Union Special 36200L220-60 Parts List

ADJUSTING INSTRUCTIONS / ILLUSTRATED PARTS LIST

11/22/06

MANUAL NO. PT0204-GR

FOR STYLE

36200L220-60

Manual No. PT0204-GR llustrated Parts List for 36200L220-60 Series Machines

First Edition Copyright 2006

By

Union Special Corporation Rights Reserved In All Countries

Printed in U.S.A. Nov 2006

PREFACE

This parts manual has been prepared to assist you in locating individual parts or assemblies on 36200L220-60 Series

machines.

It is the desire of Union Special that each machine run at its optimum performance. Parts listed in this manual are designed

specifically for your machine and are manufactured with utmost precision to assure long lasting service.

This manual has been comprised on the basis of available information. Changes in design and/or improvements may

incorporate a slight modification of configuration in illustrations or part numbers.

On the following pages are illustrations and terminology used in describing the parts used on 35600 Series machines.

TERMS

Prices are net cash and subject to change without notice. All shipments are forwarded F.O.B. shipping point. A charge is made

to cover postage and insurance.

CONTENTS

PREFACE .......................................................................................................................................................................................2

TERMS............................................................................................................................................................................................2

IDENTIFICATION OF MACHINES ..................................................................................................................................................3

TORQUE REQUIREMENTS .............................................................................................................................................................. 3

DESCRIPTION OF MACHINES.......................................................................................................................................................3

STYLE OF MACHINES ....................................................................................................................................................................3

IDENTIFYING PARTS ...................................................................................................................................................................... 4

NEEDLES ........................................................................................................................................................................................4

SAFETY RULES:...............................................................................................................................................................................5

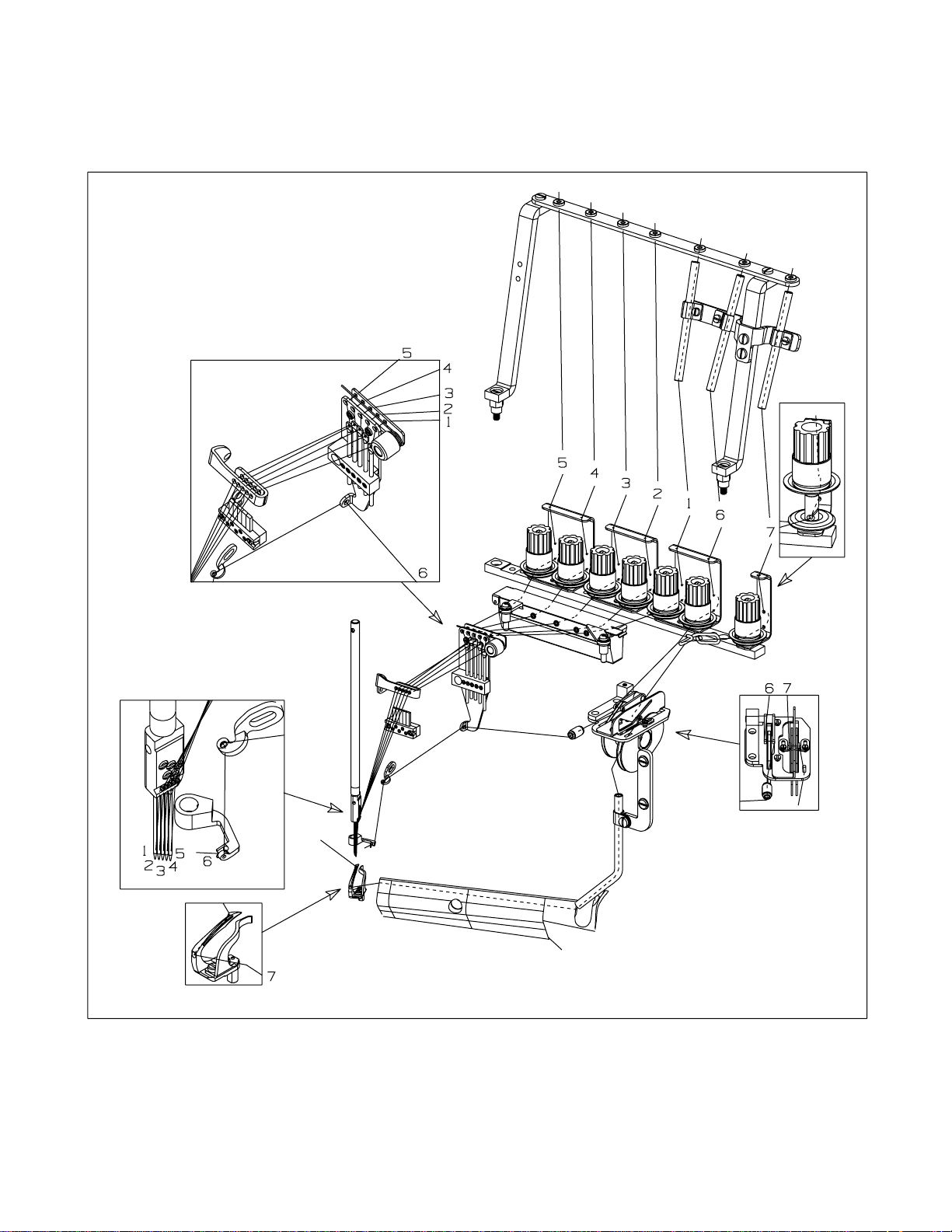

THREADING ..................................................................................................................................................................................6

OILING ..........................................................................................................................................................................................7

ADJUSTING INSTRUCTIONS..........................................................................................................................................................8

SETTING THE NEEDLE BAR HEIGHT & ALIGNMENT ....................................................................................................................... 8

SETTING THE NEEDLE BAR HEIGHT & ALIGNMENT (CONT) .........................................................................................................9

ALIGNING THE CYLINDER ............................................................................................................................................................9

SETTING THE LOOPER TRAVEL USING GAUGE 21227CN .......................................................................................................... 10

SETTING THE LOOPER TRAVEL ....................................................................................................................................................10

TIMING THE NEEDLES TO THE LOOPER .......................................................................................................................................11

INSTRUCTIONS FOR USING SYNCHRONIZING GAUGE 21227CG ...........................................................................................11

TIMING THE NEEDLES TO THE LOOPER (CONT.) ........................................................................................................................11

LOOPER ADJUSTMENTS ..............................................................................................................................................................12

LOOPER ADJUSTMENTS (CONT.) ............................................................................................................................................... 13

SETTING THE FRONT NEEDLE GUARD .........................................................................................................................................13

SETTING THE FEED DOGS............................................................................................................................................................13

SETTING THE REAR NEEDLE GUARD ...........................................................................................................................................14

SETTING THE STITCH LENGTH ......................................................................................................................................................14

DIFFERENTIAL FEED CONTROL ...................................................................................................................................................14

2

SETTING THE PRESSER FOOT ....................................................................................................................................................... 14

SETTING THE PRESSER FOOT (CONT.) ........................................................................................................................................15

SETTING THE PRESSER FOOT (CONT.) ........................................................................................................................................16

SETTING THE KNIFE DRIVE LEVER................................................................................................................................................16

SETTING THE KNIFE DRIVE LEVER (CONT.) .................................................................................................................................17

SETTING THE TRIMMING KNIVES FOR LAP SEAMING ................................................................................................................17

NEEDLE THREAD ADJUSTMENTS .................................................................................................................................................18

LOOPER THREAD ADJUSTMENT..................................................................................................................................................18

COVER THREAD ADJUSTMENT ...................................................................................................................................................18

TENSION RELEASE.......................................................................................................................................................................19

HUNG FOOT ADJUSTMENT......................................................................................................................................................... 19

SETTING THE LAP FORMER.......................................................................................................................................................... 19

OIL SIGHT GAUGES, TOP COVERS & MISCELLANEOUS TAKEUP & EYELET PARTS.................................................................... 21

MAIN FRAME, BUSHINGS & MISCELLANEOUS EYELET & COVER PARTS ..................................................................................23

MAIN SHAFT & MISCELLANEOUS OILING .................................................................................................................................25

CRANKSHAFT & NEEDLE LEVER PARTS .......................................................................................................................................27

TENSION PARTS ..........................................................................................................................................................................29

DETACHABLE HEAD, HEAD COVERS, NEEDLE BAR & NEEDLE BAR HEAD ................................................................................ 31

DETACHABLE HEAD, HEAD COVERS, NEEDLE BAR & NEEDLE BAR HEAD ................................................................................ 33

DIFFERENTIAL & MAIN FEED BARS, FEED DOGS & FEED LIFT ECCENTRIC ASSEMBLY ..............................................................35

FEED DRIVE ASSEMBLY, FEED ROCKER & LOOPER AVOID PARTS .........................................................................................37

KNIFE DRIVING PARTS ................................................................................................................................................................39

LOOPER ROCKER SHAFT & LOOPER ROCKER DRIVE PARTS ..................................................................................................... 41

LAP FORMER, MISCELLANEOUS CYLINDER COVERS, THROAT PLATE, & CHAIN CUTTING KNIFE ...........................................43

CYLINDER BUSHINGS, DIFFERENTIAL FEED CONTROL ASSEMBLY & MISCELLANEOUS CYLINDER COVERS........................45

PRESSER FOOT ............................................................................................................................................................................47

THREAD STAND ........................................................................................................................................................................... 49

