Page 1

CATALOG

NO.

Adjusting

instructions

and

IO3XQA

Edition

First

SERIES

9M

illustrated

parts

list

U,

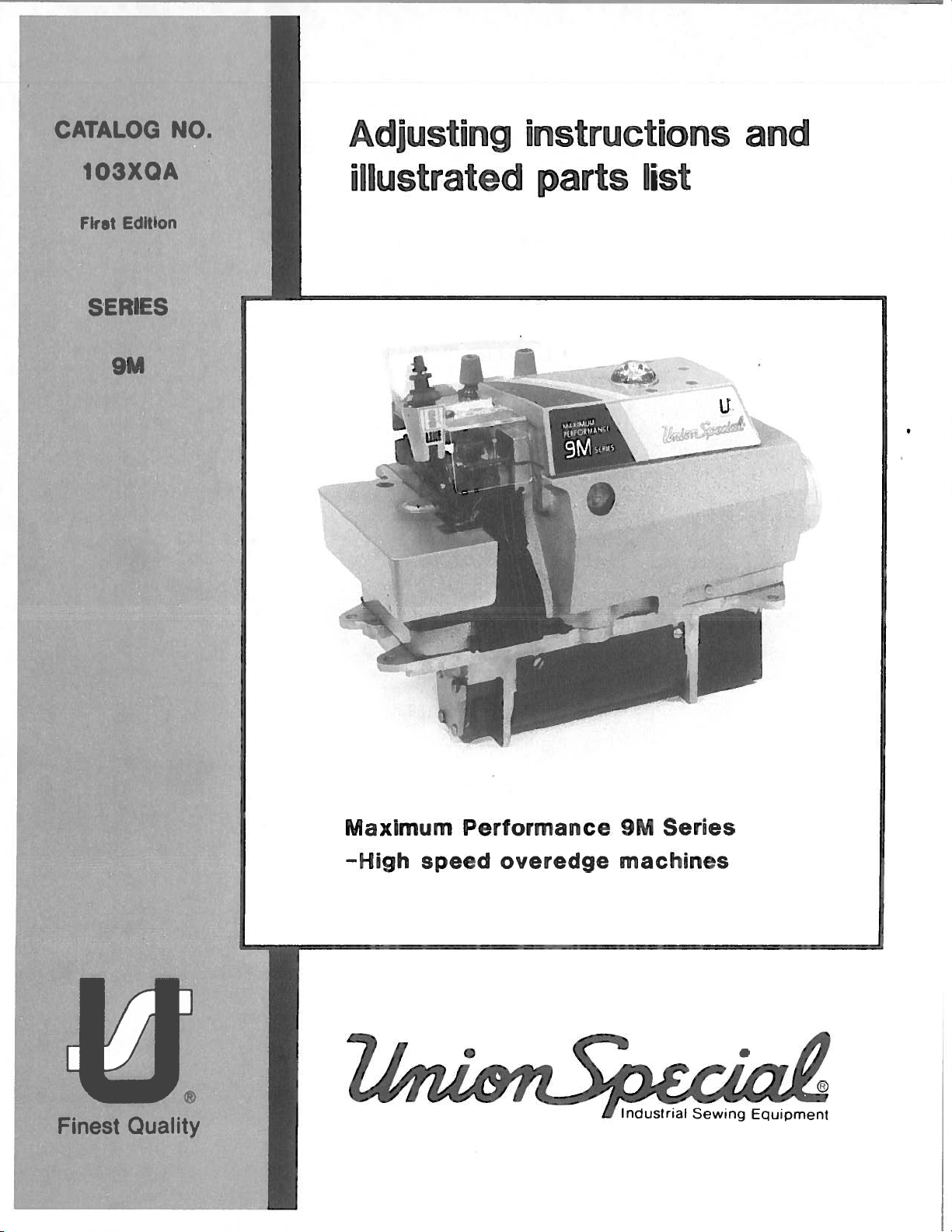

Maximum

-High

U

Finest

Quality

Zua

Performance

speed

overedge

9M

Series

machines

Equipment

Page 2

CATALOG

NO.

103

XQA

39500

39500

39500

39500

39500

XQA

XQB

XQJ

XRB

XRC

ADJUSTING

ILLUSTRATED

MAXIMUM

PERFORMANCE

INSTRUCTIONS

AND

FOR

STYLES

39500

39500

39500

39500

39500

First

Edition

Copyright

PARTS

-

XRN

XSD

XTA

CXQA

CXQB

1983

LIST

9M

SERIES

39500

39500

39500

39500

39500

CXQJ

CXRN

CXSD

XSQB

CXSQB

Rights

Union

Reserved

Special

Printed

January

By

Corporation

All

in

U.S.A.

in

1983

2

Countries

Page 3

FORE

WARD

This

your

ating

forinance

proper

pleting

ments

plished.

the

ficant

downs.

machine,

designed

assure

new

The

Adjustments

function

Implementation

technical

UNION

and

adjusting

and

reliability

Adjusting

setting

the

functions

using

improvements

long

reference

Some

of

Whenever

be

sure

specifically

lasting

manual

SPECIAL

these

Instruction

for

each

of

letters

are

presented

adjustments

other

it

to

related

of

in

becomes

insist

for

service.

has

machine.

machines

designed

of

the

preventative

operator

your

components

the

machine.

to

in

performed

parts.

necessary

on

genuine

machine

been

prepared

Careful

will

and

built

portion

point

sequence

out

maintenance

productivity

to

UNION

attention

enable

this

of

related

Figures

out

specific

so

of

sequence

make

SPECIAL

and

manufactured

to

you

into

manual

are

that

by

repairs

guide

procedures

avoiding

to

to

every

to

used

a

Repair

you

the

maintain

explains

forming

items

logical

may

or

in

instructions

UNION

illustrate

to

discussed.

have

can

costly

replace

Parts.

with

the

maintenance

the

superior

SPECIAL

in

detail

the

stitch

progression

an

adverse

bring

equipment

parts

These

utmost

precision

for

machine.

the

and

the

adjust

is

effect

about

break

on

your

parts

of

oper

per

com

accom

on

signi

are

to

by

a

KEY

parts

simplify

To

exploded

VIEW

illustrated

views.

which

indentification

These

presents

on

this

illustrations

the

page

of

epair

mechanisms

will

appear

will

of

3

parts,

usually

the

shaded

the

be

machine

in

the

mechanisms

shown

assembled.

KEY

VIEW.

are

in

conjuction

illustrated

The

specific

with

Page 4

IDENTIFICATION

MACHINES

OF

Each

is

stamped

number

is

Super

three

or

adjusted

internal

thread

feeds,

lubricating

recommended

39500

39500

XQA

XQB

UNION

in

the

stamped

high

speed

Light

thread

knit

bination

pajamas,

seams

504-SSa-l;

stitch

Same

purpose

knit

SPECIAL

style

the

in

speed,

machines.

needle

system

9000

medium

to

machine

fabrics

designed

nightgowns,

a

are

standard

range

Style

as

seaming

and

wear

machine

plate

extension

STYLES

maximum

Trimming

bearings

with

R.P.M.,

duty,

for

cotton,

of

especially

primary

per

8-30

39500

of

similar

carries

located

of

OF

performance,

mechanism

feed

for

self-contained

depending

differential

seaming

silk

similar

or

requisite.

widths

seam

inch.

XQA

except

shirts,

“T”

garments.

style

a

the

on

casting

bed

MACHINES

drive

on

light

or

for

-

polo

number,

right

or

one

with

eccentrics,

oil

operation.

feed,

medium

and

similar

on

use

articles

154

Type

and

3/32

sewing

shirts,

which

rear

of

the

at

two

curved

spring

filter

single

weight

weight

women’s

where

needle;

GAS

inch

1/8

combination

panties,

on

the

right

blade

pressed

needle

and

needle,

flat,

synthetics.

and

long

(2.4

this

machine.

base

rear

needles,

lower

cooler,

oil

cooler.

two

warp

children’

straight

seam

and

designed

infant

class

machine

Serial

machine.

of

two

knife,

improved

Maximum

looper,

ribbed

and

Sewing

slips,

hanging

specification

3.2mm);

general

for

children’s

and

cam

three

com

39500

39500

39500

39500

39500

XQJ

Light

two

and

standard

XRB

Light

spreader,

less

standard

left

XRC-045

XRC-060

Light

XRN

looper,

or

guide

stitch

to

thread

similar

to

nylon

needle;

Light

spreader,

one

hosiery

standard

stitch

Same

seam

to

one

hemming

assembly.

range

medium

machine

garments.

seam

medium

three

hosiery.

seam

stitch

to

medium

and

seam

range

as

Style

width

medium

(lower)

on

8-30

duty,

plain

for

duty,

3/16

differential

width

thread

Type

widths

approximately

range

duty,

three

socks.

width

20-100

39500

approximately

duty,

differential

spreader,

Type

per

weight

154

inch.

light

feed,

154

light,

154

(4.8mm);

for

GFS

serging

Type

inch

machine

20-100

differential

thread

Type

machine

154

approximately

inch.

per

XRC-045

7/32

two

knit

needle;

GAS

single

needle;

GAS

feed,

closing

needle;

1/8

per

GFS

except

inch

feed,

thread

fabrics.

needle,

medium

stitch

two

and

inch.

feed,

for

needle;

3/16

Type

-

(5.6mm)

single

machine

seam

one

heavy

and

specification

seam

range

needle,

sections

toe

seam

specification

5/32

two

inch

needle,

closing

seam

inch

(4.8mm)

154

from

needle,

for

Fitted

with

specification

looper,

weight

5

1/2-8

looper,

one

of

and

(3.2

one

sections

toe

specification

from

needle;

GDS

needle.

left

one

blind

a

compact

503-EFc-1;

one

trousers

503-EFd—l;

inch.

per

women’s

521-SSa-1;

4.0mm)

looper,

of

521-SSa-l;

left

standard

(upper)

stitch

hemming

spreader,

one

seam

from

men’s

needle;

welting

39500

XSD

Same

as

Style

39500

XRN

except

-

one

(lower)

spreader.

4

looper

and

one

(upper)

Page 5

MACHINE

STYLES

(Continued)

39500

39500

39500

39500

39500

39500

39500

39500

XTA

CXQA

CXQB

CXQJ

CXRN

CXSD

XSQB

CXSQB

Light

machine

needle;

inch

Same

cutter.

Same

cutter.

Same

cutter.

Same

cutter.

Same

cutter.

Same

(Type

Same

(Type

duty,

(1.6

as

as

as

as

as

as

162

as

162

for

seam

to

Style

Style

Style

Style

Style

Style

SAS)

Style

SAS)

differential

toe

closing

specification

2.4mm)

39500

39500

39500

39500

39500

39500

which

39500

which

feed,

on

depending

XQA

except

XQB

except

XQJ

except

XRN

except

XSD

except

XQB

except

reduces

CXQB

reduces

single

women’s

505-tEe-i;

on

-

-

-

-

-

-

needle

except

needle

seamless

material;

fitted

fitted

fitted

fitted

fitted

designed

cutting.

-

designed

cutting.

needle,

standard

with

with

with

with

with

to

two

hosiery.

stitch

Power

Power

Power

Power

Power

use

to

looper,

seam

width

range

“AIR-KLIPP”®

“AIR-KLIPP”

“AIR-KLIPP”

“AIR—KLIPP”

“AIR-KLIPP”

SHORT,

use

SHORT,

Type

15-100

three

154

1/16

STIFF

STIFF

thread

GAS

to

3/32

per

inch.

chain

chain

chain

chain

chain

NEEDLE

NEEDLE

39500

maximum

lower

speed.

recommended

The

9M

is

factory

Use

viscosity

F.

