CATALOG

NO.

Adjusting

instructions

and

103PA

First Edition

STYLES

39500PA

39500PE

39500PF

39500PP

39500PT

39500PW

illustrated parts list

([)

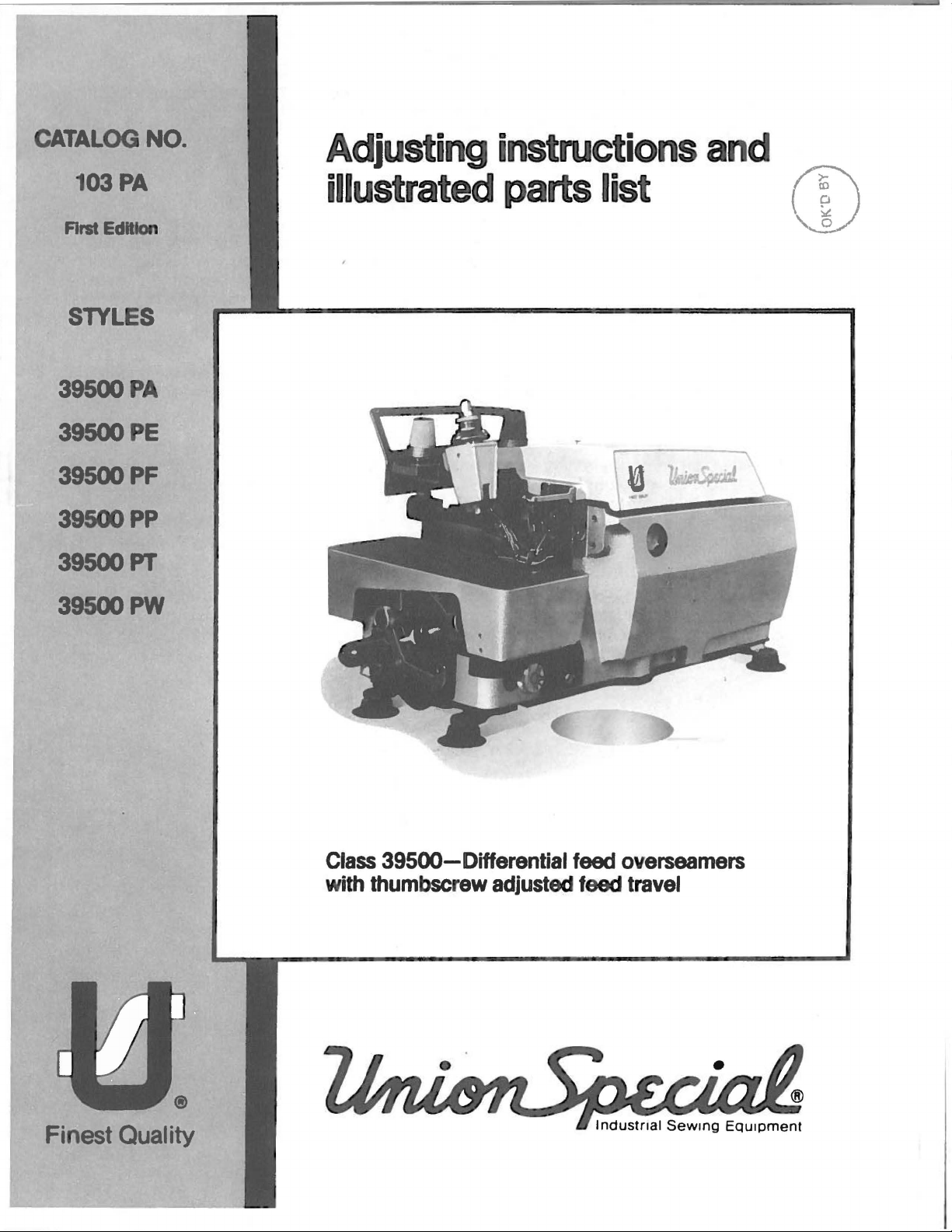

Class

with thumbscrew adjusted

Finest Quality

39500-Differential

feed overseamers

feed travel

FOREWORD

This technical

new

UNION

SPECIAL

adjusting these

liability

setting

functions

Check

rectly.

designed

The

Adjusting Instructions portion of

for

each

of

the machine.

and

Procedure.

The

Procedure

manual

has

machine. Careful

machines

and

of

will enable

built

the

components

into every

The

The

Check

is

given to explain the proper steps to

been

prepared to guide

attention

related to forming the

text

of the Adjustments

depicts conditions

adjustments are required. Figures are

ence

letters

to point out

specific

items discussed.

Adjustments are presented in sequence

plished.

the function of other

Some

adjustments performed out of sequence

related

parts.

Implementation of preventative maintenance procedures

cant

Whenever

sure to

fically

improvements

it

becomes

insist

for

on

your

in operator productivity

necessary to

genuine

machine

UNION

and

make

SPECIAL

manufactured with utmost precision to assure long

ing service.

you

in the maintenance

to the instructions for operating

you

to maintain the superior performance

UNION

used

repairs

Repair Parts.

SPECIAL

this

manual

machine.

explains in

stitch

is

divided into

when

the parts are adjusted cor-

be

to

illustrate

so

that

a logical progression

by

avoiding costly equipment

or

replace parts

the adjustments using

may

have

an

can

bring about

on

These

parts are designed speci-

detail

and

taken in the event

adverse

your machine,

of

your

and

and

re-

the proper

completing the

two

sections -

refer-

is

accom-

effect

on

signifi-

breakdowns.

be

last-

To

simplify

exploded views.

VIEW

which

illustrated

presents the

on

identification

These

illustrations

mechanisms

this

page

will appear

of

repair

will usually

of the

shaded

Catalog

For

39500

39500

39500

PA

PE

PF

First

Copyright

Union

Special Corporation

Rights Reserved

parts,

machine

in the

No.

103

Styles

Edition

1981

By

In

All

the

mechanisms

be

shown

assembled.

KEY

PA

39500

39500

39500

pp

PT

PW

Countries

are

illustrated

in conjunction with a

The

specific

VIEW.

by

KEY

parts

Printed

May,

In

1981

2

U.S.A.

High

Speed,

ential

feed overseaming machines. Fabric trimmer with spring pressed lower knife.

Independent

automatic

one

and

two

thumbscrew

lubrication

CLASS

curved needles,

adjustments for

system.

Fan

cooled.

DESCRIPTION

two

loopers, three

main

and

differential

and

four thread,

feed

travel.

differ-

Enclosed

39500

woven

PAfabrics.

straight

(2.4mm),

STITCH

SEAM

FEED

MAXIMUM

(Depending

AND

TYPE

..........

SYSTEM

........

SPEED

on

Operation)

LUBRICATION

One

needle,

........

Stitch

seams

l/8

on

inch

pajamas

(3.2mm),

......

low

range

504

.

512

Independent

.

Main

6500

.

7000

Enclosed Automatic Splash

.

Return

capacity

is

8-20

and

women's

5/32 inch

TECHNICAL

SSa-1, Styles

SSa-2, Style

DATA

39500

39500

thumbscrew

and

Differential Feeds.

RPM,

RPM,

Styles

Styles

39500

39500

Pump

MACHINE

machine

S.P.I.

STYLES

for

sewing

Typical application -

underwear. Available

(4mm).

PA,

PE,

PF, PP,

PT

PW

adjustments for both

PF,

PP,

PT,

PW

PA,

PE

System

light

with

to

mediumweight

Seam

Widths: 3/32 inch

For

Oil

seaming

knit or

long

39500

tion -

39500

PE -Same

Seaming

PF -Same

heavyweight knit

T.P.I.

39500

39500

Maximum

39500

1 7 I

64

Each

stamped

The

Stitch

PPPT -Same

shirring

PW -Same

inch (

UNION

in the

serial

Same

6.

7mm)

SPECIAL

number

machine.

as

39500

women's

as

39500

or

woven

range

as

as

is

39500

39500

ratio

as

39500

.

machine

style

plate

is

stamped

PA

except

robes

PA

and

except

fabrics.

8-16

S.P.I.

PF

except equipped with a

PF

except prepared

is

3 to

PP

except

fitted

lingerie.

machine

Also

1.

Available

machine

IDENTIFICATION

carries a style

located to the

in the extension of casting

with

narrow

is

high capacity

sewing

equipped with a

main

for

continuous or

Seam

Width:

has

two

needles. Available

OF

MACHINES

number,

right

which

rear

of

parts.

for

sewing

main

feed

feed

dog

having

intermittent

1/8 inch

on

this

(3.2mm).

class

the machine.

at

the

right

Typical applica-

dog

medium

having

12

to

16

T.P.I.

shirring.

Seam

Width:

machine

is

rear base of

3

TO

PREVENT

THIS

SAFETY

PERSONAL

SYMBOL

INJURY:

SAFETY

A

CAUTION!

INDICATES

YOUR

RULES

PERSONAL

SAFETY

IS

INVOLVED.

-All

-

-

-

mineral

equivalent to

oil

bulb

Clean

Oil

power

justing

Wear

All

shields

DO

NOT

Oil

Machine

level

on

To

magnetic plug of

MUST

sources to the

or replacing

safety glasses.

tamper

capacity

oil

with a Saybolt

at

oil

drain

be

and

guards

with

of

UNION

is

filled

sight

level

changed

indicator

oil

remove

machine

parts.

MUST

safety

Class

SPECIAL

gauge

periodically

shields,

39500

viscosity

specification

with

oil

on

front

will

magnetic plug

any

metallic material

MUST

be

TURNED

be

in position before operating

guards,

LUBRICATION

is

eight

at

spring

of

register

to minimize wear.

ounces

of

90

to

No.

cap

machine.

between

from

THREADING

back

OFF

etc.,

that

while

(227

milliliters).

125

seconds

175.

in top cover. Before operating,

When

proper

red

of

machine

may

gauge

before threading,

machine.

machine

at

oil

near

have

accumulated in crankcase.

100

level

lines.

is

degrees

bottom

oiling,

in operation.

