flat

belt

pulley.

belt

lacing

the

belt,

placing

pulley,

the

lacing

are

well

clinched.

true;

this

to

operate

to

turn

shaft

it

will

end

in

for

any

the

line

the

transmitter

not

be

of

the

relation

transmitter

screws

be

table

proper

brake

of

The

the

fastened

the

edge

in

purpose

the

last

the

transmitter

to

the

for

by

placing

angle,

pulley.

into

the

the

hole

diameter

slightly

10

elongated, a wider

transmitter

to

the

Its

use

rapidly

be

so

set

should

but

this

already

and

screw

tighten

required

Join

provided

it

then

conforms

is

the

the

slight

shaft,

being

necessary

transmitter

with

should

the

remaining

of

correcting

one

replaced,

.shaft.

the

round

said

which

When

bench

to

secure

bevel

of

the

to

under

is

quite

moving

that

be

about

distance

in.

Swing

toward

and

tightening

the

front

to

go

around

the

two

for

that

over

the

two

drive

the

to

the

curvature

Turn

the

best

test

center

of

error

in

the

alignment

remove

as

required.

in

proper

alignment

to

insert a shim

frame

both

the

be

permanently

holes.

the

otherwise

out

of

alignment.

belt, a 34-inch

rod

in

the

would

only

if

the

angle

enough

the

proper

square

holes

should

take

up

the

side

of

imperative

belts.

its

center

is

one

may

the

the

line

the

screw

the

ends

of

purpose.

pulleys

lacing

pulleys

of

proper

crown

the

left-

In

and

the

line

shaft

If

a

position

it

groove

projected

is

ascer

to

hold

angle

may

be

not

range

of

belt.

the

work

as

a

directly

inch

back

be

varied

INSTALLATION

according

treadle

pitman

and

suit

vertical

to

rest

rod

may

be

the

operator's

jiosition.

j „

i

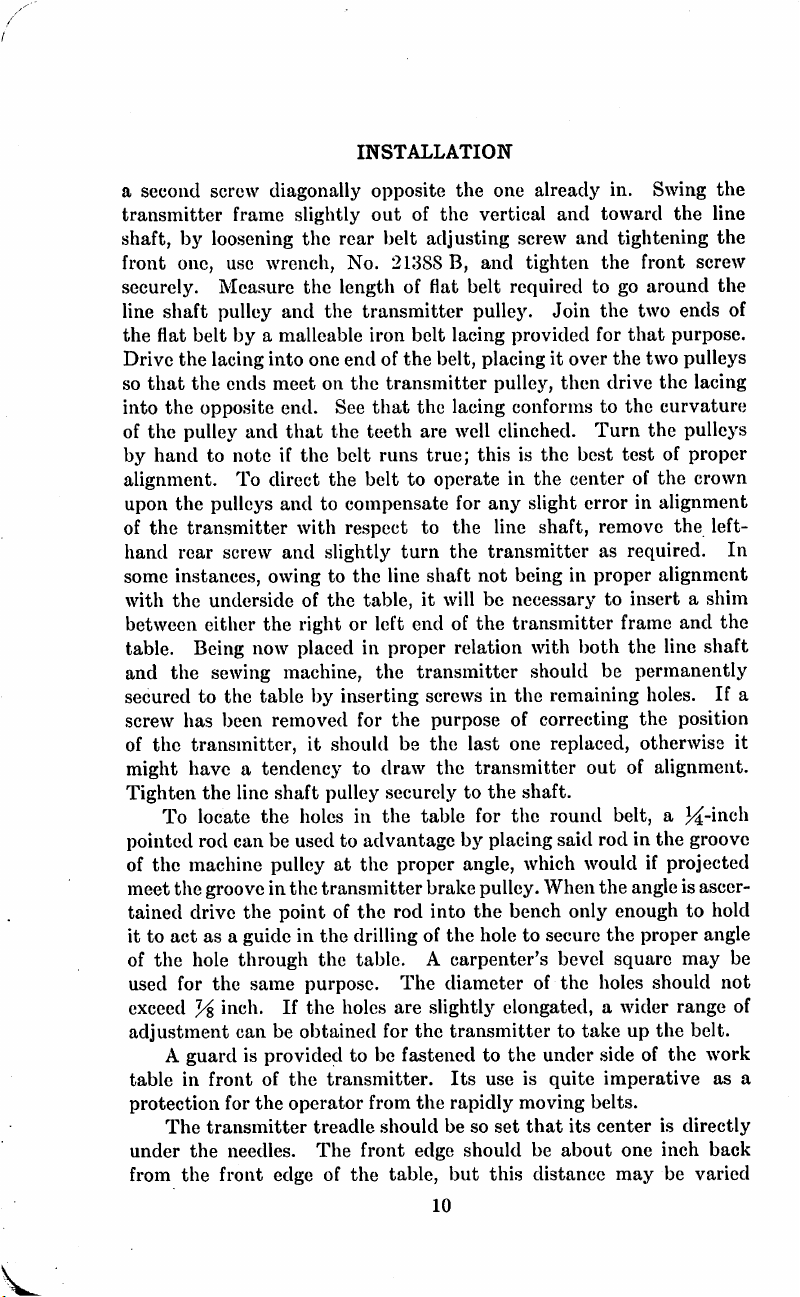

hrecid

One

of

those

machines.

distance

to

the

operation

should

should

adjusted

be

be

convenience;

j

otands

styles

of

It

should

the

be

right.

for

which

set

with

the

attached

in

length

Tiie

styles

suitai)le

]ilaccd

to

so

it

accompanying

of

thread

units

back

the

machine

enclosed

the

riglit-hand

that

the

incline

need

not

stands

is

furnished

of

the

machii\e

is

to

be

used.

The

end

to

the

right.

side

of

the

of

the

treadle

necessarily

illustrations

set

up

with

pulley

siiow

ready

each

and a short

treadle,

iiang

in

for

of

these

Tlie

will

a

two

use.

.

root

No.

sewing

LilttBT

422,

connected

machine.

right-hand

the

right

of

This

pj-csser

by a chain

The

corner

of

the

transmitter

is a device

foot.

with a lever

hole

for

the

the

machine.

treadle.

sometimes

It

consists

chain

should

The

treadle

furnished

for

of a small

attached

to

be

bored

should

the

raising

foot

treadle,

rear

near

the

be

placed

of

the

the

rear

to

Simplicity

of

machinery,

Obviously,

threading

In

opportunity

they

practice

and

oiling

OPERATING

isolated

will

the

factories

readily

increase

machine,

to

observe

adapt

the

and

where

operators

the

working

themselves

proficiency

in

handling

to

of

the

have

of

Union

the

operator

work.

but

scant

any

kind

Specials.

in

_

To

Set

point

about

the

shank

Insert

with

the

line

with

with

the

\Jtling

The

so-called

machines,

r at

the

3^

to

the

the

needles

long

grooves

the

direction

screw

driver

Sewing

Qf

qJj

"stainless"

