Page 1

®

INDUSTRIAL

SEWING

FINEST QUALI

TY

STYLES

41400A

414008

41400C

LEWIS

•

CO

L

UMBIA

MACHI.NES

CATALOG

CLASS

41400

No.

CONTINUOUS

FEED

123M

WITH

NEEDLE

MACHINE

CHICAGO

CUP

FEED

COMPANY

FEED

..

'

Page 2

Catalog

No.

123M

41400

The

furnished

A

parts

at

LIST

CLASS

listed

list

First

OF

Styles

41400

in

prices

Edition

PARTS

41400

B

this

for

catalo

repair

41400

g

are

s

c

only.

Copyright

1962

by

Union

Rights

Re

Special

se

rv

e d

Machine

in

All

MACHINE COMPANY

INDUSTRIAL

P r inte d

SEWING

CHICAGO

in

MACHINES

U

.S.A.

Co

Countr

.

i

es

Page 3

IDENTIFICATION

OF

MAC H

INES

Each

1e

name pl

tandard

letter

When

standard

Sty

which differs

Union Special machine

ate

Style numb

''Z".

only

Ex

minor ch

Style number.

le s of

from

This catalo

herein.

Reference

operato

is

away from the

It

can

to

r ' s positi

High Speed Con

Horizontal

Height

Knife Ass

Ne

edle

of Uncurler,

embly,

on the machi

er s

ampl

e:

ne.

have on

"Styl

anges are

Exampl

machines

the st

s imilar

yle

numb

APPLICATIO

g appl

als

ies

specifica

o be a ppl" ed wi

di ection, s uch

on

wh

ile seat

op rato

tinuou

r .

s Run

ning Cup Fee

Travel, Fab

Auto

m atic

Singl e R

eser

is ide

Styl

e 414

made in

as

ed

STYL

r ic

Thread

voir

ntified

e n

umb

e or

00

e:

mo

A" .

"Style 41400

by a Style number

er s are

r e lette

classified

rs

suffixed,

SpecialStylenumberscontainthelett

a standar d

mach

ine, a

AZ".

in construction are group

er , in

th

lly

discre

rig

ht, lef

at

the

ES OF

Uncu

that

it conta

N O F

to the sta

tion

to some Specia

t, front,

mac

hine.

MACIDNES

d Machine

r ler, K

Rat

nee

io Con

ins

no lett

CATALOG

nda

r d

Styl

back,

Operatin

With

Controlled

trol,

Fabric

Needle

Automatic Lubricating

which

as

standard

but nev

"Z"

ed

und

ers. Ex

es

of m achine s as li

l m a chin

is stamp

er

is s uf

er a cl

ampl

es

and spe

conta

fix

a s s

e:

in this

etc., are given fr

g dir e

Puller

ction

Feed,

Device

For

and

of

Single

Increasing

Chain

System.

ed

into

cial.

in

the

er trz".

ed

to

the

number

" 4

1400

sted

class.

om

the

handwheel

Needle,

Cutting

11

•

41400

41400

41400

numb

The

A

For

hosiery,

and stit

Spec

ifi

B

Same

s e

with circular or square hee

ch

ton

cation

as

sup por t • 0 55 i

C

Sa

m e

as

E

ach Un

er

size

ion Sp

denotes

num be r , stamp

amin

gu s

504

-SSa-1.

414

nch high

414

ecial needle h

the

kin

blade measured in tho

Collect

(.

076

and grooves,

sample needle,

on

ivel

St

andard need

inch

To

have needl

lab

el.

y,

the type numb

le

for

diam

ete

r), round

two

step r

e orders

or the type

A c

omplete

g a

ll

weights

upport.

00

A ,

065 inch hig

ex

of

cept e

cotton,

l.

h a

quipp

Ma

nd fabric

ed

.

00

A ,

exce

pt e

d of s

ed

usan

Sty

hank, poin

on

dths of

er

les

414

point,

quipp

NEE

as

both a type num

the needl

an inch,

an

d the

00

A,

Class

ed

DL

ES

t, length, groov

e sh

ank, denot

midway

size

B a

nd

C is

" X" l

eduction, spotted, pla in finis

promptly and

and

ord

er

would

s i

ze

numb

r ead:

accurately fill

e r

should

"1000

ra

yon,

chine

s i

lk

is

equipped

and

uncurler

with needle gua

with

ber

fabr

ic

and a si

uncurler

e, finis h

es the large

numb

Type 155

eng

th,

betwe

en the

er is the

F.

doubl

e g

h -size

ed,

be

for warde

Needles, Typ

nylon

No.

rd

ze

full

with

needle guard

29450

a nd sti

No.

number.

and

oth

fashioned

P.

tch tongue

29450

The type

er details.

st diam et e r

It

roov

shank

compl

has

and the e

ete s

a r ou

ymbol.

nd

e, under size eye

027.

an empty package

d.

e 1

Us e de s

55

F ,

Si

cripti

ze

Seam

R.

of

ye.

shank

, a

on

027".

Se

lect

ion of the p r

Thread should pass

ormation.

f

oper nee

free

ly through needle eye in or d

dle

size s

hould

3

be deter m ined

er

to

by siz

produc

e of thread used.

e a g

ood stit

ch

Page 4

USE

GENUINE

NEEDLES

AND

REPAIR

PARTS

Success

Union

Company.

to

Maximum

parts

guarantee

number.

permit,

ones.

appear.

OF

Special

the

most

Genuine

are

Where

Part

IMPORTANT!

MACHINE

in

the

Needles

its

subsidiaries

approved

efficiency

needles

stamped

of

the

construction

On

some

an

identification

numbers

FOR

operation

and

are

with

highest

of

the

represent

ON

WHICH

and

Repair

and

scientific

durability

packaged

the

quality

permits,

smaller

letter

the

ALL

ORDERS,

PART

of

these

Parts

authorized

principles,

with

Union

in

IDENTIFYING

each

parts,

is

stamped

same

IS

machines

as

are

assured.

labels

Special

materials

Union

part,

PLEASE

ORDERED.

can

furnished

distributors.

and

are

marked

trade

and

and

in

regardless

mark.

workmanship.

PARTS

Special

on

those

to

distinguish

INCLUDE

be

secured

by

the

Union

They

made

are

with

1IAwm.SpcciaL

Each

part

is

where

of

the

PART

the

only

designed

utmost

.

trade

stamped

construction

part

catalog

NAME

with

genuin

Special

Genuine repair

mark

from

in

Machin

according

precision.

with

its

does

similar

which

AND

STYLE

is

e

your

part

not

they

Prices

shipments

unless

must

viscosity

sight

be

is

keeping

Excessive

machine

otherwise

The

be

Oil

is

gauge

maintained

8

ounces.

A

daily

are

oil

filled

of

filled

the

check

oil

just

are

forwarded

has

been

before

200

to

at

on

the

between

The

main

in

the

below

strictly

directed.

drained

beginning

250

seconds

the

spring

right

the

machine

reservoir

before

main

the

net

f.

o.

side

red

filled,

the

reservoir

top

cover.

cash

b.

A

OILING

from

cap

of

is

morning

and

shipping

charge

the

to

ope0ate.

at

100

in

machine,

lines

automatically

is

may

TERMS

are

point.

is

made

AND

the

on

THREADING

machine

Fahrenheit.

top

in

the

gauge.

necessary.

start

should

be

subject

Use a straight

cover

front

lubricated

drained

Parcel

to

cover

before

and

of

the

The

be

at

to

the

capacity

made

the

change

Post

shipping,

pulley.

shipments

the

postage

mineral

oil

level

and

and

plug

no

oil

without

and

oil

is

The

of

the

oiling,

added

screw

notice.

are

insured

and

insurance.

the

reservoir

with a Saybolt

checked

oil

level

oil

if

on

the

at

should

reservoir

other

required.

