Page 1

FINEST

STYLES

33700A

--

33700C

QUALITY

LEWIS·

INDUSTRIAL

SEWING

MACHINES

COLUMBIA

CLASS33700

HIGH SPEED RIGHT HAND CYLINDER BED

CATALOG

HEMMING MACHINES

No.253

~

MASCHINENFABRIK

~:~

:

STUTTGART W SCHWABSTRASSE

33

Page 2

CATALOG

No.253

INSTRUCTIONS

FOR

ADJUSTING

Ll

ST

OF

PARTS

AND

CLASS33700

STYLES

33700A

33700C

OPERATING

The parts listed in this catalog are furnished at list prices for repairs only.

First Edition

Printed by

~

JUSCHINENFABRIK

~:~

:

STUTTGART·W

SCHWAISTIASSE

33

October,

1965

Page 3

ADJUSTING INSTRUCTIONS

33700

33700

33700

A-16

A-16-1

C

1/2

Streamlined,

with

Two

armholes

feed

from

same.

gauge

set

Same

from

Streamlined,

with

Two

the

and

Standard

range

Speed

CAUTION:

DESCRIPTION

needle

needle,

of

dog.

3/8

at

as

3/4

needle

needle,

two

similar

Split

to

Seam

No.16.

12

S.P.I.

33700

to

operation

gauge

8

to

of

these

Operating

plain

bearing

one

bathing

3/4

specification

Needle

A-16

1

1/2

plain

bearing

one

garment.

14,

feed,

looper

folding

inch

1/2

inches

feed,

looper

covered

No.

16.

set

at

machines

direction

OF

MACHINES

right

crankshaft

machine

suits,

attachement

fold

Type

crankshaft

Seam

and

406-EFa-1

124

except

of

right

machine

seam

specification

Needle

10

S.P.I.

is

hand

and

for

with

knee

B.

attachment

fold.

hand

and

for

on

Type

4200

of

cylinder

feed

hemming

fabric

press

(inverted).Standard

Stitch

feed

the

knitted

121 GS.

R.P.M.

machines

drive

folded

that

cylinder

can

for

range

can

drive

second

406-SSh-2.

is

outerwear

machine

mechanism.

necks

next

be

adjusted

opening

8

to

be

adjusted

machine

mechanism.

part

Stitch

clockwise.

and

to

14,

of

Needle

Check

grooves.

points

the

Lubrication

As

reservoir

Arctic

of

from

always

side

must

filled

located

beginning

of

Please

oiling

lubricated.

arrow

the

200

any

of

be

the

Lever

the

vertically

oil

Oil

to

between

with

machine,

note

by

location

The

must

has

must

C

250

UNION

the

lower

added.

oil

in

the

with

that

hand

Stud

stud

point

been

be

Heavy

seconds

SPECIAL

the

The

on

base

this

below

only

twice

of

the

is

set

upward.

upward

drained

filled

or

a

at

representation.

two

red

bed.

oil

the

plate

number

the

the

a

week.

If

should

right

needJe

correctly

On

to

from

before .starting

straight

100°

lines

the

on

the

pulley.

six

lever

machines

the

the

mineral

Fahrenheit

of

level

be

renewed

side

machines

The

drain

oil

remaining

at

holes

when

with

left

machine

the

is

the

with

plug

stud

Be

below

in

the

arrow

Serial

with

oil

marked

an

before

to

operate.

oil

with

(Spec

sure

gauge

the

once a year.

top.

The

serial

screw

mechanism

relation

stamped

No.

angle

a

83),

that

on

lower

drain

numbers

is

located

with

to

D

85891

of

45°.

shipment

Use

Gargoyle

Saybolt

which

the

oil

the

right

red

The

plug

red

colour

is

automatically

its

oil

on

the

to

the

viscosity

can

be

level

front

line,

reservoir

screw

below

on

the

need

head

D

85910

obtained

is

oil

is

is

95731;

side

Cleaning

The

machine

Important:

to

operate

bearings.

to

carry

at

the

to

operate

of

Machine

must

remove

remove

Run

machine

oil

to

the

recommended

the

machine.

be

cleaned

throat

the

bearings.

speed

plate

cover

slowly

for

thoroughly

and

clean

on

the

top

for

several

Then

five

repeat

minutes.

before

feed

of

the

minutes

oiling

oiling

dog

cylinder

Close

slots.

to

and

the

the

and

allow

run

cover

six

oil

Before

oil

the

the

machine

and

starting

all

oil

begin

holes.

wicks

Page 4

Setting

Put

in

for

Style

needles

The

long

of

one

center

groove

Needles

pair

33700

in

of

C

of

needles

size

the

the

as

front

needles

Type

specified

ends

must

124 B for

and

of

the

be

directed

Style

turn

needle

the

33700

needle

slots

towards

of

A

and

bar

the

the

Type

so

throat

operator.

121

that

GS,

the

plate.

Looper

Adjust

hand

its

advantageously

When

the

can

After

move

Height

Set

inch

point

no

as

disc.

Looper

When

rear

This

the

driving

3

and 4 on

diagram

Gauge

the

needle

extreme

adjusting

looper

be

turned

again

freely

of

the

needle

below

is

lateral

this

would

Avoid

the

of

the

adjustment

looper

lever.

17998

Needle

even

Looper

looper

to

the

right

for

the

driving

until

tightening

in

its

bar

the

looper

with

motion

impair

Notion

moves

right

of

shaft

These

the

rear

M).

so

that

looper

position.

making

looper,

lever

the

complementary

Bar

so

the

of

needle

the

after

side

When

must

looper

the

that

when

left

the

looper

the

clearance

to

the

as

looper

loosening

clamp

of

inserting

the

distance

point

Looper

this

adjustment.

hexagonal

be

has

two

screws

the

top

the

looper

side

left

close

avoid

screws

the

is

3/16

gauge

screw

loosened.

the

parts.

of

of

the

drive

between

the

as

possible

motion

the

clamp

are

cylinder.

screws

from

correct

the

the

is

lever

looper

accessible

the

inch

No.

74

Then

looper

left

moving

left

occurs

take-up

can

screws

(See

3

and 4 use

center

when

21225

and

the

distance

thread

needle's

to

needle.

point

without

be

after

oiling

of

the

looper

3/16

set

screw

looper

the

left

Please

when

plate

should

contacting.

changed

in

the

removing

and

a

cement

the

can

be

96 B on

drive

to

the

take-up

eye

is

and

note

it

is

and

pass

by

looper

threading

right

is

in

used

lever

needle.

must

3/64

its

that

turned

take-up

the

turning

avoid

screws

material.

Looper

The

looper

and

barely

.002

of

Rear

Set

its

is

make

throat

the

Stitch

Regulating

at

altered

screw.

Turning

shortens

in

to.005

the

Needle

the

most

necessary

sure

needle

Range

the

left

operating

Needle

needle

touches

left

rear

forward

that

plate.

hole

the

after

it

to

it.

Guard

inch

needle.

