Page 1

®

INDUSTRIAL

SEWING

FINES,T

STYLE

39500

QUALITY

JR

LEWIS

•

COLUMBIA

tf

.

..

MACHINES

~

CLASS

HI-STYLED

CATALOG

No.

103

JR

THREE

FOR

TO

PERMA-PRESS

CHICAGO

THREAD

ATTACHING

39500

HIGH

SPEED

PLAIN

FEED

ZIPPERS

MATERIALS

Page 2

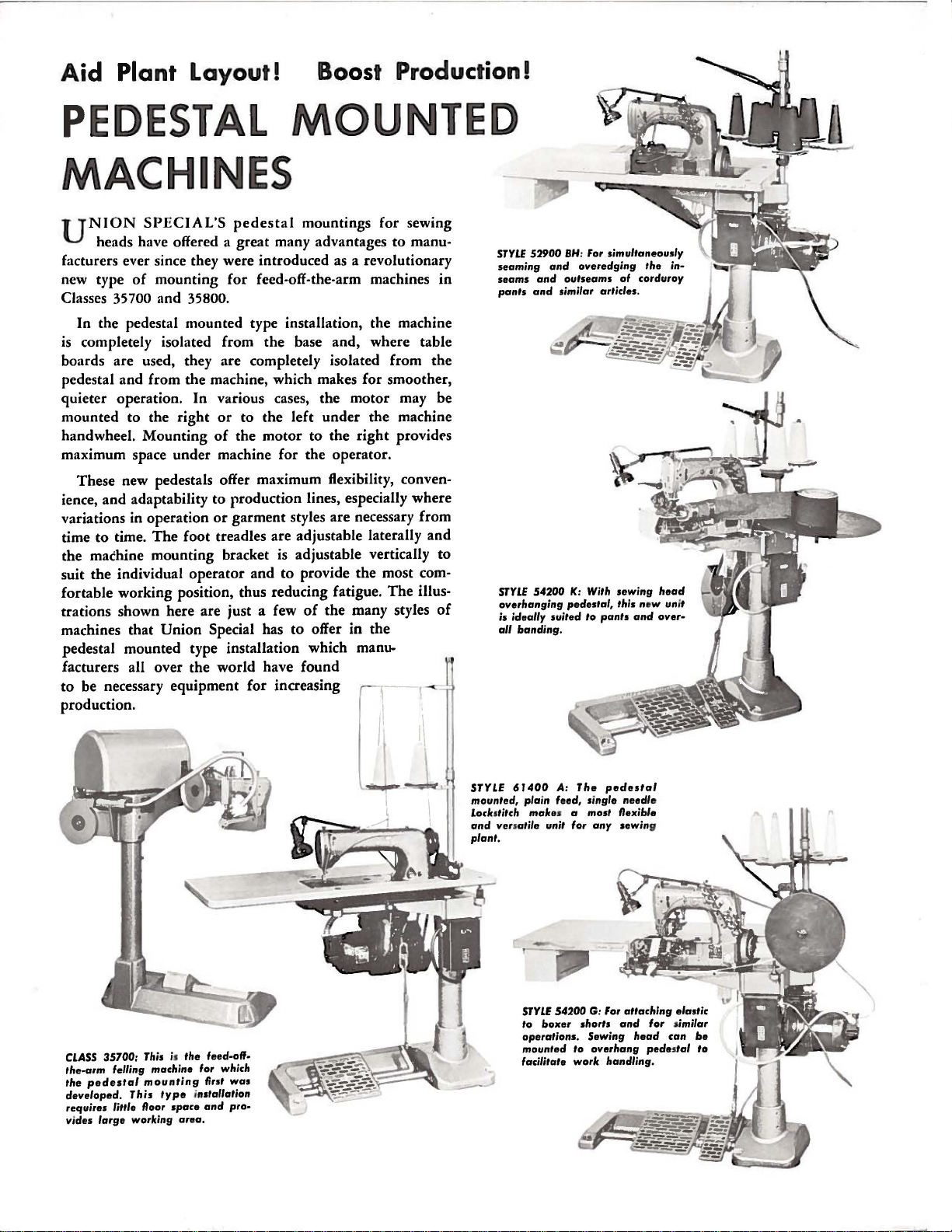

Aid

Plant Layout!

Boost Production!

PEDESTAL

MOUNTED

MACHINES

UNION

heads have offered a great many advantages

facturers ever since they were introduced as a revolutionary

new type

Classes 35700 and 35800.

In the pedestal mounted type installation, the machine

is

completely isolated from the base and, where table

boards are used, they are completely isolated from the

pedestal and from the machine, which makes for smoother,

quieter operation. In various cases, the motor may be

mounted to the

handwheel. Mounting

maximum space under machine for the operator.

These new pedestals offer maximum flexibility,

ience,

variations in operation

to

time

the machine mounting bracket is adjustable vertically to

suit the individual operator and

fortable working position, thus reducing fatigue.

trations shown here are just a few

machines that

pedestal mounted type installation which

facturers all over the world have found

to

be necessary equipment for increasing

production.

of

and

adaptability

time.

SPECIAL'S

pedestal

mountings for sewing

to

mounting for feed-off-the-arm machines

right

or

to the left under the machine

of

the

motor

to

production lines, especially where

or

garment styles are necessary from

The

foot treadles are adjustable laterally

to the

to

provide the most com-

right

providt>s

The

of

the many styles

Union

Special has

to

offer

in

the

manu-

r-

1

I

manu-

in

conven-

and

illus-

of

STYlE

52900

seaming

seams

pants

STYLE

overhanging

is ideally

all

and

and

and

54200

banding.

SH

: For simultaneously

overedging

outseams

similar articles.

K:

With

pedestal,

suited

to

pants

the

corduroy

head

and

over·

in-

of

sewing

this new unit

CLASS

35700:

the-arm

the

pedestal

developed.

requires

vides

large

This

is

the

type

space

feed-off-

first

installation

and

area.

was

pro-

felling machine for which

mounting

This

little floor

working

STYLE 6 J

mounted, plain feed, single

Locbtitch

and

plant.

