Page 1

®

INDUSTRIAL

SEWING

FIN

EST

STYLE

39SOOMH

QUALITY

LEWIS

•

COLUMBIA

MACHINES

CLA

SS

HI-STYLED

CATALOG

No.

SINGLE

103MH

ZIPPER

. .

NEEDLE

DIFFERENTIAL

ATTACHING

CHICAGO

3950

HIGH

0

SPEED

THREE

FEED

MACHINES

THREAD

Page 2

Here

O

il

are

Specifications

for

Union

Sewing

roleum

mended

machines.

roleum

white

mount.

roleum

hi

mitters.

3. Where

used.

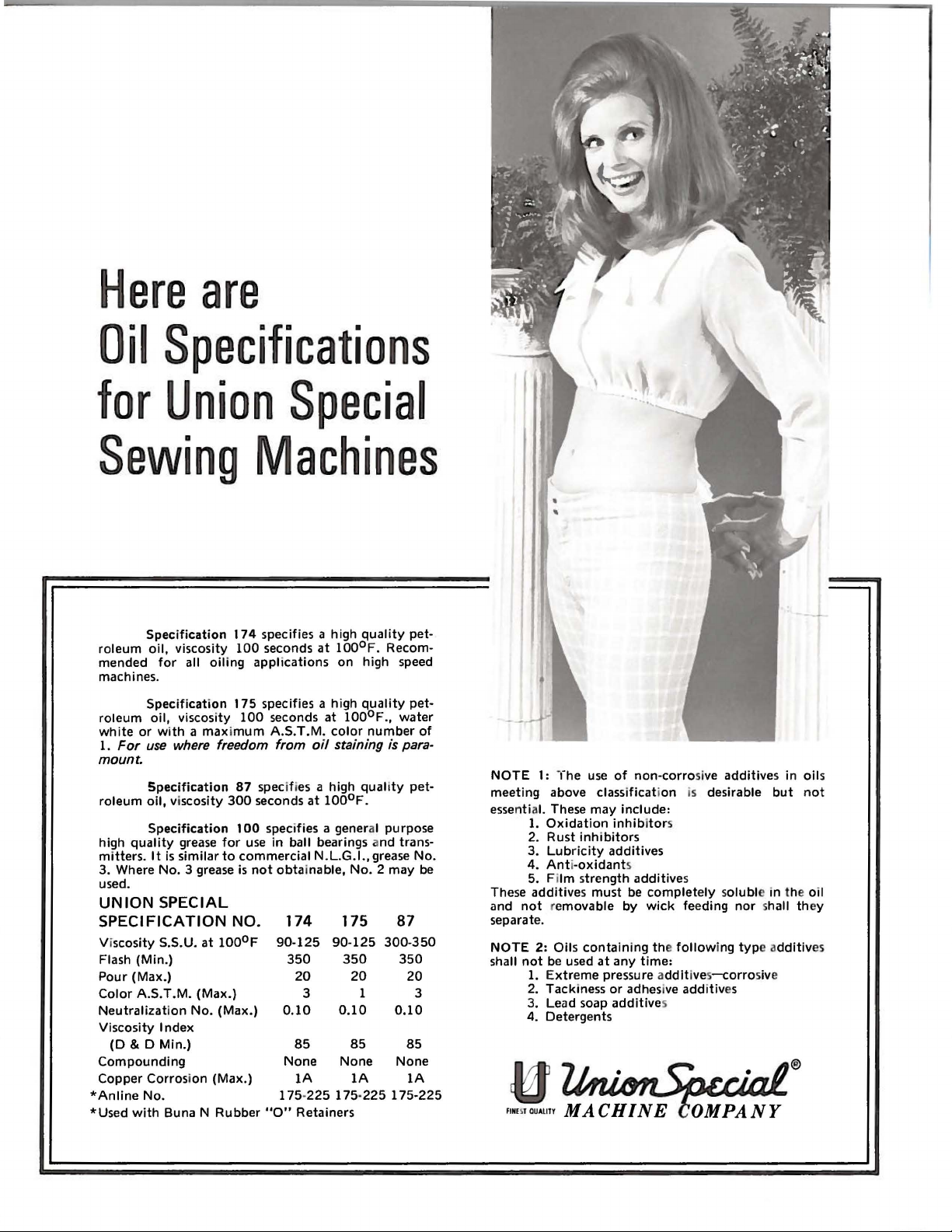

UNION

Specification

oil, viscosity

for

Specification

oil,

or with a maximum

1.