Guard

end

remains

needle

point

after

the

Make

in

desired

of

loosening

the

To

loosen

direction.

guard

the

guard

every

entire

sure

the

the

right

is

set

front

between

so

of

travel.

change

bottom

that

presser

number

main

the

lengthens

the

lock

correctly

of

that

the

foot.

of

shaft.

nut

the

right

the

looper

it

barely

Readjustment

of

stitch

of

the

needles

stitches

The

and

turning

the

stitch,

nut

use

when

needle

length.

presser

do

per

number

wrench

it

point

contacts

of

foot

not

contact

inch

of

the

stitch

and

No.

moves

and

a

and

the

the

For

contacts

is

stitches

turning

21388

to

the

left

space

the

needle

uniform

when

accomplished

regulating

of

rear

needles

guard

entering

can

to

the

and

turn

feeding

the

be

side

at

left

it

Page 5

Stitch

Range

(Continued)

Apply

the

has

The

has

Height

The

3/64

position.

important

All

perfect

performance

The

lift

Do

(11743)

To

feed

cylinder

driving

height

for

the

right

been

rear

been

Adjustment

feed

inch

the

proper

driving

not

try

secure

dog

is

inserting

differential

parallelism.

for

lever

wrench

hand.

made.

needle

altered.

dog

is

above

When

to

observe

of

height

lever

to

adjusting

the

remove

and

loosen

obtained,

with

Always

guard

of

set

the

setting

the

machine

of

33735

use

the

reauired

the

33735

the

plug

the

tighten

must

Feed

correctly

throat

the

the

following

parts

This

the

feed

B.

left

the

parallelism

two

plug

the

two

B

turn

tighten

screw.

left

Dog

parallelism

height

be

readjusted

when

plate

height

of

the

and

dog

feed

screws

clamp

the

the

hand

the

when

must

rocker

of

feed

clamp

and

hold

lock

the

of

instructions:

feed

is

when

screws

nut

tips

the

the

mechanism

is

be

maintained

to

be

(11742)

the

feed

setting

1

and 2 on

shaft

screws

the

carefully

each

feed

essential

22569

time

of

feed

dog

adjusted

dog.

33734

and

machine

its

dog

are

under

or

right

the

the

B

on

A.

use

the

teeth

is

it

for

only

height

rear

the

When

after

stitch

in

is

extremely

factory

trouble

all

feed

side

feed

the

a

cement

pulley

a

change

length

project

its

highest

set

free

circumstances.

on

the

rocker

of

the

of

lift

proper

material

with

to

feed

the

Looper

The

looper

It

consists

the

thread

finger

cylinder

near

The

and

moved

and

a

The

The

thread

When

the

it

before

has

Threading

Dra~

diagram

double

a

the

hole

double

thread

notch

from

entered

the

screw

vertical

the

looper

Thread

thread

eyelet

33704,

and

looper

cam

screw.

in

the

thread

control

eyelet

looper

of

being

it

has

of

17098

Take-up

of

the

thread

on

front

33758

the

slack

dropped

the

the

and

M

is

the

33758

thread

(see

33723

the

to

the

The

eyelet

returns

cam

triangle

Machine

needle

and

controlled

double

eyelet

threading

is

needle

lever

screw

side

finger

A

to

should

and

off

threads

start

cam

33723,

A

on

the

eyelet

11550

adjustably

driving

after

is

accessible

of

the

33757

33704

the

left

from

give

the

take-up

it

the

thread

of

the

operating

by a swinging

the

looper

33758

at

diagram

fastened

lever.

loosening

cylinder.

is

fixed

is

adjustable

and

left

a

slight

threads.

into

drive

B

at

the

front

17988

for

to

to

end

the

looper

control

the

machine

on a piece

double

the

M).

with

It

can

the

the

the

the

right.

of

its

tension

finger

type

thread

lever,

front

left

the

be

nut

screw

bed

up

and

travel

thread,

on

according

of

fabric.

take-up

eyelet

the

right

side

ball

turned

with

driver

and

is

down,

should

its

after

system.

thread

side

of

the

stud

radial

wrench

not

and

to

the

further

the

to

33757,

control

of

cylinder

nut

and

21388

through

adjustable.

the

right

keep

motion

needle

threading

the

Check

threads

to

the

the

tips

are

seam

chafed

of

produced

or

those

cut.

feed

by

unravelling

If

dog

they

teeth

are,

which

the

apply

stitches

are

a

too

and

triangular

sharp.

check

oil

if

stone

the

Page 6

Thread

The

tension

produce

The

looper

the

tension

Tension

on

uniform

thread

which

the

stitches

tension

is

needle

applied

threads

on

the

should

to

should

bottom

be

approximately

each

needle

only

side

be

of

the

thread.

sufficient

fabric.

one

fourth

to

of

Needle

Set

scr

ew

wire

when

the

so

the

Thread

frame

is

in

that

loop

Take-up

needle

the

the

of

middle

thread

the

thread

of

of

right

eyelet

the

the

needle

slot.

right

in

Set

is

such

the

hand

dropped

needle

a

way

needle

from

that

contacts

thread

the

the

looper.

fastening

take-up

the

wire

Page 7

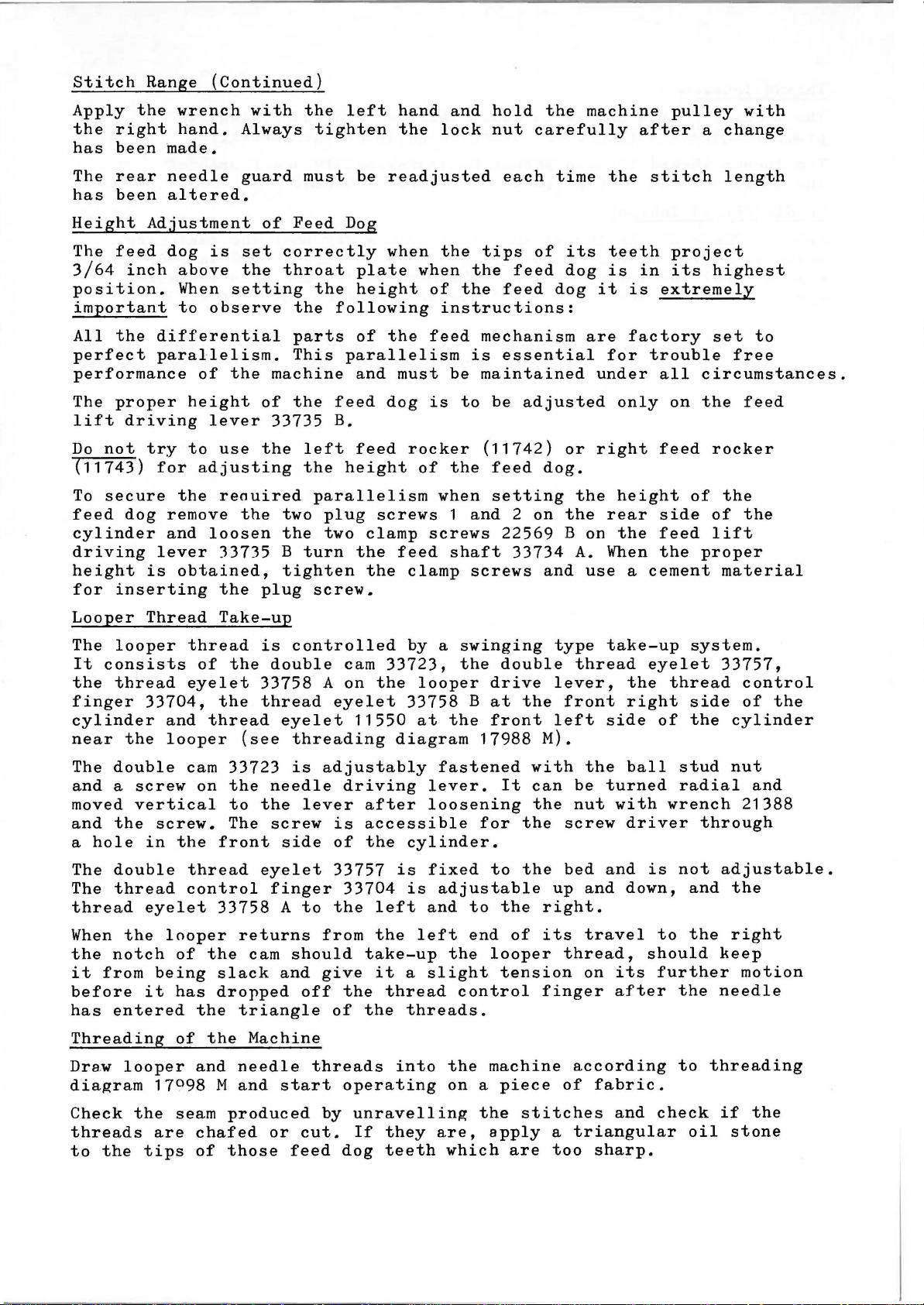

Der Nadelhebelbolzen mun

so

eingebaut sein, dan

Pfeil

nach oben

der

/...-1

_/·"'"'"