400

A:

make

versatile unit for

s a most flexible

STYLE

54200

to

boxer

operations.

mounted

facilitate work handling.

The

any

G: For

shorts

Sewing

to

overhang

pedestal

needle

sewing

attaching

and

head

elastic

for

similar

can

pedestal

be

to

Page 3

Catalo

g

No

.

103

JR

(Supplement

ADJUSTING

to

Catalog

INSTRUCTIONS

FOR

AND

LIST

CLASS

OF

Style

39500

PARTS

39500

JR

No.

OPERATING

103

FJ)

January,

1968

F

irst

Copyri

E

dition

g

ht

1968

By

Union

Rights

Special

Reserved

Machine

in

All

MACHINE COMPANY

INDUSTRIAL

Printed

SEWING

CHICAGO

in

MACHINES

U.S.A.

Co.

Countrie

s

3

Page 4

IDENTIFICATION

OF

MACHINE

Each

the

machine.

numbers

"Style

changes

ber.

39500

are

Example: "Style

Styles

which

differs

39500".

This

junction

F J

are

therewith.

illustrated

illustration

and

the

number

numbers

ference

ber

numbers

listed

This

in.

It

can

39500.

from

References

the

handwheel

Union

Special

Style

have

one

JR".

made

of

machines

from

catalog

will

only~

in

and

the

catalog

also

be

operator's

is

away

machine

numbers

or

more

Special

are

letters

Style

in a standard

39500

similar

the

Style

number

APPLICATION

is a supplement

Only

and

be

found a listing

of

pieces

merely

should

second

applies

applied

to

those

listed

at

required.

indicate

never

column.

specifically

with

directions~

position

from

operator.

is

identified

classified

suffixed~

numbers

machine~

JRZ".

in

construction

in

that

to

Catalog

parts

the

of

used

back

the

parts~

Numbers

the

position

be

used

discretion

while

to

such

seated

in

the

to

as

by a Style

as

standard

but

never

contain

a

"Z"

is

are

it

contains

OF

CATALOG

No.

on

Style

of

this

with

of

ordering

standard

some

right~

at

the

contain

the

suffixed

grouped

103

FJ

39500

catalog.

their

in

the

that

parts.

Style

Special

left~

machine.

number

and

special.

the

letter

to

"Z".

the

under a Class

no

letters.

and

should

JR~

but

On

part

first

part

column

in

Always

of

machine

Styles

front~

back~

Operating

on a name

Standard

letter

''Z''.

When

standard

only

Style

Example:

be

used

not

on

Style

the

page

numbers~

opposite

description

are

the

illustration.

use

the

part

as

listed

of

machines

etc.,

direction

plate

on

Style

Example:

minor

num-

number~

"Class

in

con-

39500

the

reference

Re•

num-

here-

in

Class

are

given

of

Hi-StyledHigh

seaming

Knife,

39500

Machine.

Automatic

JR

flies

and

or

and

similar

SSj-1.

Medium

adjusted

CAUTION!

filled

straight

should

before

mineral

be

used.

Machine

gauge

lines

on

front

when

machine

Machine

main

reservoir

SpeedSingle

Plain

Lubricating

to

heavy

zipper

tapes

operation

Standard

feed.

Maximum

Oil

was

beginning to

oil

of a Saybolt

is

filled

of

with

machine.

is

is

automatically

filled.

STYLE

Curved

Feed,

System.

duty

to

pants

of

Perma-Press

seam

width

recommended

drained

operate.

oil

at

spring

Red

stationary.

lubricated.

Check

oil

Blade

Trimming

machine

fronts;

3/16

from

Oil

viscosity

bulb

on

daily

OF

MACHINE

Needle~

Mechanism

for

also

material.

inch.

OILING

machine

capacity

of

cap

in

oil

level

No

before

Two

Looper,

simultaneously

attaching

Seam

speed

when

200

top

cover.

Stitch

of

to

range 6 to

6500

shipped,

Class

250

indicator

oiling

the

is

necessary~

morning

with

Spring

zippers

Specification

R.

P.M.

so

39500

seconds

Oil

level

should

start;

Three

Pressed

attaching

to

right

16

per

reservoir

is

si:'&

at

100

is

checked

show

between

other

add

oil

Thread

right

flies

504-SSa-1

inch;

must

ounces.

Fahrenheit

at

than

keeping

as

required.

Over•

Lower

pants

only

cam

be

A

sight

gauge

The

oil

It

is a magnetic

have

entered

drain

plug screw

screw

the

crank

is

designed

case.

located

to

accumulate

It

should

at

be

back

4

of

machine

possible

removed

and

near

foreign

cleaned

bottom

edge

materials

periodically.

of

which

base.