MISCELLANEOUS GAUGES & TAPE REEL PARTS ........................................................................................................................51

THREAD LUBRICATOR .................................................................................................................................................................53

NUMERICAL INDEX OF PARTS.................................................................................................................................................... 54

NUMERICAL INDEX OF PARTS.................................................................................................................................................... 55

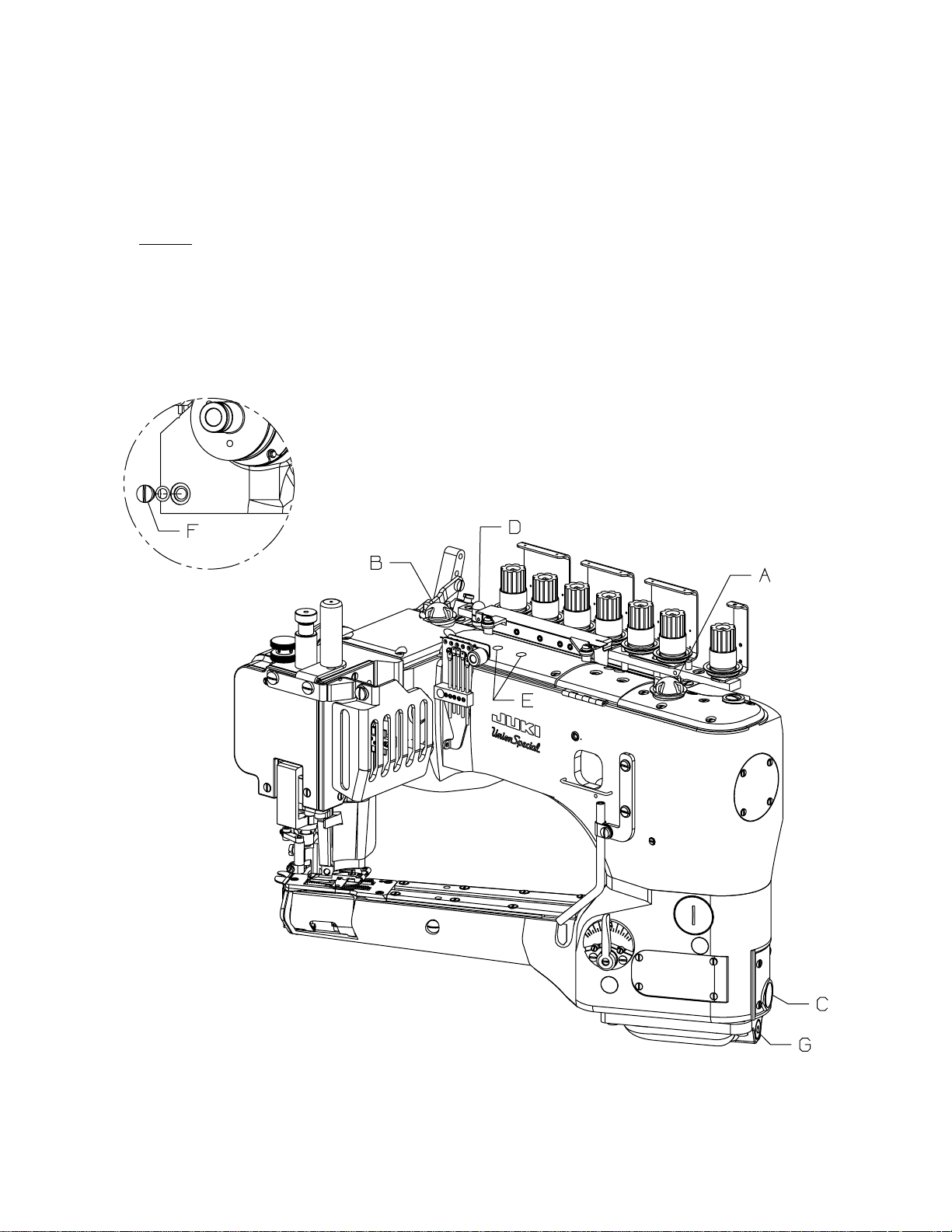

IDENTIFICATION OF MACHINES

Each UNION SPECIAL machine is identified by a style number, which is stamped into the style plate affixed to the middle of the

machine under the tension assembly.

The serial number is stamped in the casting at the right rear base of the machine.

TORQUE REQUIREMENTS

Torque (measured in inch-pounds) is a rotating force (in pounds applied through a distance by a lever (in inches or feet). This is

accomplished by a wrench, screwdriver, etc. Many of these devices are available, which when set at the proper amount of torque

will tighten the part to the correct amount and no tighter.

All straps and eccentrics should be tightened to 19-21 inch-pounds (22-24cm/kg) unless otherwise noted.

All other nuts, bolts, screws, etc. should be tightened by hand as tightly as possible, unless otherwise noted.

DESCRIPTION OF MACHINES

Universal style, Feed-off-the-arm, high speed, medium throw, five or six thread machine. There are four needles and one retainer

abreast, one looper and a manually adjusted differential feed control. There is an enclosed automatic lubricating system, filter

type oil return pump, visual sight oil action and supply gauges. The maximum work space in front of the needles is 8 inches

(203.2mm). Recommended maximum speed - 3200 R.P.M. for all Styles. Machines can be used on either table or pedestal mount.

STYLE OF MACHINES

36200L220-60 LAP FLATSEAMER: For simultaneously trimming right and left plies and lap seaming with 5 needles for increased

(was 35600JU)

seam strength on swimsuits, leotards, sports workout wear, etc.

Seam specifications 610-LSa-1. Components produce a .236" (6.0mm) wide seam.

3

ILLUSTRATIONS

This manual has been arranged to simplify ordering repair parts. Exploded views of various sections of the mechanism are shown

so that the parts may be seen in their actual position in the machine. On the page opposite the illustration will be found a listing

of the parts with their part numbers, description and the number of pieces required in the particular view being shown.

Numbers in the first column are reference numbers only, and merely indicate the position of the part in the illustration. The

reference number should never be used in ordering parts. Always use the part number listed in the second column.

Component parts of sub-assemblies which can be furnished for repairs are indicated by indenting their descriptions under the

description of the main sub-assembly. As an example refer to the following text.

9. 29126 EC Upper Looper Drive Shaft Assembly ................................................................................. 1

10. 22503 F Screw ....................................................................................................................................... 1

11. 39543 E Cam Follower Locking Clamp ..................................................................................... 1

It will be noted in the previous example that the cam follower, bushing and cam guide and the upper looper drive shaft are not

listed. The reason is that replacement of these parts individually is not recommended, so the complete upper looper drive shaft

assembly should be ordered.

When a part is common to all machines covered in this manual, no specific usage will be mentioned in the description. However,

when the parts for the various machines are not the same, the specific usage will be mentioned in the description and, if necessary,

the difference will be shown in the illustration.

A numerical index of all the parts shown in this manual is located at the back. This will facilitate locating the illustration and

description when only a part number is known.

IDENTIFYING PARTS

Where the construction permits, each part is stamped with its part number. On some of the smaller parts and on those where

construction does not permit, an identification letter is stamped in to distinguish the part from similar ones.

PLEASE NOTE: Part numbers represent the same part, regardless of which manual they appear. On all orders please include

part number, name and style of machine for which the part was ordered.

NEEDLES

Each needle has both a type and size number. The type number denotes the kind of shank, point, length, groove, finish and other

details. The size number, stamped on the needle shank, denotes the largest diameter of the blade measured between the shank

and the eye. Collectively, the type number and size number represent the complete symbol which is given on the label of all

needles packed and sold by Union Special.

TYPE DESCRIPTION

116GKS Round shank, round point, extra short, double groove, struck groove, spotted, chromium plated needle.

.048 (1.2mm) Diameter Shank. Size 065/025 available only.

When changing the needle, make sure it is fully inserted in the needle driving arm before the clamp screw is tightened.

To have needles promptly and accurately filled, an empty package, a needle sample, or the type and size number should be

forwarded. Use the description on the label. A complete order should read as follows: "100 needles, type 116 GKS, size 065/025".

4

SAFETY RULES:

1. Before putting the machines described in this manual into service, carefully read the instructions. The

starting of each machine is only permitted after taking notice of the instructions and by qualified

operators.

IMPORTANT! Before putting the machine into service, also read the safety rules and

instructions from the motor supplier.

2. Observe the national safety rules valid for your country.

3. The sewing machines described in this instruction manual are prohibited from being put into service until

it has been ascertained that the sewing units which these sewing machines will be built into, have

conformed with the EC Council Directives (89/392/EEC, Annex II B).

Each machine is only allowed to be used as foreseen. The foreseen use of the particular machine is

described in paragraph “STYLES OF MACHINES” of this instruction manual. Another use, going beyond

the description, is not as foreseen.

4. All safety devices must be in position when the machine is ready for work or in operation. Operation of

the machine without the appertaining safety devices is prohibited.

5. Wear safety glasses.

6. In case of machine conversions and changes all valid safety rules must be considered. Conversions and

changes are made at your own risk.

7. The warning hints in the instructions are marked with one of these two symbols:

8. When doing the following the machine has to be disconnected from the power supply by turning off the

main switch or by pulling out the main plug:

8.1 When threading needle(s), looper, spreader etc.

8.2 When replacing any parts such as needle(s), presser foot, throat plate, looper, spreader, feed dog,

needle guard, folder, fabric guide etc.

