Page 1

®

INDUSTRIAL

SEWING

FINE

ST

S

39

500AR

QUALITY

TYLE

LEWIS

•

COLUMBIA

MACHINES

CLASS

39500

CATALOG

No.

103AR

HIGH

STREAMLINED

SPEED

CHICAGO

OVERSEAMERS

Page 2

INDUSTRIAL

...

for

Every

Purpose!

SEWING

MACHINES

Job requirements

variety

of

specially designed sewing machines.

why Union

vary-

that's why Union Special builds a wide

It

is also the reason

Special field representatives make a careful study

requirements before giving you detailed recommendations

of

kind

equipment to install. Plants equipped with modern, high

speed Union Specials have an important advantage. Union

machines are built to

they stay on the job with minimum time

do

the job faster

...

better .

out

for

..

cheaper, and

repairs.

ahead when you use Union Special.

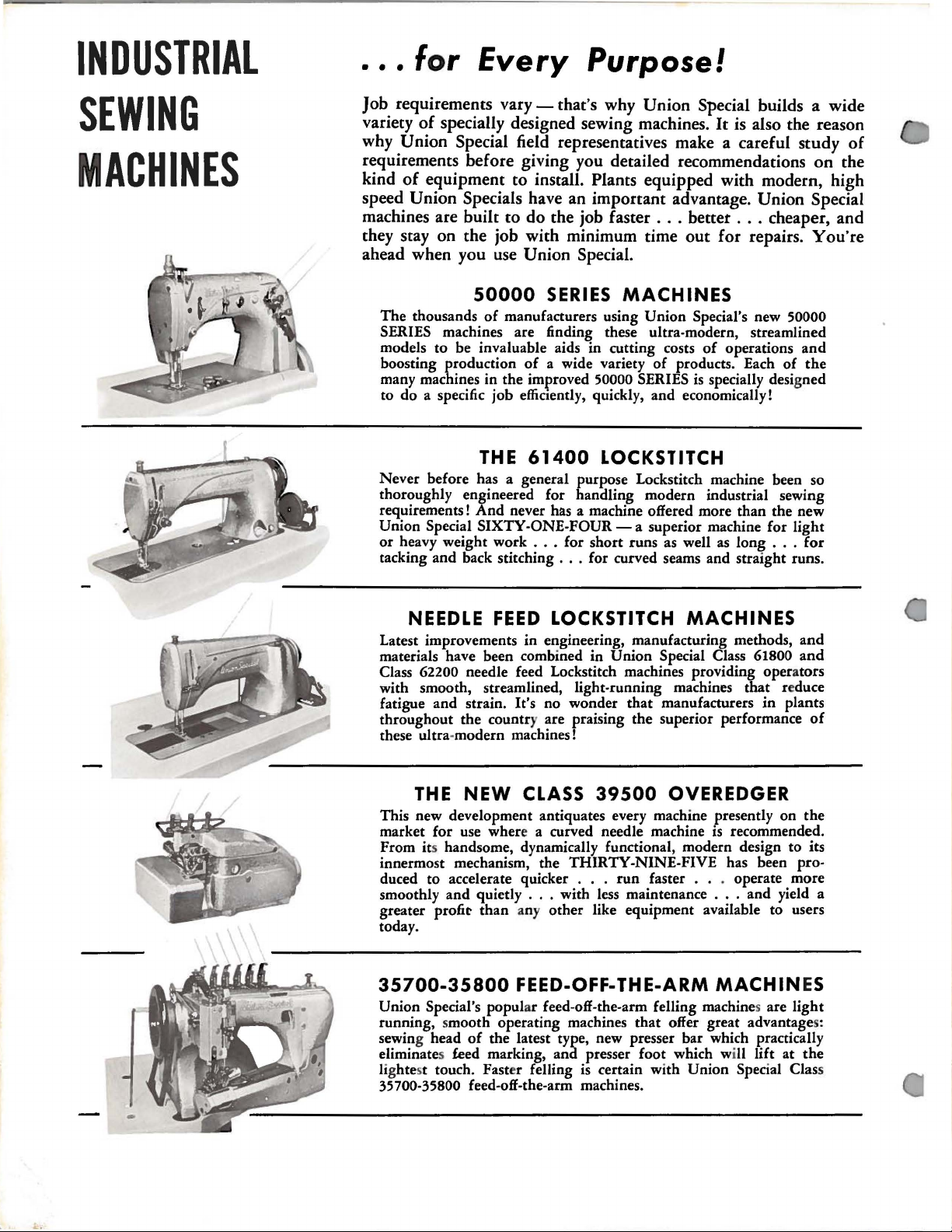

50000

The

thousands

SERIES machines are finding these ultra-modern, streamlined

models

boosting production

many machines in the improved 50000 SERIES

to

to

do

a specific job effic1ently, quickly, and economically!