/./

/./·

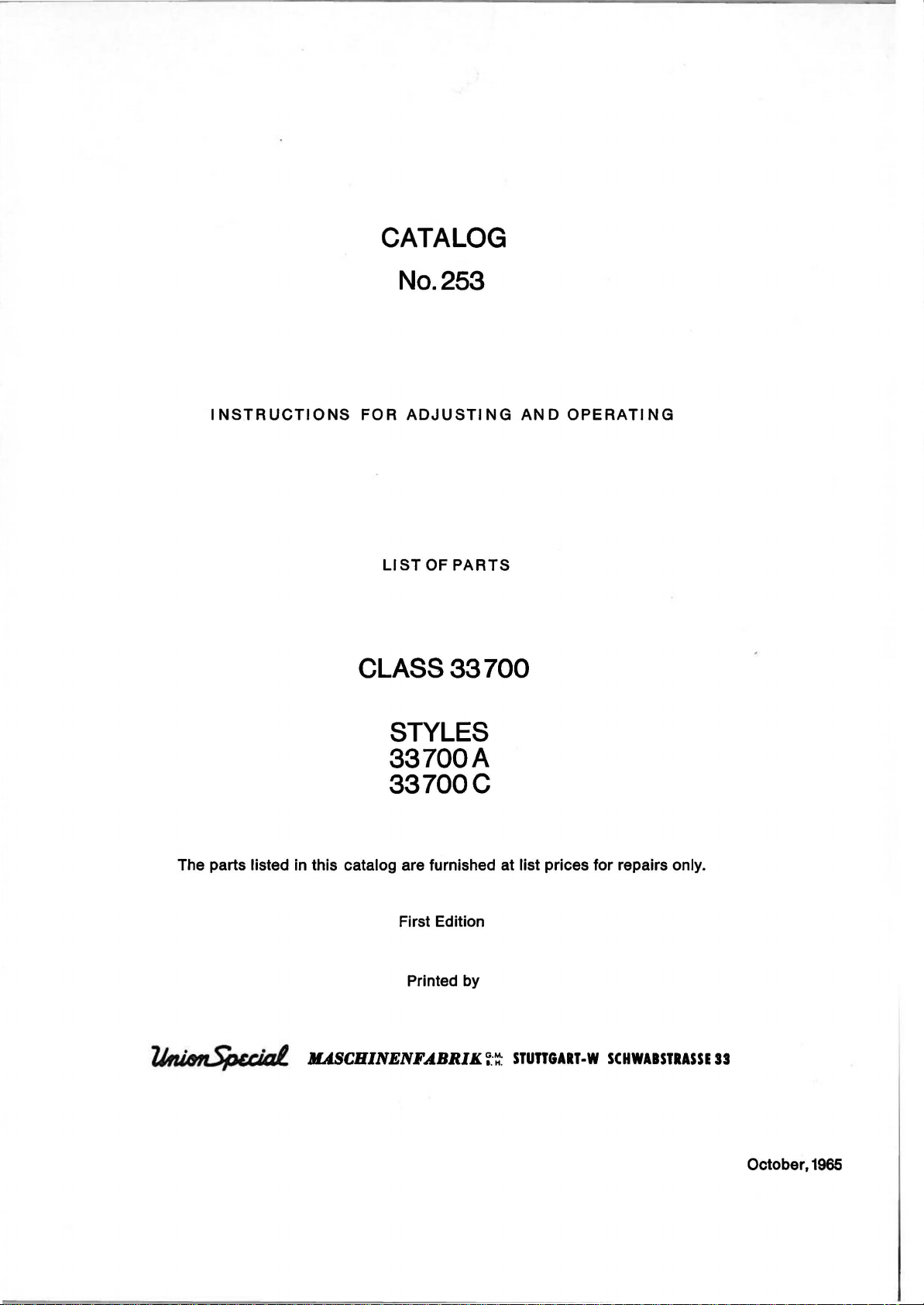

Olstellen

Woche

2x

OIL

HOLES

A WEEK.

TWICE

VIEW

IN

DIRECTION

OF

THE

ARROW

A+F

geolt

A-F

MUST BE DILEO

mussen pro

werden.

Kugeliil

SPRING

er

VAlVER

0 und F

OiliN

G 0 AKO F

Beachte:

Maschine

Vor

unbedingt

wird

lnbetriebnabme

mit

Geeignetes

Mobil

D.T..

E.

Unter.

gen

Olwechsel

CAUTION:

FILL ALL

STARTI N

DRAINED

RECOMMENDED

MOBIL

ON

NORMAL OPERATING CONDITIONS

CHANGE THE

auglas

ULspiegel

Oil

normalen Betriebsbedingun-

OIL

RESERVOIRS BEFORE

G.

MACHINE HAS BEEN

BEFORE SHIPPING.

OIL:

D.T.E.

OIL MEDIUM.

OIL

fur

mun immer zwischen

..

ohne

OL

geliefert.

Beholter

OL

fVLLen.

OL:

Medium.

1x

pro Jahr.

ONCE

A YEAR.

Hauptolbeholter.

roten Strichen sein.

Die

Olablan-Schraube

Clbeholter

befindet sich in

fur

Haupt-

der

Grundplatte unter dem Handrad.

OIL

IN

MAY

BE

LOCATED

MAIN RESERVOIR

DRAINED

IN

THE

AT

PLUG

BASE PLATE.