This

fication

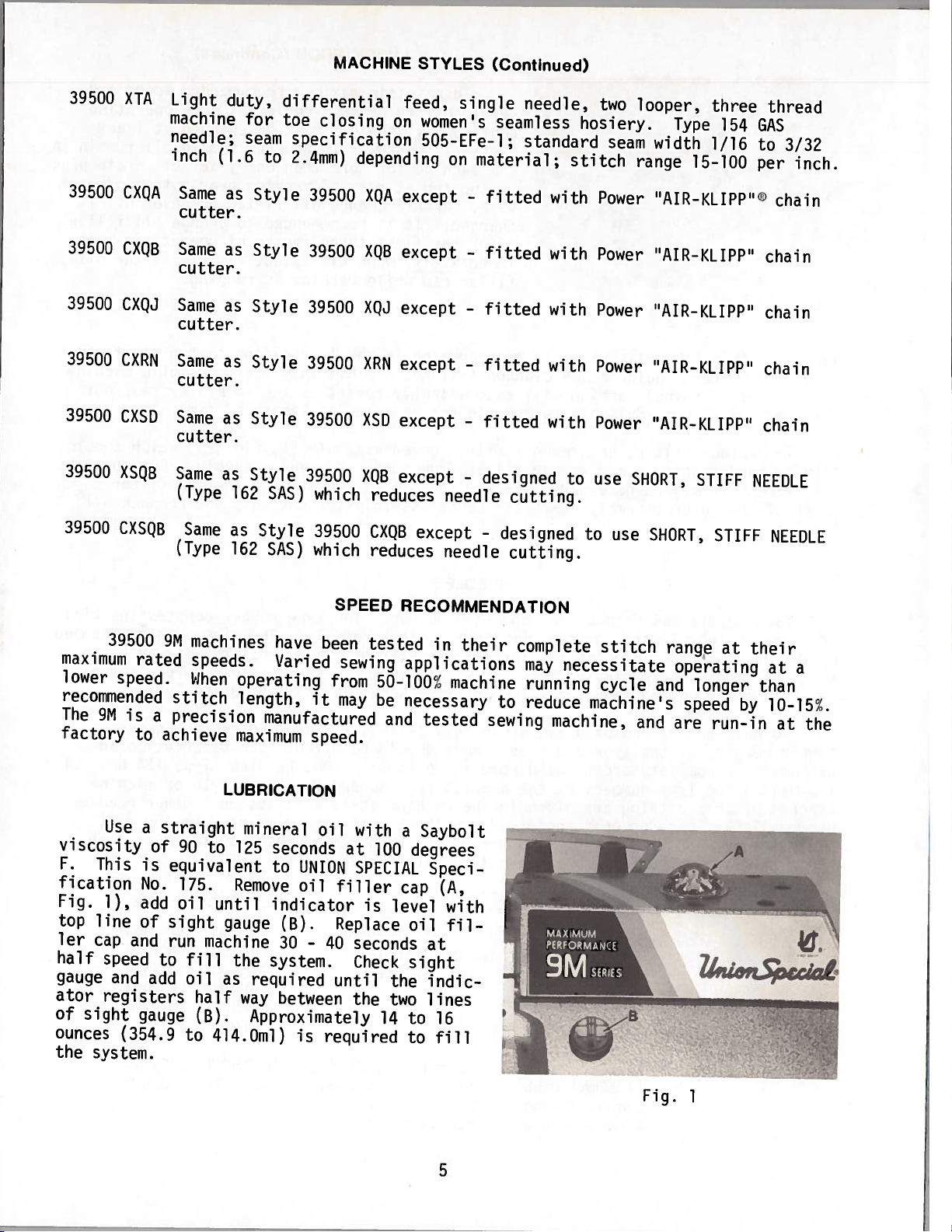

Fig.

top

ler

half

gauge

ator

of

ounces

the

1),

line

cap

speed

and

registers

sight

system.

and

(354.9

rated

a

to

a

of

is

No.

add

of

to

add

gauge

9M

machines

speeds.

When

stitch

precision

achieve

straight

90

to

equivalent

175.

oil

sight

run

machine

fill

oil

half

(B).

to

have

Varied

operating

length,

manufactured

maximum

LUBRICATION

mineral

125

seconds

to

Remove

until

gauge

indicator

(B).

30

the

system.

as

required

way

between

Approximately

414.Oml)

is

SPEED

been

from

it

may

speed.

oil

UNION

oil

filler

Replace

-

40

until

required

tested

sewing

50-100%

be

with

at

100

SPECIAL

is

seconds

Check

the

14

RECOMMENDATION

in

their

applications

machine

necessary

and

a

tested

Saybolt

to

sewing

degrees

Speci

cap

(A,

level

oil

with

fil

at

sight

the

indic

two

lines

to

16

fill

to

complete

may

necessitate

running

reduce

machine,

stitch

cycle

machine’s

and

range

operating

and

speed

are

at

longer

run-in

Z1aL

their

by

at

than

10-15%.

at

a

the

5

Fig.

1

Page 6

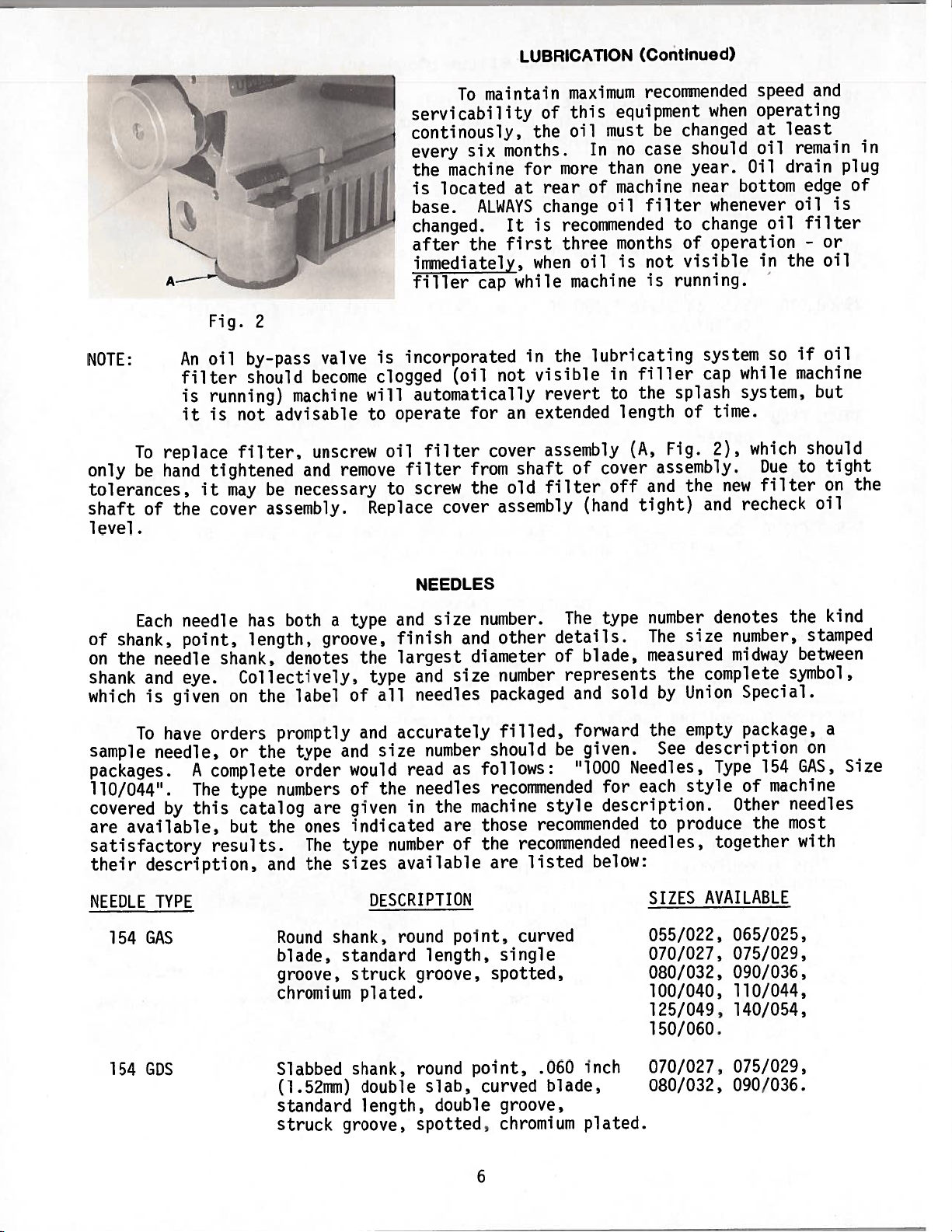

LUBRICATION

(Continued)

NOTE:

To

only

be

tolerances,

shaft

of

level.

An

filter

is

it

replace

hand

it

the

Fig.

2

oil

by-pass

should

running)

is

not

filter,

tightened

may

cover

valve

become

machine

advisable

unscrew

and

be

necessary

assembly.

is

clogged

will

to

remove

Replace

servicability

continously,

every

the

is

located

base.

changed.

after

immediately,

filler

incorporated

automatically

operate

filter

oil

filter

screw

to

cover

maintain

To

six

machine

ALWAYS

the

cap

(oil

for

cover

from

the

of

the

months.

for

rear

at

change

is

It

first

when

while

in

visible

not

revert

extended

an

assembly

shaft

filter

old

assembly

maximum

equipment

this

must

oil

In

no

of

than

machine

more

oil

recommended

oil

months

is

three

machine

lubricating

the

in

to

length

(A,

cover

of

off

(hand

reconnended

when

be

changed

one

should

year.

case

near

filter

change

to

of

visible

not

running.

is

system

filler

the

cap

splash

of

Fig.

assembly.

the

and

tight)

and

speed

operating

at

oil

Oil

bottom

whenever

oil

operation

in

while

system,

time.

which

2),

Due

filter

new

recheck

least

drain

the

so

and

remain

edge

is

oil

filter

-

or

oil

if

oil

machine

but

should

tight

to

on

oil

in

plug

of

the

Each

of

shank,

on

shank

which

the

needle

and

is

To

sample

needle,

packages.

110/044”.

covered

are

available,

satisfactory

their

NEEDLE

154

description,

TYPE

GAS

needle

point,

eye.

given

have

by

shank,

orders

A

complete

The

this

results.

both

has

length,

denotes

Collectively,

label

the

on

promptly

the

type

or

order

type

numbers

catalog

the

but

and

Round

blade,

groove,

chromium

groove,

are

ones

The

the

a

type

the

type

all

of

and

size

and

would

the

of

given

indicated

number

type

sizes

DESCRIPTION

shank,

standard

struck

plated.

NEEDLES

size

and

finish

largest

size

and

needles

accurately

number

as

read

needles

the

in

are

of

available

round

point,

length,

groove,

number.

other

and

diameter

number

packaged

filled,

should

follows:

recommended

machine

those

the

recommended

are

curved

single

spotted,

type

The

details.

blade,

of

represents

and

forward

given.

be

“1000

for

style

description.

recommended

listed

below:

sold

Needles,

each

needles,

number

size

The

measured

the

Union

by

empty

the

See

description

style

to

produce

SIZES

055/022,

070/027,

080/032,

100/040,

125/049,

150/060.

denotes

the

number,

midway

complete

symbol,

Special.

package,

Type

of

Other

the

154

machine

needles

most

together

AVAILABLE

065/025,

075/029,

090/036,

110/044,

140/054,

kind

stamped

between

a

on

GAS,

with

Size

154

GDS

Slabbed

(1.52mm)

standard

struck

shank,

double

length,

groove,

round

slab,

double

spotted,

point,

curved

.060

blade,

groove,

chromium

6

inch

plated.

070/027,

080/032,

075/029,

090/036.

Page 7

NEEDLES

(Continued)

NEEDLE

154

162

TYPE

GFS

SAS

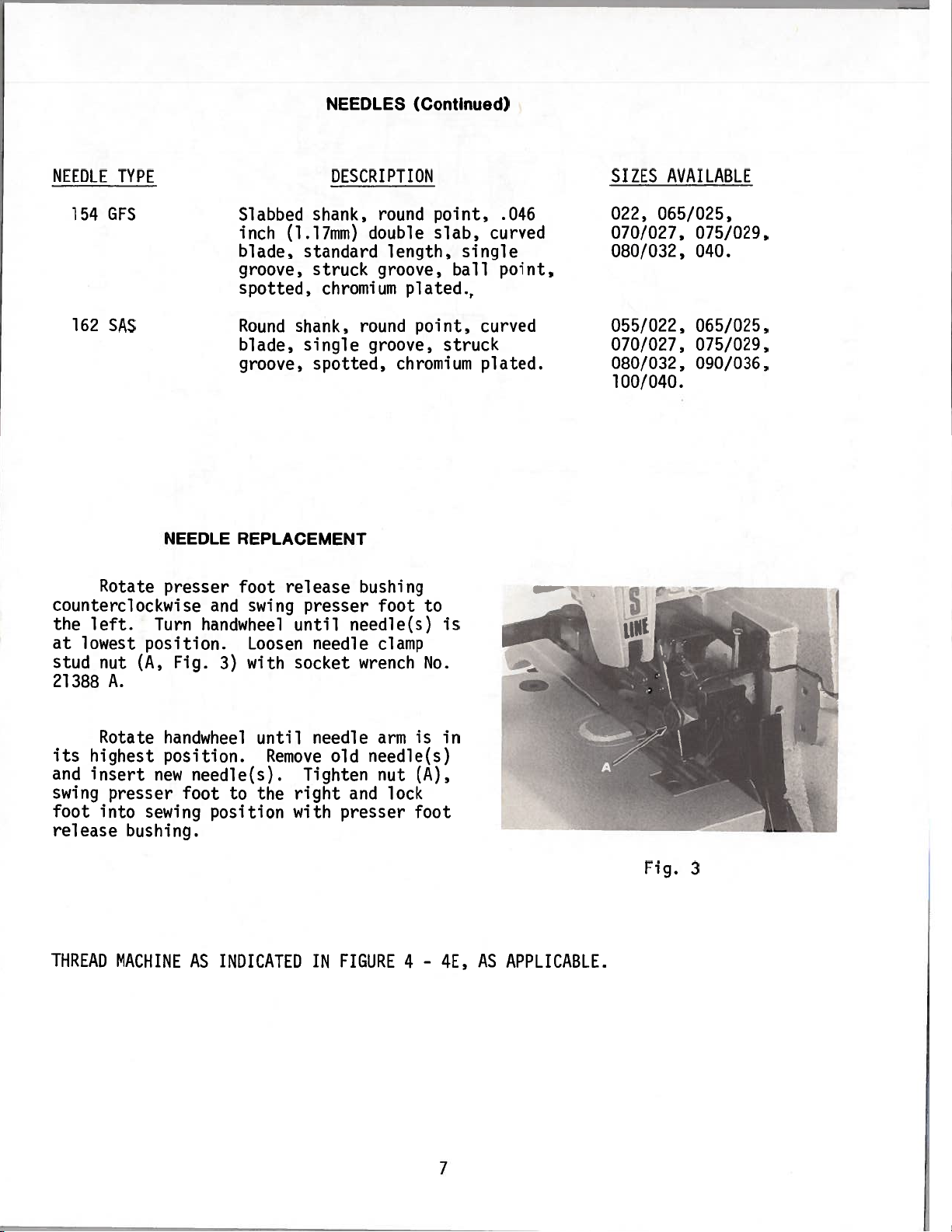

Rotate

NEEDLE

presser

counterclockwise

the

at

lowest

stud

21388

left.

nut

A.

