Page 1

®

INDUSTRIAL

SEWING

F

INEST QUALITY

S

TYLE

395

00A

C-

060

LEWIS

•

TY

SEWING SUPPLy

UNI 824

Lo

a ,Angeles,

COLUMBIA

E.

8th St.

CA

90021'.

MACHINES

CO.

CATALOG

No.

103AC

HIGH

CLASS

STREAMLINED

SPEED

39

500

OVERSEAMERS

MACHINE

C H'l C A G 0

f:J-

(_

COMPANY

Page 2

Catalog

(Supplement

INSTRUCTIONS

No.

to

Catalog

FOR

103

No.

AC

103

S)

The

furnish

ADJUSTING

LIST

parts

e d

at

CLASS

39500

l i

sted

list

A N D

O F

Style

AC-060

in

prices

OPERATING

PARTS

39500

this

for

catalog

repairs

are

only.

F i

R

Union

ights

Copyright

Special

R

eserved

rst

Edition

1961

by

Machine

in

All

MACHINE COMPANY

INDUSTRIAL

Printed

SEWING

CHICAGO

in

2

MACHINES

U.S.A.

Co.

Countries

February.

1967

J

Page 3

IDENTIFICATION

OF

MACHINE

the

Each

name

Union

plate.

Machines

no

letters.

standard

Style

as a suffix

construction.

This

catalog

Parts

illustrated

machines.

to

help

locate

Opposite

description,

Adjusting

39500

and

AC-060.

This

can

catalog

also

References

operator's

is

away

from

Special

similar

Example:

of a machine.

to

the

is a supplement

in

For

clarity,

39500

the

illustration

and

amount

and

operating

applies

be

applied

to

direction,

position

operator.

machine

in

construction

"39500".

standard

this

catalog

certain

AC-060

required.

specifically

with

such

while

is

identified

are

Letters

Example:

Style

identification

APPLICATION

to

Catalog

represent

39500

A,

parts.

page,

parts

instructions

to

the

discretion,

as

right,

seated

at

the

by a Style

grouped

suffixed

"39500

OF

No.

103

parts

B,

are

identified

included

standard

to

some

left,

front,

machine.

number

by a Class

to a Class

AC-060''.

to

specify

CATALOG

Sand

not

used

P

and

AF

by

represent

Styles

Special

back,

Operating

number,

should

in

parts

detail

only

of

machine

machines

etc.,

which

number

Letter''

machine

be

used

39500

are

shown

number,

areas

are

direction

is

stamped

which

indicates

Z"

is

reserved

is

of

"Special"

in

conjunction.

A,

B,

in

part

concerned

as

listed

of

Class

taken

from

of

handwheel

into

contains

the

P

or

AF

phantom

number,

with

herein

39500.

the

Two

Needle,

Machine.

Automatic

39500

AC-060

specification,

Stitch

capacity.

CAUTION!

filled

before

straight

should

be

Machine

gauge

on

lines.

Machine

main

reservoir

One

Differential

Lubricating

range

Oil

beginning

mineral

used.

is

filled

front

of

machine.

is

automatically

filled.

Looper,

For

Special

20

to

was

oil

of a Saybolt

with

STYLE

One

Spreader,

Feed,

Trimming

System, • 060

closing

men's,

SSa-1;

100

per

inch;

drained

to

operate.

oil

at

Red

from

spring

bulb

lubricated.

Check

oil

daily

OF

Mechanism

Inch

women's

standard

standard

OILING

machine

Oil

viscosity

cap

on

oil

before

MACHINE

Three

Needle

seam

setting

when

capacity

of

200

in

top

cover.

level

No

indicator

oiling

the

morning

Thread,

With

Spacing.

and

children's

width

45

shipped,

of

Class

to

250

is

necessary,

Low

Throw

Spring

Pressed

approximately

per

inch. 3/16

so

39500

seconds

Oil

level

should

start.

Add

half

reservoir

is

sia

at

100

is

checked

show

other

oil

Overseaming

Lower

hose.

Knife,

Seam

1/8 inch.

inch

sewing

must

ounce

s . A

Fahrenheit

at

between

than

as

gauge

keepin

required.

be

sight

g

Drain

magnetic

entered

plug

screw

the

screw

crank

is

located

designed

case.

at

to

accumulate

It

should

back

be

of

machine

possible

removed

3

foreign

and

near

cleaned

bottom edge

materials

periodically.

of

base.

which

It

is a

may have

Page 4

NEEDLES

Each

denotes

Union Spec

the

kind

number1 stamped

in

thousandths

size

number

packaged

39500

Type

154

represent

and

sold

AC-060

GDS.

length1 curved

needle

sample

on

should

needles

reputation

more

in

To

have

needle.

label.

Selection

pass

Success

packaged

than

size

029.

needle

A

complete

of

freely

in

the

for

producing

three-quarters

ial

needle

of

shank~

on

the

needle

of

an

inch~

the

by

Union

uses a curved

It

is a slabbed

blade.

double

orders

or

the

type

order

proper

needle

through

operation

under

has

point~

length~

shank~

midway

complete

symbol

Special.

blade

shank,

groove.

promptly

and

size

would

read:

size

needle

of

our

highest

eye

Union

brand

quality

Special

of a century.

both

type

groove~

denotes

between

needle.

round

struck

and

accurately

number

"1000

is

determined

in

order

name.

needles

and

size

finish

largest

shank

which

The

and

is

given

standard

point, • 060

groove~

should

be

Needles.

by

to

produce

machines

~-

in

materials

number.

and

other

diameter

eye.

Collectively~

on

the

needle

inch

filled,

double

spotted~

an

forwarded.

Type

size

of

a

good

can

be

secured

which

The

details.

of

blade1 measured

label

for

chromium

empty

Use

154

GDS,

thread

stitch

is

and

workmanship

type

of

all

this

slab,

package.

description

Size

used.

formation.

only

by

backed

number

The

size

type

and

needles

style

is

standard

plated

11

029

Thread

use

of

by

for

a

•

a

Release

(P,

Fig.

operating

socket

1/4

left,

in

turn.

