Union Special 395 Series User Manual

CATALOG

NO.

Adjusting

instructions

and

395M

First

Edition

STYLES

395-20

395-21

395-22

395-23

395-26

395-26V

395-28

illustrated

parts

list

395-28V

395-40

395-40V

395-42

395-42V

Finest

•••

Quality

6M

Classic

-Differential

Series

feed

overseamers

Equipment

ADJUSTING

INSTRUCTIONS

AND

ILLUSTRATED

6M

CLASSIC

FEED

OVER

Catalog

395-20

395—21

395-22

395-23

395-26

395—26V

PARTS

SERIES

SEAMING

No.

For

Styles

LIST

ON

-

DIFFERENTIAL

MACHINES

395

M

395-28

395—28V

395-40

395-40V

395-42

395-42V

Rights

Union

Reserved

First

Copyright

Special

Printed

September,

Edition

1981

By

Corporation

In

All

In

U.S.A.

1981

2

Countries

EQ

REWO

RD

This

new

UNION

adjusting

liability

The

setting

functions

Check

and

rectly.

adjustments

ence

letters

Adjustments

plished.

the

function

Implementation

cant

improvements

Whenever

sure

to

fically

ing

service.

technical

SPECIAL

these

designed

Adjusting

for

each

of

Procedure.

The

are

Some

it

becomes

insist

for

your

machine.

machines

of

the

machine.

Procedure

required.

to

point

are

adjustments

of

other

in

genuine

on

machine

manual

will

and

built

Instructions

components

the

The

Check

is

given

Figures

out

specific

presented

performed

related

preventative

of

operator

necessary

UNION

and

has

been

Careful

enable

into

every

portion

The

text

depicts

to

explain

are

items

in

sequence

parts.

productivity

make

to

SPECIAL

manufactured

prepared

attention

you

to

UNION

of

related

of

the

conditions

used

discussed.

of

out

maintenance

by

repairs

Repair

with

guide

to

to

the

maintain

SPECIAL

this

manual

forming

to

Adjustments

when

proper

the

illustrate

to

so

that

a

sequence

procedures

avoiding

replace

or

Parts.

utmost

in

you

instructions

the

superior

machine.

explains

the

stitch

is

divided

the

steps

the

logical

may

have

can

costly

parts

These

parts

precision

the

maintenance

for

performance

in

and

into

parts

to

be

are

taken

adjustments

progression

an

adverse

bring

equipment

on

your

are

to

assure

operating

detail

completing

two

adjusted

in

about

breakdowns.

machine,

designed

the

sections

the

using

is

accom

effect

signifi

long

of

and

proper

cor—

event

refer

on

be

speci

last

your

and

re

the

-

To

exploded

VIEW

which

illustrated

simplify

views.

presents

on

identification

These

the

this

page

illustrations

mechanisms

will

of

appear

repair

will

of

the

shaded

parts,

usually

machine

in

the

be

assembled.

the

KEY

mechanisms

shown

3

in

VIEW.

are

illustrated

conjunction

The

specific

with

parts

a

by

KEY

CLASS

DESCRIPTION

I-ugh

Speed,

overseaming

cam

driven

395-20

-

hemmer

cular

inch

one

and

machines.

main

and

STITCH

SEAM

FEED

MAXIMUM

AND

TYPE

SYSTEM

SPEED

(Depending

operati

on)

LUBRICATION

One

needle,

assembly

blind

hemming/welting

(3.2mm).

two

curved

Fabric

differential

on

thread

two

with

overhanging

needles,

trimmer

feeds.

TECHNICAL

EFc-l,

503

SSa-l,

504

40V,

512

SSa—l,

Independent,

Differential

6000

Enclosed

Reservoir.

MACHINE

machine

operations

two,

with

42,

RPM,

produces

hem

three

spring

Enclosed

DATA

Styles

Styles

42V.

Styles

Cam

Feeds.

All

Styles.

Automatic

STYLES

guides.

on

“I”

and

pressed

automatic

395-20,

395-26,

395-22,

Driven

Splash

break

Typical

shirts.

four

lower

21.

26V,

23.

Main

System,

open

thread,

knife.

lubrication

28,

and

Single

seam.

Fitted

Application

Available

differential

Independent

system.

40,

28V,

with

-

Flat

seam

compact

or

width:

feed

cir

1/8

395-21

395-22

duces

dresses

395-23

395-26

cal

3/32

395-26V

395-28

395-28V

395-40

Application

3/32

395-40V

395-42

-

Same

-

Two

simulated

-

Same

-

One

Application

inch

-

Same

-

Same

-

Same

-

One

inch

-

Same

-

Same

as

Style

needle,

and

draperies.

as

Style

needle,

(2.4mm),

as

as

Style

as

needle,

-

(2.4mm),

as

as

Style

Style

Style

For

Style

395-20

four

‘Safety

395-22

three

-

For

1/8

395-26

395-26

395-28

three

curved

1/8

395-40

395-40

thread

Stitch”.

Available

thread

curved

inch

thread

inch

except

machine

except

(3.2mm),

except

except

except

seams

(3.2mm),

except

except

extra

Typical

seam

extra

machine

seams

fitted

extra

fitted

machine

on

knit

fitted

extra

stitch

prepared

width:

stitch

prepared

knit

on

5/32

with

stitch

with

prepared

undergarments.

5/32

with

stitch

cams

with

and

high

Application

17/64

cams

and

high

with

undergarments.

inch

(3.9mm).

“AIR-KLIPP’

and

cams

“AIR-KLIPP”

with

inch

low

(3.9mm).

“AIR-KLIPP”

and

cams

needles

throw

-

inch

needles

needles

throw

Available

needles

crankshaft.

Seaming

(6.7mm)

throw

Available

chain

chain

crankshaft.

chain

are

furnished.

bathing

furnished.

are

crankshaft.

seam

cutter.

are

furnished.

cutter.

seam

cutter.

are

furnished.

Pro

suits,

Typi

widths:

Typical

widths:

395-42V

-

Same

as

Style

395-42

except

fitted

with

“AIR-KLIPP”

4

chain

cutter.

Each

UNION

stamped

The

serial

machine

in

-

SPECIAL

the

style

number

machine

plate

stamped

is

IDENTIFICATION

carries

located

in

the

a

style

the

to

extension

OF

number,

right

of

MACHINES

which

rear

of

casting

on

the

at

this

class

machine.

the

right

machine

rear

base

is

of

TO

PREVENT

-

All

power

justing

-

Wear

-

All

shields

-

DO

NOT

Oil

mineral

equivalent

THIS

or

safety

tamper

capacity

oil

to

SAFETY

PERSONAL

sources

replacing

glasses.

and

guards

with

of

with

a

Saybolt

UNION

SYMBOL

INJURY:

to

the

parts.

MUST

safety

Class

SPECIAL

INDICATES

machine

in

be

shields,

395

is

eight

viscosity

specification

SAFETY

RULES

A

CAUTION!

YOUR

MUST

position

guards,

LUBRICATION

of

be

TURNED

ounces

90

to

No.

PERSONAL

etc.,

before

(227

125

175.

SAFETY

OFF

before

operating

while

milliliters).

seconds

IS

threading,

machine.

machine

at

100

INVOLVED.

is

in

operation.

Use

a

degrees

oiling,

straight

F.

This

ad

is

oil

bulb

Clean

Oil

and

in

operating

240

on

the

Styles

looper

Machine

level

on

oil

To

drain

magnetic

MUST

Before

cloth

are

furnished

Be

sure

following

using

Thread

thread,

at

level

be

changed

threading

plate

machine

is

filled

sight

oil

plug

out

direction

with

machine

pages.

three

two

with

gauge

indicator

remove

of

any

periodically

machine;

of

position

until

machine

is

threaded

threads

in

the

thread

oil

on

front

will

magnetic

metallic

needle

Use

Figure

and

following

styles

at

of

register

plug

to

unlock

and

aid

to

properly

Figure

DO

spring

cap

machine.

between

from

material

minimize

THREADING

presser

pull

is

upper

at

in

threading.

highest

according

1

for

Styles

lB

for

sequences:

require

NOT

5

back

that

wear.

foot

two

in

top

When

of

looper

using

needle

(1)

this

cover.

proper

red

gauge

machine

may

have

release

thread

position.

the

to

two

lower

step.

oil

lines.

near

accumulated

bushing,

threading

threads,

Styles

looper

(3)

Before

level

bottom

tube

Thread

using

thread

needle(s).

operating,

is

swing

Turn

up.

tweezers

diagrams

Figure

four

reached,

edge

in

crankcase.

presser

handwheel

lA

threads.