SCREW

OL-UND EINFADELANLEITUNG FOR MASCHINEN DER

OILING-AND

THREADING

DIAGR.AM FOR

MACHINES

KLASSE

CLASS

33

700 A

UNO

33700 A AND

C

C

~~~9-

~~:

22423

-a

Page 8

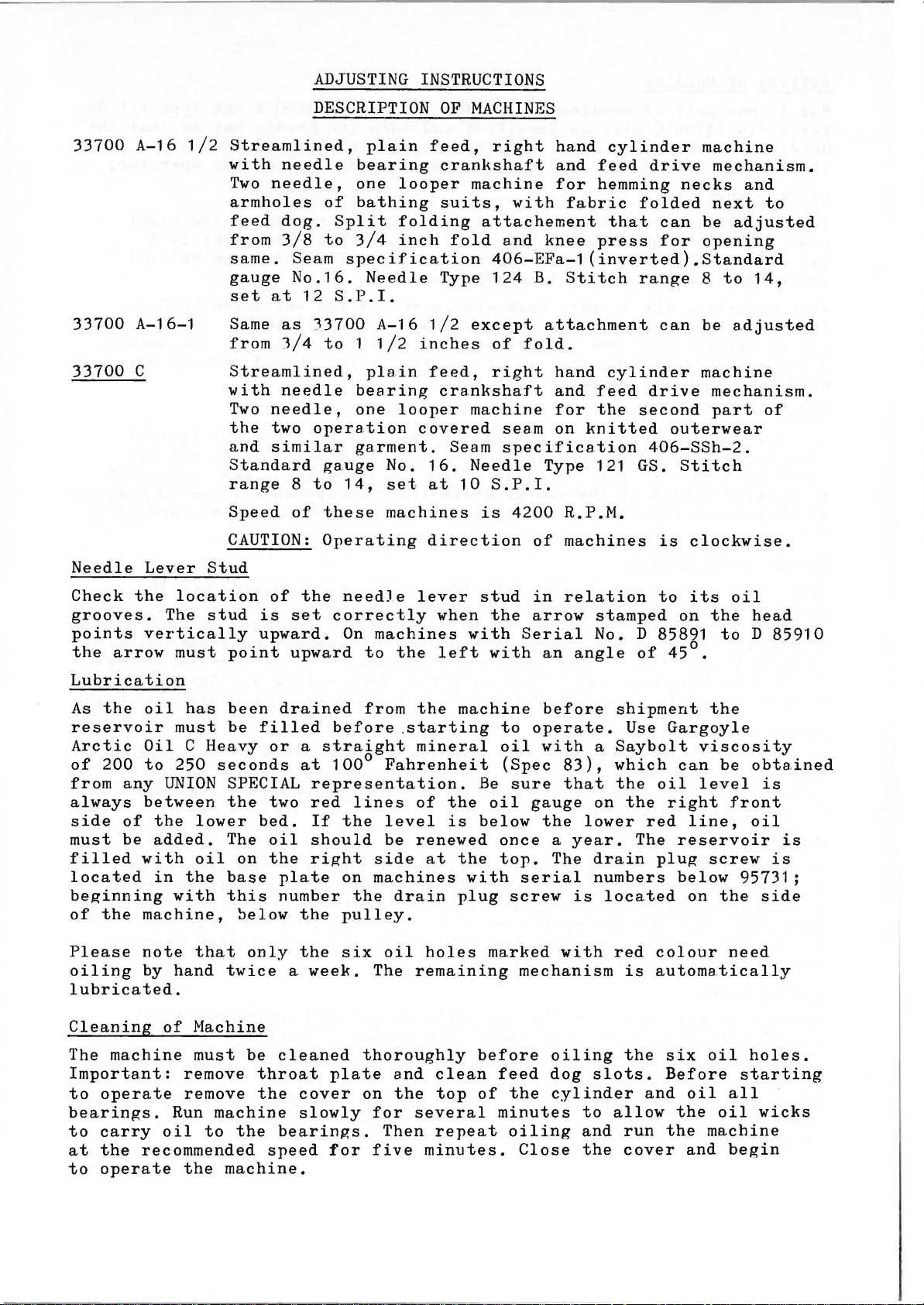

-1-

3

24

14

'

14(

/

/

24

'\------

'

~~

'

'

'

'

10~,

2

'

11~,

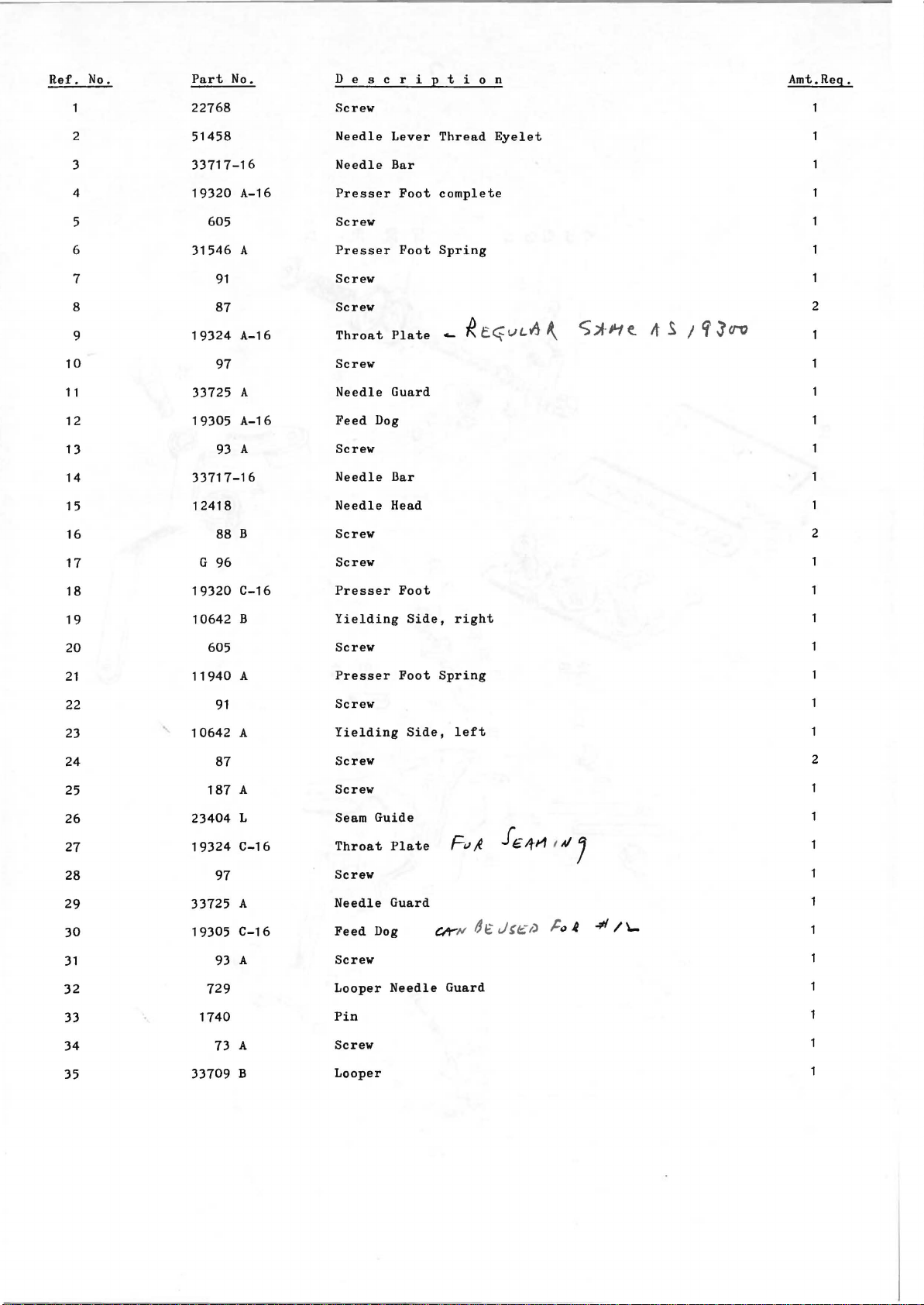

Page 9

Ref.

No.

Part

No. D e s

22768

Screw

c r

t i

o n

Amt.Reg.

i

E

10

11

12

13

14

15

16

17

2

3

4

5

6

7

8

9

51458

33717-16

19320

31546

19324

33725

19305

33717-16

12418

G

605

91

87

97

93

88

96

A-16

A

A-16

A

A-16

A

B

Needle

Needle

Presser

Screw

Presser

Screw

Screw

Throat

Screw

Needle

Feed

Screw

Needle

Needle

Screw

Screw

Dog

Lever

Bar

Foot

Foot

Plate

Guard

Bar

Head

Thread

complete

Spring

....

Eyelet

R

c~vL~

S;tJ~te.

A._

It S 1

'i

Jcro

2

2

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

19320

10642

605

11940

91

10642

87

187

23404

19324

97

33725

19305

93

729

1740

C-16

B

A

A

A

L

C-16

A

C-16

A

Presser

Yielding

Screw

Presser

Screw

Yielding

Screw

Screw

Seam

Guide

Throat

Screw

Needle

Feed

Dog

Screw

Looper

Pin

Foot

Side,

Foot

Side,

Plate

Guard

Needle

right

Spring

left

FIJ~

dt

Ck

N

Guard

f€/fM

J~f£t)

u / J

~

"

~

2

-*1\...

34 73

35

33709

A

B

Screw

Looper

Page 10

-2-

Page 11

Ref.

No.

Part

No.

D e s c r i p t i o n

Amt.Req.

2

3

4

6

7

10

11

1 2

13

14

1 5

1 6

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

12

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

22768

51458 A

J 87 J

33759

57

57

57

WB

we

WD

A

5

8

9

51458

22768

22889

539

20

22848

22849

A

33704

33757

22766

33723

22849

33658

A

A

33758

33758

c

22768

33758

33758

73

A

A

B

77 p

33792

G

50-153

G

1346

D

51959 B

51959

c

51959 D

33760

c

23388 L

90968

51292 c

51292

51292

F-2

F-8

109

51292 G

51292 A

51292 D

51491

c

43266

668-25

668-28

52892

21657-3

Screw

Needle

Bar

Screw

Nipper

Nipper

Nipper

Spring

Spring

Tension

Shoulder

Needle

Lever

Screw

Adapter

Frame

Needle

Washer

Screw

Screw

Looper

Looper

Thread

Thread

Screw

Looper

Thread

Screw

Looper

Thread

Thread

Channel

Cylinder

Screw

Looper

Thread

Screw

Looper

Thread

Screw

Spacing

Pin

Thread

Thread

Thread

Thread

Lifter

Nipper

Nipper

Nipper

Nipper

for

Torsion

Screw

(Class

Tension

Tension

Tens1on

Tension

Tension

Tension

Tension

Lead -in

Nut

Eyelet

Locking

Tension

Tension

Thread

Screw

Screw

Looper

Stud

Hemming

Spring

Nut

Spring

Spring

Disc

Post

Post

Thread

Thread

Ring

Post

Disc

Eyelet

Base

Plate

Spring

Thread

Thread

Pull-off

Guide

Take-up

Guide

Guide

Thread

Guide

Guide

Tension

Disc

Spring

Nut

Attachement

(Class

33700

A)

(Looper)

(Needle)

Ferrule

Eyelet

Guide

Support

Separator

Eyelet

Eyelet

Eyelet

Post

33700

A)

(Class

33700

2

2

2

2

A)

3

2

6

3

3

3

3

1

6

6

Page 12

~

-~-

/~

/ _ _ _

-

-------

Houp

tw.

Bu

MAIN SHAFT BUSHI

---"I

__

)!

53

-

(1")

ch~

e

lin

ks.

NG,

LEFT

F1

tl

I

v

52

1L.

15

16

17

J

">

">

I

I

w

n

--r::·., ..

-+-

---

2o

I

11

.: ' •

I

=

~~

(~~ablaOschraubo)

ORA

IN

PLUG

SCREW

25

(

5.)

26

~~

-

,

Page 13

Ref.

10

11

12

13

14

15

16

17

18

1 9

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

Part

51256

51254

22586

51250

51250

660-212

51250

51150

719

719

90

33782

660-207

666-170

52883

660-212

21657

99274

22569

33791

33790

41394

999-4

22733

90939

33742

22580

22539

666-121

22580

15430

999-2

999-19

999-1

50-506

15430

w

97

22539

33790

33794

HA

73

33742

33742

33794

33794

33790

73

96300

33794

22562

22585

80699

51254

33755

80273

No.

N

c

R

F

D

A

AE

R

X

B

A

A

B

II

c

L

L

c

c

c

B

E

c

A

B

c

B

A

D

A

D e s c r i p t i o n

Presser

Needle

Screw

Gasket

Washer

Oil

Bushing

Needle

Screw

Screw

Screw

Needle

Oil

Felt

Foot

Oil

Tension

Screw

Screw

Crankshaft

Bushing

Gasket

Felt

Plug

Screw

Looper

Screw

Plug

Oil

Screw

Felt

Gasket

Felt

Retaining

Oil

Felt

Wick-Yarn

Plug

Main

Oil

Screw

Bushing,rear

Bushing,front

Oil

Oil

Crankshaft

Screw

Split

Oil

Screw

Screw

Dowel

Needle

Presser

Presser

Spring

Bar

Seal

Ring

Lever

Lever

Seal

Ring

Wick

Lifter

Seal

Ring

Release

Oil

Wick

Screw

Drive

Screw

Wick

Wick

Ring

Set

Wick

Screw

Shaft

Tube

Tube

Channel

Pin

Tube

Pin

Bar

Bar

Foot

Bushing

Shaft

Bearing

Lever

Bearing

Lever

Ring

llushing

Bushing

Bushing

Bushing

Guide

Regulating

Stop

Bushing

Lever

Housing

Shaft

left

middle

Lower

Bar

Oiler

Shaft

Lower

Bushing

Stud

Collar

Amt.Req.

1

Bushing

4

3

2

5

2

No.

2

3

4

5

6

7

8

9

G

G

Page 14

~

~

---

11

12

(C

omp

l.l

1

3

\

{~)

~--

~

£·

~~

