INDUSTRIAL

SEWING

F

INE

ST

QUALITY

ST

YLES

435 000

435 00 F

435 00 L

®

C 0 L U M 8 I A®

MACHINES

CATALOG

No.

134M

Second

Edition

CLASS

HI-STYLED

S

INGLE

PLAIN

CURVED

FEED

43500

HIGH

UNION SPECIAL

C H

ICAGO

SPEED

NEEDLE

MACHINE

S

CORPORATION

C a t a 1 o g

INSTRUCTIONS

FOR

No.

1 3 4 M

ADJUSTING

43500

Union

Rights

LIST

CLASS

D

Second

Special

Reserved

AND

OF

Styles

43500

@

1969

By

OPERATING

PARTS

43500

F

Edition

Corporation

in

All

43500L

Countries

UNION SPECIAL

INDUSTRIAL

CHICAGO

Printed

CORPORATION

SEWING

in

2

MACHINES

U.S.

A.

March,

1976

IDENTIFICATION

OF

MACHINES

Each

on

the

Style

Example:

minor

Style

which

43500".

herein.

Class

given

of

Hi-Styled

machine,

43500

numbers

changes

number.

Styles

differs

This

43500.

from

handwheel

D

on

range 6 to

R.P.M.

UNION

machine.

"Style

of

machines

from

catalog

It

can

also

References

the

is

High

with

For

seaming

medium

SPECIAL

Style

have

Example:

operator's

Single

43500

are

applies

be

away

Speed

to

heavy

12

per

one

F".

made

the

applied

from

Plain

Enclosed

canton

inch.

machine

numbers

or

more

Special

in a standard

''Style

similar

Style

specnically

to

position

weight

43500

in

number

APPLICATION

with

directions,

operator.

STYLES

Feed

Reservoir

flannel

materials.

Cam

is

identified

are

classified

letters

Style

construction

discretion

while

Single

adjusted

FZ".

in

to

OF

and

that

suffixed,

numbers

machine,

the

such

seated

for

jersey

feed.

by a Style

as

standard

but

contain

a ''Z"

are

grouped

it

contains

OF

CATALOG

Standard

to

some

as

right,

at

the

MACHINES

Curved

Seam

Needle,

Automatic

cloth

specification

Maximum

number

never

the

is

suffixed

no

letters.

Styles

Special

left,

machine.

Medium

Lubrication.

gloves

recommended

on a name

and

special.

contain

letter

under a Class

of

Styles

front,

Operating

and

the

letter

"Z".

to

the

Example:

machines

of

machines

back,

to

Heavy

similar

401-SSa-1.

operations

speed

When

plat

Standard

"Z".

only

Standard

number

"Class

as

listed

etc.,

direction

are

Duty

Stitch

6500

e

in

43500

43500

filled

straight

should

sight

tween

main

It

may

F

For

Seam

feed.

L

For

presser

Cam

CAUTION!

before

mineral

be

Machine

gauge

gauge

Machine

reservoir

The

oil

is a magnetic

have

seaming

specification

Maximum

side

foot.

adjusted

beginning

used.

is

on

lines

is

drain

entered

feed.

Oil

was

oil

filled

front

when

automatically

filled.

plug

screw

the

trousers,

401-SSa-1.

recommended

seaming

Seam

specification

Maximum

drained

to

operate.

of a Saybolt

with

of

Check

screw

crank

oil

machine.

machine

designed

case.

coats,

trousers,

from

Oil

viscosity

at

spring

Red

is

stationary.

lubricated.

oil

daily

is

located

to

It

jackets,

Stitch

speed

recommended

OILING

machine

bulb

before

at

accumulate

should

NEEDLE

range 8 to

6500

etc.,

401-SSa-1.

capacity

of

cap

on

No

back

with

when

90

in

oil

oiling

the

of

be

dresses

R.

P.M.

yielding

Stitch

speed

shipped,

of

Class

to

125

top

cover.

level

is

necessary,

morning

machine

possible

removed

and

14

per

section

range

6500

43500

seconds

Oil

indicator

start;

near

foreign

and

cleaned

similar

inch.

8

R.

P.

so

reservoir

is

at

level

should

other

add

bottom

materials

garments.

Cam

on

left

to

14

per

M.

six

ounces.

1000

oil

Fahrenheit

is

checked

show

than

as

required.

edge

periodically.

adjusted

side

inch.

must

be-

keeping

of

base

which

of

be

A

at

•

Each

denotes

number,

in

thousandths

size

needles

UNION

the

stamped

number

packaged

SPECIAL

kind

of

of

represent

shank,

on

the

an

and

needle

inch,

sold

needle

point,

midway

the

complete

by

has

length,

shank,

Union

both

groove,

denotes

between

symbol

Special.

3

type

shank

and

finish

largest

and

which

size

number.

and

other

diameter

eye.

is

Collectively,

given

The

details.

of

blade,

on

the

type

measur

label

number

The

size

type

of all

ed

and

li]

Tcnslon

IIT

cnslon

[!)T

ension

ll)spr lng Shlt·

gT,

•ns!on

IIT<>n

sion P

OTcn

slon

Iii

Tension

fl1

Fran• Thre

Nul

s,,rtn

~

PoRI

ld

msc~...,..

