Page 1

V/ni(m5p€cial.

INEST

STYLE

2800

OUALITY

:

E-2

j

■

■

■ ■ ■

AUTOMATED

SYSTEMS

INSTRUCTIONS

AND

PARTS

FOR

No.

501A

1

Ij/rWQTlSpCCicdL

TROUSER

400

N.

FLY

FRANKLIN

SEWING

ST.,

CHICAGO,

LIST

STATION

CORPORATION

ILL.

60610

Page 2

This

technical

needed

and

so

The

functions

to

the

no

figure

electrical

malfunctions.

An

INDEX

shoot a particular

Station

nearly

matches

TROUBLESHOOTING

Each

STEP*

outlines

action

to

are

to

be

scribe

how

next

and

manual

has

do a particular

illustrations

numbers

in

OF

refer

the

be

taken.

to

how

are

never

or

references

portion

the

of

2800

the

E-2

MALFUNCTIONS

problem.

to

the

INDEX

the

problem.

section,

troubleshooting

entire

troubleshooting

taken,

and

the

Each

perform

to

bubble

that

interpret

FOREWORD

been

prepared

job

in

illustrated,

referenced

are

in

the

easy

in

the

needed.

to

text - The

TROUBLESHOOTING

Trouser

action.

the

Fly

Sewing

is

provided

To

use

the

manual

OF

MALFUNCTIONS

The

INDEX

and

gives

procedure

OF

the

page

is

presented

procedure.

arrangement

also

results

of

the

has a code

The

flow

lines

of

the

action

Station,

to

Each

bubbles

letter

STEP*

MALFUNCTIONS

leading

format.

follow

steps.

illustration

section

and

allow

you

to

troubleshoot

and

number

in a logic

"bubble"

in

which

out

just

taken.

The

No

provides

to

determine

to

refer

locate

on

which

sequence

of

the

the

chart

keys

it

of

each

fi^re

is

the

to

a

the

lists

each

flow

shows

to a series

bubble

procedures

numbers

always

information

"probable

the

malfunctioning

malfunction

the

procedure

flowchart,

provide

next

procedure

the

are

used

to

in

the

text

needed

failures"

to

causing

needed

Trouser

description

malfunctions

begins.

or

chart

contains a statement

the

order

of

illustrated

show

which

covered

"bubble

in

chart"

which

these

steps

action

information

this

format,

it

supports,

define

mal

such

to

trouble-

Fly

Sewing

that

most

in

the

which

of

an

actions

which

to

de

perform

SIMPLIFIED

TECHMQVES

'

EMPHASIZING

PERFORMANCE

570

Seventh

Developed

IT/

Avenue,

(NDUSmiAl

TCACKWe

CORPORATION

New

FOR

by

SYSTEMS

York,

New

York

CORPORATION

10018

Page 3

Catalog

INSTRUCTIONS

No.

FOR

501

A

LEFT

ADJUSTING

TROUSER

FIRST

AND

FLY

2800

EDITION

OPERATING

SEWING

E-2

STATION

Copyright

1973

By

May,

Union

Rights

1973

Special

Corporation

Chicago,

Resen/ed

Printed

in

in

III.

All

Countries

U.S.A.

Page 4

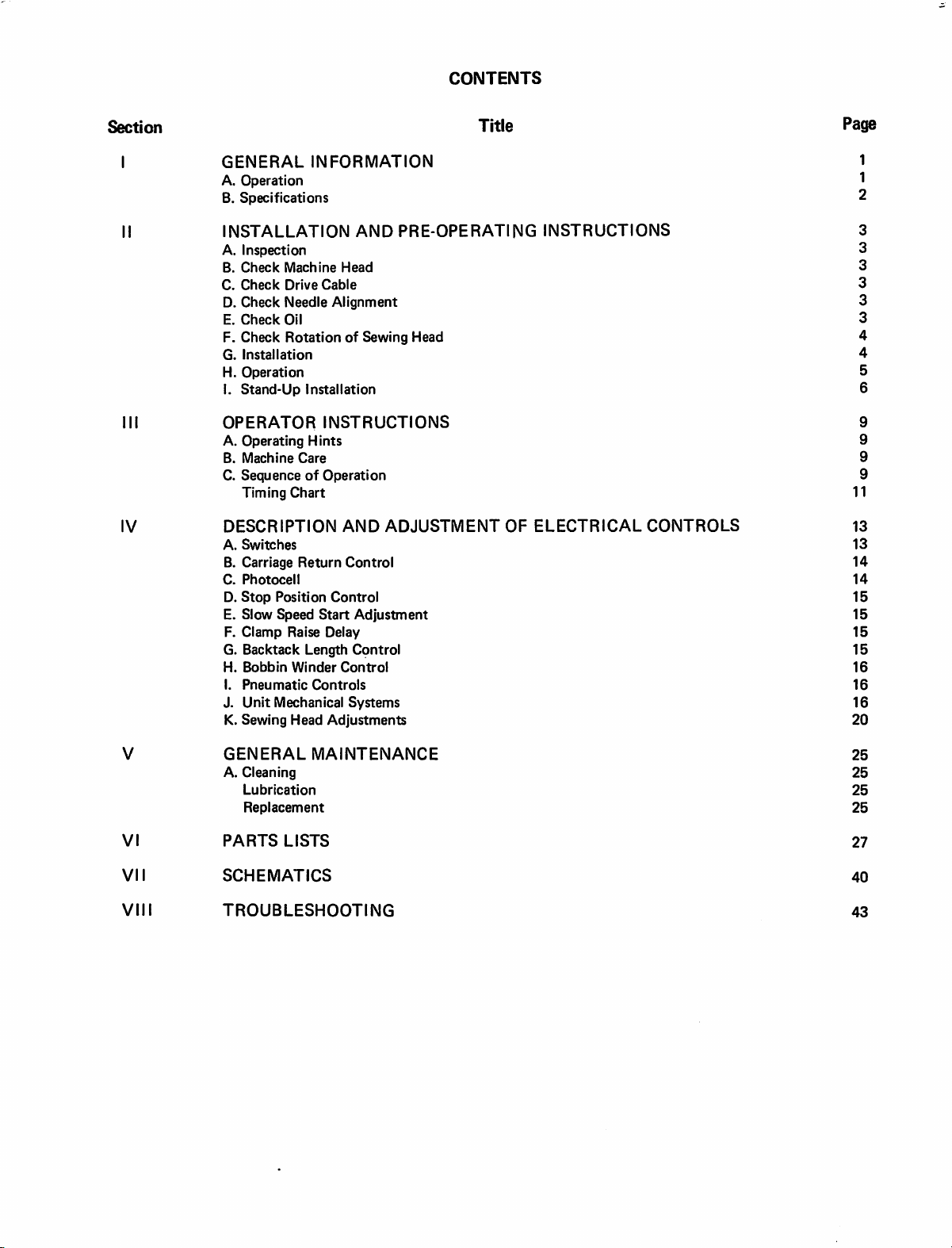

CONTENTS

Section

I

II

III

IV

GENERAL

A.

Operation

B.

Specifications

INFORMATION

INSTALLATION

A.

Inspection

B.

Check

Machine

C.

Check

Drive

Cable

D.

Check

Needle

Alignment

E.

Check

Oil

F.

Check

Rotation

G.

Installation

H.

Operation

I.

Stand-Up

OPERATOR

A.

Operating

B.

Machine

C.

Sequence

Timing

DESCRIPTION

A.

Switches

B.

Carriage

C.

Photocell

D.

Stop

E.

Slow

F.

Clamp

G.

Backtack

H.

Bobbin

I.

Pneumatic

J.

Unit

K.

Sewing

installation

INSTRUCTIONS

Hints

Care

of

Operation

Chart

Return

Position

Speed

Mechanical

Control

Start

Raise

Delay

Length

Winder

Controls

Head

Adjustments

AND

PRE-OPERATING

Head

of

Sewing

AND

ADJUSTMENT

Control

Adjustment

Control

Control

Systems

Head

Title

OF

INSTRUCTIONS

ELECTRICAL

CONTROLS

Page

1

1

2

3

3

3

3

3

3

4

4

5

6

9

9

9

9

11

13

13

14

14

15

15

15

15

16

16

16

20

V

VI

VII

VIII

GENERAL

A.