~~~

-:_---

13

14

5

15

.t---

1

43

~~

32

~~

i2

(h)

OJ)

G)rffij

18

19

Page 15

No.

Ref

.

2

3

4

5

6

7

8

9

10

12 52882

13

14

1 5

16

17

18

19

20

21

22

23 22849

24

25 22766

26 525

27 523

28 524

29

30

31

32 33785

33

34

35

36

37

38

39

40

41

42

43

44 61321

45

Part

No. D e s c r i

33782

22569

33782

33782

A

AE

90

52882

AA

50-789

52882

39582

22541

AC

L

B

AD

90

52882

33782

33782

51190

G

33782

99273

33757

33782

33782

33785

p

y

B

D

50-434

K

A

A

G

F

c

22564

33785

A

B

G

353

357

97

352

96851

660-202

311

21

A

31175

22894

B

G

22581

61321

J

L

22574

Head

Cover

Screw

Gasket

Needle

Lever

Screw

Oil

Drip

Pin

Spring

Oil

Cap

Screw

Crank

Chamber

Screw

Gasket

Baffle

Plate

Gasket

Gasket

Oil

Sight

Gasket

Screw

Gasket

Gasket

Screw

Oil

Reservoir

Screw

Cylinder

Cylinder

Spring

Cylinder

Screw

Spring

Cylinder

Hinge

Spring

Screw

Screw

End

Cap

Pin

Oil

Ring

Pulley

Belt

Guard

Screw

Screw

Handwheel

Washer

Screw

Plate

Gauge

Cover

Cover

Cover

End

Hinge

t

i

E

Bearing

Cover

Cover

Bolt

Bolt

Cap

o n

Plate

Knob

Amt.Req.

