Page 1

CATALOG

NO.

Adjusting

instructions

and

1O3WA

First

SERIES

8M

Edition

illustrated

parts

list

\

U

Finest

Quality

Maximum

-High

with

thumbscrew

Performance

speed

Z7Ut.aISE

differential

adjusted

8M

feed

Series

overseamers

feed

Page 2

CATALOG

NO.

103

WA

39500

39500

39500

39500

39500

39500

39500

39500

39500

MAXIMUM

WA

WC—l.98

WE

WF

WK-l.98

WP

WW

CWA

CWC—1.98

ADJUSTING

INSTRUCTIONS

AND

ILLUSTRATED

FOR

PERFORMANCE

STYLES

39500

39500

39500

39500

39500

39500

39500

39500

39500

PARTS

—

LIST

8M

CWE

CWF

CWK—1.98

CWP

SWA

SWC—L98

SWE

SWF

SWK—1.98

SERIES

39500

39500

39500

39500

39500

39500

39500

39500

39500

SWP

CSWA

CSWC-1.98

CSWF

CSWK—1.98

CSWP

SWAL

SWFL

SWPL

Union

Rights

First

Copyright

Special

Reserved

Printed

October,

Edition

1983

By

Corporation

in

in

US.A.

1983

All

Countries

2

Page 3

FORWARD

This

new

UNION

adjusting

reliability

The

setting

functions

reference

Adjustments

plished.

the

function

Implementation

ficant

downs.

machine,

designed

assure

technical

SPECIAL

these

machines

designed

Adjusting

for

each

of

the

letters

Some

adjustments

of

other

improvements

Whenever

be

sure

specifically

long

lasting

manual

machine.

and

Instruction

of

the

machine.

to

point

are

presented

related

of

in

it

becomes

insist

to

for

service.

has

been

Careful

will

enable

built

into

portion

components

Figures

out

specific

in

performed

parts.

preventative

operator

necessary

on

genuine

your

machine

prepared

attention

you

every

of

related

are

used

sequence

out

maintenance

productivity

to

UNION

and

to

to

to

maintain

UNION

this

forming

to

to

items

so

of

discussed.

that

sequence

by

make

repairs

SPECIAL

manufactured

guide

the

instructions

the

SPECIAL

manual

illustrate

a

logical

may

procedures

avoiding

Repair

you

in

superior

machine.

explains

the

stitch

the

have

can

costly

or

replace

Parts.

with

the

maintenance

for

performance

in

detail

and

adjustments

progression

an

adverse

bring

equipment

parts

These

utmost

precision

operating

the

completing

using

is

accom

effect

about

signi

break

your

on

parts

of

your

and

and

proper

the

on

are

to

To

exploded

VIEW

which

illustrated

TO

PREVENT

—

All

justing

—

Wear

simplify

views.

power

safety

These

presents

on

this

THIS

SAFETY

PERSONAL

sources

or

replacing

glasses.

indentification

illustrations

the

mechanisms

page

will

SYMBOL

INJURY:

to

the

machine

parts.

of

repair

will

of

the

appear

shaded

SAFETY

CAUTION!

INDICATES

MUST

usually

machine

A

YOUR

TURNED

be

parts,

in

the

RULES

PERSONAL

the

mechanisms

be

shown

assembled.

KEY

VIEW.

SAFETY

OFF

before

in

conjuction

The

IS

threading,

are

illustrated

with

specific

INVOLVED.

oiling,

parts

a

by

KEY

ad

—

All

sheilds

—

DO

NOT

tamper

and

with

guards

safety

MUST

shields,

be

in

position

guards,

3

before

etc.,

operating

while

machine.

machine

is

in

operation.

Page 4

IDENTIFICATION

MACHINES

OF

Each

stamped

is

number

is

High

four

three

or

independently

improved

Maximum

internal

recommended

operation.

39500

39500

WA

WC-1.98

UNION

the

in

stamped

speed,

thread

adjustable

Light

light

a

are

SSa—1;

inch

SPECIAL

Style

the

in

maximum

machines.

lubricating

speed

medium

to

medium

to

primary

standard

(4.0mm);

Heavy

of

duty,

heavy

21/64

SSa—1;

514

inch.

per

NOTE:

machine

plate

extension

performance,

thumbscrews

8000

duty,

weight

requisite.

seam

stitch

weight

inch

(8.3mm)

standard

Second

needle

located

system

two

needle

machine

carries

of

STYLES

Trimming

R.P.M.,

single

knitted

Type

widths:

range

needle,

loosely

wide.

seam

a

on

bed

OF

one

for

with

depending

needle,

3/32

8—16

high

knitted

width;

is

5/64

location.

Style

the

casting

or

number,

right

at

MACHINES

curved

two

mechanism

differential

main

and

self—contained

on

low

GAS

inch.

fabrics

needle;

(2.4mm),

or

154

per

woven

inch

capacity

fabrics

Type

8454

1/4

inch

(1.98mm)

rear

the

with

stitch

capacity

machine

with

GS

needle;

inch

which

the

of

right

blade

spring

oil

length

machine

where

seam

1/8

a

(6.4mm);

to

this

on

machine.

base

rear

needles,

pressed

feeds,

filter

and

and

long

specification

inch

for

(3.2mm),

seaming

reinforcing

seam

specification

stitch

RIGHT

the

Class

two

lower

needle

type

for

straight

of

machine

Serial

of

machine.

loopers,

cooler,

cooler.

oil

of

seaming

504

5/32

all

tape

range

single

knife,

seams

types

up

12—26

to

39500

39500

39500

39500

39500

Same

WE

control

Same

WF

seaming

seams

WK-l.98

WP

Same

having

Heavy

WW

weight

154

inch

NOTE:

Style

as

when

Style

as

medium

are

Same

weight

wide.

NOTE:

as

Style

12

duty,

knitted

needle;

GAS

(6.7mm);

Second

machine

sewing

primary

a

as

knitted

Stitch

Second

needle

T.P.I.

two

39500

39500

to

Style

39500

or

stitch

needle

location.

WA

curves

WA

heavy

requisite.

39500

fabrics

range

needle

machine

WF

needle,

woven

seam

except

or

except

weight

WC—1.98

with

per

8—16

is

5/64

location.

except

capacity

high

fabrics

specification

7/64

8—16

inch

range

is

fitted

-

irregular

heavy

—

knitted

Stitch

except

reinforcing

inch.

inch

equipped

—

requiring

per

(2.78mm)

512

inch.

with

shapes.

duty,

woven

or

range

for

-

(1.98mm)

with

machine

a

SSa—2;

narrow

high

fabrics

8—16

seaming

tape

to

main

for

simulated

standard

the

to

sewing

capacity

per

to

up

the

and

seaming

LEFT

parts

machine

where

inch.

types

all

13/64

RIGHT

differential

medium

safety

width

seam

of

single

for

long

of

inch

of

single

stitch.

better

for

straight

light

(5.2mm)

feeds

heavy

to

17/64

needle

Type

4

Page 5

MACHINE

STYLES

(Continued)

39500

39500

39500

39500

39500

39500

39500

39500

39500

39500

CWA

Same

CWC-1.98

CWE

CWF

Same

Same

CWK—1.98

CWP

SWA

Same

Same

162

SWC-1.98

SWE

Same

162

SWF

Same

162

as

Style

Same

chain

as

Style

Style

as

Same

chain

as

Style

as

Style

SAS)

which

Same

NEEDLE

as

Style

SAS)

which

Style

as

SAS)

which

as

cutter.

as

cutter.

as

(Type

39500

Style

39500

39500

Style

39500

39500

reduces

Style

39500

reduces

39500

reduces

WA

39500

WE

WF

39500

WP

WA

39500

162

WE

WF

except

WC—1.98

except

except

WK—1.98

except

except

needle

WC—1.98

SDS)

except

needle

except

needle

—

-

—

—

cutting.

which

-

cutting.

—

cutting.

fitted

except

fitted

fitted

except

fitted

designed

except

reduces

designed

designed

with

—

with

with

—

with

to

-

needle

to

to

Power

fitted

Power

Power

fitted

Power

use

designed

use

use

hlAir_KlipphDchain

with

Power

“Air—Klipp”

“Air—Klipp”

with

Power

“Air—Klipp”

SHORT,

to

STIFF

use

SHORT,

cutting.

SHORT,

SHORT,

STIFF

STIFF

cutter.

“Air

Klipp”

chain

chain

cutter.

cutter.

“Air—Klipp”

chain

NEEDLE

cutter.

(Type

STIFF

NEEDLE

NEEDLE

(Type

(Type

39500

39500

39500

39500

39500

39500

39500

39500

39500

39500

SWK—1.98

SWP

Same

162

CSWA

Same

CSWC—1.98

CSWF

Same

CSWK—1.98

CSWP

SWAL

Same

Same

seam

SWFL

Same

seam

SWPL

Same

seam

Same

NEEDLE

as

Style

SAS)

which

Style

as

Same

chain

Style

as

Same

chain

as

Style

as

Style

width

Style

as

width

Style

as

width

as

as

as

cutter.

1/8

1/8

1/8

Style

(Type

39500

reduces

39500

Style

cutter.

39500

Style

39500

39500

39500

39500

inch

inch

inch

39500

162

WP

SWA

39500

SWF

39500

SWP

SWA

(3.2mm).

SWF

(3.2mm).

SWP

(3.2mm).

WK—1.98

SDS)

except

needle

except

SWC—1.98

except

SWK-.1.98

except

except

except

except

which

—

cutting.

except

reduces

designed

—

fitted

except

—

fitted

except

—

fitted

—

equipped

—

equipped

—

equipped

—

designed

needle

to

with

—

with

—

with

with

with

with

use

Power

fitted

Power

fitted

Power

to

cutting.

SHORT,

“Air—Klipp”

with

‘Air—Klipp”

with

“Air—Klipp’

Latch

Latch

Latch

SHORT,

use

STIFF

STIFF

NEEDLE

chain

Power

“Air—Klipp”

chain

Power

“Air—Klipp”

chain

Tacker.

Tacker.

Standard

Standard

Tacker. Standard

(Type

cutter.

cutter.

cutter.