Turn

position.

(A,

and

handwheel

Fig.

Slabbed

inch

blade,

(1.17mm)

standard

groove,

spotted,

Round

blade,

shank,

single

groove,

REPLACEMENT

foot

swing

release

presser

until

Loosen

3)

with

socket

DESCRIPTION

shank,

round

double

length,

struck

groove,

chromium

round

groove,

spotted,

chromium

bushing

foot

needle(s)

needle

clamp

wrench

point,

slab,

plated.,

point,

struck

to

is

No.

single

ball

.046

curved

point,

curved

plated.

SIZES

022,

070/027,

080/032,

055/022,

070/027,

080/032,

065/025,

100/040.

AVAILABLE

075/029,

040.

065/025,

075/029,

090/036,

Rotate

its

highest

and

insert

swing

foot

presser

into

release

THREAD

handwheel

position.

new

foot

sewing

bushing.

MACHINE

needle(s).

to

position

AS

INDICATED

until

Remove

right

the

with

needle

old

Tighten

presser

FIGURE

IN

arm

needle(s)

nut

and

lock

4

is

(A),

foot

-

in

4E,

7

AS

APPLICABLE.

Fig.

3

Page 8

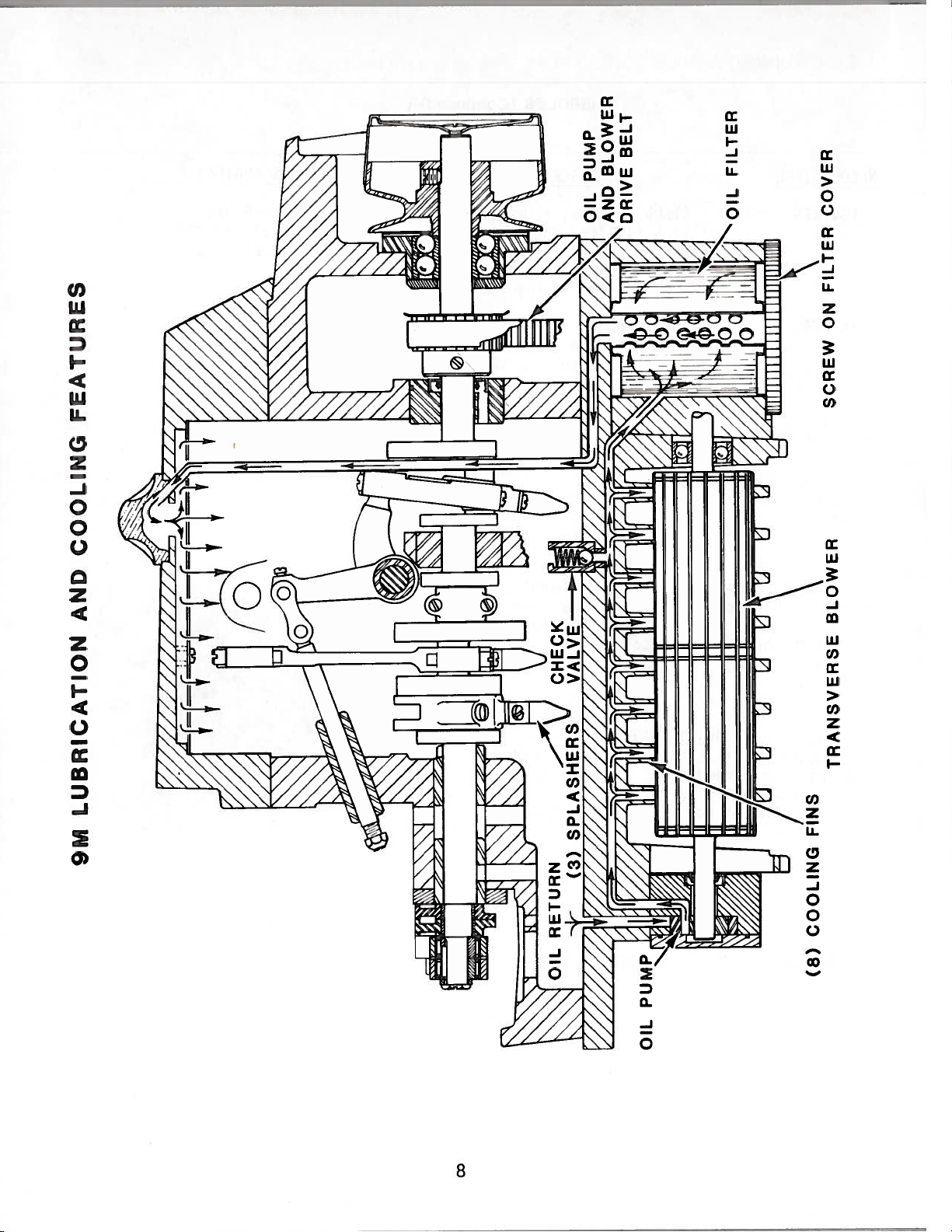

BELT

BLOWER

PUMP

FILTER

FEATURES

COOLING

AND

OIL

AND

DRIVE

OIL

COVER

FILTER

ON

SCREW

B

LUBRICATION

9M

TRANSVERSE

FINS

COOLING

(8)

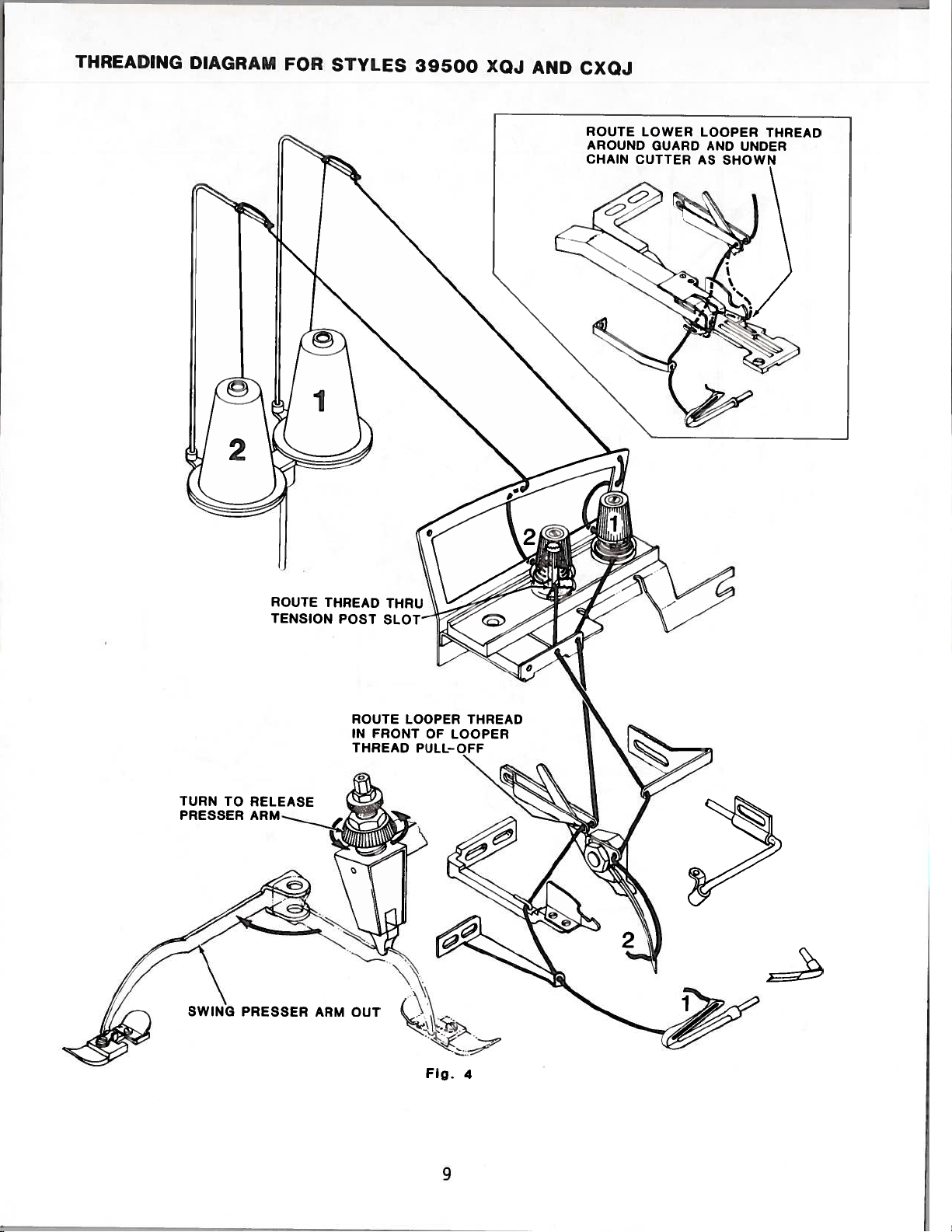

Page 9

-.

THREADING

DIAGRAM

FOR

STYLES

39500

XOJ

AND

CXOJ

ROUTE

AROUND

CHAIN

LOWER

GUARD

CUTTER

LOOPER

AND

AS

SHOWN

THREAD

UNDER

TURN

PRESSER

SWING

TO

PRESSER

ROUTE

TENSION

RELEASE

THREAD

POST

ARM

ROUTE

FRONT

IN

THREAD

OUT

LOOPER

OF

PULL-OFF

THREAD

LOOPER

Fig.

4

9

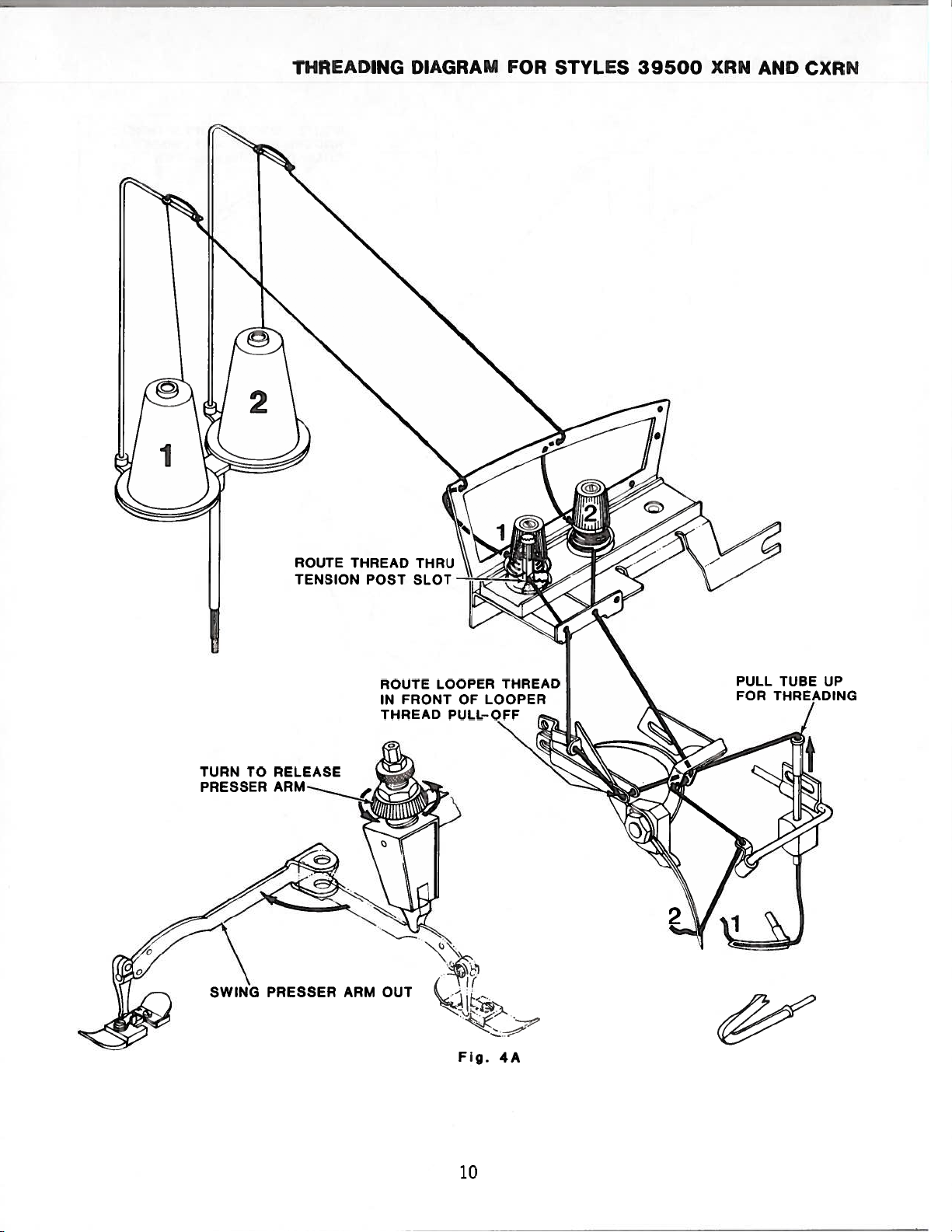

Page 10

THREADING

DIAGRAM

FOR

STYLES

39500

XRN

AND

CXRN

TURN TO

PRESSER

ROUTE

TENSION

RELEASE

PRESSER

THREAD

POST

ARM

SLOT

ROUTE

FRONT

IN

THREAD

OUT

LOOPER

OF

PULL-OFF

THREAD

LOOPER

PULL

TUBE

UP

Fig.