8.3 When leaving the workplace and when the workplace is unattended.

8.4 When doing maintenance work.

8.5 When using clutch motors without actuation lock, wait until the motor is stopped totally.

9. Maintenance, repair and conversion work (see item 8) must be done only by trained technicians or

special skilled personnel under consideration of the instructions.

10. Any work on the electrical equipment must be done by an electrician or under direction and supervision

of special skilled personnel.

11. Work on parts and equipment under electrical power is not permitted. Permissible exceptions are

described in the applicable sections of standard sheet DIN VDE 0105.

12. Before doing maintenance and repair work on the pneumatic equipment, the machine has to be

disconnected from the compressed air supply. In case of existing residual air pressure, after disconnecting from compressed air supply (i.e. pneumatic equipment with air tank), the pressure has to be

removed by bleeding.

5

THREADING

6

OILING

Referring to Fig. 1, fill the machine at (A) and (B). Oil capacity of class 36200 is 2.5 ounces in the bottom

reservoir and 2.5 ounces in the top reservoir. Use a straight mineral oil, Saybolt viscosity of 90 to 125 seconds

at 100° Fahrenheit. The oil level is checked at gauges (C) and (D). Maintain oil level between the red lines

of these gauges.

This machine is automatically lubricated by a continuously driven rotary pump. Oil flow can be observed

through windows (A) and (B). When installing a new machine or starting a machine that has been idle for

some time, priming may be necessary. Remove plug screws (E), fill holes with recommended oil and replace

screws

Remove screw 22733B (F, Fig. 1 inset) to drain oil from the top reservoir. To drain oil from bottom reservoir

remove screw 999-196 (G).

Occasionally, it is necessary to oil the linkage of the presser foot, the knife holder shank (36273A), guide

collar (36273K) and the various links and bearings of the presser foot lifting mechanism and thread tension

release.

BEFORE operating. If oil does not flow while machine is running, pump is inoperative.

FIG. 1

7

ADJUSTING INSTRUCTIONS

Instructions stating direction or location, such as right, left, front or rear of the machine are given relative to

the operator's position at the machine unless otherwise noted. The handwheel rotates clockwise in

operating direction.

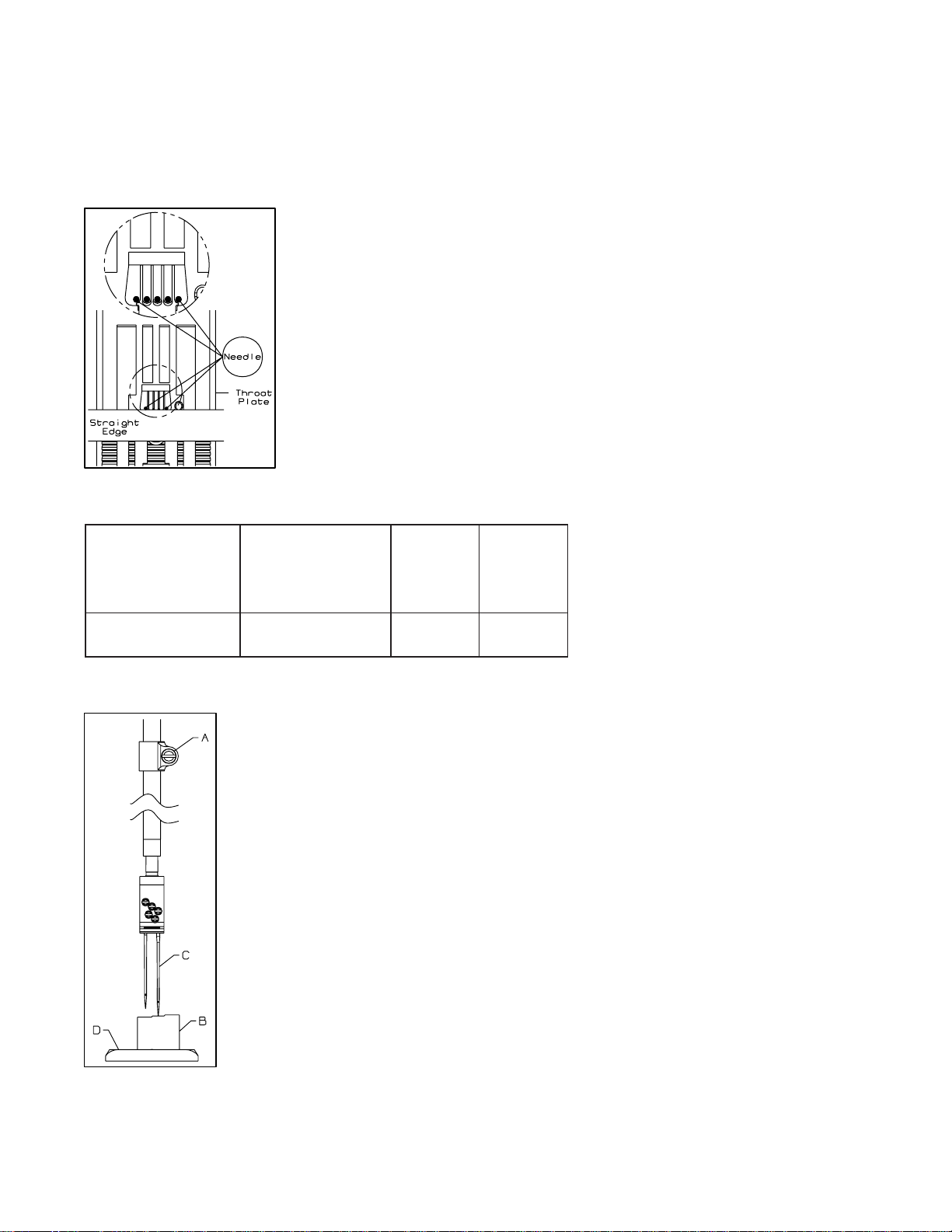

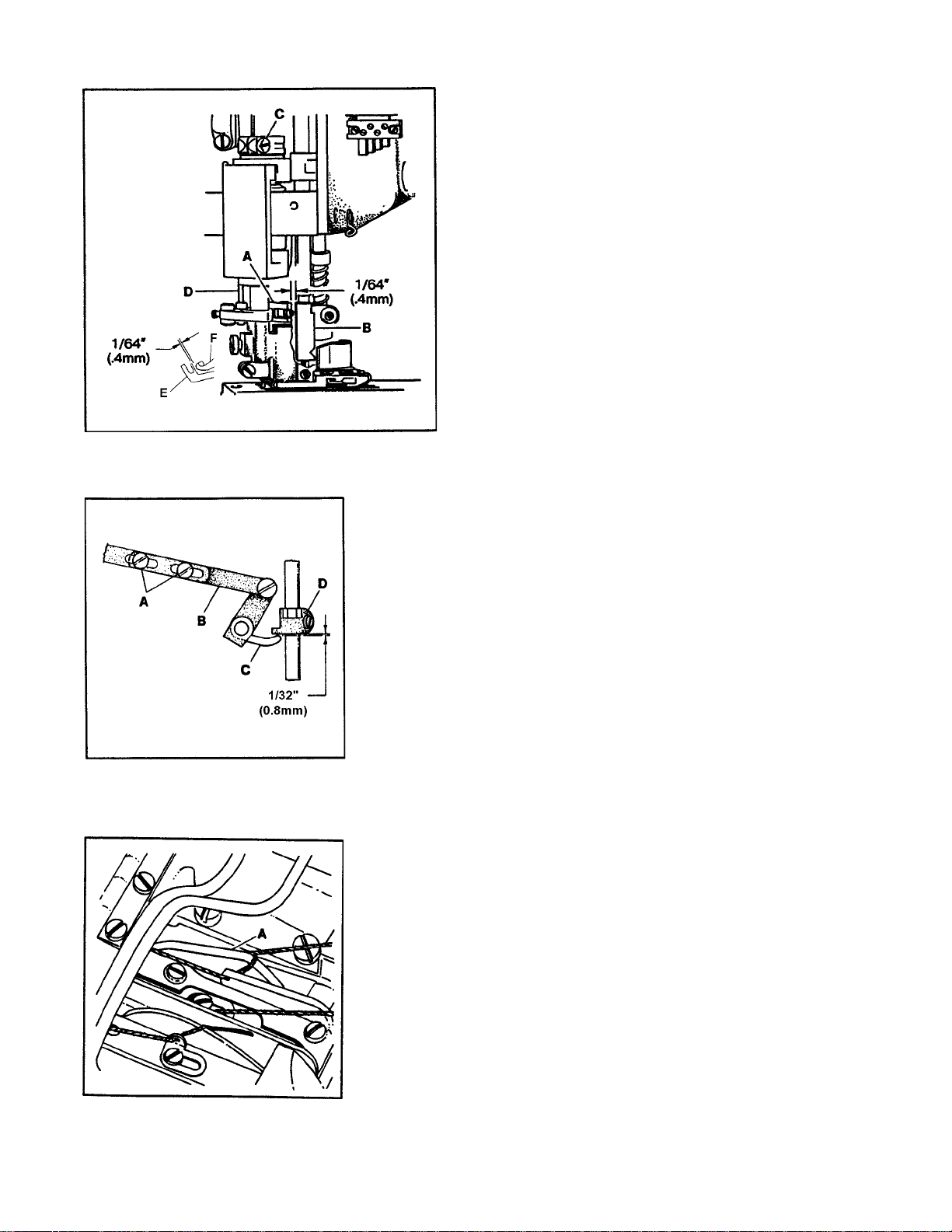

SETTING THE NEEDLE BAR HEIGHT & ALIGNMENT

Insert the first (left) and fifth needles into the needle head. The needles for this

Class of machine are made with two flats on the front of the shank This will

enable you to correctly position the needles in the needle head. Make

certain the needle shank is fully inserted and that the screw is seated firmly

on the flat.