back

All

the

than

of

The

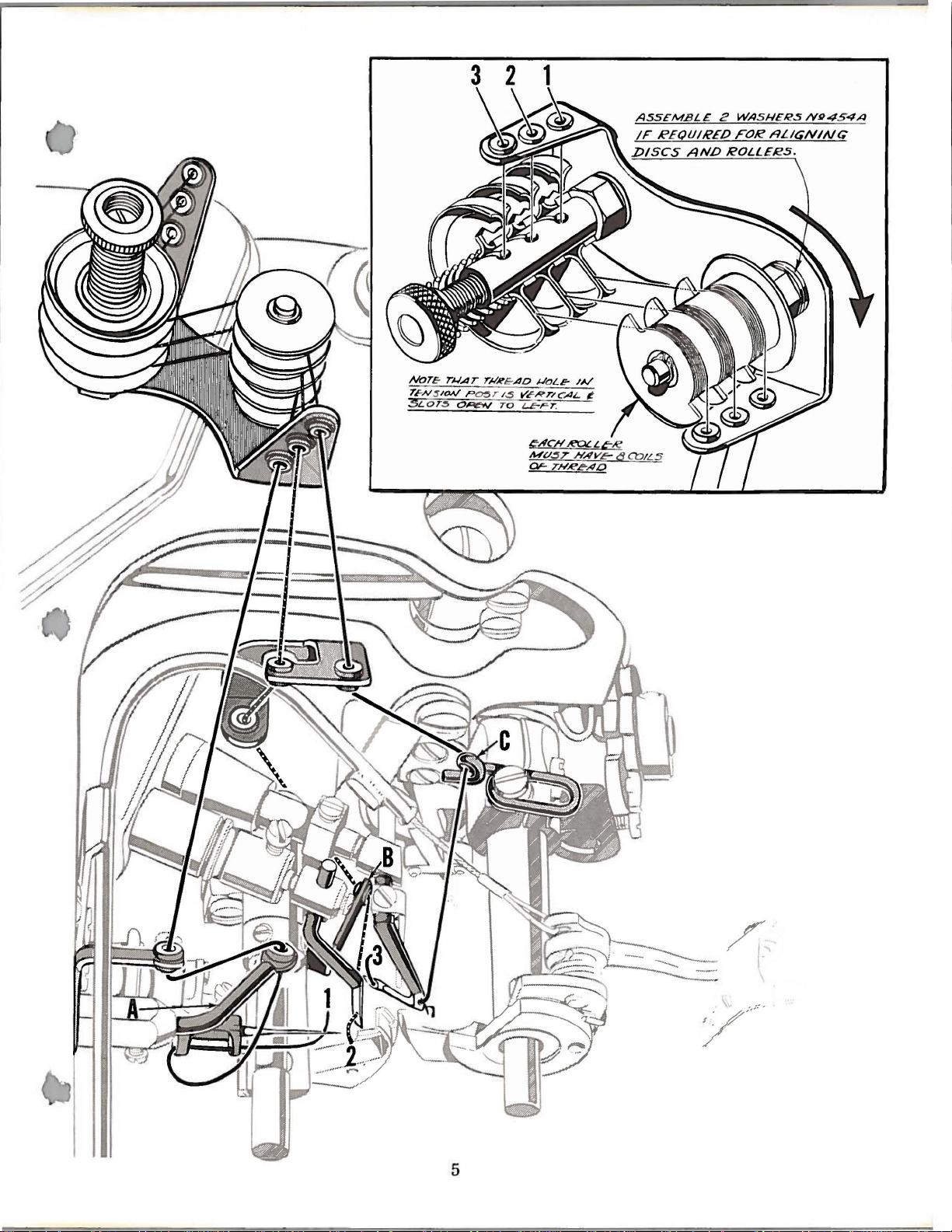

Please

that

the

top.

drawings

note

that

short

on

the

groove

the

next

needle

with

page

is

the

show

inserted

spot

or

the

into

scarf

manner

the

is

up.

4

in

needle

Thread

which

holder

the

the

as

needle

machine

far

as

from

is

threaded,

it

will go,

bottom

and

to

Page 5

NoTE-TJ./.A T T;./KE-

TFNSIOA/

Sl.

0 T

!5

P = r /

0~

TO

.40

J./Ol.E-

PT/CAL

T.

IN'

It

.$

Vr

L.£-F

5

Page 6

ADJUSTING

AND

OPERATI

NG IN

STRUCTIONS

Fe

d s pr o

18

stitch

is

No. 41457

othe

r wise sp

Listed

paper)

2

scr

take left si

in

of

shaf

the

below

that these

To

cha

ews in

elongat

mach

ine, remov

t.

To

2 s

et

cke

ts us

ed

in

this

mach

es p

er inc

ecified,

are some

h.

It

A , wh

(Checke

il

combinations

tch

Sti

es Per

wi

ll

be

e th

at

machine

spr

ocket

d On

Paper)

of the fe ed driven

Inch

12

13

14

15

16

17

18

19

20

nge s

de

ed slot . N

continu , remove feed dr

s c r e ws

prockets,

pulley

cover

on

th

e f

(on

left sid

off.

Remov

ext, take off bel

e 2 s et

the

scre

hub and

FEED

noted

wi

combination

should produce.

ollowin

e of

e idler

ws

sli

SPROCKETS

ine ha

ll

machine

located

de off shaft

ve been select

that the

be s hipped

g pr ocedure is suggested: A

sp r

t .

ive sprocke

part

s and

), remove pull

ocket

To chan

within

ed

to

produce appr oximately

number

sprocket

with

the sti

and sprocket a r m by removing s crew

ge feed d

tee

t, also on main s h

.

of the feed driv

is

No. 41457

above sprocket c

tch

es p

er

inch

Sp

r o

cket

Combinations

41457 C and

4

1457 B an

4

14

57 B a

41

45

7 Band F

414

57 B a

41457

4

41457

41

th a

A and F

1457 A and

457

ey fr

riv

en s pr ock

nd pull from

nd

nd

and

an

om

D

d D

E

G

G

F

d G

fter loosening

main

et nearest top

aft

, by

e s pr

F.

ombination.

(check

wo

U

shaft,

r m ·

loo

s e

ocket

nless

ed

on

and

Install

a

gainst

sprocket bea

nd

a

become

a

nd

un

curler, the st

loop

gauge

bea r ing. Ti

Replac

Aft

belt.

pull

Before assemb

er

Clean

e f

er sel

Take

s just taut. Be sur

ey.

need

the

(on

right sid

replacement feed driv

ght

en s et scre

eed

dr ive s

rs

against ball bearin

ecte

d c

ombination

up slack

A

SSEMBLI

ling se

itch

le gua r d. T

machine

e of

prock

in be

win

tongue,

hen

thorou

mac

et

of s

lt

e be

lt does

NG AND

g pa rts,

s titc h tongue support, s

, f

ollow this s ugg

MA

ghly.

hine)

en

sprock

ws.

by

pushin

g.

prock

by

movin

NOT

ADJUSTING SEWING

remove

CHINE OIL

Fi

ll oil res

is betw

et by pus hi

Check

g on

Tight

ets has b

g idl

r ub

the fabric

este

LE

een

r e d line

for bind.

to shaft with hub

en

er

agains

erv

ng onto

set

scre

een inst

spr ock

d s equen

VE L

oir s o the o

alled, inse

et arm v

t casting.

pull

tationa

ce:

s.

shaf

t unt

il

hub b ar

to

the outsi

ws. Check for bind.

