Page 1

®

INDUSTRIAL

SEWING

F

INE

ST

STYLE

39

SOOAD

QUALITY

LEWIS

•

COLUMBIA

MACHINES

CLASS

39500

CATALOG

No.

103AD

HIGH

CHICAGO

STREAMLINED

SPEED

OVERSEAMERS

-

Page 2

Catalog

No.

103

AD

(Supplement

ADJUSTING

to

Catalog

INSTRUCTIONS

FOR

AND

LIST

CLASS

OF

Style

39500

No.

OPERATING

PARTS

39500

AD

103

U)

The

Rig

ht

MA

INDUSTRIAL

parts

furnished

for

Union

s

Res

CHINE

listed

repairs

Fi

rst

Copyri

Specia

er

ved

SEWING

CHICAGO

in

this

at

li

s t

pric

o n

ly.

E

dition

g

ht

1960

by

l

Machine

in

All

Countries

COMPAN

MACHINES

catalo

es

Co.

Y

g

Printed

in

2

U.S.A.

Page 3

Each

name

Union

plate.

Special

IDENTIFICATION

machine

is

identified

OF

MACHINE

by a Style

number

which

is

stamped

into

the

Machines

letters.

Style

standard

Parts

For

parts.

description,

39500

can

to

direction,

while

Two

Feed,

System.

Example:

of a machine.

Style

This

catalog

illustrated

clarity,

Opposite

Adjusting

AD.

This

catalog

also

be

seated

Needle,

Trimming

similar

"39500".

identification

is a supplement

in

this

certain

the

and

and

applied

suchas

at

Two

39500

illustration

amount

operating

applies

with

right,

the

machine.

Looper,

Mechanism

in

construction

Example:

to

APPLICATION

catalog

S,

required.

instructions

specifically

discretion,

left,

Four

Letters

"39500

specify

to

Catalog

represent

T,

and U parts

page,

Operating

with

parts

to

to

front,

STYLE

Thread,

Spring

are

grouped

suffixed

AD".

machine

OF

No. 103 U

parts

are

are

included

the

standard

some

Special

back,

etc.,

direction

OF

MACillNE

Overseaming

Pressed

by a Class

to a Class

Letter

is

CATALOG

identified

of

"Special"

not

shown

represent

Style

machines

are

of

Lower

"Z"

and

used

in

taken

handwheel

Machine.

number,

number

is

reserved

construction.

should

in

39500

phantom

by

detail

only

of

machine

ofClass

from

Knife,

which

indicates

as a suffix

be

used

S,

T,

or U machines.

to

help

locate

number,

areas

the

is

away

Intermittent

Automatic

concerned

as

listed

39500.

operator's

from

contains

the

standard

in

conjunction.

39500

part

number,

herein

References

position

operator.

Differential

Lubricating

to

with

no

the

AD

and

39500

before

oil

on

reservoir

magnetic

the

the

on

midway

symbol

AD

house

press

pressure

specification

ratio

setting

CAUTION!

beginning

of a Jaybolt

Machine

front

Machine

Drain

crank

Each

kind

the

needle

For

seaming

dresses,

controlled

plate

up

to 3 to 1 depending

14

per

is

of

machine.

is

filled.

plug

screw

case.

Union

ofshank,

shank,

betweenshankand

which

children's

intermittent

attachment.

512-SSa-1.

inch.

Oil

was

to

operate.

viscosity

filled

is

with

Red

automatically

Check

screw

designed

It

should

Special

point,

denotes

given

and

intermittently

drained

Oil

of

200

oil

at

bulb

oil

daily

is

located

to

accumulate

be

needle

length,

largest

eye.

on

the

wear,

differential

Three

Standard

on

stitch

from

capacity

to

250

spring

on

oil

lubricated.

before

at

back

removed

has

both

groove,

diameter

Collectively,

label

of

gathering operations

ladies'

width

OILING

machine

seconds

cap

level

possible

and

NEEDLES

finishandotherdetails.

undergarments

feed

thread

length.

of

in

No

the

of

cleaned

type and size

all

overedge

of

seam

when

Class

at

top

cover.

indicator

oiling is

morning

machine

forei

of

blad

type and

needles

from

Stitch

395go

100

periodically.

e,

and

left

shipped,

is

Fahrenheit

Oil

should

necessary,

start.

near

gn

materials

number.

measured

size

packaged

on

pajamas,

and

similar

independent

and

reinforcing

needle

range 8 to

so

six

ounces. A straight mineral

level

show

Add

bottom

Thesizenumb

in

numberrepresenttheco

and

swing-out

17/64

20

reservoir

should

is

checked

between

other

oil

as

edge

which

The

type

thousandths of

sold

bathing

articles.

stitch -seam

inch.

per

inch,

must

be

used.

at sig

gau

than

keeping main

required.

of base.

may

hav

numb

er

by

Union Specia

suits,

auxiliary

Gatherin

standard

be fill

ht gau

ge lines

It

e entere

er de

not

, stamp

an inch,

mplete

Kne

is a

e

g

ed

ge

.

d

es

ed

l.

3

Page 4

NEEDLES

(Continued)

Style

style

shallow

022,

To

a

sample

scription

Size

is

Type

spot,

025,

have

036".

39500

027,

needle

needle,

on

label.

Selection

Thread

should

formation.

use

Success

of

needles

in

by a reputation

manship

Release

(S,

Fig.

ating

socket

about

withdraw

for

1)

and

direction

wrench

1/4

turn.

needles.

more

pressure

AD

uses

154GAS.

long

029,

tapered

032,

orders

or

the

A

complete

of

proper

pass

the

operation

freely

packaged

for

producing

than

swing

until

presser

needles

No. 21388

Again

curved

It

is a curved

point,

036,

040,

promptly

type

and

order

needle

through

of

Union

under

our

highest

three-quarters

CHANGING

on

presser

arm

are

at

AU,

furnished

turn

handwheel

blade

struck

size

size

needle

brand

foot

(H)

their

needles.

blade,

groove,

044.

and

accurately

number

would

read:

is

determined

eye

Special

name,

quality

of a century.

NEEDLES

by

turning

out

of

position.

lowest

with

until

needles

The

standard

chromium

should

"1

000

{n

order

machines

~

needles

presser

point

machine,

standard

length,

filled,

be

Needles,

by

to

can

in

Turn

of

travel.

loosen

are

needle

single

an

plated

empty

in

packag

forwarded.

size

Type

of

154GAS,

thread

produce a good

be

secured

which

materials

foot

release

handwheel

Using

needle

at

their

is

and

hexagonal

clamp

high

position;

in

for

this

groove,

sizes

Use

de -

used.

stit

only

backed

work-

bushing

oper-

nut

e,

ch

by

To

replace

to

the

left,

they

rest

until

holder

arm

{H)

After

up

through

adjustable

tension

hand

and

hole.

on

through

Only

Parts

It

are

will

threading

Before

ating

foot

of

direction

by

turning

position.

insert

against

is

to

position;

threads

back

thread

thread

Then

parts

placed

simplify

lower

beginning

needles,

needles

stop

again

at

come

eyelets.

guide.

guide

wire

thread

thread

involved

in

their

threading

looper

until

needles

presser

leave

pin.

its

re-lock

needle

in

holder,

Keeping

low

point

presser

THREAD

from

then

cones

down

Next.

(A).

down

continues

guide

(B).

in

threading

relative

this

first.

to

thread, swing

foot

upper

(L)

are

release

holder

one

on

needles

of

travel;

foot

STAND

on

thread

through

they

are

threaded

through

between

THREADING

are

shown

positions

machine

looper

cloth

at

high

position.

bushing

at

high

each

in

then

release

stand

front

right

tension

for

to

follow

second,

plate

{S);

position

side

of

this

position,

tighten

bushing

(Z.

Fig.

eyelets

through

hand

discs

in

threading

clarity.

recommended

and

open.

turn

release

and

swing

spacer

nut.

(S).

1).

