Page 1

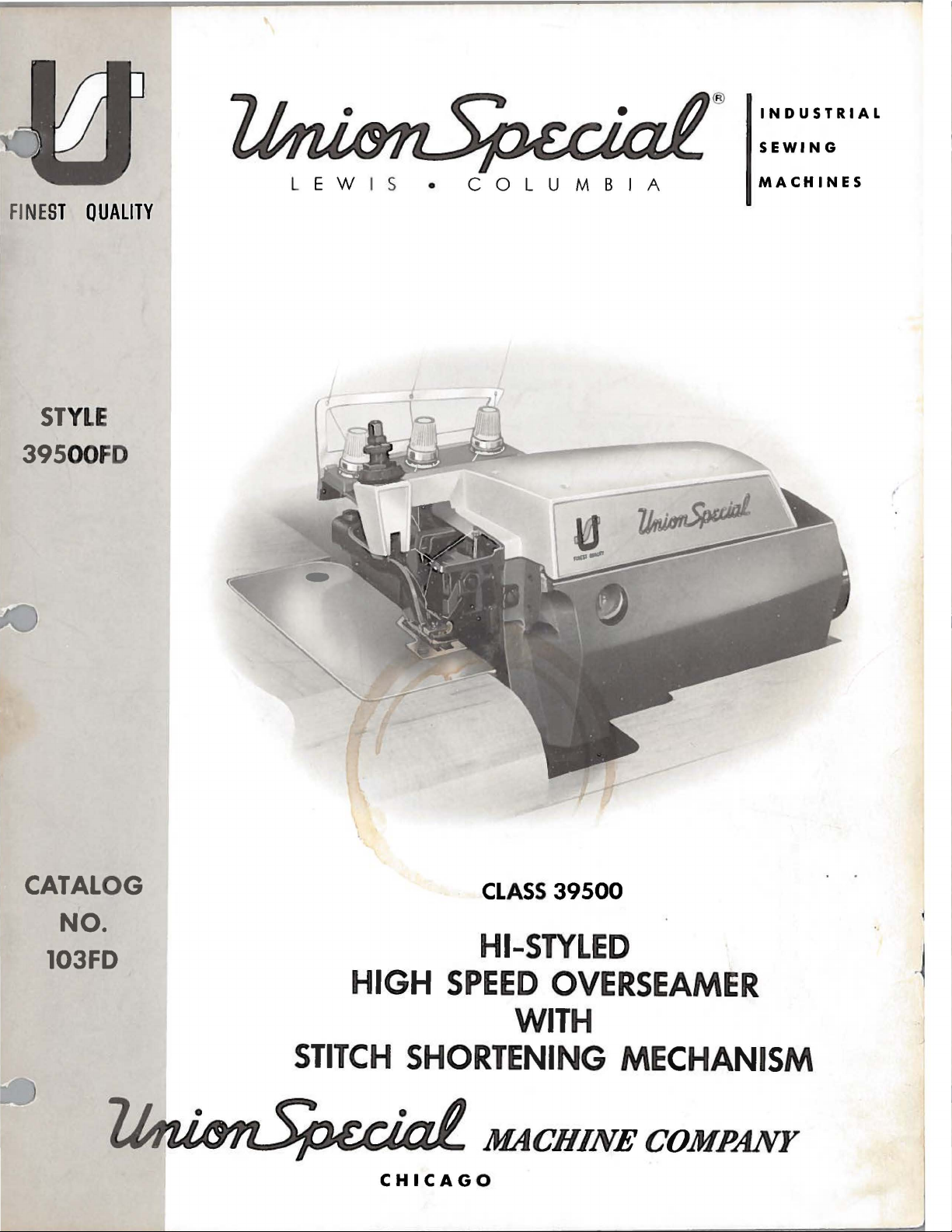

®

INDUSTRIAL

SEWING

FI

NEST QUALITY

ST

YLE

395

00FD

L

EW

I S •

COLUMBIA

MACHINES

CATALOG

CL

ASS

39500

NO.

103FD

HIGH

HI-STYLED

SPEED

OVERSEAMER

WITH

STITCH

SHORTENING

CHICAGO

MECHANISM

Page 2

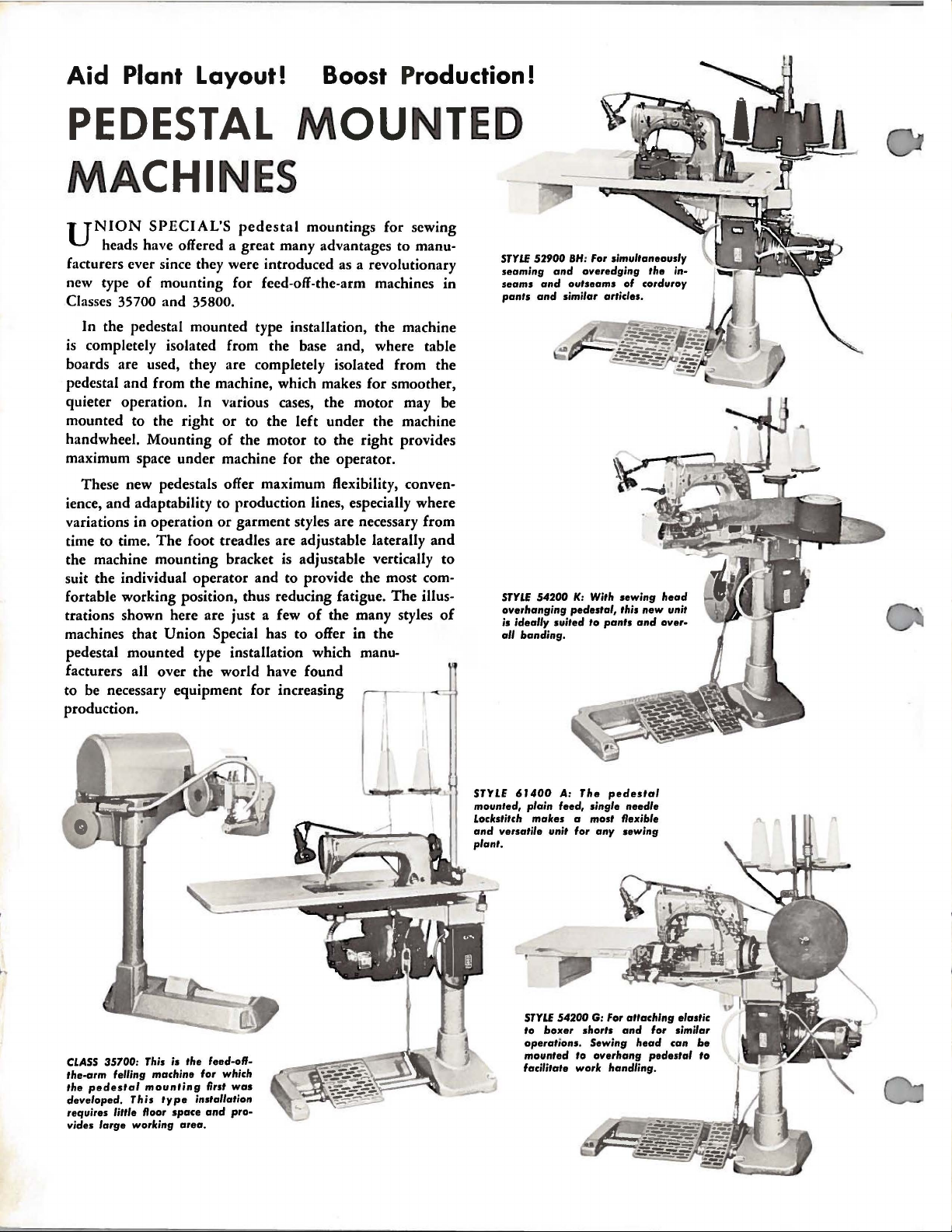

Aid

Plant Layout! Boost Production!

