Page 1

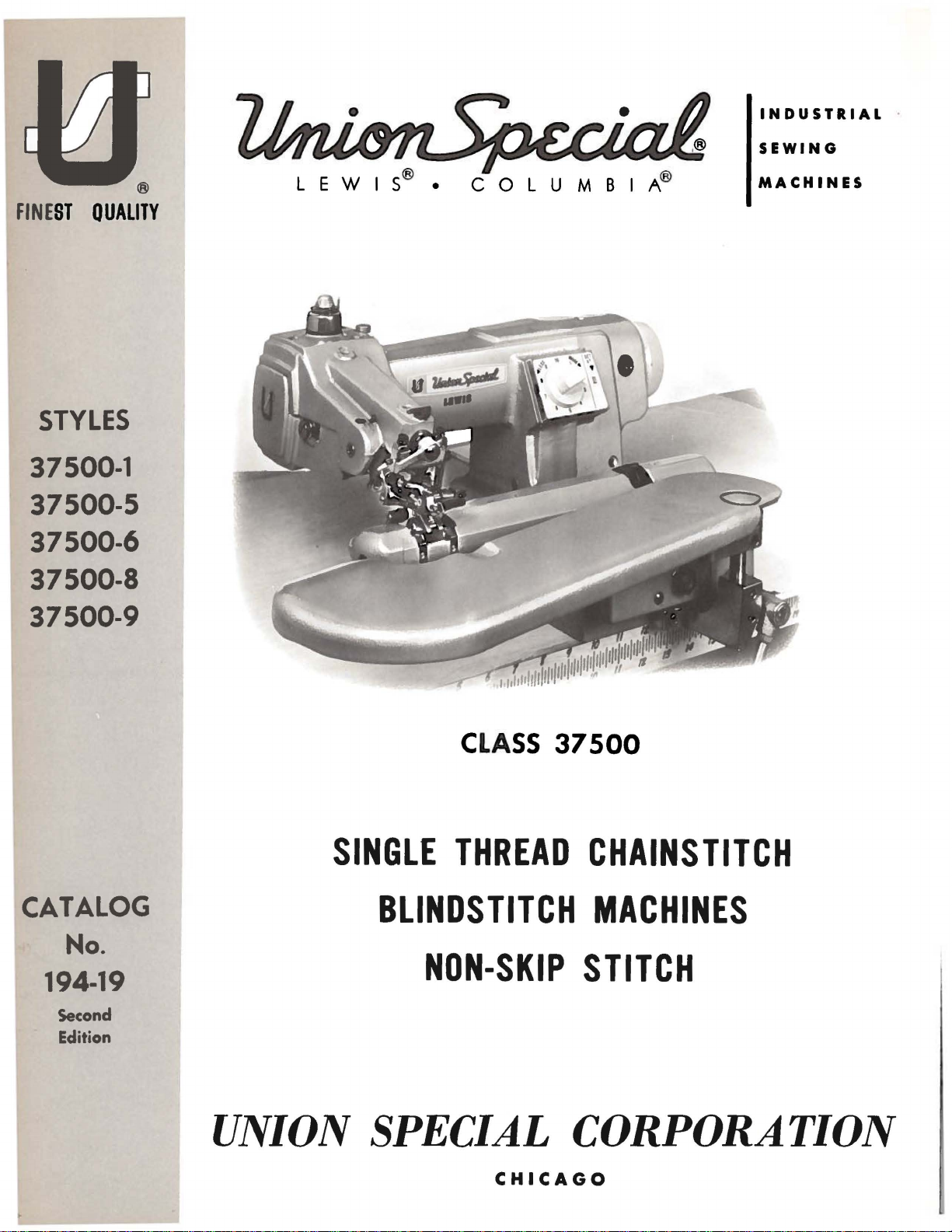

INDUSTRIAL

·

FINE

ST

QUALITY

STYLES

37500-1

37500-5

37500-6

37500-8

®

~~

L E W I S® • C 0 L U M B I A®

SEWING

MACHINES

37500-9

CATALOG

No.

194-19

Second

Edition

CLASS

SINGLE

THREAD

BLINDSTITCH

NON-SKIP

37500

CHAINSTITCH

MACHINES

STITCH

UNION SPECIAL

CHICAGO

CORPORATION

Page 2

Catalog

No.

INSTRUCTIONS

FOR

194-19

ADJUSTING

LIST

37500-1

37500-5

Second

AND

AND

OF

FOR

CLASS

STYLES

37500-9

OPERATING

PARTS

37500

37500-6

37500-8

Edition

Union

Rights

Copyright

Special

Reserved

1973

by

Corporation

in

All

&

UNION SPECIAL CORPORATION

INDUSTRIAL

Printed

SEWING

CHICAGO

in

2

MACHINES

U.S.A.

1976

Countr

i

es

January,

1979

Page 3

Each

the

style

machine

UNION

plate

is

stamped

SPECIAL

located

in

IDENTIFICATION

LEWIS

on

the

right

the

base

at

machine

end

of

the

back.

OF

MACHINES

carries a style

the

machine

number

base.

The

which

serial

is

stamped

number

of

into

each

This

catalog

It

can

also

ences

to

direction,

operator's

Single

Left

Thread,

to

Right

Adjustment,

to-Read

and

Indicator

Removing

(177. 8 mm),

37500-1

Equipped

material

also

felling

103-EFm-1

37500-5

For

garments.

37500-6

For

heavy

37500-8

Equipped

trousers.

37500-9

Fitted

where

103-EFl-1.

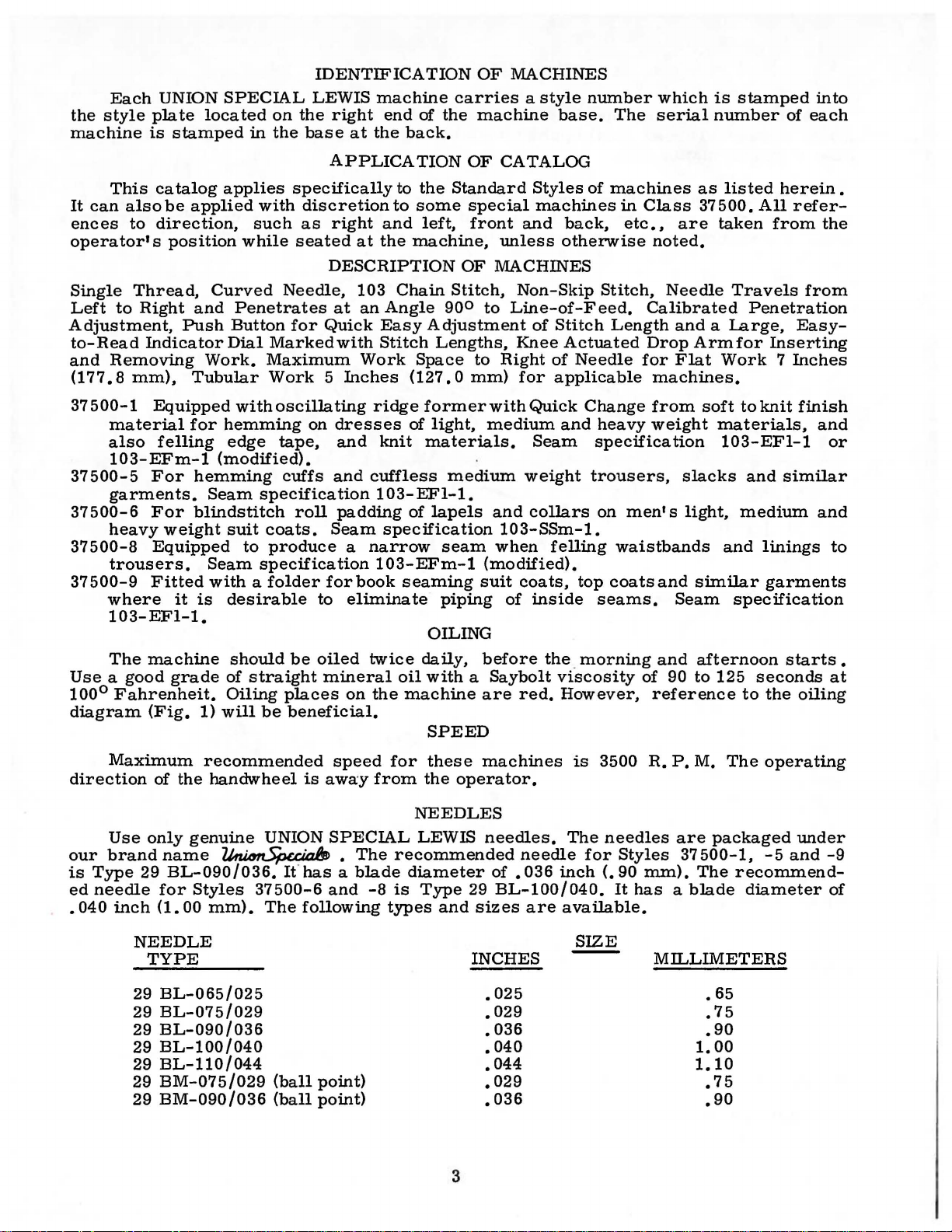

The

machine

Use a good

100°

Fahrenheit.

diagram

(Fig.

be

applied

position

Curved

and

Push

Work.

Tubular

for

hemming

Seam

blindstitch

weight

Seam

with a folder

it

is

grade

1)

applies

while

specifically

with

such

seated

discretion

as

Needle,

Penetrates

Button

Dial

for

Marked

Maximum

Work 5 Inches

withoscillating

hemming

edge

tape,

(modified).

cuffs

specification

roll

suit

coats.

to

produce

specification

desirable

should

of

Oiling

will

be

straight

places

be

beneficial.

APPLICATION

to

to

right

at

and

the

DESCRIPTION

103

Chain

at

an

Angle

Quick

with

Easy

Stitch

Work

ridge

on

dresses

and

knit

and

cuffless

103-EFl-1.

padding

Seam

specification

a

narrow

103-EFm-1

forbook

to

eliminate

oiled

mineral

on

seaming

twice

oil

the

OF

CATALOG

the

Standard

some

machine,

left,

special

front

unless

OF

MACHINES

Stitch,

900

to

Adjustment

Lengths,

Space

to

Right

(127. 0 mm)

formerwithQuick

of

light,

medium

materials.

medium

of

lapels

and

103-SSm-1.

seam

when

(modified).

suit

piping

of

OILING

daily,

before

with a Saybolt

machine

are

SPEED

Styles

of

machines

machines

and

back,

otherwise

Non-Skip

Stitch,

Line-of-Feed.

of

Stitch

Knee

of

for

applicable

Actuated

Needle

Change

and

heavy

Seam

weight

collars

specification

trousers,

on

felling

coats,

inside

top

seams.

coats

the. morning

viscosity

red.

However,

in

Class

etc.,

are

noted.

Needle

Calibrated

Length

and a Large,

Drop

for

Flat

machines.

from

weight

slacks

men's

waistbands

and

Seam

and

of

90

reference

as

listed

37

500.

