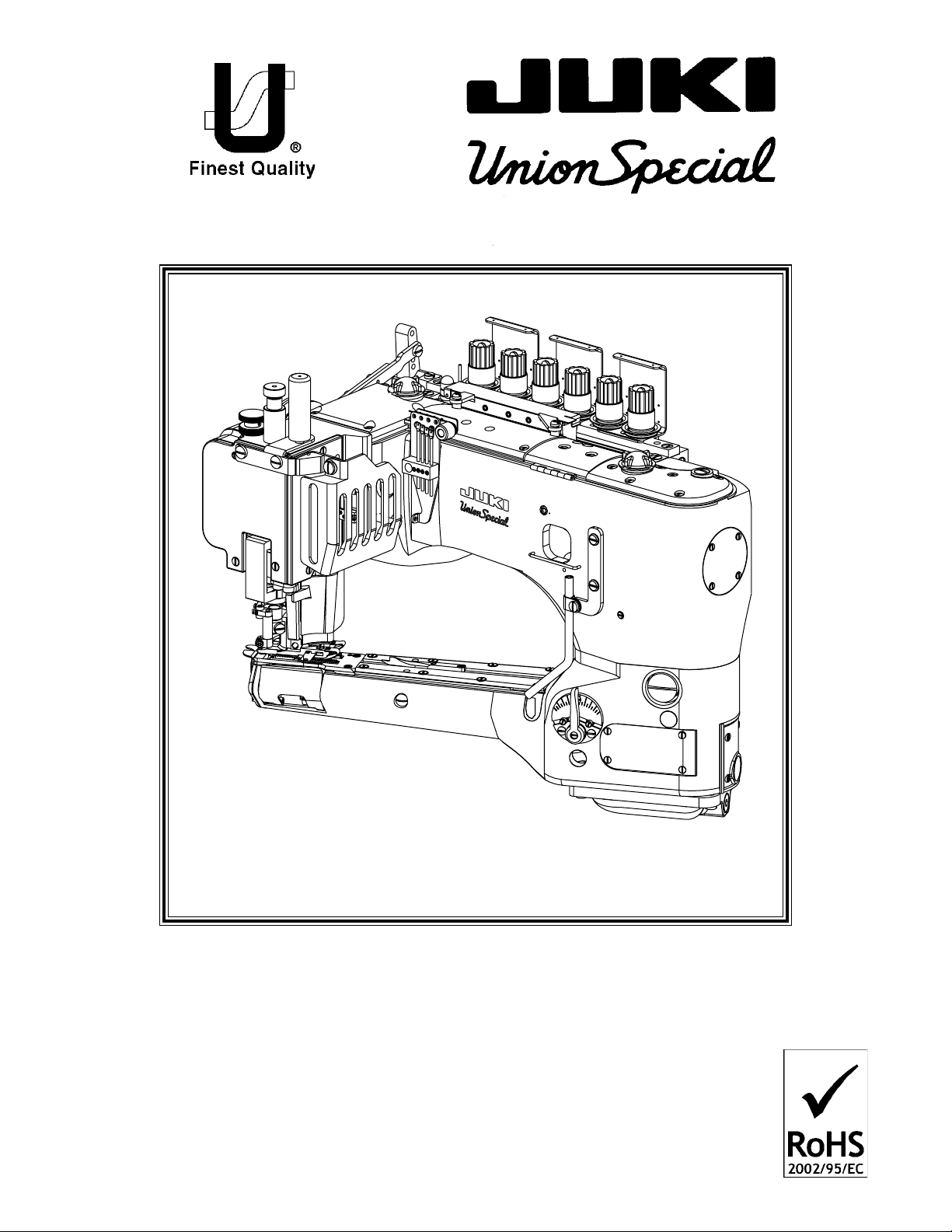

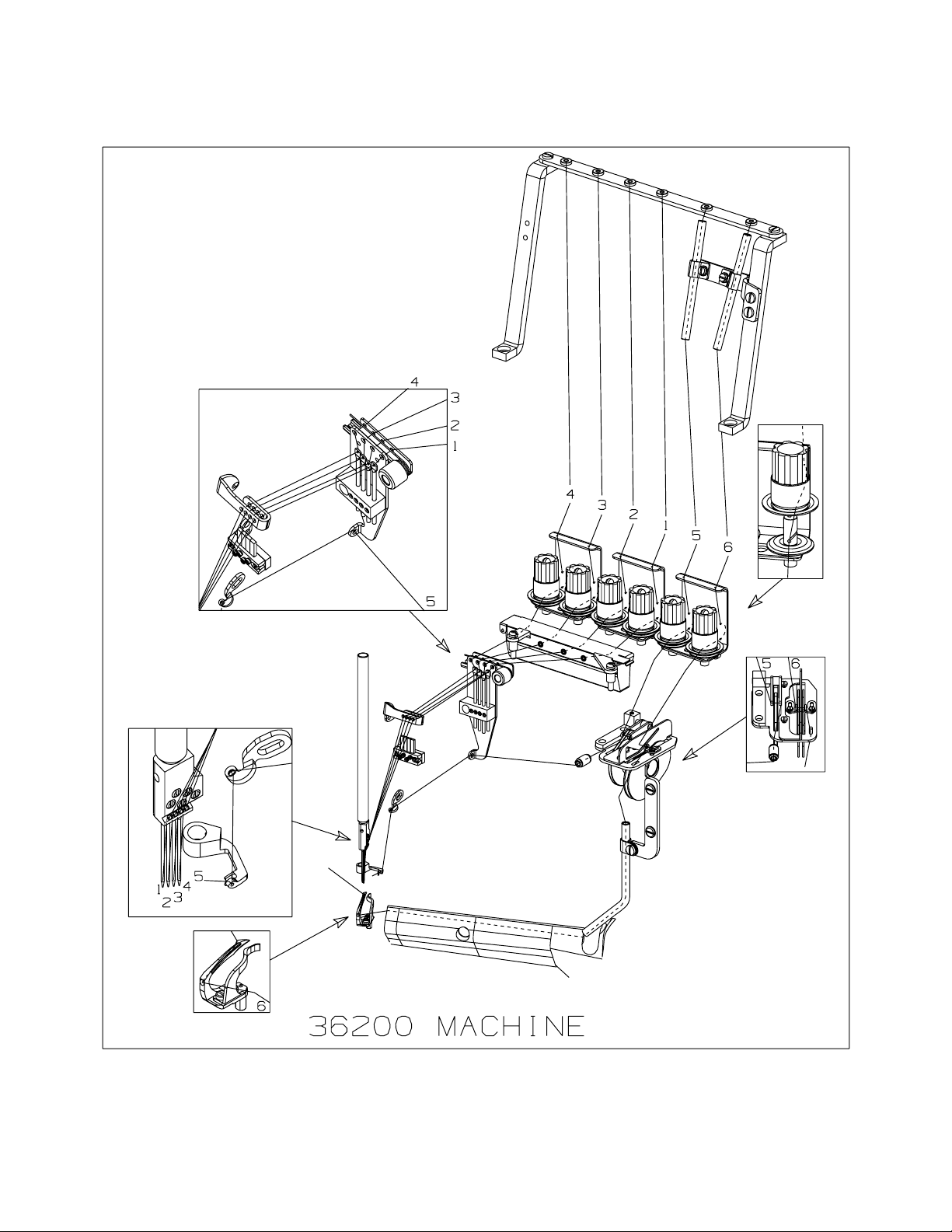

Union Special 36200L100-52, 36200L100-60, 36200L200-52, 36200L200-60, 36200L201-60 Parts List

...

ADJUSTING INSTRUCTIONS / ILLUSTRATED PARTS LIST

02/08/08

Oil - Less

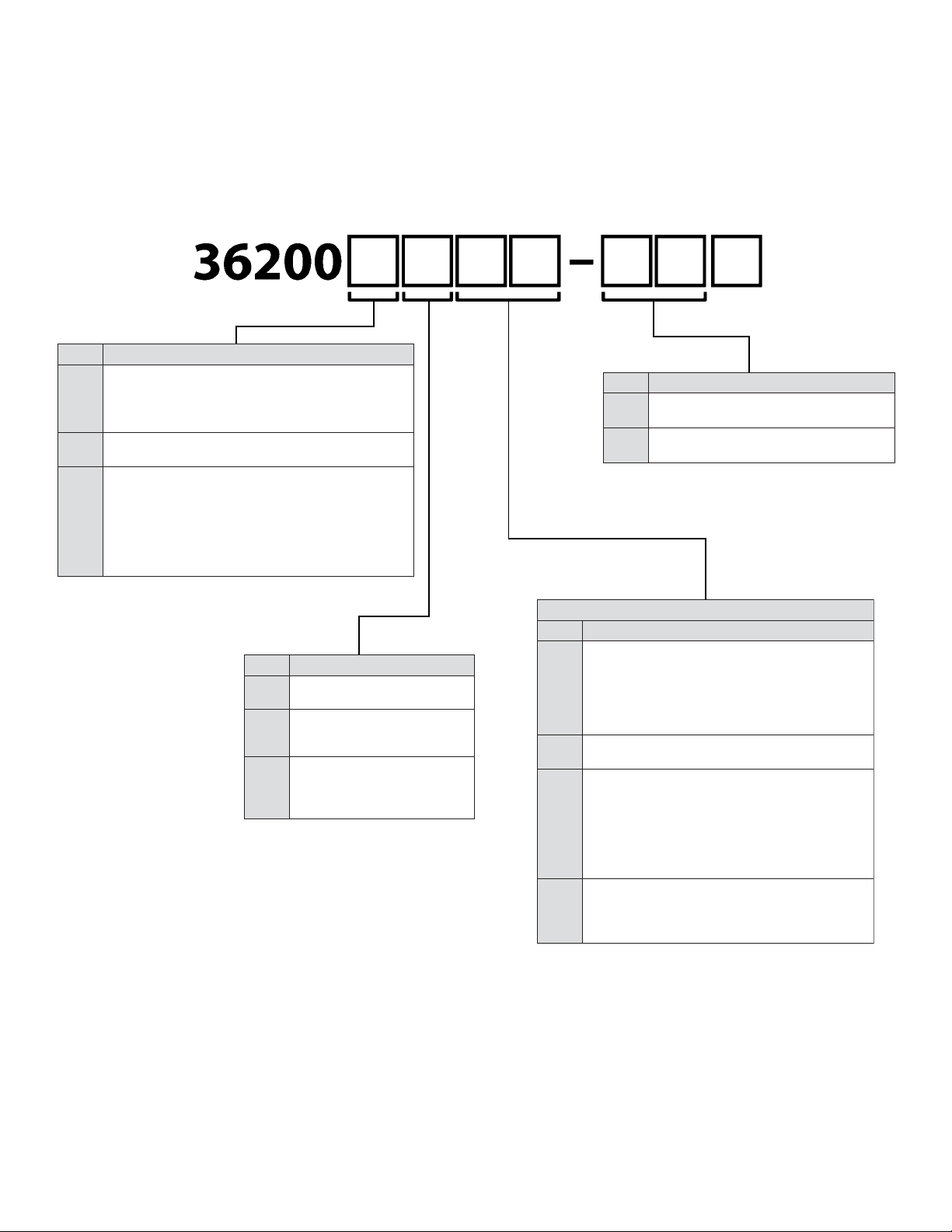

36200 CLASS

MANUAL NO. PT0405-GR

FOR STYLES

36200L100-52 36200L100-60

36200L200-52 36200L200-60

36200L202-52 36200L201-60

36200L210-52 36200L202-60

36200T300-52 36200L210-60

36200U300-52 36200T300-60

36200U300-60

Manual No. PT0405-GR llustrated Parts List for 36200 Series Machines

First Edition Copyright 2006

By

Union Special Corporation Rights Reserved In All Countries

Printed in U.S.A. August 2006

PREFACE

This parts manual has been prepared to assist you in locating individual parts or assemblies on 36200 Series machines.

It is the desire of Union Special that each machine run at its optimum performance. Parts listed in this manual are designed

specifically for your machine and are manufactured with utmost precision to assure long lasting service.

This manual has been comprised on the basis of available information. Changes in design and/or improvements may

incorporate a slight modification of configuration in illustrations or part numbers.

On the following pages are illustrations and terminology used in describing the parts used on 36200 Series machines.

IDENTIFICATION OF MACHINES

Each UNION SPECIAL machine is identified by a style number, which is stamped into the style plate affixed to the middle of the

machine under the tension assembly.

The serial number is stamped on a plate attached to the right rear top of the machine.