as

they

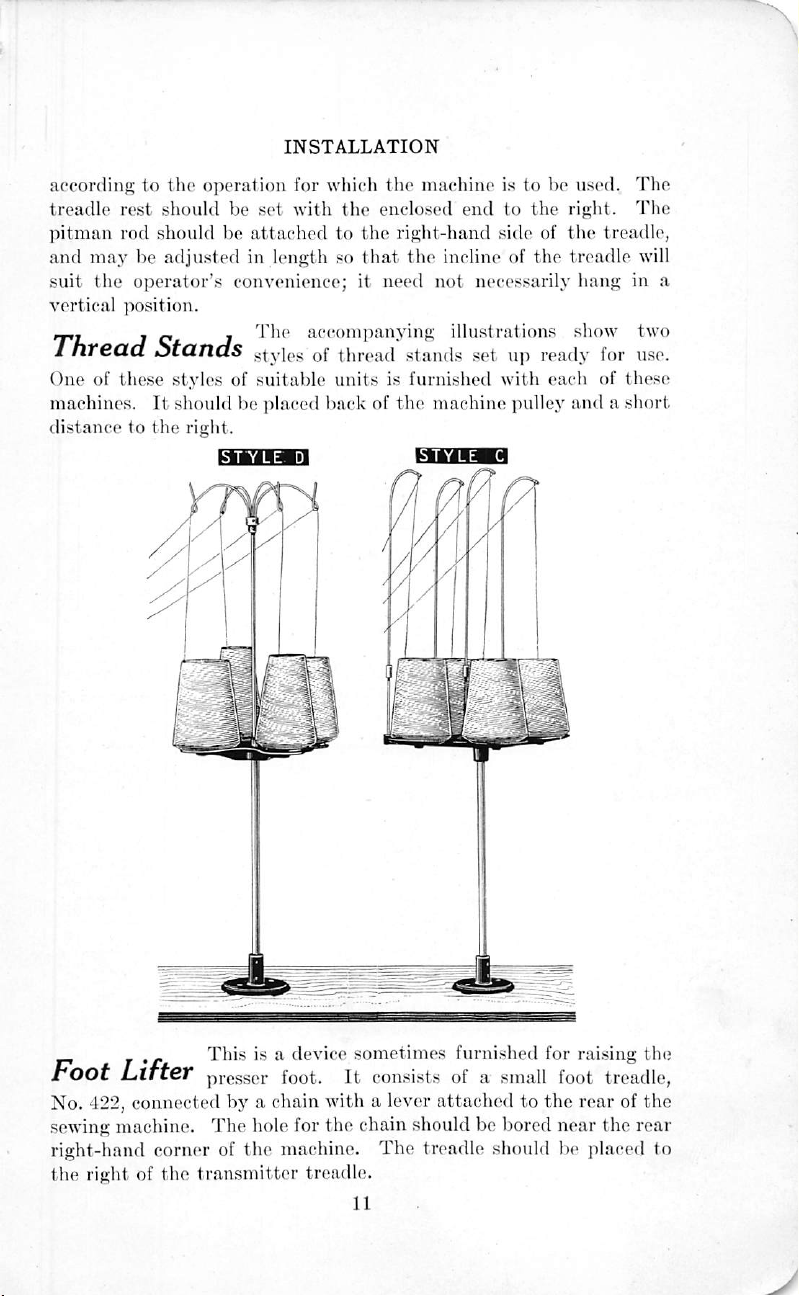

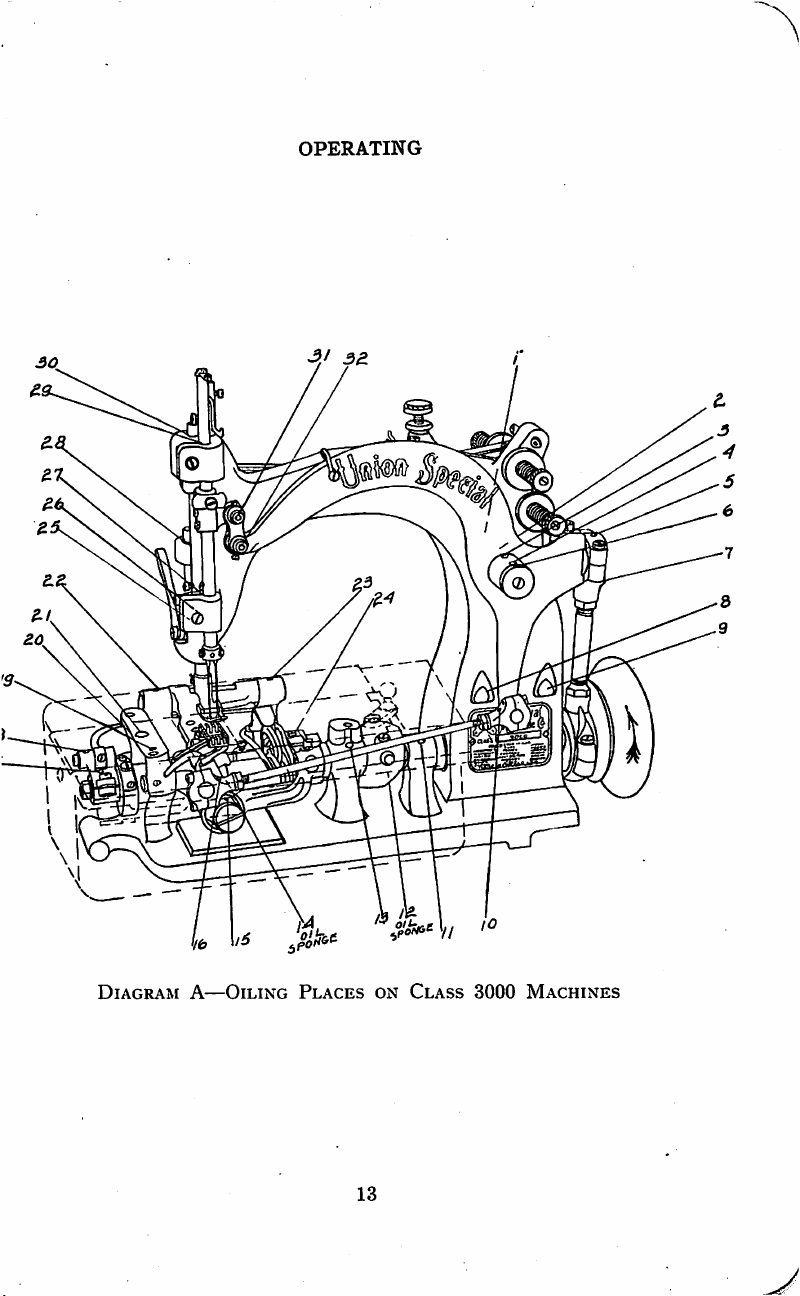

Diagram A shows

3000

D,

3000 E and

3000

M,

3000 P and

anism.

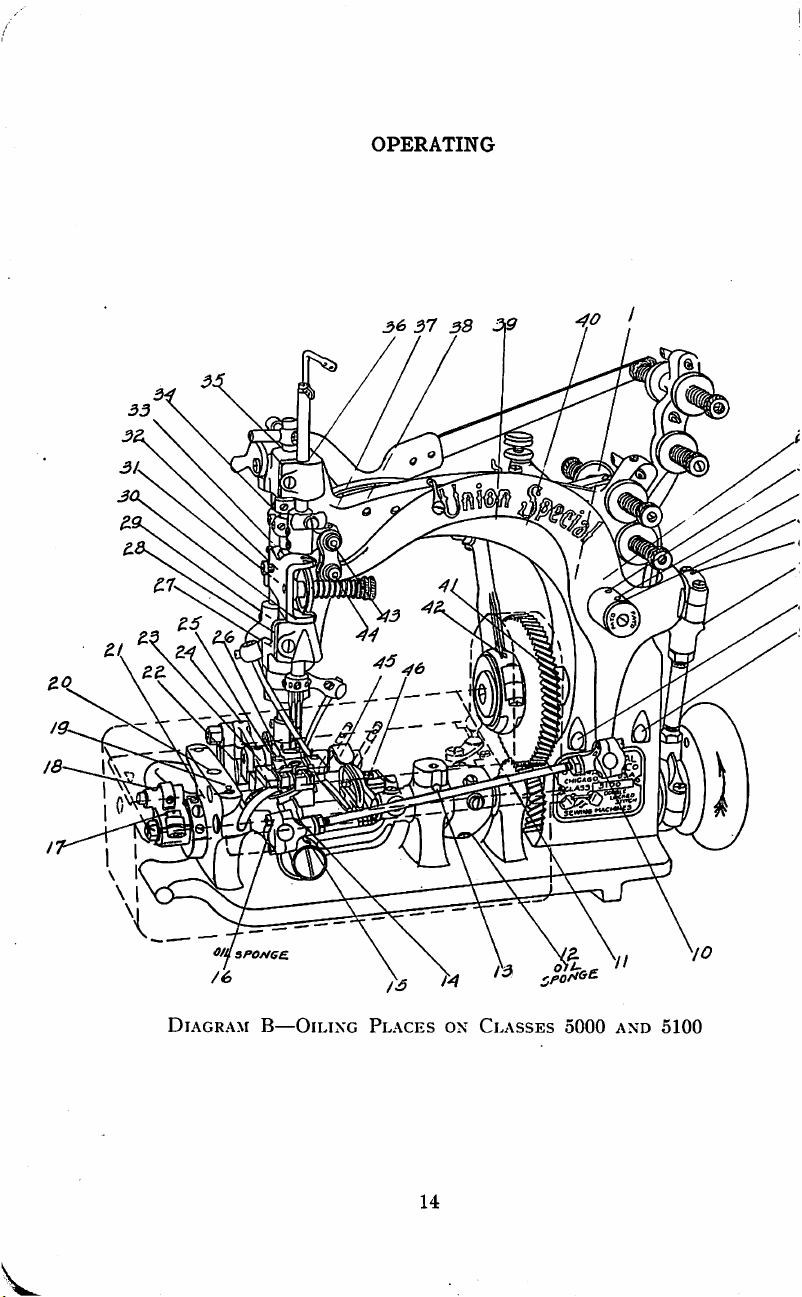

Diagram B shows

It

is

very

working

having

spout.

the

quantity

possibility

is

oiling

hollow

screwed

pression

be

part

contacts

The

left

end

ball

valves.

