Page 1

•

•

®

STYLES

39500AB

39500AC

39500A

INDUSTRIAL

MACHINES

CLASS

CATALOG

No.

103AB

HIGH

STREAMLINED

SPEED

CHICAGO

39500

OVERSEAMERS

Page 2

Catalog

(Supplement

INSTRUCTIONS

No.

to

Catalog

FOR

103

No.

AB

103 S)

ADJUSTING

39

500

The

furnished

AB

parts

at

LIST

CLASS

listed

list

First

AND

OF

Styles

39500

prices

OPERATING

PARTS

39500

AC

in

this

Edition

for

39500

catalog

repairs

AE

are

only.

Union

Rights

Copyright

by

Special

Reserved

1960

Machine

in

All

Countries

MACHINE COMPANY

INDUSTRIAL

Printed

SEWING

CHICAGO

in

MACHINES

U.S.A.

Co.

Page 3

IDENTIFICATION

OF MACJITNE

Each

into

the

Union

name

Machines

contains

i

ndicatesthe

is

reserved

is

of

This

no

letters.

as a suffix

"Special"

catalog

standardStyleof

conjunction.

39500

parts

number,

A,

B,

are

Opposite

description,

P

shown

the

Adjusting

concerned

This

herein

Class

with

catalog

and

39500.

can

aretakenfromthe

direction

of

handwheel

Special

plat

similar

machine

e.

in

Example:

to

construction.

APPLICATION

is a supplement

Parts

or

illustrated

AF

machines.

in

phantom

illustration

and

and

operating

39500

applies

also

AB,

specifically

be

applied

References

operator'sposition

is

is

identified

construction

the

11

39 500

a

machine.

standard

to

in

this

For

to

help

page,

amount

parts

required.

instructions

AC

and

AE.

with

to

direction,

away

from

by a Style

are

grouped

11

•

Letters

Example:

Style

OF

CATALOG

Catalog

catalog

clarity,

locate

are

to

the

standard

discretion,

such

while

seated

operator.

number

by a Class

suffixed

"39500

identification

No.

103 S

represent

certain

39500

AB,

identified

included

Styles

to

some

as

right,

at

left,

the

which

to a Class

AB".

to

specify

and

should

parts

39500

A,

AC

by

detail

represent

of

machine

Special

front,

machine.

is

number,

I:..etter

be

not

B,

P

and

AE

number,

only

machines

back,

Operating

stamped

which

number

"Z"

machine

used

used

and

AF

parts.

part

areas

as

listed

etc.,

in

in

of

Two

Needle,

seaming

Pressed

39500

AB

Special

range

39500

AC

standard

inch;

39500

AE

Attachment.

approximately

70

per

CAUTION!

be

filled

A

straight

before

Fahrenheit

One

Machine.

Lower

For

closing

SSa-1;

20

to

For

seam

standard

For

closing

inch.

beginning

mineral

should

Looper,

Differential

Knife,

standard

100

per

closing

width

setting

Seam

3/32

Oil

was

oil

be

STYLES

One

Automatic

women's

seam

inch;

standard

men's

approximately

35

per

women's

specification,

inch.

Stitch

drained

to

operate.

of a Saybolt

used.

OF

Spreader,

Feed,

Lubricating

seamless

width

hosiery.

inch.

seamless

range

OILING

from

machine

Oil

viscosity

MACJITNES

Three

Trimming

System.

nylon

is

approximately

setting

80

Seam

1/8

inch.

hosiery.

Special

20

SSa-1;

to

when

capacity

Thread,

Mechanism

hosiery.

per

Seam

inch.

specification,

Stitch

range

Prepared

standard

100

per

inch;

shipped,

of

of

Class

200

to

39500

250

Low

Throw

with

specification,

3/32

inch.

Special

20

for

seam

standard

so

reservoir

is

seconds

Over-

Spring

Stitch

SSa-1;

to

100

per

Paramount

width

setting

must

six

ounces

at

100

is

6

Machine

at

sight

between

is

gauge

gauge

filled

on

front

lines.

with

of

oil

at

spring

machine.

Red

cap

bulb

in

top

on

cover.

oil

level

3

Oil

level

indicator

is

checked

should

show

Page 4

OILING

(Continued)

Machine

keeping

oil

It

is a magnetic

may

denotes

size

main

as

required.

Drain

have

Each

the

number,

plug

entered

Union

measured

Collectively,

given

these

double

spotted,

on

39500

styles

slab,

the

AB,

chromium

is

automatically

reservoir

screw

screw

the

Special

kind

of

stamped

in

thousandths

type

label

is

AC

Type

of

and

standard

filled.

is

designed

crank

needle

shank,

on

and

size

all

AE

154

length,

plated

lubricated.

Check

located

case.

point,

the

at

to

accumulate

It

has

both

length,

needle

of

an

number

needles

packaged

use a curved

GCS.

It

curved

needle

No

oil

daily

back

should

of

machine

be

NEEDLES

type

and

groove,

shank,

inch,

denotes

midway

represent

and

blade

is a slabbed

blade,

in

sizes

025,

oiling

before

possible

removed

size

number.

finish

the

sold

needle.

shank,

double

027,

is

necessary,

the

morning

near

bottom

foreign

and

cleaned

and

largest

between

complete

by

Union

The

round

groove,

029,

032.

edge

materials

periodically.

The

Type

other

details.

diameter

shank

symbol

Special.

standard

point, • 046

struck

other

start.

of

number

of

and

which

needle

groove,

than

Add

base.

which

The

blade,

eye.

is

for

inch

To

have

a

sample

needle,

description

154

GCS,

Size

Selection

should

use

pass

freely

Success

of

needlespackagedunderourbrandname,

in

by a reputation

ship

for

more

Release

(N,

Figs. 1 and

in

the

operating

Using

needle

high

hexagonal

clamp

position;

needle

on

label.

025".

of

proper

through

the

operation

for

producing

than

pressure

2),

direction

socket

nut

about

withdraw

orders

or

promptly

the

type

A

complete

needle

size

needle

of

highest

three-quarters

CHANGING

on

presser

and

swing

presser

until

wrench,

1/4

turn.

needles.

and

and

size

order

is

determined

eye

in

Union

Special

quality

of a century.

foot

needles

No.

21388

Again

accurately

number

would

order

needles

NEEDLES

by

turning

arm

(E)

are

AU,

turn

filled,

should

read:

by

size

of

to

produce a good

machines

~

can

in

materials

presser

out

ofposition.

at

their

lowest

furnished

handwheel

an

be

"1000

thread

be

foot

with

until

empty

package,

forwarded.

Needles,

used.

stitch

secured

which

artd

release

formation.

workman-

Thread

only

is

backed

bushing

Type

Turnhandwheel

point

machine,

of

travel.

loosen

needles are

Use

by

at

To

to

the

left,

needles

travel,

foot

bushing

replace

in

this

then

insert

position,

tighten

(

N).

needles,

needles

nut.

leave

in

holder

turn

Return

needle

holder

until

handwheel

presser

they

until

4

rest

arm

at

high

against

holder

(E)

position

is

to

position;

the

aga

in

and,

stop

at

re-lock

pin.

its

with

low

the

flats

Keeping

point

of

presser

Page 5

THREAD

STAND

39500

is

eyelet

and

then

thread

39500

brought

(X)

Next,

guide

(Figs. 1 and

complete

needle,

are

position

foot

presser

AC

ONLY

After

brought

up

thread

up

(R,

Fig.

through

through

continued

guide

AB

After

through

thread

wire

Only

AND

thread

up

through

(A),

parts

(B) •

slot

is

2).

