Page 1

®

INDUSTRIAL

SEWING

FINEST QUALITY

STYLE

39500AK

LEWIS

•

COLUMBIA

MACHINES

CLASS

39500

STREAMLINED

CATALOG

HIGH

No.

103AK

SPEED

CHICAGO

OVERSEAMERS

Page 2

C

atal

(Suppl

o g N

eme

nt

INSTRUCTIONS

to C

FOR

o.

atalo

103

g N

o.

AK

103

S)

ADJUSTING

The

furnished

parts

at

LIST

CLASS

l i

list

39500

sted

AND

OF

39500

St

y l e

in

prices

OPERATING

P A

RTS

AK

this

for

catalog

repairs

are

only.

First

Copyright

Edition

1962

by

Union

Rights

Special

Reserved

Machine

in

All

Countries

MACHINE COMPANY

INDUSTRIAL

Print

SEWING

CHICAGO

e d

in

MACHINES

U.S

. A .

Co.

Page 3

IDENTIFICATION

0[•

MACHINE

Each

the

name

Standard

letter

"Z"

.

to the standard

Styles

wh i

ch

This

therewith.

are

This

It

can

Reference

operator's

is

away

Union

plate

Style

"Z".

When

of

differs

catalog

Only

illustrated

catalog

also

be

to

position

from

Example:

only

Special

on

the

numbers

minor

Style

machines

from

the

is a

those

and

listed

applies

applied

direction,

the

operator.

machine

machine.

have

''Style

changes

number.

similar

style

supplement

with

while

number,

APPLICATION

parts

which

at

the

specifically

discretion

such

seated

is identified

Style

one

39500

Example:

back

as

numbers

or

AK".

are

made

in

construction

in

to

Catalog

are

used

of

to

to

right,

at

the

STYLE

more

that

the

some

by a Style

are

lette

Special

in a standard

"Style

it

contains

OF

CATALOG

No.

103 S and

on

Style

the

book.

Standard

Special

left,

machine.

front,

OF

MACHINE

number

classified

r s

suffixed,

Style

39500

a re

AKZ".

grouped

no

39500

Style

Styles

back,

Operating

whi

ch s stamp

as

standard

but

neve r c

numbers

1nachinc, a "Z"

letters.

should

AK

and

of

machine

of

machines

etc

direction

conta

under a class

Example:

be

used

not

on

as

.•

are

given

ed

and spe

onta

in the

in the

in

conjunction

Style

listed

in

of

lett

is

suffix

number

"39500".

39500

he

this

class.

from

hand

wheel

into

cial.

er

ed

B

rein.

the

Single

Machine,

and

Variable

39500

filled

straight

should

gauge

lines.

main

AK

of

cotton,

"T"

of

mechanism

lace,

1/8

CAUTION!

before

Machine

on

Machine

reservoir

Curved

Differential

For

shirts,

material

etc.

inch;

mineral

be

used.

is

front

is

Blade

Width

seaming

silk,

polo

permits

Seam

stitchrange,

Oil

beginning

filled

of

automatically

filled.

Needle,

Feed,

Knife

or

similar

shirts,

requiring

specification,

was

oil

of a Saybolt

with

machine.

Check

quick

Two

Trimming

Shift

light

drained

to

and

panties

an

change

8

to

operat

oil

at

Red

lubricated.

oil

Looper,

Mechanism

Mechanism,

medium

weight

adjustable

30

from

e.

viscosity

spring

bulb

daily

synthetics.

and similar

from

504-SSa-1;

perinch;

OILING

machine

Oil

cap

on

oil

before

Three

Automatic

weight

bite.

narrow

camadjustedmainanddifferentialfeeds.

capacity

of

in

top

lev

No

Thread,

with

flat,

For

garments

The

to wide

standard

when

of

200

to

cover.

l i

ndicator

oiling is

the

morning

Low

Spring

Lubricating

warp

general

variable

bite

shipped,

Class

250

seconds

Oil

should

necessary,

start;

Throw,

Pressed

and

which

when

seam

so

39500

level

System.

ribbed

purpose

have var

width

crossing

widths,

reservoi

is

si x

at

100°

is

checked

show

add

between

oth r than

oil

Overseaming

Lower

knit

seaming

knife

ounces.