.

~~~~If}

os

t Slot ~ •..

Di

sc

Felt ·..

•.-~-:.."'.:~

Thre

ad G

uide

ad Gui

de

IIJ

Iii

CJ

Needle-----

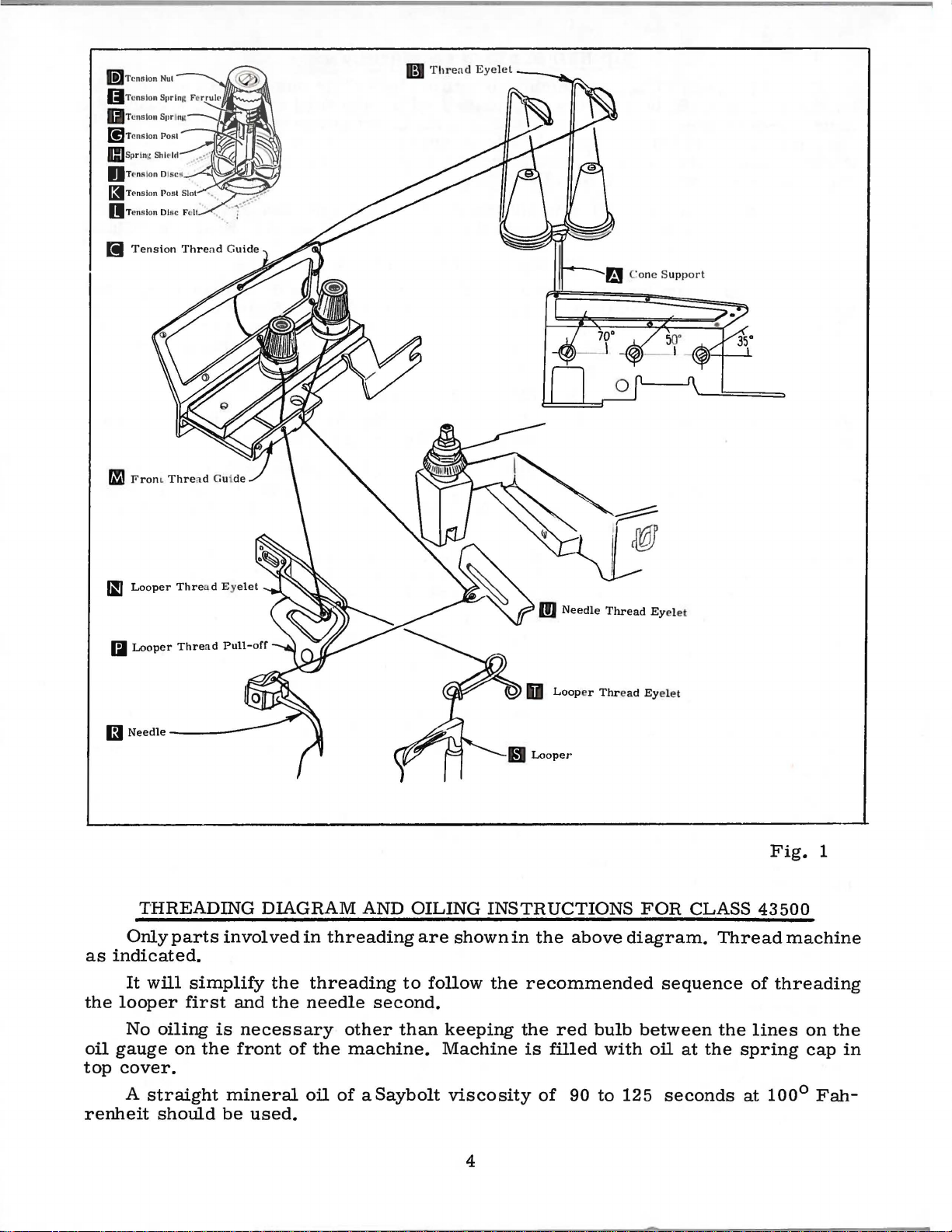

Only

as

indicated.

It

the

looper

No

oil

gauge

top

cover.

Looper

Thre

a d E y

Looper

Thread

Pull-off

THREADING

parts

will

involved

simplify

first

oiling

on

is

the

elet

DIAGRAM

the

and

the

necessary

front

of

AND

in

threading

threading

needle

other

the

machine.

OILING

are

to

second.

than

shown

follow

keeping

Machine

INSTRUCTIONS

in

the

above

the

recommended

the

red

bulb

is

filled

with

FOR

CLASS

diagram.

sequence

between

oil

at

Thread

the

the

spring

Fig.

43500

machine

of

threading

lines

1

on

cap

the

in

A

renheit

straight

should

mineral

be

used.

oil

of

aSaybolt

viscosity

of

4

90

to

125

seconds

at

100°

Fah-

NEEDLE

(Continued)

Class

needle

is

mended

Type

157

sample

on

No.

GJS

To

label.

have

needle,

Selection

should

pass

Success

use

of

needles

reputation

more

than

43500

Type

157

needle.

Round

A.

chromium

100/040. 110/044. 125/049.

needle

or

A

complete

of

proper

freely

in

the

packaged

for

producing

three-quarters

G

machines

GJS.

Below

shank.

double

orders

the

type

order

needle

through

operation

A

use a curved

is

the

round

groove.

plated

promptly

and

size

would

read:

size

needle

under

highest

of

UNION

our

quality

eye

of a century.

blade

description

Description

point.

struck

and

is

available

and

accurately

number

''1.000

is

determined

in

order

SPECIAL

brand

name,

needles

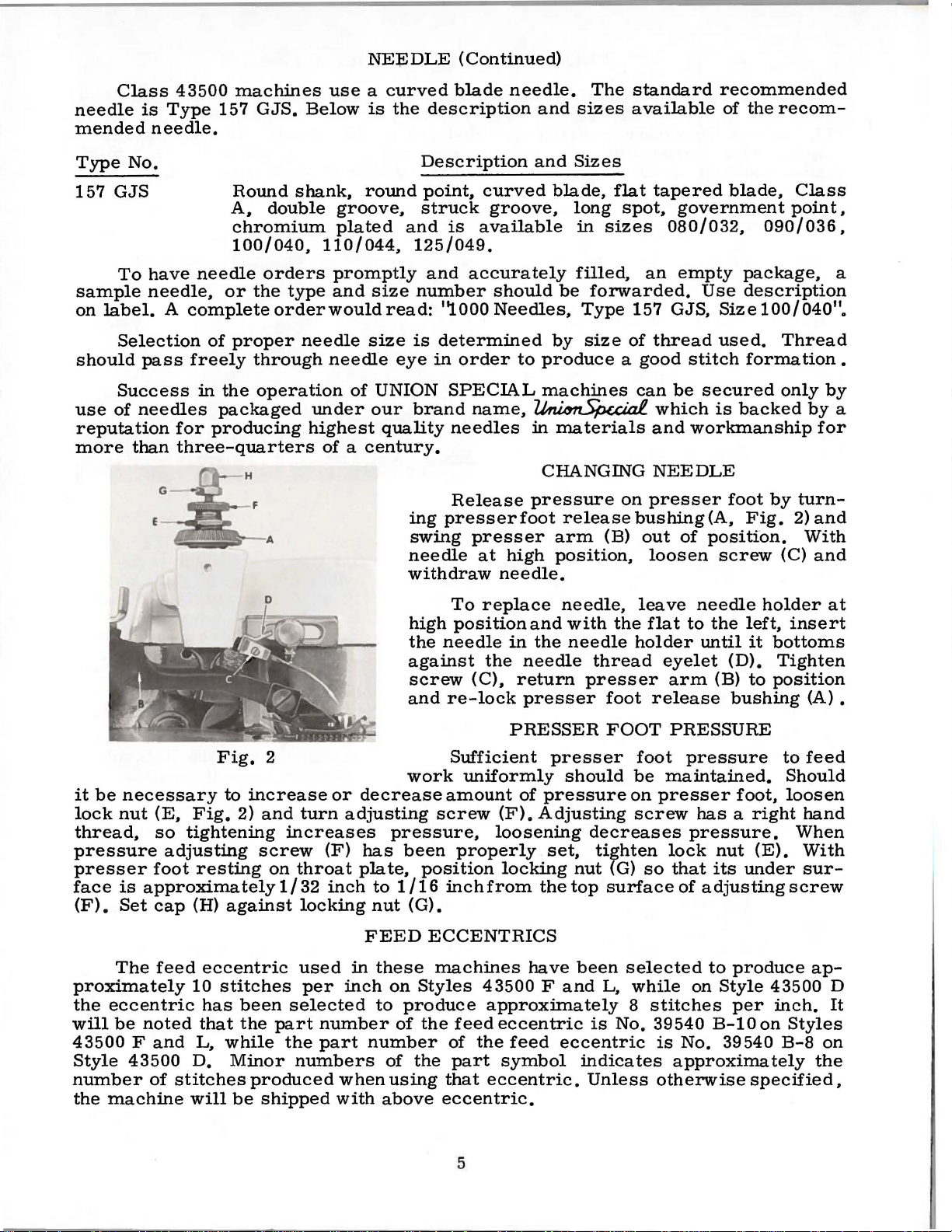

Release

ing

presser

swing

needle

presser

at

withdraw

needle.

and

curved

groove.

should

Needles,

to

~

in

pressure

foot

high

needle.

The

standard

and

sizes

available

Sizes

blade.

be

by

flat

long

in

spot.

sizes

filled,

forwarded.

Type

size

157 GJS,

of

tapered

an

thread

produce a good

machines

can

which

materials

CHANGING

release

arm

(B)

position.

and

NEEDLE

on

presser

bushing

out

loosen

recommended

of

the

blade.

government

080/032.

empty

Use

package.

description

Size

used.

stitch

be

formation

secured

is

backed

workmanship

foot

(A.

Fig.

of

position.

screw

recom-

Class

point.

090/036.

100/040".

Thread

only

by

by

for

by

turn-

2)

and

With

(C)

and

a

•

a

it

be

necessary

lock

nut

(E.

thread.

pressure

presser

face

(F).

so

adjusting

foot

is

approximately

Set

cap

The

feed

proximately

the

eccentric

will

be

noted

43500 F and

Style

number

the

43500

of

machine

stitches

Fig.

to

increase

Fig.

2)

and

tightening

screw

resting

(H)

against

eccentric

10

stitches

has

been

that

the

L.

while

D.

Minor

produced

will

be

shipped

2

turn

increases

on

throat

1/32

locking

used

per

selected

part

the

numbers

or

decrease

adjusting

(F)

has

plate.

inch

nut

FEED

in

inch

number

part

number

when

with

high

the

against

screw

and

work

pressure.

been

position

to

1/16

(G).

these

on

Styles

to

produce

of

the

of

the

using

above

To

replace

position

needle

(C).

re-lock

the

and

in

the

needle

return

presser

PRESSER

Sufficient

uniformly

amount

screw

of

(F).

Adjusting

loosening

properly

locking

inch

from

the

ECCENTRICS

machines

have

43500 F and

approximately

feed

eccentric

of

the

feed

part

that

symbol

eccentric.

eccentric.

needle,

with

needle

thread

presser

presser

should

pressure

decreases

set.

tighten

nut

top

been

L,

is

eccentric

indicates

Unless

leave

the

flat

holder

foot

release

FOOT

foot

be

on

screw

(G)

so

surface

selected

while

8

stitches

No.

39540

is

otherwise

needle

to

the

left.

until

eyelet

arm

(D).

(B)

it

to

bushing

PRESSURE

pressure

maintained.

presser

foot,

has a right

pressure.

lock

that

of

adjusting

to

on

nut

its

under

produce

Style

(E).

per

B-10

No.

39540

approximately

specified,

holder

insert

bottoms

Tighten

position

(A) •

to

feed

Should

loosen

hand

When

With

sur-

screw

43500

inch.

on

Styles

B-8

at

ap-

D

It

on

the

5

The

- 5, - 6, - 7,

-

34,-36,

may

be

ordered

number

11

39540

suffixed

B-10".

following

-8,

-9,-

-

40.

Only

separately.

stitch

FEED

number

ECCENTRICS

feed

eccentrics

(Continued)

are

available

under

10,-11,-12,-13,-14,-15,-16,-18,-20,-22.-24,-26,-28,-30,-32,

one

to

indicate

eccentric

is

supplied

To

order

an

approximately

with

each

eccentric,

the

number

machine.

use

No.

of

stitches

Additional

39540 B with a minor

No.

desired.

39540

B-4,

eccentrics

Example:

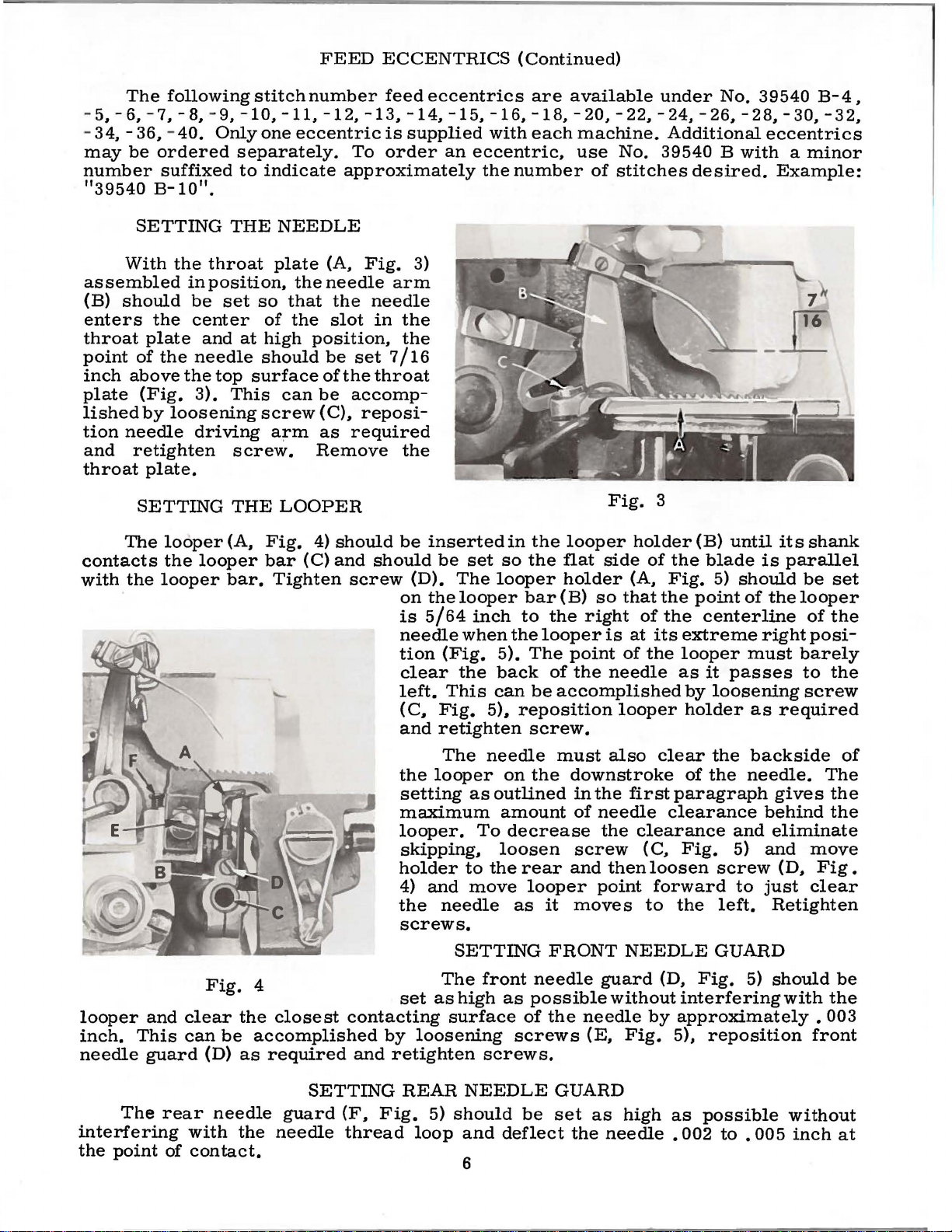

SETTING

With

assembled

(B)

should

enters

throat

point

inch

plate

lished

tion

and

throat

plate

of

above

(Fig.

by

needle

retighten

plate.

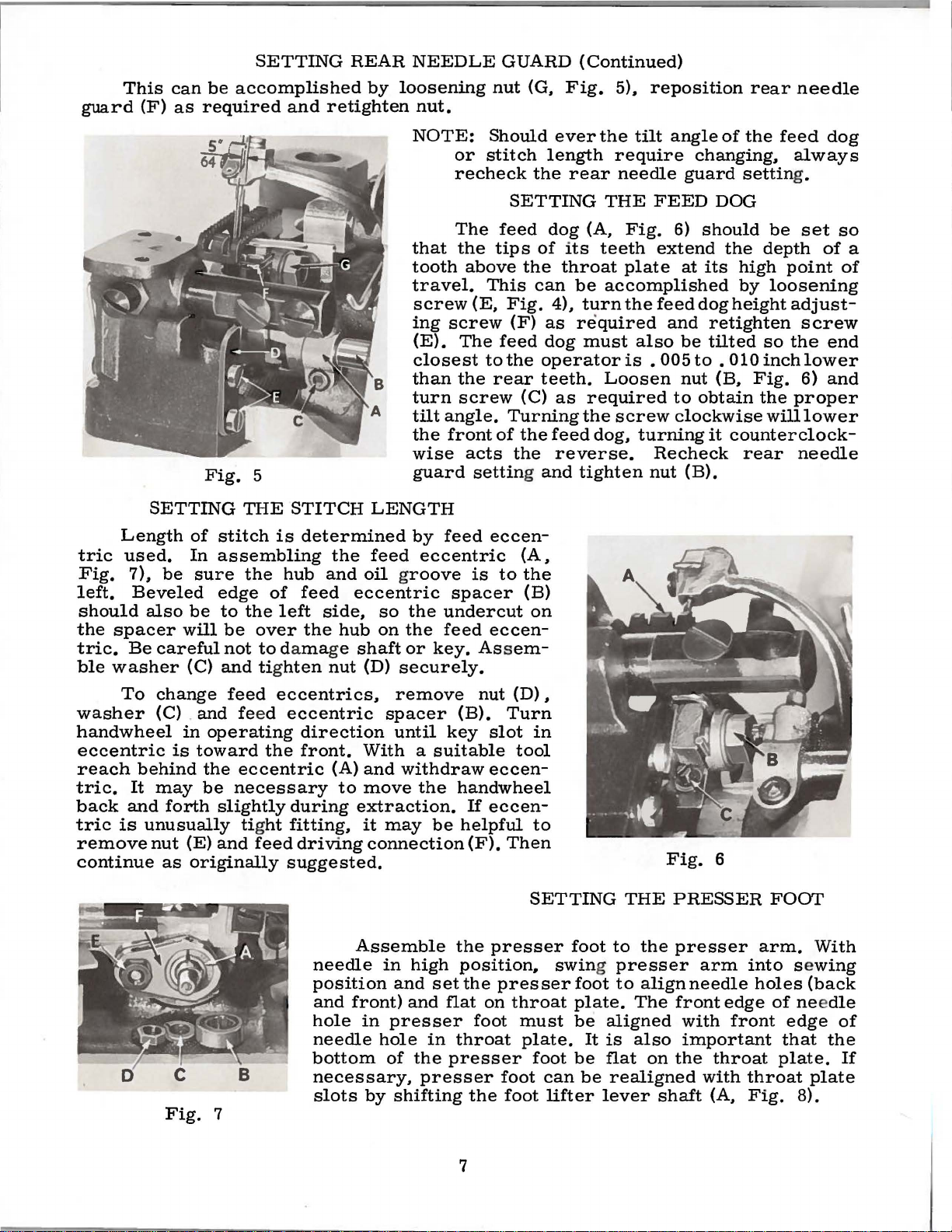

SETTING

The

contacts

with

the

·

the

in

be

the

center

and

the

needle

the

3).

loosening

driving

looper

the

looper

looper

THE

throat

position,

set

so

of

at

high

should

top

surface

This

screw

screw.

THE

(A,

Fig.

bar

bar.

NEEDLE

plate

the

that

the

(A,

needle

the

slot

position,

be

of

can

be

(C),

a;rm

as

Remove

LOOPER

4)

(C)

Tighten

Fig.

needle

in

set

the

throat

accomp-

reposi-

required

should

and

should

screw

3)

arm

the

the

7/

16

the

be

(D).

on

is

needle

tion

clear

left.

(

C,

and

inserted

be

set

The

the

looper

5/64

inch

when

(Fig.

the

This

Fig.

retighten

in

so

the

looper

bar

to

the

5).

The

back

can

5),

reposition

screw.

the

looper

flat

side

holder

(B)

so

the

right

looper

point

of

the

be

accomplished

Fig.

holder

of

(A,

that

of

is

at

of

the

needle