The

following

threading

and

conclude

given

Prior

below.

to

to

bring

threading,

by a counterclockwise

arm

(E)

comes

from

BACK

1).

Next,

left

hand

between

39500

hole

tension

AE

comes

the

BACK

(V),

and

extended

through

holes

involved

Parts

are

recommended

of

upper

by

complete

swing

needles

out

of

position.

thread

thread

thread

of

ONLY

from

down

down

in

presented

looper,

(M)

into

turn

cones

eyelet,

is

extended

the

tension

discs

cones

thread

(W),

(positioned

eyelet,

through

through

in

the

the

thread

THREADING

threading

in

procedure

progress

threading

cloth

high

of

plate

position.

the

(positioned

then

down

thread

through

then

FRONT

left

hand

guide

are

shown

their

relative

simplifies

to

for

left

open,

turn

Release

release

on

down

through

through

guide

slot

on

cone

continues

thread

hole

(B).

in

threading:

complete

needle.

handwheel

bushing

cone

support

FRONT

the

right

wire

(VL

(A) •

and

support

between

eyelet

in

the

tension

threading

positions

Beginning

threading

Steps

pressure

(

N),

and

hand

Thread

on

(P)},

(R,

diagrams

for

for

threading

in

operating

on

then

(P)),

thread

hole

through

it

felt

pads

Fig.

thread

clarity

with

of

right

presser

swing

it

is

is

2).

.

CAUTION!

guide

slots

wire

(V)

Turn

thread

through

Thread

looper

and

using

Pull

each

eye

thread

down

the

thread

machine.

from

CAUTION!

passing

Turn

position.

needle

holes

thread

in

threaded

top

cover

Make

(A,

Figs. 1 and

of

the

tension

handwheel

through

both

must

auxiliary

eyes

pass

tube

through

forked

out

bottom

Push

front

to

Be

from

tube

handwheelin

Insert

both

eyel

top

cover

in

the rig

needle thread

sure

posts

TO

until

of

upper

in

front

assembly

thread

end

of

oftube

tube

back.

sure

upperlooperthread

assembly

operating

needle

et

(H),

needle

ht

hole

eyelet.

thethreads,

2),

are

(U).

THREAD

point

looper

looper

of

thread

thread

as

between

UPPER

upper

they

looper

eyelet

eyelet

oflooperthreadpull-off

(K),

lead

the

thread

tube

under

thread

and

assembly

the

threading

using

down,

to

upper

TO

THREAD

threads

neck

the

hooked

and

then

looper

direction

from

of

top

eyelet

left

(J).

needle

Thread

(K).

wire,

NEEDLES

until nee

right

cover cas

needles from

extendfrom

tension

LOOPER

(D)

under

This

end

oftweezers,

insert

is

under

eye.

to left,

The rig

thre

ad

discs

(L)

is

(C)

from

from

(F).

neck

is

easily

supplied

thread

the

dles

( M) a r e

tin

g a

ht nee

throu

the front.

(W)

all

the

back

left

After

of

with

also

through

needle

throu

nd

dle

gh

the

the

tension

and

in

diagonal

way

left.

to

front,

to

right.

pulling

top

up

cover

accomplished

each

machine.

supplied

upper

threads

at

their

gh

BOTH

then

down

thread

left

throu

should

hole

thread

Lead

then

NOTE:

upper

casting

by

with

looper

when

highest

eyes

of

gh

be

of

the

The

knurled

sufficient

amount

tension

to

secure

of

tension

nuts

(S, Fi

proper

THREAD

on

the nee

gs. 1 and

stitch

TENSION

dle

and

looper threads

2).

Tension

formation.

5

on

threads

is

regulated

should

by

be

thr

only

ee

Page 6

~~Te

m

U s

rlJ

ns

Tension

lot

Tension

i

on

Nut

Post

Discs

one

Support

n

Tension

fal

Guide Wire

r.:ii'I

Auxiliary

i!IJ

Eyel

l'i:t

Upper

~

Eyelet

et

Looper

Thread

Looper

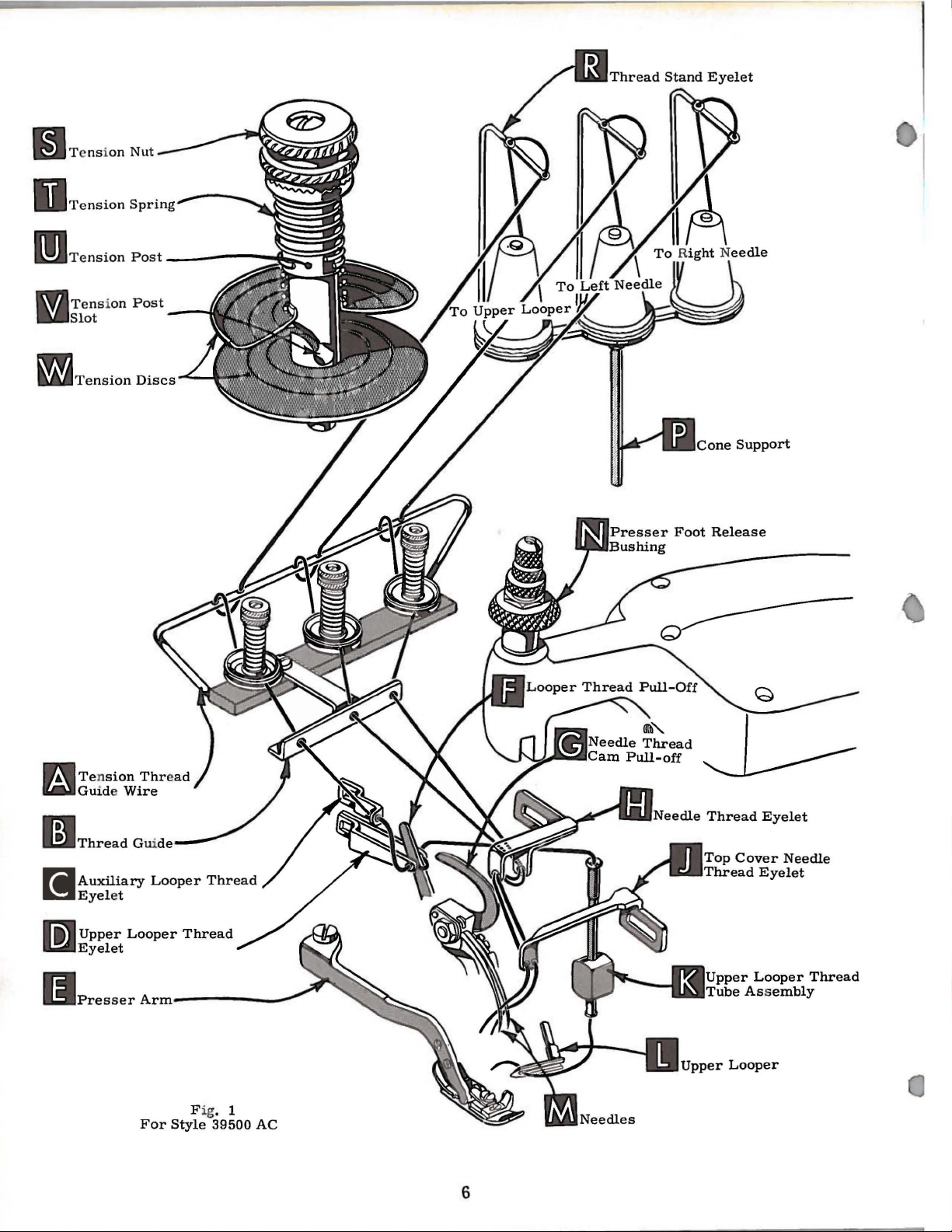

For

Style

Thread

Thread

Fig. 1

39500

AC

6

r

Looper

Assembly

Thread

Page 7

m Te

U s

l'f:llTension

~

Et

nsion Post

lot

Discs

Tension

Pads

one

Support

NOTE:

are

used

stand

tension

i

nverted

n

Tension

ifa1

Guide

m

Thread

r.iii

Auxi.liary

~!!Ey

Tension

only

with

eyelet

discs

at

Wire

(R)

(W)

(R)

Thread

Looper

elet

pads

thread

(X)

and

are

only.