(2)

of

No.

shown

for

upper

check

red

base.

arm

660—

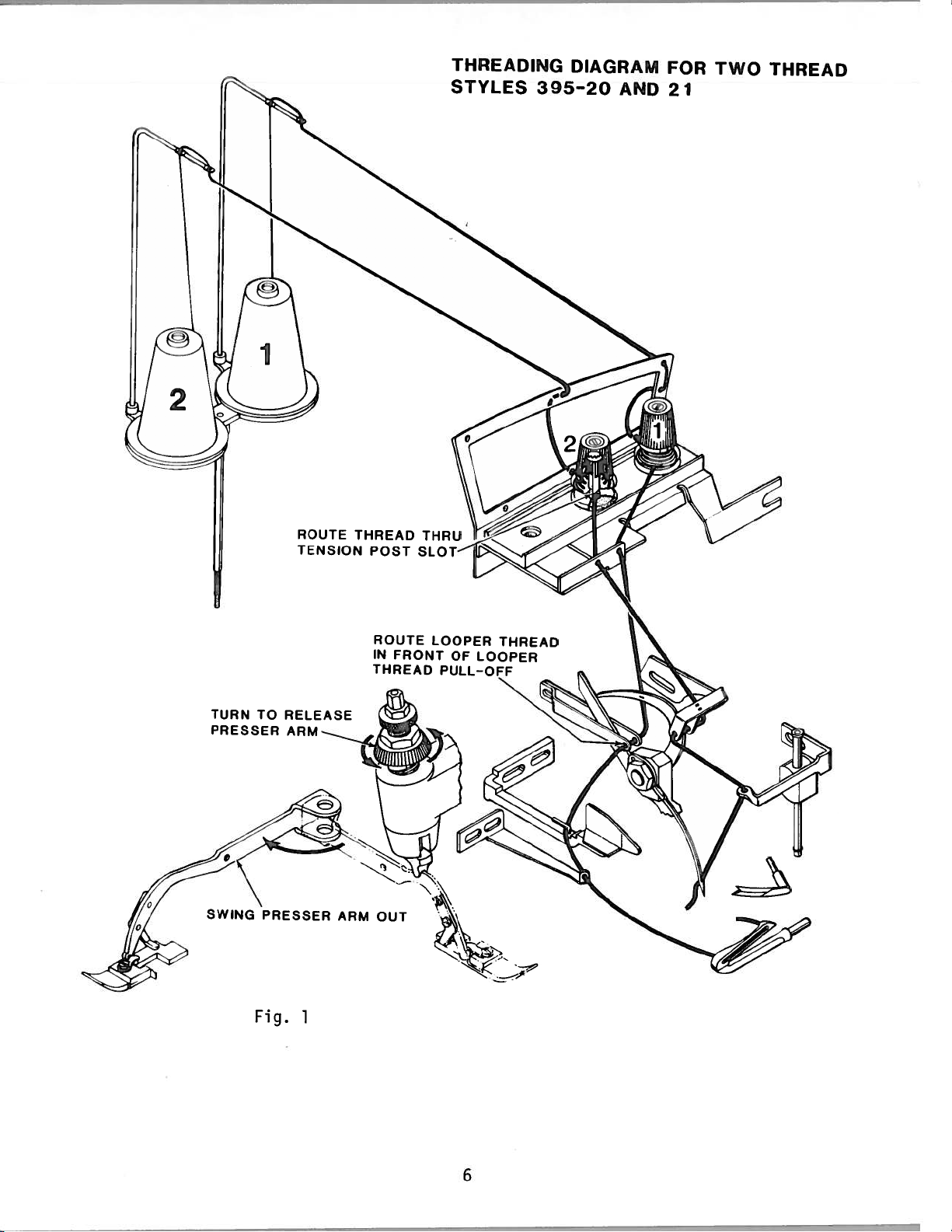

THREADING

STYLES

395-20

DIAGRAM

AND

FOR

21

TWO

THREAD

TURN

PRESSER

TO

ROUTE

TENSION

RELEASE

ARM

THREAD

ARM

POST

ROUTE

IN

FRONT

THREAD

OUT

LOOPER

OF

PULL-OFF

THREAD

LOOPER

--—-A

Fig.

1

6

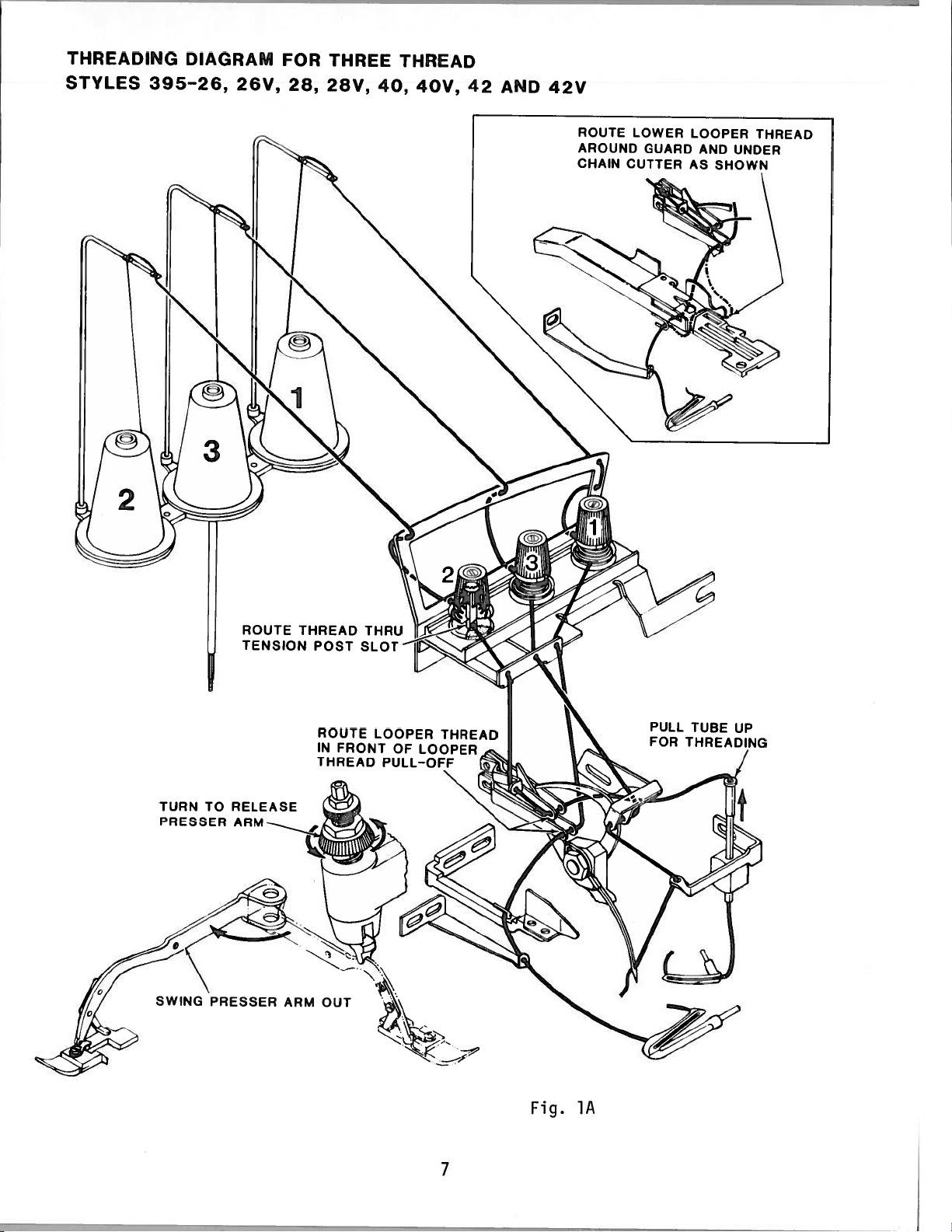

THREADING

STYLES

395-26,

DIAGRAM

26V,

FOR

28,

THREE

28V,

THREAD

40,

40V,

42

AND

42V

ROUTE

AROUND

CHAIN

LOWER

GUARD

CUTTER

LOOPER

AND

AS

SHOWN

THREAD

UNDER

TURN

PRESSER

SWING

RELEASE

TO

ARM

PRESSER

TENSION

ARM

ROUTE

IN

FRONT

THREAD

OUT

LOOPER

OF

PULL-OFF

THREAD

LOOPER

PULL

FOR

TUBE

THREADING

UP

Fig.