Cleaning

Lubrication

Replacement

PARTS

MAINTENANCE

LISTS

SCHEMATICS

TROUBLESHOOTING

25

25

25

25

27

40

43

Page 5

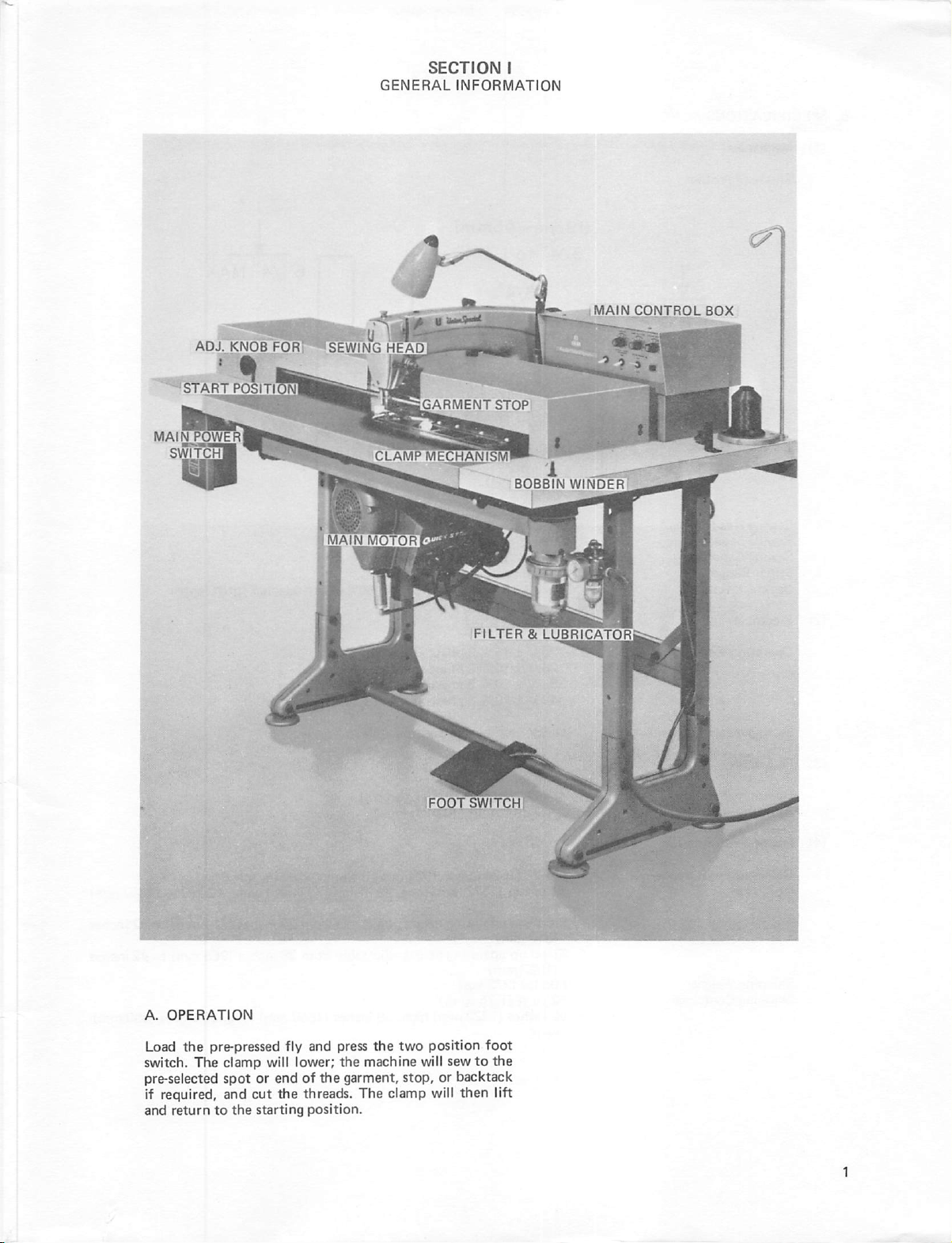

ADJ.

KNOB

F0"RT-^SEWING

GENERAL

HEAD

SECTION

INFORMATION

I

MAIN

CONTROL

BOX

START

MAINTOWER

SWITCH

POSITI

GARMENT

STOP

FILTER & LUBRICATOR

A.

OPERATION

Load

the

pre-pressed

switch.

pre-selected

if

and

The

clamp

spot

required,

return

and

to

the

fly

will

lower;

or

end

of

cut

the

threads.

starting

and

press

the

machine

the

garment,

The

position.

the

two

clamp

position

will

stop,

or

will

foot

sew

to

the

backtack

then

lift

Page 6

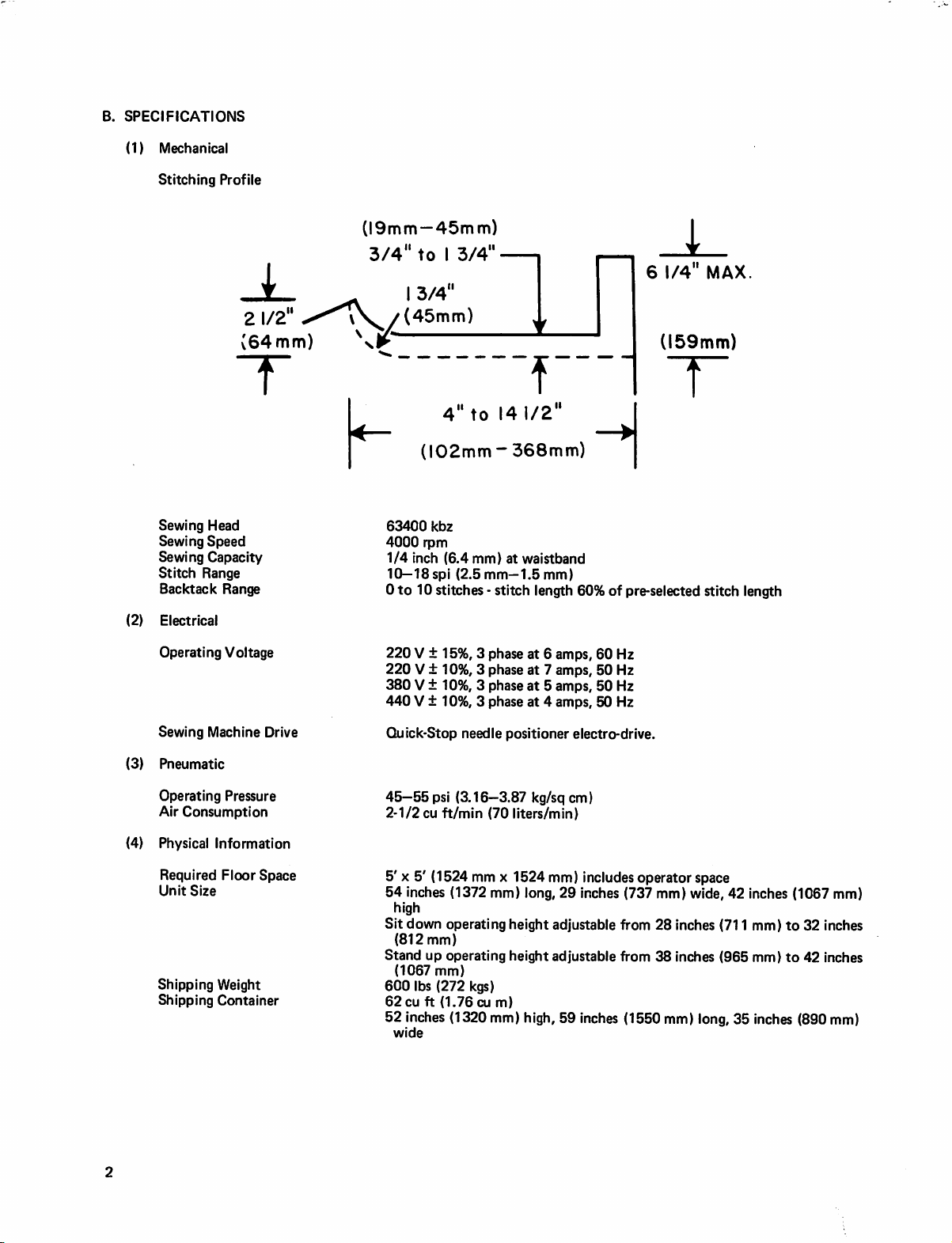

B.

SPECIFICATIONS

(1)

Mechanical

(2)

Stitching

Sewing

Sewing

Sewing

Stitch

Backtack

Electrical

Profile

Head

Speed

Capacity

Range

Range

2

1/2

(64mm)

(19mm—45mm)

3/4"to I 3/4"

3/4"

(45mm)

I

I

63400

4000

1/4

10—ISspi

0

4"to

(102mm

kbz

rpm

inch

(6.4

to

10

stitches - stitch

(2.5

f

l4i/2"

~

368mm)

mm)

at

waistband

mm—1.5

mm)

length

60%

i

6

1/4"

(159mm)

T

I

|

of

pre-selected

MAX

stitch

length

Sewing

(3)

Pneumatic

Operating

Air

(4)

Physical

Shipping

Shipping

Operating

Required

Unit

Voltage

Machine

Pressure

Consumption

Information

Floor

Size

Weight

Container

Drive

Space

220 V ±

220 V ±

380 V ±

440 V ±

Quick-Stop

45—55psi

2-1/2

5' X 5'

54

high

Sit

(812

Stand

(1067

600

62

52

wide

15%, 3 phase

10%, 3 phase

10%, 3 phase

10%, 3 phase

(3.16—3.87

cu

ft/min

(1524

inches

(1372

down

operating

mm)

up

operating

mm)

lbs

(272

cu

ft

(1.76

inches

(1320

needle

positioner

(70

liters/min)

mm x 1524

mm)

long,

height

height

kgs)

cu

m)

mm)

high,

at 6 amps,

at 7 amps,

at 5 amps,

at 4 amps,

kg/sq

60

50

50

50

electro-drive.

cm)

mm)

includes

29

inches

adjustable

adjustable

59

inches

Hz

Hz

Hz

Hz

operator

(737

mm)

from

28

from

38

(1550

space

wide,

inches

inches

mm)

long,

42

(711

(965

35

inches

(1067

mm)

to

mm)

to

inches

(890

32

inches

42

inches

mm)

mm)