(Y)

each

hole

(U),

needles

handwheel

pressure

presser

and,

washer,

turn

Return

they

and

pair

and

up

through

diagram

third.

with

the

handwheel

presser

are

brought

through

of

holes

through

slot

(Fig.

sequence

in

on

presser

arm

oper-

(H)

flats

until

the

in

left

{T).

1).

of

out

\

Be

sure

tension

discs

threads,

(U)

and

as

they

in

diagonal

come

from

slots

the

(T)

tension

in

tension

4

thread

posts

guide,

(V).

are

between

Page 5

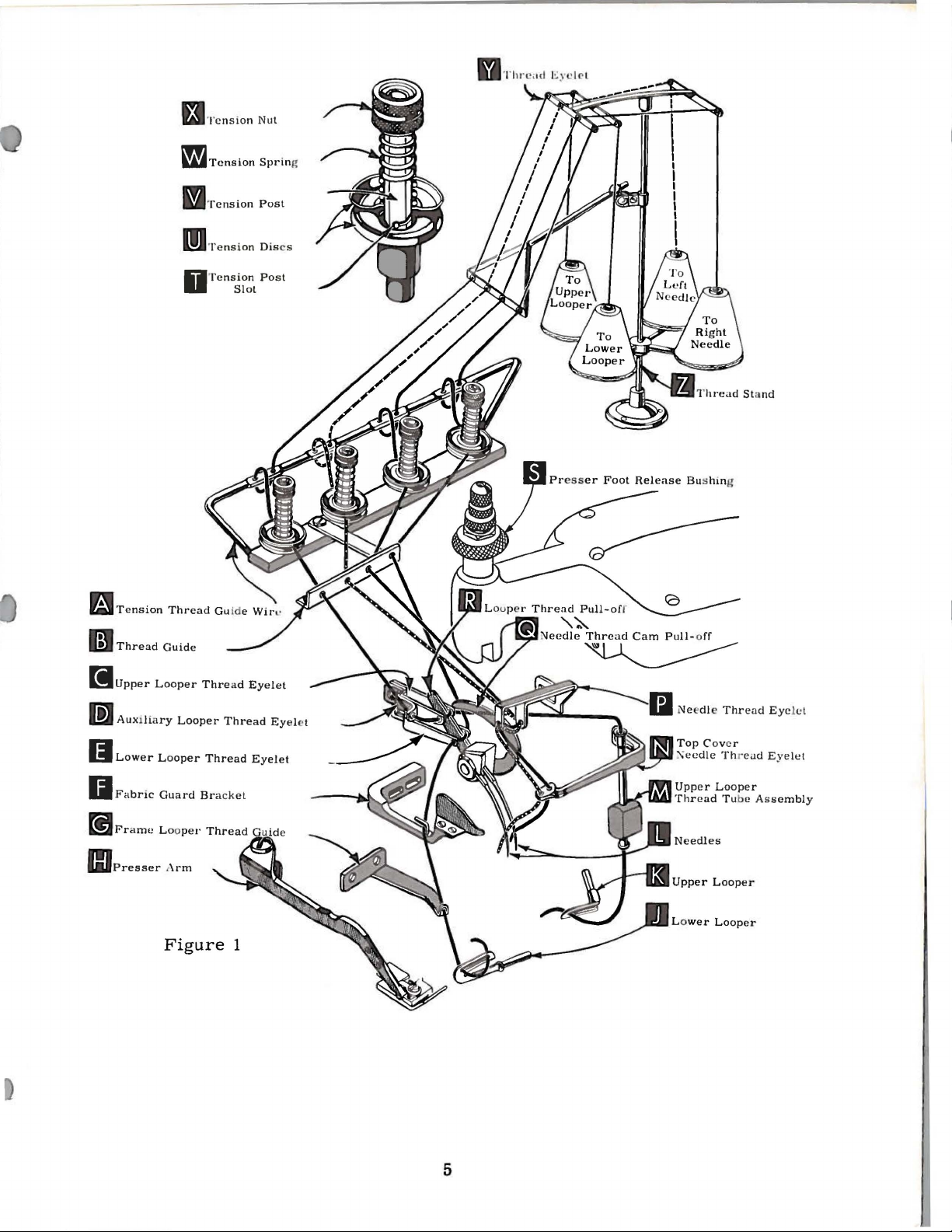

t3Tension

Nut

riTension

mTension

~~~Tension

T

D

ension

Slot

Sprin

Post

Dis

Post

g

cs

liJ

Thread

rilupper

m

II

Lower

~~Fabric

~~~Presser

Auxilia

Guide

Looper

Thre

ry

Looper

L o

oper

Thread

Guard Brack

A

rm

Figure

ad

Eyelet

Thread

et

1

Eyel

Eyelet

et

Needle Thre

Top

Cove r

:\e

edle Threa

Upp

er

Loop

Thread Tube As

wer

Lo

er

Looper

ad E yel

d Eyelet

sembl

et

y

5

Page 6

TO

THRE

D

LOWER

LOOPER

Double

eyelet

thread

looper

lower

left

to

in

left

Turn

thread

throu

gh

thread

looper

and

down

push

tube

CAUTION!

passing

Turn

highest

eyes

of

through

end

of

(E,

Fig.

1)

pull-off

(R).

thread guide

looper

right.

(J)

Left

is

hand.

handwheel

through

both

must

thread

auxiliary

eyes

pass

tube

through

down,

then

Be

from

tube

handwheel

position.

needle

hole

in

thread

top

thread

from

right

Lead

(G).

all

the

eye

of

TO

until

of

upper

in

front

assembly

thread

insert

sure

assembly

in

operating

Insert

eyelet

cover

and

thread

Turn

way

lower

THREAD

point

looper

looper

of

looper

tube

thread

upper

to

TO

THREAD

both

needle

lead

it

to left.

behind

hand

to

the

looper

of

thread

thread

(M),

lead

assembly

throu

looper

upper

direction

needle

(P),

under

thread

through

Note:

wheel

left;

UPPER

upper

thread

thread

looper

THE

threads

eyelet

thread

fabric

in

then

can

be

looper

eyelet

eyelet

pull-off

thread

(M).

gh

upper

NEEDLE

until

neck

both

guard

operating

thread

threaded

LOOPER

(K)

(D)

(C)

under

Pull

looper

is

under

eye.

needles

from

of

top

(N).

eyes

must

through

is

from

from

(R).

neck

thread

lower

(L,

right

cover

Thread

of

lower

pass

(F)

and

direction

easily

all

the

back

left

After

of

top

out

eye

from

looper

F i

to

left,

casting;

needles

looper

in

front

through

both

if

tweezers

way

to

to

right.

pulling

cover

bottom

front

g.

1)

through

of

until

eyes

left.

front,

up

thread

are

then

from

thread

loop

fram

heel

from

are

Lead

then

Note:

upper

casting

of

tube;

to bac

when

at

their

both

down

front.

e r

e

of

k.

The

amount

knurled

to

secure

tension

proper

PRESSER

Sufficient

be

maintained.

de

crease

lo

ck

nut

pressure

amount

(A, F ig . 2)

Adjusting screw

increases

Wh

en

set, tig

on

throat

under

from

(D) aga

Feed

imately

e

ccentrics

main

number

machine

pressu

hten

surface

the

top

inst

eccentrics

10

feed.

of

will

pressure,

re adjusting screw

lock

plate,

is

surface

locking

stitches

are

Minor

stitches

be

of

tension

nuts

(X,

Fig.

stitch

formation.

FOOT

to

feed

Should

of

it

be

pressure

and

has a right

loosening

nut

(A).

position

approximately

of

adjusting

nut

(C).

used

in this m a

per inch.

No.

39540-10

numb

er s

when using

shipped

with

THREAD

on

needle

1 ).

PRESSURE

work uni

necessary

on

turn

hand

adjusting

thread;

decreases

(B)

With

presser

locking

1 I 32

FEED

It

for

of the

above

TENSIO

and

Tension

formly

to

presser

foot,

so

has

been

foot

nut

(C)

inch

to

screw

(B).