2

CONTENTS

PREFACE ............................................................................................................................................................................................................. 2

IDENTIFICATION OF MACHINES ........................................................................................................................................................................ 2

DESCRIPTION OF MACHINES ............................................................................................................................................................................. 4

REPLACEMENT PARTS ......................................................................................................................................................................................... 6

SAFETY RULES: ..................................................................................................................................................................................................... 7

ILLUSTRATIONS .................................................................................................................................................................................................... 8

IDENTIFYING PARTS ............................................................................................................................................................................................ 8

NEEDLES .............................................................................................................................................................................................................. 8

APPLICATION ..................................................................................................................................................................................................... 8

TORQUE REQUIREMENTS .................................................................................................................................................................................... 8

INSTALLATION ..................................................................................................................................................................................................... 9

OILING ................................................................................................................................................................................................................ 9

THREADING ...................................................................................................................................................................................................... 10

ADJUSTING INSTRUCTIONS .............................................................................................................................................................................. 11

SETTING THE NEEDLE BAR HEIGHT & ALIGNMENT ........................................................................................................................................... 11

SETTING THE NEEDLE BAR HEIGHT & ALIGNMENT (CONT) .............................................................................................................................. 12

ALIGNING THE CYLINDER ................................................................................................................................................................................ 12

SETTING THE LOOPER TRAVEL USING GAUGE 21227CN ................................................................................................................................ 12

INSTRUCTIONS FOR USING SYNCHRONIZING GAUGE 21227CG .................................................................................................................. 13

SETTING THE LOOPER TRAVEL .......................................................................................................................................................................... 13

TIMING THE NEEDLES TO THE LOOPER ............................................................................................................................................................. 13

TIMING THE NEEDLES TO THE LOOPER (CONT.) .............................................................................................................................................. 14

LOOPER ADJUSTMENTS .................................................................................................................................................................................... 15

LOOPER ADJUSTMENTS (CONT.) ..................................................................................................................................................................... 16

SETTING THE FRONT NEEDLE GUARD ............................................................................................................................................................... 16

SETTING THE FEED DOGS .................................................................................................................................................................................. 16

SETTING THE REAR NEEDLE GUARD ................................................................................................................................................................. 17

SETTING THE STITCH LENGTH ............................................................................................................................................................................ 17

DIFFERENTIAL FEED CONTROL ......................................................................................................................................................................... 17

SETTING THE PRESSER FOOT ............................................................................................................................................................................. 17

SETTING THE PRESSER FOOT (CONT.) ............................................................................................................................................................... 18

SETTING THE PRESSER FOOT (CONT.) ............................................................................................................................................................... 19

SETTING THE KNIFE DRIVE LEVER ...................................................................................................................................................................... 19

SETTING THE KNIFE DRIVE LEVER (CONT.) ....................................................................................................................................................... 20

SETTING THE TRIMMING KNIVES FOR FLAT SEAMING (STYLES 36200L100-52, L100-60, T300-52, T300-60, U300-52, U300-60) .................. 20

SETTING THE TRIMMING KNIVES FOR LAP SEAMING (STYLES 36200L100-52, L100-60, L200-52, L200-60, L202-52, L202-60, L210-52, L210-

60, U300-52, U300-60) ............................................................................................................................................................................. 20

SETTING THE TRIMMING KNIVES (ALL STYLES) (CONT.) .................................................................................................................................. 21

NEEDLE THREAD ADJUSTMENTS ....................................................................................................................................................................... 21

LOOPER THREAD ADJUSTMENT ........................................................................................................................................................................ 22

COVER THREAD ADJUSTMENT ......................................................................................................................................................................... 22

TENSION RELEASE ............................................................................................................................................................................................. 22

HUNG FOOT ADJUSTMENT ............................................................................................................................................................................... 23

SETTING THE LAP FORMER ............................................................................................................................................................................... 23

LAP SEAMING ................................................................................................................................................................................................... 23

REPLACING PRESSER FOOT SHOES .................................................................................................................................................................. 24

OIL SIGHT GAUGES, TOP COVERS & MISCELLANEOUS TAKEUP & EYELET PARTS .......................................................................................... 27

MAIN FRAME, BUSHINGS & MISCELLANEOUS EYELET & COVER PARTS ......................................................................................................... 29

MAIN SHAFT & MISCELLANEOUS OILING ........................................................................................................................................................ 31

CRANKSHAFT & NEEDLE LEVER PARTS ............................................................................................................................................................. 33

TENSION PARTS................................................................................................................................................................................................. 35

DETACHABLE HEAD, HEAD COVERS, NEEDLE BAR & NEEDLE BAR HEAD ...................................................................................................... 37

DETACHABLE HEAD, HEAD COVERS, NEEDLE BAR & NEEDLE BAR HEAD ...................................................................................................... 39

DIFFERENTIAL & MAIN FEED BARS, FEED DOGS & FEED LIFT ECCENTRIC ASSEMBLY .................................................................................... 41

FEED DRIVE ASSEMBLY, FEED ROCKER & LOOPER AVOID PARTS ............................................................................................................... 43

KNIFE DRIVING PARTS ...................................................................................................................................................................................... 45

LOOPER ROCKER SHAFT & LOOPER ROCKER DRIVE PARTS ............................................................................................................................ 47

LAP FORMER, MISCELLANEOUS CYLINDER COVERS, THROAT PLATE, & CHAIN CUTTING KNIFE ................................................................. 49

CYLINDER BUSHINGS, DIFFERENTIAL FEED CONTROL ASSEMBLY & MISCELLANEOUS CYLINDER COVERS .............................................. 51

PRESSER FOOT FOR STYLES 36200L200-52, L200-60, L201-60, L210-52, L210-60, U300-52, U300-60 ........................................................... 53

PRESSER FOOT FOR STYLES 36200L100-52, L100-60, T300-52, T300-60, U300-52, U300-60 ........................................................................... 55

PRESSER FOOT FOR STYLES 36200L202-52, L202-60 ........................................................................................................................................ 57

PRESSER FOOT SHOE CHART ............................................................................................................................................................................ 58

PRESSER FOOT SHOE CHART ............................................................................................................................................................................ 59

THREAD STAND ................................................................................................................................................................................................. 61

MISCELLANEOUS GAUGES & TAPE REEL PARTS .............................................................................................................................................. 63

THREAD LUBRICATOR ....................................................................................................................................................................................... 65

NUMERICAL INDEX OF PARTS .......................................................................................................................................................................... 66

NUMERICAL INDEX OF PARTS .......................................................................................................................................................................... 67

3

DESCRIPTION OF MACHINES

Universal style, Feed-off-the-arm, high speed, medium throw, five or six thread machine. There are four needles and one retainer

abreast, one looper and a manually adjusted differential feed control. There is an enclosed automatic lubricating system, filter

type oil return pump, visual sight oil action and supply gauges. The maximum work space in front of the needles is 8 inches

(203.2mm). Recommended maximum speed - 4200 R.P.M. for all Styles. Machines can be used on either table or pedestal mount.

edoC noitacilppA

gnimaeSpaL .maesdeppalrevonasecudorpenihcam:

L

T

U

gnimaeSepaT .maesrevoepatasecudorpenihcam:

esoprupitluM na—smaesowtsecudorpenihcam:

nacseires001Leht:etoN(

).maesttubrotalfagnicudorp

.003TsaylnoelbaliavA

o—teefresserptnereffidowthtiwsemoc

maes)ttub(talfgnimmirt

.gnimaespalgnimmirtcirbafedisowtrof

.003UsaylnoelbaliavA

.012L,202L,102L,002L,001LsaylnoelbaliavA

rofdetcelesebosla

elytssiht:etoN.maes)ttub(talfadna,maesdeppalrevo

toofresserpen

cirbafedisrognimaespalmirtcirbafedisenorof

toofresserpdnocesadna,gni

edoC eguaGeldeeN

25

06

siseldeenedistuoneewtebgnicapS.mm2.5

siseldeenedistuoneewtebgnicapS.mm0.6

).elytsynanoelbaliavA(

).102LtpecxeelytsynanoelbaliavA(

edoC mirT

1

2

3

A

sledombuS

edoC straP

00 otthgilfoyteiravediwagnipatrognimaesroF

sicirbafehtfoedisenoylnO

.001LsaylnoelbaliavA.demmirt

eracirbafehtfosedishtoB

.012L,202L,102L

,002LsaylnoelbaliavA.demmirt

rocirbafehtfoedisenorehtiE

ebnaccirbafehtfosedishtob

.enihcamemasehtno,demmirt

.003U,003Tsaylnoelbaliav

10 htiwtub00sastcudorpemasehtgnimaesroF

20 tinkthgiewmuidemotthgilfohctorcehtgnisolcroF

.sgoddeefhtootenifgnoldna,stols

.202LsaylnoelbaliavA

01 otyvaehmuidemgnisolchctorcdnagnimaesroF

tsmm2.1dradnatssesu

.012LsaylnoelbaliavA

olopsahcusstcudorptinkthgiewyvaehmuidem

strihstaewseceelf,stekcajeceelfralop,strihs-Tdna

.cte,sfeirbs'nemdnaseitnap'seidal,stnaptaewsdna

.strapgniwestalfdradnatssesuenihcaM

.003U,003T,002L,001LsaylnoelbaliavA

.102LsaylnoelbaliavA.desugniebsirenrubdaerht

sesuenihcaM.gnidnibgelediwhtiwsfeirbrexob

,setalpediugelbaegnahchtiwtoofresserplaiceps

toofresserplaicepsdnanoitcesgnidleiyediw

deefgnolhtiwetalptaorht,gnidnibediwrofseohs

enihcaM.gnidnibgelhtiwsfeirbtinkthgiewyvaeh

.strapgniwesdeppe

4

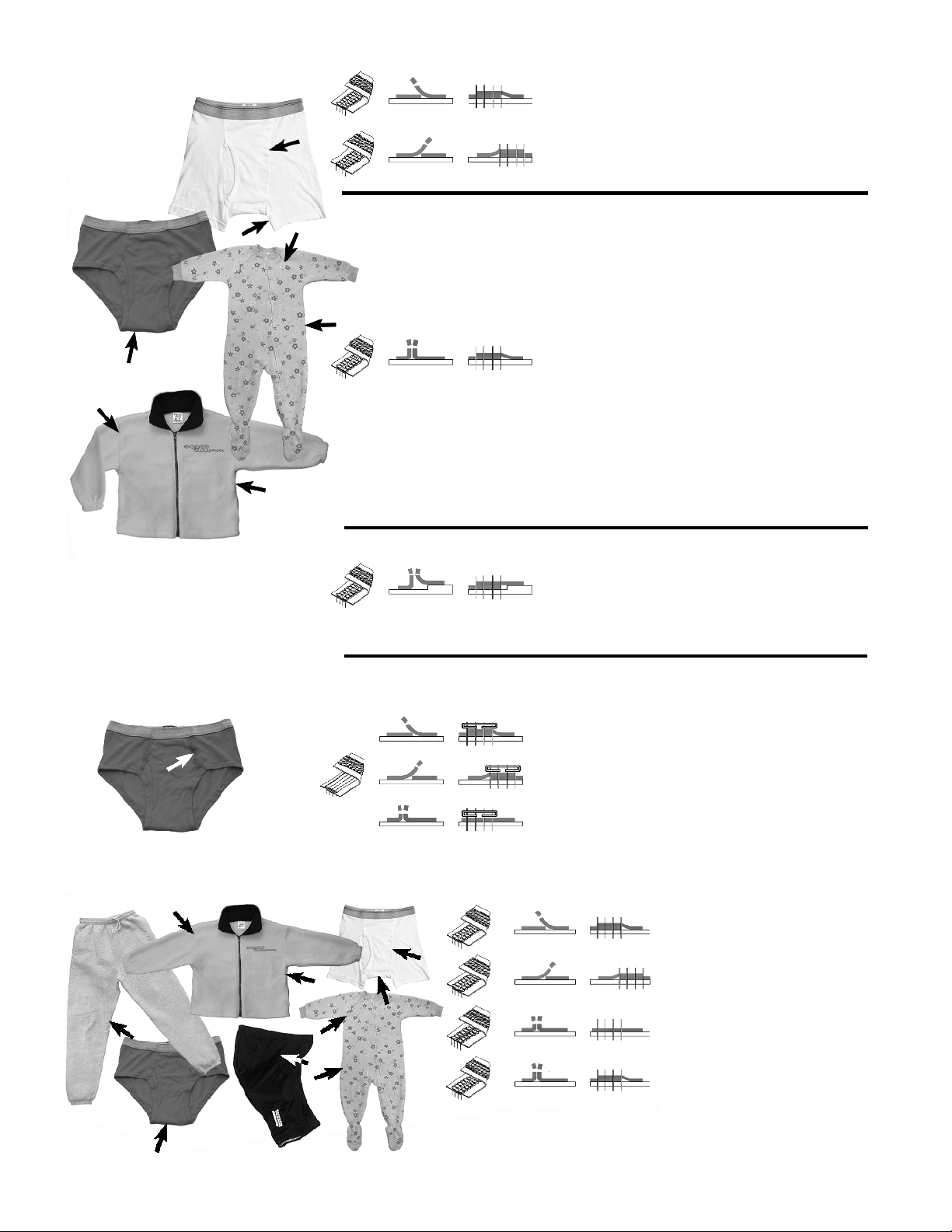

LAPSEAMING

36200L100–52/60

4 Needle One Side Trim Lapseamer

Fitted with one side fabric trimming lapseam presser foot, edge

guide and spreader.

Standard: Trimming right side of fabric edge, left side fabric edge

trimming can also be done by moving edge guide.

For closing the crotch of briefs and panties, sleeves of T-shirts and

polo shirts, etc.

36200L200–52/60

4 Needle Both Side Trim Lapseamer

Fitted with both side fabric trimming presser foot, lap former and

spreader, to achieve smooth even seams on top and bottom of

fabric.

For side seaming swimsuits, jogging pants, biking shorts, knitted

jackets and T-shirts, and crotch seaming briefs and panties.

36200L201–60

Same as 36200L200, except with large cover thread hook and

long presser bar for use with thread burner.

36200L202–52/60

4 Needle Both Side Trim Lapseamer

Fitted with special both side fabric trimming sewing combination,

lap former and spreader, to achieve smooth, even seams on top

and bottom of fabric.

Specifically for knit boxer briefs.

JOINING & TAPING

MULTIPURPOSE: LAPSEAMING & FLATSEAMING

36200L210–52/60

4 Needle Both Side Trim Lapseamer for Heavy Weight

Fabrics

Fitted with both side fabric trimming 1.2mm stepped presser

foot, throat plate and feed dogs, lap former and spreader.

For crotch seams with binding on briefs.

36200T300–52/60

4 Needle Seamer for Attaching Tape

Fitted with one side fabric trimming or both side fabric trimming

presser foot without spreader, and taping folder. folder uses ¾"

(19mm) tape with 3/8" (9.5mm) finish.

For attaching the tape on the front fly of briefs,

thermal underwear and similar garments.

36200U300-52/60

4 Needle Multipurpose Seamer

for Lapseaming and Flatseaming

Fitted with one side fabric trimming

lapseam or both side fabric trimming

flatseam presser foot, edge guide and

spreader. Includes both side fabric

trimming lapseam presser foot, lap former

and spreader.

For closing crotch of briefs and panties,

side seaming swimsuits, jogging pants,

biking pants, knitted jackets and T-shirts,

etc.