Thread

Top

Cover

Thread

Needle

Eyelet

l'ii:l

upper

~!'.~

Eyelet

~~

Presser

Looper

Arm--------

For

Styles

Thread

Fi

g. 2

39500

AB,

AE

7

r

Looper

r

Looper

Assembly

Thread

Page 8

PRESSER

FOOT

PRESSURE

Sufficient

should

increase

presser

turn

right

pressure,

When

properly

presser

locking

be

maintained.

or

foot,

adjusting

hand

loosening

pressure

set,

foot

nut

approximately

top

surface

(D)

against

Feed

produce

eccentrics

and

on

locking

eccentrics

approximately

have

the

approximately

that

the

part

of

the

differential

symbol

that

shipped

shipped

eccentric,

main

indicate

eccentric.

with

with

while

and

differential

pressure

decrease

loosen

screw

thread;

adjusting

tighten

resting

(C)

so

1/32

of

the

adjusting

nut

been

39500

70

stitches

AE

number

feed

approximately

Unless

above

combination

39540-60

the

to

feed

Should

amount

lock

(B).

Adjusting

tightening

decreases

the

on

throat

that

inch

its

to

(C).

used

80

selected

machine,

per

of

the

eccentric

otherwise

main

39500

feed

AE

eccentrics.

the

it

be

nut

(A,

screw

lock

under

1/16

screw

FEED

in

the

stitches

to

inch.

main

the

of

feed

machine

work

uniformly

necessary

of

pressure

Fig.

3),

screw

will

the

nut

plate,

pressure.

(B)

(A).

increase

has

position

surface

inch

from

(B).

Set

ECCENTRICS

39500

AB

per

produce

approximately

eccentrics

It

will

feed

eccentric

is

No.

39540-70.

number

specified,

eccentrics.

eccentric

will

to

on

and

has

been

With

is

the

cap

machine

inch.

have

be

of

be

a

On

been

noted

is

No.

Minor

stitches

the

39 500

The

39500

and

39540-30

shipped

have

the

39500

35

selected

on

the

39540-100,

numbers

obtainable

AB

AC

with

Fig.

been

3

selected

AC

stitches

to

39500

AB

when

machine

machine

differential

39540-70

machine,

per

produce

machine

while

of

the

using

will

will

as

to

inch,

that

part

be

be

feed

both

Generally

number

relation

operation.

Following

5,

6,

7,

8,

36,

40,

50,

Additional

with

a

Example:

Fig.

of

stitches

to

degree

stitch

9,

10,

60,

eccentrics

minor

39540-70.

4

speaking,

produced.

and

number

11,

12,

70,

100.

may

number

fabric

knife

sequence:

the

position,

throat

differential

Main

direction

feed

of

eccentrics

13, 14,

Only

be

two

ordered

suffixed

ASSEMBLING

Before

assembling

guard,

holder

With

throat

front

end

the

plate

(right

(left

stretch

15,

16,

eccentrics

separately.

to

indicate

AND

chip

assembly.

SETTING

plate

of

needle

needle

(Fig.

points

4)

hand)

hand)

of

material

are

18,

20,

are

ADJUSTING

sewing

guard,

THE

in

position,

slot.

should

for

39500

feed

feed

eccentric

available

22,

24,

supplied

To

number

parts,

upper

Then,

NEEDLE

needles

When

be

AC.

eccentric

being

under

26,

with

order,

of

stitches

SEWING

remove

knife

assembly,

follow

needles

set

15/32

is

sewn,

No.

28,

each

use

this

should

determines

selected

or

type

39540-

30,

32,

34,

machine.

No.

39540

desired.

PARTS

cloth

plate,

lower

suggested

center

are

at

high

inch

above

in

of

4,

in

8

Page 9

SETTING

the

set7/16inchabovethethroat

plate.

arm

clamp

throat

lower

into

spreader

stroke,

point

left

gauge

not

de

Tighten

THE

For

needle

(A,

plate.

At

spreader

bar

1/8

needle,

No.

have

f1

e c

NEEDLE

39500AB,

points

Move

Fig.

screw

this

tin

nut

(C).

at

the

set

inch

21225

lower

g

(B).

needle

4)

from

(Continued)

39500

should

driving

byloosening

(B).

point,

left

the

using

the

Remove

(A,

Fig.

With

end

spreader

center

G-1/8.

spreader

needles.

insert

looper

AE

be

5)

lower

of

its

of

Do

Fig.

5

Set

with

position

the

nP.edle

spreader

set

spring

•

When

either

rear

SETTING

Now,

into

002

to • 004

SETTING

Assemble

lower

Fig.

rear

guard

the

forward

needle

lower

to

deflect

needle

finish

moves

needle

spreader

6

guard.

and

THE

lower

from

inch.

THE

front

SETTING

guard

spreader

needle

lower

LOWER

spreader

to

the

scarfs

rear

FRONT

needle

is

guard,

guard

needles

Screw

and

After

sure

between

THE

as

high

or

forward.

Make

spreader.

SPREADER

right,

(A,

springing

set

its

Fig.

guard

NEEDLE

guard ( C,

set

as

close

without

(D)

front

this

there

the

is

is

REAR

as

possible

movement

002

sure

there

adjustment.

point

7)

surface

needle

the

setting,

no

should

until

GUARD

front

as

possible

touching.

used

needle

to

needle

interference

NEEDLE

of

to • 004

is

no

As

be

needles

another

Fig.

off

6).

back

needle

adjust

guard.

make

guards

GUARD

(A,

Fig.

lower

inch.

interference

to

knife

Screw

and diff

6)

without

holder,

er e

interfering

(B)

is

used

between

F ig. 7

ntial

but

still

to

the

feed do

in

set

rear

g.

Fig.

8

SETTING

Insertupperlooper(A,

holds

in

holder

or

upper

out

or

into

looper

turned

upper

in

its

around

looper

9

THE

holder

its

UPPER

Fig.

shank.

shaft

8)

and

(if

LOOPER

inits

permits

Insert

not

holder.

it to

already

Screw

be

upper

in

(B)

pushed

loop

er

place).

Page 10

SETTING

THE

UPPER

LOOPER

(Continued)

Screw

upper

holder

upper

shank

of

point

the

needle

and

(C)

looper

(Fig.

When

the

looper

back

Next,

its

turn

travel.

with

following

to

point

distance

on

of

respect

approximately

NOTE:

setting

is

approximately

upper

looper

of

the

ForStyles

the

clamp

in

its

holder

8).

upper

holder

looper

should

vertical.

the

handwheel

Check

the

to

dimensions;

of

looper

from

throat

15/32

inch

39500AB,

upper

looper

7/16

holder

(A,

quickly

when

of

holds

needle

should

plate

on

the

upper

so

that

the

is

at

the

be

set

to

until

looper

dimensions

and

throat

distance

be

approximately

to

point

39500

AC

shank

right

position

of

plate

from

of

machine.