looper

3

the

Fig.

the

the

its

as

(B)

until

blade

5)

point

centerline

extreme

looper

it

passes

by

loosening

holder

its

is

should

of

the

right

must

as

required

shank

parallel

be

set

looper

of

the

posi-

barely

to

the

screw

looper

inch.

needle

and

This

guard

The

interfering

the

point

clear

can

rear

of

Fig.

(D)

needle

with

con

4

the

closest

be

accomplished

as

required

guard

the

needle

tact.

contacting

and

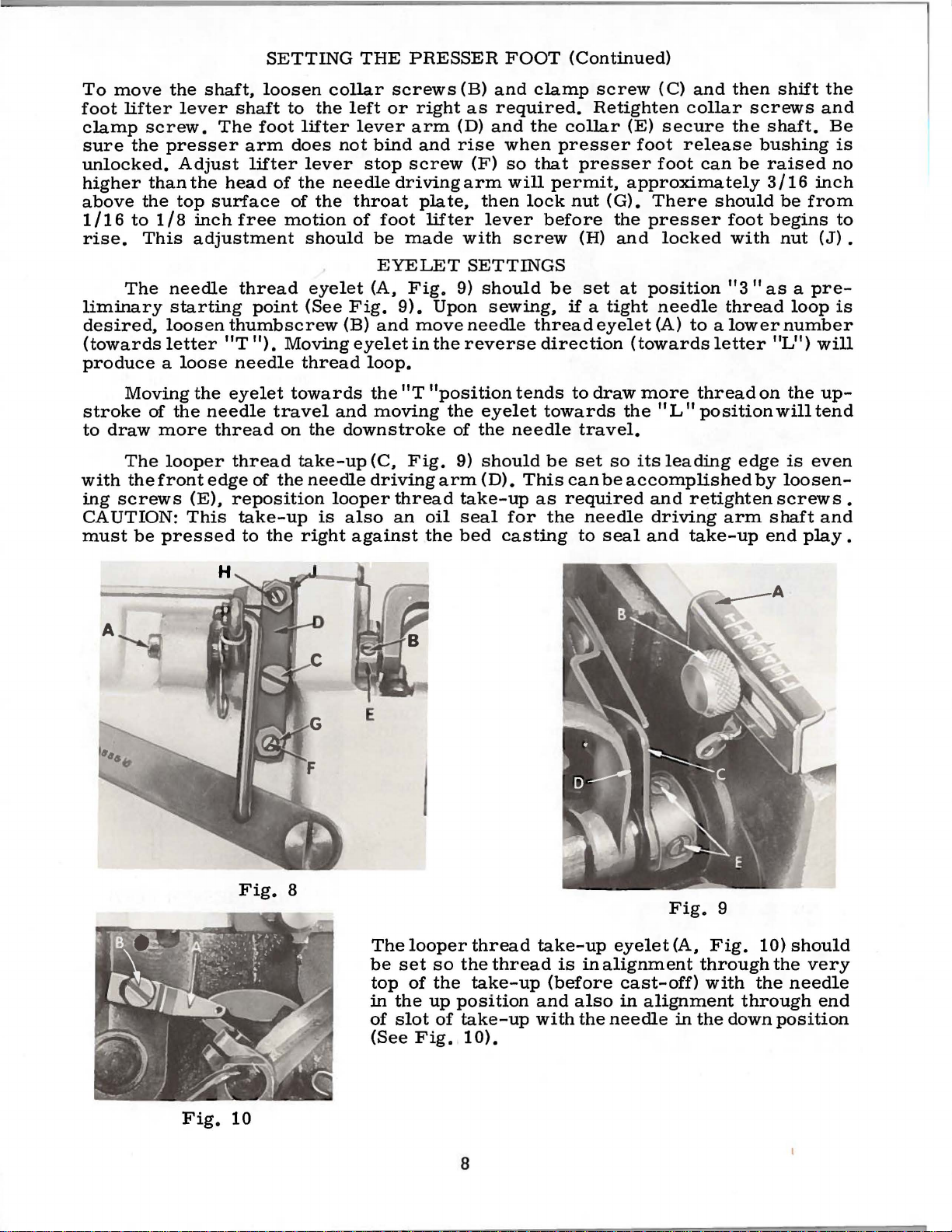

SETTING

(F,

Fig.

thread

The

the

looper

setting

maximum

looper.

skipping,

holder

4)

and

the

needle

screws.

The

set

as

by

loosening

retighten

REAR

5)

loop

needle

on

as

outlined

amount

To

decrease

loosen

to

the

move

as

SETTING

front

high

as

surface

screws

screws.

NEEDLE

should

and

deflect

6

must

the

rear

looper

it

FRONT

needle

possible

of

the

GUARD

be

set

also

downstroke

in

the

first

of

needle

the

clearance

screw

and

moves

then

point

(c.

loosen

forward

to

NEEDLE

guard

without

needle

(E.

as

the

by

Fig.

high

needle • 002

clear

of

the

the

needle.

paragraph

clearance

and

Fig.

5)

screw

to

the

left.

GUARD

(D.

Fig.

5)

interfering

approximately

5),

reposition

as

possible

to • 005

backside

gives

behind

eliminate

and

move

(D,

just

clear

Retighten

should

with

without

inch

of

The

the

the

Fig.

be

the

•

003

front

at

guard

This

(F)

can

as

SETTING

be

accomplished

required

and

REAR

by

retighten

NEEDLE

loosening

nut.

GUARD

nut

(G,

{Continued)

Fig.

5),

reposition

rear

needle

Length

tric

Fig.

left.

should

the

spacer

tric.

ble

washer

SETTING

used.

7),

be

Beveled

also

Be

careful

Fig.

of

stitch

In

assembling

sure

edge

be

to

will

be

not

{C)

and tig

5

THE

the

the

over

STITCH

is

determined

hub

of

feed

left

the

to damage

hten

the

and

oil groove

eccentric

side,

hub

shaft

nut

{D)

NOTE:

that

tooth

travel.

screw

ing

{E).

closest

than

turn

tilt

the

wise

guard

LENGTH

by

feed

so

on

eccentric

the

the

or

key. Ass

securely.

Should

or

stitch

recheck

The

feed

the

tips

above

This

{E,

Fig.

screw

The

feed

to

the

the

rear

screw

angle.

front

Turning

of

acts

setting and

feed

eccen-

is

to

spacer

undercut

feed

eccen-

ever

length

the

rear

SETTING

dog

of

its

the

throat

can

be

4),

turn

{F)

as

required

dog

must

operator

teeth.

{C)

as

the

the

feed

the

reverse.

tighten

{A,

the

{B)

on

em-

the

tilt

angle

require

needle

THE

{A,

teeth

FEED

Fig.

extend

plate

accomplished

the

feed

and

also

is

•

005

Loosen

required

screw

dog,

turning

Recheck

nut

of

the

changing,

guard

settin

DOG

6)

should

the

at

its

high

by

dog

height

retighten

be

tilted

to

.

010

nut

{B,

to

obtain

clockwise

it

counterclock-

rear

{B).

feed

always

g.

be

set

depth

point

loosening

adjust-

screw

so

the

inch

lower

Fig.

the

will

6)

proper

lower

needle

dog

so

of

of

end

and

a

To

change

washer

{C) . and feed

handwheel

eccentric

reach

tric.

back

tric

remove

behind

It

may

and

is

unusually tig

nut

continue

in

operating

is

toward

the

be

forth

{E)

as

originally

Fig.

feed

the

eccentric

necessary

slightly

ht

and

feed

7

eccentrics,

eccentric

direction

front.

{A)

to

during

extraction.

fitting,

driving

suggested.

Assemble

needle

position

and

front)

hole

needle

bottom

necessary,

slots

remove

spacer

until

{B).

key

nut

slot

With a suitable

and

withdraw

move

it

may

the

be

connection

eccen-

handwheel

If

eccen-

helpful

{F).

the

in

in

hole

of

high

and

and

presser

set

in

the

position.

the

flat

on

foot

throat

presser

presser

by

shifting

the

{D)

Turn

in

tool

to

Then

SETTING

presser

presser

throat

must

plate.

foot

foot

foot

,

THE

foot

to

the

swing presser

foot

to

align

plate.

be

be

can

lifter

It

be

The

aligned

is

also

flat

realigned

lever

Fig.

PRESSER

presser

needle

front

with

important

on

the

shaft

6

arm

edge

throat

with

{A,

arm.

into

holes

front

throat

Fig.

FOOT

s e

{back

of nee

edge

that

plate.

plate

8).

With

wing

dle

of

the

If

7

To

move

foot

lifter

clamp

sure

screw.

the

unlocked.

higher

above

1 I

rise.

16

than

the

to

This

the

lever

presser

Adjust

the

top

1 I 8

inch

adjustment

shaft,

shaft

The

arm

lifter

head

surface

free

SETTING

loosen

to

the

foot

lifter

does

lever

of

the

of

the

motion

should

THE

collar

left

lever

not

stop

needle

throat

of

PRESSER

screws

or

arm

bind

screw

driving

foot

be

made

right

and

plate,

lifter

(B)

as

(D)

rise

(F)

arm

then

lever

with

FOOT

and

clamp

required.

and

the

when

so

that

will

permit,

lock

before

screw

(Continued)

screw

Retighten

collar

presser

(E)

foot

presser

approximately

nut

(G).

the

(H)

and

(C)

and

collar

secure

release

foot

There

presser

locked

then

the

can

should

foot

with

shift

screws

shaft.

bushing

be

raised

3116

begins

be

nut

the

and

Be

is

no

inch

from

to

(J)

•

The

needle

liminary

desired,

starting

loosen

(towardsletter

produce a loose

Moving

stroke

to

draw

The

with

ing

the

screws

CAUTION:

must

be

of

the

more

looper

front

(E),

This

pressed

the

needle

edge

thread

point

thumbscrew

"T").

Movingeyeletinthereversedirection

needle

eyelet

towards

travel

thread

on

thread

of

the

reposition

take-up

to

the

eyelet

(See

Fig.

(B)

thread

and

the

downstroke

take-up

needle

looper

is

also

right

against

EYELET

(A,

Fig.

9).

and

move

loop.

the

"T

moving

(C,

Fig.

driving

thread

an

SETTINGS

9)

should

Upon

sewing,

needle