Use a straight

is

reached, red

edge

F.

ad-

This

of base.

is

check

Be

sure

machine

Styles

arm

wheel

No. 660-240

thread, (3) needle thread.

arm

wheel

No.

thread, (3)

39500

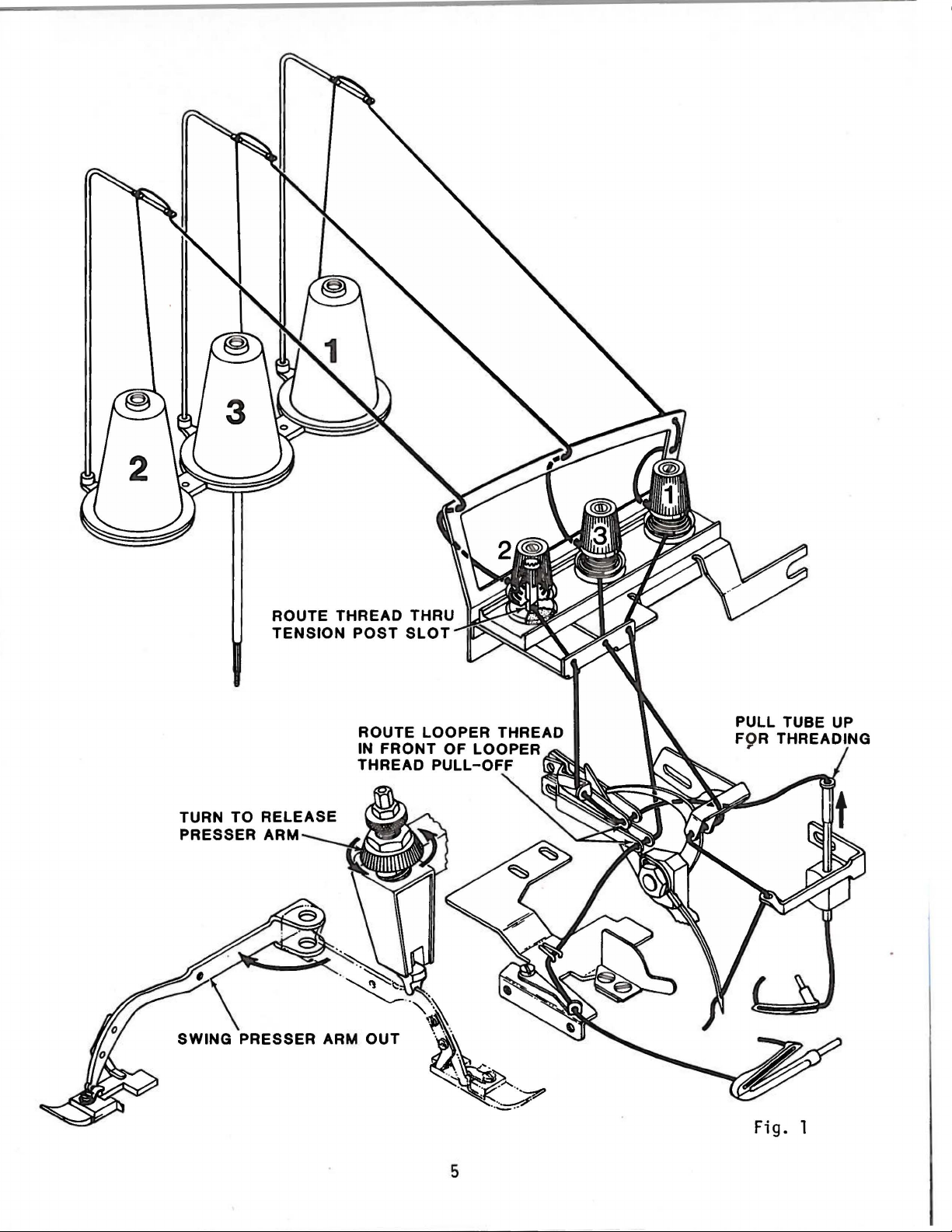

Before threading machine; unlock presser foot release bushing,

and

in operating

Thread

Before threading machine; unlock presser foot release bushing,

and

in operating

660-240

Thread

PA,

cloth plate out

are furnished with

machine

cloth

plate

are furnished with

machine

right

is

threaded properly according to threading diagram Fig. 1,

PE,

PF, PP,

THREADING

of

direction

in sequence

out

of

direction

in sequence

needle thread

PT,

or Fig. lA,

DIAGRAM

position

until needle

THREADING

position

until

STYLES

and

machine

as

shown;

DIAGRAM

and

needles are

machine

as

shown;

and

(4)

for

Style

39500

pull

is

to aid in threading.

(1) lower looper thread, (2) upper looper

STYLE

pull upper looper thread tube

to aid in threading.

(1) lower looper thread, (2)

left

4

PA,

uppe

r looper thread tube

at

highest position.

at

needle thread.

39500

PE,

39500

highest position.

PF, PP,

PW

PW.

PT

swing

up.

Thread

swing

up.

Thread

upper

presser

Turn

tweezers

presser

Turn

for

hand-

hand-

tweezers

looper

ROUTE

TENSION

THREAD

POST

THRU

SLOT

TURN TO

PRESSER ARM

SWING PRESSER ARM

RELEASE

··

·

~.

ROUTE

IN

THREAD

"'--

OUT

LOOPER

FRONT

PULL-OFF

··"~

~\,~

THREAD

OF

LOOPER

..

A

~··~

~

..

~

5

Fig.

1

TURN

TO

PRESSER ARM -

RELEASE

---.ll"!:j

6

Fig. 1 A

ADJUSTING

INSTRUCTIONS

CLASS

39500

NOTE:

Instructions

stating

of machine, are given

handwheel

right

rotates

end

of machine.

NEEDLES

EXAMINE

TYPE

CHECKS

FORE

LE

NEEDLE

AND

SIZE

RELATED

ADJUSTING

GUARDS.

AND/OR

IS

BEING

TO

NEEDLE(S)

THE

NEEDLE(S),

DISCARD

AND

NEEDLE(S).

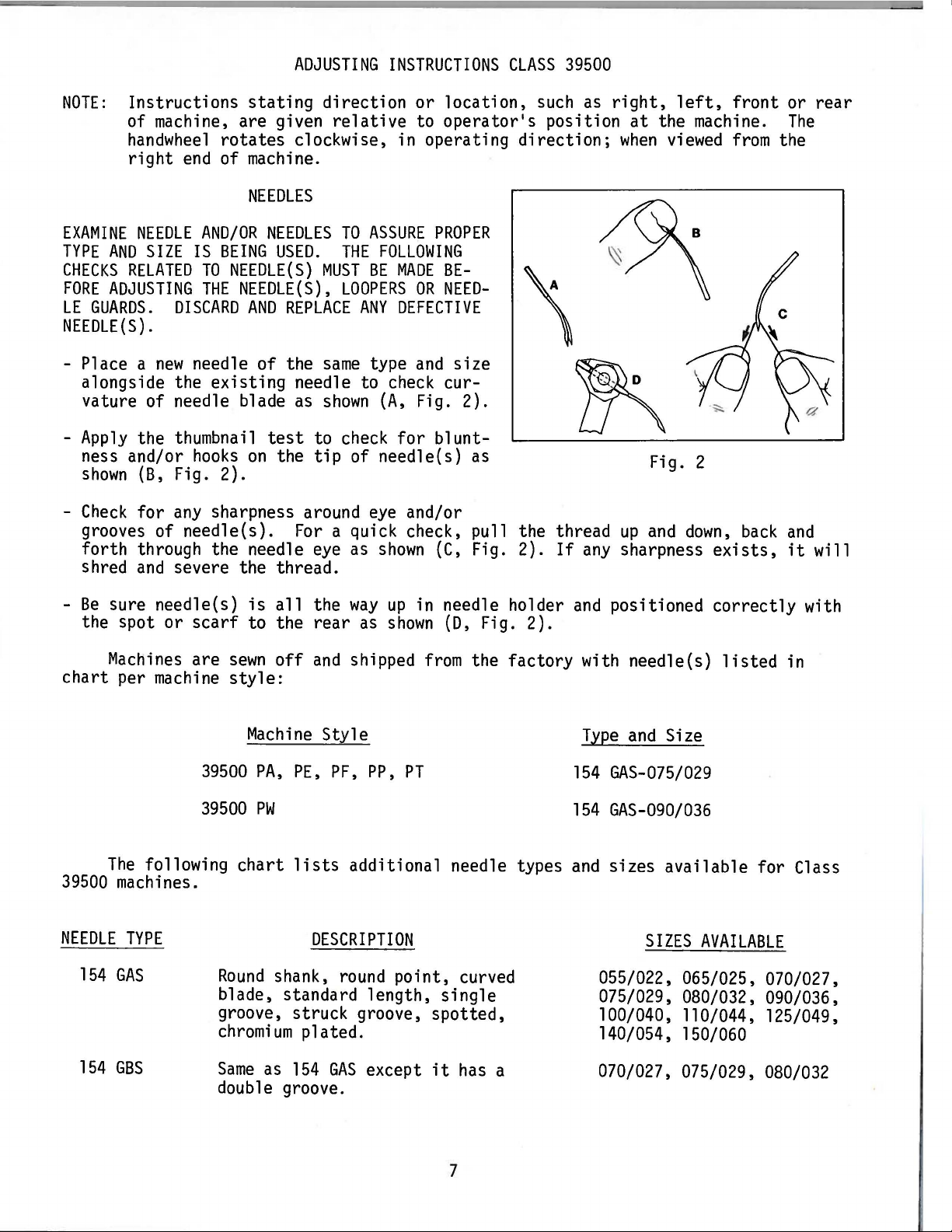

- Place a

alongside the

new

needle of the

existing

vature of needle blade

-

Apply

ness and/or

shown

-

Check

the thumbnail

hooks

(B,

Fig. 2).

for

any

sharpness around

on

grooves of needle(s).

forth through the needle

shred

and

severe the thread.

direction

relative

or

location,

to

operator's

clockwise, in operating

NEEDLES

USED.

REPLACE

as

test

the

TO

ASSURE

THE

FOLLOWING

MUST

same

needle to

shown

to

tip

For

eye

BE

MADE

LOOPERS

ANY

OR

DEFECTIVE

type

and

check

{A,

Fig. 2).

check

for

of needle(s) as

eye

and/or

a quick check, pull

as

shown

PROPER

BENEED-

cur-

blunt-

(C,

size

Fig.

such

as

position

direction;

the thread

2).

If

any

right,

when

left,

at

the machine.

viewed

Fig. 2

up

and

sharpness

down,

exists,

front

from

back

or

The

the

and

it

rear

will

-

Be

sure needle(s)

the spot or

Machines

chart

per

The

39500

NEEDLE

154

machines.

TYPE

GAS

scarf

are

machine

39500

39500

following

groove, struck groove, spotted,

chromium

is

all

the

way

up

in needle holder

to the rear

sewn

off

and

as

shown

shipped

(D,

Fig. 2).

from

the factory with needle(s)

style:

Machine

PA,

PE,

Sty

PF,

le

PP,

PT

PW

chart

lists

additional needle types

DESCRIPTION

Round

shank,

round

point, curved

blade, standard length, single

plated.

and

positioned

correctly

listed

Type

and

Size

154

GAS-075/029

154

GAS-090/036

and

sizes available for Class

SIZES

AVAILABLE

055/022, 065/025, 070/027,

075/029, 080/032, 090/036,

100/040, 110/044, 125/049,

140/054, 150/060

with

in

154

GBS

Same

as

154

GAS

except

it

has

a

double groove.

7

070/027, 075/029,

080/032

NEEDLE

TYPE

DESCRIPTION

SIZES

AVAILABLE

154

GES

154

GHS

154

GJS

154

GLS

To

have

needle orders promptly

needle or type

complete order

Same

as

154

GAS

shorter blunt point.

Same

Same

Same

as

154

ba

11

point.

as

154

tapered b

as

154

GAS

GAS

1 a de.

GAS

ball eye.

and

size

would

number

read 111000

except

except

except

except

and

should

needles,

it

has

a

it

has

a

it

has

a

it

has

a

accurately

be

forwarded.