The

lower,

right-hand

When

Frequent

recommended

four

The

main

required

end

of

oil

should

systematically

of

missing

oiling

times a day.

power

shaft

up

about

cup

should

oftener

JI

Needles

inch

above

eye.

in

furnished

machines

do

not

3000

3000 Q will

the

plain

that

of

the

These

bearing

of

the

be

any

is

that

the

transmitter

from a single

once a week.

be

than

groove

the

eye

as

far

up

front,

so

of

the

stitching.

for

require

not

gum

oils

are

have

sufficient

the

oiling

F.

oiling

lubricant

with

another.

needle

are

oiled

of

the

machine

inserted

performed,

place,

necessary,

sewing

is

lubricated

screwed

once

in

needles

and a long

into

that

that

not

places

The

be

readily

places

lever

by

sectional

is

therein

and

in a surprisingly

as

machine

compression

If

up

several

12

have

two

extending

the

the

purpose.

careful

by

friction-heat

recommended

viscosity

on

few

on

should

is fitted

pressing

from

groove

needle

eyes

of

Then

tighten

oiling

to

Styles

additional

found

Classes

be

with

the

needle

oiled

through

through

oiling

lint

the

can

quickly

head

with

solid

cup

bearings

immediately.

months.

grooves: A short

the

shank

extending

bar

as

they

will

the

needles

with a good

or

for

serve

3000

places

in

the

5000

used

hollow

ball

lever

the

the

valve

be

short

absorbs

be

given a thorough

oil

which

run

Refilling

will

the

set

quality

air-exposure.

our

high

the

purpose.

A,

3000

on

feeding

and

5100.

wherever

link

with

the

oil-can

connection

tube. A liberal

opening.

done

without

time.

the

oil.