PEDESTAL

MOUNTED

MACHINES

UNION

heads have offered a great many advantages to manufacturers ever since they were introduced as a revolutionary

new type

Classes 35700 and 35800.

In the pedestal mounted type installation, the machine

is

completely isolated from the base and, where table

boards are used, they arc completely isolated from the

pedestal

quieter operation. In various cases, the motor may be

mounted to the

handwheel. Mounting

maximum space under machine for the operator.

These new pedestals offer maximum flexibility, convenience,

variations in operation

time to time.

the machine mounting bracket is adjustable vertically

suit the individual operator

fortable working position, thus reducing fatigue.

trations shown here are just a few

machines

pedestal mounted type installation which

facturers all over the world have found

to be necessary equipment for increasing

production.

SPECIAL'S

of

mounting for feed-off-the-arm machines

and

from the machine, which makes for smoother,

right

and

adaptability to production lines, especially where

The

foot treadles are adjustable laterally

that

Union

pedestal

or

to the left under the machine

of

the

or

garment styles are necessary from

and

mountings for sewing

motor

to the

right

to provide the most com-

of

the many styles

Special has to offer in the

manu-

provid('s

The

illus-

in

and

to

of

STYLE

52900

SH

seaming

seams

pants

and

STYLE

54200 K: With sewing

overhanging pedestal, this

ideally

is

all banding.

: For simultaneously

and

overedging

and

outseams

similar articles.

suited

to

of

pants

the

corduroy

head

new

and

over-

in-

unit

STYLE

61400

A:

STYLE

54200 G: For

to

boxer

operations. Sewing

mounted to

facilitate worlc

CLASS 35700: This is

the-arm felling machine for

the

pedestal

developed.

requires

vides

little floor

large

This

worlcing

mounting

type

space

area.

the

installation

feed-off-

which

first

was

and

pro-

mounted, plain feed, single needle

Loclcstitch malces a most

and

versatile unit for

plant.

The

any

shorts

overhang

pedestal

flexible

sewing

attaching

and

head

handling.

elastic

for similar

can

pedestal

be

to

..

Page 3

Catalog

No.

103

FD

(Supplement

ADJUSTING

INS

LIST

CLASS

to

C

TR

AND

OF

Style

39500

atalog

UC

FOR

39500

No.

TIONS

OPERATING

PARTS

FD

103

F

A)

June,

1967

Union

Rights

Reserved

MACHINE

INDUSTRIAL

Print

First

Copyri

Special

SEWING

CHICAGO

e d

Edition

g

ht

by

1967

Machine

in

All

Countries

COMPANY

MACHINES

in

U.S.

A.

Co.

3

Page 4

IDENTIFICATION

OF

MACHINES

Each

on

the

Style

Example:

only

dard

which

39500".

junction

are

parts

Numbers

position

ordering

herein.

Class

given

of

numbers

minor

Style

Styles

differs

This

illustrated.

with

This

39500.

from

handwheel

Union

machine.

"Style

changes

number.

of

machines

from

catalog

therewith.

their

in

the

of

that

parts.

catalog

It

can

also

References

the

is

Special

Style

have

operator's

one

39500

Example:

the

is a supplement

Only

On

the

part

first

part

in

Always

applies

be

away

machine

numbers

or

FD".

are

made

similar

Style

parts

page

numbers,

column

the

use

applied

from

is

identified

are

classified

more

APPLICATION

illustration.

the

specifically

to

position

operator.

letters

Special

in a standard

"Style

number

found

opposite

are

part

with

directions,

39500

in

construction

in

to

Catalog

description

reference

number

discretion

while

suffixed,

Style

on

the

to

numbers

FDZ".

that

it

OF

Style

illustration

Reference

the

such

seated

by a Style

as

but

machine,

are

contains

CATALOG

No.

103

39500

and

the

numbers

numbers

listed

standard

to

as

some

right,

at

the

in

standard

never

contain

a

"Z"

grouped

no

letters.

FA

and

FD,

but

will

number

only,

the

second

Styles

Special

left,

machine.

number

and

contain

the

is

under a Class

should

not

be

and

should

of

Styles

front,

on a name

special.

letter

suffixed

Example:

on

found a listing

of

pieces

merely

never

column.

machines

back,

Operating

the

letter

to

be

used

Style

indicate

of

machines

plat

Standard

"Z".

"Z".

When

the

stan-

number

"Class

in

39500

of

required.

be

used

as

listed

etc.,

direction

e

con-

FB

the

the

in

in

are

Hi-Styled

Overs

Lower

39500

filled

straight

should

sight

gauge

main

earning

Knife,

FD

panties,

minimize

seam

ential

CAUTION!

before

be

Machine

gauge

lines

Machineis

reservoir

High

Machine.

Automatic

Light

slips,

width

feed.

beginning

mineral

used.

is

on

front

when

STYLES

Speed

to

the

1/8

Maximum

Oil

oil

filled

machine

automaticallylubricated.

filled.

Single

Differential

Lubricating

medium

etc. , with

possibility

inch;

was

of a Saybolt

of

stitch

drained

to

with

machine.

is

Check

Curved

duty

recommended

operate.

oil

stationary.

machine

knee

of

ravelling.

range

from

viscosity

at

Red

oil

daily

OF

Blade

Feed,

System.

8-20

OILING

machine

Oil

spring

bulb

before

MACHINES

Needle,

Trimming

for

seaming

controlled

Seam

per

inch;

speed

capacity

of

cap

on

No

7000

when

200

in

oil

level

oiling

the

morning

Two

Mechanism

stitch

Specification,

cam

R.

shipped,

of

Class

to

250

top

cover.

indicator

is

necessary,

Looper,

of

"T"

shortening

adjusted

P.

M.

39500

seconds

start;

with

shirts,

504-SSa-1;

main

so

reservoir

is

at

100°

Oil

level

should

other

add

oil

Three

Spring

mechanism

six

is

show

Thread,

Pressed

polo

than

as

shirts,

standard

and

differ-

must

ounces.

Fahrenheit

checked

between

keepin

required.

to

be

A

at

g

The

drain

It

is a magnetic

have

entered

plug

the

screw

screw

crank

is

designed

case.

located

to

accumulate

It

should

at

back

be

of

possible

removed

4

machine

and

near

foreign

cleaned

bottom

materials

periodically.

edge

of

which

base.

may

Page 5

IDENTIFYING

PARTS

Where

On

some

of

identification

PART

WHICH

NUMBERS

THEY

IMPORTANT!

OF

MACHINE

Each

denotes

number,

in

thousandths

size

number

packaged

Union

the

stamped

and

Selection

used.

stitch

machine.

a

a

Thread

formation.

For

best

The

reputation

century.

the

construction

the

smaller

letter

REPRESENT

APPEAR.