"position

the

eyelet

of

the

9)

should

arm

(D).

take-up

oil

seal

the

bed

be

thread

tends

towards

needle

be

This

as

for

the

casting

set

at

if a tight

eyelet

to

draw

the

travel.

set

so

can

be

accomplished

required

needle

to

seal

position

needle

(A)

"3

thread

to a lower

(towardsletter

more

its

and

and

thread

"L"

position

leading

retighten

driving

take-up

arm

"as a pre-

loop

number

"L")

on

the

will

edge

by

is

loosen-

screws.

shaft

end

play.

is

will

up-

tend

even

and

Fig.

Fig.

10

8

The

be

top

in

the

of

slot

(See

looper

set

so

of

the

up

of

Fig.

thread

the

thread

take-up

position

take-up

10).

take-up

is

(before

and

with

8

eyelet

in

alignment

cast-off)

also

in

the

needle

Fig.

(A,

9

Fig.

through

with

alignment

in

the

10)

the

through

down

should

the

very

needle

end

position

EYELET

SETTING

(Continued)

Looper

for a preliminary

eyelet

stitch,

downward

the

pulled

CAUTION:

locking

screw

point

assembled

the

the

thread

as

move

The

thread.

up

screw

(D)

In

assembly,

of

rear.

stud

to

should

required

the

acts

looper

stitch

assembled.

removing

Stud

the

The

When

to

the

screw

the

(B)

locking

cast-off

setting.

and

looper

reverse.

thread

needle

and

still

removing

and

the

cloth

all

machine

(D)

retighten

thread

tension

thread

not

lift

upcloth

play

with

screw

so

when

Loosen

take-up

THREAD

should

tension

pucker

CLOTH

the

plate

and

yet

the

(B)

that

only

screw.

cloth

plate

screw

turn

flat

is

the

the

point

screw

Should

eyelet

TENSIONS

be

set

should

the

material.

PLATE

plate

with

and

in

and

''V"

tightened

cloth

of

the

needle

(B),

REMOVAL

(A,

the

the

plate

reposition

upward,

as

light

be

set

Fig.

the

cloth

cloth

cloth

slot

of

securely

will

more

is

at

the

top

looper

thread

to

cast

as

possible

to

produce a reasonably

11)

loosen

plate

plate

plate.

the

cloth

which

turn

stud

when

be

off

the

stud

(C)

are

The

cloth

plate

collapses

opening

later,

and

cloth

tightened

stud

of

the

thread

required

moving

still

plate

and

cloth

plate

(C)

the

or

looper

take-up

in

the

control

well

stud

plate

to

the

is

then

towards

body

closing

it

of

•

Fig.

11

9

10

MAIN

FRAME,

MISCELLANEOUS

COVERS,

PLATES

AND

EYELETS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

38A

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

Part

No.

43564

22838

39557

43557

39556

39557

39557

39557

39557

39557

39582

50-795

22562

39582

51-103

39582

39582

39582

22541

39582

667

22571

39594

22569

80

43579

43568

22569

39501

22569

22565

660-234

43594

86

41071

39582

22657

43501

43501

90

39532

25

22824

39594

39594

22513

43568

39593

660-243

22894

39582

22653

39593

93

395

39582

22569

39582

39595

22586

A

A

F

c

E

B

AH

A

w

AG

v

AF

AE

D-8

E

R

D

A

D

K

F

X

G

D

D-12

A

A

s

G

H

B

B

H

AE

F

D-4

D

c

y

XD

R

Blk.

Blk,

Description

Adjustable

Thumbscrew,

control

Presser

Presser

Presser

Presser

Lock

Presser

Presser

Presser

Top

Cover-------------------------Presser

Screw,

Oil

Hinge

Hinge

Spring,

Oil

Screw,

Top

Cover

Dowel

Magnetic

Oil

Collector

Screw,

Screw,

Supplementary

Looper

Screw,

Cloth

Screw,

Screw,

Coupling,

tube---------------------------------------

Needle

Screw,

Nut,

for

Feed

Screw,

Cloth

installation--------------------------------Cloth

Screw,

Cloth

Screw,

Screw,

Oil

Filter

Oil

Strainer--------------------------------Screw,

Looper

Oil

Sight

Oil

Gauge

Screw,

Bottom

Screw, for

extension

Oil

Gau

Oil

Gau

ottom

B

Screw,

ottom

B

Mounting Isolator,

Screw

, f

Needle

eyelet

Spring

Spring

Foot

Spring

Nut,

for

Spring

Spring

Spring

for

Guard

Pin

Bracket

for

Filler

for

top

Gasket----------------------------

Pin,

for

Oil

for

oil

for

supplementary

Thr

ea d

for

looper

Plate

Stud------------------------------

for

cloth

for

feed adj

for

Driving Arm

for

feed

feed

Mechanism

for

cloth

Plate,

Plate,

Plate

for

for

for

cloth

Latch Spr

for

mounting attachment

for

oil

Screen-----------------------------

for

looper

Thread Fra

Gau

ge

Seal

for

looper

Cover and

bottom

----------------------------------

ge

Indicator---------------------------

ge

Float------------------------------

Cover Gas

for

bottom

Cover--------------------------------

or

bottom

Thread

for

adjustable

- -

---------------------------Plunger----------------------Spacer------------------------

Release

------------------------------

plunger

Plunger

Plunger

Plunger

Foot

Release

hin

ge

-------------------------------

------------------------

---------------------------

oil

filler

Cover

cover

top

cover----------------------

Drain

Plate---------------------------

mechanism

Plug

collector

Cloth

Take-up

thread

plate

usting

needle

Bushing

mechanism

Cover-----------------------

plate

semi

non-submerged

plate

filt

er

screen

thread

me

------------------------------

Ring --------------------------

lever

Base

cover

ket-------------------------

cover----------------------

rubber---------------------

cover----------------------

Control

needle

Bushing----------------adjusting

Adjusting

Lock

Nut--------------

Cap

Nut---------------

Bushing

bracket------------------

cover----------------

-------------------------

-------------------------

----------------------

plate-------

cloth

Plate

--------------------

Eyelet

take-up

stud-------------------

pin------------------

driving

------------------------

or

latch

ing

Eyelet------------------

arm

Oil

cover--------------

cover

fully-submerged

spring-------------