rt idl

ertically

Replace side cover

PARTS

er a ssembl

ry

needle g

il lev

y, the fabric

uar

el

in

er

spr

until

d,

the si

de

and t

ght oi..c

until

ock

belt

s

et

he

6

Page 7

SETTING

THE

FRONT

FEED

CUP

SEPARATING

LEVER

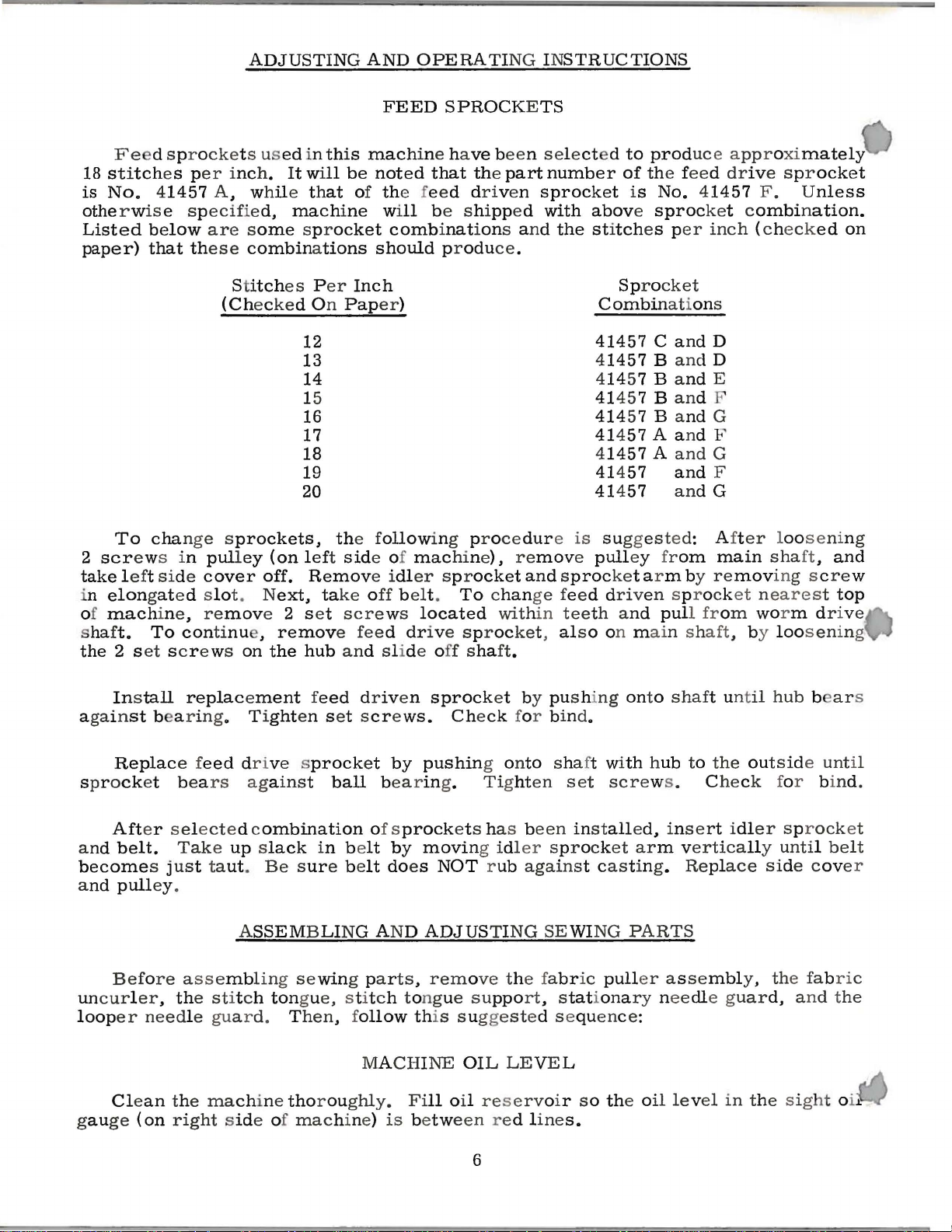

Observe

with

respect

sting).

nust

be

approximately

between

rod

Pull

Push

exerts

of

collar

rod

down

tothebottom

To

obtain

collar

this

rod

its

yoke

slightly.

Check

the

rod

and

(E)

position

to

front

Between

two

parts.

this

(C).

freeing

down.

up

1/32

pressure

bottom

will

Exerting

SETTING

the

height of

of

the

of

front

feed

this

1/32

making sure

inch

against

be

1/32

needle

lever

1/32

inch

the

separating

and

of

top

more

THE

the

cup

rear feed

bar

feed

separating

and

inch

clearance

clearance,

retighten

collar

underside

inch

when

pressure

REAR

(B).

cup

separating

the

rod

it

and

(C).

FEED

cup

Using

lever

separating

to

prevent

loosen

for

vertical

separating

screw

Distance

surface

separatin

will

open

CUP

(A,

Fig.

gauge

laid

(C)

between

underside

been

run

rod

(under

screw

(B).

of

g r

front

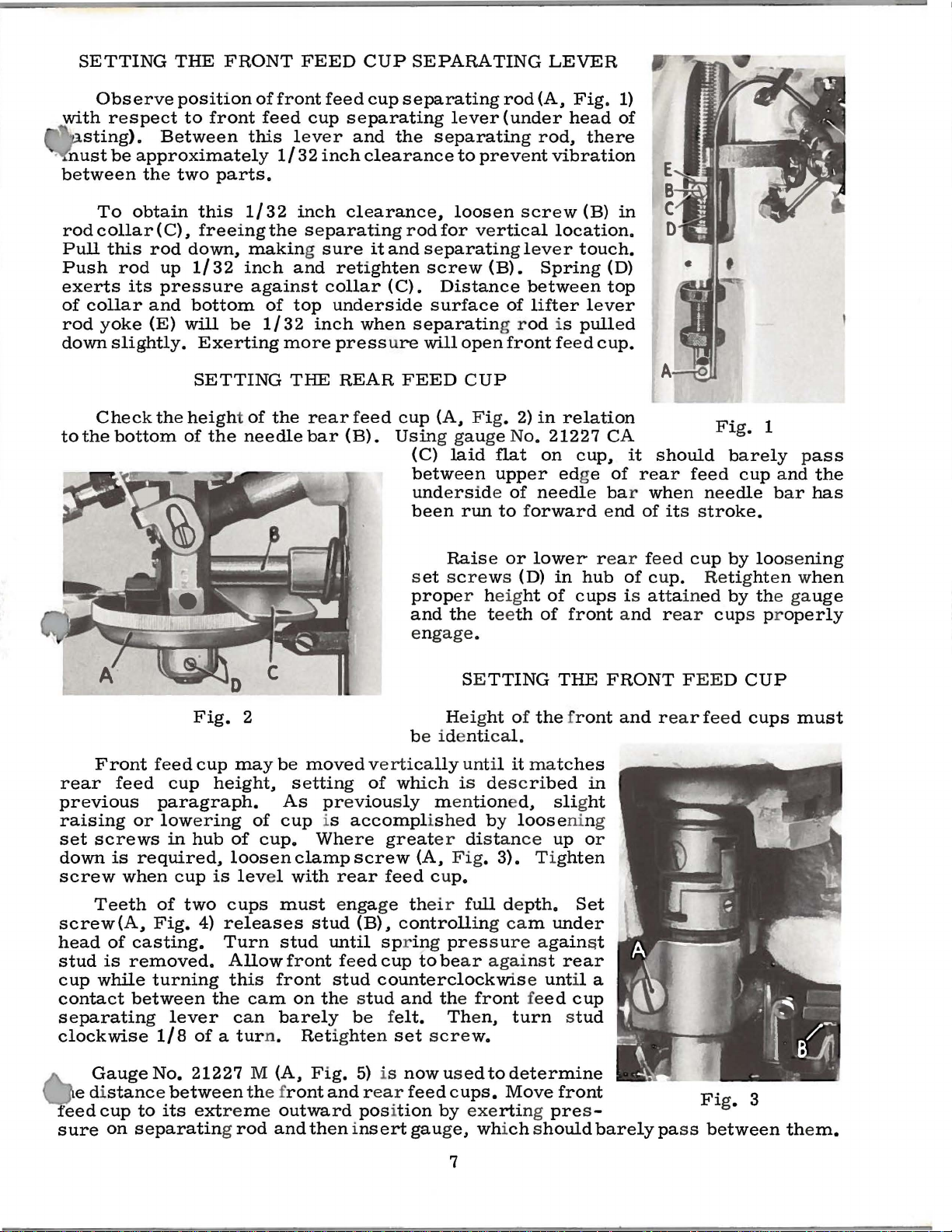

2)

No.

flat

upper

of

to

(A.

Fig.

head

rod.

vibration

location.

lever

between

lifter

od

forward

touch.

Spring

is

pulled

feed

in

relation

21227

on

cup.

ed

ge

needle

1)

of

there

(B)

in

(D)

top

lever

cup.

CA

it

of

bar when

end

should

rear

of

its

Fig.

barely

feed

needle

stroke.

cup

1

bar

and

pass

the

has

Front

rear

previous

raising

set

down

screw

screw(A.

head

stud

cup

contact

separating

clockwise

feed

or

screws

is

when

Teeth

of

casting.

is

removed.

while

between

Fig.

feed

cup

cup

paragraph.

lowering

in

hub

required.

cup

of

two

Fig.

turning

lever

1/8

4)

of a tur

2 H

may

be

moved vertica

height.

of

loosen

is

lev

cups

releases

Turn

Allow

this

the

can

setting

As

of

cup

cup.

clamp

el

with

must enga

stud

front

front

cam

on the s

barely

n.

of

previously men

is

accomplish

Where

screw

rear

ge thei r

stud

(B).

until spring pres s u

feed

cup

stud

counterclockwis

tud

be felt.

Retighten set scr

Raise

s

et scre

prope

and the te e

en

gage

be ide

lly until

which

great

feed cup.

controlling cam under

and the

is d

ed

er distan

(A.

Fig. 3).

to bea r

Then.

or

lower

ws (D)

r h

eig

ht

th

of

.

SE

TTING

eig

ht

of

the front

ntical.

it matches

esc

ribed

tioned,

by

loose

ce

Ti

full depth.

re again

agai

nst

e

front feed

turn stud

ew.

in

of

THE

slight

up

ghten

rear

until

r ear feed

hub

of cup.

cups

front and

ning

Set

cup

is attained

FRONT FEED CUP

and rear fe

in

or

st

a

cup

r ear

by

loosening

Retighten w

by the gauge

cup

s pr

operly

ed

cups

must

hen

te di

feed

sure

Gauge

cup

No.

21227 M (A.

stance

on

between the f

to

its

extreme outward

separating rod

Fig.

ront

and

then insert

5)

is

and rear

position

now used

feed

cups.

by

exe

gauge. whi

7

to

determine

Move

rti

ng

ch should

front

pre

s -

barely pas s

Fi

g. 3

between the

m.