To

this

wrench

replace

insert

position,

tighten

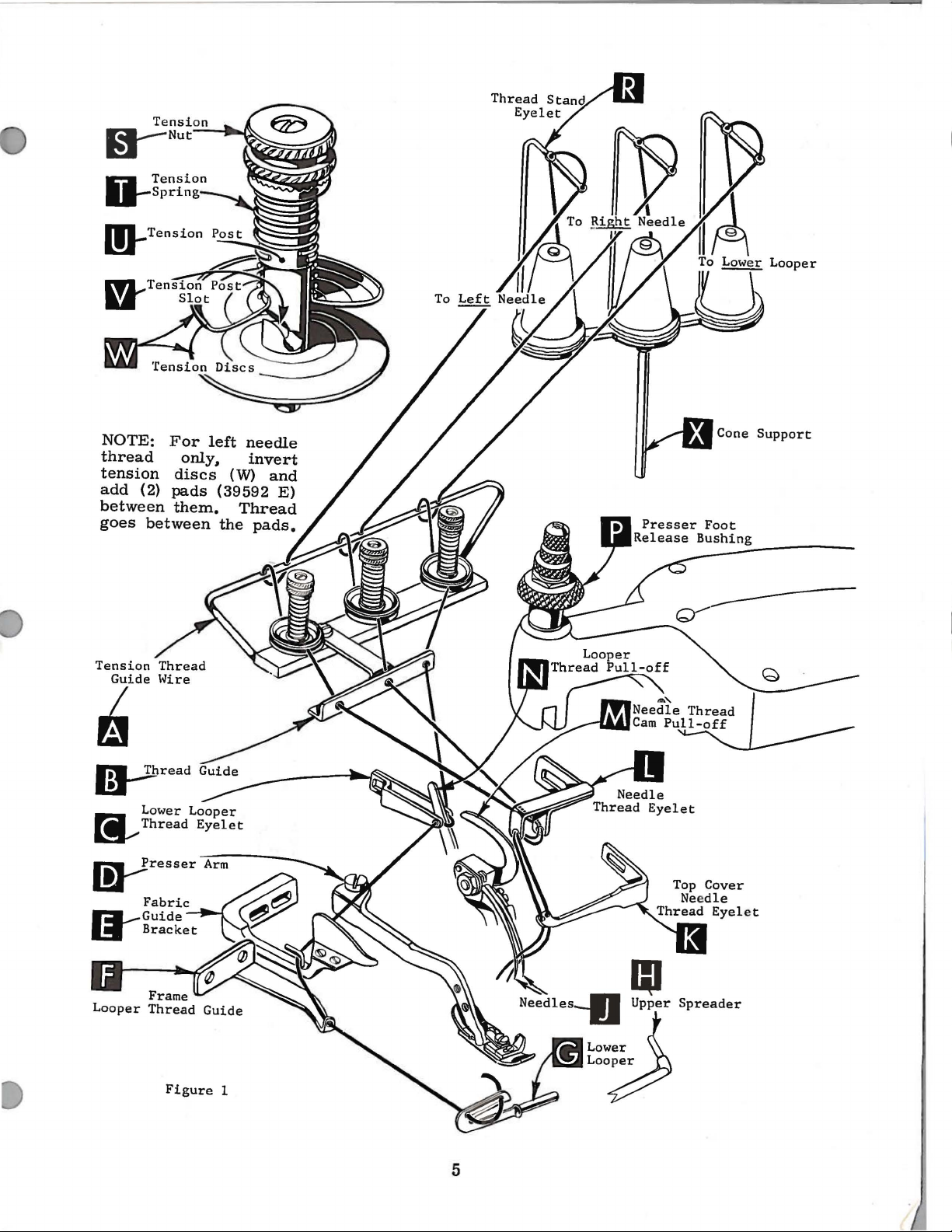

After

brought

(R.

Fig.

left

hand

tension

pressure

1).

and

swing

direction

No.

until

21388

Againturnhandwheel

needles,

nut.

thread

up

1).

hole

discs

needles

Return

through

Next,

ofthe

(W),

turn

comes

BACK

thread

tension

through

in

handwheel

presser

on

presser

presser

needles

AU,

leave

holder

from

thread

is

thread

slot

CHANGING

foot

arm

are

attheir

furnished

until

needles

needle

until

holder

they

until

arm

(D)

THREAD

thread

eyelet,

extended

guide

(V)

and

1

THREADING

by

(D)

with

rest

holder

to

position;

cones

down

wire

on

NEEDLES

turning

out

of

position.

lowest

machine.

are

athighposition.

at

high

against

is

again

re-lock

STAND

(positioned

then

down

through

(A).

Thread

through

presser

point

loosen

position

the

stop

at

its

on

through

the

right

thread

foot

Turn

oftravel.

needle

and,

pin.

low

point

presser

cone

FRONT

hand

is

then

guide

release

handwheel

Using

clamp

Withdraw

with

the

Keeping

of

travel,

foot

bushing

support

thread

hole

and

continued

(B).

bushing

in

hexagonal

nut

about

needles.

flats

to

needles

then

(P).

(X)),

it

eyelet

up

through

between

the

the

is

Only

are

The

complete

and

on

following

parts

presented

following

threading of

conclude

involved

in

their

by

complete

pages.

in

threading

relative

recommended

lower

looper~

threading

are

positions

procedure

progress

for

shown

for

left

in

threading

clarity.

simplifies

to

complete

needle.

4

diagram

threading:

threading

Steps

for

threading

(Fig.

1).

Beginning

of

right

are

Parts

with

needle~

given

Page 5

NOTE:

thread

tension

add

between

goes

Tension

Guide

For

only,

discs

(2)

pads

them.

between

~

~read

left

(W)

(39592

Thread

the

needle

invert

and

E)

pads.

Lower

~Thread

~resser

~Guide

1!1

Bracket

Fabric

Figure

Looper

Eyelet

Needles-IJ

1

I

5

IU

Upper

Low~r

La~

Spreader

{

Page 6

THREADING

(Continued)

Priortothreading.

to

bring

counterclockwise

out

of

CAUTION!

wire

tension

Double

(C)

from

Lead

guide

the

way

lower

Turn

position.

thread

cover

right

thread

needles

position.

(A,

Fig.

posts

right

thread

(F).

to

looper

handwheel

Insert

eyelet

needle

hole

eyelet.

(

end

through

Turnhandwheelin

the

can

(L).

thread

and

(J)

turn

Make

1).

are

U).

of

thread

to

left.

left;

be

both

under

the

Thread

swing

into

of

sure

between

and

Note:

eyelet

then,

threaded

in

operating

needle

neck

eyelet

left

needle

needles

cloth

high

the

the

TO

THREAD

lead

thread

on

top

operating

thread

easily

TO

threads

of

(K).

plate

position.

release

threads,

tension

it

through

of

fabric

through

THREAD

direction

from

top

cover

The

thread

from

open,

bushing

as

discs

LOWER

must

direction

if

tweezers

right

through

the

front.

turn

Release

(P).

they

pass

guard

both

right

casting

extend

(W)

both

in

eyes

NEEDLES

until

to

needle

handwheel

pressure

and

and

LOOPER

eyes

front

(E)

and

untilheel

from

are

in

needles

left,

and

then

thread

the

left

then

from

of

of

through

the

in

diagonal

lower

looper

through

oflower

left

left

hand.

(J)

down

should

hole

in

operating

on

swing

tension

looper

thread

eye

to

right.

are

BOTH

through

of

the

presser

presser

slots

thread

of

frame

looper

at

their

eyes

be

threaded

top

direction

foot

arm

thread

(V)

pull-off

(G)

Right

of

holes

cover

by

(D)

guide

of

the

eyelet

(N).

thread

is

all

eye

of

highest

needle

in

top

in

the

needle

a

The

amount

knurled

secure

should

increase

foot.

screw

tightening

the

been

presser

nut

inch

screw

On

approximately

that

differential

indicate

Unless

39

540-60

tension

proper

Sufficient

be

or

loosen

(B).

will

pressure.

properly

foot

(C)

sothatits

to

1/16

(B).

the

the

part

approximately

otherwise

main

maintained.

of

nuts

stitch

PRESSER

pressure

decrease

lock

Adjusting

inch

39500

feed

nut

increase

When

set.

resting

under

from

Set

cap

AC-060

35

stitches

number

eccentric

specified,

feed

tension

(S,

Fig.

formation.