5

Page 6

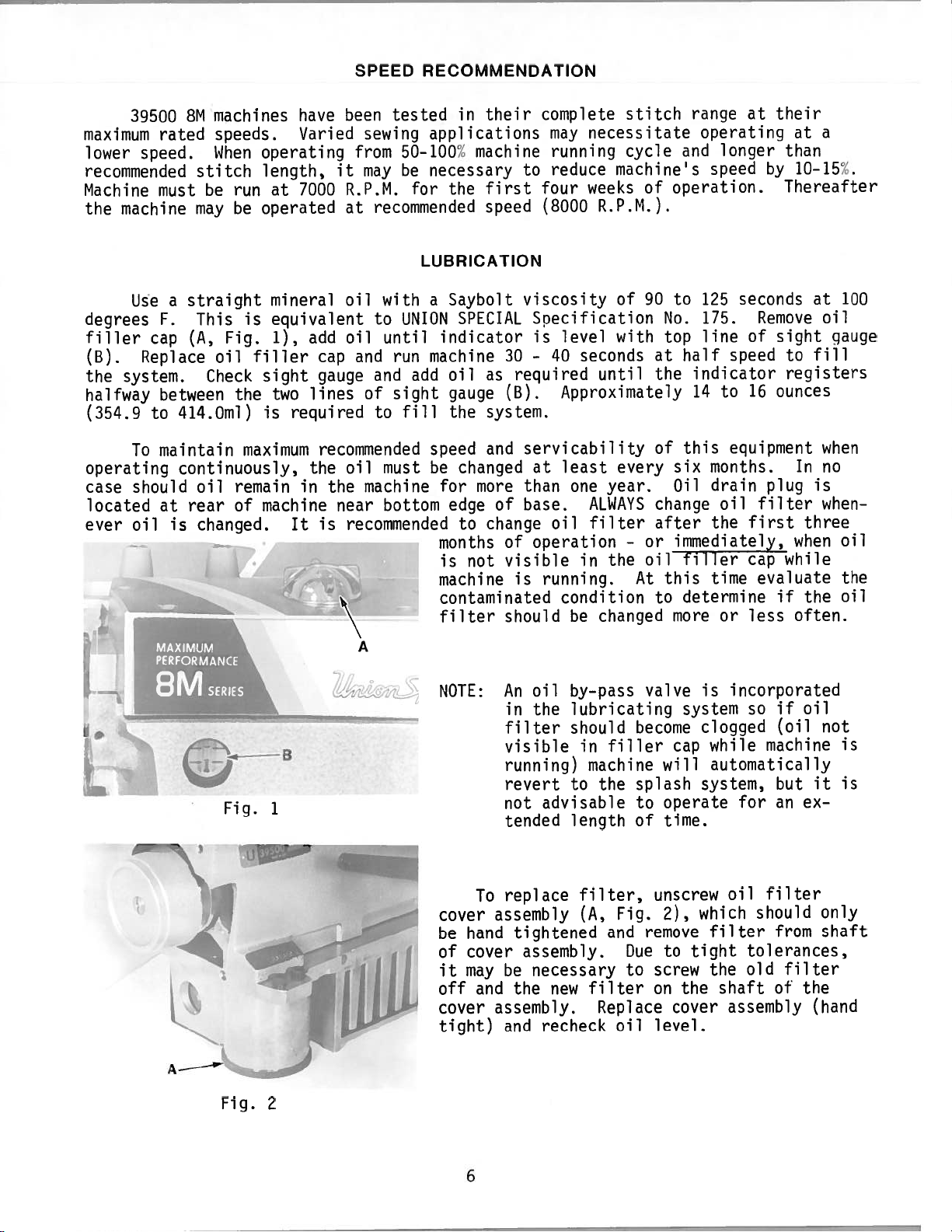

SPEED

RECOMMENDATION

39500

maximum

lower

rated

speed.

recommended

Machine

the

must

machine

Use

degrees

filler

(B).

the

halfway

(354.9

F.

cap

Replace

system.

between

to

To

maintain

operating

case

ever

located

should

at

oil

8M

machines

speeds.

When

stitch

be

run

may

be

a

straight

This

Fig.

(A,

oil

Check

the

414.Oml)

continuously,

remain

oil

of

rear

is

changed.

have

Varied

operating

length,

7000

at

operated

mineral

is

equivalent

1),

filler

sight

two

required

is

maximum

machine

It

been

sewing

from

it

may

R.P.M.

at

oil

oil

add

and

cap

gauge

lines

of

recommended

the

oil

in

the

machine

near

recommended

is

tested

in

applications

50—100%

be

necessary

the

for

recommended

LUBRICATION

Saybolt

UNION

until

run

sight

fill

a

indicator

machine

add

SPECIAL

oil

gauge

the

with

to

and

to

speed

must

be

changed

for

bottom

edge

months

is

machine

contaminated

filter

their

machine

first

speed

as

system.

and

more

to

change

not

to

viscosity

Specification

is

30

—

required

(B).

servicability

at

than

of

base.

operation

of

visible

is

should

complete

may

necessitate

running

reduce

weeks

four

(8000

R.P.M.).

level

40

seconds

until

Approximately

least

one

year.

ALWAYS

oil

filter

the

in

running.

condition

changed

be

stitch

cycle

machine’s

of

operation.

of

90

No.

with

top

at

the

of

every

Oil

change

after

or

—

oil

this

At

to

more

ranqe

at

operating

longer

and

speed

125

seconds

to

175.

of

line

half

speed

indicator

14

this

six

16

to

equipment

months.

drain

oil

first

the

immediately,

filler

cap

time

determine

or

less

their

at

than

by

10-15%.

Thereafter

Remove

sight

to

registers

ounces

In

plug

filter

when

while

evaluate

if

often.

a

at

oil

fill

when

no

is

when

three

the

100

gauge

oil

the

oil

is

oil

NOTE:

An

in

filter

visible

e_B

running)

revert

Fig.

1

not

tended

replace

To

hand

cover

may

and

assembly

tightened

assembly.

be

the

assembly.

and

cover

be

of

it

off

cover

tight)

A

—-

Fig.

2

-

by—pass

lubricating

the

should

in

to

advisable

length

filter,

(A,

necessary

new

recheck

machine

the

filter

Replace

filler

Fig.

and

oil

valve

become

splash

to

of

unscrew

remove

Due

to

screw

on

level.

system

cap

will

operate

time.

2),

to

the

cover

incorporated

so

clogged

while

automatically

system,

for

oil

which

filter

tight

the

tolerances,

old

shaft

assembly

if

(oil

machine

but

an

filter

should

from

filter

of

oil

it

ex

the

(hand

not

is

is

only

shaft

6

Page 7

NEEDLES

Eich

of

shank,

on

the

shank

and

which

To

sample

packages.

Size

110/044”.

ine

covered

needles

most

their

satisfactory

description,

NEEDLE

154

GAS

162

SAS

needle

is

given

have

needle,

are

TYPE

needle

point,

eye.

orders

A

complete

by

available,

has

lenqth,

shank,

Collectively,

the

on

promptly

or

the

The

type

this

catalog

results.

and

both

groove,

denotes

label

type

order

numbers

but

the

Round

blade,

groove,

chromium

Round

blade,

struck

plated.

a

and

the

sizes

type

the

type

of

all

and

size

would

are

ones

The

shank,

shank,

and

size

finish

largest

and

size

needles

accurately

number

read

as

of

the

given

in

indicated

type

number

available

DESCRIPTION

round

standard

struck

plated.

round

Class

“D”,

groove,

number.

and

other

diameter

number

packaged

filled,

should

follows:

needles

the

of

are

point,

length,

groove,

point,

single

spotted,

The

details.

of

represents

be

recommended

machine

are

those

the

recommended

listed

curved

single

spotted,

curved

groove,

chromium

type

blade,

and

sold

forward

given.

“1000

style

recommended

below:

number

The

size

measured

the

Union

by

the

empty

See

Needles,

for

each

description.

needle,

denotes

number,

midway

complete

Special.

package,

description

Type

style

to

produce

together

SIZES

AVAILABLE

055/022,

070/027,

080/032,

100/040,

125/049,

150/060.

055/022,

01O/07,

080/032,

100/040,

the

symbol,

154

GAS,

of

Other

065/025,

075/029,

090/036,

110/044,

140/054,

065/025,

075/029,

090/036,

110/044.

kind

stamped

between

a

on

mach

the

with

162

SOS

8454

OS

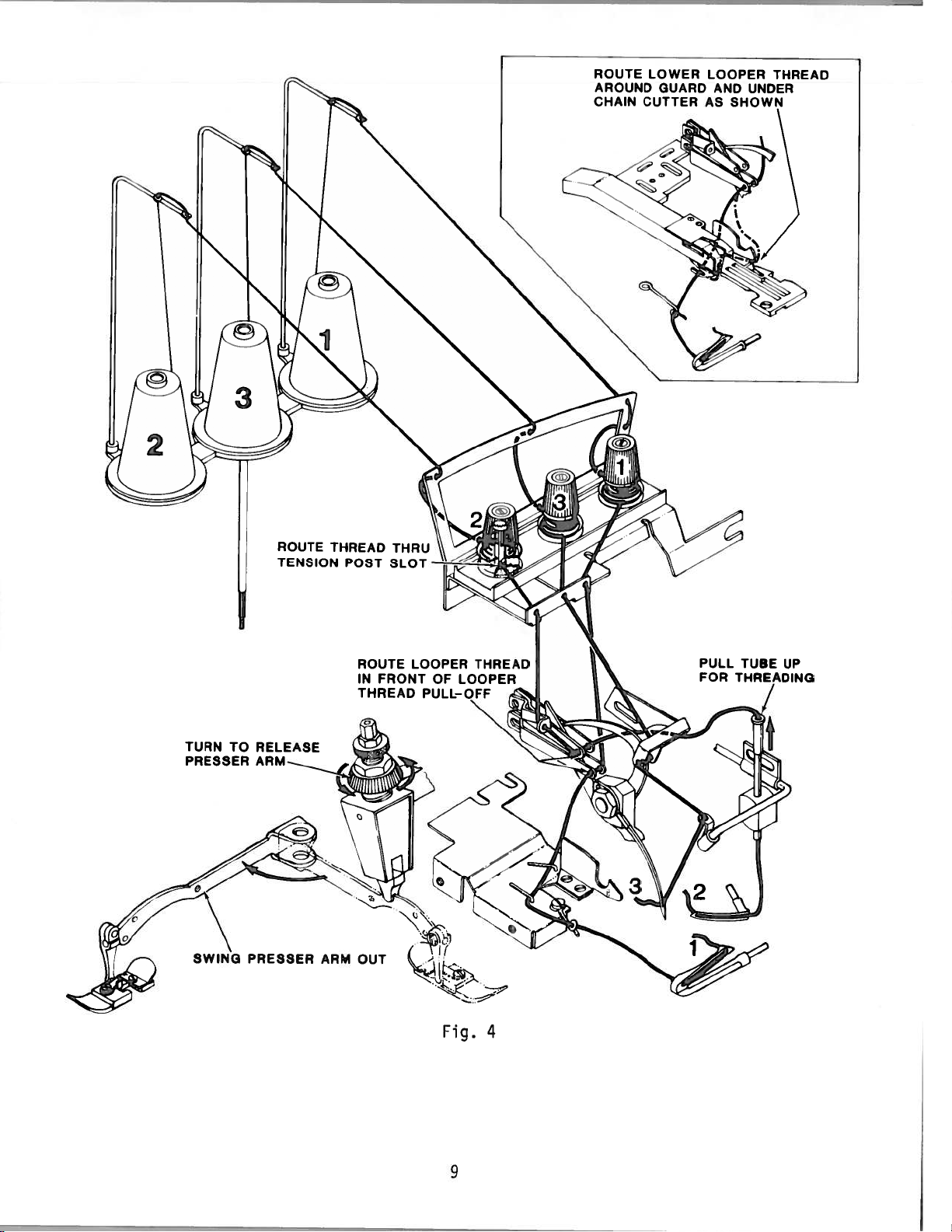

With

presser

and

swing

handwheel

position.

(A,

Fig.

Rotate

its

highest

and

insert

swing

into

presser

sewing

bushing.