Fahrenhe

as

Knife

fabrics

ying

plies

shift

elastic,

3/32

r

required.

and

must

at

sight

gauge

keeping

on

be

A

it

Drain

a

magnetic

entered

the

plug

screw

crank

scr

designed

case.

w is

located

to

It

should

at

back

accumulate

be

removed

of

machine

possible

3

and

near

foreign

cleaned

bottom edge

materials

periodically.

of

base.

which

may

It

is

have

Page 4

IDENTIFYING

PAI-n'

S

Where

smne

identification

a

ppear.

OF

s

hipments

unl e

number

The

blade

Collectively,

of

the

Part

IMPORTANT!

MACHINE FOR

Pric

ss

Each

numb

es

otherwise

Union Spe

denotes

size

number,

measured

construction

small

are

are forwarded

e r

le

tter

er s r e

the type

is

present the

ON

WHICH

strictly

directed.

cial

the kind

stamped

in

thousandths

parts

ALL

permits,

stamped

ORDERS,

PART

net

f.

o.

needle

of

number

and

cash

b.

shipping

A

has

shank,

on

the nee

each

on

in

same part, regardless

IS

charge

both a type

of

and

part

those

to

distingui

PLEASE

ORDERED

TERMS

and

a r e

point.

is

NEEDLES

point,

dle

an

inch,

the

is

s t

wher

e cons

INCLUDE

.

subject

Parcel

made to

number

length,

shank,

midway

s i

ze

number

amp

sh the

to

cover

groove,

denotes

between

ed

with its

truction

part

of

catalog

PAHT

change

Post

and a size

shipments

postage

finish

the

is

the

the

part

number.

does

from

without

largest

not per

similar

in

which the.)

NAME

number.

and

shank and the

complet

AND

notice.

are insur

and

oth

diam

insurance.

e r de

e

m i

t,

ones.

STYLE

Th

tails.

eter

sy

mbol.

On

an

All

ed

type

of

ye.

Style

is

Type

single

032,

To have

sample needl

on

label.

Selection

Thread

formation.

Success in the

Union

Company,

to

the

Maximum

39500

154

groove,

036,

040, 044,

A

should

Special

its

most

effi

AK

uses a curved

GAS.

needle

e,

complete

of the

subsidiaries

approv

ciency and

struck

or the

pass

Needl

It

has a round

049,

orders

proper

freely

U

SE

operation

es a nd R

ed scientific pr

groove,

054.

promptly

type

and

order

GENUINE

needle

and

dur a

would

through

epair

bility

blade

shank,

spotted,

size

read:

s i

NEEDLES

of

these

Parts

author

inciples, and

are ass u

needle.

round poi

chromium

and

accuratel

number

"1000

ze

should

needle

machines

ize d distr ibutors.

eye

A D

as

fu r nis he d by t

red.

The

nt,

plated

should

Needles,

be

determined

in

RE

can

are

standard needle

curved

y filled,

be forwarded.

ord

er

PAIH PARTS

be s ecur ed only with genu

ma

blade, standa

in size

an emp

Type

by size

to

produce

he

Uni

Th

ey are

de with

s

022, 025,

154

on Special

de si

for

ty package

Us

e descript

GAS,

of threa

a g

gned acc

utmost

Siz e

prec

th is Sty

r d leng

027, 029,

ood

Ma

th,

, a

ion

027''.

d used.

sti

tch

ine

chi

or ding

is ion.

le

ne

parts

g

uarant

Genui

ne needles a r e

are

stamp

ee

of

the highe

ed wi

packaged

th th

e Union Special

st qua

lity

with

labels rna ked

in materials

4

tra

and

de m

wor km

ark. Ea

Un.um..Spcciai.

ch trade

anship.

.

Genuine repa

ma

rk

ir

is your

Page 5

are

All

instructions

the

same

as

for

with

Style

CHANGING

regards

39500 B covered

to

ChangingNeedles,

NEEDLES,

in

Catalog

ETC.

No.

Thread

103

Stand,

S.

and

Threading

All

instructions

those

instructions

These

Upper

move

obtaining

while

ti

constant

down

tighten

lever

for

Loosen

ghten

Next.

