Union Special 39500N User Manual

®

INDUSTRIAL

S E

WING

FINEST

STYLES

39500N

QUALITY

LEWIS

•

COLUMBIA

MACHINES

CLASS

39500

CATALOG

S

No.

TREAMLINED

103R

SECOND

EDITION

HIGH

SPEED

CHICAGO

OVERSEAMERS

.

Catalog

INSTRUCTIONS

No.

FOR

103

R

ADJUSTING

LIST

Second

CLASS

Style

39500

AND

OF

OPERATING

PARTS

39500

N

E

clition

Union

Rights

Copyright

by

Special

Reserved

1957

Machin

in

All

e

Countries

MACHINE COMPANY

INDUSTRIAL

Printed

Fe

br~a

ry.

1971

SEWING

CHICAGO

in

3

MACHINES

U.S.A.

Co.

FOREWORD

The

streamlined

performance

precision

It

enable

Specials.

and

Union

anxious

Class

methods

is

our

the

illustrates

to

39500

styling,

are

constant

customer

The

following

and

Special

cooperate

machine

automatic

characteristics

insuring

aim

to

describe

representatives

with

complete

to

secure

pages

you

furnish

the

is

lubrication,

of

all

possible

contain

parts

will

to

plan

Union

these

interchangeability.

carefully

and

Special'

machines.

advantages

valuable

for

Styles

be

found

estimate

and

prepared

operating

in

in

~

s·

latest

light

All

Class

all

manufacturing

requirements.

overedger.

running

parts

information

from

the

and

39500.

MACH/NECOMPANY

high

are

made

that

use

of

adjusting

centers,

New

speed

by

will

Union

data,

4

Engineering

Department

IDENTIFICATION

OF

MACHINE

Each

plate

on

Standard

the

letter

letter

is

"Z".

suffixed

Styles

ber,

which

This

herein.

Class

back,

39500.

etc

Operating

Single

chine.

Curved

Plain

Automatic

39500

N

fabrics.

inch;

plain

Union Spe

the

machine.

Style

"Z".

numbers

Example:

When

to

the

of

machines

contains

catalog

It

can

applies

also

All

.•

are

taken

direction

Blade

Feed,

Lubricating

For

seaming

Seam

stitch

range

feed.

cial

carries

Style

have

"Style

only

minor

standard

Style

similar

no

letters.

APPLICATION

specifically

be

applied

references

from

of

the

handwheel

Needle,

Trimming

System.

garment

specification

8-20

per

a

Style

numbers

one

or

39500

changes

number.

in

construction

Example:

to

with

to

directions,

operator's

is

STYLES

Two

Looper,

Mechanism

pockets

504

inch1 standard

number

are

classified

more

letters

N".

are

made

Example:

"Class

OF

CATALOG

the

standard

discretion

position

away

OF

from

MACHINES

and

similar

SSa-1,

which

Special

in a standard

are

to

such

while

operator.

Three

with

Spring

standard

setting

is

stamped

as

standard

suffixed,

Style

"Style

grouped

39500".

Styles

some

as

of

special

right

seated

Thread,

Pressed

operations

seam

12

per

in

the

and

but

never

numbers

contain

machine, a "Z"

39500

NZ".

under a Class

machines

machines

and

left,

at

the

front

machine.

Overseaming

Lower

on

heavyweig-ht

width

inch;

3/16

cam

name

special.

contain

the

num-

as

listed

and

Ma-

Knife,

to

7/32

adjusted

in

CAUTION!

must

oun8es.

1 00

be

filled

A

Fahrenheit

Machine

at

sight

gauge

gauge

lines

Machine

keeping

oil

as

main

required.

Drain

It

is a magnetic

may

have

cally.

Each

denotes

size

UnionSpecialneedle

the

number,

measured

tively,

the

type

label

of

Oil

before

straight

is

filled

on

when

is

automatically

reservoir

plug

screw

screw

entered

kind

of

stamped

in

thousandths

and

size

all

needles

was

beginning

mineral

should

with

front

of

machine

is

designed

the

crank

shank,

on

number

drained

oil

be

used.

oil

at

machine.

is

stationary.

lubricated.

filled.

located

case.

has

point,

the

needle

of

an

represent

packaged

OILING

from

to

operate.

