Page 1

®

I

NDUSTRIAL

SE WI N G

OUAUT

•

ST

YLE

S

39

500

39

500

8

39500P

39500AF

Y

~

LEWIS

•

COLUMBIA

MACHINES

CATALOG

No.

10

35

SECOND

EDITION

H

IGH

CL

ASS

39500

STREAMLINED

SPEED

OVERSEAMERS

-

~

.

;,·

.

CHICA

G O

Page 2

Catalog

INSTRUCTIONS

No.

FOR

103

S

ADJUSTING

The

furnished

39500

39500

parts

at

LIST

CLASS

A

B

listed

list

Second

AND

OF

Styles

in

prices

Edition

OPERATING

PARTS

39500

39500

39

500

this

catalog

for

p

AF

repairs

are

only.

•

"__._

..

_

Union

Rights

MAC

Copyright

Special

Reserved

HINE

INDUSTRIAL

CHI CA

Printed

1957,

by

Machine

in

COMP

SEWING

in

2

1960

All

AN

MACHINES

GO

U.S. A.

Countries

Co

Y

.

March,

1964

Page 3

FOREWORD

The

streamlin

performance

Class 395

ed s

tyli

00

ng.

are characteristics

machine is

automatic

precision methods insuring

It

is

enable

Specials.

nd

illustrat

a

Union Sp

anxious

our consta

the

cus

The following

e a

ecia

to

cooper ate

nt

aim

tom

er

to

secure

nd describe the

l r epresentativ

with

complete

to

furnish

pages

you

to plan

lubr

of the

all

possible

contain

parts

es

will

Union

ica

int

ca

Special's

tion,

se

machines.

er change

refully

and light

prepared

advantage

valuable operating

for

Style

be found

and

s in

in all

estim ate r equir em

~

latest ove

ability.

s

Cla

ss

m anufa

redger.

running hi

All

part

s a

information

from the use

an

d a

djusti

39500

.

cturing

ents.

MACHI

gh

re

NEC

Ne

s peed

made

that

of

by

will

Union

ng data,

centers,

OMPA

NY

w

3

Engineerin

g Department ·

Page 4

IDENTIFICATION

OF

MACHINES

Each

plate

Standard

the

letter"

letter

is

suffixed

Styles

number,

This

herein.

Class

back,

Operating

Single

chine.

Knife,

39500

Union

on

the

Style

Z".

"Z" . When

to

of

which

catalog

lt

can

39500.

etc.,

direction

Curved

Differential

Automatic

A

For

fabrics

nation

slips,

seams

seam

main

has

pajamas,

are a primary

widths,

and

39500 B For

fabrics

nation

has

shirts,

Seam

stitch

specification,

range,

39500 P For

fabrics

underwear

seam

width,

differential

39500

AF

Same

seaming

rayon

and

widths,

and

differential

Special

machine.

numbers

Example:

only

the

standard

machines

contains

applies

also

All

references

are

taken

Blade

Lubricating

seaming

of

cotton,

been

3/32

differential

seaming

of

cotton,

been

panties,

8-30

seaming

made

and

from

similar

1/8

feeds.

as

all

types

silk

3/32

and

carries

Style

numbers

have

"Style

minor

Style

similar

no

letters.

APPLICATION

specifically

be

applied

from

of

the

handwheel

STYLES

Needle,

Feed,

silk,

Trimming

light

or

and

designed

nightgowns,

requisite.

and

1/8

feeds.

light

silk,

designed

infants'

and

or

for

and

504-SSa-1;

per

inch;

medium

cotton

garments.

inch;

39500

fabrics.

1/8

and

stitch

P,

weights

Seam

inch;

feeds.

a

Style

one

or

more

39500

changes

number.

in

construction

Example:

to

with

to

discretion

directions,

operator's

is

away

OF

Two

Looper,

System.

medium

similar

especially

or

similar

Seam

inch;

stitch

medium

similar

general

children's

standard

cam

to

heavy

and

wool,

Seam

range,

except

fitted

of

specification,

stitch

range,

number

are

classified

letters

A".

Special

are

made

Example:

OF

CATALOG

the

standard

such

position

from

MACIDNES

Three

Mechanism

weight

weight

for

use

synthetics.

articles

specification,

range,

weight

weight

synthetics.

purpose

knit

seam

adjusted

weight

used

specification,

8-20

per

with

flat,

warp

8-20

which

is

stamped

as sta

ndard

suffixed,

Style

numbers

in a standard

are

"Class

Styles

to

some

as

while

"Style

grouped

right

39500

39500".

of

machines

special

and

seat

ed

operator.

Thread,

with

flat,

Overseaming

Spring Pressed

warp, and

The

on

women's

where

long

504-SSa-1;

8-30

flat,

per

warp,

inch;

The

seaming

wear,

widths,

main

flat,

on

snow

of

and

and

differential

warp,

suits,

similar

3/32

504-SSa-1,

inch;

cam

adjusted

39500 B sewing

and

ribbed

504-SSa-1;

per

inch;

cam

and

but

never

machine,

under

m'}ChineS

left,·

at

the

sewing

and

straight

cam

and

sewing

"T''

shirts,

and

and

sweat

parts.

knit

cotton,

standard

adjusted

in

the

special.

contain

contain

a

AZ".

a

Class

as

listed

front

machine.

Lower

ribbed

combi-

children's

hanging

standard

adjusted

ribbed

combi-

garments.

1/8

feeds.

ribbed

shirts,

standard

main

seam

name

the

11 Z 11

in

and

Ma-

knit

knit

polo

inch;

knit

and

For

wool

main

OILING

CAUTION!

must

be

ounges.

100

Fahrenheit

Ma

at

sight

between

filled

A

chine

gauge

gauge

Oil

before

straight

should

is

filled

on

front

lines.

was

drained

beginning

mineral

be

with

of

machine.

oil

used.

oil

from

to

operate.

of a Saybolt

at

spring

Red

4

machine

Oil

viscosity

cap

in

bulb

on

capacity

top

oil

when

cover.

level

shipped,

of

of

200

Oil

indicator

Class

to

250

level

so

reserv.o

39500

seconds

is

should

1r

is

six

at

checked

show

Page 5

OILING

(Continued)

Machine

keeping

oil

as

main

required.

Drain

It

is a magnetic

may

have

cally.

Each

denotes

size

Union

the

number,

measured

tively,

the

label

type

of

39500

standard

length,

needle

single groove,

chromium

is

automatically

reservoir

plug

screw

screw

entered

Special

kind

stamped

in

thousandths

and

size

all

needles

A,

39500

for

plated

the

of

these

in

filled.

is

located

designed

crank

needle

shank,

on

point,

the

of

number

packaged

B,

39500 P and

styles

shallow

sizes

022,

lubricated.

Check

at

back

to

accumulate

case.

It

NEEDLES

has

both

length,

needle

an

inch,

shank,

representthe

and

39500

is

Type

spot,

025,

027, 029,

No

oil

daily

of

machine

should

type

and size

groove,

midway

complete

sold

by

AF

154GAS.

long

oiling

is

before

near

possible

be

removed

number.

finish

denotes

largest

between

symbol

Union

Special.

use a curved

It

is a curved

tapered

032,

036,

necessary,

the

morning

bottom

foreign

and

and

other

diameter

shank

and

blade

point,

040,

edge

materials

cleaned

Th

e t

details.

eye.

which

needle.

blade,

struck

044.

other

start;

of

periodi-

ype

number

of

Collec-

is

given

standard

groove,

than

add

base.

which

The

blade,

on

The

To

have

a

sample

scription

Size

036".

needle,

on

Selection

should

pass

tion.

Success

use

of

needles

by a reputation

manship

for

Release

(U,

ating

socket

about

·

draw

Fig.

1)

and

direction

wrench

1/4

turn.

needle.

needle

label.

of

freely

in

the

orders

or

A

proper

through

operation

the

complete

packaged

for

producing

more

than

pressure

swing presser

until

No.

needle

21388

Again

type

needle

under

three

on

presser

AS,

turn

promptly

and

size

order

size

is

determined

needle

of

eye

Union

our

brand

highest

-quarters

CHANGING

foot

arm

(H)

is

at

its

furnished

handwheel

and

accurately

number

would

Special

in

read:

order

machines

name,

quality

of a century.

NEEDLES

by

turning

out

of

position.

lowest

with

until

point

machine,

needle

filled,

should

"1000

by

to

produce a good

size

be

forwarded.

Needles,

of

thread

can

~

needles

presser

in

materials

foot

Turn

of

travel.

loosen

is

at

high

an

empty

Type

used.

stitch

be

secured

which

release

handwheel

Using

needle

position;

package,

Use

de-

154GAS,

Thread

forma-

only

by

is

backed

and

work-

bushin

in

operhexagonal

clamp

nut

with-

g

To

to

the

needle

travel;

foot

release

replace

left,

in

this

then tig

needle,

insert

position,

hten

bushing

leave

needle

turn

nut.

(U).

needle

in

holder

handwheel

Return

holder

until

presser

it

until

arm

at

high

rests

holder

(H)

against

is

to

5

position

again

position;

and,

stop

at

re-lock

its

with

pin.

low

the

flat

Keeping

point

of

presser

Page 6

THREAD

STAND

Afterthread

throu

is

right

gh

back

thread eyele

threaded thr ough

hand

hol

tension dis cs

Only parts i n

Pa

rt s are

It

threading low

placed

will simplify

er

Before beg

at

ing dir e c

foot

by

of

positio

tion

turning presser

n .

Be sure threads,

tension

dis

cs (AD)

Double end

eye

let (E, Fig.

thread

of

heel

pull-o

frame

of

looper

lower

ff

looper

from left to r ig

are in

left

hand.

com

es from

each

e a

nd

up

(AD),

volved

in

their

threading thi

looper firs

inning

unt

il

needle

to

as

and

of

thread

1)

from rig

(T). Lead

thread gui

(K)

ht.