FOOT

to

Should

amount

(A,

Fig.

screw

pressure,

pressure

tighten

on

throat

surface

the

top

(D)

of

the

the

eccentric

THREAD

on

the

1).

PRESSURE

feed

against

machine,

per

main

is

number

the

it

of

pressure

2).

has a right

loosening

adjusting

the

lock

plate.

is

surface

FEED

inch.

No.

the

39500

and

TENSION

needle

Tension

be

and

approximately

locking

feed

39540-30 • Minor

of

39

540-30

and

looper

on

threads

work

nut

position

of

ECCENTRICS

eccentrics

It

stitches

uniformly

necessary

on

presser

turn

eccentric

adjusting

hand

decreases

screw

(A).

the

adjusting

nut

will

be

AC-060

differential

obtainable

thread;

(B)

With

locking

1/32

(C).

noted

is

machine

to

has

have

on

No. 39

threads

should

~

~

f\J

been

the

39500

540-60 • while

numbers

when

will

feed

eccentric.

is

regulated

be

only

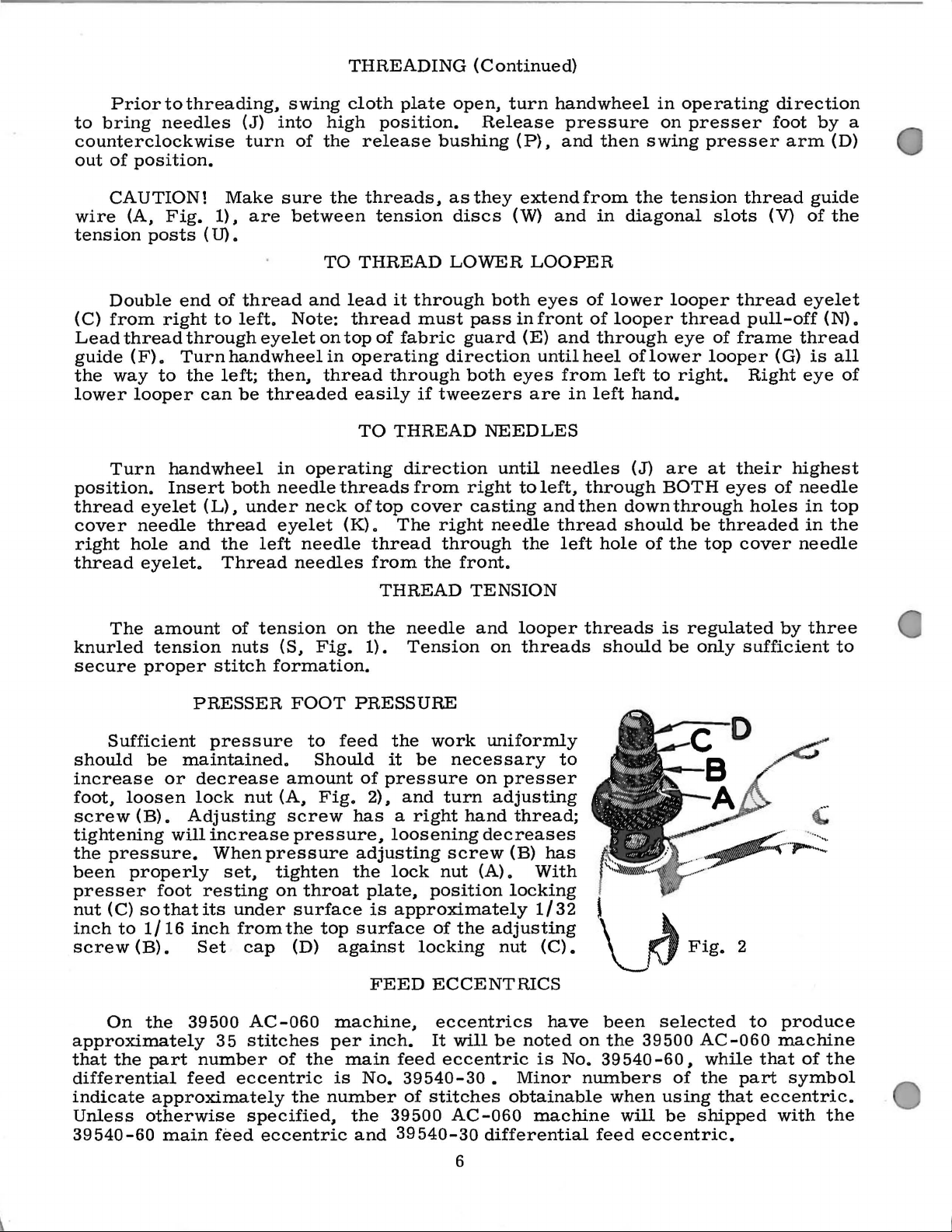

Fig.

selected

AC-060

of

the

using

be

that

shipped

by

sufficient

2

to

produce

machine

that

of

part

symbol

eccentric.

with

three

to

the

the

6

Page 7

FEED

ECCENTRICS

(Continued)

Generally

of

stitches

and

direction

Following

7.

a.

9,

60,

70,

eccentrics

number

Fig.

Atthis

lower

from

not

looper

center

have

produced.

10.

11.

100.

may

suffixed

3

point,

at

ofleft

lower

speaking,

of

stretch

stitch

12.

number

13.

Only

be

ordered

to

insert

the

left

needle,

looper

differential

Main

of

14,

two

eccentrics

indicate

Before

guard,

Then.

With

front

end

needle

lower

end

of

deflecting

(right

(left

hand)

material

feed

15.

being

eccentrics

16.

18.

are

separately.

number

ASSEMBLING

assembling

chip

guard.

follow

points

its

using

this

throat

of

needle

should

looper

stroke.

looper

plate

(A,

the

hand)

feed

eccentric

sewn.

are

20.

22.

supplied

To

of

stitches

AND

sewingparts.