Page 8

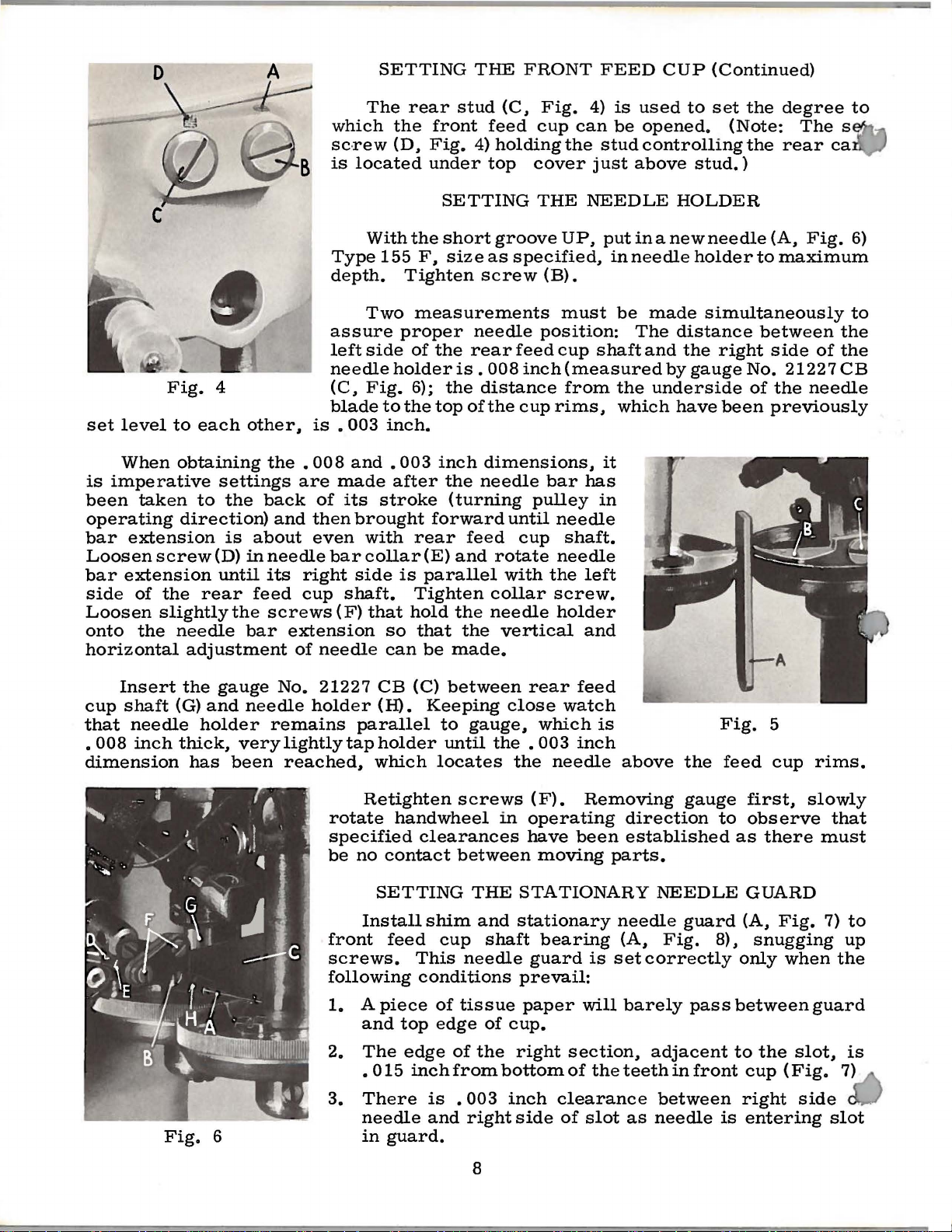

A

The

which

screw

is

located

SETTING

rear

the

front

(D.

Fig.

under

THE

stud

4)

FRONT

(C,

feed

holding

top

cover

Fig.

cup

can

the

FEED

4)

is

be

stud

just

CUP

used

above

to

opened.

controlling

stud.)

(Continued)

set

the

degree

(Note:

the

The

rear

to

s

ca

set

level

When

is

imperative

been

operating

bar

Loosen

bar

side

Loosen

onto

horizontal

taken

extension

screw

extension

of

slightly

the

Fig.

the

4 (

to

each

obtaining

settings

to

direction)

(D)

until

rear

needle

adjustment

other,

the

is

in

the

bar

the • 008

are

back

and

about

needle

its

right

feed

cup

screws

extension

of

With

Type155

depth.

Two

assure

left

side

needle

C,

Fig.

blade

is • 003

and • 003

made

of

its

then

brought

even

with

bar

collar

side

shaft.

(F)

needle

that

SETTING

the

short

F,

sizeasspecified,

Tighten

measurements

proper

of

the

holder

6);

the

to

the

top

inch.

inch

after

stroke

so

can

forward

rear

(E)

is

parallel

Tighten

hold

that

be

the

(turning

groove

screw

needle

rear

is.

008

distance

ofthe

dimensions,

needle

until

feed

and

rotate

with

collar

the

needle

the

vertical

made.

THE

(B).

position:

feed

inch

cup

rims,

bar

pulley

cup

the

screw.

NEEDLE

UP,

put

inneedleholdertomaximum

must

cup

(measured

from

needle

shaft.

needle

holder

be

shaft

the

which

it

has

in

left

and

HOLDER

ina

new

made

The

distance

and

the

by

gauge

underside

have

needle

simultaneously

right

been

(A,

between

side

No.

21227

of

the

previously

Fig.

of

needle

6)

to

the

the

CB

Insert

cup

shaft

that

needle

•

008

inch

dimension

the

(G)

thick,

Fig.

gauge

and

holder

has

6

No.

21227

needle

verylightlytapholder

been

holder

remains

reached,

rotate

specified

be

front

screws.

following

1. A

2.

3.

CB

(H).

parallel

which

Retighten

no

SETTING

Install

piece

and

The

•

015

There

needle

in

(C)

between

Keeping

to

gauge,

until

locates

handwheel

clearances

contact

shim

feed

guard.

cup

This

conditions

of

top

edge

edge

inchfrombottomof

is • 003

and

the • 003

screws

in

between

THE

and

shaft

needle

tissue

of

of

the

right

rear

close

the

operating

have

STATIONARY

stationary

guard

prevail:

paper

cup.

right

inch

side

feed

watch

which

inch

needle

(F).

been

moving

bearing

section,

clearance

of

is

Removing

parts.

is

set

will

theteethinfront

slot

above

direction

established

needle

(A,

barely

as

the

gauge

NEEDLE

guard

Fig.

correctly

pass

adjacent

between

needle

Fig.

feed

first,

to

observe

as

GUARD

(A,

8),

snugging

only

between

to

cup

right

is

entering

5

cup

there

Fig.

when

the

(Fig.

rims.

slowly

must

7)

guard

slot,

side

that

to

up

the

is

7)