FOR

Special

kind

of

on

of

an

represent

sold

of

proper

should

results,

are

packaged

for

producing

parts.

is

stamped

ON

ALLORDERS,

WHICH

needle

shank,

the

needle

inch,

the

complete

by

Union

needle

pass

use

only

permits.

and

in

THE

PART

point,

shank.

midway

Special.

size

freely

genuine

under

highest

on

those

to

distinguish

SAME

PLEASE

IS

ORDERED.

NEEDLES

has

both

length.

between

symbol

should

through

our

brand

quality

each

where

PART,

type

groove,

denotes

which

be

the

Union

name,

needles

part

is

construction

the

INCLUDE

and

finish

largest

shank

is

determined

needle

Special

~.

stamped

with

does

part

from

similar

REGARDLESS

PART

size

number.

and

other

diameter

and

eye.

given

eye

needles

Collectively,

on

the

by

the

in

order

in

the

which

for

more

than

its

part

not

permit,

ones.

OF

CATALOG

NAME

The

AND

type

details.

of

blade,

label

size

to

produce a good

measured

of

all

of

the

operation

is

backed

three-quarters

number.

STYLE

number

The

size

type

and

needles

thread

of

this

by

an

IN

of

Style

Type

single

022,

154

groove,

025,

To

sample

on

label.

Success

Union

Special

Company.

to

the

most

efficiency

Genuine

repair

your

parts

guarantee

Prices

forwarded

wise

directed.

39500

GAS.

027,

have

needle

needle,

A

complete

in

its

scientific

and

needles

are

f.

o.

FD

uses

It

has a round

struck

groove,

029, 032,

orders

or

the

type

order

USE

the

operation

Needles

subsidiaries

principles,

durability

are

are

stamped

of

the

highest

net

cash

b.

shipping

A

charge

curved

blade

shank,

needles.

round

spotted,

036, 040, 044, 049,

promptly

and

size

would

GENUINE

of

and

Repair

and

authorized

are

assured.

packaged

with

quality

these

the

and

number

read: 111000

NEEDLES

machines

Parts

and

are

with

Union

in

TERMS

and

is

subject

point.

made

Parcel

to

cover

to

The

point,

chromium

054.

accurately

should

Needles,

AND

as

furnished

distributors.

made

labels

marked

Special

materials

change

post

shipments

postage

standard

curved

plated

filled,

be

forwarded.

REPAIR

can

be

by

They

with

utmost

trade

and

workmanship.

without

and

insurance.

needle

blade,

and

is

an

empty

standard

available

Use

Type

154

GAS,

PARTS

secured

the

Union

are

only

Special

designed

precision.

7Jnimz.Spcciai

mark.

notice.

are

Each

All

insured

for

this

package,

description

Size

with

according

Maximum

•

trade

shipments

unless

style

is

length,

in

sizes

11

027

•

genuine

Machine

Genuine

mark

is

are

other-

a

are

All

instructions

the

same

for

Style

with

39500

CHANGING

regards

FD

as

NEEDLES,

to

Changing

for

Style

5

Needles,

39500

ETC.

FB

Thread

covered

Stand,

in

Catalog

Threadin

103

FA.

g

Page 6

IP]

Tension

(I

Tension Spring

Nut

Fer~

~~

Thread

Eyelet

O Tension

[!]Tension

IIJ

spring

O Tension Disc s <.>

l3 Tension

II Tension Disc

[i

Tension

~Front

fmupper

Spring--1J

Post

Shield / --:

Post

Slot :

Felt

'·.