THREAD

AS

MACHINE

APPLICABLE.

needle

foot

presser

until

Loosen

3)

new

NEEDLE

in

release

foot

needle(s)

needle

with

socket

handwheel

position.

needle(s).

foot

position

INDICATED

AS

Slabbed

inch

Class

groove,

Slabbed

inch

standard

struck

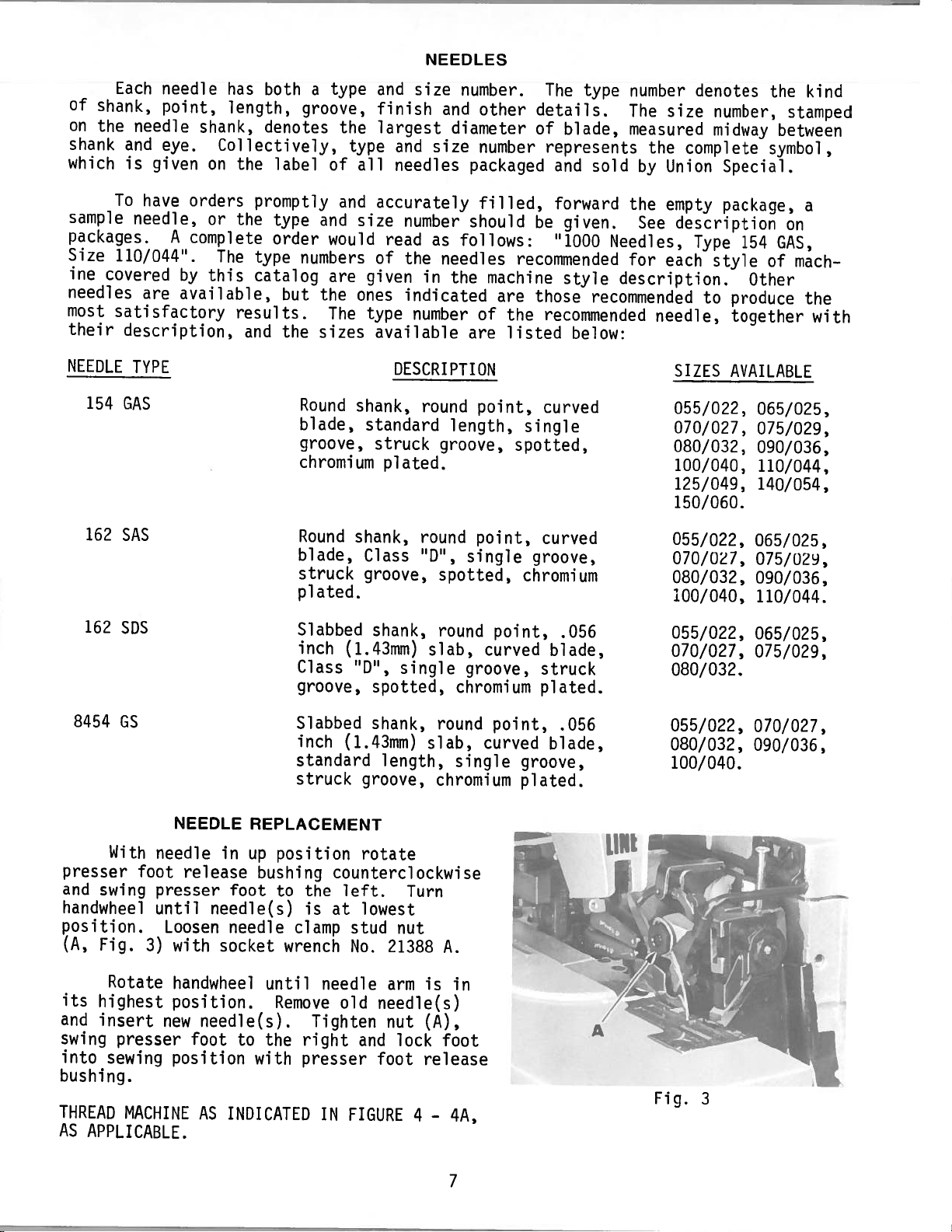

REPLACEMENT

position

up

bushing

the

to

is

clamp

wrench

until

needle

Remove

Tighten

the

to

with

right

presser

IN

shank,

(1.43mm)

“D”,

round

slab,

single

spotted,

shank,

(1.43mm)

round

slab,

length,

groove,

chromium

rotate

counterclockwise

left.

at

stud

No.

old

and

FIGURE

lowest

nut

21388

arm

needle(s)

nut

lock

foot

Turn

A.

is

(A),

foot

release

4—4A,

point,

curved

groove,

chromium

point,

curved

single

in

.056

blade,

struck

plated.

.056

blade,

groove,

plated.

055/022,

070/027,

080/032.

055/022,

080/032,

100/040.

Fig.

065/025,

075/029,

070/027,

090/036,

3

7

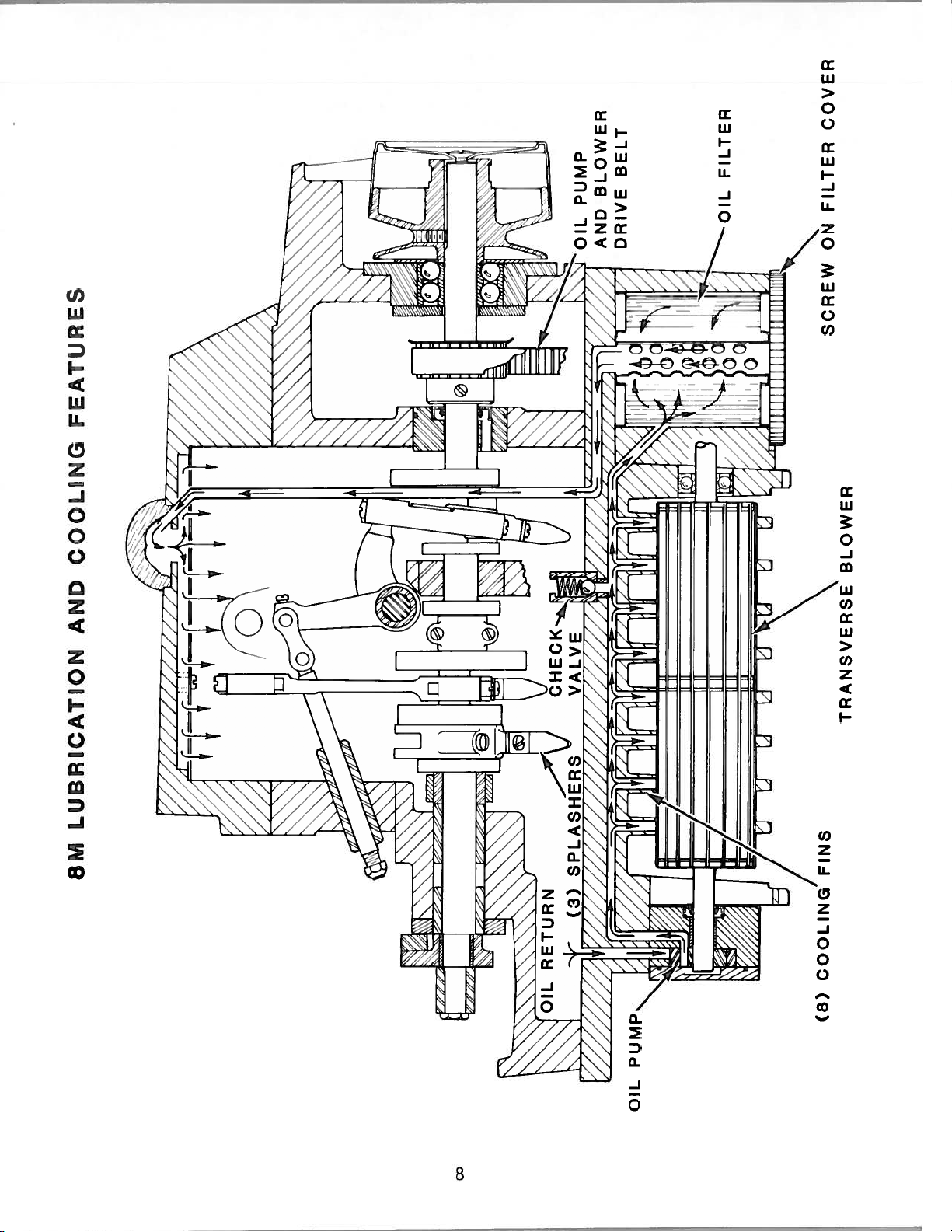

Page 8

C,)

Ui

D

I

4

Ui

LI

z

-J

0

0

C-)

z

4

z

0

w

0

-J

w

Cl)

u-i

>

Cl)

z

I-

4

C.)

D

-J

I—

D

0

-J

0

8

Page 9

ROUTE

AROUND

CHAIN

LOWER

GUARD

CUTTER

LOOPER

AND

AS

SHOWN

THREAD

UNDER

TURN

PRESSER

TO

PRESSER

ROUTE

TENSION

RELEASE

ARM

THREAD

POST

ARM

SLOT

ROUTE

IN

FRONT

THREAD

OUT

LOOPER

OF

PULL-OFF

THREAD

LOOPER

UP

DING

4

Fig.

9

Page 10

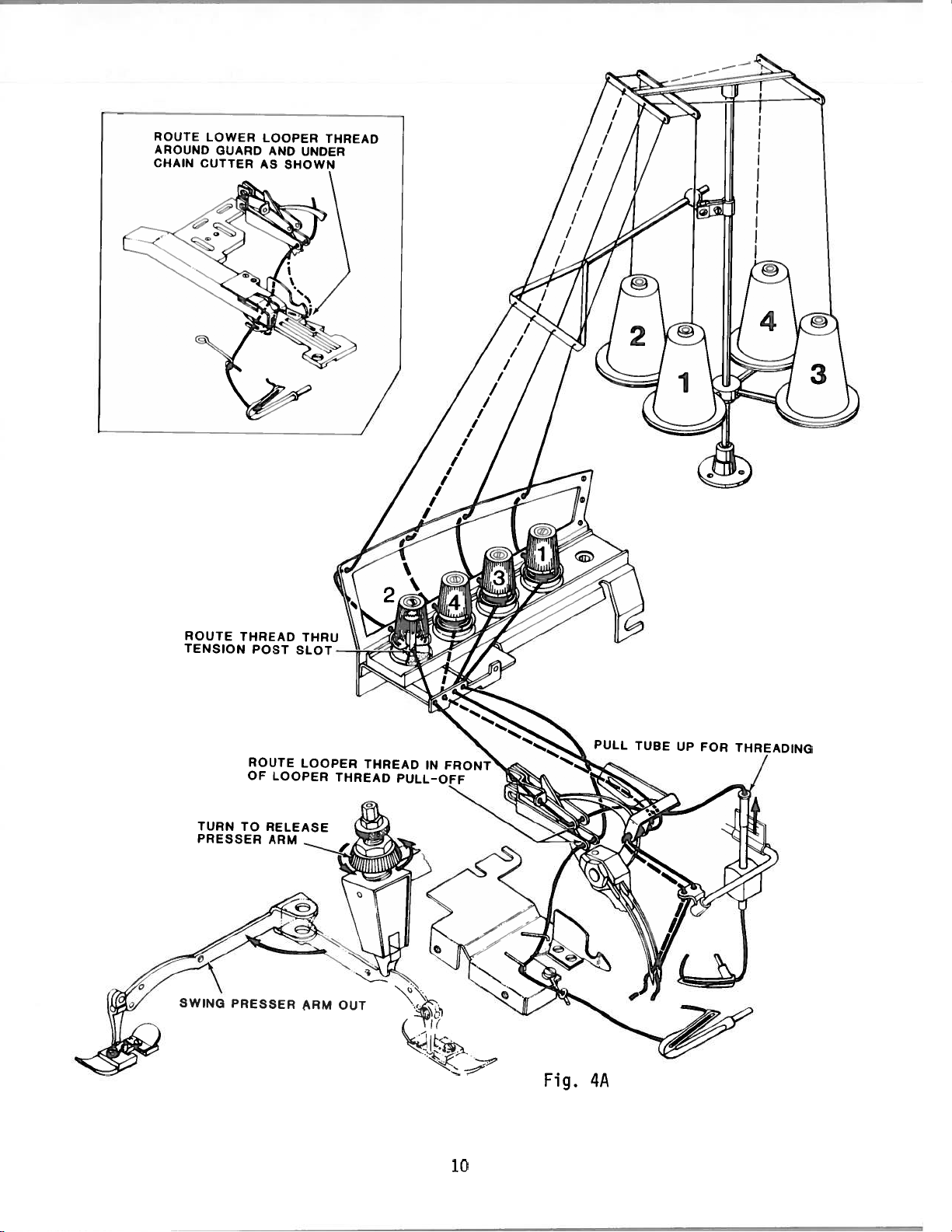

ROUTE

AROUND

CHAIN

LOWER

GUARD

CUTTER

LOOPER

AND

AS

SHOWN

THREAD

UNDER

TURN

PRESSER

SWING

TO

RELEASE

PRESSER

ARM

ARM

OUT

10

Fig.

