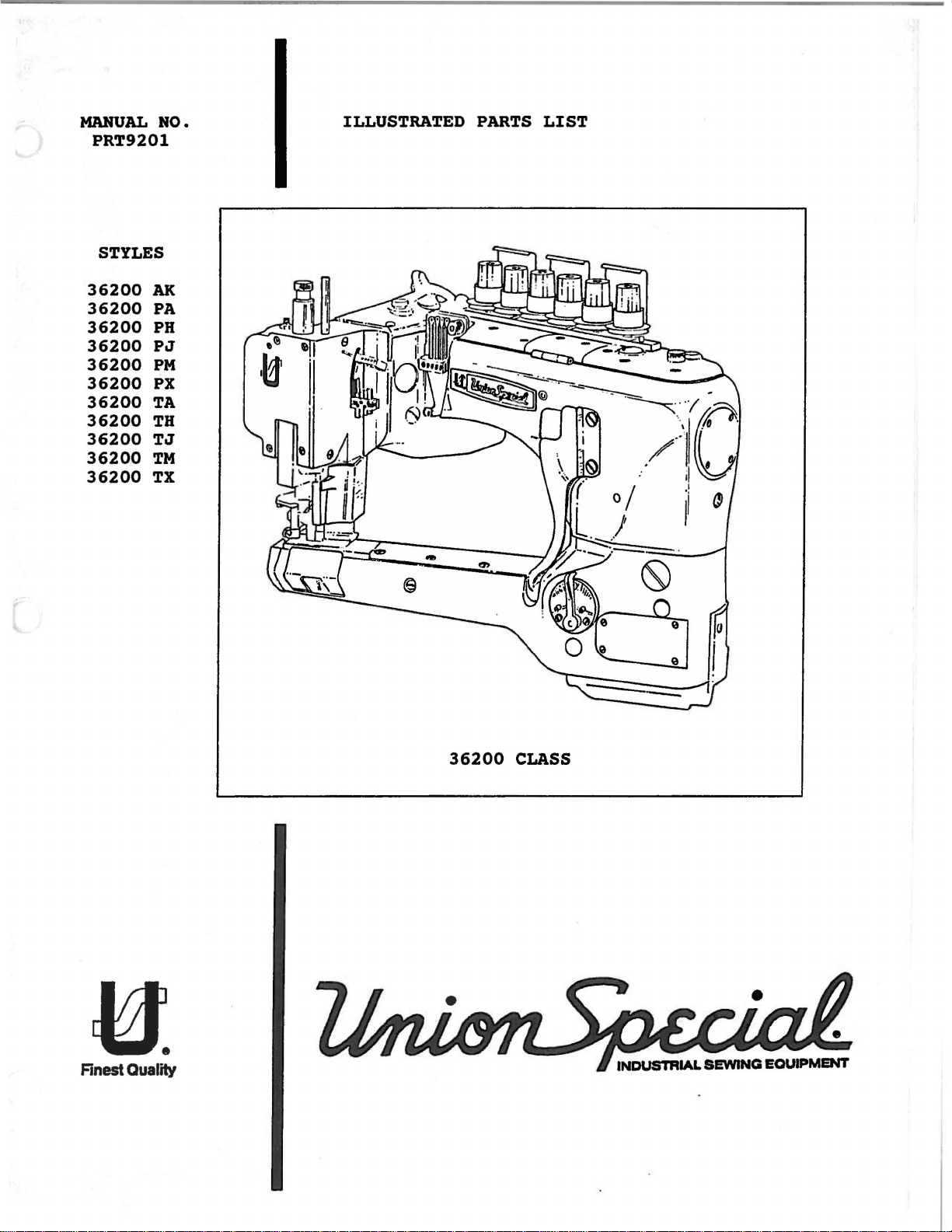

Union Special 36200AK, 36200PA, 36200PH, 36200PJ, 36200PM User Manual

...

MANUAL

PRT9201

STYLES

NO.

ILLUSTRATED

PARTS

LIST

36200

36200

36200

36200

36200

36200

36200

36200

36200

36200

36200

AK

PA

PH

PJ

~M

PX

TA

TH

TJ

TM

TX

a.

Finest Quality

36200

CLASS

INDUSTRIAL

SEWINGE

QUIP

MENT

Manual

No.

PRT9201

36200

36200

33200

36200

36200

33200

Illustrated

AK

PA

PH

PJ

PM

PX

Union

for

36200

Styles

First

Copyright

Edition

By

Special

Parts

the

Series

Corporation

List

1992

36200

36200

36200

36200

36200

TA

TH

TJ

TM

TX

Rights

Reserved

Printed

March.

In

in

All

U.S.A.

1996

Countries

PREFACE

This

parts

conjunction

It

performance.

your

lasting

This

Changes

of

On

in

Este

Cambios

de

parts

or

is

the

machine

service.

manual

in

configuration

the

following

describing

manual

endiseno

la

configuracion

manual

assemblies

with

desire

Parts

and

has

been

design

the

se

ha

has

on

Union

of

Union

listed

are

and/or

in

illustrations

pages

parts

hecho

y

la

en

been

manufactured

comprised

mejoras

prepared

the

36200

Special

Special

in

this

improvements

will

las

be

used

con

on

la

puede

ilustraciones

to

assist

Series

Adjusting

that

manual

with

on

the

may

or

part

found

the

informacion

illustrations

36200

incorporar

you

machines.

Manual

each

utmost

basis

incorporate

machine

are

designed

of

numbers.

Series

basica

una

o

numero

in

locating

INS9202.

precision

available

a

and

machines.

disponible.

pequena

de

It

can

run

at

specifically

to

slight

terminology

modificacion,

partes.

individual

be

used

its

optimum

assure

information.

modification

long

used

in

for

En

las

siguientes

en

la

descripcion

Dieses

Konstruktionsanderungen

Veranderung

Auf

Beschreibungen

warden.

den

Handbuch

der

folgenden

der

wurde

Abbildungen

paginas

de

partes

und/oder

Seiten

Teile,

encontrara

usadas

auf

finden

die

Basis

oder

in

ilustraciones

en

las

maquinas

vorhandener

Weiterentwicklungen

der

Teilenummern

Sie

die

Abbildungen

den

Maschinen

der

y

treminologia

Serie

Information

konnen

bedingen.

und

Baureihe

eine

die

36200

36200.

erstell

geringfiigige

technischen

verwendet

usada

t.

3

1.