For

use

where freedom from

Specification

oil,

viscosity

Specification

gh

quality

It

is

No.

SPECIAL

all

viscosity

grease

similar

3 grease

SPECIFICATION NO.

Viscosity S.S.U . at

Flash

(Min.)

Pour

(Max.)

Color

A.S.T.M.

Neutralization

Viscosity

(D

Compounding

Copper Corrosion (Max.)

*Anline

*Used

Index

& D

Min.)

No.

with

Buna N Rubber

174

100

oiling

175 specifies a high

100

87

300

100

for

use

to

commercial

is

100°F

(Max.)

No.

(Max.)

Special

Machines

specifies a high

seconds

appli

cations

seconds at

A.S.T .M.

oil

specif i

es

seconds

not

at

specifi

es

in ball bearings and trans-

N.L.G

obta

inable,

174 175 87

90-125 90-

350

20 20

3

0.10

85 85 85

None None None

1A 1A 1A

175-225

"0"

Retainers

quality

at

100°F.

on

high speed

quality

100°F.,

color

staining

a high quali

100°F.

a general purpose

.I.,grease

No. 2 may

125

350

1 3

0.10

175-225

Recom-

water

number

is

para-

ty

300-350

350

0.10

175-225

pet-

pet-

pet-

20

of

No.

be

NOTE

meeting above classification is desirable

essenti

These

and

separat

NOTE

shall

1: "

lhe

use

al. These

1.

2.

3.

4.

5. Film strength

additives must

not

e.

2:

not

1. E

2.

3. Lead soap

4.

may

Oxidation

Rust

inhibitors

Lubricity

Anti-oxidant

removable

Oils containing the

be used

Tackiness

Detergents

at

xtr

eme pressure a

of

non-corrosive

include:

inhibitor

additives

any

or

additive

s

s

additive

be

completely solubl

by

wick

time:

dditives-corro

adhesi

ve

s

s

fee

ding

following

addi

tiv

additive

nor

typ

es

s in

oil

but not

e in the oil

shall they

e a

dditiv

sive

®

s

es

Page 3

(Supplement

Catalog

to

Catalo

INSTRUCTIONS

FOR

No.

103

g

MH

No.

103

FA)

ADJUSTING

Union

Rights

LIST

CLASS

Style

First

Copyright

Special

Reserved

AND

OF

39500

Edition

by

in

OPERATING

PARTS

39500

MH

1972

Machine

All

Countries

Co.

February.

MACHINE

INDUSTRIAL

CHICAGO

Print

1972

COMPANY

SEWING

e d

in

3

MACHINES

U.S.

A.

Page 4

IDENTIFICATION

OF

MACHINES

Each

the

machine.

numbers

Example:

only

minor

ard

Style

Styles

which

differs

39500".

This

junction

39500

the

ion

FP

illustration

and

the

numbers

Reference

number

This

herein.

Class

given

of

39500.

from

handwheel

Union

Style

have

"Style

changes

number.

of

machines

from

catalog

therewith.

are

illustrated

will

number

only,

numbers

listed

in

catalog

It

can

also

References

the

operator's

is

Special

machine

numbers

one

or

more

39500

are

MH".

made

Example:

similar

the

Style

APPLICATION

is a supplement

Only

those

and

be

found a listing

of

pieces

and

merely

should

the

second

applies

be

specifically

applied

to

position

away

from

operator.

is

identified

are

classified

letters

Special

in a standard

"Style

number

39500

in

construction

in

to

Catalog

parts

listed

at

of

required.

indicate

never

be

column.

with

discretion

directions,

while

as

suffixed,

Style

machine, a "Z"

MHZ".

that

OF

used

the

back

the

parts,

Numbers

the

position

used

to

in

the

such

seated

by a Style

standard

but

numbers

are

it

contains

CATALOG

No.