Left

cone on thread s

throu

throu

t, then

pair

gh slot

of

gh l e

down throu

hol

es

in

ft hand

hol

(AE),

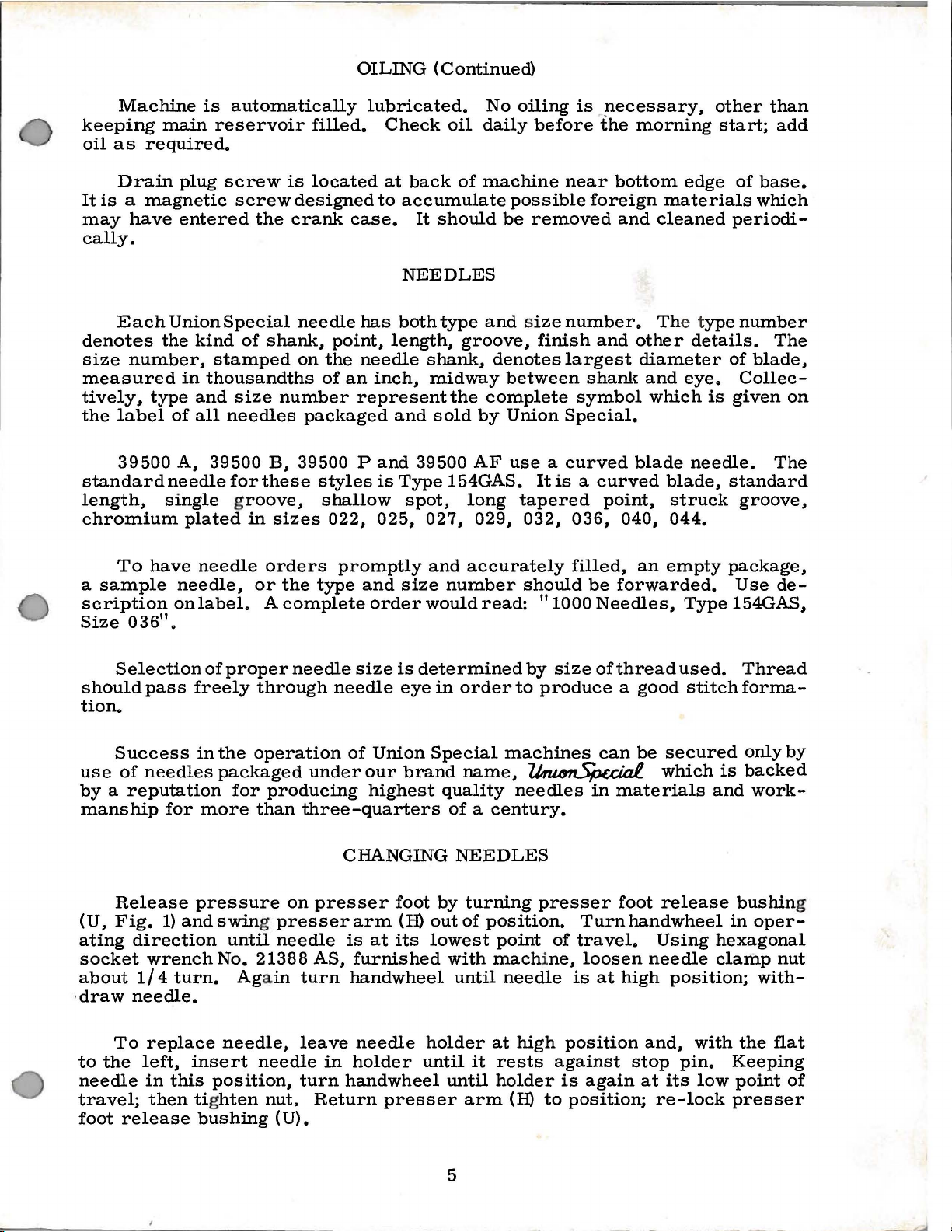

THREADI

in

thread

relative pos

ing are shown

ition

s m a chine to

t,

upper

thread,

loop

er second,

swing cloth pla

(N) i s at high position, re

foot

r el

ease bu

t hey

in

TO

come

diagonal

THREAD

and

lead

ht

to

left. Note:th

thread behind

de

(G).

is

all

the

eye

of

low

s hing (U); a

from

slots

LOWER

it

throu

fabric guard

Turn

way

er

handwheel

to the

loop

the

(AE)

e r

tand

(V,

Fig.

1),

it

is

gh

front thre

ten

sion thread guide

ad

eyelet (W) .

wire (A),

e . Then thread continues

and on

throu

gh

thread

NG

in

thr

eading diagr am (Fig. 1).

s f

or clarity

follow

.

recommend

ed seq

and needle third.

te open

tension

in

, t

lea

nd swi

thread guid

tens

ion

urn handwheel

se pressure

ng p

resser

e, a r e betwe

posts (AC).

LOOPER

gh

both eyes o f

r ea d

must

(F) and

in ope

left; th

can

be

en thr e

thread

low

er

looper

pass

in front of

throu

gh

rating direction

ad

throu

ed eas

ily

brought

Next it

down

between

guide

(B).

uence

in ope

on presser

arm

(H)

thread

looper

both

hole

unt

gh

both eye s

if

tweezers

up

of

r-

out

en

s

il

Turn

thre

ad

throu

through

bo

threadmu

loop

er

thread

and

down throu

ush

tube down, then

p

CAUTIO

pass ing

fr

T ur n ha

highest pos

eedle

n

hol

knurl

to secu

thread eyele

e in

top cov

T

he amou

ed tens

re

handwheel

gh

auxiliary

t h e

yes

of

s t pass

N !

om

ndw

tube

gh

Be

tube

heel

in

front

assembly

thread

sure

assembly

in oper

ition. Inser

t (R) ,

er needle thread

nt

of tensi

ion

nut

s (AA, Fig.

prop

er s

titch

TO

THREAD

until

point

loop

upper loop

of

loop

e r

UPPER

of

upper loop

thread

er

thread

er

thread

(M), lead thread

tube

as s em b

insert

thread

throu

upperlooperthr

to

upper loop

TO

THREAD

ati

ng dir

ecti

t needle thread from

under neck of

eyelet

THRE

on

on needle and

form

ation.

AD

1).

Tension on

LOOPER

er

(L)

is

all the way le

eye

let (D)

eye

let

pull-off

(C)

(T).

from

from

under neck

ly

(M). Pull

gh

upp

ea

d is

er ey

THE NE

on unt

r ig

top

cover cas

(P).

Thread

er

E D

il needle

thread

looper

ey

underlowerlooper

e.

LE

ht

to

left,

tin

ne

edle from

TENSION

looper threads is reg

threads

back

left

Aft

er

of top cov

out bottom

e f

rom front

(N, Fig

throu

g; th

en

should

ft. Lea

to

fron

to right .

pulling up

er cas

of

to

th

r e

adwh

.

1)

is

gh

both eye s of

down

throu

front.

ulated

be

by

only

d

t, then

Not

e:

upp

e r

tin

g

tub

e;

bac

k.

en

at

its

gh

thr

ee

enou

gh

6

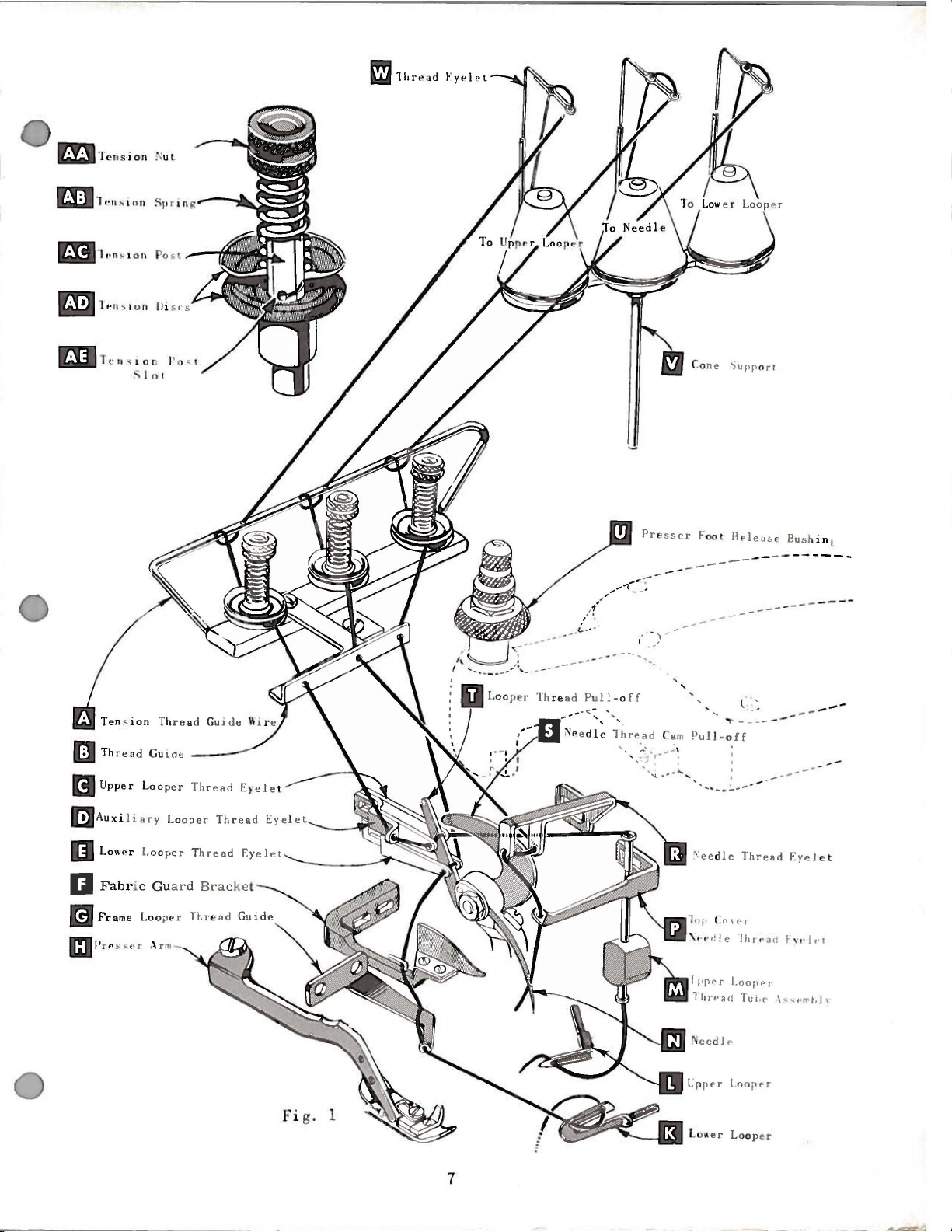

Page 7

~T

e nsion

Nul

rJiT,·nqon

IJ:I

T.,.,, ,

:;; )

Ten.,io

1!1

Thr e a d Gu 1

B U

pp

e r Loope

Posl

on

o!

n Th read

oe

r Thread E)·ele t

--

-

---

Pu

--

ll-

--

a

Thread

Presser Fool

---

....

,..

...

~

r·

"

"'-

Cam Pu

_..;

\

....

....

'

, _

ff

" ,-··

R~lea~~

-------------

--

Bushinl

----

-

--

,.

...

...

ll-off

...

...

____

---

..

,

--

--

-

......

--

-

I!JAuxil

D Loll

IJ F

B

iary

f'

r Looper T

abr

ic Guard Bracke

Fra

me

Lo opPr

Looper Th

hrea

read Eye

d Ey

elet

t

l e

Fi g. 1

7

~ eedle

Lp

pPr

Thread Fyel

l.oo

pn

~

_.,.

J,. \

et

___

.....