To position the needle head square with the throat plate, use the upper knife

or a straight edge to align the needles with the cross grooves in the throat

plate. (See Fig. 2)

Refer to table 1 for the dimension from the fifth (lowest) needle to the surface

of the throat plate and for the number of the needle bar height gauge.

FIG. 2

HT5MORFNOISNEMID

ELYTS

06-022L00263)MM7.21("2/1SD72212005.

OTELDEEN)TSEWOL(

ETALPTAORHT

ECAFRUS

ELDEEN

RAB

THGIEH

EGUAG

REBMUN

TABLE 1

CAUTION: If the needle head has been replaced it must be torqued to 17 in. lbs.

(20cm/kg). Or until torque bar (21227AR), inserted into cross hole in the needle bar,

bends. It will not seat against the bottom of the needle bar. After tightening, check

for expansion of the needle bar by positioning it up into the lower bushing hole. If the

bar has expanded it will bind in the bushing. The bar must be replaced or lapped to

reduce the bell shape. Align and set needle bar height as described above.

Position the needle bar at its highest

point of travel. Loosen needle bar clamp

ELDEEN

screw (A, FIG.3) & use the specified

THGIEH

EGUAG

S

PET

needle bar height gauge (B) to achieve

the desired height dimension from the

DEKRAM

fifth (lowest) needle (C) to the throat

plate surface (D). Tighten clamp screw

(A) and recheck setting. Care must be

taken not to disturb the needle head

alignment while making the adjustment.

Add the remaining needles.

FIG. 3

8

SETTING THE NEEDLE BAR HEIGHT & ALIGNMENT (CONT)

FIG. 4

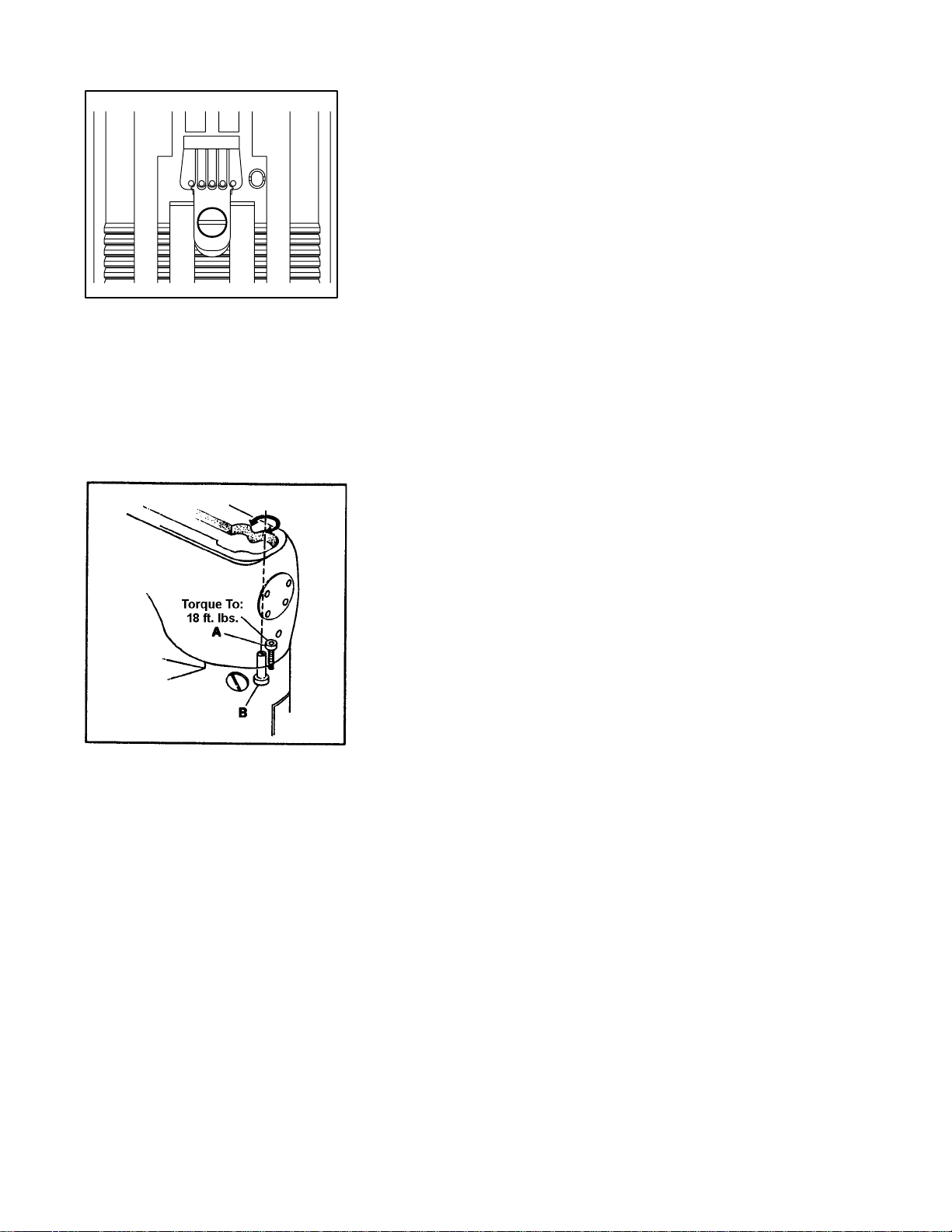

ALIGNING THE CYLINDER

Correct spacing of the needles in the throat plate stitch tongue is

imperative to proper sewing conditions. Improper relationship of the

needles to the stitch tongue often results in malformed stitches. When

replacing the stitch tongue make sure needles are aligned properly

(see Fig. 4).

If the stitch tongue and throat plate are properly seated and the

needle position is not correct, the cylinder has probably been forced

out of position. If realignment is necessary, refer to the section

"Centering the Cylinder".

When the needles are correctly positioned in the throat plate they are

centered in the stitch tongue (see Fig. 4). Actually, the needle bar is

centered to the throat plate and cylinder, however, to provide clearance on the left side of the needle for the needle loops passing

around the looper during the down stroke of the needles, the slots in

the stitch tongue are made off-center to the left. Accurate positioning of the needles may be obtained by repositioning the cylinder.

FIG. 5

Remove the top front cover and gasket from the main frame. Loosen

cylinder holding screw (A, Fig. 5). Turn eccentric screw (B) clockwise to move the cylinder so the needles are closer to the right side

of the stitch tongue. Turn the stud counterclockwise to locate the

needles closer to the left. Tighten screw (A) and recheck settings.

NOTE: The cylinder may not move freely when the eccentric is turned

because the joint sealant compound has set. Light tapping with a

wooden block at the joint or midpoint of the arm may be necessary.