ECCENTRICS

chine

will

the dif

have

be

ferential

part

that

eccentric.

combination

6

N

looper

on

threads

should

increase

loosen

screw

tightening

pressure.

properly

resting

so

that

1 I

16

Set

been

not

ed

symbols

threads

or

(B).

its

inch

cap

selected

that

the par t

feed

and No. 3954

indicate

Unless

of

eccentrics.

is

regulated

should

be

Fig.

to

produce approx-

numbers

approximately

otherwise

by

four

only enough

2

of f

eed

0-12

for

the

the

specified,

Page 7

FEED

ECCENTRICS

(Continued)

Following stit c h

5, 6, 7, 8, 9,

36,

40.

Only

trics

a

may

minor

be

numb

"39540-12".

Before

g

uard,

suggested

upper

sequence:

number

10,

11,

one eccentric

ordered

er

suffixed

ASSEMBLING

assembling

knife

assembly,

in

p o s

should

above

Move

(A,

clamp

the

feed

12, 13, 14,

is

supplied

separately.

to

indicate

AND

sewing

parts,

lower

SETTING

With

the

it

the

front

ion,

be

end

set

throat

needle

Fig.

3),

screw

throat

plate.

eccentrics

15,

16,

with

To

order

number

ADJUSTING

remove cloth

knife

THE

throat

needle

of

plate

needle

points

15 I 32

plate

(Fig.

driving arm

by

loosening

(B).

Remove

are

available

18,

20, 22,

each

an

eccentric,

of

SEWING

holder

NEEDLE

in

position,

slots.

inch

3).

24, 26 ,

machine.

stitches

plate,

assembly;

When

under

Additional

use

desired.

PARTS

fabric

needles

needles

No.

28,

No.

then

should

39540-

30,

32,

39540

Example:

guard,

follow

are

at

4,

34,

eccen-

with

chip

this

center

high

~::::..1.

...

.-

~---

Fig.

Fig.

3

5

pull-off(A,

looper

separate

thread

When

~

pull-off

take

driving

If

needle

thread

by

pull-off

re-tightening

screw,

up

end

arm.

At

sert

lower

Fig.

With

the

at

the

stroke,

inch

left

usin

No.

from

needle

g

21225-1116.

Set

Sl

ble, wit

movement

to

deflect

(B)

is

there

and

lower

thread

Fig.

4)

overlaps

pull-off

moving looper

to

back.

looper

be

sure

play

in

needle

this

point,

looper

6)

into

ba r

lower

left

set poi

loop

end of

nt

center

(Fig.

loop

er

gauge

SETTING

rear

hout

of

needl

inte

lower

needles forward . 002-.

used

is

to

no

interferenc

set r e

looper.

cam

(B),

to

in(A,

(B).

er

its

1 I 16

of

6),

THE

e g ua

r fe r ing

knife hol

REAR

rd

NEEDLE

(A,

Fig

with either

der,

ar

need

l e g

e b etween re

Fig.

Fi

.

5)

but

004

uard.

4

g . 6

GUARD

as high

lower

still

inch.

ar

needl

as pos-

loop

er

in

position

Sc r ew

Make sur

e gua

or

e

rd

7

Page 8

SETTING

THE

LOWER

LOOPER

Now,

moves

of

the

ward

Assemble

looper

guard

Use

screw

setting,

guards

finish

to

the

left

needle

from

SETTING

is

springing

as

closely

(D)

make

and

lower

right,

(A,

rear

guard

THE

front

needle

needles

as

to

adjust

sure

there

differential

(B)

pushed

looper

in

in

shank

looper

its

point

Fig.

7)

surface

FRONT

guard

possible

and

is

feed

Insert

holds

place.

the

shaft.

extends

adjustm

ent .

should

until the needl

another

NEEDLE

(C,

Fig.

off

back

guard,

to

needles

set

front

no

interference

dog.

SETTING

upper

upper

in

or

holder

Screw

out

into

looper

or

(C)

Locate

1 I 1 6

As lower

be set

into the

es s

.

002-.

pring for-

004

GUARD

5).

When

set

front

without

touching.

needle guard.

between

looper

turned

upper

on

upper

to

THE

clamp

3 I 32

(A,

in

its

looper

UPPER

Fig.

around

looper

inch

looper

s c

arf

inch.

lower

needle

After

needle

8)

holder,

its

shaft,

holds

beyond

LOOPER

in

its

and

shank.

if

the

upper

in

its

Fi

holder.

permits

it

is

looper

holder

holder.

g . 7

Insert

not

so

Screw

it

to

be

upper

already

holder

that

the

Fi

Fig.

Dimension

clockwise

by

pulling

changes

shank

slightly

g. 8

9

looking

upper

are

made,

17 I 32

from

looper

to

maintain

When

upper

shank

out

the

looper

back

By

of

upper

looper

looper

the

left

0.

002

Next,

per

looper

travel.

looper

needle

resetting

the

upper

Figure

setting.

inch

is

left

holder

it

may

the

of

adjusting

looper

around

point

to

of

the

0.

to

004

turn

is

Check

point

and

with

throat

is

necessary,

looper

10

represents

increased

end

of

left,

be

necessary

the

condition

upper

holder

vertical

looper

shaft

its

cross

lower

clearance

the

handwheel

at

the

dimensions

respect

plate

holder

by

machine.

out

looper

should

(Flg.

and

shank,

lower

looper

left

(Fig.

do

(A,

the

turning

of

the

to

shown

is

at

the

be

set

to

8).

holder

by

turning

set

in

upper

looper

eye

with

(Fig.

to

until

end

of

the

upof

upper

right

10).

it

by

moving

Fig.

10).

dimensional

upper

Dimension

upper

turn

in

the

Fig.

looper

upper

right

position

or

to

9) .

its

If

looper

1 I 8

9.

end

of

its

upper

Fig.

holder

inch

shaft.

10

counter-

is

increased

After

looper around

stroke,

looper

these

its

8

Page 9

SETTING

THE

UPPER

LOOPER

(C

ontinued)

When

quickly

when

the

upper

Check

a

nd needle

of

upp

rotat

from

of Fig. 9,

feed

dogs

differential

c

haining feed dog

the

as

follows:

upper

looper

looper

setting to

on nee

er loope

e looper a

left e

nd

10,

at

their

feed dogs (A, B)

correct

settin

As

eye centers

and needle s ho

avoid

dle

downstroke.

r,

pull

looper

short

of

distance

machine.

11.

Fig.

highest

is

made

g is o

upp

er looper

interference

out

Reset

12

point

should

as

on

btained,

on the needl

is

moving

it can

e,

uld align exactly

between

If

of

its

counter-

to

of

travel,

be

integral

needle

holder

clockwise,

maintain

3/64

rubs

the

inch

part

be

checked

to

the

right,

the

eyes

(Fig.

upper

looper

the

slightly

looking

dimensions

SETTING

Assemble

differential

Fig.

12).

feed

with

by

ing

dog3

respect

rotating

pin

lowers

bar.

The

level

at

appear

Screw

adjusting

top

of

the

above

of

the

main

of

11).

back

and

(C).

the

feed

the

above

(D)

pin

teeth

the

Fig.

THE

FEED

the

main

feed dogs (A,

Main

feed

should

to

feed

This

back

dogs

time

the

locks

in

on

throat

and

differential

be

the

throat

tilting

pin

end

of

should

the

throat

feed

place.

the

plate.

dog.

teeth

11

DOGS

leveled

adjust-

raises

the

be

plate.

tilting

With

main

and

B,

plate

or

feed

set

first

the

and

The

Replace

knife

flush

made

knife.

knife,

width

(A,

with

with

Lower

so

of

Lower

tightening

port

latch

always

bracket.

pin

be

tightened

Replace

knife

clamp

guard

inch

(D,

(F)

(J)

behind

SETTING

lower

Fig.

throat

hexagonal

knife

no

lateral

trim

is

knife

screw

for

the

locked

against

SETTING

upper

Fig.