slot

8

Page 9

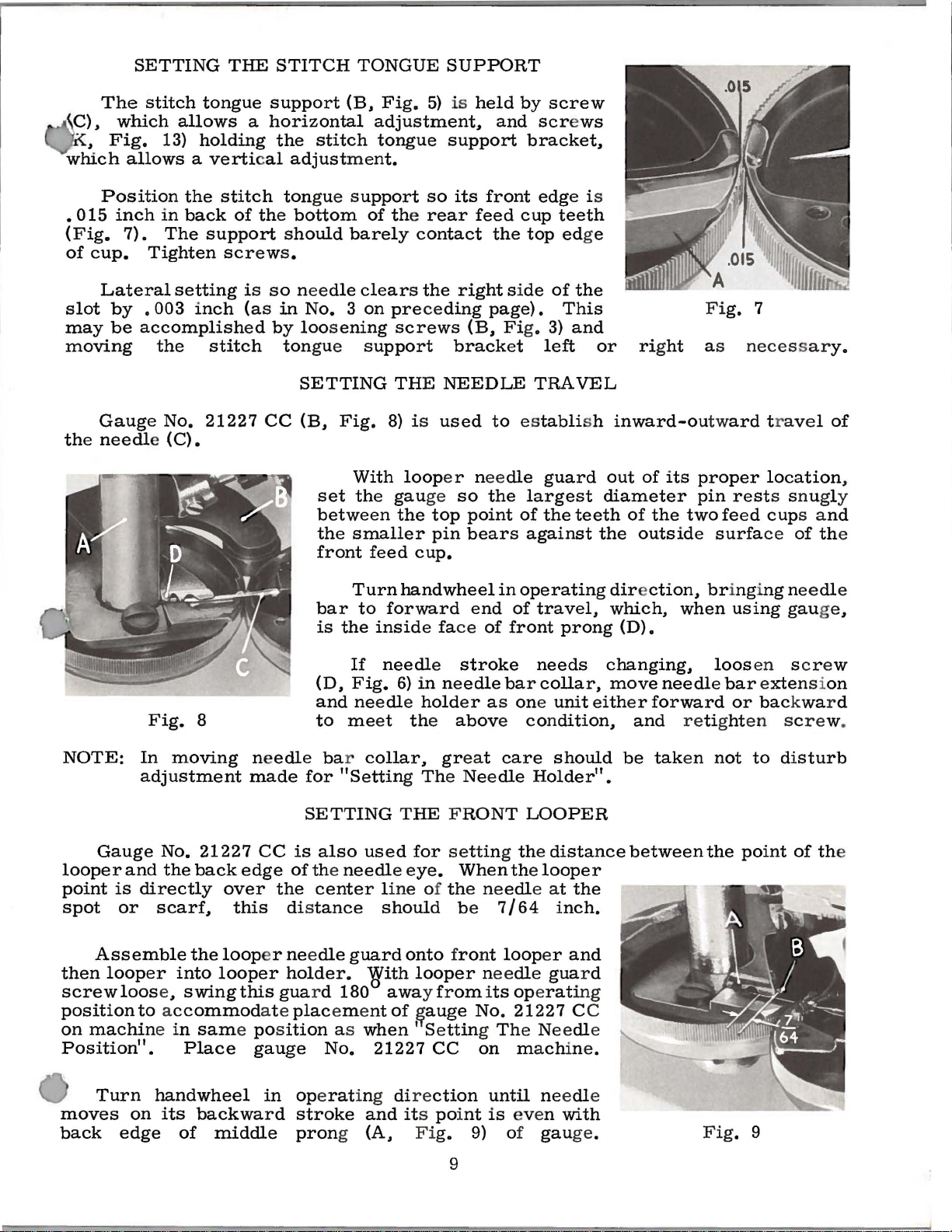

The

C),

· ,

which

SETTING

stitch

which

Fig.

allows

13)

THE

tongue

holding

allows a vertical

STITCH

support

a

horizontal

the

adjustment.

(B,

stitch

TONGUE

Fig.

5)

adjustment,

tongue

SUPPORT

is

held

by

and

support

screw

screws

bracket,

Position

•

015

inch

(Fig.

of

cup.

Lateral

slot

by • 003

may

be

moving

Gauge

the

needle

the

in

back

7).

The

support

Tighten

setting

inch

accomplished

the

No.

stitch

21227

(C) •

stitch

of

the

screws.

is

so

(as

CC

tongue

bottom

should

needle

in

No. 3 on

by

loosening

tongue

SETTING

(B,

set

between

the

front

bar

is

support

of

barely

clears

support

Fig.

With

the

smaller

feed

Turn

to

the

inside

so

its

the

rear

contact

the

preceding

screws

bracket

THE

8)

NEEDLE

is

used

looper nee

gauge

the

so

top

pin

cup.

hand

wheel

forward

face

front

feed

right

page).

(B,

the

point

bears

end

of

cup

the

top edge

side

Fig.

TRAVEL

to

establi

dle

largest

of

against

in

operating

of

front

edge

teeth

of

the

This

3)

and

left

guard

the

teeth

travel,

prong

is

or

right

sh

inward-outward

out

of

its

diameter

of

the

two

the

outside

direction, bringi

which,

when

(D).

Fig.

as

proper

pin

rests

feed

surface

using

7

necessary.

tr

avel

of

location,

snugly

cups

ng

and

of

the

needle

gauge,

NOTE:

Gauge

looper

point

spot

and

is

or

Assemble

then

looper

screw

loos

position

on

machine in

Position".

Turn

moves

back

on

edge

Fig.

In

8

moving

adjustment

No.

21227

the

back

directly

scarf,

into

e,

over

the

loop

looper

swing

this

to accommod

same position

Place

handwheel

its

backward

of

middle

needle

made

CC

edge

er nee

this

at e

gauge

in

(D,

and

to

bar collar,

for

SETTING

is

also

of the

the

center

distance

dle

holder.

gua

r d

plac

No.

operat

stroke

pron

If

needle

Fig.

needle

meet

"Setting

used

needle

line

should

guard

With

180°

em e

nt

as

when'

21227

ing dire

and its poi

g

(A,

6)

in

holder

the

The

THE

for

eye.

onto

looper

away

of

~auge

Fi

stroke

needle

above

great

Needle

FRONT

setting

When

of

the

be

front

from

Setting

CC

ction

nt

g.

9)

needs

bar

collar,

as

one

unit

condition,

care

should

Holder".

LOOPER

the

distance

the

looper

needle

7/64

at

inch.

looper

needle

its

No.

The

on

guard

operating

21227

Needle

machine.

until needle

is

even

of

with

gauge.

either

the

and

CC

changing,

move

needle

forward

and

be

taken

between

re

tighten

the

Fig.

loosen

bar

extension

or

backward

not

to

point

9

screw

screw

disturb

of the

.

9

Page 10

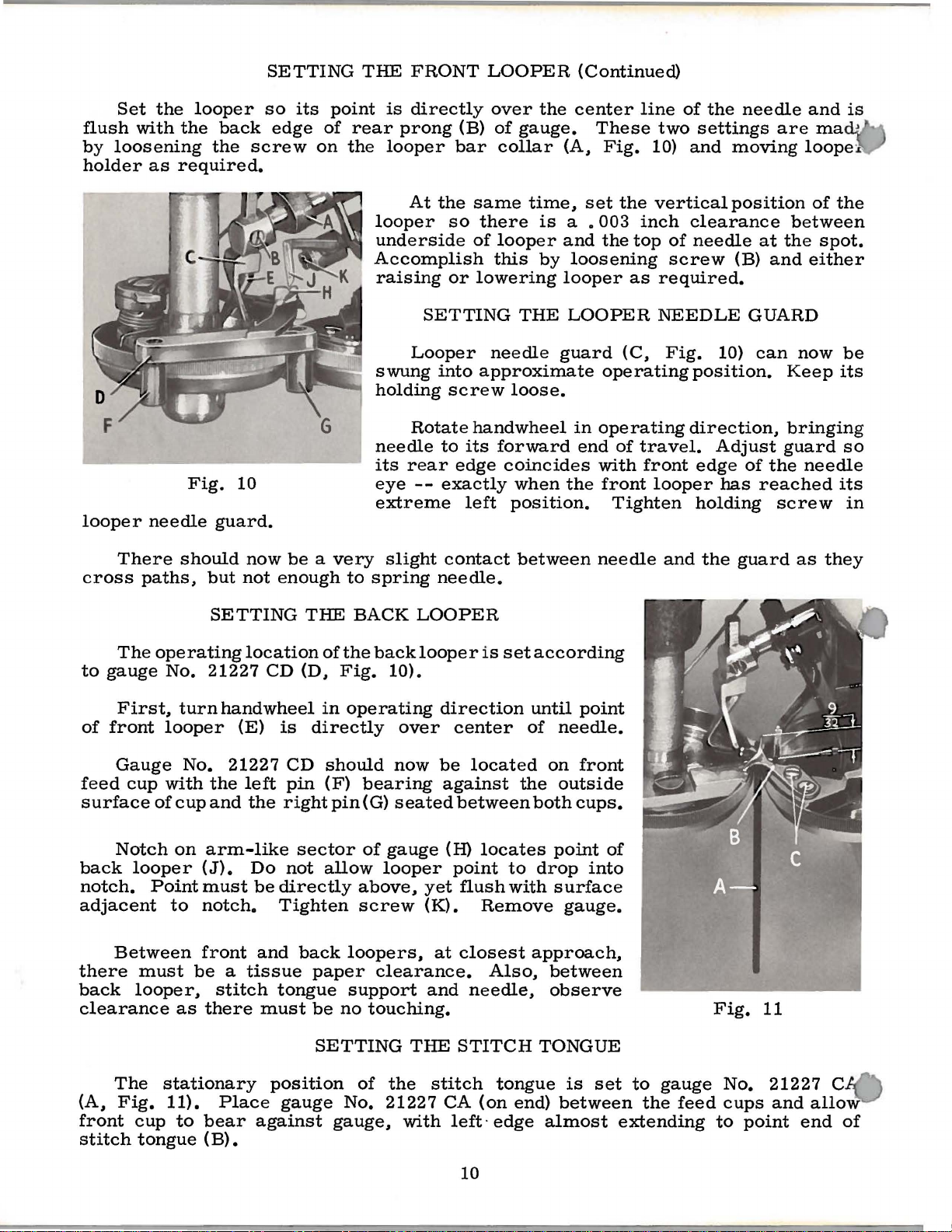

Set

flush

by

loosening

holder

the

with

as

looper

the

back

the

required.

SETTING

so

its

edge

screw

point

of

on

THE

rear

the

FRONT

is

directly

prong

looper

At

looper

underside

Accomplish

raising

(B)

bar

the

so

or

LOOPER

over

of

gauge.

collar

same

time1 set

there

of

looper

this

lowering

(Continued)

the

center

(A~

is

a •

and

by

loosening

looper

These

Fig.

the

003

the

top

as

line

of

two

10)

vertical

inch

of

screw

required.

the

needle

settings

and

moving

position

clearance

needle

at

(B)

and

are

loope

between

the

and

either

rna

of

spot.

is

•

·

the

Fig.

looper

cross

needle

There

paths1 but

guard.

should

SETTING

The

operating

to

gauge

No.