103

on

Style

of

this

with

in

of

ordering

Standard

to

some

as

right,

at

the

number

and

never

contain

grouped

no

letters.

FA

and

39500

catalog.

their

the

first

that

part

parts.

Style

Special

left,

machine.

on a name

special.

contain

the

is

suffixed

Standard

the

letter

under a Class

Example:

should

MH,

On

part

column

be

but

the

numbers,

are

in

the

Always

of

machine

Styles

front,

of

back,

Operating

plate

letter

"Z".

to

the

stand-

number

"Class

used

not

page

in

on

opposite

descript-

reference

illustration.

use

the

as

listed

machines

etc.,

direction

on

Style

"Z".

When

con-

Style

part

in

are

Hi

-Styled

seaming

Lower

39500

flies

and

3/8

Maximum

CAUTION!

filled

straight

should

Machine

sight

gauge

gauge

Machine

main

reservoir

High

Machine.

Knife,

MH

and

similar

inch.

before

mineral

be

used.

lines

Speed

Automatic

Medium

zipper

operations.

Stitch

recommended

Oil

beginning

oil

is

filled

on

front

when

machine

is

automatically

filled.

Single

Curved

Differential

Lubricating

to

heavy

tapes

range

was

to

6-16

drained

to

operate.

of a Saybolt

with

of

oil

machine.

is

stationary.

Check

STYLE

Blade

Feed,

duty

machine

pants

Seam

speed

fronts;

specification

per

inch.

6500

from

Oil

viscosity

at

spring

Red

lubricated.

oil

daily

OF

Needle,

Trimming

System.

Cam

R.

OILING

machine

capacity

cap

bulb

on

No

before

MACHINE

Two

Mechanism

for

simultaneously

also

attaching

504-SSa-1.

adjusted

P.M.

when

of

of

90

to

125

in

top

oil

level

oiling

is

morning

Looper,

zippers

main

shipped,

Class

39500

seconds

cover.

Oil

indicator

necessary,

start;

Three

with

Thread,

Spring

attaching rig

to

right

Standard

and

differential

so

reservoir

is

at

level

should

other

add

s~

100

oil

seam

Fahrenheit

is

checked

show

than

as

Over-

Pressed

ht

pants

flies

only

width

feed.

must

ounces.

between

keeping

required.

be

A

at

The

oil

It

is a magnetic

have

entered

drain

plug screw

screw

the

crank

is

designed

case.

It

located

to

accumulate

should

at

back

be

removed

4

of

machine

possible

and

near

foreign

cleaned

bottom

edge

materials

periodically.

of

which

base.

may

Page 5

NEEDLES

Each

denotes

number,

in

thousandths

size

number

packaged

Class

needle

able

Type

154

for

of

No.

GAS

To

sample

on

label.

Selection

should

pass

Success

of

needles

putation

more

than

Union

the

kind

stamped

represent

and

sold

39500

Style

the

recommended

Round

struck

025,

have

needle

needle,

A

complete

of

freely

in

packaged

for

producing

three-quarters

Special

of

shank,

on

of

an

by

machines

39500

shank,

groove,

027,

or

the

proper

through

the

operation

the

needle

inch,

the

Union

MH

029,

orders

type

order

needle

under

highest

needle

point,

has

length,

shank,

midway

complete

Special.

use a curved

is

Type

154

needle.

round

point,

spotted,

032,

036,

promptly

and

size

would

read: "1000

size

needle

our

of

eye

Union

brand

quality

of a century.

both

type

groove,

denotes

between

symbol

shank

which

blade

GAS.