PULL

4A

TUBE

UP

FOR

Page 11

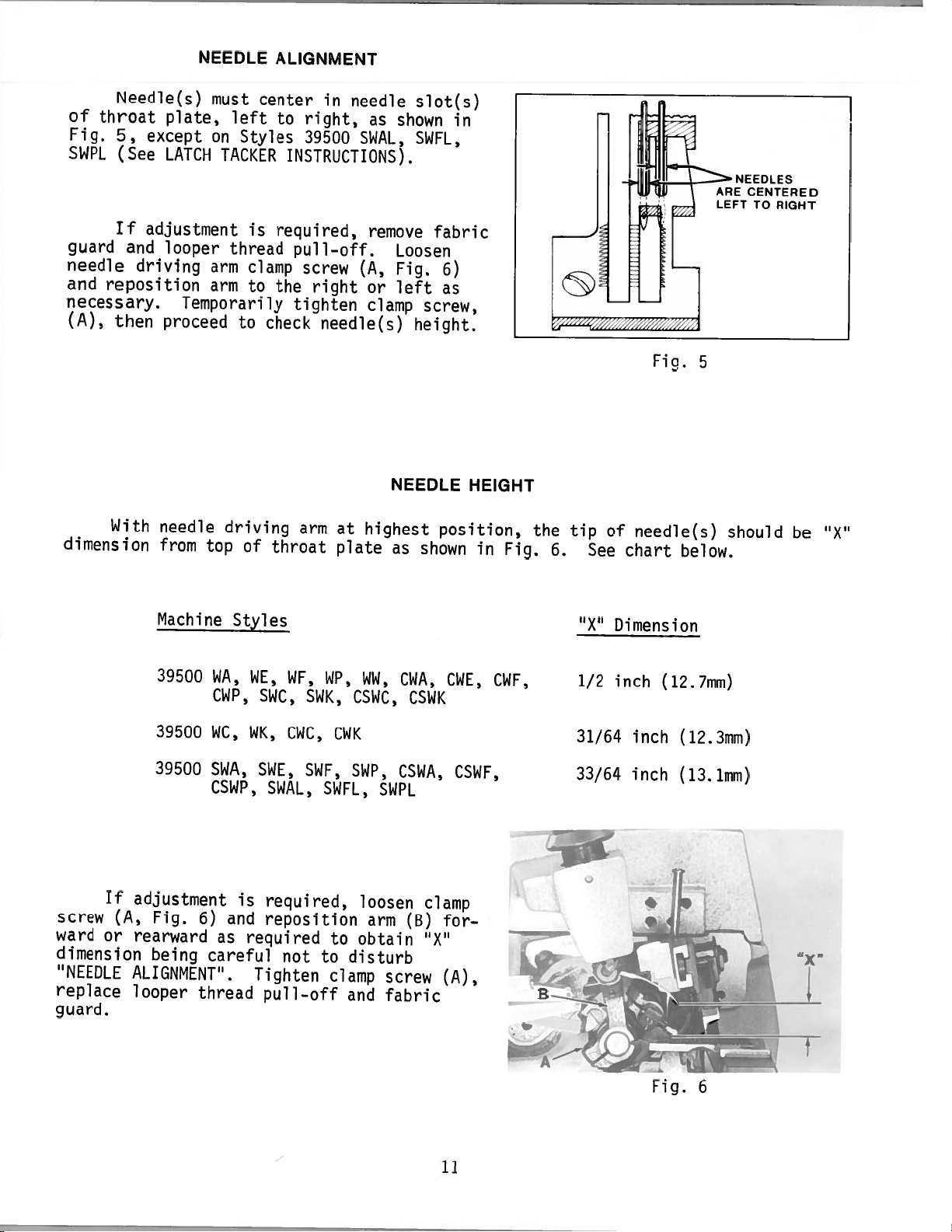

NEEDLE

ALIGNMENT

Needle(s)

of

throat

Fig.

5,

SWPL

guard

needle

and

necessary.

(A),

dimension

(See

If

reposition

then

With

plate,

except

LATCH

adjustment

and

looper

driving

proceed

needle

from

must

left

on

Styles

TACKER

is

thread

arm

clamp

arm

to

Temporarily

to

driving

top

of

center

to

required,

the

check

throat

in

needle

right,

39500

INSTRUCTIONS).

pull—off.

screw

right

tighten

needle(s)

arm

at

plate

as

shown

SWAL,

remove

Loosen

(A,

Fig.

left

or

clamp

NEEDLE

highest

as

slot(s)

in

SWFL,

fabric

6)

as

screw,

height.

position,

shown

HEIGHT

in

Fig.

the

6.

tip

See

of

chart

Fiq.

needle(s)

below.

5

LEFT

should

TO

RIGHT

be

“X”

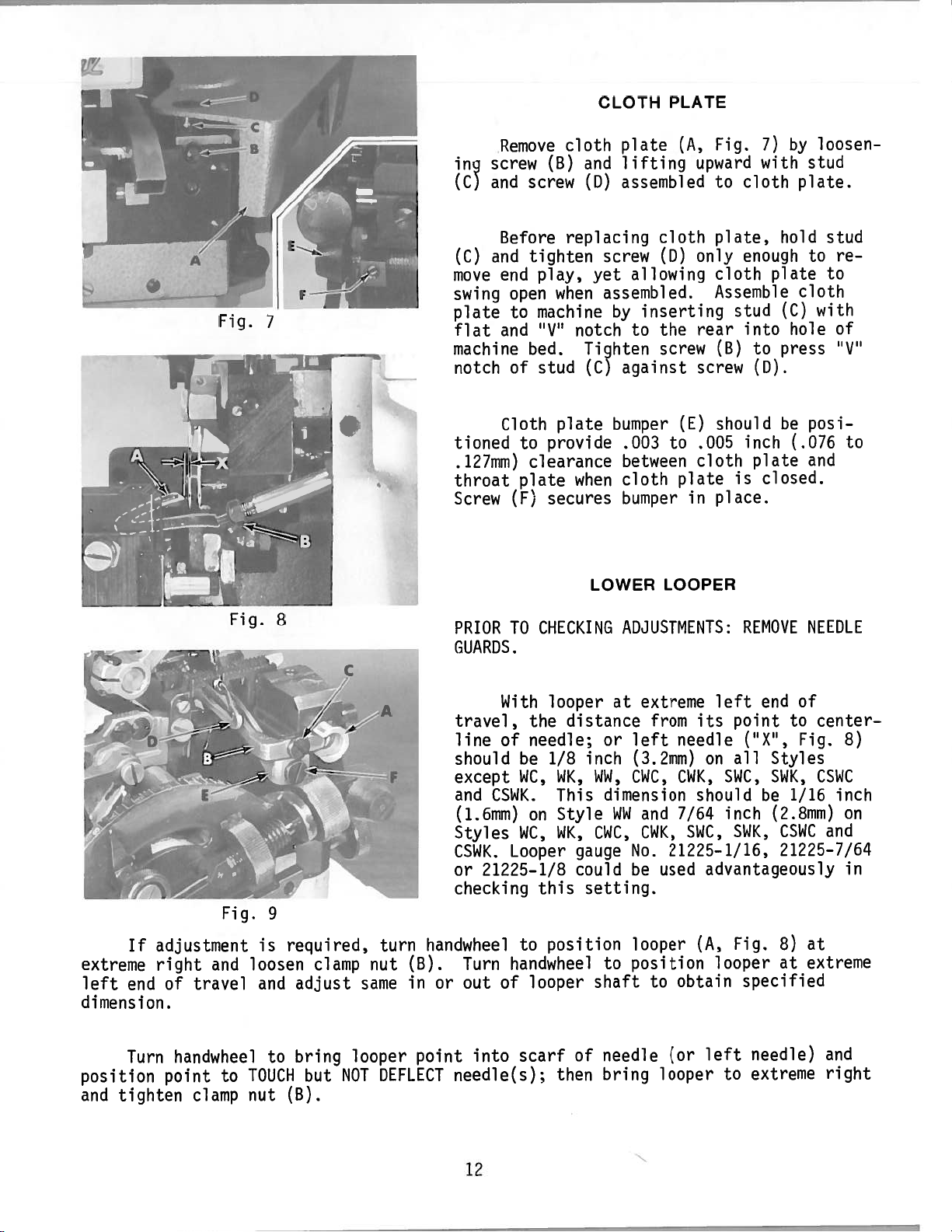

If

screw

ward

dimension

‘NEEDLE

replace

guard.

(A,

or

Machine

39500

39500

39500

adjustment

Fig.

rearward

being

ALIGNMENT”.

looper

WA,

CWP,

WC,

SWA,

CSWP,

6)

and

as

careful

thread

Styles

is

WE,

WF,

SWC,

WK,

CWC,

SWE,

SWAL,

required,

reposition

required

not

Tighten

pull—off

WP,

SWK,

CWK

SWF,

SWFL,

to

to

clamp

WW,

CSWC,

SWP,

SWPL

loosen

arm

obtain

disturb

screw

and

fabric

CWA,

CSWK

CSWA,

clamp

(B)

“X”

CWE,

CSWF,

for

(A),

CWF,

“X”

1/2

31/64

33/64

Dimension

inch

inch

inch

(12.7mm)

(12.3mm)

(13.1mm)

1

11

Fig.

6

Page 12

in

(C)

Remove

screw

and

(B)

screw

cloth

and

(D)

CLOTH

plate

lifting

assembled

PLATE

(A,

upward

Fig.

to

7)

with

cloth

by

stud

plate.

loosen—

_z]_

Fig.

L

Before

and

(C)

end

move

swing

plate

flat

machine

notch

open

to

and

of

Cloth

tioned

.127mm)

throat

Screw

8

PRIOR

(F)

TO

replacing

tighten

play,

when

machine

‘V’

notch

bed.

stud

plate

to

provide

clearance

plate

when

secures

CHECKING

screw

yet

assembled.

Tighten

(C)

LOWER

cloth

(D)

allowing

inserting

by

to

the

screw

against

bumper

.003

to

between

cloth

bumper

LOOPER

ADJUSTMENTS:

only

rear

screw

(E)

.005

cloth

plate

in

plate,

cloth

Assemble

(B)

should

place.

hold

enough

plate

into

to

(D).

(C)

press

stud

be

inch

plate

closed.

is

REMOVE

to

cloth

with

hole

posi—

(.076

and

NEEDLE

stud

re

to

of

“V’

to

GUARDS.

If

extreme

left

end

dimension.

Turn

position

and

tighten

adjustment

right

of

and

travel

handwheel

point

to

clamp

Fig.

TOUCH

9

is

loosen

and

to

nut

required,

clamp

adjust

bring

but

(B).

nut

same

looper

NOT

turn

handwheel

(B).

in

or

point

DEFLECT

With

travel,

line

of

should

except

and

CSWK.

(1.6mm)

Styles

CSWK.

or

Looper

21225—1/8

checking

Turn

out

handwheel

of

into

needle(s);

looper

the

needle;

be

WC,

on

WC,

this

position

to

looper

scarf

distance

1/8

WK,

This

Style

WK,

gauge

could

of

then

at

or

inch

WW,

dimension

14W

CWC,

setting.

to

shaft

needle

bring

extreme

from

left

needle

(3.2mm)

CWC,

CWK,

and

7/64

CWK,

No.

21225—1/16,

be

used

looper

position

to

obtain

(or

looper

end

left

its

point

(“X”,

all

on

SWC,

should

be

inch

SWC,

SWK,

advantageously

Fig.

(A,

looper

specified

left

to

needle)

extreme

of

to

center

Fig.