----------------------

-------------------

frame

shaft------------------

Plate

Extension

and base

Eyelet

screw----------

Screw--------

Guide

plate-----------

---------------eyelet

bushing

Tube----------

screw----------

installation-----

---------------

eyelet

plate

thread

-

-

----------

--------

---------

--------

-------

-------Pin

-

oil

------

---

Amt.

Req.

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

8

1

2

1

1

1

1

1

1

1

1

- 1

1

1

1

1

1

1

1

1

1

2

1

2

2

1

1

1

1

1

1

2

1

2

1

1

1

14

1

4

1

11

A-NEEDLE

B-PIVOT

C-LOOPER

DRIVE

SHAFT

DRI

BEARING

BEARING

VE BE

ARING

12

CRANKSHAFT

MECHANISM

AND

BUSHINGS

Ref.

No.

--

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Part

No.

22569

660-219

43534

39590

43555

39573

39555 N

39573

43552

39552

39644 c

39590 T

39644

39690

22894

39591

39591 L

39590 J

39590

39590 R

39590 s

39590 H

22541 A

39521 G

39521 D

22769 B

29477

C0-67

39541 A

29477 MD

22768

22596

22587

39690 A

39690 B

39590 N

39691

22747 B

39591 K

39594 N

E

A

K

AA

B

p

s

666-94

660-443

D

H

G

660-268

95

JV

258

40-46

E

30-106

51-228

c

H

M

97 A

u

87

E

Elk.

Elk.

Description

Screw.

Roll

Feed

Arm

Crankshaft

Foot

Pivot

Foot

Pivot

Needle

Needle

Looper

Crankshaft

Looper

Oil

Crankshaft

"O"

Screw.

Chamber

Char.nber

ThrustWasher--------------------------------Crankshaft

Crankshaft

Ball

Spacer

Crankshaft

Screw.

Pulley

Pulley

Screw.

Crankshaft

Stud.

Crankshaft

Stud.

Crankshaft

Screw.

Crankshaft

Screw.

Oil

for

feed

bar

thrust

Pin.

for

feed

bar

Bar

Thrust

Bushing.

Bushing,

Lifter

Shaft

Lifter

Shaft

Wick

Ring.

Bearing

Screw.

Nut.

Washer.

Cork

Wood

Feed

Vent

Needle

RodAsser.nbly-----------------------------

for

Screw.

for

Splasher-----------------------------------

Shaft

Bushing,

Shaft

Bushing.

Arm

Arm

Drive

Bushing.

Drive

and

Bearing.

for

for

fan

Cooling

Cooling

Ball

Ball

Collar----------------------------------

Ball

for

ball

---------------------------------------for

Cap

------------------------------------

for

pulley

and

for

Plug.

Plug

Drive

Plug.

Driving

Screw.

rodpin-------------------------------Screw.

Screw.

rod-----------------------------------

crankshaft

Split

for

split

Counterweight.

for

counterweights

Counterweight.

for

oil

Washer

left

---------------------------left------------------------

Bushing.

left------------------------

Bushing.

right-----------------------

Bushing.

Bushing.

Shaft

Shaft

Spring

crankshaft

Stop

crankshaft

for

---------------------------------

for

for

bearing--------------------------

splasher

Bushing.

inner

Bushing.

---------------------------inner

collar---------------------------

Fan

Fan---------------------------

Bearing

Bearing

Collar------------------------

Bearing

bearing

pulley---------------------------

cap---------------------------

Needle

crankshaft----------------------

for

crankshaft

Eccentric

for

crankshaft

Arr.n

for

needle

needle

needle

bearing---------------------

Bearing------------------------

split

bearing---------------------

washer

thrust

left----------------------right----------------------

Collar--------------------

Driving

-------------------------

-------------------------

washer

and

left------------------right

right

left-------------------

left-----------------

right

bearing.

Housing-----------------

------------------------

Retainer

housing------------------

Key

Crank

driving

driving

driving

right-----------------

---------------------left

---------------

Needle

-----------------

---------------

----------------inner

Plate-----------

Crank-------------

-------------------

-------------------

------------------and

Connecting

arr.n

arm

arr.n

------------------

------------Driving

right-----

connecting

crank

connecting

------

Amt.

Req.

3

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

3

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

1

4

1

1.

1

13

14

42

~

43

~

NEEDLE

GUARD.

AND

NEEDLE

FEED

DRIVE

DOGS.

MECHANISM

FEED

MECHANISM

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

28A

28B

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

Part

No.

39536

39536

22565

39535

39535

39535

53634

22569

43534

43535

53634

22569

538

39536

39538

258 A

43534

43525

43525

22863

43534

39540

39540

39536

39540

40-46

258

93

9205

56305

43505

87 u

43552

43552

28 c

22596

157

43568

88

660-207

39552

39543

22782

39552

39594

87

K

E

F

c

J

c

D

c

B

J

c

B

A

c

B

B-10

B-8

AF

K

A

E

A

E

GJS

c

y

A

R

N

u

Description

Feed

Nut.

Screw.

Feed

Feed

Main

Washer.

Screw.

Main

Main

Washer.

Screw.

Feed

Feed

Feed

Nut.

Stabilizing

Clamp

Needle

Tilting

Feed

Main

Main

Feed

Feed

Washer.

Nut.

Screw.

Feed

Feed

Feed

Screw.

Needle

Needle

Needle-------------------------------------------

Looper

11011

Take-up

Needle

Needle

Oil

Screw.

Bar

Driving

for

feed

for

feed

Adjusting

Bar

Guide

Feed

Feed

Feed

Dog

Bar

Lift

for

Dog

Feed

Fand L -----------------------------------------

Feed

Bar

Eccentric

for

Dog.

Dog.

Dog.

Screw.

Screw.

Screw.

Ring.

Screw.

Splasher

Bar

for

feed

for

left

Bar-----------------------------------Bar

for

feed

for

right

Height

Driving

Block-----------------------------------

feed

Washer.

Washer.

Guard.

Screw.

Holder----------------------------------

Driving

Driving

Driving

for

feed

feed

for

feed

16

16

12

for

needle

Driving

Driving

for

for

Thread

for

for

Lever

Lever

for

Lever

--------------------------------------

for

oil

Connection

bar

driving

adjusting

Pin--------------------------------

Block