5

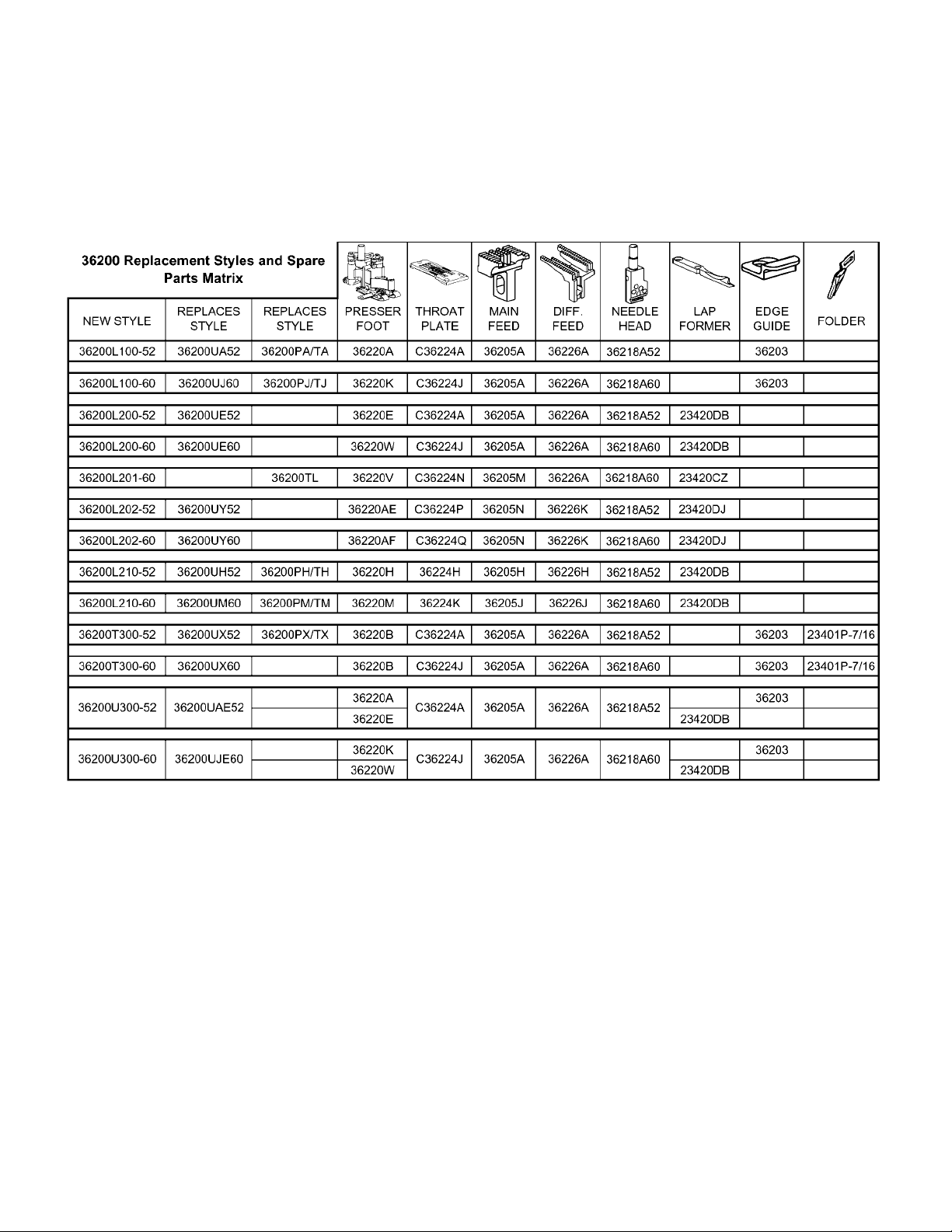

REPLACEMENT PARTS

6

SAFETY RULES:

1. Before putting the machines described in this manual into service, carefully read the instructions. The

starting of each machine is only permitted after taking notice of the instructions and by qualified

operators.

IMPORTANT! Before putting the machine into service, also read the safety rules and

instructions from the motor supplier.

2. Observe the national safety rules valid for your country.

3. The sewing machines described in this instruction manual are prohibited from being put into service until

it has been ascertained that the sewing units which these sewing machines will be built into, have

conformed with the EC Council Directives (89/392/EEC, Annex II B).

Each machine is only allowed to be used as foreseen. The foreseen use of the particular machine is

described in paragraph “STYLES OF MACHINES” of this instruction manual. Another use, going beyond

the description, is not as foreseen.

4. All safety devices must be in position when the machine is ready for work or in operation. Operation of

the machine without the appertaining safety devices is prohibited.

5. Wear safety glasses.

6. In case of machine conversions and changes all valid safety rules must be considered. Conversions and

changes are made at your own risk.

7. The warning hints in the instructions are marked with one of these two symbols:

8. When doing the following the machine has to be disconnected from the power supply by turning off the

main switch or by pulling out the main plug:

8.1 When threading needle(s), looper, spreader etc.

8.2 When replacing any parts such as needle(s), presser foot, throat plate, looper, spreader, feed dog,

needle guard, folder, fabric guide etc.

8.3 When leaving the workplace and when the workplace is unattended.

8.4 When doing maintenance work.

8.5 When using clutch motors without actuation lock, wait until the motor is stopped totally.

9. Maintenance, repair and conversion work (see item 8) must be done only by trained technicians or

special skilled personnel under consideration of the instructions.

10. Any work on the electrical equipment must be done by an electrician or under direction and supervision

of special skilled personnel.

11. Work on parts and equipment under electrical power is not permitted. Permissible exceptions are

described in the applicable sections of standard sheet DIN VDE 0105.

12. Before doing maintenance and repair work on the pneumatic equipment, the machine has to be

disconnected from the compressed air supply. In case of existing residual air pressure, after disconnecting from compressed air supply (i.e. pneumatic equipment with air tank), the pressure has to be

removed by bleeding.

7

ILLUSTRATIONS

This manual has been arranged to simplify ordering repair parts. Exploded views of various sections of the mechanism are shown

so that the parts may be seen in their actual position in the machine. On the page opposite the illustration will be found a listing

of the parts with their part numbers, description and the number of pieces required in the particular view being shown.

Numbers in the first column are reference numbers only, and merely indicate the position of the part in the illustration. The reference

number should never be used in ordering parts. Always use the part number listed in the second column.

Component parts of sub-assemblies which can be furnished for repairs are indicated by indenting their descriptions under the

description of the main sub-assembly. As an example refer to the following text.

9. 29126 EC Upper Looper Drive Shaft Assembly ................................................................................. 1

10. 22503 F Screw ................................................................................................................................. 1

11. 39543 E Cam Follower Locking Clamp ..................................................................................... 1

It will be noted in the previous example that the cam follower, bushing and cam guide and the upper looper drive shaft are not

listed. The reason is that replacement of these parts individually is not recommended, so the complete upper looper drive shaft

assembly should be ordered.

When a part is common to all machines covered in this manual, no specific usage will be mentioned in the description. However,

when the parts for the various machines are not the same, the specific usage will be mentioned in the description and, if necessary,

the difference will be shown in the illustration.

A numerical index of all the parts shown in this manual is located at the back. This will facilitate locating the illustration and

description when only a part number is known.

IDENTIFYING PARTS

Where the construction permits, each part is stamped with its part number. On some of the smaller parts and on those where

construction does not permit, an identification letter is stamped in to distinguish the part from similar ones.

PLEASE NOTE: Part numbers represent the same part, regardless of which manual they appear. On all orders please include

part number, name and style of machine for which the part was ordered.

NEEDLES

Each needle has both a type and size number. The type number denotes the kind of shank, point, length, groove, finish and other

details. The size number, stamped on the needle shank, denotes the largest diameter of the blade measured between the shank

and the eye. Collectively, the type number and size number represent the complete symbol which is given on the label of all

needles packed and sold by Union Special.

TYPE DESCRIPTION

118GAS Extra short, double groove, struck groove, .060" diameter shank, chromium plated needle.

Sizes available 065/025, 070/027, 075/029, 080/032, 090/036.

118GBS Extra short, single groove, struck groove, spotted .060" diameter shank, chromium plated needle.

Sizes available 075/029, 080/032.

118GHS Same as 118GBS, except with ball point. Sizes available 070/027, 075/029, 080/032.

118GJS Same as 118GHS, except with tapered blade and ball point. Sizes available 065/025, 070/027, 075/029.

118GKS Round shank, round point, extra short, double groove, struck groove, spotted, chromium plated needle.

Sizes available 070/027, 075/029, 080/032.

36211 Retainer needle, no scarf, chromium plated. Sizes available 065/025, 070/027, 075/029.

APPLICATION

When changing the needle, make sure it is fully inserted in the needle driving arm before the clamp screw is tightened.

To have needles promptly and accurately filled, an empty package, a needle sample, or the type and size number should be

forwarded. Use the description on the label. A complete order should read as follows: "100 needles, type 118 GKS, size 075/029".

TORQUE REQUIREMENTS

Torque (measured in inch-pounds) is a rotating force (in pounds applied through a distance by a lever (in inches or feet). This is

accomplished by a wrench, screwdriver, etc. Many of these devices are available, which when set at the proper amount of torque

will tighten the part to the correct amount and no tighter.

All straps and eccentrics should be tightened to 19-21 inch-pounds (22-24cm/kg) unless otherwise noted.

All other nuts, bolts, screws, etc. should be tightened by hand as tightly as possible, unless otherwise noted.

8

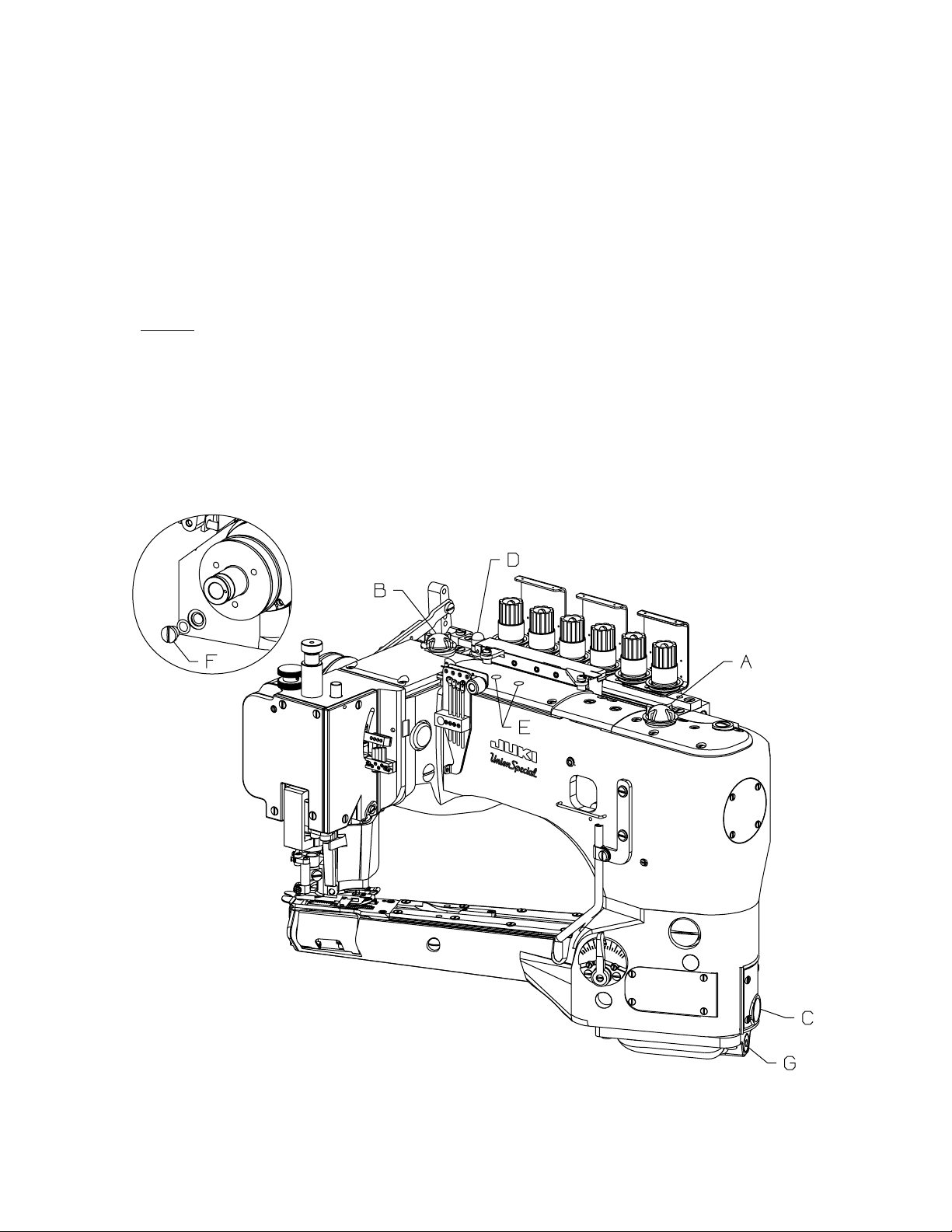

INSTALLATION

Make sure that the Machine is LEVEL when attaching to the installation (table or pedestal), or if machine is

moved to a new location.

OILING

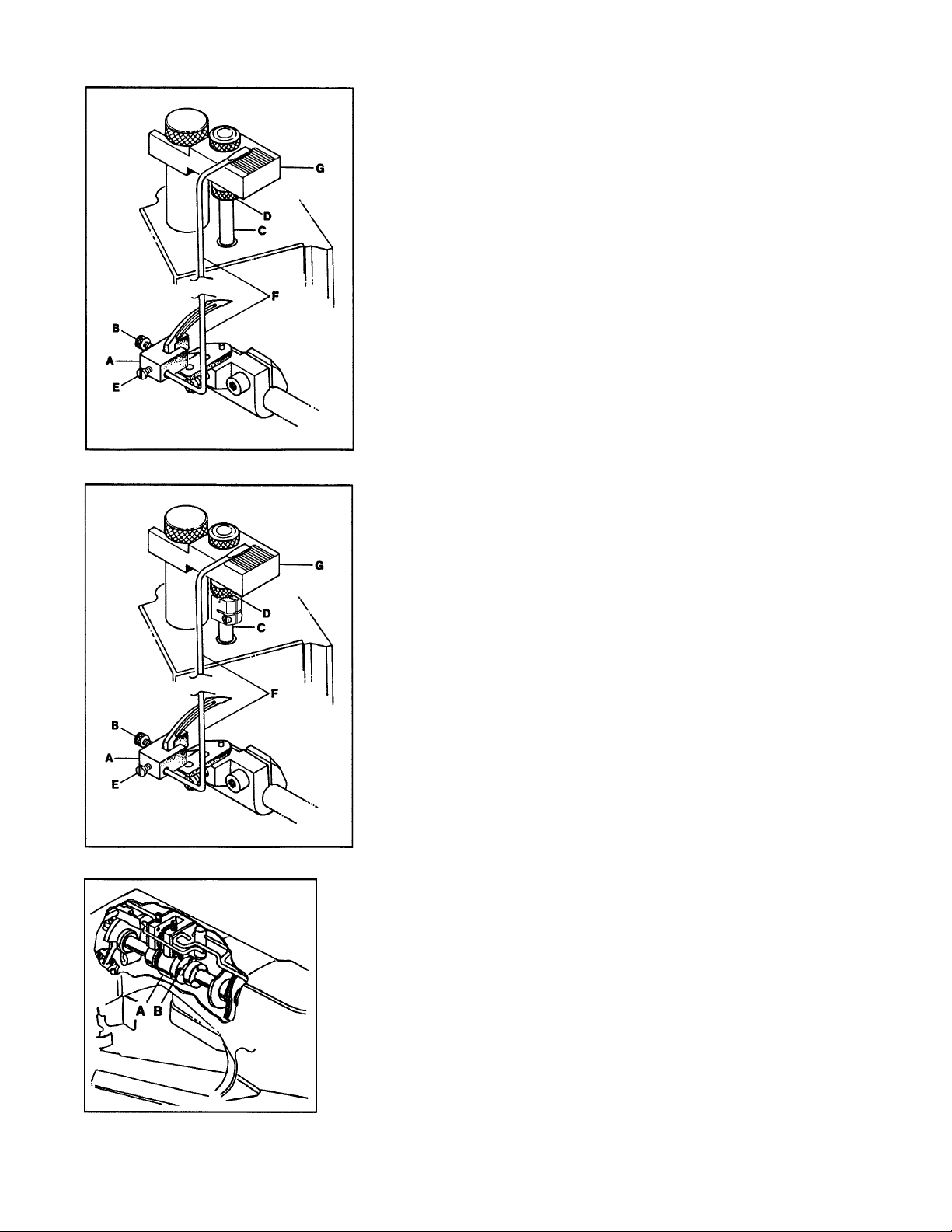

Referring to Fig. 1, fill the machine at (A) and (B). Oil capacity of class 36200 is 2.5 ounces in the bottom

reservoir and 2.5 ounces in the top reservoir. Use a straight mineral oil, Saybolt viscosity of 90 to 125 seconds

at 100° Fahrenheit (Union Special Spec 175 part no. 28604R). The oil level is checked at gauges (C) and (D).