Page 8

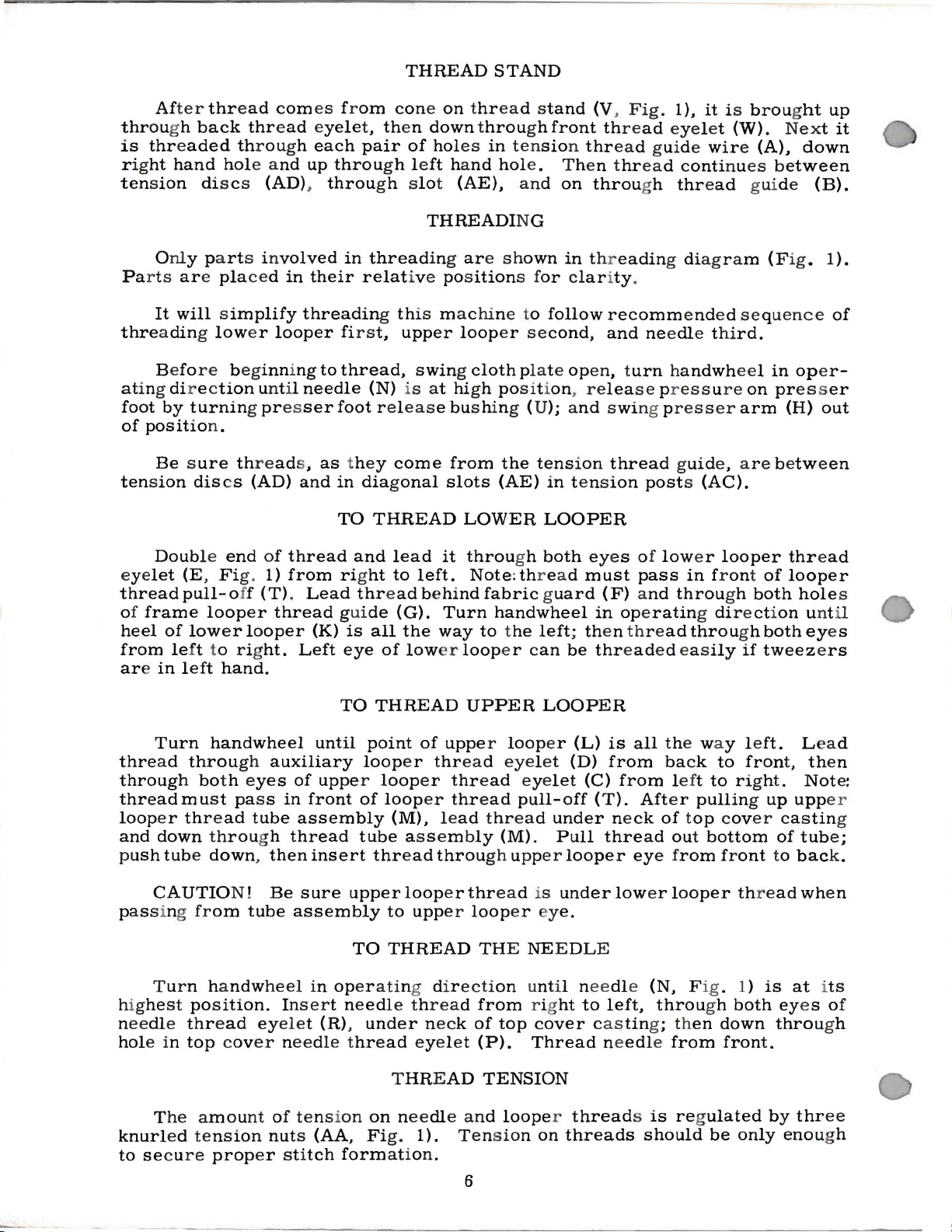

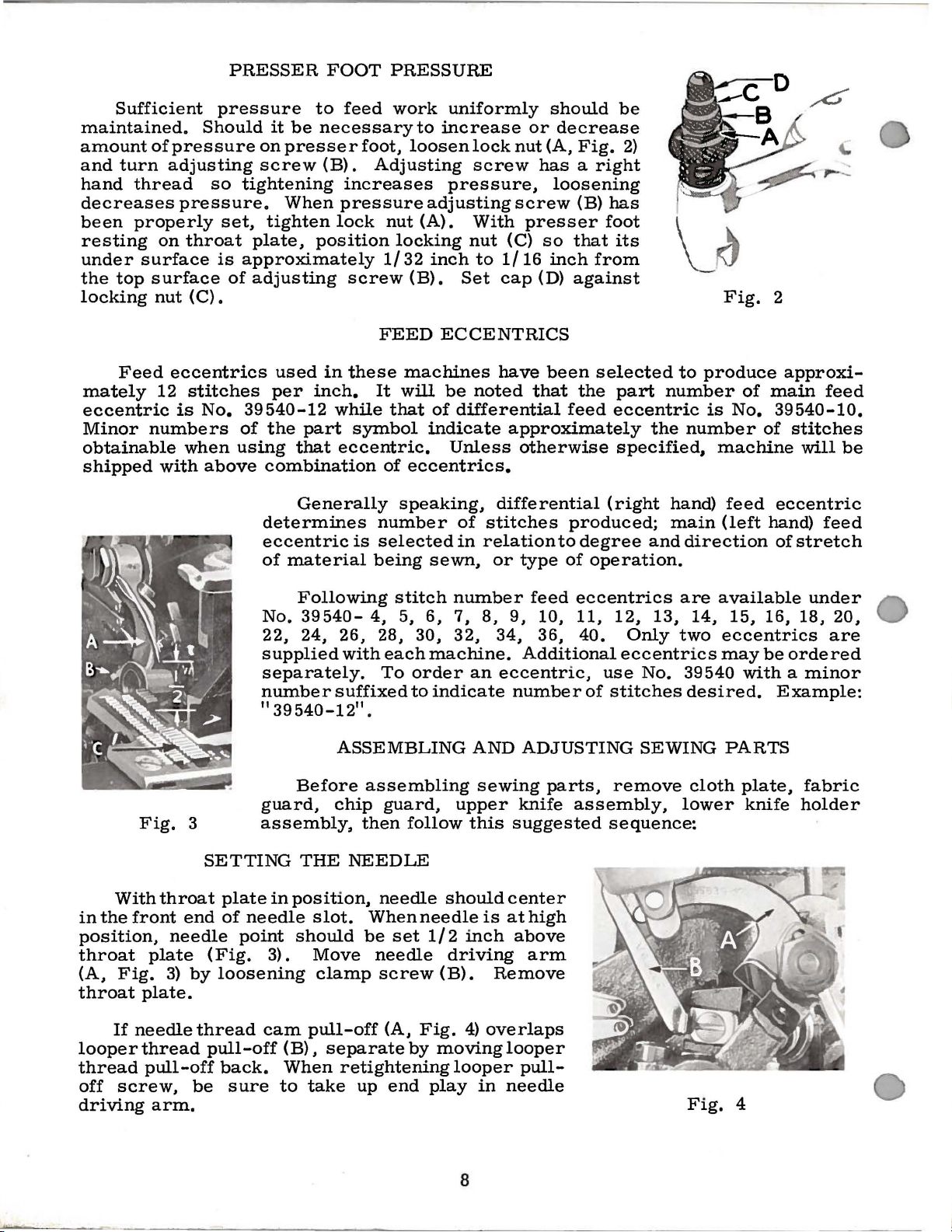

PRESSER

FOOT

PRESSURE

Sufficient

maintained.

amount

and

hand

of

turn

thread

decreases

been

resting

under

the

locking

properly

on

surface

top

surface

nut

Feed

mately

12

eccentric

Minor

numbers

obtainable

shipped

with

pressure

Should

pressure

adjusting

so

pressure.

set,

throat

is

of

(C) •

eccentrics

stitches

is

No.

when

using

above

to

feed

it

be

necessary

on

presser

screw

(B).

tightening

When

tighten

plate,

pressure

lock

position

approximately

adjusting

used

per

39540-12

of

the

inch.

part

that

in

while

eccentric.

combination

Generally

determines

eccentric

of

material

work

foot,

loosen

Adjusting

increases

nut

locking

1/32

screw

(B).

FEED

these

machines

It

will

that

symbol

of

eccentrics.

speaking,

number

is

selected

being

uniformly

to

increase

lock

screw

pressure,

adjusting

(A).

With

nut

inch

to

1/16

Set

cap

ECCENTRICS

have

be

noted

of

differential

indicate

Unless

differential

of

stitches

in

relation

sewn,

or

should

or

decrease

nut

(A,

Fig.

has a right

loosening

screw

presser

(C)

so

inch

(D)

been

that

(B)

has

foot

that

from

against

selected

the

feed

eccentric

approximately

otherwise

(right

produced;

to

degree

type

of

operation.

be

2)

its

to

part

number

the

specified,

hand)

main

and

Fig.

produce

of

is

No.

number

machine

feed

(left

direction

2

approxi-

main

feed

39540-10.

of

stitches

will

eccentric

hand)

of

feed

stretch

be

Fig.

With

in

the

front

position,

throat

(A,

Fig.

throat

If

needle

looper

thread

off

screw,

driving

3

throat

end

needle

plate

3)

by

plate.

thread

pull-off

arm.

SETTING

plate

of

needle

point

(Fig.

loosening

thread

pull-off

back.

be

sure

Following

No.

3954022, 24, 26,

supplied

with

separately.

number

11

39540-12

suffixed

ASSEMBLING

Before

guard,

chip

assembly,

THE

in

position,

NEEDLE

slot.

should

3).

Move

clamp

cam

pull-off

(B).

separate

When

to

retightening

take

stitch

4,

5,

6,

28,

30,

each

machine.

To

order

11

to

•

assembling

guard,

then

follow

needle

Whenneedle

be

set

1/2

needle

screw

(A,

Fig.

by

up

end

play

number

7,

8,

32,

an

indicate

AND

sewing

upper

this

should

is

inch

driving

(B).

4)

overlaps

moving

looper

in

feed

9,

10,

34,

36,

Additional

eccentric,

number

ADJUSTING

parts,

knife

suggested

center

at

high

above

arm

Remove

looper

pull-

needle

eccentrics

11,

12,

40.

Only

eccentrics

use

No.

of

stitches

SEWING

remove

assembly,

sequence:

13,

are

available

14,

two

eccentrics

may

39540

desired.

PARTS

cloth

lower

Fig.

under

15,

16,

18,

be

ordered

with a minor

Example:

plate,

knife

fabric

holder

4

20,

are

8

Page 9

SETTING

THE

NEEDLE

(Continued)

Fi

g. 5

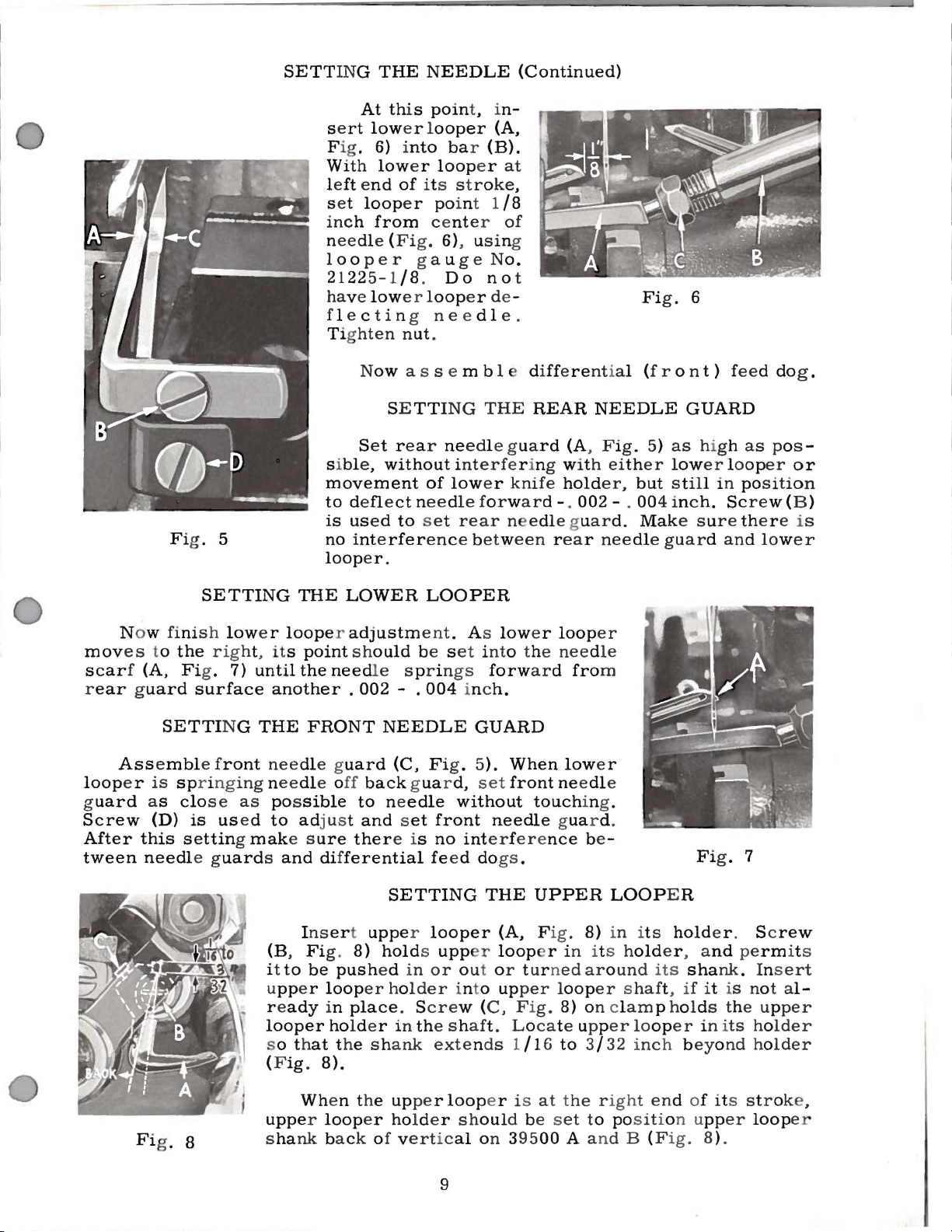

At this

se

rt

low

ig

. 6) i

F

W

ith

low

left e

nd

loop

s et

inch from

needl

l

21225-1/8.

ha

fl

Tighten nut

si

movement

to deflect needle

is used

no interference betw

looper.

e (Fig. 6), using

oo

per

ve

low

e c

tin

N

ow

Set r ea r need

bl

e,

without

poin

t, i

er l

ooper

nto

er

loop

of its s t r oke,

e r

po

center

g a u

Do

e r l

oop

g

needl

.

as

s e m b 1 e differential (fro n

SE

TT

ING

of

to

s et

(A,

bar (B).

er

int 1

ge No.

no

er de -

THE

le gua

int

erfe

low

er

for ward-. 002-

rear

n-

at

/8

of

t

e .