Guide.

main

Guide.

main

Adjusting

dog

for

rear

for

Spacer-----------------------------

driving

dog

teeth

teeth

teeth

Arm

Arm.

needle----------------------------needle

Take-up----------------------------

looper

looper

Thrust

Drive

needle

Drive

splasher

----------------------------left

bar

guide

feed

right------------------------

bar

guide

feed

Stud-----------------------------

holder

for

feed

rear

-------------------------------

feed

dog

Eccentric.

Eccentric.

Connection-----------------------

driving

eccentric

-------------------------------

per

inch.

per

inch.

per

inch.

driving

Thread

marked

driving

thread

thread

Washer----------------------

Shaft

drive

Shaft

----------------------------

Bushing

stud

----------------------

pin-----------------------

------------------------screw-------------------

bar

guide

screw-------------------

bar

Screw

--------------------------dog

needle

holder

for

for

eccentric------------------

for

for

for

arm

Thrust

--------------------------

thread

Ej>;elet------------------

'H

arm------------------

take-up

take-up

shaft

-----------------

guide----------------

-------------------

holder--------------

guard---------------

-----------------Styles

Style

--------------------Style

Style

Style

11

------------------

Collar

thrust

---------------

43500

43500 D ------

43500 F ------43500 L ------43500

eyelet

---------------

----------------

-------------

D-------

---------

collar-------

Amt.

Req.

1

1

1

1

1

1

2

2

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

15

16

THROAT

PLATE,

THROAT

PLATE

SUPPORT,

LOOPER

AND

LOOPER

DRIVE

MECHANISM

Ref.

No.

4

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

36A

37

37A

37B

37C

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

1

2

3

5

6

7

8

SA

BB

9

Part

No.

43580

43

578 B

22784 E

660-334

43580

22656

87

43524

43524

0112

22564 D

43508

22503

39543 E

39644 L

39644

22775

22781

41336

43544

A

98

43544

39573 A

39573 E

55235 D

6042 A

55235 E

39673

22587 E

39644 M

22565

22565 L

v

39644

39644 p

98

39644 E

J-4

226 53

43578

43578

43503

43503

43503

22542

43578

22585

4352

14077

22892 B

22653

39580 F

39644 A

39543

39644

39644 N

39543

22562 A

39644

22729 D

22729 E

39644

39644

39644 X

22894 c

c

c

B

A

c

25

A

5

B-12

p

660-206

1VI

u

R-2

R-5

538

482

c

A

A-6

A

F

w

c

c

Description

Throat

Fabric

Screw,

Retaining Rin

Throat

Screw,

Screw,

Throat

Throat

Throat

Screw, for

Looper,

Screw,

Cam

Cam

Looper

Screw,

Screw,

Looper

Thrust

Looper

Washer,

Pivot

Looper

Looper

Set

Spot

Bushing

Thrust

Looper

Fabric

Fabric Gua

Edge

Ed

Ed

Sc

Scr

Pivot Shaf

Screw,

Needle

Nut, f

Locking Screw, for

Screw,

Wa

Looper Bar

Thrust Was

Looper

Looper

11

0'

Clamp

Looper

Shim,

Shim,

Ball

Screw,

Looper

Plate

Support

Guard

for

Plate

for

for

Plate,

Plate,

Plate,

for

Follower

Follower-------------------------------------------

Bar

for

for

Avoid

Collar,

Screw,

Avoid

Shaft

Locking

Washer, for

Nut,

Avoid

Screw,

Avoid

Screw,

Screw,

Collar

Screw,

Holder----------------------------------------------------

Screw,

Guard,

Guide,

ge

Guide

ge

Guide,

rew,

for

ew,

for fabric

for

Guard,

or

for throat plate support bra

sher----------------------------------------------------------

Drive Lever----------------------------------------------Drive Lever Shaf

Rin

g, for

Collar-----------------------------------------------------

Screw,

Drive

Screw,

Screw,

for

for

Joint

for

Drive

Screw,

Position

fabric

g,

Support

throat

throat

for

for

for

looper-------------------------------------------------

marked

cam

Locking Clamp--------------------------------------

Sleeve-----------------------------------------------looper

looper

Link

for

Pivot Shaft------------------------------------------

for

pivot

Drive

Stud,

for

driving lever-----------------------------------------

Connecting Rod

for

Link------------------------------------------------

for

bushing and

for

and

Cam

----------------------------------------------------

for

for

for

rd,

for Sty

for Styles 43500 F a

Bracket, for

for

No. 43503 A

t,

for fabr

front needl

front-----------------------------------------------

locking scr

------------------------------------------------------

her, for

looper

for

Lever

for

connecting

for

connecting

ball

joint

ball

joint

Guide

ball

joint guide

Lever

for

collar-----------------------

Bracket

ing Fing

guard pos

for

pivot

Plate-----------------------------------------

plate

support plate-------------------------------plate-------------------------------------------Style

43500 F -----------------Style

43500 L -----------------------------------Style

43500 D ------------------------------------

11

"CT

follower

for

thrust

connecting rod-------------------------------------

bushing an

thrust

looper

Sty

clamp

Fork

--------------------------------------------

avoid

avoid

Pin

--------------------------------------------

pivot

collar---------------------------------------

shaft--------------------------------------------

Lever

for

driving lever---------------------------------

driving lev

Guide--------------------------------------------

collar---------------------------------------

holder--------------------------------------

Style

le

le 43500

gua

rd and

ic

gua

e g

ew

--------------------------------------------

cloth

looper bar-------------------------------------

driv

collar---------------------------------------

Connecting Rod

guide

guide fork,

------------

Shaft

-------------------------------------er

-----------------------------------

itioning

shaft -------------------------------------