Below

Description

curved

chromium

040,

and

044, 049,

accurately

number

is

determined

in

order

Special

name,

.

~.

needles

and

finish

largest

is

needle.

is

and

blade,

plated

should

Needles,

to

produce a good

machines

in

materials

size

and

diameter

and

eye.

given

The

the

Sizes

standard

and

054,

filled,

be

forwarded.

by

size

number.

other

of

Collectively,

on

the

label

standard

description

length,

is

available

060.

an

Type

can

154

of

thread

be

which

secured

is

and

The

type

details.

blade,

The

measured

type

of

all

recommended

and

sizes

single

in

sizes

empty

Use

GAS,

package,

description

Size

used.

stitch

formation.

only

backed

by

workmanship

number

size

and

needles

avail-

groove,

022,

040".

Thread

by

use

are-

for

a

Release

Fig.

1)

direction

No.

21388

Again

turn

To

left,

insert

position,

nut.

Return

(AG).

After

through

eyelet.

front

that

to

the

through

and

third

tension

front

thread

pressure

and

swing

until

AU,

handwheel

replace

needle

turn

presser

thread

back

Next

it

back

lower

the

upper

through

discs

guide

presser

needle

furnished

needle,

in

handwheel

comes

hole

and

of

is

threaded

then

looper

hole

the

(J),

through

(M).

on

presser

is

at

until

leave

holder

until

arm

from

thread

through

thread

back

lower

CHANGING

arm

its

lowest

with

machine,

needle

needle

until

holder

(U)

to

cones

eyelet

through

the

is

threaded

to

front,

hole

tension

foot

(U)

out

point

is

at

holder

it

rests

is

position

THREAD

on

(B),

the

lower

second

back

to

post

NEEDLES

by

turning

of

position.

of

travel.

~oosen

high

position;

at

against

again

at

andre-lock

STAND

cone

then

upper

holes

support

down

holes

from

through

through

front.

slot

All

(K)

presser

needle

high

its

the

threads

in

Turn

Using

withdraw

position

stop

low

pin.

point

presser

(A,

through

of

tension

back

tension

the

tension

foot

release

handwheel

hexagonal

clamp

and

Keeping

of

foot

Fig.

the

thread

to

front.

thread

middle

then

post

socket

nut

about

needle.

with

travel;

release

1),

it

is

front

hole

guide

It

should

guide

hole

continue

(G)

and

bushing

in

operating

1/4

the

flat

needle

then

brought

of

(C),

front

between

on

(AG,

wrench

turn.

to

in

this

tighten

bushing

thread

(C)

from

be

noted

first

to

back

through

the

up

the

5

Page 6

li]

Tension

(I

Tension

II

Tension

[!]

Tension

IIJ

spring

O Tension

Nut

Spring

Spring~

Post

Shield

Discs ·-.

Ferrule

..

·

:<:

~

~

....

··

·.

~.-~~

.,...

......

(3

II

[i

fiJ

~U

I3

Tension

Tension

Tension

Front

pper

Lower

Post

Disc

Thr

Looper

Looper

Slot :

Felt · ..

Thread

ead Guide

Thread

Thread

Guide

Eyel

et

Eyelet

Cone Support

,.....,

"1'1~~::.

~

...

..

Presser

Release

~

Cam

II

eedle

~

Top

Needle

Foot

Bushing

Pull-off

rlW

Thread

Cover

Thread

Eyel

et

Eyelet

Frame

D

Thread

m

Press

Looper

Guide

er

Arm

F ig . 1

6

Upper

Thread Tube

Looper

Assembly

Page 7

THREADING

Only

are

placed in

It

threading

Before

ting

direction

by

turning

position.

Be

tension

Thread

double

Fig.

1)

{AF).

thread

{V)

is

eye

of

Thread

turn

handwheel

through

eyes

of

front

.

assembly

tube

assembly

thread

parts

will

lower

sure

discs

end

of

from

Lead

guide

all

the

lower

auxiliary

upper

of

looper

{AA),

through

involved

their

simplify

looper

beginning

until

presser

threads,

{J)

and

lower

looper

thread

right

to

thread

{T).