21227

First1 turnhandwheel

of

front

Gauge

feed

surface

looper

cup

with

ofcupand

No.

the

10

now

not

location

CD

(E)

21227

left

the

be a very

enough

is

CD

pin

THE

of

the

(D,

Fig.

in

directly

should

(F)

to

BACK

operating

rightpin(G)

Looper

swung

holding

Rotate

needle

its

rear

eye

--

extreme

slight

spring

LOOPER

back

10).

over

now

bearing

seated

SETTING

needle

into

approximate

screw

handwheel

to

its

edge

exactly

left

contact

needle.

looper

is

direction

center

be

located

against

between

THE

guard

loose.

forward

coincides

when

position.

between

set

according

until

of

needle.

on

the

outside

both

LOOPER

(C,

operating

in

operating

end

of

with

the

front

Tighten

needle

point

front

cups.

NEEDLE

Fig.

direction,

travel.

front

looper

and

GUARD

10)

can

position.

Adjust

edge

of

has

holding

the

guard

now

Keep

bringing

guard

the

needle

reached

screw

as

be

its

so

its

in

they

Notch

back

notch.

adjacent

Between

there

back

clearance

The

(A1 Fig.

front

stitch

on

looper

Point

to

must

looper,

as

stationary

11).

cup

to

tongue

arm-like

(J).

must

notch.

front

Do

be

directly

Tighten

and

not

be a tissue

stitch

there

tongue

must

position

Place

bear

gauge

against

(B).

sector

allow

back

loopers~

paper

support

be

no

SETTING

No.

gauge,

of

gauge

looper

above~

screw

yet

(K).

at

clearance.

and

touching.

THE

of

the

stitch

21227

with

(H)

locates

point

flush

to

with

Remove

closest

Also,

needle,

STITCH

tongue

CA

(on

left· edge

point

drop

surface

approach,

between

observe

TONGUE

end)

between

almost

10

of

into

gauge.

is

set

to

gauge

the

feed

extending

Fig.

No.

cups

to

11

21227

and

point

allow

end

C

of

Page 11

The

back

crews

(C)

adjustment

edge

hold

of

stitch

SETTING

of

the

stitch

tongue.

stitch

tongue

THE

tongue

onto

STITCH

point

stitch

TONGUE

must

tongue

(Continued)

be

flush

support,

with

and

the

when

back

loosened,

edge

of

gauge.

allow

NOTE:

NOTE:

On

Set

from

mately

rear

feed

If

tongue

center

On

furnished

desired

in

thickness.

the

all

styles,

needle

end

of

7/8

cup

standard

laterally

of

Style

width

other

SETTING

thread

needle

inch.

as

possible

stitch

needle

tongue

to

obtain a measurement

of

9/32

(No.

inch

(Fig.

41400 B only, 3 shims

for

raising

One

two

sent

check

THE

take-up

bar

bushing

Eyelet

of

forfrontand

drawn

of

machine.

end

not

the

seam.

shim

is

along with

THREAD

eyelet

to

should

without

The

only

needle

of

stroke,

taut.

stitch

Each

added

back

(A,

center

be

turned

making

needle

on

with

When

machine.

EYELETS

its

41397

(No.

tongue

shim

under

looper

Page

of

eyelet

contact.

thread

the

backward

material

needle

thread

B,

marked 11DF

between

11).

41298-5)

to

secure

being • 005

stitch

clearance.

5)

so

distance

is

approxi-

down

as

close

should

is

at

forward

is

just

the

are

the

inch

tongue,

to

be

stroke

in

the

snug,

11

)

is

stitch

used,

tongue

Fig.

set

point

12

stitch

and

on

Fig.

Be

sure

threads

13

machine

should

to

as

outside

should

top

about

the

thread

motion

With

just

NOTE:

is

threaded

be

sufficient

Set

the

stitch

high

tongue

as

of

be

just

of

its

upward

Set

the

horizontal

center

should

which

looper

snug.

Under

while

backward

threads

drawn.

STARTING

according

rear

eyelet

rear

front

of

is

at

normal

to

steady

looper

support

slot

feed

pulled

stroke.

looper

and

distance

the

clamp

be

drawn

right

extreme

the

needle

stroke.

should

TO

OPERATE

to

thread

intermediate

allows

cup

drive

up

snug

as

thread

from

screw

only

to

left,

right

end

conditions,

is

moving

When

be

pulled

Threading

them

and

eyelet

and

shaft

back

eyelet

the

is

on

the

with

material

of

stroke,

all

at

extreme

taut

Diagram

produce

(B,

bracket)

is

about

bushing.

looper

(C,

center

about

portion

threads

toward

with

(Page

Page

so

7/16

approaches

Page

of

the

3/8

inch.

of

in

the

thread

should

the

forward

NO

thread

5).

a

uniform

5)

(attached

it

is

inch

The

5)

so

eyelet

Looper

the

machine.

should

be

end

position,

Tension

raised

from

thread

the

it

is

to

looper

be

drawn

of

its

being

seam.

11

Page 12

SETTING

THE

FEED

CUP

PRESSURE

Adjust

pressure

tightening

Make

Operate

The

Adjustments can

It

with

the

that

the

the

latter

Vertical

First,

pins

(E)

the

onthefront

sewing

machine

uncurling

sh

ould

underside

space

is

loosen

are

at

presser

of

presser

test

at

device (A,

be

be

adjust

of

between the

at

right

adjustment

screw

the

proper hei

made

and a counterclockwise

has

been

give the

beginning

set,

tighten

proper

height

of a stocking.

spring

regulating

feedcuptofeed

spring

by

producing a "mock"

5500

SETTING

R.

P .

regulating

M.

THE

Fig.

vertically

ed

vertically

the

stitch

so

tongue

uncurler

end

of

stroke.

is

(C)

and

direction

screw

of

uncurler

Tighten

made

ght.

tighten

(C)

using

Turning

will

and

when

screw

screw(A,

the

workproperly.

Observe

FABRIC

13)

should

and

horizontally.

that

the

at

needle

and

the

theknurled

screw

in a clockwise

raise

loosen

lifter

(D)

screw

seam

fabric

UNCURLER

be

lower

line

looper

(D).

the

uncurler.

screw

lever

to

hold this

Fig.

12)

so

Maintain

nut

(B)

in

on a light wei

for

needle

centered

edge

and

needle

nut

(B)

Turn

between

of

the

can

be

guard

atopthe

knurled

direction

When

(D)

and

adjust

(F)

is

pulled

adjustment.

it

exerts

correct

clockwise

ght

knitted

or

the

guide

swung

pins

horizontally

is

1/32

uncurler

nut

(B)

lowers

height

knurled

downwardly,

only

other

feed

inch,

unt

the

of

enough

setting

fashion.

fabric.

are

bracket.

il

uncurler

guide

nut

(B)

at

bt

cuts.

cups.

level

so

when

guide

pins

to

the

Horizontal

feed

cups

of

1/32

right end

support

interfere

Set

(J)

in

one

least

tension,

tension

Adjust

the

cha

in

Make a test

have

been

NOTE:

adjustment

and

retightening

inch

between

of

stroke.

bracket

wi

th

other moving

SETTING

the

pressure

of

three

the

and

the

puller

cutting

on a full

made

A

complete

or

dered

the

(H)

. s e

THE

desired

holes

back

one

generally

plate

knife

properly

set

under

is

made

screw.

uncurler

To

make

t,

and

parts.

FABRIC

on

in

the

hole for

on

arm

is aga

inst

fashioned

and

of

gauges

the

number

by

loosening

Uncurler

and

the

this

adjustment,

retighten

PULLER

the

fabric

the

used

(L) s o

screws.

fabric

puller

most

for

avera

that

AND

arm.

stocking, sewing

have

the

proper

mentioned

21227

CF.

screw

should

looper

CHAIN

puller

by

supporting

tension,

ge

work.

its end

clearances.

in

It

be

needle

loosen

Check

placing

and

just

slowly

the

comes

(G)

to

center

adjusted

guard,

screws on

to

see

that

CUTTING

the

arm

the

clea

(L);

middle

r s

at fir

foregoing

complete

uncurlerbetween

so

that

there

when

the

hub

uncurler

ASSEMBLY

end

of

torsion

the

front

hole

the

rear feed

st

to

insure

instructions

with

leather

latter

of

uncurler

hole

for

is

space

is

do

e s

not

spring

for

the

average

cup

and

settings

may

case.

at

be

12

Page 13

EXPLODED

AND

VIEWS

DESCRIPTION

FOR

CLASS

OF

41 4

PARTS

00

13

Page 14

14

Page 15

MISC

ELLANEOUS COVERS, BUS

HIN

GS,

PULLEYS,

AND

THREAD RATIO CONTROL

Ref.