All

taken

Travels

Penetration

Armfor

Work 7 Inches

soft

to

knit

materials,

103-EFl-1

and

light,

medium

and

linings

similar

specification

afternoon

to

125

seconds

to

herein

refer-

from

the

from

Easy-

Inserting

finish

and

similar

and

garments

starts

the

oiling

.

or

to

•

at

Maximum

direction

Use

our

brand

is

Type

ed

needle

• 040

inch

of

the

only

genuine

name

29

BL-090/036.

for

Styles

(1.

00

NEEDLE

TYPE

29

BL-065/025

29

BL-075/029

29

BL-090/036

29

BL-100/040

29

BL-110/044

29

BM-075/029

29

BM-090/036

recommended

handwheel

UNION

~

If

has a blade

37500-6

mm).

The

following

(ball

(ball

speed

is

awa:y

SPECIAL

•

and

point)

point)

for

from

NEEDLES

The

recommended

diameter

-8

is

types

these

the

operator.

LEWIS

Type

and

3

machines

needles.

needle

of

.036

29

BL-100/040.

sizes

are

INCHES

• 025

• 029

• 036

• 040

• 044

• 029

.036

is

3500

The

needles

for

Styles

inch(.

90

It

available.

SIZE

R.

P.M.

are

The

packaged

37500-1,

mm).

The

has a blade

MILLIMETERS

• 65

.75

.90

1.

00

1.10

.75

.90

operating

under

-5

and

recommend-

diameter

-9

of

Page 4

NEEDLES

(Continued)

Selection

material

good

sample

label.

stitch

To

used.

have

needle,

A

complete

of

proper

Thread

formation.

needle

or

the

order

needle

should

orders

Type

would

size

pass

promptly

number

read:

is

determined

freely

and

should

"100

through

accurately

be

forwarded.

Needles,

by

size

needle

filled,

Type

of

eye

Use

29

thread

in

order

an

empty

the

description

BL-090

and

to

produce

package,

/036".

weight

on

of

a

a

the

When

far

as

it

Immediately

improper

To

carrier

Refer

changing

will

needle

thread

is

in

to

go

and

discard

penetration

the

machine,

its

highest

the

threading

the

needle,

tighten

CHANGING

make

clamp

any

needle

will

turn

position.

diagram

Fig.

sure

screw

which

result.

THREADING

handwheel

(Fig.

1

NEEDLES

that

it

securely.

may

in

2).

4

is

inserted

have a hooked

operating

in

the

direction

needle

or

blunt

until

carrier

point,

the

needle

as

as

Page 5

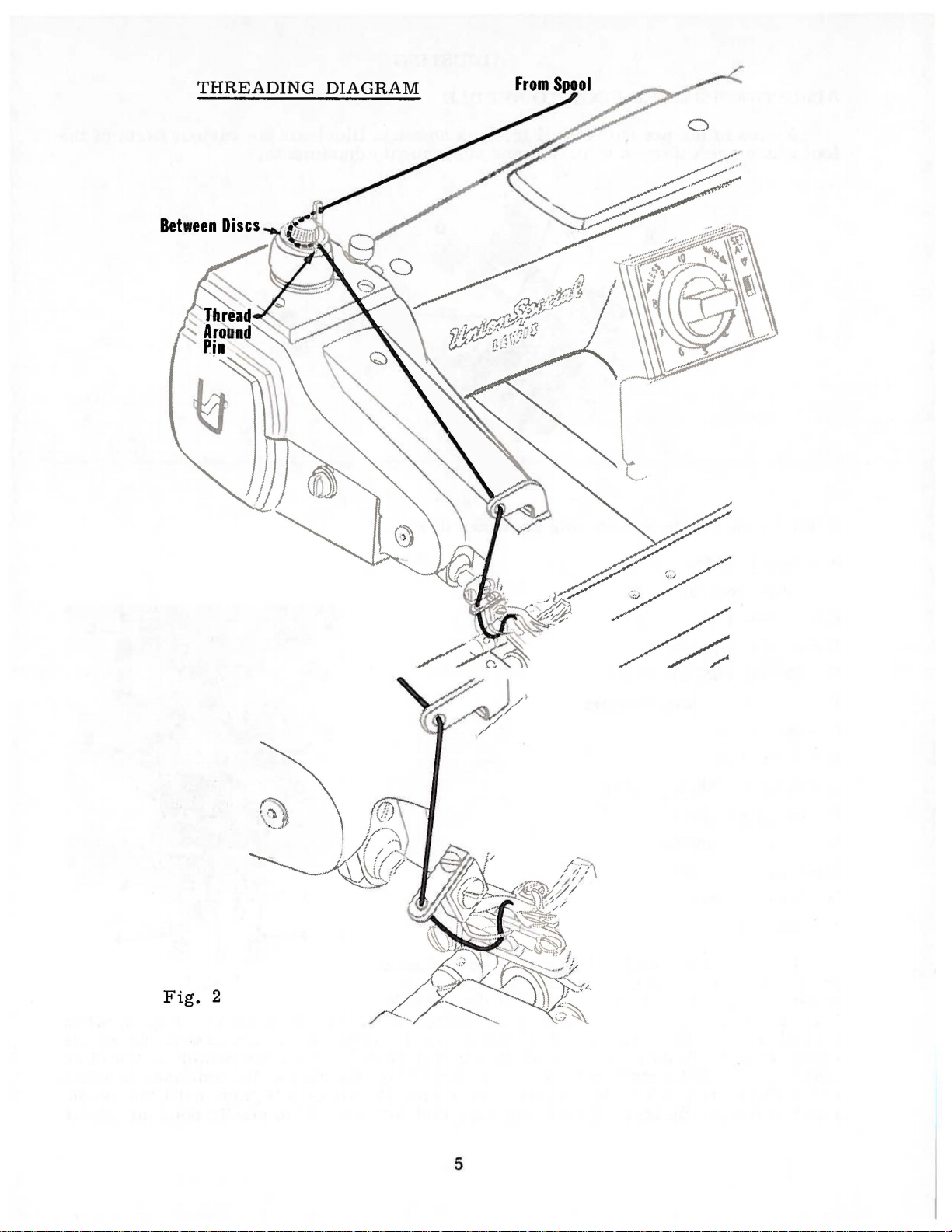

THREADING

DIAGRAM

Fig.

2

5

Page 6

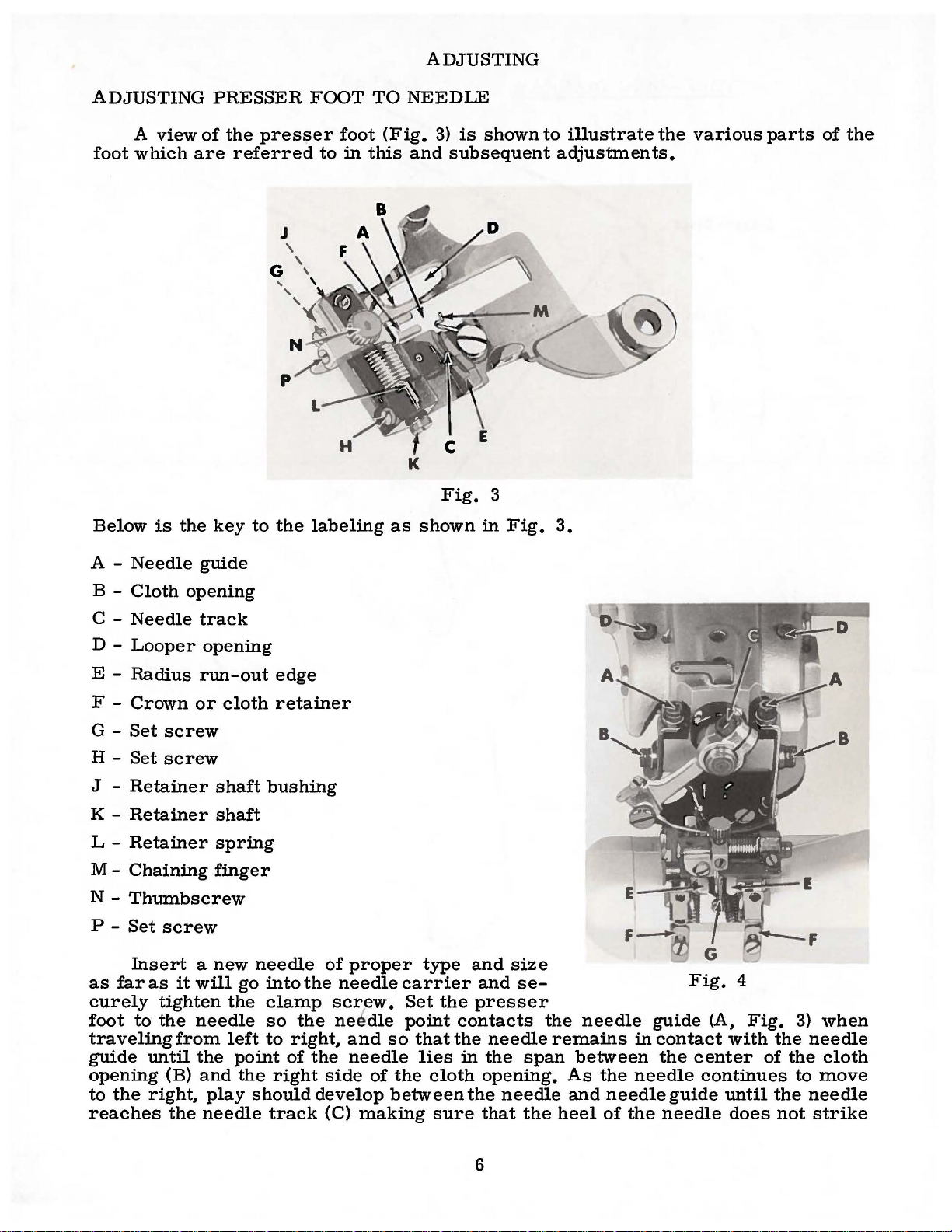

ADJUSTING

ADJUSTING

A

view

foot

which

Below

is

are

the

PRESSER

of

the

presser

referred

key

to

the

FOOT

foot

to

in

this

labeling

TO

NEEDLE

(Fig.

and

K

as

3)

is

subsequent

Fig.

shown

shown

3

in

Fig.

to

illustrate

adjustments.

3.

the

various

parts

of

the

A -

Needle

B -

Cloth

C -

Needle

D -

Looper

E -

Radius

F -

Crown

G-

Set

H-

Set

J -

Retainer

K -

Retainer

L -

Retainer

M-

Chaining

N -

Thumbscrew

P-

Set

Insert a new

as

far

as

curely

foot

to

the

traveling

guide

until

opening

to

the

right.

reaches

guide

opening

track

opening

run-out

or

screw

screw

screw

it

will

tighten

needle

from

the

(B)

and

play

the

needle

cloth

shaft

shaft

spring

finger

needle

go

the

left

point

the

should

edge

retainer

bushing

into

the

clamp

so

the

to

right.

of

the

right

develop

track

of

proper

needle

screw.

ne~dle

and

carrier

Set

point

so

needle

side

of

the

between

(C)

making

type

the

that

lies

cloth

sure

and

size

and

presser

contacts

the

needle

in

the

opening.

the

needle

that

se-

span

the

the

needle

remains

between

As

and

heel

in

the

needle

needle

of

the

Fig.

guide

contact

the

center

continues

guide

needle

(A.

until

4

Fig.

with

does

the

of

the

3)

the

to

not

when

needle

cloth

move

needle

strike

6

Page 7

the

needle

farther

top

ofthe

the

upper

these

equally, a little

on

the

be

attempted.

guide

to

the

presserfootbrackets,

screws

screws

sides

(B)

have

ADJUSTING

(A,

Fig.