Screw

holding

for

instructions

Knife",

knives

seated

set

trim

on

lever

set

(G)

Style

the

move

is

39500

pertaining

on

SETTING

set

screws

(E

and

standard

at

the

screws

line.

knives

(G)

screws

pulled

(H)

holds

the

tension

ASSEMBLING

pertaining

B,

described

to

the

variable

and

Fig.

Page

and

(B).

11.

THE

(A

F)

3/32

machine.

(A).

to

rotate

downwardly.

the

post

13A

VARIABLE

and

by

pushing

or

This

This

variable

will

the

right

will

mounting

AND

to

should

B,

Fig.

1/8

rotate

position

collar

position

when

shift

ADJUSTING

the

adjustment

in

Catalog No.

width

follow

WIDTH

13A)

down

inch

to

seam

collar

the

obtain

(D)

counterclockwise

the

crossing

mechanism

bracket.

knife

on

on

the

of

the

KNIFE

pawl

pawl

width.

(C)

clockwise

knives

variable

knives

elastic,

SEWING

Style

103

S,

shift

mechanism

two

paragraphs

SHIFT

shaft

lever

From

for

the

trim

for

the

etc.

in

place,

PARTS

39500

except

stop

(G)

AK

are

the

same

with

the

additional

described

on

"Setting

MECHANISM

collars

to

position

the

operator's

to

its

Standard

line

des

to

its

variable trim line when

while screw (J)

(C

upper

upper position

position

s e

am

ir ed

below.

and

D)