7

A

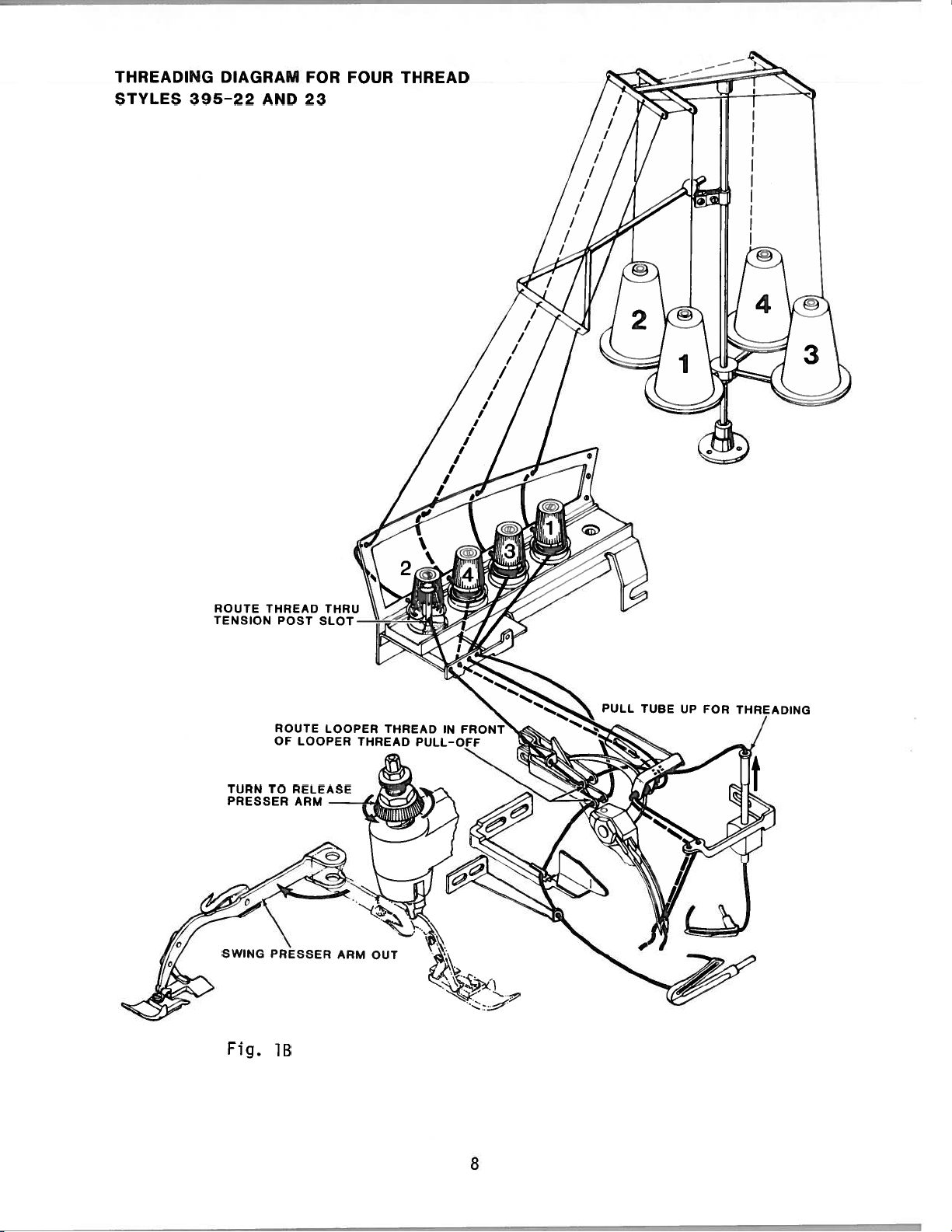

THREADING

STYLES

395-22

DIAGRAM

AND

FOR

23

FOUR

THREAD

TURN

PRESSER

SWING

Fig.

TO

RELEASE

ARM

PRESSER

18

ARM

OUT

PULL

TUBE

UP

FOR

8

—

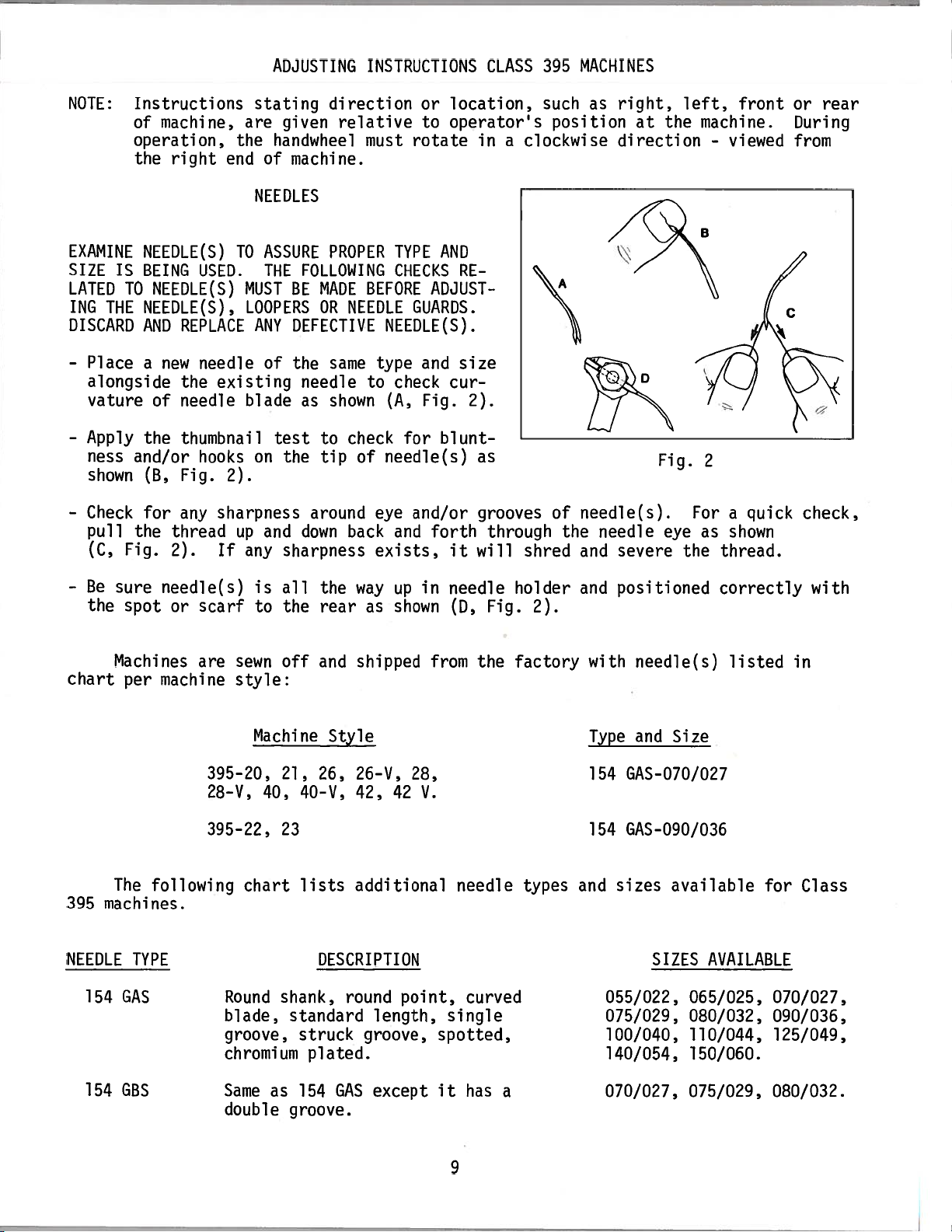

NOTE:

EXAMINE

SIZE IS

LATED

ING

DISCARD

-

TO

THE

Place

alongside

vature

-

Apply

ness

shown

-

Check

pull

(C,

Fig.