Page 7

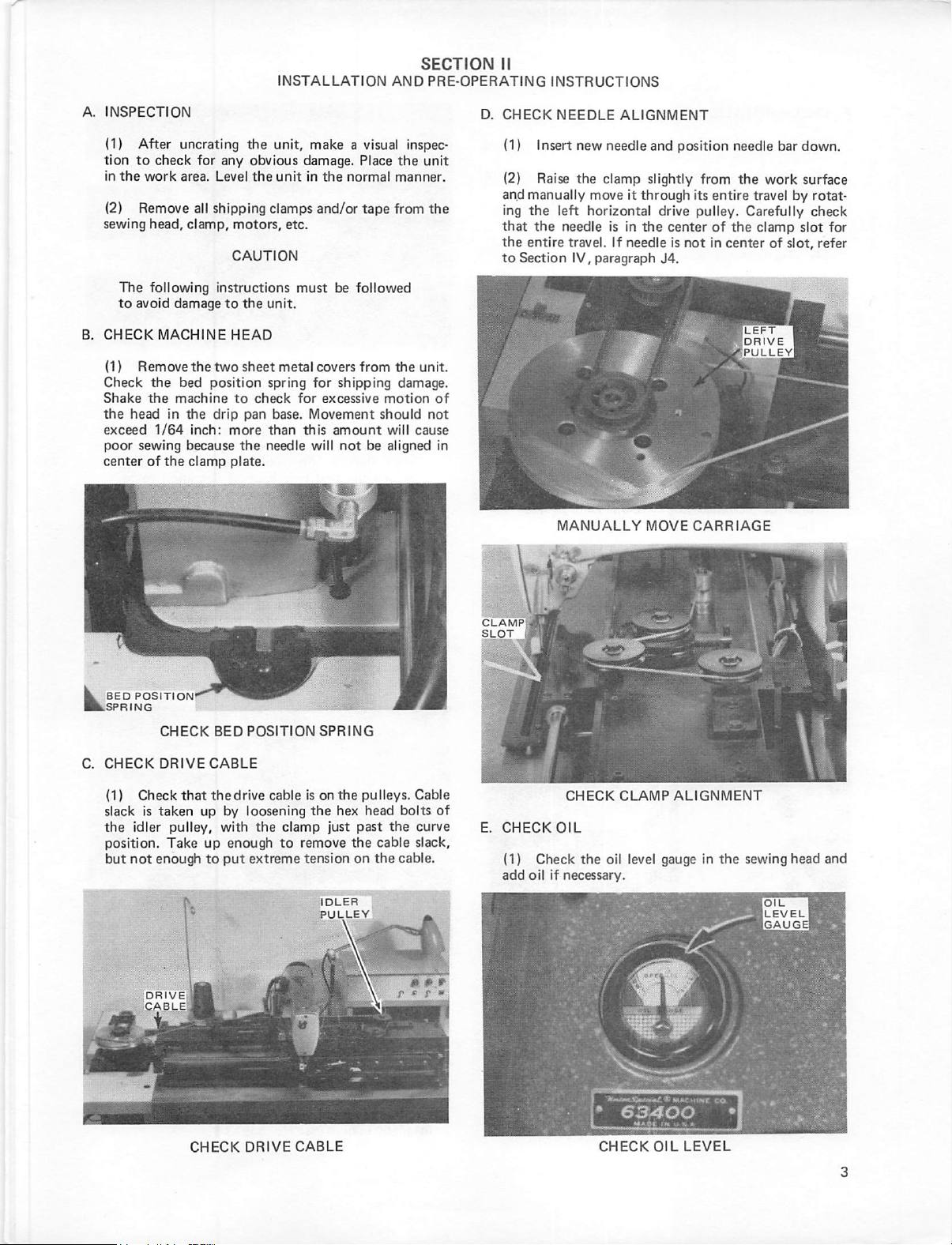

A.

INSPECTION

11)

tion

in

(2)

sewing

B.

CHECK

(1)

Check

Shake

the

exceed

poor

center

After

to

check

the

work

Remove

head,

The

following

to

avoid

Remove

the

the

head

1/64

sewing

of

uncrating

for

area.

all

shipping

clamp,

damage

MACHINE

the

bed

position

machine

in

the

drip

inch:

because

the

clamp

INSTALLATION

unit,

any

Level

obvious

the

damage.

unit

clamps

motors,

CAUTION

instructions

to

HEAD

two

the

unit.

sheet

etc.

must

metal

spring

to

check

for

pan

base.

more

than

this

the

needle

plate.

AND

make a visual

Place

the

in

the

normal

and/or

be

covers

for

shipping

excessive

Movement

amount

will

not

manner.

tape

from

followed

from

the

damage.

motion

should

will

be

aligned

SECTION

PRE-OPERATING

inspec

unit

the

unit.

of

not

cause

in

D.

II

CHECK

(1)

(2)

an.d

manually

ing

the

that

the

the

entire

to

Section

INSTRUCTIONS

NEEDLE

Insert

new

Raise

the

move

left

horizontal

needle

travel.

IV,

paragraph

ALIGNMENT

needle

clamp

slightly

it

through

is

in

the

If

needle

and

position

drive

center

is

not

J4.

needle

from

the

its

entire

pulley.

Carefully

of

the

in

center

bar

work

travel

by

clamp

of

slot,

down.

surface

rotat

check

slot

for

refer

E.

CHECK

MANUALLY

CHECK

OIL

CLAMP

MOVE

CARR

I

ALIGNMENT

AGE

CHECK

DRIVE

CABLE

CHECK

OIL

LEVEL

Page 8

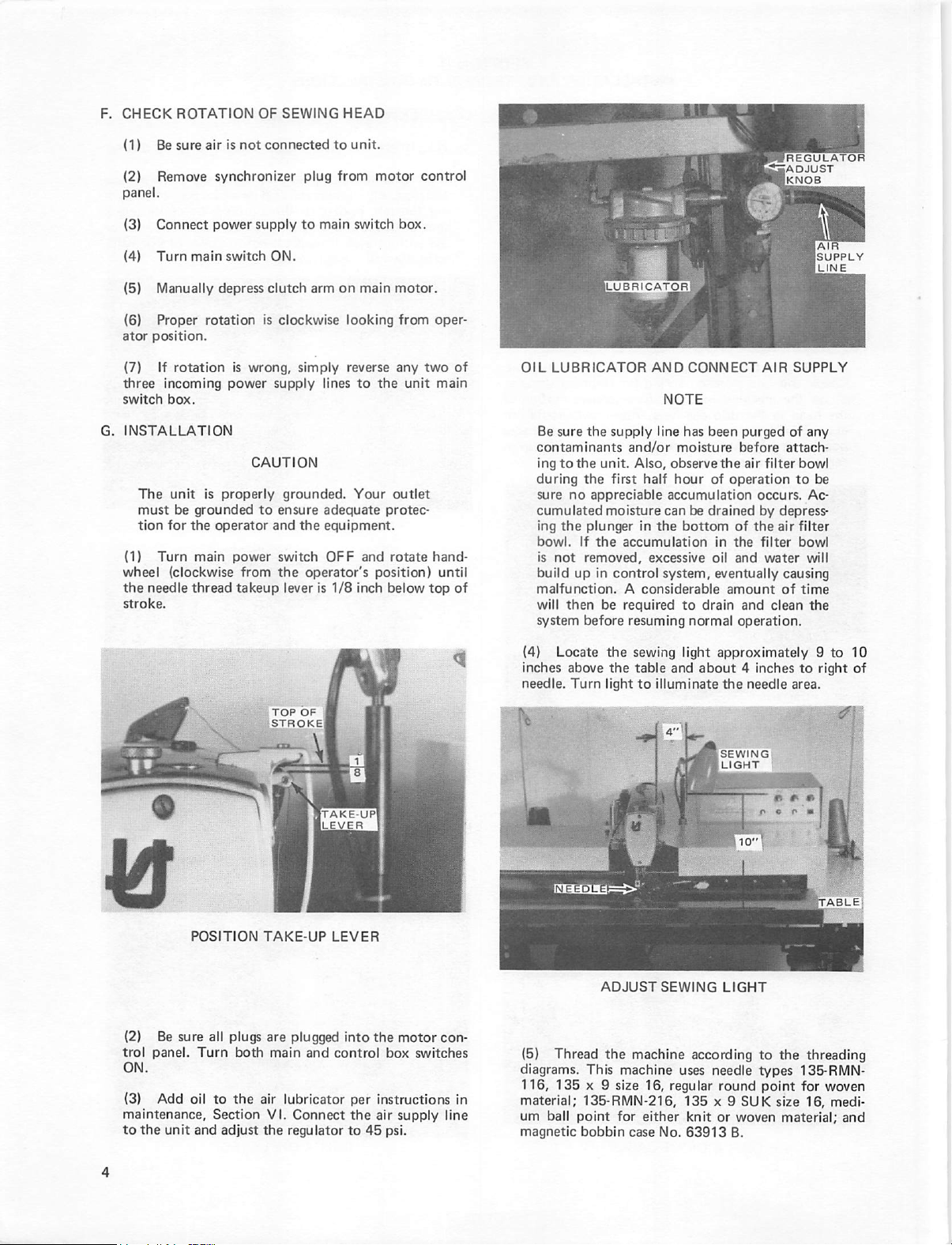

F.

CHECK

(1)

(2)

panel.

(3)

(4)

(5)

(6)

atCH-

(7)

three

switch

G.

INSTALLATION

The

must

tion

(1)

wheel

the

stroke.

ROTATION

Be

sure

Remove

Connect

Turn

main

Manually

Proper

position.

If

rotation

incoming

box.

unit

be

grounded

for

the

Turn

main

(clockwise

needle

thread

OF

SEWING

air

is

not

connected

synchronizer

power

supply

switch

ON.

depress

rotation

is

operator

clutch

is

clockwise

is

wrong,

power

supply

CAUTION

properly

to

ensure

and

power

switch

from

the

takeup

grounded.

lever

HEAD

to

unit.

plug

from

to

main

switch

arm

on

main

looking

simply

reverse

lines

to

Your

adequate

the

equipment.