of

be invaluable aids in cutting costs

THE

Never before has a general purpose Lockstitch machine been so

thoroughly engineered for handling modern industrial sewing

!

requirements

Union Special

or

heavy weight work

tacking

And

SIXTY-ONE-FOUR-

and

back stitching

SERIES

manufacturers using

of

a wide variety

61400

never has a machine offered more than the new

...

for

...

MACHINES

Union

Special's new 50000

of

operations

of

products. Each

is

specially desig

of

LOCKSTITCH

a superior machine for

short

runs

as

well

as

long

for curved seams and straight runs.

light

...

on

Special

You

and

the

ned

for

of

the

're

NEEDLE

Latest improvements in engineering, manufacturing methods,

materials have been combined in Union Special Class 61800

Class

62200

with smooth, streamlined, light-running machines that reduce

fatigue and strain. It's no wonder

throughout

these ultra-modern machines!

THE

This new development antiquates every machine presently on

market for use where a curved needle machine

From its handsome, dynamically functional, modern design to its

innermost mechanism, the THIRTY-NINE-FIVE has been

duced to accelerate quicker . . .

smoothly

greater

today.

and

profit

35700-35800

Union Special's popular feed-off-the-arm felling machines are light

running, smooth operating machines

sewing head

eliminates

lightest touch. Faster felling

35700-35800 feed-off-the-arm machines.

FEED

needle feed Lockstitch machines providing operators

the

country are praising

NEW

quietly

than

of

the latest type, new presser bar which practically

feed marking,

LOCKSTITCH

that

the

CLASS

...

any other like equipment available to users

39500

run

with less maintenance

FEED-OFF-THE-ARM

that

ana

presser foot which will lift at

is

certain with Union Special Clas s

MACHINES

manufacturers

superior performance

in

plants

OVEREDGER

is

recommended.

faster . . . operate more

...

and yield a

MACHIN

offer great advantages:

and

and

of

the

pro-

ES

the

Page 3

Catalog

(Supplement

INSTRUCTIONS

No.

to

Catalog

FOR

103

No.

AR

103 S)

ADJUSTING

The

furnished

parts

at

LIST

CLASS

listed

list

First

AND

OF

Style

39500

prices

OPERATING

PARTS

39500

AR

in

this

Edition

for

catalog

repairs

are

only.

Union

Rights

Copyright

by

Special

Reserved

1963

Machine

in

All

MACHINE COMPANY

INDUSTRIAL

Printed

SEWING

CHICAGO

in

MACHINES

U.S.A.

Co.

Countries

Page 4

IDENTIFICATION

OF

MACillNE

Each

the

name

Standard

letter

"Z".

to

the

"Z".

When

standard

Styles

which

diff

This

therewith.

39500

P~

This

It

can

also

Reference

operator's

is

away

Union Speci

plate

on

the

Style numbers

Example:

only min

Style

of

machines

ers from

catalog

Only

the

is a

those

are illustrated

catalog

be

to

app

applied

direction,

position

from

the

op

al

machine

machine.

have

"Style

or

changes are

number.

is

Style

one

39500

Example:

similar

style

number~

APPLICATION

supplement

parts

and lis

lies

specifically

which

ted

with discretion

such

while

as

seated

rator.

STYLE

identified

numbers

or

more letters

AR".

ma

in

construction

in

that

to

Catalog

are

at

the

to

the

to

some

right~

at

the

OF

by a Style

are

Special

de

in a standard

"Style 39500

number

classified

suffixed~

Style

numbers

machine,

ARZ".

are grouped

it

contains

OF

CATALOG

No.

