Page 1

FEED

ECCENTRICS

(Continued)

The

- 4,

- 26, -

-5,

28, -30, -32

machine.

use

number

sired.

After

t

hrough

threaded

wire

and

(A).

on

through

following

- 6, -

7,

Additional

39540

Example

INSTRU

thread

back

thread

down

Then

stitch

number

- 8, - 9, , -

34

, -

eccentrics

B

with a minor

:

"39540

B-5"

CTIONS

comes

from

eyelet,

through right

thre

thread

ad

continues

guide

feed

10, -11,

36, -40.

may

number

FOR

THREADING

THREAD

cone

then

hand

down

hole

between

(B).

eccentrics

-12,

- 13, -

Only

be

ordered

suffixed

STA

on

thread

through

of

each

14, -15

one

separately

to

STY

ND

stand

front

pair

tension

ar e

available

, -

eccentric

indicate

LES 39500

(R,

thread

of

holes

discs

under

16, -18,

is

supplied

.

To

order

number

J & K

Fig. 1),

eyelet

in

tension

(AD),

through

- 20, -

of

it

is

(S).

No.

39540

22, -24,

with

an

eccentric,

stitches

brought up

Next

thread

slot

guide

(AE)

B:

each

de

-

it

is

,

Only

Parts

It

are

will

threading

Before

ing

by

position

direction

turning

.

Be

tension

discs

Double

(C,

Fig

. 1)

pull-off

looper

lo

oper

right.

thread

(

Rig

parts

placed

lower

sure

(D).

II)

ht

involved

in

their

in

relative

simplify threading

looper

beginni

until

presser

threads

(AD)

ng

and

first

to thread

needl

foot

,

as

in

e (L) is

release

they

diagonal

TO

end

is

of

from

Lead

guide

all

eye

thread

right

to

thread

(F).

the

way

of lower

and

left

behind

Turn

to

looper

threading

positions

th

is

,

needle

,

swing

at high

come

THREAD

lead

.

it

NOTE:

handwheel

the

left;

can

THREADING

are

shown

for cla

machi

second

ne

to

. )

clo

th

plate

position; release

bushing

from

slots

(AE)

(P) and

the

in

LOWER

through

both

Thread

fabric

be

gua

in

then

threa

r d

operating

thread

ded

in

threading

rity

.

follow

open, turn

swing

tension

tension

LOOPER

eyes of

mu

st

pass

(E)

and

direction

through

easily

if

diagram

recommended

handwheel

pressure

presser

thread

posts

lower

in

thr

ough

guide,

(AC). C

looper

front

both

until

both

twee

eyes

zers

on

arm

of

looper

holes

are

(Fig.

sequence

in

ope

presser

(G)

are

between

thread

thre

of

heel

of lower

from

in

left hand.

1).

of

rat-

foot

out of

eyele

t

ad

frame

left

to

~

•

•

"

<

~

•

•

(

~

c

C'

~

•

~

11

~

TO

•

position

eyelet

thread

tension

proper

Turn

.

(N),

pull-off

The

amount

nuts

stitch

handwheel

Insert

under

need

neck

eyelet

of

tension

(A.A, Fig

for

matio

in

operating

le

thread

of

top

(M).

. 1) .

n.

on

THREAD

from

cover

Thread

THREAD

needle

Tension

THE

direction

back

casting

needle

TENSION

and

on

looper

threads

7

unt

to

,

then

from

NEEDLE

il needle

front

, t

right

front

.

threads

shou

(L,

Fig

hrough

to

left

is

regulated

ld

be

. 1)

eye

through

only

enough

is

of

by

at

its

needle

hole

in

two

to

highe

st

thread

needle

knurled

sec

ure

Page 2

Be

sure

machine i s

STARTING

threaded

according

TO

co

OPERA

thre

TE

adi

~LES

ng

diagram (Fig

39500

J & K

. 1, page 8).

front

freely

required

position

•

>-

...

z

0

With thr

to

Operate machine

.

Swing

While sewmg

ead

tensions

back

for

needle thre

location

presse

the

r foot

on

stitch

ligh

t ,

set looper thread

.

slowly, without

mater

ad

eye

into

shou

position;

ial,

let

ld

check

be

(N)

LOWER

presser foot

insert

NE

EDLE

needle thread

drawn

farther

on

needle

to

LOOPER

eyelet

in

place,

materi

THREAD

the rear.

al;

control

downstroke

THREAD CONTROL

(C) about

to

sew

slowly.

CO

NT ROL

as

. To

horiz.ontal

make

follows: About

sure

increase

chain

thread

and m

forms and moves

75%

the

middle

of

needle thread

draMl

on

downstroke,

of its

off

tongu

:.:

o5

..,

enough

<)'

elet

Wi

th

material

so

thread

(C)

should

0 Frame lo

0

of

looper

11'1

(H)

o-

M

11'1

...

...

>-

....

Ill

tl>ese

Before

tensions

•

SKIPP

oper

heel

proce

will

I

1\

G:

under

is

a

be about

tl>read

eyelet

eding,

not markedly

For

presser

little

guide

t>alance

occasional

foo t ,

slack

horizontal.

(f)

at

the

time lower

both

effect

skipping,

set

when

should

spreader reaches

tensions

SPECIA

lower l

be

set

looper

THREAD

to

the purl.

L

check

ooper thread

its

extreme

with

give

its

left

i s at extreme

TENSIONS

a normal app

ADJUSTMENTS

and/

or

adj

ust

eyelet (C, fi

left

hand

left

earing

as

outlined

eyelet

end

stitch

g.

1)

back and do•n

position

approximately

of

its

below:

. Looper

travel.

. Moder

1/8

ate

change 1n

far

thread

inch

right

!.

Recheck lower

2. Recheck

3.

Check

past

Settings

sk

ip

is

definitely

sli¢>t!y one! bringing

change,

C..\l'

left

increase

TION:

position, or

spreader

clearance

needle

1 and 2

not a needle

loope

l.oo

!'er thread

stitch

looper -needle

-

lo~<

er

between

.

should

eyelet

r thread tens

be

ho

nust, as

will

appear

les

setting

loopel' ctossinf_.

needle

made

loop

in

ion

and

quite

skip,

close

as

before

tisht

spreader

carefu

reposition

to

much

, be slightly

on top

.

See

:Oee "Setting tloe

lly.

bend in

as

possible

side

16

"Setting

.

See that

If

it

can be determi ned by appearance t

looper

looper thread

slack as

.

thread

without di

tl>e

Needle",

spreader

eyelet

spreader

page

Spreacet·",

moves

(C) by lowering i t

pull-off

storting

reaches its

11.

page

far

(D).

stitch

12.

enough

After th

.

extreme

left

hat

i s

Page 3

Be

sure

machine

STARTING

is

threaded

TO

OPERATE

according

to

threading

STYLES

diagram

39

500 L & M

(Fig

. lA,

p.

9).

ll~th

and

in

Operate machine

off

the

Sw·ing

llhile

required

To

the

rear.

thread

the

middle

tongue

presser

sewing on

for

incre

the

ase

tensions

of

freely

foot

stitch

thread

light,

their

slowly,

.

material,

front

1nto

should

dr~n

set

upper and low

to

back

without

position,

locations

presser

ins

NEEDLE

check

be

on downstroke,

needle

drawn on

foot

ert

in

materia

THREAD

thread

needle

position

do~nstroke.

er

looper

.

place,

l,

and

CONTROL

control

needle

thread

to

sew

as

follows

thread

make

slowly

eyelets

sure

.

: About

eyelet

(C &

that

chain forms

60?1

(R, Fig.

E)

about

of

lA)

hori

needle

farther

wntal

and

thread

rooves

to

•

>

-

2

c

right

lower

upper

Set

lower

Frame

of

lower

1\lth

looper

looper

loope~

looper

looper

material

thr

ead

reaches

thread

thread

heel

under

eyelet

the

LOWER

eye

let

guide

(G)

eyelet,

should

when

UPPER LOOPER

presser

(E), and back

left

end

foot,

of

LOOPER

(E,

Fig. lA)

be

lower

set

upper

far

its

stroke.

THREAD

about

set

with

looper

is

THRE

looper

enough so upper

CONTROL

horiwntal

its

left

at

the

AD

CO

thread

and

hand

left

eyelet

end

NTROL

eyelet

looper

thread

all

of

(C,

the

way

forward

approximately

its

stroke.

