Union Special 39500AB, 39500AC, 39500AE User Manual

•

•

®

STYLES

39500AB

39500AC

39500A

INDUSTRIAL

MACHINES

CLASS

CATALOG

No.

103AB

HIGH

STREAMLINED

SPEED

CHICAGO

39500

OVERSEAMERS

Catalog

(Supplement

INSTRUCTIONS

No.

to

Catalog

FOR

103

No.

AB

103 S)

ADJUSTING

39

500

The

furnished

AB

parts

at

LIST

CLASS

listed

list

First

AND

OF

Styles

39500

prices

OPERATING

PARTS

39500

AC

in

this

Edition

for

39500

catalog

repairs

AE

are

only.

Union

Rights

Copyright

by

Special

Reserved

1960

Machine

in

All

Countries

MACHINE COMPANY

INDUSTRIAL

Printed

SEWING

CHICAGO

in

MACHINES

U.S.A.

Co.

IDENTIFICATION

OF MACJITNE

Each

into

the

Union

name

Machines

contains

i

ndicatesthe

is

reserved

is

of

This

no

letters.

as a suffix

"Special"

catalog

standardStyleof

conjunction.

39500

parts

number,

A,

B,

are

Opposite

description,

P

shown

the

Adjusting

concerned

This

herein

Class

with

catalog

and

39500.

can

aretakenfromthe

direction

of

handwheel

Special

plat

similar

machine

e.

in

Example:

to

construction.

APPLICATION

is a supplement

Parts

or

illustrated

AF

machines.

in

phantom

illustration

and

and

operating

39500

applies

also

AB,

specifically

be

applied

References

operator'sposition

is

is

identified

construction

the

11

39 500

a

machine.

standard

to

in

this

For

to

help

page,

amount

parts

required.

instructions

AC

and

AE.

with

to

direction,

away

from

by a Style

are

grouped

11

•

Letters

Example:

Style

OF

CATALOG

Catalog

catalog

clarity,

locate

are

to

the

standard

discretion,

such

while

seated

operator.

number

by a Class

suffixed

"39500

identification

No.

103 S

represent

certain

39500

AB,

identified

included

Styles

to

some

as

right,

at

left,

the

which

to a Class

AB".

to

specify

and

should

parts

39500

A,

AC

by

detail

represent

of

machine

Special

front,

machine.

is

number,

I:..etter

be

not

B,

P

and

AE

number,

only

machines

back,

Operating

stamped

which

number

"Z"

machine

used

used

and

AF

parts.

part

areas

as

listed

etc.,

in

in

of

Two

Needle,

seaming

Pressed

39500

AB

Special

range

39500

AC

standard

inch;

39500

AE

Attachment.

approximately

70

per

CAUTION!

be

filled

A

straight

before

Fahrenheit

One

Machine.

Lower

For

closing

SSa-1;

20

to

For

seam

standard

For

closing

inch.

beginning

mineral

should

Looper,

Differential

Knife,

standard

100

per

closing

width

setting

Seam

3/32

Oil

was

oil

be

STYLES

One

Automatic

women's

seam

inch;

standard

men's

approximately

35

per

women's

specification,

inch.

Stitch

drained

to

operate.

of a Saybolt

used.

OF

Spreader,

Feed,

Lubricating

seamless

width

hosiery.

inch.

seamless

range

OILING

from

machine

Oil

viscosity

MACJITNES

Three

Trimming

System.

nylon

is

approximately

setting

80

Seam

1/8

inch.

hosiery.

Special

20

SSa-1;

to

when

capacity

Thread,

Mechanism

hosiery.

per

Seam

inch.

specification,

Stitch

range

Prepared

standard

100

per

inch;

shipped,

of

of

Class

200

to

39500

250

Low

Throw

with

specification,

3/32

inch.