4A

10

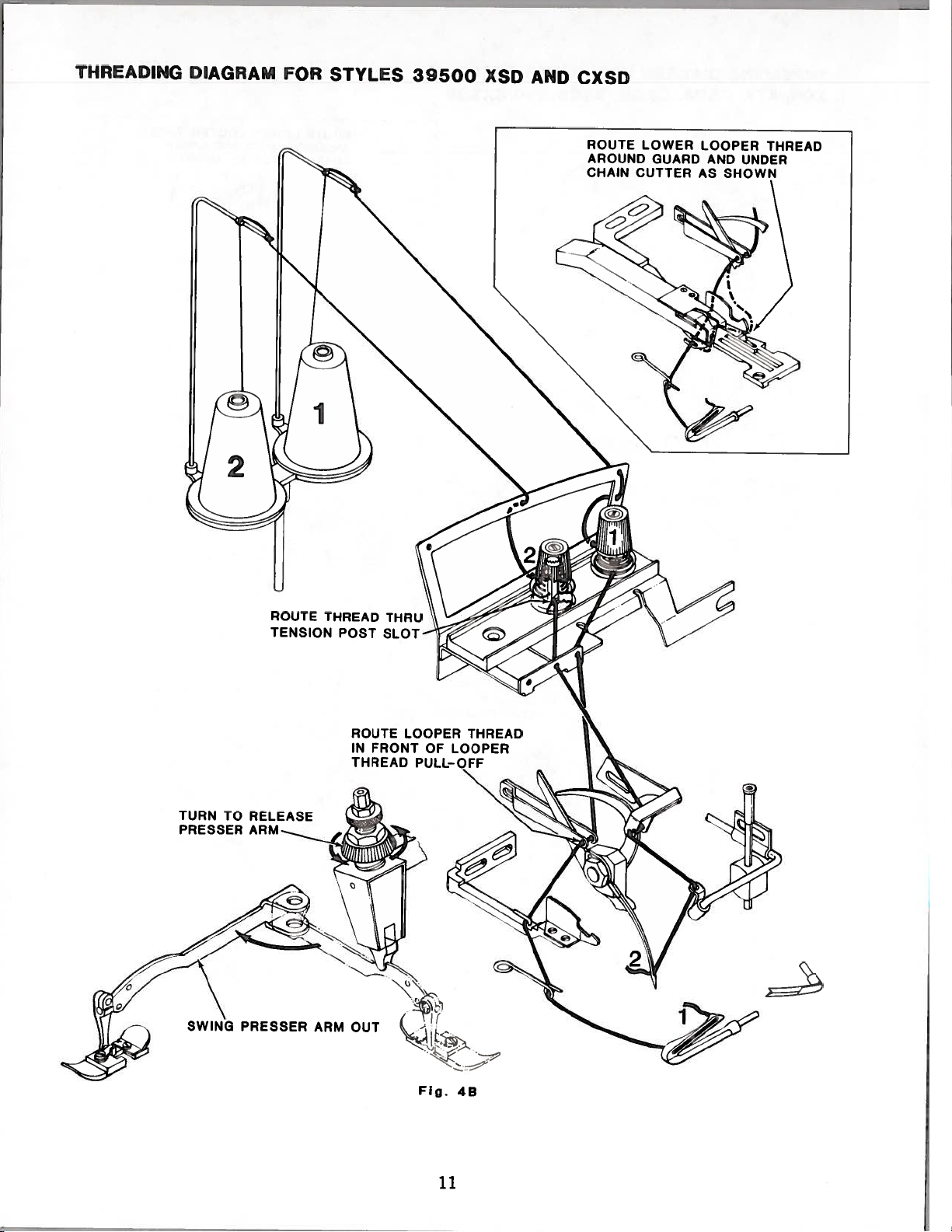

Page 11

THREADING

DIAGRAM

FOR

STYLES

39500

XSD

AND

CXSD

ROUTE

AROUND

CHAIN

LOWER

GUARD

CUTTER

LOOPER

AND

AS

SHOWN

THREAD

UNDER

TURN

PRESSER

TO

PRESSER

ROUTE

TENSION

RELEASE

THREAD

POST

ARM

SLOT

ROUTE

IN

FRONT

THREAD

OUT

LOOPER

OF

PULL-OFF

THREAD

LOOPER

Fig.

48

11

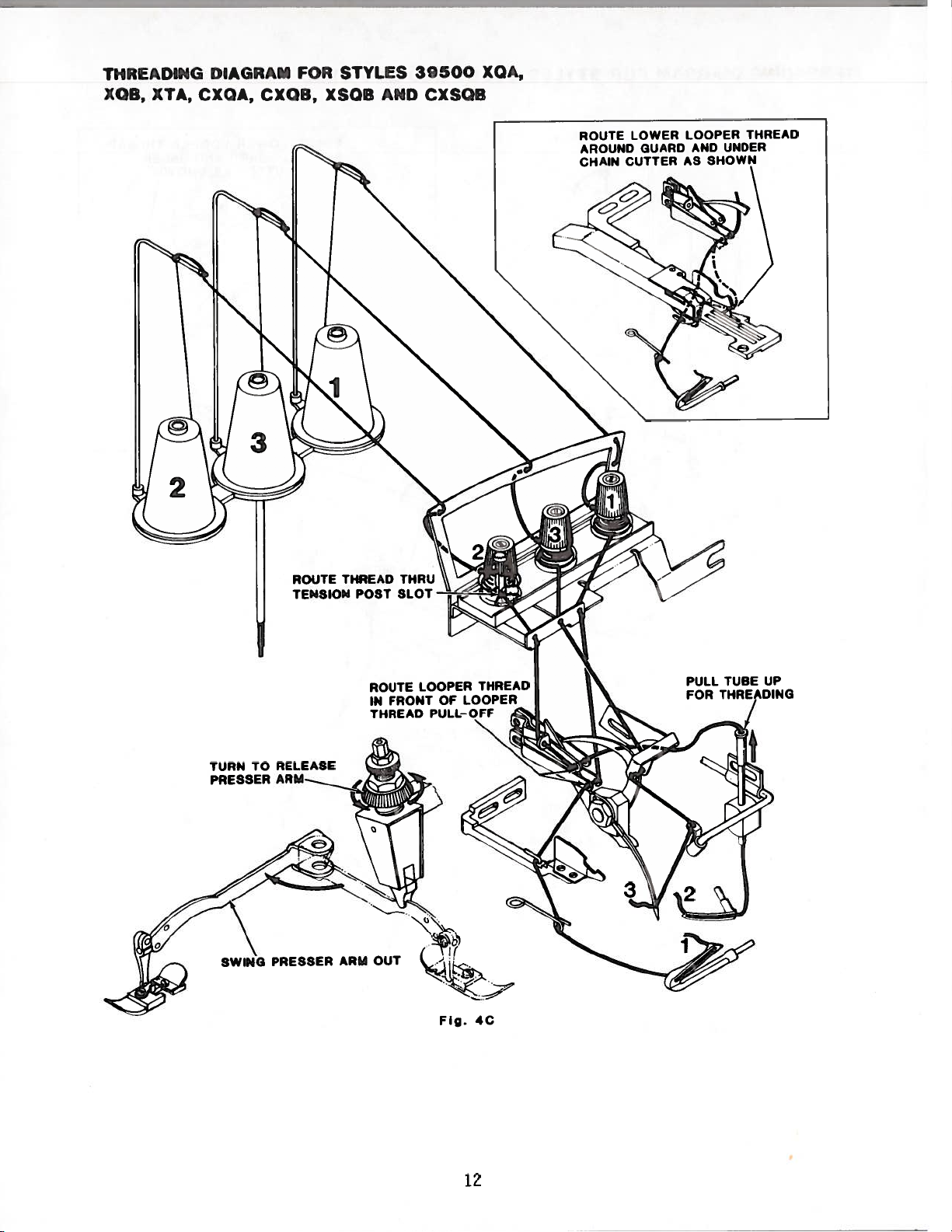

Page 12

I

THREADING

XQB,

XTA,

DIAGRAM

CXQA,

FOR

CXQB,

STYLES

XSQB

AND

39500

CXSOB

XQA,

TURN

PRESSER

TO

ROUTE

TENSION

RELEASE

AR

THREAD

POST

ROUTE

IN

THREAD

SLOT

FRONT

LOOPER

OF

PULL-OFF

Fig.

THREAD

LOOPER

4C

PULL

FOR

UP

TUBE

THREADING

12

Page 13

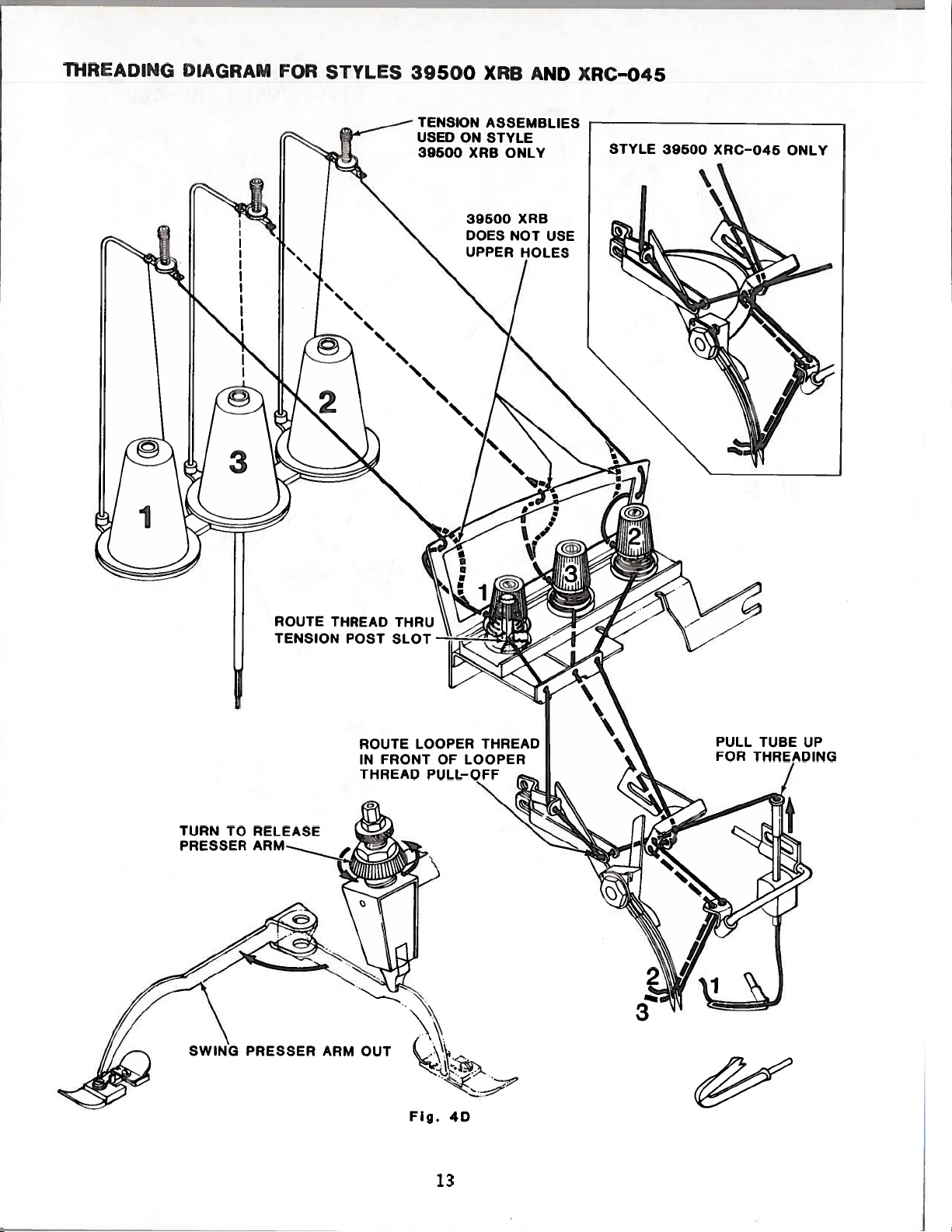

ThREADING

DIAGRAM

FOR

STYLES

39500

XRB

AND

XRC-045

TENSION

USED

39500

ASSEMBLIES

ON

STYLE

XRB

39500

DOES

UPPER

ONLY

XRB

NOT

HOLES

USE

STYLE

39500

XRC-045

ONLY

TURN

PRESSER

TO

PRESSER

ROUTE

TENSION

RELEASE

THREAD

POST

ARM

THRU

SLOT

ROUTE

FRONT

IN

THREAD

OUT

LOOPER

OF

PULL-OFF

THREAD

LOOPER

UP

Fig.