Styles

SWK,

1/16

CSWC

inch

(2.8mm)

and

CSWC

21225—7/64

at

8)

at

extreme

and

right

8)

on

in

12

Page 13

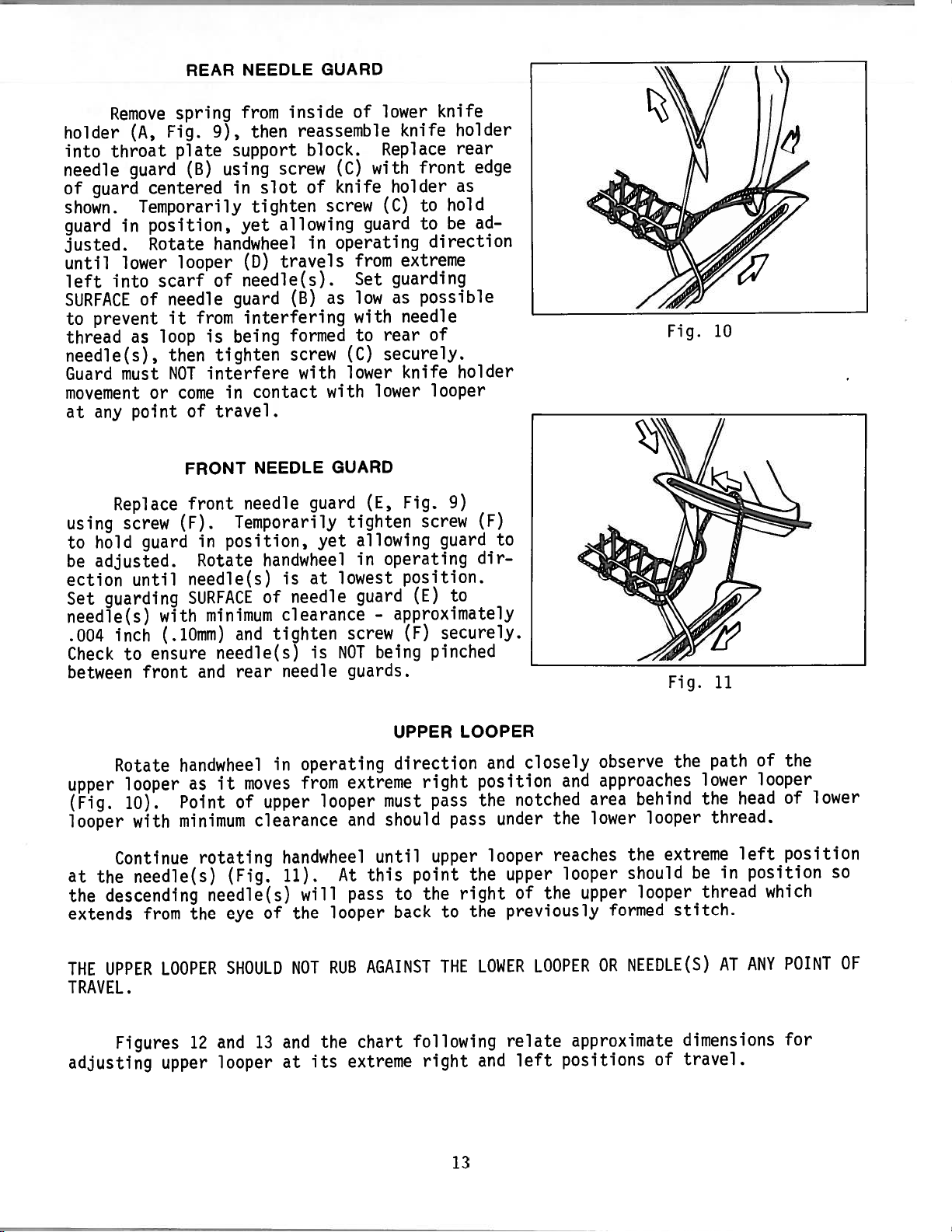

REAR

NEEDLE

GUARD

Remove

holder

throat

into

needle

of

guard

guard

shown.

guard

in

justed.

until

left

lower

into

SURFACE

prevent

to

thread

needle(s),

Guard

must

movement

at

any

Replace

using

to

be

screw

hold

adjusted.

ection

Set

guarding

needle(s)

inch

.004

Check

to

between

spring

Fig.

(A,

plate

(B)

centered

Temporarily

position,

Rotate

looper

scarf

needle

of

from

it

as

loop

then

NOT

come

or

guard

of

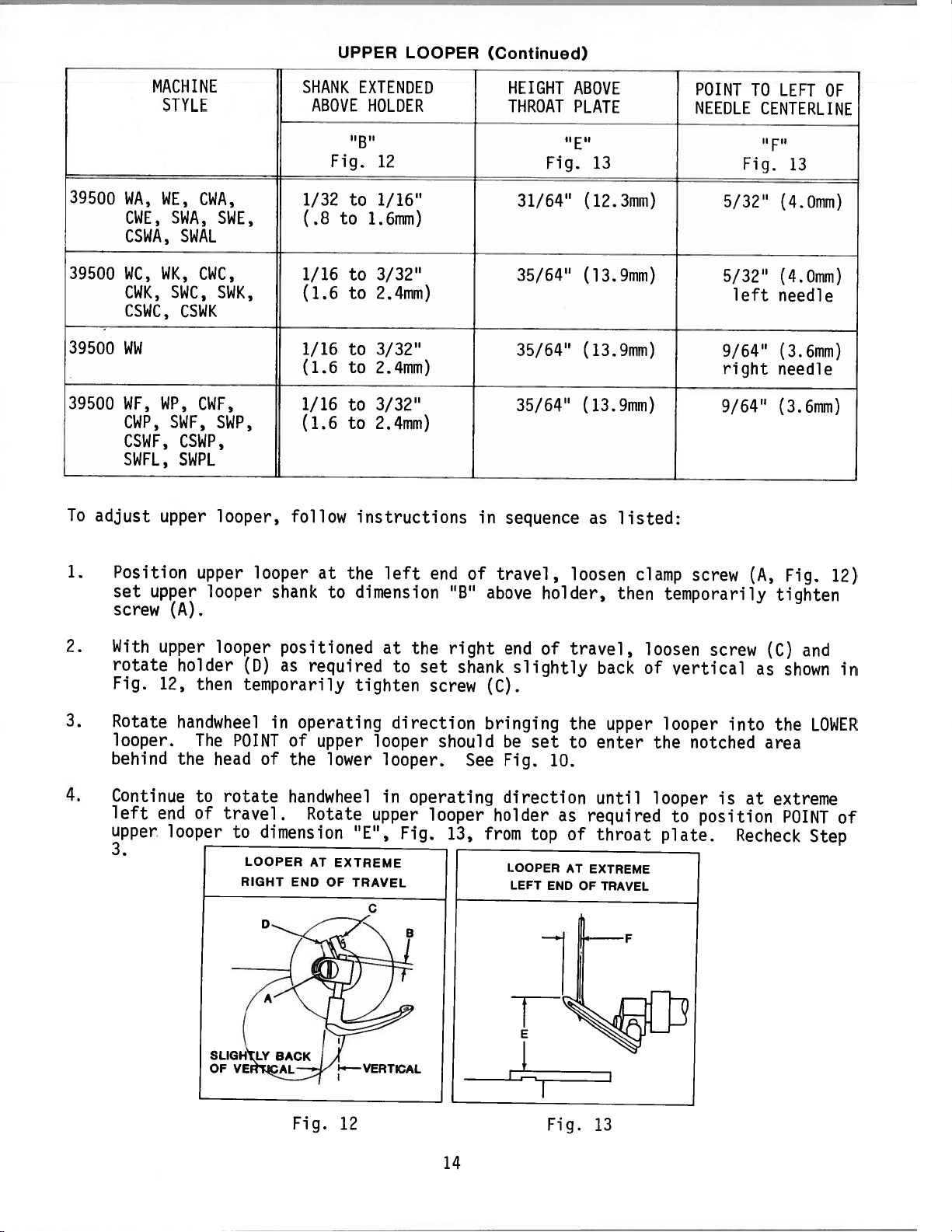

FRONT

front

(F).

in

point

Rotate

until

needle(s)

SURFACE

with

(.10mm)

ensure

front

and

from

then

9),

support

using

slot

in

tighten

yet

handwheel

CD)

needle(s).

of

guard

interfering

being

is

tighten

interfere

contact

in

travel.

NEEDLE

needle

Temporarily

position,

handwheel

of

minimum

and

needle(s)

rear

inside

reassemble

block.

screw

of

allowing

in

travels

(B)

formed

screw

with

guard

yet

at

is

needle

clearance

tighten

is

needle

of

with

(C)

knife

screw

guard

operating

from

Set

low

as

with

to

(C)

lower

with

GUARD

(E,

tighten

allowing

in

lowest

guard

screw

NOT

guards.

lower

knife

knife

Replace

front

holder

to

to

hold

be

(C)

direction

extreme

guarding

possible

as

needle

of

rear

securely.

knife

lower

looper

Fig.

screw

guard

operating

position.

(E)

—

approximately

securely.

(F)

being

pinched

holder

rear

edge

as

ad

holder

9)

to

(F)

dir

to

Fig.

Fig.

10

11

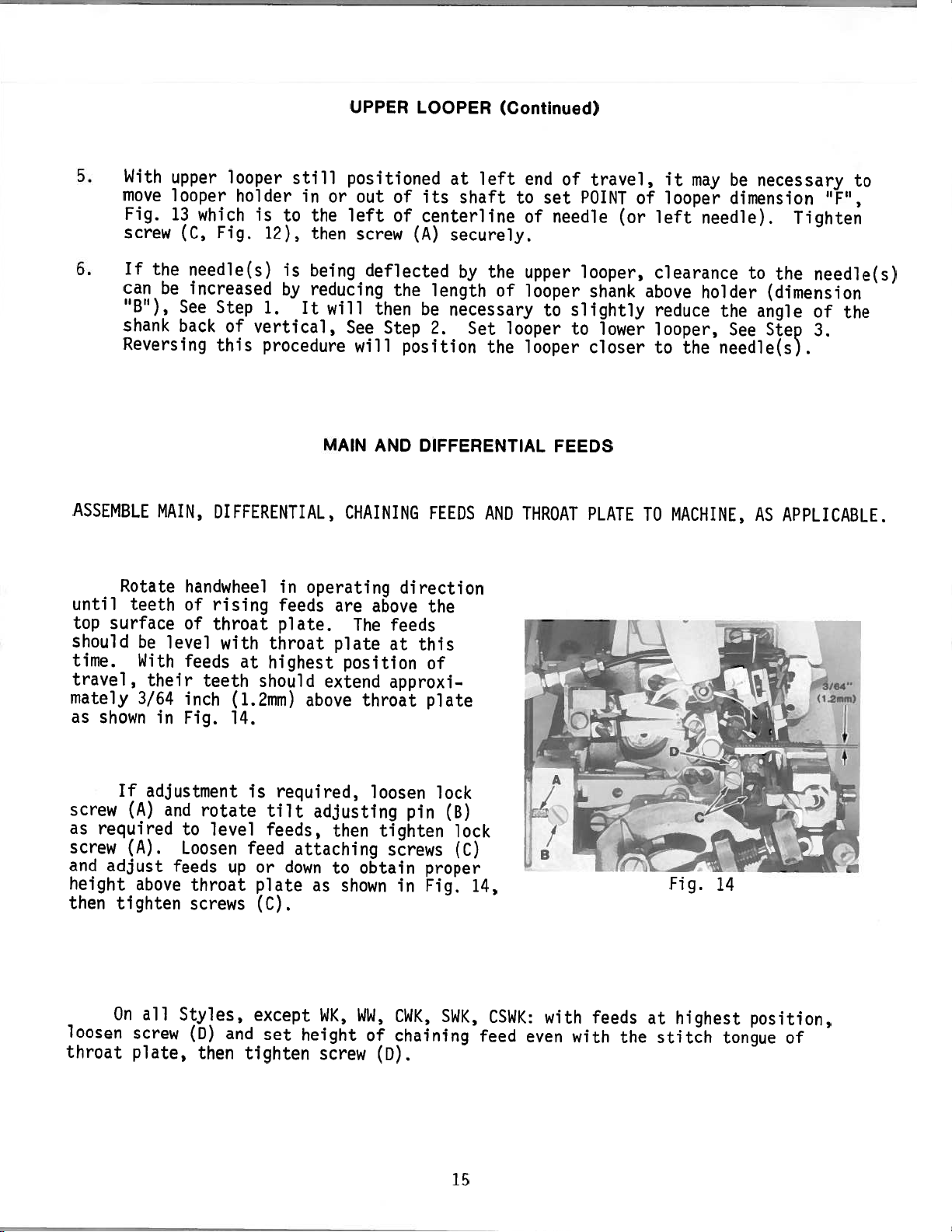

Rotate

upper

(Fig.

looper

10).

looper

Continue

at

the

the

descending

extends

THE

UPPER

TRAVEL.