through

should

hot,

the

will

to

a

from

go,

be

in

screw

speed

C,

Styles

mech

one

pins

on

It

the

be

com

not

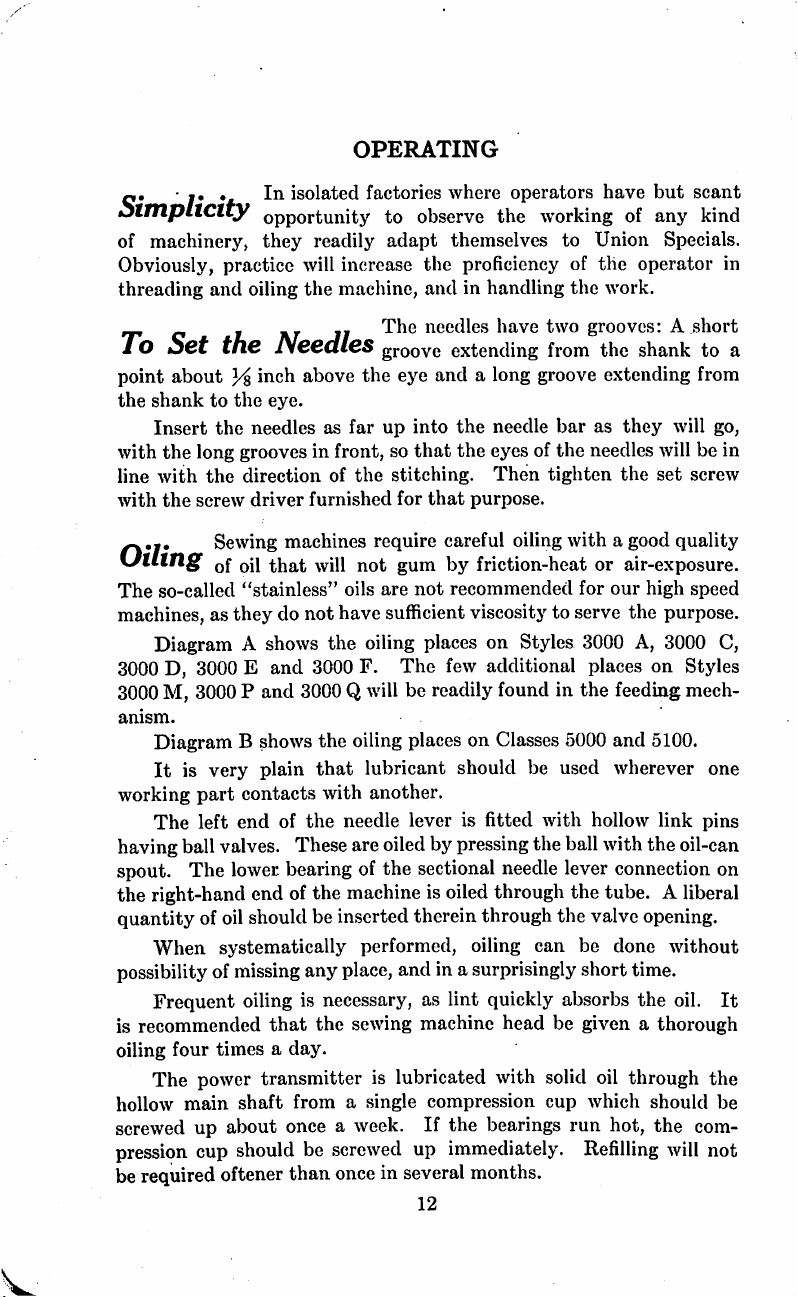

OPERATING

30

2d

Diagram

A—Oiling

Places

13

on

Class

3000

Machines

OPERATING

36

37

38

39

/3

Diagram

B—Oiling

Places

14

on

Classes

5000

and

5100

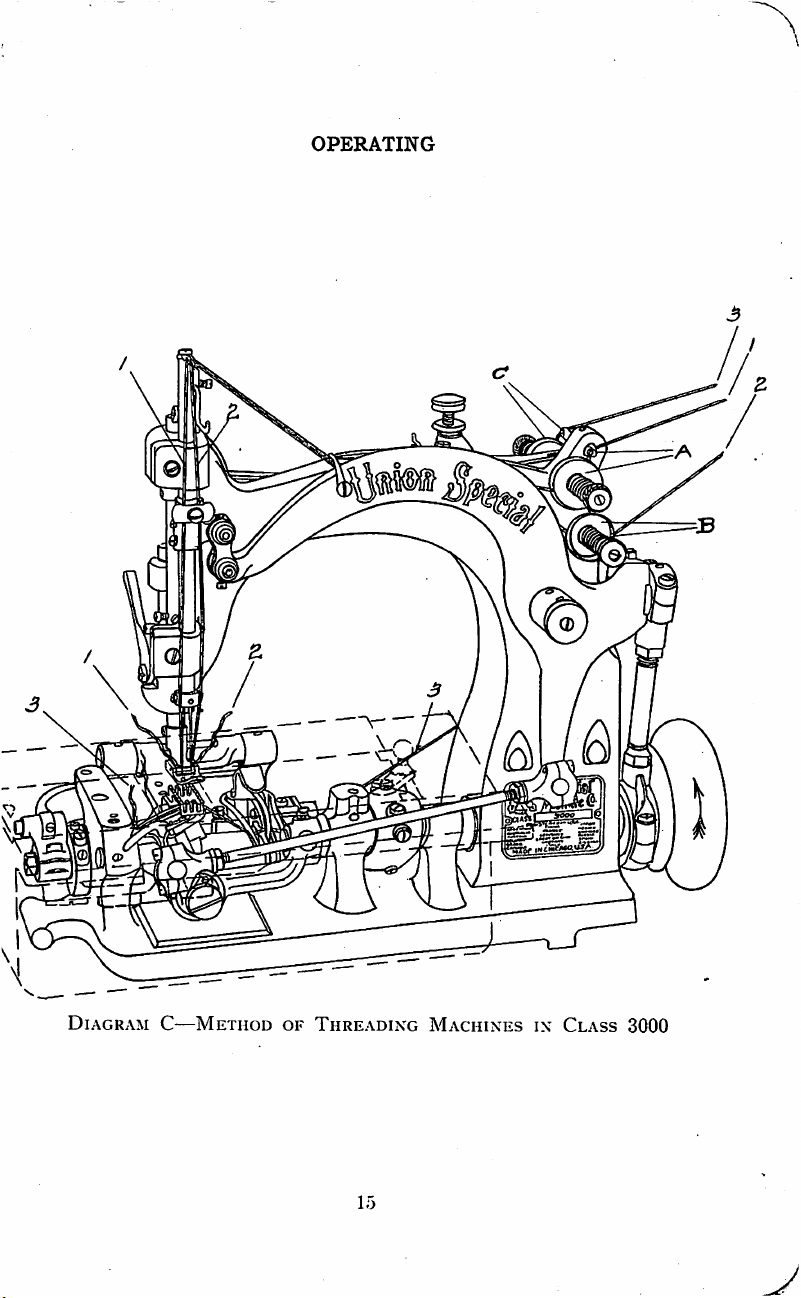

OPERATING

a

Diagram

C—Method

of

Threading

15

Machines

in

Class

3000

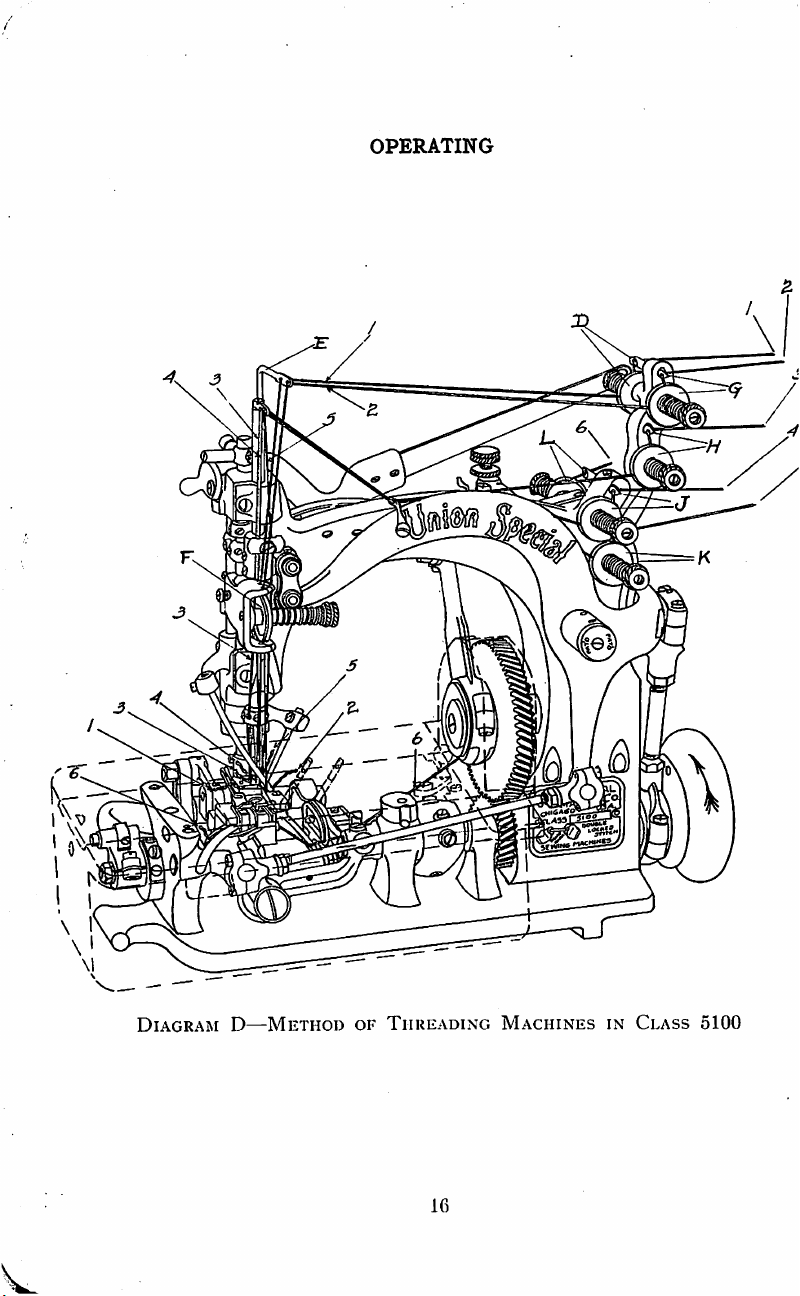

OPERATING

a

Diagram

D—Method

of

Threading

16

Machines

in

Class

5100

OPERATING

Cl&anina

constant

operator

wear

Twice a week

given a thorough

oil

holes,

T

lo

the

pulley

lowest

to

the

pulley

hinged

can

now

toward

Thrt>nrl'

o

accumulation

to

keep

in

the

bearings.

feed

dog

D

Remove

in

position.

base.

until

the fingers

cover

can

be

removed

the

operator.

o

box. A thread

thread

opening

thread

the

raised

neither

through

but

the

from

shows

shows

of

5100

The

through

following

without

is

under

in

from

opening.

for

be

the

under

post.

The

illustrations

the

the

the

threading

with

threads

the

the

Turning

guided

from

the

the

the

convenience

twisted

tension

no

spools

method

method

machines

the

are

proper

this

method

necessity

to

every

accumulated

the

the

cleaning.

slots

M.1

the

the

operative

Remove

If

the

oiling

lint

of

lint

machine

cloth

plate

Lint

and

looper

.r

Cloth

the

machine

have

be

raised.

by

passing

method

noted

when

hook.

No.

118,

cloth

plate.

cloth

plate

at

stationary

The

front

nor

discs

circumstances

pages

and

of

of

threading

elimination

numbered

eyelet

end

in

threading

cross

each

so

that

should

15

passed

through

threading

in

Class

of

to

tensions,

the

machine

of

changing

Diagram C it

the

thread

will

stand

operation

should

and

as

clean

should

and

be

dirt

as

be

dirt

grooves

ni

.

Plate

direction

three

is

fitted

passed

Raise

it

of

the

machine

is

Insert

the

in

of

the

other.

it

and

16,

Remove

blunting

until

screws

with

to a point

the

presser

slightly

threading

furnished

the

right

of

the

rear

take-up

its

Each

is

drawn

it

be

show

the

machines

machines

5000

thread

enable

thread

be

to

17

is

the

marked

eyes,

may

the

tensions.

noted

the

in

in

the

be

eye

the

overflowed

carefully

makes

possible,

removed

should

with a pin

the

which

■wiped

it

necessary

in

order

and

be

removed

or

the

needles

their

needle

hold

thread fingers,

where

foot.

to

the

left

should

is

taken

from

for

drawing

thread

the

eyes.

guided

how

thread

Class

Class

same

needles

rethreaded

that

of

hook

needles

of

the

frame

thread

The

thread

against

the

completely

the

threads

wires.

3000.

5100.

as

for

No. 3 in

operator

and

thread

eyelet

marked

oil

up.

to

the

machine

from

needle.

to

points.

bar

is

the

cloth

turn

the

cloth

The

cloth

and

drawing

be

carefully

the

shipping

the

through

and

draw

up

through

eyelet

threads

must

be

tension

are

Diagram

Diagram

The

method

those

in

the

diagram.

to

pass

loopers.

at

any

marked

A,

and

the

The

for

the

prevent

the

avoid

Turn

at

its

plate

the

plate

plate

it

looper

the

the

can

be

should

passed

post,

around

taken

C

D

Class

them

By

time

No.