40

13

Page 14

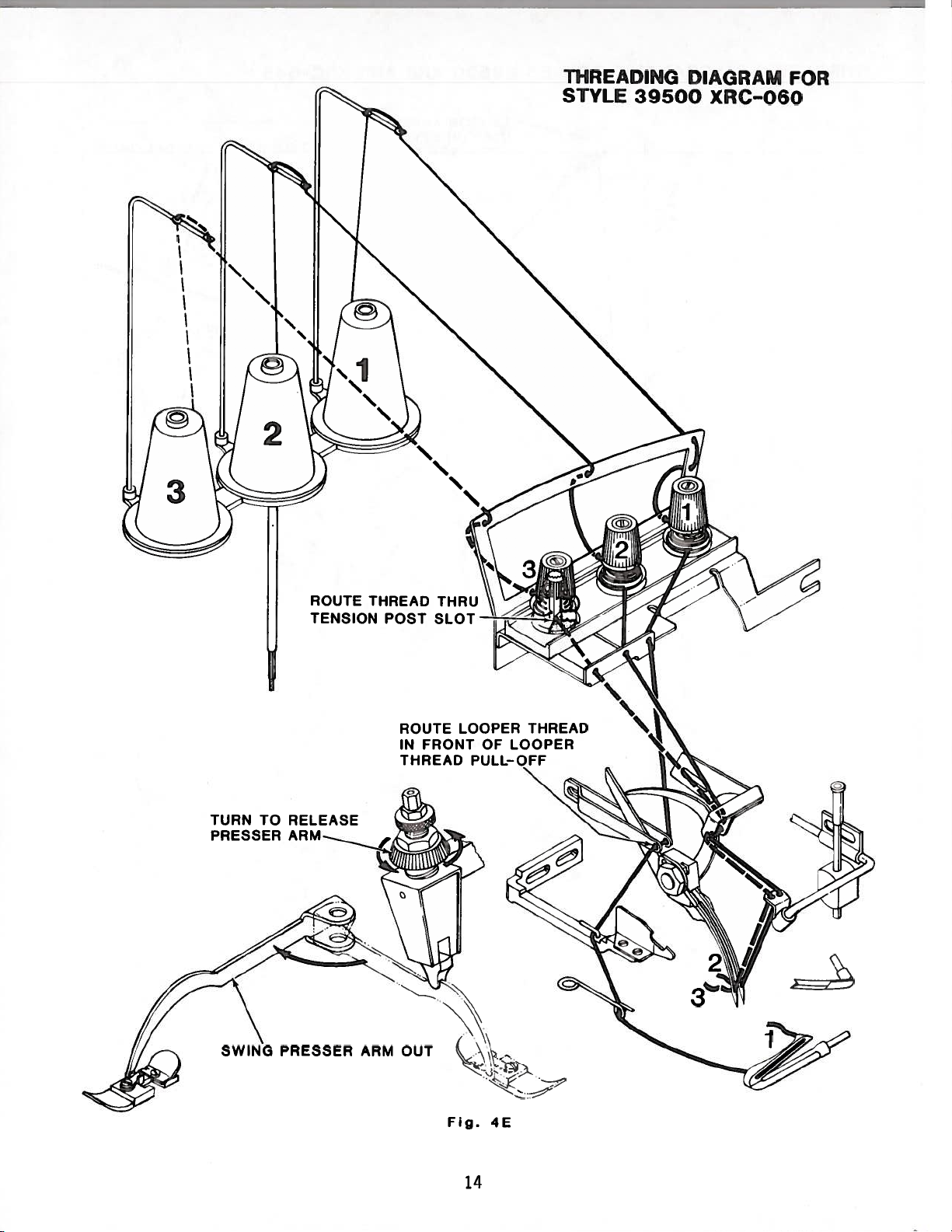

THREADING

STYLE

39500

DIAGRAM

XRC-060

FOR

TURN

PRESSER

SWING

TO

PRESSER

ROUTE

TENSION

RELEASE

ARM

THREAD

POST

ARM

SLOT

ROUTE

IN

FRONT

THREAD

OUT

LOOPER

OF

PULL-OFF

THREAD

LOOPER

Fig.

4E

14

Page 15

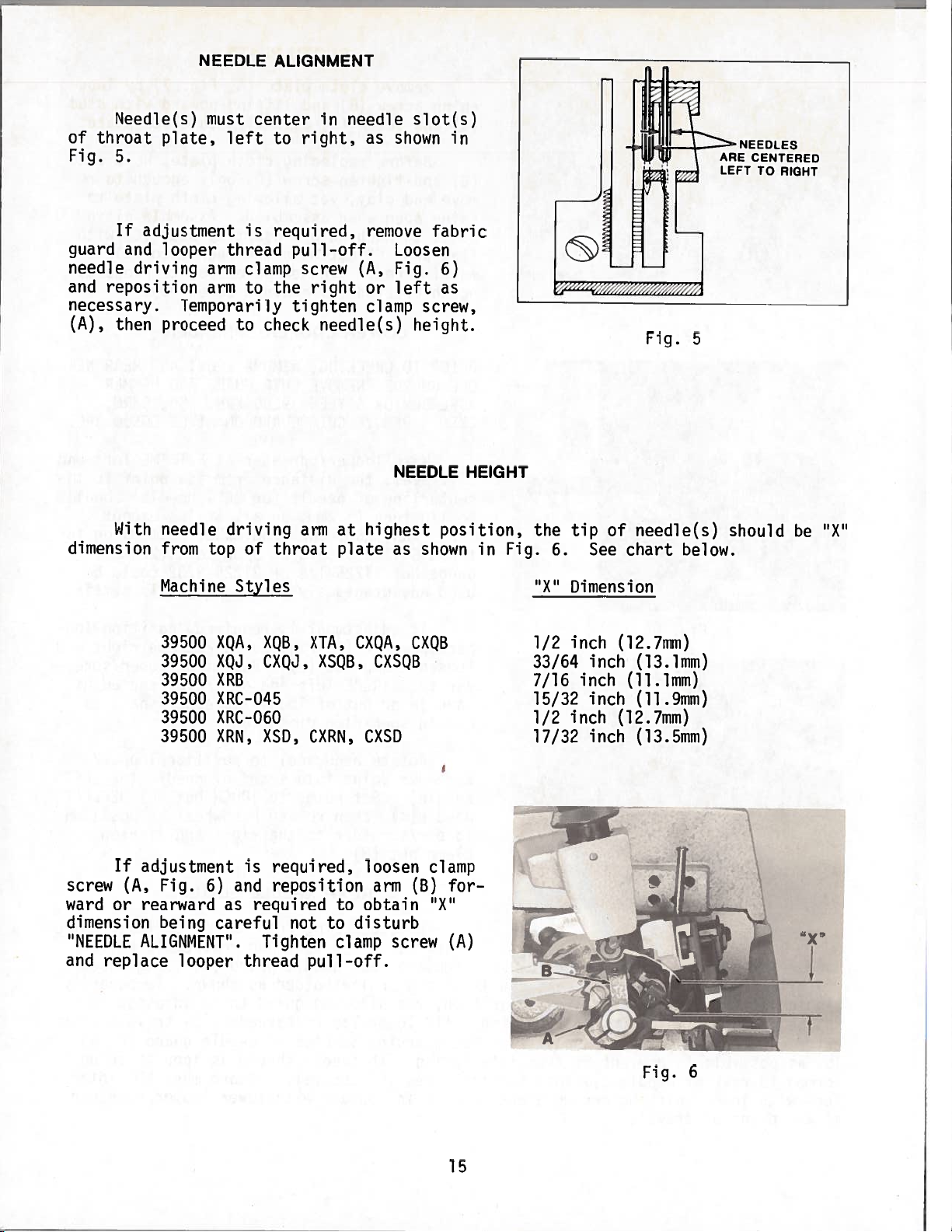

NEEDLE

ALIGNMENT

Needle(s)

of

throat

Fig.

guard

needle

and

necessary.

(A),

5.

If

and

reposition

then

With

dimension

plate,

adjustment

looper

driving

Temporarily

proceed

needle

from

must

left

thread

arm

arm

driving

top

center

is

clamp

to

to

of

right,

to

required,

pull-off.

screw

the

tighten

check

arm

throat

in

needle

right

needle(s)

at

plate

slot(s)

as

shown

remove

(A,

or

clamp

highest

fabric

Loosen

Fig.

NEEDLE HEIGHT

left

6)

as

screw,

height.

position,

as

shown

in

in

Fig.

the

6.

tip

See

needle(s)

of

chart

Fig.

5

below.

NEEDLES

ARE

LEFT

should

CENTERED

TO

RIGHT

be

“X”

If

screw

ward

dimension

“NEEDLE

and

(A,

or

replace

Machine

39500

39500

39500

39500

39500

39500

adjustment

Fig.

rearward

being

ALIGNMENT”.

looper

Styles

XQA,

XQJ,

X

RB

XRC-045

XRC-060

XRN,

and

6)

as

careful

XQB,

CXQJ,

XSD,

required,

is

reposition

required

Tighten

thread

XTA,

CXRN,

not

pull-off.

XSQB,

to

to

disturb

clamp

CXQA,

CXSQB

CXSD

loosen

arm

obtain

screw

CXQB

clamp

(B)

“X”

for—

(A)

“X”

1/2

33/64

7/16

15/32

1/2

17/32

——1

Dimension

inch

inch

inch

inch

(12.7mm)

(13.1mm)

(11.1mm)

(11

(12.7mm)

(13.5mm)

inch

inch

.9mm)

.4

15

Fig.

6

Page 16

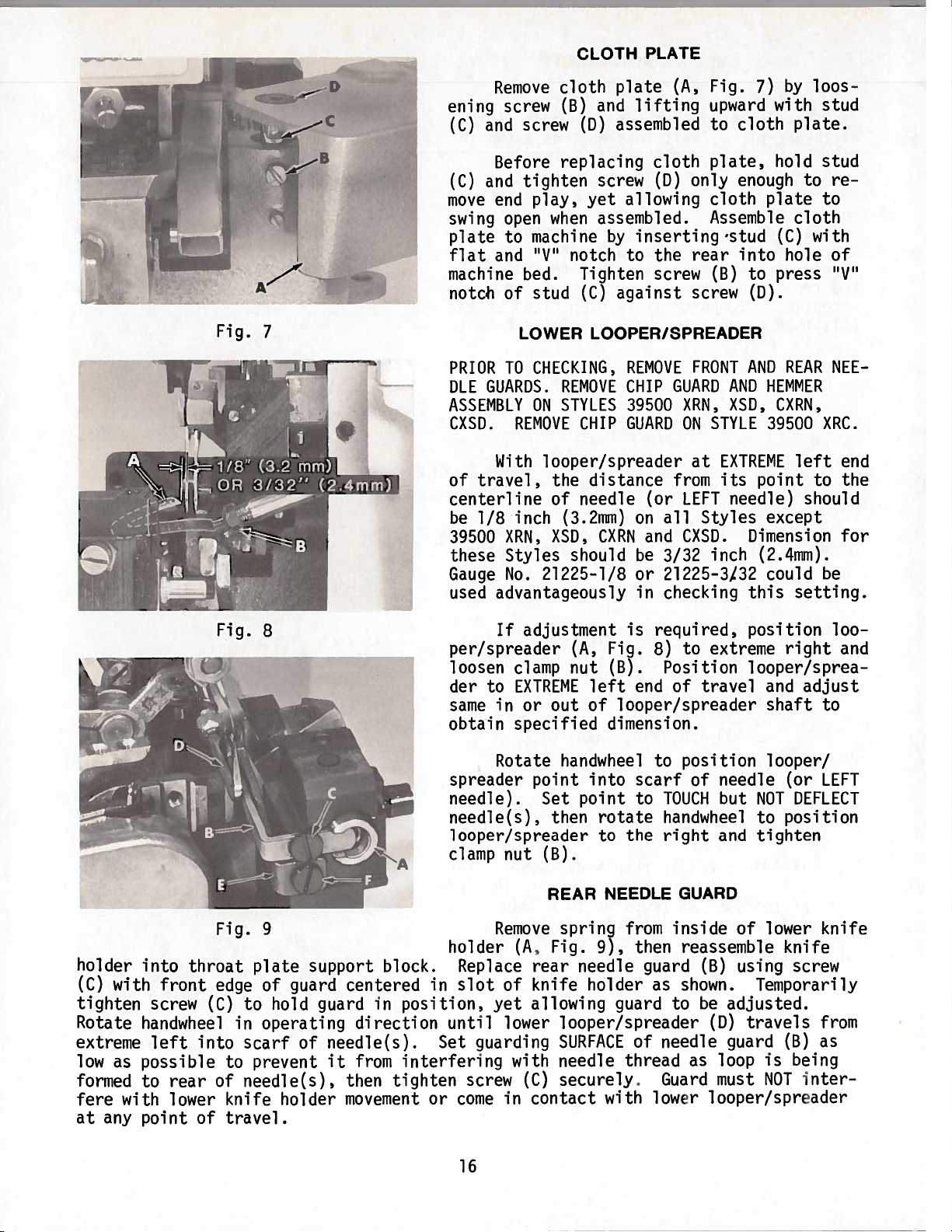

CLOTH

PLATE

Fig.

Fig.