Maintain oil level between the red lines of these gauges.

This machine is automatically lubricated by a continuously driven rotary pump. Oil flow can be observed

through windows (A) and (B). When installing a new machine or starting a machine that has been idle for

some time, priming may be necessary. Remove plug screws (E), fill holes with recommended oil and replace

screws

Remove screw 22733B (F, Fig. 1 inset) to drain oil from the top reservoir. To drain oil from bottom reservoir

remove screw 999-196 (G).

Occasionally, it is necessary to oil the linkage of the presser foot, the knife holder shank (36273A), guide

collar (36273K) and the various links and bearings of the presser foot lifting mechanism and thread tension

release.

BEFORE operating. If oil does not flow while machine is running, pump is inoperative.

9

THREADING

FIG. 1

10

ADJUSTING INSTRUCTIONS

Instructions stating direction or location, such as right, left, front or rear of the machine are given relative to

the operator's position at the machine unless otherwise noted. The handwheel rotates clockwise in

operating direction.

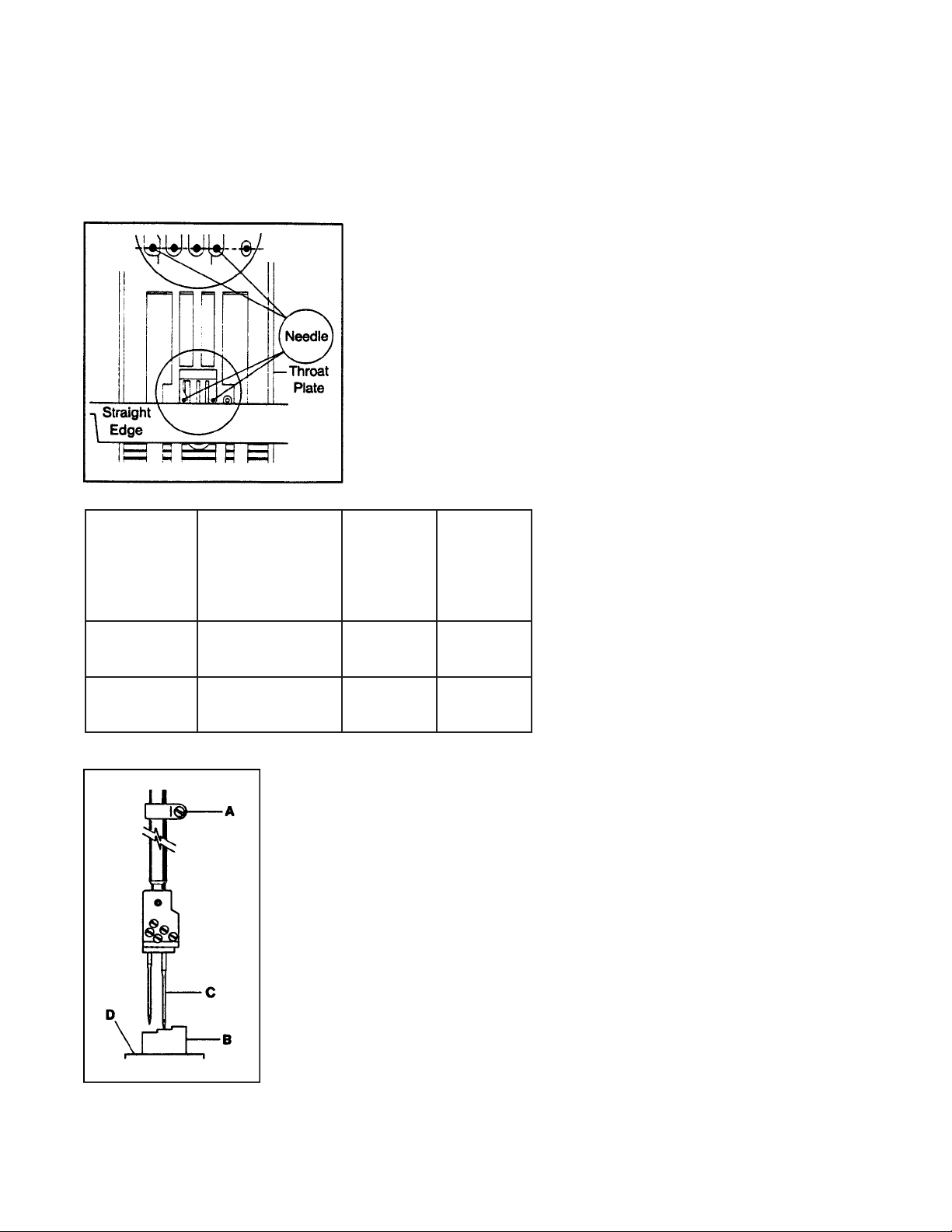

SETTING THE NEEDLE BAR HEIGHT & ALIGNMENT

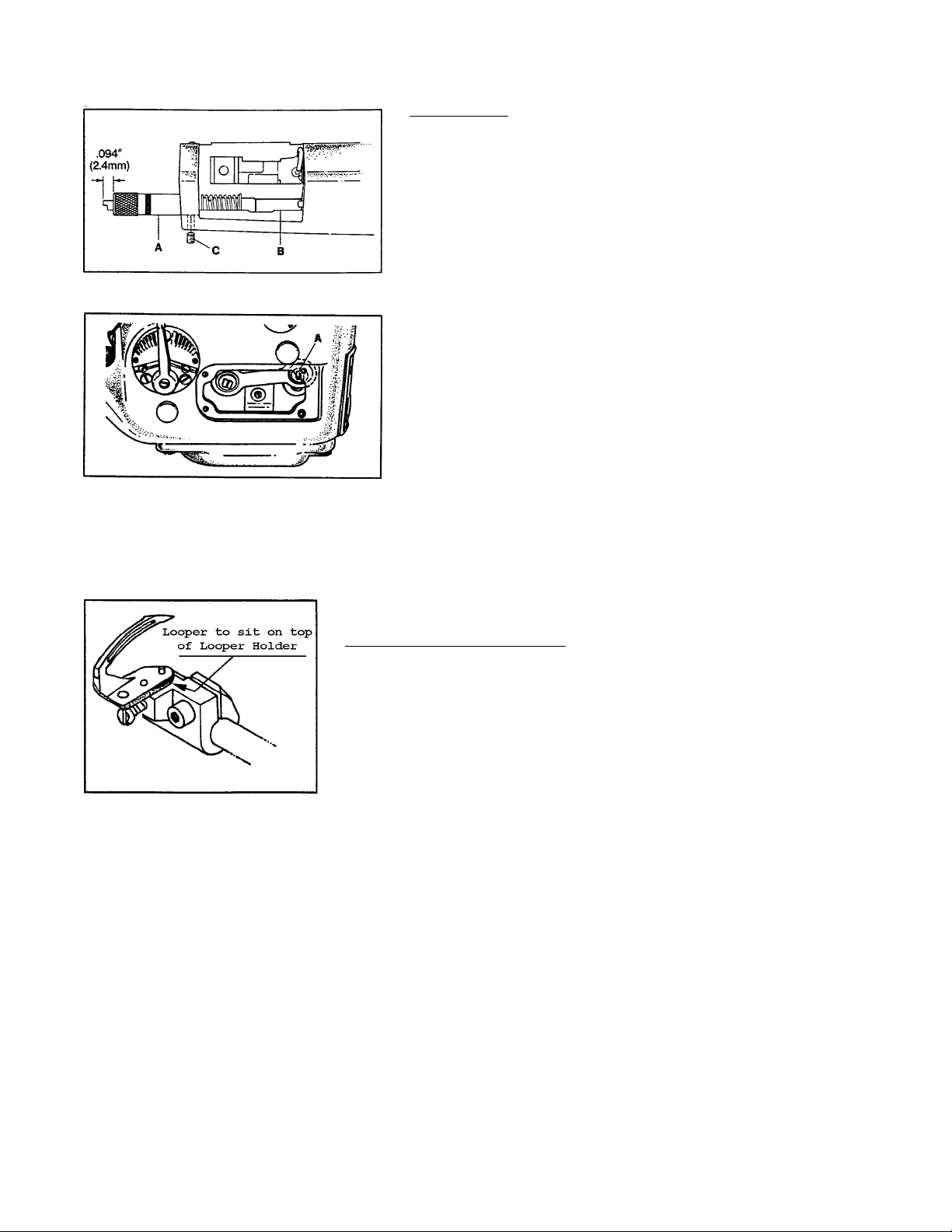

Insert the first (left) and fourth needles into the needle head. The

needles for this Class of machine are made with two flats on the front

of the shank. This will enable you to correctly position the needles in

the needle head. Make certain the needle shank is fully inserted and

that the screw is seated firmly on the flat.

To position the needle head square with the throat plate, use the

upper knife or a straight edge to align the needles with the cross

grooves in the throat plate. (See Fig. 2)

Refer to table 1 for the dimension from the fourth (lowest) needle to

the surface of the throat plate and for the number of the needle bar

height gauge.

FIG. 2

MORFNOISNEMID

)TSEWOL(HT4

ELYTS

EGUAG25)MM5.31("23/71UB72212135.

EGUAG06)MM7.21("2/1SD72212005.

OTELDEEN

ETALPTAORHT

ECAFRUS

ELDEEN

RAB

THGIEH

EGUAG

REBMUN

ELDEEN

THGIEH

EGUAG

PET

S

DEKRAM

Position the needle bar at its highest point

of travel. Loosen needle bar clamp screw

(A, FIG.3) & use the specified needle bar

height gauge (B) to achieve the desired

height dimension from the fourth (lowest)

needle (C) to the throat plate surface (D).

Tighten clamp screw (A) and recheck setting. Care must be taken not to disturb the

needle head alignment while making the

adjustment. Add the two middle needles

and the retainer.

FIG. 3

TABLE 1

CAUTION: If the needle head has been replaced it must be torqued to 17 in. lbs.

(20cm/kg). After tightening, check for expansion of the needle bar by positioning it up into the lower bushing hole. If the bar has expanded it will bind in the

bushing. The bar must be replaced or lapped to reduce the bell shape. Align

and set needle bar height as described above.

11

FIG. 4

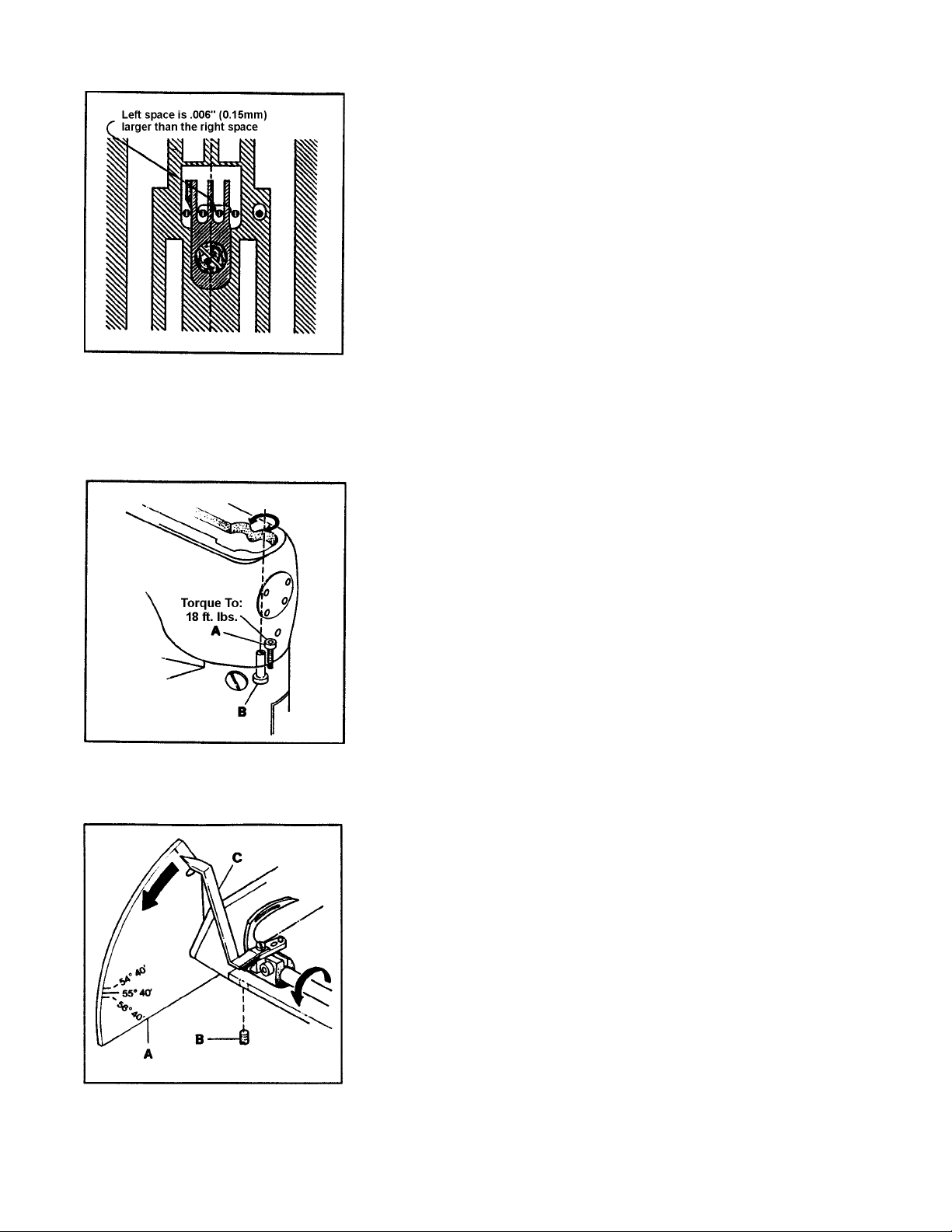

SETTING THE NEEDLE BAR HEIGHT & ALIGNMENT (CONT)

Correct spacing of the needles in the throat plate stitch tongue is

imperative to proper sewing conditions. Improper relationship of the

needles to the stitch tongue often results in malformed stitches.