machine

of a Saybolt

spring

Check

at

to

accumulate

Red

back

It

should

cap

tip

oil

NEEDLES

both

type

length,

shank,

inch,

midway

the

and

sold

5

Oil

viscosity

in

top

of

oil

No

daily

of

machine

possible

be

and

groove,

denotes

between

complete

by

Union

when

capacity

cover.

indicator

oiling

before

removed

size

finish

largest

Special.

shipped,

of

of

90

Oil

should

is

necessary,

the

near

bottom

foreign

and

number.

and

shank

symbol

so

Class

to

125

level

show

morning

edge

materials

cleaned

The

other

details.

diameter

and

eye.

which

reservoir

39500

seconds

is

checked

between

other

start;

of

periodi-

type

number

of

Collec-

is

given

is

six

at

than

add

base.

which

Th

blade,

on

e

NEEDLES

(Continued)

Style

style

shallow

022,

To

a

sample

scription

Size

39500 N uses a curved

is

Type

spot,

025,

have

needle,

on

036".

Selection

should

pass

tion.

Success

use

of

needles

backed

by a reputation

workmanship

Release

(U,

Fig.

1)

ating

socket

direction

wrench

about 1 /4

draw

needle.

154GAS.

long

027'

needle

label.

of

freely

in

the

packaged

for

pressure

and

swing

No.

turn.

It

is a curved

tapered

point,

029, 032, 036, 040,

orders

or

A

proper

through

operation

more

the

complete

type

needle

needle

under

for

producing

than

promptly

and

order

size

of

Union

our

three-quarters

CHANGING

on

presser

until

21388

Again

presser

needle

AU

turn

arm

is

at

furnished

handwheel

blade

blade,

struck

044,

and

size

number

would

is

determined

eye

in

Special

brand

hi0hest

NEEDLES

foot

by

(H)

out

its

lowest

with

needle.

standard

groove,

049,

accurately

read:

order

to

machines

name,

quality

of a century.

turning

of

position.

point

machine,

until

needle

The

standard

length,

chromium

054

..

filled,

should

"1

by

000

size

be

forwarded.

Needles,

of

thread

produce a good

can

~,

needles

presser

of

Turn

travel.

loos

is

at high

foot

handwheel

en nee

needle

single

plated

an

empty

Type

used.

stitch

be

secured

in

materials

release

Usin

g hexag

dle

position; with-

for

groove,

in

sizes

package,

Use

154GAS,

Thread

forma-

only

which

bushin

in

oper-

onal

clamp

this

de-

by

is

and

g

nut

To

replace

to

the

needle

travel;