Type

154

filled,

GAS,

NEEDLE

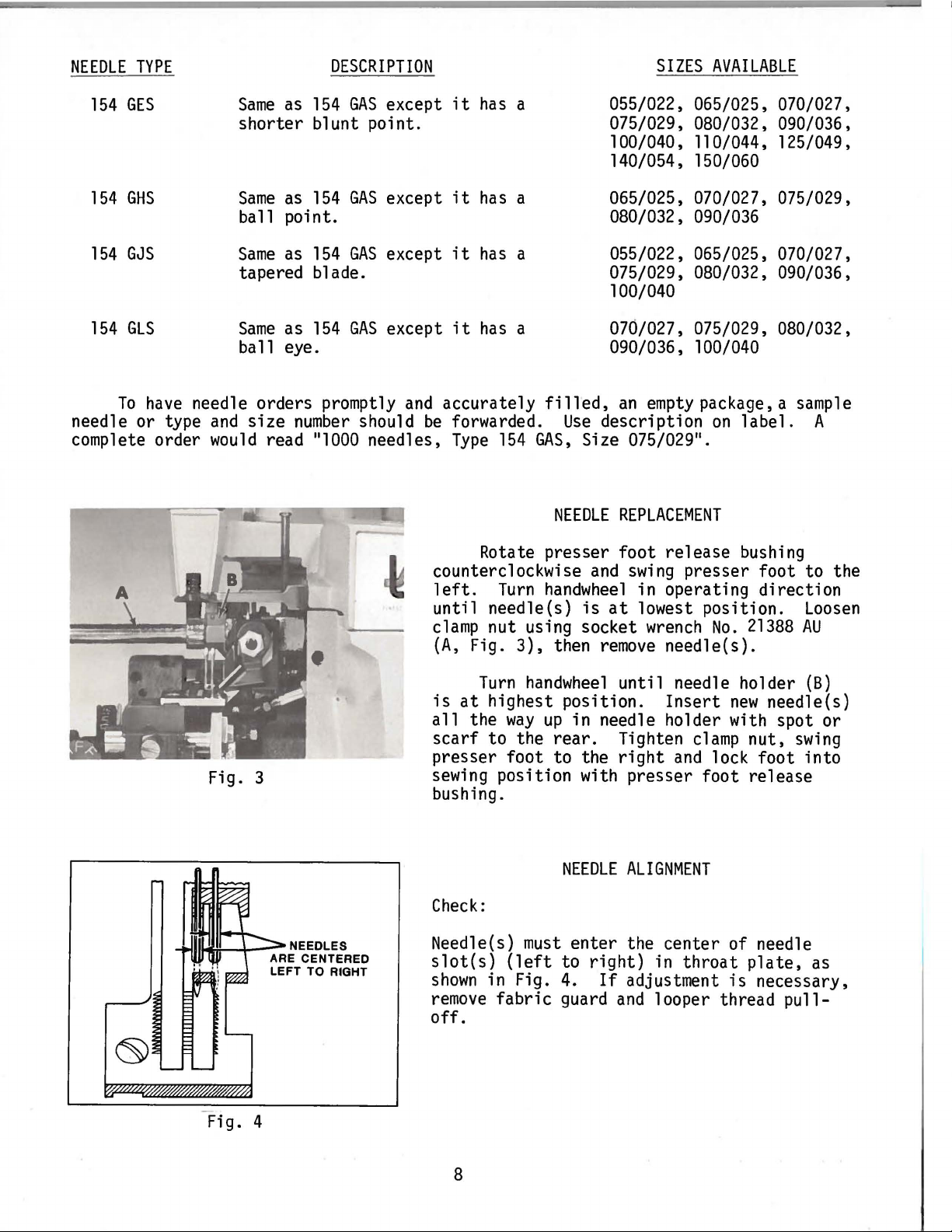

Rotate presser foot release bushing

counterclockwise

left.

Turn

handwheel

until needle(s)

clamp

(A,

nut using socket

Fig.

3),

then

055/022, 065/025, 070/027,

075/029, 080/032, 090/036,

1 00/040,

11

0/044, 125/049,

140/054, 150/060

065/025, 070/027, 075/029,

080/032, 090/036

055/022, 065/025, 070/027,

075/029, 080/032, 090/036,

100/040

070/027, 075/029, 080/032,

090/036, 100/040

an

Use

description

Size 075/029

empty

package, a

on

label.

11

•

REPLACEMENT

and

swing

presser foot to the

in operating direction

is

at

lowest position.

wrench

remove

needle(s).

No.

21388

sample

A

Loosen

AU

Fig. 3

Fig. 4

is

at

all

the

scarf

Turn

handwheel

highest position.

way

up

in needle holder with spot or

to

the

rear.

presser foot to the

sewing

position with presser foot release

bushing.

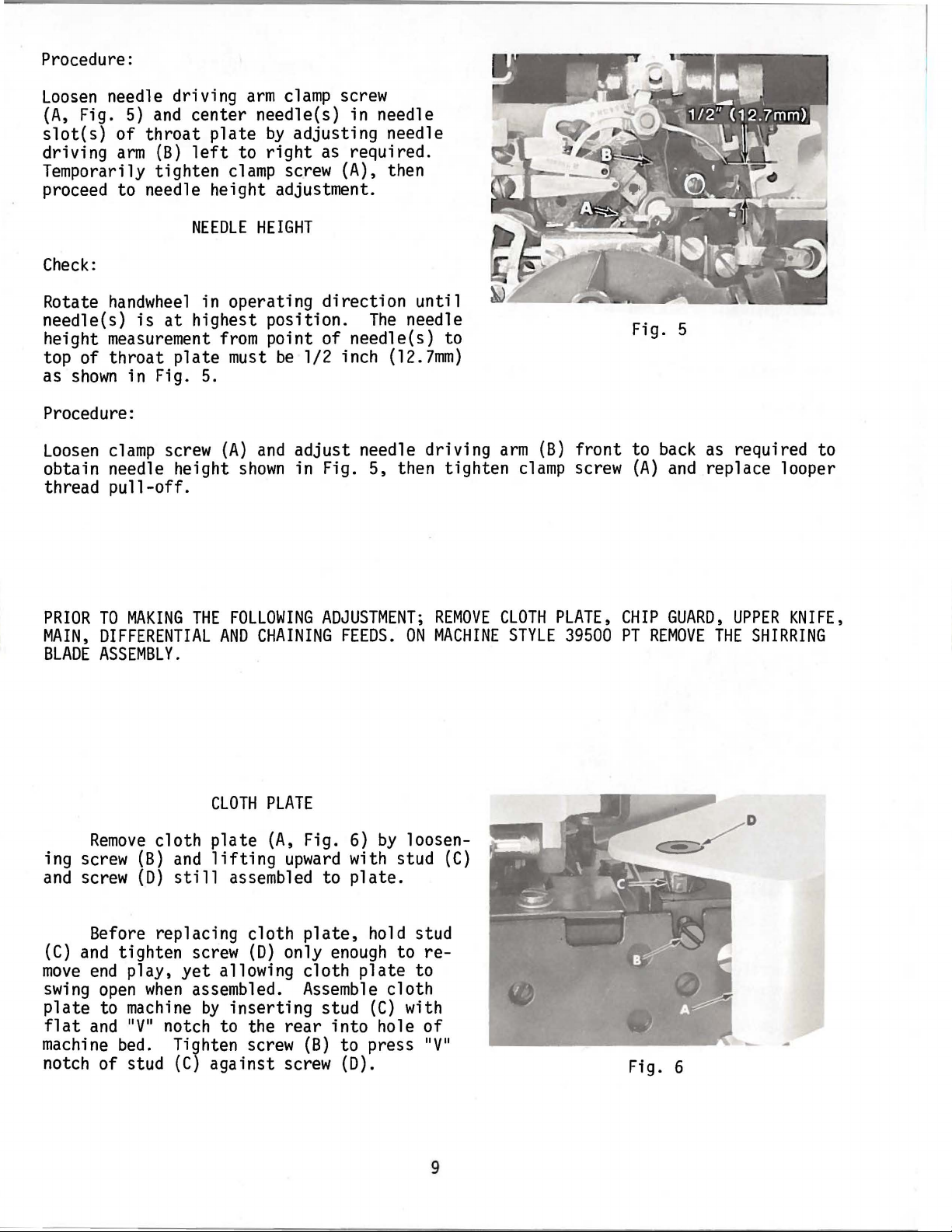

NEEDLE

Check:

Needle(s)

slot(s)

shown

remove

must

(left

to

in Fig. 4.

fabric

guard

enter

right)

off.

until needle holder

Insert

Tighten

right

and

new

clamp

nut,

lock foot into

ALIGNMENT

the center of needle

in

If

adjustment

and

looper thread

throat

plate,

is

(B)

needle(s)

swing

as

necessary,

pull-

8

Procedure:

Loosen

(A,

slot(s)

driving

Temporarily tighten

needle driving

Fig.

5)

and

of

throat

arm

(B)

arm

clamp

screw

center needle(s) in needle

plate

left

by

to

right

clamp

adjusting needle

as

required.

sc.rew

(A), then

proceed to needle height adjustment.

NEEDLE

HEIGHT

Check:

Rotate

needle(s)

height

top of

as

handwheel

measurement

throat

shown

in Fig. 5.

is

in operating

at

highest position.

from

plate

point of needle(s) to

must

be

direction

1/2 inch

Procedure:

Loosen

obtain needle height

thread

clamp

screw

pull-off.

(A)

shown

and

adjust

needle driving

in Fig. 5, then tighten

until

The

needle

(12.7mm)

arm

clamp

(B)

front

screw

Fig.

to

(A)

5

back

and

as

required to

replace looper

PRIOR

MAIN,

BLADE

TO

MAKING

DIFFERENTIAL

ASSEMBLY.

Remove

ing screw

and

screw

{B)

(D)

Before replacing cloth

(C)

and

tighten screw

move

swing

plate

flat

machine

end

play,

open

to

machine

and 11V

bed.

when

11

notch of stud

THE

FOLLOWING

AND

CLOTH

cloth

plate

and

lifting

still

yet

assembled to

allowing cloth

assembled.

by

inserting

notch to the

Tighten screw

(C)

against screw

ADJUSTMENT;

CHAINING

PLATE

{A,

Fig.

upward

plate,

(D)

only

Assemble

stud

rear

(B)

FEEDS.

6)

by

ON

loosenwith stud

plate.

hold stud

enough

to

plate

to

cloth

(C)

with

into hole

to press 11V

(D).

REMOVE

MACHINE

(C)

re-

of

11

CLOTH

PLATE,

STYLE

39500

CHIP

GUARD,

PT

REMOVE

Fig. 6

UPPER

THE

SHIRRING

KNIFE,

9

Check:

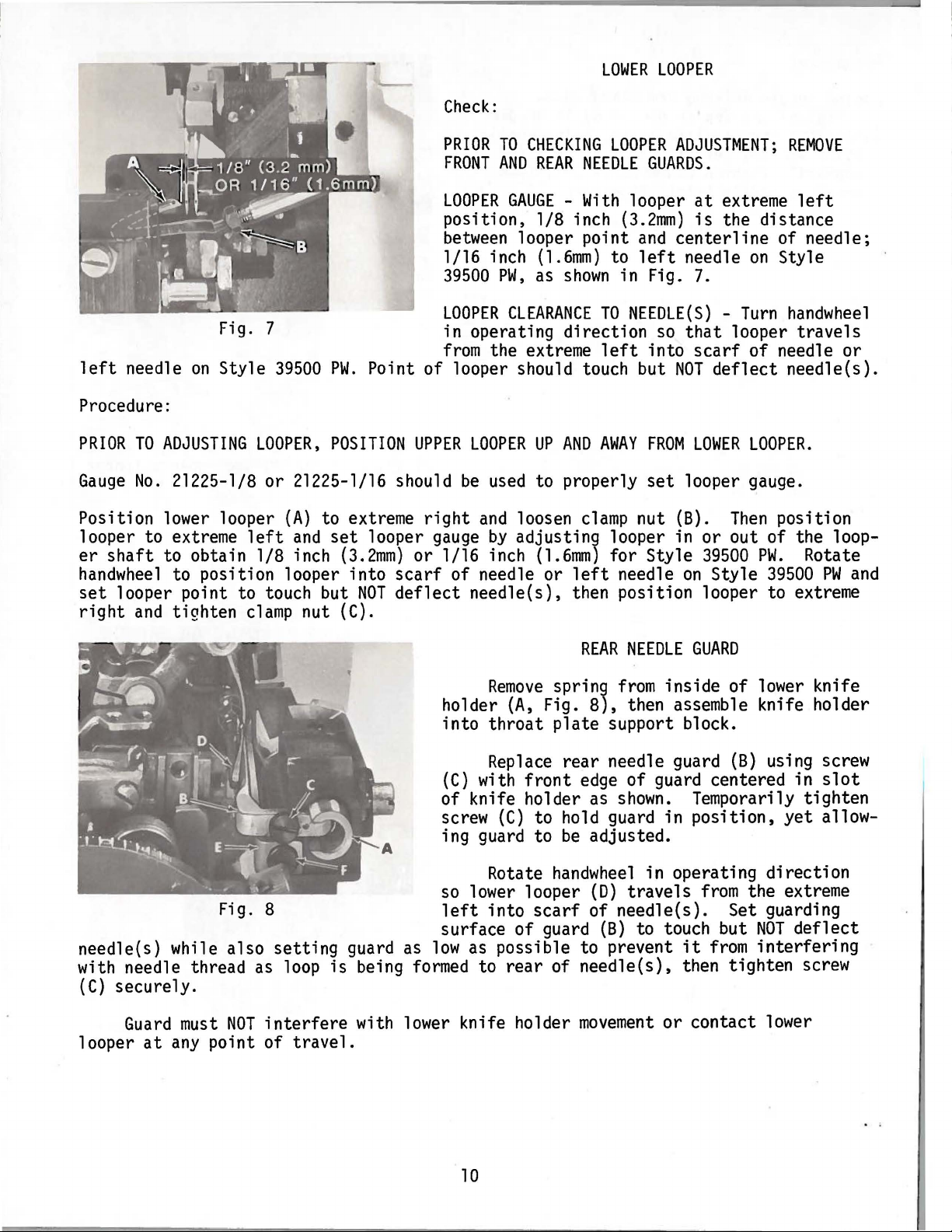

LOWER

LOOPER

Fig. 7

left

needle

on

Style

Procedure:

PRIOR

Gauge

TO

ADJUSTING

No.