13)

in

its

should

the

cutting

THE

knife

13)

should

plate

is

adjustment

changed.

may

(B)

and

Because

cloth

with

lower

THE

knife

in

position,

most

be

positioned

LOWER

holder

be

assembly.

set

surface.

head

screw

spring pressed

is

be

secured

locking

screw

plate

nut

knife

(C)

nut

(B)

latch

even

holder.

UPPER

assembly.

setting

clockwise

edge

and

position

so

that

in

contact

KNIFE

with

cutting

Adjustments

which

holds

against

necessary

in

any

position

(C)

against

also

serves

spring,

when

screw

KNIFE

Clamp

nut

(E)

against

the

guarding

with

Lower

it

should

to

the

edge

are

lower

upper

when

by

sup-

as

is

not

upper

hold

upper

section

tops

knife.

is

urface

Fig.

Upper

13

knife

approximately

of

the

upper

chain

1/64

knife.

9

Page 10

not

At

less

the

than

bottom

1/64

SETTING

of

its

stroke.

inch

below

THE

cutting

UPPER

front

KNIFE

cutting

edge

of

(Continued)

edge

of

lower

upper

knife.

knife

should

extend

After

tightened

resetting

upperknife

to

lock

when

upper

Differential3 plain3 or

ential

the

lever(A)

top

Amount

and

(located

clockwise

creases

clockwise

the

are

feed

action

micrometer

The

position

is

governed

stop

(B)

and

of

movement

{C)

determines

Rotation

near

(moving

differential

turn

The

micrometer

top

stop

is

encountered.

adjusting

of

the

of

tension

acts

ideal

has

the

upper

knife

SETTING

is

obtainable

the

differential

bytwo

lower

by

feed

adjusting

top

action.

the

adjusting

for

been

set

knife

is

replaced.

THE

reverse

thru

screw

settings--the

stop

screw

lever

between

action.

thumbscrew

post

stop

down)

A

reverse.

screw

continuous

for

proper

holding

block

DIFFERENTIAL

differ-

use

of

(Fig.

14).

control

(C).

(B)

assembly)

in-

counter-

for

shirring

width

(H)

in

of

place.

RATIO

operations

trim3 screw(G)

This

Fig.

where

will

14

various

must

simplif

sizes

be

y

For

intermittent

sothe

for

adjusting

upper

position.

The 3 to 1 ratio

differential

maximum

Be

Pa

ge 5).

horizontal

slowly.

off

the

sew

slowly.

While

all

needle

thread

to

pull

at

bottom

cam

pull-off

differential

sure

With

and

without

tongue

sewing

thread

should

down

of

screw

feed

dogs

machine

thread

in

the

presser

freely.

on

be

just

slightly

stroke,

(Q)

just

operations3 it

stop(B)

machines

from

3

striking

and

STARTING

is

threaded

tensions

middle

foot

in

Swing

NEEDLE

material,

is

drawn

tight

if

excessive

on

enough

position

contacts

may

isforlower

are

screw

light.

of

their

place.

presser

THREAD

check

needle

to

thread

needle

needle

be

advantageous

stop.

equipped

the

throat

should

TO

not

OPERATE

according

set

looper

front

to

foot

to

make

into

CONTROL

needle

thread

down

feed

cha

is

pulled

thread

thread.

and

the

with a stop

plate

be

to

when a machine

removed.

threading

thread

back

locations.

sure

that

position,

control

stroke.

in

off

stitch

on

the

eyelet

(P,

to

reverse

stationary

screw

eyelets

chain

insert

as

At

top

tongue.

up

stroke.

Fig.

{D)

diagram

(C

and

Operate

forms

material,

follows:

of

needle

Stitch

With

1)

so

the

stops--

stop

to

prevent

is

(Fig.

E)

machine

and

Usually

that

(C)

set

about

moves

and

stroke,

tends

needle

needle

is

at

1.

10

Page 11

With

back

far

its

most

distance

should

heel

eyelet

material

enough

rearward

behind

be

set

with

at

LOWER

under

so

thread

position.

needle

its

the

time

presser

is a little

thread

eyelet

lower

LOOPER

foot,

THREAD

set

slack

Looper

cam

thread

pull-off

approximately

looper

CONTROL

lower

looper

thread

eyelet

whenlooperthread,pull-off(R)

is

pull-off

(Q).

1/8

at

Frame

inch

extreme

to

(R)

looper

right

left

is

set

ofl9wer

end

about

thread

of

(E,

Fig.

reaches

1/8

guide

looper

its

travel.

1)

inch

(G)

(J)

While

A

portion

lower

drawn

lower

looper

Before

all

four

tensions

During

will

draw

thread

looper

To

Fig.

1)

better

sewing

of

looper

through

proceeding

tensions

will

needle

upper

is

drawn,

thread

movethe

should

to

have

lower

thread.

the

thread

to

not

markedly

thread

pull-off

purlmore

be

slightly

on

material,

looper

thread

comes

tension

eyelet

while

(E)

UPPER

to

adjust

give a normal

effect

down

stroke,

through

upper

looper

reaches

POSITIONING

underthe

raised

keeping

more

check

should

off

upper

lower

down,

keeping

LOOPER

upper

appearing

the

forward

the

thread

its

most

the

pull-off

drawing

be

drawn

looper.

looperthread

the

THREAD

looper

thread

purl.

stroke

tension.

will

have

rearward

THE

edge,

bothlooperthreadeyelets

same

on

upper

off

To

same

CONTROL

stitch.

of

When

almost

position.

PURL

amount

thread

of

looper

through

increase

is

on

amount

eyelet

Moderate

looper

normal

of

pull-off.

than

the

upper

(

C,

thread

all

thread

tension

amount

looper,

of

pull-off

Fig.

change

amount

slack

on

lower

as

follows:

of

action.

1),

balance

in

pull-off

of

looper

taken

(C

and

Usually

thread.

before

thread

move

these

(R)

up

as

E,

it

is

If

it

up

all

located

the

purl

will

form

The

material

as

high

looper

the

chain

becomes

end

play

so

that

will

nearer

needle

being

as

possible

thread

increases,

necessaryto

in

it

tend

to

bottom

thread

sewn.

tension

needle

is

higher

form

edge.

tension

In

without

should

or

until

move

drive

over

near

top

THREAD

general,

causing

be

the

looper

shaft

throat

edge.

TENSIONS

required

lower

needle

increased

purl

is

11

thread

before

plate

tightening.

than

If

upper

is a function

looper

thread

as

pulled

too

thread

long

pull-off

(R),

If

recommended

looper

of

is

too

needle

tension

to

be

pulled

as

the

far

over

the

be

sure

upper

in

low, the

should

down.

elasticity

top.

to take

loop

(Fi

g.

thread

er is

10),

purl

an

d

be set

Upp

er

of

Page 12

~

~

12

Page 13

The

the

Tor

parts

parts

U.

illustrated

that

are

on

used

the

preceding

on

Style

page

39500

AD.

and

but

described

are

not

on

used

this

on

page

Styles

represents

39500

s.

Those

common

Use

Catalog

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

14A

14B

15

16

17

18

19

20

21

22

23

24

25

25A

25B

26

27

28

29

30

31

32

33

34

35

36

37

38

39

,40

parts

to

108

51292

51292

107

109

35792

39592

39563

39582

39582

39582

39563

39551

39552

22596

39551

39524

39525

39525

605

39556

22704

39556

39520

39597

39530

22768

39526

39505

8372

22728

39536

39536

39536

161

39536

161 A

22764

43139

22569

shown

Styles

No.

Part

No.

F-4

F-8

H

G

K

T

L

51-103

v

L

c

F

51-45

E

D

w

G

F

A

H ,

K

AD

AD

B

AD

AD

A

cc

25

A

AC

AA

AD

88

AB

A

c

in

39500

103

Blk.

·

phantom

AD

U

for

Tension

Tension

Tension

Tension

TensionDisc----------------------------Tension

Tension

Frame

Top

Top

Needle

Needle

Needle

Needle

Throat

Needle

Needle

Screw-----------------------------------

Presser

Screw----------------------------------Chain

Presser

views

and

39500

all

Cover-------------------------------

Oil

Hinge

Spring

Cover

Stop

Screw--------------------------------

Cutting

Stitch

Hinge

and

bearing

s. T

parts

Description

Post

Spring.