Before

starting

operators.

putting

of

each

the

machines

machine

described

is

only

In this

permitted

SAFETY

manual

after

taking

RULES

into

notice

service,

of

carefully

the

instructions

read

the

instructions. The

and

by

qualified

IMPORTANT! Before

2.

Observe

3.

The

it

has

conformed

Each

described

the

4. All

the

5.

Wear

6. In

case

changes

7.

The

the

sewing

description,

safety

machine

warning

machines

been

ascertained

with

machine

in

devices

safety

of

machine

are

putting

motor

national

paragraph

without

glasses.

made

hints

supplier.

the

EC

Is

only

is

not

must

conversions

at

in

the

the

safety

described

allowed

the

rules

that

the

Council

to

"STYLES

as foreseen.

be

in

position

appertaining

your

own

instructions

machine

valid

In this instruction

sewing

Directives (89/392/EEC,

be

OF

and

risk.

Into service, also

for

your

country.

manual

units

which

used as foreseen.

MACHINES"

when

safety

changes

are

marked

the

machine

devices

all

of

this

valid

with

safety

read

are

prohibited

these

is

one

sewing

Annex

The

foreseen

instruction

is

ready

prohibited.

rules

of

these

the

safety

II B).

manual.

for

must

two

rules

from

machines

use

of

Another

work

or

be

considered.

symbols:

and

being

will

the

particular

in

operation.

instructions

put

into

service

be

built

into,

machine

use,

going

Operation

Conversions

from

the

until

have

beyond

and

is

of

8.

When

doing

main

switch

8.1

When

8.2 When

dog,

8.3 When

8.4 When

8.5 When using

9.

Maintenance,

special

0.

Any

1

11. Work

12. Before

work

supervision

on

described

disconnected

disconnecting

to

be

removed

the

following

or

by

pulling

threading

replacing

needle

leaving

doing maintenance

skilled

on

of

parts

in

doing

guard,

the

clutch

repair

personnel

the

electrical

special

and

equipment

the

applicable

maintenance

from

from

compressed

by

bleeding.

the

out

needle(s),

any

parts such as

folder,

workplace

motors

and

conversion

under

skilled

the

compressed

machine

the

main

looper,

fabric

and

work.

without

consideration

equipment

personnel.

under

sections

and

repair

air

supply

has

to

be

plug:

spreader

needle(s),

guide

when

actuation

work

(see

must

electrical

of

standard

work

air

supply.

(i.e.

disconnected

etc.

presser foot,

etc.

the

workplace

lock,

item

8)

of

the

instructions.

be

done

power

sheet

on

the

pneumatic

In

pneumatic

wait

until

must

by

is

not

DIN

VDE

case

equipment

from

the

throat

is

unattended.

the

be

done

an

electrician

permitted.

0105.

equipment,

of

existing

power

plate,

motor

only

Permissible

residual

with

supply

looper,

is

stopped

by

trained

or

the

air

tank),

by

under

exceptions

machine

air

pressure,

the

turning

spreader,

totally.

technicians

direction

pressure has

has

off

to

the

feed

or

and

are

be

after

4

1.

Ordering

Repair

Parts

CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

2o

3o

4o

Main

5o

Main

6o

Crankshaft

7o

Foot

8o

Detachable

9o

Differential

Torque

Oil

Sight

Eyelet

Needle

Eccentric

Illustrations

Identifying

Needles

Terms

Requirements

Frame,

Shaft

Lifter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gauges,

Parts

Bushings

Parts

&

Needle

&

Head,

Bar

Head

&

Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Top

Covers

.......................................

&

Miscellaneous

&

Miscellaneous

Lever

Tension

Head

Main

Parts

Covers,

00000000000

Feed

...............................

Parts

Bars,

&

Miscellaneous

Oiling

Needle

Feed

Dogs & Feed

Eyelet

Bar

&

Ta.ke-up

&

Cover

Lift

&

.

Parts

.

6

6

7

7

8

11

13

15

17

19

21

23

10o

11o

12o

13o

14o

15o

16o

17

18o

19o

20o

21o

Feed

Knife

Looper

Lap

Former,

Chain

Cylinder

Miscellaneous

Presser

Presser

0

Presser

Thread

Miscellaneous

Drive

Numerical

Drive

Driving

Rocker

Cutting

Feet

Feet

Foot

Stand

Unit,

Assembly,

Parts

Shaft

Miscellaneous

Knife

Bushings,

Cylinder

Feed

Rocker

&

Looper

Avoid

Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

&

Looper

..................................

Differential

Rocker

Cylinder

Covers

Drive

Covers,

Feed

oooooo•••················

Control

Parts

Throat

Assembly

Plates

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shoes

Gauges

Belt

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

&

Guard

of

Tape

&

Parts

Reel

Table

Parts

Mounting

Parts

&

.

25

27

29

&

31

33

35

37

39

41

43

45

46

5

ILLUSTRATIONS

ORDERING REPAIR

PARTS

This

views

may

the

manual

of

be

seen

illustration

description

shown.

Numbers

the

position

never

the

be

second

Component

indicated

main

and

20

21

22

23

24

25

26

27

sub-assembly.

the

29478CU

35851L

22729C

269

4761

39145A

22727C

various

in

the

used

parts

by

text

18

has

been

in

their

will

and

the

first

of

the

in

column.

of

indenting

below.

Looper

arranged

sections

actual

be

found a listing

number

column

part

in

of

are

the

ordering

sub-assemblies

their

As

an

Drive

Ball

Nut,

Joint,

Screw

left

Connecting

Nut,

Ball

right

Joint,

Screw

to

simplify

of

the

position

pieces

reference

illustration.

parts.

descriptions

example

Connecting

. . . . . . . . . . . . . . . . . . . . . . . . . . 2

thread

Rod

thread

. . . . . . . . . . . . . . . . . . . . . . . . . . 2

ordering

mechanism

in

the

machine.

of

the

required

numbers

Always

which

use

can

under

refer

to

Rod

upper

•••••••••••••.•.•••

•••••••••••.••••••.•

••.•••••••••••••••••••

•••••••••••••.•••••

lower

•••••••••••••••••••

repair

are

shown

parts

in

with

the

only,

The

reference

the

part

be

furnished

the

the

illustration

Assembly

parts.

so

that

On

the

their

particular

and

merely

number

for

description

••••.

the

page

part

view

number

listed

repairs

on

1

1

1

1

1

1

Exploded

parts

opposite

numbers,

being

indicate

should

in

are

of

the

page

28

It

will

The

so

the

be

ordered.

When a

usage

the

in

the

be

reason

complete

part

will

various

description

noted

is

that

upper

is

common

be

mentioned

machines

illustration.