OFF

and

operator's

is

1/8

inch

motor

control

box.

motor.

from

oper-

any

two

the

unit

main

outlet

protec

rotate

hand-

position)

below

until

top

of

of

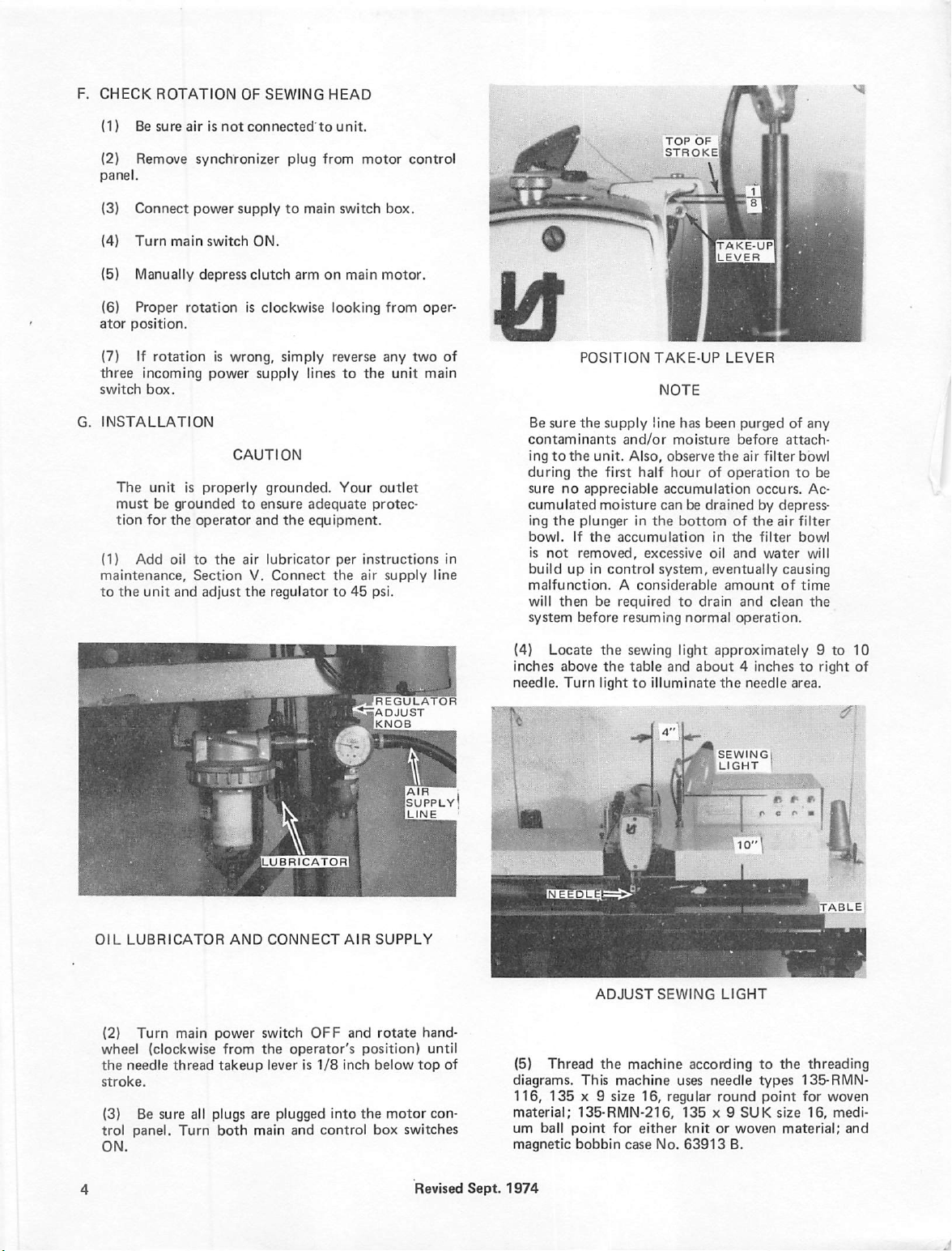

Ilubricator!

OIL

LUBRICATOR

Be

sure

the

contaminants

ing

to

the

unit.

during

the

sure

no

appreciable

cumulated

ing

the

plunger

bowl.

If

the

is

not

build

malfunction. A considerable

will

system

removed,

up

in

then

before

be

AND

NOTE

supply

line

and/or

Also,

first

half

moisture

control

can

in

the

accumulation

excessive

system,

required

resuming

moisture

observe

hour

accumulation

to

CONNECT

has

been

the

of

operation

be

drained

bottom

in

oil

eventually

amount

drain

normal

IREGULATOR

EADJUST

Iknob

AIR

SUPPLY

purged

before

air

filter

of

attach

to

occurs.

by

depress

of

the

air

filter

the

filter

and

water

causing

of

and

clean

operation.

AIR

SUPPLY

LINE

any

bowl

be

Ac

bowl

will

time

the

POSITION

(2)

Be

sure

all

trol

panel.

Add

unit

Turn

oil

to

Section

and

ON.

(3)

maintenance.

to

the

TAKE-UP

plugs

both

the

air

adjust

the

take-up

LEVER

LEVER

are

plugged

main

and

control

lubricator

VI.

Connect

regulator

into

the

motor

box

switches

per

instructions

the

air

45

supply

psi.

to

con

line

in

(4)

Locate

inches

above

needle.

Turn

(5)

Thread

diagrams.

116,

material;

um

magnetic

This

135 X 9

135-RMN-216,

ball

point

bobbin

the

sewing

the

light

ADJUST

the

machine

machine

size

for

case

light

table

and

about 4 inches

to

illuminate ti^e

SEWING

according

uses

16,

regular

135 x 9

either

knit

No.

63913

approximately 9 to

to

right

needle

area.

SEWING

LIGHT

LIGHT

to

the

threading

needle

types

round

SUK

or

woven

135-RMN-

point

for

size

16,

material;

woven

medi

B.

10

of

and

Page 9

F.

CHECK

(1)

Be

(2)

Remove

panel.

(3)

Connect

(4)

Turn

(5)

Manually

(6)

Proper

ator

position.

(7)

If

three

incoming

switch

box.

G.

INSTALLATION

The

must

tion

for

(1)

Add

maintenance,

to

the

unit

ROTATION

sure

air

is

synchronizer

power

main

switch

depress

rotation

rotation

is

power

unit

is

properly

be

grounded

the

operator

oil

to

the

Section

and

adjust

OF

SEWING

not

connected'to

plug

supply

to

ON.

clutch

is

clockwise

wrong,

simply

supply

CAUTION

grounded.

to

ensure

and

the

air

lubricator

V.

Connect

the

regulator

HEAD

unit.

from

main

switch

arm

on

main

looking

reverse

lines

to

Your

adequate

equipment.

per

the

to

motor

control

box.

motor.

from

oper

any

two

the

unit

main

outlet

protec

instructions

air

supply

45

psi.

of

in

line

fa

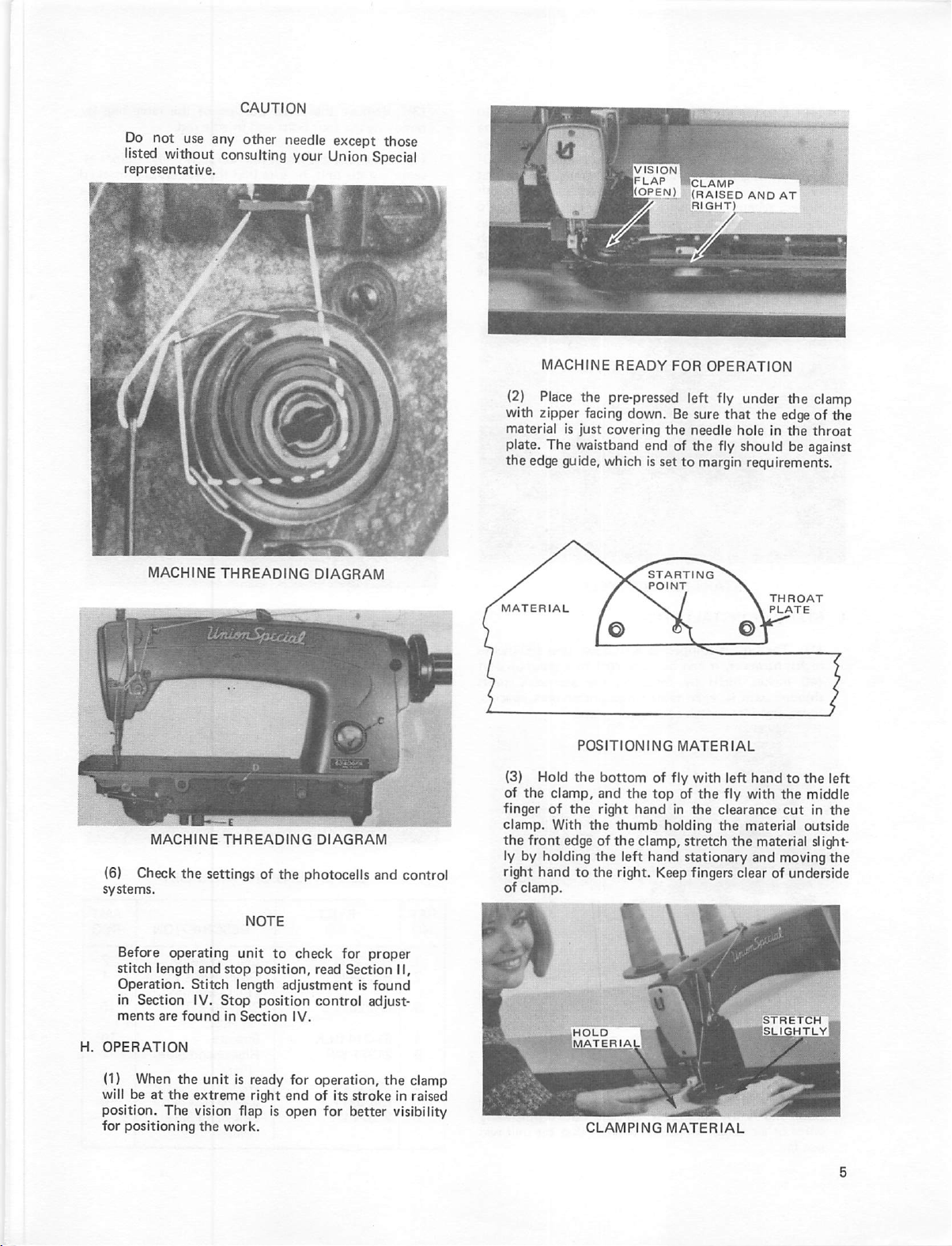

POSITION

Be

sure

the

supply

contaminants

ing

to

the

during

sure

no

cumulated

ing

the

bowl.

If

is

not

build

up

malfunction. A considerable

will

then

system

and/or

unit.

the

first

appreciable

moisture

plunger

the

accumulation

removed,

in

control

be

required

before

resuming

TOP

STROKE!