10 3 S

used

back

on

of

Standard

Special

left~

front~

no le

and

Style

the

book.

Style

Styles

back~

tt

should

39500

of

machine

of

etc.~

machine. Operating

MACHINE

which

as

standard

but

never

contain

a "

under a cla

rs.

Example:

be

used

AR~

and

as

machines

are

direction

is

stamp

and

contain

Z"

is suffixed

ss

in

conjunction

not

listed

in

this

given

of

handwheel

ed

special.

the

letter

number

"39

on

herein.

class.

from

into

the

11

500

Style

the

•

Single

Two

Curved

Thread~

Blade

High

Mechanism With

39500

AR

For break

garments

without

material,

wi

the

a f

hingedopen

per

CAUTIO

filled bef

straight

should

be

Machine

gauge

on front

inch;

mineral

cam

N!

ore beg

used.

is

filled

of

lines.

Machine is

main

r e

servo

automatically

ir f

Needle~

Throw~

Spring

open

Two

Overseaming

Pressed

seaming

th either a two

standard

abric

to

make

adjusted

Oil

was drain

inning

oil

with

machine.

of a

trimming

guide

LSa-1;

main

to

operate.

Saybolt

oil

at spring

Red

lubricated.

illed.

Check

Looper-Three

Lower

and

or

three

knives.

is

included.

standard

and

differential feeds.

OILING

ed

from

machi

Oil

viscosity

cap

bulb

on

oil

daily

before the

Thread

Machine.

Knife~

attaching elastic

thread

stitch.

F or

tho

Seam

seam

ne

width

when

capacity

oil

of 200

in

top

lev

No

cover.

el

indicator

oiling

to

morning

Or

One

Looper-One

Differential

Automatic

to

girdles

Machine

se who

do

specification,

1/4

inch;

shipped~

of

Class

250

39500

seconds at

Oil level

should

is

nee

ssary,

start;

Feed~

Lubricating

and

can

be

not wish

503

or

stitch

so res

range~

ervoir

is

sia

100

is

checked

show

between

other than

add

oil

as required.

Spreader-

Trimming

System.

foundation

used

with

to

trim

505-SSa-1~

must

ounces.

8

to

or

the

30

be

A

Fahrenheit

at

sight

gauge

keeping

Drain

magnetic

a

entered

plug

screw

screw designed

the

crank

case.

is

located

to

accumulate

It

should

at

back

be

removed

of

machine

po

ssi

ble

and

near

foreign

clean

4

bottom edge

materials

ed pe

riodically.

of bas

which

e.

may

It

is

have

Page 5

IDENTIFYING

PARTS

Where

some

identification

appear.

OF

forwarded

directed.

number

The

blade

Collectively,

of

the

Part

IMPORTANT!

MACHINE

Prices

Each

numbers

A

Union

denotes

size

number,

measured

construction

smaller

letter

represent

ON

are

f.

o.

charge

FOR

the

WHICH

net

b.

shipping

Special

the

stamped

in

type

cash

thousandths

parts,

is

ALL

is

made

kind

permits,

stamped

ORDERS,

PART

and

point.

needle

of

on

number

and

the

subject

Parcel

to

cover

has

shank,

the

of

and

each

on

in

same

IS

both a type

part

those

to

distinguish

p3.rt,

PLEASE

ORDERED.

TERMS

to

change

Post

postage

NEEDLES

point,

needle

an

inch,

the

length,

size

is

stamped

where

regardless

INCLUDE

without

shipments

and

number

shank,

midway

number

with

construction

the

part

of

PART

notice.

are

insured

insurance.

and a size

groove,

denotes

between

finish

the

is

its

does

from

catalog

NAME

largest

the

the

part

number.

not

similar

in

AND

All

shipments

unless

number.

and

other

diameter

shank

complete

and

permit,

ones

which

STYLE

otherwise

The

details.

the

symbol.

On

an

.

they

are

type

of

eye.

Style

is

Type

single

027, 029, 032, 036,

To

sample

on

label.

Selection

Thread

formation.