upper

knife

suggested

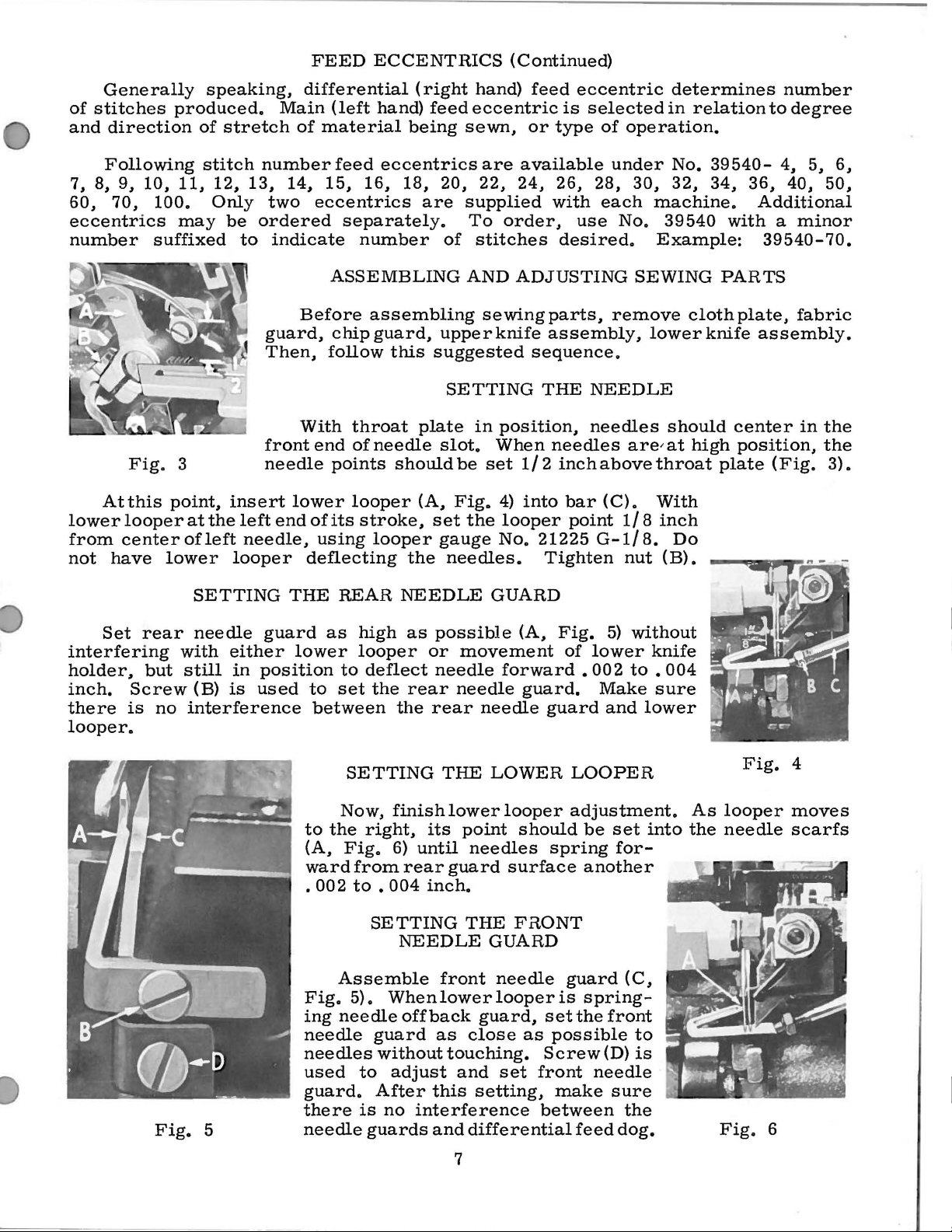

SETTING

in

position.

slot.

set

gauge

be

Fig.

the

When

set

4)

No.

needles.

feed

eccentric

is

selected

or

type

available

24.

26.

with

order.

use

desired.

ADJUSTING

assembly.

sequence.

THE

needles

needles

1/2

inchabovethroat

into

bar

looper

point

21225

Tighten

of

operation.

under

2a.

3o.

each

machine.

No.

Example:

SEWING

remove

lower

NEEDLE

are/ at

(C).

With

1/8

G-1/8.

nut

determines

in

relation

No.

39540-

32. 34.

39540

with a minor

PARTS

clothplate.

knife

should

high

plate

inch

Do

(B).

number

to

degree

4,

36,

4o.

Additional

39540-70.

assembly.

center

position.

(Fig.

5,

6,

5o.

fabric

in

the

the

3).

Set

rear

interfering

holder.

inch.

there

but

Screw

is

looper.

SETTING

needle

with

still

(B)

no

interference

Fig.

5

guard

either

in

position

is

used

THE

as

lower

to

between

to

(A.

ward

.

002

Fig.

ing

needle

needles

used

guard.

there

needle

REAR

high

looper

to

deflect

set

the

SETTING

Now,

the

finish

right.

Fig.

from

to • 004

SETTING

Assemble

5).

When

needle

guard

without

to

adjust

After

is

no

guards

NEEDLE

as

possible

or

movement

needle

rear

the

needle

rear

THE

lower

its

point

6)

until

rear

guard

inch.

NEEDLE

front

lower

off

back

as

touching.

and

this

interference

and

GUARD

(A.

forward

guard.

needle

guard

LOWER

looper

should

needles

surface

THE

FRONT

GUARD

needle

looper

guard,

close

set

as

Screw

set

front

setting.

between

differential

Fig.

of

5)

lower

• 00 2

Make

and

LOOPER

adjustment.

be

set

spring

for-

another

guard

is

spring-

the

front

possible

(D)

needle

make

sure

feed

without

knife

to • 004

sure

lower

into

(C,

to

is

the

dog.

As

the

Fig.

looper

needle

Fig.