When replacing the stitch tongue make sure needles are aligned

properly (see Fig. 4).

If the stitch tongue and throat plate are properly seated and the

needle position is not correct, the cylinder has probably been forced

out of position. If realignment is necessary, refer to the section

"Aligning the Cylinder".

When the needles are correctly positioned in the throat plate the

space to the left of the needles in the stitch tongue slot is .006"

(0.15mm) more than the space to the right (see Fig. 4). Actually, the

needle bar is centered to the throat plate and cylinder, however, to

provide clearance on the left side of the needle for the needle loops

passing around the looper during the down stroke of the needles, the

slots in the stitch tongue are made off-center to the left. Accurate

positioning of the needles may be obtained by repositioning the

cylinder.

ALIGNING THE CYLINDER

FIG. 5

Remove the top front cover and gasket from the main frame. Loosen

cylinder holding screw (A, Fig. 5). Turn eccentric screw (B) clockwise to move the cylinder so the needles are closer to the right side

of the stitch tongue. Turn the stud counterclockwise to locate the

needles closer to the left. Tighten screw (A) and recheck settings.

NOTE: The cylinder may not move freely when the eccentric is turned

because the joint sealant compound has set. Light tapping with a

wooden block at the joint or midpoint of the arm may be necessary.

SETTING THE LOOPER TRAVEL

USING GAUGE 21227CN

Attach looper travel gauge plate (A, Fig. 6) to the rear of the cylinder

arm. Set the bottom of the gauge so it is approximately horizontal

and lock lightly in place with screw (B) directly underneath. Attach

looper travel gauge pointer (C) to the looper using the left needle

guard screw hole. Turn the handwheel in operating direction until the

looper is positioned to the far right. Set pointer (C) at zero degrees

by rotating gauge plate (A) and lock in place. Continue turning the

handwheel until the pointer stops. If the looper travel is correct the

pointer should indicate 55°40'.

FIG. 6

12

SETTING THE LOOPER TRAVEL

To adjust the looper travel remove the top front cover and the end

cover. Loosen left-handed locknut (A, Fig. 7) and turn screw (B)

clockwise to decrease the looper travel or counterclockwise to

increase the looper travel. Tighten locknut (A) and recheck setting.

NOTE: After setting the looper travel the machine must be checked

for synchronization.

FIG. 7

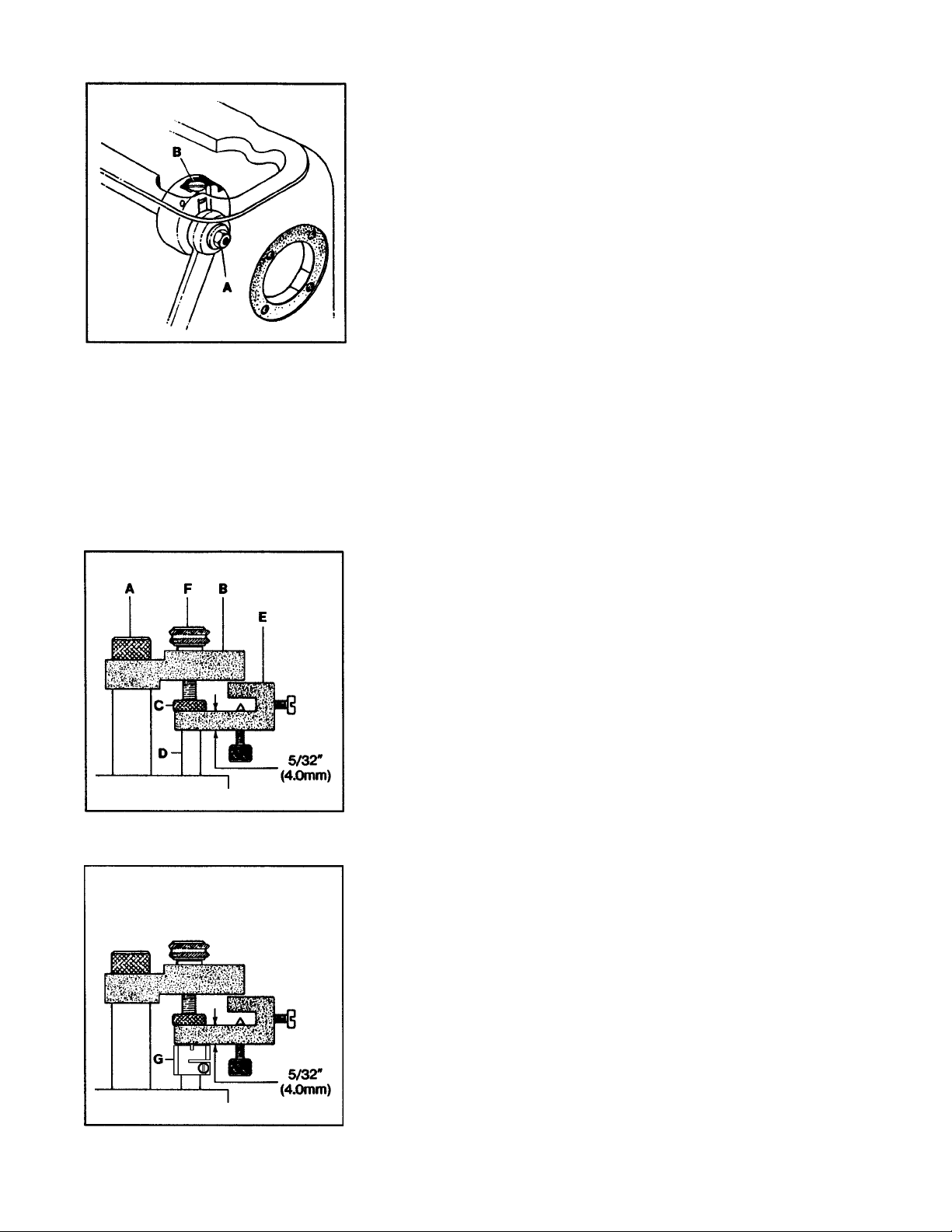

TIMING THE NEEDLES TO THE LOOPER

To visually check the timing of the needles to the looper, turn the handwheel in operating direction until the

needle bar has reached its lowest position and has risen 5/32" (4.0mm). At this time the looper point should

appear at the same relative position to the needles whether rotation of handwheel is clockwise or

counterclockwise.

INSTRUCTIONS FOR USING

SYNCHRONIZING GAUGE 21227CG

FIG. 8

Turn the handwheel until the needle bar is at its lowest point. Loosen

presser bar regulating screw (A, Fig. 8) and insert needle bar setting

block (B) under the head of the screw (A) with stop screw (C) above

needle bar (D). Tighten screw (A).

The long portion of the looper clamp and height gauge (E, Fig. 8) laid

on its side is the 5/32" (4.0mm) gauge used to set the distance

between stop screw (C) and the top of the needle bar (D) at its lowest

position. Tighten nut (F) to clamp stop screw (C) into place.

NOTE: If needle height has already been set attach gauge 21227FD

(G, Fig. 8A) to the top of the needle bar to obtain the 5/32" (4.0 mm)

setting.

FIG. 8A

13

FIG. 9

TIMING THE NEEDLES TO THE LOOPER (CONT.)

Attach the looper clamp and height gauge (A, Fig. 9) to the heal of

the looper by tightening screw (B). Turn the handwheel slowly in a

clockwise direction until needle bar (C) touches stop screw (D).

Loosen screw (E) and set synchronizing gauge rod (F) so the flat end

is on one of the lines in the center of the block (G). Tighten screw

(E).

Turn the handwheel in the opposite direction until the needle bar

(C, Fig. 9) or gauge block (Fig. 9A) touches stop screw (D, Fig. 9).

Synchronizing rod (F) should come to the same line on block (G).

The difference must not exceed one line.

If the setting cannot be achieved, main shaft coupling (A, Fig. 10)

must be repositioned. Remove the crank chamber cover and

gasket. Loosen the three coupling screws (B). If synchronizing rod

(F, Fig. 9) moves more to the right while the handwheel is rotated in

a clockwise direction, the looper is too fast and the main shaft

should be retarded. If the rod moves more to the right when the

handwheel is rotated in a counterclockwise direction the looper is

too slow and the mainshaft should be advanced. Tighten screws (B,

Fig. 10).

NOTE: If the stationary Knife interferes with the synchronizing

rod (F) remove the knife to make the adjustment.

FIG. 9A

FIG. 10

14

FIG. 11

FIG. 12

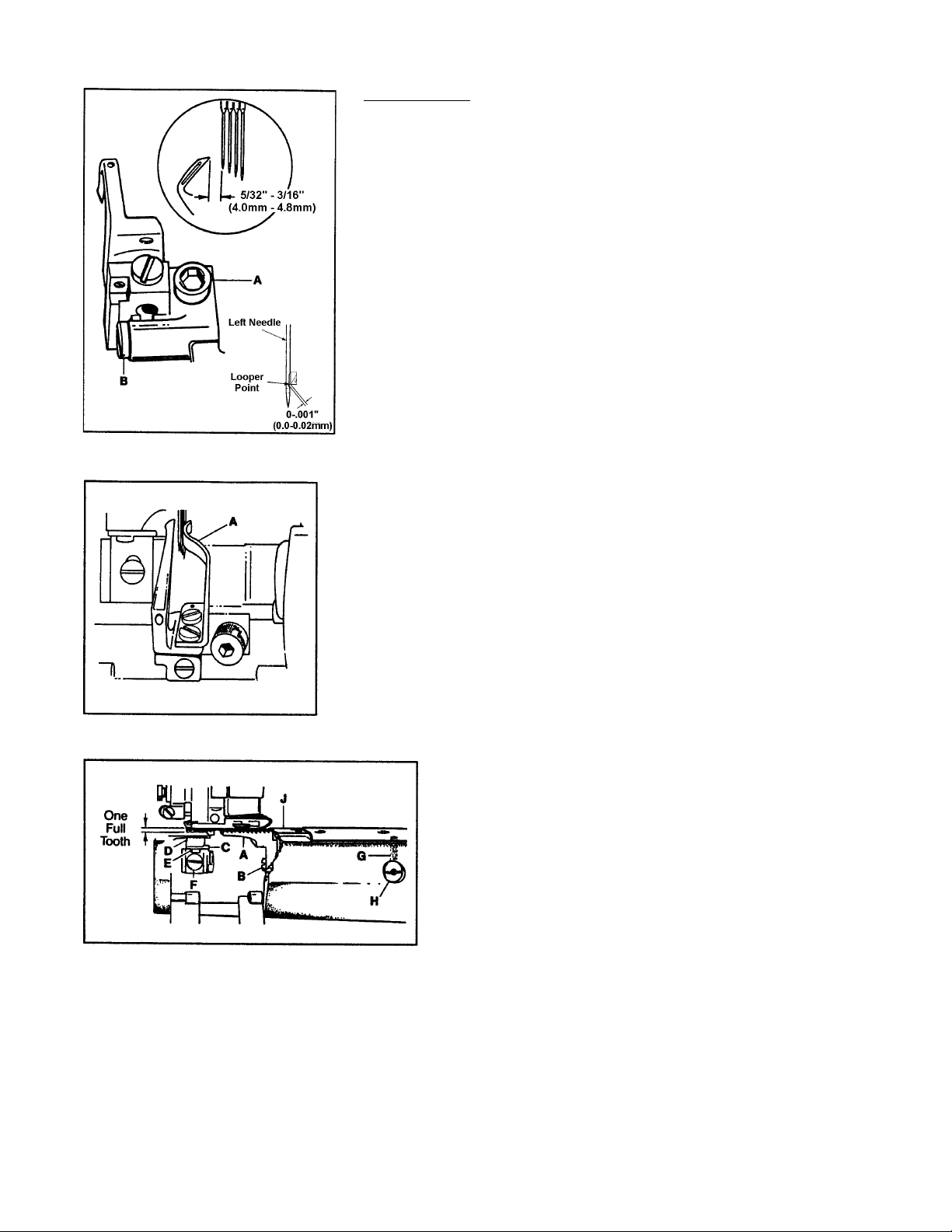

LOOPER ADJUSTMENTS

Looper Avoid

The looper avoid is set at .094" (2.4mm). Using gauge no.

21227BV (A, Fig. 11), position looper shaft (B) fully to the rear

(away from operator) and insert the gauge through the looper

shaft hole in the end of the cylinder until the plunger is fully

extended from the gauge. Tighten clamp screw (C). When the

looper is positioned fully to the front, the end of the plunger

should be flush with the end of the gauge. The motion of the

plunger from the extended position to flush represents .094"

(2.4mm) travel. To adjust the looper avoid remove the cylinder

cover and loosen screw (A, Fig. 12) with TT-85 wrench. Raise the

ball joint to shorten the avoid motion or lower it to lengthen the

avoid motion. Tighten screw (A). Reposition gauge (A, Fig. 11)

and recheck the setting.

FIG. 13

Vertical Adjustment of Looper

Looper to sit on top of looper holder.