Turn

way

to

looper

upper

looper

until

looper

looper

thread

lead

(AA).

upper

in

relative

threading

first.

to

needle

foot

as

in

diagonal

and

lead

left.

behind

handwheel

the

left;

can

be

point

thread

pull-off

thread

Pull

looper

threading

positions

upper

thread,

{X)

is

release

they

come

TO

THREAD

thread

it

Note:

fabric

then

threaded

TO

THREAD

thread

of

thread

eyelet

under

thread

eye

are

this

looper

swing

at

high

bushing

from

slots

through

through

thread

guard

in

thread

easily

through

upper

eyelet

(N)

(AF).

neck

out

from

shown

for

clarity.

machine

second

cloth

position,

{AG)

the

{K)

in

tension

LOWER

right

both

must

{S)

and

operating

through

if

UPPER

left

looper

{P)

from

from

left

After

of

top

bottom

front

to

in

threading

to

follow

and

plate

open,

release

and

tension

LOOPER

eyelet

eyes

pass

of

in

through

direction

both

tweezers

LOOPER

eyelet

{W)

of

is

back

to

right.

pulling

cover

of

casting

tube;

back.

recommended

needle

turn

pressure

swing

thread

posts

of

{G).

front

lower

front

eyelet

until

eyes

are

held

front

all

the

to

front,

Note:

up

upper

push

diagram

third.

handwheel

presser

guide

thread

looper

of

looper

hole

heel

from

in

thread

way

thread

looper

and

down

tube

{Fig.

on

arm

{C),

guide

thread

thread

of

of

left

left

guide

left.

then

through

down.

1).

sequence

in

presser

{U)

are

between

{M).

eyelet

frame

lower

to

right.

hand.

{M).

Lead

through

must

thread

then

Parts

of

opera-

foot

out

of

Then

{R.

pull-off

looper

looper

Left

Then

thread

both

pass

in

tube

thread

insert

CAUTION!

passing

from

Threa9

handwheel

Insert

{AD),

thread

those

The

heading

Para.

Para.

needle

under

eyelet

All

instructions

for

differences,

and

1..

3...

tube

needle

in

operating

neck

{AC).

Style

paragraph

.

the

point

lower

of

Be

sure

assembly

thread

direction

thread

of

from

top

Thread

ASSEMBLING

pertaining

39500

FP

covered

applicable

where

With

front

throat

end

should

At

this

looper

needle (Fig.

upper

to

TO

through

right

cover

needle

only

they

"SETTING

plate

of

be

set

point,

at

left

5),

looper

upper

THREAD

middle

until

to

left,

casting;

from

AND

to

the

in

Catalog

to

Style

can

assembled

needle

15/32

insert

end

using

thread

looper

eye.

THE

eyelet

needle

(X,

through

then

down

front.

ADJUSTING

adjustment

No.

39500

be

found

THE

slot.

inch

lower

of

its

looper

NEEDLE"

When

above

looper

stroke, set

gauge

is

under

NEEDLE

of

front

Fig.

both

through

SEWING

of

Style

103

FA

MH

are

in

Catalog

in

position,

needle

throat

(A,

looper

No.

lower

thread

1)

is

at

eyes

of

hole

PARTS

39500

with

the

described

No.

needle

is

at

high

plate.

Fig.

point

21225-3/32.

looper

guide

its

( M).

highest

needle

in

top

MH

are

following

below.

103

FA.

should

position,

5)

into

3/32

thread

Then

position.

thread

cover

the

same

exceptions.

under

center in

bar

(B).

from

when

turn

eyelet

ne

edle

as

the

needle

With

center

7

Page 8

33

/

,(

{

..-~-

···

'~/

./1

I

I

I

/

/

/

/

15

21

18

8

7

Page 9

The

that

parts

are

illustrated

used

on

Style

on

the

39500

preceding

MH,

but

page

not

and

used

described

on

Style

below

39500

represent

FP.

the

parts

Those

common

Use

in

Reference

descriptions,

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

Catalog

this

39592

39540

39540

39505

39526

39505

39503

39503

12957

22758

22569

39503

39571

39572

39570

39578

39549

39550

39550

39524

39556

39556

22798

39556

39520

39530

39530

39530

39578

parts

to

catalog.