Figures

adjusting

handwheel

Point

with

minimum

needle(s)

from

LOOPER

upper

as

it

rotating

needle(s)

the

12

and

looper

in

moves

upper

of

clearance

handwheel

(Fig.

eye

11).

of

SHOULD

13

and

at

operating

from

looper

At

will

looper

the

RUB

NOT

the

its

extreme

must

should

and

until

this

pass

AGAINST

chart

extreme

UPPER

direction

right

pass

upper

point

the

to

back

to

THE

following

right

LOOPER

and

position

the

pass

looper

the

right

the

LOWER

and

13

closely

notched

under

upper

of

the

previously

LOOPER

relate

left

observe

approaches

and

area

lower

the

reaches

looper

upper

formed

OR

approximate

positions

the

lower

behind

the

looper

extreme

the

should

looper

be

thread

stitch.

NEEDLE(S)

dimensions

travel.

of

path

head

thread.

left

in

AT

of

the

looper

of

position

position

which

POINT

ANY

for

lower

so

OF

Page 14

UPPER

LOOPER

(Contirwed)

39500

39500

39500

39500

To

adjust

MACHIN[

STYLE

WA,

WE,

CWE,

CSWA,

WC,

WK,

CWK,

CSWC,

WW

WP,

WE,

CWP,

CSWF,

SWFL,

upper

CWA,

SWA,

SWAL

CWC,

SWC,

CSWK

CWF,

SWF,

CSWP,

SWPL

SWE,

SWK,

SWP,

looper,

SHANK

ABOVE

1/32

(.8

1/16

(1.6

1/16

(1.6

1/16

(1.6

follow

EXTENDED

HOLDER

Fig.

12

to

1/16”

to

1.6mm)

to

3/32”

to

2.4mm)

to

3/32”

to

2.4mm)

to

3/32”

to

2.4mm)

instructions

in

sequence

HEIGHT

THROAT

Fig.

31/64”

35/64”

35/64”

35/64”

ABOVE

PLATE

13

(12.3mm)

(13.9mm)

(13.9mm)

(13.9mm)

as

listed:

POINT

NEEDLE

Fig.

5/32”

5/32”

left

9/64”

right

9/64”

TO

LEFT

OF

CENTERLINE

F”

13

(4.0mm)

(4.0mm)

needle

(3.6mm)

needle

(3.6mm)

4.

1.

2.

3.

Position

set

upper

screw

With

upper

rotate

Fig.

12,

Rotate

looper.

behind

Continue

left

end

upper

3.

upper

looper

(A).

looper

holder

then

handwheel

The

the

head

to

of

looper

looper

CD)

temporarily

POINT

of

rotate

travel.

to

dimension

LOOPER

RIGHT

at

shank

positioned

as

required

operating

in

of

upper

the

handwheel

Rotate

AT

END

the

dimension

to

tighten

lower

“E”,

EXTREME

OF

TRAVEL

left

at

to

direction

looper

looper.

in

upper

C

end

the

set

screw

should

operating

looper

Fig.

“B

right

shank

13,

of

above

(C).

bringing

See

from

travel,

end

slightly

set

be

Fig.

direction

holder

top

LOOPER

LEFT

loosen

holder,

of

travel,

the

to

10.

as

of

AT

END

back

upper

enter

until

required

throat

EXTREME

OF

TRAVEL

then

clamp

temporarily

loosen

of

vertical

looper

the

looper

to

plate.

screw

screw

into

notched

is

position

(A,

tighten

(C)

as

the

area

at

extreme

POINT

Recheck

Fig.

and

shown

LOWER

Step

12)

in

of

Fig.

12

Fig.

14

13

Page 15

2:

5.

With

move

Fig.

screw

6.

If

the

can

“B”),

shank

Reversing

ASSEMBLE

upper

looper

13

which

(C,

needle(s)

be

increased

See

back

MAIN,

looper

holder

Fig.

Step

of

this

still

in

is

to

12),

is

by

1.

It

vertical,

procedure

or

the

then

being

reducing

will

MAIN

DIFFERENTIAL,

UPPER

positioned

out

left

screw

LOOPER

of

of

(A)

deflected

the

then

See

Step

will

position

DIFFERENTIAL

AND

CHAINING

left

at

its

shaft

centerline

securely.

by

length

be

necessary

2.

Set

FEEDS

(Continued)

end

to

of

the

upper

of

looper

looper

looper

the

AND

THROAT

of

set

needle

to

FEEDS

travel,

POINT

looper,

shank

slightly

lower

to

closer

PLATE

of

(or

it

looper

left

clearance

above

reduce

looper,

the

to

MACHINE,

TO

may

needle).

holder

the

needle(s).

be

necessary

dimension

to

the

(dimension

angle

See

Step

AS

APPLICABLE.

“F”,

Tighten

needle(s)

of

3.

to

the

until

top

should

time.

travel,

mately

as

screw

as

required

screw

and

height

then

loosen

throat

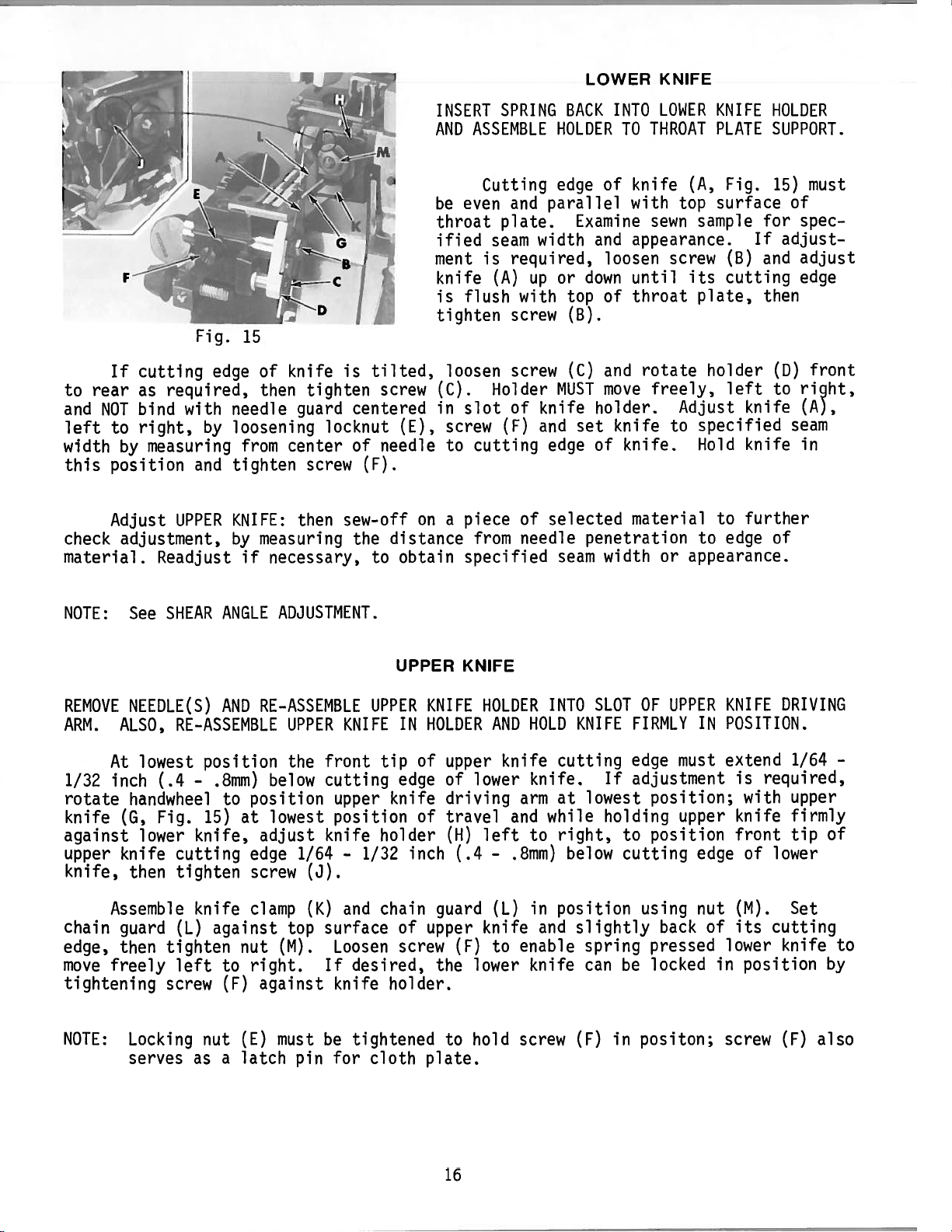

Rotate

teeth

surface

shown

If

(A)

(A).

adjust

tighten

On

screw

plate,

handwheel

of

of

be

level

With

feeds

their

3/64

in

inch

Fig.

adjustment

and

to

Loosen

feeds

above

all

Styles,

rising

throat

with

teeth

rotate

level

throat

screws

CD)

then

throat

at

highest

should

(1.2mm)

14.

is

tilt

feeds,

feed

up

or

plate

(C).

except

and

set

tighten

operating

in

feeds

plate.

extend

above

required,

adjusting

attaching

down

as

WK,

height

screw

are

The

plate

position

throat

then

obtain

to

shown

WW,

of

direction

above

feeds

at

approxi-.

loosen

tighten

screws

in

CWK,

chaining

(D).

this

pin

the

of

plate

lock

(B)

lock

(C)

proper

Fig.

SWK,

14,

CSWK:

feed

with

even

with

feeds

the

at

stitch

Fig.

highest

14

tongue

position,

of

15

Page 16

LOWER

KNIFE

rear

to

and

NOT

left

to

width

this

position

Adjust

check

material.

If

cutting

required,

as

bind

right,

measuring

by

adjustment,

Readjust

Fig.

edge

with

by

and

UPPER

15

of

then

needle

loosening

from

tighten

KNIFE:

by

measuring

if

necessary,

knife

tighten

guard

center

screw

then

is

centered

locknut

of

(F).

sew-off

the

tilted,

screw

needle

distance

obtain

to

(E),

INSERT

AND

be

throat

ified

ment

knife

is

tighten

loosen

(C).

in

screw

to

a

on

SPRING

ASSEMBLE

Cutting

even

and

plate.

seam

is

required,

up

(A)

flush

with

screw

screw

Holder

slot

of

(F)

cutting

from

of

needle

piece

specified

BACK

HOLDER

edge

parallel

Examine

width

or

top

(B).

(C)

MUST

knife

and

set

edge

selected

seam

INTO

THROAT

TO

of

knife

with

sewn

and

appearance.

loosen

down

until

of

throat

and

rotate

move

freely,

holder.

knife

of

knife.

material

penetration

width

LOWER

(A,

top

sample

screw

its

plate,

holder

Adjust

to

specified

Hold

to

or

appearance.

KNIFE

PLATE

Fig.

surface

If

(B)

cutting

left

knife

knife

to

further

edge

HOLDER

SUPPORT.

must

15)

of

spec

for

adjust

adjust

and

edge

then

front

(D)

ri9ht,

to

(A),

seam

in

of

NOTE:

REMOVE

ARM.