Fig. lA)

is

a

to

little

1/8

rest

slack

in its

inc

on

top

when

slot.

h

of

:E

Oi

-

c

c

"

0

f':

..

"

-

>

...

"

Position

thread

looper thread

tensions

To

reduce mount

of

l

o~~r

.

tension.

looper

of

lower

POSITIONING

thread

looper

at

the

thread

THE

edge

1n

is

the

SQUARE

located

stitch,

17

EDGE

by

balancing

or

close

the

needle

edge

more,

and upper

1ncrease

looper

lower

Page 4

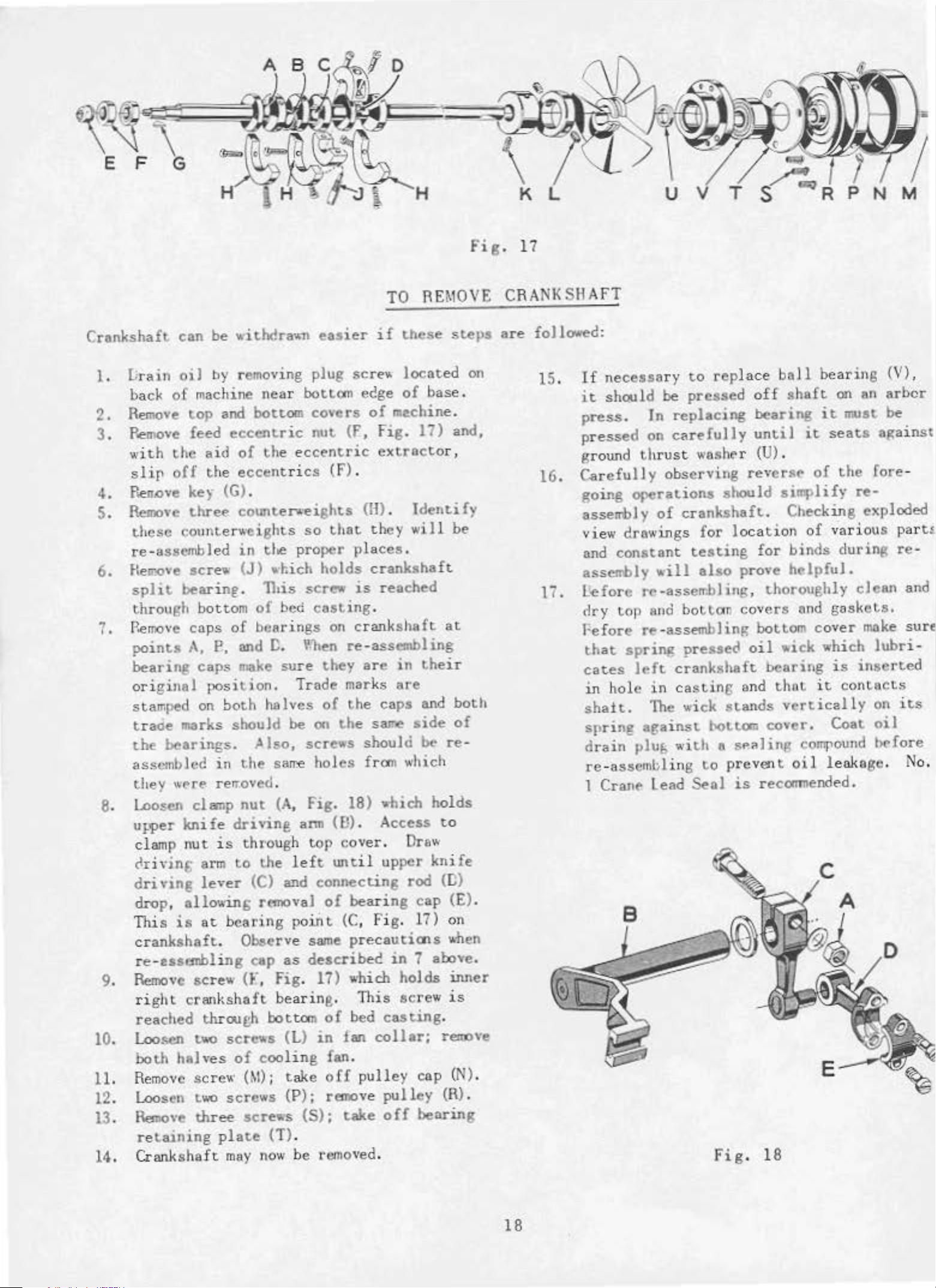

Fig.

17

Crankshaft

1.

~

rain

back

2.

Remove

can

oil

of

machine

top

be

by

and

3. Remove feed

with the aid

slip

4 . Ren.ove ke)· (G) .

5.

Remove

these

re-a

6.

Hell'Ove

split

through

7.

P.emove ca

points

off

the

three

counterweigh

ssembl

ed

sere

..

bearinr

bottom

ps

A,

£?,

bearing caps

ori

gin

al

posil

stamped

trade

the

assembled

they

8. Loosen

uwer

clamp

clri vin& arm

driving

drop,

This

crank

re-usanb

9.

Remove

right

reached

10

.

l...oo

sen

both

1

1.

Remove

12. Loosen two

13

.

Remo•·e

retaining

14

. Crank

on

both

marks

bearings.

in

WP

rf!

rerroved.

clsnp

knife

nut

is

lever

allowing rEmOval

is

at

shaft

. Observe

ling cap

screw

crankshaft

through

two

halv

es

screw

three

plate

sha

ft

with<!ra"n

remov

eccentric

of

eccentrics

coiDite,.,...eights

in

·

(J)

.

of

and!:.

make

should

t.he sarre

nut

drivine

through

to the

bearing

ing

near

bottom

the eccentric

ts

the

..

hich

This

of

bed

bea

rings

sure they are in

..

ioo.

halves

~)so,

(A

(C)

and

eaner

plug

bott<ltn

covers

nut

so

proper

holds

screw

cMting

¥-l•en re-as

Trade

of

be

on

screws

holes

,

Fig

arm

top

left

connecting

of

poii>t (C,

same

as

describe<!

(F,

Fig

.

17)

bearin

bottom

scr.,..s

of

coo

(M);

screws

screws

may

now

(L)

lin

take

(P);

(1')

of

in

g fan.

(S)

.

be

removed.

TO

if

screw

ecge

of

(f,

fig.

extra

(f).

(1-1)

.

that

on

.

(B)

IDitil

g.

off

remove

;

they

places.

crankshaft

is

reached

.

crankshaft

sembling

mar

ks are

the

caps

the

sarre

should be

from which

18)

which

. Ac

cover

. Draw

upper

bearing

Fig.

precauticns

which

This

bed

casting.

fan

collar;

pulley cap

pulley

take

off

REMOVE

these

locat

of

me.chine.

cess

in

holds

screw

ed

base.

11)

cto

r,

Identify

will

at

their

and

side

re·

holds

to

knife

rod

<nl

cap

17)

on

,.h

7 a bove.

is

rem:~ve

(R).

bearing

steps

on

and,

be

both

of

(E)

.

en

inner

(N

).

CRANK

are

foJJ....,d:

15. If

16. Ca

l7

SH

AFT

necessa

it

sh<~ll

press

pressed

ground thrust

going

asserrbl y of

.

refull

r y

to

d

be

pressed

In

replacing

on

car~fu)]y

washer

y

observing

orerations

crankshaft.

replace

revers~

should

view drawings for location

and

assembly

.

L'efore

dry top

Fe

that

cates

in

sha

sprin8

d

rain

re-ass

1

constant

re

ond

fore

re-assembling

spring

]rft

hole

it.

in cas

The wi

against

plu(; witlo a

embli

Cran~

lead

testing

,·ill

-

also

assen.bl

bottor

pressea

crankshaft

tin

ck

~~tom

ng tO

Seol

Fig.

prove

ing, thoroughly

covers

oil

s

And

stands

sP.a!in~

prevent

is

boll

off

bearing

until

(U) .

simplify

for

bottom cover

•ick

bearing

thot

vertically

bearing

shaf

t

on

on

it

must be

it

seats

of

the

re-

Checking

of

binds

h~lpful.

ond

which

it

exploded

various

during

clean

gaskets.

make

is

inserted

contucts

cover. Coat oiJ

compound l>t'fore

oil

leakage

recomnended.