15

FIG. 15

LOOPER ADJUSTMENTS (CONT.)

Looper Gauge

Turn the handwheel in operating direction until the looper has traveled fully to the left. Loosen screw (A, Fig. 15) and move the looper

holder to the right or left until the distance from the point of the looper

to the center of the first (left) needle is 5/32" - 3/16" (4.0mm - 4.8mm).

Set looper point .000-.001" (0.0-0.02mm) to first needle. Turn screw (B)

until the proper dimension is achieved. Tighten screw (A). Looper

point should not deflect or pinch needles.

NOTE: Looper gauge may need to be increased or decreased slightly

to obtain a proper stitch.

SETTING THE FRONT NEEDLE GUARD

Install needle guard (A, Fig. 16) with looper point at the middle of the

first needle set guard to touch but not deflect or pinch .000-.001" (0.0-

0.02mm) the first needle. Slowly turn the handwheel in operating

direction and check the needles to make sure they are not pinched

between the looper and the needle guard.

FIG. 16

FIG. 17

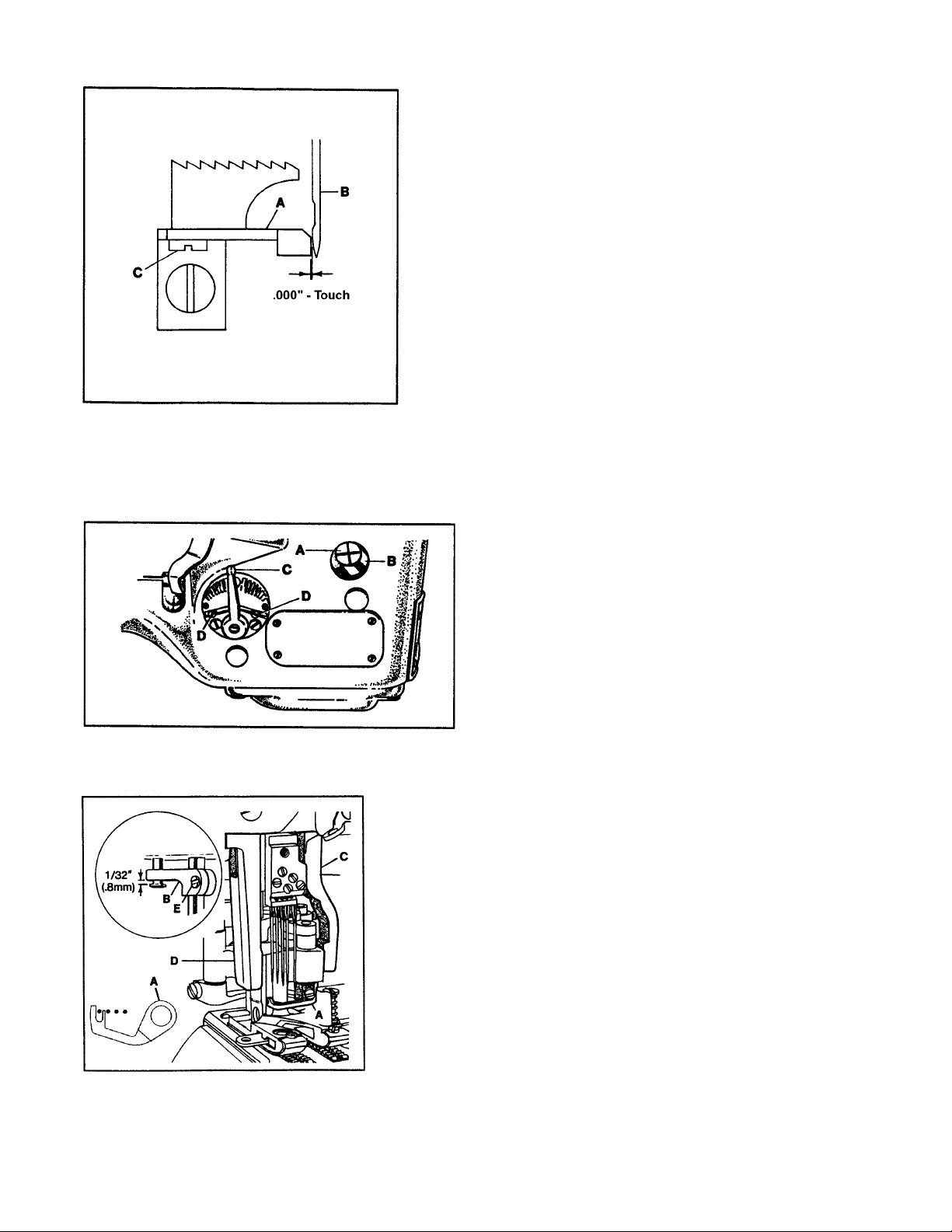

SETTING THE FEED DOGS

Preliminary Setting:

Install the differential feed dog (A, Fig. 17) with screw (B).

Attach rear needle guard (C) to main feed dog (D),

pushing in fully to the rear and tighten screw (E). Install

main feed dog with screw (F).

As a starting point loosen screw (G) and set the slot in feed

bar eccentric stud (H) in a horizontal position. Tighten

screw (G). At the highest point of travel feed dogs (A and

D) should be the depth of one full tooth above throat plate

(J). Loosen screws (B and F) and adjust the height of each

feed dog by moving them up or down in the elongated

slot of the shank. Tighten screws (B and F). Loosen screw

(G) and turn stud (H) until the top of the feed dogs are

parallel to the throat plate. Rotating stud (H) will simultaneously level both feed dogs.

NOTE: When setting eccentric stud (H) if turned clock-

wise feed dogs should go up if turned counterclockwise feed dogs should go down.

Final Setting:

Both the main and differential feed dogs may be individually adjusted to height. Main feed dog (D) at its highest

position should rise above the top of the throat plate the

depth of one full tooth when the normal presser spring

pressure is applied. The differential feed (A) may then be

raised to it.

16

FIG. 18

SETTING THE REAR NEEDLE GUARD

Set rear needle guard (A, Fig. 18) so it touches the first (left)

needle (B) but does not deflect. Check the guard position to

the other needles to avoid pinching. Loosen screw (C) and

reposition guard (A) as necessary. Tighten screw (C).

SETTING THE STITCH LENGTH

This machine is designed to sew 10 to 16 stitches per inch. The

normal factory setting is 12 stitches per inch. To change the

stitch length remove the plug screw located directly above

the cylinder side cover. Loosen screw (A, Fig. 19) in lever (B)

and move up to increase the stitch length or down to decrease the stitch length. Tighten screw (A) and replace the

plug screw.

CAUTION: If the stitch length is changed the rear needle

guard setting must be checked and readjusted

if necessary. Failure to do so may result in

needle and/or parts breakage.

CAUTION: When making stitch length adjustment do not

exceed maximum recomended stitch length

due to possible part damage.

FIG. 20

DIFFERENTIAL FEED CONTROL

The amount of differential feed is controlled by lever

(C, Fig. 19). The adjusting plate is numbered from 1 to

9. When the lever is set from numbers 1 to 4 reverse

differential or stretching occurs. The numbers from 4

to 5 produce equal feed stitching while numbers 5 to

9 produce a gathering stitch. The two stop screws (D)

can be set to limit the movement of lever (C) or lock

the lever in one position.

FIG. 19

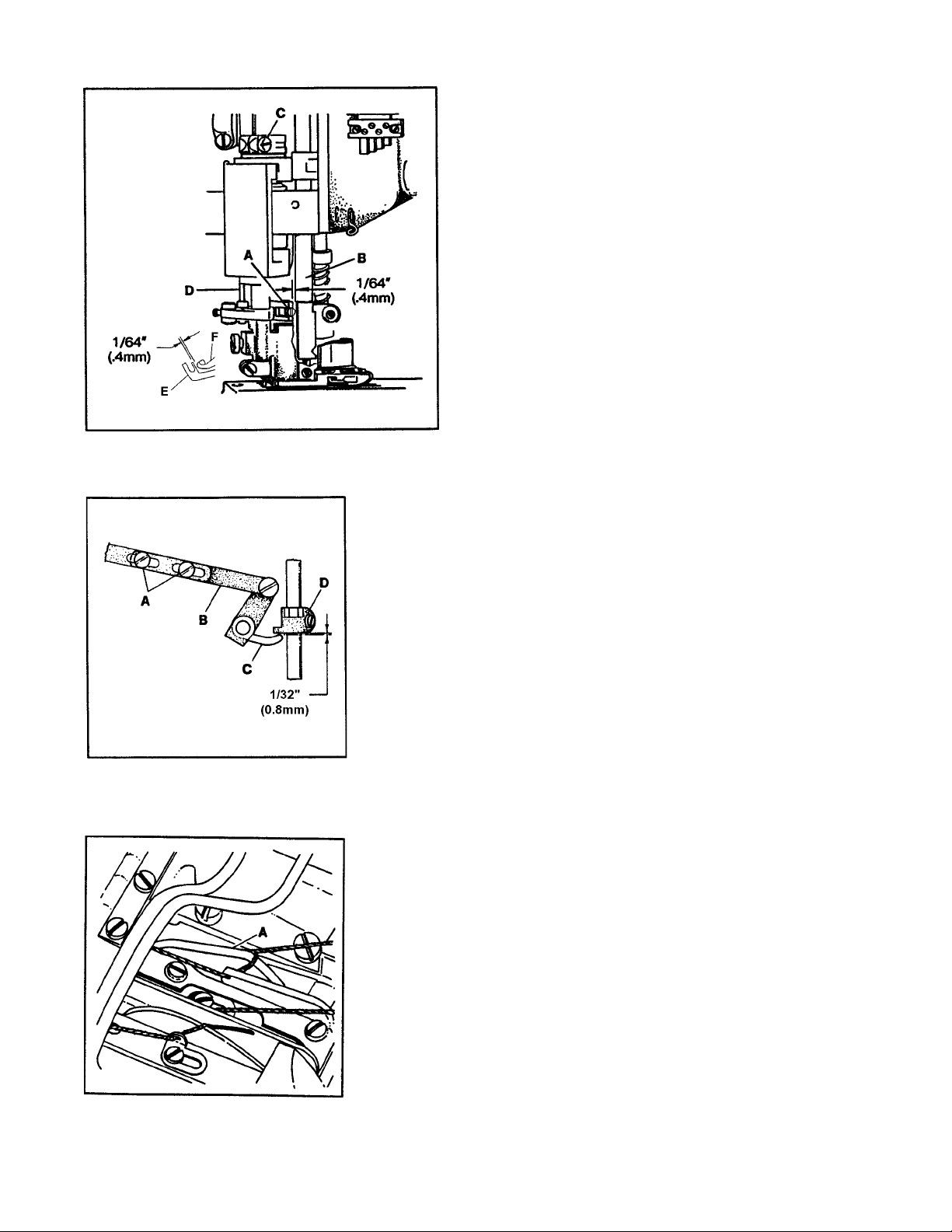

SETTING THE PRESSER FOOT

Remove the presser bar regulating screw and the presser spring.

Raise the needle bar to its highest position and remove the retainer. As the foot is slipped under the needles, swing the upper

knife into the opening on the right side of the foot and slide the

linkage onto the hook driving sleeve. Insert the presser bar

through the linkage and into the presser foot shank. Tighten

presser foot screw. With the presser bar inserted properly into the

presser foot, position the foot left to right so the finger of cover

thread carrier (A, Fig. 20) is between the first and second needles.

Set presser bar guide (B, Fig. 20 Inset) so foot will not move. Set

right presser foot guide (C) and left presser foot guide (D) to

maintain setting. Loosen presser bar guide screw (E Fig. 20 Inset)

and check to see that foot has vertical freedom with no right to left

play, no bind. Put the needle bar is in its lowest position, and set

1/32"(0.8mm) above head of presser bar guide stud. Tighten

presser bar guide screw (E).

17

FIG. 21

SETTING THE PRESSER FOOT (CONT.)

Turn the handwheel in operating direction until link (A,

Fig. 20) has traveled fully to the front. There must be a

1/64" (0.4mm) clearance between link (A) and the back

of needle bar (B) when link (A) starts to jackknife.

Loosen screw (C) and rotate driving sleeve (D) to position link (A). Tighten screw (C).

Add the cover thread hook(F) and cover thread carrier(E)

if they are not in place. Position carrier so the thread

loop will be carried behind the first two needles. There

should be a maximum 1/64"(0.4mm) clearance between the hook and the carrier at their closest position.

Replace the presser spring and the presser bar regulating screw.

Loosen screws (A, Fig. 22) in lifter lever link assembly (B) and position

lever (C) so there is 1/32" (0.8mm) clearance between it and presser

bar guide (D) when the feed dogs are below the throat plate.

FIG. 22

FIG. 23

When the hook swings to the left it will pass over the cover thread. On

its return travel, the thread will "pop" into the slot on the underside of

the hook and is carried to the right. This thread forms a triangle for

the third and forth needle threads to pass through. As the cover

thread "pops" into the slot it must cast-off the high point of take-up (A,

Fig. 23) at the same time. Loosen the two screws in the cover thread

take-up and reposition if necessary. If there is difficulty in making

this adjustment, check the thread tension and make sure the hook

point has an extremely high polish and the angle is correct. Due to

clearance requirements bending the hook is not recommended.

18

FIG. 24

SETTING THE PRESSER FOOT (CONT.)

The presser foot lifter stop

plunger must be set so the

cover thread hook will not hit

the bottom of the needle

head as the presser foot is

being lifted. Position the

needle bar to its lowest point

of travel. Loosen nut (A, Fig.

24) and turn plunger (B)

clockwise until it strikes the

crankshaft counterweight.

While applying pressure to

lifter (C) to lift the foot, back

out of the plunger until the

distance between the hook

FIG. 25

To adjust the position and tension of frame chip guard (A, Fig. 26),

slightly loosen screw (B) and turn washer (C) with 21388Y spanner

wrench until spring (D) snaps the guard into the closed position.

Tighten screw (B). A light resistance should be felt when opening the

guard.

and the underside of the

needle head is 1/64" (0.4mm)

(see Fig. 25). Tighten nut (A,

Fig. 24).