39500AE,

point

inch.

Fig.

When

upper

the

upperlooperandrightneedle

If

9).

the

as

follows:

looper

with

respect

resetting

correct

setting

As

eye

looper

extends

end

of

its

upper

is

at

the

the

upper

(Fig.

centerline

looper

the

dimensional

to

throat

is

necessary,

is

upper

looper

centers

holder

in

1/32

stroke,

looper

left

end

looper

9)

and

of

left

5/3 2 inch

should

be

plate

do

obtained,

is

on

the

right

should

the

shaft.

to

1/16

so

by

it

can

moving

needle,

align

inch

Fig.

moving

be

to

the

(Fig.

Locate

beyond

9

the

checked

r i

ght,

the

eyes

10).

Fig.

and

main

same

plane.

checked

feeding

straight

faces

with

faces

should

the

by

adjusting

raises

end

of

both

same

time.

The

should

time

feeding

appears

plate.

tilting

adjusting

feed

by

surface

edge.

throat

rotating

pin

or

lowers

feeding

be

set

above

Screw

10

dog

(B)

This

sighting

Feed

now

plate

feed

(D).

feed

bars

level

surface

the

(E)

locks

pin

Check

looper and

the

slightly

looking

dimensions

Assemble

so

that

can

across

with

sur-

be

leveled

sur-

tilting

This

the

back

at

pin

the

surfaces

at

the

first

throat

feed

in

place.

back

be

a

of

and

from

top

setting

needles

upper

rotate

left

suggested

SETTING

and

surfaces

to

on

looper.

a

end

set

the

of

avoid

needle

short

of

machine.

above

THE

differential

the

feeding

interference

down

pull

stroke.

looper

distance

and

in

FEED

surfaces

Fig.

11

between

If

needles

out

of

its

counterclockwise.

Reset

Figs.

to

maintain

9

and

DOGS

feed

dog

(A,

Fig.

all

lay

upper

rub

holder

10.

11)

in

the

10

Page 11

SETTING

THE

FEED

DOGS

(Continued)

Now,

top

Set

of

set

its

chaining

Replace

knife

flush

made

knife.

knife,

width

(A,

with

with

Lower

so

of

Lower

tightening

port

latch

always

bracket.

pin

be

tightened

Replace

knife

(D,

clockwise

edge

lower

and

of

knife.

slightly

feeding

travel.

SETTING

lower

Fig.

throat

hexagonal

no

lateral

trim

knife

screw(B)

for

the

locked

against

SETTING

upper

Fig.

position

upper

back

feed

12)

plate

knife

is

changed.

may

Because

cloth

with

lower

12)

knife

The

from

surfaces

dog

THE

knife

should

surface.

head

is

spring

adjustment

be

and

locking

screw

plate

nut

knife

THE

knife

in

position,

against

should

chain

the

so

they

(C)

level

LOWER

holder

be

set

screw

pressed

secured

nut

(B)

latch

(C)

even

holder.

UPPER

assembly.

upper

extend

guard

(J)

cutting

rise

with

top

KNIFE

assembly.

with

cutting

Adjustments

which

holds

against

is

necessary

in

any

position

(C)

against

also

spring,

when

screw

KNIFE

Clamp

setting

knife.

not

At

less

should

edge.

about

of

Lower

serves

it

should

nut

(E)

bottom

than

be

set

3/64

throat

edge

are

lower

upper

when

by

sup-

as

is

not

upper

to

1/64

down

plate

hold

of

its

inch

inch

when

clamp

stroke,

below

against

above

Fig.

(F)

cutting

the

throat

feed

12

in

front

upper

plate.

dog

its

cutting

edge

is

at

most

of

knife

After

be

tightened

resetting

Length

of

feed

Fig.

inner

13)

(right)

(front)

In

facing

key.

in

oil

To

end

of

tion

until

hooked

chine,

draw

eccentrics.

wheel

upper

to

when

SETTING

of

stitch

eccentrics

actuates

eccentric

feed

dog.

assembling

each

Tighten

tube

shaft

other.

(F)

change

(D).

key

nut

feed

slot

eccentric

reach

back

behind

and

knife

lock

upper

has

upper

knife

THE

is

determined

used.

main

been

knife

STITCH

Outer

(rear)

(B)

feed

(C)

touches

eccentrics,

Be

careful

securely.

feed

eccentrics,

Turnhandwheelin

in

eccentric

extractor

eccentrics

It

may

benecessaryto

forth

slightly

set

holding

is

replaced.

by

(left)

feed

actuates

not

to

Be

eccentric

remove

is

toward

(E),

supplied

as

during

for

proper

block

LENGTH

the

combination

eccentric

dog;

the

differential

be

sure

damage

sure

connections.

nut

operating

front.

shown

move

extraction.

while

hubs

shaft

wool

(C)

direc-

with

and

width

(H)

in

(A,

the

are

or

yarn

from

Using

ma-

with-

hand

of

trim,

place.

screw

This

Fig.

(G)

will

13

should

simplify

11

Page 12

SETTING

THE

STITCH

LENGTH

If

fitting~

Fig.

14)

ful

to

(Continued)

eccentrics

in

additionto

from

remove

connection

originally

suggested.

shaft

nut

(H).

are

unusually

removing

(D)~

it

(G) and·

Then

nut

may

be

feed

driving

continue

tight

(C~

help-

as

throat

plate

Footlifterlever

presser

arm

unlocked.

needle

hole,

Adjustlifterlever

that

presser

than

upper

nut

(D).

sition~

upper

foot

pressing

manually

To

turn

looper

tongue.

the

lower

adjustment

tongue

There

free

presser

ment

with

does

should

motion

foot

is

made

nut

(F).

slots

does

To

center

loosen

foot

looper

find

the

is

Raise

presser

is

not

be

of

begins

Fig.

by

shifting

14

arm

not

presser

presser

can

be

will

permit;

this

maximum

handwheel

directly

presser

the

toe

correct

contact

from

foot

lifter

to

rise.

with

screw

(A1 Fig.

bind

stop

raised

foot

of

if

the

1/16

foot

and

foot

foot

screw

nohigher

then~

so

over

foot

treadle

foot.

presser

upper

to

lever

This

(E),

lifter

15)

rise

and

hinge

(C)

lock

safe

popoint

presser

by

de-

and

Height

foot

looper.

1/8

inch

before

adjust-

locked

arm.

swing

and

presser

lever

and

when

stitch

screw.

so

of

SETTING

Assemble

With

presser

lock

foot

shaft.

collar(B)

presser

tongue

THE

presser

needle

arm

in

can

secure

foot

with

PRESSER

into

place.

be

the

release

respect

Fig.

foot

in

high

sewing

If

realigned

shaft.

to

throat

15

FOOT

to

presser

position~

position

necessary~

with

Be

sure

bushing

is

plate

Finally,

Be

sure

(either

Fig. 1 or

(D ~ Figs. 1 and

machine

and

moves

material~

While

FOR

39500

About

remaining

position

just

contacts

re-assemble

machine

Fig.

2)

about

slowly,

and

off

without

the

sew

sewing

AC

60o/o

of

needle

40o/o

is

drawn

needlethread

needle

chip

STARTING

is

threaded

2).

With

horizontal

presser

tongue

slowly.

NEEDLE

on

material~

thread

on

eyelet

thread.

guard~

according

thread

freely.

is

the

(H~

fabric

TO

tensions

and

back

foot

in

Swing

THREAD

check

drawn

from

upstroke.

Fig.