3)

right.

To

accomplish

(B)

on

the

just

enough

at a time,

been

tightened,

PRESSER

and

lift

off

these

so

that

side

to

to

hold

obtain

no

of

FOOT

the

the

each

the

the

further

TO

needle

adjustments,

heads

bracket,

presser

aforementioned

adjustment

NEEDLE

track

donot

(C)

loosen

contactthe

move

foot

up.

of

(Continued)

while

presser

Adjust

settings.

the

advancing

screws

foot

the

top

screws

(A,

washers.

up,

top

screws

After

screws

the

needle

Fig.

(A)

4)

Loosen

retighten

should

on

(A)

(B)

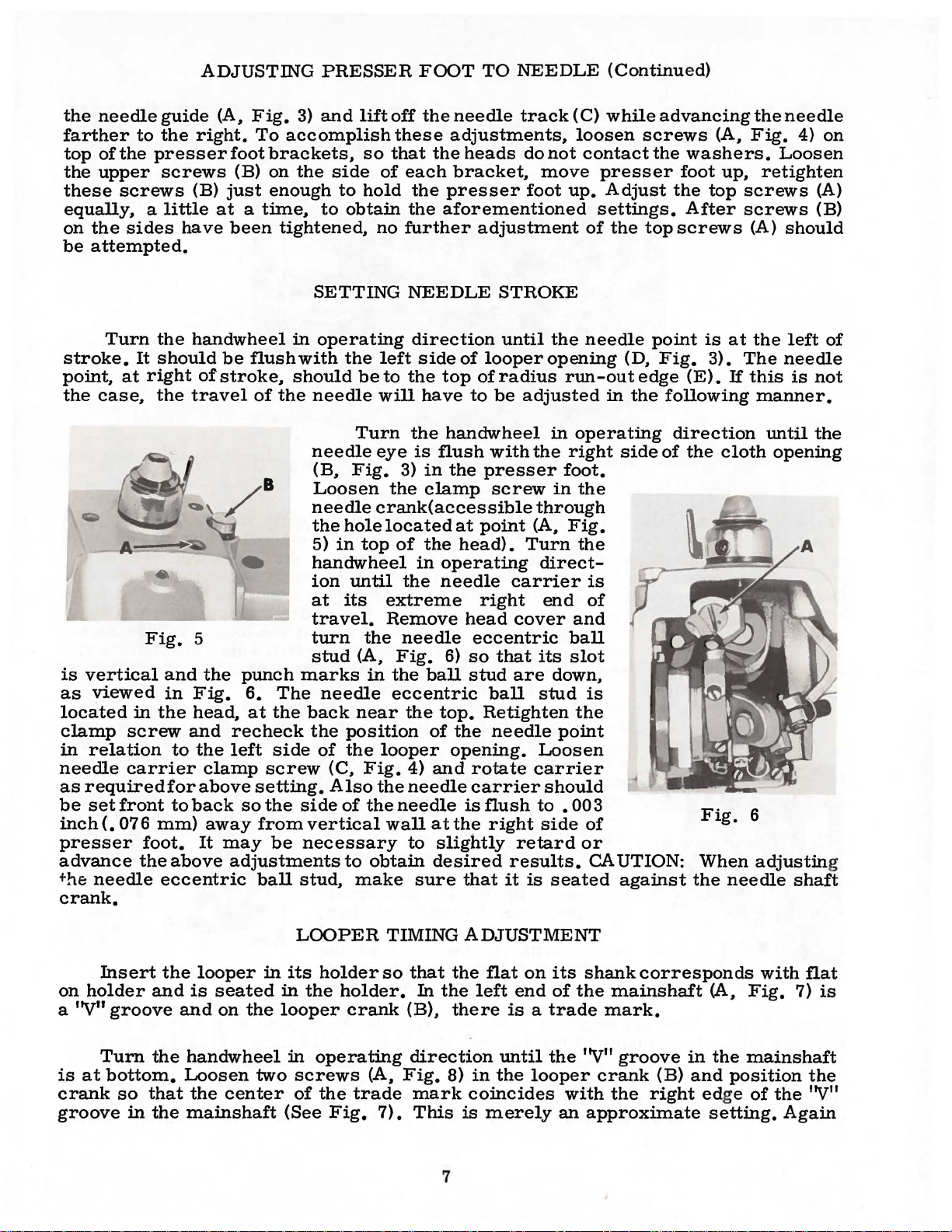

Turn

stroke.

point,

the

case,

is

vertical

as

viewed

located

clamp

in

relation

needle

as

required

be

set

front

inch

(.

07 6

presser

advance

the

needle

crank.

the

It

should

at

right

the

Fig.

and

in

in

the

screw

carrier

mm)

foot.

the

eccentric

handwheel

be

ofstroke,

travel

5

the

Fig.

head,

and

to

the

clamp

for

above

to

back

away

It

may

above

SETTING

in

operating

flushwith

should

of

the

needle

needle

(B,

Loosen

needle

the

5)

handwheel

ion

at

travel.

turn

stud

punch

6.

at

recheck

left

so

adjustments

marks

The

the

back

the

side

screw

setting.

the

side

from

ball

vertical

be

necessary

stud,

needle

of

the

be

Turn

Fig.

hole

in

top

until

its

the

(A,

in

near

position

the

(C,

Fig.

Also

of

the

to

obtain

make

NEEDLE

direction

left

side

to

the

top

will

have

the

handwheel

eye

is

flush

3)

in

the

the

clamp

crank(accessible

located

of

the

in

operating

the

needle

extreme

Remove

needle

Fig.

the

eccentric

looper

the

needle

wall

6)

ball

the

top.

of

4)

and

needle

at

to

slightly

desired

sure

opening.

STROKE

until

of

looperopening

ofradius

to

be

with

presser

screw

at

point

head).

right

head

eccentric

so

that

stud

ball

Retighten

the

needle

rotate

carrier

is

flush

the

right

that

it

the

adjusted

in

the

in

through

(A,

Turn

direct-

carrier

end

cover

its

are

down,

stud

point

Loosen

carrier

should

to

• 00 3

side

retard

results.

is

seated

needle

(D,

run-out

in

operating

right

foot.

Fig.

and

ball

slot

side

the

the

is

of

is

the

of

or

CAUTION:

against

point

Fig.

edge

the

following

of

is

at

3).

(E).

If

direction

the

cloth

Fig·

When

the

needle

the

left

The

needle

this

manner.

until

opening

6

adjustin

is

not

the

shaft

of

g

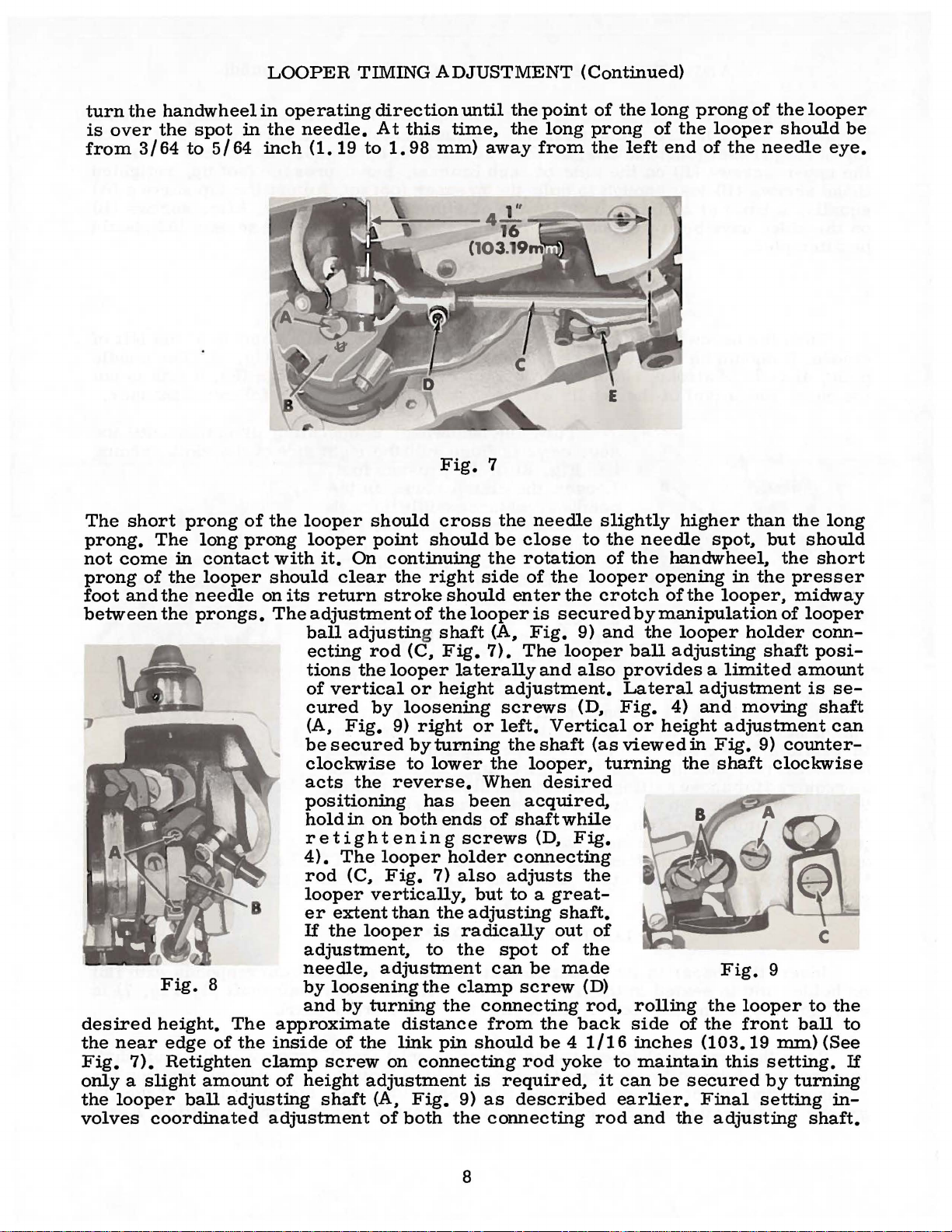

Insert

on

holder

a "V"

Turn

is

at

bottom.

crank

groove

and

groove

the

so

that

in

the

the

looper

is

seated

and

on

handwheel

Loosen

the

mainshaft

in

the

two

center

LOOPER

its

holder

in

the

looper

in

operating

screws

of

the

(See

Fig.