TAKE-UP

NOTE

line

has

moisture

Also,

observe

half

hour

accumulation

can

be

in

the

bottom

excessive

system,

to

normal

OF

I

tTAKE-UPl

LEVER

LEVER

been

purged

before

attach

the

air

filter

of

operation

drained

drain

occurs.

by

depress

of

the

air

in

the

oil

filter

and

water

eventually

amount

causing

of

and

clean

operation.

of

any

bowl

to

be

Ac

filter

bowl

will

time

the

OIL

<2)

wheel

the

stroke.

(3)

trol

ON.

LUBRICATOR

Turn

main

(clockwise

needle

thread

Be

sure

panel.

Turn

all

AND

power

from

takeup

plugs

are

both

main

LUBRICATOR

CONNECT

switch

the

operator's

lever

is

plugged

and

AIR

OFF

and

1/8

inch

into

control

W^REGULATOR

ADJUST

KNOB

SUPPLY

rotate

below

motor

box

switches

hand-

top

position)

the

until

of

con

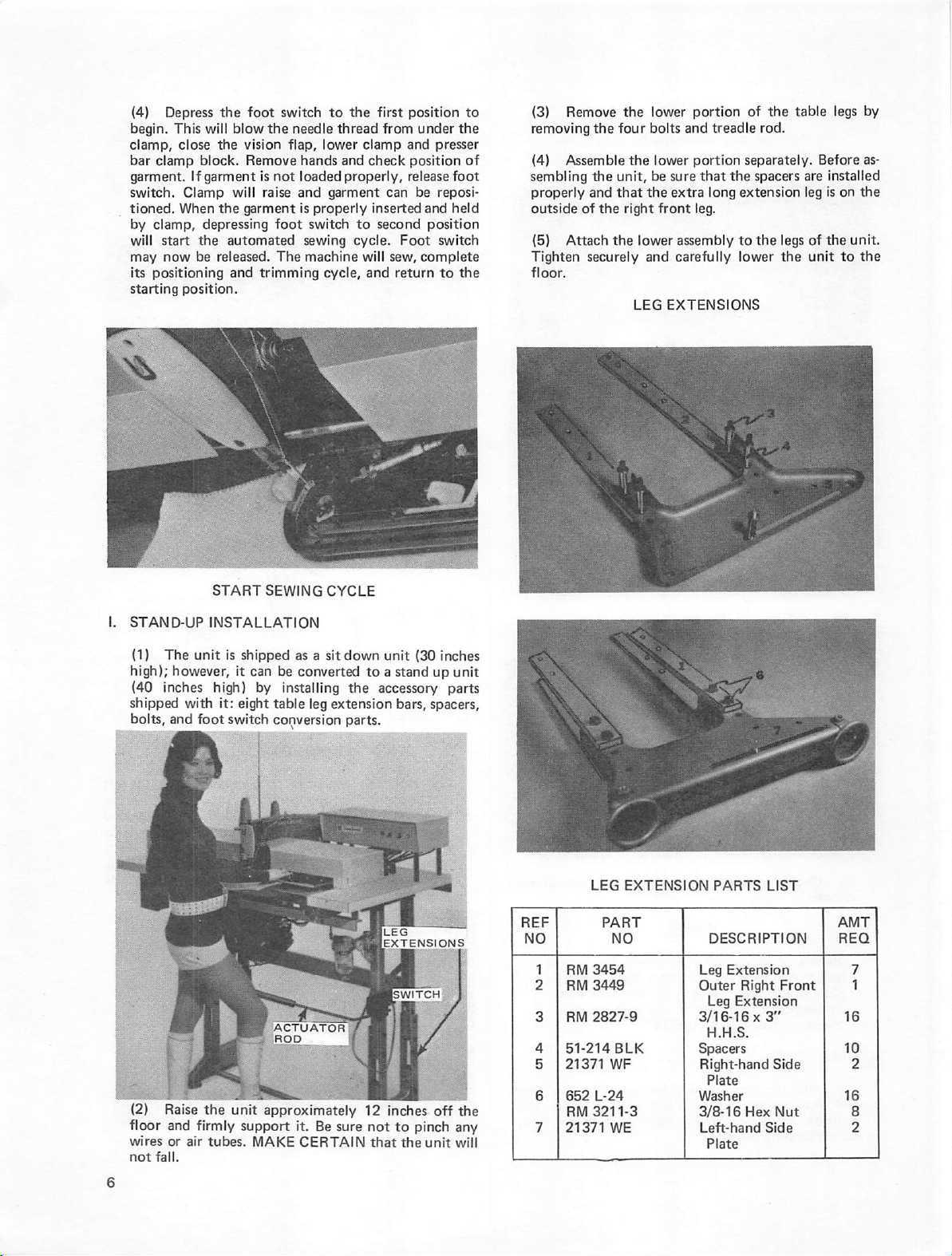

(4)

Locate

inches

above

needle.

(5)

diagrams.

116,

material;

um

magnetic

Turn

Thread

135 X 9

135-RMN-216,

ball

point

bobbin

the

the

light

ADJUST

the

This

sewing

table

to

illuminate

SEWING

machine

machine

size

16,

for

either

case

No.

light

approximately 9 to

and

about 4 inches

the

needle

SEWING

LIGHT

LIGHT

according

uses

needle

regular

round

135 x 9

knit

or

63913

SUK

woven

B.

to

area.

to

the

types

135-RMN-

point

for

size

material;

10

right

of

threading

woven

16,

medi

and

Revised

Sept.

1974

Page 10

Do

not

use

any

listed

without

representative.

CAUTION

other

needle

consulting

your

except

Union

Special

1

those

(6)

Check

systems.

MACHINE

MACHINE

the

r-.

THREADING

Uni^n^ujuoji

THREADING

settings

of

DIAGRAM

DIAGRAM

the

photocells

and

control

MACHINE

(2)

Place

with

zipper

material

piate.

The

the

edge

MATERIAL

(3)

Hold

of

the

clamp,

finger

of

clamp.

the

ly

right

of

With

front

by

holding

hand

clamp.

READY

the

pre-pressed

facing

down.

Is

just

covering

waistband

guide,

which

POSITIONING

the

bottom

and

the

the

right

the

to

of

the

the

the

thumb

left

right.

edge

FOR

Be

the

end

of

is

set

to

STARTING

POINT

MATERIAL

of

fly

top

of

hand

in

holding

clamp,

hand

Keep

OPERATION

left

fly

under

sure

that

the

needle

hole

in

the

fly

should

margin

requirements.

THROAT

PLATE

with

left

hand

the

fly

with

the

clearance

the

stretch

stationary

fingers

material

the

material

and

clear

of

the

clamp

edge

of

the

the

throat

be

against

to

the

left

the

middle

cut

in

the

outside

slight

moving

the

underside

NOTE

Before

stitch

Operation.

in

ments

H.

OPERATION

(1)

will

position.

for

operating

length

and

Stitch

Section

When

be

positioning

are

at

The

IV.

found

the

the

extreme

vision

unit

the

unit

stop

position,

length

Stop

in

Section

is

ready

right

flap

work.

to

check

read

adjustment

position

end

is

open

IV.

for

control

operation,

of

for

for

proper

Section

is

found

adjust

its

stroke

better

II,

the

clamp

in

raised

visibility

HOLD

MATERIAL

CLAMPING

MATERIAL

STRETCH

SLIGHTLY

Page 11

(4)

Depress

begin.

This

clamp,

bar

close

clamp

garment.

switch.

tioned.

by

will

may

its

starting

Clamp

When

clamp,

start

now

positioning

position.

the

foot

will

blow

the

vision

block.

Remove

If

garment

will

the

garment

depressing

the

automated

be

released.

and

switch

the

needle

flap,

hands

Is

not

loaded

raise

and

is

properly

foot

switch

sewing

The

machine

trimming

to

the

thread

lower

clamp

and

check

properly,

garment

to

cycle.

will

cycle,

and

first

position

from

under

and

position

release

can

be

inserted

second

and

position

Foot

sew,

complete

return

to

the

presser

of

foot

reposi-

held

switch

to

the

(3)

Remove

removing

(4)

Assemble

sembling

properly

outside

(5)

Tighten

floor.

the

and

of

Attach

securely

the

the

the

the

lower

four

bolts

the

lower

unit,

be

that

the

right

lower

and

LEG

portion

and

portion

sure

that

extra

front

leg.

assembly

carefully

EXTENSIONS

of

treadle

separately.

the

spacers

long

extension

to

the

lower

the

rod.

table

are

leg

legs

of

the

legs

Before

installed

is

on

the

unit.