may

Page 5

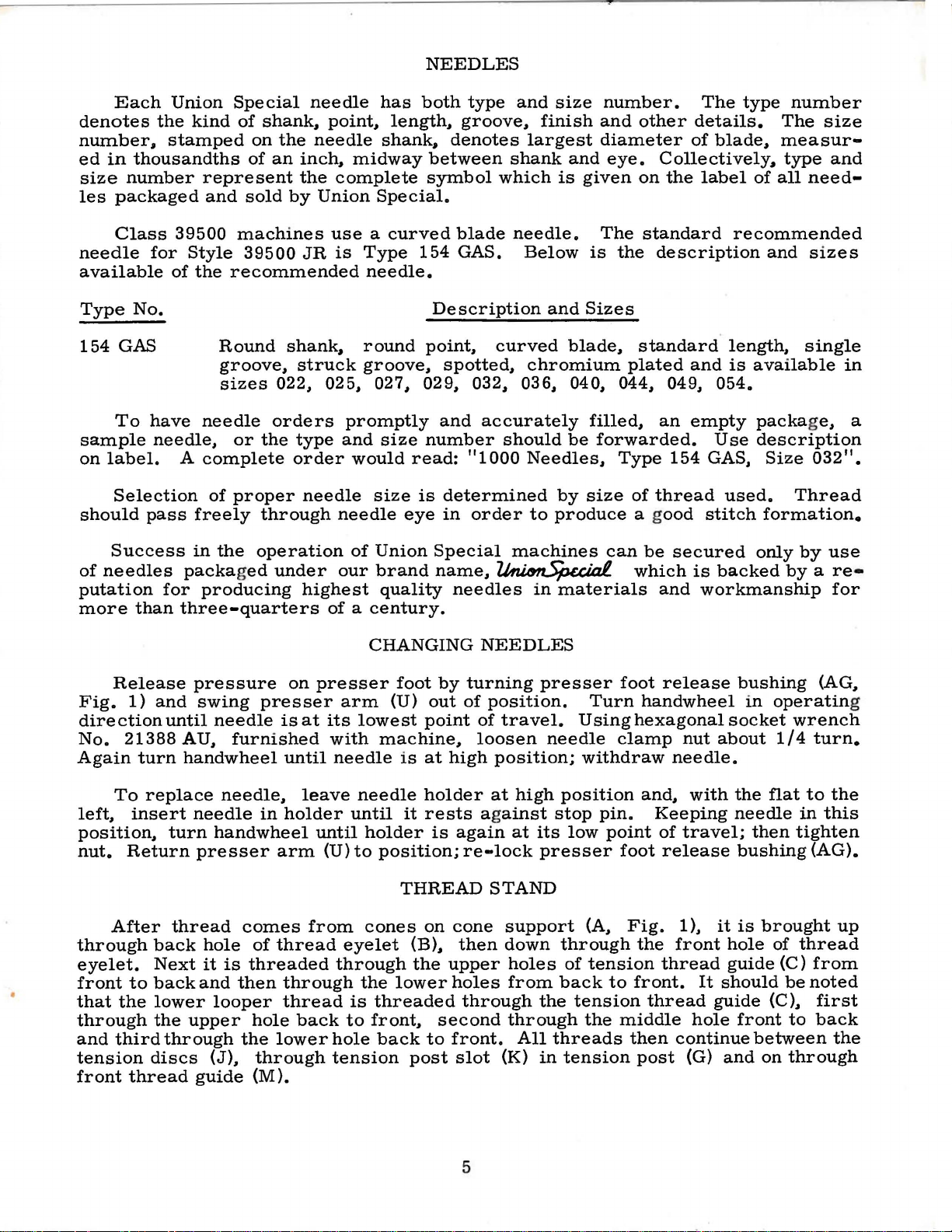

NEEDLES

Each

denotes

number,

ed

in

thousandths

size

les

number

packaged

Class

needle

available

Type

154

No.

GAS

To

sample

on

label.

Selection

should

Success

of

needles

putation

more

than

Union

the

kind

stamped

represent

and

39500

for

Style

of

the

Round

groove,

sizes

have

needle

needle,

A

complete

of

pass

freely

in

the

packaged

for

producing

three-quarters

Special

of

shank,

on

of

sold

machines

39500

the

an

needle

point,

needle

inch,

the

complete

by

Union

use a curved

JR

is

recommended

shank,

struck

022, 025,

orders

or

the

type

order

proper

needle

through

operation

under

highest

of a century.

has

length,

shank,

midway

Special.

Type

needle.

round

groove,

027,

promptly

and

size

would

size

needle

of

Union

our

brand

quality

both

between

symbol

154

De

point,

spotted,

029,

and

number

read:

is

determined

eye

in

Special

name,

type

groove,

denotes

blade

GAS.

scription

and

finish

largest

shank

which

needle.

Below

curved

chromium

size

and

is

and

blade,

number.

and

diameter

eye.

given

The

is

the

Sizes

plated

other

on

standard

standard

032, 036, 040, 044, 049,

accurately

should

"1000

order

~

needles

Needles,

to

machines

in

filled,

be

forwarded.

by

size

produce

can

materials

Type

of

a g

be

which

The

type

details.

of

blade,

Collectively,

the

label

recommended

description

length,

and

is

054.

an

empty

Use

154

GAS,

thread

ood

used.

stitch

secured

is

backed

and

workmanship

number

The

size

measur-

type

and

of

all

need-

and

sizes

single

available

package,

description

Size

032".

Thread

formation.

only

by

use

by a re•

for

in

a

CHANGING

Release

Fig.

1)

direction

No.

21388

Again

turn

To

left,

insert

position,

nut.

Return

replace

pressure

and

swing

until

AU,

handwheel

needle

turn

presser

on

presser

needle

is

furnished

until

needle,

in

holder

handwheel

arm

presser

at

its

with

needle

leave

until

(U)

arm

lowest

needle

until

holder

to

foot

(U)

out

point

machine,

is

at

holder

it

rests

is

position;

THREAD

After

through

eyelet.

front

•

that

the

through

and

third

tension

front

thread

back

Next

to

back

lower

the

through

discs

thread

hole

it

is

and

looper

upper

(J),

guide

comes

of

thread

threaded

then

through

thread

hole

the

lower

through

(M).

from

back

cones

eyelet

through

the

is

threaded

to

front,

hole

back

tension

on

(B),

the

lower

to

post

NEEDLES

by

turning

of

of

loosen

high

ag

again

re-lock

cone

then

upper

holes

through

second

front.

slot

presser

position.

travel.

needle

position;

at

high

ainst

at

its

presser

STAND

support

down

holes

from

the

through

All

(K)

in

Turn

Using

withdraw

position

stop

pin.

low

(A,

through

of

tension

back

tension

the

threads

tension

foot

handwheel

hexagonal

clamp

and,

point

foot

Fig.

the

to

front.

thread

middle

then

post

release

nut

needle.

with

Keeping

of

travel;

release

1),

front

thread

It

guide

hole

continue

(G)

bushing

in

socket

about

the

needle

then

bushing

it

is

hole

guide

should

front

between

and

operatin

wrench

1/4

turn.

flat

to

in

tighten

(AG).

brought

of

thread

(C)

from

be

noted

(C),

first

to

back

on

through

(AG,

g

the

this

up

the

5

Page 6

li]

Tension

IJ

Tension

II

Tension

[!]