5

Oiler

2

1

3

2

4

1

1

5

2

2

3

Page 16

-5-

N

c.o

~~~e~

Page 17

Ref.

2

3

4

5

6

7

8

9

10

11

1 2

13

14

1 5

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

No.

Part

33783 H

660-207

402

22596

21657

318

33783

33783

33783

21657

21657

51216

51

216

29066

51216 p

51216

22559

33716

G

29348

33715

51250

22768

51458

666-149

51054

51254

22562

33755

51257

33783

G

52888

22562

53783

22758

53783

33783

G

22557

51256

33783

77

54

78

88

402

No.

y

N

T

u

X

w

K

L

R

N

G

G

c

D

F.

H

A

K

B

A

c

L

s

B

c

M

D e s c r i

Seal

Stud

Pin

Foot

Ring

Lever

Lever

Spring

Release

Release

Lever

Lever

Lever

Lever

Lever

Lever

Lever

Lever

Bar

Foot

Bar

Bar

Bar

Lever

Lever

Lever

Spring

Lever

Presser

Oil

Screw

Screw

Connection

Screw

Lifter

Lifter

Return

Tension

Tension

Needle

Ball

Needle

Nut

Washer

Screw

Needle

Needle

Needle

Needle

Screw

Screw

Needle

LUbricating

Link

Needle

Screw

Needle

Screw

Presser

Presser

Presser

Screw

Shoulder

Presser

Screw

Lifter

Screw

Lifter

Lifter

Shoulder

Presser

Lifter

l! t i o n

Lifter

Link

internal

Return

Holder

Conn.Rod

Connecting

Connecting

Asserr.bly

Stud

Thread

Felt

Link

Connection

Guide

Connection

Screw

Stop

Link

Bell

Bell

Screw

Connecting

Lever

Lever

Bar

Collar

Crank

Crank

Lever

Spring

Shaft

Shaft

Bearing

Eyelet

Rod

Rod

Spring

Rod

Bushing

upper

Ball

Joint

Assembly

Amt.Rcq.

upper

2

2

2

2

2

2

1

1

Page 18

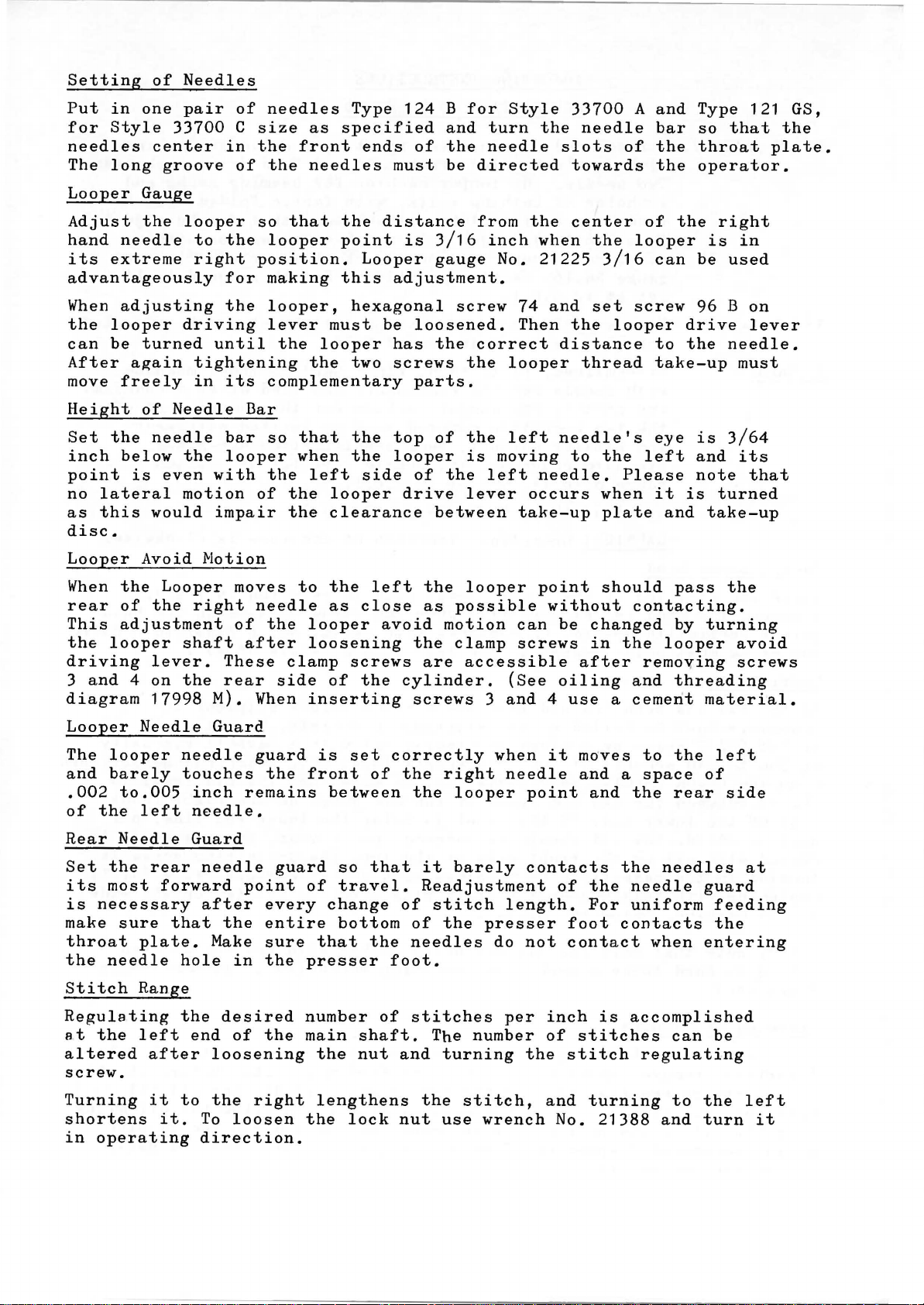

Oil-Wick

Oldocht.

----------..

96

----------------

95

------

94----~

+~'b

(Compl.)

Oil-Wick

o~f~

~~~©

88~

'-.,-'

87

!Compl.J

j

-:::::::::----\

\

78

r;

6

f

1

(Compl.

l

'

~

~

0

,

e _

.

---.---

\

r f (

i i ! " • i

71

__...-

(eom,u

fir"

...--

. . .,. I ,

.

70

---

----·-----·

~

18

~

Ill

jJ

, I

!Compl.l

7

-~

[f"

'