Thread

Thread

Looper

Guide

Guide

Thread

,..~~

IC.'\

~~~~~~

Eyelet

Cone Support

I3

Lower

D

Frame

Thread

m

Presser

Looper

Looper

Guide

Arm

Thread

Eyelet

6

_.._,.

Top

Needle

Upper

Thread

Cover

Thread Eyelet

Looper

Tube

Ass

embly

Page 7

All

those

(Changes

for

1.

ASSEMBLING

instructions

Style

are

Under

With

resting

center

39500

underlined).

heading

throat

on

in

pertaining

FB

plate

the

the

front

AND

to

(described

"SETTING

attached

throat

end

plate

of

ADJUSTING

the

adjustment

in

Catalog

THE

to

needle s ot.

NEEDLE".

the

suptort

SEWING

103

throat

bracket

of

Style

FA)

(Page

plate

{39580

PARTS

39500

except

9,

support

FD

for

Catalog

AB).

are

the

following:

(39580

needle

same

103FA):

as

C)

and

should

2.

Simulated

inch

per

the

While

that

throat

number

lever

sewn

inch

effective

sewing

when

plate

stop.

tacking

is

the

of

stitches

at

SETTING

the

start

increased

feed

dog

on

material,

knee

to

a

height

(New

is

obtained

by

travel.

press

per

THE

to

or

raising

required

inch

LIFTER

Style

by

finish

adjust

is

engaged,

sewn.

LEVER

39500

increasing

of a garment.

the

throat

the

to

obtain

Screw

FD)

plate

lifter

the

(C)

STOP

the

number

The

lever

lifter

the

desired

is

used

number

which

stop

lever

to

of

stitches

in

effect

(A,

Fig.

(B)

increase

secure

of

stitches

reduces

19)

raises

in

thelifter

per

so

the

the

NOTE:

No.

machines

29480

The

and

CC

those

stitch

and

shortening

can

be

equipped

mechanism

applied

with

intermittent

Fig.

to

19

all

7

can

be

Styles

in

differential

purchased

Class

39500

feed.

complete

except

under

hemming

Page 8

8

Page 9

The

used

parts

on

illustrated

Style

39500

on

FD,

the

but

are

preceding

not

used

page

on

and described

Style

39500

FB.

below

represent

parts

Parts

Styles

Use

rated

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

shown

39500

Catalog

or

described

Part

No.

29480

39581

22585

39581

39581

53634

22541

22526

39581 A

39581

39581

39581 E

22596

39581

39580

22524

39580

39580

22516 A

89

in

FD

103

cc

c

F

G

c

B

c

D

D

c

D

AB

phantom

and

39500

FA

for

here.

view

FB.

all

parts

Stitch

Screw,

Screw,

and

and

Shortening

Throat

Screw,

Lifter

Lifter

Feed

Screw,

Screw,

Lifter

Lifter

Lifter

Screw,

Lifter

Screw,

Lifter

Throat

Throat

Throat

Lever

Lever

Bar

Lever

Lever

Lever

Lever

Lever

bearing

instructions

Description

Mechanism,

Plate

for

for

for

for

for

Plate

for

Plate

Plate

for

Lifter

lifter

Stop

Stop

Guide

Washer-----------------------lifter

throat

Clamp

Clamp

Shaft-----------------------------

lifter

Bearing

lifter

Shaft

Support

throat

Retaining

Support

lifter

no

r efe

rence

applicable

Lever----------------------

lever

----------------------------Block------------------------

lever

plate

lever

lever

plate

lever

stop

stop

lifter

---------------------------

Spring---------------------

shaft--------------------

Block

clamp-------------------

Stud

------------------------

-------------------------retaining

Plate

Bracket-------------------

bearing

numbers

to

39500

complete--------------

--------------------

block---------------

lever--------------

--------------------

plate-----------

------------------block------------

are

FB

common

not

illust-

Amt.

Req.

to

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

2

NOTE:

421

660-168

660-264

9271

98

21661

21662

21663

21663

21664

21665

69

Knee

D-10

A

FD

press

parts

Control

Knee

"S"

Collar,

Knee

Knee

Knee

Knee

Knee

Knee

Press

Hook,

Screw,

Press

Press

Press

Press

Press

Press

Set

not

KNEE

Chain,

for

Screw

shown

PRESS

10

Plate

for

control

knee

for

collar

Bracket

Bracket------------------------------Lever---------------------------------

Plate

Plate

Rod

------------------------------------

on

picture

PARTS

inches

Pad,

press

Rod

---------------------------------

Connection

long

rubber----------------------

chain------------------------

shaft

-----------------------------

Shaft--------------------------

-----------------------------

plate.

----------------------

bracket

------------------------

----------------

1

1

2

2

1

1

1

1

1

1

2

2

9

Page 10

®

FINEST

t H

ondlo

Union

t

Hand

le

lew

All

others

certa

in

o•coptionJ,

AL

ABAMA

8oldwin, Tel.

ALABAMA, MONTGOMERY

H. Hamlet, Tol. 265 094 7, P.O . Box

To

l. 265-

AR

KANSAS,

Tol. (501)

CALIFORNIA,

Boyleu , Tal.

*CALIFORNIA,

Paul M. Mason, Mgr., Tot. Madison 5·5828.

CALIFORNI

J. Vall, Tel. Underhill 1-

!CALIFORNIA,

Machine Co., I I SS Missio n 51., Tel.

COLORADO, ARVADA, Casey's

5719

Rood

CONNECTICUT,

Golno•, Tel.

FLORIDA, MIAMI,

Equipme nt, Inc. , Tel. 633·1138

FLORIDA,

Morgan,

*GEORGIA,

Morr

ill

GEORGIA,

Te

l. 335·

GEORGIA,

Tol.

377-5559.

GEORGIA,

272-4663.

GEORGIA, GAINES

Cummins, Ga. 887-.4732 .

GEORGIA, WINDER, 805 Pinkney,

B67-3208.