Spring.

Post

Post-----------------------------

Post

Thread

Filler

Pin

------------------------------Needle

Clamp

Driving

Pin------------------------------

----------------------------------

Spacer

Plate-----------------------------

Guard.

Guard.

Foot

Foot

Tongue------------------------Spring--------------------------

and

not

illustrated

Nut-------------------------

Looper

Needle

Ferrule---------------------

Mounting

Guide----------------------

Cover

---------------------------Thread

Stud------------------------

Arm

Washer

rear-----------------------

front

Hold

Knife-----------------------

----------------------------

Down

no

U.

Thread------------

Thread

Bracket

----------------------

Eyelet-----------

----------------------

--------------------

---------------------Plate

reference

or

described

------------

------------

-------------

numbers

Screw-------------------------------- 1

Differential

Main

Washer----------------------------------

Feed

Screw----------------------------------- 1

Screw----------------------------------Feed

Feed

Spring

Stop

Control

Control

Washer

Collar

Feed

Dog--------------------------.-

------------------------------

Dog---------------------

Adjustable

Mounting

---------------------------

Stop

Bracket

--------------

------------

Screw-------------------------------- 1

Feed

Stop

Control

Collar

Adjusting

------------------------------

Rod----------------

Screw-------------------------------- 1

Nut

-------------------------------------

Screw----------------------------------- 2

are

here.

Amt.

Req.

4

2

2

4

8

4

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

2

13

Page 14

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

26A

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Part

No.

21101

H-4

21114 H-4

22652 CD-4

21114 M

21114 L

21104 v

21114 w

258A

21114

652-16

S-4

21114

21114 M

21114 L

21114 D-4

22651

CD-5

21114 T

22651

CD-4

22810

21114 A

22651

CD-5

u

21114

652-16

21104 H

21104 B-20

660-168

21664

69

FD

21663

c

21665

69

FD

21662

SC330

21664 B

9271

98

21664 E

22557

A

43137 E

39536

AD

21664 c

SC30

3

421 D-10

21664 D

THREAD

Thread Stand,

EyeletSupport---------------------------------------------------------

Screw------------------------------------------------------------Eyelet Locking Ring

Eyelet-------------------------------------------------------------

Felt

Pad--------------------------------------------------------------

Spool

Pin

Nut------------------------------------------------------------------Spool Seat

Washer--------------------------------------------------------------LeadEye1et-----------------------------------------------------------

Eyelet

Eyelet-------------------------------------------------------------

Spool Seat Support

Screw-------------------------------------------------------------

Lead Eyelet Socket Ball

Screw-------------------------------------------------------------

Screw

re

ad Stand

Th

crew-------------------------------------------------------------

S

Lead Eyelet Ball

Washer--------------------------------------------------------------Nut------------------------------------------------------------------Thread

Knee

Press

Knee

Press Plate

Screw

Press Plate Rod-----------------------------------------------------

Knee

Knee

Pres

Screw

Kn

ee

Press

Screw--------------------------------------------------------------------

Press

Knee

Collar

--------------------------------------------

Screw

Connection

rew--------------------------------------------------------------------

Sc

Washer

Spring

B

Scr ew

Treadle

Bell

----------------

Washer------------------------------------------------------------

ellCrank

---------------------------------Chain

Crank--------------------------

STAND

Description Req.

complete----------------------------------------------------

------------------------------------------------------------Disc--------------------------------------------------------

Locking Ring

----------------------------------------------------------------

Base----------------------------------------------------

Stand

Rod------------------------------------------------------

Pad-----------------------------------------------------------

---------------------------------------------------------------s R

od

Connection

----------------------------------------------------------------

Bracket-------------------------------------------------------

Bracket

----------------------------------------------------------------

Rod-----------------------------------------------------------

Bracket---------------------------------------------------

-------------------------

AND

KNEE

PRESS ASSEMBLY

------------------------------------------------

------------------------------------------------

-----------------------------------------------------

------------------------------------------------

Split

Socket--------------------------------------------

NEE PRES

K

-----------------------

Shaft--------------------------------------------------

S PARTS

-

---------------------------------

------------------------------------------------

-

----------------------

-

----------------------------------------------

-

--------------------------------

---

--------------------------------

- -

--------------------------------

14

---1

- -

---

--

Amt.

- 1

1

1

2

8

8

4

4

8

4

4

1

4

4

1

2

1

2

1

1

2

2

1

1

1

1

1

1

1

1

2

1

2

1

2

2

1

1

1

1

2

1

Page 15

Sales Agents

UNION

SPECIAL

For

Also

Machines; (C)

Agent for

COLUMBIA

(L)

LEWIS

and

where marked.

AFRICA

KENYA,

NAIROBI

Tongonyiki,

MAURITIUS,

Machinos) Hall, Genova, Langlois, Ltd.,

Nowlan

MOROCCO,

Soldot Sonchoz.

REPUBLIC

2166

Un

ion of South Africa.)

SOUTHERN

NYASALAND,

Bros. (R

SALISBURY-(Tox

bury) Pvt.

ch

inos) South African

Angwa

SUDAN

305.

TUNISIA,

8

Ruo

UNION

Machinos)

~~https://manualmachine.com/:~

58 Quean St.

i?~~Nta~S~~y~?u~~.a~flv~~~~B~:~~~~e

BLOMFONTEIN

Breo

38 Argyle St.;

PIETERMARITZBURG,

WORCESTER.

- Pollack (E.A.)

Cotner

Hou5&,

PORT

LOUI

St

.•

1'.0.

Box

CASABLANCA-R. Geissmann & Fils,

(L)

OF

CONGO,

(sub .

agont

Borzack Bros.

RHODESIA,

BULAWAYO

hodesia), 16·14th Ave.

tlle Machinos) Berzack Bros. (Salis-

Ltd

.,

102

Sts.

, KHARTOUM-Franco Pinto (Sudan)

TUNIS-camptoir

du

18 Janvior 1952. (l)

OF

SOUTH

AFRICA,

Borzack

Bros.,

.!i2-~~t

~~~;,:,'c

(L)

- 53 Zostron St.;

Sts.;

DURBAN-22

PORT

AUSTRALIA

Sole Distributor- Capron, Carter (Ply.)

NEW

SOUTH

WALE

S,

QUEENSLAND,

N.l

.

SOUTH

AUSTRALIA,

TA~MANi.f.t~oflR~~~~:t.!t~ents)

105

MacQuarie St.

VICTORIA,

WEST

AUSTRALIA,

789 Hay St.

CAMBODIA,

(C & L)

HONGKONG-G

30B,

Bonk

(L & C)

INDIA, CALCUTTA-Don, Watson & Co., (Pvt.)

British lnd;

JAPAN, OSAKA-Kondo Sewing Machine Co., 153

Umegae-Cho, Kita -ku.

KOREA,

SEOUL-Uebo,ee-Handel A.G., Rm. 604, Banda

Bldg., 180 1-ka Ulchiro; Chung-Ku, Int. P.O.

(L)

LAOS

, VIENTIANE-Oenis Frores, P.O.

PAKISTAN,

Zeenat Man si

(B

og

Closm~

kcoy,

ltd

TAIWAN,

THAILAND, BANGKOK

vt :

JAMAICA.

B

TAIPEI-

16

Nan

Yan~

rN1~

·. <r

P.O.

Freros,

KINC.STON

AHAMAS, NASSAU

Avo., Mia

SYDNEY-B6

BRISBANE-454 Brunswick St., Valley,

ADELAIDE

MELBOURNE

of Canton

an

KARACHI

., 15 Baltic Stre

xrG't,'Nk~

BRITISH

mi

- 78 A'Beckett St.

PERTH-(Sub-agents) Thomoons, Ltd.,

PHOM-PENH-Den

. R. Coleman Co. (Hongkong) Ltd.,

St.

(L)

- 2- Universai Trad

on,

Mclood Road. (Tcxtil

and

Baq Making Mochin

G.

R. Coleman

St

. (L & C)

- Yip

~c~.

Box

444, 4

Union Special International,

- Morrh

- H.

37, Flori

~d.-

Also:

Uganda

and

AUSTRIA,

Hord

ingD Streot (l

S--(

Bog Closing & B

n.

ELIZABETHVILLE

(L)

FEDERATION

Sinioo St.

Scale

ELIZABETH-Box

PRETORIA,

ltd

- (Toxtilo Machines) Bertack

(L)

(L)

- (Bag Closing Me-

Co., Pty.,

lndustriel & Menoger C.I.M .

JOHANNESBURG-(Textile

Ltd

.,

Borbro

;

~~~~~~;-v~c)R~B

CAPETOWN-Wa

Aliwal St.;

Livorpool S

- (Sub-agents) Topp &

Reliance Trading Ca.,

!..