Tension

IIJ

spring

O Tension Discs -c

13

Tension

II

Tension Disc

Nut

Spring

Spring--../

Post

----

Shield

Post

Slo~

Felt

Ferrule

,.

:;

:

-

.

--..

·· ..

~

~

'.:~~~

~

1

;

J1:l,

~

m

~

~

Thread

Eyelet

fiJ

Front

im

upp

m Lower Looper

m

Fabr

D

Fram

Thread Guide

ID

Pr

Thread

er Looper

ic Guard

e Looper

esser

Arm

Guide

Thread Eyelet

Thr

ead E

yelet

Bra

cket

~)

~~~~

~

1J11~

..

u.;:iill

Top

Needle Thr

Thread Tube Assembly

Cover

ead Eyelet

Upper Looper

Fig

. 1

6

Page 7

THREADING

Only

are

placed

It

will

threading

Before

direction

turning

Be

sure

tension

Double

(R. Fig.

off

(AF).

looper

looper

Left

thread

(V)

eye

Turn

through

of

upper

of

looper

(AA)..

lead

sembly

throu

gh

parts

in

their

simplify

lower

beginning

until

presser

threads,

discs

(J)

end

1)

from

Lead

guide

is

all

of

lower

handwheel

auxiliary

looper

thread

thread

(AA).

upper

Pull

looper

involved

relative

threading

looper

to

needle

foot

release

and

in

of

thread

right

thread

(T).

the

way

looper

until

looper

thread

pull-off

under

thread

eye

in

threading

first,

thread,

(X)

is

as

they

diagonal

TO

and

to

left.

behind

Turn

to

can

TO

point

thread

eyelet

(AF).

neck

out

from

positions

this

upper

swing

at

high

bushing

come

slots

THREAD

lead

Note:

fabric

handwheel

the

left;

be

threaded

THREAD

of

upper

eyelet

(N)

from

After

of

top

bottom

front

are

for

machine

looper

position,

(AG);

from

it

through

thread

then

cover

of

to

shown

clarity.

second,

cloth

plate

and

the

(K)

in

LOWER

must

guard

in

thread

easily

UPPER

looper

(P)from

left

to

pulling

casting

tube

back.

in

threading

to

follow

open,

release

swing

tension

tension

LOOPER

both

eyes

pass

(S)

and

operating

through

if

tweezers

LOOPER

(W)

back

right.

up

upper

and

and

push

and

presser

thread

posts

of

in

through

is

all

to

front,

Note:

looper

down

tube

diagram

recommended

needle

turn

third.

handwheel

pressure

arm

guide

(G).

lower

front

looper

of

looper

eyelet

direction

both

are

the

eyes

way

until

in

left.

then

thread

must

thread

through

down;

(Fig.

on

presser

(U)

out

(C),

thread

hole

heel

from

left

hand.

through

pass

tube

thread

then

insert

1 ).

sequence

in

operating

foot

of

position.

are

between

eyelet

thread

of

frame

of

lower

left

to

Lead

thread

both

in

assembly

tube

thread

Parts

by

pull-

r ig

ht.

eyes

front

as-

of

CAUTION!

passing

from

Turn

position.

eyelet

needle

(AD),

thread

The

regulatedby

on

threads

formation.

Sufficient

should

be

decrease

nut

(A,

screw

sure,

has a right

loosening

properly

locking

the

top

nut

surface

Be sure

tube ass

handwheel

Insert

needle thread

under

eyelet

THREAD

amount

of

three

should

PRESSER

presser

maintained.

amount

Fig.

2)

decreases

set,

tighten

(C)

so

that

of

embly

in

operating

neck

(AC).

tension

knurled

be

only

FOOT

foot

Should

of

pressure

and

turn

hand

thread

lock

its

adjusting

upper

to

upper

TO

from

of

top

cover

Thread

TENSION

on

needle

tension

enough

PRESSURE

pressure

it

be

on

adjusting

so

pressure.

nut

(A).

under

surface

screw

looper

THREAD

direction

nuts

to

necessary

presser

thread

looper

right

castin

needle

and

(D,

secure

to

feed

screw

is

eye.

THE

to

looper

until

left,

g;

from

Fig.

NEEDLE

needle

throu

then

front.

threads

1).

proper stitch

work

to

increase

foot,

loosen

(B).

uniformly

tightening increases

With

(B).

When

presser

is

pressure

foot

approximately

Set

cap

(D)

under

lower

(X.

gh

both

down

through

is

Tension

or

lock

Adjusting

pres-

adjusting

resting

1 I 32

against

looper

Fig.

eyes

screw

on

throat

inch

locking

1)

of

hole

to

nut

is

at

needle

Fig.

(B)

plate,

1 I

16

(C).

thread

its

in

top

2

has been

position

inch

when

highest

thread

cover

from

7

Page 8

The

imately

entric

dicates

Unless

the

numh~r

feed

12

on

eccentric

stitches

Style

39500

approximately

otherwise

of

stitches

used

per

inch.

JR

is

the

specified#

as

outlined

FEED

in

this

It

No.

39540

number

machine

machine

will

of

above.

ECCENTRICS

has

be

noted

B-12.

stitches

will

be

that

Minor

produced

shipped

been

the

selected

part

number

when

with

the

to

number

of

the

using

eccentric

produce

of

the

part

symbol

that

to

approx-

feed

ecc-

in-

eccentric.

produce

Following

-6~

-7~

-8~

-36~

-40.

may

be

number

Before

chip

guard,

suggested

With

should

needle

1/2

needle

needle

screw

inch

If

needle

center

is

or

driving

{C).

separate

screw,

..

9~-10#

Only

ordered

suffixed

assembling

upper

sequence:

SETTING

throat

at

high

above

set

the

Remove

by

moving

be

sure

stitch

-11#

one

separately.

to

knife

plate

in

the

position,

throat

height

arm

thread

to

take

number

-12,13#

eccentric

feed

-14~

is

To

indicate

number

ASSEMBLING

and

adjusting

assembly,

THE

NEEDLE

assembled

front

end

of

needle

plate

above

{B,

throat

cam

looper

up

Fig.

plate.

pull-off

thread

end

{A~

the

3)

play

eccentrics

-15#

...

supplied

order

of

AND

sewing

lower

in

position,