REAR

rd

r ing w

knife

n edle guard.

een rear needle

NEEDLE

(A, F ig . 5)

ith eith

hold

er,

Fi

g . 6

t) feed do

GUARD

as

high

er low

but still

. 00 4 inc

Mak

er loop

in positi

h. Scre

e s u

re ther e i s

guard and lower

as

g .

pos -

er

or

on

w (B)

Now fini

mov

es

scar

f (A, Fig. 7)

ear guard

r

Assembl

loop

e r

uard

g

Screw

After

tween

as

this

needl

SETTING

s h

low

to

the rig

SETTI

is spr inging needle o

clo

(D)

is used

setting mak

ht, its

surface

NG

e f

ront

se

as pos

e g

uards and dif

THE

e r

looper adjustm

point should

until

the

another . 002

THE

FRONT

needle g

sible

to adj us t

e s

ure

Insert upper looper

(B, Fi

it

upper

r e

looper holder in the s h

s o th

(Fig.

to

ady

g.

be

loop

in

at

8).

LOWER

need

le s pr in

NEEDLE

uard

ff

ferential

push

the s h

(C, Fig. 5).

back guard,

to needle

and set

ther

e is

SETTING

8)

holds upp r loop

ed in

er holder

place

ank

LOOPER

ent . As

be se t into the

- .

004

front

no

fe

ed dogs

or

. S

cre

extends 1/16 to

low

gs

forward

inc

h.

GUARD

set

without

needle gua

interfere

THE

(A, Fig. 8) in it s

out o r t ur n

into upper loop

w (

C,

aft.

er

loop

er

needle

fro

m

When

front needle

Fig. 8) on

L ocate upp

touch

nce

.

UPPER

er

low

e r

ing.

r d .

be-

in its h

ed aro

er shaft,

3/ 32 inch beyo

LOOP

und

clam

er loop

E R

old

er , a

its

p holds the up

er

Fi

g. 7

hold

er . Sc

nd permits

shank. Ins

if

it

is not a

in i

ts holder

nd holder

rew

ert

l-

per

Wh

Fi

g . 8

en the upper loop

upper loop

ha

nk

s

back of vertical

er holder shoul

9

er is

d be s

on 395

at the right en

00

d of its str oke ,

et

to position upper

A a nd B (F

ig.

8).

loop

er

Page 10

SETTING

THE

UPPER

LOOPER

(Continued)

NOTE:

holder

about

clearance

looper

the

lower

0.

**

looper

002

to

vertically.

holder

looper

*

On

should

between

around

o.

004

Fig.

Styles

be

in

or

its

to

clearance

10

39500 P and

set

to

position

Be

sure,

heel

of

out

of

upper

shank,

the

left

looper

check

point

throat

is

(A,

setting

*1/2

increased

wise

inch

of

may

slightly

the

on

all

looper

(Fig.

Next,

necessary,

NOTE:

is

upperlooper

and

looper

set

upper

of

the

lower

9).

turn

is

at

the

dimensions

with

plate

Fig.

and

looking

be

respect

(Fig.

10).

for

Styles

ForStyles

;~:*9/64.

by

increased

necessary

to

maintain

AF,

the

upper

styles,

casting.

shaft

looper

looper

handwheel

left

end

of

10).

do

it

Figure

39500 A and

Forexample,

turning

from

left

by

shaft.

to

upper

looper

By

and

point

of

upper

to

by

39500 P andAF,

upper

pulling

Afterthese

turn

the

looper

shank

there

adjusting

by

turning

to

cross

eye

until

its

travel;

looper

needle

If

resetting

moving

10

represents

looper

end

of

upper

upper

condition

is

with

and

the

B.

machine;

a

upper

the

thesettings

dimension

holder

dimension

looper

changes

looper

shown

around

in

Fig.

looper

counterclock-

holder

9

holder

dimensional

31/64inchis

left,

are

made,

its

shank

Fig.

9.

are

5/32

out

it

When

quickly

when

needle

looper

upper

looper

back

and

looking

dimensions

as

upper

eye

(Fig.

NOTE:

looper

Check

and

of

upper

rotate

from

the

correct

follows:

looper

should

11)

For

and

setting

needle

looper,

looper

of

Figs.

for

Styles

needle

on

left

setting

As

eye

be

about

Styles

to

needle

a

end

9,

Fig.

upper

centers

level

39500 P

should

avoid

downstroke.

pull

looper

short

of

10, 11.

12

is

obtained,

looper

on

39500 A and

interference

distance

machine.

the

with

and

align

out

is

needle,

top

AF,

exactly.

of

10

it

can

be

checked

moving

surface

B.

If

its

counterclockwise,

Reset

to

the

bottom

of

upper

the

eyes

between

needle

holder

to

three

so

in

checked

with a straight

should

plate

tilting

raises

both

of

upper

rubs

slightly

maintain

SETTING

On

feed

the

top

the

feed

right,

of

Style

same

now

surface

adjusting

or

the

the

the

THE

39500

dogs

surfaces

plane.

by

sighting

be

leveled

lowers

bars

FEED

(A,

of

edge.

by

pin

the

atthe

Fig.

11

A,

B, C,

teeth

This

across

Feed

with

rotating

(D).

back

same

DOGS

set

Fig.

all

can

teeth

dogs

throat

feed

This

end

time.

all

12)

lay

be

pin

of

Page 11

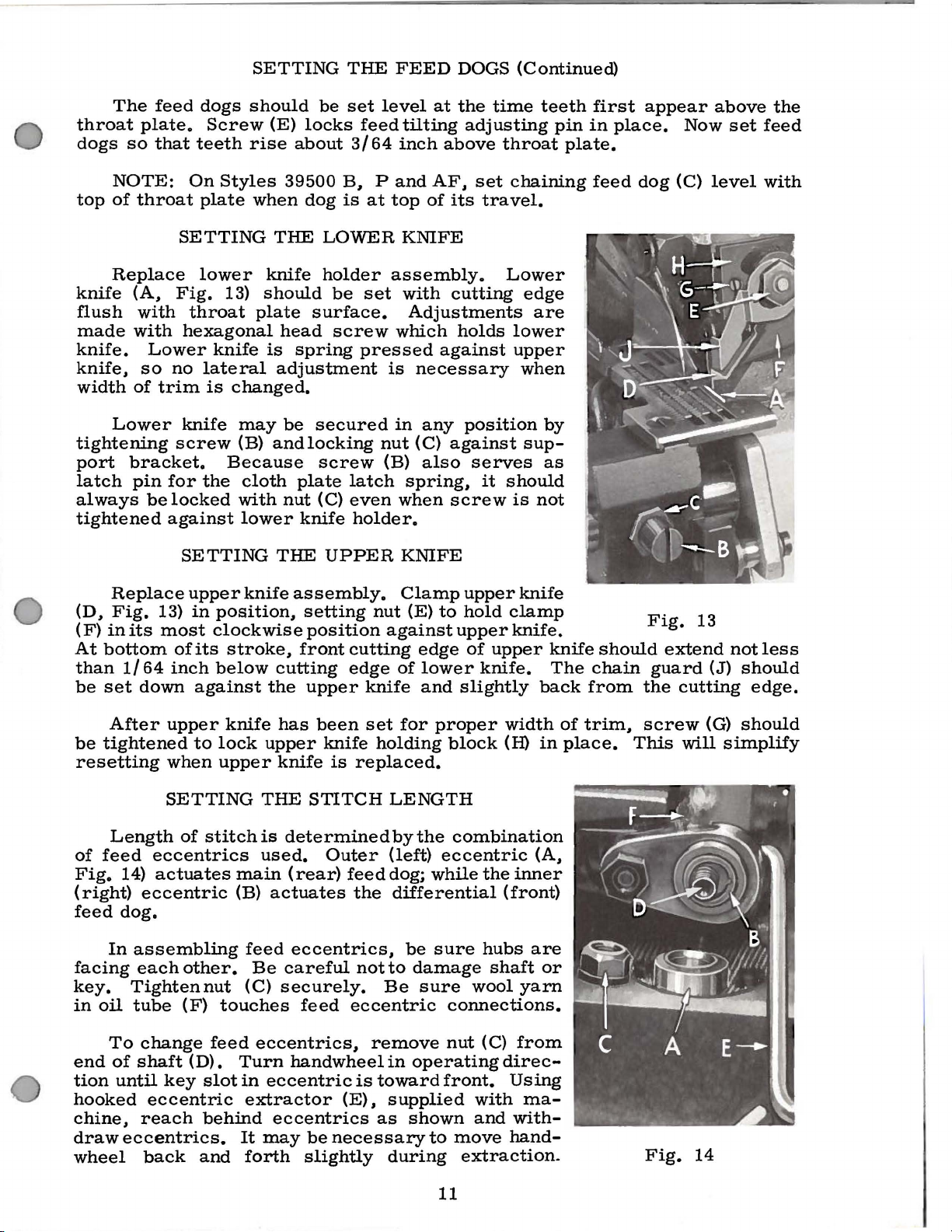

The

throat

dogs

plate.

so

feed

that

dogs

Screw

teeth

SETTING

should

(E)

rise

be

locks

about

THE

set

feed

3/64

FEED

level

tilting

inch

DOGS

at

the

adjusting

above

(Continued)

time

teeth

pin

throat

first

in

plate.

appear

place.

above

Now

set

the

feed

NOTE:

top

of

throat

Replace

knife

flush

made

knife.

knife#

width

(A#

with

with

Lower

so

of

Lower

tightening

port

latch

always

bracket.

pin

belocked

tightened

Replace

(D #

Fig.

(F)

in

its

At

bottom

than

be

set

1/64

down

On

plate

SETTING

lower

Fig.

throat

hexagonal

no

lateral

trim

is

knife

screw

for

the

against

SETTING

upper

13)

in

most

of

its

clockwise

inch

against

Styles

when

THE

knife

13)

should

plate

knife

is

adjustment

changed.

may

(B)

andlocking

Because

cloth

with

lower

THE

knife

position#

stroke#

below

cutting

the

39500

dog

LOWER

holder

be

surface.

head

screw

spring

be

secured

screw

plate

nut

(C)

knife

UPPER

assembly.

setting

position

front

upper

B# P and

is

at

top

KNIFE

assembly.

set

with

Adjustments

which

pressed

is

necessary

in

nut

(C)

(B)

latch

even

spring#

when

holder.

KNIFE

Clamp

nut

(E)

against

cutting

edge

of

knife

AF#

of

its

cutting

against

any

against

also

screw

to

edge

lower

and

set

travel.

Lower

holds

position

serves

it

should

upper

hold

upper

of

upper

knife.

slightly

chaining

edge

are

lower

upper

when

by

sup-

as

is

not

knife

clamp

knife.

knife

The

back

feed

should

chain

from

dog

Fig.

guard

the

(C)

level

13

extend

(J)

cutting

with

not

less

should

edge.