foot

release

left,

in

this

then

insert

tighten

bushing

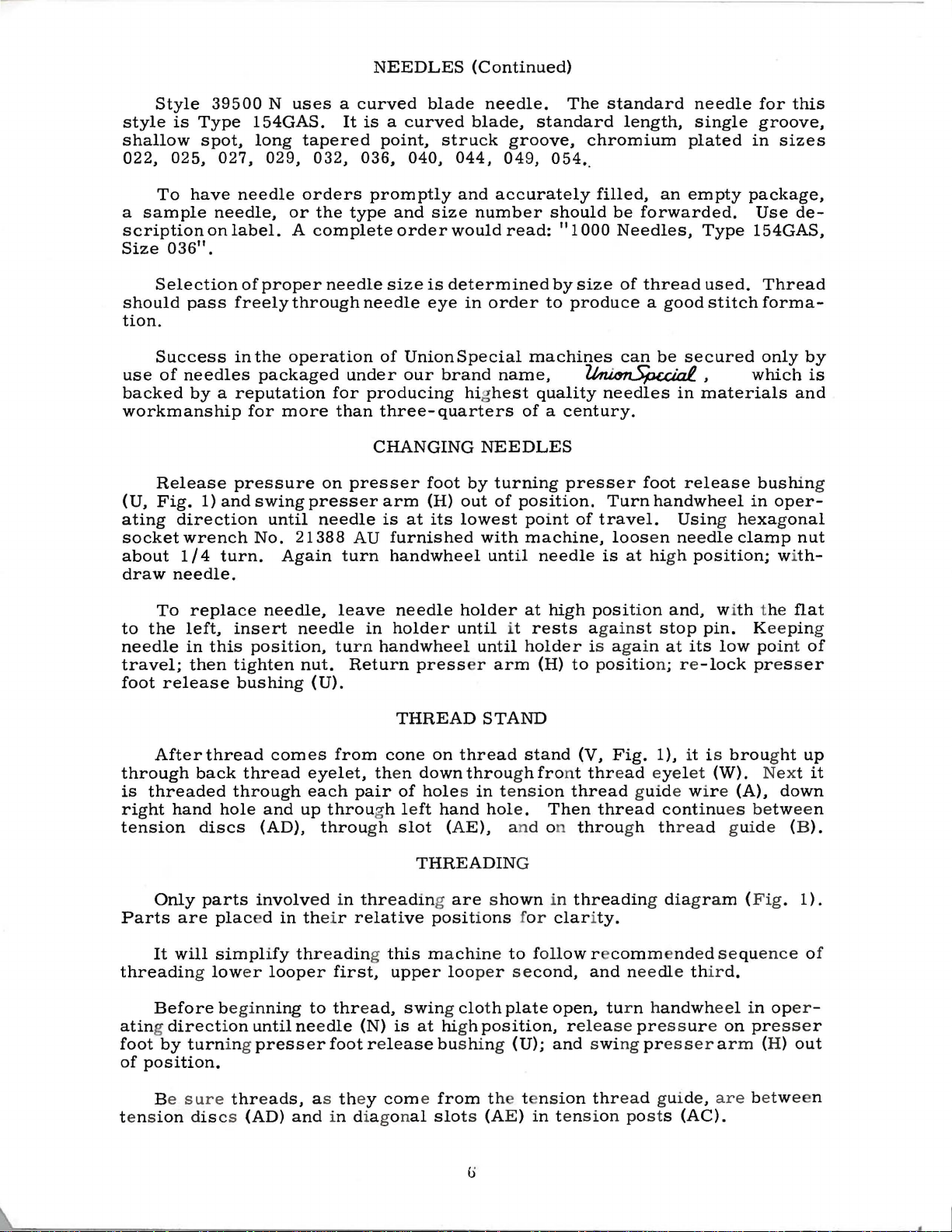

Afterthread

through

is

threaded

right

tension

Parts

hand

Only

are

It

will

back

through

hole

discs

parts

plac

simplify

threading low

Before begi

ating direction

foot

by

turn

ing

of

position.

needle,

position,

comes

thread

and

(AD),

involv

ed

in their

er

looper

nning

until nee

presser

leave

needle

turn

nut.

needle

in

holder

handwheel

Return

(U).

THREAD

from

cone

eyelet, then

each

pair

of

up

throu

throu

ed in

gh l e

gh

slot

threading are shown

relative

threading this

first,

to

thread,

dle

foot

upper

swing clo

(N)

is

r e

lease bus hing (U);

holder

until

until

press

er

arm

STAND

on

thread

down

throu

holes in

ft

hand

tens

hol

(AE),

THREADIN

positions

m achine

looper second,

th

at high

position, release pressure

at

high

it

rests

holder

(H)

stand

gh

fro

ion

e .

Then

and on

G

in

for

to foll

plate

open, tur n h

and swi

position

against

is again

to

positio

(V,

Fig.

nt

thread

thread guid

thread

throu

gh threa

threadin

clarity.

ow

r e

commend

and needle thir

ng presser arm

and, with

stop

pin. Kee

at

its

n; r e

-lock pres s

1), it i s

eyel

et

(W).

the

low point

brought

Next it

e wir e (A).

continu

es between

d guide (B

g di agr am (

ed sequ

Fig

ence

d.

andwheel in oper

on presse

(H)

flat

pin

of

er

up

down

).

. 1

).

of

r

out

g

Be

tens

sure

ion dis

threads,

cs (AD)

as they

and

come from the

in diagon

al

slots (A

tension

E ) in tension posts

(j

thread gui de,

(AC).

are betwee

n

.,.,.,

, '

llilitll

Cll

S I 011

1

ut

I'J:IIren

BJT,

1!1

B Upper Looper

~

ion

· ns

aon

;';

Ten:<ion

Thread

Po

l' o.<t

lot

Thread

Guioc

s t

Thread Eye!

et

---

---

---

Thread Pull-o

-·<-

~

'

NPPdle Thread C

----

..

',

..

ff

Pres.rr

' ·

am

Cone Suppo!'l

foot

HP!

en•e

-------------

---

---

-

--

--

'

"t----------

!

~11-off

.....

__

.:.,.

.,

...

--

Hus

hin

~

---

---

--

-

-

--

---

~Auxiliary

IJ

Lower

IJ

Fabric

Looper

Looper

Thr ad E

Guard Brac

Thr ead Eyele

yel

et

ket

a F'rame LoopPr

CJrr,.~

~•·r

Arm

Fig.