A

numerical

back.

only

This

a

part

index

will

number

facilitate

IDENTIFYING PARTS

Where

On

an

the

construction

some

of

the

identification

smaller

ones.

PLEASE NOTE:

Part

manual

name

in

the

above

replacement

ball

to

all

in

are

not

and,

of

all

is

if

the

known.

permits,

parts

letter

is

numbers

they

and

Style

example

of

these

joint

and

machines

the

description.

the

same,

necessary,

parts

locating

each

and

on

stamped

represent

appear.

of

that

parts

lower

covered

the

the

shown

the

part

those

in

to

the

On

all

machine

the

individually

ball

However,

specific

difference

in

this

illustration

is

stamped

where

construction

distinguish

same

orders

for

which

ball

joint

in

this

manual

part,

please

studs

is

are

not

sub-assemblies

manual,

when

usage

will

and

with

will

be

is

located

description

its

does

the

part

regardless

include

the

part

not

listed.

reconunended,

should

no

specific

the

parts

be

mentioned

shown

in

at

part

from

was

not

part

number.

permit,

similar

of

which

number,

ordered.

for

the

the

when

6

NEEDLES

Each

kind

number,

blade

and

of

118GAS

118GBS

118GHS

118GJS

118GKS

needle

of

Size

all

has

shank,

stamped

measured

number

needles

DESCRIPTION

Extra

chromium

080/032, 090/036.

Extra

shank,

Same

070/027,

Same

Sizes

Round

groove,

075/029,

both a Type

point,

on

between

represent

packed

short,

short,

chromium

as

as

available

shank,

length,

the

the

and

double

plated.needle.

single

Type

075/029,

Type

spotted,

080/032.

and

Size

groove,

needle

plated

118GBS,

118GHS,

round

shank,

shank

the

sold

065/025, 070/027,

chromium

and

complete

by

groove,

Sizes

groove,

needle.

except

080/032.

except

point,

plated

number.

finish

denotes

the

eye.

symbol

Union

struck

available

struck

with

with

extra

The

and

the

Collectively,

which

Special.

groove,

groove,

Sizes

ball

tapered

075/029.

short,

needle.

Type

other

largest

is

.060"

065/025,

spotted,

available

point.

blade

double

Sizes

number

details.

diameter

the

given

diameter

070/027,

.060"

075/029,

Sizes

and

groove,

available

denotes

The

Type

on

the

075/029,

diameter

080/032.

available

ball

070/027,

the

Size

of

the

number

label

shank,

point.

struck

36211

118GKS

118GKS

When

head

To

sample,

on

Type

TERMS

Prices

are

and

changing

before

have

the

118GKS,

forwarded

insurance.

Retainer

065/025,

75/029

80/032

needles

or

the

label.

are

net

the

the

promptly

Type

A

Size

cash

F.O.B.

needle,

070/027,

needle,

clamp

and

Size

complete

075/029".

and

shipping

no

scarf,

075/029.

APPLICATION

Recommended

36200AK, PA, PH,

Recommended

36200PX,

make

screw

and

number

order

subject

sure

is

tightened.

accurately

should

should

to

change

point.

chromium

for

for

TX

it

filled,

A

Styles

PJ,

Styles

is

fully

be

forwarded.

read

without

charge

plated.

PM,

an

as

is

TA, TH,

inserted

empty

Use

follows:

notice.

made

Sizes

TJ,

in

package,

the

description

"100

All

to

cover

available

TM

the

needle

a

needle

needles,

shipments

postage

7

TORQUE

REQUIREMENTS

Torque

through

by a wrench,

when

amount

All

unless

tightened

Screws

set

and

straps

otherwise

requiring

(measured

a

at

distance

screwdriver,

the

proper

no

tighter.

and

eccentrics

by

hand

in

inch-pounds)

by a lever

amount

noted.

as

tightly

a

specific

etc.

should

All

torque

of

(in

Many

torque

be

tightened

other

as

possible,

is

a

inches

of

nuts,

will

rotating

these

will

be

or

feet)

devices

tighten

to

19-21

bolts,

unless

indicated

force

.

the

inch-pounds

screws,

in

This

are

part

otherwise

on

the

pounds

is

accomplished

available,

to

the

(22-24cm/kg)

etc.

illustrations.

should

noted.