After

be

tightened

resetting

Length

of

feed

Fig.

14)

(right)

feed

dog.

In

facing

key.

in

Tightennut

oil

tube

To

end

of

tion

until

hooked

chine#

draw

eccentrics.

wheel

upper

to

lock

when

SETTING

of

stitchis

eccentrics

actuates

eccentric

assembling

each

other.

(F)

change

shaft

key

feed

(D).

slot

eccentric

reach

back

behind

and

knife

upper

upper

THE

used.

main

(B)

actuates

feed

Be

(C)

touches

eccentrics#

Turn

in

eccentric

extractor

eccentrics

It

may

forth

has

been

knife

STITCH

knife

is

replaced.

set

holding

LENGTH

determinedbythe

Outer

(rear)

feed

the

(left)

dog;

differential

eccentrics#

careful

securely.

feed

not

to

Be

eccentric

remove

handwheel

is

(E)#

in

toward

supplied

as

be

necessary

slightly

during

for

proper

block

combination

eccentric

while

be

sure

damage

sure

connections.

nut

operating

front.

shown

to

move

width

(H)

in

(A#

the

inner

(front)

hubs

wool

(C)

shaft

yarn

from

are

or

direc-

Using

with

and

ma-

with-

hand-

extraction.

of

trim#

place.

screw

This

Fig.

(G)

will

14

should

simplify

11

Page 12

SETTING

Fig. 15

THE

STITCH

LENGTH

If

(Conti

eccentri

nue d)

cs a

fitting. in addition

Fig. 15) from s

ful

to

remove

connec

n

all

a r m .

press

lo

foo

s

lots by shiftin

tion

y s ug

SE

A

ges

TTI

ss

emble press

With needle in high posi

er arm into sewi ng position

ck

in

plac

t c

an

be r e

haft

nut (G) a

(H) . Then c

ted.

NG

THE

e .

If

ali

gne

g f

re

unusua

to remov

(D),

it

m ay

nd feed driving

ontin

PR

ESSER F

er foot to

necessary,

d wi

th

oot

lift

er

lly tig

ing nut

be help-

ue

as

or ig

OOT

pres

tion, swin

presser

thr oa t

plate

lever s

ht

(C,

i-

ser

g

and

haft.

Foot

and

collar

presser

presser foot

To

center

lifter

(B) s e c

arm does

r elea s e bushi

pr

ess

with respect to

loose

n p r e s s e r f

Adjust lifter lev

that presse

than

nut

s i

ton

upper

(D).

tio

n, tur n the h

upper

loope

gue.

the pr

low

er the toe of f

not con

motion

is

made wit

ina

F

r foot

looper wi

To

find

r is di

Ra

ise

pr es s er foot

esser foot treadle and

tact the upper

of

foot lift

h s crew

lly

, re-as

lever

ure

not

arm

the

(A, Fig. 16)

s h

bind and

ng is un

er

foot

and stitch tongue

throat pla

oot

er

can

ll per

stop

be

te need

hi

n g e s c r e w.

s crew (C) s o

r a ised

mit; the

this maximum

andw

rec

hee

l s o point of

tly over presser

by

oot.

Height a d

looper.

er

lever before presse

(E),

loc

ked with

semble

ch

STARTING TO

aft

. Be sur e

rise when

locked.

le hole,

no hig

her

n, lock

safe

po-

foo

t

dep

ress

ing

man

ually

justment

There

is c

sh

r f

nut (F ).

ip guard, fabr

orrect

ould

oot

if pres

be from

beg

ins

ic guard, clot

OPERATE

to

Fi

g.

ser

1 I 16

r i

se.

h pl

16

foot

to

Th

ate.

ton

gue does

1 I 8

inch free

is

adjustment

Be

sure ma

7). W

zontal

s

lowly

off

se

it

h thr e

and in t

, without presser foot

the

tongue freely.

w s lowly .

While sewi ng on

a

ll needle thr ead is dra

threa

to pu

at

th

d s h

ll

bottom

rea

d cam

ould

dow

n slightly

chine

ad

is threa

tensions

he middle

ma

be just tight enou

if excessi

of stro

pull-o

ke, pos ition n

ff (S) ju

ded

Swin

NEE

ter ia

wn

accordi

ligh

t,

set

of their

in place, to

g press

DLE

TH

l, check nee

on n

eed

gh to

ve

thread

eedle

fro

er foot in

le

ng

to thr

loo

per thr e

nt t o b

make sure

RE AD CON

dle thread

dow

n s

feed chai

is

pull

thread eyel

st contacts needle thread.

12

ad

ack

to

posit

trok

n off s t

ed

eading diagram

eyel ets (C &

locations

that

cha

.

in

ion, inse

TROL

control

e.

At

itc

on the

et

(R,

as

top

h tongue.

up strok

Fig . 1) s o that nee

(Fi~

.

E) about

Op

e ra

te machine

forms and

rt

m ateria

follow

of

s : Us

needle s

Sti

tch

e .

With needle

1, p

age

hori

mov

l,

an

ually

troke,

tend

dle

-

es

d

s

Page 13

On

eyel

e t we

the nee

NEEDLE

Styles 39500 P and

ll-

dl e

forwar d

thread.

(towa

THREAD

AF,

it is d

r d the oper

CONTROL

esi

ra b

le

ato

r)

to dela

(Continued)

to a

dju

y.

st the need

slig

htl

y. the

le

thread

tighte

pull-o

ning

ff

of

W i

th

materi

1)

back

far enou

reaches its

1/8

inch distan

guide

of

of

(G)

lower

its

travel.

should

looper

While s

portion

A

lower loop

drawn

lower loop

all three

tensio

throu

er

Befo

re

tensio

ns will not marke

LOWER

al

und

gh

so

mo

st r

earward

ce

behind nee

be

(K)

heel eyelet

ewing on

of

low

er

looper

er thr

gh the t

ead

thread

ension

eyel

proceeding

ns

to give a normal

er pre

thread

set

with

mat

eri

comes

t (E)

UPPER

to adjust

dly

LOOP

E R

TH

READ

sser foot. set lower

is a littl

e sla ck

position. Loop

dle

thread

its left h

at the tim e

cam pull-off (S).

and

eye

low

al. check drawing

thread

off

while low

LOOPER

effe

should

upp

er

looper

er l

down. keep

THREAD

upper

loop

appe

ct the

purl.

be drawn

ooper thre

ing the s

er thre

a r

ing stitch.

CONTROL

looper

when

er

let

er

looper thread

thread

approximately

loope

off

of

throu

.

To incr

ad

ame

CONTROL

ad eyelet (C. Fig.

thread

pull-of

Fr

r is

loop

er

gh

ease

is

on

amount

Mod

era

eyel

et

(E.

pull-o

f (T)

is set

ame loop

ff (

abo

er threa

1/8 inch rig

at extreme left e

thread

the

amo

upp

er

of

te

as follow

tension

unt of thre

looper.

pull-o

ff action.

1)

chan

ge

befor

mov

balanc

in these

F ig .

T)

ut

d

ht

nd

s :

e

ad

e

e

During needle down

will draw upper

oop

e r t h

l

up

as

To

F

ig.

bett

er t o

If

up

all end

that

so

will tend

n

earer

The needl

terial

high

thread

creas

read is

looper thread

movethe purl

1) s

hould

have slig

it

becomes

play

in needle drive

it

is

highe r over t

to

for m n

bot

tom e d

e thre

being sewn. In

as

possibl

e without

t ension should be

es. or until the

looper

drawn.

be r a

ne

ear

ge.

stroke, forwa

thre

ad

throu

upper

looper thr

r d s

gh the tension.

pull-off reaches its mo

POSITIONING

more

ised keeping

htly

cessary

top edge.

ad

tension requ

pur

unde r

mo

r e

pull-off

to

move

shaft

hroat

plate than

THREAD

general.

low

causing need

increased

l is

pulled

the

edg

the

same amount

on

loop

before

If

upper loop

TENS

ir e d

er loope r t hr e

le thread to

as

lon

too

tro

ke

of

loope

ead

will

have almost all slac

st r

earward

THE

e.

er thre

is

PURL

both looper thread eyelets

upp

er

thre

ad pull-o

tighte

rec

nin

ommend

er

is too

IO

S

g.

a function

ad

be

pull

g as t

far over the

he

elasticity

top

r thread pull-off

When

norm

position.

of

pull-o

ad

than

ff

(T).

If

upp

er

ed

in

(F i

low. the pu

of needle thread and

tension shoul

ed

dow

.

(T)

al

am

oun

t of

k t ake n

(C &

ff.

Usually

it

on lower thread

be

sure

to take

loop

er is loca

g.

10). the pur l

te d

rl will form

ma-

d be

set

n. Upper loope

of the

cha

in in-

E,

is

.

as

r

13

Page 14

H

TO

REMOVE

Fi

g. 17

CRANKSHAFT

Crankshaft

1.

Drain

cated

edge

2.

Remove

on

of

can

oil

back

base.

top

chine.

3.

Remove

and,

feed

with

tractor,

4.

5.

6.

7.

Remove

Remove

Identify

they

per

Remove

shaft

reached

Remove

at

key

these

will

places.

screw

split

through

caps

points

assembling bearing

they

are

Trade

halves

should

ings.

marks

ofthe

be

Also,

assembled

8.

which

Loosen

holds

Access

cover.

until

they

clamp

upper

to

Draw

upper

connecting

moval

bearing

shaft.

of

point

Observe

re-assembling

above.

9.

Remove

inner

screw

screw

right

is

reached

casting.

10.

11.

12.

13.

bearing

14.

Crankshaft

Loosen

remove

Remove

(N}.

Loosen

(R}.

Remove

two

both

screw

two

three

retaining

be

withdrawn

by

removing

of

machine

and

bottom

eccentric

the

aid

slip

off

(G).

three

counterweights

be

re-assembled

(J}

bearing.

bottom

of

bearings

A, B,

in

their

are

caps

on

the

same

screws

in

the

were

removed.

nut

knife

clamp

driving

knife

rod

driving

(D)

bearing

(C,

same

cap

(K,

crankshaft

through

screws

halves

(M};

screws

screws

may

easier

plug

screw

near

covers

nut

(E,

of

the

eccentric

the

eccentrics

counterweights

in

the

which

and

holds

This

of

bed

on

D.

caps

original

screw

crankshaft

When

make

position.

stamped

and

both

trade

side

of

the

should

same

(A,

driving

nut

Fig.

is

arm

holes

18}

arm

through

to

lever

drop,

cap

Fig.

allowing

(E).

17}

This

on

precautions

as

described

Fig.

17}

which

bearing.

bottom

(L}

in

fan

of

cooling

take

off

pulley

(P};

remove

(S};

take

plate

(T}.

now

be

removed.

if

these

lo-

bottom

of

rna-

Fig.

17}

ex-

(F).

(H).

so

that

pro-

crank-

is

casting.

re-

sure

on

both

marks

bear-

be

re-

from

which

(B).

top

the

left

(C)

and

re-

is

at

crank-

when

in

holds

This

of

bed

collar;

fan.

cap

pulley

off

steps

15.

16.

17.

are

followed:

If

necessary

(V},

it

should

an

arbor

it

it

(U}.

must

seats

be

Carefully

foregoing

re-assembly

ing

exploded

ti

on

of

testing

will

for

also

to

press.

pressed

against

observing

operations

of

view

various

binds

prove

replace

be

pressed

In

ground

crankshaft.

parts

during

helpful.

Beforere-assernbling,

clean

and

bottom

pressed

crankshaft

in

The

spring

drain

fore

leakage.

and

dry

gaskets.

cover

oil

wick

bearing

casting

wick

and

stands

against

plug

with a sealing

re-assembling

No. 1 Crane

top

Before

make

which

that

v e r t i c

bottom

replacing

on

carefully

thrust

reverse

should

drawings

and

re-assembly

thoroughly

and

bottom

re-assembling

sure

lubricates

is

inserted

it

contacts

cover.

compound

to

prevent

Lead

ball

off

that

ally

bearing

shaft

bearing

until

washer

of

simplify

Check-

for

loca-

constant

covers

spring

left

in

hole

shaft.

on

Coat

be-

Seal

on

the

its

oil

oil

is

recommended.