TIMING

so

holder.

crank

(A,

trade

7).

that

the

In

the

(B),

there

direction

Fig.

8)

mark

This

is

7

ADJUSTMENT

flat

on

its

left

end

of

is a trade

until

in

the

coincides

merely

the

looper

an

shank

the

''V"

with

approximate

corresponds

mainshaft

mark.

groove

crank

the

(A,

in

the

(B)

and

position

right edge

setting.

with

flat

Fig.

7)

is

mainshaft

the

of

the

''V"

Again

Page 8

turn

is

over

from

the

handwheel

the

3/64

spot

to

5/64

LOOPER

in

operating

in

the

inch

needle.

(1.19

TIMING

direction

At

this

to

1.

98

ADJUSTMENT

until

time,

mm)

the

the

away

point

long

from

(Continued)

of

the

long

prong

the

left

of

end

prong

the

looper

of

the

of

the

should

needle

looper

be

eye.

The

short

prong.

not

prong

foot

between

The

come

of

and

in

the

the

the

Fig.

desired

the

Fig.

near

7).

height.

edge

Retighten

only a slight

the

looper

volves

coordinated

prong

long

contact

looper

needle

prongs.

8

of

amount

ball

adjusting

of

the

prong

with

should

on

The

The

approximate

the

inside

clamp

of

adjustment

looper

looper

it.

On

clear

its

return

adjustment

ball

adjusting shaft

ecting

tions

of

the

vertical

cured

(A,

Fig.

be

secured

clockwise

acts

the

positioning

hold

in

retightening

4).

The

rod

(C,

looper

er

extent

If

the

adjustment,

needle,

by

loosening

and

by

of

the

screw

height

shaft

Fig.

should

point

cross

should

continuing

the

right

stroke

rod

of

(C,

should

the

Fig.

looper

or

height

by

loosening

9)

right

by

turning

to

lower

reverse.

has

on

both

ends

looper

Fig.

7)

vertically,

than

the

looper

is

to

adjustment

the

turning

the

distance

link

pin

on

connecting

adjustment

(A,

Fig.

of

both

7

the

be

the

side

looper

(A,

7).

laterally

screws

or

left.

the

When

been

of

screws

holder

also

but

adjusting

radically

the

spot

can

clamp

connecting

from

should

is

required,

9)

as

the

connecting

needle

close

to

rotation

of

the

looper

enter

is

Fig.

The

and

the

secured

9)

looper

also

adjustment.

(D,

Vertical

the

shaft

(as

looper,

desired

acquired,

shaft

(D,

while

Fig.

connecting

adjusts

the

to a great-

shaft.

out

of

of

the

be

made

screw

(D)

rod,

the

back

be 4 1/16

rod

yoke

described

slightly

the

of

the

higher

needle

handwheel,

spot,

opening

crotch

and

of

the

by

manipulation

the

looper

ball

adjusting

looper,

provides a limited

Lateral

Fig.

or

viewed

turning

adjustment

4)

and

height

in

the

Fig.

shaft

Fig.

to

it

can

earlier.

rod

rolling

side

inches

maintain

be

and

the

of

the

(103.19

secured

Final

the

adjusting

than

but

the

should

the

in

the

presser

midway

of

looper

holder

shaft

amount

moving

adjustment

9)

counter-

clockwise

9

looper

front

ball

mm)

this

setting.

by

turning

setting

long

short

conn-

posi-

is

se-

shaft

can

to

the

to

(See

If

in-

shaft.

8

Page 9

stud

marks

as

required,

down

Fig.

in

10

retighten

stud

to

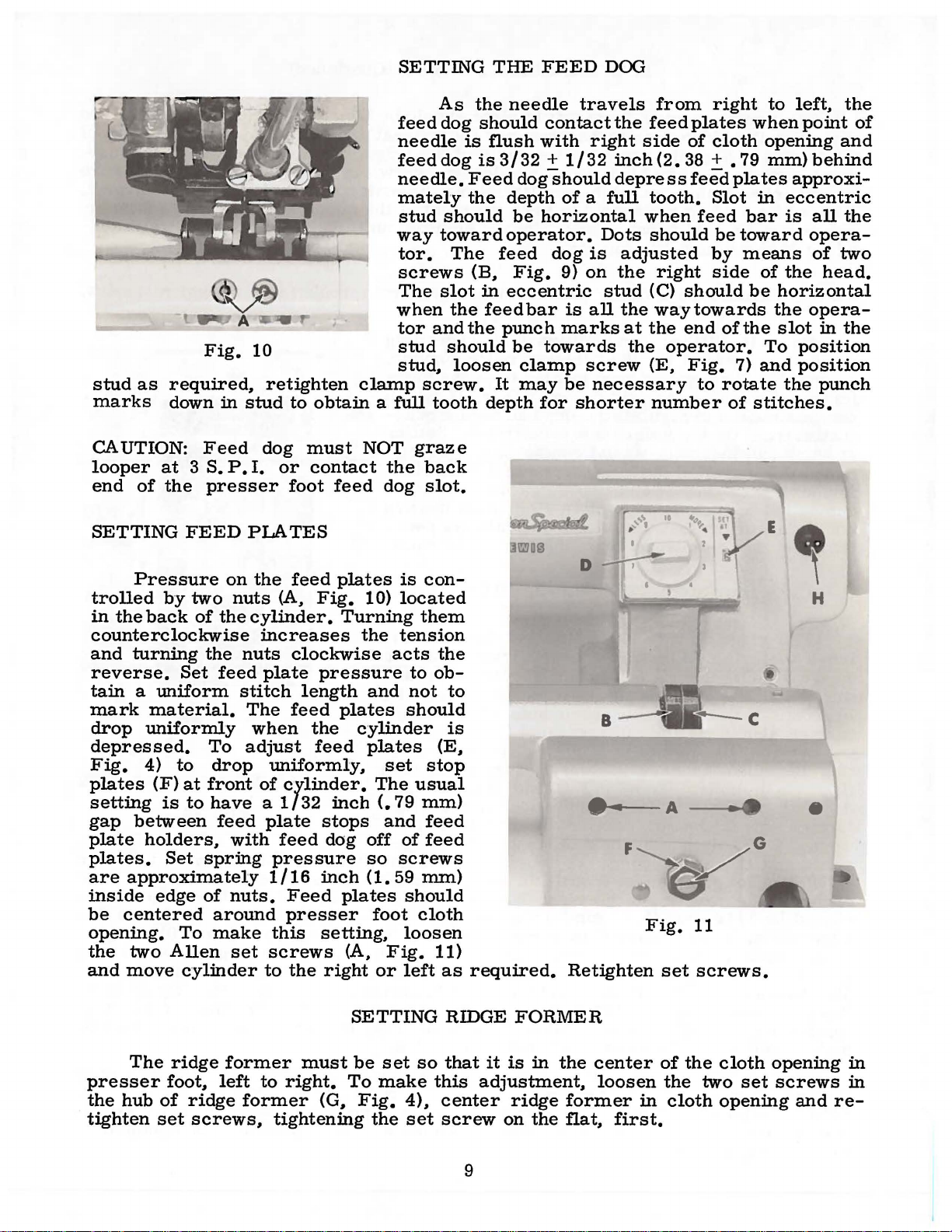

SETTING

feed

needle

feed

needle.

mately

stud

way

tor.

screws

The

when

tor

stud

stud,

clamp

obtain a full

As

dog

is

dog

Feed

the

should

toward

The

slot

the

and

the

should

loosen

screw.

tooth

THE

the

needle

should

flush

is

3/32,:!:

depth

operator.

feed

(B,

in

eccentric

feed

punch

It

depth

FEED

contact

with

dog

should

be

horizontal

dog

Fig.

bar

be

towards

clamp

may

for

DOO

travels

the

right

1/32

of a full

9)

is

marks

be

inch(2.

depress

Dots

is

adjusted

on

the

stud

all

the

at

the

screw

necessary

shorter

from

feed

side

38,:!:.

tooth.

when

should

right

(C)

should

way

the

end

operator.

(E.

number

right

plates

of

cloth

feed

plates

Slot

feed

be

by

side

towards

of

Fig.

to

7)

rotate

of

to

left,

when

opening

79

mm)behind

approxi-

in

eccentric

bar

is

toward

means

of

the

be

horizontal

the

the

slot

To

position

and

position

the

stitches.

point

all

opera-

of

head.

opera-

in

punch

the

of

and

the

two

the

CAUTION:

looper

end

of

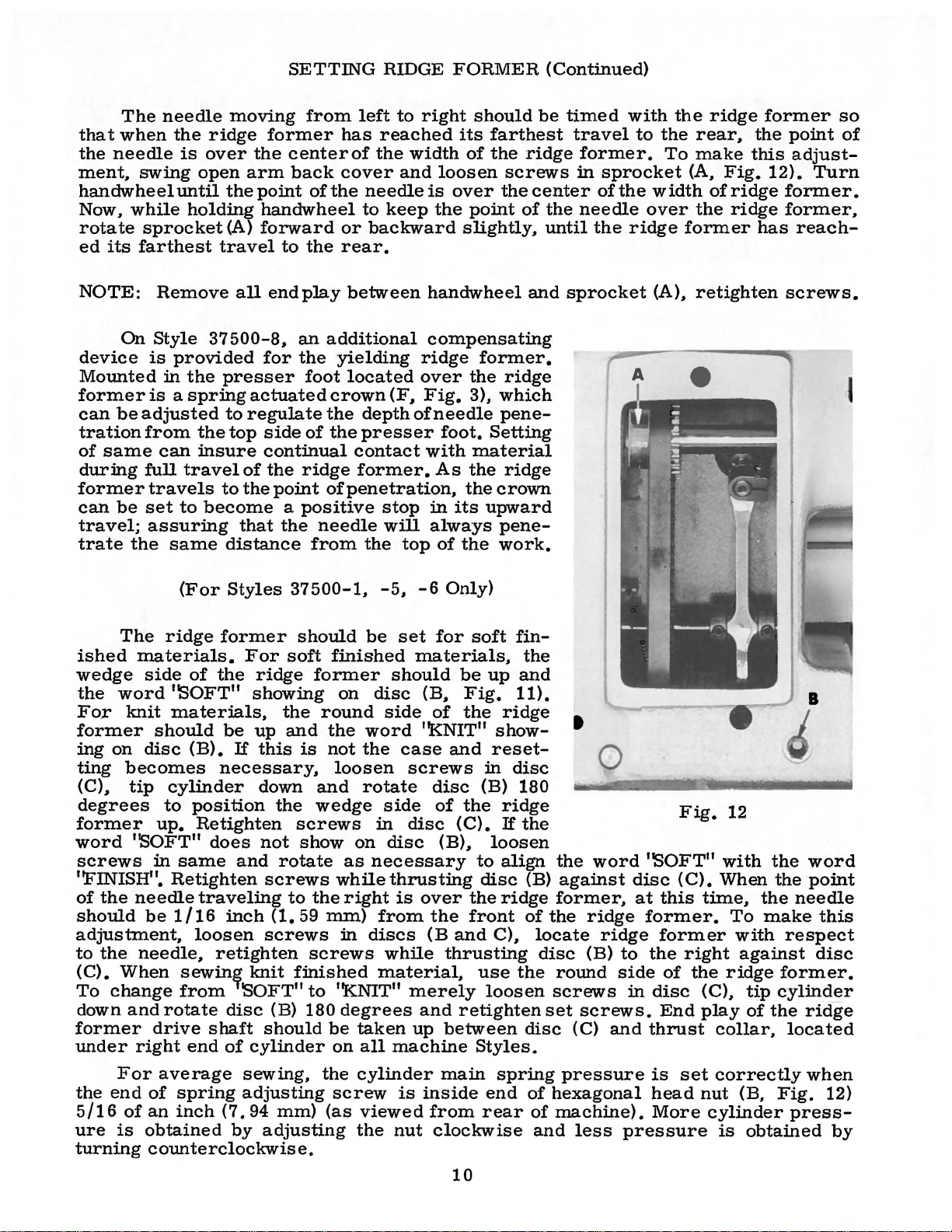

SETTING

Pressure

trolled

in

the

back

counterclockwise

and

turning

reverse.

tain a uniform

mark

drop

depressed.