Instructions

of

machine,

operation,

the

right

NEEDLE(S)

BEING

NEEDLE(S),

AND

a

USED.

NEEDLE(S)

REPLACE

new

needle

the

of

needle

the

thumbnail

and/or

(B,

for

the

hooks

Fig.

any

thread

2).

ADJUSTING

stating

are

the

handwheel

end

of

NEEDLES

TO

ASSURE

THE

MUST

LOOPERS

ANY

of

existing

blade

test

on

2).

sharpness

and

up

If

any

direction

given

relative

machine.

PROPER

FOLLOWING

BE

MADE

OR

NEEDLE

DEFECTIVE

same

the

needle

as

shown

check

to

the

tip

around

down

back

sharpness

INSTRUCTIONS

or

location,

to

operator’s

must

BEFORE

of

rotate

TYPE

CHECKS

GUARDS.

NEEDLE(S).

type

and

to

check

Fig.

(A,

for

needle(s)

eye

and/or

and

exists,

AND

ADJUST

cur

blunt

forth

it

CLASS

in

a

RE

size

2).

as

grooves

through the

will

MACHINES

395

such

position

clockwise

needle(s).

of

shred

and

as

right,

direction

needle

severe the

at

left,

the

machine.

Fig.

2

Foraquick

eye as

-

viewed

shown

thread.

front

or

rear

During

from

check,

-

Be

sure

the

Machines

chart

The

395

machines.

NEEDLE

154

spot

per

TYPE

GAS

needle(s)

scarf

or

are

machine

395—20,

28-V,

395-22,

following

is

all

to

the

sewn

off

style:

Machine

21, 26,

40,

23

chart

Round

shank,

blade,

groove,

chromium

the

way

rear

shipped

and

Style

26—V.

40-V.

lists

42,

additional

DESCRIPTION

round

standard

struck

plated.

up

as

shown

42

point,

length,

groove,

in

28,

V.

needle

(D,

from

needle

curved

single

spotted,

the

Fig.

holder

2).

factory

types

and

positioned

with

Type

154

154

and

needle(s)

and

Size

GAS-O70/027

GAS-090/036

sizes

available

SIZES

055/022, 065/025,

075/029, 080/032,

100/040,

140/054,

correctly

listed

AVAILABLE

110/044,

150/060.

in

for

Class

070/027,

090/036,

125/049,

with

154

GBS

Same

double

as

groove.

154

GAS

except

it

has

a

9

070/027,

075/029,

080/032.

NEEDLE

TYPE

DESCRIPTION

SIZES

AVAILABLE

154

154

154

154

To

needle

complete

GES

GHS

GJS

GLS

have

or

type

order

needle

and

would

Same

shorter

Same

ball

Same

tapered

Same

ball

orders

size

read

as

154

blunt

as

154

point.

as

154

blade.

as

154

eye.

number

“1000

GAS

point.

GAS

GAS

GAS

promptly

should

needles,

except

except

except

except

and

accurately

be

counterclockwise

left.

until

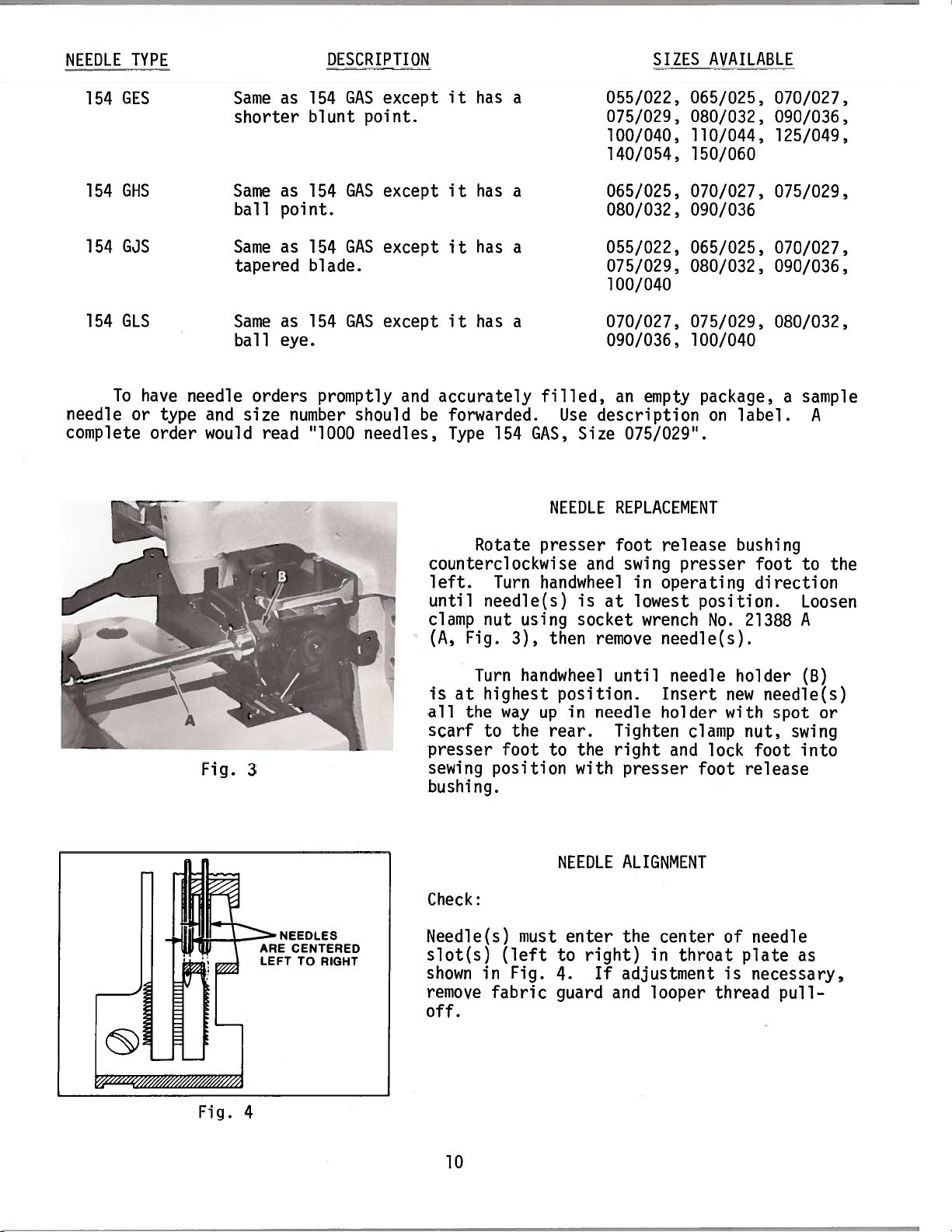

clamp

(A,

it

has

it

has

has

it

has

it

forwarded.

Type

154

Rotate

Turn

needle(s) is

nut

Fig.

a

a

a

a

filled,

GAS,

presser

handwheel

using

3),

Use

description

Size

NEEDLE

and

socket

then

remove

055/022, 065/025,

075/029,

100/040,

140/054,

080/032, 090/036,

110/044, 125/049,

150/060

065/025, 070/027,

080/032,

055/022,

075/029,

090/036

065/025,

080/032,

100/040

070/027, 075/029,

empty

100/040

package,

on

label.

090/036,

an

075/029”.

REPLACEMENT

bushing

position.

No.

at

foot

swing

in

lowest

release

presser

operating

wrench

needle(s).