4

moves

scarfs

6

7

Page 8

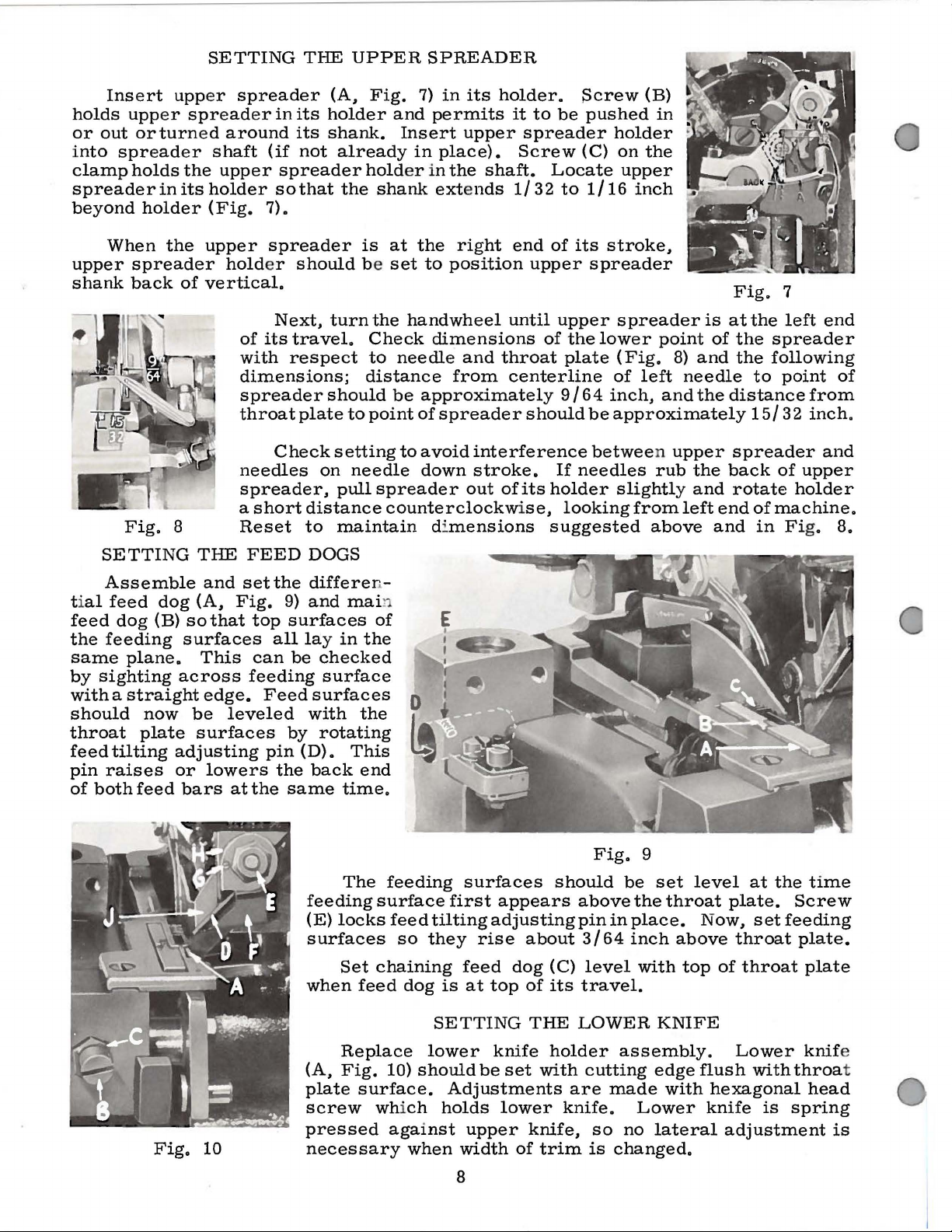

SETTING

THE

UPPER

SPREADER

Insert

holds

or

out

i

nto

clamp

spread

upp

orturn

holds

upp

er

er

er

spread

ed

shaft

the

upper

spreaderinitsholder

beyond

upper

shank

holder

When

spreader

back

Fig.

the

of

8

(Fig.

upper

vertical.

spreader

er

in

its

around

(if

its

not

spreader

sothat

7).

spreader

hold

er

should

Next,

of

its

travel.

with

respect

dimensions;

spreader

throat

plate

Check

needles

spreader,

a

short

Reset

(A,

holder

shank.

already

the

is

be

turn

should

to

setting

on

needle

pull

distance

to

maintain

Fig.

hold

the

Check

to

distance

point

7)

and

permits

Insert

in

er in

shank

at

set

extends

the

to

handwheel

dimensions

needle

be

approximately

of

to

avoid

down

spreader

in

its

upper

place).

the

shaft.

right

position

and

from

spreader

interference

stroke.

out

holder.

counterclockwise,

di

mensions

it

to

be

spreader

Screw

Locate

1/32

end

to

of

upper

until

upper

of

throat

plate

centerline

9/64

should

If

of

its

holder

looking

suggested

Screw

pushed

(B)

in

holder

(C)

on

the

upper

1/16

its

inch

stroke,

spreader

spreader

the

lower

point

(Fig.

of

left

inch,

be

approximately

and

between upper

needles

rub

slightly

from

above

is

8)

and

needle

the

the

and

left

Fig.

at

the

of

the

the

distance

15/32

spreader

back

rotate

end

and

7

left

spreader

following

to

point

of

upper

holder

of

machine.

in Fig.

end

of

from

inch.

and

8.

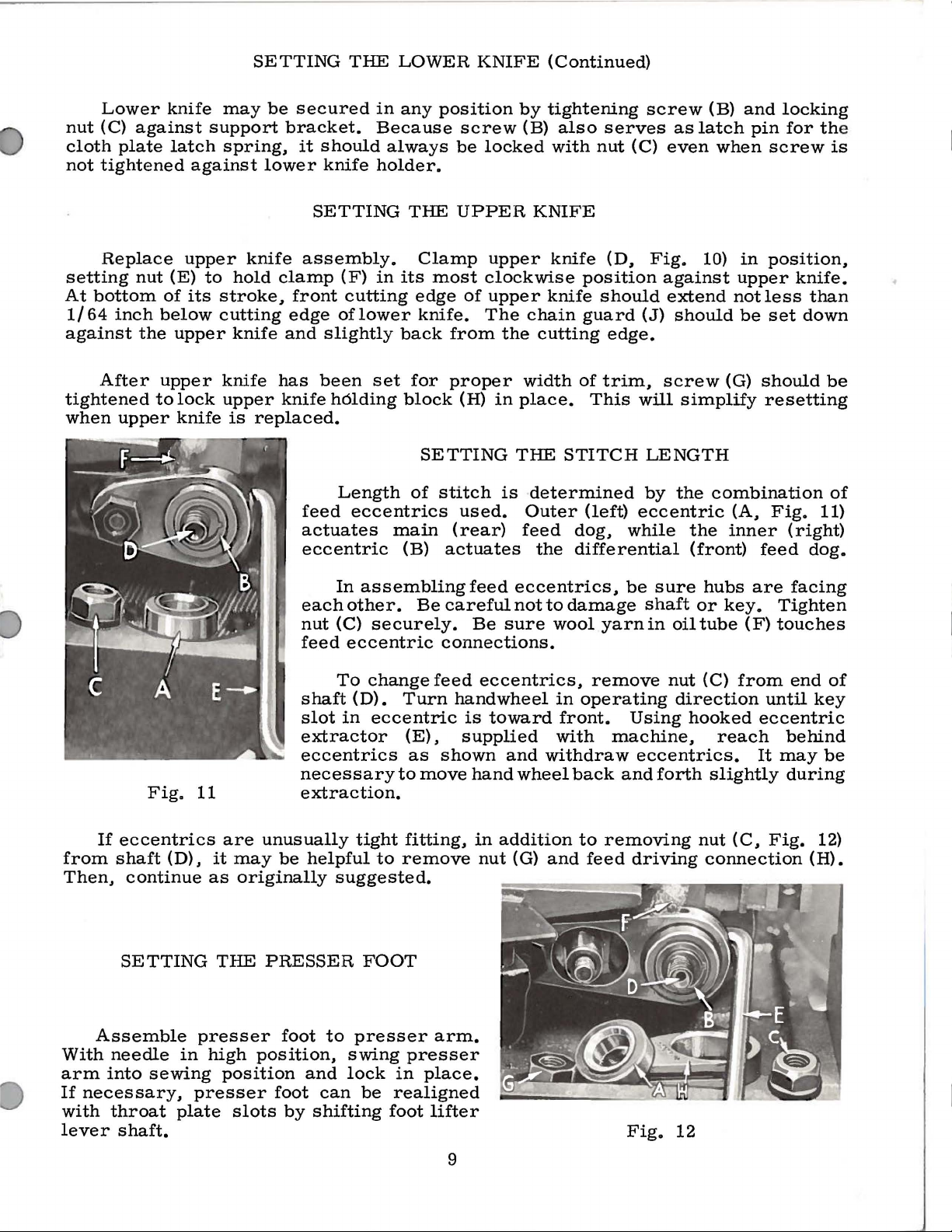

SETTING

Assemble

ti

al

feed

the

same

by

sighting

feed

feeding

dog

plane.

dog

(B)

across

with a straight

should

throat

feed

pin

of

both

now

plate

tilting

raises

feed

adjusting

or

THE

and

(A,

Fig.

so

that

surfaces

This

edge.

be

leveled

surfaces

lowers

bars

at

FEED

set

the

9)

top

surfaces

all

can

feeding

Feed

by

pin

the

the

same

DOGS

differe

and

lay

be

checked

surface

surfaces

with

rotating

(D).

back

feeding

(E)

surfaces

when

ma

in

the

the

This

end

time.