* ILLINOIS, CHICAGO

Ullrick,

KANSAS,

PRAIRIE VILLAGE, 73

Tol.

HE

KENTUCKY,

Hinlon, Tel. 5B

lOUISIANA, MET

Te

s"om,

MARYLAND,

Fodor, Tel.

I

MARYLAND, BALTIMORE

Bo

lllmore 51., Tol.

QUALITY

Special

and

is

and

hand

le Union

UNITED

, BIRMINGHAM,

833-

0942.

LITTLE

FR

2-2356.

LA

330-3043.

LOS

A,

SAN FRANCISCO 7, 1275

SAN

51., Tel.

DANBURY,

746·3652.

PLANT

Tel.

752-1829.

ATLANTA,

M.

Amb

COMMERCE,

4061.

DECATUR,

DUBLIN,

Mg

r., Tol.

2-170

5.

LOUISVILLE

7-0042

AIRIE, 707 Trudeau DrJve, Charlo' Wtckor·

l. 729·

411

BALTIMORE

727-8499.

Columbia

Columb

ia

only,

Spacial,

lewh

STATES

732

-8Aih

9904.

ROCK,

PUENTE,

ANGELES

FRANCISCO 3, Appare l Clly Sowing

424-6630

2519

CITY,

2120 Ploolo u Bridge Rood, N.E ..

tose, Mgr., Tel. 87

lakev

1713 Coventry Road, Joe V. Porker.

1615

VILLE, RFD II,

10,

644-6920.

7, P.O.

.

5.

LEx

lnglon 9-1 838.

Slreel, Soulh, Lloyd D.

7,

1959 Amelio Drive, Garno!

P.O.

Box

1783,

1527 Chon nelwood Drive, Bill

21,

1580.

Sew

.

22 Barnum Rood, Rober! W.

N. W.

2nd

.

506

N. Gordon 51., Jomoo C.

iew Drlvo,

Knox 51., John W. Joneo, Tel,

400

N. FronkHn 51., Orville A.

) 1 Rosewood, Cleo

Box

15,

P.O. Box

1, J. Doshew, Inc.,

SALES

only.

and

Columbia

7203,

lar

ry Crh le1,

Jomeo

T. Taylor,

1100

E. Plco Blvd.,

Mlu

lon 51., Roborl

MArht

1·

6660

.

6ng Machi

ne

Service,

Ave.,

Tr~m

co

Sewing

.5

·9237.

J.

Tom

Han ley,

John Bradberry, Tel.

B.

D. Smllh, Tel.

C. Smilh.

726i,

Raymond E.

2505, Rolph B.

417

LEWIS

INDUSTRIAL

OFFICES

t*MASSACHUSETYS,

f .

'"''"

with

N

OHIO.

OKLAHOMA, OKLAHOMA

• ENNSYl VANIA,

PENNSYLVANIA, BET

W

·

IMASSACHUSmS,

Tel. B28-

oon,

IMASSACHUSmS, TAUNTON, P.O .

Woller P. Godek, Tel. VanDyke 2-6149.

MICHIGAN,

MINNESOTA, MINNEAPOLIS,

Park 26, M•nn., leonard W. Koehler, Tel.

MISSISSIPPI, JACKSON

Boyette, Tel. Fleetwood 5-1976, 1717 CapUol

lancaster, Tel. 354·3080.

MISSISSIPPI,

VI

2-5B48.

IMISSOURI,

Broadway, Tel. VIctor

MISSOURI, ST. lOUIS

Mclaughlin, Tel. Chestnut 1·23

Jerry Hicks.

!N

EW

HAMPSHIRE,

Haberman Jr. , Tel. Tuxedo 2·

!N

EW

JERSEY,

log

Joooph

!NEW

JERSEY,

Whlhon, Tel. Geneva

N

EW

JERSEY,

Tel. 767-4350.

NEW

YORK,

Wheeler, Tel. State 5-6371.

*NEW

YORK,

Bld

g. ), Crarence

4-88

00.

NEW

YORK,

bohm, Tel.

lN

EW

YORK,

Rd.,

Tel. BUller

N

EW

YORK,

To

l. Ivanhoe

ORTH

CAROLINA, GREENSBORO, P.

D. Harrod, Tel. 299-9367.

E. Miller, Tel. 292-0734.

OHIO,

CLEVELAND,

Co

., Tol.

COLUMBUS,

i

lle

r 1-1222.

51

.,

G. 1 . Wiley,

Casse ll,

Te

Te

l.

868

-82

AND

BOSTON 11.

Mor

.. Tol. Llbortv 7-

CANTON, York 51.,

1412.

DETROIT,

John Joyce, Tol.

TUPELO,

606 Racove Drive, Bill Haywood, Tol.

KANSAS

CITY

NASHUA,

NORTH ARL

llacl, Tol.

RUTHERFORD,

WEST

BERLIN,

LATHAM,

NEW YOlK I ,

l.

ROCHESTER,

Ll

4-1882.

ROCHESTER

8-7250.

UNIONDALE, 873 Henry 51., Anlhony Candell,

3·7An.

4914

661-5901.

P.O. Box

Tel. 685-7

ALL

ENTOWN, P.O.

l. 797·2 111.

HLEHEM,

04.

and COLUMBIA

SEWING

MACHINES

REPRESENTATIVES

179

Lincoln St ., Wlll lom

0147

RFD,

Roy

T. Peeler·

Box

1 2 Raynham,

584·4210.

2BOO

Toxoo

Ave.,

51.

lou

6AA

·6236.

3,

327

Eoohlew 51., Jomlo A.

5,

Todllo

2~9558.

34,

9860

Gulhr

68,

P.O.

9698.

INGTON, 32M Gordon Terrace,

991·8211.

246 Sylvan 51., Richard W.

8·2178.

P.O.

lox

57 Sylvan Ave., Clarence

370

71h

Rosenquist, Mar., Tel. Chickering

1A

Strathmore Circle, James

9,

A.

J.

Adams

A216

Pennydale Dr., Harold

Pearl Rood, Cut & S

874,

Larry Kolsen , Tel.

CITY

19, 2226 Soulhwoot 53rd

836

.

1212 Como< 51

Ave

.,

Machinery Co.,

io Avo., Carl E.

39AO

Shenandoah St.,

Box

257, Horman E.

26, f rank A. Noll,

Avo., (Po• n Terminal

Co.,

1051 Culver

O. Box

226,

William

ow Equl

pmonl

AXm

Box

542, Lulhor D

.,

Ed Deegan,

larry

Hal

915

lo

PENNSYLVANIA,

Fadden,

PENNSYLVANIA,

John

*PENNSYLVANIA,

Ave.,

!PENNSYLVANIA, NEW

285.

h

A.

·

W.

PENNSYLVANIA, REAMSTOWN,

Bonder, Tel.

PENNSYLVANIA,

854-B040, aloo

SOUTH

Crisler, Tel. Sunset 7-0863, P.O.

Tel.

254-4255.

SOUTH

CAROLINA, GREENVILLE, 25 Sir Abbot

W. Grogory, Tol.

John lawrence,

TENNESSEE,

Clinard, Tel.

E.

TENNESSEE,

horst, Tel. Mutual 5-6750.

TENNESSEE,

William J. Brauch, Tel. Cypress 2·5123.

Dr

lvo,

*TEXAS,

J. H. Muir, Mgr., Tel. lakesi

TEXAS,

Tol. CH

TE

XAS,

598 -2928.

TEXAS,

Tel.

Dl

UTAH,

SALT

Roovo

ll,

VIRGINIA,

84!5·8901, ah.o Gerald Morrison.

WASHINGTON,

Tot.

MA

Union

BRITISH

Ma

dilon Ave., Tel.

MANITOIA,

Bldg.,

*ONTARIO,

King S

*QU

f BEC,

Mo

lloro St., Tol.

WORLD'S

FINEST

QUALITY

*

BERWICK,

1013

E.

Tel. 752-2442.

CLARKS

Tol

, JUniper 7-2B20.

PHILADELPHIA

ALEXANDRIA,

267-6109.

YORK,

P.O. Box

A. C. Davis.

COLUMBIA,

Cedar

Tel

. 235-2213.

58B-i865

17,

12,

19,

4200

1404 Fonnidolto, Jo

Box

CITY,

1215

7-6931.

SEATTLE,

SUMMIT,

19,

858 Soulh 1481h,

J,

Lofter,

Ben

W. Merz, Mar., Tel. Gladstone 5-9800.

Dolo Spoor, Tol. (Pittoburgh) 563-358

CAROLINA,

KNOXVILLE

MEMPHIS

NASHVILLE

F.

M.

Blunkoll, Tel. 883-3352.

DALLAS