Remove

C

B

(C)

(C)

move

swing

plate

ening

flat

machine

notch

7

PRIOR

DLE

screw

and

Before

and

end

open

to

and

of stud

TO

GUARDS.

ASSEMBLY

CXSD.

With

of

travel,

centerline

be

1/8

39500

these

Gauge

used

XRN,

Styles

No.

advantageously

cloth

(B)

screw

CD)

replacing

tighten

play,

when

machine

“V’

notch

bed.

Tighten

(C)

LOWER

CHECKING,

REMOVE

STYLES

ON

REMOVE

CHIP

looper/spreader

the

of

needle

inch

(3.2mm)

XSD,

should

21225-1/8

plate

and

assembled

screw

allowing

yet

assembled.

by

to

against

LOOPER/SPREADER

REMOVE

CHIP

39500

GUARD

distance

CXRN

(A,

lifting

cloth

(D)

inserting

the

screw

GUARD

XRN,

ON

from

(or

LEFT

all

on

and

CXSD.

be

3/32

21225—3/32

or

in

checking

upward

to

plate,

only

cloth

Assemble

‘stud

rear

(B)

screw

FRONT

AND

XSD,

STYLE

at

EXTREME

its

needle)

Styles

inch

cloth

enough

by

7)

with

plate.

hold

plate

cloth

(C)

into

hole

press

to

(D).

REAR

AND

HEMMER

CXRN,

39500

left

point

except

Dimension

(2.4mm).

could

this

setting.

loos

stud

stud

to

re

to

with

of

“V’

NEE

XRC.

to

should

be

end

the

for

holder

with

(C)

tighten

Rotate

extreme

low

as

formed

fere

at

any

into

front

screw

handwheel

left

possible

to

with

point

throat

rear

lower

of

(C)

into

Fig.

Fig.

edge

to

in

scarf

to

of

needle(s),

knife

travel.

8

9

plate

of

guard

hold

operating

of

prevent

holder

support

centered

guard

needle(s).

it

then

movement

block.

position,

in

direction

from

interfering

tighten

If

per/spreader

loosen

der to

in

same

obtain

Rotate

spreader

needle).

needle(s),

looper/spreader

clamp

nut

Remove

holder

Replace

in

slot

of

yet

until

Set

lower

guarding

screw

come

in

or

adjustment

(A,

clamp

nut

EXTREME

or

out of

specified

handwheel

point

Set

then

(B).

REAR

spring

Fig.

(A,

rear

needle

knife

allowing

looper/spreader

SURFACE

with

(C)

needle

securely.

contact

is

Fig.

(B).

left

end

looper/spreader

dimension.

into

scarf

point

to

rotate

the

to

NEEDLE

from

then

9),

holder

guard

of needle

thread

with

required,

to

8)

Position

of

to

position

TOUCH

handwheel

right

GUARD

inside

reassemble

guard

as

shown.

to

as

Guard

lower

position

extreme

looper/sprea

travel

and

shaft

looper/

needle

of

but

NOT

to

and

tighten

of

lower

using

(B)

Temporarily

be

adjusted.

(D)

travels

guard

loop

must

is

NOT

looper/spreader

loo

right

adjust

to

LEFT

(or

DEFLECT

position

knife

knife

screw

from

as

(B)

being

inter

and

16

Page 17

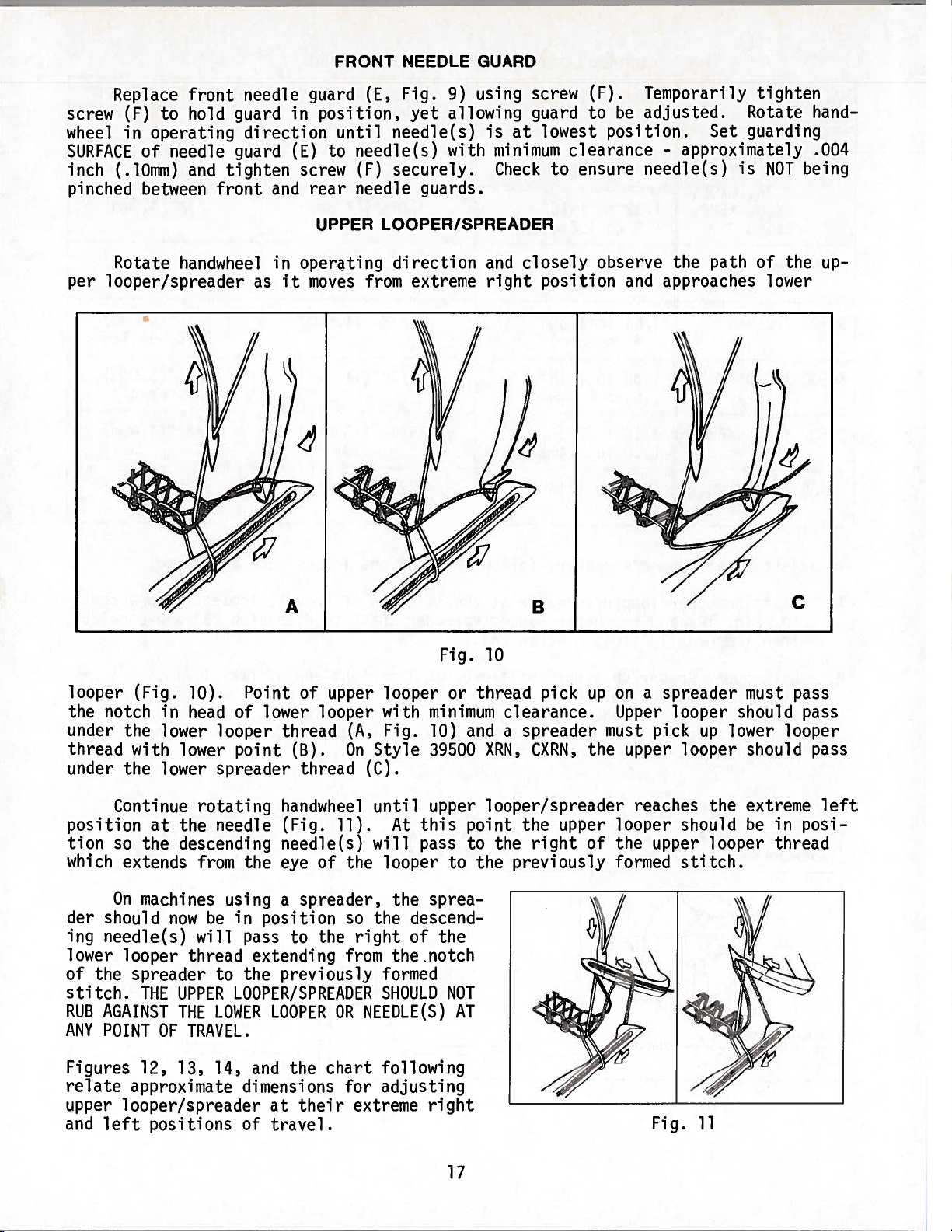

FRONT

NEEDLE

GUARD

Replace

screw

wheel

(F)

in

SURFACE

inch

(.10mm)

pinched

Rotate

per

looper/spreader

front

to

hold

operating

needle

of

and

between

handwheel

guard

guard

tighten

front

needle

in

direction

CE)

and

in

as

it

guard

position,

until

needle(s)

to

screw

rear

needle

UPPER

operating

moves

Fig.

yet

9)

allowing

(E,

needle(s)

with

(F)

securely.

guards.

LOOPER/SPREADER

direction

from

extreme

using

is

at

minimum

Check

and

right

screw

guard

lowest

to

closely

position

(F).

to

be

position.

clearance

ensure

observe

Temporarily

adjusted.

-

approximately

needle(s)

the

and

approaches

tighten

Rotate

Set guarding

is

NOT

path

of the

lower

hand-

.004

being

up

looper

the

notch

under

thread

under

position

tion

which

der

should

ing

needle(s)

lower

of

the

stitch.

RUB

AGAINST

ANY

POINT

(Fig.

in

the

lower

with

the

lower

Continue

at

so

the

extends

On

machines

looper

spreader

THE

OF

10).

head

looper

lower

spreader

rotating

the

needle

descending

from

using

now

be

will

thread

to

UPPER

THE

LOWER

TRAVEL.

Point

of

lower

thread

point

handwheel

needle(s)

eye

the

a

in

position

pass

extending

the

previously

LOOPER/SPREADER

of

looper

(B).

thread

(Fig.

of the

spreader,

the

to

upper

(A,

On

11).

so

right

from

looper

with

Fig.

Style

(C).

until

will

looper

the

formed

SHOULD

LOOPERORNEEDLE(S)

Fig.

minimum

10)

39500

upper

this

At

pass

sprea

the

descend

the

of

the.notch

10

or

thread

clearance.

andaspreader

XRN,

looper/spreader

point

to

to

the

the

the

previously

NOT

AT

B

pick

CXRN,

upper

right

up

onaspreader

Upper

must

the

pick

upper

reaches

looper

the

of

upper

formed

looper

up

looper

should

stitch.

should

lower

the

looper

must

looper

should

extreme

in

be

thread

C

pass

pass

pass

left

posi

Figures

relate

upper

and

left

12,

13,

14,

approximate

looper/spreader

positions

and

dimensions

at

of

travel.

the

their

chart

for

following

adjusting

extreme

right

17

Fig.

11

Page 18

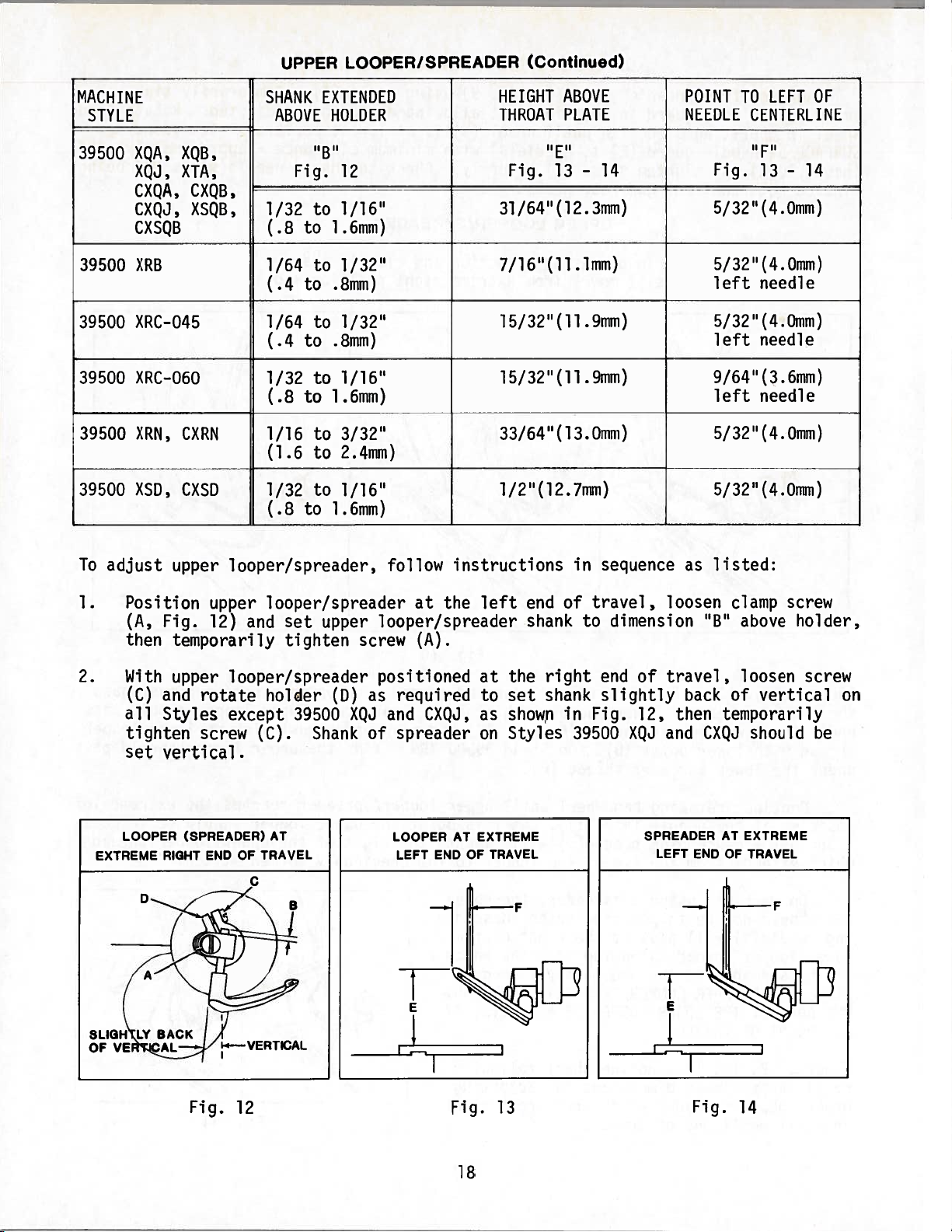

UPPER

LOOPER/SPREADER

(Continued)

MACHINE

STYLE

39500

XQA,

XQJ,

CXQA,

CXQJ,

CXSQB

39500

39500

39500

39500

39500

XRB

XRC—O45

XRC-06O

XRN,

XSD,

XQB,

XTA,

CXQB,

XSQB,

CXRN

CXSD

SHANK

ABOVE

“Bt’

Fig.

to

1/32

to

(.8

to

1/64

to

(.4

to

1/64

to

(.4

to

1/32

to

(.8

to

1/16

(1.6

to

1/32

to

to

(.8

EXTENDED

HOLDER

12

1/16”

1.6mm)

1/32”

.8mm)

1/32”

.8mm)

1/16”

1.6mm)

3/32”

2.4mm)

1/16”

1.6mm)

HEIGHT

THROAT

Fig.