1

7

Nee

Low

dle

er Loo

Thread

per

E

yelet

TO

THREAD

LOWER

LOOPER

Double end

e

yel

et

t

hread

of

frame

heel

of

from

are

left

in

Turn

thread

through

thread

looper

and

down

push

tube

CAUTION!

passing

Turn

highest

needle

hole

in

(E, Fig.

pull-off

looper

lower

left

to

hand.

looper

right.

handwheel

through

both

eyes

must

pass

thread

through

down,

from

handwheel

position.

thread

top

cover

of

thread

1)

from

(T).

thread

auxiliary

in

tube

thread

then

Be

tube

Insert

eyelet

needle

and

right

Lead

thread

guide

(K)

is

Left

eye

TO

until

of

upper

front

of

assembly

tube

insert

sure

upper

assembly

TO

in

operating

needle

(R),

thread

lead

to

left.

behind

(G).

all

the

of

lower

THREAD

point

of

looper

looper

looper

(M),

assembly

thread

looper

to

upper

THREAD

thread

under

eyelet

it

through

Note:thread

fabric

Turn

way

to

looper

UPPER

upper

thread

thread

thread

lead

through

thread

looper

THE

direction

from

neck

of

(P).

both

guard

handwheel

the

left;

can

LOOPER

looper

eyelet

eyelet

pull-off

thread

(M).

under

Pull

upper

is

eye.

NEEDLE

until

right

top

cover

Thread

eyes

must

in

then

be

threaded

(L)

(D)

(C)

(T).

looper

under

needle

to

casting;

of

pass

(F)

and

operating

thread

is

all

from

from

After

neck

thread

eye

lower

(N,

left,

needle

lower

in

front

through

through

easily

the

way

back

left

to

pulling

of

top

out

bottom

from

looper

Fig.

through

then

from

looper

of

both

direction

both

if

tweezers

left.

to

front,

right.

up

cover

of

front

to

thread

1)

is

both

eyes

down

through

front.

thread

looper

holes

until

eyes

Lead

then

Note;

upper

casting

tube;

back.