Fig.

plates

setting

gap

plate

plates.

are

inside

be

opening.

the

and

material.

uniformly

4)

(F)

between

holders

approximately

edge

centered

two

move

Feed

at 3 S.

the

presser

FEED

by

two

of

the

Set

To

to

drop

at

front

is

to

have a 1/32

..

Set

spring

of

around

To

make

Allen

cylinder

the

feed

feed

dog

P.

I.

PLATES

on

the

nuts

cylinder.

increases

nuts

plate

stitch

The

when

adjust

uniformly,

of

plate

with

1/16

nuts.

set

screws

to

must

or

contact

foot

feed

feed

(A,

Fig.

clockwise

pressure

length

feed

the

feed

cylinder.

inch

stops

feed

dog

pressure

inch

Feed

presser

this

the

setting,

right

NOT

the

dog

plates

10)

Turning

the

acts

and

plates

cylinder

plates

set

The

(.

and

off

so

(1.

plates

foot

(A,

Fig.

or

graze

back

slot.

is

con-

located

them

tension

the

to

ob-

not

should

(E

stop

usual

79

mm)

feed

of

feed

screws

59

mm)

should

cloth

loosen

11)

left

as

to

is

..

required.

D

...

F

Retighten

A

Fig.

set

E

H

•

11

screws.

The

presser

the

hub

tighten

ridge

foot..

of

set

former

left

ridge

screws,

to

right.

former

tightening

must

(G

SETTING

be

set

To

make

..

Fig.

the

so

4),

set

RIDGE

that

this

center

screw

9

FORMER

it

is

in

the

adjustment,

ridge

on

the

center

loosen

former

flat,

in

first.

of

the

the

cloth

cloth

two

set

opening

opening

screws

andre-

in

in

Page 10

The

that

when

the

needle

ment,

swing

handwheel

Now~

rotate

ed

while

its

sprocket

farthest

needle

the

ridge

is

over

open

until

holding

moving

the

arm

the

point

handwheel

(A)

forward

travel

SETTING

from

former

centerof

back

of

to

the

left

has

cover

the

or

rear.

needle

to

RIDGE

to

right

reached

the

width

and

loosen

is

keep

the

backward

FORMER

should

its

farthest

of

the

(Continued)

be

timed

ridge

screws

over

the

center

point

slightly~

of

the

until

travel

former.

in

sprocket

of

the

needle

the

with

to

the

width

over

ridge

the

rear~

To

make

(A,

the

former

ridge

Fig.

of

ridge

ridge

former

the

this

12).

former.

former,

has

point

adjust-

Turn

reach-

so

of

NOTE:

device

Mounted

former

can

tration

of

same

during

former

can

travel;

trate

ished

wedge

the

For

former

ing

ting

(C)~

degrees

former

word

screws

Remove

On

Style

is

in

is a spring

be

adjusted

from

can

full

travels

be

set

assuring

the

The

ridge

materials.

side

word

knit

should

on

disc

becomes

tip

to

up.

''SOFT"

in

''FINISH".

of

the

needle

should

be

adjustment.

to

the

needle,

(C).

When

To

change

down

former

under

and

right

rotate

drive

all

end

37500-8~

provided

the

for

presser

actuated

to

regulate

the

top

side

insure

travel

to

become a positive

same

(For

continual

of

the

to

the

point

that

distance

Styles

the

37500-1~

former

For

soft

of

the

ridge

''SOFT"

mater:ials,

(B).

showing

be

up

If

this

the

and

necessary,

cylinder

position

down

the

Retighten

does

same

Retighten

traveling

1/16

loosen

and

inch

not

rotate

screws

to

(1.

screws

retighten

sewin~

from

end

'SOFT"

disc

shaft

of

knit

(B) 180

should

cylinder

play

between

an

additional

the

yielding

foot

located

crown

the

of

the

contact

ridge

of

penetration~

needle

from

should

finished

former

on

round

the

is

not

loosen

and

wedge

screws

show

on

as

while

the

right

59

mm)

in

screws

finished

to

''KNIT"

degrees

be

on

(F~

depth

ofneedle

presser

former.

stop

will

the

top

-5~

be

set

materials~

should

disc

side

word

the

case

screws

rotate

side

in

disc

disc

necessary

thrusting

is

from

discs

while

material,

merely

taken

all

up

machine

handwheel

compensating

ridge

over

Fig.

former.

the

ridge

3),

which

pene-

foot.

with

As

in

always

of

-6

for

(B~

of

''KNIT"

disc

of

(B).

material

the

the

its

upward

the

Only)

soft

be

Fig.

the

and

in

(B) 180

the

(C).

to

Setting

ridge

crown

pene-

work.

fin-

up

11).

ridge

show-

reset-

disc

ridge

If

loosen

align

disc

over

the

the

front

(Band

ridge

C),

thrusting

use

loosen

and

retighten

between

Styles.

and

the

and

the

(B)

of

locate

disc

the

disc

sprocket

t

the

against

former,

the

ridge

(B)

round

screws

set

screws.

(C)

Q

word

ridge

to

side

in

and

(A)~

Fig.

''SOFT"

disc

(C).

at

this

former.

former

the

of

disc

End

thrust

retighten

1

2

with

When

time,

To

with

right

the

against

ridge

(C),

play

collar,

the

the

the

make

tip

cylinder

of

the

screws.

I

word

point

needle

this

respect

disc

former.

ridge

located

For

the

end

5/16

ure

of

is

turning

average

of

spring

an

inch

obtained

counterclockwise.

sewing,

adjusting

(7.

94

by

adjusting

mm)

the

screw

(as

cylinder

is

viewed

the

nut

main

inside

from

end

rear

clockwise

spring

of

of

and

pressure

hexagonal

machine).

10

less

is

set

head

More

pressure

correctly

nut

(B,

cylinder

is

obtained

Fig.

press-

when

12)

by

Page 11

On

Styles

all

machine

former

enough

penetration

(E).

The

needle

cylinder

and

hexagonal

end

of

machine

1/2

turn.

37500-1.

Styles.

to

note

dial

(D.

graze

turning

nut.

Remove

below

Retighten

-5.

At

maximum

the

Fig.

setting

screw

all

the

handwheel.

nut.

SETTING

-6

rotate

needle

11)

should

is

made

(G)

as

free

play

NOTE:

NEEDLE

disc

penetration

lifting

be

set

by

required

in

knee

after

Recheck

GRAZE

to

soft

finish.

the

off

of

the

at

"1

0 ".

loosening

to

get

the

press

loosening

''NEEDLE

then

needle

needle

with

"6'

hexagonal

proper

with

the

stop

nut.

GRAZE

proceed

should

~ide.

graze

At

showing

nut

(F)

needle

screw

then

graze.

located

back

SETTING".

as

follows

this

in

the

at

the

off

for

the

ridge

time

the

window

front

Retighten

on

right

the

screw

of

and

be

screw

right

an

eccentric.

Press

The

as

(G

as

the

Fig.

crown

or

close

and

H.

required.

to

shaft

to

13

cloth

to

the

Fig.

3)

Tighten

position

the

left

retainer

needle

and

the

against

as

adjust

screw

crown

CHANGING

holding

ting

felt

Continuing

in

operating

length

the

on

the

(F.

Fig.

possible.

the

shaft

(G)

against

or

retainer

the

bushing

Press

plunger

direction

to

drop

and

stitch

Stitch

the

indicator

window

3)

should

To

adjust

bushing

bushing

and

THE

plunger

until

into

to

hold

direction

in

opposite

length.

lengths

(H.

Fig.

FURTHER

(For

Styles

be

crown

as

close

tighten

STITCH

(B.

Fig.

in.

turn

stitch

the

slot

the

plunger

are

indicated

dial

and

11).

ADJUSTMENTS

37

centered

or

(J)

and

(J).

Turn

as

set

LENGTH

5)

handwheel

regulating

of

in.

to

increase

direction

are

in

the

500-1.

over

retainer.

shaft

(K)

shaft

possible

screw

in

firmly.

feed

turn

to

by

graduations

viewed

belt

-5.

-6.

ridge

to

(K)

to

the

(H).

While

in

opera-

finger

is

regulator.

handwheel

the

stitch

decrease

through

guard.

-8)

former

loosen

the

which

left

set

or

is

needle.

Normal

(L.

Fig.

taken

of

finger

the

On

from

right

(M.

stitch.

on

top

of

of

the

crown

to

the

adjusting

rating

loose.

On

possible.

Folder

of

folder

be

assembled

using

can

obtain

ly.,

clamp

be

accomplished

desired

adjust

crown

3)

rests

this

presser

Fig.

Style

A

finer

the

37500-8.

crown

with a nylon

Style

37500-9.

with

must

also

are

available

on

on

results

thumbscrew

or

cloth

in

the

position

foot

3)

should

adjustment

of

the

thumbscrew

the

the

ridge

be

positioned

to

the

top

top

or

bottom

by

and

(D).

retainer

''Vee"

and

on

moved

boss.

be

set

the

penetration

can

be

presser

plug

behind

through

folder

former

to

suit

the

of

bottom

of

same.

loosening

retighten

spring

top

to

for

additional

as

close

of

pressure

the

the

as

dial

made

foot.

(A.

by

There

it.

Tightening

the

nylon

Fig.

13)

positioned

clear

path

convenience

of

bracket

Moving

the

screw

screw.

To

11

is

when

right

''Vee'~

presser

located

tension.

possible

should

adjusting

is

to

be

the

also a set

this

plug

should

to

present

of

of

(C)

the

in

raise

which

be

looper.

the

operator.

or

the

folder

clamp

or

lower

the

foot

to

the

if

required.

the

needle.

set

so

thumbscrew

screw

set

screw

prevents

set

as

close

raw

edge

Four

settings

bracket

laterally

(B).

position

the

right

boss.

rear

as

to

applies

of

Folder

can

or

entire

leg

of

the

spring

The

leg

can

near

The

the

chaining

obtain a blind

(N.