9

FIG. 6

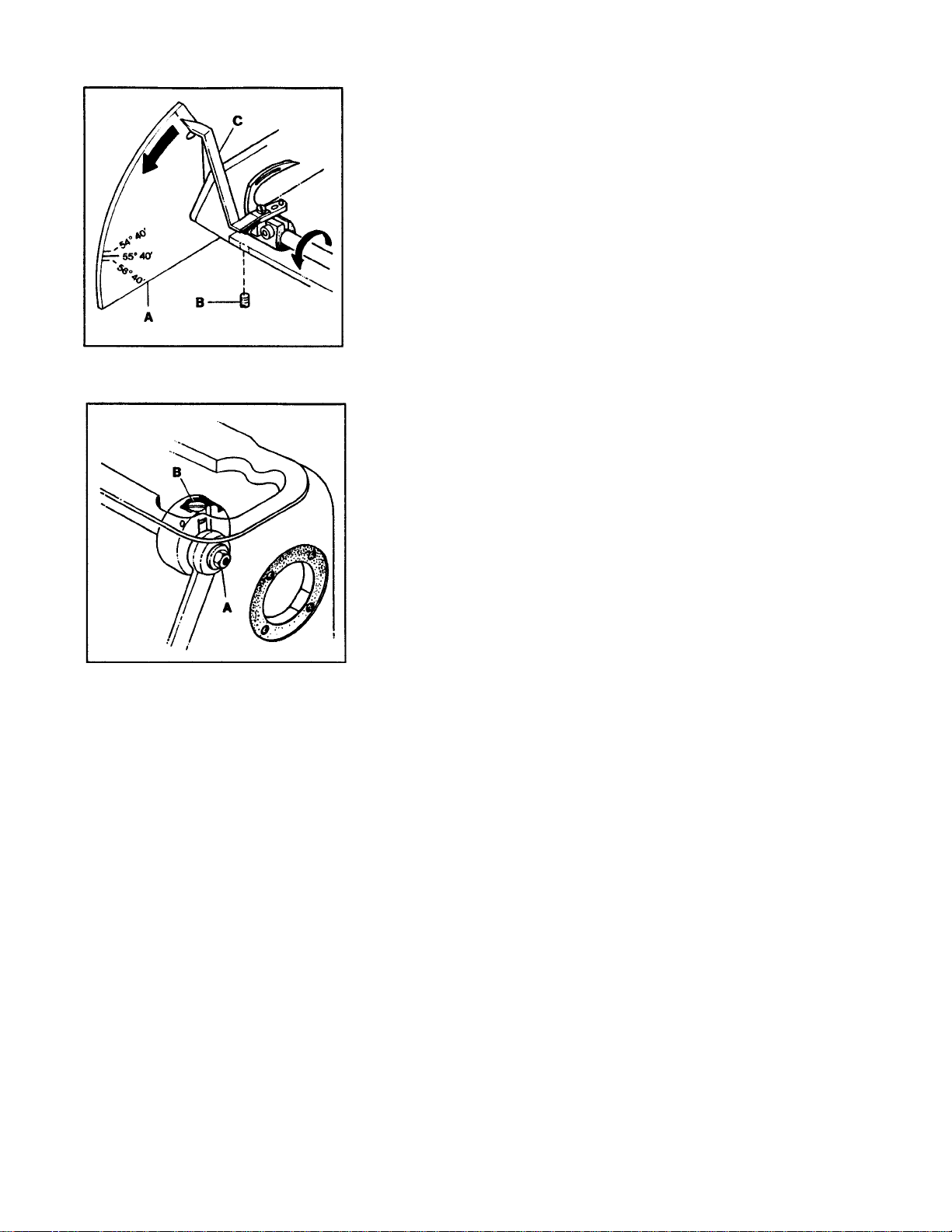

SETTING THE LOOPER TRAVEL USING GAUGE 21227CN

Attach looper travel gauge plate (A, Fig. 6) to the rear of the cylinder

arm. Set the bottom of the gauge so it is approximately horizontal

and lock lightly in place with screw (B) directly underneath. Attach

looper travel gauge pointer (C) to the looper using the left needle

guard screw hole. Turn the handwheel in operating direction until the

looper is positioned to the far right. Set pointer (C) at zero degrees

by rotating gauge plate (A) and lock in place. Continue turning the

handwheel until the pointer stops. If the looper travel is correct the

pointer should indicate 55°40'.

SETTING THE LOOPER TRAVEL

To adjust the looper travel remove the top front cover and the end

cover. Loosen left-handed locknut (A, Fig. 7) and turn screw (B)

clockwise to decrease the looper travel or counterclockwise to

increase the looper travel. Tighten locknut (A) and recheck setting.

NOTE: After setting the looper travel the machine must be checked

for synchronization.

FIG. 7

10

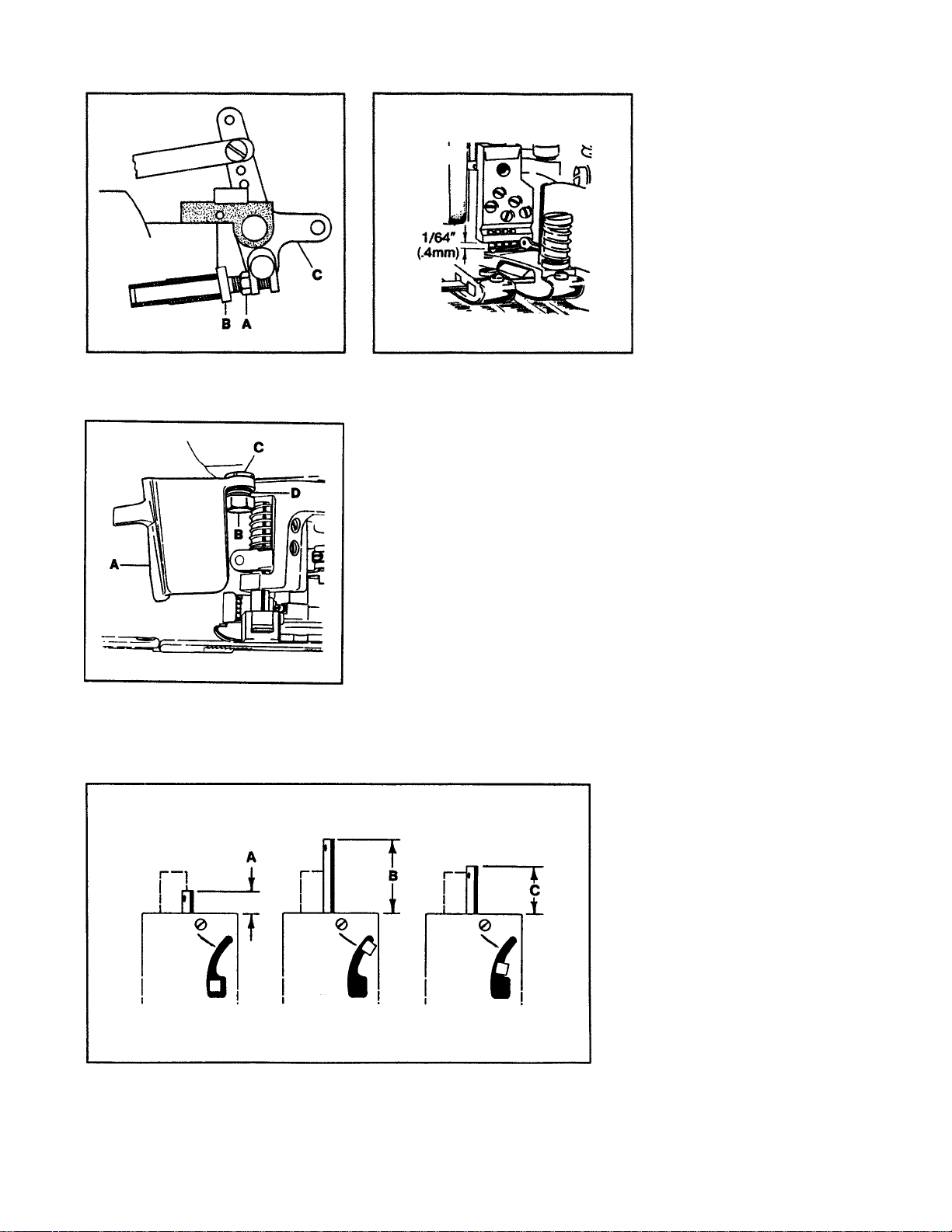

TIMING THE NEEDLES TO THE LOOPER

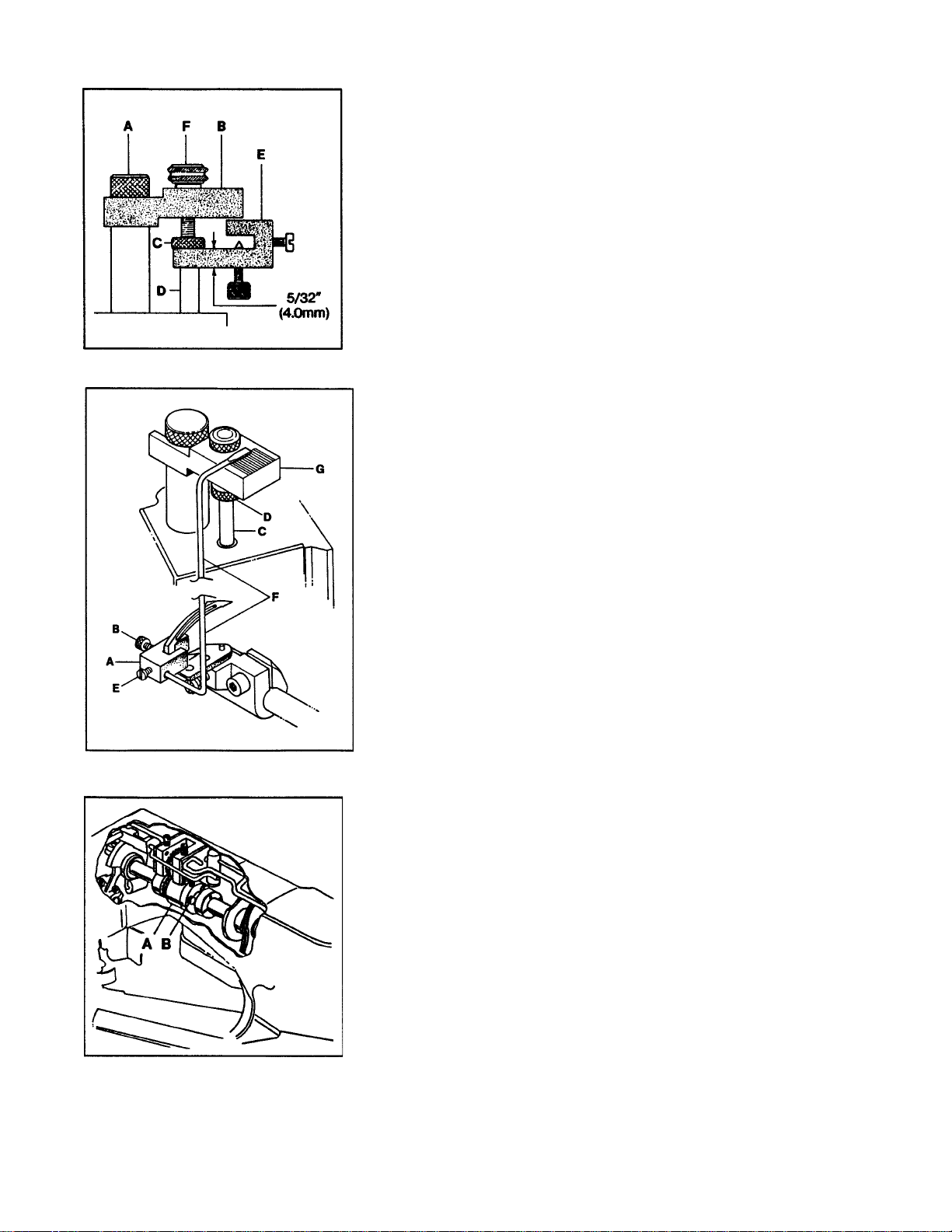

To visually check the timing of the needles to the looper, turn the

handwheel in operating direction until the needle bar has reached

its lowest position and has risen 5/32" (4.0mm). At this time the looper

point should appear at the same relative position to the needles

whether rotation of handwheel is clockwise or counterclockwise.