unit

to

by

as

the

the

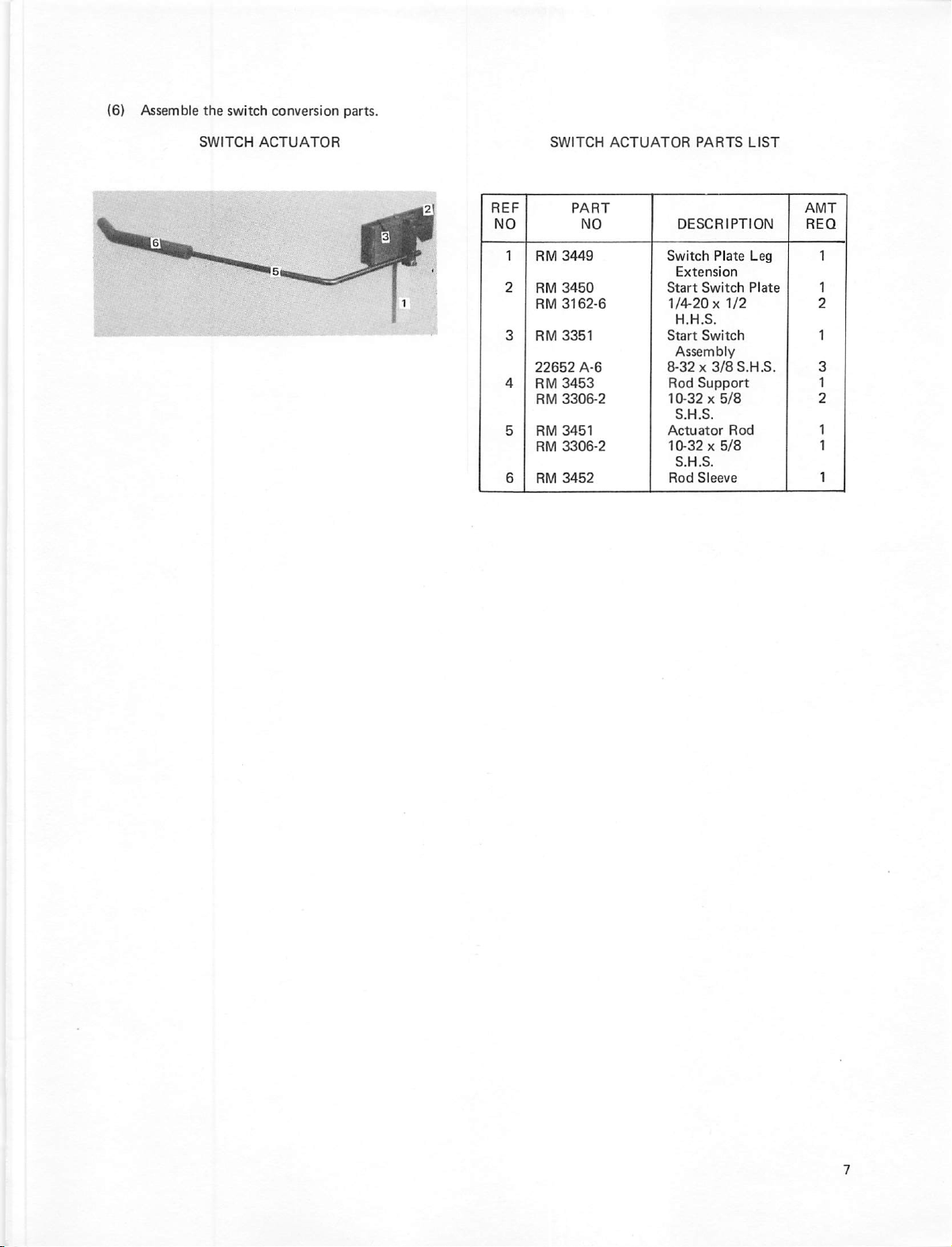

I.

STAND-UP

(1)

high);

(40

shipped

bolts,

(2)

floor

wires

not

The

unit

however,

inches

with

and

foot

Raise

the

and

firmly

or

air

fall.

START

INSTALLATION

high)

SEWING

is

shipped

it

can

be

by

it:

switch

unit

installing

eight

table

conversion

approximately

support

tubes.

MAKE

CYCLE

as a sit

down

converted

the

leg

extension

parts.

12

it.

Be

sure

CERTAIN

unit

(30

to a stand

up

accessory

bars,

spacers,

inches

off

not

to

pinch

that

the

unit

inches

unit

parts

the

any

will

LEG

RM

2827-9

51-214

21371

652

L-24

RM

3211-3

21371

EXTENSION

PART

NO

BLK

WF

WE

PARTS

DESCRIPTION

Leg

Outer

Leg

3/16-16 X 3"

H.H.S.

LIST

Extension

Right

Extension

Spacers

Right-hand

Plate

Washer

3/8-16

Left-hand

Plate

Side

Hex

Side

Front

Nut

Page 12

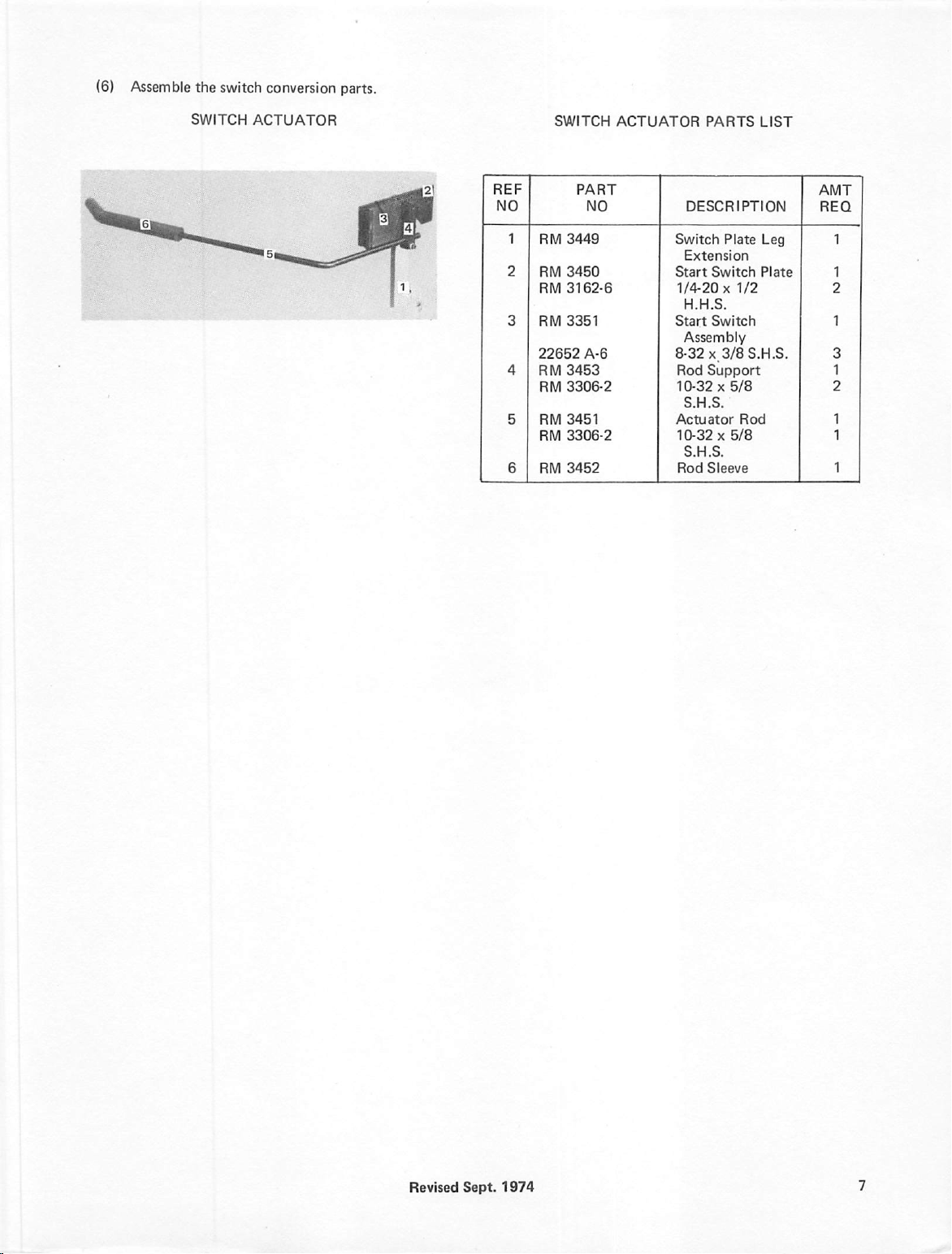

(6)

Assemble

the

switch

conversion

parts.

SWITCH

ACTUATOR

EF

JO

1 RM

2 RM

RM

3 RM

22652

4 RM

RM

5 RM

RM

6 RM

SWITCH

PART

NO

3449

3450

3162-6

3351

A-6

3453

3306-2

3451

3306-2

3452

ACTUATOR

PARTS

DESCRIPTION

Switch

Plate

Extension

Start

Switch

1/4-20 X 1/2

H.H.S.

Start

Switch

Assembly

8-32 X 3/8

Rod

Support

10-32 X 5/8

S.H.S.

Actuator

10-32 X 5/8

S.H.S.

Rod

Rod

Sleeve

LIST

Leg

Plate

S.H.S.

Page 13

(6)

Assemble

the

switch

conversion

parts.

SWITCH

ACTUATOR

SWITCH

EF

JO

1 RM

2 RM

RM

3 RM3351

22652

4 RM3453

RM

5 RM

RM

6 RM

PART

NO

3449

3450

3162-6

A-6

3306-2

3451

3306-2

3452

ACTUATOR

PARTS

DESCRIPTION

Switch

Start

Start

Plate

Extension

Switch

1/4-20 X 1/2

H.H.S.

Switch

Assembly

8-32

x,3/8S.H.S.

Rod

Support

10-32x5/8

S.H.S.

Actuator

Rod

10-32 x 5/8

S.H.S.

Rod

Sleeve

LIST

Leg

Plate

Revised

Sept.

1974

Page 14

A.

OPERATING

(1)

fly

(2)

(3)

cycle

(4)

needle;

(5)

check

8.

MACHINE

(1)

ating;

level

If

either

(2)

moved,

Section

C.

SEQUENCE

Be

sure a slight

and

held

until

Do

not

pull

Do

not

assist

is

completed.

If

machine

check

for

If

bobbin

threading

CARE

Every

day:

check

oil

in

air

lubricator

oil

level

Mid-day

blow

lint

IV).

OF

HINTS

clamp

on

garment

the

skips

proper

thread

of

bobbin

replace

sight

mounted

is

low,

and

end

from

OPERATION

amount

of

contacts

once

material

stitches

in

or

threading.

does

not

case.

needle

gauge

first

on

sewing

on

notify

the

of

day:

hook

area

OPERATOR

stretch

it.

clamp

is

any

way

breaks

thread,

cut

at

end

thing

head;

right

front

mechanic

with

bobbin

with

air

SECTION

is

applied

down.

until

after

check

of

cycle,

before

oper

check

table

at

once.

case

hose

(see

INSTRUCTIONS

to

oil

leg..

re

III

c.

Vision flap

d.