FIG. 26

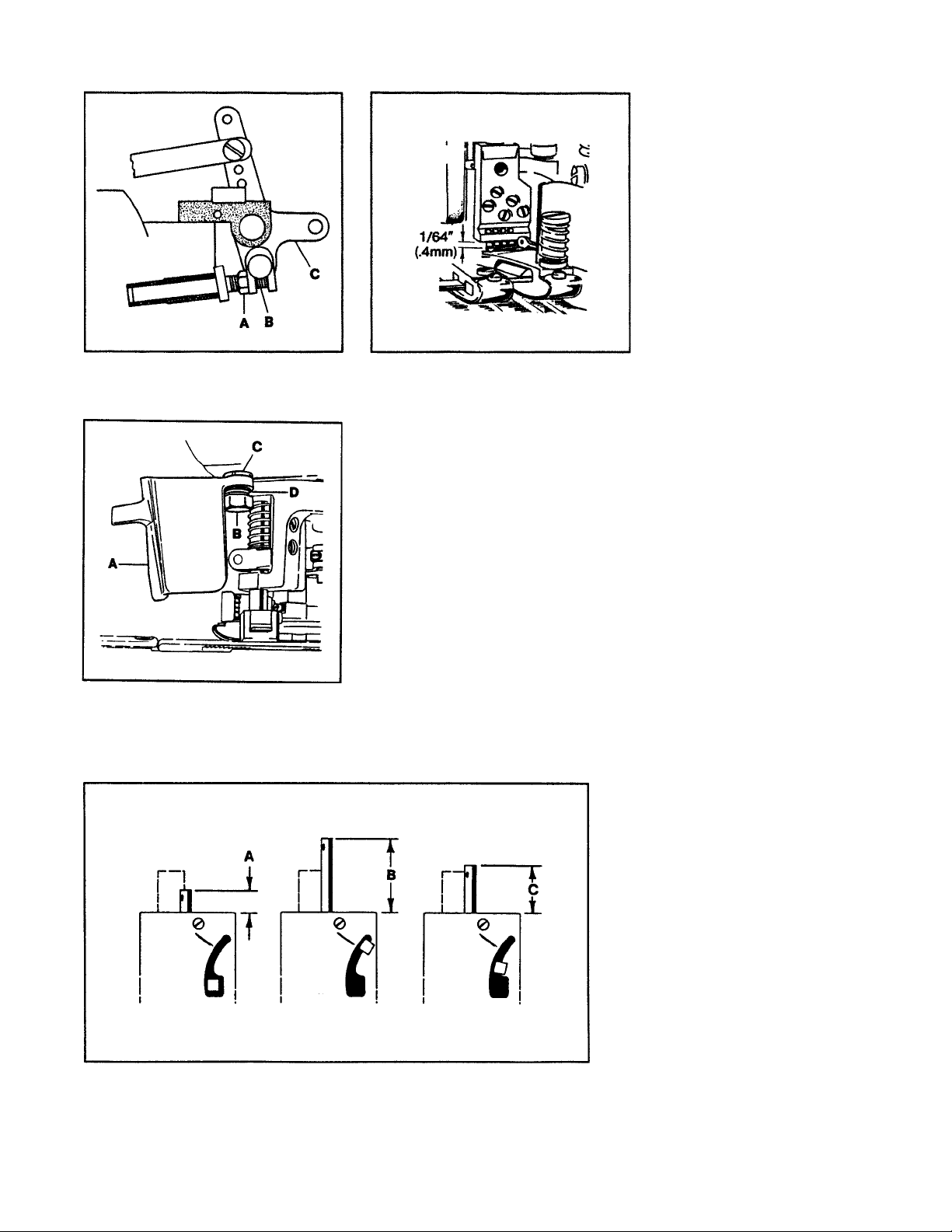

SETTING THE KNIFE DRIVE LEVER

FIG. 27

Position the needle bar at the bottom of its stroke. Measure from the

top of the needle bar to the top of

the casting to obtain dimension "A"

(see Fig. 27).

Position the needle bar at the top

of its stroke. Measure from the top

of the needle bar to the top of the

casting to obtain dimension "B".

Subtract dimension "A" from dimension "B" and divide by two. Add

this number to dimension "A" to

obtain "C". Set a caliper to the "C"

dimension and turn the handwheel

in operating direction until the

height of the needle bar is at the

"C" dimension

19

SETTING THE KNIFE DRIVE LEVER (CONT.)

At this time the knife drive lever should be in the 6 o'clock

position. If adjustment is necessary, loosen screws (A, Fig. 28)

in the needle lever and reposition knife drive lever (B) to the

6 o'clock position. Tighten screws (A). The dimension between the centerline of right and left knife drive connection

ball joints (C and D) must be 2 27/32" (72.2mm). Loosen left

hand thread nut (E), right hand thread nut (F) and turn connecting rod (G) until dimension is achieved. Tighten nuts (E

and F).

FIG. 28

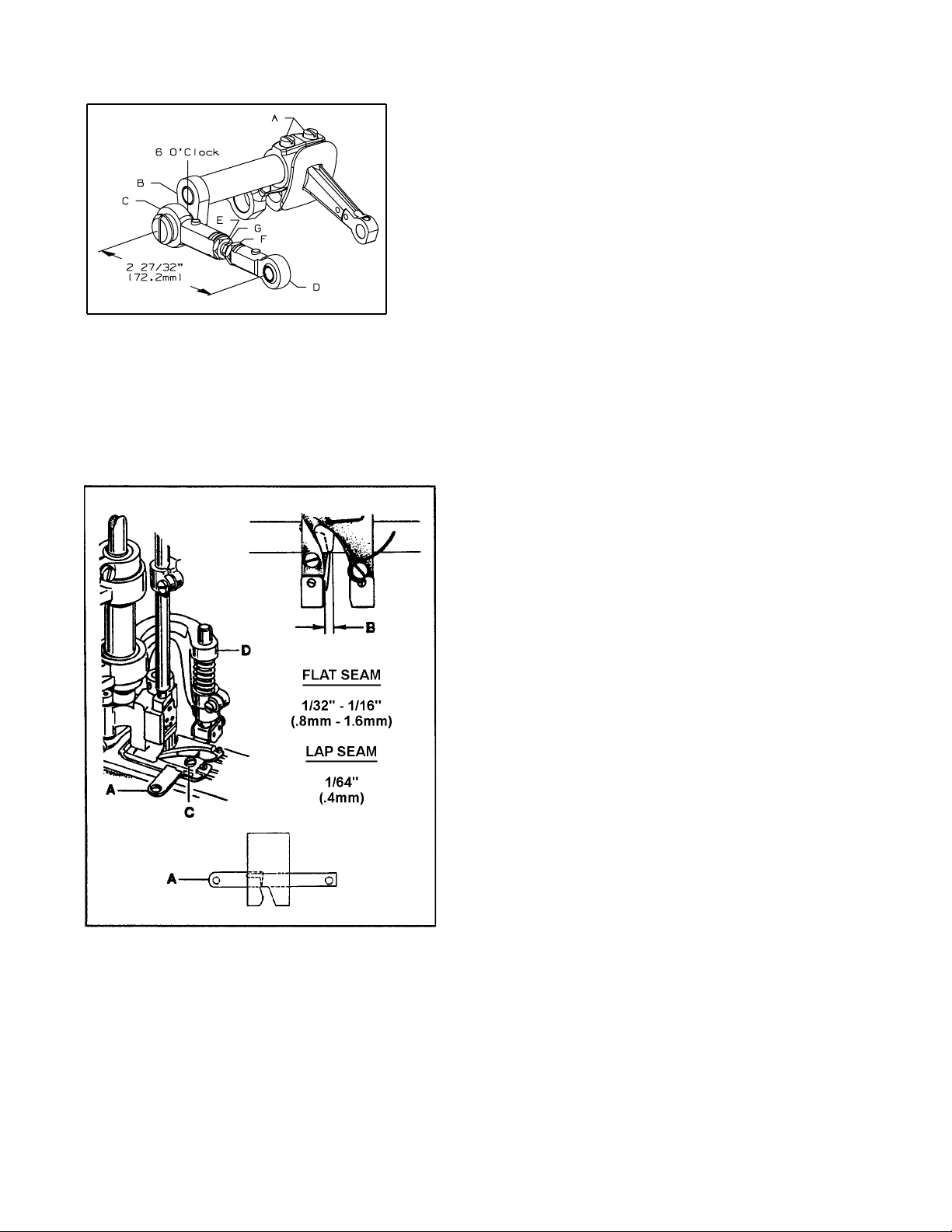

SETTING THE TRIMMING KNIVES FOR FLAT SEAMING

(STYLES 36200L100-52, L100-60, T300-52, T300-60, U300-52, U300-60)

To make the adjustments for a flat seam, position lower

knife (A, Fig. 29) in the foot so it extends 1/32" to 1/16"

(0.8mm to 1.6mm) past the right side of the left toe (B)

(approximately between the second and third needles).

Loosen screw (C) and move knife in or out as required.

Tighten screw (C) securely.

FIG. 29

SETTING THE TRIMMING KNIVES

FOR LAP SEAMING

(STYLES 36200L100-52, L100-60, L200-52, L200-60,

L202-52, L202-60, L210-52, L210-60, U300-52,

U300-60)

To make the adjustments for a lap seam, position lower

knife (A, Fig. 29) in the foot so it extends 1/64" (0.4mm)

past the right side of the left toe (B) (approximately even

with the first needle). Loosen screw (C) and move knife

in or out as required. Tighten screw (C) securely.

(ALL STYLES )

Turn handwheel in operating direction until knife driving

bracket (D) is positioned to the extreme left. At this time

the front edge of both knives should be parallel with

each other and the upper knife cutting edge should

overlap lower knife cutting edge by 1/64" (0.4mm)

20

FIG. 30

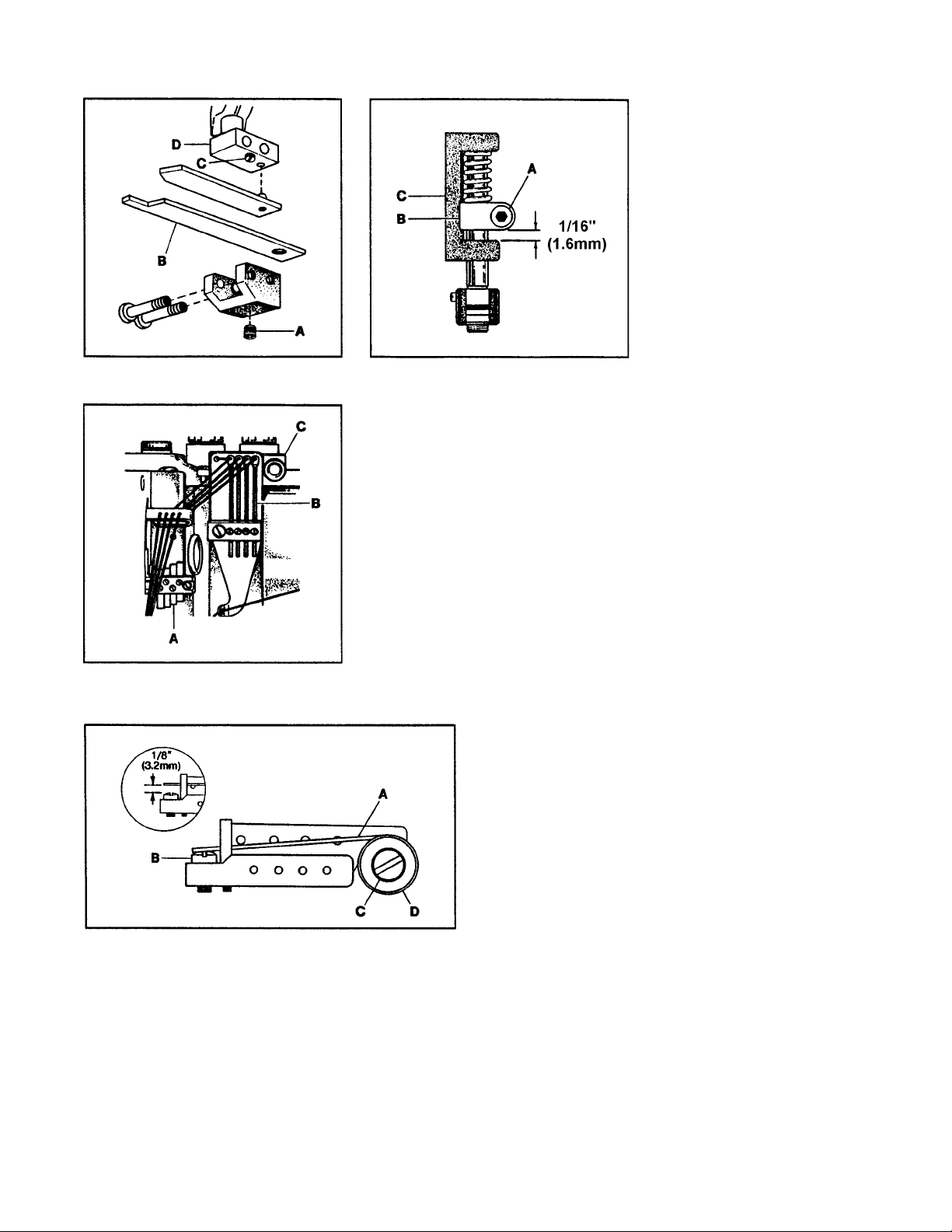

SETTING THE TRIMMING KNIVES

(ALL STYLES) (CONT.)

If necessary loosen screw (A,

Fig. 30) and move knife (B) to

the right or left as required.

Tighten screw (A).

If the shear angle between

the knives has to be changed,

raise or lower screw (C, Fig.

30) in knife holder shank (D).

To set spring pressure between the knives loosen

screw (A, Fig. 31) and raise

knife holder guide collar (B)

1/16" (1.6mm) from knife driv-

FIG. 31

NOTE: More or less spring pressure may be required depend-

ing on the type of material being sewn. Also, both

knives may have to be repositioned after a trial seam

is made so there is an equal margin from the edges of

the two plies to the center rows of stitching.

ing bracket (C). Tighten

screw (A).

NEEDLE THREAD ADJUSTMENTS

Four needle thread strike-off pins (A, Fig. 32) are provided for independent needle thread control. Level the take-ups to the height of

the thread in the needle lever eyelet at its lowest position. Raise the

first take-up (nearest the operator) 1/8" (3.2mm) and the second

FIG. 32

FIG. 33

Turn screw (B) up or down so unlocking spring (A) will have 1/8" (3.2mm) drop from the bottom of the thread

holes to the top of screw (B). Loosen screw (C) and turn knurled knob (D) to adjust the spring tension. Tighten

screw (C).

take-up 1/16" (1.6mm). Further adjustment may be necessary to

obtain proper needle loop size so skipped stitches may be avoided.