applied

which

correct

be

8

EXPLODED

AND

VIEWS

DESCRIPTION

OF

PARTS

9

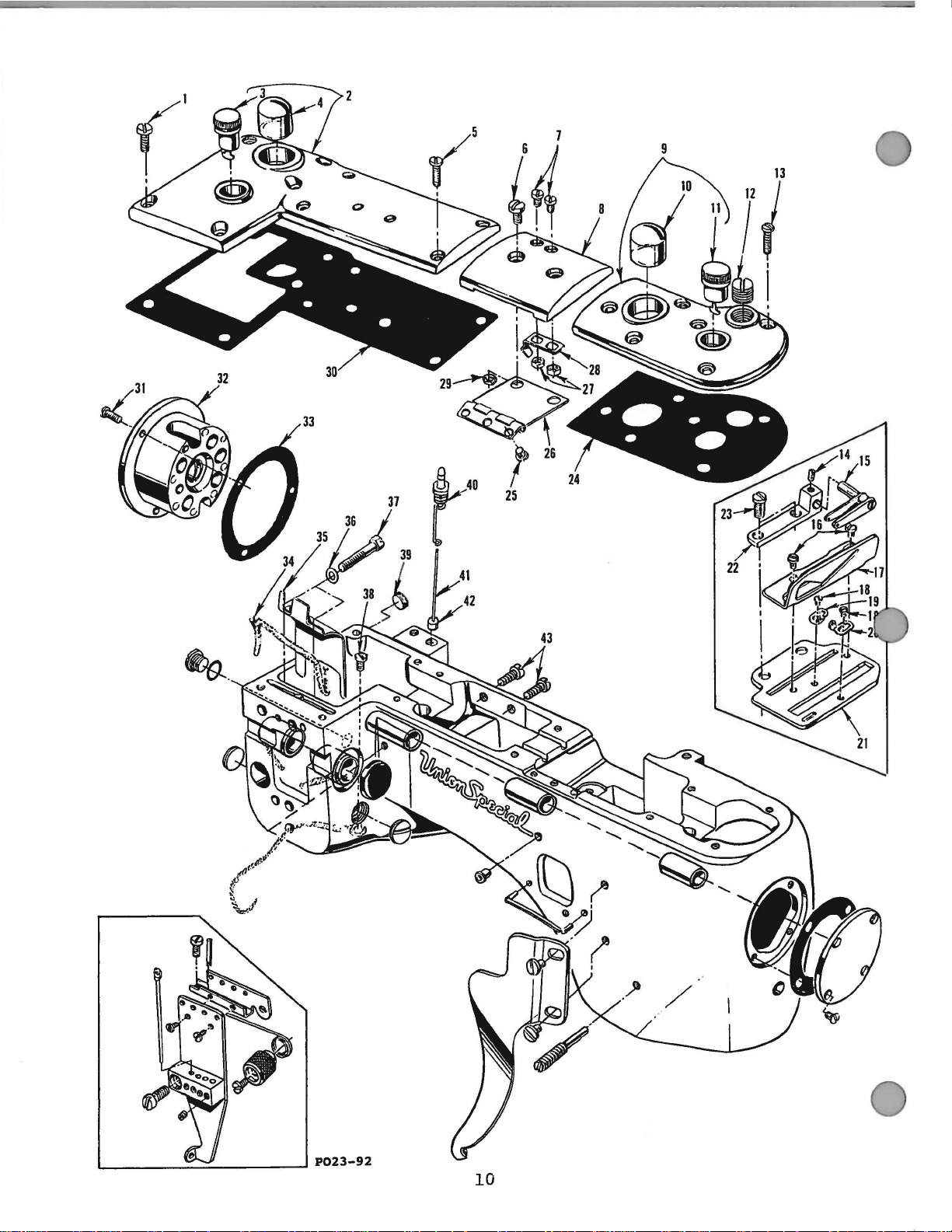

P023-9

2

10

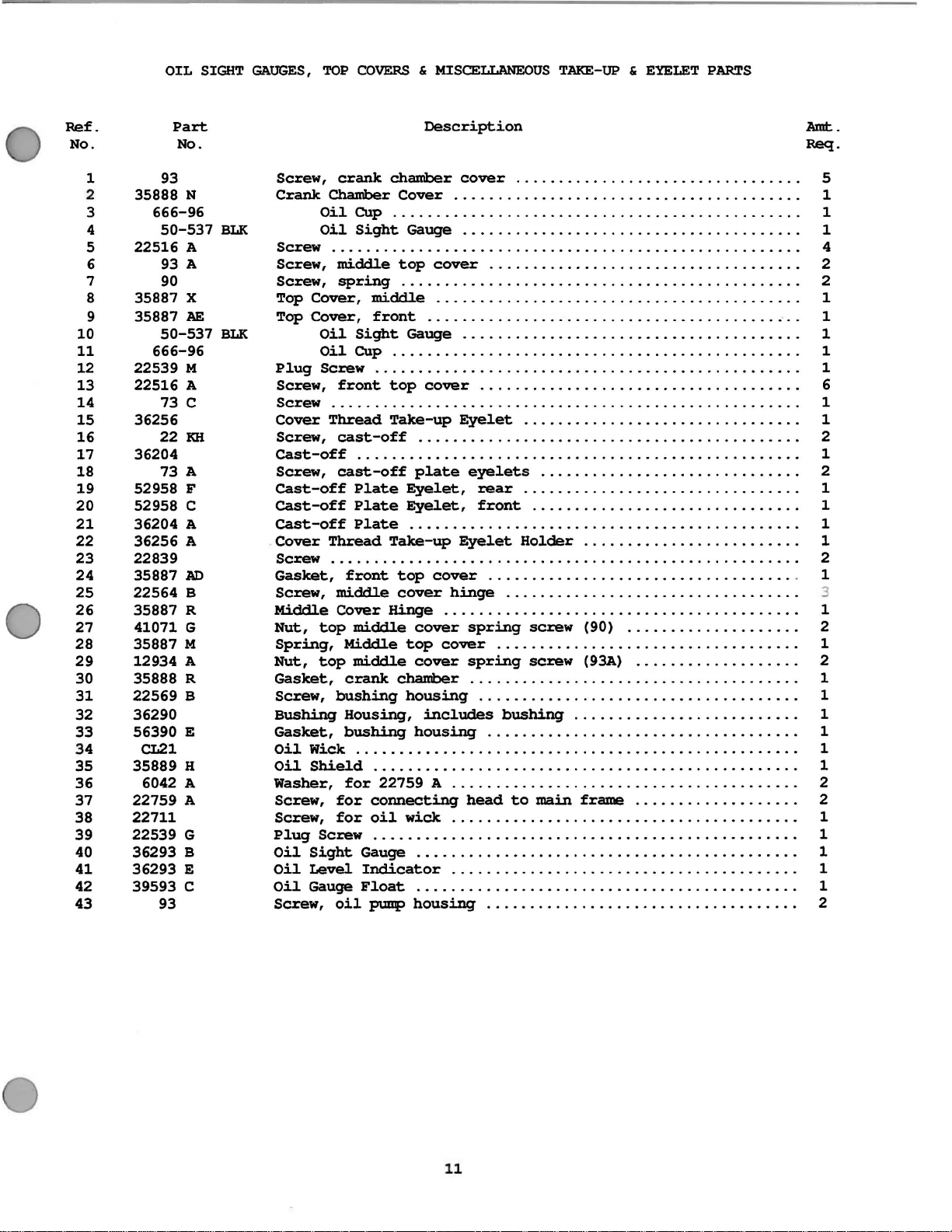

OIL

SIGHT

GAUGES,

TOP

COVERS & MISCELLANEOUS

TAKE-UP & EYELET

PARTS

Ref.

No.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

1

2

3

4

5

6

7

8

9

Part

No.

93

35888

N

666-96

50-537

22516 A

93 A

90

35887 X

35887 AE

50-537

666-96

22539 M

22516 A

73 c

36256

22

KH

36204

73

A

52958 F

52958 c

36204 A

36256 A

22839

35887

AD

22564 B

35887 R

41071 G

35887 M

12934 A

35888 R

22569 B

36290

56390

E

CL21

35889 H

6042 A

22759 A

22711

22539

G

36293 B

36293 E

39593 c

93

BLK

BLK

Description

Screw,

Crank

Screw

Screw,

Screw,

Top

Top

Plug

Screw,

Screw

Cover

Screw,

cast-off

Screw,

cast-off

cast-off

cast-off

Cover

Screw

Gasket,

Screw,

Middle

Nut,

Spring,

Nut,

Gasket,

Screw,

Bushing

Gasket,

Oil

Oil

Washer,

Screw,

Screw,

Plug

Oil

Oil

Oil

Screw,

crank

Chamber

Oil

Oil

chamber

Cover

cover

.................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Sight

Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

middl.e

spring

Cover,

Cover,

Oil

Oil

top

cover

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

middl.e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

front ............