when

at

its

of

The

knurled

to

secure

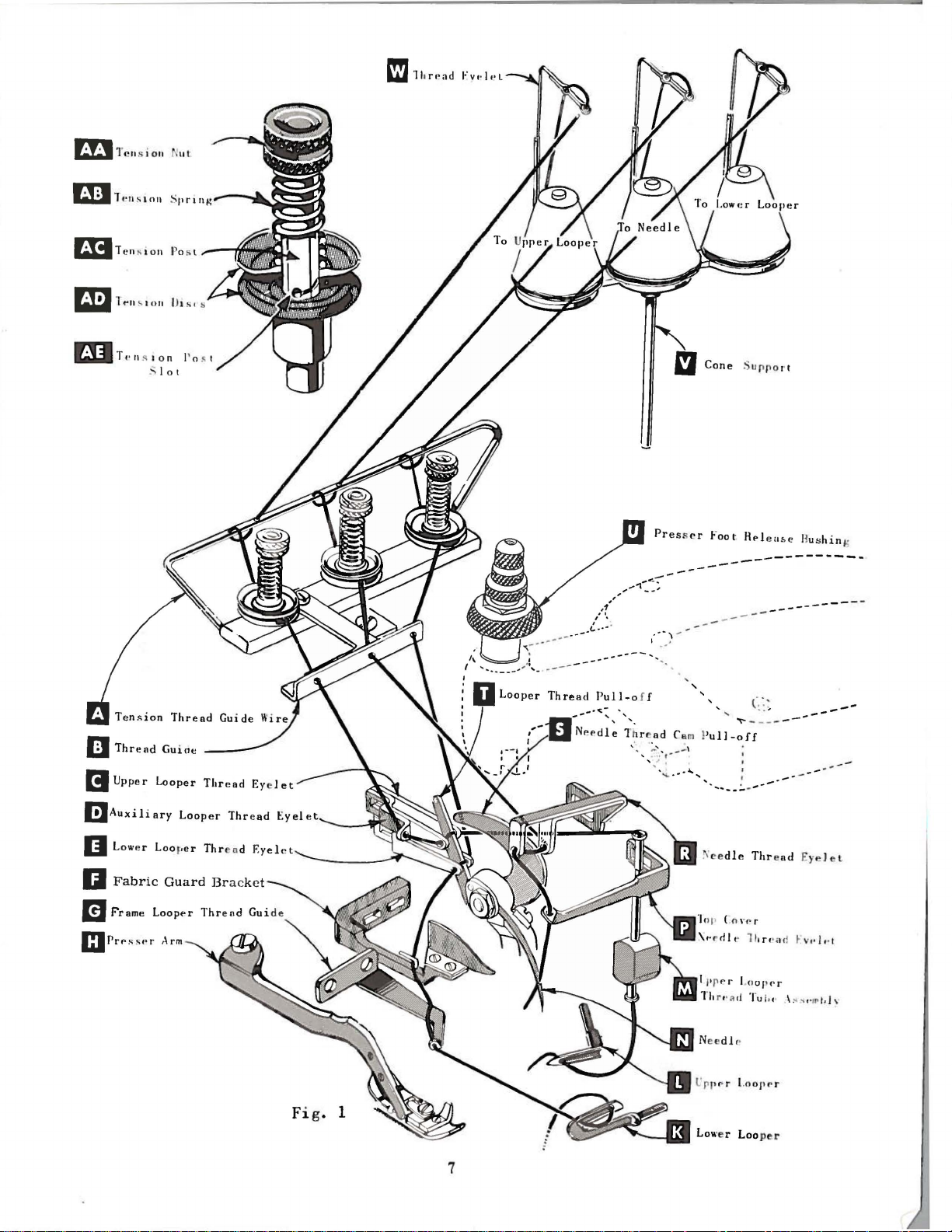

Sufficient

be

maintained.

decrease

lock

nut

Adjusting

increases

When

set,

on

under

from

(D)

pressure

tighten

throat

surface

the

against

Feed

imately

eccentric

imately

specified,

amount

tension

proper

PRESSER

pressure

amount

(A,

Fig.

screw

pressure,

lock

plate,

is

top

surface

locking

eccentric

12

stitches

is

No.

the

number

machine

of

tension

nuts

(AA,

stitch

formation.

FOOT

to

Should

of

it

be

pressure

2)

and

has a right

loosening

adjusting

nut

screw

(A).

position

approximately

of

adjusting

nut

(C).

used

per

in

inch.

39540-12.

of

stitches

will

be

THREAD

on

needle

Fig.

PRESSURE

feed

work

necessary

on

turn

adjusting

hand

decreases

(B)

With

locking

1/32

FEED

this

machine

It

Minor

when

shipped

TENSION

and

1).

Tension

uniformly

to

increase

presser

thread;

has

presser

nut

screw

been

(C)

inch

foot,

so

foot

to

(B).

ECCENTRICS

has

will

be

number

using that

with

above

looper

on

should

loosen

screw

tightening

pressure.

properly

resting

so

that

1/16

Set

been

noted

of

the

eccentric.

threads

threads

or

(B).

its

inch

cap

selected

that

the

part

symbol

eccentric.

is

regulated

should

to

produce

part

indicates

Unless

be

only

Fig.

2

number

otherwise

by

three

enough

approx-

of

feed

approx-

8

FEED

ECCENTRICS

(Continued)

Following

5, 6,

36,

trics

a

11

7,

40.

may

minor

39540-8

Before

guard.

upper

suggested

Fig.

stitch

8,

9, 10,

Only

one

be

ordered

number

11

•

assembling

knife

sequence.

3

number

11,

12, 13, 14,

eccentric

separately.