21225-l/8 or 21225-1/16 should

LOOPER,

Position lower looper

looper to extreme

er

shaft

handwheel

set

looper point to touch but

right

to obtain

to position looper into

and

tighten

left

l/8

clamp

39500

(A)

and

inch

nut (C).

PW.

Point of looper should touch but

POSITION

to extreme

set

looper

(3.2mm)

scarf

NOT

deflect

PRIOR

FRONT

LOOPER

TO

CHECKING

AND

REAR

GAUGE -With

position, 1/8 inch

between

1/16 inch

39500

LOOPER

looper point

(1.6mm)

PW,

as

shown

CLEARANCE

in operating direction

from

UPPER

right

gauge

or 1/16 inch

the extreme

LOOPER

be

and

by

UP

used

to properly

loosen

adjusting looper in or out of the loop-

(1.6mm)

of needle or

AND

left

needle(s), then position looper to extreme

LOOPER

NEEDLE

GUARDS.

looper

(3.2mm)

and

to

left

in Fig.

TO

NEEDLE(S) -Turn

left

into

AWAY

FROM

set

clamp

nut (B).

for Style

needle

ADJUSTMENT;

at

extreme

is

the distance

centerline

needle

on

7.

so

that

looper

scarf

NOT

LOWER

of needle or

deflect

LOOPER.

looper gauge.

Then

on

39500

Style

PW.

REMOVE

left

of needle;

Style

handwheel

travels

needle(s).

position

Rotate

39500

PW

and

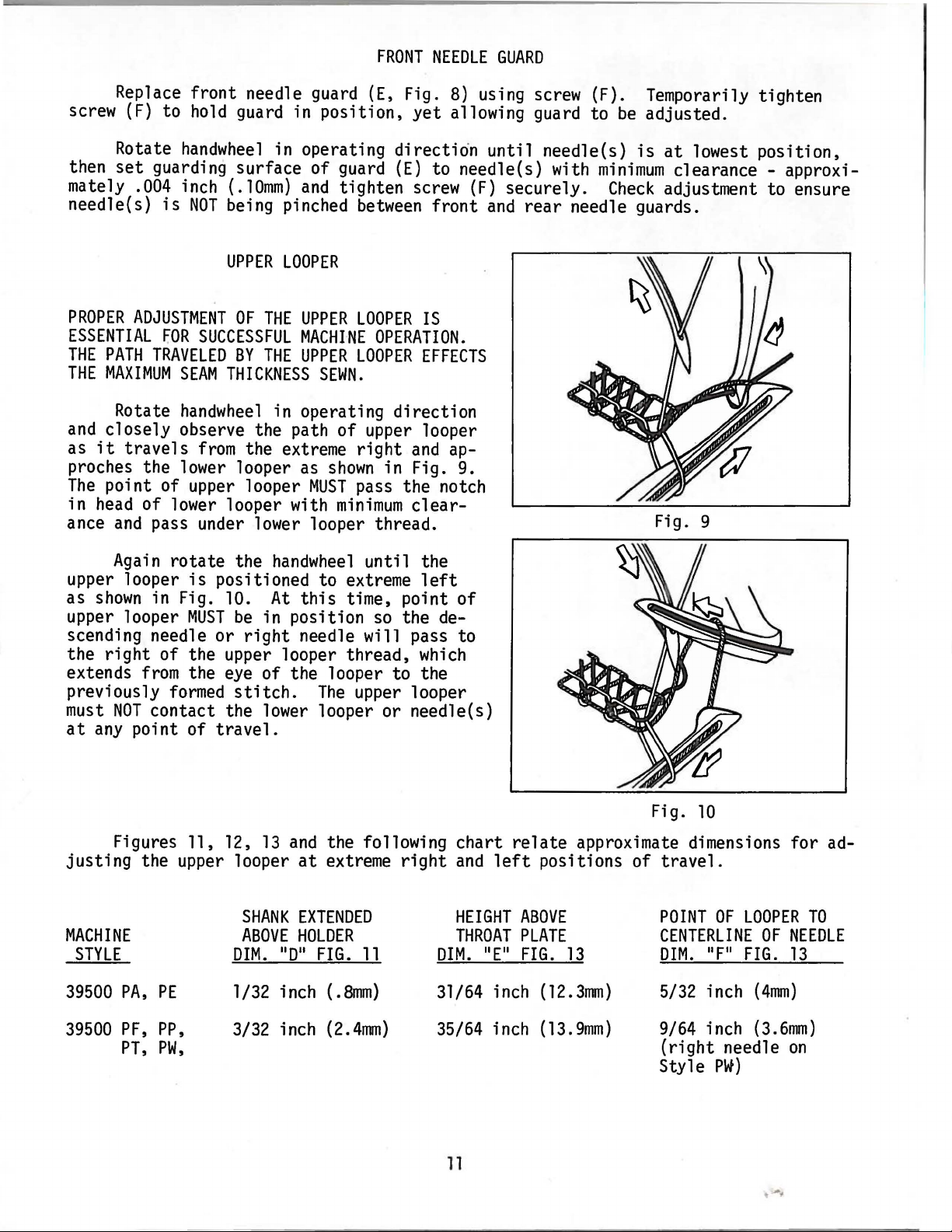

Fig. 8

needle(s) while also

setting

with needle thread as loop

(C)

securely.

Guard

looper

at

must

any

NOT

interfere

point of

travel.

Remove

holder

into

{A,

throat

Replace

(C)

with

of knife holder as

screw

(C)

ing guard to

Rotate

so

lower looper

left

into

surface of guard

guard as

is

being

low

formed

as possible to prevent

to

rear

with lower knife holder

REAR

NEEDLE

spring

Fig.

plate

from

8),

then assemble knife holder

support block.

rear needle guard

front

edge

of guard centered in

shown.

to hold guard in

be

adjusted.

handwheel

scarf

(D)

of needle(s). Set guarding

in operating direction

travels

(B) to touch but

GUARD

inside of lower knife

(B)

using screw

Temporarily tighten

position,

from

yet

the extreme

NOT

it

from

interfering

of needle(s), then tighten screw

movement

or contact lower

slot

allow-

deflect

10

FRONT

NEEDLE

GUARD

Replace front needle guard

(F)

to

hold

screw

Rotate

then

mately

set

.004 inch (.

needle(s}

PROPER

ADJUSTMENT

ESSENTIAL

THE

PATH

THE

MAXIMUM

Rotate

and

closely observe the path of upper looper

it

as

travels

handwheel

guarding surface of guard

is

FOR

TRAVELED

SEAM

handwheel

proches the lower looper

The

in

ance

point of

head

of

and

upper

lower

pass under lower looper thread.

guard in position,

in operating direction until needle(s)

lOmm)

NOT

being pinched

UPPER

OF

SUCCESSFUL

BY

and

LOOPER

THE

UPPER

MACHifiE

THE

UPPER

THICKNESS

in operating direction

from

the extreme

as

looper

looper with

SEWN.

MUST

(E,

tighten

between

LOOPER

OPERATION.

LOOPER

right

shown

in Fig. 9.

pass the notch

minimum

Fig.

8)

using screw (F). Temporarily tighten

yet

allowing guard to

(E)

to needle(s) with

screw

(F)

front

securely.

and

IS

EFFECTS

and

ap-

clear-

rear

be

adjusted.

is

at

minimum

Check

clearance - approxi-

adjustment to ensure

needle guards.

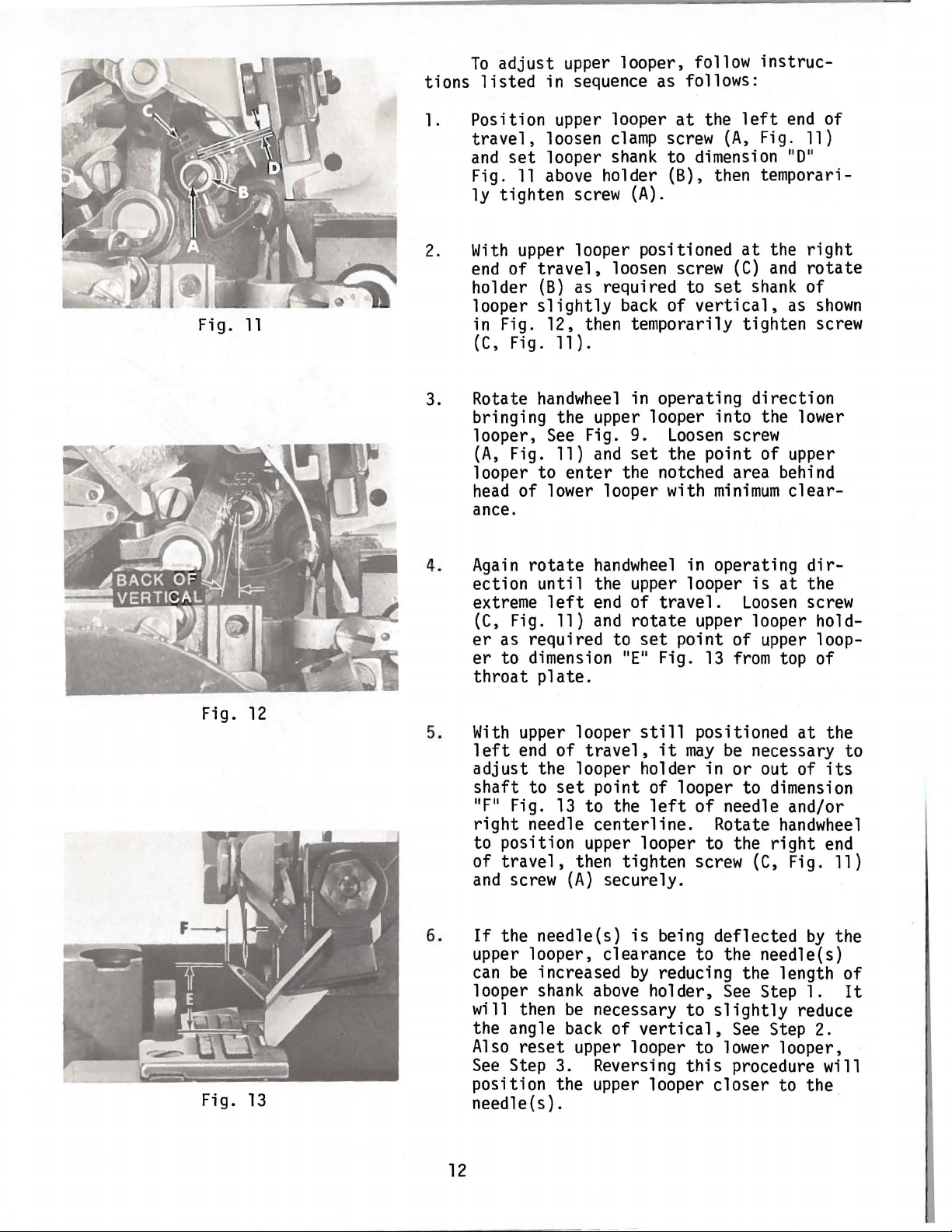

Fig. 9

lowest position,

Again

upper looper

as

shown

upper looper

rotate

is

positioned to extreme

in Fig. 10.