needle

point

Fig.

should

3).

throat

by

loosening

(A,

Fig.

pull-off

in

needle

are

available

16

..

-18~

-20,

with

each

an

eccentric~

stitches

desired.

ADJUSTING

parts,

knife

remove

holder

needle

slot.

plate,

To

When

be

set

align

move

clamp

4)

overlaps

back.

When

driving

under

-22~

-24,-26,

machine.

use

No.

Example:

SEWING

cloth

assembly,

looper

retightening

arm.

No.

39540

-28

..

-30,-32,

Additional

B-4,

·34,

eccentrics

39540 B with a minor

"39540

B-12".

PARTS

plate,

thread

then

Fig.

looper

fabric

follow

3

pull-off

guard~

this

{B),

pull•off

-5~

Screw

between

Fig.

(B)

rear

is

4

used

needle

to

guard

set

rear

and

At

this

into

bar

stroke,

needle

Do

not

nut

have

{C).

Now

set

{Fig.

assemble

SETTING

Set

rear

possible~

per

or

movement

position

needle

lower

to

guard.

looper.

8

point,

{B).

looper

5),

lower

needle

without

deflect

insert

With

lower

point

using

looper

the

THE

guard

interfering

of

lower

needle

Make

lower

looper

1 I 8

looper

gauge

deflecting

main

REAR

feed

NEEDLE

{A..

with

knife

forward . 002-.

sure

there

looper

at

left

inch

from

No.

needle.

dog.

GUARD

Fig.

6)

either

holder~

is

no

interference

{A~

Fig.

end

of

center

21225-1/8.

Tighten

as

high

lower

but

004

loo-

still

inch.

5)

its

of

as

in

Page 9

SETTING

THE

LOWER

LOOPER

Now

looper

into

the

springs

.

002-.

SETTING

Assemble

lower

set

front

without

set

front

sure

there

and

main

finish

moves

needle

forward

004

inch.

looper

needle

touching.

needle

is

feed

lower

to

the

scarf

from

THE

front

is

FRONT

needle

springing

guard

Screw

guard.

no

interference

dog.

looper

right,

(A,

rear

as

close

its

upper

mits

ed

looper

if

(C,

looper

upper

shank

holder

adjustments.

its

point

Fig.

7)

guard

NEEDLE

guard

(C,

needle

as

possible

(D)

is

used

After

this

between

SETTING

Insert

holder.

looper

it

to

be

around

holder

it

is

not

Fig.

8)

holder

looper

extends

(Fig.

should

until

surface

GUARD

Fig.

off

back

to

setting

needle

THE

upper

Screw

in

pushed

its

intoupper

already

on

clamp

in

1 I

8).

As

the

another

6).

to

adjust

guards

UPPER

looper

(B,

its

holder,

in

shank.

in

in

the

its

holder

16

to

lower

be

set

needle

When

guard,

needle

and

make

(A,

Fig.

or

out,

Insert

looper

place.

holds

shaft.

3 I 32

LOOPER

Fig.

8)

and

or

8)

holds

per-

turn

upper

shaft,

Screw

the

upper

Locate

so

that

inch

beyond

in

e

the

Fig.

5

As

the

heel

looper

Next,

travel;

needle

do

it

10

represents

Fig.

the

head

check

and

by

6

upper

of

the

with

turn

dimensions

throat

moving

looper

up_per

1/32

looper

to

handwheel

plate

the

the

(Fig. 1 0).

upper

dimensional

When

right

holder

looper

(Fig.

looper

of

upper

shank,

left

of

(Fig.

moves

1116

until

of

upper

looper

end

should

shank

8).

and

looper

set

the

9)

toward

should

inch

looper

holder

setting

the

upper

of

its

stroke,

be

slightly

Be

sure,

the

casting.

shaft

upper

lower

the

pass

clearance.

is

at

looper

If

resetting

(A,

looper

set

to

looper

looper

top

behind

the

point

Fig.

for

Style

upper

position

back

there

By

and

point

eye

of

left

with

is

10).

is

at

the

looper

upper

of

vertical

is a clearance

adjusting

by

turning

to

cross

its

the

end

respect

with

stroke,

lower

of

its

to

. 002

necessary,

Figure

39500

JR.

looper

the

looper

lower

to

Fig.

between

holder

around

looper

. 004

7

heel

in

or

out

its

to

the

clearance

of

9

Fig.

8

Page 10

SETTING

THE

UPPER

LOOPER

(Continued)

NOTE:

point

at

left

upper

9/64

shaft.

around

the

needle.

downstroke.

slightly

of

machine.

12).

throat

pin

appear

adjusting

point

should

feed

The

and

31 I 64

end

looper

inch

After

its

When

upper

Check

Assemble

raises

The

Main

plate

of

be

dog

the

the

and

feed

above

travel,

teeth

dimensions

of

its

holder

is

increased

these

shank

correct

looper

eyes

setting

If

rotate

Reset

SETTING

chaining

feed

by

or

lowers

dogs

the

pin

in

3/64

inch

(B)

are

inch

rotating

from

travel.

counterclockwise.

by

pullingupper

changes

slightly

is

of

to

needle

looper a short

to

dog should

should

throat

place.

the

top

above

flush

to

setting

moving

the

avoid

rubs

maintain

THE

feed

feed

the

back

be

plate.

With

of

the

the

with

9/64

top

For

are

maintain

is

to

upper

interference

the

FEED

dog

be

set

throat

the

inch

of

throat

example.

made,

obtained,

the

right

looper

back

distance

dimensions

DOGS

to

main

levelled

tilting

end

of

level

Screw

the

feed

teeth

top

from

plate

dimension

looking

looper

it

the

condition

it

and

and

between

of

upper

feed

with

adjusting

the

feed

at

the

(D)

dogs

on

the

plate.

of

the

throat

center

to

upper

from

holder

may

can

the

needle

looper.

counterclockwise,

of

Figs.

dog

respect

pin

bar.

time

locks

at

their highest

main

Now

line

looper

31/64

left

end

to

the

be

necessary

shown

be

checked

upper

upper

(A,

(C).

teeth

feed

feed dog (A)

set

plate.

in

looper

should

looper

pull

9, 10,

B, Fig.

to

the

Thi