1

then

OPERATING

between

through

of

the

eye

.stand

the

the

front

to

Thread

marked

tension

machine

of

the

the

threading

raise

and

left-hand

the

upper

tion

looper

is

guided

the

the

let

tension

through

guided

tween

through

of

marked

hole

thread

around

eyelet

the

the

the

needle

needle

of

under

top

the

bar

the

left-hand

to

the

side

of

eye

of

right

No. 3 is

C,

marked

at

the

take-up

Thread

looper

cloth

thread

plate

the

the

take-up

pass

the

eye,

right

hand

nipper

the

thread

can

now

Turning

from

discs

and

back

eye

hole

of

the

marked

the

from

the

discs

the

tension

F,

through

of

the

left-hand

stand

the

on

the

the

then

bracket,

discs

and

around

adjustable

lever

nipper

eyelet

eyelet,

plate

needle.

eyelet

the

of

marked

of

tension

frame,

needle

its

screw,

guided

marked

the

bar

and

from

between

C,

through

the

rear,

between

thread

hook

take-up

thread

hold

spring;

to

Diagram D it

the

around

of

tension

hole

the

front

to

under

top

eyelet

No.

11

from

the

to

the

right

thread

thread

through

the

end

place

the

by

should

be

thread

F,

thread

the

be

threaded.

thread

the

guide

bracket,

through

of

right-hand

stand

and

around

eye

of

between

the

lower

finger.

eye

side

of

of

frame,

<S

eyelet

dropping

stand

under

thread

of

the

on

the

the

back

eye

to

the

Thread

B,

then

B,

front

eye

eyelet,

under

through

the

thread

the

discs

and

the

vertical

the

thread

and

then

will

be

found

vertical

of

the

eyelet

to

the

the

right-hand

of

the

thread

thread

underneath

the

carried

between

will

be

to

the

side

marked

then

the

lower

finger.

to

the

the

under

guide

the

discs

hole

of

Thread

eyelet

tension

the

marked

marked

rear

18

under

side

top

of

the

of

the

left

of

its

No. 2 is

between

through

of

the

the

needle

the

the

eye

of

stand

around

eyelet

nippers,

through

of

great

eyelet

up

needles.

is

as

follows:

under

with

take-up

the

noted

that

eye

of

eyelet

of

the

tension

E,

down

between

holes

Thread

eye

of

eyelet

side

marked

and

to

tension

marked

eye

bracket

No. 3 is

H,

H,

of

of

tension

frame,

needle

bar

screw

and

guided

from

the

discs,

adjustable

lever

needle

through

bar

the

right-hand

to

the

the

under

in

the

through

the

looper.

assistance

the

An

excellent

with

side

of

the

eye,

then

the

left

hand

the

hooked

thread

the

of

eyelet

nipper

thread

marked

marked

to

the

rear

discs

tension

marked

marked

of

tension

E,

through

the

front

and

guided

between

through

the

the

needle

marked

the

back

eyelet,

under

through

the

thread

and

around

eyelet

eyelet,

nipper

plate

needle.

eye

of

eyelet

side

of

base

of

both

eyes

in

drawing

opening

plan

one

finger

cloth

plate,

through

and

with

end

of

into

posi

springs.

marked

to

No.

D,

between

D,

through

upper

eye

the

rear

bracket

No. 2 is

G,

then

marked

front

of

tension

through

from

the

discs,

adjustable

lever

eyelet,

A,

eye

the

on

the

the

the

in

for

the

the

The

1

of

and

be

G.

hole

the

the

and

the

rear

eye

plate,

through

the

discs

adjustable

lever

bar

No. 5 is

then

K,

eye

under

of

marked

marked

through

the

machine

of

the

the

threading

raise

and

left-hand

the

upper

position

The

through

the

left-hand

thread

nipper

stand

and

around

eyelet

eyelet,

the

plate,

guided

between

through

of

the

the

the

needle

the

needle

needle

clamp

No. 6 is

L,

then

the

wire

stationary

at

the

the

take-up

Thread

looper

cloth

hook

thread

plate

the

the

take-up

pass

the

eye,

right

hand

nipper

the

thread

looper

can

of

the

needle

the

left-hand

needle.

to

the

the

under

on

the

center

from

the

adjustable

eye

and

through

the

discs

and

lever

eyelet,

bar

collar

nipper

guided

between

eyelet,

prongs,

rear,

thread

to

take-up

between

eyelet

No.

118

from

the

through

the

right

thread

thread

thread

hold

spring;

through

the

place

the

end

by

should

now

be

threaded.

OPERATING

bar

eyelet,

hole

Thread

eye

of

side

top

of

the

of

the

the

thread

stand

around

eyelet

the

plate,

and

through

from

the

the

discs

between

the

the

and

will

be

vertical

of

the

eyelet

eyelet

to

the

of

the

thread

dropping

be

carried

under

of

the

needle

marked

eyelet

marked

of

tension

frame,

needle

the

bar

center

eyelet,

needle.

through

the

under

on

the

top

of

front

eye

of

through

the

right-hand

thread

to

the

vertical

thread

then

found

eyelet

stand

the

left

moving

eyelet

nippers,

through

of

great

up

needles.

is

as

follows:

the

under

right-hand

thread

underneath

with

the

take-up

between

the

needle

clamp

No. 4 is

J,

marked

center

the

side

the

the

the

to

of

tension

prongs

guided

then

between

J,

through

eye

of

under

Thread

eyelet

of

tension

frame,

needle

right-hand

needle.

the

eye

of

pull-off

in

the

through

the

looper.

assistance

through

An

the

excellent

with

side

of

the

cloth

eye,

then

through

the

left

hand

the

hooked

thread

the

nipper

bar

nipper

collar

and

from

the

the

the

needle

the

needle

marked

marked

bar

marked

marked

the

front

eyelet,

hole

Thread

of

eyelet

K,

L,

and

base

of

the

both

eyes

in

drawing

opening

one

plan

for

finger

in

plate,

the

and

with

end

of

the

eyelet

into

springs.

T

/O

i^ommence

foot.

The

looper

in

the

cloth

plate

on

top

of

the

slide,

or

cover,

and

the

throat

the

looper

needle

revolution

thread

holes

of

cloth

as

plate.

therein.

the

c •

bewing

thread

to

the

should

right

plate.

the

looper

The

drawn

machine,

from

To

assist

needle

underneath

be

brought

of

the

throat

Do

not

close

thread

machine

loosely

would

will

start

below

the

throat

in

forming a stitch

hold

the

19

threads

to

the

rear

up

through

plate

and

the

right-hand

be

held

between

sewing

plate

ends

of

should

be

of

the

the

its

free

cloth

the

without

up

through

with

all

the

passed

presser

opening

end

plate

slide,

having

the

threads.

left

the

first

On

machines

also

carried

T

C*

i O ocOp

applied

quickly

stopped

_

_

To

Remove

articles

desirable

the

pulley

highest

springs

its

highest

thread

thread

the

the

The

toward

needle

thus

slack

thread

work

automatically

in

to

the

s-h.

t/ie

to

the

transmitter

stopped,

by a heel

and

separate

to

remove

in

the

position

and

can

position,

with

the finger

drawn

to a point

off

as

can

then

the

rear

of

threads

will

tied,

OPERATING

Class

5000

and

underside

lUt

D^OLChine

and

U'

pulley,

but

if

necessary,

pressure

_

the

the

operating

at

which

be

drawn

by

in

close

be

the

be

on

--- - When

Work

the

article

work

direction

time

without

raise

the

through

engaging

rear

of

to

the

removed

work

plate.

drawn

preventing

5100,

the finger

the

rear

of

When

Jg

the

released,

which

the

machine

the

treadle.

to

by

while

possible

form a chain

cutting

still

under

until

the

looper

breaking.

presser

the

it

underneath

the

upper

by

to

raveling

foot,

tensions,

presser

surface

drawing

In

this

the

underside

of

threads

the

presser

pressure

a

brake

causes

the

may

allow

between

the

chain

the

presser

the

needle

thread

foot

manner

the

the

of

it

then

away

is

free

With

draw

take

presser

and

then

the

from

the

of

seam.

the

work

the

should

foot.

on

the

is

automatically

machine

instantly

the

the

of

stitches.

foot,

bar

reaches

of

the

needle

sufficient

up

the

foot

cut

as

the

cut

ends

material

be

treadle

to

be

be

stitches

sewed

If

turn

its

nipper

bar

at

needle

slack

to

carry

or

break

possible.

operator

of

the

and

rr'

n

To

Reguldte

found

lock

screw

the

nut.

by

turning

driver

lock

nut

right

hand.

small

screws

to

the

stitch.

lator

to a point

Do

A

small

the

stitch

disconnecting

be

removed,

feed

slots

I

.

stitch

To

change

it

in a direction

wrench,

with

the

On

with a larger

right

lengthens

Care

must

where

not

fail

ferrule

from

the

thus

in

the

r

Length

regulating

the

left

the

be

to

tighten

is

being

feed

allowing

throat

device,

length

catalog

hand

main

shaft, a cap

screw

the

stitch;

exercised

the

motion

the

placed

over

lengthened

crank

the

plate

of

of

stitch,

toward

No.