Special

20

for

seam

standard

so

reservoir

is

seconds

Over-

Spring

Stitch

SSa-1;

to

100

per

Paramount

width

setting

must

six

ounces

at

100

is

6

Machine

at

sight

between

is

gauge

gauge

filled

on

front

lines.

with

of

oil

at

spring

machine.

Red

cap

bulb

in

top

on

cover.

oil

level

3

Oil

level

indicator

is

checked

should

show

OILING

(Continued)

Machine

keeping

oil

It

is a magnetic

may

denotes

size

main

as

required.

Drain

have

Each

the

number,

plug

entered

Union

measured

Collectively,

given

these

double

spotted,

on

39500

styles

slab,

the

AB,

chromium

is

automatically

reservoir

screw

screw

the

Special

kind

of

stamped

in

thousandths

type

label

is

AC

Type

of

and

standard

filled.

is

designed

crank

needle

shank,

on

and

size

all

AE

154

length,

plated

lubricated.

Check

located

case.

point,

the

at

to

accumulate

It

has

both

length,

needle

of

an

number

needles

packaged

use a curved

GCS.

It

curved

needle

No

oil

daily

back

should

of

machine

be

NEEDLES

type

and

groove,

shank,

inch,

denotes

midway

represent

and

blade

is a slabbed

blade,

in

sizes

025,

oiling

before

possible

removed

size

number.

finish

the

sold

needle.

shank,

double

027,

is

necessary,

the

morning

near

bottom

foreign

and

cleaned

and

largest

between

complete

by

Union

The

round

groove,

029,

032.

edge

materials

periodically.

The

Type

other

details.

diameter

shank

symbol

Special.

standard

point, • 046

struck

other

start.

of

number

of

and

which

needle

groove,

than

Add

base.

which

The

blade,

eye.