fir st

tiltin

chain

ing

of

needle

is

of

left.

Fig.

quickly

align

looper

11.

s

g

to

point.

increased

machine;

out

of

to

turn

9.

as

eye

exactly

and

needle

out

looking

upper

when

by

dimension

upper

upper

follows:

centers

(Fi

on

of

its

from

looper

looper

turning

looper

looper

on

g. 11 ).

needle

holder

left

is

As

the

end

pin

with

Fi

g.

10

for the

nut

(C)

cloth

even

SETTING

bly.

be

set

plate

with

lower

pressed

lateral

width

Lower

position

locking

Be cause s

plate

when screw

latch spring,

Replace

Lower

with

surface.

hexagonal

knife.

against

adjustment

of

trim

knife

by

nut

cr

is

not

THE

lower

knife

cutting

Adjustments

head

Lower

is

tightenin

(C)

again

ew (B)

it

should

tighten

LOWER

knife

(A,

edge

screw

knife

upper

is

necessary

changed.

may

be

g s

st s

also

always

ed agains t

holder

Fi

g.

flu

sh

which

knife,

sec

ured

crew

upport

ser

ves

KNIFE

assem-

13)

should

with

throat

are

made

holds

is

sprin

so

no

when

in

any

(B)

and

bracket.

as

latch

be

lock

ed

lower knife

g

holder.

Fi

g. 9

Fig.

11

10

Page 11

SETTING

THE

UPPER

KNIFE

be

tightened

ting

when

Length

entric

the

B

sure

edge

the

over the

to

used

feed

...

12.

In

assembling

the

of

left side,

dama

Fig.

to

lock

upper

SETTING

of

stitch

in

machine.

eccentric

hub

and

feed

ge

hub

shaft

eccentric

so

on

12

upper

knife

the

the

or

is

THE

STITCH

is

for

Style

the

feed

oil groove

spacer

undercut

feed

key.

knife

replaced.

determined

Note

eccentric

eccentric.

holding

LENGTH

that

39500

is

to

(B)

on

by

the

JR

(A,

the

should

the

block

the

part

number

is

No.

Fig.

left.

spacer

Be

careful

Clamp

position,

(F)

against

stroke,

knife

inch

The

against

back

proper

(J)

feed

39540

14),

Beveled

also

will

Replace

After

in

ecc-

of

be

be

to

be

not

upper

in

its

upper

should

below

chain

the

from

width

place.

setting

most

front

extend

cutting

guard

upper

the

upper

of

This

upper

knife

nut

knife.

cutting

(G)

cutting

knife

trim,

will

knife

(D,

Fig.

(E)

to

clockwise

At

bottom

edge

not

less

edge

of

lower

should

knife

be

and

edge.

has

been

screw

simplify

assembly.

13)

hold

clamp

position

of

of

upper

than

1 I

knife.

set

down

slightly

set

(H)

should

reset-

in

its

64

for

Tighten

To

washer

wheel

entric

extractor

eccentric

be

necessary

slightly

Assemble

presser

and

back)

be

aligned

the

bottom

can

be

15).

a

collar

nd

To

then

nut

(C)

securely.

change

(D)

and

in

operating direction

is

toward the fr

(E),

as

during extraction.

arm

and

reali

move the shaf

shift the

screws

feed eccentrics,

feed eccentric

suppli

shown and

to

move

the pres

into sewi

flat

on

throat

with

front

of

the

presser

gned wi

th

foot lifter l e

and

clamp screw.

ed

throat plate s

ont.

with

withdraw

handwheel

SETTING

ser

foot

ng

position

plat

ed

ge

foot

t,

loosen

remove

spacer

until

Using

machine,

eccentric.

to

presser

and

e.

The fr

of needle

be

flat

lots by shifting the

coll

ver

sha

(B).

key

slot

hooked

reach

back

THE

set

ont edge

hol

e in

on the

ar

scr

ft

to the left

nut

Turn

PRESSER

the

hand

in

ecc-

eccentric

behind

It

may

and

forth

arm.

pre

sser foot

thro

thro

at p

ews (B,

With

(C),

of

at

or

...

FOOT

needle

needle

plate.

late.

foot

Fig.

r i

to

alig

hole

It

If

necessary,

lifter

15)

ght

as

Fi

in high

n needle hol

in

presser

is

also

lever

and

clamp screw

required.

g. 13

position, swin

es (fr

foot

must

important

presser foot

shaft

(H,

Fig

Retight

g

ont

that

.

(G)

en

11

Page 12

SETTING

The

(B)

secure

bind

locked.

and

foot

rise

lifter

the

THE

shaft.

when

PRESSER

lever

arm

Be

presser

sure

foot

FOOT

(A.

Fig.

the

release

(Continued)

15)

and

presser

bushing

arm

the

does

collar

not

is

un-

without

freely.

While

needle

be

just

if

excessive

tion

needle

contacts

Fig.

presser

Swing

sewing

thread

tight

thread

needle

14

foot

presser

on

is

drawn

enough

thread

thread.

in

place,

material,

on

to

feed

is

pulled

eyelet

then

foot

guard,

its

thread

foot

needle

(AD.

Adjust

can

be

lock

inch

screw

guard.

diagram

of

free

begins

(E)

highest

Be

eyelets

their

to

make

into

position.

NEEDLE

check

down

chain

on

off

the

Fig.

lifter

raised

the

motion

to

and

fabric

turn

handwheel

position.

sure

(Fig.

front

sure

THREAD

needle

stroke.

stitch

up

stroke.

1)

lever

no

higher

nut

(D).

of

rise.

locked

guard

STARTING

machine

1).

(Nand

to

so

This

With

back

that

insert

CONTROL

thread

At

tongue.

With

that

needle

chain

stop

screw

than

There

foot

lifter

adjustment

with

nut

and

cloth

until

is

R)

locations.

material.

upper

TO

threaded

thread

about

forms

control

top

of

Stitch

needle

thread

(C)

upper

should

lever

(F).

OPERATE

horizontal

needle

Re-assemble

plate.

knife

according

tensions

Operate

and

and

sew

as

follows:

stroke,

tends

at

bottom

cam

so

that

looper

be

from

before

should

To

assembly

light.

and

machine

moves

slowly.

to

pull

of

pull-off

presser

will

permit;