desired

position

width

by

pushin

is

as

The

and

for

and

or

g

and

used

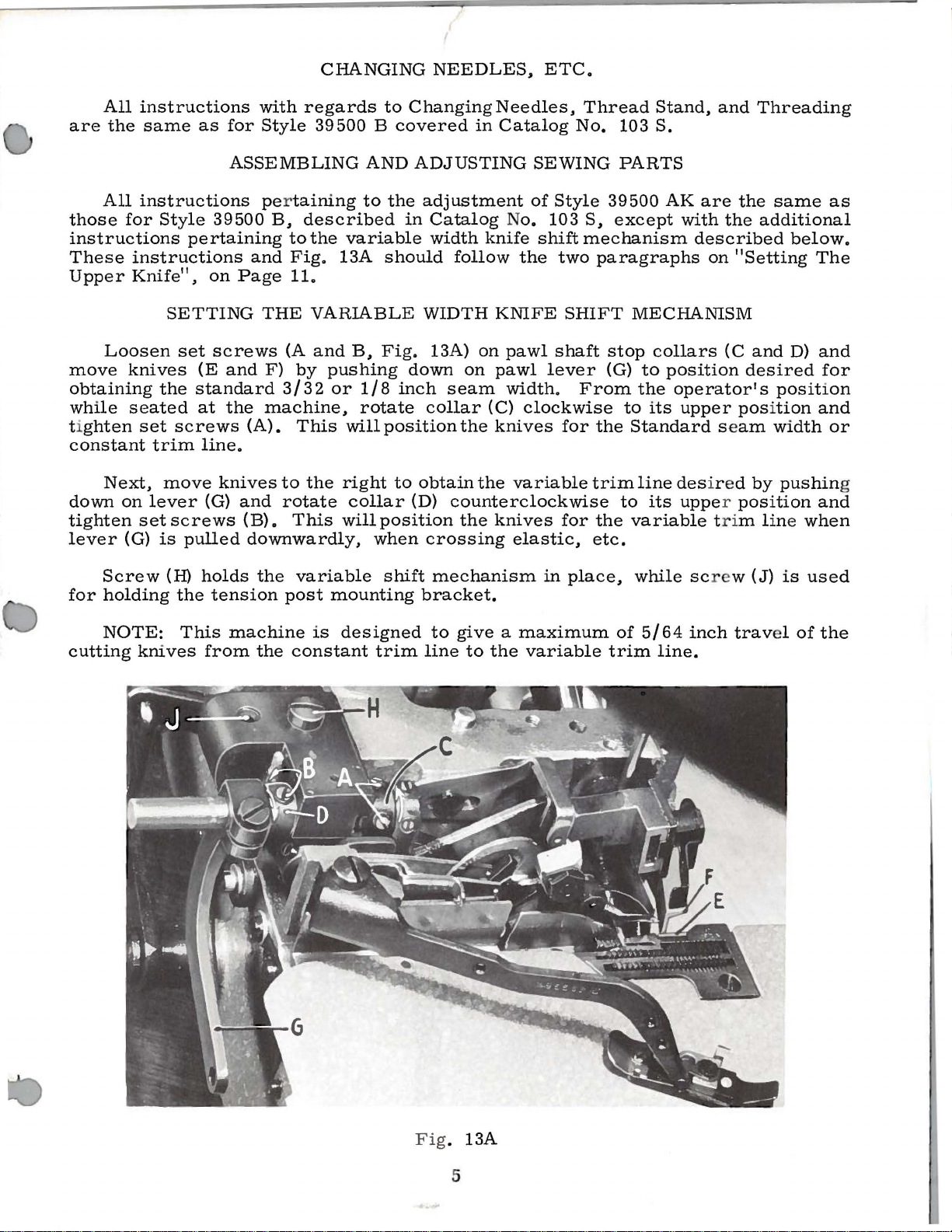

NOTE:

cutting

This

knives

machine

from

the

is

designed

constant

trim

to

give a maximum

line

to

the

variable

of

trim

5/64

line.