suffixed

to

ASSEMBLING

sewing

assembly,

SETTING

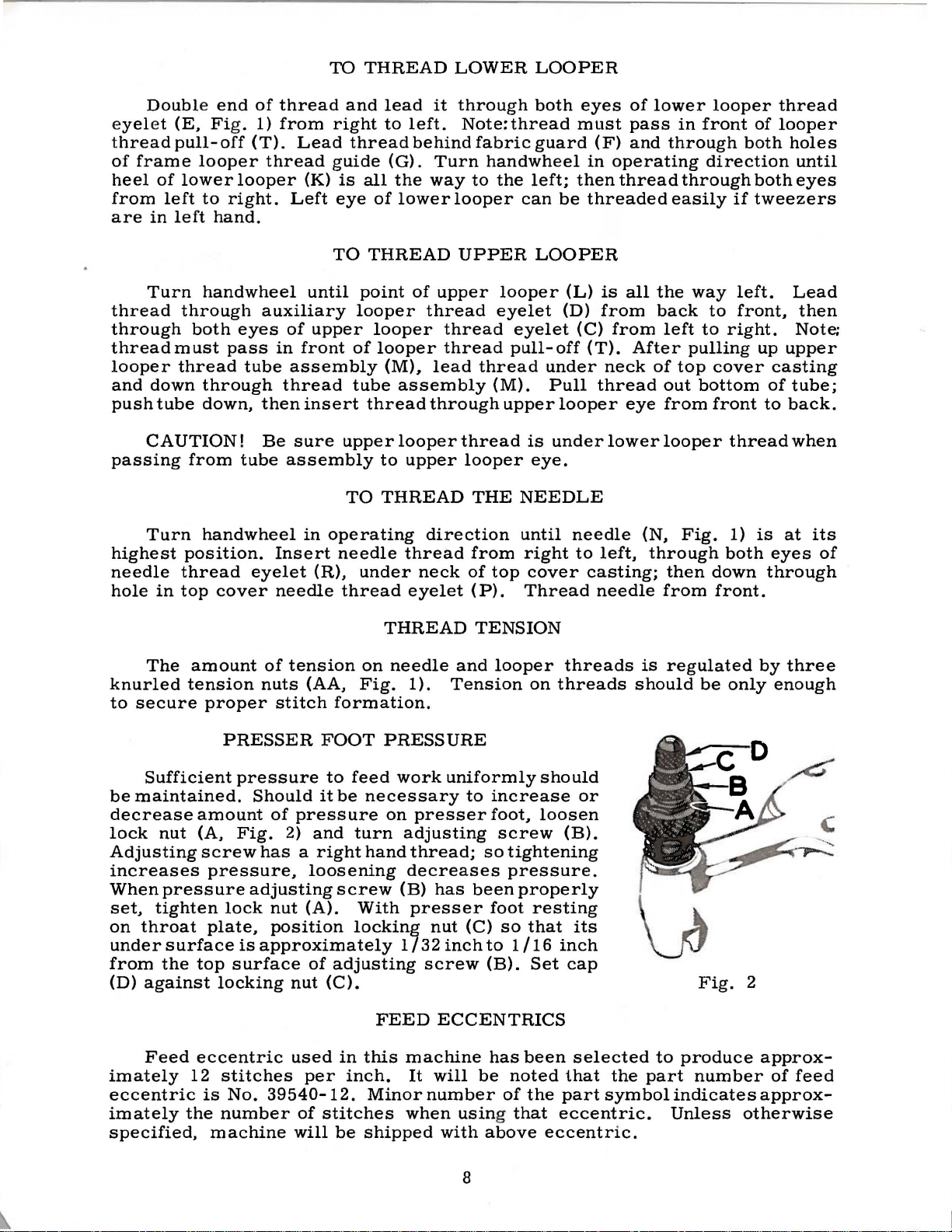

With

the

front

needle

1/2

(Fig.

point

inch

3).

driving

loosening

Remove

If

needle

pull-off(A,•Fig.

looper

thread

separate

thread

pull-off

retightening

·

screw,

end

be

play

arm.

feed

is

supplied

indicate

AND

parts,

lower

throat

end

above

Move

arm

clamp

throat

by

sure

in

eccentrics

15,

16, 18,

with

To

order

number

ADJUSTING

remove

knife

THE

plate

of

needle

should

throat

needle

(A,

Fig.

screw

plate.

t h r e a d

4)

overlaps

pull-off

moving

looper

back.

looper

needle

pull-off

to

take

driving

are

each

an

holder

NEEDLE

in

position,

slot.

be

set

plate

3)

by

(B).

cam

(B),

When

up

available

20,

22.

machine.

eccentric,

of

stitches

SEWING

cloth

plate,

assembly;

When

needle

under

24,

use

desired.

PARTS

needle

No.

26,

28,

Additional

No.

fabric

then

should

is

at

high

Fig.

4

39540-

30.