1/16

the

presser

be

made

the

assemble

reaches

to

threading

set

in

the

off

the

Usually

thread

down

stroke,

slightly

(AE)

foot

to

1/8

with

chip

chip

looper

middle

slowly,

tongue

all

should

posi-

just

It

pull-off

a

tor)

needle

LOWER

With

looper

so

thread

pull-off

tion.

1/8

inch

pull-off

should

inch

to

the

time

its

travel.

is

desirable

eyelet

to

delay.

thread.

material

thread

is a little

(AF)

Looper

distance

(AE).

be

set

right

lower

to

adjust

well-forward

slightly,

LOOPER

under

eyelet

reaches

thread

with

of

slack

behind

Frame

its

lower

looper

(R.

its

pull-off

eyelet

looper

the

(toward

the

THREAD

presser

Fig.

looper

is

1)

when

most

(AF)

needle

approximately

(V)

at

extreme

needle

the

tightening

CONTROL

foot.

back

looper

rearward

thread

is

thread

heel

set

far

set

guide

eyelet

left

thread

operof

the

lower

enough

thread

posi•

about

cam

(T)

1/8

at

end

of

12

Fi

g.

15

Page 13

LOWER

LOOPER

THREAD

CONTROL

(Continued)

While

portion

looper

the

tension

eyelet

Before

three

will

draw

is

pull-off

Fig.

to

all

that

to

edge.

tensions

not

During

upper

drawn,

To

1)

have

If

end

it

form

sewing

of

lower

thread

while

(R) down,

proceeding

markedly

needle

looper

upper

reaches

move

should

slightly

it

becomes

play

is

in

higher

near

on

looper

comes

to

the

be

more

needle

over

top

off

lower

keeping

give a normal

effect

down

thread

looper

its

most

purl

raised,

necessary

edge.

material,

thread

upper

looper

the

UPPER

to

adjust

the

purl.

stroke,

through

thread

rearward

more

pull-off

drive

throat

keeping

If

upper

under

to

plate

check

should

looper.

thread

same

LOOPER

upper

appearing

forward

the

will

POSITIONING

upper

move

shaft

than

looper

drawing

be

To

is

amount

looper

tension.

have

position.

the

edge,

the

same

thread

looper

before

recommended

is

on

THREAD

stroke

almost

off

drawn

increase

upper

of

stitch.

THE

amount

than

thread

tightening.

too

through

looper,

pull-off

thread

Moderate

of

When

all

PURL

both

on

low,

of

looper

the

amount

move

action.

CONTROL

eyelet

looper

normal

slack

looper

of

lower

pull-off

the

thread

taken

thread

pull-off.

thread.

(AF),

If

upper

in

Fig.

purl

will

thread

tension

of

thread

lower

(N.

Fig.

change

amount

up

Usually

looper

1

o.

form

as

before

drawn

looper

1)

in

these

pull-off

of

looper

as

looper

eyelets

be

sure

is

the

purl

nearer

follow

lower

through

thread

balance

tensions

(AF)

thread

thread

(N

and

it

is

better

to

take

located

will

bottom

s: A

all

will

R.

up

so

tend

The

being

ble

should

purl

forwarded

wi

Union

Company,

ing

efficiency

pair

your

sewn.

without

is

Prices

se

directed.

Success

Special

to

the

Genuine

parts

guarantee

be

pulled

needle

In

causing

increased

are

f.

o.

in

its

most

and

needles

are

thread

general,

too

far

net

b.

shipping

A

the

Needles

subsidiaries

scientific

durability

stamped

of

tension

needle

as

over

cash

charge

USE

GENUINE

operation

and

are

the

highest

THREAD

required

lower

long

and

is

principles,

are

packaged

with

looper

thread

as

the

top.

subject

point.

made

of

Repair

and

authorized

assured.

the

quality

thread

to

be

the

elasticity

TERMS

to

Parcel

to

cover

NEEDLES

these

Parts

and

with

Union

in

machines

labels

materials

TENSIONS

is a function

tension

pulled

change

post

as

distributors.

are

Special

down.

of

the

without

shipments

postage

AND

furnished

made

REP

can

with

marked

trade

and

of

needle

should

chain

and

AIR

be

by

utmost

mark.

workmanship.

be

Upper

increases,

notice.

are

insurance.

PARTS

secured

the

They

~.

thread

set

as

looper

All

insured

only

Union

are

precision.

Special

designed

Each

and

material

high

as

possi-

thread

shipments

unless

with genuine

trade

tension

or

until

other-

Machine

accord-

Maximum

Genuine

mark

the

are

re-

is

13

Page 14

~

~

49

(~

1

lv

" r

-

~l~

~

-

47

(

~

t_.;.,P--:.

21

~

~

~

::

J.__

--

~

...

....

...

r'

;:·-

~

,;,

-;

,

_'j

~---

.

,

)-"'"

-~

,_.:-_,.;

)

41

~

23

""

14

Page 15

The

Style

parts

39500

illustrated

JR,

but

not

on

the

preceding pa

used

on

Style

ge

39500

and descr

FJ.

ibed

below,

represent

the

parts

that

are used

on

Those

and

39500

Use

Catalog No.

Re

fe r

indicate

Re

f.

o.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

4

46

47

48

49

50

51

52

parts shown

FJ.

ence

numbers

they

are

Part

N

o.

39

592

39592

39592

39592

39 592 AE- 4

39592 AE-8

39592

39

592 AD

39592

39592

8372 A

39592 AH

39578

22569

39563

39551 A

154

39563

87

39508

39549

39550

39570

39525

39578

39580

29477

29477

22596 G

22587 M

39516-62

39516-626

39516-627

30-92 Blk.

C067

40-46

258

39

541 A

5

39

540 B

22528

22 KH

39

505 AM

39

505 AF

39

524 AK

39520

39530

39530

395

30

87 u

28

39

563 H

43139

39

568 L

39

568 B

3

76

39

568 E

in

phantom

103

F J

that

component par

AB

AA

AC

AK

AJ

AF

AL

are insi

s

B

F

GAS

G

u

A

s

TA

A

KE

JN

5

E

1-22

8 Blk.

-7

AJ

v

w

A

A

views

(Style