No.

1

2

3

4

5

6

7

8

9

9A

9B

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

Part

105-4

213

53 A

660-156

41395

41395 B

41395 A

41421

98

660-204

2283

7

41480 A

22585

95

41458

660-219 B

41394

41480 c

22516 A

22539

22764 A

41458

22597

22539 E

41394 D

22597 A

230

41394 B

41480

22804

53678 N

39582

43443 Q

39582 v

39582 L

51-103

75

41480 B

22

541

41490

41490 A

41364 N

41361

41463 A

41476

668-25

668-28

90

41376 G

668-28

668-25

41476 A

668-28

668-25

41476

22768

43266

41478

29485 D

454A

41378 X

41378 v

660-210

41378

K

51292

51292 c

109

41378 J

41378

668-28

668-26

562

41493

41396

c

6956

41342 A

No.

c

c

c

c

c

u

J

c

F-1

Blk.

Des

cripti

on

M

achine

Wa

Wa

I

solato

achine

M

achine

M

Pulley

''O'' Ring

Screw---------------------------------------------------------------------

Belt

Screw--------------------------------------------------------------------Screw,

Worm Drive Shaft

oll

R

Rear

RearCover---------------------------------------------------------------Screw---------------------------------------------------------------------

Plug Screw---------------------------------------------------------------Screw,

Worm Drive Shaft Bushin g, right

Screw,

Plug Screw----------------------------------------------------------------

Worm

Scre

Screw, for

Top

Top

Screw---------------------------------------------------------------------

Belt

Screw--------------------------------------------------------------------Crankshaft

Feed

Front Feed

Feed

Needle

Screw--------------------------------------------------------------------Looper

Needle

Eyelet

Tension

Thread

Thread

Tens

TensionSpr

Tension

Tens

Tension

Thread

Screw

Oil

Locking Pin,

Spring ----------------------------------------------------Back

Mounting

sher, steel ---------------------sher, fel

r,

rubber

Locat

Mounting Ga

--------------------------------------------------------------------

-----------------------------------------------------------------

Screw

-----------------------------------------------------------------

Chamber

for

41360-----------------------------------------------------------

Pin-------------------------------------------------------------------

Cover

for

41432

for

41432

Shaft Hole

w,

for

41458 J

Cover

Cover-----------------------------------------------------------------

Screw

Washe

Hinge

Nut-------------------------------------------------------------------Tors

Oil

Hinge Pi

Bushing----------------------------------------------------------------

Eyelet----------------------------------------------------------------Eyelet

Eyelet

Eyelet-----------------------------------------------------------------

Eyelet

Eyelet-----------------------------------------------------------------

Screw

Washer----------------------------------------------------------------

Axle

Thread

Retainin

ion

ion Dis

Eyelet

Eyelet-----------------------------------------------------------------

Sight Gauge

41432

Gasket----------------------------------------------------------

---------------------------------------------------------------

r---------------------------------------------------------------Bracket----------------------------------------------------------

ion

Filler

Chamber

Bushing Housing

Cup Shaft Bushing, front,

Cup Shaft Bushing,

Thread

Locking Ring

Thread Eyelet

Locking Ring

Thread

Locking Ring

Adaptor

-----------------------------------------------------------------

Post

Ratio

Ratio

Stud

Ratio

g Washe

Disc

ing

Regulatin g Nut

c--------------------------------------------------------------

Post

Ratio

Locking Ring

Pin,

for

Looper

Screw----------------------------------------------------

-

t---------------------------------------------------------------

-----------------------------------------------------------

ing

Pin-------------------------------------------------------

sket

---------------------------------------------------

Cover,

Gasket---------------------------------------------------------

Spr

Cover--------------------------------------------------------

n----------------------------------------------------------

Cover,

Cup

Eyelet-------------------------------------------------------

Eyelet-------------------------------------------------------

Stud

Nut----------------------------------------------------------Control

Control-------------------------------------------------------

--------------------------------------------------------------

Spacing

-------------------------------------------------------------

--------------------------------------------------------------

Control Frame ------------------------------------------------

machin

for

Bar

left--------------------------------------------------

Bush

ing, lef

C--------------------------------------------------------E---------------------------------------------------------

Gasket

---------------------------------------------------------

C---------------------------------------

ing

---------------------------------------------------------

rig

Pivot

Shaft

-----------------------------------------------------

------------------------------------------------------

-----------------------------------------------------

-----------------------------------------------------

--------------------------------------------------------

Frame

Control

r-------------------------------------------------------

Collar-------------------------------------------------

-----------------------------------------------------

-----------------------------------------------------

e mounting scre

-----------------------------------------------------------machine mountin g screw

Bushing---------------------------------------------------

t----------------------------------------------

----------------------------------------------------

ht--------------------------------------------------

------------------------------------------------upper

Bush

rear

Roller

ing

-----------------------------------------------

Space

---------------------------------------------

--------------------------------------

--------------------------------------------

section

-----------------

r------------------------------------------

w--------------------------------------

---------------------------------

------------------------------------

-

------------------------

-

-----------------

-----

----------

-

---

Amt.

Req.

- 2

- 1

-- 1

2

1

1

1

2

1

1

6

1

1

6

6

1

1

1

1

1

1

1

2

2

2

1

2

2

2

2

2

1

2

1

1

6

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

8

1

3

1

1

1

1

1

1

1

1

2

3

3

1

1

1

1

1

1

1

1

1

15

Page 16

41

L---=-=~~

-

---

-

-

-

-

16

Page 17

CRANKSHAFT,

NEEDLE

BAR

AND

NEEDLE

BAR

DRIVING

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

32A

33

34

35

36

37

38

39

40

41

42

43

44

45

Part

N

o.

41418

22798 A

605

41418 A

39543 A

22

660-202

667

41456 F

69 H

22653

41255 B

22747

29126

22764 A

88

22587 E

22559 D

41457

41457 A

41457 B

41457 c

88

660-281

39590 J

41422

41

432 K

77

22

564

414 32 G

41432

D

22729 D

41491

89

51236 A

41

456 D

258 A

414

17

41

456 E

22894 J

41456 A

94

41456 B

18

51216 N

97

39544 J

39544 N

22729 D

KH

B-10

B-8

DM

Descr

Needle

Screw--------------------------------------------

Needle Bar

Ne

Screw---

"0"

Dowel

Fulcrum

VVasher----

Holder,

Screw---------------

edle

Hold

mark

Exte

nsion,

er

Collar -------------------

------------------------ --------- --------

Rin

g,

for

needle

Pin

------------

Pin

Housing --------------------

---------- ------------------ -----------

iption

ed

"AL"

marked

bar

-

- - - -

-

-------------------------

bushing----------

---------------

------------------

"AM" ----------------

-

----------

----

-

--------

-

---------

------

-

Screw---------------------- ---- ------------------

Guide

Screw-------

Needle

Feed

Feed

combination)-------------------------------------

Feed

combination)------------------------------------

Feed

combination)------------------------------------

Crankshaft

Crankshaft

Crankshaft----------------------------------------

Oil

Screw--------------------------

Screw ------------------------------------------Oil

Looper

Crankshaft

Fork

Time

SetScrew-----------------------------------Bearing

Bearing

Drive

combination)------------

Drive

Drive

Drive

Screw-----------------------------------------

Splasher

Splasher

Screw---------------------------

Bar

Spot

Lever

--------

-

------------------------------------

Frame

Screw------------------

Cap

Cap

Sprocket

Sprocket

Sprocket

Sprocket

Ball Bear

Thrust

-------

-------------------------------------Connect

Thrust

-

------------------------------

Connecting Rod

Screw----------------------------Screw-----------------------------

(Refer

(Refer

(Refer

(Refer

ing--

Washer-----------------

-

----------------

ing

Collar--------------

to

Page

-

---------------------

to

Page

to

Page

to

Page

--------------------------

Rod-----------------------

Assembly---------

-

------------

6

for sprocket

6

for

sprock

6

for sprock

6

for

sprocket

-

--------

-

------------

-

----------------

-

-------------

-

-------

et

et

-

-

----

Screw---------------------------------------

Link

Needle

Nut

Needle

Fulcrum

Screw----------------

Needle

Needle

Nut

VVasher------------~-------------------

Screw-----------------------------------------

Guide

Needle Drive

Pin-------------

Feed Dri

ve

---------------

Bar

------------

Pin--------------

Bar

Frame-------------------------

Screw

----------------------------------------------

Sc

---------------------------------------

Bar

Guide---------------------------------

Fork

---------------------------------------

Connecting Rod

rew---------------------------------------

-

----------------------------

Ball

Stud------------------

-----

--~----------- -

- -------

-

---

-

-------

-------------------

-------

------

- - -- - - - - -----

-

-------------

-

------------

-

----------

-

-

-----

-

---

-------

- - -

---

-----

---

- -

- -

--

--

--

Amt.