21206.

while

the

between.

to

of

lock

the

and

stitch

will

20

Stitch

held

in

the

the

rear

It

machine

will

turning

prevent

the

feed

nut

after

stitch

regulating

beyond a reasonable

feed

crank

to

be

permit.

the

main

its

adjusted

lock

nut

must

of

the

should

be

Turning

it

adjusting

dog

each

lengthened

be

pulley

found

to

the

would

adjustment.

stud,

is

this

left

the

be

screw

the

left-hand

shaft

will

position

be

loosened

machine

applied

held

secured

larger

shortens

reversed.

ferrule

as

using

to

with

by

screw

stitch

regu

to

prevent

limit.

far

as

end

by

the

the

two

the

By

may

the

be

a

It

is

difficult

ment

of

specially

thread

to

apply

ment

rr r I

be

in

which

of

long

blunted.

fl

and

successfully

in

nearly

is

permissible.

f_f . When a machine

avoided

(1)

every

(2)

the

(3)

groove

(4)

at

surface

by

Note

respect,

may

have

See

threads..

Examine

in

Remove

The

and

ADJUSTMENT

to

formulate

fitted

yarn

frequently

sew

all

cases,

bearing

carefully

especially

accumulated.

that

the

the

front

the

best

note

sewing

with

them.

but

though

in

mind

whether

required

needle

and

inserted

needle

possible

if

the

point

INTRODUCTORY

instructions

machines.

require

We

if

necessary a slight

which

slightly

believe

fails

apparently

the

at

the

amount

to

as

and

test

is

in

good

following

the

machine

tensions,

of

temsion

see

whether

far

up

in

see

whether

is

to

roll

concentric

apply

to

Different

different

our

instructions

deviation

to

work

satisfactorily,

repair,

suggestions:

is

threaded

and

remove

is

applied

it

is

straight

the

needle

it

the

with

has

become

shank

the

shank.

bar

on a perfectly

the

adjust

qualities

adjustment

in

delay

as

as

of

will

adjust

might

directed

any

lint

to

each

with

the

possible.

bent

or

(5)

rethread

(6)

needles.

(7)

so

causing

ing

out

(8)

(9)

for

grooves

(10)

may

be

^

^

Remove

it.

Clean

The

breaking

the

See

Examine

If

assumed

. The

all

and

oil

throat

of

holes

with a narrow

that

the

thread

cut

by

passage

the

foregoing

that

machine

or

contacts

the

threads

the

plate

needle

the

threads.

machine

eyelets,

of

the

machine

should

before

from

machine

thread,

measures

thoroughly.

holes

This

strip

of

feeds

the

take-up

causing

needs a general

be

turned

being

operated

21

the

may

may

emery

work

fail

to

machine

Try a new

have

become

be

remedied

cloth.

correctly.

wire,

and

breaking

relieve

by

the

re-adjustment.

hand

by

power.

and

carefully

set

roughened

by

smooth

tension

of

thread.

difficulty

to

detect

of

posts

it

binds

ADJUSTMENT

17

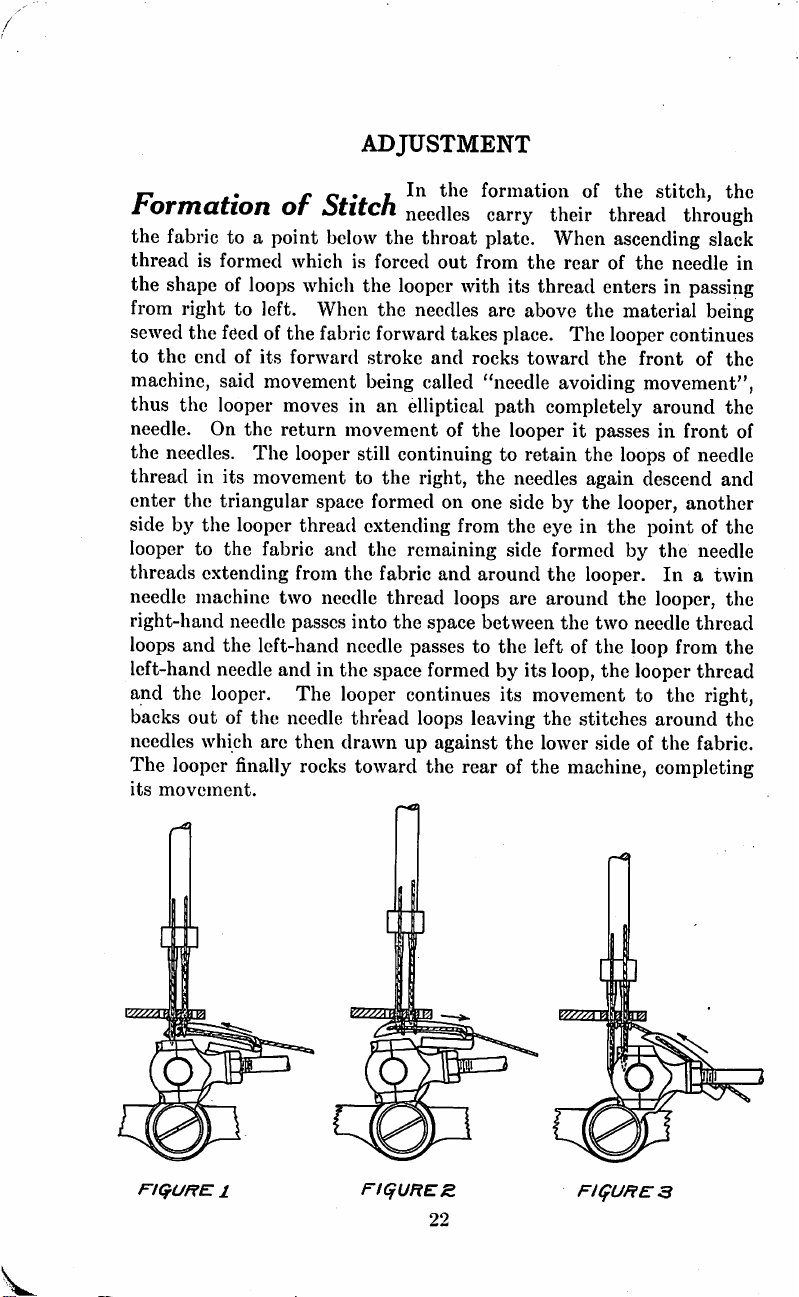

rOYtnCLZlOn

the

thread

the

from

sewed

to

the

machine,

thus

needle.

the

thread

enter

side

looper

threads

needle

right-hand

loops

left-hand

and

backs

needles

The

its

*•

fabric

is

formed

shape

right

the

feed

end

said

the

looper

On

needles.

in

the

triangular

by

the

to

extending

machine

and

needle

the

looper.

out

which

ot

to a point

of

loops

to

left.

of

the

of

its

movement

moves

the

return

The

its

movement

looper

the

fabric

two

needle

the

left-hand

and

of

the

are

looper finally

movement.

which

which

forward

looper

thread

from

passes

The

needle

then

rocks

C*'*

stitch

When

fabric

space

in

L

below

the

is

forced

the

the

forward

stroke

being

in

an

movement

still

to

the

formed

extending

and

the

the

fabric

needle

thread

into

the

needle

the

space

looper

thread

drawn

needles

looper

elliptical

continuing

remaining

passes

continues

up

toward

formation

carry

throat

out

plate.

from

with

needles

called

takes

and

arc

place.

rocks

"needle

path

of

the

to

right,

the

on

one

from

the

side

and

around

loops

space

between

to

the

formed

by

its

loops

leaving

against

the

the

rear

of

of

their

When

the

rear

its

thread

above

the

The

toward

the

avoiding

completely

looper

side

are

it

passes

retain

the

needles

its

again

by

the

eye

in

formed

the

looper.

around

the

left

of

loop,

two

the

movement

the

stitches

lower

.side

the

machine,

the

stitch,

thread

through

ascending

of

the

needle

enters

in

passing

material

looper

continues

front

of

movement",

around

in

front

loops

of

needle

descend

looper,

the

the

the

another

point

by

the

In a twin

looper,

needle

loop

from

looper

to

the

around

of

the

of

needle

thread

thread

fabric.

completing

the

slack

in

being

the

the

of

and

the

the

the

right,

the

nquREi

1

FiqUHKS.