31/64(12.3mm)

ABOVE

PLATE

“E”

13

-

7/16(11.1mm)

15/32(11.9mm)

15/32(11.9mm)

33/64(13.0mm)

l/2”(12.7mm)

14

POINT

NEEDLE

Fig.

5/32(4.0mm)

5/32(4.0mm)

left

5/32(4.0mm)

left

9/64(3.6mm)

left

5/32(4.0mm)

5/32(4.0mm)

OF

LEFT

TO

CENTERLINE

“F”

13-14

needle

needle

needle

To

adjust

1.

2.

EXTREME

Position

(A,

then

With

(C)

and

all

Styles

tighten

set

vertical.

LOOPER

RIGHT

upper

upper

Fig.

12)

temporarily

upper

rotate

screw

(SPREADER)

END

looper/spreader,

looper/spreader

and

set

upper

tighten

looper/spreader

holder

(C).

AT

TRAVEL

C

39500

Shank

except

OF

looper/spreader

screw

positioned

as

(D)

XQJ

of

follow

at

(A).

required

CXQJ,

and

spreader

LOOPER

LEFT

instructions

the

left

at

to

as

on

EXTREME

AT

OF

END

the

set

shown

Styles

TRAVEL

end

shank

right

shank

in

of

to

in

39500

sequence

travel,

dimension

end

slightly

Fig.

XQJ

of

12,

as

loosen

travel,

back

then

and

listed:

clamp

“B”

above

loosen

of

temporarily

CXQJ

should

screw

holder,

vertical

screw

on

be

Fig.

12

Fig.

13

18

Fig.

14

Page 19

UPPER

LOOPER/SPREADER

(Continued)

6.

4.

5.

3.

Rotate

the

LOWER

er

should

Fig.

See

Continue

is

at

extreme

quired

POINT

With

of

upper

necessary

of

looper

Fig.

14,

en

screw

If

the

the

needle(s)

above

ly

holder

reduce

spreader

the

looper/spreader

handwheel

looper.

be

set

10.

to

rotate

to

position

upper

looper/spreader

to

move

dimension

which

Fig.

(C,

needle(s)

(dimension

the

to

lower

in

The

to

handwheel

LEF7

end

POINT

spreader

looper/spreader

is

to

12),

is

being

can

be

angle

of

looper,

closer

operating

POINT

enter

of

of

to

“F”,

Fig.

the

left

then

increased

“B”),

the

direction

of

the

notched

in

travel.

upper

dimension

still

13

of

screw

deflected

by

See

shank

See

Step

to

the

upper

operating

Rotate

looper

“E”,

positioned

holder

LOWER

or

centerline

(A)

by

reducing

Step

back

3.

needle(s).

bringing

looper

area

direction

upper

to

Fig.

in

POINT

securely.

the

1.

of

vertical,

Reversing

THREAD

or

behind

looper/spreader

dimension

14

at

left

out

or

of

needle

of

upper

the

length

It

will

the

upper

looper/spreader

PICK-UP

the

head

of

until

froni

end

of

“E”,

top

its

of

upper

Fig.

of

travel,

shaft

spreader

left

(or

looper/spreader,

of

looper/spreader

then

See

this

be

necessary

Step

procedure

of

the

looper/spreader

holder

13

throat

to

dimension

needle).

clearance

2.

Set

will

upper

lower

or

it

set

to

looper/

position

spread

looper,

as

LOWER

plate.

may

POINT

“F”,

Tight

shank

slight

into

re

be

to

ASSEMBLE

AND

THROAT

Rotate

until

teeth

surface

level

feeds

teeth

with

at

should

(1.2mm)

15.

If

screw

as

screws

as

(A)

required

(C)

shown

On

tion,

throat

loosen

plate,

MAIN

MAIN,

PLATE

handwheel

of

of

throat

throat

highest

extend

above

throat

adjustment

and

rotate

to

and

Fig.

in

all

Styles

screw

then

AND

DIFFERENTIAL

DIFFERENTIAL,

TO

MACHINE,

in

operating

rising

position

plate.

plate

feeds

The

at

of

approximately

plate

is

required,

tilt

adjusting

level

adjust

15,

feeds,

then

fitted

CD)

feeds

tighten

with

and

tighten

CHAINING

AS

are

feeds

this

travel,

as

shown

then

or

up

separate

set

height

screw

FEEDS

FEEDS

APPLICABLE.

direction

above

the

top

should

time.

With

their

in

pin

inch

Fig.

lock

(B)

to

lock

obtain

(C).

3/64

loosen

tighten

down

screws

chaining

of

chaining

(D).

be

screw

proper

feeds,

feed

(A).

height

with

even

Fig.

Loosen

feeds

with

15

feed

above

the

throat

at

stitch

attaching

highest

plate

posi

tongue

of

19

Page 20

LOWER

KNIFE

Holder

slot

screw

cutting

check

ial.

MUST

of

knife

(F)

and

edge

Adjust

adjustment,

Readjust

Fig.

niove

holder.

set

of

knife.

UPPER

if

16

freely,

knife

KNIFE:

by

measuring

necessary,

left

Adjust

to

Hold

then

to

knife

specified

knife

sew-off

the

obtain

to

right,

(A),

seam

in

this

onapiece of

distance

specified

INSERT

AND

ASSEMBLE

be

even

throat

ified

ment

knife

is

flush

tighten

loosen

rear

to

and

NOT

left

width

position

from

SPRING

Cutting

and

plate.

seam

is

required,

A)

with

screw

If

cutting

screw

as

bind

right,

to

by

needle

seam

BACK

HOLDER

edge

parallel

Examine

width

or

up

top

(B).

(C)

required,

with

measuring

and

selected

width

INTO

TO

knife

of

with

and

appearance.

loosen

down

edge

of

and

until

throat

of

rotate

then

needle

loosening

by

from

tighten

material

penetration

or

LOWER

THROAT

KNIFE

PLATE

(A,

top

surface

sewn

sampe

screw

its

plate,

knife

is

holder

tighten

guard

locknut

center

screw

(F).

to

to

appearance..

Fig.

for

If

(B)

and

cutting

then

tilted,

(D)

screw

centered

of

further

edge

HOLDER

SUPPORT.

must

16)

of

spec

adjust

adjust

edge

front

(C).

in

(E),

needle

of

mater

to

NOTE:

REMOVE

ARM.

ALSO

At

inch

1/32

rotate

knife

against

upper

knife,

Assemble

chain

edge,

move

guard

then

freely

tightening

NOTE:

See

shear

NEEDLE(S)

RE-ASSEMBLE

lowest

(.4

handwheel

(G,

Fig.

lower

knife

then

cutting

tighten

(L)

tighten

left

screw

Locking

also

angle

AND

position

-

.8mm)

to

16)

knife,

knife

against

to

(F)

serves

adjustment

RE-ASSEMBLE

UPPER

the

below

position

at

lowest

adjust

edge

1/64

screw

clamp

top

(M).

nut

right.

against

nut

(E)

as

must

a

front

cutting

knife

(J).

(K)

surface

If

latch

UPPER

KNIFE

upper

position

-

1/32

and

Loosen

desired,

knife

be

pin

UPPER

KNIFE

HOLDER

IN

tip

of

edge

knife

of

holder

inch

chain

of

upper

screw

holder.

tightened

for

upper

of

driving

travel

(H)

(.4

guard

(F)

the

cloth

KNIFE

HOLDER

AND

knife

lower

left

-

(L)

knife

to

lower

hold

to

plate.

HOLD

knife.

arm

and

to

.8mm)

in

and

enable

knife

INTO SLOT

KNIFE

cutting

If

lowest

at

while

holding

right,

below

position

slightly

spring

can

screw

(F)

OF

UPPER

FIRMLY

edge

adjustment

position;

to

position

cutting

using

back

pressed

be

locked

in

position;

IN

must

upper

edge

nut

of

KNIFE

DRIVING

POSITION.

extend

is

required,

with

knife

front

of

lower

(M).

its

cutting

lower

in

knife

position

screw

1/64

upper

firmly

tip

Set

(F)

-

of

to

by

20

Page 21

SHEAR

BE

SURE

ADJUSTED

SHEAR

ANGLE.

ANGLE

LOWER

AND

PROPERLY

ADJUSTMENT

UPPER

BEFORE

KNIVES

SETTING

ARE

With

position,

between

lower

in

Fig.

lent

to

er

gauge

sults

are

properly

adjusting.

If

adjustment

throat

and

lock

away

from

screw

guide

ed

to

attain

(E)

in

clamping

lower

tighten

cutting

knives

17.

a

at

are

plate,

lower

(C),

plate

angle

proper

position

screw

knife

locknut

upper

the

knife

proper

edge

is

1

Approximately

.003

inch

this

obtained

sharpened

in

loosen

knife

upper

clamp

(E)

top

knife

screw

forward

front

shear

while

(D).

holder

(A)

PRESSER

at

shear

of

degree

(.076mm)

point.

if

both

required,

locknut

holder

with

edge

angle.

tightening

Loosen

to

float

and

FOOT

lowest

angle

upper

as

shown

equiva

Best

knives

prior

remove

out

screw

(D)

and

or

rearward

of

Hold

screw

left

replace

ALIGNMENT

and

feel

re

to

(A)

adjust

lower

of

(B).

guide

screw

(B)

to

throat

position

Loosen

(wedge)

as

requir

knife

plate

(C)

allowing

right,

plate.

to

and

Fig.

17

LOCK

THE

ROTATE

POSITION.

Right

with

left

as

shown

must

lie

stitch

stitch

18.

foot

clamp

shaft

of

(A,

If

in

Fig.

screw

(D)

presser

needle

Point

Fig.

(E)

A,

19)

so

mediate

Fig.

18)

19).

and

throat

39500

ment

XQJ,

of

feeding.

PRESSER

HANDWHEEL

edge

of

edge

Ref.

flat

tongue

tongue

of

Point

on

on

of

adjustment

sewing

19),

position

loosen

(C),

left

slot

Fig.

and

its

lever

foot

in

stop

to

aligns

throat

18.

while

screw

(G),

Plunger

adjust

plate

presser

as

XRB,

stitch

shown

XRC,

foot,

FOOT

UNTIL

presser

needle

A,

throat

presser

throat

is

then

right

Tighten

holding

tighten

should

and

IN

SEWING

NEEDLE(S)

slot

Fig.

plate.

foot

plate

required,

by

release

collar

adjust

until

with

plate

collar

lifter

(F)

is

clamp

clear

tongue

in

Fig.

CXQJ;

forward

foot

in

18.

must

as

screws

lifter

the

the

as

against

(C)

18,

-

POSITION

IS

must

throat

Presser

The

adjustable

center

shown

lock

bushing

(B)

lever

right

left

shown

screws

lever

screw

presser

left

then

pivot

a

rearward

AT

LOWEST

align

in

presser

and

edge

in

inter

(C).

to

tighten

type

AND

plate

foot

edge

Ref.

(B,

arm

arm

right,

and

over

Fig.

of

Completely

without

screw

presser

flatness

to

:.

binding.

center

(B).

foot

on

1116’’

unlock

over

On

shank

throat

Fig.

(1.6mm)

Fig.

release

Loosen

stitch

all

Styles

allows

plate

18

19

bushing

screw

tongue

precise

for

(B,

of

except

optimum

(A,

Fig.

adjust

21

Page 22

PRESSER

FOOT

LIFT

Lift

tion.

If

adjustment

presser

Loosen

is

approximately

starts

Sufficient

spring

If

adjustment

differential

and

19)

and

less

pressure,

NOTE:

Lock

and

(N)

screw

(M)

presser

Upper

foot

locknut

to

rise,

pressure

turn

Adjusting

(A).

unlocked.

be

following

presser

adjust

as

to

foot

looper/spreader

is

required,

not

and

1/16

interfere

set

inch

tighten

will

(K)

then

pressure

will

is

adjusting

then

cause

required,

feeds

tighten

are

screw

screw

Plunger

When

held

firmly

adjustment

(P)

in

in

up

Fig.

foot

nut

shown

highest

loosen

stop

(1.6mm)

must

feeds

rotate

positioned

(M)

must

release

against

position

or

19.

must

with

screw

locknut

PRESSER

be

(M)

locknut

will

clear

must

down

Hold

position

contact

not

locknut

upper

(F)

motion

free

(K).

FOOT

maintained

presser

and

handwheel

below

clockwise

(L).

effect

presser

bushing

throat

made.

be

with

so

its

nut

rotate

and

presser

Fig.

(H,

looper/spreader,

upper

on

in

PRESSURE

feed

to

foot

operating

in

throat

more

for

function

the

when

arm

is

locked

plate.