CARROLLTON,

2-5309.

El

PASO, P.O.

SAN ANTONIO, Jerry Gregory,

2-5924.

LAKE

Tel

. IN

LYNCHBURG, P.O.

4-8083.

CANADA

Sptdal

Mathlne Co.

COLUMBIA,

70

t.

N.

BURNA

MU

3-391

WINNIPEG 2, Frank Thiermon, Rm.

Arthur S

t.,

Tel. WHi

TORONTO 28, Polor Fowler, Mgr. -Rep., 355

Wes

t,

Tol.

Emplro

MONTREAL

10,

276-2575.

16th 51., Dona ld Mc-

42B Wosl

24, 4234

(Pitllbur9h)

P.O.

Box

BU,

Harding T. Powell ,

P.O.

Box

Box

.4112, J. W. Carter,

9-,39,

lewis VIllage,

3905

Greenleaf

.

4695 Dunn Rd., Ri

1602

South Oboorvolory Drive,

Hlneo Blvd ,, P.O.

de

6·8369.

9573,

Edward E. Smith, Tot.

P.O. Box

E.

131h Soulh

Box

1075,

Tom

of

Canada,

BY

2,

James Murray,

7.

teha

ll

3-4933.

6·2939.

John Coachollo,

176,

4246,

Avo., Horace

chard

2.517

hn

St.,

Lou

Mgr.-Rop

Grove

Avo

Mocoloslor

P.O.

Box

9.

David

Vlrlyn R.

St.,

Orville

Ap1 9-E,

J. Lind·

Woodberry

Box

6727

D.

Troeger,

13126,

Lorry

Traylor, Tol.

io Spencer,

ltd.

1522

201,

Whillo

.,

40

..

M.

F.

FINEST

QUALITY

WORK

•

•

HIGHEST

PRODUCTION

RATES

•

•

LOWEST

MAINTENANCE

COSTS

Page 11

Also

Agent for Ill

Sales Agents For

LEWIS

UNION

and

SPECIAL

(C)

COLUMBIA

Machines;

where marked.

(TEXTil E &

(BAG

AL

ETHIOPIA,

IVORY

KENYA, NAIROBI-

MAlAGA

MAURITIUS,

MOROCCO,

NIGERIA,

SUDAN,

TUNISIA,

BAG

MAKING

R[PUBli C OF S

Prllchard St . CAPETOWN-

7'1/7~

Commerci

Shoot.

RHOD

ESIA, BUIAWAY0- 133

IO

l Slnloa St.

-

CLOSING

MACHIN

REPUBliC OF SOUTH

Ud.

32 Von Brand is St.

CAPETOWN- Wales and Broo

EAST

lONDON

St.

3

55

Murthl

PIETERMARITZBURG,

WORCESTER.

Rh

KITWE.Biantyre Road.

GERIA, ALCIER S- E

Adaha

(l

Kolnonoe

gonvlk

De

(l & C)

Machlncnl

Newton

ldrh

ltd

305. (L & C)

du

ton

odet Street. SALISBURY-95

& C)

RHODESIA

ASMARA

Woot.en

COAST

·ABIDJAN -Eh.

St. ( P.O . Bar

<t

onrf Zonrlbor)

SY REPUBliC- TANANARIVE - Soc. Ind.

l'

f myrne, Bolle Polfole 1078, 17

PORT

Hall,

St.

CASABLANCA-H.

ol

Eo

Sakall

APAPA,

. 9

Warehouse

KHARTOUM

TUNI$-Comptolr

18

Jan•lo

r 1952

MACHINES)

OUTH

AFRICA

- JOHANN ES

al

, PORT EliZABETH-Box 611 . Ah a

(l

Genova

(L)

LAG05-Sunflag Knitti

78

Roa

d.

PORT

(l)

ES)

South African Scale Ca. Ply.,

AFRICA

BLOM

FONTEIN-

- 3B Argyle S

PRETORIA,

, BUlAWAY0

iab. Sayag,

- S.A. Calderon! Afri

& C)

Jean

Tranu:and

la ,

$933)

ll

LOUI5-(Bag

,

langlois,

Golnmann

Rood.

tl

& C)

- Franco Pinto (Sudan)

Industrial

(L)

Borzack

Darling St.

EliZABETH- 277 Main

fifo

St. SAliSBURY

- JOHANNESBURG-

53

Sh.

DURBAN

t.,

lADYSMITH,

VEREENGING

-2

leander

VIctoria

Street,

8 Ruo

Altohac.

ca,

Abllo·Gal,

ltd

.,

Collage

& C)

1A

ho

Rue

Closing & Bag Making

ltd

.,

A2

& Flit,

ng Millo

Ltd

& Menoger, 8 Rue

ASIA

AFRICA

CAMBODIA,

woth, P .0 .

HONG KONG- G. R. Colom

30.5, Wino

INDIA, CAlCUTIA- Parrot Sewing Machine (P.)

5oYar

JAPAN, OSKA- Kondo Sewl

Cho Kifa·ku.

a h Ashik

KOREA

Bldg.

LAO

PAKISTAN, (WES

29

al"d

Baltic

REPUBliC

(Ta

THAILAND,

Bo

VIETNAM, SAIGON-S.A

IA7

PHOM·PENH

Box

ling

om

Bv

aaa

, SE

OUL-Uebersee-Handel A.C., Rm. 60

180

1-ka Ulchlra; Chung-Ku, Int. P.

S,

VIETIANE-Don

Zeonot Ma nsion ,

bag

mold

Street,

Of

CHINA, TAIWAN, TAIPEI -

iwan)

ltd.,

BANGKOK-Yip

x 23 .

(L & C)

Trinh Mlnn -Tho

- Den h Frero o,

AS.

(C

&

Building, 7 ·13

ock

St.

(l & C)

(lJ

Branch-To~yo

, Fulcat,

Nagoya

lo Froro•, P.O.

T)

KARACHI·2-Unl•enal

Mcleod

nrt mac

hines) Thomas C. Keay,

Dundee,

Scotland

16

Nan Yang 51.

. Pour

(B.

P.

L)

a"

Co. (Hong Kong)

ng

Machine Co.

, Nti

Rood. (E

.

In

AAA)

219 P.B.

Wellington St.

aata. and

Box

AST)

G.

& C)

Rlr

ot

163. Umegoe.

O.

133.

Trading Corp.,

R. Coleman Co .

l ' lndutrl (Sari)

6.3 Gln1:a, Choo-

(L

Tool & Ca.,

lo

(C & L)

AUSTRALIA

SOL

E DISTRIBUTORS t

po

ol

Street, SYDNEY

Br

unswick S

St. AGENTS

Ch

arl

lck Ltd., london Road, Mi

PERTH-T

homJons Pty.

LAUNCESTON-Sow Knit

Capron,

Carter

. Branches a h

t.,

Valley, N.

l.

, SOUTH AUSTRAIIA-ADE

MEUOURNE-15

le End.

lid

., 789

Ply

. Ltd., 72·7A George St.

Ply. ,

ltd

BRISBANE-

LAIDE-WiWam

WESTE:RN

Hoy St . TASMANIA,

Bros

.,

BURG

135/7

DUR8AN

Zostron St.

- 22 Allwal

Nata

Hause,

ZAMBIA

AYonuo

Box

1798.

Houae,

Uganda,

Et

Cam.

Clemenceau

Sir Willi

Ruo

(Nigeria)

., P.O.

Slto•

ltd.,

Ltd. 9/

Ku. Aha

Olcovama.

..

, R

ondo

Bor

1268.

(C

& L)

(Bag closing

ltd.,

Ltd.,

P.O

., ! 6 Liver·

.. A'Bock

AUSTRALIA

(L

ltd

EUROPE

.

AUS

TRIA, VIENNA- Firma Noeschusler, Morlohll"orstr.

(L)

BELGIUM,

DENMARK

FINLAND,

at

FRANCE,

P.

GERMANY,

GREAT

El

GREECE,

ICELAND, REYKJAUIK-Magnus Thorgol rsson, Skolavordustfg

IRELAND,

ITALY, MILANO-Gio•annl

1

MAlTA, VAllETTA- A.

THE NE

NORWAY, MANGLERUDPORTUGAL,

SPAIN,

SWEDEN,

.

SWITZERlAND,

ARGENTINA, BUENOS AIRE5-IROMAC S.A.C. , DI

5

.4

BRAZil, SAO

C)

CHILE,

COLOMBIA,

COSTA

DOMINI

BRUSSELS-Un

of America ,

(

C)

, COPENHAGEN - Rolhonborg

Sy-

lndustr

lon A/ S, Nikola i Pla<h 2 3. Offices

BORG, HERNIN

AND SILKEBORG. (L

HELSINKI·

Valtunt