locking clamp------------------------------

link--------------------------------------link

pin------------------------------------

shaft--------------------------------------

------------------------------------------er

cam guide-------------------------------

d ca m g

43500

43500

Style 435

D--------------------------------------

on Style

edge

rd---------------------------------------

uard--------------------------------------

pla

te lat

t------------------------------------------

e lever

rod--------------------------------

rod-------------------------------------

fork, . 002 inch

fork-----

Collar

finger---------------------------

-------------------------------------

--------------------------------------

uide------------------------------

F-----------------------------------L--------------------------------

nd

L-------------------------------

00 D ------------------------------

43500

guide

shaft

. 00 5

-----------------------------------

D----------

No.

ch spring--------------------------

cket-----------------------------

------------------------------

--------------------------------

thick-----------

inch thick---------------as

-

-------------------------------..

-------------------------------

-

-----------------

-

--------

-

-----------------

43503 C -------------------

-

---

as

-

---------------------

Amt.

-

---

-

----

required

required

Req.

1

1

2

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

2

1

1

1

2

2

1

2

1

1

2

1

1

1

2

2

1

2

1

2

17

18

PRESSER

FEET,

FOOT

LIFTER

PARTS

AND

THREAD

TENSION

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

Part

No.

43556

22791 H

258 A

43555

12865

88

39555 c

627

12538

22597 E

39555 F

660-142

39555 D

39555 B

39855

43520

604

56330

61430

43530

22799 G

43530

56330 B

43530

22566 B

43520

43530

22799 H

43530

A

51330 w

43530

43556

F

A

22585 B

39592

39592

39592

39592

AB

AC

AK

AR-2

43592-8

39592

39592

39592

39592

39592

8372

39592

AJ

AD

AF

AL

AG-3

A

AM

22847 B

22806

A

652-16

39592

43520

AH

B

43530

43530

G

22799 H

A

AR

BT

D

B

c

Description

Presser

Screw,

Nut,

Foot

Thrust

Foot

Foot

Cotter

Foot

Foot

Foot

Presser

Arm

for

for

presser

Lifter

Collar,

Screw,

Lifter

Screw,

Lock

Nut,

Screw,

Lifter

Pin,

Lifter

Lifter

Lifter

Foot

Screw,

Spring,

Spring,

-----------------------------------

presser

Lever

for

Lever

for

for

Lever

for

Intermediate

Lever

Lever

Assembly,

for

for

for

arm--------------------------

arm

screw----------------------

Shaft

for

thrust

--------------------------

foot

lifter

collar----------------------

Arm---------------------------

lever

for

lever

arm------------------------

lever

arm

arm------------------------

Connecting

connecting

link--------------------

Lever

Spring-------------------------

------------------------------for

spring

yielding

chaining

--------------------------section-------------------

section

PresserFootShank-------------------------Hinge

Presser

Chaining

Yielding

Screw,

Presser

for

Foot

Screw,

Foot

for

presser

Bottom

------------------------

Section-----------------------------

Section-----------------------------

foot

lifter

Assembly,

lever-----------------------

for

PresserFootShank-------------------------Hinge

Presser

Spring,

Chaining

Chain

Screw,

Looper

Needle

Tension

Looper

Needle

Spring

Thread

Tension

Thread

Tension

Washer,

Tension

Screw,

Screw,

Washer,

Shoulder

Presser

Presser

Presser

Hinge

Screw,

Foot

for

for

presser

Bottom

chaining

------------------------

section

Section-----------------------------

Cutting

for

Tension

Tension

Spring

Tension

Tension

Knife------------------------------

chain

cutting

Nut,

Nut,

red

Ferrule

knife

blue

------------------------

-------------------------

--------------------------

Spring------------

Spring

---------------------------

Shield------------------------------------

Tension

Disc

Tension

Post

for

Post

for

tension

for

tension

for

Nut,

Foot

Screw

Disc-----------------------------

Felt

thread

-------------------------------

Post

Mounting

---------------------------Bracket

tension

post-------------------

Bar--------------------------------

post

mounting

post

mounting

bracket

for

Assembly,

Foot

Foot

screw----------

thread

tension

for

Style

Shank-------------------------Bottom,

marked

--------------------------------

19

lever

shaft-----------

--------------------Link

----------------

-------------------

Style

43500 L ---------

------------------

foot

bottom----------

Style

43500 F ---------

foot

bottom----------

------------------

and

presser

....

--------------

foot

-------------------

bracket

bracket

----------

----------

-

------------

post--------------

43500

"BX

D---------

11

----------

-----

Amt.

Req.

1

1

1

1

1

2

1

1

2

2

1

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

4

2

2

1

2

1

1

1

2

2

1

1

1

1

20

b

~

29

THREAD

STAND

AND

ACCESSORIES

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

*22

23

24

25

26

27

28

29 WR64

30

Part

No.

21101

SC303

22810

21114

22651

21114

258 A

21114

652-16

21114

21104

21114

22651

21104

21114

22651

21104

652-16

21114

21114

22651

21225-5/64

660-272

660-264

421

21388

21207

21388

WR70

28604

660-458

H-2

T

CD-4

S-2

w

v

H-2

CD-4

B-24

D-2

CD-5

H

u

A

CD-4

D-34

w

A

AU

R

Description

Thread

Looper

Thread

11

"S

Foot

Wrench,

Screwdriver.

long------------------------------------------

Socket

feed

Wrench.

Wrench.

Container

Dust

Stand,

Wood

Clamp

Lead

Screw----------------------------------

Thread

Nut---------------------------------------Spool