070/027,

075/029,

070/027,

090/036,

080/032,

foot

direction

21388

sample

a

to

Loosen

A

A

the

Fig.

Fig.

4

3

ARE

LEFT

NEEDLES

CENTERED

TO

RIGHT

Turn

is

at

all

the

scarf

presser

sewing

bushing.

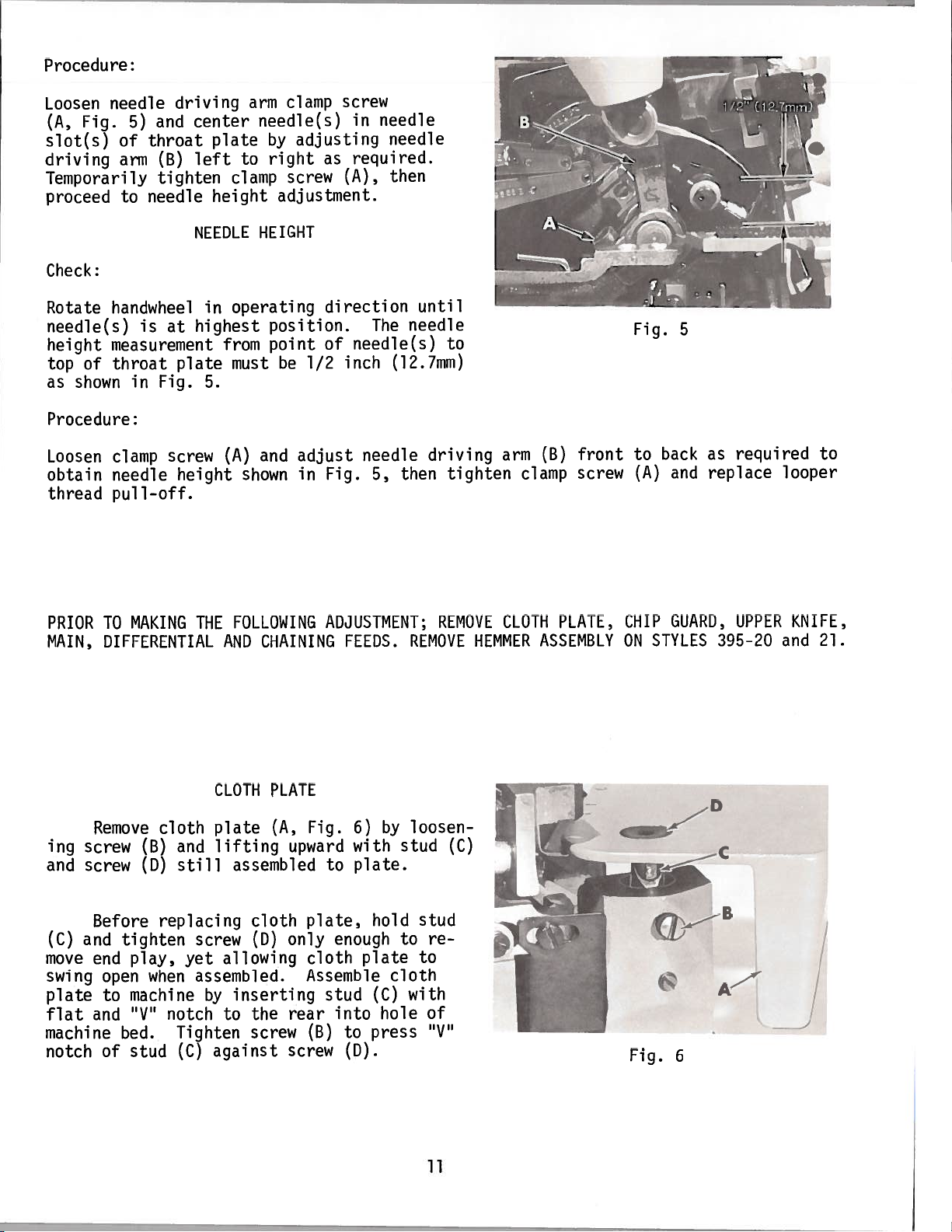

Check:

Needle(s)

slot(s)

shown

remove

off.

highest

way

the

to

foot

position

(left

in

Fig.

fabric

handwheel

position.

in

up

rear.

to

the

with

NEEDLE

must

enter

to

4.

guard

until

needle

Tighten

right

presser

ALIGNMENT

the

right)

If

adjustment

and

needle

Insert

holder

and

center

in

throat

looper

clamp

lock

foot

thread

holder

new

with

nut,

foot

release

of

needle

plate

is

necessary,

(B)

needle(s)

spot

swing

into

as

pull-

or

10

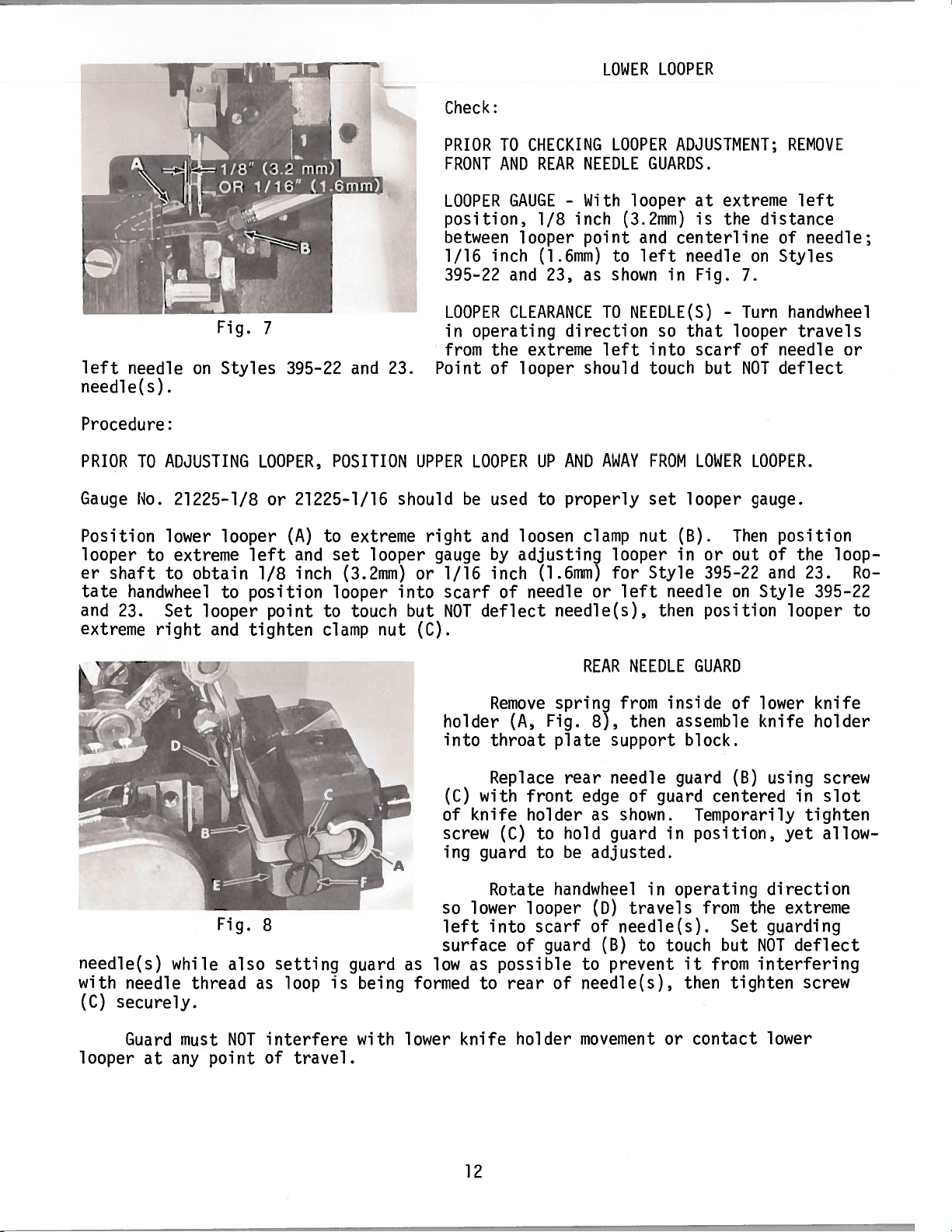

Procedure:

Loosen

(A,

slot(s)

driving

Temporarily

proceed

Check:

Rotate

needle(s)

height

top

as

Procedure:

Loosen

obtain

thread

needle

Fig.

handwheel

measurement

of

throat

shown

clamp

needle

pull-off.