7

Fi

g. 18

14

Page 15

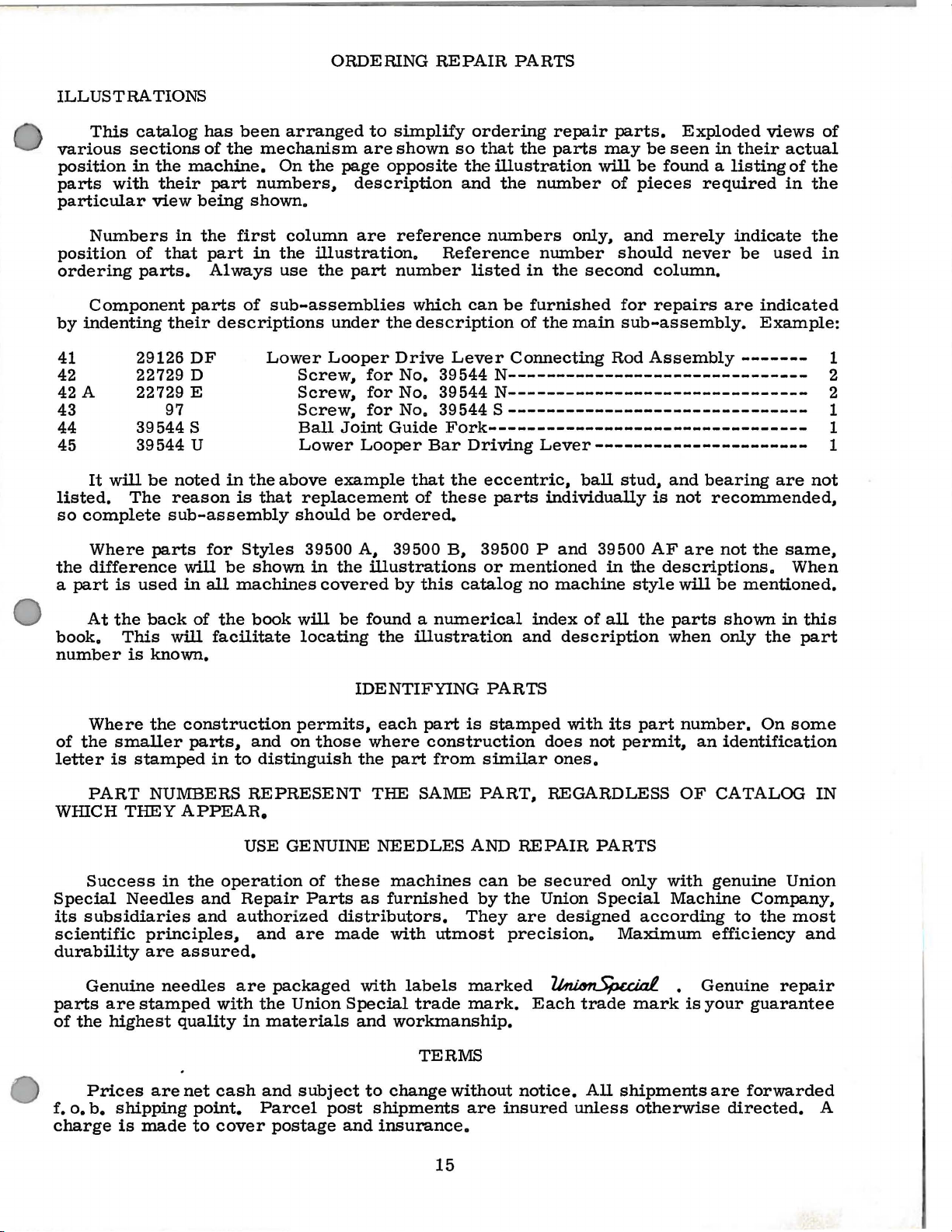

ILLUSTRATIONS

This

catalog

various

position

parts

particular

sections

in

with

view

the

their

machine.

being

has

of

part

been

arranged

the

mechanism

On

numbers~

shown.

ORDERING

to

are

the

page

description

REPAIR

simplify

shown

opposite

ordering

so

that

the

illustration

and

PARTS

the

the

number

repair

parts

parts.

may

will

of

Exploded

be

seen

in

be

found a listing

pieces

required

views

their

of

actual

of

the

in

the

Numbers

position

ordering

Component

by

indenting

41

42

42 A

43

44

45

It

will

listed.

so

complete

Where

the

difference

a

part

At

book.

number

of

parts.

29126

22729 D

22729 E

39544

39544

be

The

is

used

the

back

This

is

in

the

that

part

Always

parts

their

descriptions

DF

97

s

u

noted

reason

sub-assembly

parts

will

known.

for

will

in

all

of

the

facilitate

in

be

first

in

column

the

use

of

sub-assemblies

Lower

Screw~

Screw~

Screw~

Ball

Lower

the

above

is

that

replacement

should

Styles

shown

39500

in

machines

book

will

locating

are

reference

illustration.

the

part

number

under

Looper

for

for

for

Joint

the

Drive

No.

No.

No.

Guide

Looper

example

be

ordered.

A.

39500

the

illustrations

covered

be

by

found a

the

numbers

Reference

listed

which

can

description

Lever

39544

39544

in

be

of

Connecting

N------------------------------N-------------------------------

only~

number

the

second

furnished

the

main

and

should

for

sub-assembly.

Rod

39544 S -------------------------------

Fork---------------------------------

Bar

Driving

that

the

eccentric~

of

these

B~

39500 P and

or

this

catalog

numerical

illustration

Lever----------------------

ball

stud~

parts

individually

39500

mentioned

no

machine

index

and

in

of

all

description

the

style

the

merely

never

column.

repairs

are

Assembly

and

bearing

is

not

recommended~

AF

are

not

descriptions.

will

be

parts

when

shown

only

indicate

be

used

indicated

Example:

-------

are

the

same~

When

mentioned.

in

this

the

part

the

in

1

2

2

1

1

1

not

Where

of

the

smaller

letter

is

PART

WHICH

Success

Special

its

subsidiaries

scientific

durability

Genuine

parts

of

the

are

highest

Prices

f.

o.

b.

shipping

charge

is

the

construction

stamped

NUMBERS

THEY

APPEAR.

in

Needles

principles,

are

assured.

needles

stamped

quality

are

net

made

parts,

in

the

operation

and

and

with

cash

point.

to

cover

permits~

and

on

those

to

distinguish

REPRESENT

USE GENUINE

of

these

Repair

authorized

and

are

the

in

Parcel

Parts

are

packaged

Union

materials

and

subject

distributors.

made

post

postage

IDENTIFYING

each

part

where

the

THE

construction

part

from

SAME

NEEDLES

machines

as

furnished

with

utmost

with

labels

Special

and

trade

workmanship.

TERMS

to

change

shipments

and

insurance.

PARTS

is

stamped

similar

PART,

AND

can

by

They

marked

mark.

without

are

insured

with

does

ones.

REGARDLESS

REPAIR

be

secured

the

Union

are

designed

precision.

~

Each

notice.

unless

its

not

PARTS

Special

Maximum

trade

All

part

number.

permit,

OF

only

with

Machine

according

•

mark

is

shipments

otherwise

On

an

identification

CATALOG

genuine

Company~

to

the

efficiency

Genuine

your

guarantee

are

forwarded

directed.