emenkatu

slolo.

TURKU,

PAR

Fr

Dhecleur. Bran ch otr ROUBAIX (

LYON,

TOULOUSE (HAUT

G.m.

D

AT, BERLIN,

B

(NR. LEICESTER)

Mandervoll Rood , Industri

Ma

agor).

Ride•. Klng

Derric k R. Robins

LONDON,

Ltd

SmUh,

NORTHERN

hill

9 Stevenson Stroot. (C)

chinos) SCOTLAND,

Baltic

lrakl St.

Ia

Pofno

Mach

Scotl

18.

Bakery Stroot.

C. & H. Vor

ARNHEM, ENSCHEDE,

TARO, TILBUR

11

de

norlgaton

MAlMO, S.

t..

(Postfach) , (l·Buttan Sower)

Po,.,

Machi

ercio,

Ruo

Isab

117

Santa

B

B

33/3

MEDELLIN-Carrera

n . (L & q

l9A9

quez

IS- Cio . des Machines Union

ance

,

91

VIIIEURBANNE

STUTTGART

b.H., Sc

tr

odor.

Th.

UR

G,

KOLN,

BRITAIN-(Tod

oagor. LONDON- 108 City Road (H. 0 . Hall, Man.

SALES

owood, SCOTLAND, MILNGAV IE (CLASGOW) -

W. 1

.,

~8

Groat Tltchflold Stroot.

(Manchot

IRE

Road. SCOTLAND,

Shoot-Agent

ATHENS-Georges

(L

& C)

(L & C)

.

DUBLIN-(Toxtllo Machines) W. Blythmon,

ll

Str

eet

il'l

es)

Thomas C. Koay, Ltd., 15 Balt ic St .,

and.

(L

& C)

THERLANDS,

7,

BERG

EN- Bfornoongot H . (C)

OPORTO-Rost & Janus

Fo

rtostor

BARCELONA

BORA5-Rud. Nystrom & Co

6. Branches

/ 8

Fonberg

Un

aco

Coslura,

ne

Company),

Ruo Au

Voluntar

el

105

; RIO

. (C &

L)

SANTIAGO-Lowonotoln & Stewart, S.A.C., Calle

Dom

ingo

BOGOTA-

ranches at

UCARAMANGA

5. MA

NIZALES-E.

RICA,

. (L & C)

CAN

REPUBLIC,

, G

••

Calle Dr. Pedro Ur

ion

90

Ruo

G,

Humoll

Ava.

hwabstr. 33

M. Boonstra,

BIELEFE

MUNCHEN,

- Unlon

Special

do

Ia

Ca.orne, Gu•to

KOIDING, ODENSE, RISS

& Cl

LAUTTASAARI~Suomon

13. Branches

do

E GARONNE) 12, B

at

stonkatu

7· 8.

Ia Ropubllqu

NOR0)-50

(RHONE) 58 rue

- Union

Special

- A. W. Krieg

Director

LD, EBIN

GEN,

OCHTRUP.

llo Machlnory)- ENGLAND-

Special

Machine Company,

al

Estate. Mr. A.

OFFICES, BRISTOl,

on,

.C8

Cloc

-G.

ter)

LAND-8ELFA

(l

hbor

John

son & Son (Sowlno ·Machinery),

Pork

GlASGOW

(Bag

entl

to

Yannakouras·D

C)

f8ag Cloll

Grove

ST 1

Clot

MANCH

~.

ing

Brlthh

ltd.,

DUNDEE-Thomas

for

&

Conti & Nlpoti, Via Vareoo

C.

Wlomayor & Co

(L

&

C)

AMSTERDAM

bft

k, Klove nlenburgwol 77. Offices a h

G.

(L

&

914.

(L)

- Rapl

Fontandogalan 16. Sub-Agent

& Kato,

URDORF

LA

TIN

ton

Special

S.A

(l

PAULQ-Pancolfura

rora

'9A·71.

ios

do

DE

JANEIRQ-SIL!a

11AO. (L

Macalrada,

BARRANQU ll

- Callo 34 1 17-AS.

~1,

SAN JOSE- Enrl

- H.

GRONINGEN, ROTI E

C)

Jac. Jacobsen

, Succs.

da,

S.A., Via Layetana

at

OREBRO-Sto(dgatan 37-39,

Tomtebogotvn 38.

(ZH)-Bourquln

AMERICA

International,

.,

Son Jose 350 . (Union Speci

&

CJ

S.A.

Branches

Patrfa

533;

& C)

Lido., Carr

LA-Carrero

Broolauor, Carrera 22 l l

36·1B.

PERELRA-Cr

quo

Rodrlguos

SANTA

DOMINGO-Roberta

ena

19.

l-

and

Tan-

Box

Rm.

..

&

-

-

am

(L)

15

ett

ECUADOR, GUAYAQUIL- DIIIrl

51,

Machi

ne

Corporation

vo Thlerie, Mgr.

Speclolmasklner

af

t AAL·

KOV·AARHUS

Kanolliko 0 / Y,

TAMPERE·P1~teallttuo.

(L & CJ

Spe

,.

de

Avo. J,

Ale•andro

Montplaioir.

Ma1

chlnenfobr

er,

Managing

BRANCHE

FRANKFURT,

cia l

Saml

Boutin.

e-Tho

D,

of Sales,

OADBY

B.

Fitzpatrick,

L.

J. Hoard, 19 Tho

Avenue

. SUB-AGENTS:

ESTE

R 19- S. A.

Works,

levonthul

Aktox

Ltd

. 186

S. E.-AII

ard

lco & Co .,

and

Bog Making Ma·

C. Keay,

Ltd

hlo

t.

fmoults,

30 Po·

ng

and

Bag Mak ing

Dundee,

.,

Ltd.,

62

V.

Machlnohandol

RDAM,

A/S,

Enebakkvei

lda

••

Rua

AlB,

lllla

37

.,

EL

GUATEMAlA, G

for

HONDURAS, SAN

MfXICO,

de

yen,

lebas

.

NICARAGUA,

PANAMA, PANAMA-

lk,

PERU, LIMA, Brena- Unlled Agencies, :i.A. (Peru) Av.

S

HAM

·

PUERTO

SUR

Ltd

.,

URUGUAY,

VENEZUElA,

mo.

C

CGYe

·

IRAN,

., "

IRAQ

ISREAL,

JORDAN-Bandor

LEBANON

22A

SYRIA, DAMAS-Bondar

TURKEY,

U.A. R., Calr

Old

SOLE

SIT·

en

Barao

(Ll

Bran·

STOCKHOLM.

& Clo

.,

Vogolauolr.

HAWAII,

PHILIPPI

Inc.

-Industr

at

PORTO AL£GRE-

RECIFE-Rua

Alexandre

45-8 # 3

CALI-Ca,ora 7 #

(l

& C)

ia e Com·

MocKonz:

era

30 #12·99

4·'•

a. B-1

S.,

Yis

lon

Princesa

·

13·

B.

AA.

22·

P.O. Box

Domin·

WEST

al

JAMAICA, KINGSTON- Morris E. Parkin, 96 King St .

TRINIDAD,

lo

.

S.

A.,

Molocon Simon Bolivar #

Aventda

Potrio

768.

SALVADOR,

nia

Valro.

So Avenl

da Sur

Box S59

(L

MONTERREY, N.L.

de

C.V

.,

JARA,

JAL.-Hidalga

dora

Union E1pocl

(Apartada

Royoo

80 .

1303.

(L)

lAS.

Alfonso Ugarte IAA5·14A7.

RICO, SAN

B

a•

2352.

INAM, PARAMARIBO-Kirpalanl'

St. (L &

C)

Mercedes 1

Chorro 29.

YPRUS,

NICOSIA-Chriltadoulldoo

coupph St . ( L)

TEHERAN-Suva

881.

Sar

ay

, BAGHDAD-Sons of 0 .

2021,

Alwlyah.

TEL

(L & C)

, BEIRUT-Sons

(L

& C)

ISTANBUL-M

Han Nr.

•6-~7

Tech

Sub-Aaettt-A

~huhro

'.l &

DISTRIBUTOR, H.

AUCKLAND

St.

Neh on

St.

Islands,

Gilbert

Tahiti,

and

CHURCH-90

P.

O.

Box

Box

602. (L)

Box

P.O.

(l & C)

SAN

SALVADOR-Va

(LJ

UATEMALA-Campan

Zona

1.

PEDRO

ol,

Agendas

JUAN-Abarca

& C)

SULA-Jacobo

Norte

A5

S.A.

LUIS

& C)

Cuouhtemoc

28070); SAN

(L)

MANAGUA-Coso

(L

MONTEVtDEO-Storet & Cia

312. (L)

CARACAs-H

NEAR

Saadlyoh.

AVIV-L.

o-Misr