is

for

inch

To

have

a

sample

needle,

description

154

GCS,

Size

Selection

should

use

pass

freely

Success

of

needlespackagedunderourbrandname,

in

by a reputation

ship

for

more

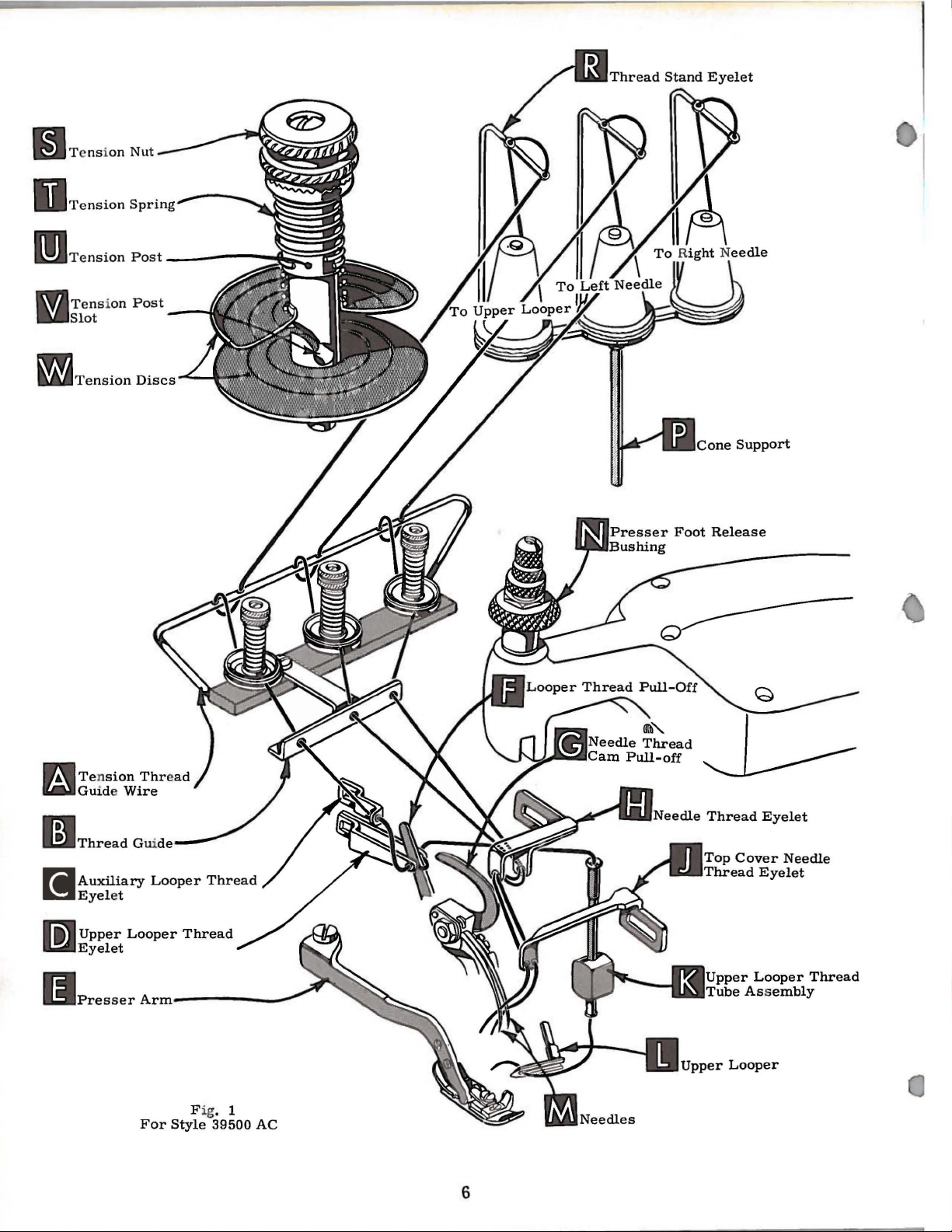

Release

(N,

Figs. 1 and

in

the

operating

Using

needle

high

hexagonal

clamp

position;

needle

on

label.

025".

of

proper

through

the

operation

for

producing

than

pressure

2),

direction

socket

nut

about

withdraw

orders

or

promptly

the

type

A

complete

needle

size

needle

of

highest

three-quarters

CHANGING

on

presser

and

swing

presser

until

wrench,

1/4

turn.

needles.

and

and

size

order

is

determined

eye

in

Union

Special

quality

of a century.

foot

needles

No.

21388

Again

accurately

number

would

order

needles

NEEDLES

by

turning

arm

(E)

are

AU,

turn

filled,

should

read:

by

size

of

to

produce a good

machines

~

can

in

materials

presser

out

ofposition.

at

their

lowest

furnished

handwheel

an

be

"1000

thread

be

foot

with

until

empty

package,

forwarded.

Needles,

used.

stitch

secured

which

artd

release

formation.

workman-

Thread

only

is

backed

bushing

Type

Turnhandwheel

point

machine,

of

travel.

loosen

needles are

Use

by

at

To

to

the

left,

needles

travel,

foot

bushing

replace

in

this

then

insert

position,

tighten

(

N).

needles,

needles

nut.

leave

in

holder

turn

Return

needle

holder

until

handwheel

presser

they

until

4

rest

arm

at

high

against

holder

(E)

position

is

to

position;

the

aga

in

and,

stop

at

re-lock

pin.

its

with

low

the

flats

Keeping

point

of

presser

THREAD

STAND

39500

is

eyelet

and

then

thread

39500

brought

(X)

Next,

guide

(Figs. 1 and

complete

needle,

are

position

foot

presser

AC

ONLY

After

brought

up

thread

up

(R,

Fig.

through

through

continued

guide

AB

After

through

thread

wire

Only

AND

thread

up

through

(A),

parts

(B) •

slot

is

2).

The

following

threading

and

conclude

given

Prior

below.

to

to

bring

threading,

by a counterclockwise

arm

(E)

comes

from

BACK

1).