Part

No.

604

605

87 u

28

shown

Styles

No.

numbers

indicate

AR-4

B-7

B-8

AR

AR

A

D

E

E

c

c

c

A

J

TA

J

p

R

X

M

L

D

X

K

J

s

in

phantom

39500

103

FP

and

FA

(Style

that

are

inside a bracket

they

Upper

Main

Differential

Chaining

Differential

Main

Edge

Screw,

Edge

Washer,

Screw,

Screw,

Edge

Upper

Upper

Upper

Chip

Lower

Lower

Lower

Throat

Screw,

Chain

PresserArm---------------------------------------Presser

Fabric

are

and

Feed

Feed

Guide------------------------------------------

for

Guide

for

for

Guide

Knife

Knife

Knife

Guard------------------------------------------

Knife----------------------------------------Knife

Knife

Plate,

for

Cutting

Chain

Screw-------------------------------------------

Foot---------------------------------------Presser

Hinge

Screw------------------------------------------Edge

Screw-------------------------------------------

Guard----------------------------------------

views

MH.

39500

component

Lower

Driving

Feed

Feed

for

Guide,

Dog,

Feed

Dog,

edge

Swinging

swinging

swinging

mounting

Mounting

Clamp

Holder

-----------------------------------------

Holder

Holder

marked

chain

Knife-----------------------------------

Cutter

Foot

Spring-------------------------------------

and

bearing

FP)

for

all

parts

on

the

picture

parts

Description

Looper

Eccentric--------------------------

Driving

20

teeth

Dog,

marked

guide

cutting

Blade-------------------------------

Bottom-----------------------------

marked

marked

--------------------------------

Arm-----------------------------

arm

arm

bracket

Bracket--------------------------

Stud-------------------------------

Block-----------------------------

Spring---------------------------Locating

"AR"

knife

of a complete

Thread

Eccentric--------------------

per

"FD",

"FC",

-----------------------------

"A"

16

----------------------------

--------------------------

Stud----------------------

---------------------------

-------------------------

-------------------------

no

reference

not

illustrated

plate

Tension

inch-------------------

teeth

Spring---------

16

teeth

per

and

part

per

inch

numbers,

have

or

or

described

assembly.

inch

--------

are

indented

Amt.

Req.

2

1

1

1

--

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

9

Page 10

BOOST

PRODUCTION

WITH

WORK

UNION

THESE

AIDS

SPECIAL

FROM

PNEUMATIC

conventional

ssor-act

sci

pos

itive

AIR

FABRIC

signed

to remove

knit materials as fabric passes

area.

Style

CHAIN·CUTTER-for

Class

ion mechanism

cut.

Style

Class

curls

2899

UNCURLER

39500

from

B-1

for

39500

and

2899

A· I

machines, uses

top

and

that

bottom

39600

- This

use

is

a durable

makes a clean

unit,

air

plies

through

sewing

of

on

de-

jets

flat

PNEUMATIC

operated

machines

simply

by

CHAIN

CUTTER-

small

pneumatic

for

installatron as an accesso •y unit

36200

Flatseamers.

FOOT

fool

lifter

allows

the

knee-touching

The

chain

Style

LIFTER-The

for

use on

operator

an

above

cutter

2899A-6

Class

the

shows

on

39500

Class

to raise

actuating swi

photo

that is available

air-

foot

tch.

the

KNIFE

GRINDER

type knives,

nates defective garments caused by

sharpens

is

simple and easy

straight

to

operate,

dull kno

®

u

fiNISIQUALIIY

MACHINE

ELECTRONIC

wheel to move

insuring

better

the

needle up

control, uni

NEEDLE

or

form

POSITIONERS

down

.••

quality

AMCO

or

angle

ves.

allows

HEAT

uml

o

il

quires

eliminate

elimi-

this

and increased pr

DISPELLER-Union

(arrow)

temperature

the

is

it.