18

(V)

,

arbcr

against

fore

-

pa

r t~

re·

and

sure

lubri

on

-

its

.

No

.

18

Page 5

ILLUSTRATIONS

ORDERING

REPAIR

PARTS

•

This

various

position

the

parts

particular

Numbers

position

ordering

Component

by

indenting

41

42

42A

43

44

45

29126

22729

22729

39544

39544

catalog

sections

in

the

with

view

in

of

that

parts

.

their

DF

D

E

97

s

u

has

of

machine

their

being

the

part

Always

parts

been

the

part

shown.

first

in

of

descriptions

Lower

arranged

mechanism

.

On

the

page

number,

column

the

use

sub-assemblies

illustration.

the

Looper

Screw,

Screw,

Screw,

Ball

Lower

are

part

under

for No.

for

for

Joint

Looper

to

simplify

are

shown

opposite

description

reference

Reference

number

which

the

description

Drive

No. 39544 N ----------

No.

Guide

Lever Connecting

39544 N ---------39544 S ----------

Fork

Bar

ordering

so

that

the

and

numbers

listed

can

---

Dr

iving

be

repair

the

parts

illustration

the

number

numbers

in

the

furnished

of

- ---------------Lever-

second

the

may

only,

main

Rod

-----

--------

-

--

of

--

------

parts

wi

and

should

for

sub-assembly

.

Exploded

be

seen

ll

be

found a

pieces

mere

column.

repairs

Assembly

-----------

------------

required

never

- -

------

- -

-----------

--

------

in

their

ly

indicate

be

are

.

-----

views

actual

listing

in

used

indicated

Example:

----

- -

---

- -

---

-----

- -

- 2

----

of

of

the

the

in

1

2

2

1

1

It

will

not

mended,

difference

part

book

number

some

fication

WHICH

listed.

Where

is

used

At

the

.

This

is

Where

of

letter

PART

THEY

be

noted

The

so complete

parts

will

in

back

will

known.

the

the

smaller

NU

reason

for

be

all

of

facilitate

construction

is

stamped

MBERS

APPEAR

in

the

is

sub-

Styles

shown

machines

the

parts,

assembly

in

book

in

REPRESENT

.

above

that

39500

the

covered

will

locating

permits,

and

to

example

replacement

illustrations

be

on

distinguish

that

of t

should

J,

39500

by

found a

the

IDENTIFYING

each

those

THE

be

ordered

K,

39500 L and

or

this

illustration

catalog

numerical

par t

where

the

part

SAME

the

eccentric,

hese

mentioned

PARTS

is

construction

from

PART,

parts

.

no

machine

index

and

stamped

similar

REGARDLESS

ball

individually

39500

in

of

description

M

the

style

all the

with

does

ones

descriptions

not

stud,

are

will

parts

when

its

permit,

.

and

not

part

OF

bearing

is

not

the

be

shown

only

number

CATALOG

recom-

same,

.

When

mentioned

in

the

an

identi

are

this

part

.

the

a

.

On

-

IN

Success

Special

its

subsidiaries

scientific

durability

Genuine

parts

of

warded

directed

the

Prices

are

highest

in

Needles

principles,

are

stamped

f. o. b.

. A

assured

needles

quality

are

charge

USE

the

operation

and

and

net

shipping

Repair

authorized

.

are

with

in

cash

is

GENUINE

of

Parts

and

the

made

are

packaged

Union

materials

and

point

to

NEEDLES

these

distributors.

made

Special trademark.

and

subject

.

Parcel

cover

machines

as

furnished

with

with

labels

workmanship

TERMS

to

change

post shipments

postage

utmost

19

AND

can

by

They

marked

without

and

REPAIR

be

secured

the

precision

insurance

are

.

Union

designed

~

Each

PARTS

Special

.

Maximum

trademark

notice.

are

insured

.

only

with

Machine

according

is

All

shipments

genuine

efficiency

.

Genuine

your

unless

Union

Company,

to

the

most

repair

guarantee

are

otherwise

and

for-

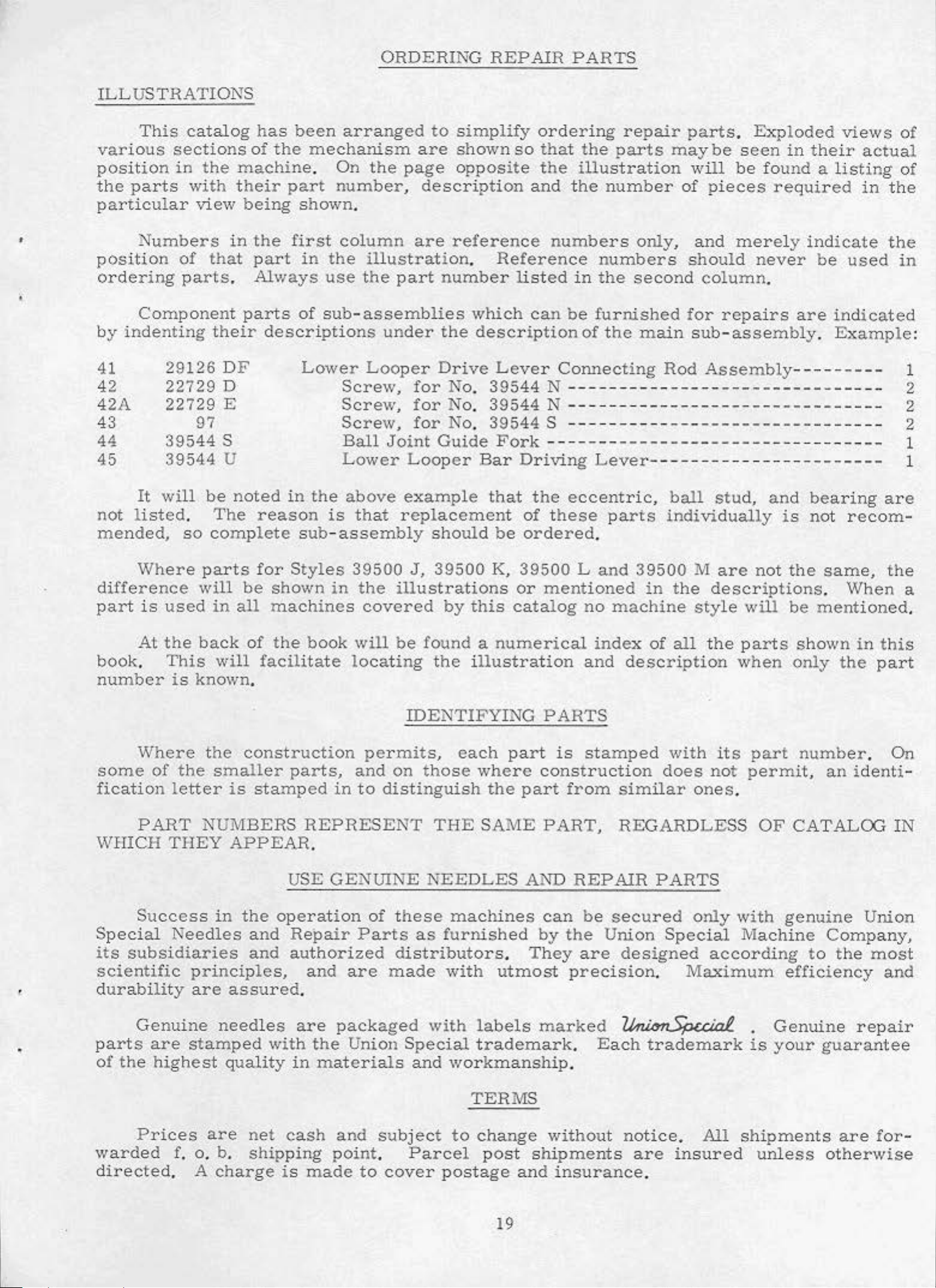

Page 6

20

Page 7

MAIN

FRAME,

MI

SCELLANEOUS

COVERS,

PLATES

•

•

Ref.

No.

1

2

3

4

5

6

8

9

10

11

12

13

14

17

18

19

20

21

21A

22

23

24

25

27

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

52A

53

54

55

56

57

58

Part

No.