Next,

left

hand

between

39500

hole

tension

AE

comes

the

BACK

(V),

and

extended

through

holes

involved

Parts

are

recommended

of

upper

by

complete

swing

needles

out

of

position.

thread

thread

thread

of

ONLY

from

down

down

in

presented

looper,

(M)

into

turn

cones

eyelet,

is

extended

the

tension

discs

cones

thread

(W),

(positioned

eyelet,

through

through

in

the

the

thread

THREADING

threading

in

procedure

progress

threading

cloth

high

of

plate

position.

the

(positioned

then

down

thread

through

then

FRONT

left

hand

guide

are

shown

their

relative

simplifies

to

for

left

open,

turn

Release

release

on

down

through

through

guide

slot

on

cone

continues

thread

hole

(B).

in

threading:

complete

needle.

handwheel

bushing

cone

support

FRONT

the

right

wire

(VL

(A) •

and

support

between

eyelet

in

the

tension

threading

positions

Beginning

threading

Steps

pressure

(

N),

and

hand

Thread

on

(P)},

(R,

diagrams

for

for

threading

in

operating

on

then

(P)),

thread

hole

through

it

felt

pads

Fig.

thread

clarity

with

of

right

presser

swing

it

is

is

2).

.

CAUTION!

guide

slots

wire

(V)

Turn

thread

through

Thread

looper

and

using

Pull

each

eye

thread

down

the

thread

machine.

from

CAUTION!

passing

Turn

position.

needle

holes

thread

in

threaded

top

cover

Make

(A,

Figs. 1 and

of

the

tension

handwheel

through

both

must

auxiliary

eyes

pass

tube

through

forked

out

bottom

Push

front

to

Be

from

tube

handwheelin

Insert

both

eyel

top

cover

in

the rig

needle thread

sure

posts

TO

until

of

upper

in

front

assembly

thread

end

of

oftube

tube

back.

sure

upperlooperthread

assembly

operating

needle

et

(H),

needle

ht

hole

eyelet.

thethreads,

2),

are

(U).

THREAD

point

looper

looper

of

thread

thread

as

between

UPPER

upper

they

looper

eyelet

eyelet

oflooperthreadpull-off

(K),

lead

the

thread

tube

under

thread

and

assembly

the

threading

using

down,

to

upper

TO

THREAD

threads

neck

the

hooked

and

then

looper

direction

from

of

top

eyelet

left

(J).

needle

Thread

(K).

wire,

NEEDLES

until nee

right

cover cas

needles from

extendfrom

tension

LOOPER

(D)

under

This

end

oftweezers,

insert

is

under

eye.

to left,

The rig

thre

ad

discs

(L)

is

(C)

from

from

(F).

neck

is

easily

supplied

thread

the

dles

( M) a r e

tin

g a

ht nee

throu

the front.

(W)

all

the

back

left

After

of

with

also

through

needle

throu

nd

dle

gh

the

the

tension

and

in

diagonal

way

left.

to

front,

to

right.

pulling

top

up

cover

accomplished

each

machine.

supplied

upper

threads

at

their

gh

BOTH

then

down

thread

left

throu

should

hole

thread

Lead

then

NOTE:

upper

casting

by

with

looper

when

highest

eyes

of

gh

be

of

the

The

knurled

sufficient

amount

tension

to

secure

of

tension

nuts

(S, Fi

proper

THREAD

on

the nee

gs. 1 and

stitch

TENSION

dle

and

looper threads

2).

Tension

formation.

5

on

threads

is

regulated

should

by

be

thr

only

ee

~~Te

m

U s

rlJ

ns

Tension

lot

Tension

i

on

Nut

Post

Discs

one

Support

n

Tension

fal

Guide Wire

r.:ii'I

Auxiliary

i!IJ

Eyel

l'i:t

Upper

~

Eyelet

et

Looper

Thread

Looper

For

Style

Thread

Thread

Fig. 1

39500

AC

6

r

Looper

Assembly

Thread

Loading...

Loading...