MUST

scending needle or

right

the

extends

previously

must

NOT

at

any

of the upper looper thread,

from

the

eye

formed

contact the

point of

travel.

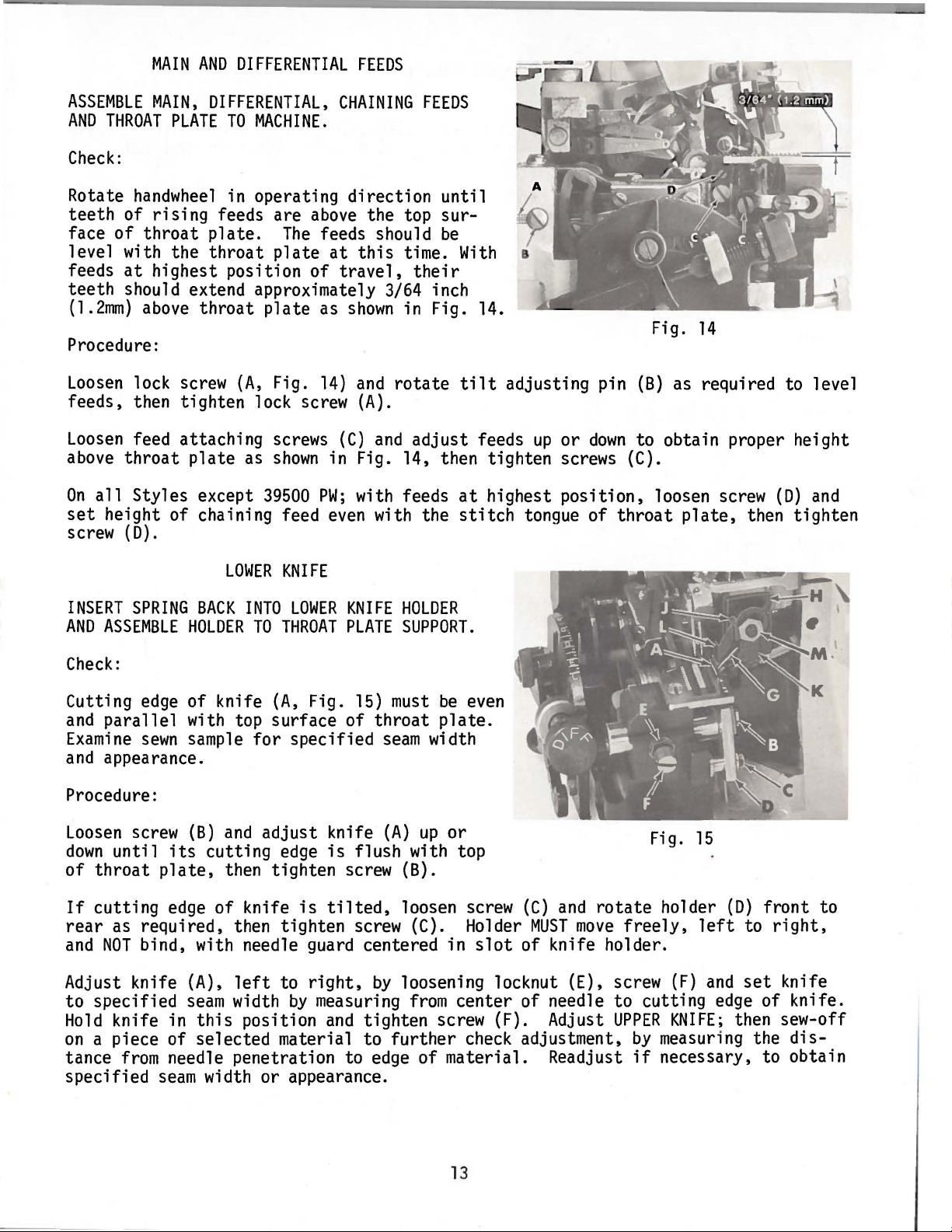

Figures 11, 12,

justing

the upper looper

MACHINE

STYLE

39500

PA,

PE

the

handwheel

At

be

in position

right

needle will pass to

this

until the

time, point

so

of the looper to the

stitch.

lower

13

SHANK

ABOVE

DIM.

l/32 inch

The

upper looper

looper or needle(s)

and

the following chart

at

extreme

EXTENDED

HOLDER

non

FIG.

11

8mm}

(.

left

the de-

which

right

DIM.

31/64 inch

of

relate

and

left

HEIGHT

THROAT

nEn

ABOVE

PLATE

FIG.

10

Fig.

approximate dimensions for ad-

positions of

13

(12.3nm)

travel.

POINT

CENTERLINE

DIM.

5/32 inch

OF

nFn

LOOPER

OF

FIG.

(4nm)

TO

NEEDLE

13

39500

PF,

PT,

PP,

PW,

3/32

inch

(2.4mm)

35/64 inch

(13.9mm)

11

9/64 inch

(right

Style

needle

PW)

(3.6mm)

on

t

...

tions

To

adjust

listed

upper looper, follow

in sequence as follows:

instruc-

Fig.

11

1. Position upper looper

travel,

and

Fig.

ly tighten

2.

With

end

holder

looper

in

(

C,

3. Rotate

bringing the upper looper into the lower

looper,

(A,

looper to

head

ance.

4.

Again

ection

extreme

(C,

er

er

throat

loosen

set

looper

11

above

upper looper positioned

of

travel,

(B)

slightly

Fig. 12, then temporarily tighten screw

Fig.

11

handwheel

See

Fig.

11)

of lower looper with

rotate

until

left

Fig.

11}

as required to

to dimension

plate.

clamp

shank

holder (B), then temporari-

screw

as required to

) .

enter

(A).

loosen screw

back

in operating direction

Fig. 9.

and

set

the notched area behind

handwheel

the upper looper

end

of

and

rotate

set

"E"

at

the

left

end

screw

to dimension "0"

of

Loosen

the point of upper

travel.

point of

Fig.

{A,

Fig.

11)

at

the

right

(C)

and

rotate

set

shank

vertical,

screw

minimum

in operating

is

Loosen

upper looper hold-

13

from

as

clear-

at

upper

top of

of

dirthe

screw

of

shown

loop-

Fig.

Fig.

12

13

5.

6.

With

upper looper

left

end

of

travel,

adjust the looper holder in

shaft

"F"

right

to position upper looper to the

of

and

If

upper looper, clearance to the needle(s)

can

looper

will then

the angle

Also

See

position the upper looper

needle(s).

to

set

point of looper to dimension

Fig.

13

to the

needle

travel,

screw

the needle(s}

be

increased

shank

reset

Step 3. Reversing

centerline.

then tighten screw

(A)

above

be

necessary to

back

upper looper to lower looper,

still

it

left

securely.

is

being deflected

by

reducing the length

holder,

of

vertical,

positioned

may

be

necessary to

or

of

needle and/or

Rotate

{C,

See

slightly

See

this

procedure will

closer

at

out of

handwheel

right

Fig.

by

Step 1.

reduce

Step 2.

to the

the

its

end

11}

the

of

It

12

MAIN

AND

DIFFERENTIAL

FEEDS

ASSEMBLE

AND

THROAT

Check:

Rotate

teeth

face

level with the

feeds

teeth

(1.2mm)

Procedure:

Loosen

feeds, then tighten lock screw

Loosen

above

On

all

set

height of chaining feed

screw

MAIN,

handwheel

of

rising

of

throat

at

highest position

should extend approximately 3/64 inch

above

lock screw

feed attaching screws

throat

Styles except

(D).

DIFFERENTIAL,

PLATE

TO

MACHINE.

in operating

feeds are

plate.

throat

throat

(A,

plate

as

plate

39500

above

The

feeds should

plate

of

as

Fig.

14)

shown

in Fig. 14, then tighten screws (C).

PW;

even

at

CHAINING

direction

the top sur-

this

travel,

shown

and

(A).

(C)

and

with feeds

with the

FEEDS

time.

their

in Fig. 14.

rotate

adjust

until

be

With

tilt

at

stitch

adjusting pin

feeds

highest

up

or

position,

tongue of

Fig.

(B)

down

to obtain proper height

throat

14

as required to level

loosen screw

plate,

then tighten

(D)

and

LOWER

INSERT

AND

Check:

Cutting

and

Examine

and

Procedure:

Loosen

down

of

If

rear

and

Adjust knife

to

Hold

on

tance

specified

SPRING

ASSEMBLE

edge

parallel

sewn

appearance.

screw

until

throat

cutting

as required, then tighten screw (C). Holder

NOT

bind, with needle guard centered in

specified

knife in

a piece of selected material to

from

BACK

HOLDER

of

knife

with top surface of

sample

(B)

and

its

cutting

plate,

edge

needle penetration to

seam

then tighten screw (B).

of

(A},

left

seam

width

this

width or appearance.

KNIFE

INTO

LOWER

TO

THROAT

(A,

for

specified

adjust

edge

knife

position

is

to

by

Fig.

right,

measuring

KNIFE

PLATE

knife

is

tilted,

and

HOLDER

SUPPORT.

15)

must

throat

seam

(A)

flush with top

by

tighten screw (F). Adjust

further

edge

be

even

plate.

width

up

or

loosen screw

slot

loosening locknut (E), screw

from

center of needle

check

of material. Readjust

Fig.

(C)

and

rotate

MUST

move

of knife holder.

adjustment,

freely,

to

cutting

UPPER

by

if

15

holder

(F)

KNIFE;

measuring the

necessary, to obtain

(D)

front

left

to

and

set

edge

of knife.

then sew-off

to

right,

knife

dis-

13

UPPER

KNIFE

REMOVE

ARM.

NEEDLE(S)

ALSO

RE-ASSEMBLE

AND

Check:

At

lowest position the front

inch (.4 -

.8mm)

below

Procedure:

With

upper

knife

(G,

knife firmly against

front

of

Assemble

guard

then tighten nut

tip

lower

(L)

of upper knife cutting

knife, then tighten

knife

clamp

against top surface of

{M).

RE-ASSEMBLE

UPPER

cutting

Fig.