39557 B

39557 E

39557

c

39557 F

39557

39556

A

39557 A

22541

51

s

- 103

39582

39582 L

39582 v

39582

All

.

22571 E

22565

29477

GW

22743

39568

39568

J

G

39534 R

90

660-234

39594 A

22569

39501 A

39501

39501

c

39501 B

90

39532 A .

39582 K

41071 G

86 X

22569 A

39594 G

39594 H

39578

BB

22569 D

39593

c

39593 D

660- 243

39593 E

22894

AD

22565

39582

y

39582 X

22569 c

22586 R

22653 D- 4

39582

F

39578 F

138

22657 D-

12

39501 K

Blk.

Pre

Presser

Presser

Lock

Presser

Pres

Presse

Screw

Top

sser

Nut

ser

r

-

Cover

H

inge

Oil

Spring

Spring Plunger

Spring

- A

djust

Spring----------------

Fo

ot

Release

Spring

Top

Fill

Cover--

-----

Pin---

er

Cover------------------------------

Spring------

Top Cover

Oil

Drain

Sc

rew

Upper

Feed Bar Oil

Screw

Oil

Fe

ed

Screw-

Cloth

Cloth

Cl

oth

Cl

oth

Screw-

Cloth

Feed Mechanism

NutScrew

Screw

Oil Filter

O

il Strainer

Chip

Screw

Oil

Oil

Oil

Oil

Screw

Screw

Bottom

Bottom

Screw

Screw

Screw-

Bottom

Clo

Screw

Screw

Stud-

Looper

Screw

Looper

Thread Tube

-

Tube

Eccentric

Plate

Plate,

Plate,

Plate,

Plate

Feed

-

-

Guard-----

-

Gauge

Gauge

Gauge

Sight

-

-

-

-

th

Plate

- F

-

Cloth

Gasket

Plug

Upper

Thread

-

Tube

Thread

Shield

Feed

Coupling--------------------------------

Cloth

Latch

Feed

Oil

Bar

Plate

,

semi-submerged

nonsubmerged

semi-submerged

nonsubmerged

Spring

Latch

Mechanis

Mechan

Screen

Screen

-----

Chip

Gauge--Lowe

Upper

Cover

Cover---

Bottom Cover

Bottom

Bottom

Cover Extension--

Cloth

Guard-------------------------------

Float ----

Indicator

Seal

r L

Gasket------

Fa

bric

abric

P l

P l

ate--

Description

Plunger

Plunger

ing

Plunger

--

- -

---

Cap

Locking

Adjusting

Screw------------

Bushing

----

-----------------------

----------

-----

Nut -------------------

Nut

----

Screw--

--

--

--

----------

--

----

- - - -

-

-----------

- -

---------------

-------------------

----------------------------

-------------

Screw

Looper

- -

Spacer

Sp

Cover--

---------------

----------------------------Thread

Tube

Tension

Tube

----------

------

Oil

Sh

Oil

Stud---

-- -

ring

m

Cover-

ism

and

Str a

Assembly------

Spring-

Tension

- - -

ield

-----------------------

Tube-------

-

installation---

installation-

--

-----

--------------------------

-

--------

Cover----

iner-

-------------

-

-----

---------

Ring

Loop

Guard-------

-----

-------

ooper

er

-

--------

Cover--------------------------Cover

Guard---

ate-

-

----------

-

-------------------------

-

----

-

--

Bar

Drive

---------------------------Extension----------------

--

--

-- -

---

----

Lever

Lever

-

-

--------

- - - -

------

--

--

-

------------------

Tube

- - -

--

------

------installation

installation

- -

-

- - - -

- - -

- -

--

--

- - -

--- ---

- - -

- -

---------------------

Assembly-------

-

-----

Spring-

----

- -

----

--

--

- -

--

- -

----------

-

-------

-

-------------

----------------

- - -

------

--

- - - -

-------------------

-

--

--

------

-----------

-----Shaft----

Shaft

------

-

---------

--

-

----

------------

-------------

-----

- - - - -

--------

--

-

------

--

--

-----

-------

-

--------

-

------

-

-- --

-

--

-------

-

----------

-------

--

---

-------

---------

-

------------

------------

-----------

------

--------

-

--

- - -

------

- - -

-

-----

--

----

--------

--

-----------

-

-------

-

-----

- - -

---

- - - - - - 1

- -

-------

------------

--

- -

-------

---

--

--------

----

- -

- - -

--

-----

----

----

- - - -

---

----

-

-

----

--

----

Amt

-

-

-

---

-

--

-

-

-

--

- -

-

- -

--

---

--

- 1

- 1

-

--

- - 1

- 1

.

Req.

1

1

1

1

1

1

1

8

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

3

1

1

1

2

1

1

2

2

1

1

14

2

1

2

1

21

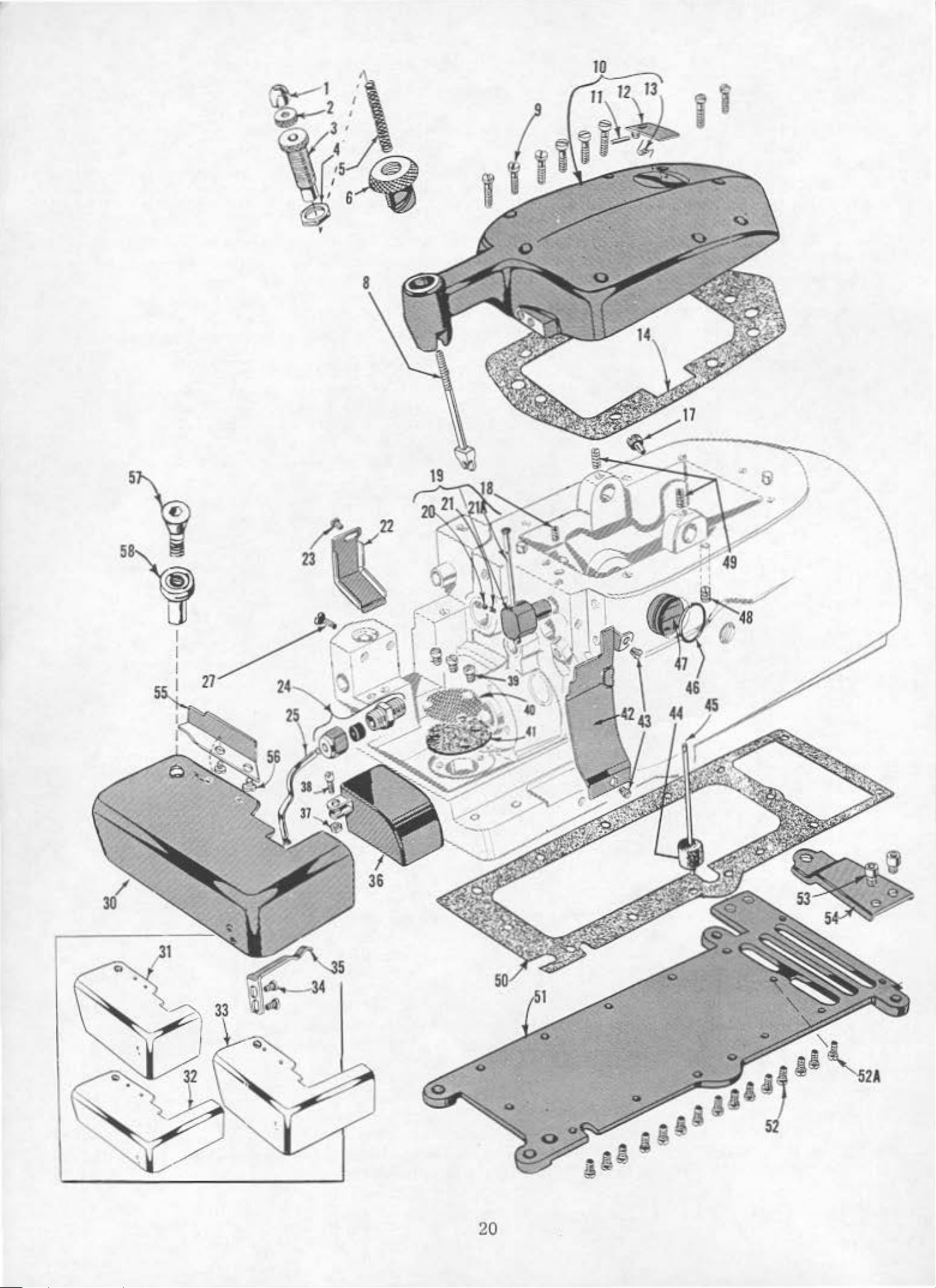

Page 8

A -

~EED L£

8 -

SPRfADER -UPFER

DR

C -

lJPPEil

D -

LO'!Eil

DfU

IV£

llEARII'G

KNIFE

J.OOI'!ll D\JV[

\'1:

BEAR lNC

D\l'E

LOOPER

llEARJNG

BEARING

22

Page 9

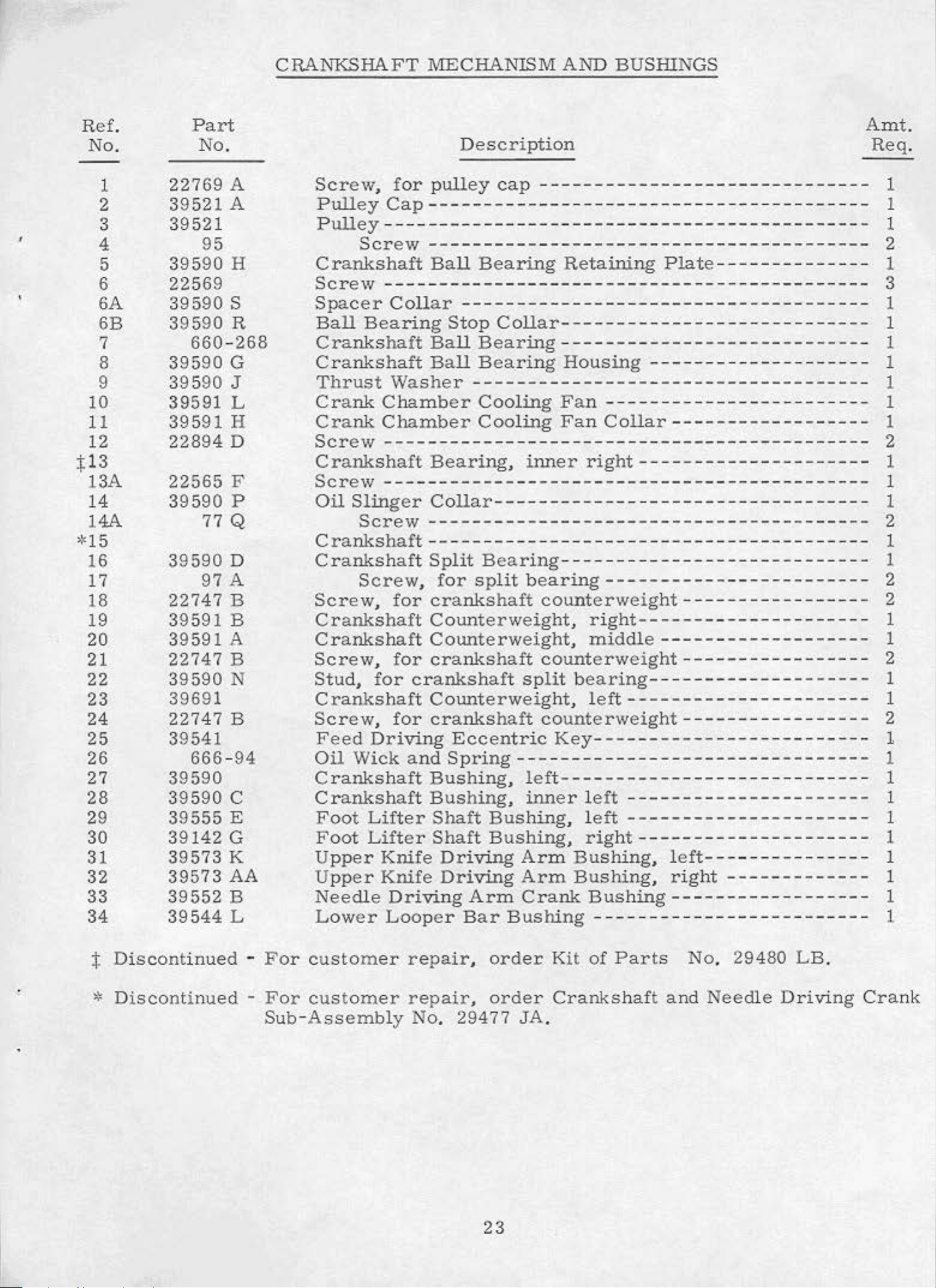

CR.J\.NKSH.J\.FT

MECHANISM

AND

BUSHINGS

'

Ref.

No.

1

2

3

4

5

6

6A

6B

7

8

9

10

11

12

P3

13A

14

14A

*15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Part

No.

22769

39521

39521

95

39590

22569

39590

39590

660-268

39590

39590

39591

39591

22894

22565

39590

77

39590

97

22747

39591

39591

22747

39590

39691

22747

3

9541

666-94

39590

39590

39555

39142

39573

39573

39552

39544

A

A

H

s

R

G

J

L

H

D

F

p

Q

D

A

B

B

A

B

N

B

c

E

G

K

AA

B

L

Screw

Pulley

Pulley

Cr

Screw ---

Spacer

Ball

Crankshaft

Crankshaft

Thrust

Cr

Crank

Screw-----

Crankshaft

Screw

Oil

Crankshaft

Cr

Screw

Cra

Crankshaft

Screw

Stud,

Crankshaft

Screw

Feed

Oil

C

ra

Crankshaft

Foot

Foot

Upper

Upper

Needle

Lower

,

for

Cap-----

--------------

Screw

ank

shaft

Collar-

Bearing

Washer

ank

ankshaft Spl

Ch

Chamber

--------------------------------------------

Slinger

Screw

Screw,

,

for cranks

nkshaft

,

for

for crankshaft

,

for

Driving

Wick

nks

haft

Lifter

Li

fter

Knife

Knife

Drivi

Looper

Descr

pulley

-----------------------------------

-----------------------

Ball

- -

-----------------------

Ba

Ball Bear

amber

-----------------------

Bearing,

Collar

----------------------------------------

---------------------------------------for

Counterweight,

Counterweight,

cra

Counterweight, left---------cranks

and

Bushing, left--------Bus

Shaft

Shaft

Driving

Driving

ng

Bearing

-----------------------

Stop

ll

Bearing

-

-------------

Cooling

Cooling

it

Bearing

split

nks

Eccentric

Spring

hin

Ar

Bar

ipt

ion

cap

Collar----

----------------------------------

haft

haft

haft

g,

Bus

Bushing,

m

------

----------------------------Retaining

-

ing

inner

bearing---

split

--------------inner left

hing, left--------------

Ar

Arm

Crank

Bushing

Housing

Fan

Fan Collar------------------

-----------------------

counterweight

counterw

co

unterwei

Key-----------------

m

-

---

-------- ---

Plate

- -

-------

--------------------------

--------------------

--------------------

------------------------

right

right----------middle---------

bearing

right

Bus

Bushing

Bushing---

----------------------

---

------

eight

-------

ght--------------

-------------------

----

----------------

hin

g, left----

,

- -

----

------------------

-----

--------------

-----------------

------------------

rig

- -

-----

--------------

-

--

----------

----------

-

--------------

--

--------------

-

---

---

-----

-

-----------

----------

-

---------

--

- -

--

- -

----------

- -

---

---------

ht -

---

---------

---------------

-------

--

----

-----

-------

------

- -

-

---

Amt.

- 1

---

---

- 1

- - 1

---

-

--

---

--

- 1

- 1

--

--

- 1

Req

1

1

2

1

3

1

1

1

1

1

2

1

1

1

2

1

1

2

2

1

1

2

1

1

2

l

1

1

1

1

1

1

.

:t

Discontinued

*

Discontinued

-

For customer

-

For

Sub-Assembly

customer

repair,

repair,

N

o.

29477

order

order

23

Kit

Crankshaft

JA.

of

Parts

No. 29

and

480

Needle

LB

.

Driving

Crank

Page 10

26A

17

16 15

24

Page 11

Ref.

No.

Par

No

NEEDLE

t

.

DRIV

E Al'ID

FEED

MECHANISM

Description

Am

He

t.

q.