Fig.

(P)

at

the

pressure

same

to

hem

be

tipping

the

to

for

clamp

turned

as

required

folder

from

needle

needle.

the

height

(B)

over.

its

slight-

be

top

3)

front

vib-

as

can

nose

to

Page 12

TERMS

Prices

forwarded

wise

directed.

Torque

a

distance

driver,

amount

unless

hand

etc.

of

All

straps

otherwise

as

tightly

The

are

f.

o.

b.

A

(measured

by a lever

Many

torque

and

as

screws

net

cash

shipping

charge

of

will

eccentrics

noted.

possible,

and

point.

is

made

TORQUE

in

inch-pounds)

(in

inches

these

tighten

All

other

unless

subject

Parcel

to

or

devices

the

part

should

nuts,

requiring a specific

to

change

post

cover

REQUIREMENTS

shipments

postage

is a rotating

feet).

otherwise

This

are

available,

to

the

be

tightened

bolts,

torque,

is

correct

screws,

noted.

will

without

notice.

are

and

insurance.

force

(in

accomplished

which

when

amount

to

19-21

inch-pounds

etc.,

be

indicated

All

insured

pounds)

applied

by a wrench,

set

and

no

tighter.

should

on

the

be

picture

shipments

unless

other-

through

at

the

proper

(22-24

em/kg)

tightened

plates.

are

screw

by

12

Page 13

EXPLODED

AND

VIEWS

DESCRIPTION

SINGLE

BLINDSTITCH

NON-

FOR

CLASS

THREAD

SKIP

OF

PARTS

37

500

CHAINSTITCH

MACHINES

STITCH

13

Page 14

27

l

'

28

14

Page 15

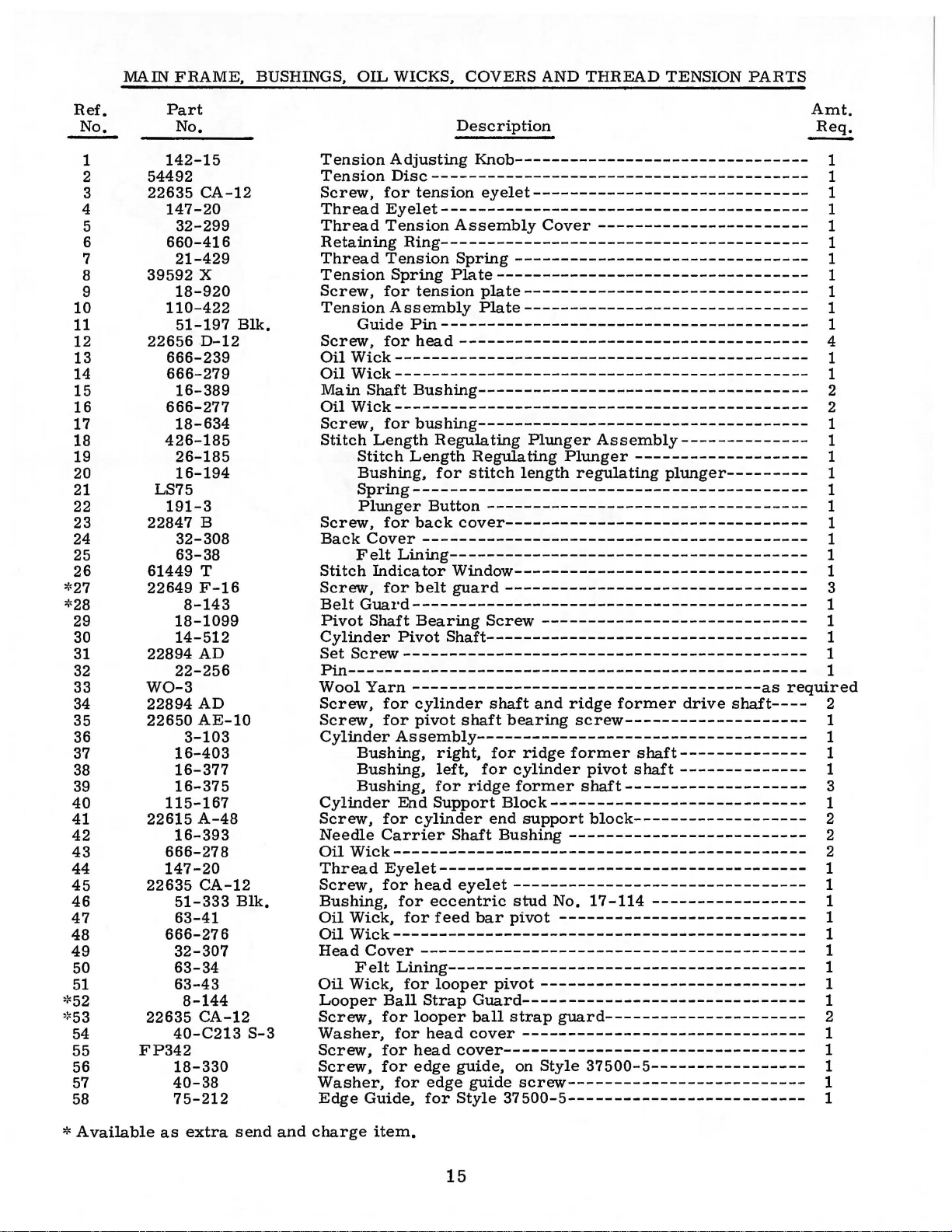

MAIN

FRAME,

BUSHINGS,

OIL

WICKS,

COVERS

AND

THREAD

TENSION

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

:0:<27

*28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

·~52

·~53

54

55

56

57

58

Part

No.

142-15

54492

22635

147-20

32-299

660-416

21-429

39592

18-920

110-422

51-197

22656

666-239

666-279

16-389

666-277

18-634

426-185

26-185

16-194

LS75

191-3

22847 B

32-308

63-38

61449 T

22649

8-143

18-1099

14-512

22894

22-256

W0-3

22894

22650

3-103

16-403

16-377

16-375

115-167

22615

16-393

666-278

147-20

22635

51-333

63-41

666-276

32-307

63-34

63-43

8-144

22635

40-C213

FP342

18-330

40-38

75-212

CA-12

X

Elk.

D-12

F-16

AD

AD

AE-10

A-48

CA-12

Elk.

CA-12

S-3

Description

Tension

Tension

Screw,

Thread

Thread

Retaining

Thread

Tension

Screw,

Tension

Screw,

Oil

Oil

Main

Oil

Screw,

Stitch

Adjusting

Knob--------------------------------

Disc-----------------------------------------

for

tension

eyelet------------------------------

Eyelet----------------------------------------

Tension

Assembly

Cover

-----------------------

Ring----------------------------------------

Tension

Spring

for

Assembly

Guide

for

Pin----------------------------------------

Spring

--------------------------------

Plate----------------------------------

tension

plate-------------------------------

Plate-------------------------------

head-------------------------------------Wick--------------------------------------------Wick---------------------------------------------

Shaft

Bushing------------------------------------

Wick---------------------------------------------

for

bushing------------------------------------

Length

Stitch

Bushing,

Regulating

Length

for

Plunger

Regulating

stitch

length

Assembly--------------

Plunger

-------------------

regulating

plunger---------

Spring-------------------------------------------

Plunger

Screw,

Back

Cover

Felt

Stitch

Indicator

Screw,

Belt

Guard-------------------------------------------

Pivot

Shaft

Cylinder

Set

Screw--------------------------------------------

Button

for

back

------------------------------------------

Lining---------------------------------------

-----------------------------------

cover---------------------------------

Window--------------------------------

for

belt

guard---------------------------------

Bearing

Pivot

Screw

-----------------------------

Shaft-----------------------------------

Pin-------------------------------------------------Wool

Screw,

Screw,

Yarn

--------------------------------------as

for

for

cylinder

pivot

shaft

shaft

bearing

and

ridge

former

screw--------------------

CylinderAssembly------------------------------------

Bushing,

Bushing,

Bushing,

Cylinder

Screw,

Needle

Oil

Thread

Screw,

for

Carrier

Wick---------------------------------------------

Eyelet----------------------------------------

for

Bushing,

Oil

Wick,

Oil

Wick---------------------------------------------

Head

Cover------------------------------------------

Felt

Oil

Wick,

Looper

Screw,

Ball

for

Washer,

Screw,

Screw,

for

for

Washer,

Edge

Guide,

End

Support

cylinder

head

for

eccentric

for

right,

left,

for

feed

for

for

ridge

ridge

cylinder

former

former

pivot

shaft--------------

shaft--------------

shaft--------------------

Block----------------------------

end

Shaft

support

Bushing

block-------------------

--------------------------

eyelet--------------------------------

stud

No.

bar

pivot

17-114

---------------------------

-----------------

Lining---------------------------------------

for

looper

for

head

edge

for

looper

Strap

head

edge

for

pivot

----------------------------Guard------------------------------ball

strap

cover

guard----------------------

------------------------------cover--------------------------------guide,

guide

Style

on

Style

37500-5-----------------

screw--------------------------

37500-5--------------------------

drive

shaft----

Amt.

~

1

1

1

1

1

1

1

1

1

1

1

4

1

1

2

2

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

1

required

2

1

1

1

1

3

1

2

2

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

*Available

as

extra

send

and

charge

item.