The

locks

Set

feed

n-

in

of

feeding

surface

feed

so

they

chaining

dog

surfaces

first

tilting

feed

is

at

appears

adjusting

rise

about

dog

top

of

should

above

pin

3/64

(C)

level

its

travel.

Fig.

in

9

be

set

the

place.

inch

with

level

throat

Now,

above

top

plate.

throat

of

throat

at

set

the

time

Screw

feeding

plate.

plate

Fig.

10

Replace

(A,

Fig.

plate

screw

surface.

which

pressed

necessary

SETTING

lower

10)

should

against

when

be

Adjustments

holds

upper

width

8

knife

set

lower

of

THE

holder

with

knife.

knife,

trim

LOWER

assembly.

cutting

are

made

so

no

is

changed.

KNIFE

edge

with

Lower

lateral

Lower

flush

with

hexagonal

knife

adjustment

is

knif

throa

head

spring

is

e

t

Page 9

SETTING

THE

LOWER

KNIFE

(Continued)

Lower

nut

(C)

cloth

not

plate

tightened

Replace

setting

At

bottom

1/64

inch

against

After

tightened

when

upper

knife

against

latch

upper

nut

(E)

of

below

the

upper

upper

to

lock

knife

may

support

spring,

against

to

hold

its

stroke,

cutting

knife

knife

upper

is

be

secured

bracket.

it

lower

knife

assembly.

clamp

front

edge

and

has

knife

replaced.

feed

actuates

eccentric

in

Because

should

knife

always

holder.

SETTING

(F)

in

cutting

oflower

slightly

been

set

h6lding

Length

eccentrics

any

position

THE

Clamp

its

most

edge

knife.

back

for

block

SETTING

of

stitch

main

(B)

screw

be

locked

UPPER

upper

clockwise

of

upper

The

from

the

proper

(H)

in

is

used.

(rear)

actuates

by

tightening

(B)

also

with

KNIFE

knife

position

knife

chain

guard

cutting

width

of

place.

THE

STITCH

determined

Outer

feed

the

(left)

dog,

differential

serves

nut

(D,

should

edge.

trim,

This

screw

as

(C)

even

Fig.

against

extend

(J)

should

screw

will

simplify

LENGTH

by

the

eccentric

while

(B)

and

latch

pin

when

10)

in

upper

notless

be

(G)

combination

(A,

the

inner

(front)

feed

locking

for the

screw

position,

knife.

than

set

down

should

resetting

Fig.

11)

(right)

dog.

is

be

of

If

from

shaft

Then,

Assemble

With

arm

If

with

needle

into

necessary,

throat

lever

Fig.

eccentrics

(D),

continue

SETTING

in

sewing

plate

shaft.

11

are

it

may

as

originally

THE

presser

high

position

presser

slots

each

nut

feed

shaft

slot

extractor

eccentrics

necessary

extraction.

unusually

be

helpful

PRESSER

foot

to

position,

and

foot

can

by

shifting

In

assembling

other.

(C)

securely.

eccentric

To

change

(D).

in

Turn

eccentric

(E),

as

to

tight

fitting,

to

remove

suggested.

FOOT

presser

swing

lock

in

be

realigned

presser

foot

feed

Be

careful

Be

connections.

feed

eccentrics,

hand

is

supplied

shown

move

hand

in

nut

arm.

place.

lifter

eccentrics,

not

sure

wheel

toward

and

wheel

addition

(G)

to

damage

wool

yarn

remove

in

operating

front.

with

machine,

withdraw

back

to

removing

and

feed

be

sure

shaft

in

oil

nut

direction

Using

eccentrics.

and

forth

driving

Fig.

12

hubs

or

tube

(C)

are

key.

(F)

from

hooked

reach

slightly

nut

(C,

connection

facing

Tighten

touches

end

until

key

eccentric

behind

It

may

during

Fig.

12)

(H).

of

be

9

Page 10

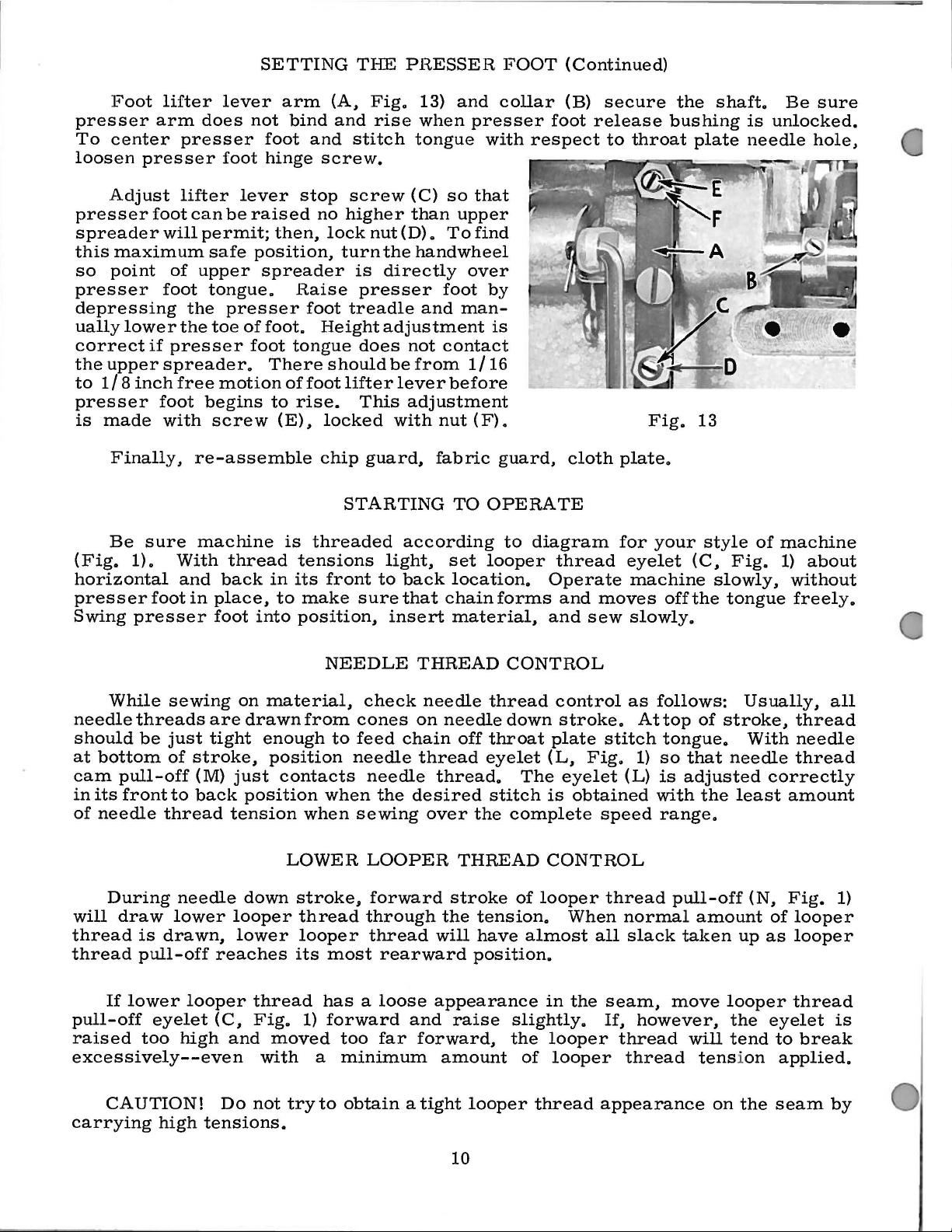

SETTING

THE

PHESSER

FOOT

(Continued)