5)

of

arm

to

in

and

throat

(B)

tighten

needle

is

Fig.

driving

center

left

NEEDLE

at

plate

screw

height

plate

clamp

height

operating

in

highest

from

must

5.

(A)

arm

needle(s)

by

right

to

HEIGHT

position.

point

and

shown

clamp

screw

adjustment.

be

screw

adjusting

as

direction

of

1/2

adjust

in

Fig.

needle

in

required.

(A),

The

needle(s)

inch

needle

5,

needle

then

until

needle

(12.7mm)

driving

then

to

tighten

arm

(B)

clamp

front

screw

Fig.

to

(A)

5

back

and

required

as

replace

to

looper

PRIOR

MAIN,

ing

screw

and

screw

(C)

and

move

swing

plate

flat

machine

notch

MAKING

TO

DIFFERENTIAL

(B)

(D)

tighten

play,

when

machine

“V’

bed.

stud

cloth

and

still

replacing

yet

notch

Tighten

(C)

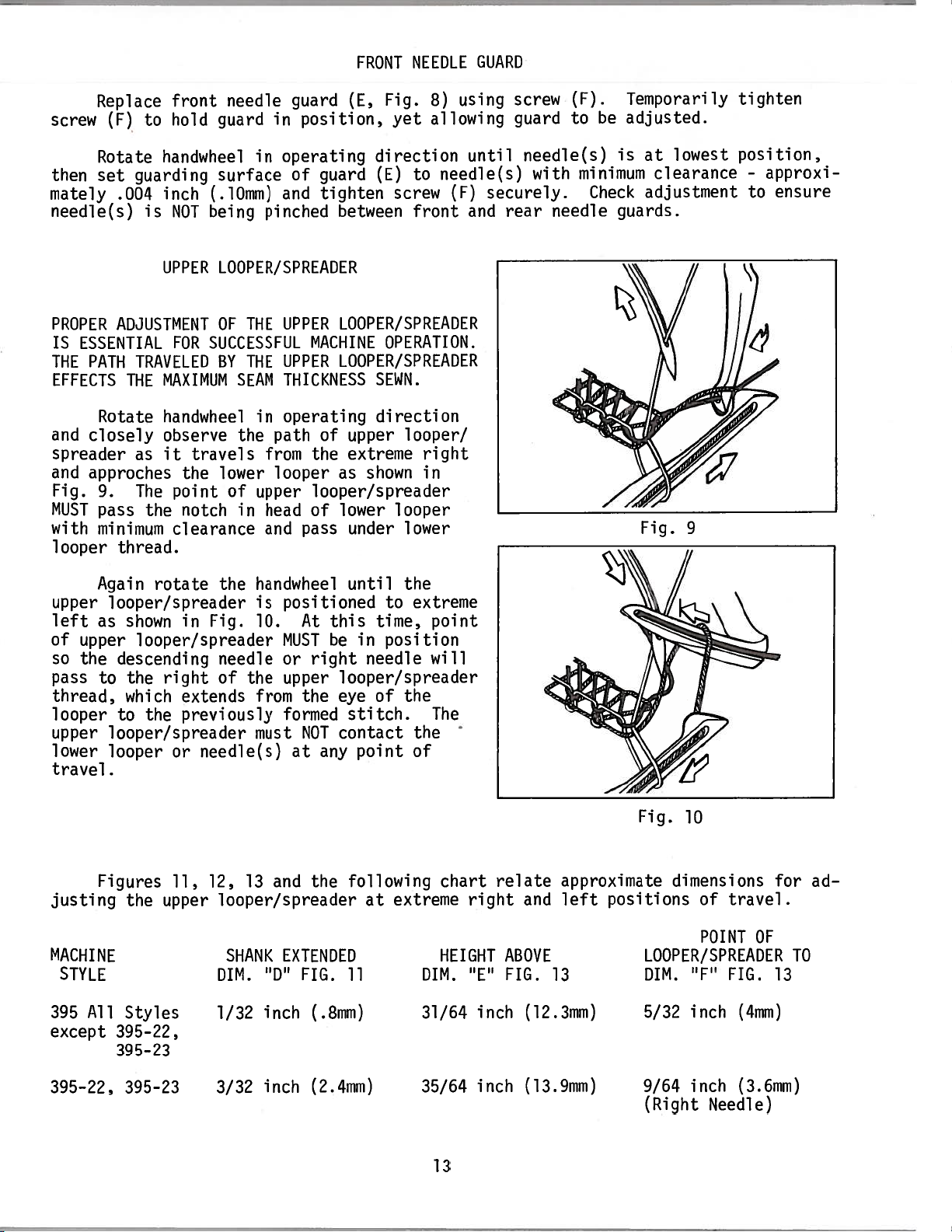

Remove

Before

end

open

to

and

of

FOLLOWING

THE

AND

CLOTH

plate

lifting

assembled

cloth

allowing

inserting

to

against

(D)

the

screw

screw

assembled.

by

ADJUSTMENT;

CHAINING

PLATE

(A,

Fig.

upward

to

plate,

only

cloth

Assemble

stud

rear

(B)

screw

FEEDS.

6)

with

plate.

enough

plate

into

press

to

(D).

by

hold

cloth

(C)

hole

REMOVE

REMOVE

loosen-

stud

to

(C)

stud

re

to

with

of

“V

CLOTH

HEMMER

PLATE,

ASSEMBLY

zc

CHIP

ON

Fig.

GUARD,

STYLES

6

UPPER

395-20

A

KNIFE,

and

j

21.

11

Check:

LOWER

LOOPER

left

needle(s).

Procedure:

PRIOR

Gauge

Position

looper

er

tate

and

extreme

needle

TO

No.

shaft

handwheel

23.

L

on

ADJUSTING

21225-1/8

lower

to

extreme

to

obtain

Set

looper

right

U

Fig.

Styles

looper

to

and

‘

Z

7

LOOPER,

or

left

1/8 inch

position

point

tighten

395-22

POSITION

21225-1/16

(A)

to

set

and

(3.2mm)

looper

to

clamp

and

23.

extreme

looper

touch

nut

UPPER

should

right

or

into

but

(C).

PRIOR

FRONT

LOOPER

position,

between

1/16

395-22

LOOPER

in

from

Point

gauge

1/16

scarf

NOT

TO

AND

GAUGE-With

inch

and

CLEARANCETONEEDLE(S)-Turn

operating

the

of

LOOPERUPAND

be

used

and

by

inch

of

deflect

CIIECKING

REAR

inch

1/8

looper

(1.6mm)

23,

direction

extreme

looper

properly

to

loosen

adjusting

(1.6mm)

needle

needle(s),

LOOPER

NEEDLE

looper

(3.2mm)

point

to

as

shown

left

should

AWAY

clamp

looper

for

or

left

ADJUSTMENT;

GUARDS.

at

is

and

centerline

left

needle

in

Fig.

so

that

into

scarf

touch

FROM

LOWER

set

looper

nut

(B).

in

or out

Style

needle

then

395-22

position

extreme

the

but

distance

on

7.

looper

of

NOT

LOOPER.

gauge.

Then

of

and

on

Style

REMOVE

left

of

needle;

Styles

handwheel

travels

needle

deflect

position

the

23.

395-22

looper

or

loop

Ro

to

needle(s)

with

(C)

looper

needle

securely.

Guard

NEEDLE

REAR

(A,

front

holder

looper

of

rear

holder

spring

Fig.

plate

rear

to

hold guard

be

to

handwheel

scarf

guard

of

Remove

holder

into

throat

Replace

with

(C)

of

knife

screw

ing

so

Fig.