.C)

ag

Making

42

Sir William

Rue

- Progres.,

., Johonnosburg,

OF

RHODESIA

Ltd., forbes

Ltd

., P.O. !lox

House,

135n

B.

E~zlisrT~~

SI. Sa~!~c~::ic:,~

EAST

VEREENIGING

Ltd.

LONDON-

611

. Also

(l)

t.

les &

ASIA

is Freres, P.O.

Bldg

., 6

Dos

(l)

et,

Oundco, Scotland.

In Tsoi & Co.,

~:od~

;·~r

Rue

Tu Do.

WEST

INDIES

E. Park

L.

Simon &

da

Voeux St., Contra!.

Co. (Hongkong)

zg

S'l:fi~~

(C & L)

in, 02 King St.

Co

Box

Room

ltd

.,

Box

1268.

Box

133.

(C & l)

ing Corp.,

os.

Me~chim

u

Thomas

Ltd

i.i~

.

Onlv)

ltd.,

., P.O.

•. oenls

es)-

Inc

.. 2650 N.W. 5th

51.

(L)

BELGIUM,

of America, 23 Rue Philippe

Deloof, Mgr. (C)

du

BRITISH

Thomas

P.

DENMARK,

lor

Sy-lndustrion A/ S, Nikolai Plod• 23.

AALBORG,

&

AND

SILKEBORG.

EIRE,

DUBltN-(Textilo

Upper Abbey St.

Machine•) Thomas

Scotland.

&

ENGLAND-(Textile Machinos)-LEICESTER, Union Special

Machine Co.,

A.

B. Fitzpatritk, Mgr.

111

Alderton Heights, Moortown.

Un

ion Special Machine Co.,

John•on & Son (Sewing Machinery

G.

Titchf.old St.

(Manchester) Ltd., 34 Oxford Road.

Saunders Machine Co., (Portsmouth) Ltd., 110 Kir1gston

Crescent. (Bag Clo1ing and Bag Making Machi

Thomas

land

.

FINLAND,

0 / Y, Vattuniomenkotu 13. Branches

tonkatu 16.

at

FRANCE,

and

Franco,

GERMANY,

G.m.b.H., Schwabstr.

Di

toctor. Blfl

2~4.

EBINGEN

FRANKFURT

burgstr. 8.

Lappenborpsallo 4d.

Hunnenrutken 25.

GREECt,erA~tl'EN~~~c~J·

(L & C)

ITALY,

MILANo-G

18. (L)

THE

NETHERLANDS,

C. & H. Verbeek, Klovan

ENSCHEDE,

NORTHERN

J. Bogod & Co.,

-4B.

NORWAY,

(Tullingardon); BERGEN-Bjornsongit 24. (C)

PORTUGAL,

Barao

de

SCOTLAND,

19

(Bag Closing

SCOTLAND,

& Co., 9 Stevenson St .

SPAIN,

BARCELONA- Rapida, S.A., Avina 9.

SWEDEN,

nerigaten 6. Branches

MALMO,

A/ 8

29

C.

(l)

Fo

SWITZERLAND, ZURICH-M.

straue

ARG

ENTINA, BUENOS

San Jo

se

BRAZIL, SAO

Comorcio,

ALEGRE-Rua

Princes

a Isabel 105;

MacKenzio 117.

VIENNA- Firma Niihschu•lor, Mariahillorstr.

BRUSSELS-Union Speci

ISLES-(Bag Closing

C.

COPENHAGEN-

C.

HELSINKI-LAUTTASAARI- Suomon , Konellike

PARIS-Cie.

91

STUTTGART-Union Special Maschinenlabrik,

IRELAND,

OSLO-Joe

OPORTO-Ro•t & Janus, Succs. Lda., Rua

Forro1ter 914.

DUNDEE-Tho

GLASGOW,

BORA

S.

n b

e,.

226

.

Union Sp cdaf ln te

350

Rua

EUROPE

al

Machine Corporation

de

Champagne, Henri

and

Koay,

ltd.,

HERNING,

(l)

(C)

C.

Keay,

Ltd

., 25 Bade Street, Braunstone Gate.

london

W-1. MANCHESTER

Koay,

ltd.,

TAMPERE

-Pionteoilisuo stalo

AYe.

GRONINGEN,

g &

des Machines Union Special

de

Ia

Ropublique,

EFELD

BRANCH,

BRANCH,

BRANCH,

HAMBURG

KOLN

MUNCHEN

iovanni Conti & Nipoti, Via Varese

AMSTERDAM-N.

BELFAST-(Textile Machines) W. &

Ltd

., 6

. Jacobs

and

Bog Making Machines).

S.E.-(Textilo

S--

Rud

. Nystrom & Co., A/

Forstadsgatan 16. Sub-A!!ent S

kato

, Tomtebogatan 38.

LATIN

AIRE

(Un

ion Special Machino Company),

PAULO-

Aurora 5

Volunlarios do Patria 533;

RIO

(C & L)

Bag Making Machines)

15 Baltic St., Dundoo, Scotland.

Rothenborp Specialma1kiner

KOLDING,

Machines) Machine•,

(Bag Closing

LEEDS,

15 Baltic

33

, A. W.

Ebingon/Wurtt., Gartenstr. 44.

Frankfurt/M-Rodolhoim, Reichs-

BRANCH,

BRANCH, Koln

l,~l

ien

ROTTERDAM,

linenhall

on

(L)

>. C. Keay,

at

OREBRO·Odro Bangatan 18;

RISSKOV-AARHUS

and

Ltd

.,

15

Baltic St., Dundee,

YORKSHIRE,

LONDON, E.C.

Ltd

., 15-

Street,

at

Georges

Krieger,

Bielofold, Dotmolder Str.

Hamburg-Eimsbuttel,

BRANCH,

oi~.~ri-;:is

V.

burgwol

5

1.

(C)

A/S,

Kr. Augustsg

ltd.,

Machines) Allardice

l.

Bou

rquin, Albisrieder-

AMERICA

rnu

tionul, Inc.

S-P

amoto Co

Pancostura, S.

9A·7

DE JANE

A.

1. Bronchus a t PORTO

IRO-Rua Ale

17

ltd.)

1,

PORTSMOUTH,

Dundee, Scot-

TURKU,

(L

& C)

/ Rh., Auf dem

Gmund/Togorn-

3~u'l:'.~r~k~es~:

Machinehandol

77

. O

SITTARD. (L

15 Baltic St.

B,

-lndu

RECIFE-Rua

Of!icu at

Ltd

.,

Bag Maki

C.

Waters,

City Road,

.53

Great

S.

A.

Smith

nas)-

Yliopis·

Linotte, Mgr.

Managing

ffice' at·

& C)

ate

(L)

Lilla Bran-

TOCKHOLM,

stura, S.A.,

(L)

(Cl

,tria o

xandre

CHILE,

SANTIAGO- Lowonstoin &

Santo Domingo 1140.

COLOMBIA,

53.

BUCARAMANGb,

#14

C~~~~-

CUBA,

IIIIa Yarn

BACOA,

:

Vilato, Edificio

DOMINICAN

2-4

IJUe

ng

ECUADOR,

Octubro 211-213. Branch

zar 659.