Sight

Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

..

........

.

..................

Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

front

top

cover

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Thread

cast

Take-up

-off

Eyelet .........

..

...........

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

......

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

cast-off

Plate

Plate

Plate

Thread

plate

Eyelet,

Eyelet,

eyelets

.........

.

..........

rear ................................

front

..................

.

.........

.

............

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Take-up

Eyelet

Holder

.........................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

front

middl.e

Cover

top

Middl.e

top

crank

bushing

Housing,

bushing

top

cover

Hinge

middl.e

middl.e

chamber

cover

top

cover

cover

cover

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

hinge ...

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

spring

spring

..........

screw

..............

screw

..

...................

(90) . . . . .

..

...................

(93A)

...................

...........

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

housing

includes

housing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

bushing

.......

..............

.

.......

.

..................

.

.......

Wick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Shield

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

for

22759 A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

for

connecting

for

oil

wick

head

to

main

frame

.......

. . .

.........

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Sight

Level

Gauge

Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Indicator

Float

oil

punp

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

housing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

·. . 1

...

. .

..

. . 1

Amt.

Req.

5

. 1

2

1

1

1

3

. 2

1

2

1

2

11

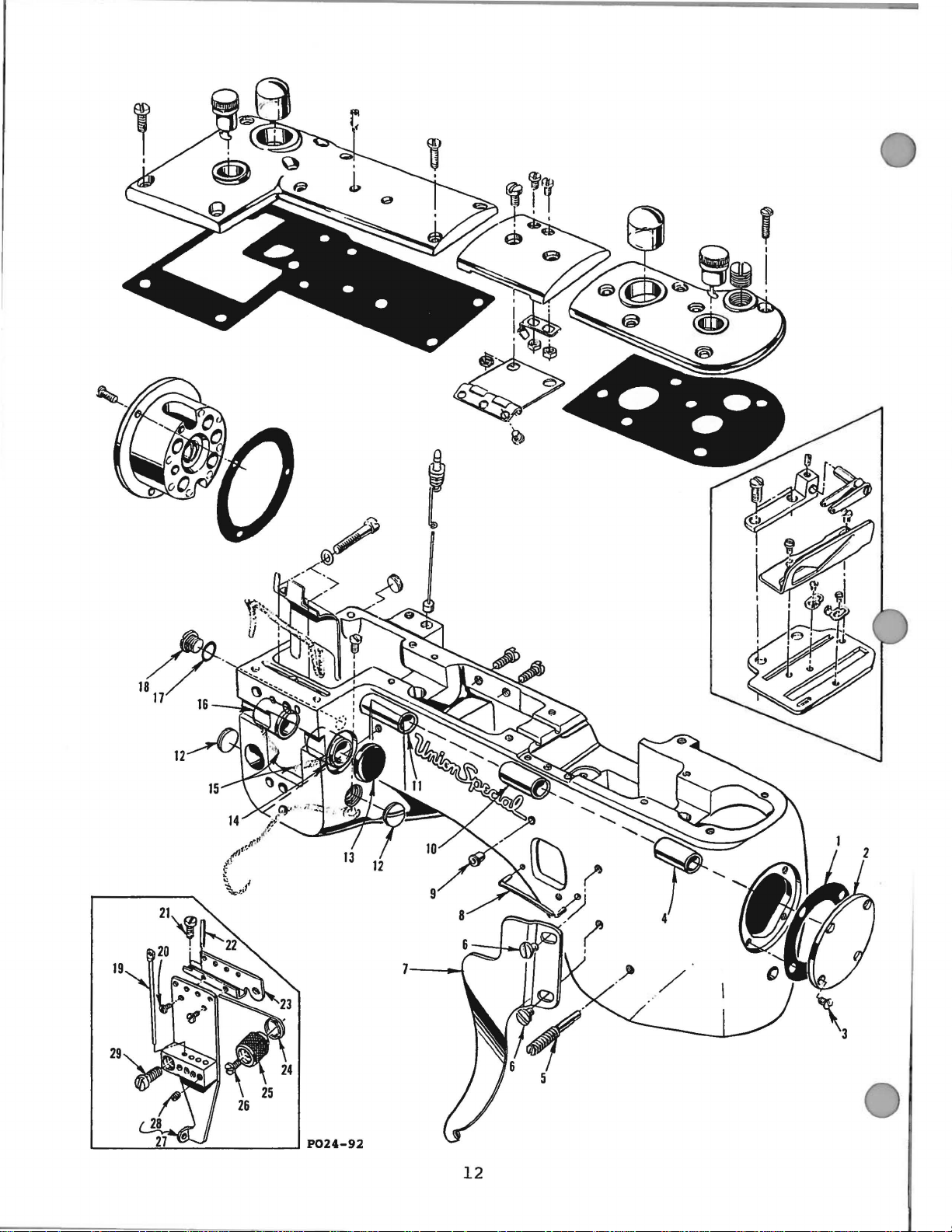

P024-92

12

~N

FRAME,

BUSHINGS & MISCELLANEOUS

EYELET & COVER

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Part

35887

35887

22564

36290

22791

22829

36281

35781

62271

36290

35890

22539

35761

35760

CL21

36260

660-206

22733

36271

73

22768

22799

36271

36271

36271

22593

36271

28

22569

No.

A

A

A

A

B

B

G

E

H

c

D

v

z

B

B

D

D

B

E

T

D

D

B

Gasket,

End

Cover

Screw,

Main

Screw,

Screw,

Looper

Looper

Thread

Main

Crankshaft

Plug

Bushing

Needle

Oil

Needle

Rubber

Oil

Frame

Screw,

Screw,

Screw

Stitch

Unlocking

Spring

Screw

Needle

Screw,

end

Shaft

for

looper

Thread

Thread

Guide

Shaft

Screw

Lever

Wick

Lever

"0"

Drain

Needle

needle

unlocking

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unlocker

Bolder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Thread

Screw

needle

Description

end

cover

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

cover

Bushing,

36253B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Bushing,

Bushing,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

cap

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Shaft

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Shaft

Ring

Screw

Thread

thread

Spring

Eyelet..........................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

thread

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

front.......

looper

thread

Shield

Guide

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Wire..........

rear...........

front.....................

Bushing,

Bushing,

. .