1)

guard~

OPERATE

to

diagram

light~

in

its

front

place~

to

presser

CONTROL

needle

cones

With

sothat

needlethread

make

thread

on

needle

12

cloth

for

your

setlooper

to

back

sure

foot

into

needle

at

plate.

style

thread

location.

that

chain

position~

control

down

as

stroke.

bottom

cam

pull-off

of

machine

eyelet

Operate

forms

insert

follows:

The

of

stroke~

(G)

Page 13

NEEDLE

The

eyelet

obtained

speed

FOR

39500

Usually,

thread

down

slightly

with

range.

should

is

adjusted

the

least

AB

AND 39500

all

needle

be

just

if

excessive

amount

thread

tight

correctly

AE

enough

thread

positionneedlethreadpull-offeyelet

the

proper

amount

of

needle

thread

THREAD

in

of

needle

is

drawn

to

feed

is

pulled

to

its

(H,

satisfy

CONTROL

front

thread

on

needle

chain

off

on

the

Fig.

(Continued)

to

back

position

tension

stitch

up

stroke.

2)

sothattheneedlethreadpull-off

the

above

down

tongue.

when

stroke.

With

conditions.

when

sewing

At

Needle

needles

top

the

desired sti

over

of

threads

at

bottom

the

needle

tend

of

(G)

tch

is

complete

stroke,

to

pull

stroke,

draws

During

will

draw

drawn,

reaches

FOR

If

eyelet

moved

minimum

FOR

If

eyelet

thread

upper

upper

its

39500

needle

AC

looper

most

down

looper

rearward

upperlooperthread

(D,

Fig.

1)

forward

too

far

forward,

39 500

upper

(D,

will

amount

AB

Fig.

tend

AND

looper

2)

to

of

thread

forward

break

stroke,

thread

thread

the

looper thread

39 500

excessively--even

applied.

CAUTION!

high

tensions.

Do

nottry

to

obta

POSITIONING

If

the

purl

is

at

the

top

appearance.

when

opened.

FOR

39500 AC

Raising

thread

the

to

purl

forward,

With a reasonable

thread

FOR

pull-off eye

39500

Moving the

from

the

more

on

become

If,

and bri

be

pulled

to

form

however,

AB

cones

the

top

slack

however,

more

let

AND

needle

a s

the

of t

at

the

nging

from

onthe

the

thread

amount

should

39500

thread

needles

he

edge.

top

of

the

the

With a reasonable minimum

pull-off

eyelet

should

be

adjusted

THREAD

FOR

39500

The

ewn.

s

causingthe

prevent

FOR

39500

The

uniformity

pads

(X, F

these

settings to

tension

AC

needle thr

In general,

needle

looper

thre

AB

AND 39500

needle thr

of sti

tch.

ig.

2) should

tension

pads and

insure uniformity

disc

s ,

which

ead

tension

upper looper

threads

ad

breakage.

eads

and

NOTE:

only

the

are

mounted

UPPER

LOOPER

forward

through

will

have

stroke

the

almost

position.

has

alooseappearancein

and rai

se

looper

slightly.

thread

tension

AE

has

loose

slightly.

in a

edge

the

purl

looper

cones

top

tight

THE

of

the

of

is

thread

as

the

appearance

If,

however,

looper

PURL

garment,

under

the

edge.

becomes

of

looper

be

thread

adjusted

AE

pull-off

travel

the

stroke

needle

If

the

thread

to

eyelet

to

the

eyelet

and

position

TENSIONS WITH R

required

to

be

pulled

thread

is a function

tension

too far

AE

looper

be

tension

thread

Tension

enough

to

discs mounted

of sti

tch

on

the

applied

prevent the thre

should

THREAD

CONTROL

oflooperthreadpull-off(F,

tension.

all

If,

will

When

normal

slack

the

taken

seam,

however,

tend

to

applied.

in

the

seam,

the

eyelet

with a minimum

thread

TO

the

pull-off

looper

If

too

tight,

tension

to

position

(H,

Fig.

top

of their stroke

is

moved

the

chain

tension

the

appearance

OBTAIN

the

seam

edge,

a l

eyelet

travels

the

eyelet

resulting in

to

the

2)

back

back

will

to

insure

purl

as

A F

ess flat

to the top

insu

purl

not

desired.

ESPECT

of

needle

should

be set

over the top

tensions

to

should

the

threads

ads from

on

the

machine.

be

obtained

machine.

amount

up

move

the

eyelet

break

excessively--even

move

is

too

amount

LAT

can

be

(D, Fig.

is

raised

re a

flexible

as

desired.

causes

and

too

far,

feed

off

uniformity,

TO

STITCH

thread

as

of

the

be set

at

by

vary

Fi

of

looper

as

far

of

on

looper

looper

is

looper

looper

the

thread

thread

raised

thread

forward,

thread

seam

SEAM

opened

and

of

looper

into a near

tighter seam res

1)

forward

its

stroke

and

brou

thread

chain,

less

thread

causes

the

however,

the

throat

the

and

the

material

high

as

possible without

seam

and low

at a minimum

the

thread stand tensi

becomin

All

ing

g s

controll

the

tens

g. 1

or Fig.

thread

pull-off

pull-off

too

high

and

with

pull-off

the

looper

tension

by

carrying

butted

ults

cau

ses

less

and

causes

ght

too

far

breakage.

the looper

to

be

pulled

purl

to form

the

threads

plate

tongue.

needle

thread

bein

enough

to

to insure

on

lack between

ing

tension

ions at the

2)

is

a

g

13

Page 14

14

Page 15

The

parts

parts

orAF.

used

illustrated

on

Styles

on

the

39500

preceding

AB.

AC.

page

and

AE.

and

but

described

not

used

on

on

this

Styles

page

represent

39500

A,

B.

the

P.

Parts

39500

Use

Ref.

shown

A,

B,

Catalog

P,

No.

Part

No. No.

1

2

3

4

5

6

7

39552

22596

50-774

154

39563

39551

51292

51292

51292

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

39555

88

39555

39592

39556

39520_AB

39530

22738

39530

22768

39597

22738

39530

22569

39563

39557

39563

39578

39563

39560

39505

39526

39505

39505

39505

39526

39582

39582

39582

22585

39525

39525

39524

39524

39580

in

phantom

and

103 S

G

E

GCS

p

E

F-1

F-1

F-2

G

D

H

E

J

R

G

B

AB

p

D

N

G

M

BC

R

B

E

AC

AC

AB

AB

GG

J

H

G

H

J

AB

AC

AA

views.

AF

and

39500

for

all

Needle

Screw--------------------------------------------Stop

Needles-----

Needle

Needle

Looper

Needle

Looper

Presser

Screw -Presser

Presser

Pad.

for

Presser

Presser

Chain

Screw -Chain

Hinge

Screw -Tongue

Presser

Screw -Chip

Presser

Screw -Needle

Needle

Presser

Top

Cover

Chip Guard

Top

Cover

Lower

Spreader---------------------------------------

Chaining

Differential

Main

Feed

Chaining

-

Main

Feed

Differential

Side

Cover.

Rivet

Spring

Screw -Side

Needle

Needle

Throat

Throat

Throat

bearing

AB.

parts

AC.

not

illustrated

no

reference

AE.

numbers.

or

described

Description

Driving

Arm

-----------------------------------

Pin-------------------------------------------

-----------------------------------------

Thread

Clamp

Thread

Thread

Thread

Foot

Foot

Pull-off.

forStyles

39500

Stud-------------------------------------

Tension

Tension

Tension

Lifter

Foot

Lifter

Spring.

Spring

Spring.

Extension.