inch

trav

el

of

the

Fig

. 13A

5

Page 6

6

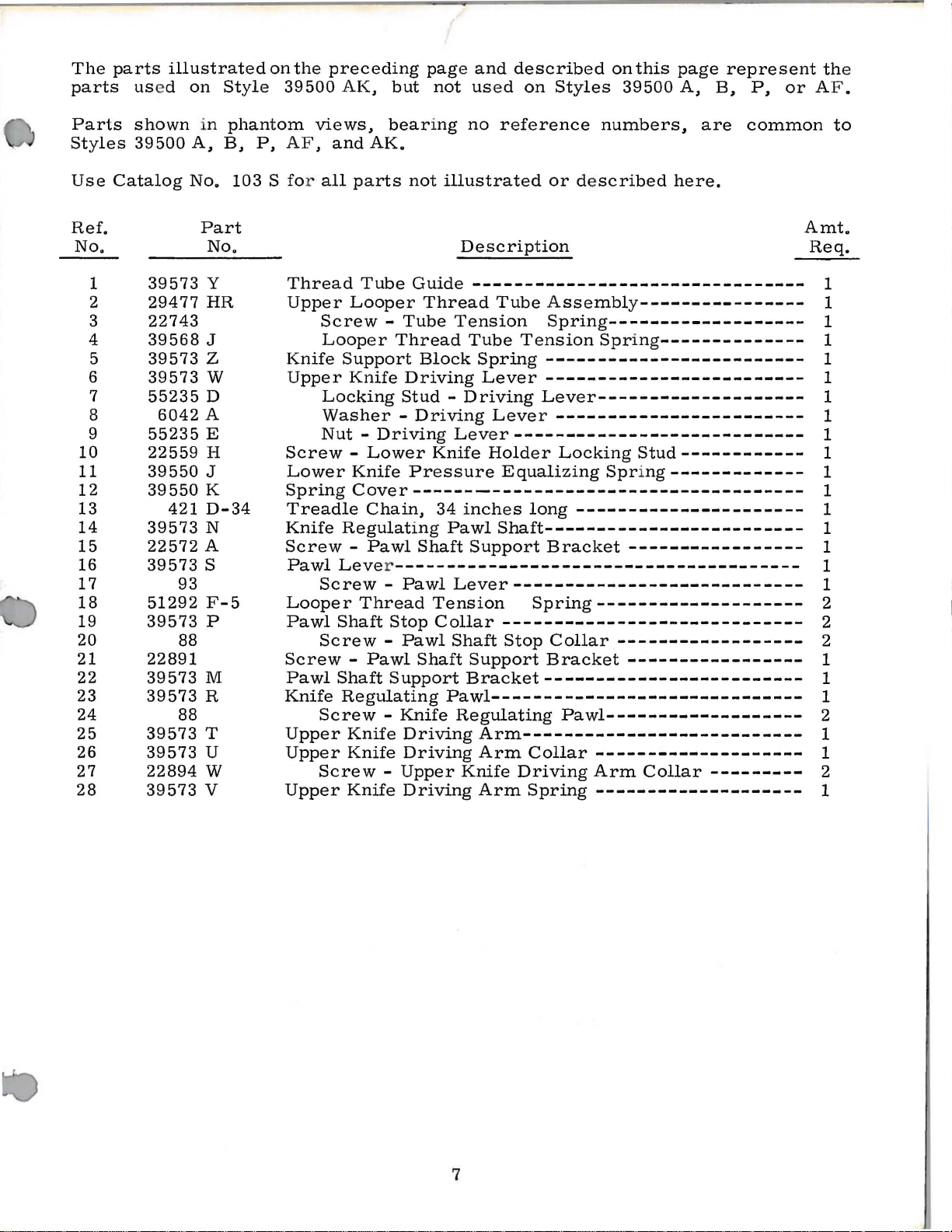

Page 7

The

parts

parts

us

illustrated

ed

on

Style

on

the

39500

preceding

AK,

but

page and

not used

described

on

Styles

on

this

39500

page

A,

represent

B,

P,

or

th

AF .

e

Parts

Styles

Use

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

shown

39500

Catalog

39573

29477

22743

39568

39573

39573

55235

6042

55235

22559

39550

39550

421

39573

22572

39573

51292

39573

22891

39573

39573

39573

39573

22894

39573

93

88

88

in

A,

No.

Part

No.

y

HR

J

z

w

D

A

E

H

J

K

D-34

N

A

s

F-5

p

M

R

T

u

w

v

phantom

B,

P,

103

S for

views.

AF .

and

all

Thread

Upper

Screw -Tube

Looper

Knife

Upper

Locking

Washer -Driving

Nut -Driving

Screw -Lower

Lower

Spring

Treadle

Knife

Screw -Pawl

Pawl

Looper

Pawl

Screw -Pawl

Pawl

Knife

Upper

Upper

Upper

Regulating

Lever---------------------------------------

Screw -Pawl

Shaft

Screw -Pawl

Shaft

Regulating

Screw -Knife

Screw -Upper

bearing

AK.

parts

Tube

Looper

Support

Knife

Knife

Cover-------------------------------------

Thread

Knife

Knife

Knife

not

Thread

Driving

Stud -Driving

Pressure

Chain,

Stop

Support

Driving

Driving

Driving

no

r e

ference

illustrated

Description

Guide

Thread

Block

Shaft

Shaft

-------------------------------Tube

Tension

Tube

Spring

Lever

Lever

Lever----------------------------

Knife

34

Tension

Collar

Holder

inches

Pawl

Pawl------------------------------

Shaft-------------------------

Support

Lever----------------------------

Shaft

Support

Bracket-------------------------

Regulating

Arm--------------------------Arm

Knife

Arm

or described

Assembly---------------Spring-------------------

Tension

-------------------------

-------------------------

Lever--------------------

Equalizing

long

Bracket

Spring--------------------

----------------------------Stop

Collar

Bracket

Collar

Driving

Spring

numbers,

Spring--------------

-----------------------Locking

Spring-------------

----------------------

Pawl-------------------

--------------------

Arm

--------------------

are

here.

Stud------------

-----------------

------------------

-----------------

Collar

---------

common

Amt.

Req.

to

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

1

1

1

2

1

1

2

1

7

Page 8

WORLD'S

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains sales

and

facilities throughout the world. These offices

aid

you

in

the selection of the right sewing

equipment for your particular operation. Union

Special representatives

tory trained

promptly

tion,

serve you.

ATLANTA,

BOSTON,

CHICAGO,

DALLAS, TEXAS

LOS

ANGELES, CAL.

NEW

YORK,

PHILADELPHIA,

and

there

GA.

MASS.

ILL.

N.

is

Check with

PA.

and

efficiently. Whatever your loca-

a Union Special Representative to

Y.

are

and

service men

able

to serve your needs

him

today.

MONTREAL, QUEBEC

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS, FRANCE

STUTTGART, GERMANY

service

will

are

fac-

ENGLAND

ENGLAND

404

Representatives and

industrial

MACHINE

N.

FRANKLIN

cities

distributors

throughout

COMPANY

ST.,

CHICAGO

In

the

all

Important

world.

10,

ILL.

Loading...

Loading...