Foot

presser

To

center

loosen

presser

spreader

this

so

presser

depressing

ually

correct

the

to

presser

is

(Fig.

horizontal

presser

Swing

presser

Adjust

maximum

point

lower

if

upper

1/8

inch

made

Finally,

Be

sure

1).

presser

lifter

arm

foot

foot

does

presser

lifter

can

will

permit;

of

upper

foot

the

the

presser

spreader.

free

foot

begins

with

re-assemble

machine

With

and

in

lever

not

foot

lever

be

raised

safe

position,

spreader

tongue.

presser

toe

of

foot

motion

screw

thread

back

place,

foot

into

arm

bind

foot

hinge

stop

then,

H.aise

foot.

tongue

There

of

to

rise.

(E).

is

tensions

in

its

to

make

position,

(A.

and

and

stitch

screw.

screw

no

higher

lock

turn

is

presser

foot

treadle

Height

does

should

foot

lifter

This

locked

chip

STARTING

threaded

front

sure

Fig.

nut

guard,

13)

rise

when

tongue

(C)

than

(D).

the

hand

directly

and

adjustment

not

be

from

lever

adjustment

with

according

light,

to

back

that

insert

and

presser

with

so

that

upper

To

find

wheel

over

foot

man-

contact

1/16

before

nut

(F).

fabric

TO

set

looper

location.

chain

material,

collar

by

is

guard,

OPERATE

to

forms

(B)

foot

respect

cloth

diagram

thread

Operate

and

and

secure

release

to

plate.

for

eyelet

moves

sew

the

bushing

throat

Fig.

your

machine

offthe

slowly.

shaft.

plate

13

style

(C,

slowly,

is

unlocked.

needle

of

Fig.

tongue

Be

sure

hole,

machine

1)

about

without

freely.

While

needle

should

at

bottom

cam

pull-off

in

its

frontto

of

needle

During

will

draw

thread

thread

If

pull-off

raised

excessively--even

CAUTION!

carrying

sewing

threads

be

just

of

thread

lower

is

drawn,

pull-off

lower

eyelet

too

high

stroke,

(M)

back

needle

looper

high

tensions.

on

are

drawn

tight

just

position

tension

down

looper

lower

reaches

thread

(C,

Fig.

and

Do

not

material,

from

enough

position

contacts

when

LOWER

stroke,

thread

looper

its

1)

moved

with

try

a

to

NEEDLE

check

cones

to

feed

chain

needle

needle

when

most

has a loose

forward

the

desired

sewing

LOOPER

forward

through

thread

rearward

and

too

far

minimum

obtain a tight

THREAD

needle

on

needle

off

thread

thread.

over

will

appearance

forward,

eyelet

the

THREAD

stroke

the

tension.

have

position.

raise

amount

looper

CONTROL

thread

down

throat

stitch

control

plate

(L,

The

is

complete

CONTROL

of

looper

almost

in

slightly.

the

looper

of

looper

thread

stroke.

stitch

Fig.

eyelet

obtained

speed

thread

When

all

the

seam,

If,

appearance

as

follows:

Attop

tongue.

1)

so

(L)

is

with

range.

normal

slack

however,

thread

thread

of

stroke,

that

adjusted

the

pull-off

amount

taken

move

will

tension

on

Usually,

With

needle

correctly

least

(N,

of

up

as

looper

the

eyelet

tend

the

all

thread

needle

thread

amount

Fig.

looper

looper

thread

to

break

applied.

seam

by

1)

is

10

Page 11

If

butted

seam

the

purl

appearance.

results

when

POSITIONING

is

at

the

top

If,

however,

opened.

THE

edge

PURL

of

the

the

TO

garment.

purl

is

OBTAIN A FLAT

the

under

seam

the

can

edge. a less

SEAM

be

opened

into a near

flat

and

tighter

Raising

less

thread

and

causes

brought

thread

flexible

purl

as

The

being

sewn.

without

low

enough

and

to

be

the

too

far

breakage.

chain,

desired.

needle

thread

In

causing

to

prevent

bringing

pulled

purl

forward,

to

the

from

form

however,

looper

more

With a reasonable

the

looper

THREAD

thread

TENSIONS

tension

general.

the

lower

needle

threads

looper

thread

the

cones

on

the

pull-off

required

looper

to

thread

pull-off

as

the

the

top

of

thread

amount

eyelet

WITH

RESPECT

is a function

thread

be

tension

pulled

breakage.

eyelet

looper

the

edge.

becomes

of

looper

should

of

should

too

far

(C.

travels

If

too

thread

be

TO

needle

be

over

Fig.

to

the

the

eyelet

tight.

resulting

tension

adjusted

STITCH

thread

set

as

the

top

1)

forward

top

and

high

of

of

is

to

to

position

the

as

the

causes

its

stroke

raised

in

looper

insure

material

possible

seam

and

a

the

and

11

Page 12

12

Page 13

The

parts

parts

used

illustrated

on

Style

on

the

39500

preceding

AC-060,

page

but

not

and

used

described

on

Styles

on

this

39500

page

A,

represent

B,

P,

or

the

AF.

Parts

39500

Use

Ref.

No.

-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

**-

*-

*-

shown

A,

B,

Catalog

39552

22596

154

39551

51292

51292

39592

39592

39556

39520

39530

22738

39530

22768

39597

22738

39530

39568

39505

39526

39505

39525

39525

39528

39508

39560

39578

39563

39522

39540

39540

39568

in

phantom

P,

No.

Part

No.

H

E

50-774

GDS

F

F-1

F-2

E

E

J

AC

R

G

B

AB

p

B

E

AC

AC

93 A

H

J

AC

B

A

BB

X

cc

B-30

B-60

R

and

AF

103 S for

Blk.

views,

and

bearing

39500

all

parts

Needle

Screw-----------------------------------Stop

Needle

Needle

Needle

Looper

Pad,

Pad,

inverted

PresserArm--------------------------------Presser

Chain

Screw -Chain

Hinge

Screw -Tongue

Presser

Screw -Chip

Presser

Looper

Chaining

Differential

Main

Screw -Main

Needle

Needle

Throat

Lower

Upper

Chip

Top

Crankshaft

Differential

Main

Frame

Guard-----------------------------------

Cover

no

reference

AC-060.

not

illustrated

Description

Driving

Pin----------------------------------

(size

Clamp

Thread

Thread

for

39592

for

left

tension

Foot---------------------------------

Thread

Feed

Feed

Guard,

Guard,

Plate,

Looper--------------------------------

Spreader-------------------------------

Feed

Looper

Arm,

029)-----------------------------Stud

Tension

Tension

F------------------------------

needle

Shield------------------------------

Spring

Foot

Foot

Eyele~-------------------------

Dog

Feed

Dog,

Needle

----------------------------------Feed

Driving

Dog--------------------------

marked

Feed

front--------------------------rear

marked

Driving

Thread

numbers,

or

marked

----------------------------

thread

discs------------------------

Shield

----------------------------and

Stitch

Guard

Chip

----------------------------

Dog------------------------

--------------------------"AY"

Thread

Eccentric-------------------

Guide

are

common

described

"A"---------------

Spring------------------

Spring------------------

only,

----------------------

Spring----------------Tongue,

-----------------------

Guard

"AM"------------------

------------------

--------------------

Eyelet----------------

Eccentric-------------

-------------------

here.

between

marked

to

"EK"---

Styles

Amt.