ALSO,

At

1/32

inch

rotate

knife

(G,

against

upper

knife

knife,

Assemble

chain

edge,

move

guard

then

freely

tightening

NOTE:

SHEAR

See

NEEDLE(S)

RE-ASSEMBLE

(.4

position

—

lowest

handwheel

Fig.

15)

lower

knife,

cutting

then

tighten

knife

CL)

tighten

left

screw

Locking

serves

nut

as

ANGLE

AND

.8mm)

position

to

at

edge

screw

clamp

against

nut

right.

to

(F)

CE)

a

latch

ADJUSTMENT.

RE-ASSEMBLE

UPPER

the

below

KNIFE

front

cutting

upper

1/64

position

knife

—

1/32

lowest

adjust

(J).

(K)

and

surface

top

(M).

against

must

pin

Loosen

If

desired,

knife

be

tightened

for

UPPER

UPPER

IN

tip

edge

knife

holder

inch

chain

of

screw

holder.

cloth

KNIFE

KNIFE

HOLDER

of

upper

of

driving

of

travel

(H)

(.4

guard

upper

(F)

the

to

plate.

HOLDER

AND

knife

lower

arm

and

left

—

.8mm)

(L)

knife

to

enable

lower

screw

hold

INTO

HOLD

cutting

knife.

at

while

right,

to

in

position

and

knife

SLOT

KNIFE

lowest

below

slightly

spring

can

(F)

OF

FIRMLY

edge

If

adjustment

holding

to

cutting

using

be

positon;

in

UPPER

IN

must

position;

upper

position

edge

nut

back

pressed

locked

KNIFE

POSITION.

extend

is

with

knife

front

of

CM).

of

its

lower

in

position

screw

DRIVING

1/64

required,

upper

firmly

tip

lower

Set

cutting

knife

(F)

—

of

to

by

also

16

Page 17

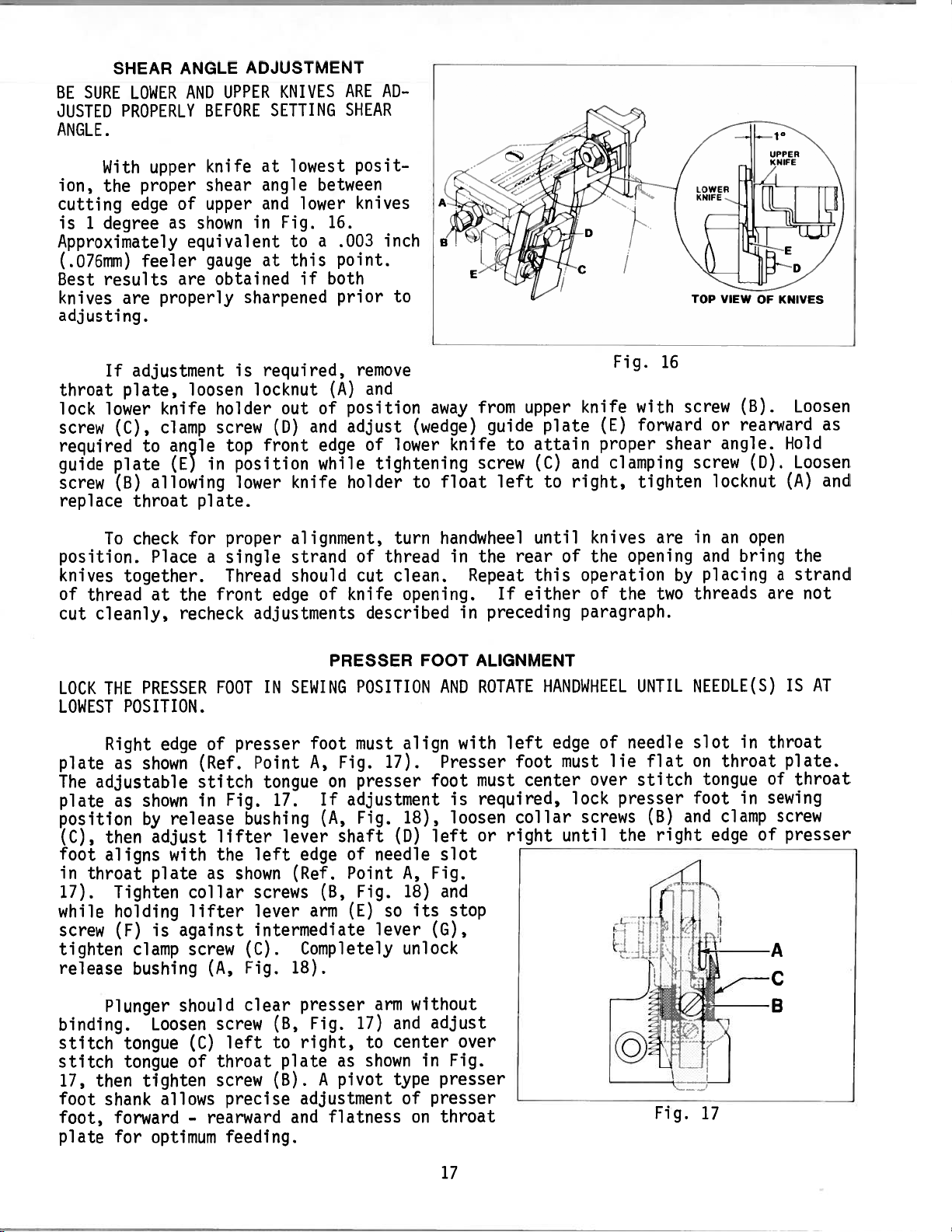

SURE

BE

JUSTED

ANGLE.

SHEAR

LOWER

PROPERLY

ANGLE

AND

BEFORE

ADJUSTMENT

UPPER

KNIVES

SETTING

AD

ARE

SHEAR

1

With

the

ion,

cutting

is

1

degree

Approximately

(.076mm)

Best

knives

adjusting.

throat

lock

screw

required

guide

screw

replace

position.

knives

of

thread

cut

cleanly,

proper

edge

feeler

results

are

If

adjustment

plate,

lower

(C),

to

plate

(B)

throat

To

check

together.

upper

allowing

at

of

as

equivalent

are

properly

loosen

knife

clamp

angle

CE)

for

Place

the

recheck

knife

shear

upper

shown

gauge

obtained

holder

screw

top

in

plate.

proper

a

single

Thread

front

at

angle

and

Fig.

in

at

sharpened

is

required,

locknut

out

CD)

front

position

lower

edge

adjustments

lowest

between

lower

16.

a

if

and

knife

.003

point.

both

prior

(A)

of

edge

while

of

position

adjust

holder

knife

to

this

alignment,

strand

should

posit

knives

inch

to

remove

and

of

lower

tightening

turn

of

thread

clean.

cut

described

away

(wedge)

knife

to

float

handwheel

in

opening.

from

guide

screw

the

Repeat

in

preceding

to

left

If

upper

attain

(C)

until

rear

this

either

plate

to

of

Fig.

knife

(E)

proper

clamping

and

right,

knives

the

operation

of

the

paragraph.

16

with

forward

shear

tighten

are

opening

two

screw

screw

in

by

threads

(B).

or

rearward

angle.

locknut

an

bring

and

placing

(D).

open

are

Loosen

Hold

Loosen

(A)

the

a

strand

as

and

not

LOCK

THE

LOWEST

Right

plate

The

plate

position

(C),

foot

in

17).

while

screw

tighten

release

binding.

stitch

stitch

17,

foot

foot,

plate

as

adjustable

as

then

aligns

throat

Tighten

holding

Plunger

then

shank

forward

for

PRESSER

POSITION.

edge

shown

shown

release

by

adjust

with

plate

is

(F)

clamp

tongue

tongue

against

bushing

should

Loosen

tighten

allows

optimum

FOOT

of

(Ref.

stitch

in

lifter

the

as

collar

lifter

screw

(A,

screw

(C)

of

throat

screw

-

rearward

IN

presser

Point

tongue

Fig.

bushing

left

shown

screws

lever

intermediate

(C).

Fig.

clear

left

precise

feeding.

SEWING

foot

A,

17.

lever

edge

(Ref.

arm

Completely

18).

presser

Fig.

(B,

right,

to

plate

(B).

adjustment

and

PRESSER

POSITION

must

Fig.

presser

on

If

adjustment

Fig.

(A,

shaft

of

Point

(B,

Fig.

CE)

17)

as

A

pivot

flatness

17).

(D)

needle

so

lever

arm

and

center

to

shown

type

FOOT

align

foot

18),

left

Fig.

A,

18)

its

(G),

unlock

without

adjust

in

presser

of

on

ALIGNMENT

ROTATE

AND

with

Presser

must

required,

is

loosen

or

slot

and

stop

over

Fig.

presser

throat

HANDWHEEL

edge

left

must

foot

center

collar

right_until

over

lock

screws

of

lie

presser

the

—

UNTIL

needle

flat

stitch

(B)

right

Fig.

NEEDLE(S)

slot

on

foot

and

in

throat

tongue

in

clamp

edge

17

throat

plate.

of

sewing

screw

of

presser

-A

-c

-B

IS

throat

AT

-

17

Page 18

116”

(1.6mm>

Fig.

18

-.

/

p

PRESSER

Lift

and

rotate

Upper

any

loosen

screw

with

Loosen

upper

looper

point

locknut

(J)

upper

locknut

end

approximately

lifter

rise,

FOOT

lever

then

PRESSURE

PRESSER

presser

handwheel

must

of

travel.

(H,

so

presser

looper,

(K)

of

lifter

1/16

before

tighten

foot

in

not

Fig.

foot

then

and

lever

inch

presser

locknut

FOOT

to

LIFTER

highest

operating

contact

If

adjustment is

18)

and

will

tighten

set

stop

arm

(1.6mm)

foot

(K).

presser

adjust

not

locknut

screw

so

there

free

starts

position

direction.

foot

required,

stop

interfere

(F)

is

motion

at

(H).

on

in

to

spring

If

adjustment

and

18)

less

NOTE:

Sufficient

pressure

differential

and

turn

pressure,

Adjusting

Plunger

When

against

ment

is

adjusting

then

must

release

throat

must

pressure

will

required,

feeds

tighten

screw

clear

bushing

be

made.

cause

are

screw

CM)

plate.

must

feeds

rotate

positioned

(M)

locknut

will

presser

is

maintained

be

and

clockwise

effect

locked

If

these

presser

handwheel

below

(L).

the

arm

when

in

conditions

to

foot

in

throat

for

function

pressure

position,

feed

work

to

operating

plate.

more

pressure

of

release

presser

do

wear

pressure

not

uniformly.

prematurely

direction

Loosen

or

bushing

foot

exist

Excessive

when

until

locknut

counterclockwise

release

must

the

following

is

be

bushing

unlocked.

held

chaining.

both

(L,

main

Fig.

for

(A).

firmly

adjust

Lock

(N)

screw

and

(M)

presser

adjust

as

shown

nut

foot

(P)

in

in

up

Fig.

position

or

down

18.

so

Hold

with

its

nut

pressure

under

(P)

surface

in

release

position

18

bushing

is

and

1/16

inch

tighten

(A);

loosen

(1.6mm)

capnut

capnut

above

(N).

Page 19

The

usually

per

inch

distance

ing

above

The

to

a

great

The

differential

independent

gather

or

stitched.

On

(A,

Fig.

longest

indicates

To

clockwise

desired

tial

feeds,

SETTING

actual

measured

of

seam.

feeds

the

resulting

extent

of

stretch

the

graduated

19)

the

stitch

shortest

adjust

to

increase

stitch

also

stitch

as

travel

throat

feed

the

forward

length

stitch

length

check

STITCH

the

This

stitch

by

main

the

stitch

length

number

is

with

plate.

travel

travel

feed

fabric

scale

marking

and

length

feed

is

obtained

clearance

LENGTH

produced

of

determined

their

length

of

the

can

and

prior

of

indicator

rear

the

length.

turn

travel

is

stitches

by

teeth

is

be

is

“L”

both

or

check

between

protrud

determined

main

marking

feed.

adjusted

used

to

being

indicates

main

counterclockwise

the

sewn

the

to

plate

‘S’

and

clearance

the

differential

throat

to decrease

between

plate

thumbscrews

the

both

and

Fig.

feed

main

feeds.