'

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

26A

27

28

29

30

34

35

36

37

38

39

40

43

44

45

46

47

48

49

50

51

52

53

55

56

57

58

59

60

61

62

63

87

39578

39578

M

R

22569 B

8372 A

39578

p

22565 F

39

535 c

39

535 F

53634

c

22569

39535

39535

53634

J

D

c

22569 8

22569 G

39534 H

39538

39534

G

39505 J

22528

39505 K

22768

39536

B

A

39540 B- 5

39540 J

18

20

39

536 E

39

536 c

39536 D

39536 B

14077

39563 z

39552

22596 E

50- 774

39551 F

22564

39

568 A

395

68 y

88

B

3955 2

39552

c

A

39552 E

22587

J

39594 N

77

660 - 207

22569 c

39503 c

22758

E

12957 E

39503 D

604

39503

A

22570

39503

Blk

Screw -Fabric

Fabric Guard

Fabric

Screw-

M

ounting

Fabric

Screw-

Feed

Main

Feed

Screw

Fe

ed

Feed

Feed

Screw

Screw

Gaurd, for

M

ounting

Bracket

Guard

Adjusting Pin---

Tilti

Feed

ng

Bar

Bar Guide

-

Feed

Ba

r G

uide

Bar

Bar

Guide, right---------Guide

-

Feed

-

Thrust

Feed Bar Thru

Feed Lift

Main

Main

Feed

Feed

Screw

Chaining

Screw

Main

M

Fe

Feed

ain

Feed Dr

ed

Eccentric

Bloc

Bar---Dog ----

-

Main

F'ee

-

Chaining

Bar

Nut-Crankshaft-----W

ashe

r - - -

---

Nut-Feed Bar Driving

Feed

Fe

Feed

ed

Bar

Bar

Bar

Driving

Spacer

Driving Stud

Nut-Needle

Needle

Thread

Needle--------

Needle

Drivin

Screw -Needle

.

Stop

Needle

Screw

Looper

Looper

Screw

Pin

Clamp Stud-----

-

Looper

Thread

Thread ?ull-off

- Looper

Needle Driving

Needle Drivi

Nee

dle

Driving

Screw

Oil Spla

Screw

-

Oil Seal

Scr

ew

-

Edge

Scre

Swing

Edge

Guide

w -

ing

Guide

Screw -Ad

Edge

Scre

Guide, adjustable, for Style

w - S

-

sher-

Oil

Ring------------

Mounting

Swinging

Arm

justable

tationary

Edge Guide, stationary

, f

Guard

or

-------Style

Styles

Bracket-Washer

Mo

unting

Adjusting

Bracket

Pin-

Guide, left

Washer

Bar

Guide,

Block

----------

Washer

Bar

Gu

Washer

st

Washer-

k--

- - --

ide,

- - - -------

------------

- -

--------------

------

Feed

d Dog - -- -

Dog--

Feed

---------Dog----

Driving

iving

Eccentric

Sp

acer

and Oil

---------------

--

---

- - -

-----

Connection

--------

- -

Clamp

Stud---

Pull-off

-

----

g A

- -

rm-----

----

Driving

-

Needle

Th

Pull-off

Driving Arm-------

read

----

Thread

ng

Arm

Arm

Arm

Crank

Crank

Crank

Connecting

- - -

-----

---

Splasher-------

Bracket------

Mounting

Bracket

Arm, for

Spring

Swinging

Washe

Arm

Edge

Edge

,

-

-----------

39500 J

39500

----

K,

--

- - - -- -

--

-------

L,

- - -

-

------

-----------

--

- - -

-------

-- --

--------left---

- -

--

-

-----

- ----------------------

- -

- -

------

---- - - - -

right-------

- - -

------------

---

-------------

-----

- -

-----------

--

-

--------------------

Connect

ion------

, . 124 i

Slinger-

Stud

-----

--Bus

- - -

---hing-----------------

---------------

------------

- - - -

Eyelet

----

----

---------

------

- -------Arm

----

--

---

- - -

----

Pull-off--- - -

--

Leve

----

r---

--------

- - - - - - - - -

Pull-off Lever-

Thrust

- - - - - Connec

Rod

- -

- - -

--------

W

---tin

----

------

- -

--

- - -

-----------

-----

---

- ---- -

Styles

r,

, f

or

Guide

395

for

Styles

Styles

, f

or

s 39500 J & L --

Guide, for

for Styles

39500 K & M - -

-

-

-------

M - ----

------------

----

- -

--------

----

----

--

- - - - - -

- - -

-

-

----

------

- ------------

-

- -

-- --

------

--

- - - --

-----

-----

-

----

-------

--

---------------------

- - - ---- - -

--

--

- - ----

------

-- - - - ----

--

-----

-

----------

- - -

---

- - -

-

-- --

- -

--

nch

- -

- ---- -

--

--

throw-----

- - - - - - - - -

-------

---

----------------

--

---

--

- -

---.

---

-----------

- - - -

- ---- - -

- - -

---

--

--

---

------------

--

- -

--------

--

-------------

------

- -

-------- -----

-----

----

--

- ----

---

--

-----

------

---- -

------

- ---- - -

- - - - - - 1

-----

------

- - - - - - - 1

--

--------

- - -

--

---

--

--------

- ---- - - - - -

--

--------

---

-----

-

-------

--

- -

-

--------

-----------

---

-----

--------

- - - ----

----- -

---

------------

- -

------

asher--

- -

----

g Hod

-----

------ --

-

-------

---- - -

--

--

-------

-

---

- ---- -

------------

---

- - -

---

--

---

- -

-------

-- - - - - -

----

--- ---

-----

- ~

--------

00 J & L -- - - -

39500 J & L

39500 J & L --------

Styles

35900 J & L

--------

Styles 39500

K & M - -

----

---

--

-

----

--

--

-- --

-

---

- -

--

----

- - - - 2

----

---

-----

----

---

- - - - 1

---

--

----

--

--

-----

- - - 1

---

-----

--

---- 1

--

---

- - 1

---

- - 2

--

--

--

--

----

--

---

--

- - 1

----

---

- -

--

- - l

- - - 1

-- --

---

--

- - - - l

2

1

- 1

2

2

1

1

1

1

2

1

1

2

2

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

l

l

1

1

1

2

1

- 1

2

1

1

2

- 1

1

2

l

2

25

Page 12

m

Tenaion

Nut

~

•

>-

...

z

0

~

oil

...

0

0

11'1

().

I")

Ill

...

...

>-

._

Ill

Tenston

Slot

Tcn~Jion

D

lbrud

Post

Thread

Guld•·-----

--

'

•

-

-

--

~--

Presser

--

.~·

.....

' .

..

'•.

-

'

--

'

Cone

Foot

--

---

---

'

'

..

...

3vpport.

Hcl

cue

---

_

.........

(.:~

.

..

.,.

-

___

Bubia

-------

___

-

____

......

...

-

1

,

•

B Lower

m

Looper

0

fabn.e

IJ

fre.ae

~~

Presser

Looper

Thrud

Looper

Ar•

Thread

Pull-of!

Thrud

Eyelet

Gaide

____

._ ~

"

"'•

Needle

PuJl

Needle

.. o

Tbrud

ff

£yC!Ile t.

Fis.

1

8

Page 13

~\

9

29/

~

28

26

Page 14

Ref

No .

SPREADER

.

Part

No .

/U

PPER

LOOPER

AND

LOWER

Description

LOOPER

DRIVING

PARTS

Am

Req

t.

.