............................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Eyelet....................

spring

MOunting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

drive

shield...................

. . . . . . . . . . . . . . . ...

front.............

rear..............

eyelet...................

height

Bracket..

eyelet...................

.

.............

lever

adjusting......

shaft

....

.

...........

.

..........

.

...........

. . . . 1

_ . . . . 1

.

Amt.

Req.

1

2

1

1

1

1

1

4

2

1

1

1

1

13

II

TORQUE

19-21

in.

{22-24

em/kg)

TO

lbs.

21

'

I

P025-92

14

r------------_J

I

27--/

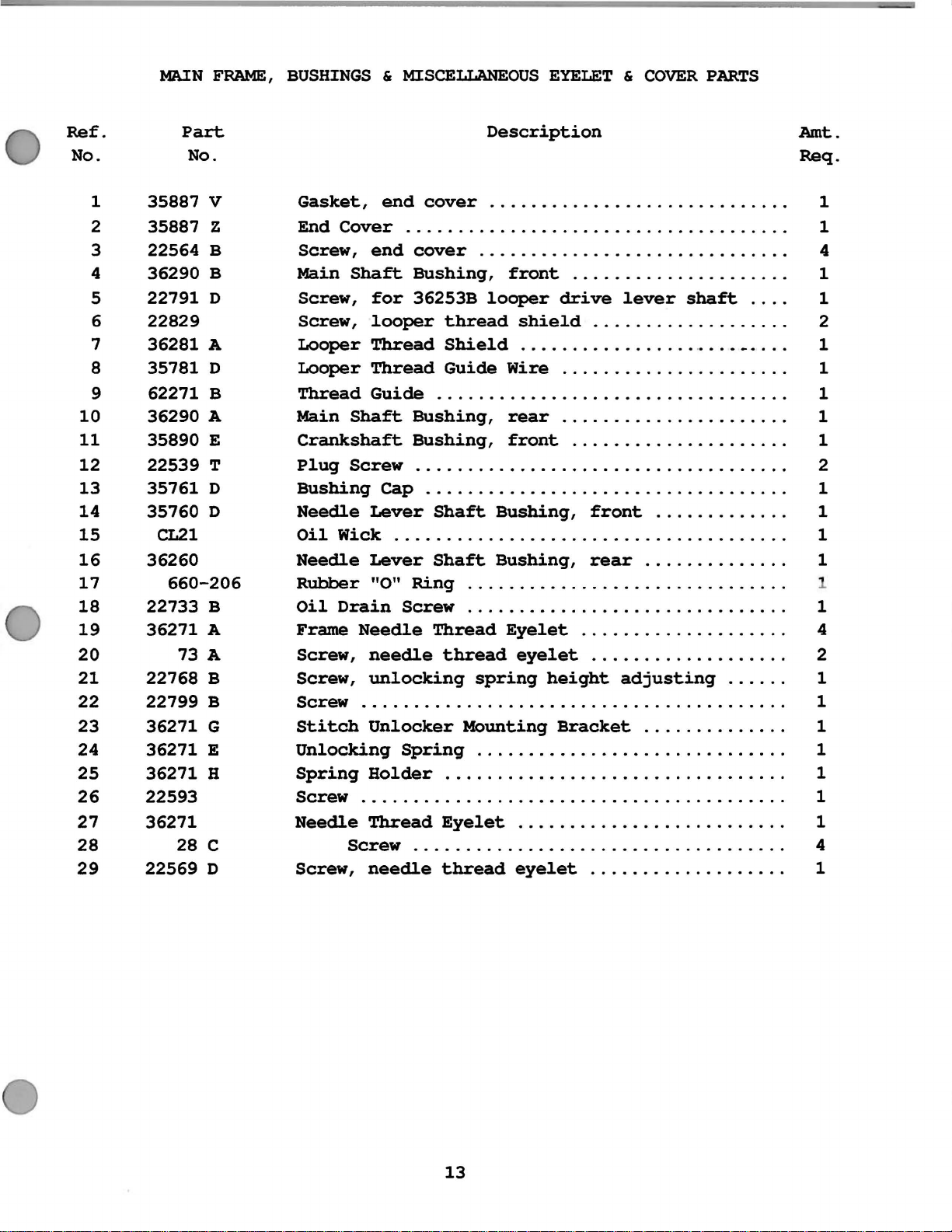

MAlN

SHAFT

PARTS & MISCELLANEOUS

OILING

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Part

No.

22585

660-207

35897

35894

21756

35897

29472

36297

35897

29472 AC

36297 M

22571 B

41071 G

22565 A

90

80265

36261 A

35861 D

35894 L

660-202

29101 J

22587 E

22894 w

29103 T

22587 E

22894 w

660-219

28 36222 c

29

30

31

32

33

34

35

36

37

38

39

22801

36223

22580

36223 A

22580

35895 y

22894

35895 X

22519 F

80265

22894 J

40 22894 K

A

BU

J

G

BW

y

J

BV

AM

p

Description

ScJ:ew,

Oil

Reservoir

Oil

Vent

Gasket

Pump

housing

Seal

Ring

Reservoir,

Screw

cover

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Outlet

Tube

back

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Assembly

Housing

Pump

Housing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Cover

Intake

Body

Cover

Plug

Nut

and

Oil

Tube,

Filter

and

Gear

and

Screw

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Assembly...................

Oil

Tube,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

rear......................

front

.....................

.

ScJ:ew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ScJ:ew,

Spacer

Take-up

Oil

Oil

Feed

take-up

Washer

Shield

Gasket

Reservoir,

Seal

Ring

Drive

Eccentric

shield

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Assembly....................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

front

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Assembly..............................

ScJ:ew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Set

Feed

Lift

SCJ:eW

Set

Roll

Pin

Main

Shaft

SCJ:eW

Double

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Disc

Screw

Cover

ThJ:ead

Screw

Crankshaft

Screw

Main

Shaft

Screw

Eccentric

Screw

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Assembly...............................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Take-up

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Take-up

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Thrust

Collar

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Coupling

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ScJ:ew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Washer

Set

Spot

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Screw

SCJ:eW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

.......

..

Amt.

Req.

1

1

1

1

1

1

1

15

r------

--

---

I

I

!

-J

19-21 in.