15

Page 16

8~

I

16

35

Page 17

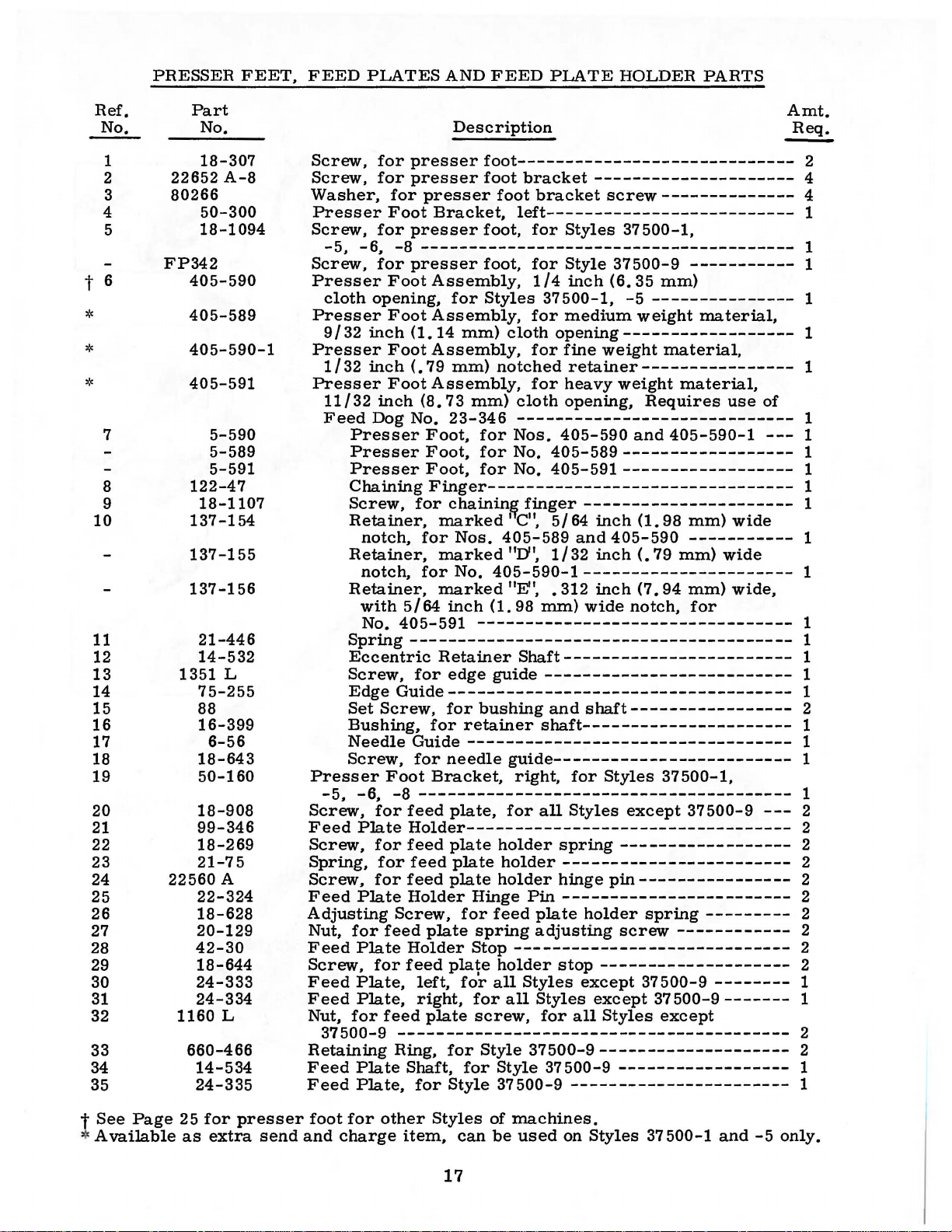

PRESSER

FEET,

FEED

PLATES

AND

FEED

PLATE

HOLDER

PARTS

Ref.

t

..

~

*

*

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

No.

1

2

3

4

5

6

7

8

9

Part

No.

18-307

22652

80266

50-300

18-1094

FP342

405-590

405-589

405-590-1

405-591

122-47

18-1107

137-154

137-155

137-156

21-446

14-532

1351

75-255

88

16-399

18-643

50-160

18-908

99-346

18-269

21-75

22560

22-324

18-628

20-129

42-30

18-644

24-333

24-334

1160

660-466

14-534

24-335

A-8

5-590

5-589

5-591

L

6-56

A

L

Screw,

Screw,

Washer,

Presser

Screw,

-5, -6,

Screw,

Presser

cloth

Presser

9/32

Presser

1/32

Presser

11/32

Feed

Presser

-5, -6,

Screw,

Feed

Screw,

Spring,

Screw,

Feed

Adjusting

Nut,

Feed

Screw,

Feed

Feed

Nut,

37500-9

Retaining

Feed

Feed

opening,

inch

inch

Dog

Presser

Presser

Presser

Chaining

Screw,

Retainer,

notch,

Retainer,

notch,

Retainer,

with

No.

Spring

Eccentric

Screw,

Edge

Set

Bushing,

Needle

Screw,

Plate

Plate

for

Plate

Plate,

Plate,

for

Plate

Plate,

Description

for

presser

for

presser

for

presser

Foot

Bracket,

for

presser

-8

---------------------------------------

for

presser

Foot

Assembly,

Foot

Assembly,

(1.14

Foot

Assembly,

(.

79

Foot

Assembly,

inch

(8.

No.

Foot,

Foot,

Foot,

Finger--------------------------------

for

for

for

5/64

405-591

---------------------------------------for

Guide------------------------------------

Screw,

for

Guide

for

Foot

Bracket,

-8

---------------------------------------

for

feed

Holder----------------------------------

for

feed

for

feed

for

feed

Holder

Screw,

feed

plate

Holder

for

feed

left,

right,

feed

plate

-----------------------------------------

Ring,

Shaft,

for

foot----------------------------foot

bracket

foot

bracket

left--------------------------

foot,

for

foot,

for

1/4

for

Styles

mm)

mm)

73

mm)

23-346

for

for

for

chainin~

marked'

Nos.

marked

No.

405-590-1----------------------

marked

inch

(1.98

---------------------------------

Retainer

edge

guide

for

bushing

retainer

----------------------------------

needle

plate,

plate

plate

plate

Hinge

for

feed

spring

Stop

pla~e

for

all

for

screw,

for

Style

for

Style

37500-1,

for

cloth

for

notched

for

cloth

-----------------------------

Nos.

No.

No.

finger

C",

405-589

"D'',

"E'', • 312

mm)

Shaft------------------------

--------------------------

shaft----------------------

guide-------------------------

right,

for

all

holder

holder

holder

Pin

plate

adjusting

-----------------------------

holder

Styles

all

Styles

for

37500-9

Style

37

37

500-9

--------------------screw--------------

Styles

Style

medium

opening------------------

fine

heavy

opening,

405-590

405-589

405-591

5/64

1/32

and

spring

------------------------

hinge

------------------------

stop

500-9

37500-9

inch

(6.

weight

retainer----------------

weight

---------------------inch

and

405-590

inch(.

inch

wide

shaft-----------------

for

Styles

Styles

pin----------------

holder

--------------------

except

except

all

Styles

--------------------

------------------

-----------------------

37

500-1,

-----------

35

mm)

-5

---------------

weight

Requires

and

------------------

------------------

(1.

79

(7.

notch,

except

------------------

spring

screw

37

material,

material,

material,

405-590-1

98

mm)

-----------

mm)

94

mm)

for

37500-1,

37500-9

---------

------------

500-9

37

500-9

except

wide

--------

-------

use

wide

wide,

of

---

---

Amt.

Req.

2

4

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

2

2

2

2

2

2

2

2

2

1

1

2

2

1

1

t

See

Page

*

Available

25

as

for

extra

presser

send

foot

and

for

other

charge

Styles

item,

can

of

machines.

be

used

on

17

Styles

37500-1

and

-5

only.

Page 18

19

TORQUE

19-21

in.

(22

-24

em/kg)

57

TO

lbs.

TORQUE

19-21

(22-24cm/k

in.

TO

lbs.

g)

18

Page 19

FEED,

LOOPER

AND

NEEDLE

DRIVING

PARTS

Ref.

~

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

·~25A

25B

*25C

*25D

*25E

26

27

28

29

30 22894 c

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47 22894 u

48

49

50

51

52

53

54

55

56

57

58

59

60

Part

No.

61256 G

17-177

666-170

137-19

660-220

666-239

48-186

22652

447-140

22559 D

18-492

40-199

660-204

666-239

666-279

33-149

21-439

22-53

149-33

46-202

22652

17-150

17-114

18-732

23-343

23-342

23-340

23-341

23-346

45-478

22652

48-188

22652

22894 D

14-524

439-7

SB15

118-37

22652

87

147-21

18-1101

29

29

17-179

41332 J

61434 G

16-392

22652

79-41

4124-60

18-1100

63-39

36-16

22652

4118-36

1170 L

449-35

22652

115-166

22652

22651

22-8

A-8

A-8

A-16

A-8

A-6

u

BL-090/036

BL-100/040

A-8

A-8

A-6

A-8

AB-3

for

Amt.

~

1

1

1

1

2

1

1

2

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

Description

VVasher-------------------------------------------------------Stud,

for

looper

Oil

VVick---------------------------------------------------

Retainer---------------------------------------------------

"O"

Ring-------------------------------------------------------

Oil

VVick-------------------------------------------------------

Looper

Needle

Oil

Feed

Spring,

Pin,

Stitch

Feed

Stud,

Eccentric

Screw,

Feed

Feed

Feed

Feed

Feed

Feed

use

Feed

Crank,

Needle

Collar---------------------------------------------------------

Needle

Needle,

Needle

Loope;

Thrust

Thrust

Thrust

Screw--------------------------------------------------------Ball,

Looper

Looper-------------------------------------------------------Screw---------------------------------------------------------

Looper

Looper

Looper

Pin,

Driving

Screw-----------------------------------------------------

Drive

Screw,

Spot

Screw,

Fiber

"O"

Ring---------------------------------------------------

Oil

VVick---------------------------------------------------

VVick-------------------------------------------------------

Driving

for

for

stitch

Regulator------------------------------------------------

Driving

Screw-----------------------------------------------------

for

feed

for

Dog,

Dog,

Dog,

Styles--------------------------------------------------------

Dog,

Dog,

Dog,

with

presser

Driving

Screw-----------------------------------------------------

for

Screw----------------------------------------------------Set

Screw--------------------------------------------------

Spot

Screw-------------------------------------------------

Carrier

Screw-----------------------------------------------------

Carrier------------------------------------------------Clamp

Screw----------------------------------------------------Thread

Thumb

for

for

Ball

VVasher,

VVasher,

Bushing-------------------------------------------------

for

looper

Screw-------------~---------------------------------------

Ball

Screw----------------------------------------------------Oil

VVick---------------------------------------------------

Carrier

Screw-----------------------------------------------------

Carrier

Screw-----------------------------------------------------

Carrier

Clamp

Set

Screw--------------------------------------------------

for

looper

driving

Crank-------------------------------------------

Eccentric

for

connecting

for

VVasher

Lever

stitch

regulator

Lever

driving

Stud

-------------------------------------------------

feed

dog---------------------------------------------

See

Ref.

knurled

coarse

fine

teeth,

rubber

coarse

Lever---------------------------------------------

needle

Shaft--------------------------------------------

Screw-----------------------------------------------

Eyelet----------------------------------------------

Screw

Styles

Styles

Joint

Adjusting

right,

left,

connection--------------------------------------

Connection

Shaft

Yoke

Yoke

Screw-----------------------------------------------

carrier

crank

-----------------------------------

Ball

Joint

rod-----------------------------------

eccentric-----------------------------------

----------------------------------------------

Eccentric

regulator--------------------------------------

------------------------~---------------

Link----------------------------------------

lever

Nos.

teeth,

teeth,

padded----------------------------------------

teeth,

foot

carrier

---------------------------------------------37500-1,

37

25A,

16

10

21

t.

p.

10

No.

405-591

shaft----------------------------------

500-6

for

looper

for

looper

-----------------------------------------

-------------------------------------------

------------------------------------------Block--------------------------------------

yoke

Assembly-----------------------

-----------------------------------

link----------------------------------

25B,

25C,

25D

t.

p.

i.,

(1.

t.

p.

i.,

i.,

(1.

t.

p.

i.,

-5,

-9-------------------------------

-8

----------------------------------

Shaft---------------------------------

ball

------------------------------------

59

(2.

54

21

mm

(2.