15)

lower

knife, adjust knife holder

UPPER

KNIFE

tip

of upper knife cutting

edge

at

lowest position of travel

edge

screw

(K)

and

chain

upper

KNIFE

IN

HOLDER

HOLDER

AND

INTO

HOLD

SLOT

KNIFE

edge

of lower knife. ·

and

(H)

left

l/64 - l/32 inch (.4 -

(J).

guard

(L)

knife

in position using nut

and

slightly

back

OF

UPPER

FIRMLY

must

extend l/£4 - l/32

KNIFE

IN

POSITION.

while holding upper

to

.8mm)

of

right,

below

(M).

its

to position

cutting

Set chain

cutting edge,

DRIVING

edge

Loosen

If

screw

{F)

desired, the

to enable spring pressed lower knife to

lower

knife

can

be

locked in position

knife holder.

NOTE:

Locking

nut

{E)

must

be

tightened to hold

also serves as a latch pin for cloth

plate.

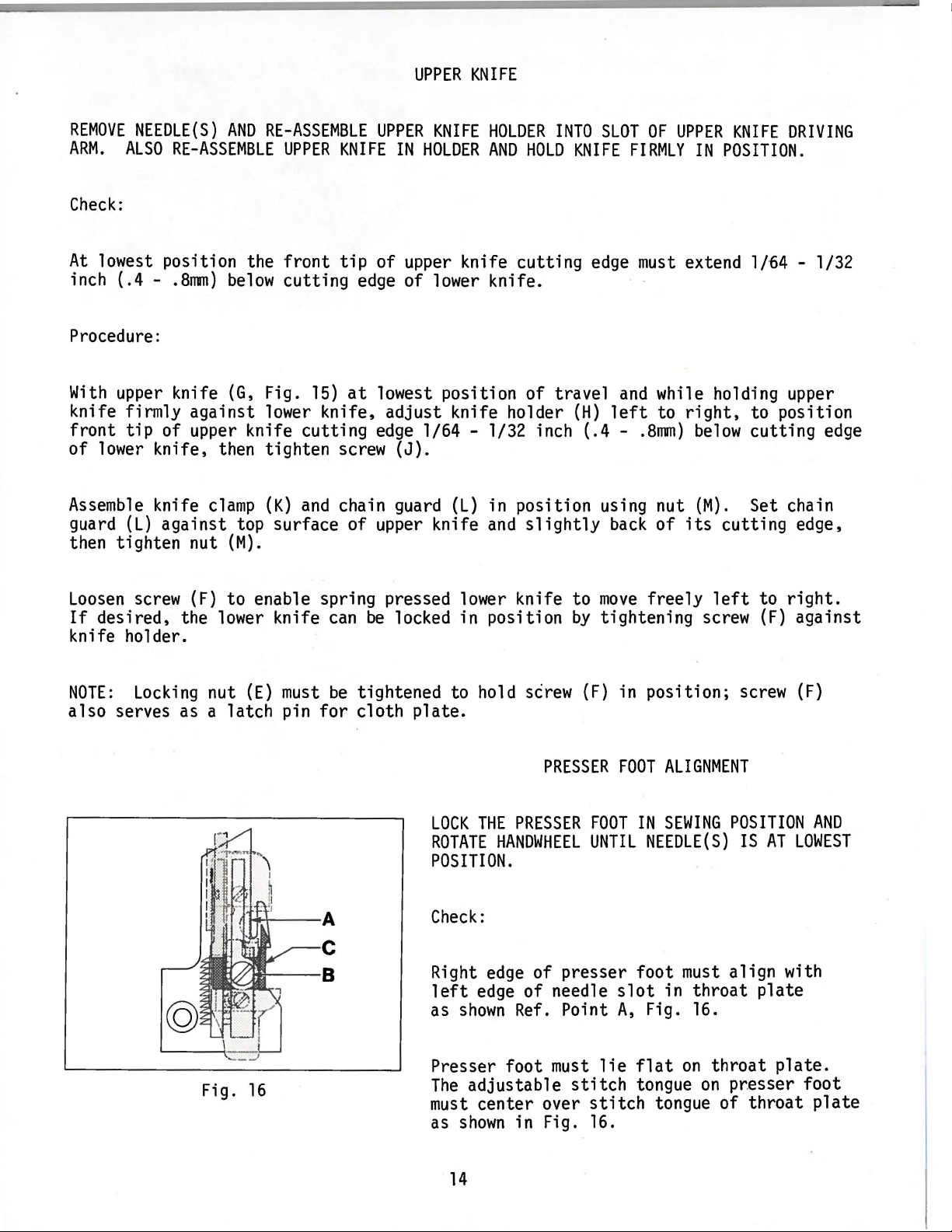

LOCK

THE

ROTATE

POSITION.

Check:

Right

left

as

edge

shown

by

screw

(F)

PRESSER

PRESSER

HANDWHEEL

edge

of presser foot

FOOT

UNTIL

of needle

Ref.

Point

move

freely

tightening

in position;

FOOT

ALIGNMENT

IN

SEWING

NEEDLE(S)

must

slot

A,

in throat plate

Fig.

left

screw

screw

POSITION

IS

align with

16.

to

(F)

AT

right.

against

(F)

AND

LOWEST

Fig.

16

Presser foot

The

adjustable

must

as

center over

shown

must

in Fig.

14

lie

stitch

stitch

16.

flat

on

throat

tongue

on

pr.esser foot

tongue of throat

plate.

plate

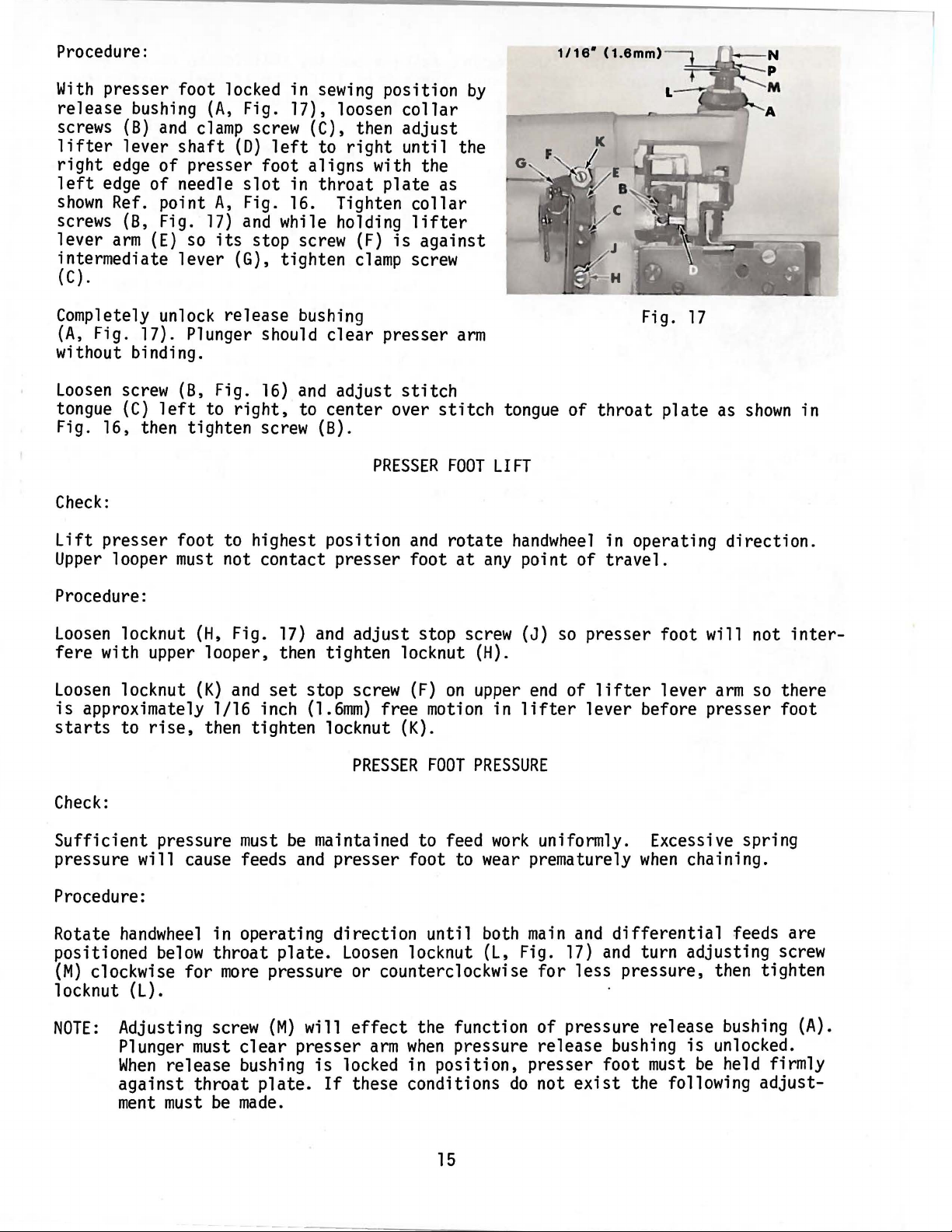

Procedure:

With

release bushing

screws

lifter

right

left

shown

screws (8, Fig.

lever

presser foot locked in

(A,

Fig. 17), loosen

(B)

and

lever

edge

edge

shaft

of

of needle

Ref. point

arm

(E)

clamp

presser foot aligns with the

so

screw (C), then adjust

(D)

left

slot

A,

Fig. 16. Tighten

17)

and

its

in

while holding

stop screw

sewing

to

right

throat

intermediate lever (G), tighten

(C).

Completely unlock release bushing

(A,

Fig. 17). Plunger should

clear

without binding.

Loosen

tongue

screw (8, Fig.

(C)

left

to

right,

16)

and

adjust

to center over

Fig. 16, then tighten screw (B).

Check:

position

collar

until the

plate

(F)

is

clamp

presser

stitch

PRESSER

as

collar

lifter

against

screw

arm

stitch

FOOT

by

tongue of

LIFT

Fig.

throat

17

plate

as

shown

in

Lift

Upper

presser foot to highest position

looper

must

not contact presser foot

Procedure:

Loosen

fere

Loosen

is

starts

locknut

(H,

Fig.

with upper looper, then tighten locknut

locknut

(K)

and

set

approximately 1/16 inch

to

rise,

then tighten locknut

Check:

Sufficient

pressure

must

pressure will cause feeds

Procedure:

Rotate

positioned

(M)

handwheel

below

clockwise

in operating direction

for

throat

more

plate.

pressure or counterclockwise

locknut (L).

17)

and

adjust

stop screw

(1.6mm)

free

(K).

PRESSER

be

maintained to feed

and

presser foot to

Loosen

and

rotate

at

stop screw

(H).

(F)

on

upper

motion

FOOT

PRESSURE

until

locknut

handwheel

any

point of

(J)

in

lifter

work

wear

both

(L,

Fig.

in operating direction.

travel.

so

presser foot will not

end

of

lifter

lever

arm

so

lever before presser foot

uniformly. Excessive spring

prematurely

main

and

17)

for

less pressure, then tighten

when

chaining.

differential

and

turn adjusting screw

feeds are

inter-

there

NOTE:

Adjusting screw

Plunger

When

against

ment

must

clear

release bushing

throat

must

be

made.

(M)

presser

plate.

will

effect

arm

is

locked in position, presser foot

If

these conditions

the function of pressure release bushing

when

pressure release bushing

do

not

15

exist

is

unlocked.

must

be

held firmly

the following

(A).

adjust-

Lock

and

adjust nut

(M)

as

presser foot in position with pressure release bushing

(P)

up

or

down

so

its

shown

in Fig. 17.

Hold

nut

under surface

(M)

in position

is

l/16

and

tighten capnut

(A);

inch

loosen capnut

(1.6mm)

above

(N).

(N)

screw

position,

to the

differential

Fig.

loosen screws

18

feed

maintaining the 1/32 inch

and

underside of presser foot.

Fig.