El

nia Vairo.

GUATEMA.LA,

I,

S.A.,

MEXICO,

S.A.

GUADALAJARA,

D.F.-D

Pino Suarez 99-a (Apart

S.l.P

NI~1~~G(~~·

P~~t~~:~~~NAMA-Agenciai

PEr8·

de

PUt_tg0

SUJ~~~t,\(~R~rARIB

URUGUAY,

Mercedes

VENEZUELA, CARACAS--H. Blohm, S.A., Dr. Paul

Chorro

BOGoTA-Macalzado,

(L)

Branches

-33/35. MEDElliN- Carrera 51, (

RICA,

HAVANA-(Textile & Bag Maki

& Supply

HAVANA-(Bag

Apartado

644, Havana .

z, S., Calle

GUAYAQUIL-Richard

SALVADOR, SAN

(L)

9a

Aven1da

MONTERREY,

de

C.V., Cuauhtomoc Norte

istribuidora Union E, pe

.-J.

de

LIMA-A

~~~.h.SfL~

80

MONTEVIDEO-Starer & Cia,. S.A., Uruguaya,

13

29

(L)

(L)

at

BARRANQUILLA-Callo 37

- Colle 34

SAN

JOSE-Champion

Co

., 5. A., Factoria 70. (L) G

Mart

inez y

REPUBLIC,

MANAGUA-ca•a

12.

CIUDAD

19

do Marzo #

SALVADOR-Vairo Hermanos, Colo-

GUATEMALA-Com~ania

Sur

#10-43. (L

JAL.-H;

lo1

Royos

. y F. Wiese, S.A., Esq.

JUAN-Abarca

O-Ki

(L)

NEAR

CYPRUS,

EGYPT,

IRAN

IRAQ

19

ISRAEL,

LEB~NON,

SYRIA,

TURKEY

Sol~

AUCKLAND-171 Albert S

CHRISTCHURCH-(Sub-agenl) Glendermid,

DUNEDIN-(Sub-agent) Glendermid,

WELLINGTON-Ford

LARNACA-choupourian Agenties, P.O.

194. (L)

CAIRO-A

kat.

(L)

. TE

6.55.

(L

, BAGHDAD-Sons of 0 .

(L & C)

11

65.

(L & C)

Hamdi

Dh

tributor-H. A.

r.eld St.

(L &

C)

. Kavaldjian,

HUAN-Sava

& C)

TEL

AVIV-L.

BEIRUT-Sonl of

(l

& C)

DAMAS--Eiias Aractingi & Fils, Sidi Amoud.

ISTANBUL-David ve

Bey

Gecidi 36, 38,

(l & C)

Trading Corp., Ave. Bozar(omehrl

Taube,

NEW

ZEALAND

Tuck & Co

t.

Bldg., Courtenay Place.

PACIFIC

HAWAII,

HAWA

PHILIPPINE IS

HONOLULU

Sales Co.,

Machines)

kin•, Kroll

Branch

Machine1.

Co.,

5-40

Kamani St.

II, HONOLULU-(B

H.

S.

Gray Co_.

LANDS,

& Co., Inc., 124 Myen

at CEBU

. (

Earn.shaw

L)

)

Tacoma & 2nd Sts., Part Ar

13-(Text

ag

MANILA-(Textlle Machines) At·

(Bag Closing

t Docks & Hono lulu Iron Work•

Stewart,

ltda

#17-45.

Co., Llda.,

Closing Machines) Miguol A.

V&lato,

TRUJillO-lui

2.5.

(L)

0. Cus

at

QUITO-Carrera

5.

N.l

ado

80. (

C)

. - Tallereo Perez

dolgo

45 y 47; MEXICO,

ci

al, S.

12770); S

L)

Hentgen,

Hagus, S.A. Ave.

r~alani'

•·

EAST

-4

Midan el Cheikh Bara-

0.

Agopian,

ltd

.,

1.5

0.

0.

Agopi

leon

-40,

Pos

ta

Kutusu

.,

ltd.

(L

&

C)

ltd

ISLANDS

ile Machines) Territorial

(L)

Closing a nd Bag Making

, 759 Puuloa

ea.

S.A.C., Calla

., Callo 13

CALi-Carrera

Bolivar) #41

ng

335.

Nunez

Warehouse

Lili

Yarber

., 18 Dowling St.

Bl

and

#39-51.

-180. (l )

Apartado

Machines) An·

UANA

Via Blanca Rd.,

s Domln-

ter,

S.A., 9

Bonalca·

Arga

-Comorclal,

Zozaya,

Branch

e-s

A.

do

C.

V., Avo.

AN

LUIS

POTOSI,

Ia

Ave. S.E.

7a

y Filipinos.

1

Corp.,

Lt

d., 17-

27

Maag

P.

0.

Box 121.

onblom St.

on,

P.O. Bax

ve

Serikl,

3B5.

(l & C)

(l)

ltd

., 78 lich-

(l

& C)

Rd.

dg., Port Area.

Bag Mak ing

#22-

7a

·

de

a h

Cen-

-

A.

Box

(L)

,

...

,

Additional Sales Agents for

AUSTRALIA,

Pty.,

AUSTRIA,

BELGIUM,

beek,

BRITISH

Lane, Croyden, S

Repair Shop: 15-17 City Road, London, E.C

LEEOs..-4

CHILE,

Tl59. (C)

CUBA,

ganes

DENMARK,

lndustrimaskine

EIRE,

Machine Co

ENGLAND-CROYDON

v:~:~nL~~~e!~

(L

ENGLAND,

Road, London,

FRANCE,

ley"'*·

FRANCE,

Fon

GERMANY,

~ehalt

of!iceo

GERMANY,

Strasse 104.

INDIA, DELHI-Munshi

Ka

MELBOURNE

ltd.,

«1

VIENNA- Franz Korpert,

BRUSSEL

57 A Blvd.

ISLES--Eastman Mach ine Co.,

Varn

SANTIAGO-Roberto

HAVANA-American Sewing Machine Co., Ora·

202. (C)

COPENHAGEN - Dimas, Dot lntornatlonale

DUBLIN-W. Blythman (Sub-Agent

.:,

)

LONDON-W

PARIS--Soti ote G. Arnon & Cio., 36

(L)

PARIS--Aspe ·Dumont & Cie.,

taine-Au-Ra;.

BIELEFELD-Durkoppwerko-Ma ochinen Ge•ell·

.m.b.h.

of

DUrkoppwerko).

KREFELD-

(C

shmere

Gate.

- Michaelis, Hallenstein & Ca.,

Lonodal

e Street. (C)

S--

N.

du

Jard

urr

ey

1

on

St., Manchoster·60-62 Corporat;on St.

A/

S,

Gronnegade

224 Parne

, S

URREY-Eastman

~·t~

~~~sr

. & J. Bogod & Co.,

E. C. 1 (C)

(C)

(L)

exce

pt

Herbert

tio machine s only)

Ram

(L)

Wahr

V.

Machinehandol C & H Ver·

in Botani

f ngland.

E.

ll

Street.

ingerstr. 141.

que,

Buy I Bu

Ltd

(L)-Showroom

Gottlieb & CIA, Catodral

10. (C)

(l)

E~~o-~2anc~~

button •

•wen (aha

Jan

sson, Alto Linner

B.St., Above Keventers,

., 89 Beddin!lfon

of

Moch

;

13

(L)

LEWIS

and (C)

ISRAEL, TEL

(C)

ITALY,

ildin

g.

and

.I, England.

The Easlman

;ne Com·

.~~ti~~E~~

Ltd

., 85 City

Rue

Debe!·

Rue

do lo

branch

MEXICO,

(L)

MOROCCO, CAS

NORTHERN,

NORWAY,

THE

~

PUERTO

6m,

SOUTHERN

NYASALAND,

sY1toe"N.n

ga

29, S

SWEDEN,

golan

SWITZERLAND,

stran e 27.

SWITZERLAND,

stra

UNION

Sew ing Math ine Comp

Street.