INSTRUCTIONS FOR USING

SYNCHRONIZING GAUGE 21227CG

Turn the handwheel until the needle bar is at its lowest point. Loosen

presser bar regulating screw (A, Fig. 8) and insert needle bar setting

block (B) under the head of the screw (A) with stop screw (C) above

needle bar (D). Tighten screw (A).

FIG. 8

FIG. 9

The long portion of the looper clamp and height gauge (E, Fig. 8) laid

on its side is the 5/32" (4.0mm) gauge used to set the distance

between stop screw (C) and the top of the needle bar (D) at its lowest

position. Tighten nut (F) to clamp stop screw (C) into place.

TIMING THE NEEDLES TO THE LOOPER (CONT.)

Attach the looper clamp and height gauge (A, Fig. 9) to the heal of

the looper by tightening screw (B). Turn the handwheel slowly in a

clockwise direction until needle bar (C) touches stop screw (D).

Loosen screw (E) and set synchronizing gauge rod (F) so the flat end

is on one of the lines in the center of the block (G). Tighten screw (E).

Turn the handwheel in the opposite direction until the needle bar

touches stop screw (D, Fig. 9). Synchronizing rod (F) should come to

the same line on block (G). The difference must not exceed one line.

If the setting cannot be achieved, main shaft coupling (A, Fig. 10)

must be repositioned. Remove the crank chamber cover and gasket. Loosen the three coupling screws (B). If synchronizing rod (F,

Fig. 9) moves more to the right while the handwheel is rotated in a

clockwise direction, the looper is too fast and the main shaft should

be retarded. If the rod moves more to the right when the handwheel

is rotated in a counterclockwise direction the looper is too slow and

the mainshaft should be advanced. Tighten screws (B, Fig. 10).

FIG. 10

NOTE: If the stationary Knife interferes with the synchronizing rod (F)

remove the knife to make the adjustment.

11

FIG. 11

FIG. 12

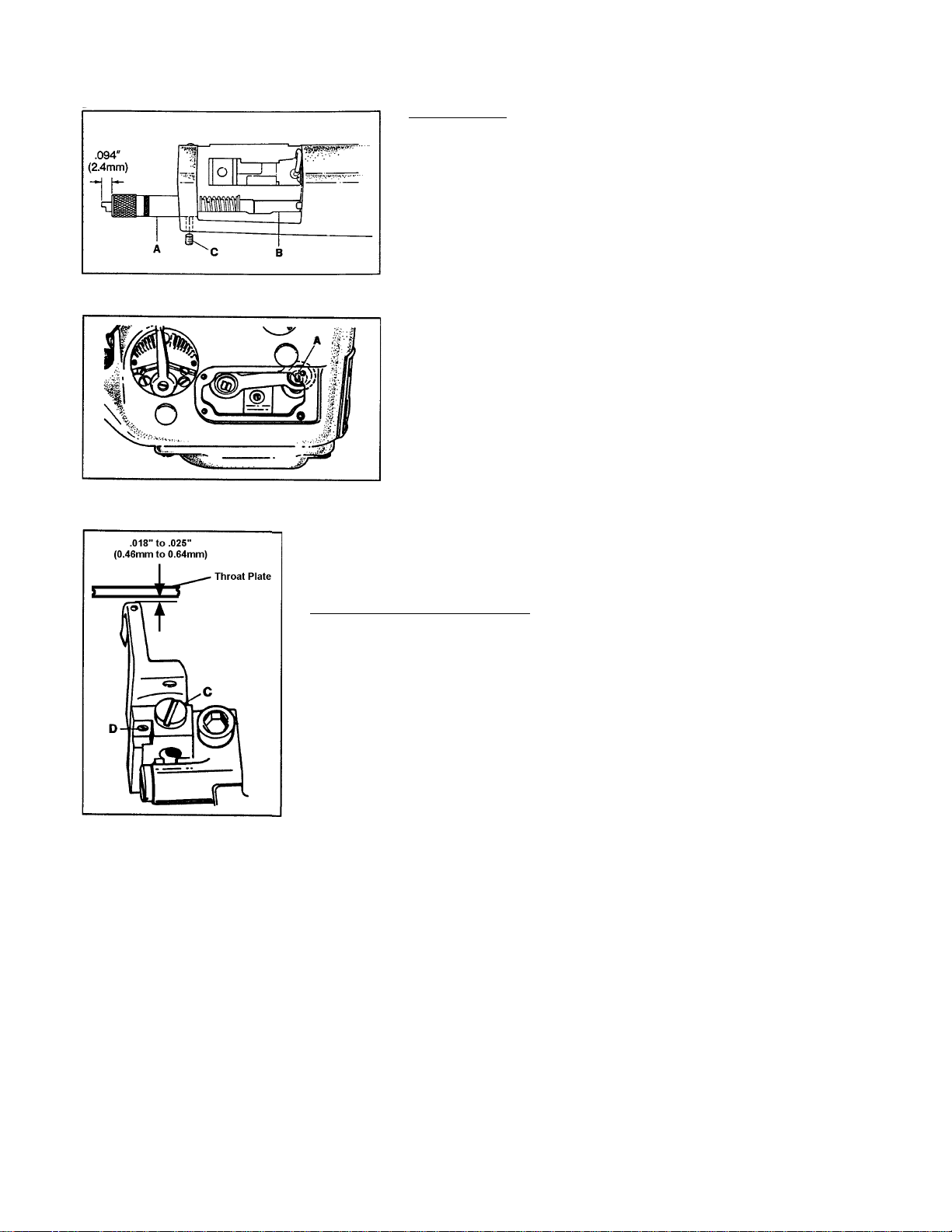

LOOPER ADJUSTMENTS

Looper Avoid

The looper avoid is set at .094" (2.4mm). Using gauge no.

21227BV (A, Fig. 11), position looper shaft (B) fully to the rear

(away from operator) and insert the gauge through the looper

shaft hole in the end of the cylinder until the plunger is fully

extended from the gauge. Tighten clamp screw (C). When the

looper is positioned fully to the front, the end of the plunger

should be flush with the end of the gauge. The motion of the

plunger from the extended position to flush represents .094"

(2.4mm) travel. To adjust the looper avoid remove the cylinder

cover and loosen screw (A, Fig. 12) with TT-85 wrench. Raise the

ball joint to shorten the avoid motion or lower it to lengthen the

avoid motion. Tighten screw (A). Reposition gauge (A, Fig. 11)

and recheck the setting.

FIG. 13

Vertical Adjustment of Looper

A clearance of .018" to .025" (0.46mm to 0.64mm) should be maintained

between the top of the looper and the bottom of the stitch tongue. Loosen

screw (C, Fig. 13) and turn screw (D), directly under the looper, up or down as

required. Make sure the looper is seated and tighten screw (C). Check for

clearance.