19

(D)

dog

(.8mm)

and

teeth.

set

shirring

Hold

clearance

SHIRRING

Replace

shirring

sewing

in

shirring

blade in

position

ating direction

highest position.

and

adjust

so

the

flat

on

bracket

inch

of

(.8mm)

shirring

presser

With

blade

shirring

shirring

the feed

(B)

forward

clearance

blade

foot,

then

feed

(C)

dogs

so

blade in position

between

To

ential

(A,

Fig. 19), actuating

lever

shaft

center

dog.

both

(F)

blade

(A

While

collars

to eliminate

shaft,

and

adjusted

(C)

in the

en

its

top

front

center

shirring

feed dog, loosen screws in

(C)

and

loosen tension screw

(E)

to the

shirring

holding blade in position,

(A

then tighten screws in

B).

With

and

in

slot

screw.

BLADE

FOR

blade assembly.

position,

and

turn

until

feed

Loosen

blade

blade

dog

(C)

teeth.

or

rearward to obtain 1/32

between

(C)

and

tighten

still

its

front

and

tighten screws

edge

blade

collar

left

or

blade over

and

B)

against

any

end

the

shirring

position,

of the

shaft

STYLE

39500

PT

lock presser foot

handwheel

dogs

are

screws

mounting

is

level

at

(A,

Fig. 18)

bracket

and

in oper-

Position mounting

top

front

the underside of

screws

at

their

edge

of

shirring

(C)

(A).

highest

is

parallel

over

blade

collar

(B), operating

(D).

right

as required to

differential

shaft

play in the

bracket

shirring

collars

blade properly

set

operating

bracket

and

With

their

(B)

lies

edge

(D)

differ-

Move

feed

thrust

lever

tight-

Tension

by

turning

When

the proper

LENGTH

measured

the distance feeds travel with

wrench

tained,

The

sewn

teeth

per inch of

protruding

Class

-MAIN

No.

21388

hold

actual

39500

(rear)

Y,

furnished with machine.

shirring

blade in position

stitch

seam.

above

machines

and

DIFFERENTIAL

SETTING. STITCH

length produced

This

the

is

throat

are

fitted

determined

plate.

with a feed system having

(front).

tained

and

is

usually

by

16

tighten screw

on

the

shaft

(D).

as the

shirring

collar

amount

number

two

separate feed

blade

can

(G)

with spanner

of tension

of

stitches

their

be

is

obob-

dogs

The

resulting

to

a great extent

The

differential

independent

or

gather

stretch

of

stitch

by

travel

feed travel

the

main

the

fabric

length

feed

stitched.

On

the graduated scale of

(A,

Fig.

20)

longest

stitch

indicates

To

adjust

and

differential

the forward

length

shortest

stitch

thumbscrews

stitch

marking 11L

and

the

length.

length turn both

wise to increase feed travel

wise to decrease feed

travel.

is

of

the

main

can

be

and

is

prior

(B

or

to being

indicator

11

rear

marking 11S

and

counterclock-

determined

feed.

adjusted

used

to

plate

indicates

main

C)

clock-

11

Fig.

20

After desired

differential

an

adjustment

handwheel

way

to the

ance

is

em/kg).

If

differential

the

bed

directly

feeds, also

in operating direction

rear.

obtained.

If

clearance cannot

desired,

feed or.by tightening pressure plug screw for the

accidental changing of

NEEDLE

stitch

is

necessary,

Loosen

Hold

thumbscrews

above

THREAD

length

check

set

nut

(D)

ferrule

the

main

stitch

CONTROL

Check:

The

needle thread

thread

thread

eyelet

ed

eyelet

cam

is

in the screw

lower the

pull-off

set

eyelet

is

controlled

(A,

Fig.

21)

and

(B).

so

the securing screw

slot

to

front

have

The

to back. Raise

the needle thread

barely touch the needle thread

when

tion.

the needle thread in the

eyelet

the needle

Moving

down

and

carrier

the

eyelet

is

up

in

and

stitch,

forward acts in the reverse.

is

obtained

clearance

the feeds to

until

and

the

rotate

in position

be

obtained,

can

be

locked in position

feed

stitch

length during

by

the needle

the needle

needle thread

is

center-

cam

pull-off

its

lowest posi-

back

increases

moving

the

check

between

have

differential

eccentric

and

See

the clearance

the

throat

the

ferrule

same

travel,

feed

plate

is

(E)

torque nut to 19-20

FEED

DRIVE

SEGMENT

by

tightening nut

between

and

the

both feeds.

then turn the

positioned

until

maximum

in.

lbs.

ADJUSTMENT.

(F)

main

feed, located in

regulating screw. This will prevent

machine

operation.

or

Fig.

21

main

all

the

clear-

(22-23

for the

and

If

Procedure:

To

adjust needle thread

described in check.

control,

Hold

eyelet

loosen screw

in position

17

(C)

and

position thread

and

tighten screw (C).

eyelet

(A)

as

Check:

LOOPER

THREAD

PULL-OFF

Clearance

(B)

should

Fig.

21.

between

be

only

looper thread

enough

to ensure proper take-up

pull-off

Procedure:

Loosen

needle driving

(E)

screws

be

sure to take

(E)

shaft

and

rotate

looper thread

until proper clearance

up

all

end

play in needle drive

LOOPER

Check:

When a normal

be a little

amount

slack

of looper thread

when

needle(s)

is

Position guide so the looper thread

with the lower looper

The

auxiliary

set

slightly

upper looper thread guide should

above

at

its

extreme

a horizontal position.

(D,

Fig.

pull-off

is

obtained. Before tightening screws

THREAD

is

at

highest position.

is

held in a

left

CONTROL

drawn,

end

of

upper

be

21)

and

of

looper thread as

lever

shaft.

and

lower looper threads will

straight

travel.

centered in

needle thread

cam

shown

(F)

front

line

to the lower looper,

its

to

back

adjusting

pull-off

in

on

slot

and

Fig.

lower looper thread

tion

and

tighten screw (C).

To

set

frame

its

extreme

in a

straight

NOTE:

Moving

the system

lower looper thread guide

left

end

line

eyelets

and

moving

Procedure:

Loosen

er

set

let

Loosen

eyelet

let

screw

thread

eyelet

(B)

in position

(A,

eyelet

in a horizontal position.

screw (C). Center upper looper thread

(D)

in

so

it

rests

looper thread

eyelet

auxiliary

its

adjusting

above

upper looper thread guide

loosen screw

22

eyelet

of travel

(D)

thread

Center

in

slightly

and

auxiliary

(F)

and

position the guide

to the lower looper. Tighten screw

(B

and

D)

to the

them

forward reduces the

rear

increases the

amount

Fig. 22). Center lower loop(B)

in

its

adjusting

slot

Hold

and

tighten screw

its

adjusting

on

the top surface of lower

eyelet

and

slot

back

and

set

of

lower looper

eye.

upper looper thread guide

slot

and

set

guide

so

a horizontal position.

(E)

in posi-

(G)

and

move

so

the looper thread

lower looper to

is

{G).

amount

of

thread in the system.

of

looper thread in

(A).

eye-

it

Hold

held

and

eye-

(E)

is

18

If

the needle thread loop

set

properly as

seam

grinning

adjustments

this

condition include:

POSITIONING

shown

would

which

in Fig. 23, excessive

result.

should

THE

PURL

Thread

be

checked to

is

NOT

being

control

correct

Lower

-

-

Needle

Lower

Needle

-

edge

unbalance

cated,

edge

under the edge,

looper thread tension too

thread

eyelet

looper thread

thread tension too loose.

If

the purl

of the

between

and

would

improper coverage

occur.

is

fabric

the looper threads

check

control adjustments:

-

Lower

-

Lower

Upper

-

looper thread too

looper thread

looper thread

rear.

-

Upper

looper thread tension too loose.

tight.

too high.

eyelet

NOT

as

shown

If

the purl

too

being

in Fig. 24,

of

far

formed

the

is

being pulled

the following thread

tight.

eyelet

eyelet

too

too

far

far

forward.

on

the

an

is

indi-

seamed

forward.

to the

Fig.

Fig.

23

BOTTOM VIEW

24

If

edge

the purl

as

shown

is

being pulled over the

in Fig. 25, check the following

thread control adjustments:

Upper

-

-

Upper

Lower

-

looper thread tension too

looper thread

looper thread

eyelet

eyelet

too

too

tight.

far

far

forward.

to the

rear.

TOP VIEW

-

Lower

looper thread tension too loose.

Thread

tension

is

regulated

Fig.

25

THREAD

by

the tension assemblies. Turning tension nuts

TENSIONS

clockwise increases tension applied to thread, counterclockwise reduces tension.

Normally, tension

on

the threads should

be

only

enough

to produce a balanced

stitch.

19

Fig.

26

ADJUSTING

1.

2.

3. Thrust the feed control

4.

Assemble

shaft

Thrust feed bars

side of

rear

ring

thrusted against the

Main

with

collars

parts as

(B); including feed bars.

main

of feed bars with

(J)

and

feed control link

main

feed rocker lever

(P

and

illustrated

(C

feed bar

flush against the recess in the

Q).

INSTRUCTIONS

to feed control

and

D)

against

(C)

with

tilt

adjusting pin

bed

shaft

casting

(L)

(A)

and

(N)

FOR

FEED

differential

left

feed bar

and

assuring

and

tightened securely.

main

feed drive lever

to avoid binding

20

that

DRIVE

shaft

thrust

thrust

washer

washer

bed

casting. Collar

and

MECHANISM

(A,

Fig.

26)

and

feed rock

guide

guide (E). Align

(F)

(H)

(M)

secured in position

on

bed.

and

guide pin

is

against retaining

(K)

must

be

in alignment

Thrust

and

thrust

(G).

should

by

left

be

5.

Feed

(R)

in

this

bed

rock

shaft

upwards

position

casting.

(B)

should

and

thrusted against the

by

thrusting collars

be

positioned with the

main

feed

(S)

against thrust

opening

rock

lever

of the retaining ring

(N).

washers

Secure shaft

(T)

against the

(B)

6. Differential feed control link

be

7.

in alignment with

the

differential

lever

(N).

cured in place

Lever

by

A bind could occur in the

(V)

and

lever

is

not properly aligned. Oversize holes are provided in plate

ing

screws

differential

(Z)

to allow repositioning to eliminate bind.

differential

feed rocker lever

(V)

and

rocker lever

their

clamp

main

feed indicator lever

DIFFERENTIAL

1.

2. Rotate

3.

Move

differential

feed rocker lever

differential

is

at

Clamp

the rear

the indicator lever

end

rocker lever

(W).

feed indicator lever

of the scale.

(X)

(U)

and

differential

feed

rocker lever

(W)

must

(W)

thrust against the

can

screws.

feed drive lever

FEED

CONTROL

block

(AA)

to lowest position in

(X)

with

screw

(AB).

feed control lever

(W)

to avoid binding.

be

positioned

(M),

differential

(X)

if

the indicator plate

main

as

required

(Y)

feed control

for

(V)

must

Also

feed rocker

and

se-

(Y)

its

mount-

ADJUSTMENT

differential

counterclockwise until the pointer

DIFFERENTIAL

1.

Move

differential

rocker lever block

clockwise.

2.

3.

Turn

Loosen

4.

Operate

screw

differential

( N).

the

handwheel

feed rocker lever

differential

(AC)

when

the

feed rocker lever

until the feed bar

clamp

feed indicator lever

differential

DIFFERENTIAL

Standard location of the drive pin

feed drive lever

hole of lever

(AE).

(AE).