Success

Union

Company,

to

the

Maximum

Genuine

parts

guarantee

39500

154

groove,

have

needle,

A

should

Special

its

most

efficiency

are

stamped

of

AR

GHS.

ball

needle

or

complete

of

the

pass

USE

in

the

Needles

subsidiaries

approved

needles

the

highest

uses a curved

It

has a round

point,

040.

orders

the

proper

freely

operation

and

are

with

struck

promptly

type

and

order

GENUINE

and

scientific

packaged with

would

needle

through

Repair

and

durability

the

quality

blade

shank,

groove,

size

read:

size

NEEDLES

of

these

Parts

authorized

principles,

are assured.

Union

Special

in

materials

needle.

round

and

number

"1000

should

needle

machines

as

distributors.

labels

The

point,

spotted,

accurately

should

Needles,

be

determined

eye

in

order

AND

furnished

marked

trade mark.

and

and

REPAIR

can

are

wo r

standard

curved

chromium

filled,

be

forwarded.

Type

to

PARTS

be

secured

by

the

They

made

~

Each

kmanship.

needle

blade,

plated,

an

empty

154

by

size

produce

Union

are

designed

with

trade

for this

standard

in

sizes 025,

packag

Use

description

GHS,

only with genuine

Special

utmost

•

of

a g

Ge

mark

thread

nui

Size

precision.

Style

length,

e, a

032".

used.

ood

stitch

Machine

according

ne

repair

is

your

5

Page 6

~Tensi

l'l]Tension

..W:.Tension

~

S

lot

on

N

ut

(]Thread

0Lower

IJ

Fabric

m

Presser

Gu

ide

Looper

Guard

Arm

Thre

Bracket

ad Ey

el

Needle

Presser

Thread

...

'

...

:.~·,

..

...

Cam

.:

~

Foot

Release

-----------·

---

-

--

( ::

....

.,...

__

...

_

Pull-o

ff

__

.:..,

.........

--

__

Bush

--

....

---

---

ing

--

Fig.

F

or

Type

1

503

Stitch

6

Page 7

r:JThread Eyelet

ttJTension

IJ!I

Tension

ft':IITension

~Slot

Nut

Post

Presser

Cone

Foot

---

Support

Release

---------·

---

Bush

ing

~]Thread

Bupper

I!JAuxiliary

DLower

DFabric

CJPresser

Gui<ie·----

Looper

Looper

Looper

Guard

Arm

Thread

Thread

Bracket

Thread

Needle

Thread

..

~

:.

.....

" • ' I '

..

-·' '

' ·

..,L

~

....

_

Cam

..:.

,

·'

...

Top

Needle

Pull-off

----

Needle

Cover

----

---

---

---

---

Thread Eyelet

Thread Eye

let

For

Fig.

Type

lA

505

Stitch

7

Upp r Looper

Page 8

CHANGING

NEEDLES,

ETC.

(Pages 5 and

6)

All instructions

are

the

same

following

lined

below

Fig.

tension

(Fig.

Use

lA)

posts

threading

as

those

exceptions.

with

page

3

(AC).

for

Type

with

regards

for

The

numbers

Only

diagrams

positions

It

sequence

and

needle

Before

wheel

release

bushing

Be

are

between

diagram

505

stitch.

to

Style

differences,

where

parts

(Fig. 1 and

for

clarity.

will

simplify thr

of

threading

third.

beginning

in

operating

pressure

(U);

and

sure

threads,

tension

(Fig.

1)

Changing

Needles,

39500 P covered

applicable

each

is

found

THREADING

involved

in

Fig.

1A).

eading

threading

this

lower

to

thread,

direction

on

presser

swing

for

Type

presser

as

they

discs

until

foot

come

(AD)

503

Thread

by

only

to

in

(Page

Parts

machine

looper

swing

by

arm

and

stitch,

Stand,

Catalog

Style

Catalog

39500

No.

6)

are

areplacedintheir

to

follow

first,

cloth

needle

turning

(H)

from

and

(N)

out

the

in

diagonal

use

upper

plate

presser

of

tension

Threading, etc.

No.

103 S with the

AR,

are

103

S.

shown

in

threading

recommended

looper

is

open,

at

high

turn

position,

foot

position.

thread

slots

threading

under-

relative

second,

hand-

release

guide,

(AE)

diagram

,

in

Double

(C,

Fig. 1 and

thread

looper

looper

Left

pull-o

thread

(K)

eye

Turn

left.

back

(E)

thread

Lead

to front,

from

pull-off ( T).

assembly

down

tube;

through

push

from front

CAUTION!

thread

wh

end

ff

is

all

of

TO

hand

thread

left

(M),

tube

to

en

ASSE

of

thread

Fig.