Washer-----------------------------------Spool

Pad,

Thread

Thread

Thread

Nut----------------------------------------

Washer------------------------------------

Lead

Thread

Hook.

for

Screw

Screw

Screw

Gauge,

Tweezers-------------------------------

Lifter

curved

Wrench.

eccentric---------------------------------

3/32

7/64

Cover

complete

Screw,

Screw-------------------------------

Eyelet

Stand

Seat

Pin

Stand

Stand

Stand

Eyelet

Stand

for

Treadle

of

Oil.

(not

for

Socket

Lead

Disc-----------------------------

----------------------------------

thread

Eyelet

--------------------------------Rod---------------------------

Spool

---------------------------------

Ball

Base--------------------------

--------------------------------5/64

treadle

double

1/8

inch

for

inch

hexagonal---------------------

inch

hexagonal---------------------

16

shown)--------------------------

-------------------------

thread

Eyelet

cone------------------------

Split

inch------------------------

chain----------------------

Chain.

end,

diameter.

3/8

inch

fluid

stand

Ball

---------------------

-------------------

Support

Seat

Support--------------

Socket-----------------

34

inches

9/32

hexagonal

ounces

base-----------

-----------------

long---------

inch

opening-----

4

3/16

(not

inches

nut

holding

shown)-------

Amt.

Req.

1

3

1

1

1

1

4

2

2

2

2

1

1

1

1

2

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

*

Available

as

extra

send

and

charge

item.

21

NUMERICAL

INDEX

OF

PARTS

Part

No.

25

c

..........

25

s

..........

28

c

..........

30-106

40-46

50-575

51-103

51-228

WR64

C0-67 E ........•.

WR70

80

86 X ..••••••••

87

87

88

90

93

9 5 • • • • • • • • • • • •

97

98

0112

157

258

258 A ..•••..•..

SC303

421

482

538

604

62 7 • • • • • • • • • • • •

652-16

660-142

660-206

660-207

660-219 E ••••••

660-234

660-243

660-264

660-268

660-272

660-334

660-443

660-458

666-94

667

6042

8372 A ..••••••..

Blk

•...••..•

Blk

Blk

Blk

•••••••••...

..•.....•.•.

. . • • • . . . • • . • 11

.....••••...

u

..........

••..•.•.•.•.

• • . • • • • • • • • .

A

••••••••..

A • • • • • • • • • •

. . . • • • . . . . • .

• . . . • • • . . • • .

GJS

..••••..

...•.•••....

....••••••••

D-34

c

.•••.••••...

• • • • • • • . • • • .

D-8

A . • • • . • • . . •

••••..•

..........

•••••••••

.•.•••••

• • • • • • • .

.•••••••

.••••.••

. • . • • • • .

•••••.•.

••••••..

••••.••.

••.•.••.

••.•••••

•.••••••

•••••••••

• • • • • . • •

••...

•...•

..•..

...•.

Page

No.

17

11

15

13

13,

15

11

11

13

21

13

21

11

17

13,

15

15,

19

11

15

13

13

17

17

15

13,

15

15, 19,

21

21

17

15,17

19

19

19,

21

19

17

15

13

11

11

21

13

21

17

13

21

13

11

17

19

Part

No.

9 20 5 E • • • • • • . • • • .

12538

12865

14

21101

21104

21104 H ••..•.••...

21104

21114

21114 A .••.•.•..•.

21114

21114

21114

21114 T •••....•...

21114

21114

21207 A •.•••••..•.

21225-5/64

21388

21388

22

22513 B ••••••••••.

22541

22541 A •.••••.•...

21

22

22562A

22

22565C

22565

22565 L •.•••.•.••.

225-66 B

22569

22569 B ...........

22569 D .••••••.•••

22571 E •.•••.•.•••

22585

22585 B ...........

22586 R ••••.•••••.

22 58 7 E • • • • • • • • • • •

22587 M •••••.••••.

22596 E •••••••.•••

22596 H ...........

22597 E .••••••••••

22651

22651

22653

22

2 2 6

..•••••..•...

•••••.•••.•..

07 7 • • • • . . . • • . . . •

H-2

B-24

v

...........

.•••••••..•..

D-2

H-2

S-2

u

...........

w

...........

w

...........

AU

.•.•••....

50 3 F . . . . . . . . . . .

•.•••..•.•..•

542

• • • • • • • • • • . . .

...••••••.•

564

D • . • • • • • • • • •

•••••••••••

F

•.•••.••.••

••.•••••..•

.............

••••••.•••..•

CD-4

CD-5

B-12

653

D-4

53 J -4.

Page

No.

15

19

19

17

.........

•••...•.

•.•.•••.•

.•••••.••

•••.••••.

•...•...

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

17

11

11

13

17

11,17

17

17

11,

17

19

11,

15

11

11

17

19

11

17

13

15

13

19

•.•••••.

•••...••

........

••.••••••

• • • • • . . • . 1 7

21

21

17

11

15

13,

15

Part

No.

22656

22657

22729 D ..........

22729 E •.•••••.•.

22747 B •••.•.....

22768

22769 B •..••••..•

22775

22781

227

22784 E ..........

22791 H .••••..•..

22799 G •••.••••••

22799 H ..........

22806

22810

22824

228 38 • • • . • • • . • . • .

22847 B ..•..••...

22863

22892 B ..........

22894C

22894D

22894

28604 R .•.••..•..

29477

29477

39501

39521 D ..........

39521 G •••••••...

39532 A ..........

39535

39535

39535 J •.••••••.•

39536 E •••••••.••

39536 J ••••••••••

39536

39536

39538

39540

39540

39540

39541 A ••••..•.•.

39543 E ..........

39543 M •..•••••.•

39543

39543

39552

A-6

•...••••

D-12

c

• • • • • • • • • • • •

..••..•.•.•.

82 A • • • • . • • . • .

A

............

............

c

AE

JV

MD

K

.••..•••••..

c

K

AF

•••••••.••.•

B-8

B-10

K

p

y

c

.•.•...

..........

••••••••••

..........

..........

..........

..•••••.•

.........

••....•..

•••••••.••

..........

••••••••••

•••••••.•

••••••••

••..••.

..........

..••......

..........

..........

Page

No.

17

11

17

17

13

13

13

17

17

15

17

19

19

19

19

21

11

11

19

15

17

17

13

11

21

13

13

11

13

13

11

15

15

15

15

15

15

15

15

15

15

15

13

17

17

17

15

15

22

NUMERICAL

INDEX

OF

PARTS

Part

No.

39552

39552

39555 B •••.••.•••.

39555

39555 D •••••••.•••

39555 F •.•••.•••..

39555 N •.•.•.•••••

39556 A •.•.••••.••

39557

39557 A •..••••••.•

39557 B •.•••.•.•••

39557

39557 E •••••.••.•.

39557 F •.•.••.••••

39573 A •.•.••.•••.

39573 E ••.•••.•..•

39573 K •.•••••••••

39573

39580 F •.•••.•••••

39582 D ...........

39582 F •.•••••..••

39582

39582

39582

39582

39582