54

only--------------------------

ball

joint

joint-------------------------

and

mm

per

mm

per

per

tooth)---------------

mm

per

-----------------------

25E

tooth)

tooth)

tooth),

-------------

-----------

for

all

wide,

*Available

as

extra

send

and

charge

item.

19

Page 20

20

Page 21

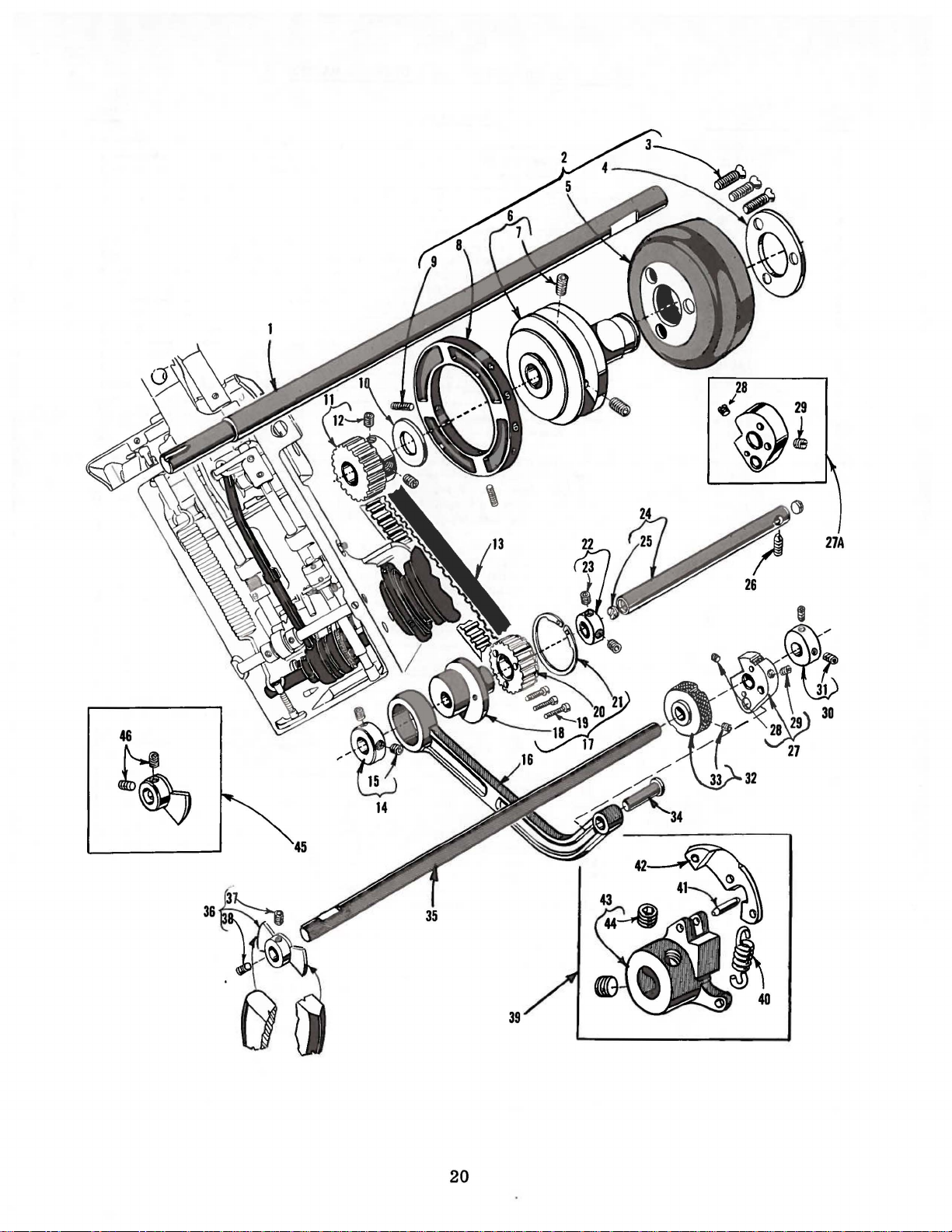

MAIN

SHAFT, HANDWHEEL, RIDGE FORMERS

RIDGE FORMER

DRIVING

PARTS

AND

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

27A

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

Part

No.

14-515

37521 B

22574

61321 L

63921

37521 c

22894 v

22650 AA-7

22894 AD

22894 c

22653

22894

22894 H

22894 AD

22597 A

22894 T

22651

22894 T

22894

22894 T

22894 T

c

BA

155-21

40-197

161-6

171-11

39-146

47-138

433-163

33-163

L-8

161-5

660-414

39-144

c

14-528

18-800

48-189

48-190

39-145

142-16

AB-4

22-333

14-533

44-326

c

444-327-1

21-442

22-337

44-327

99-357

44-333

Description

Main

Handwheel

ThrustWasher-----------------------------------Ridge

Ridge

Thrust

Ridge

Ridge

Collar,

Ridge

Spot

Ridge

Ridge

Thrust

Ridge

Ridge

Ridge

Ridge

Yielding Ridge

Ridge

Shaft----------------------------------------

Assembly

Screw---------------------------------------Hub

Washer

Handwheel-----------------------------------Pulley---------------------------------------

Set Screw

Stitch Length

Set Screw

Former

Screw----------------------------------------

Former

Collar,

SetScrew------------------------------------

Former

Former

Ridge

Screw----------------------------------------

Sprocket

Retaining

for

SetScrew------------------------------------

Former

Screw----------------------------------------

Screw---------------------------------------

Former

-6

---------------------------------------------

Former

Set Screw

SetScrew------------------------------------

Collar

Set Screw

Former

-5,

-6------------------------------------------ 1

SetScrew------------------------------------

Former

Former

Former,

Set Screw

SetScrew------------------------------------

37500-8

Spring

Pin------------------------------------------

Ridge

Ridge

Set Screw

Former,

SetScrew------------------------------------

-----------------------------------Drive

Drive

for

Connecting

Drive

Former

------------------------------------Ring--------------------------------

ridge

Drive

Drive

Drive

------------------------------------

------------------------------------

-----------------------------------Regulating Knob,

Drive

Shaft

for

-----------------------------------Former

----------------------------------------

---------------------------------------

Forming

Forming

for

------------------------------

----------------------------------

--------------------------------

Indicator-------------------------

Sprocket

Belt

ridge

Eccentric-----------------------

former

Styles

Disc--------------------------Disc

-------------------------------Style 37500-9

former

Eccentric

Shaft--------------------------

Crank,

Crank,

Pin-----------..:---------------

-------------------------------

Assembly,

Holder

----------------------

-------------------------drive

Rod----------------------

Assembly------------

drive

37500-1,

shaft

for

Styles

for

Styles 37500-8,

for

--------------------

-------------------

shaft----------

----------------

37

Styles 37500-1,

-5,

-6-----------

for

Style

500-1,

-5,

-9

---

Amt.

Req.

1

1

3

1

1

1

2

1

2

1

1

2

1

1

2

1

1

1

3

1

1

1

2

1

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

2

1

2

21

Page 22

22

~

29

Page 23

Ref.

No.

Part

No.

CYLINDER

STITCH

DEPTH

ADJUSTING

REGULATING

PARTS

Description

AND

PARTS

Amt

Req.

..

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22 88

23

24

25

26

27

28

29

30

31

32

33

34

39-144

22894

14-531

45-483

39-148

22653

41332

18-1104

70-75

22617

43232

110-433

660-219

51241 c

39668

110-431

142-18

660-219

22651

110-434

12865

39-147

22894

41375

71-118

18-1098

12990

18-633

471-C544

21-C54

18-C884

20-C117

22894

c

B-8

J

JA-24

R

H

CB-4

T

G

AD

v

w

B

Collar.

Penetration

Penetration

Collar.

Thrust

Penetration

Stitch

Screw.

Spring

Penetration

Spring

Counter

Penetration

Penetration

Collar.

Collar.

Spring.

Cylinder

Adjusting

Nut.

Screw.

KnuckleAssembly--------------------------------

MainSpring------------------------------------Screw.

Nut.

Set

for

penetration

Set

Screw

for

Screw

Washer

Depth

for

Washer

Roll

Pin

Pin-----------------------------------------

Washer-----------------------------------

Plate

Roll

Pin

Screw---------------------------------------

for

Screw---------------------------------------

for

Set

Screw

for

Push

Screw.

for

adjusting

for

for

for

Screw----------------------------------------

main

-----------------------------------

Adjusting

Adjusting

penetration

--------------------------------------

----------------------------------

Adjusting

Regulator

penetration

----------------------------------

Dial

Mounting

------------------------------------

-----------------------------------

Dial

Knob

------------------------------------

Dial

Plate----------------------------

adjusting

cylinder

-----------------------------------

cylinder

Rod

for

screw--------------------------

knuckle

main

spring---------------------------

spring

adjusting

Lever

Lever

adjusting

Screw

Adjusting

dial

mounting

Plate

----------------------------

sleeve----------------------push

push

-------------------------------

assembly----------------------

rod---------------------rod----------------------

cylinder

screw

-----------------------

shaft--------------

Shaft------------------

---------------------screw-------------

----------------------

Sleeve

-------------------

push

rod-------------

plate----------

------------

2

2

1

1

1

1

2

1

1

5

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

23

Page 24

25

15

24

Page 25

PRESSER

FEET

AND

ATTACHMENTS

Ref.

No.

1

1A

2

3

4

5

6

6A

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

Part

No.

18-1094

FP342

405-590

405-590-3

5-590

122-47

18-1107

137-154

137-157

21-446

14-532

1351 L

75-255

88

16-399

6-56

18-643

450-306

18-1111

89-64

22743

660-219

50-305

30-93

22652

D-8

40-C213

431-L187-1/4

431-L187-3/8

431-M187-1/4

431-M187-3/8

431-H187-1/4

431-H187-3/8

405-592

18-1107

122-48

5-592

22738 F

6-74

405-590-2

5-590

122-47

18-1107

126-60

1732

L

89-64

22743

21-446

14-532

88

1351 L

75-255

16-399

18-643

6-56

Description

Screw,

I

Screw,

Presser

for

Presser

for

presser

for

presser

Foot

Style

37500-1,

Foot

Presser

Chaining

Screw,

Retainer,

for

No.

Retainer,

foot,

for

all

foot,

Assembly,

-5

Assembly,

Styles

for

Style

1/4

inch

----------------------------------for

Style

except

37500-9-----------------

(6. 35

mm)

37500-6-----------------

Foot---------------------------------------

Finger-------------------------------------

for

chainin

marked'

~

finger----------------------------

C",

5/64

inch

(1.

98

405-590------------------------------------

for

No.

405-590-3--------------------------

37500-9

cloth

mm)

opening,

wide

------

notch,

Spring----------------------------------------------

v

Eccentric

Screw,

Edge

Set

Bushing,

Needle

Screw,

Presser

Adjusting

Nylon

Set

Roll

Folder

Folder

Screw,

Foot

Screw-------------------------------------------

Bracket,

Clamp,

Retainer