(T).

guide

the

lower

THREAD

wheel

then

to rig

lead

thread

dow

back.

Be s

pa

ssi

MB

TO

1A)

from

Lead

(G).

way

looper

until poi

through

through

ht.

Note:

After

thread

tube

n,

then

ure

upper

ng f

rom

LING

THREAD

and

lead

right

thread

Turn

to

the

can

UPPER

nt

auxiliary

both

LOWER

it

through

to lef

behind fabric guard

handwheel

left;

then, thread through

be

thread

LOOP

of

upper loop

loop

eyes

of lower l

thread must pa

pulling

under

assembly

insert

up upper looper thread

neck

(M).

thread

looper thre

tube assembly to

AND

ADJUS

LOOPER

both

t.

Note: thread

in

operating

ed e

asily

E R

(Pa

ge

(Page

eyes

if

6)

er ( L) is

er

thread eyel

ooper

ss in f

of

top cover

Pull

thr e

thr ough

ad

is under

upp

thread eye

ront

ad

out

upp

er

lower loop

er loop

TING SEWING P

6)

of

(F)

upper

must

and

looper

pass

through

direction

both

eyes

tweezers

all

the

way

et (D)

from

let

of

looper

tube

casting and

bottom

looper

of

ey

er

er

eye

ARTS (P

until

from

ar e

e

.

age

thread

in front

hole of

heel

left

in

F ig. 10

8)

of

of

to

left

eyelet

looper

frame

lower

right.

hand.

All

instructions perta

those for

The

dif

ferences,

with page

Style 39500 P covered

applicable only

numbers where each

ining to

is

the ad

by Catal

to

Style 395

found

justme

og N

nt of

o.

103 S with th

00

AR, are underli

in Catalog N

8

Sty

o.

le

103

39500

e f

S.

AR

are the sam e as

ollowi

ned on f

ng exceptions .

ollowin

g p

age

Page 9

SETTING

THE

NEEDLE

(Page

S)

With

When

plate

(Fig.

Remove

NOTE:

should

by

turning

from

by

left

pulling

shaft.

to

turn

the

condition

When

quickly

when

upper

throat

needle

is

3).

throat

SETTING

For

be

as

in

upper

end

of

upper

After

these

upper

shown

the

correct

as

follows:

looper

plate

at

high

Move

plate.

THE

St

le

Fig.

10.

looper

machine;

loop

changes

looper

in

As

eye

in

position,

position,

needle

UPPER

39500

Dimension

holder

dimension

er

holder

around

Fig.

setting

upper

centers

the

"Setting

Type

driving

LOOPER

AR

are

made,

its

9.

is

looper

upper

NOTE:

503

needle

needle

arm

should

point

(A,

(Page

the

dimensional

15 32

inch

counterclockwise

9/64

left,

shank

obtained,

is

on

the

loop

inch

out

of

it

may

slightly

it

moving

needle,

er

and

can

"Settin

the

Upper

Looper • when

stitch.

center

should

Fig.

3)

in

be

by

10) 4

sett

is

increased

lookin

is

increased

upper

be

to

needle

looper

necessary

to

maintain

be

checked

the

right,

the

eyes

should

the S reade

the

front

set

15/32

loosening

~

in

g

of

align

r "

will

making

end

of

needle-slot.

inch

above

clamp s rew

Fig.

exactly

be used

SA

(Fi

in

adjustments

throat

(B).

g.

11).

lace

of

or

Preliminary

holder

vertical

extend

Next,

its

travel·

extends

Fig.

9A

Setting:

should

(F

be

i • 8A).

set

about 5 64 inch

turn

handwheel unt

check settin so

about

5 32 i

to

To

above

nch

Insert

(B,

Fig.

spreader

Screw

shaft,

When

spreader

8A)

to

(C.