-

--

-

--

-

- 1

- 1

- 1

--

-

Req.

1

1

2

1

1

1

2

2

1

3

3

1

1

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

2

1

1

4

17

Page 18

18

Page 19

LOOPERS

AND

LOOPER

DRIVING

PARTS

Ref.

No.

1

2

3

Part

No.

41442

22562

41442 A

4 605

5

41409

6 258

7

41442 B

8 22894

9

10

41442

97 A

11 22747

12

41255

13 18

14

15

16

35851 G

269

29126

17 96 A

18

95

19 22587 E

20

21

22

41432

22562 A

41432

23 39147 D

24

25

26

27

28

29

30

31

32

33

34

35

88

41432

660-220

41432

41432

41432

41432

88

41408

41310

22547

39543

36 22

37

38

39

40

41

42

43

44

45

46

47

48

660-204

41432

22768

41458

22874

22528

41458

41458

11342

816

39543

22503

c

c

B

DN

H

J

c

E

F

A

A

A

KH

B

H

E

F

E

E

F

Description

Back

Back

Looper

Screw

Looper

Bar-----------------------------------

----------------------------------------Holder,

marked

"P"

--------------------

Screw--------------------------------------------Looper

, I

back

marked

"CF"

------------------------

Nut-----------------------------------------------

Back

Looper

Screw---------------------------------------------

Guide

Nut,

Connecting

Nut,

Looper

Thrust

Thrust

Thrust

Looper

"0"

Front

Front

Cam

Front

Screw--------------------------------------------Looper

Front

Looper

Screw---------------------------------------------

11011

Front

Screw--------------------------------------------Idler

Looper

Screw

Bar

Screw

Drive

-----------------------------------------

Ball

Lever---------------------------

Joint

Assembly---------------------

-----------------------------------------

Fork----------------------------------------

rightthread-----------------------------------

Rod

------------------------------------

left

thread------------------------------------

Rocker

Set

Screw--------------------------------------

Spot

Screw-------------------------------------

Bearing

Eccentric

Cap

Screw------------------------------

Assembly------------------

Collar--------------------------------------

Screw

-----------------------------------------

VVasher-------------------------------------

Collar--------------------------------------

Screw

R.

Follower

Screw

R.

Sprocket

Screw

-----------------------------------------

Lever

lng------------------------------------------

Looper

Looper

Looper

front

, .

Looper

Holder

Shaft---------------------------------

Bar----------------------------------

Bar

Bushing

-------------------------------------

Holder,

marked

Needle

----------------------------------------Collar-------------------------------

Guard

and

marked

"CH"

-------------------------

Cam

"N

Guide

11

-------------------

------------------------

------------

lng------------------------------------------

Looper

Drive

Lever

--------------------------

Bracket------------------------------

-----------------------------------------

Screw---------------------------------------------

Idler

Idler

Ferrule------------------------------------------Screw-------Follower

Adjusting

Sprocket

Sprock

Arm---------------------------------

et ---

----------------------------------

-

------------------------------------

Clamp------------------------------------

Screw------------------------------------

Arnt.

Req.

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

1

2

2

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

19

Page 20

20

Page 21

FABRIC

PULLER

FRONT

AND

FEED

CHAIN

CUP

CUTTING

AND

CUP

KNIFE

DRIVI NG

ASSEMBLY,

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Part

No.

41467

41480

D

22849

41367

41367

C41

25 s

41367

G

138

94

41367

41367

s

41375

41375

41375

41375

4

A

G

1375

22584

4137

5 Q

4137

5

41375

4

1360

41360

22764

41361

G

A

u

22517

41365

22560 A

1363

4

A

227 43

22516

A

41363 N

4

1363

2274 3

22516 A

41361

41361

2251 7

HA81

22591

1758

5

53678 N

2280 4

41425

41425

-0

-06

22585 c

41445

-2

41445- 3

41

445-4

41

445

-5

4

1445-6

41445

414

-7

45-8

41445-9

4146

3 B

41362

A

88

c

R

J

u

v

F

p

55

Fabr

ic

Puller

Cove

Screw

Tension

F

abric

crew--------

S

Sc r e

Chain

Screw---------------Screw------------------------

Fabr

bl

Ca

Press

er Sp

Regulating Screw

L

ift

e r Lever

Yoke Spr ing-----------

Yoke

Collar--------------------------------------------

Screw---------------------

Presser Sp

Lifter Lev

Presse

Fe

Fe

r Spring Wa s her

ed

Cup

ed

Cup Adj

Screw--------------

F r ont

F e

Cup Lif

Sc

r e

w------------

ed

Cup Driving Gear

Screw----------

Front

Feed Cup

Set Scr ew--

Screw---------

F

ront

Feed

ront

F

Feed

Set

Screw------------

Screw---------------

Front

F

Cup

ront Cup

Screw---------------Sp

ot

S

et

Scr

ront

F

Loop

Washer------------

Scr

ew-

- --

Ne

edle

Guard,

5

Ne

edle

Guard.

Sc

rew

--------

dle Gua

ee

Needle Guard Shim

Needle Gu

Ne ed

le

Gua

eedle

N

Needl

Needl

Needle

Fe

eed Cup ---

F

Gua

e Gua rd Shim • .

e Gua r d Shim , .

Gua

ed Cup Shaft Bearing

crew------

S

Descriptio

and

Cha

in

Cutt

ing Kni

r , f

or

feed

cup sep

arati

----------------Sprin

g - -

-----------------------------

Puller Suppo

r ting Ar m

-

---------------------------

w------------------

Cutting

Knife---

------------

- - -

ic Pul

e a

ler

Plat

e- ----

nd

Tube, complete ---------

ring Regulatin

Lock

Rod Yoke

Nut

----

-------

g Sc r e w and Bushing

------------------

--

- - ----------------------

r ing

--------------------------------

er Rod

Adju

----

- - - - - ---- - -

sting Stud

----

---------

------------------------

usting Eccentric

- - - - - -

te r Lever

-----

----

------------------------------------

------------------------------------

-

--------------------------

Sha

ft, upper se

-------------

----

-----

Cup

Cup

Shaft Flo

Shaft. low

ating

er section------------------------

-

---

- - - - -

Pivot

Sha

Sha

ft ---------

ft B r acket--- - - -------

--

Screw-------------

ew--------------

er

Thr

ead Eye

---

--

let -------------------------------

-------- - -

-------ma

-

rke

---d

- - -----

11

LA

- 055

marked 11LA- 065

----

rd Shim, . 002 inch thick,

-------

--

•. 003 inch thick

a r d Shim • • 004 inch

r d Shim , . 005 in

r d Shi

m, . 006

007

008 inc

r d Shim

•• 009 inch thick

ch

inch

inc h thick------------

h th

-------

---------

--------

- -------

- - -

-----------------------

n

fe Assembly -------------

ng mechanis

-------------------

-------------

-

------

- - -

--------

----

-

-------------

------------

- - -

----------------------

-----------------------

-----------------------

Colla

r - -

----------------------

---

- - - - -

----

- -

cti

on-----------------------

--

--------------

m----------

-

-----------

---

- -

-

-----------

--------------------

-

--------------

-

--------------------

-----------

-

----

- - -

--------------

-----

-

-----------

-

---------

- -

-------

-

----------

-

----------

-

----------

-----------------

---------------------

--

---------

-

------------

- - ---------------------------Connection

- -

---------------------------

---------------

-------

-----------------

-

------------

-

--------------------

---------

-

-------------

------------------------------

- - --------------------------

-----------------------------

----------------------------

-----------------

11

, f

or

11

- -

----------------------------

Style 41400 B ----------

• f

or

Style

s 414

as

r eq

uire

--------------

-

----------

00

A. C -----

d-------------

--

--------thick--------------------thi

ck--------------

thi

ck- ----

---------

-

---------

-

----------

- ----

ick-------------------

----------------------

-

--------------------

-----------

-

-------

-

-

----

- -

------

--------

-

---

--------

------

- - - - 1

- -

---

-

---

-

-

- -

--------

-

-----

-

-

-----

-------

-

-------

Amt.

Req.

- - 1

- - 1

- - 1

- - 1

- - 1

--

--

- 1

- 1

- - 1

- 1

--

-

--

- - 1

- 1

2

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

1

1

1

2

2

2

21

Page 22

' '

----t 1

22

23

[1]

Page 23

STITCH

REAR

TONGUE,

FEED

CUP

STITCH

AND

CUP

TONGUE

DRIVING

SUPPORT,

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Part

No.

41458

41457

41457

41457

41457

22560

61242

88

77

41458

41458

41458

41365

22560 A

41463

22548

41366

41476

668-28

668-25

22561

94

22798

41397

A

B

41298-5

41466

41466

41466

A

B

22570 A

41363

u

22743

41362

A

88

660-279

A

D