BA

UR

UGUAY,

torc

WALES,

Rood.

AVIV

Halovy St.

MILANO-Mario

MEXICO,

Co

•er, Aparr

Bn,curn

ama

Ltd., 6

IRELAND,

Linonhall Stree t (C)

O~LO-J

PHILIPPINES,

55-

~57

Junn Luna.

RICO,

Lo

ixa Stat

RHODESIA,

k

o~'i"~~

tan 28.

(L)

TOCKHOLM-Kungsgatan 18.

BORAS-Husqvarna

3~.

(C)

(L)

u e 15. (C)

OF SOUTH

Branches at: C

N- 16 Saville St. (C)

MONTEVI

omp ltda

CARDIFF-W & J Bogod & Ca ..

(C)

COLUMBIA

- Israel Sowing Machine Co., 22 Yehuda

(Cl

.), Convencl

Jeri, Via Morigi 13.

D.F.-ca

ado Postal 7259.

ABLANCA

{C)

Bellast-W.

.

A. Johans on A/S, Torvgatan 10.

MANILA-J.

(C)

SANTURCE-Humberto A. Collado,

ion (C)

FEDERATION

BULAWAYO-African Sewing Machine

~~~e

~:~~

Branches

at MALMQ-St

ZURICH-Fritz Zollweg

ZURIC

H 4-

AFRICA,

any

APE

DEO-Campania Recon

an

Machines

sa Diaz

(C)

- Durkopp Coudrox, 25 Rue

B.

Y.

~etlt~:

G. Gu

lndu

strisymaskiner, Kung

A.

Brun~e

JOHAN

(Pty.)

TOWN- 110 Plein St.; DUR-

1374. (C)

(C)

de

Maquinas

& J.

Bogod & Co

Tanlimco Son

OF

er

hwiler

NESBURG-

ltd., 85/87 PrUchard

•,

Inc.,

RHODESIA

sta

fson ,

Kun

ora

Kvorng a to n

& Ca., Selnau -

,

S

trauburg-

African

s S.A. (In·

ltd

., Newpor

Box

qs-

de

(l)

s-

.,

&

t

Page 16

,...o

..

~

...

0

WORLD'S

,_,lf

FINEST

QUALITY

*

SALES

ALLENTOWN, PA., P.O.

Swift

7-2111.

*ATLANTA, GA., 2120 Plasters Br

G. Booth, Mgr.

BALTIMORE

Sar.

BELLEVILLE

BIRMINGHAM,

Baldwin, Tel. Varnon 3·9904.

*BOSTON

Mgr.,

CANTON,

Canton 6-1412.

*CHICAGO

CINCINNATI, OHIO, P.O.

Tel.

CLEVELAND

COLUMBIA,

COMMERCE, GA., Lakeview Drive, J.

*DALLAS 19,

Zatk

DANBURY,

DECATUR,

Drake

DENVER

Carter, Tel. Spruto 7-7060.

DETROIT

University 3-4948.

DUBLIN, GA., 1615 Knox St., John W. Jones,

EL

GREENSBORO,

Tel. Broadway

GREENVILLE,

Tel.

(HAZ~LTON)

Vclgt, Tel. Sunset B-5556.

15, MO., P.O.

7-8499.

, N. J., 83 Floyd St

Plymouth 9-2006.

II,

Tol.

Liberty 2-0147.

MASS

Ullritk, Mgr., Tel. SUperi

Co.,

Crisler, Tel. Sunset 7-0863.

Federal 5·4061 .

Tel

2-4663.

Lynwood B-2928.

Stone,

10,

Chorry 1-5558.

3, OHIO, 6020 Eudld Avo., Sydney L. Hirsch

Tel. Express 1-8811 .

S. C., 2039 Winsor Hills Drive, Vlrlyn

TEXAS,

X.

Bennett, Mgr., Tel. Lakesi

CONN., B Merrimac St., Robert W. Gaines,

. Pioneor 8-9333.

GA.,

7-5559.

10, COLO.,

35, MICH., 16630

PASO,

TEXAS,

lei.

Broadway 5-4285.

S.

Cedar

9-5539.

CONYNGHAM, PA., P.O.

Box

542,

luther

D.

idge

Tol

. Trinity 5-9237.

Bo><

ALA

., 8630 First Ave. South , Lloyd

MASS

., 179 Lincoln St., Will iam E. Palm,

., York St

.,

ILL

., 400 N. Franklin St., Orville

or

Box

4200 Hlnos Blvd., P.O.

B02

Dorrydown

1801

Ward

P.O.

Box

N. C., P.O.

C., 25 Sir Abbot St., Orville W. Gregory,

Bo><

3-7648. 1330 Mayfair Ave., Fr

Road,

2505, Ralph B. Foster, Tel.

.,

Joseph Logllsd, Tel.

RFO,

Roy

T. Pederson, Tel.

7-6920.

n4,

Raymond E. Hinton,

Tom

de

6·8369.

Way,

Joe

V. Parker, Tel.

South Marlon St., Louis

Avo., John

5134, Edward E. Smith, Tel.

226, William

Bo><

Canol!,

N.E

., William

Hanley,

Box

F.

Tol.

D.

46,

Robert

OFFICES

Tel

.

D.

A.

R.

Tol.

6727,

E.

Lu><,

Tel.

Broad

Harrod,

ank

B.

OKLAHOMA

S.

INDUSTRIAL

UNITED

JACKSON 3, MISS., 327 Eastvi

Tel. Fleotwood 5·1976.

JOHNSON

KANSAS

KNOXVILLE

LEBANON, PA., P.O.

*LOS

LOUISVILLE

LYNCHBURG,

LYNDHURST,

MEMPHIS

MIAMI

MINNEAPOLIS, MINN., 2800 Texas Avo., Sr. Louis Park

MONTGOMERY

NASHUA,

NASHVILLE

NEW

*NEW

*PHILADELPHIA 24, PA., 4234 Mocaleotor Ave.,

CITY,

Swarlhmoro

Biggo

Clinard, Tel. B·1B65.

Crestview 2-6292.

Mason, Mgr.,

Rogers,

llictor 6-1215.

Wheelor, Tel. Wobster

Tel

Tel. Franklin 3-7363.

26, Minn.,

Hamlet, Te

Haberman Jr., Tel. Tuxedo 2-969B.

William J, Brauch,

Larry A. Van Hooser,

Ro

315

Mgr.,

315 W. 35th

Tel. Chickering 4-8800.

G.

Merr, Mgr.,

7-3994.

CITY

37, MO., 10904 Grandvi

,.

, Tel. South 1·5030.

19, TENN., 3905 Greenleaf Avo., Horace

ANGELES

1B, KY., 3122 McMahan Blvd., Bernard

Tel

. Glendale 4-4956.

VA., P.O. Box 1075, Clarence

N. J., 339 Harding Avo., Clarence A.

17,

TENN

. Mulual 5-6750.

37,

FLA.,

Leonard

l.

N. H.,

12, TENN., 1602 South Observatory Drive,

ORLEANS,

YORK

senquis

t, Mgr.,

W.

35th St., New York

Tel

. Chlckoring 4-8800. Lewis-Columbia Machines,

CITY

B.

Wiley, Tel. Mutual 5-2836.

Tel

SEWING

AND

MACHINES

REPR

ESENTATIVES

STATES

ew

St.,

Jamie

A.

Boyette,

N. Y.,

471

Main St., John J. Lafler, Tel.

ew Road,

Terrio 0 .

Box

274, David

15,

CALIF.,

Tel

. Richmond 7·91B7.

., 4695 Dunn Rd., Richard J. Lindhorst,

2650 N.W. 5th Ave., Hyman L. Simon,

7,

ALA.,

Amherst 5-0942.

21

LA.,

16, N. Y., 116 E. 27th St., Clarence L.

St., Now

19,

. G

119

9-4143.

W. Koehler, Tel. Mi

1959 Amelia Drive,

Alder Dr., Forest Pk., Horman

Tel

. Cypress 2-5123.

P.O.

Box

Tel