Tonga. SUB

40

20A. (l)

Trading Corp., Avo. Boza, (omehrl

(L

& C)

(L & C)

Taube,

& Aroctlngl, B.P. 1

af

& Aractlngl , B.P.

. Benmoyor, Mahmutposo

(L

& ct

lmDort &

tCavoldii

c'

NEW

ZEALAND

A. Tuck & Ca

. aRANCH AT, WELLINGTON, leo• Bldg.,

(LJ

Also-New

llland

•, New Hobride•,

.AGENTS

Orboll St.

.

(CJ

FIJI

SUVA-Karl

SAMOA (WESTERN) ,

PACIFIC

HONOLULU-(Toxl

Co.,

508 Atklnson Drive.

lng

Machines) H.

NE

Jnc. ,

313 Molugoy Str

CEBU.

(L

(L & C) Also-BAR

S. Gray

ISLANDS,

MAKATI,

& C)

INDIES

PORT

eet,

FEDERATION,

Union

Special

OF SPAIN- Ackrlll & Co., 17 Henry St .

BADOS, G RENADA, TOBAGO.

buldara

Richard 0 . Custer,

2308

. Branch

lro Hormones, Colo·

ia Agra Camorclal, S.A.,

ll

& C)

- Talloroo Poror

335

y A7; MEXICO,

de

C.V., Ave

. e

ranche

.,

POTOSI, S.

E.

s

al

D.F.-Diltrlbul

Plno SuareJ: 99·a

L.P

Hontuon, 3A

Hagut,

S.A

., Ave. 7 A

(L & C)

Warohouoe

o,

Ltd., 17-

.,

S.A

. Blohm, S .

A.,

EAST

Bras. & Co.,

0.

Agopl

an

(IRAQ), P. O. Box

ltd.,

15

Llllonblom 51.

U"-Domas,

0 .

0.

Agopi

an,

11AA. (L & C)

hDort

Co. , 6 Rue Adty-

CM

S. A.R.l.

.,

ltd.,

Caledonia,

DUNEDIN-192·196

Cook h la nds, E

Samoa (Ame rica n),

Clende

tmtd,

R.

Flelschman . P.

APIA-S

ISLANDS

ile Machines) Territori

(L).

(Sa

~

Closing a nd B

Co. , 7S9 Puuloo Rd.

RIZAL-At

(Buendia Extensi

klns,

on)

JAMAICA

International,

Inc.

at

QUITO

Handel, P.

Zaraya,

S.A.

GUADALA-

.- J.

de

Calle N.O.

Espc~no

Carp

.,

P.O

27

Maagdon

.,

Uruguoya,

Dr. Paul A.

9A

SyrJo

P.O . 1165 .

Abut

Efend'

. 100

Shorlo

171

Albert

Ltd

., CHRIST·

Cast lo St .,

. C. Porcl•a

al Sale1

ag

Mok·

Kro

ll & Co.,

. Branch

Trl·

ll1

-

O.

los

(L)

(L)

·

.

ce

O.

l,

at

AUSTRIA

IV, VIE

Wiedner

BELGIUM,

Kruldtuinlaon

FRANCE,

(LI-Aspo

(C)

GERMANY, KREFELD-Herbert

(C.

tie

GREAT

Machi

DON,

MANCHESTER,

GLASGOW

IR

ElAND, 8Elf

Park.

Ltd

., 223

ISRAEL,

Halovy St. (C)

NNA-Franz

Hauplstra n o

BRUSSEIS-N

PARIS-Societe

·Dumont & Cl

mach.)

BRITAIN-ENGlAND,

ne

Company,

89

REPUBLI

1

TEL

36

. V. Machlnohandol C & H Vorbeok,

57o,

Buyl Bldg.

G.

e.,

Ltd., 128-132 Curtain Road.

Beddi

ngton

I 05·1

07

52-

4

AVIV-Israel

A Co rpo

1 1 Drum rooch Place,

AST lA-

C OF IRE

Patnell

Stret!ll.

. (C)

Lane.

Additional Sales Agents for

Kootper

t &

Sohno, K.G.,

(l)

Arnon & Cle .,

13 Rue

Jannson,

W. F. Ma,....ail, 50

LAND, DUBIIN-Wm. Blyt

(LJ

Sowing Machine

14

Rue Commlnes

de

Ia Fontolno . Au-Ro •

Aile

Linno,.tr. 104

LONDON, E.C.

LEEDS-60

ration Street. SCOTLAND,

Merrlon Stroot .

Toryl)l

en NORTHERN

Co.,

2-Ea

22 Yohudo

otman

CROY

Gla•bryn

hmon,

MEXICO, MEXICO, O. F -Cota Dia

-

Caser,

Av. Republic Del Svlv

MOROCCO, CASABLANCA-Ourlcopp Co u

nona

. (C)

NORWAY,

OSLO-J

l

EPUBLIC

OF

Sewlng Machi

Stroot.

Broncho

-9 Njew

Mles

SOUTH

ne

~o

a t:

ter

Ill

LEWIS

,_

,,

odo

r 8

. A. Johanoen

Compa ny (Ply. )

CAP

Lana (C)

A/S,

AFRICA, JOHANNESBUR

E

TOWN-I

and

(C)

t.

de Maqulnos

9-93

(CJ

drex,

25 Rue Bascu·

Torvg

Ltd

.,

11

l O Ple in St.;

COLUMBIA

atan 10.

G-African

8 Presi

dent

DURBAN

Machines

RHODESIA,

SPAIN, BARCELONA-Arblo

SWEDEN,

SWEDEN,

de

SWITZERLAND, ZURICH-Frttz: Zellwog

(L)

U~UGUAY

FEDERATION

BULAWAYQ-Afr

(Pvt.)

Katrl

nodal,gata

I

MALMQ-tsak Slakto

-STOCKHOLM-B

Firma Hla lmor Svensson, Tingshusg

Br

anches: MALMO-Soved,gatan

gatan

-Symodcinnerksladen specJol, Kung s

naustr. 27.

Slhlstra u e 37. (CI

Rincon

lcon Sow ing Machl no

Ltd

., 2

Leonidas

BORAS-Hu&qvarna,

n 1

3.

runnogatan 6 ·

BORA5-A/B, A. C. Guotah

18 Ulrtceham-Hofdgat

(L.

except

.

MONTEVIDEO-C. Brandoo & Cia., S.A.,

658-60

fCl

OF

RHODESIA & NYASALAND,

House,

138

Rhodes Ave.

5/A,

Gorona

lndustr

Brancho•f GOTE B

reg

aton

9-0REIRQ-Siortoa

8.

Aganto-UIRICEHAM

atan

1

4.

STOCKHOL

an

20

.

Sub.Agent-GOT

haios

Button

Sewer) Guttlnaer A.G

Company

(Rhodesi

63.

(C)

b ymasklner A/&-

ORG--St

igborg tlide n

z. (C)

an,

Skolg

ata

n 3

M-Ku

EBO

ga ton 7. (Ll

er

& Sohno,

el 19

ng•·

RG

Se

Call•

a)

-

0,

l·

.,

J

Page 12

.,.o

...

..

'

0

WORLD'S

,_,Lf

FINEST

QUALITY

*

,,

"'

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains sales

facilities throughout the world. These offices

aid

you

in

the selection of the right sewing

equipment for your

Special representatives

tory trained

promptly

tion, there

and

is

serve you. Check with

ATLANTA,

BOSTON,

CHICAGO,

DALLAS, TEXAS

LOS ANGELES,

NEW

PHILADELPHIA,

MASS.

YORK,

GA.

ILL.

CAL.

N.

PA.

and

a Union Special Representative to

Y.

particular operation. Union

and

service men

are

able

to serve your needs

efficiently. Whatever your loca-

him

today.

MONTREAL,

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS, FRANCE

STUnGART,

and

service

are

QUEBEC

ENGLAND

ENGLAND

GERMANY

will

fac-

400

Representatives

MACHINE

N.

FRANKLIN

industrial

and

cities

distributors

throughout

COMPANY

ST.,

CHICAGO,

In

all Important

the

world.

ILL.

60610

Loading...

Loading...