If

pressure

under

(P)

surface

in

position

19)

end

lifter

work

wear

to

plate.

pressure

pressure

in

these

release

handwheel

and

at

adjust

foot

then

lifter

of

lever

uniformly.

prematurely

direction

Loosen

pressure

of

position,

conditions

bushing

is

1/16

and

operating

in

point

any

stop

tighten

lever

before

Excessive

until

locknut

or

counterclockwise

release

release

bushing

presser

do

(A);

inch

tighten

(1.6mm)

capnut

of

screw

locknut

arm

presser

when

both

foot

not

loosen

direc

travel.

(3)

there

so

foot

chaining.

main

Fig.

(L,

bushing

is

must

exist

capnut

above

(N).

50

(H).

for

the

HEMMING

(STYLES

-

I

Loosen

Assemble

knife

the

the

side

guide

be

support

knurled

left

of

tip

slightly

lock

side

the

screw

the

adjusting

right

is

in

to

(A,

hemming

bracket

its

of

feed

this

the

right

GUIDE

39500

Fig.

guide

means

by

screw

is

tip

slot

position,

of

XRN,

20),

support

(C),

even

in

parallel.

SUPPORT

XSD,

then

screw

of

set

with

throat

the

the

front

BRACKET

CXRN,

proceed

bracket

(B,

edge

the

and

or

CXSD)

as

onto

Fig.

guide

parallel

plate.

leading

follows;

the

20).

(D)

to

When

edge

lower

With

so

the

the

that

right

edge

should

L

the

the

20).

the

Fig.

the

tighten

spring;

screw

against

stop

hinge

Under

to

edge

21)

spring

support

is

com

sec

then

then

Fig.

21

-4

This

screw

block

normal

pensate

The

amount

guide

and

adjusting

pin,

and

bracket

urely.

remove

replace

tightened

screw.

set

adjustment

Fig.

(A,

and

edge

conditions,

for

the

of

tip

can

located

Fig.

(E,

If

movement

screw

lock

screw

set

against

can

located

21)

guide

the

differences

movement

be

set

the

screw

in

the

20).

of

(B,

and

pin

be

support

edge

and

removing

by

which

hinge

Replace

the

Fig.

lock

and

riade

towards

bracket

guide

in

pressure

presses

block

edge

21),

screw.

lock

by

is

the

lock

lock

guide

set

screw

positioning

the

front

Fig.

(E,

spring

material

applied

screw

against

edge

and

is

sure

is

and

not

and

tightened

screw

screw

Be

of

loaded

thickness.

to

(B,

guide

required,

set

22

Page 23

FINAL

(STYLES

ADJUSTMENT

39500

XRN,

OF

XSD,

HEMMING

CXRN

AND

GUIDE

CXSD)

Adjust

that

the

fabric.

hanging

(D)

corresponds

Fig.

(C,

per

distance

and

(D).

so

that

vertically.

(ALL

Length

combination

(left)

(rear)

(B)

eccentric

feed

actuates

the

stitches

At

this

guide

21)

Remove

the

tip

SETTING

STYLES

of

of

dog

edge

are

point

(F,

Fig.

with

and

holding

between

lock

the

of

Replace

STITCH

EXCEPT

stitch

eccentrics

feed

(A,

while

differential

guide

(D,

located

re-tighten

so

20)

thickness

the

screw

the

edge

screw

overhanging

lock

Fig.

LENGTH

39500

is

determined

22)

screw

inner

(front)

Fig.

in

that

CD),

guide

(F)

XQJ,

used.

actuates

(right)

the

screw

and

(F)

CXQJ)

feed

20)

folded

space

of

the

now

and

adjust

guide

and

by

the

Outer

main

eccentric

dog.

by

turning

edge,

(A,

between

material

move

overhanging

the

stop

is

tighten

Fig.

the

screw

located

against

the

yet

20)

its

to

hinge

at

knurled

not

do

securely.

guiding

be

hemmed.

block

guide.

that

the

stop

-

F

show

edge

CE)

is

in

center

screw.

adjusting

on

Adjust

and

Loosen

to

obtain

Re-tighten

front

of

4I

the

the

the

the

of

screw

face

over

edge

set

the

screws

lock

edge

(C)

of

guide

screw

pro

screw,

guide

so

the

(C)

When

hubs

are

to

damage

eccentrics,

from

end

Turn

position

front

and

supplied

and

withdraw

slightly

unusually

to

remove

(G);

possibly

Then

continue

assembling

facing

shaft

remove

of

shaft

handwheel

key

groove

using

with

machine,

same,

back

and

tight

nut

(F)

nut

as

feed

each

or

other

key.

screw

(E).

in

in

hooked

while

forth.

fitting,

and

(H)

originally

eccentrics,

To

(C),

operating

eccentric

eccentric

reach

rocking

If

it

feed

and

connection

and

be

replace

and

behind

eccentrics

may

be

driving

suggested.

be

careful

feed

spacer

direction

towards

extractor

eccentrics

handwheel

are

necessary

connection

(J).

sure

not

(0)

the

to

.4—

C

Fig.22

.

‘I’

Fig.

23

23

Page 24

—

-

thread

in

ed

barely

Needle

cam

the

touch

thread

pull-off

screw

needle

Fig.

slot,

24

is

controlled

(B).

front

thread

NEEDLE

Needle

to

cam

by

thread

back.

pull-off

23)

are

damage

tric,

(D)

shaft

direction

towards

extractor

eccentric

handwheel

tric

necessary

connection

suggested.

THREAD

needle

eyelet

Raise

when

When

and

facing

shaft

remove

and

(E).

is

CONTROL

thread

is

lower

or

needle

SETTING

(STYLES

STITCH

39500

assembling feed

eccentric

each

or

spacer

other

key.

screw

eccentric

Turn

to

front

the

spacer

handwheel

position

and

supplied

and

withdraw

slightly

so

tightly

then

(A,

the

eyelet

unusually

remove

to

(G),

eyelet

set

the

carrier

(C),

with

back

nut

continue

Fig.

securing

is

LENGTH

XQJ,

eccentric

(B),

be

and

To

replace

crankshaft

(B)

grooe

key

using

machine,

same,

and

fitted,

(F)

24)

to

in

its

CXQJ)

be

careful

from

in

operating

hooked

while

forth.

and

as

and

screw

have

lowest

(A,

sure

not

feed

spacer

end

in

eccentric

eccentric

reach

rocking

If

it

may

driving

feed

originally

needle

is

needle

Fig.

hubs

to

eccen

of

behind

eccen

be

center

thread

position.

the

eyelet

loosen

and

tighten

pull-off

in

Fig.

back

screws

Moving

screw

Clearance

(B)

24.

on

needle

be

(E)

When

a

-:

the

down

(C)

screw

should

Loosen

sure

normal

eyelet

forward

and

and

(C).

between

be

screws

driving

to

amount

up

position

looper

only

shaft

take

-—

and

acts

enough

(E)

up

of

back

the

thread

LOOPER

thread

and

until

end

all

LOOPER

looper

f

increases

reverse.

eyelet

THREAD

pull-off

to ensure

rotate

proper

play

THREAD

thread

will

highest

for

CXSD).

guide

adjusting

horizontal

25).

in

horizontal

the

To

(A)

PULL-OFF

(D,

proper

looper

clearance

needle

in

CONTROL

is

drawn,

be

Styles

The

(A,

Center

adjusting

its

needle

adjust

required.

as

Fig.

take-up

thread

is

little

a

position

39500

auxiliary

Fig.

slot

position.

position.

thread

24)

pull-off

obtained.

drive

upper

25)

and

lower

needle

and

of

shaft.

and

slack

(lower

XQJ,

should

set

looper

slot

in

thread

Hold

needle

looper

lower

when

looper

XRN,

upper

slightly

Loosen

and

the

eyelet

lever

Before

XSD,

looper

be

thread

set

stitch,

control,

thread

thread

(F)

tightening

looper

needle(s)

thread

CXQJ,

centered

above

screw

eyelet

eyelet

position

in

cam

as

front

threads

thread

(B,

in

moving

shown

to

is

at

only

CXRN,

its

in

a

Fig.

(C)

a

eyelet

Hold

On

CXQJ,

Fig.

25

screw

XRN,

(B).

XSD,

24

(C)

all

CXRN,

in

Styles

CXSD;

position

except

loosen

and

39500

screw

tighten

XQJ,

(D).

Page 25

LOOPER

THREAD

CONTROL

(Continued)

Center

on

the

eye.

so

it

auxiliary

lower

thread

NOTE:

SETTING

The

after

line

replacing

connected

depress

fully

press

With

er

knife

front

(B),

left

of

reposition

or

screws

upper

top

Center

is

slightly

looper

is

KNIFE

knife

treadle

to

the

slightly

(B)

looper

surface

auxiliary

upper

thread

held

Moving

in

the

system.

CROSS

against

treadle

the

upper

and

of

above

looper

a

in

eyelets

system

cross

or

repairing

air

to

until

still

upper

knife

air

to

recheck

thread

lower

upper

a

thread

eyelet

straight

and

POWER

OVER

over

motor

air

the

moving

depressed,

knife

motor

the

right

cross

eyelet

looper

looper

horizontal

(F)

line

and

(C

moving

AIR-KLIPP

is

set

knives.

for

motor

is

as

shown

(C)

over.

(E)

thread

thread

guide

(A)

loosen

to

to

E)

them

at

the

“AIR-KLIPP”

begins

drive

check

positioned

in

slightly

if

lower

its

in

position.

in

screw

the

lower

the

forward

CHAIN

factory,

With

to

link

the

Fig.

to

knife

adjusting

eyelet

guide

position

(G)

looper.

rear

increases

sewing

chain

operate,

(A,

Fig.

knife

correctly,

26.

If

the

left

is

and

back

in

(A)

Hold

upper

and

position

and

reduces

CUTTER

however

motor

cutter

in

and

26)

cross

when

adjustment

if

lower

positioned

and

slot

lower

of

its

adjusting

looper

tighten

the

Tighten

the

amount

the

amount

ADJUSTMENTS

adjustment

switch

(see

until

over.

out.

the

in

setting

air

lower

is

With

The

required,

knife

too

far

set

thread

screw

eyelet

screw

“OFF”

motor

is

right.

eyelet

looper

slot

(B).

(G).

of

looper

of

thread

will

pressure

forefinger,

stops.

cross

knife

positioned

so

thread

and

eyelet

To

so

the

be

necessary

position

over

is

loosen

Retighten

it

thread

in

2/3

rests

eyelet

set

CE)

set

looper

the

and

valve)

care

of

from

screws

to

guide

frame

the

far

and

air

low

the

CAUTION!

SETTING

If

clockwise

checking

to

cut

mately

switch

SETTING

Torsion

tal

in

knife.

spring

knife);

to

the

SETTING

Regulate

air

motor

imately

Regulate

suction

FABRIC

chain

cutter

Check

“AIR-KLIPP”

at

KNIFE

adjustment

small

(a

with

the

thread

turn

1/4

“ON”

KNIFE

spring

its

free

More

pressure

slightly

(H)

less

pressure

right

(towards

PRESSURE

of

the

20-22

valve

air

to

TO

BE

SEWN

knives.

to

ensure

point

(B).

CUTTING

is

amount

a

piece

and

and

lock

PRESSURE

(H)

state

to

VALVES

valve

on

“AIR-KLIPP”

psi

(1.5

on

pneumatic

obtain

will

that

chain

required,

at

of

thread

the

shear

with

initially

and

then

can

be

the

left

-

by

bending

lower

pneumatic

bar)

when

control

maximum

not

be

lower

cutter

a

time)

nut

lifted

obtained

(away

knife).

chain

suction,

cut

tube.

loosen

see

to

angle

(E).

should

spring

control

cutter

air

device

by

knife

nut

while

if

is

zero,

Check

be

over

by

bending

from

device

motor

yet

the

“AIR-KLIPP”

does

A

slight

(E)

manually

knives

horizon

the

lower

slightly

to

approx-

is

operating.

for

so

that

not

and

are

turn

cutting

for

the

strike

clearance

turn

operating

cutting.

screw

action

E7

the

lower

jr213

against

must

knife

knife

As

(F)

counterclockwise

knives

of

—

inside

be

provided

adjusting

lever

soon

_

Fig.

as

with

--

26

of

(G),

the

---

A

screw

continously

knives

approxi

sewing

BC

--

F

(F)

fail

motor

25

Page 26

N)

Page 27

MAIN

FRAME,

MISCELLANEOUS

PRESSER

COVERS

FOOT

RELEASE

PLATES

AND

PARTS,

Ref.

No.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

30A

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

1

2

3

4

5

6

7

8

9

-

thru

76

Part

No.

39557

39557

39557

39557

39557

39556

39557

22569

21237

21237

660-372

671

671-17

671

671

22585

21695

21695

39594

660

39582

39582

22564

39582

22541

667

22565

22569

22565

22571

39534

39534

39501

22569

22565

29477

39568

39568

22743

39594

22569

22894

39593

660-243

39593

39593

90

B

E

C

F

H

A

A

B

CR

DK

C—13

F-62

F-4

R

AT

AU

Y

705

DV

DS

D

BZ

D—8

S

D

E

R

RB

K

F

GW

G

J

R

K

AE

H

D

C

Nut,

cap,

Nut,

locking

Screw,

Nut,

Spring,

adjusting

lock,

presser

Bushing,

Plunger,

Screw,

Cooler,

Cooler,

needle

needle

needle,

Connector

Bushing,

Valve,

Elbow,

Fitting,

Screw

Bracket,

Shield,

Cap,

“0”

Cover,

sewing

oil

Ring

top