32,

eccen-

39540

Example:

guard,

follow

center

position,

4,

34,

with

chip

this

in

is

rear

used

needle

Fig.

to

set

guard

5

rear

needle

and

lower

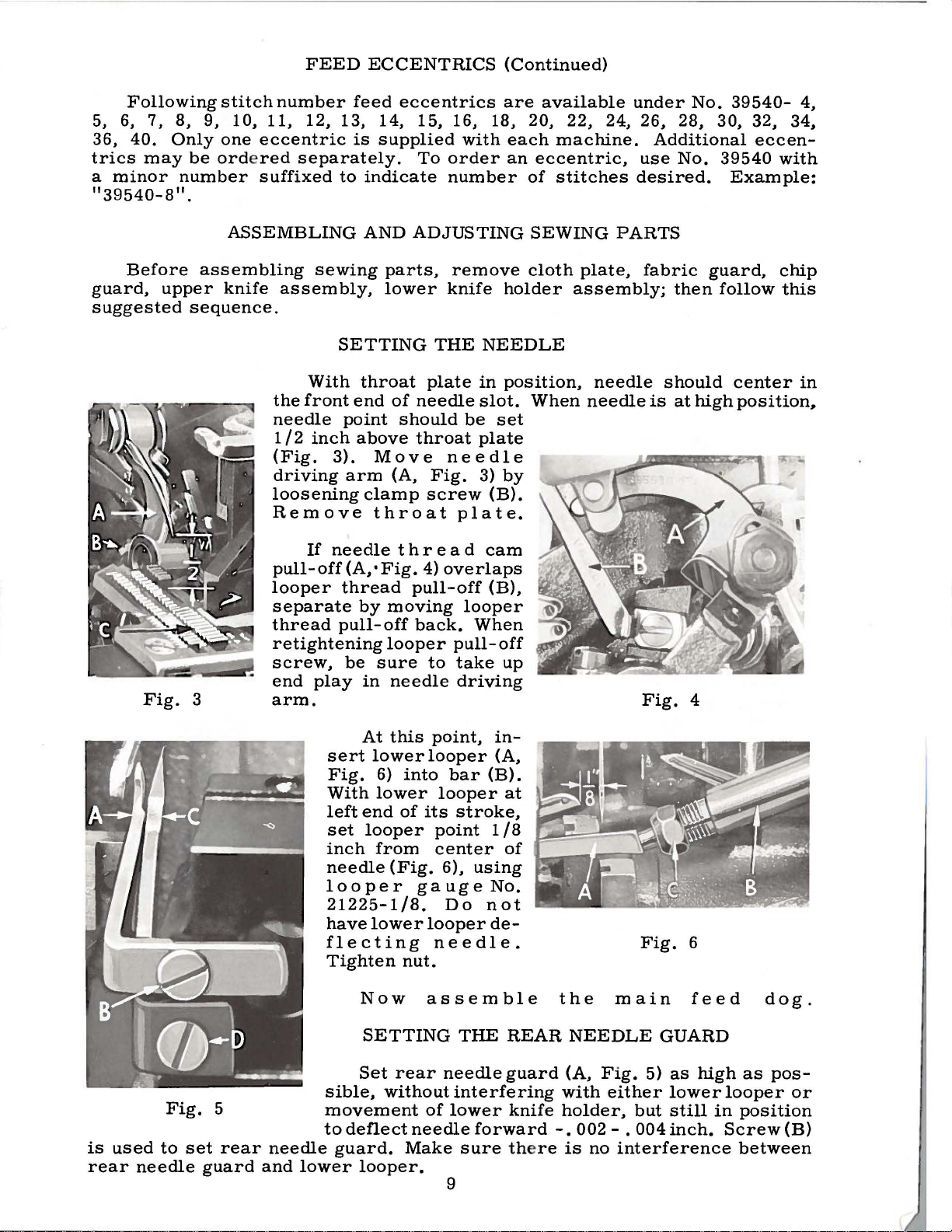

At

this

sert

lower

Fig.

With

left

set

inch

needle

6)

lower

end

of

looper

from

(Fig.

looper

21225-1/8.

have

lower

flecting

Tighten

Now

SETTING

Set

rear

sible,

without

movement

to

deflect

guard.

looper.

point,

looper

into

looper

its

point

center

6),

gauge

Do

looper

needle.

nut.

assemble

needle

of

needle

Make

in(A,

bar

(B).

at

stroke,

1/8

of

using

No.

not

de-

THE

REAR

guard

interfering

lower

knife

forward

sure the

9

the

NEEDLE

(A,

with

holder,

-.

re

is

main

Fig.

either

002 - .

no

interference

Fig.

GUARD

5)

as

lower

but

still

004

inch.

6

feed

high

in

dog.

as

looper

position

Screw

between

pos-

or

(B)