Lifter

Lever

Extension

Spring.

for

Styles

-------------------------for

Style

for

Style

for

39592----------------------------------------

Arm

Foot

-----------------------------------------

-----------------------------------------

Shield---------------------------------------

Shield

-------------------------------

Spring---------------------------------------

and

Spring--------------------------

Foot

Foot

Thread

Spring

Needle

-------------------------------------------

Needle

Feed

Feed

Dog.

Feed

Dog,

Feed

for

Stitch

Guard

Chip

Thread

Eyelet,

Tongue

-------------------------

--------------------------------

Guard

Eyelet

for

---------------------------

--------------------------

Styles

39500

Plunger--------------------------------

Dog.

Dog,

for

Dog.

for

Dog,

Style

Thread

Thread

for

Style

for

Styles

Eyelet,

Eyelet.

Style

for

39500

Styles

for

39500

39500

Style

39500

39500

Styles

AE

for

Styles

for

Style

AC

39500

AC----------------

AC----------------------

AB,

AB.

AE

39500

-------------------------

---------------------------------------------

-------------------------------------------Cover------------------------------------

Guard,

Guard,

Plate,

Plate.

Plate

front

-----------------------------------

rear------------------------------------

for

Styles

for

Style

Support

39500

39500

Bracket,

AB,

AE-

AC------------------------

for

Style

are

common

here.

AB.

AE---------39500AB.

39500

39500

AC-------AE--------

------------------

Style

AB.

39500

AE

---------39500AB,

39500

AC------

------------------

AE

-------------

----------------

AB.

AE-

---------

-----------------

39500

AE---------

to

AE

----

AE-----

AE

Styles

Amt.

Req.

--

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

15

Page 16

15

16

Page 17

THREAD

STAND

AND

MISCELLANEOUS

TOOLS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

14A

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Part

No.

21113

21114

21114

22565

39592

39592

51292 F-1

21113

21114

21114

21104

21130

22650

22650

21104

WA9A

21202

21227

21388

39599

G

M

L

c

D

109

E

107

108

F

M

L

v

69 s

W-3

CB-4

CE-6

AA

652

J-24

652

J-16

651

A-16

421

D-34

BF

AU

660-240

A

116

Description

For

Styles

Thread

Eyelet

Eyelet

Screw -Tension

Tension

Tension

Tension

Tension

Tension

Tension

For

Thread

Eyelet

Eyelet

For

Styles

Felt

Pads----------------------------------Spool Pin----------------------------------Cone

Thread

Washer------------------------------------Washer------------------------------------Lock

Nut

Screwdriver

Treadle

Cam

Socket

Thread

Threading

Wrench,

Support--------------------------------

Screw -Thread

Screw -Thread

Washer--------------------------------

----------------------------------------

Extractor------------------------------

Wrench,

eccentrics---------------------------------

39500

Stand

Locking Ring----------------------

----------------------------------

Post--------------------------------

Disc

Spring

Spring-------------

Post

Post

Style

Stand

Locking

----------------------

39500

Stand

--------------------------------

Chain-------------------------------

Tweezers----

Wire

for

9/32

AB

and

AE

Eyelet

(inverted}

Ferrule-----------------------Nut----------------------------

39500

Eyelet

Rod----------------------------

and

Support

Post---------------------

----------------------

Pad--------------------------

-

----------------

AC

and

Support

Ring----------------------

AB,

AC

and

AE

Stand

Stand

for

3/8

----------------------------inch

Eyelet

Rod-----------------

inch

nuts

-

-----------------------

nuts-------------------

Rod

----------

Rod

----------

-

-----------

--------------

holding

feed

Amt.

Req.

3

6

6

3

3

6

6

3

3

3

3

6

6

3

3

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

17

Page 18

,..o

...

...

'

q

WORLD'S

....

l f

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

ALLENTOWN, PA., P.O.

Swift 7-2111.

*ATLANTA,

G. Booth, Mgr. Tel. Trinity 5-9237.

BALTIMORE

Sor.

BELLEVILLE,

Plymouth 9·2006.

BIRMINGHAM, ALA.,

Boldwln,

*BOSTON 11,

Mgr., Tel. Uberty

CANTON, MASS., York St.,

Conlon 6-1412.

*CHICAGO 10,

Ullrlck, Mgr.,

CINCINNATI, OHIO, P.O.

Tel

CLEVELAND

Co

COLUMBIA,

Alpine

COMMERCE,

Federal

*DALLAS 19,

Zock

DANBURY,

Gaines,

DECATUR,

Drake

DENVER

Carter, Tel. Spruce 7-7060.

DETROIT

Un

DUBLIN, GA., 1615

way

EL

Lynwood 8-2928.

GREENSBORO,

Tel

Stone, Tel. &roadway

GREENVILLE,

Tel.

(HAZELTON)

Vogt,

GA

15,

7-U99

.

N. J., 83 Floyd St., Joseph Logliscl, Tel.

Tel

. Vernon

. Cherry

1·.55.5B.

3,

.,

Tel

. Expre11

S. C.,

~-13.51.

GA., Lakevi

5-~061.

TEXAS,

X.

Bennett, Mgr

CONN., 25

Tel

. Pioneer B-9333.

GA.,

7-5.559.

10, COLO.,

35, MICH., 16630 Word Ave., John F.

iversity

3-~9~

2-~663

PASO,

.

TEXAS,

. Brnodway

N. C., P.O.

S. C., 25 Sir Abbot St., Orv

Cedar

9·

5.539.

CONYNGHAM, PA., P.O.

Tel. Sunset 8-

Box

., 2120 Plaster Bridge Rood, N.E., William

MD.,

P.O.

Box

8630 First Ave. South, Lloyd

3-990~.

MASS

., 179 Lincoln St., William

2·0U7

.

ILL

., 400 N. Franklin St., Orville

Tel.

SUperior 7-6920.

Box

OHIO, .6020 Euclid Ave., Sydney

1-BBJI

.

261~

Kershaw St., Virlyn R. Crisler, Tel.

ew

~200

.,

Tel. La

Padanaram

B02

,Derrydown

1801

.

Knox

St., John W. Jones,

P.O.

Box

Box

3-76~8

.

1330 Mayfair Ave

.5-~285.

55.56

.

SALES

5~2,

Luther

D.

Co11ell, Tel.

2505, Rolph

RFD, Roy

77~.

Drive, J.

Hin

os

kesi

Way,

South Marlon St., Louis

.513~

.

226, William D. Harrod,

B.

Foster,

E.

T.

Pedersen, Tel.

Raymond E. Hinton,

L.

Tom

Hanley,

Blvd., P.O. Box 6727,

de

6-8369.

Road, Robert W.

Joe

V.

Parker,

Lux,

Tel

. Brood·

Edward E. Smith,

.,

Fronk B.

ill

e W. Gregory,

Box

~.

Robert S.

Tel

Palm,

Hirsch

Tel

Tel

Tel.

Tel

OF

FICES

AND

UNITED

JACKSON 3, MISS., 327 Eastview St.,

Tel. Fleetwood 5-1976.

.

D.

A.

.

.

E.

.

JOHNSON

KANSAS

KANSAS

KNOXVILLE

LEBANON,

*LOS

LOUISVILLE

LYNCHBURG, VA

LYNDHURST

MEMPHIS

MIAMI

MINNEAPOLIS

MONTGOMERY

NASHUA,

NASHVILLE

NEW

*NEW

OKLAHOMA

*PHILADELPHIA

CITY,

Swarthmore 7

Farland,

Biggers, Tel. South 1·5030.