FI(fURE3

22

n

L#

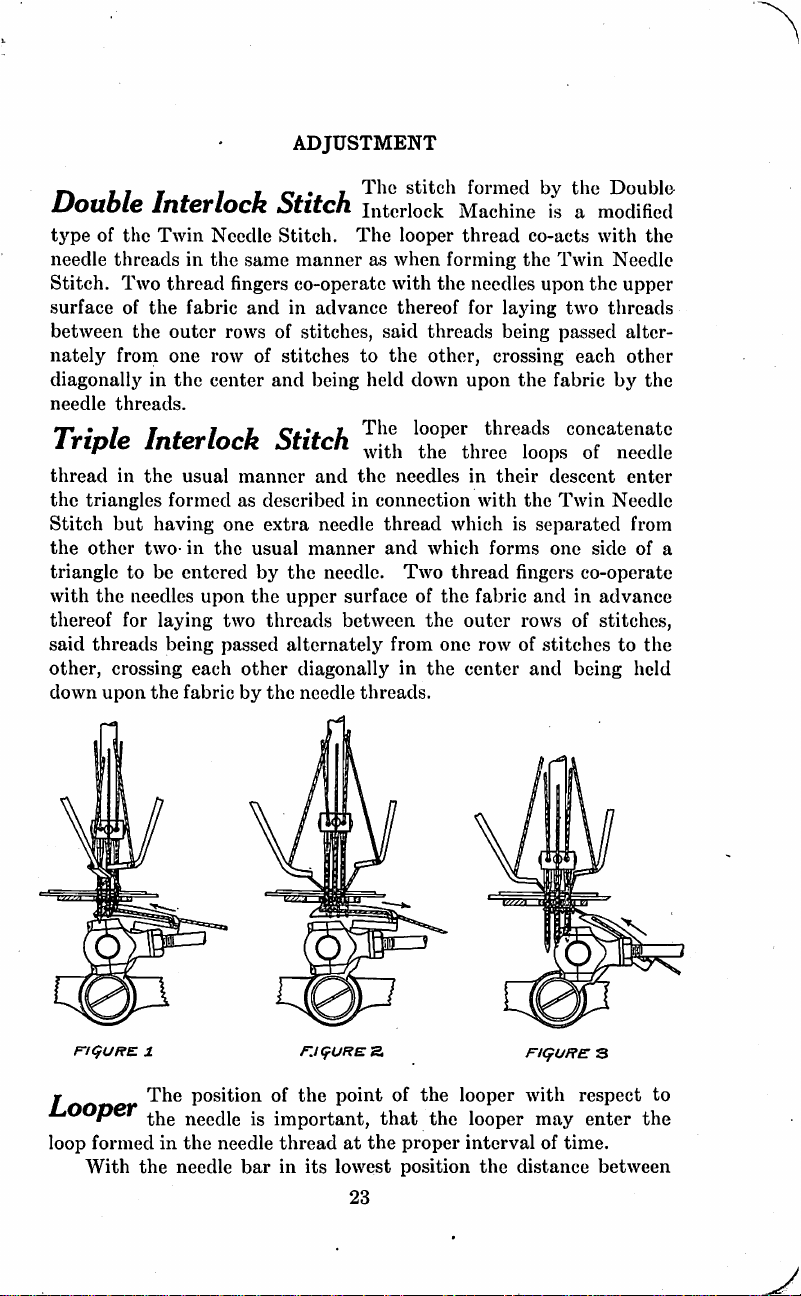

Uouble

type

needle

Stitch.

surface

between

nately

diagonally

needle

Triple

thread

the

triangles

Stitch

the

other

triangle

with

thereof

said

threads

other,

down

f*

interlock

of

the

Twin

threads

Two

of

the

the

from

in

threads.

Interlock

in

the

but

having

two-

to

be

the

needles

for

laying

crossing

upon

the

ADJUSTMENT

#

I.C*

btltcn

Needle

in

the

thread fingers

fabric

outer

one

row

the

center

same

and

rows

of

Stitch.

co-operate

in

of

stitches

and

Stitch

usual

manner

formed

being

as

one

in

the

usual

entered

upon

by

the

two

passed

each

other

fabric

by

described

extra

the

upper

threads

alternately

the

2L

manner

stitch

interlock

The

looper

as

when

with

advance

stitches,

being

and

needle

manner

needle.

thereof

said

to

the

held

The

with

the

needles

in

connection

thread

and

Two

surface

between

from

diagonally

needle

in

threads.

formed

Machine

thread

forming

the

needles

for

laying

threads

other,

down

looper

the

being

crossing

upon

threads

three

in

their

with

which

which

forms

thread fingers

of

the

fabric

the

outer

one

row

the

center

by

the

is a modified

co-acts

the

upon

the

loops

descent

the

is

separated

one

Double

with

Twin

Needle

the

upper

two

threads

passed

fabric

concatenate

Twin

each

by

of

Needle

side

alter

other

needle

enter

co-operate

and

in

advance

rows

of

stitches,

of

.stitches

and

to

being

the

the

from

of

the

held

a

nquREL

r

loop

1

The

"

the

formed

With

the

position

needle

in

the

needle

r.KfURE^

of

the

is

important,

needle

bar

thread

in

point

its

lowest

at

23

the

of

the

that

the

proper

position

nquRE

looper

interval

with

looper

may

of

the

distance

s

respect

enter

time.

between

to

the

the

be

as

cS

gauge

12

gauge

1()

gauge

20

gauge

point

of

follows:

the

looper

to

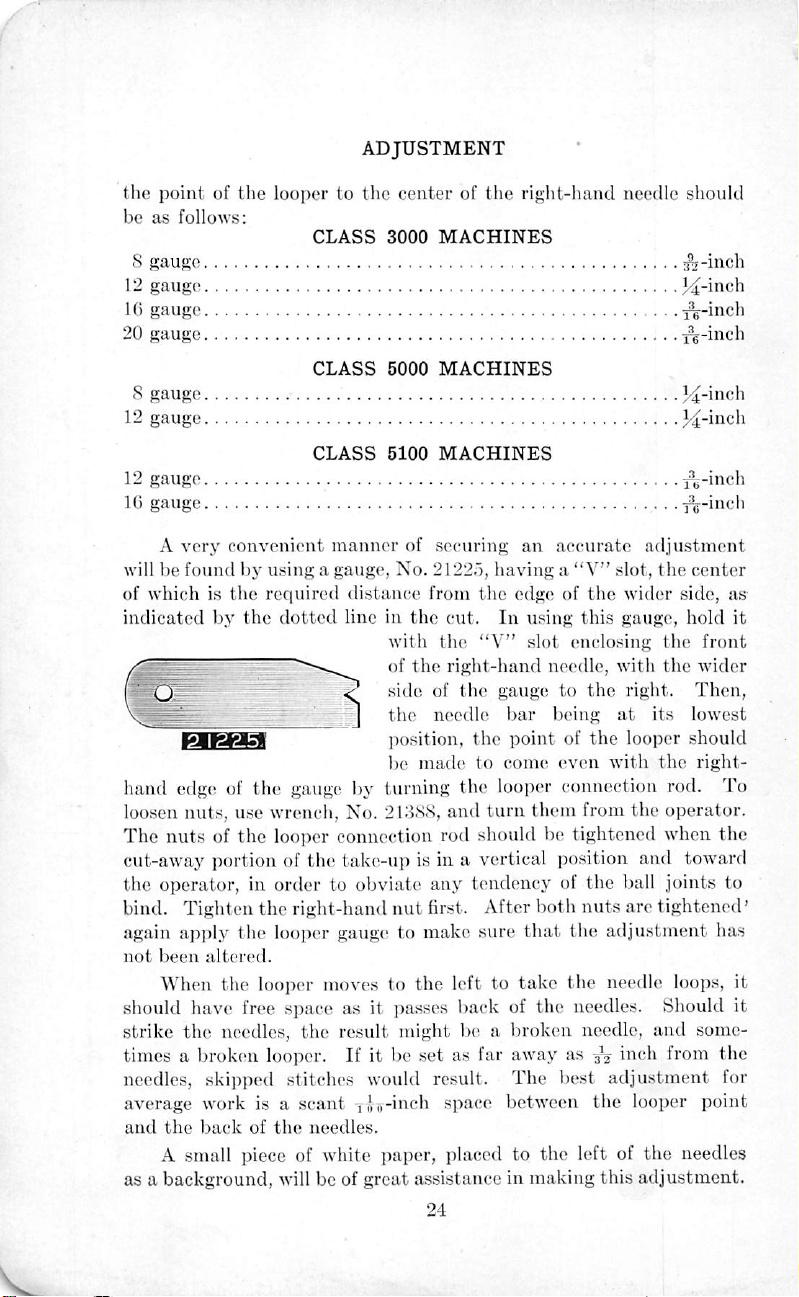

CLASS

ADJUSTMENT

the

center

3000

MACHINES

of

the

right-hand

needle

should

^-inch

3<i-irich

j^-inch

-j^-inch

S

gauge

12

gauge

12

gauge

IG

gauge

A

very

convenient

will

be

found

by

using a gauge,

of

which

is

the

required

indicated

by

the

^

^

ieMtSWJi

hand

edge

of

the

loosen

The

cut-away

the

bind.

again

not

should

strike

times a broken

needles,

average

and

as a background,

nuts,

use

nuts

of

the

portion

operator,

Tighten

api)ly

been

When

the

in

the

alt(;red.

the

hav(;

free

needles,

the

looper

looper.

skipped

work

is a scant

the

back

of

A

small

piece

CLASS

CLASS

manner

distance

dotted

--

line

^

J

gauge

wrench.

loo])er

of

order

looper

space

stitches

the

will

by

No.

connection

the

take-up

to

obviate

right-haml

gauge

moves

as

it

the

result

If

it

would

y'n-inch

needles.

of

white

be

of

great

5000

MACHINES

5100

MACHINES

of

securing

No.

21225,

from

in

the

cut.

with

the

of

the

right-hand

side

of

the

the

needle

position,

be

turning

215SS,

the

mad(;

the

and

rod

is

in a vertical

any

tendency

nut first.

to

make

to

the

left

passes

be

might

set

as

back

Ix; a broken

result.

space

paper,

placed

assistance

an

accurate

having a "V"

the

edge

In

u.sing

"V"

slot

needle,

gauge

to

looper

turn

should

After

sure

to

far

to

bar

being

point

come

even

them

be

position

of

both

that

take

of

the

away

The

best

between

to

the

in

making

J^-inch

J£-inch

i%-inch

]%-inch

adjustment

slot,

the

of

the

wider

side,

this

gauge;,

enclosing

the

of

the

connection

from

tightened

the

nuts

the

the

needles.

needle,

as ^ inch

the

with

the

right.

at

its

looper

with

the

rod.

the

operator.

when

and

toward

ball

joints

arc

tightened'

adju.stment

needle

loops,

Should

and

from

adjustment

the

looper

left

of

the

needles

this

adjustment.

center

as

hold

it

front

wider

Then,

lowest

should

right-

To

the

to

has

it

it

some

the

for

point

To

change

the

needles,

fork

to

the

to

be

moved

When

front

of

between

looper

eccentricity,

to

greater

looper

or

can

the

back

In

machines

or

in

smaller

spondingly

agonal

adjusting

to

needles.

front

in

moved

the

and

the

head

needles

looper

to

the

loosen

looper

to

the

the

looper

the

needles

the

back

be

altered

without

of

the

lesser

its

loop

needle

changed.

screw

screw

to

and

The

primary

rear

of

rock

the

required

position

the

two

rock

shaft.

required

moves

to

enable

of

the

by

destroying

needle.

provided

space

can

taking

can

and

be

To

on

the

the

right

to

the

left

adjustment

the

needles

shaft

position.

ADJUSTMENT

of

the

looper

screws

which

This

permits

position.

to

the

right,

the

needles,

looper

and

its

using a looper

its

correct

with

the

adjustable

be

had

between

loop

leaving

used

and

the

accomplish

adjustable

to

to

is

sleeve

this

change

move

effected

the

in a path

of

which

the

eccentric flange

with

respect

secure

it

thread.

eccentric

movements

path

the

the

looper

should

as

they

The

adjustment

looper

the

path

of

looper

adjustment

path

of

looper

farther

looper

by

loosening

will

in

permit

to

the

back

of

looper

pass

descend,

of

traversed

whereby a larger

the

the

eccentric

and

its

rocker

close

to

to

position

greater

travel

loosen

and

away

relation

looper

of

or

with

respect

eccentric

by

corre

the

turn

travel

closer

from

to

three

screws

to

the

pass

the

less

the

hex

the

the

the

be

a

TU

A

flYBClu.

cations

one

is

carried

set

changed

hand

with

be

the

longer

plane

reciprocate

finger

needles

other

which

center

J

J7*

ringCTS

of

the

needles.

being

longer

screws.

by

thread

the

guide

positioned

set

screws

thread

below

should

than

and

operated

Its

loosening

finger

bar,

with

securing

finger

that

past

each

be

whereby

in

the

center

in a Triple

needle.

movement

They

the

right-hand

by

the

position

of

equally

the

Interlock

with

the

is

operated

but

having

respect

the

has

its

thread

the

shorter

other

without

divided

threads

of

the

thread

are

to

of

fingers

different

one.

guide

bar,

respect

set

screws

by a segment

its

direction

to

the

needle

segment

attached

guiding

or

right-hand

striking.

upon

carried

space

machine

by

between

would

25

are

every

two

lengths,

The

left-hand

it

being

to

the

needle

and

adjusting

attached

of

travel

clamp

to

eye

moving

The

opposite

the fingers

the

be

directly

given

one

complete

the

thread finger

held

thereon

bar

lug

it.

to

and

reversed.

collar

by

the

guide

in a horizontal

finger.

They

travel

of

sides

of

will

two

outside

in

front

complete

recipro

left-hand

can

The

moving

It

loosening

bar.

should

the

thread

the

cross

needles,

with

be

right-

can

The

outer

each

of

the

The

timing

the

eccentric

Therefore

distance

the

screws

to

the

direction

their

lowest

across

sides

to

arms.

the

collar

iveeaie

is

bar

each

of

the

needle

The

reciprocation

(Catalog

If

even

should

•^•inch

little

lower

the

sewed

looper

the

fere

the

height,

lower

to

described

with

looper

than

gear

to

time

apart,

in

the

main

shaft

until

the

position.

others

the

needles.

as

presser

No.

n

oar

with

the

be

positioned

below

the

when

articles.

enter,

the

adjustment.

the

large

to

take

the

needle

the

right

ADJUSTMENT

of

the

thread

with

respect

the

thread

with

respect

eccentric

and

needles

paths,

possible

foot

of

21213)

Turn

^he

left

gear

turn

are

Do

not

but

Position

before

should

the

thread

on

the

looper

side

of

that

under

side

it

is

desirable

To

avoid a large,

needle

bar

The

needle

each

seats

loop,

loop

are

needle.

fingers

fingers,

to

the

they

the

is

to

the

the

needles,

pinion

(Catalog

eccentric

within

at

one-eighth

this

time

should

guiding

securing

not

raise

high

fingers.

the

reduced

pulley

starts

the

in

the

to

move

left-hand

the

entire

of

the

looper.

to

"chain

out"

variable