Style

the

necessity

operator to keep

oduction.

an effective means

where heavy

2899

E-1

Special's auxiliary

duty

of

reaching f

both

hands

for

reducing

service re-

or

the

on

the

hand-

work,

Page 11

He

lpful,

c

ient

types

mac

hine

Sales

Promotion

esting,

obligation

illustrated

authoritative

of

equi

sewed

article

Department.

bulletins

are the

following:

information

pment

is available

for

that

on

making virtually

from

Among

the

are available wi

the

most

Union

many inter-

effi

any

Special's

thout

-

HERE

ARE

HELPFUL

No.

240,

"Men's,

No.

249,

"Rainwear"

No.

250,

"Men's

No.

251,

"Service

No.

252,

"Men's

No.

253,

"Overalls, Coveralls, and

No.

254,

"Men's

No.

256,

"Knit

No.

259,

"Men's

No.

260,

"Work

No.

262,

"Cotton,

Bags"

No.

263,

"Men's

No.

264,

"Men's

No.

265,

"Women's

No.

266,

"Women's

No.

26 7, "Corsets, Girdles, Brassieres"

No.

268,

"Children's

No.

269,

"Mattresses,

Upholstery"

No.

271,

"Awnings,

No.

273, "Curtains & Drapes"

No.

610,

"Kiipp-it"

No.

710,

"MCS

No.

730,

"MCS

Hemmer"

No. 740,

No.

No.

No.

"

Columbia

ing Mac

No. 1500,

750,

1100,

1105,

hines"

"MCS

"Fusing

"Lew

stitch,

"Button

Women's,

Dress

Shirts

Shorts

Knit

Outerwear"

Sports

Gloves"

Burlap,

Clothing"

Women's,

ForMation

Automatic

Automat

Presses"

is

Blindstitch,

Machines"

Sewers-

Blindstitch,

"Alteration

Shirts"

and

and Pajamas"

Underwear"

Shirts"

Jute,

Children's

Wear"

Wear

And

Wear"

Slip

Covers,

Canopies, Tents,

Unit"

Dual

ic

Rib-Knit

Saddle

Department

Children's

Pants"

Dungarees"

and

High

Furniture

Underfront

Chainstitch,

Ticket

Tackers"

Stitch

Machines"

Footwear"

Multiwall

Jackets"

Fashion"

Tarps"

Cuff

Machine "

Lock·

, a

nd Tie

Paper

Shirt

Clo

BULLETINS

TO

HELP

SEWING

s-

and

YOU

CATALOGS

SOLVE

PROBLEMS

®

Page 12

,...o

"'

...

'

0

WORLD'S

,..tlf

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

facilities throughout

aid

you

SPECIAL

in

the selection of the right sewing

maintains sales

the

world. These offices

and

equipment for your particular operation. Union

Special representatives

tory trained

promptly

tion,

there

and

and

is

a Union Special Representative to

serve you. Check with

ATLANTA,

BOSTON, MASS.

CHICAGO,

DALLAS,

LOS ANGELES, CAL.

NEW

PHILADELPHIA,

GA.

ILL.

TEXAS

YORK, N.

Y.

PA.

efficiently. Whatever your loca-

are

and

service men

able

to serve your needs

him

today.

MONTREAL, CANADA

TORONTO, CANADA

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS, FRANCE

sTunG

ART, GERMANY

service

will

are

fac-

ENGLAND

ENGLAND

400

Representatives

MACHINE

N.

FRANKLIN

industrial

and

cities

distributors

throughout

COMPANY

ST.,

CHICAGO,

In

the

all

Important

world.

ILL.

60610

Loading...

Loading...