~

I,,, t

d

~I

~~~~.

~~¥,

L

23

~

.

DiJ~!

--

29

l L

•

r,

l:

~~J-~fiiiiiii';;r...;

J__.--y

32

··-

55

(Compl.l

~~

1'i-~;;r-~~~~~e~-->------~;.;-

~~:;;;;;;~;;:;;;.~~~65

tJ'

'';,1

lf

1

73

n I ' $

_k~

w-ss I

-~"

sa-&'--"

---·

------------------

' . " I\

·

__J

------

53~

51

~49

1

('

)'5

/

{.®~~

@_

·

~

i

,,.

~

~

\\' \\

__

48

/

~-38

""'

®----39

40

\,;

47

1.6

\

'

~43

'~

~43

en

I

Page 19

Ref,

10

14

15

33

34

35

36

37

38

40

41

42

43

44

45

46

47

48

49

50

51

52

53

56

57

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

11

12

13

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

39

54

55

58

No.

1

2

3

4

5

6

7

8

9

Part

No,

G 29476 H

33706

33735 c

22894 D

p

1-18

666-82

G 29476

33714 A

33745

22894 D

22894 D

666-82

p

1-18

51236 A

666-149

51236 A

666-149

33735 B

22569 B

HA

73

33744 B

HA

73

22569 B

G 29476

GA

B

B

T

33722 E

51216 M

J

51216

G 22559 C

33743

33743 B

97

A

33766

22894

X

33743 A

80175

33742 G

39243 H

51242 M

18

89

99280

33742 H

22580

33742 A

96

B

22829 A

12538

E

21657

74 A

33737 A

33736

33739 A

22562

A

36

G 29163 A

33733

1096

11513

22565

88

c

33744

12982

77

A

33744

J 80 K

82

304

77A

17

33722

33745 A

33745 B

999-50

33745

A-1

61434 G

18

305 A

11743

98

88

33734

A

33734

22706 A

11742

98

22580

33734 B

80090 E

c

12964

HA

1286 B

33734

B-1

33734 c

80090

E

12964

1286 B

33734

c

C-1

HA

D e s c r i p t i o n

Feed

Drive

Drive

Wick

Avoid

Avoid

Eccentric

Connecting

Eccentric

Sleeve

Connecting

Eccentric

Feed

Screw

Pin

Felt

Looper

Eccentric

Looper

Screw

Screw

Pelt

Wick

Pin

Link

Pin

Oil

Wick

Link

Pin

Oil

Wick

Feed

Drive

Lever

Screw

Screw

Looper

Avoid

Drive

Lever

Screw

Screw

Crankshaft

Crankshaft

Needle

Connecting

Screw

Looper

Ball

Bearing

Lever

Stud

and

Rod

Bearing

Needle

Roller

Bearing,

Screw

Stop

Collar

Screw

Guide

Pork

Screw

Looper

Locking

Washer

Nut

Screw

Screw

Looper

Screw

Looper

Drive

Stud

Drive

Drive

Lever

Lever

Lever

Shaft

intermediate

Screw

Screw

Nut

Washer

Screw

Looper

Ball

Ball

Screw

Ball

Looper

Looper

Adjusting

Looper

Screw

Screw

Locking

Lever

Washer

Stud,

Stud,

Rocker

Rocker

Rocker

Washer

Connecting

right

left

Assembly

Cone

Screw

Nut

Screw

Looper

Locking

Stitch

Feed

Screw

Peed

Main

Peed

Bushing

Needle

Feed

Washer

Nut

Eccentric

Peed

Screw

Screw

Peed

Peed

Screw

Peed

Shaft

Screw

Regulating

Crank

Crank

Shaft

Crank

Bearing

Drive

Stud

Rocker,

Bar

Rocker

Rocker,

Stud

Stud

Link

Link

right

Shaft

left

Screw

Cap

Assembly

Screw

Screw

Feed

Bar

Plug

Ball

Spring

Feed

Peed

Plug

Screw

Bar

Bar

Screw

Driving

Driving

Driving

Stud,

Stud

Stud,

Ball

Spring

Feed

Bar

Driving

Stud

and

Link

Link

and

Link

Bearing

lower

Rod,

right

left

Assembly

Link

Assembly

compl.

Assembly

Amt.Req.

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

2

1

1

1

2

1

1

28

1

2

1

1

2

1

2

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

4

2

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

Page 20

-7-

Page 21

Ref.

No.

Part

No. D e s c r i

:2

t i o n

Amt.Reg.

2

3

4

5

6

7

8

9

10

11

12

13

14

15

23389

23)88

90

23389

187

22524

23388

23388

605

23388

23389

531

12934

22514

240

23388

Attachment,

c Hemmer

Screw

B

A

D

E

F

A Hemmer

A Nut

J

Hemmer

Screw

Screw

Hemmer

Hemmer

Screw

Hemmer

Screw

Screw

Link

Folder

Scroll,

Tongue,

Sliding

Edge

Scroll

Base

Stud

Rod

complete

adjustable

adjustable

Block

Guide

Rod

(Ref.No.1-12)

2

2

2

2

2

2

16

17

23388

25

K

cc

Folder

Screw

Rod

Extension

2

Page 22

-8-

AUSROCKHEBEL

LIFTER

FOR KNEE PRESS-OPERATION

FOR

-----

- ·

-·

-·

-·

FOR

APPARAT

SPLIT TUBE HEMMING ATTACHEMENT

__

.-4.~

~

/ '

_

...

/ - -

~

.'\

------

/ .---

./

~

--.::.

.-.----.---

23389

~~-

L 1

I

""~~--~~

I

FOR

FOR

-r-

~

KNIEHEBELBETATIGUNG

CLASS

-

i 1

~-

-~

I I

..

/

·:-.,

,,

_ _u

23389

33700

A

2

-·~

---

·

3

21691

Kniehebel kompl.

Knee

Lever

compl.

I i

I i

J...i-

h

-1

12

7

9

Zchg.

18

.8.

65

Nr.

22413-0

Page 23

Ref.

No.

Part

No.

D e s c r i p t i

o n

Amt.Req.

2

3

4

10

11

12

1 3

Lever

21691

33760

c

421

D-10

21679

28505

5

6

7

8

9

660-128

98

9271

69

21665

21677

21664

21661

21662

FD

Knee

Folder

Knee

Chain

Chain

Chain

Screw

Collar

Set

Chain

Plate

Knee

Knee

h.nee

Press

Screw

Operating

Rod

Spring

Rod

Rod

Spring

Rod

Rod

Press

Press

Press

compl.

Chain

and

Plate

Plate

Jracket

Bracket

Lever

Screw

Connection

Shaft

Eye

2

2

5

2

Page 24

~

---

--

-

-9-

E'

m

M

N

N

.ci

:Zz

•

01

UIC

01

"-

.c.~

uo

NL.

0

z

0

I

a..

(J)

U")

.....

z

0

I

a..

(J)

--'

:o

Page 25

Ref.

No.

Part

No.

D e s c r i p t i o n

Amt.Reg.

53394

2 53394

3

G

4

5

6

7

8

9

1 0

11

1 2

13

14

15

50-520

G

50-521

666-209

666-201

21212

51294

31194

43443

31194

666-214

31194

75

87

p

R

N

Q

u

A

B

Oil

Siphon

Oil

Siphon

Screw

Oil

Tube

Siphon

Siphon

Felt

Oil

Siphon

Oil

Tube

Oil

Siphon

Nut

Screw

Oil

Tube Clamp

Felt

Felt

Cup

Plug

Connection

Lint

Assembly

Clamp

Disc,

Connection

Tube

Filter

felt

Locki

ng

Page 26

-10-

~

30

Page 27

Ref.

No.

Part

No.

D e s c r i p t i o n

Amt.Req.

10

11

1 2

13

14

1 5

16

H-4

21101

2

3

4

5

6

7

8

9

21114

21114 M

21114 L

21114

21114 w

21104 v

21114

S-4

258

A

652-16

H-4

21114 L

21114

M

22651 CD-4

21104

B-24

21114

D-4

22651 CD-5

Thread

Thread

Eyelet

Eyelet

Nut

Washer

Spool

Spool

Pad,

Thread

Eyelet

Eyelet

Screw

Thread

Thread

Screw

Stand,

Stand

Locking

Seat

Pin

for

Stand

Locking

Stand

Stand

Disc

thread

Eyelet

Rod

complete

Lead

Eyelet

Ring

Ring

Seat

4

4

8

4

4

4

4

Support

8

8

2

2

17

18

19

20

21

22

23

24

25

26

27

28

29

30

21104 H

652-16

21114 u

21114 T

22651

CD-4

22810

21114 A

22651 CD-3

21201

660-240

21388

21388

421

AE

D-38

21388 w

Nut

Washer

Split

Lead

Socket

Eyelet

Screw

Screw

Thread

Stand

Screw

Screw

over-all

Driver,

7

Tweezers

Wrench,single

Wrench

Treadle

Wrench,

9/32

Chain

curved

Socket

Base

9/64

5/8

end,

inch

Ball

inch

inches

3/8

socket

double

round

inch

with

end,

blade

opening

extension

9/32

inch

2

2

2

length

opening

Page 28

Part

No.

17

•....•..•••

18

..•••.•••••

PI

18

••...•..•••

20

•••.•.•.•.•

25

cc

36 A

....•..••

G

50-153

G

50-434

G

50-506

50-520

G

G 50-521

50-789

54

•.........•

57

WB

57

we

57

WD

69

FD

73 A

•••••••••

HA

73 B

•.......•

73 c

.........

74

A

•••••••••

75

•.•••••...•

77

••••••...••

77

A

•••••••••

77 P •••••••••

78

...•.•....•

J 80 K

J 87 K

G 96

w

82

87

87 u

88

88

89

90

91

93A

96 B

97

97

98

109

•••••••••

•...•.....•

•....•...•.

.........

•••••••••

•••••..••••

B

•••••••••

........•..

••..•.••..•