8

while

thread

must

at

any

point

also

NOT

setting

as

loop

interfere

of

travel.

is

guard

being

with

as

formed

lower

left

surface

low

guard

lower

as

to

knife

(C)

Rotate

into

possible

from

then

8),

support

needle

edge

to

needle(s),

movement

of

as

shown.

adjusted.

travels

(D)

of

needle(s).

(B)

to

prevent

inside

guard

in

in

touch

or

assemble

guard

operating

GUARD

of

block.

(B)

centered

Temporarily

position,

from

Set

but

it

from

then

tighten

contact

lower

knife

using

in

yet

direction

the

extreme

guarding

deflect

NOT

interfering

lower

knife

holder

screw

slot

tighten

allow

screw

12

FRONT

NEEDLE

GUARD

Replace

screw

Rotate

then

set

mately

needle(s)

PROPER

IS

ESSENTIAL

PATH

THE

EFFECTS

Rotate

and

closely

spreader

and

approches

Fig.

9.

MUST

with

pass

minimum

looper

front

(F)

to

hold

handwheel

guarding

inch

.004

is

NOT

UPPER

ADJUSTMENT

FOR

TRAVELED

MAXIMUM

THE

handwheel

observe

it

as

travels

the

The

point

the

notch

clearance

thread.

in

in

operating

and

pinched

guard

position,

of

guard

tighten

between

needle

guard

surface

(.10mm)

being

LOOPER/SPREADER

THE

UPPER

OF

SUCCESSFUL

UPPER

THE

BY

THICKNESS

SEAM

operating

in

the

path

from

in

looper

upper

head

lower

of

and

LOOPER/SPREADER

MACHINE

LOOPER/SPREADER

of

the

as

looper/spreader

lower

of

pass

Fig.

(E,

yet

direction

(E)

screw

OPERATION.

SEWN.

direction

upper

extreme

shown

looper

under

8)

allowing

to

front

looper/

right

in

lower

using

until

needle(s)

(F)

securely.

and

screw

guard

needle(s)

with

rear

(F).

to

minimum

needle

Temporarily

be

adjusted.

is

Check

guards.

lowest

at

clearance

adjustment

Fig.

9

tighten

position,

approxi

-

ensure

to

Again

upper

left

of

so

pass

looper/spreader

as

upper

descending

the

to

thread,

looper

upper

lower

to

looper/spreader

looper

travel.

Figures

justing

MACHINE

STYLE

All

395

except

395-22,

395-23

rotate

shown

in

looper/spreader

right

the

the

extends

previously

needle(s)

or

which

11,

the

upper

Styles

the

handwheel

is

positioned

Fig.

10.

MUST

the

or

upper

needle

of

from

formed

must

at

and

13

12,

looper/spreader

SHANK

DIM.

1/32

EXTENDED

“D”

inch

until

this

At

in

be

right

looper/spreader

eye

the

stitch.

NOT

contact

point

any

following

the

FIG.

11

(.8mm)

to

time,

position

needle

of

extreme

at

the

extreme

point

will

the

The

the

of

DIM.

31/64

chart

right

HEIGHT

“E”

inch

relate

and

ABOVE

FIG.

(12.3mm)

approximate

positions

left

13

Fig.

10

dimensions

of

travel.

POINT

for

OF

LOOPER/SPREADER

DIM.

5/32

“F”

inch

FIG.

(4mm)

13

ad-

TO

395-22,

395—23

3/32

inch

(2.4mm)

35/64

inch

(13.9mm)

13

9/64

(Right

inch

Needle)

(3.6mm)

Fig.

11

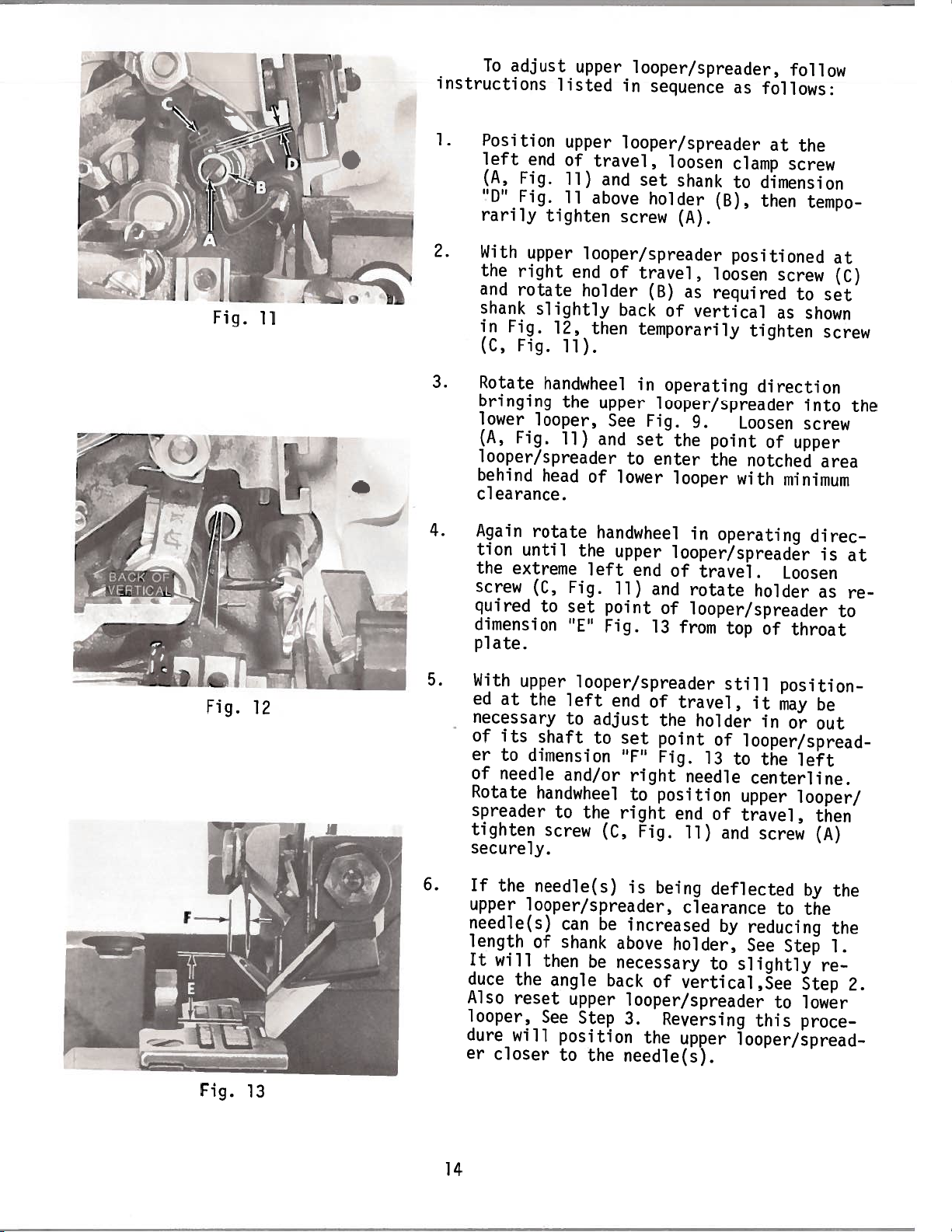

To

instructions

1.

Position

left

(A,

“D”

rarily

2.

With

the

and

shank

in

(C,

adjust

end

Fig.

Fig.

upper

right

rotate

slightly

Fig.

Fig.

upper

listed

upper

of

travel,

11)

and

11

above

tighten

looper/spreader

end

holder

12,

then

11).

looper/spreader,

in

sequence

looper/spreader

loosen

set

shank

holder

screw

of

back

travel

(B)

of

(A).

as

vertical

temporarily

(B),

,

loosen

required

follow

as

follows:

at

clamp

to

screw

dimension

then

positioned

screw

as

tighten

the

tempo

to

shown

at

(C)

set

screw

Fig.

12

3.

4.

5.

Rotate

bringing

lower

(A,

handwheel

looper,

Fig.

the

11)

looper/spreader

behind

head

clearance.