)

•

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

42A

43

44

45

46

47

48

49

482 c

22894 c

22565

7446 A

1280

39543 R

43143 N

39543 H

29126

CG

22559 A

77

39594

N

22747

41255

B

39543 M

22562 A

39543 p

39543 K

39543 s

22565 H

39543 T

39543 E

22503 F

22

KH

39543 A

39543

22564

G

39560 A

39508 A

22539 K

482 c

22894 c

22894 AD

51235 B

39508 B

39151

39544

77

39544 D

39544 B

29126

DF

22729 D

22729 E

97

39544

s

39544 u

39594 N

77

22539

K

666-255

39594 p

Spreade

Sc

rew -Spreader/Upper

Spreader/Upper

Nut Locking

Locking Stud

Spreader/Upper

Spreader/Upper

Rod

r/Upper

Screw-

Locki

Stud

Assembly

Looper

Collar---------------------------

Lo

oper

ng

Stud-

---------------------

Washer---

-

Spreader/Upper

Looper

L

ooper

-----------

Screw -Connecting

Screw -Oil

Oil Splash

Screw -Guide

Ball

Collar

D

rive

Joint

Assembly------------

Clamp-----

Screw -Collar

Spreader

Spreader/Upper

Bushing

Screw-

Cam

Cam

Follower

Follower

Screw -Locking

Splasher----------

er

--------------------Fork

Guide

/Upp

Fork

er

Looper

Looper

and

Cam

Cam

Guide--

Guide----------------

-----------------------Lo

cking

Clamp

-----------

--

----

Clamp-

Screw -Spreader/Upper

Spreader/

Spreader/Upper

U

pper

Looper

Looper

Screw -Spreader/Upper

Spreader-

Upper

Plug

ower

L

Looper-

Screw-

Looper

Screw

Screw-

Lower

Looper

Lower LooperNut

Lower

-

Lower

Looper

Screw -Connect

L

ower Looper

Lower Looper

Lower

Rod

Looper

Assembly---------

Screw,

Screw,

Screw,

Ball

Lower

Oil

Splasher

Screw,

Plug

Felt,

Oil

Screw

for

Collector

Styles

Styles

Lower

Shaft

-

Collar-

Lower

Looper

Bar

------------------------------

Looper

Bar--

ion Link Pin

Bar

Bar

Bar

upper

lower

for

No

Joint

Gui

Looper

------

for

No.

-

39594 N

Lower Looper

No. 39544 N-

Pla

te

39500 J & K

Looper

Collar-

---------------

Driving

Bar

-- --

Connection

Connection

Dri

--------------------------

-------. 39544 S

de

Fork-----

Ball

--

---

(Not

Shaft

Looper

Drive

-----------

Collar

Drive

Lever

-----------

Shaft

-

---------

Looper

Drive

Drive

Rod Ass

Lever--------------Lever

-

---------

----

embly

Connecting

----

------------------

-------

--------------------

- Spreader

-----/Upper

--

-------------

--

--

--

--

-------

----------------------------

Shaft Thrust Washer

Shaft-

-

Clamp-

-- -------------------

--

- -

-----------------

-

-------------

- - -

---------

----------------Looper Holder

Hol

der

Holder

Looper

39500 L & M

Co

--------Holder

------

Shaft-

--

--

lla

------

---------

---

-------

r---

-

-----

-----

Bar

Driving

Le

-----

--

--------

ver

-

--

Lever Shaft-

Shaft

--------------------

- -

--------------------Link

Pin---

Linl<---------------------

ving

Lever

----------

-

--

- -

and

Connecting

--------------------

---

--

---------------------------

----

Driving

- -

----------------------------

Lever

--

-------------------Shaft-

-------Illustrated)

-----

--

- - -

- -

--------------------

-

Lever

Shaft---

--------------

- -

---

--

-

------

Dr

ive

Lever

-----------

-

----

---------Looper

--

----------

- -

--

- -

------------

- -

---

-----------

-

--

---

-

----

------

Collar--

---

-----

.

-----------

----------------

--

-----------

-------

- -

-----

- -

-----------

--------------

---------

-------

----- -----

--

-----

--

-----

--

------------

-

--

--------------

-----------

-----

-- -----------

-

---

------------

-----------------

--

----

--

----

----

-------

----

----

--

------

---

----

----

----

-

--

- -

--

-------

------

-

------

- -

---

-- --

----

------

--

----

------

-------

-

-

--

----

-------

----

--

--

- - -

--

---

---

--

---

---

--

--

--

---

1

2

2

1

1

1

1

1

1

4

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

-

1

1

1

1

-

1

2

2

1

-

1

1

1

2

2

1

1

2

2

2

1

1

1

l

l

1

1

27

Page 15

12

14

1

28

Page 16

UPPER

AND

LOWER

KNIFE

ME

CHANI

SM

•

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Part

No.

39573

22587

39573

55235

6042

55235

39573

39573 H

39571

39572

22738

39570

39571 F

39571

14077

22585

39525

22585

39525

22524

39524

J

J

E

D

A

E

A

c

A

J

B

A

A

A

J

Upp

Upper

Upper

Upper

Upper

Upper

ScrewUpper

Upper

Upper

Nut

Screw-

Needle

Screw-

Ne

Screw

Throat

er

Screw

Locking

WasherNut-

-

edle

Knife

Knife

Knife Driving

Knife

Knife

Knife

Holder

Knife,

Knife

Knife

Upper

Needle

Guard,

Needle

Guard,

-

Throat

Plate,

Driving

-

Connecting

Driving

Stud-

Driving

Driving

Driving

Clamp

Holder

Block

for

Styles

Clamp

Chain

Knife

Guard,

front

Guard,

rear-

Plate

3

/16 inch

Description

Connecting

Rod

Lever

Driving

Lever

Leve

r----------------

Arm

------------

Washer

Arm--

Stud

Block

-------

Guard

Assembly

------

-------------------

----

-

Clamp

39500

------

-------------

front

----------

rear------------------------

- -

----

-----wide

Rod

---------

Le

ver--------

----

--

--------------

-----Nut

J & L

--

-----

--------

--------

----

-----

seam,

---

------------

- -

----

-----------------

----only

-------

------

-----------------

for

------------

------

-

--

------

-

--------

---------

---------

--------

--------

-------

------

-----

---------

-----

------------

----------

----------------

----------------

-

-----Styl

-

------

-------

es

-------

---

---

---

----

-----

----

-----

--

--

- 1

- 1

- 1

--

Arnt.

Req

.

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

21A

22

23

24

25

26

27

28

29

30

31

32

33

39524

39550

39550

39549

39550

39550

22588

22729

39550

14077

22892

39580

22653

K

E

B

J

M

L

A

B

c

B

A

B-12

39500J

Throat

39500

Lower

Lower

Lo\ver

Knife

Lower

Screw

Screw-

Lower

Nut -Locking

ocking

L

hroat

T

Screw

& L

P

lat

K & M

Knife

Knife

Knife

Clamp

Knife

-

Lower

Lower

Knife

Screw

Plate

-

Support

e,

----------3/16

inch

--------

Spring

Holder

------------

Spring

Clamp

Knife

Knife

Holder

Screw-

-

Lower

and

Lower Kni

Brac

------

wide

-

--

---------------

----------

---

seam,

--------

-----

-----------

--

----------

Holde

Holder

Locating

Lower

ket

r

-----

Locking

Stud

Knife

Knife

-----------

Holder--------------

fe

Support

----------for

-

-

-----------

Styles

--

----

---------

-----

----------

-----

---------------------

---

--

---

-------------

--------------------

-----------------Stud

---Holde

Bracket

-----------------

----

------------r

-----------

--

------

-----

--

-----

--------

--

--

--

- 1

1

1

1

1

1

1

- 1

- 1

1

1

- 1

1

2

•

29

Page 17

..

14--Ql

'

30

Page 18

FOOT

LIFTER

,

THREAD

TENSIONS

AND

MISCE

LL

ANEOUS

EYELETS

'

Ref

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

19

20

24

28

29

36

37

.

.

Part

No.