90

The

and

volts

The

dc,

foot

closing

occurs.

to

(3)

ing

following

a. A time

energized,

speed

mode

operation

held

Solenoid A de-energizes

pletely

is

energized,

cylinder

then

preventing

mode.

b.

The

through

c.

The

so

independent

d.

The

released,

e.

After

which

run

at

high

closes

voltage

to

preparing

switch

is

the

second

delay

control

machine

machine

the

control

that

foot

the

supplying

starts

main

circuit

the

voltages

of

the

switch

shutting

time

engages

speed.

as

the

clamp

then

motor

foot

can

when

off

delay

air

the

solenoid E is

electric

to

feed.

depressed

position

delays

from

sewing

circuit.

locks

to

solenoids E and D are

switch.

be

released

the

the

air

is

timed

to

the

clutch.

energized.

clutch

further,

switch

solenoid B being

going

in

the

unit

into

at

foot

switch

wiper.

out,

electro-drive

The

machine

is

increased

engag

FS2.

The

into

high

low

speed

automatic

this

point.

is

com

solenoid

clutch

will

B

(1)

Refer

to

position

following

mately

the

clutch

backtack

cycle.

solenoid

is

the

vision flap

(2)

foot

FS1.

energized.

closed

chine

with

conditions

a.

The

10

b.

Solenoid A is

thread

c.

Solenoid B is

cylinder

d.

Solenoid C is

lever

e.

Solenoid D is

supplies

up),

and

f.

Solenoid E is

vision

flap

The

operator

switch

The

following

a.

Air

b.

Clamp

clamp

to

operate.

volts

wiper

the

open.

to

When

timing

chart.

both

main

are

electric

clutch

dc.

system.

retracted

cylinder

de-energized.

air

to

presser

cylinder,

loads

engage

and

occurs.

wiper

blows

and

presser

the

interlock

When

the

unit

and

control

in

effect.

is

de-energized,

de-energized,

and

the

de-energized,

controlling

switches

energized

shutting

with

unit

not

shutting

the

This

the

clamp

lift

foot

cylinder

de-energized,

which

the

close

as

solenoid A is

lifter

switch

(presserfoot

shutting

is

retracted

material

the

first

bar

drop

lever

moves,

opens,

and

as

is

in

the

rest

ON,

the

with

approxi

off

air

electro-drive

sewing.

off

air

reverse

normally

cylinder

depresses

position

energized.

solenoid D is

the

preparing

(clamp

is

off

air

to

keep

switch

normally

feed

open

up).

the

the

ma

to

to

to

(4)

When

the

clamp

the

photocell

to

the

waistband, a time

machine

stop

this

clutch

operation

tion

de-energized,

flap.

10

for

before

switch

lever

next

clamp

to

will

position

delay,

the

a.

Solenoid B is

to

disengage

to

low

b.

Needle

c.

After a pre-set

of

position

allowing

d.

Solenoid E is

e.

Electric

volts

dc,

preparing

f.

The

clamp

the

clamp

When

on

the

and

closes,

After

return

start

clamp

cycle.

position.

the

g.

sewing

h.

the

continue

time

following

speed.

positioning

clutch

to

starts

the

sewing

preparing

the

motor

moves

the

machine

delay

occurs

to

run

delay

is

completed.

occurs.

de-energized,

and

bring

machine

and

time

delay

and

trimming

clamp

to

de-energized,

voltage

for

clamp

return

and

its

return

clamp

head

return

is

activated,

delay

the

raises,

is

the

raise

clamp

pants

panel,

light

at

the

before

at

high

speed

At

causing

from

trimming

to

ensure

cycles,

raise.

opening

decreases

return.

begins,

providing

presser

cycle.

the

clamp

engaged

control

circuit

delay

times

returning

exposing

end

of

the

stopping.

cycles

solenoid D is

from

bar

by

The

until

this

the

end

the

quick

high

speed

occur.

comple

up

vision

90

time

to

retract

interlock

the

lifter

for

the

out,

the

the

clamp

of

to

Page 15

i.

When

a

stud

on

return

return

(5)

loading

(6)

backtack

sired

backtack

operations

is

de-energized,

cycle

sequence

the

limit

motor.

The

unit

of

the

The

above

switch

at

the

switch

ends,

will

switch,

waistband

is

identical

main

the

clamp

left-hand

is

now

next

drive

which

in tiie

panel.

sequence

in

the

NO

end

at

the

YES

to

the

paragraph

motor

decelerates

be

as

follows.

returns

shuts

of

to

pulley

off

rest

position,

operation

position.

of

the

position.

point

4a.

When

the

start

engages

power

to

ready

is

given

If

backtack

garment,

The

sequence

at

which

solenoid

high

speed

to

slow

speed.

position,

the

clamp

the

clamp

for

the

with

the

is

de

place

the

of

sewing

The

a.

The

b.

air

to

the

arm

on

clamp

in

c.

tack

solenoid D to

d.

off,

causing

drive

to

backtack

Backtack

backtack

the

transmission

the

reverse

The

backtack

Air

supplied

the

return

timer

solenoid C is

cylinder.

direction.

timer

de-energize.

to

the

reversing

to

the

forward

is

started.

energized,

This

causes

drive

to

times

backtack

arm

on

position.

supplying

the

move,

driving

out,

causing

cylinder

the

transmission

reversing

the

back

is

shut

B

(7)

The

rest

of

the

in

the

graph

4b.

operation

non-backtack

sequence,

sequence

beginning

is

described

with

para

10

Page 16

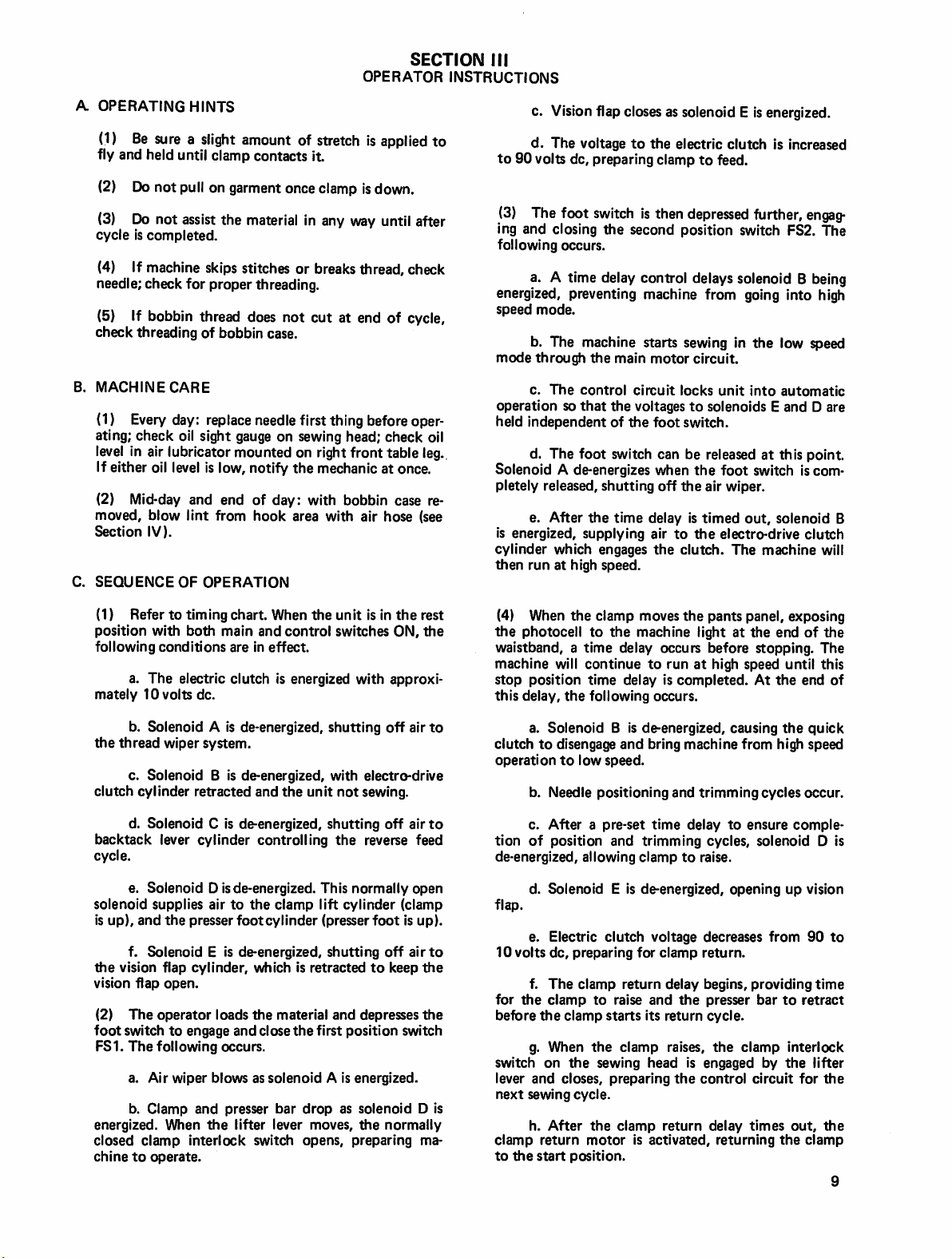

TIMING

NOTE

CHART

Foot

Switch

Air

Blower

Sol.

A

Elec.

Clutch

Vision

Flap

Sol.

E

Clamp

Sol.

D

Clamp

Switch

Foot

Switch

Slow

Sew

Timer

Latch

Slow

Speed

Contact

Return

Limit

Sw.

Quick

Clutch

Sol.

8

Photocell

Stop

Position

Timer

Back

Tack

Delay

Back

Tack

Timer

Back

Tack

Sol.C

Clamp

Lift

Delay

Clamp

Return

Delay

Clamp

Return

Motor

No.

Clamp

No.

1

2

Open

Closed

On

Off

On

Off

On

Off

On

Off

Open

Closed

On

Off

On

Off

On

Off

Closed

Open

Open

Closed

On

Off

Covered

Uncovered

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

Machine

switches

I

Is

on.

in

rest

position

n

with

both

J

main

and

L

n

control

J

n

L

n

11

Page 17

A.