some

IN

Union

most

and

repair

A

15

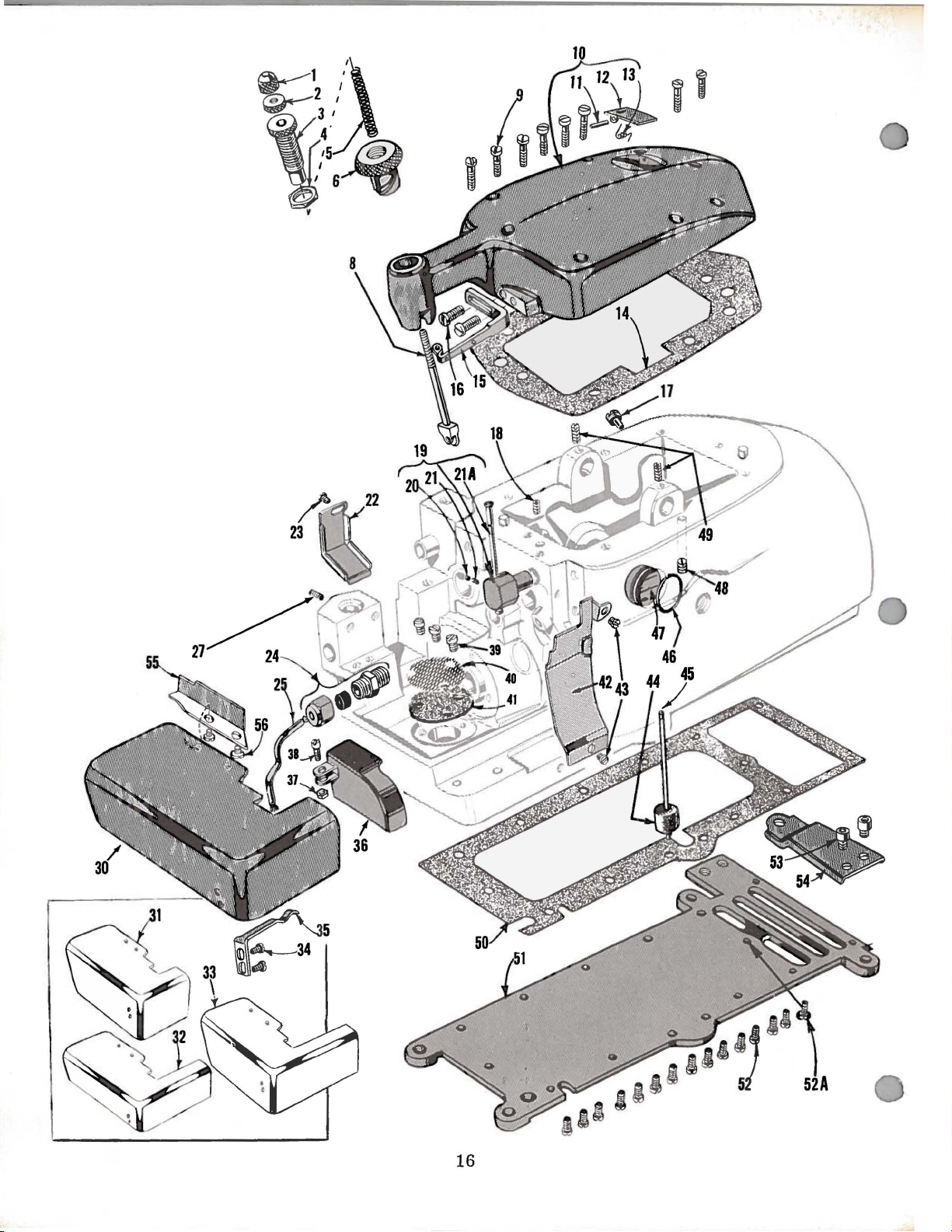

Page 16

16

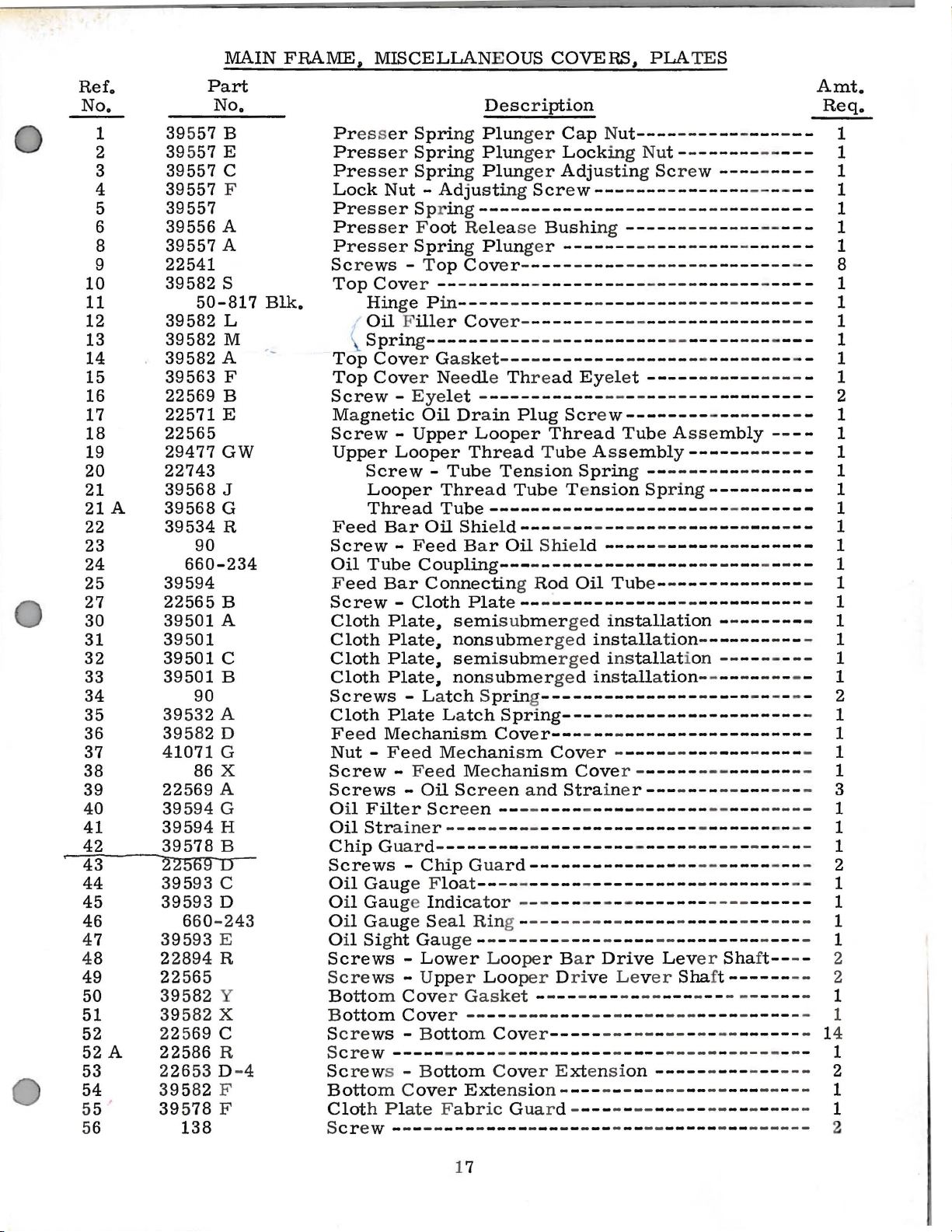

Page 17

MAIN

FRAME,

MISCELLAN

E OUS

COVERS,

PLATES

Ref.

No.

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

17

18

19

20

21

21

22

23

24

25

27

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

52

53

54

55

56

A

A

Part

39557

395

57

39557

39557

39557

39556

39557

22541

39582

39582

39582

39582

39563

22569

22571

22565

29477

22743

39568

39568

39534

39594

22565

39501

39501

39501

39501

39532 A

39582 D

4

107

22569

39

39594 H

395

A

A

s

50-817

A --

E

GW

J

G

90

660-234

B

A

c

B

90

1 G

86

X

A

594

G

78

B

nssgu

39593

39

39

2

2894

22

39582

39

225

22586

22653

3

95

39578

593

660593

565

582

69

82 F

138

c

D

E

R

y

X

c

R

D - 4

F

B

E

c

F

L

M

F

B

R

243

Blk.

Description

Pr

es s

er

Spri

ng

Plun

ger

Cap Nut---Presser Spring Plunger

Presser Spring Plunger

Lock

Presse r Spring

Press

P resse r

Screws

Top

Top

Top

Screw-

Magne

Screw-

Upper

Nut -Adjusting

er F

oot Relea

Spring Pl

- T

op

Cov

er

----------

Hin

ge Pin--

1'

Oil Fill

er

Spring------

Cov

er

Gas k

Cov

er Needle Thre

Eye

let -

tic

Oil Dra

Upper

Looper

----------------unger

Cov

e r -

- ----------

Cov

er -

-

------

et----

----------in

Loop

Thread Tub

Lock

Adju

Screw---------------

se

Bushi

-------

-----------------------

-------

-----

----------

-------ad Eyelet -----

Plug

Screw--------

er

Thread

Screw -Tube Tension Spring -Looper

Thread

Feed

Bar

Screw -Feed

Oil

Tube

Feed

Bar

Screw-

Cloth

Cloth

Cloth

Cloth

Plate,

Plate,

Plate,

Plate,

Screws

Cloth

Fe

Plate Latch

ed

Mechani

Nut -Fe

Screw

Screws -Oil

Oil

Filt

Oil

Str

ainer------

Ch

ip G

uard--------Screws -Chip Gua

Oil

Gaug

Oil

Gau

Oil Gaug

Oil Sig

ht Gauge

Screws -Low

Scre

ws - Upper

Bottom Cov

ottom

B

S

cre

ws

Screw

Screws - B

Botto

Clot

----------

m Cover

h P l

Screw - - --------------

Thre

ad

Tub

e T ensi

Tube--------------------

Oil

Shield---

Ba r

Oil

- ---------- - -

Shi

el d

Coupling-------------------

Connecting Rod

Cloth

Plate---------------

semi

s ubmerged

nonsubmerged installation---------semisub

m e

rge

nonsubmerged installation

- La

tch Spring---------------

Spring-----------------------

sm

Cover-------------------------

ed Me

- Fe ed Mecha

er

chani

sm

nism

Screen and

Screen --- -

- - -

Cov

Stra

----------------

---------------

-

---------

rd--------------

e Float---------------------

ge

Indicator - - -

e Seal

Rin

g ----

---

----

- - - - - ----

er Loope

r Ba r

Looper Dri

er Gasket

Cover ---------

- B

ottom Cover----ottom Cov

Ext

ate

Fabr ic Guar d -

- ----

- ----

er Extensi

ension-

---

-----------

- - --------

--

ing Nut--------

sting Screw -----

- --------------

ng

-----

- - - -

-

-------

- - - -

---------------

-------

--

-------

----

-----------

--

-

-----

- - - -----Tub

e A

e A s

sembly------

---

on Spring

----------

Oil

Tub

e- -

------------

--

installation

d ins

er -

tallat

----

ion

-----

Cover------

ine

r------------

-

-------

- ----

- - - - -

-------ve Lev

-------

- -

--------------

--

--------

Drive

---

- - ---- -

Lev

er

Shaft------

- ---------

---

--------

-----------

on

------------

---

- - - - - -

---

- -

---------

------------ - - -

--------

-----------

- -

---

----

--

- -

- - -

---

- -

------

- - - -

-----------

--

---

- -

---

- ---- -

---

- - -

--

---

- - - - -

----

-----------

----

----

sse

mbly ----

-----

- -

----

-----

----------

--

- - -

------

------------

- - -

-------

- - -

---

- - -

----------

- -

------

----

- - -

- ---- ---- - -

-

----

- - - - - -

--------

---

------

--

--

---

-----

-

------

- - - -

- - - ---- - -

-------

---

------

----

------

- - - -

-

---

er

Shaft--

- - - - ----

---------

- - ---------

- - -

---

-----

------

--

- -

- -

--

--

- -

- -

--

- -

--

- -

--

Amt.

-

-

-

-

-

-

-

-

-

-

-

-

Req.

1

1

1

1

1

1

1

8

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

3

1

1

1

2

1

1

1

1

2

2

1

1

14

1

2

1

1

2

17

Page 18

A -

NEFDLE

B -

SPREADER -UPPER

DRIVE

C - U

D -

LOWER

PPER

DRIVE

BEARING

KNIFE

LOOPER

29

BEARING

LOOFER

DRIVE

BEARING

DRIVE

BEARING

1

18

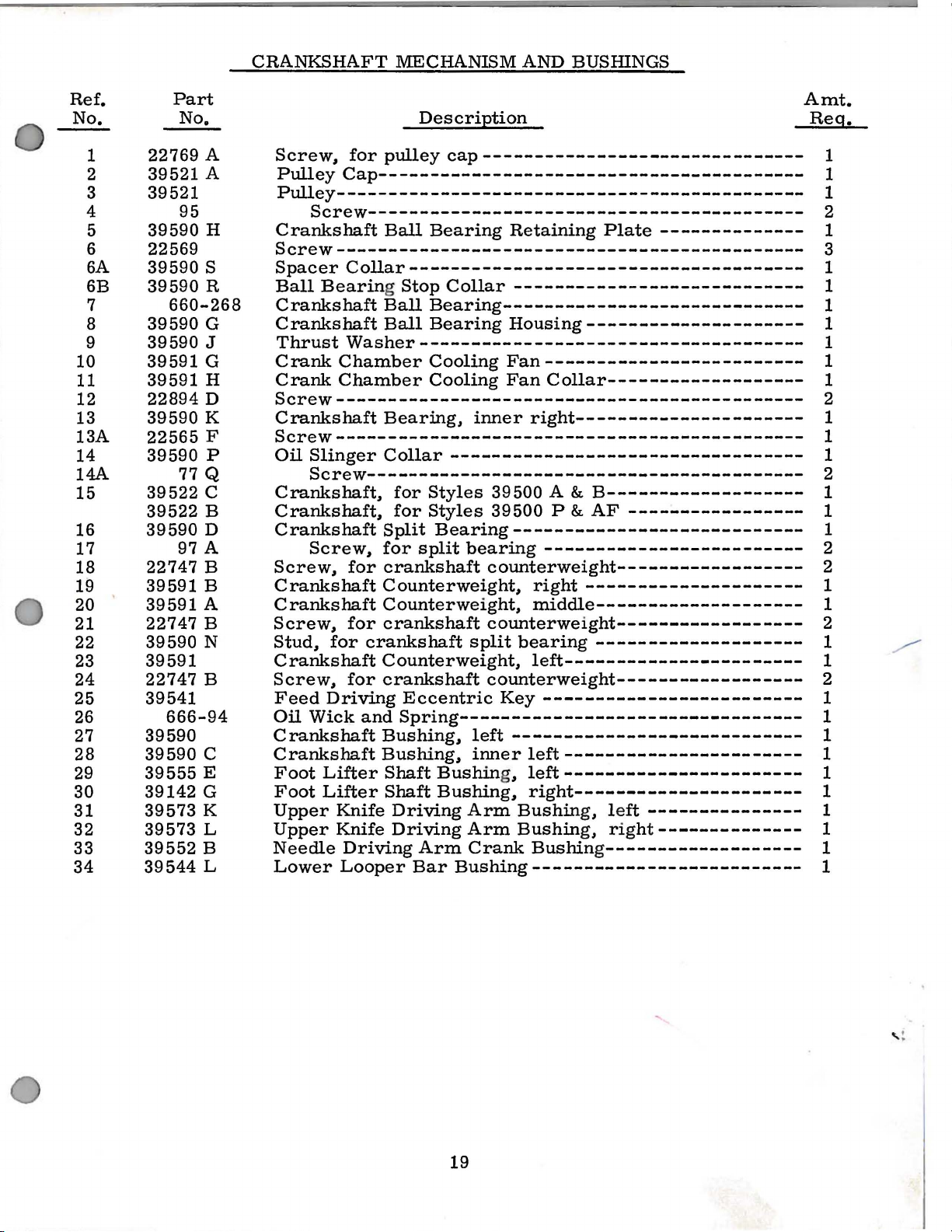

Page 19

CRANKSHAFT

MECHANISM

AND

BUSHINGS

Ref.