Again

tion

the

screw

quired

rotate

until

extreme

(C,

to

dimension

plate.

With

ed

at

upper

the

necessary

of

its

shaft

er

to

dimension

of

needle

Rotate

spreader

tighten

handwheel

to

screw

securely.

in

upper

See

Fig.

and

set

to

of

lower

handwheel

the

upper

left

end

Fig.

set

“E”

11)

point

Fig.

and

13

looper/spreader

left

end

of

to

adjust

to

set

“F’

and/or

right

to

the

right

(C,

Fig.

operating

looper/spreader

9.

Loosen

the

point

enter

looper

in

the

notched

with

operating

looper/spreader

of

travel.

rotate

of

looper/spreader

from

top

still

travel,

the

holder

point

Fig.

position

needle

end

11)

of

looper/spread

13

to

centerline.

upper

of

travel,

and

direction

of

upper

minimum

Loosen

holder

of

throat

position

it

may

in

or

the

left

looper/

screw

into

screw

area

direc

is

as

be

out

then

(A)

the

at

re

to

Fig.

6.

13

If

the

upper

needle(s)

length

It

will

duce

Also

the

reset

looper,

dure

will

er

closer

needle(s)

looper/spreader,

can

of

shank

then

angle

See

position

to

14

be

upper

Step

the

is

being

be

increased

above

necessary

back

of

looper/spreader

3.

Reversing

the

needle(s).

deflected

clearance

holder,

to

vertical

upper

to

by

reducing

See

Step

slightly

,See

to

this

looper/spread

by

the

re—

Step

lower

proce

the

the

1.

2.

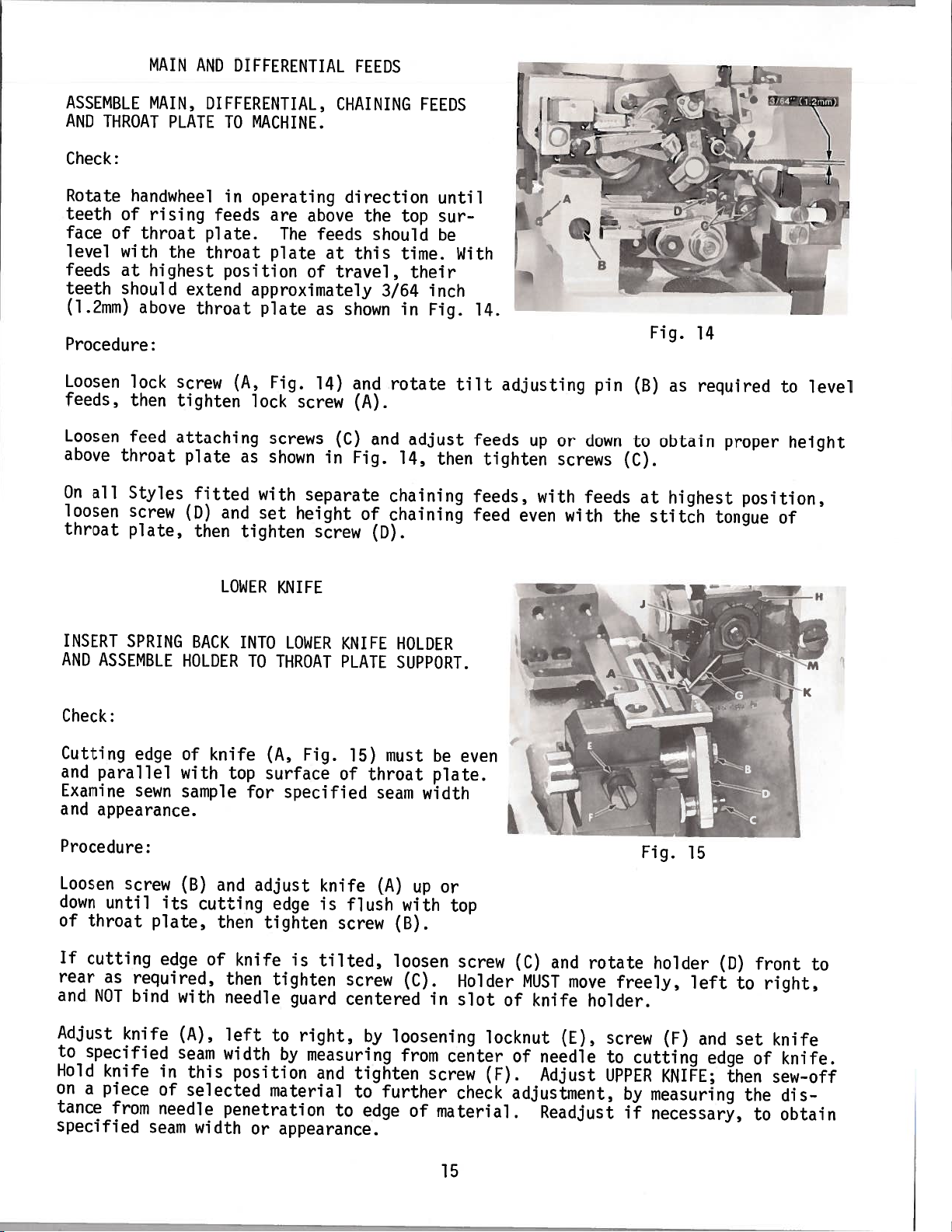

MAIN

AND

DIFFERENTIAL

FEEDS

ASSEMBLE

AND

THROAT

Check:

Rotate

teeth

face

level

feeds

teeth

(l.2iniii)

handwheel

of

of

throat

with

at

should

above

Procedure:

Loosen

feeds,

Loosen

above

On

loosen

throat

all

lock

then

feed

throat

Styles

screw

plate,

MAIN,

PLATE

rising

the

highest

extend

screw

tighten

attaching

plate

(D)

DIFFERENTIAL,

TO

MACHINE.

in

operating

feeds

plate.

throat

are

The

plate

position

approximately

throat

(A,

plate

lock

Fig.

screw

screws

as

shown

fitted

then

and

tighten

with

set

height

CHAINING

direction

above

feeds

at

travel,

of

shown

as

14)

(C)

in

separate

screw

the

this

and

(A).

Fig.

of

top

should

time.

3/64

in

rotate

and

14,

chaining

chaining

(D).

FEEDS

until

sur

be

their

inch

Fig.

adjust

then

With

14.

tilt

feeds

feeds,

feed

adjusting

tighten

even

up

with

or

down

screws

feeds

with

pin

the

(B)

to

(C).

Fig.

at

stitch

as

obtain

highest

14

required

proper

tongue

to

height

position,

of

level

INSERT

AND

ASSEMBLE

Check:

Cutting

and

parallel

Examine

and

appearance.

Procedure:

Loosen

down

until

of

throat

If

cutting

rear

as

and

NOT

Adjust

to

specified

Hold

on

tance

a

knife

piece

from

specified

SPRING

edge

sewn

screw

its

plate,

edge

required,

bind

knife

in

of

needle

seam

LOWER

BACK

HOLDER

of

knife

with

top

sample

(B)

and

cutting

then

of

then

with

seam

(A),

this

needle

left

width

position

selected

penetration

width

INTO

TO

surface

for

adjust

tighten

knife

or

KNIFE

LOWER

THROAT

(A,

Fig.

specified

knife

edge

is

is

tilted,

tighten

guard

to

right,

by

measuring

and

material

appearance.

KNIFE

PLATE

15)

of

throat

flush

screw

screw

centered

by

tighten

to

to

edge

HOLDER

SUPPORT.

must

seam

width

(A)

up

with

(B).

loosen

(C).

loosening

from

screw

further

of

be

even

plate.

or

top

screw

Holder

in

slot

center

check

material.

(C)

MUST

of

locknut

of

(F).

adjustment,

and

move

knife

(E),

needle

Adjust

Readjust

rotate

freely,

holder.

screw

to

UPPER

by

if

Fig.

holder

(F)

cutting

KNIFE;

measuring

necessary,

15

left

and

(D)

edge

then

to

set

the

front

right,

knife

of

knife.

sew—off

dis

to

obtain

to

15

Loading...

Loading...