Fig.

and

allows

spreader

position spread

end

of s reader shank

holder (Fig.

il

spread

low

er oi

to left of n

SETTING

holds

be

pushed

8A)

is

er

is

eedle

spread

on

hold

er

at the r i

er sh

8A).

at left

nt

of s read

(F

(A.

in

collar

to

ank

ig.

THE

Fig.

er in

or

out

be

ght

about

should

end of

lOA).

SPREADER

SA)

in its

its

or

turned

holds

rotated

end

spreader

or

of

er

holder.

holder,

around

adjusted

its

stroke,

Fig.

an

d permits

its

holder

laterally.

spreader

lOA

Screw

shank.

in

the

9

I

Page 10

10

Page 11

The

parts

parts

that

illustrat

are used

ed

on

on

the

Style

preceding

39500

AR,

page

but

and

are

described

not

used

on

on

this

Style

page

39500

represent

P.

th

e

Those

to

parts

Styles

39500

Use Catalog

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

39578

51292

51292

51292

39505

39540-18

39540-20

22894

39560

39526

39505

39556

39556

14

15

16

17

18

19

20

21

23

24

25

26

27

28

29

30

31

39501

39520

22738

39530

22768

39530

39597

39571

39572

39524

39580

22585

39582

39582

39582

39503

shown

AR

No.

Part

No.

BB

F-8

F-1

F-2

y

A

AA

p

E

K

90

AR

H

B

AR

c

A

AR-1/4.:

AA

G

GG

H

J

H

in

phantom

and

103 S

views

39500

for

P.

all

parts

Chip

Guard

Lower

Needle

Upper

Looper

Thread

Looper

Chaining

Differential

Main

Feed

Screw -Upper

Spreader

Differential

Main

Presser

Chain

Feed

Arm

Cutting

Screw -Chain

Cloth

Presser

Plate

Foot

Screw -Presser

Presser

Screw -Stitch

Presser

Presser

Upper

Upper

Throat

Throat

Latch

Side

Knife

Knife

Plate,

Plate

Screw

Cover--------------------------------------

Spring

Rivet

Front

Fabric

and

bearing

not

illustrated

no

reference

or

described

Description

-------------------------------------

Feed

Feed

Driving

Thread

Tension

Thread

Dog-------------------------------

Looper

Tension

Tension

Driving

Eccentric

or

Spring--------------

Spring

--------------------

Spring--------------

Eccentric

---------------

---------------------

Spreader----------------

--------------------------------------Feed

Dog,

Dog,

marked

-----------------------------------

Knife,

Cutting

marked

"J

marked

Knife

"AA"

11

----------------------

11 J11

------------------

----------------------

-------------------------------------

----------------------------------F

oot

Chain

Foot

Foot

Foot Sti

Clamp

Cha

in

Shield

Ton

gue

and

Hin

ge

Spring--------------------

tch

Tongu

Stud--------------------------

Hold r Block ------------------------

mark

and

- S "de

ed 11BC-1/4

Lower

Cov

Knife

er

------------------------

Shield-------------

--------------------

Spring

e,

marked 11EN

11

------------------

Support

--------------------------------------

-------

-

----------------------------

Guide------------------------------

numbers

here.

--------------

--------------

11

Brack

are

------

t------

common

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1 .

1

1

1

1

-

--

2

1

11

Page 12

,..o

..

..

'

Cl

WORLD'S

,..tlf

FIIEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains sales

facilities throughout the world. These offices

aid

you

in

the selection of the right sewing

equipment for your particular operation. Union

and

Special representatives

tory trained

promptly

tion, there

and

is

serve you. Check with

ATLANTA, GA.

BOSTON, MASS.

CHICAGO,

DALLAS, TEXAS

LOS ANGELES,

NEW

PHILADELPHIA, PA.

YORK,

ILL.

N.

CAL.

Y.

and

are

efficiently. Whatever your loca-

a Union Special Representative to

service men

able

to serve your needs

him

today.

MONTREAL,

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS, FRANCE

STUnGART,

and

service

are

QUEBEC

ENGLAND

ENGLAND

GERMANY

will

fac-

4 0 4

Representatives

industrial

MACHINE

N. F RANK

and

cities

L I N

distributors

throughout

COMPANY

ST.,

CHIC

In

the

all

Important

world.

A G 0 1

0,

1L L •

. .

Loading...

Loading...