39555

39555

39555

660

:39555

B

D

-1

I~

42

22566 B

39555

c

627

22597

E

12538

12865

88

39555

22791

258

39556

39520

39597

A

H

A

D

L

L

22819

39530

22768

B

108

108

512

92 F-2

51292 F- 2

51292 F- 4

51292 F

51292

-4

F- 8

Foot

Foot

Foot

Cotter Pin

Foot

Lifter

Lifter

Lifter

Lifter

Lever

Lever

Intermediate

Lever

Screw -Foot

Foot

Lif

ter

Lever

Screw-

Foot

Screw

Lock

Lifter

- Lev

Nut

Lever

Scre\v -

Foot

Screw

Nut

Presser

P

Ten

Tens

Low

39500

L

Looper

Need

for

Lower

Lifter

-

-

Presser

Lever

Presser

Arm

resser

Foot

Presser

Screw -

Presser

Screw-

sion

er

ion

Need

Pos

Post

le

J & K

ower Looper

Thread

le

and

Styles

Upper

39500

Looper

Description

----------

Spring

Connecting

Connecting

Lifter

Lever

Arm

Lever

-

Arm

er

Arm

Lever

Shaft

Collar------

Shaft

Arm

Arm

----------------

----------

Foot

Stitch

Foot

Hinge

t Nut,

Nut,

Thread

--------------

Thread

Tension

Thread

----

Stitch

Tongue

Hinge

Spring

for

for

Looper

L &

---------------

--------

Lever

Link

--------

------------------

Li

nk

--------

-------

------------

---------------

-------

Arm

-----------------------

Collar

------

----------

--------

--------

-------------

-------------------

Tongue

------

Spring

--

Styles

Sty

les

Tension Spr

Tensi

Sp

on

ring,

Thread

l\'1

--------

Tension

----------

----------

----

------39500

39500

----------

Spring,

for Sty

Spring,

--

----------

--

------

----------------

---------------

---------

----

-------------------

--

---------

----------

--------------

----------

-

----------

-

----------

---- ----

-----

---------

-

---

--------

--------

-----

----------------

-----------------

------

---------

-

------------

--------------------

--

-----

----

-

--

J & K

L & M

ing, for

Tension

---

---------

------------

--------

----------------

---

--------------

----------------

Styles

------------------

for

le

Style

39500

39500

J

Spring,

------------

for

Styles

--------

----------

-------

-----

-----

-----

-

--

-----

-

-----

I<

----

----

---

--

--

--

---

--

---

Amt

Req

- 1

1

1

- 2

1

- 1

1

- 1

2

2

1

2

1

1

1

- 1

1

1

1

1

1

2

3

1

1

1

2

.

.

,

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

56

107

107

109

109

35792

35792

39592

H

H

F

22891

22565

22565

c

c

90

39563 s

22569

39568

39568

39568

39568

376

376

43139

43139

39568

73

B

D

L

B

E

A

A

A

A

X

w

22569 D

39563

D

39500

Tension

Tension

Tension

Tension

Ten

Ten

Tension

Screw

Screw -Ten

Screw Screw -

ThreadGu

sion

sion

-

L &

:i\1

Post

Post

Disc,

Disc,

Post,

Post,

Post

Tension

sion

Tension

Thread

ide

Ferrule,

Ferrule,

i\1ounting

Screw -Eyelet

Looper Thread

ooper

L

Looper

Auxiliary

Th

read

Thread

Looper

Screw -Looper

Screw

Nut -Looper

::>iut-Looper

Screw

Frame

Screw

Needle

-

Looper

-

Frame

Thread

-

Needle

Thread

Thread

Thread

--------

for

Styles

for

Styles

for

Styles

for

Styles

Post

Post

, fo r

Post,

Guide

----

---

Mounting

Eyelet

Eyelet

Eyelet,

Thread

Thread

Thread

Eyelet,

Thread

Guide-

Thread

Eyelet

----------

for

Styles

for

Styles

39500

39500

39500

39500

Bracket

Mounti

ng

Styles

for

Styles

----------

-------Bracket

Mounting

-----for

----------------

Styles

Eyelet,

Eyelet,

Eyelet,

Eyelet,

for

for

Guide

--

Lower Loop

Eyelet

--------

----

39500

39500

J &

I<

--------

L & i\1

J &

L &

-----

I<

----------

i\1

- -

Bracket

39500

39500

-

------

------

---------

-----------

Bracket

39500

for

Styles

for

Styles

for

Styles

Styles

Styles

----

----

-----------

er

Thread

---

-----------

----

J &

L &

-

-------

I<

-------------

i\1

- -

---

----------------

----------

--------

-

-----------------

J & K

----------

L & M

-

--

--------------

-------------

-------

L & i\1

39500

39500

39500

39500

39500

J & K

L &

---

---------

----------------

--

------

------

-----

-----------

-----------

--------

----

------

------

--

------

- -

--------

----

------------

-

-------

L & M

J

&.

K

L &

!\t

--------

:11

-----

----------

--------

-----------

--

-----

---

----

-

--

---

-----

----

--

--

1

2

- 3

4

- 6

2

3

1

1

2

3

1

1

1

1

1

1

1

1

2

1

2

- 2

1

1

1

31

Page 19

2

3----

4

32

Page 20

THREAD

STAND

AND

MlSCE

LLAJ

-IEOUS TOOJ..'5

'

•

Ref.

No.

l

2

3

4

4A

5

6

7 2J. I

8

9

10

11

12

13

14

*15

16

Part

No.

21113

2!113

21104

21104

69

69

21130

21130

22650

22650

22650

04AA

652

652 J -16

WA9 A

651

116

660-240

21227

21202

21388

F

F

v

v

s

s

W-2

W- 3

CB-4

CB

-4

CE-6

.r

-24

A-

16

BF

AU

Thread

Thread

Pad,

Pad,

Spool

Spool

Cone

Cone

Thread

Washer -Thread

Washer-

Lo

ck

Nut -Th

Wrench,

Thread

Feed

Screw

Socket

Eyelet

Eyelet

for

Styles

for

Styles

Pin, for

Pin,

Sup

port,

Support,

ScrewScrew-

Screw-

Stand

Thread

\Vash

read

for

Tweezers

Eccentric

Driver

Wrench,

for

Cone

Cone Support, for

Cone Support,

Rod

er

-~----------------------

Stand

9/32

,

Description

and

Support

and

Support

39500

39500

Styles

Styles

for

for

Stand

Stand

E><tractor

3/16

for

J & K

L & M

39500

39500

Styles

Styles

Support, for

-----------------

Rod--

inch

----------------inch

3/8

Rod,

Rod, for Styles

----------

----

J & K

L & M -

39500

39500

Rod-

Rod

----------

nut

-----------Hook

diameter,

inch

J &

L & M

Styles 39500

Styles

for

all

----------

---------- -----

--------

nut

for

Styles

---------

------

---------------------

------------

-----

K--------

----

39500

Styles

---

--

---------------------------

-

------------------------------

--------

-----------

-----------------------

10

3/4

holding

feed

39500

39500

J &

K-----------

L & M

-----------------

----------------

--------

-----------------

J & K

L &. M

----

-----

-----------------

--

-----

inches

eccentrics-------------

------------

---

-------------------

----------

-----------------

--------------

-------------

---------------

--------------

-----------------long------------

-------

------

------

-----

-

-----

------

--

----

--------

---

----

----

-

------

----

Amt

Req

--

- 2

--

--

--

- - 1

---

- l

--

.

.

3

2

3

2

3

1

1

2

3

1

1

1

1

1

1

1

1

1

•

"'

Not

21227

21233

21261

21261

21261

21377

21377

21695

39556

39556

605

39595

39598

52978

21371

21371

21371

21371

21371

21371

21371

21371

21371

21371

furnished

BG

DR

M-360

M-380

l\1-400

BA

Bl•'

u

B

c

J

Ul

l

PJ-48

RD-48

RF-48

RJ-48

RG-48

RK-48

RC-47

RE-47

RH-47

with

3/4

3/4

3/4

machine

ACCESSORIES

Needle

Light

by

No

. 1

No

. I

No. 1 "V''

Tray,

Tray

to

Finger

Presser

P r

esser Arm

P r

esse

Isola

Knife

Chip

Individua

Table

in

dividual power

Nonsubmerged

Table

Table

no

Table

Table

Table

Table

for

Nonsubmerged

Table

Table

.

Curva

Fixture

"Electro

"V"

Belt,

"V''

Belt, 38

Belt, 40

1

3/4

, 1

3/4inches

right

Protector

Arm

r A

rm

tor,

Dispos

chip

line

rubber

Grinder,

l Power

Top,

Top, same

Top,

chute

Top, same

Top, same

Top, same

Top

, 4 7

s

haft

Top, sam

Top,

1\

Vl\ll"ABLE

ture

Drive"

inches

al

48

same

same

Gauge

A~sembly,

which

36

inches

inches

inch<'&

high,

high,

Chain

Chain

Chain

complete

Chute

x 20 x I

3/4

installations

e e x

Cutting

Cutting

Cutting

Table

table

-

no

except

except

except

except

except

x 16 x l

-

no

cept

except

chip

chip

AS

EXTRAS (Not

including

blue

supplies

long, for

long,

long,

for

semisubme

for

semisubmergedinstallations

Knife, lower

Knife, upper

Knife

3/4

inches, for

installation;

chute

Nonsubmerged

Nonsubmerged

Semisubmerged

t>uUy

Fully