19

travel.

and

(B

and

differen—

C)

After

If

an

the

handwheel

the

way

to

clearance

(18-20

MECHANISM.

differential

the

plate

stitch

thread

ed

barely

the

loosen

tion

If

bed

Needle

in

Moving

eyelet

and

cm/kg).

desired,

directly

and

length

cam

the

touch

screw

tighten

screw

adjustment

in

rear.

the

is

obtained.

feed

lower

pull-off

down

during

thread

needle

the

(C)

knife

slot,

eyelet

and

is

operating

Loosen

If

clearance

thumbscrews

or

by

above

and

screw

support

machine

controlled

is

(B).

front

thread

up

forward

position

the

(C).

necessary,

direction

nut

Hold

ferrule

cannot

can

tightening

main

bracket.

operation.

NEEDLE

Needle

to

cam

back

and

acts

thread

set

CD)

be

locked

be

pressure

feed

by

needle

thread

back.

pull—off

increases

the

the

until

and

rotate

in

position

obtained,

stitch

This

THREAD

eyelet

Raise

when

reverse.

eyelet

feeds

the

differential

eccentric

in

position

plug

regulating

will

CONTROL

thread

is

or

lower

needle

the

To

(A)

as

to

and

See

screw

prevent

eyelet

set

carrier

needle

adjust

required.

have

the

ferrule

torque

SETTING

by

tightening

for

the

screw

accidental

(A,

so

the

the

eyelet

thread

needle

same

feed

nut

DIFFERENTIAL

to

Fig.

securing

is

Hold

is

to

main

the

to

in

in

thread

travel,

positioned

(E)

16—17

nut

feed,

rear

changing

20)

and

screw

have

its

lowest

the

stitch,

eyelet

until

control,

then

in.

FEED

(F)

located

of

needle

needle

in

turn

all

maximum

lbs.

for

the

in

throat

of

is

center

thread

position.

moving

posi

19

Page 20

LOOPER

THREAD

PULL-OFF

When

will

be

looper

at

its

centered

Loosen

ing

slot

tighten

adjusting

eyelet

C

I

I

a

thread

extreme

screw

and

a

little

in

and

slot

normal

is

its

screw

set

back

Fig.

slack

held

left

adjusting

eyelet

(A).

and

of

20

amount

end

(A,

Loosen

set

lower

when

in

of

Fig.

in

eyelet

of

needle(s)

a

straight

travel.

slot

21).

a

screw

looper

LOOPER

looper

and

Center

horizontal

(C).

so

it

thread

THREAD

thread

line

The

set

rests

(0,

(B)

take—up

Loosen

pull—off

driving

obtained.

sure

shaft.

at

is

to

auxiliary

slightly

lower

position.

Center

on

eyelet

Clearance

Fig.

should

screws

to

CONTROL

is

drawn,

highest

the

looper

upper

the

eye.

20)

be

of

lever

shaft

take

lower

upper

above

top

between

and

only

looper

(E)

(F)

until

Before

up

upper

position.

looper,

a

thread

Hold

looper

surface

needle

enough

thread

rotate

and

front

proper

tightening

all

end

and

with

looper

horizontal

eyelet

eyelet

thread

of

looper

thread

to

as

back

to

clearance

play

lower

Position

the

thread

position.

(B)

(B)

in

eyelet

lower

thread

cam

ensure

shown

looper

screws

in

looper

lower

guide

in

position

looper

pull-off

in

on

needle

guide

its

CD)

pull-off

proper

Fig.

thread

needle

is

(E)

drive

threads

so

looper

should

adjust

and

in

thread

20.

be

the

be

its

guide

(D)

its

in

a

Center

so

auxiliary

and

set

To

extreme

straight

it

auxiliary

slightly

is

frame

end

left

line

Fig.

upper

lower

of

to

21

upper

above

looper

thread

travel

the

looper

lower

horizontal

a

thread

eyelet

and

looper.

thread

guide

(F)

position

guide

position.

CE)

loosen

the

Tighten

NOTE:

in

CE)

position

in

screw

eyelet

screw

Moving

increases

in

the

reduces

system.

its

Hold

(G)

so

(G).

eyelets

the

system

the

adjusting

lower

and

and

looper

the

(B

amount

and

amount

looper

tighten

move

and

moving

of

slot

lower

thread

D)

of

thread

and

thread

screw

looper

to the

looper

them

set

eyelet

(C).

is

held

rear

thread

forward

the

in

to

20

Page 21

POWER

“AIR_KLIPP”r

CHAIN

CUTTER

ADJUSTMENTS

SETTING

The

after

air

replacing

line

VALVES)

finger,

stops.

With

lower

from

loosen

knife

the

screws

positioned

right.

inch

(.4mm)

CAUTION!

knife

CROSS

cross

KNIFE

or

connected

depress

treadle

carefully

treadle

the

to

front

of

(B),

far

to

Retighten

clearance

Check

does

to

not

“AIR—KLIPP”

slight

at

point

OVER

over

sharpening

to

air

press

still

upper

the

upper

reposition

left

screws

between

ensure

strike

chain

clearance

(D).

is

motor

until

against

depressed,

knife

knife

slightly

or

(B)

that

against

cutter

must

set

knives.

air

is

air

and

front

lower

the

at

With

“AIR—KLIPP”

for

motor

moving

the

check

positioned

as

shown

motor

the

to

recheck

edge

knife

inside

tube.

be

provided

factory,

sewing

begins

drive

the

in

slightly

(C)

right

cross

of

air

of

A

however

motor

chain

operate,

to

link

knife

correctly,

Fig.

if

over.

tube

cross

22.

to

lower

and

adjustment

switch

cutter

(A,

over.

when

If

the

knife

There

rear

in

(See

and

in

22)

Fig.

The

the

adjustment

left

is

should

edge

will

“OFF”

SETTING

out.

until

cross

lower

is

lower

if

positioned

always

of

throat

necessary

be

position

PRESSURE

With

air

over

knife

required,

knife

be

fore

motor

of

is

2/3

is

too

1/64

plate.

and

the

far

SETTING

If

and

turn

wise

(a

operating

ing

with

are

cutting.

the

thread,

(F)

counterclockwise

lock

with

SETTING

Torsion

lifted

to

the

the

right

over

left

SETTING

Regulate

chain

cutter

Regulate

suction,

cutter

knives.

KNIFE

CUTTING

adjustment

knife

piece

knife

amount

lever

lower

small

a

As

shear

the

CE).

nut

KNIFE

PRESSURE

spring

knife.

the

(away

(towards

PRESSURE

valve

approximately

to

so

on

that

valve

yet

is

required,

adjusting

at

(G),

thread

of

soon as

angle

approximately

(H)

from

lower

lower

VALVES

on

pneumatic

pneumatic

the

time)

a

continuously

to

the

knives

is zero,

initially

More

pressure

knife);

knife).

control

FABRIC

loosen

screw

while

if

see

should

control

20—22

TO

(F)

knives

fail

turn

1/4

less

psi

device

BE

CE)

nut

clock

manually

check

to

screw

turn

be

be

can

pressure

device

(1.5

for

SEWN

will

cut

and

horizontal

obtained

for

when

bar)

the

not

by

—

by

air

air

suction

cut

be

in

its

bending

bending

motor

motor

air

by

Fig.

22

state

free

spring

spring

of

the

operating.

is

obtain

to

the

“AIR—KLIPP”

and

then

slightly

(H)

slightly

“AIR—KLIPP”

maximum

chain

to

21

Page 22

AC

23

Fig.

22

Page 23

1.

Position

(C)

and

washer

all

up

Shaft

end

(C)

components

washer

insert

(A)

should

ADJUSTING

(A,

shaft

against

play

by

turn

assembled

INSTRUCTIONS

Fig.

through

retaining

thrusting

freely

to

shaft

23),

retaining

casting,

bed

ring

collar

by

hand

loose.

(B)

(D)

with

FOR

ring

and

against

FEED

(B)

assembling

flush

against

right

left

no

DRIVE

differential

on

parts

to

MECHANISM

recess

of

side

right

as

illustrated.

inner

shake.

in

feed

bed

control

casting,

casting

Leave

the

shaft

With

take

wall.

other

NOTE:

2.

3.

NOTE:

4.

Torque

Assemble

screw (G),

to

link

(E)

drive

(N).

(L)

Torque

Assemble

screw

control

main

(S)

link

feed

(Y).

Do

not

(set

at

and

pin

With

large

(AB)

into

main

feed

bar

(F),

inner

lever

hole

casting

(AE),

in

right

approximately

washers

shaft

between

shown

(AC)

(AB).

the

in

operating

all

screws

differential

differential

with

the

to

nut

guide

into

block

main

(U)

drive

remove

factory),

washer

oil

hole

casting.

bar

(Q)

slide

shaft

wall

another

end

1/64

against

Position

edge

Fig.

24.

direction

to

feed

differential

opposite

to

16—17

(P)

feed

main

to

(X)

to

differential

however,

(AA)

to

facing

With

and

main

(AB)

and

collar

of

shaft

inch

inner

lever

of

feed

Tighten

to

19-21

drive

feed

end

in.

to

bar.

feed

the

opposite

align

upward

main

feed

through

assemble

(AD)

is

(.4mm)

walls

(AE)

drive

screw

recheck

in.

control

feed

of

lbs.

main

drive

feed

this

feed

facing

from

lever

clearance

lbs.

link

drive

drive

(18—20

feed

Assemble

link

end

bar

pin

and

thrust

and

drive

bar

guide

main

thrust

(1)

and

thrust

outer

of

casting

on

shaft

connecting

(AG)

(22-24

(E)

link

segment

bar

guide

is

to

feed

up

to

link

main

(V)

of

used

the

link

block

and

edge

(AB)

55

and

cm/kg)

to

differential

(H)

cm/kg).

with

(Q)

feed

with

segment

pin

in

rear

right,

(V)

drive

washer

washer

position

to

in.

assure

and

stud

(3)

(Z)

conjuction

of

(P)

of

casting.

remove

to

rod

lbs.

unless

differential

(K);

then

with

eccentric

screws

drive

main

(T)

segment

feed

with

unless

feed

bars.

insert

assembled

positioned

(X),

differential

(AC),

(1)

(Ac).

shaft

any

have

approximately

(AF)

(63

there

otherwise

feed

(R)

link

main

absolutely

with

feed

to

collar

check

so

Position

left

and

cheek

cm/kg),

are

bar

feed

secure

and

(T)

drive

shoulder

on

to

its

to

no

specified.

(F)

drive

differential

ferrule

thread

and

(W).

stud

feed

drive

necessary

tilt

adjusting

rocker

differential

feed

(AD),

ensure

left

collars

right

1/32

of

crankshaft

rotate

binds.

with

shoulder

segment

(NI)

shoulder

main

Assemble

link

screw

drive

feed

large

end

is

movement

inch

handwheel

and

feed

shaft

(S)

feed

(L),

drive

oil

recessed

(AD)

of

(.8mm)

as

(3)

feed

nut

stud

in

and

in

IMPORTANT:

5.

Thrust

bar

for

bars

which

NOTE:

If

repositioning

secured

rear

Link

pin

thrust

its

with

is

upper

This

SWC

front

mounting

pin

and

of

guide

tilt

secured

hole

CSWC.

adjusting

RE-ALIGNMENT

in

position

of

feed

bars

which

of

should

feed

(AH,

screws.

in

is

feed

connects

lever

be

bars

Fig.

position

necessary,

bar

guide

by

screw

as

previously

(AE)

in

into

23)

Thrust

pin

the

and

by

lever

for

lower

place