12

FIG. 15

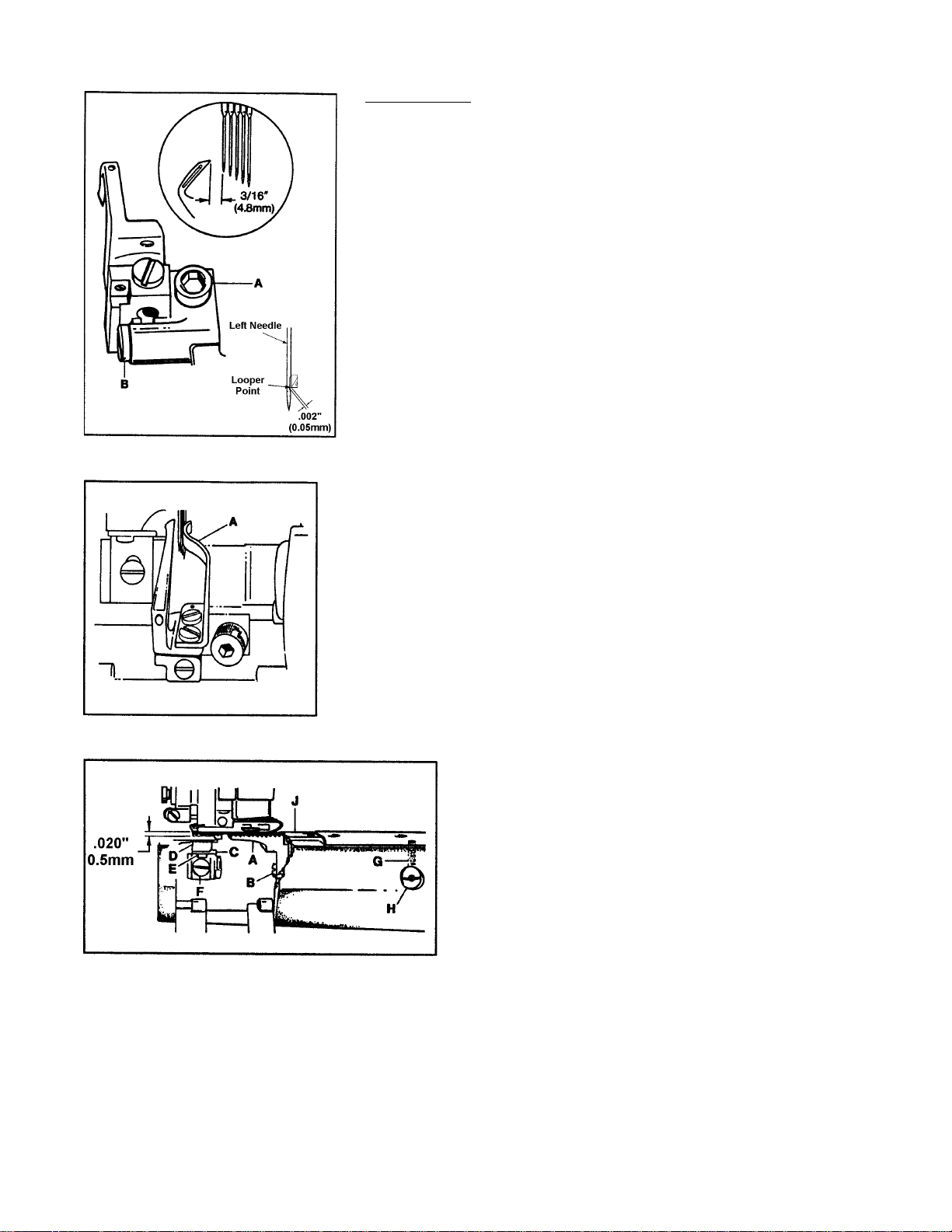

LOOPER ADJUSTMENTS (CONT.)

Looper Gauge

Turn the handwheel in operating direction until the looper has traveled fully to the left. Loosen screw (A, Fig. 15) and move the looper

holder to the right or left until the distance from the point of the looper

to the center of the first (left) needle is 3/16" (4.8mm) (Looper gauge

21225F3/16 can be used for a more accurate measurement). Clearance between the looper point and the scarf of the needle must not

exceed .002" (0.05mm). Turn screw (B) until the .002" (0.05mm)

dimension is achieved. Tighten screw (A).

NOTE: Looper gauge may need to be increased or decreased slightly

to obtain a proper stitch.

SETTING THE FRONT NEEDLE GUARD

Install needle guard (A, Fig. 16) and position it to touch but not deflect

the first needle. Slowly turn the handwheel in operating direction and

check the needles to make sure they are not pinched between the

looper and the needle guard.

FIG. 16

FIG. 17

SETTING THE FEED DOGS

Preliminary Setting:

Install the differential feed dog (A, Fig. 17) with screw (B).

Attach rear needle guard (C) to main feed dog (D),

pushing in fully to the rear and tighten screw (E). Install

main feed dog with screw (F).

As a starting point loosen screw (G) and set the slot in feed

bar eccentric stud (H) in a horizontal position. Tighten

screw (G). At the highest point of travel feed dogs (A and

D) should be the depth of .020" (0.5mm) above throat

plate (J). Loosen screws (B and F) and adjust the height

of each feed dog by moving them up or down in the

elongated slot of the shank. Tighten screws (B and F).

Loosen screw (G) and turn stud (H) until the top of the feed

dogs are parallel to the throat plate. Rotating stud (H) will

simultaneously level both feed dogs.

NOTE: When setting eccentric stud (H) if turned clock-

wise feeddogs should go up if turned counterclockwise feed dogs should go down.

Final Setting:

Both the main and differential feed dogs may be individually adjusted to height. Main feed dog (D) at its highest

position should rise above the top of the throat plate the

depth of one full tooth when the normal presser spring

pressure is applied. The differential feed (A) may then be

raised to it.

13

FIG. 18

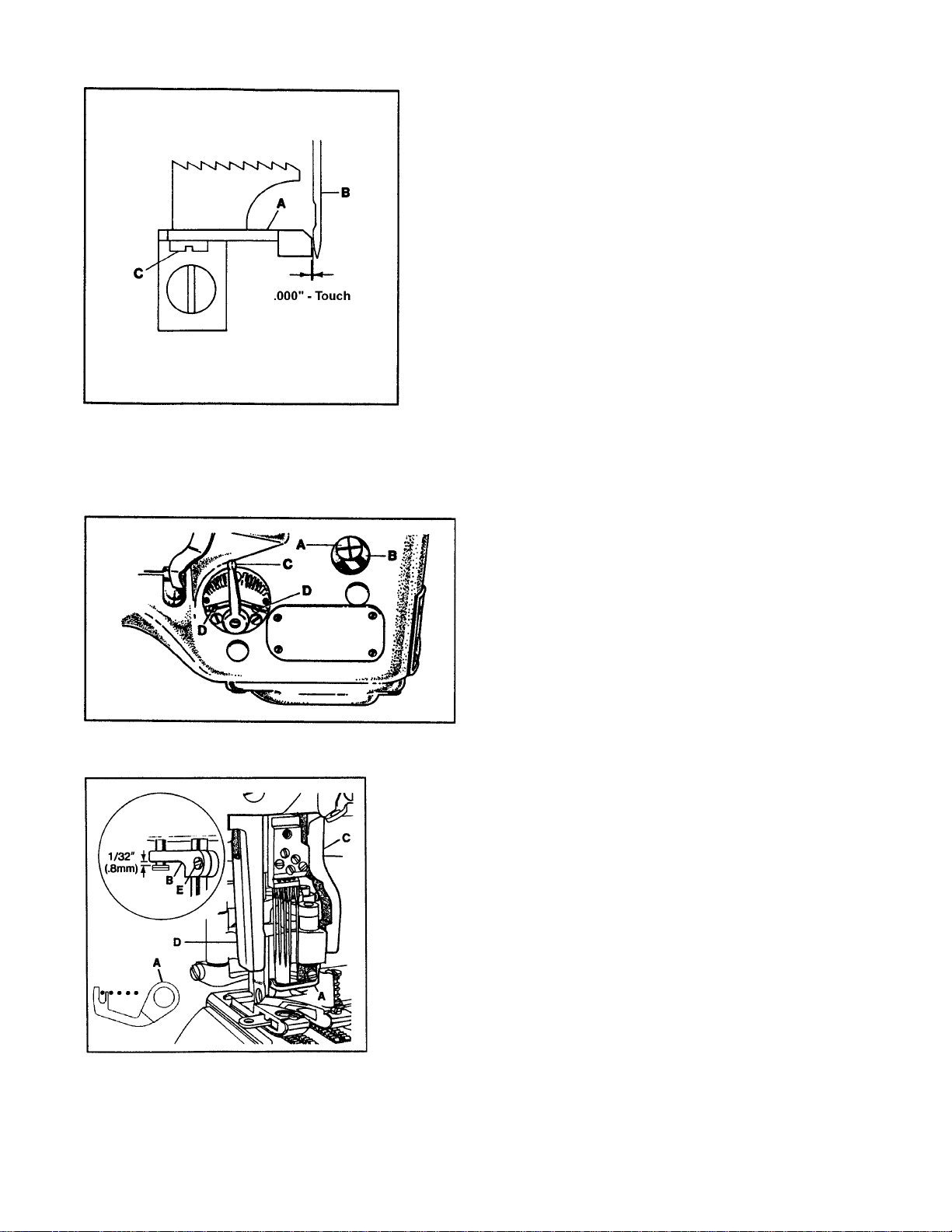

SETTING THE REAR NEEDLE GUARD

Set rear needle guard (A, Fig. 18) so it touches the first (left)

needle (B) but does not deflect. Check the guard position to

the other needles to avoid pinching. Loosen screw (C) and

reposition guard (A) as necessary. Tighten screw (C).

SETTING THE STITCH LENGTH

This machine is designed to sew 10 to 16 stitches per inch. The

normal factory setting is 16 stitches per inch. To change the

stitch length remove the plug screw located directly above

the cylinder side cover. Loosen screw (A, Fig. 19) in lever (B)

and move up to increase the stitch length or down to decrease the stitch length. Tighten screw (A) and replace the

plug screw.

CAUTION: If the stitch length is changed the rear needle

guard setting must be checked and readjusted

if necessary. Failure to do so may result in

needle and/or parts breakage.

CAUTION: When making stitch length adjustment do not

exceed maximum recomended stitch length

due to possible part damage.

FIG. 19

FIG. 20

DIFFERENTIAL FEED CONTROL

The amount of differential feed is controlled by lever

(C, Fig. 19). The adjusting plate is numbered from 1 to

9. When the lever is set from numbers 1 to 4 reverse

differential or stretching occurs. The numbers from 4

to 5 produce equal feed stitching while numbers 5 to

9 produce a gathering stitch. The two stop screws (D)

can be set to limit the movement of lever (C) or lock

the lever in one position.

SETTING THE PRESSER FOOT

Remove the presser bar regulating screw and the presser spring.