Set the four frame needle thread eyelets (B, Fig. 32)

eye with the eyelets in holder (C). Adjust as necessary so the needle thread loops around the looper

will remain firm and not seek random positions when

the needle bar descends.

Unlocking spring (A, Fig. 33) provides a proportional

amount of pull-up of the needle threads when the

machine is reversed for unlocking the stitch so the

loops will not form on the front of the needles and

become caught by the looper.

NOTE: Unlocking spring is only used when starting

and stopping on the material.

Tension of the six threads is individually controlled. The needle tension is seldom uniform; the first needle

thread having more tension than the other three. Use only enough tension to pull up the stitch. A wellbalanced stitch will have the first and fourth needle loops pulled up and the second and third needle loops

small and even.

21

FIG. 34

LOOPER THREAD ADJUSTMENT

Loosen screws (A, Fig. 34) and position looper thread cast-off (B)

flush with the right end of cast-off support plate (C). Tighten screws

(A). Loosen screws (D, Fig. 34 inset) and time take-up (E) so the

thread will cast-off when the needle bar has descended 7/64" (2.8mm)

from its highest position. When thread eyelets (F) are moved further

to the left the amount of thread pull-off will increase.

COVER THREAD ADJUSTMENT

Loosen screw (A, Fig. 35) and set the lower edge of cover thread

take-up eyelet (B) so its 3/32" (2.4mm) above the surface of cast-off

plate (C). Tighten screw (A). As the cover thread hook moves to the

left over the cover thread and the needle bar starts to rise, the cover

thread must "cast-off" from the high point of take-up (D). Loosen

screws (E) and adjust take-up (F) accordingly. make sure that takeup (F) is centered in cast-off plate slot (C) and take-up eyelet (B) is

centered to take-up (F). Tighten screws (E).

FIG. 35

TENSION RELEASE

The tension releaseshould start to function when the presser foot has

raised approximately 1/32" (0.8mm) above the surface of the throat

plate and be entirely released when the presser foot has reached its

highest position. Insert a large screwdriver into slot on the right end

of shaft (A, Fig. 36), loosen screw (B) in lifter lever (C) and turn the

screwdriver to raise or lower pins (D). Tighten screw (B).

NOTE: Make sure the 1/32" (0.8mm) clearance between the

presser bar lifter lever and presser bar guide has been

maintained. Refer to Fig. 22 if readjustment is necessary.

FIG. 36

22

HUNG FOOT ADJUSTMENT

When sewing on extremely lightweight material and/or feed cutting is a problem, the presser foot may be

"hung" by raising stud (B) until guide (A) rests on the shoulder of stud (B). This adjustment will raise the presser

foot slightly, so only the pressure of the presser foot shoes contact the material. Turn handwheel in operating

direction until the feed dogs are below the throat plate surface. At this time there should be a 1/32" (0.8mm)

clearance between the bottom of presser bar guide (A, Fig. 37) and presser bar guide stud (B). To hang

presser foot, loosen lock nut (C Fig. 37) and turn thumbscrew (D Fig. 37) so that the foot comes up slightly,

tighten nut (C Fig. 37).

SETTING THE LAP FORMER

Attach gibs (A, Fig. 38) to the cylinder cover but do not tighten screws (B); leave them snug for further

adjustment. Fasten spring (C, Fig. 38 inset) to the bottom of slide block (D) and insert between gibs (A).

Attach lap former (E) to slide block (D) with screws (F) and position it in the center of the presser foot. Position

the slide block so it has a snug (but not tight) fit the entire length of the gibs. Tighten screws (B).

FIG. 37

FIG. 38

LAP SEAMING

Lap Seaming can be accomplished using three methods:

1. Lap seaming cutting only right ply of material. (L100-52, L100-60, U300-52, U300-60)

A. Use flat seam presser foot.

B. Remove front right throat plate screw and attach 36203 edge guide with 22849 screw, and adjust

left or right for proper coverage on bottom.

C. Adjust knives left or right for proper trimming and coverage on top.

2. Lap seaming cutting only left ply of material. (L100-52, L100-60, U300-52, U300-60)

A. Use flat seam presser foot.

B. Remove left front throat plate screw and attach 36203 edge guide with 22849 screw, and adjust

left or right for proper coverage on bottom.

C. Adjust knives left or right for proper trimming and coverage on top.

3. Lap Seaming cutting two plies of material. (L200-52, L200-60, L201-60, L202-52, L202-60, L210-52, L210-60,

U300-52, U300-60)

A. Remove flat seam presser foot and replace with lap seam presser foot. Refer to pages 15, 16,

& 17 for presser foot adjustments.

B. Attach lap former and slide block with spring. See above for adjustments.

23

REPLACING PRESSER FOOT SHOES

FIG. 39

REMOVING

1. Remove screws (A, Fig. 39).

2. Remove the presser foot shoes (B, Fig. 39) from the presser foot.

3. Remove each shoe (B, Fig. 39) from the shoe holder (C, Fig. 39).

RESETTING

1. Reset each presser foot shoe (B, Fig. 39) with the shoe holder (C, Fig. 39).

2. Reset the shoes (B, Fig. 39) parallel to each other on the presser foot.

3. Tighten the screws (A, Fig. 39) securely.

24

EXPLODED

VIEWS

25

26

OIL SIGHT GAUGES, TOP COVERS & MISCELLANEOUS TAKEUP & EYELET PARTS

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

Part No.

93

35888N

22924708

660-212

22516A

93A

90

35887X

35887AE

22924708

660-212

22539M

22516A

73C

36256

29476XC

22KH

36204

73A

52958F

52958C

36204A

36256A

22839

36284T

22564B

35887R

41071G

35887M

12934A

36284M

22569B

36290M

660-1146

660-935

LA528

CO67E

36289K

6042A

22759A

22711

998-358E

22539AA

36293B

36293E

39593C

93

35890P

35893G

35893H

Description

Screw, for crank chamber cover ....................................................................

Crank Chamber Cover ...................................................................................

Oil Sight Gauge ........................................................................................

"O"Ring .....................................................................................................

Screw ..............................................................................................................

Screw, for middle top cover ............................................................................

Screw, for spring .............................................................................................

Top Cover, middle ..........................................................................................

Top Cover, front ..............................................................................................

Oil Sight Gauge ........................................................................................

"O"Ring .....................................................................................................

Plug Screw ......................................................................................................

Screw, for front top cover ................................................................................

Screw ..............................................................................................................

Cover Thread Take-up Eyelet ..........................................................................

Cast-Off Plate Assembly .................................................................................

Screw, for cast-off ....................................................................................

Cast-off ....................................................................................................

Screw, for cast-off plate eyelets ...............................................................

Cast-off Plate Eyelet, rear .........................................................................

Cast-off Plate Eyelet, front ........................................................................

Cast-off Plate ............................................................................................

Cover Thread Take-up Eyelet Holder ..............................................................

Screw ..............................................................................................................

Gasket, for front top cover ..............................................................................

Screw, for middle cover hinge ........................................................................

Middle Cover Hinge ........................................................................................

Nut, for top middle cover spring screw ............................................................

Spring, for middle top cover ............................................................................

Nut, for top middle cover spring screw ............................................................

Gasket, for crank chamber .............................................................................

Screw, for bushing housing .............................................................................

Crankshaft Bushing Housing Assembly ...........................................................

Lip Seal .....................................................................................................

"O"Ring .....................................................................................................

Directional Label ............................................................................................

Cork ................................................................................................................

Oil Shield ........................................................................................................

Washer, for screw ............................................................................................

Screw, for connecting head to main frame .....................................................

Screw, for hose clamp ....................................................................................

Hose Clamp, for pump 36293R ........................................................................

Plug Screw ......................................................................................................

Oil Sight Gauge ...............................................................................................

Oil Level Indicator ...........................................................................................

Oil Gauge Float ...............................................................................................

Screw, for oil pump housing ............................................................................

Bushing ...........................................................................................................

Seal, Upper .....................................................................................................

Seal, Lower .....................................................................................................

Amt.

Req.

5

1

1

1

2

2

2

1

1

1

1

1

6

1

1

1

2

1

2

1

1

1

1

2

1

3

1

2

1

2

1

3

1

1

1

1

1

1

2

2

1

1

1

1

1

1

2

1

1

1

27

28

MAIN FRAME, BUSHINGS & MISCELLANEOUS EYELET & COVER PARTS

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

Part No.

36284S

35887Z

22564B

36290B

92201

22829

29105BH

35866A

SS7110510SP

35866B

35883AL

35781D

660-1132

62271B

36290G

35890E

22539T

35761D

36260B

36260C

660-206

22733B

36271A

73A

22768B

36271G

36271E

36271H

36271

28C

22596D

36293N

Description

Gasket, end cover ..........................................................................................

End Cover .......................................................................................................

Screw, end cover ...........................................................................................

Main Shaft Bushing, front .................................................................................

Screw, for looper drive lever shaft ...................................................................

Screw, looper thread shield ............................................................................

Looper Thread Shield ......................................................................................

Tube .........................................................................................................

Screw .......................................................................................................

Tube Clamp ..............................................................................................

Support ....................................................................................................

Looper Thread Guide Wire ..............................................................................

Oil Seal ...........................................................................................................

Thread Guide ..................................................................................................

Main Shaft Bushing, rear .................................................................................

Crankshaft Bushing, front ................................................................................

Plug Screw ......................................................................................................

Bushing Cap ...................................................................................................

Needle Lever Shaft Bushing, front ...................................................................

Needle Lever Shaft Bushing, rear ....................................................................

Rubber “O” Ring .............................................................................................

Oil Drain Screw ...............................................................................................

Needle Thread Eyelet .....................................................................................

Screw, for needle thread eyelet .....................................................................

Screw, for unlocking spring height adjusting ..................................................

Stitch Unlocker Mounting Bracket ..................................................................

Unlocking Spring ............................................................................................

Spring Holder ..................................................................................................

Frame, Needle Thread Eyelet .........................................................................

Screw .......................................................................................................

Screw, for needle thread eyelet .....................................................................

Felt ..................................................................................................................

Amt.

Req.

1

1

4

1

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

4

2

1

1

1

1

1

4

1

1

29

30

MAIN SHAFT & MISCELLANEOUS OILING

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

Part No.

660-207

36294G

36293T

35897BW

29472AG

22585A

21756G

36297J

35897BV

29472AC

36297N

22571B

41071G

22565A

36293M

1096

36293L

50393-140

90

36261A

35894L

666-338

36293K

671B3

11550209

29101J

22587E

22894W

29103T

22587E

22894W

660-219P

36222C

22801

36223

22580

36223A

22580

35895W

22519F

22894J

22894K

Description

Oil Seal Ring ....................................................................................................

Oil Reservoir, back .........................................................................................

Oil Tube Extension ...........................................................................................

Gasket ............................................................................................................

Pump Assembly ..............................................................................................

Screw, for housing cover ..........................................................................

Vent Screw ...............................................................................................

Housing Cover and Oil Tube, rear .............................................................

Intake Filter ........................................................................................

Pump Body and Gear Assembly ...............................................................

Housing Cover and Oil Tube, front ............................................................

Plug Screw ................................................................................................

Nut ............................................................................................................

Screw .......................................................................................................

Oil Splitter .......................................................................................................

Screw .......................................................................................................

Oil Tube ....................................................................................................

Tubing ......................................................................................................

Screw, for take-up shield ................................................................................

Take-up Shield Assembly ...............................................................................

Oil Reservoir, front ...........................................................................................

Oil Seal Ring ....................................................................................................

Oil Tube Bypass ...............................................................................................

Oil Tube ....................................................................................................

Tension Spring ..........................................................................................

Feed Drive Eccentric Assembly ......................................................................

Screw .......................................................................................................

Set Screw ..................................................................................................

Feed Lift Eccentric Assembly ..........................................................................

Screw .......................................................................................................

Set Screw ..................................................................................................

Roll Pin ............................................................................................................

Main Shaft .......................................................................................................

Screw ..............................................................................................................

Double Disc Take-up .......................................................................................

Screw .......................................................................................................

Cover Thread Take-up ....................................................................................

Screw .......................................................................................................

Main Shaft Coupling .......................................................................................

Screw .......................................................................................................

Set Screw ..................................................................................................

Spot Screw ................................................................................................

Amt.

Req.

1

1

1

1

5

2

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

2

2

1

2

2

1

1

2

1

2

1

2

1

3

4

2

31

32

CRANKSHAFT & NEEDLE LEVER PARTS

Ref.

No.

Part No.

1.

36221N

2.

22574

3.

61321L

4.

61321J

5.

36221P

6.

22894E

7.

50311C

8.

36293Q

9.

SQ1110401MZ

10.

36293R

11.

50393KM

12.

50393-260

13.

50393CS

14.

36293S

15.

666-214

16.

35895Y

17.

22894AM

18.

22797

19.

35897BY

20.

22766

21.

36251N

22.

36251M

23.

36263

24.

35763G

25.

35862A

26.

22587B

27.

22894W

28.

36222A

29.

35763F

30.

36247

31.

77

32.

36264D

33.

36254B

34.

22564

35.

35816

36.

SS7110910TP

37.

36254A

38.

77

39.

36215

40.

22596B

Description

Pulley Assembly ..............................................................................................

Screw ........................................................................................................

Clamp Plate ..............................................................................................

Handwheel ...............................................................................................

Pulley ........................................................................................................

Screw, for pulley .................................................................................

Ball Bearing ...............................................................................................

Bushing Pump ..................................................................................................

Barb Fitting ................................................................................................

Pump Assembly ..............................................................................................

Tube retainer spring ..................................................................................

Tubing .......................................................................................................

Tube retainer spring ..................................................................................

Oil Tube .....................................................................................................

Oil Intake Felt ............................................................................................

Crankshaft Thrust Collar ..................................................................................

Screw ........................................................................................................

Screw ..............................................................................................................

Pump Driving Gear ..........................................................................................

Screw ..............................................................................................................

Needle Bearing Retaining Plate ......................................................................

Eccentric Bearing ...........................................................................................

Needle Bearing Rollers ....................................................................................

Needle Bearing Retaining Ring .......................................................................

Needle Lever Connecting Rod ........................................................................

Screw ........................................................................................................

Screw ........................................................................................................

Crankshaft ......................................................................................................

Needle Bearing Rollers ....................................................................................

Needle Lever Connecting Rod Pin ...................................................................

Screw ........................................................................................................