Horace

Crestview 2-6292.

ANGELES

Mason, Mgr., Tel. Richmond 7-9187.

Rogers,

Victor 6-1215.

Wheeler, Tel. Webster

Tel. Mutual 5-6750.

T ol. Frank lin 1-0323.

26, Minn

Hamlet,

Haberman

William

ORLEANS, LA., P.O. Box 1065, Chalmette, La.,

Larry

Ro

tenquist,

31$

W.

Mgr., Tel. Chickeri

315 W. 35th St., New

Tel

. Chickering

G. B. Wiley,

Morz, Mgr., Tel. Gladstone 5-9800.

N. Y.,

-399~

CITY,

KAN.,

Tel

. Mayfair 1-3325.

CITY

37, MO.,

19,

TENN

E.

Clinard, Tel. 8-IB65.

PA.

, P.O.

15,

IB,

KY.,

Tel

. Glendale

., P.O.

, N. J., 339 Harding Avo., Clarence

17,

TENN

.,

37,

FLA

., 2650 N.W. 5th Avo., Hyman L. Simon,

, MINN., 2800 Texas Ave., St.

.,

Leonard W. Koehler,

7,

ALA

Tol

. Amherst .5-0942.

N. H.,

21

Jr., Tel. Tuxedo 2-

12,

TENN.

J. Brauch,

A.

Von Hooser ,

YORK

16, N. Y ., 116 E. 27th St., Clarence

Mgr

., Tol. Murray Hill 9-1266 . Export Office,

35th St.,

New

ng

4-BBOO

CITY

19,

Tel

. Mutual 5-2836.

2~.

RE

PRESENTATIVES

STATES

Jamie

A. Boyette,

~71

Main St., John J. Lafler,

.

1621

N.

~6th

St., Durwood

1~

Grandview Rood, Torry 0 .

., 400 Bellemoode Avo., N.W.,

Box

274, David M. Bonder, Tel.

CALIF

., 119 E. Pico Blvd., Paul M.

3122 McMahan Blvd., Bernard L.

~-4956.

Box

1075, Clarence D. Mairs,

9-~143

.

~9.5

Dunn Rd., Richard J. Lindhorst,

Tel

., 1959 Amelia Drive,

Alder Dr., Forest Pk., Herman E.

, 1602 South Observatory Drive,

Tel

. Cypress 2·5123.

Tel. Edgewood

York

~-8800

York

.

OKLA

PA

.,

. Midway

969B

.

1·3106.

I,

N.Y., Herbert P. Johnson,

.

Lewis-Columbia Machines,

I.

N.

Y.,

Ben

., 2226 Southwest 53rd St.,

~23~

Mocalostor Ave.,

I.

Lou

is Pork

~-6236

Garnet

Zahler, Mgr.,

Bon

PITTSBURGH

Tel

Me

Tel

.

W.

Tel. locu•t 3·

.

PLANT

Tel.

~

RUTHERFORD,

Tel. Geneva B-2178.

ST. LOUIS

Laughlin, Tel.

James

SALT

Rosvall.

SAN

Tel.

SAN

Vall,

SEATTLE, WASH

~-8083

.

TAUNTON,

Godek,

A.

(TROY)

LeTourneur, Tel. State

TUPELO,

Vl

WORCESTER, MASS

Buckley,

YORK,

34-191.

H.

BOWNESS,

BU

*MONTREAL 10,

l.

Moliere

NORTH

planade, Tel

QUEBEC, QUEBEC,

Renaud, Tel.

TORONTO

West,

WINNIPEG, MANITOBA, Fronk Thiermon,

Bldg., 70

26, PA.,

3.589

CITY, FLA.,

3·26dl.

R.

LAKE

ANTONIO 6, TEXAS,

Di

amond

FRANCISCO

Tel

.

LATHAM,

MISS

nowood

PA., P.O.

Union Special Machine Co.

8-6796.

VANCOUVER,

Tel

.

506 N. Gordon St.,

N.

J., 246 Sylvan St., Richard W. Whitson,

3~.

MO.,

Ch

estnut 1-2368. 5707 McPherson Ave.,

McConn

ell, St.

CITY,

UTAH,

~-1158.

7,

. Underhi

ll 1-1

., 808 Motor Pl.,

MASS

., P.O.

To

l.

VanDyke 2-6149.

NEW

., 1605 rrace Ave., R. "Bill" Bradberry, Tel.

2-59~2.

.,

Tel

. Vernon

Box

ALBERTA,

QUEBEC,

St., Tel.

CRolCont 6-257

. Yukon 7-9391 .

LA

3-8126.

28, ONTARIO, Sam J. Storey, 355 King St.

. Empire 6-2939.

Ar

thur St., Tel. WHiteha

521

Brookline Blvd., W. Dale Speer,

James

C. Morgan,

PB60

Guthrie Ave., Carl E. Me·

Louis

12,

1215

CALIF.,

580.

Box

YORK,

5~6663.

II

Woodside Dr., Grafton, Gus M.

9-33~

BB~.

Mo.

E.

13th South St.,

Cleo C. Smith, P.O. Box 201,

1275 Mission St., Robert J.

Paul D. Lockett,

141, Raynham, Wolter P.

19 Ar

agon

Avo., Jack R.

.

Richard

L.

Smi

th, Tel. York

CANADA

of

P.O.

Box

B.C., James Stewart, 118

Lucien

Canada,

372, Norman W. Holt, Tel.

Clyde F. Amey, Mgr.,

5.

A.

Bouch

ard, 174 Avenue

Rm.

201, Whitla

ll

3-4933.

ltd.

Tel.

larry

E. Es·

F.

Main

~0

lEWIS-

UNITED

ATLANTA,

BALTIMORE

BOSTON

CHICAGO 7,

CLEVELAND

DALLAS

DETROIT

GA.

Peachtree St., N.E.,

St., Tel.

Co., 25 Kneel

Tel

Ave., Tel. EXpress

St., Tel. Rl.

Ave., Tel.

-cutters

1, MD.-

LEx

ington 9-1838.

11,

MASS.-Zolkind Sewing Machine & Supply

ILL.-L.

. CEntral 6·6980.

3,

2, TEXAS-Dallas Sewing Machine Co.,

7-2~91.

7,

MICH.-M.

LOrain 8·0900.

Exchange

Tel

. JAckson

J. Das

and

St.,

Tel

. HAncock 6·733B.

M. Stein Ca., Bl5 W. Van Buren St.,

OHIO-Sydney

1-B811

.

J. Foley Ca.,

AGENTS

STATES

af

Geo'l!

la,

~-2836.

hew,

Inc.,

~17

W. Baltimore

L. Hi

rsc

h Co., 6020

~2

E.

Inc., 338

Eucl

611

Main

Jeflerson

COLUMBIA

315 W.

Mgr., Tel. ChickerinA

Asst.

FOR

fALL

RIVER,

Co., 1059 S. Main St.,

KANSAS

CITY

St., Tel. Victor 2·9558.

LOS

ANGELES

liP

pony,

MIAMI

37,

Tel

. FRanklin 1·0323.

NASHVILLE

breun St.,

NEW

HAVEN

Supply Co., 430

NEW

ORLEANS, LA.-P

l. A. Van Hooser, Tel. Edgewood 1-3106.

id

NEW

YORK

1.5

W. 35th St., Tel. CHickering 4-8800.

3

NEWARK

3,

278 IJth Ava., Tel. Bi

NEWBURG,

ply Co,. 119

3.5th

MACHINES,

St.,

Ben

Zahler, M

~-8800

NEW

gr

.•

YORK

Elt

.

on

LEWIS

MASS.-Zalk

.5,

15,

E. Pica Blvd.,

FLA.-H. L.