No.

1

2

3

4 95

5

6 22569

6A

6B

7

8

9

10

11

12

13

13A

14

14A 77 Q

15

16

17

18

Hl

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Part

No.

22769

39521

39521

39590

39590

39590

660-268

39590

39590

39591

39591

22894

39590

22565

39590

39522

39522

39590

97 A

22747

39591

39591

22747

39590

39591

22747

39541

666-94

39590

39590

39555

39142

39573

39573

39552

39544

A

A

H

s

R

G

J

G

H

D

K

F

p

c

B

D

B

B

A

B

N

B

c

E

G

K

L

B

L

Description

Screw,

Pulley

for

pulley

cap-------------------------------

Cap-----------------------------------------

Pulley---------------------------------------------

Screw------------------------------------------ 2

Crankshaft

Screw--------------------------------------------Spacer

Ball

Bearing Stop

Crankshaft

Crankshaft

Thrust

Crank

Crank

Ball

Bearing

Collar--------------------------------------

Collar

Ball

Bearing-----------------------------

Ball

Bearing

Washer------------------------------------Chamber

Chamber

Cooling

Cooling

Retaining

----------------------------

Housing---------------------

Fan------------------------Fan

Collar-------------------

Plate

--------------

Screw---------------------------------------------

Crankshaft

Bearing,

inner

right----------------------

Screw---------------------------------------------

Oil

Slinger

Collar

----------------------------------

Screw------------------------------------------

Crankshaft,

Crankshaft,

Crankshaft

Screw,

Screw,

Crankshaft

Crankshaft

Screw,

Stud,

Crankshaft

Screw,

Feed

Oil

Crankshaft

Crankshaft

Foot

Foot

Upper

Upper

Needle

Lower

for

for

for

Driving

Wick

Lifter

Lifter

Knife

Knife

Driving

Looper

for

Styles

for

Styles

Split

for

split

for

crankshaft

Counterweight,

Counterweight,

crankshaft

crankshaft

Counterweight,

crankshaft

Eccentric

and

Spring---------------------------------

Bushing,

Bushing,

Shaft

Shaft

Driving

Driving

Arm

Bar

39500

39500

Bearing----------------------------

bearing

counterweight------------------

counterweight------------------

split

counterweight------------------

Key

left

inner

Bushin

Bushing,

Bushing--------------------------

g,

Arm

Arm

Crank

A &

B-------------------

P &

AF

-----------------

-------------------------

right

middle--------------------

bearing

left-----------------------

---------------------------left-----------------------

left----------------------right----------------------

Bushing,

Bushing,

Bushing-------------------

---------------------

--------------------

-------------------------

left

---------------

right--------------

Amt.

Reg.

1

1

1

1

3

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

2

2

1

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

19

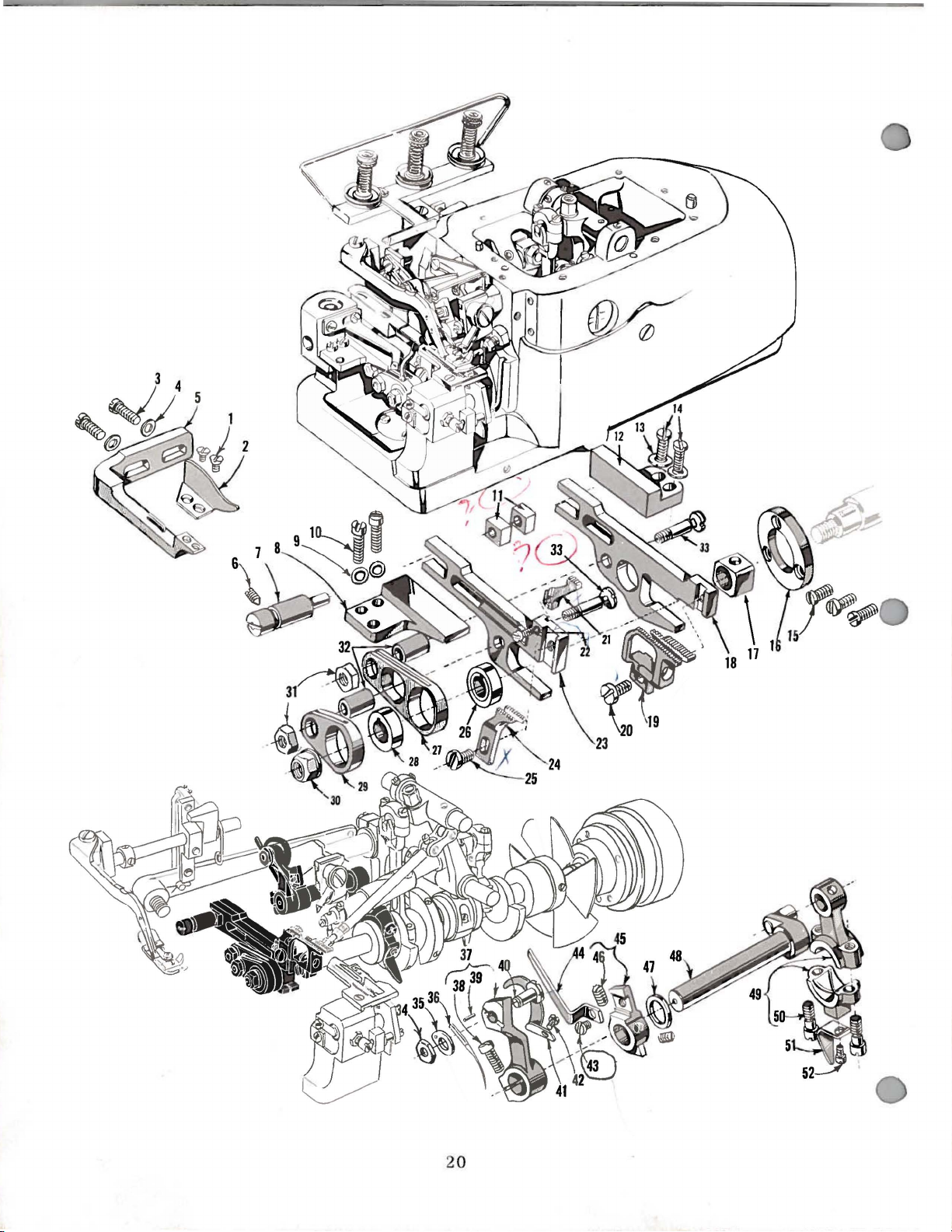

Page 20

20

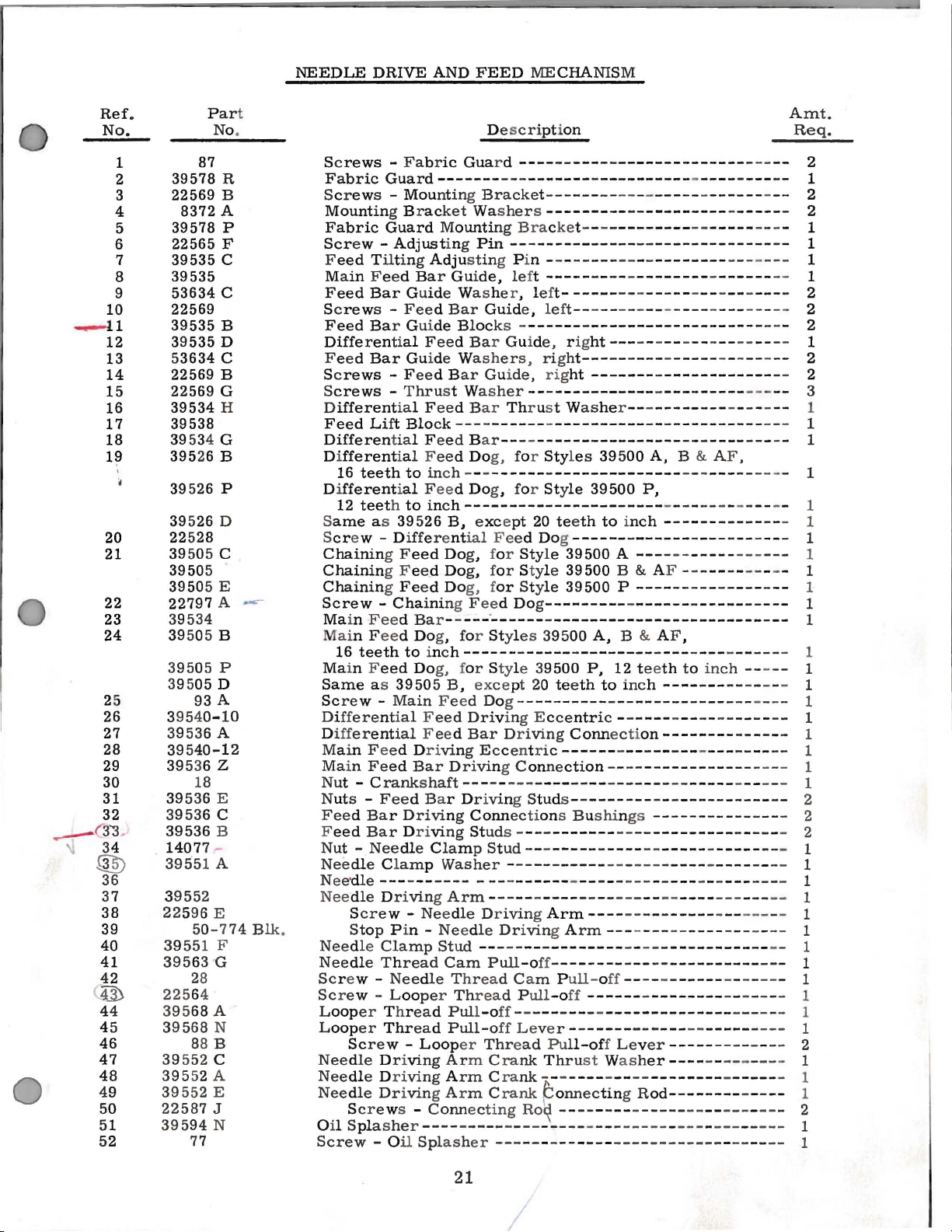

Page 21

Ref.

No.

ar

P

No.

NEEDLE

t

DRIVE

AND

FEED

Des

MECHA NISM

cripti

on

Amt.

Req.

---

1

2

3

4

5

6

7

8

9

10

-I

1

12

13

14

15

16

17

18

19

'

i

20

21

22

23

24

25

26

27

28

29

30

31

32

(3

'3

34

®

36

37

38

39

40

41

42

;rn

44

45

46

47

48

49

50

51

52

87

39578

22569 B

8372

39578 p

22565

39535

39535

53634

22569

39535

39

535

5

3634

22569 B

22569 G

39534

39538

39534

395

26 B

39526 p

39526 D

22 528

39505 c

3950

5

3950

5 E

22797

39534

39505 B

39505 p

39 5

39540-10

39 536 A

395

39 536 z

39536

39 536 c

39536

14077,..

3955

3

22

3955 1 F

395

225

39568

39568

39552

39552 A

39

22587

395

05

93 A

40-12

18

9552

596 E

50-774

63 'G

28

64

88 B

552 E

94 N

77

A

D

E

B

1 A

A

N

c

J

R

A

F

c

c

B

D

c

H

G

.--

Sc

rews -Fabric

Fabric

Screws Mount

Fabric

Scr

eed Til

F

Ma

Feed

Sc

Feed Bar Gui

Differential Feed Ba

F ee d

Sc

S

crews -Thru

D

ifferential Feed B

FeedLiftBlo

Differen

Di

16

Di

12

S

ame

Screw - D

Chainin

Chainin