.••••••.•••

..••.••••

•••••••••

•••••.•••.•

••••.....••

•.••••••.••

••.•.•.••••

•..••••••••

187 A •••••....

240

•••••.•••••

258 A •.•••••••

304

•.•.•••••.•

305 A

..•••••.•

•••••...•.•

318

•...•..••.•

352

G 353

•••••.•...•

........

•...•.•

•......

••...••

.....••

......•

•...•.•

••••••••

••••••••

••••••••

••••••••

6

6

6

2

7

6

2

4

3

9

9

4

5

2

2

2

8

1,2

3,6

3

6

9

5

6

2

5

6

6

1

9

2

5

,6

1

6

3,4

1

1,6

6

1

1,4

3

6,8

2

1,7

7

1 0

6

6

5

4

4

'7

Part

No.

357

•••.••.••••

402

..•.••....•

G 402

•••..•...••

D-1

421

421

D-38

523

••.•......•

•.•......••

524

525

•...•.....•

531

•..•......•

539

...........

605

..•....•.•.

652-16

........

660-128

660-202

660-207

660-212

660-240

666-82

•...••••

666-121.

666-149

666-170

666-201

666-209

666-214

668-25

668-28

719

729

999-1

999-2

999-4

999-19

999-50

1096

HA

1286

G

1346 D ••..•••••

1740

9271

•.••..••

...••.••

.•...•••...

•..•..•••..

.•...•.•.

.•...••••

••......•

....•.••

.•..•.••

.....•.••.•

B

•........

•..••.•••••

••••••..•••

10642 A •.••••..•

10642

11513

11742

11743

B

•••••••••

•••.•••••••

•..••••••••

••.•.••••••

11940 A •••.•••••

12418

.•.••••••••

••.•••.••••

1 2538

12934 A •..••••••

12964 c .•.••••••

12982

••..•...•••

15430

15430

G

1

........•

1

........•

0

••••••

.•.•••

...••..

•..•.•.

•..•••.

.••••••

..•••••

......

•••.•••

•....••

•••.•••

•.••.••

.••••••

NUMERICAL

4

5

5

8

1 0

4

4

4

7

2

1

'7

10

8

4

3,5

3

10

6

3

5,6

3

9

9

9

2

2

3

1

3

3

3

3

3

6

6

2,3

1

8

1

1

6

6

6

1

1

6

7

6

6

3

3

INDEX

OF

Part

19305

19305

19320

19320

19324

19324

PARTS.

No.

A-16

C-16

A-16

C-16

A-16

C-16

21101 H-4

21104

21104 H ..•..•..

211

04

v

21114

..••.....•

21114 A

21114 D-4

21114 H-4

21114 1

21114 M

21114

21114 T ........

21114 u

21114

21

21212

21388

201

w

•.••..••••

•.•••..•••

•...••.•.•

21388 w

21388

AE

21657-3

21657-E

21657

2t657

w

x

21657 y

.•....•.••

21661

•••••...••

21662

21664

•..•...•••

21665

..•••....•

21677

•••.•..•.•

21679

•..•.....•

21691

••.••.•.••

22514

•..••..•••

22524

•••.••.•.•

22539

22541

22557 B ••.•••••

G

c

B

22559 G

G

22559 C ........

22562

••••••••••

22562 A

22564

•••••.••••

22565

•••••.•.••

22569

•.••••.•••

22569 B ••...•••

22574

••.•••••••

••••.

.••..

••..•

.....

.....

....•

..•..•

B-24

....•

........

..••....

......

•.....

........

••••••••

S-4

•....•

........

........

........

.......

..••..•.

.......•

........

........

••••••••

........

........

........

........

1

1

1

1

1

1

10

10

10

1 0

10

10

10

10

10

1 0

10

10

10

1o

1 0

9

10

to

to

2

6

5

3,5

5

8

8

8

8

8

8

8

7

7

3

4

5

5

6

3,5,6

5

4

6

4

3,6

4

Part

No,

22580

..........

22581

...•.•..••

22585

..........

22586 R .......•

22596

..........

22651

CD-3

CD-4

22651

22651

CD-5

22706

A

B

22733

22758

c

22766

..........

22768

..........

22810

..........

22829 A .......•

22848

•........•

22849

........••

22849 A ......••

22889 A

22894 D

22894 G

x

22894

23388

c

23388 D

23388

E

23388

F

23388

J

........

23388

23388

23389

K

........

1

........

..•.......

23389 A •.......

23389

23404 L

28505

G 29163 A

G 29348

G 29476

G

29476 H ....•...

G

29476 T ...•....

31121 A

31175 B

31194

B

••.......•

29066 R

c

GA

•...•.....

••••••••

........

........

•...•..•

........

........

•••....•

31194 A ..•..••.

31194 B .•....•.

31546 A ..••...•

33658 A •.•.•.••

33704

•..••....•

3~706

.••...••••

33709 B ........

33714 A ••.••..•

•....

.....

.....

••••••••

........

........

•......•

•.....••

•......•

.......•

........

•......•

........

••••••••

......•

3,6

4

3

3

5

1 0

1 0

1 0

6

3

5

2,4

1

10

6

2

4

2

2

6

4

6

7

7

7

7

7

7

2

7

7

7

1

8

5

6

5

6

6

6

4

4

9

9

9

1

2

2

6

1

6

,2

,5

Page 29

Part

No.

Part

No.

NUMERICAL

INDEX

Part

OF

PARTS.

No.

Part

No.

33715 D

33716 G

33717-16

33722

..........

33722 E

33723

...••.•..•

33725 A

••...•••••

33733

••.•.•.•••

33734

33734 A

33734 B

33734

33734

33734

33735 B

33735

33736

33737 A

33739 A

33742 A

33742

33742 E

33742 G

33742 H

33743

33743 A

33743 B

33744

33744 B

33744

33745

33745 A

33745

33745 B

33755

33755 A

B-1

c

C-1

c

••..••...•

c

..••.....•

••.••.••••

c

•..•••••.•

A-1

•..•••••••

...•..••

.......•

••.•..•

••••...•

.••.•.••

...•...•

.•••.•.•

••...•

.......•

•.•..•

...•...•

........

•••.•..•

•.....••

•....•.•

........

..•....•

....•..•

...•...•

...•...•

••••••.•

•.•.••••

........

•••.••••

••••.•

•.•.••••

••.•.•.•

5

5

1

6

6

2

1

6

6

6

6

6

6

6

6

6

6

6

6

6

3

3

6

3,6

6

6

6

6

6

6

6

6

6

6

5

3

••.•••.••.

33757

33757 A

33758

•...••.•••

33758 A

33758 B

33758

33759

33760 c

33766

33782

33782 A

33782 B

33782 F

33782 G

33782 K

33782

33782

33783

33783 H

33783 M

33783 N

33783 8

33783

33783

33785

33785

33785

33790 A

33790 B

33790 c

33791

33792

33794

33794 A

33794 B

33794

c

•.••.••.••

••••••..••

••••••••••

Y

AE

.•.•....•.

T

u

A

B

c

•.•..•••••

••••••••••

••.•••••••

c

•.•....•

..•..•••

.•.•.•.•

.......•

........

.••.••••

•••..•••

•.•.•.••

•••.••••

.....•••

•.....•.

.....••

......••

•......•

..•...••

.......•

•......•

........

•......•

•..••.••

........

..•...••

.••.••••

........

.••.•.••

•..•....

........

2

4

2

2

2

2

2

2,8

6

4

4

4

4

4

4

4

3,4

5

5

5

5

5

5

5

4

4

4

3

3

3

3

2

3

3

3

3

39243 H

39582

41394 A

43266

..•.....••

43443

51054

••••••..••

51150

•.•...••••

51190

51216

51216 K

51216 L

51216

51216

51216

51236 A

51242

51250 A

51250 D

51250 E

51250 F

51254

51254 D

51254 H

51256

51256 N

51257 K

51292 A

51292

c

51292 D

F-2

51292

51292

F-8

51292 G

51294 N

51458

•.•....•.•

51458 A

51491

c

•..•.•••

1

.......•

•....•••

Q

•.••..••

D

••.•..••

J

.......•

•..•••••

•..•.•••

•••.••••

M

.•..•..•

N

p

••••••••

•.•.•..•

•.....••

M

••.•....

...•.•••

..•.•.••

•.....••

c

........

........

........

c

........

•.....••

.•.....•

.......•

........

•.•...••

•..•••

.•..••

..•••..•

•.•.••.•

•.•.....

........

6

4

3

2

9

5

3

4

6

5

5

6

5

5

6

6

3

3

5

3

3

3

5

5

3

5

2

2

2

2

2

2

9

1

2

2

,2,5

51959 B

51959

51

959 D

52882

52882

52882

52882

52883 R

52888 B

52892

••.••..•••

53394

53394 R

53783 A

53783

61321

61321 L

61434 G

80090 E

80175

••......••

80273

.•....•...

80699 A

90939

••.......•

90968

.........•

96300

.........•

96851

••........

99273 A

99274

..••.....•

99280

.........•

.......•

c

........

......••

AA

•..••.•

AD

••.•..•

AC

••....•

P

••.•.•••

.•.••..•

••••..••

P

•••..•••

.......•

•.......

1

........

J

•......•

•.......

...•.•.•

•....•.•

••......

.......•

2

2

2

4

4

4

4

3

5

2

9

9

5

5

4

4

6

6

6

3

3

3

2

3

4

4

3

6

Loading...

Loading...