Req.

1

1

1

2

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

*

Not

shown

on

picture

plate,

but

used

on

13

this

machine.

Page 14

26

24

25

14

Page 15

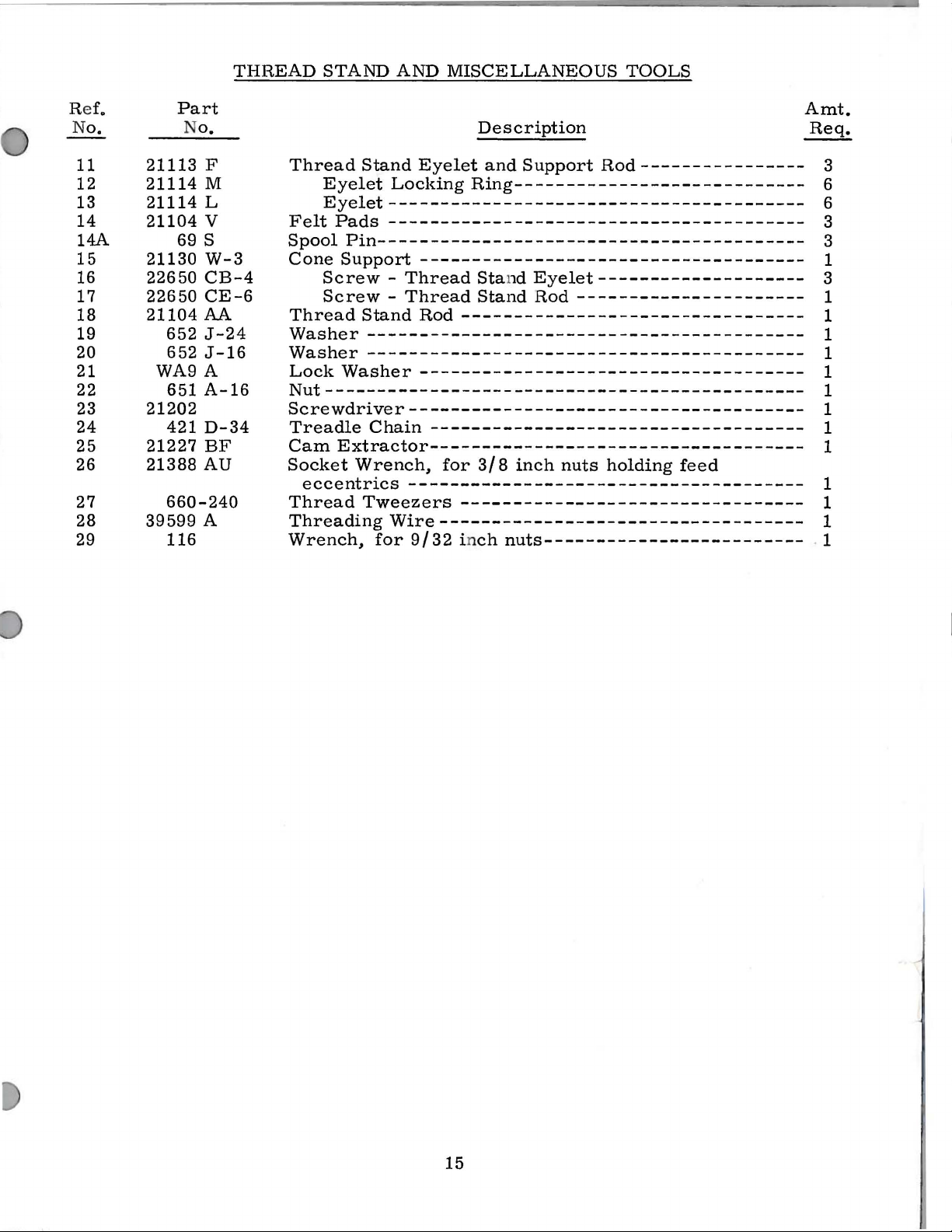

THREAD

STAND

AND

MISCELLANEOUS

TOOLS

Ref.

N

o.

11

12

13

14

14A

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Part

N

21113

21114

21114

21104

69 s

21130

22650

22650

21104

652 J -24

652

WA9A

651

21202

421

21227

21388

660-240

39599

116

o.

F

M

L

v

W-3

CB-4

CE-6

AA

J-16

A-16

D-34

BF

AU

A

Description

Thread

Fell

Spool

Cone

Thread

Washer

Washer

Lock

Nut---------------------------------------------Screwdriver--------------------------------------

Treadle

Cam

Socket

eccentrics

Thread

Threading

Wrench,

Stand

Eyelet

Eyelet----------------------------------------

Pads

Pin-----------------------------------------

Support

Screw -Thread

Screw-

Stand

------------------------------------------

------------------------------------------

Washer-------------------------------------

Chain

Extractor------------------------------------

Wrench,

Tweezers

Eyelet

Locking

----------------------------------------

-------------------------------------

Thread

Rod---------------------------------

------------------------------------

--------------------------------------

Wire-----------------------------------

for

9/32 inch

and

Support

Ring----------------------------

Sta

nd

Eyelet--------------------

Stand

for

3/8

---------------------------------

Rod----------------------

inch

nuts-------------------------

Rod----------------

nuts

holding

Amt.

Req.

3

6

6

3

3

1

3

1

1

1

1

1

1

1

1

1

feed

1

1

1

. 1

15

Page 16

.-o

..

..

'

<I

WORLD'S

,_,lf

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains sales

and

facilities throughout the world. These offices

aid

you

in

the selection of the right sewing

equipment for your particular operation. Union

and

Special representatives

tory trained

promptly

tion, there

and

is

serve you. Check with

ATLANTA,

BOSTON, MASS.

CHICAGO,

DALLAS,

LOS

NEW YORK, N.

PHILADELPHIA,

GA.

ILL.

TEXAS

ANGELES,

CAL.

PA.

and

are

efficiently. Whatever your loca-

a Union Special Representative

Y.

service men

able

to serve your needs

him

today.

MONTREAL,

BRUSSELS,

LEICESTER,

LONDON,

PARIS,

STUTTGART,

FRANCE

service

will

are

fac-

to

QUEBEC

BELGIUM

ENGLAND

ENGLAND

GERMANY

.

Representatives

Industrial

MACHINE

4 0 0 N • F R A N K L I N S-f'. I c H I c A G 0 I I L L • 6 0 6 1 0

and

cities

distributors

throughout

COMPANY

in

the

all

Important

world.

Loading...

Loading...