Upper Looper Tension

Needle

Lower

Tension

Upper and

Needle

Spr

ing

Thread

Tension

Tension

Washer, for

Nut,

Fabric

Screw, for

Top

Needle

Needle

Needle

Screw,

Upper

Lower

Lower

Upper

Needle

Chip Gua

Throat

Crankshaft

eed

F

Screw, for main

Screw, for

Main Feed Dog, marked

Chaining Feed

hroat Plate,

T

Presser Foot,

Needle

Nut,

Upper Looper Thr

Lower Looper Thread Eyelet--------------------------------------Screw,

Auxiliary

and

bearing no

39500

de a bracket

ts

for

Cover

Needle Driving

Needle Bear

Needle Bear

Needle Bear

Wood

Cork

Washer

Nut

F

Vent

Driving Eccentric--------------------------------------------

Presser

E dge

Hinge

Screw, for

Screw,

for

FJ)

for

of a complete

Ten s

ion

Looper

Spr

ing F

Low

Thread

Shield

Tension Disc

Disc Felt----------------------------------Post-----------------------------------------------------

tension post

Guard

top

Needle Thr

Clamp

----------------------------------------------------------

Thread Cam

for

needle

Looper,

Knife-----------------------------------------------------Knife Holder-----------------------------------------------

Knife------------------------------------------------------

Guard,

rd

------------------------------------------------------

Plate

and

Plug--------------------------------------------------

Plug--------------------------------------------------

--------------------------------------------------------

eed

Driving

Plug---------------------------------------------------

cha

Guide, mar

Spring

Thread Eyelet

looper thread

for

looper thread

Looper Thread Eyelet------------------------------------

or

Nut, green

Tension

errule

er

Looper Threa

Tension

----------------------------------------------------

tension

---------------------------------------------------cover

Washer---------------------------------------------

thread

marked "CC"

front-----------------------------------------------

and

Lower

Needle Driving Arm Crank Assem

Screw, for

Screw, for

ing, .

ing, .

ing, . 0627 i

----------------------------------------------------

feed dog------------------------------------------

in ing f

Dog,

m ar

ked "BX"-----------------------

with

Foot Bottom, mark

------------------------------------------------

hinge s

for edge gui

ead Eyelet---------------------------------------

refe

rence num

all

parts

not illustrated

box

on

part

----------------------------------------------

post

---------------------------------------------

needle

ead

Pull-off

Arm

Eccentr

eed dog

mar

bottom

---------------------------------------------

the picture

or

assembly.

Description

Nut,

blue

-----------------------------------

----------------------

Nut,

red------------------------------------

-------------------------------------------

Spr

Kni

needle driving

needle

0625 inch diameter-------------------------0626 inc

"CT",

ked "CJ",

ked

pring----------------------

eyelet

d T ension Spr

ing

-------------------------------------

------------------------------------------

thread

Eyelet

cam

Crank

"H"

de----------------------------------------

eyelet------------------------------------

-----------------------------------

--------------------------------------pull-o

--------------------------------------

fe

Suppo

and

driving arm

h di

nch diam

ic

Key-----------------------------

--------------------------------------teeth

mark

ed

-------------------------------------

screw---------------------------------

ber

s,

are

common

or described

plate

and

hav

ing

--------

eyelet---------------------------

ff

------------------------------

rt Bracket-----------------------

Connecting Ro

arm crank

ameter------------------

eter--------------------------

cut

22

teeth

cut

"AV"

ed

----------------------------

"AV"---------------------------

bly

d A

--------------------

connecting rod

per inch------------------

22

per inch---------------

e i

-

-----------------

----------------ssem

-

----------------

-

to

Styles

in this

ndented descripti

-

------------

-

-------------

bly--------

-----------

---------

-

-------

-

39 5

catalog.

-

----

-----

00

ons,

Amt.

Req.

3

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

28

28

28

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

JR

1

1

1

3

2

1

3

6

3

3

3

1

1

15

Page 16

,...o

...

...

'

Q

WORLD'S

,..,lf

FINEST

QUALITY

*

,,

•'

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains sales

facilities throughout the world. These offices

aid

you

in

the selection of

equipment for your

Special representatives

tory trained

promptly

tiolJ,

there

and

is

serve you. Check with

ATLANTA,

BOSTON,

CHICAGO,

DALLAS, TEXAS

LOS ANGELES,

NEW

PHILADELPHIA, PA.

MASS.

YORK,

GA.

ILL.

N.

CAL.

Y.

particular operation. Union

and

and

are

able

efficiently. Whatever your loca-

a Union Special Representative

him

the

service men

to

serve your needs

today.

MONTREAL,

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS, FRANCE

STUTTGART, GERMANY

and

service

will

right sewing

are

fac-

to

QUEBEC

ENGLAND

ENGLAND

400

Representatives

MACHINE

N.

FRANKLIN

industrial

and

cities

distributors

throughout

COMPANY

ST.,

CHICAGO,

in

the

all

Important

world.

ILL.

60610

Loading...

Loading...