For

longer

FEED

DRIVE

(AA)

is

screw

(AC).

feed bar

(W)

thrusts against the

FEED

(AD)

is

to

differential

SEGMENT

ADJUSTMENT

to top position

in

its

most

(X)

and

tighten rocker lever

(D)

shows

DRIVE

be

in the

no

LEVER

upper

feed travel

by

rotating lever

rear position.

movement.

main

feed rocker lever

hole of

move

pin

Make

differential

(AD)

clamp

sure

to

(X)

lower

21

TO

REMOVE

Fig.

27

CRANKSHAFT

Crankshaft

1. Drain

base.

2.

Remove

3.

Remove

Remove

4.

5.

Remove

be

can

be

withdrawn

oil

by

removing

top

and

bottom

feed eccentric nut

key

(C).

three counterweights

re-assembled in the proper places.

easier

plug screw located

covers of machine.

(A,

Fig.

(D).

if

these steps are followed:

27)

Identify these counterweights

22

on

and

back

remove

of

machine

the eccentric (B).

near

bottom

so

that

edge

of

they will

6.

Unscrew

tube

7.

Remove

bearing caps

stamped

side of the bearings. Also, screws should

from

8.

Loosen

upper knife driving

clamp

driving

driving lever

drop, allowing

This

crankshaft.

while re-assembling

Step 7 above.

9.

Remove

ner

is

10.

Loosen

move

oil

tube

is

reached through bottom of

caps of bearings

on

both halves

which

at

right

reached through

both halves

they

clamp

nut

is

arm

bearing point

screw

crankshaft bearing. This screw

two

screws

(E)

which

make

to the

sure they are in

were

nut

through top cover.

(C)

removal

Observe

(K,

removed.

(A,

Fig.

arm

left

and

connecting

(J,

same

cap

Fig.

27)

bottom

(L)

in fan

of

cooling fan.

holds crankshaft

on

crankshaft

of

the caps

28)

which

(B).

until

of bearing

as

Access

upper knife

Fig.

27)

precautions

described in

which

of

holds

bed

collar;

bed

casting.

at

their

and

both trademarks should

holds '

to

Draw

rod

(D)

cap

(E).

on

in-

casting.

re-

split

points

original position.

be

bearing

F, G and

re-assembled in the

H.

and

oil

When

Trademarks

be

28

Fig.

pump.

re-assembling

on

same

the

This

are

same

holes

11.

Remove

12.

Loosen

13.

Remove

collar

14. Crankshaft

15.

If

arbor press.

against

16.

Carefully observing reverse of the foregoing operations should simplify re-assembly of crankshaft.

and

17. Before re-assembling, thoroughly clean

Before re-assembling

lubricates

contacts

Coat

leakage.

screw

two

three screws (S); take

(U)

necessary to replace ball bearing (V),

ground

constant

oil

(M);

take

off

pulley

screws (P);

may

be

may

now

In

replacing bearing

thrust

testing

left

crankshaft bearing

shaft.

drain plug with a sealing

The

remove

removed

be

removed.

washer

Checking

for

bottom

wick

pulley (R).

off

at

this

(W).

exploded

binds during re-assembly will also prove helpful.

cover

stands

vertically

cap

(N).

bearing

time.

it

must

view

and

make

sure

is

inserted in hole in casting

compound

retaining

it

should

be

pressed

drawings for location of various parts

dry top

that

on

before re-assembling to prevent

plate

be

pressed

on

carefully

and

bottom

spring pressed

its

spring against

(T);

also,

off

shaft

covers

oil

and

bottom

spacer

until

and

wick

that

on

an

it

seats

gaskets.

which

it

cover.

oil

23

ILLUSTRATIONS

ORDERING

REPAIR

PARTS

This catalog

various sections of the

actual position in the machine.

the parts with

particular

Numbers

tion of

ordering

Component

indenting the descriptions under the description of the

Example:

19

20

At

This will

29126

39544

21

22729

22

22729

23

39544

24

25

39544

the

number

back

is

has

been

arranged to simplify ordering

mechanism

their

view

in the

that

parts.

first

part

parts of sub-assemblies

DF

N

E

D

s

97

u

of

the

facilitate

known.

being

in the

Always

Lower

book

part

number,

shown.

column

locating the

are reference

illustration.

use

the

Looper

Lower

Ball

Screw,

Lower

is

a numerical index

are

shown

On

the

page

description

part

number

which

Bar

Driving Lever

Looper

Screw,

Screw, for connecting

Joint

for

Looper

Connecting

for

Guide

ball

Bar

illustration

so

that

opposite the

and

numbers

Reference

which

can

be

furnished

connecting

Fork

------------------------------------

joint

guide fork

Driving

of

all

and

number

only,

numbers

is

Rod

repair

the parts

listed

and

-----------------------------rod

rod

Lever

the

description

parts.

may

illustration

of pieces required in the

and

merely

should never

in the second

for

repairs

main

Connecting

sub-assembly.

---------------------------

---------------------------

-------------------------

--------------------------parts

be

Rod

shown

when

Exploded

seen in

is a listing

indicate

are indicated

Assembly----- 1

in

only the

be

this

views

their

the posiused

column.

book.

part

of

of

in

by

1

2

2

1

2

1

IDENTIFYING

Where

numbers

USE

Success in the operation of these

SPECIAL

and

scienti.fic principles

durability

TERMS

Prices are net cash

f.o.b.

A charge

TORQUE

Torque

/kilograms.

unless otherwise noted.

must

fications

the construction permits, each

GENUINE

authorized

shipping point.

specifications

be

PARTS

represent the

REPAIR

repair

is

REQUIREMENT

secured

for connecting rods,

parts as furnished

distributors.

are assured.

made

All

straps

as

same

PARTS

and

and

to cover postage

given in

and

tightly

part,

They

are

made

subject to

ParGel

All

Post shipments are insured unless otherwise directed.

this

eccentrics

nuts,

as possible, unless otherwise noted. Special torque speci-

links,

part

is

stamped

regardless of catalog in

machines

by

the

are designed according to the

with utmost precision.

change

and

insurance.

catalog are

must

bolts,

screws,

can

be

Union

without notice.

Special Corporation,

be

tightened to 19-2lin. lbs.(22-24

screws,

etc.,

with the

which

secured only with genuine

Maximum

All

measured

etc.,

are

in inch-pounds or centimeter

without torque

shown

part

shipments are forwarded

on

number.

they appear.

its

subsidiaries

most

approved

efficiency

specifications

parts

illustrations.

Part

UNION

and

em/kg)

24

EXV'LODED

VIEWS

AND

DESCRIPTION

OF

PARTS

25

2

e

26

~

~~6

49

t-47

MAIN

FRAME,

MISCELLANEOUS

COVERS, PLATES

AND

OILING

PARTS

Ref.

~

* 8

* 9

10

11

12

13

13A

14

15

16

17

18

19

20

21

*22

*23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

41A

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

1

2

3

4

5

6

7

Part

~

22569

39582

39582

22569

53634

22569

39535

39582

22824

22569

39563

667

22565

22565

22571

22569

22569

39578

39578

29477

39568

39568

22743

39594

39594

39535

22569

666-268

39593

666-271

660-506

56393

56393

666-280

39593

22569

39593

660-243

39593

39582

22653

39582

51295

39595

39595

22586

39593

39593

22569

74

22806

22572

39582

39582

39582

39501

39501

39532

90

39501

138

39578

22657

BD

BU

J

c

c

p

BF

D

H

D-8

s

E

K

D

T

u

GW

G

J

s

T

M

B

K

G

v

L

D

J

H

F

D-4

AY

B

R

D

c

E

A

A

AZ

BA

XE

DL

DLB

A

K

F

-D-12

Screw,

Gasket, for rear cover

Rear

Screw,

Washer,

Screw,

Main

Oil

Screw,

Screw,

Needle

Dowel

Set

Spot

Oil

Screw,

Screw,

Chip

Chip

Upper

Oil

Oil

Guide, for

Screw,

Felt

Oil

Oil

Retaining Ring,

Porex

Spring, for

Oil

Spring, for

Screw,

Oil

Oil

Oil

Base

Screw,

Gasket, for

Isolator,

Isolator,

Isolator,

Screw,

Oil

Oil

Screw,

Plug

Screw,

Screw,

Bottom

Gasket, for

Bottom

Cloth

Cloth

Latch

Screw,

Cloth Plate Stud

Screw,

Cloth Plate Fabric

Screw,

for cloth plate stud

Cover

-------------------------------------------------------------

for rear cover

for

main

for

Feed

Bar

Shield,

for

for

Thread

Pin

--------------------------------------------------------------

Screw,

rock

shaft

Screw,

Drain

Plug

for

for

Guard,

Guard,

Looper

Thread

Thread

Screw,

Filter

Filter

for

Pad

---------------------------------------------------------------

Tube,

tygothane

Tube,

brass

Filter,

Tube,

tygothane

for

oil

Pump

Tube

Seal

Ring,

Sight

Gauge

Plate Extension

for base plate extension

for Styles

for Styles

for Style

for

Gauge

Gauge

bottom

Indicator

Float

for

bottom

Screw,

for

bottom

for

bottom

Cover

Cover

Plate,

Plate,

Plate

for

latch plate latch spring

for cloth plate fabric guard

for cloth

feed bar

main

feed bar

Thrust

lower

lower

needle thread

for upper looper thread tube assembly

oil

chip guard

Screen

Pad

differential

differential

oil

oil

bottom

for

bottom

Latch

------------------------------------------------------

oil

Pull-off Eyelet

------------------------------------------------------------

for

upper looper

--------------------------------------------------------sight

for

Styles

for Style

Thread

Tube

-------------------------------------------------------

Tube

Tension Spring

for

thread tube tension spring

------------------------------------------------------

---------------------------------------------------------

-------------------------------------------------------for

for

oil

tube

tube

tube spring

---------------------------------------------------------for

oil

--------------------------------------------------------

cover

cover

-------------------------------------------------------cover

machine

cover

cover plate

Plate

----------------------------------------------------cover plate

-----------------------------------------------------------

for

Styles

for

Style

Spring

------------------------------------------------------Guard

plate

Description

--------------------------------------------

-------------------------------------------------

-------------------------------------------------thrust

thrust

Guide

shield

pull-off

gauge

--------------------------------------------------

39500

39500

Tube

Assembly

feed bar

feed bar guide

---------------------------------------------------oil

tube

tube

---------------------------------------------

---------------------------------------------------

----------------------------------------------------

---------------------------------------------------

---------------------------------------------

sight

---------------------------------------------------

-----------------------------------------------

39500

PA,

39500

PA,

39500

----------------------------------------------------

PW

------------------------------------------------

-----------------------------------------------bed

plate

39500

39500

-----------------------------------------------

-----------------------------------------------

-------------------------------------------------

guide

guide

---------------------------------------------

--------------------------------------------

------------------------------------------

rock

--------------------------------------------PA,

PW

-----------------------------------------

----------------------------------------

-------------------------------------------

gauge

----------------------------------------

PE,

PE,

-------------------------------------------

--------------------------------------------

------------------------------------------

------------------------------------------

-----------------------------------------

PA,

PW

----------------------------------------

---------------------------------

----------------------------------

eyelet

shaft

PE,

--------------------------------------

---------------------------------------

-------------------------------------

PF,

PF,

PE,

-------------------------------

and

upper looper

--------------------------------

PF,

PP

and

PT

---------------------

-----------------------------

---------------------------------

PP

and

PT

PP

and

PF,

PP

------------------------------------

------------------------------------

-----------------------

PT

-----------------------

and

PT

--------------------

Amt.

~

1

1

1

4

2

2

1

1

2

1

1

2

2

1

1

1

2

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

2

4

1

1

1

11

1

1

5

1

1

1

1

1

1

2

1

2

1

1

*

Used

on

earlier

model

machines.

27

28

CRANKSHAFT

MECHANISM

AND

BUSHINGS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19