3,

TfNN.

Tel. Alpine

10,

I,

N.

NEW

NEW

S. Wil

lnd Sewi

ng

Tol.

MO.-Text

State

JERSEY-Newark Sowing Machine Co.,

YORK-Hudson Sowing Machine & Sup·

OSborne 5-

ile Machinery Co., 324 W. 9th

CALIF.-Unlon

Tel

Simon & Co., 2650 N.

-Cutt

ort Exchange, Inc.,

5-5661.

CONN.-Deitch

St., Tel. Spruce 7·2579.

.O.

Y.-Un

ion Special Machine Company,

gelow

liam St., Tel.

Machine & Supply

7U7

Special Machine Com·

. Richmond 7-9187.

Sewing Machine &

Box

1065, Chalmette, La.,

8-7200.

New

burg 3443.

I.

N. Y

S.

Rockney,

MACH

.

W.

5th Avo.,

901

Demon·

.:

I

NES

PHILADELPHIA

12th

ROCHE

Tel. B

ST. LOUI

Tel. Cen

AN

S

1309

SAN

FRANCISCO

Co., 1155 Mission St.,

SE

ATTLE, WASH.-

M

ain

7, PA.-S. Bolder & Co.,

St.,

Tel

. WAlnut 3·1080.

STER 9, N. Y.- A. J. Adam s Co., 1

Utl

er 8-7250.

S, MO.- lawrence

tral

1·7163.

ANTONIO 7,

W.

4-8083.

TEX

Commerce St., Te

.- Aiamo SowinA Machine Co.,

3,

CAL.-Appar

Tel

808 Motor Pl., P. D. Lockett,

CANADA

BOWNES

S,

ALBERTA,

Te

l. au 8-6796.

MONTREAL,

lawrence

NORTH

TORONTO,

WINNIPEG,

Blvd., Tel. Pl

VANCOUVER, B.C., Jame

anad

e, Te

pl

ONTARIO-John Gordo &

Spadina

Ave., Tel. WAlnut 3-7379.

MANITO

Bldg., 70

Arthur St., Tel. Whitehall

dUEBE

C-John

l.

Yukon 7·9391.

BA, Fronk Thiermon,

P.O.

ateau

Inc

., 129 North

051 Culver Rd.,

M.

Stein Co., 804 N. 9th St.,

l.

CA

7-6328.

ol

City Sowing

. MArket 1-6660.

Box

372, Norman W. Holt,

Gordo & Co., Ltd., 3702 S.

1766.

s Stewart, 118 E. Es·

3·4933.

Co., Ltd

Rm.

201, Whitlo

Mac

.,

hine

Tel

391

.

Page 19

Sales

Agents

UNION

SPECIAL

Also Agent for

For

Machines;

(L)

LEWIS

and

EUROPE

(C) COLUMBIA where marked.

BELGIAN

AFRICA

CONGO,

(lub-agant

South Africa.) (L)

kENYA, NAIROBI-Pollock

Hordinge Street

MAURITIUS,

Machine•) Hall, Genova, Langlois,

Howton St., P.O. Box 77.

MOROCCO, CASABLANCA-H.

Soldo! Soncho•.

SOUTHERN

NYASALAND,

Bros

. (Rhodesia),

SALISBURY

~h',:.'2s

)

Ps~u~~d.Af:~~n

Angwa

SUDAN,

KHARTOUM

305.

TUNISIA,

B

Ruo

du

UNION

OF

Machines) Borzack

Pritchard St. Branches

DURBAN

58

Quoen 5

~~~~~~~s~~:.?u~~.a

BLOMFONTEIN

Bree

Sh.;

3B

Argyle St.;

PIETERMARITZBURG,

WORCESTER.

ELIZABETHVILLE-Progren,

Benack

Bros.

Ltd

., Johanmt1burg, Union

(E.A

.)

(l

&

PORT

RHODESIA,

- (Texlile Machines)

Sts.

TUNIS-Comploir lnduslriol & Monoger C.I.M.

IB

SOUTH

- 72-74 Commerci

DURBAN-22 Allwol St.;

C)

LOUI5-(Bog

(l)

FEDERATION

BULAWAYO-(Texlilo Machines)

16-Uth

5

1

s!~~.

- Franco Pinto (Sudan)

Janvier 1952.

AFRICA,

Bros

at

1.

(L)

~

f'~~~gB~:~~~~·

- 53 Zaatron St.;

PORT

ELIZABETH-Box

PRETORIA,

Ltd.-C

Closing &

Golnmonn

Ave.

(L)

Ber>oclt

5

1

~a.~L

Pii.~o

(l)

JOHANNESBURG-(Textllo

.,

Ltd

., Berbro Hcus

CAPETOWN-7B

al Road; PORT

CAPETOWN

B. P. 2166

orner House,

Bog

Ltd.,

OF

EAST

VEREENIGING

Mak

42 Sir William

& Fils,

Rue

RHODESIA

Ber>ock

Bros. (Solis·

r

,d~!°

F

~r~e~

Lid

., P.O.

Box

e,

13Sn

Darling St.;

ELIZABETH

sl

. 58~!~.~!:'·:.~

- Wales &

LONDON-

611

. Also

and

AUSTRIA,

BELGIUM,

of

BRITISH

DENMARK,

ing

du

Elk~,

&

ENGLAND-(Toxtlle Machlneo)-

0

&

FINLAND,

-

FRANC

GERMANY,

at

AUSTRALIA

Solo

Distributor-Capron,

NEW

SOUTH

QUEENSLAND,

N.l

SOUTH

Former, Lid.,

TASMANIA,

105

VICTORIA,

WEST

789

CAMBODIA,

(C&

HONGKONG-G. R.

308, Bank

INDIA, CALCUTTA-Don, Watson & Co., (Pvt.) Lid.,

BritJsh

JA;~~Ka~~~K,tk.,~~:'a~u~inr,!:,~J,h'"..~

Taito-Ku, Tokyo-

KOREA,

Bldg

(l)

LAOS

TAIWAN,

16

VIETNAM,

Fror.s, P.O.

JAMAICA, KINGSTON-Morris

NASSAU,

Ave., Miami 37, Florida

WALES,

.

AUSTRALIA,

1n

HOBART-(Sub·agenls) Reliance Trading Co.,

MocQuarlo

MELBOURNE-78 A'Beckell St.

AUSTRALIA,

Hay St.

PHOM-PENH-Donis Frores, P.O.

L)

of

Canton Bldg., 6

Indian St.

SEOUL-Uebenee·Hondel

., 180 1-

ka

, VIENHANE-Denis Freros, P.O.

TAIPEI-G

Nan Yang St.

SAIGON-Societe

Box

BRITISH

Union Special International, Inc.

BAHAMA-H. L. Simon & Co., 2650 N.W. 5th

Carter (Ply.)

SYDNEY-B6 Liverpool St.

BRISBANE-454 Brunswick St., Volley,

ADELAIDE-(Sub-agenls) Topp &

Hindley St.

51.

PERTH-(Sub-agenls) Thomsons,

Lid.

(l)

Lid

ASIA

Box

4B.

Coleman Co. (Hongkong) Ltd.,

(l)

To.

Ulch

. R. Coleman Co. (Hongkong) Lid.,

(l)

444, 4

Des

Vooux St., Control. {

c76

A.G.,

iro; Chung-Ku, Int. P.O.

des

Rue

Tu Do. (C & L)

WEST

Rm.

Box

Rl>