(22-24

23

22

P026-92

lbs.

cmfkg)

16

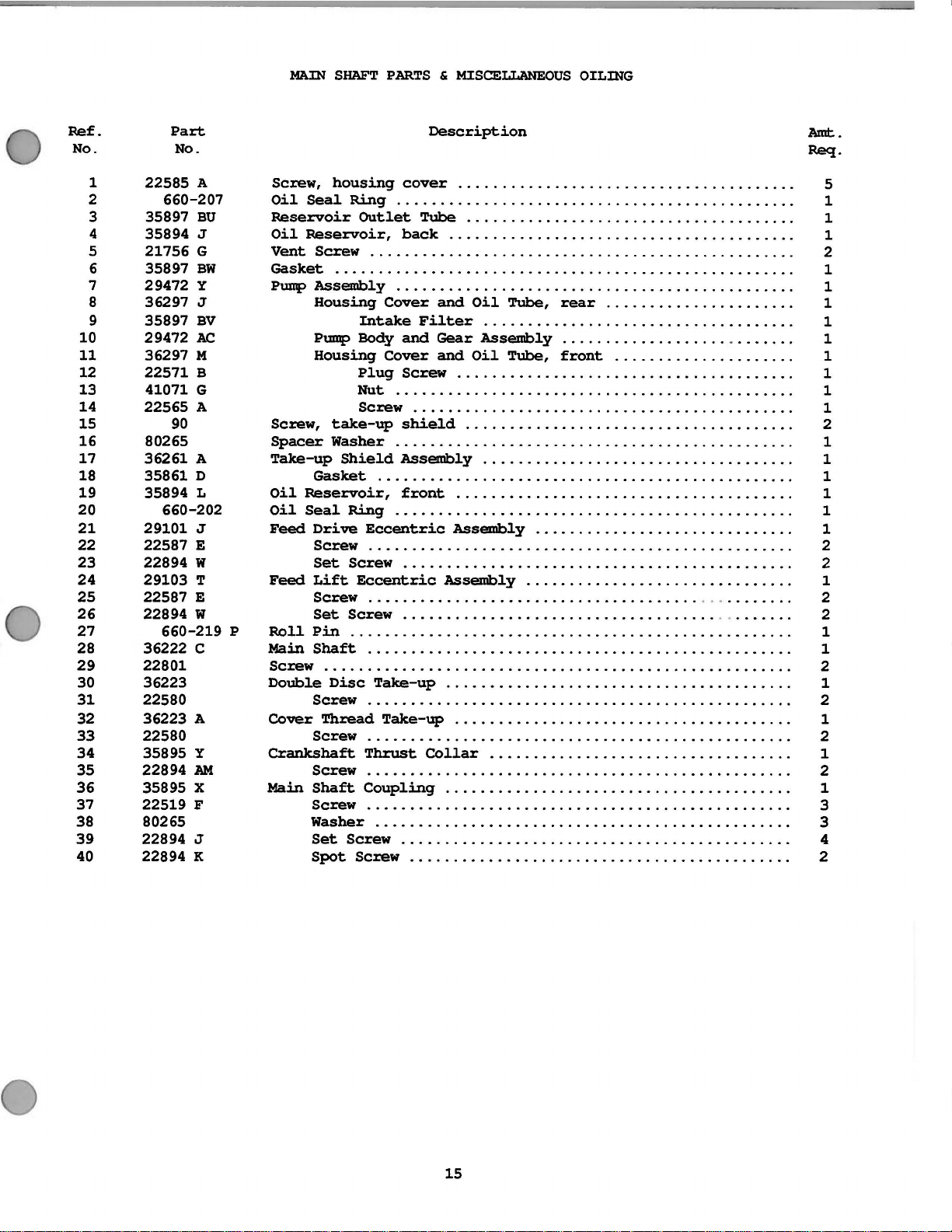

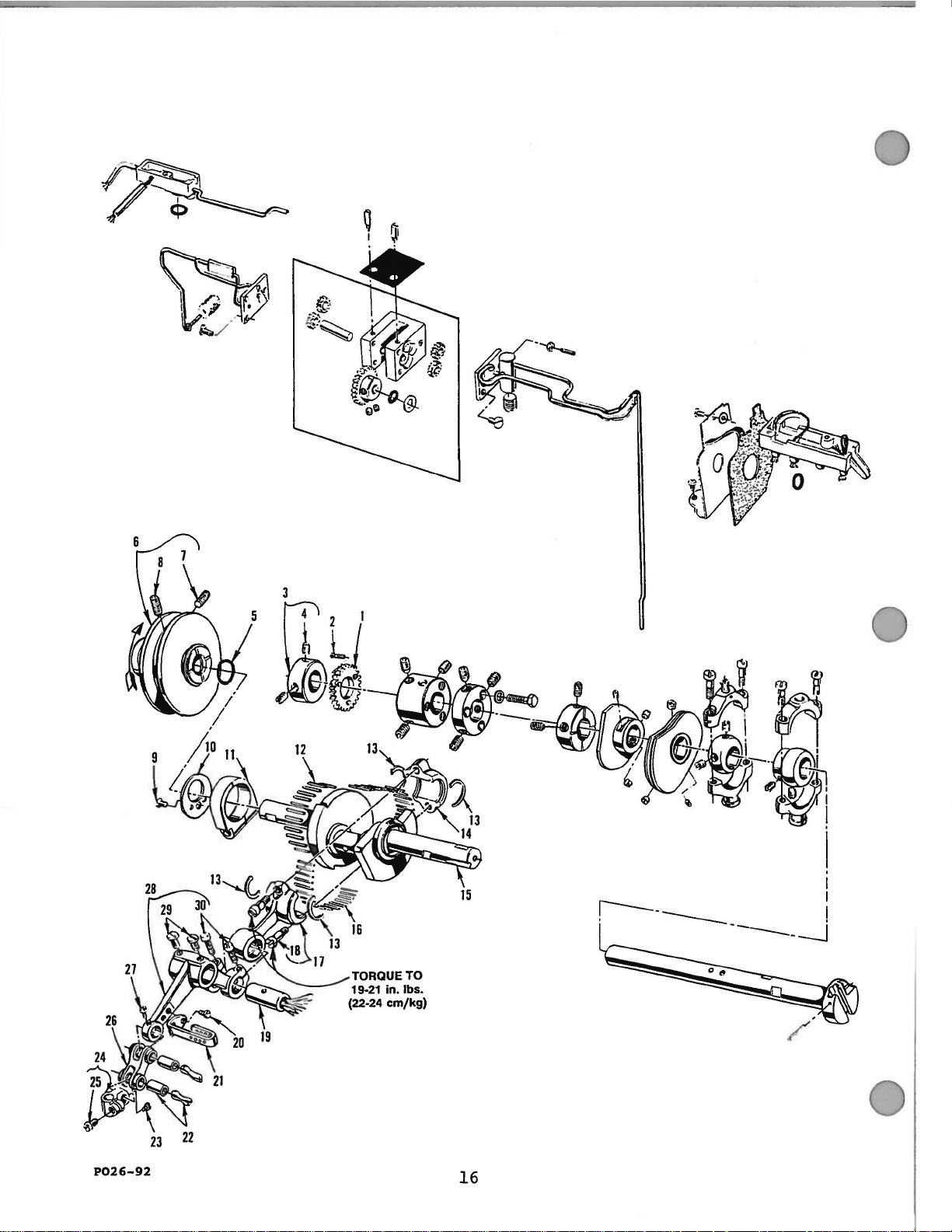

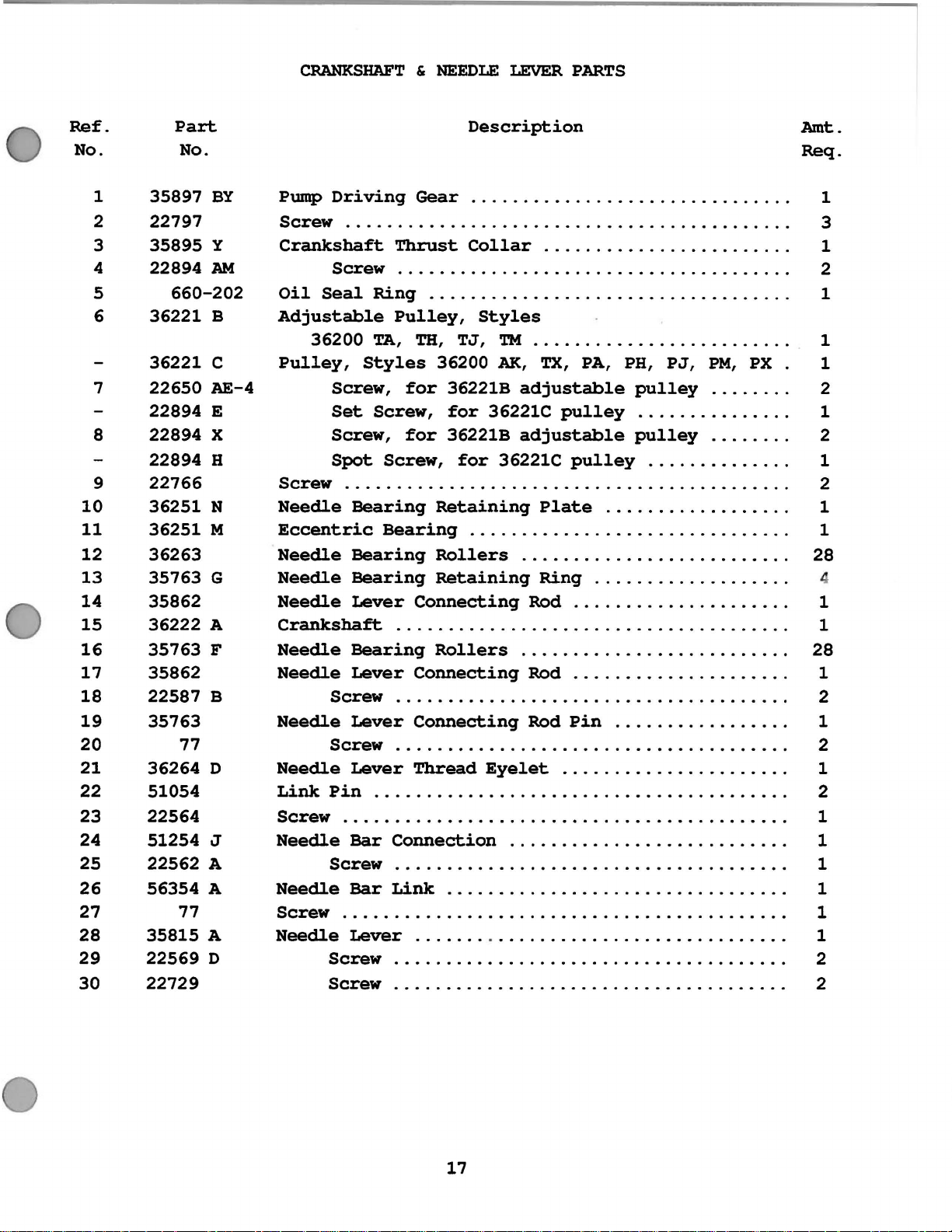

CRANKSHAFT & NEEDLE

LEVER

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Part

No.

35897

22797

35895

22894

660-202

36221

36221

22650

22894

22894

22894

22766

36251

36251

36263

35763

35862

36222

35763

35862

22587

35763

77

36264

51054

22564

51254

22562

56354

77

35815

22569

22729

BY

y

AM

B

c

AE-4

E

X

H

N

M

G

A

F

B

D

J

A

A

A

D

Description

Pump

Driving

Gear

..............................

Screw ..........................................

Crankshaft

Screw

Oil

Seal

Adjustable

36200

Pulley,

Screw,

Set

Screw,

Spot

Screw

..........................................

Needle

Eccentric

Needle

Needle

Needle

Crankshaft

Needle

Needle

Screw

Needle

Screw

Needle

Link

Screw

Pin

..........................................

Needle

Screw

Needle

Screw

..........................................

Needle

Thrust

Collar

.......................

.....................................

Ring

TA,

Styles

Screw,

Bearing

Bearing

Bearing

Bearing

Lever

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulley,

TH,

for

for

Screw,

Styles

TJ,

TM

36200

AK,

36221B

for

36221C

36221B

for

36221C

Retaining

..........••••.........•.

TX,

adjustable

pulley

adjustable

pulley

Plate

. . . . . . . . . . . . . . . . . . .

Rollers

Retaining

Connecting

.........................

Ring

Rod

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bearing

Lever

Rollers

Connecting

.........................

Rod

....................

.....................................

Lever

Connecting

Rod

Pin

.....................................

Lever

Thread

Eyelet

.....................

.......................................

Bar

Connection

..........................

.....................................

Bar

Link

Lever

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

Screw

Screw

.....................................

PA, PH,

PJ,

pulley

..............

pulley

.............

.................

...........

..................

....................

................

...........

PM,

.......

.......

......

PX

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Amt.

Req.

1

3

1

2

1

1

1

2

1

2

1

2

1

1

28

1

1

28

1

2

1

2

1

2

1

1

1

1

1

1

2

2

17

Loading...

Loading...