Raise the needle bar to its highest position and remove the

retainer. As the foot is slipped under the needles, swing the upper

knife into the opening on the right side of the foot and slide the

linkage onto the hook driving sleeve. Insert the presser bar

through the linkage and into the presser foot shank. Tighten

presser foot screw. With the presser bar inserted properly into the

presser foot, position the foot left to right so the finger of cover

thread carrier (A, Fig. 20) is between the first and second needles.

Set presser bar guide (B, Fig. 20 Inset) so foot will not move. Set

right presser foot guide (C) and left presser foot guide (D) to

maintain setting. Loosen presser bar guide screw (E Fig. 20 Inset)

and check to see that foot has vertical freedom with no right to left

play, no bind. Put the needle bar is in its lowest position, and set

1/32"(0.8mm) above head of presser bar guide stud. Tighten

presser bar guide screw (E).

14

FIG. 21

SETTING THE PRESSER FOOT (CONT.)

Turn the handwheel in operating direction until link (A,

Fig. 20) has traveled fully to the front. There must be a

1/64" (0.4mm) clearance between link (A) and the back

of needle head (B) when link (A) starts to jackknife.

Loosen screw (C) and rotate driving sleeve (D) to position link (A). Tighten screw (C).

Add the cover thread hook(F) and cover thread carrier(E)

if they are not in place. Position carrier so the thread

loop will be carried behind the first two needles. There

should be a minimum 1/64"(0.4mm) clearance between

the hook and the carrier at their closest position.

Replace the presser spring and the presser bar regulating screw.

Loosen screws (A, Fig. 22) in lifter lever link assembly (B) and position

lever (C) so there is 1/32" (0.8mm) clearance between it and presser

bar guide (D) when the feed dogs are below the throat plate.

FIG. 22

FIG. 23

When the hook swings to the left it will pass over the cover thread. On

its return travel, the thread will "pop" into the slot on the underside of

the hook and is carried to the right. This thread forms a triangle for

the third and forth needle threads to pass through. As the cover

thread "pops" into the slot it must cast-off the high point of take-up (A,

Fig. 23) at the same time. Loosen the two screws in the cover thread

take-up and reposition if necessary. If there is difficulty in making

this adjustment, check the thread tension and make sure the hook

point has an extremely high polish and the angle is correct. Due to

clearance requirements bending the hook is not recommended.

15

FIG. 24

SETTING THE PRESSER FOOT (CONT.)

The presser foot lifter stop

plunger must be set so the

cover thread hook will not hit

the bottom of the needle

head as the presser foot is

being lifted. Position the

needle bar to its lowest point

of travel. Loosen nut (A, Fig.

24) and turn plunger (B)

clockwise until it strikes the

crankshaft counterweight.

While applying pressure to

lifter (C) to lift the foot, back

out of the plunger until the

distance between the hook

FIG. 25

To adjust the position and tension of frame chip guard (A, Fig. 26),

slightly loosen screw (B) and turn washer (C) with 21388Y spanner

wrench until spring (D) snaps the guard into the closed position.

Tighten screw (B). A light resistance should be felt when opening the

guard.

and the underside of the

needle head is 1/64" (0.4mm)

(see Fig. 25). Tighten nut (A,

Fig. 24).

FIG. 26

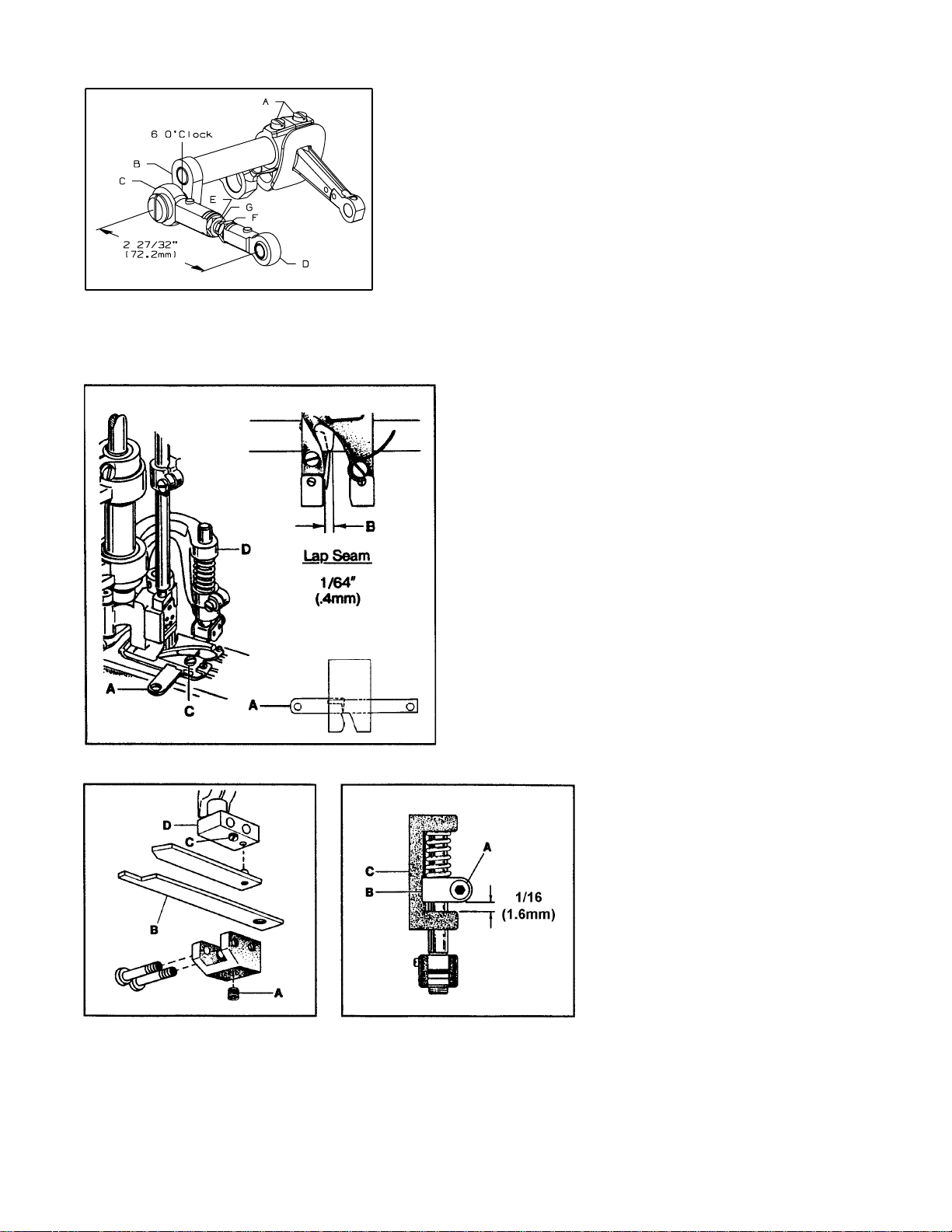

SETTING THE KNIFE DRIVE LEVER

FIG. 27

Position the needle bar at the bottom of its stroke. Measure from the

top of the needle bar to the top of

the casting to obtain dimension "A"

(see Fig. 27).

Position the needle bar at the top

of its stroke. Measure from the top

of the needle bar to the top of the

casting to obtain dimension "B".

Subtract dimension "A" from dimension "B" and divide by two. Add

this number to dimension "A" to

obtain "C". Set a caliper to the "C"

dimension and turn the handwheel

in operating direction until the

height of the needle bar is at the

"C" dimension

16

FIG. 28

SETTING THE KNIFE DRIVE LEVER (CONT.)

At this time the knife drive lever should be in the 6 o'clock position.

If adjustment is necessary, loosen screws (A, Fig. 28) in the needle

lever and reposition knife drive lever (B) to the 6 o'clock position.

Tighten screws (A). The dimension between the centerline of right

and left knife drive connection ball joints (C and D) must be 2 27/32"

(72.2mm). Loosen left hand thread nut (E), right hand thread nut (F)

and turn connecting rod (G) until dimension is achieved. Tighten

nuts (E and F).

FIG. 29

SETTING THE TRIMMING KNIVES

FOR LAP SEAMING

To make the adjustments for a lap seam, position lower

knife (A, Fig. 29) in the foot so it extends 1/64" (0.4mm)

past the right side of the left toe (B) (approximately even

with the first needle). Loosen screw (C) and move knife

in or out as required. Tighten screw (C) securely.

Turn handwheel in operating direction until knife driving

bracket (D) is positioned to the extreme left. At this time

the front edge of both knives should be parallel with

each other and the upper knife cutting edge should

overlap lower knife cutting edge by 1/64" (0.4mm)

If necessary loosen screw (A, Fig.

30) and move knife (B) to the right

or left as required. Tighten screw

(A).

If the shear angle between the

knives has to be changed, raise or

lower screw (C, Fig. 30) in knife

holder shank (D).

To set spring pressure between the

knives loosen screw (A, Fig. 31) and

raise knife holder guide collar (B)

1/16" (1.6mm) from knife driving

FIG. 30 FIG. 31

NOTE: More or less spring pressure may be required depending on the type of material being sewn.

Also, both knives may have to be repositioned after a trial seam is made so there is an equal

margin from the edges of the two plies to the center rows of stitching.

bracket (C). Tighten screw (A).

17

Loading...

Loading...