SWITCHES

(1)

ranges;

2800

E-2

is

DESCRIPTION

available

in

the

AND

following

SECTION

ADJUSTMENT

voltage

IV

OF

ELECTRICAL

CONTROLS

220 V ±

220 V ±

380 V ±

440 V ±

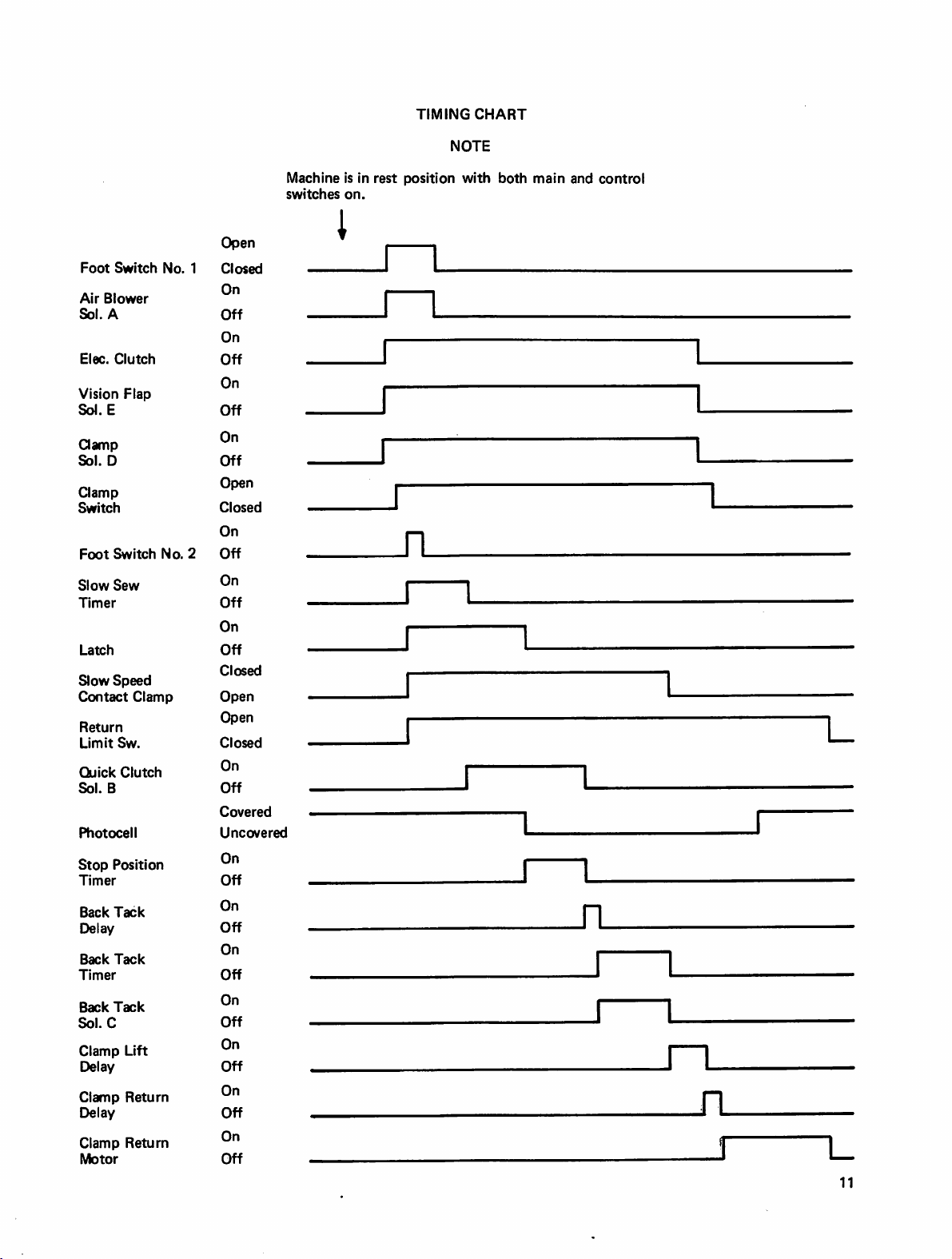

12)

Main

power

table,

controls

positioner,

box.

(3)

controls

drive,

chine

trim

MAIN

Control

all

functions

needle

light.

15%, 3 phase, 6 amps,

10%, 3 phase, 7 amps,

10%, 3 phase, 5 amps,

10%, 3 phase, 4 amps,

switch,

the

cycle,

POWER

power

positioning,

under

power

to

machine

SWITCH

switch,

of

the

trim

left-hand

the

electro-drive,

light,

BOX

on

face

unit

except

cycle,

60

Hz

50

Hz

50

Hz

50

Hz

and

POWER

SWITCH

of

and

side

of

needle

the

control

ON/OFF

control

the

electro-

box,

sewing

the

ma

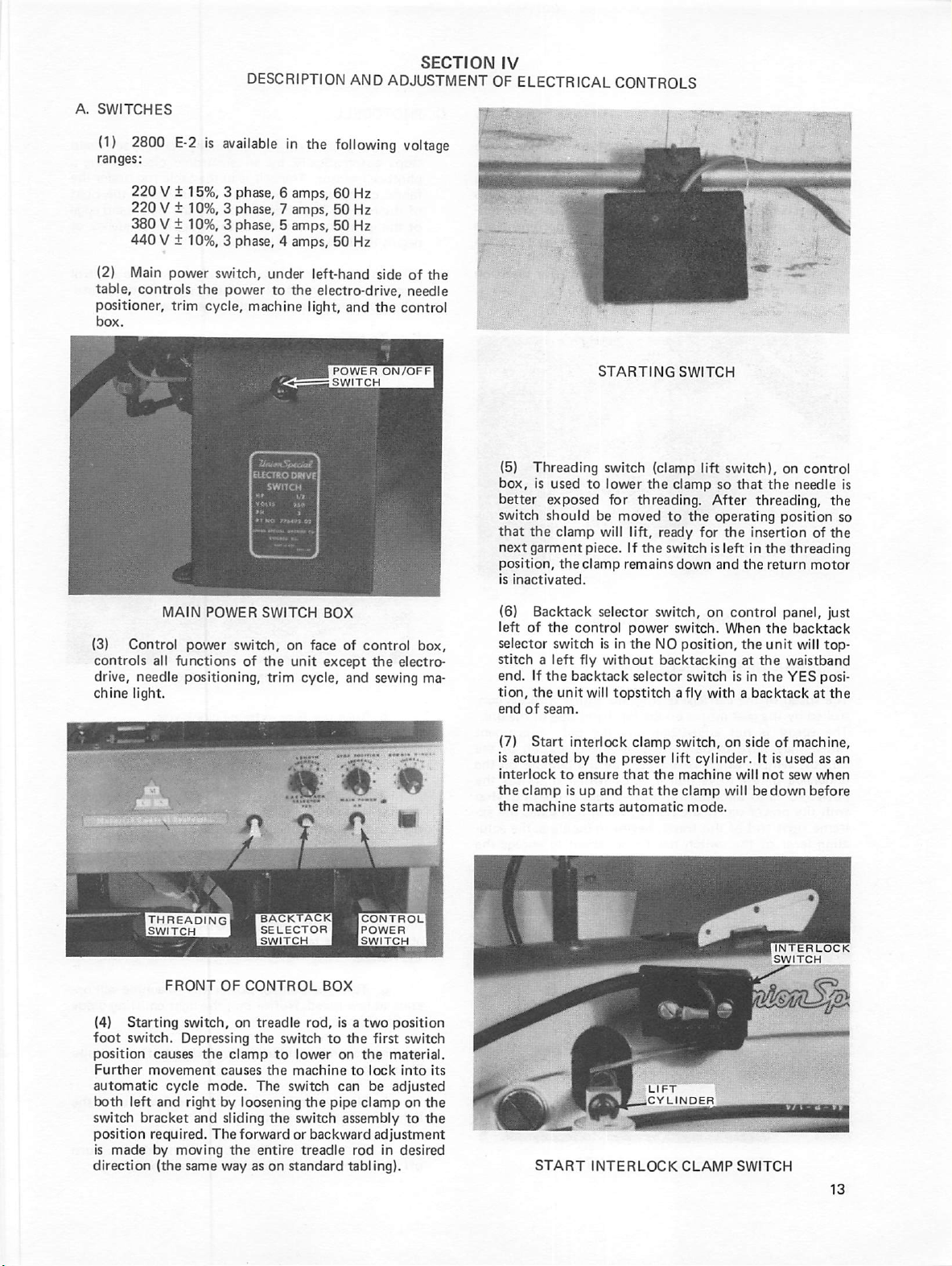

(5)

Threading

box,

is

used

better

switch

that

(6)

selector

stitch a left

end.

tion,

end

exposed

should

the

next

position,

Is

clamp

garment

the

inactivated.

Backtack

left

of

the

switch

If

the

the

unit

of

seam.

control

fly

backtack

STARTING

switch

to

lower

for

threading.

be

moved

will

lift,

piece.

If

the

clamp

remains

selector

power

is

in

the

without

selector

will

topstitch a fly

SWITCH

(clamp

the

lift

clamp

switch),

so

After

to

the

operating

ready

for

switch

switch,

NO

the

is

left

down

and

on

switch.

When

position,

backtacking

switch

with a backtack

on

that

the

threading,

position

insertion

in

the

threading

the

return

control

is

the

at

the

in

the

panel,

the

backtack

unit

waistband

YES

control

needle

is

the

so

of

the

motor

just

will

top-

posi

at

the

THREADING

SWITCH

FRONT

(4)

Starting

foot

switch.

position

Further

automatic

both

switch

position

is

direction

left

bracket

made

causes

movement

cycle

and

required.

by

(the

OF

CONTROL

switch,

Depressing

moving

same

the

causes

mode.

right

by

and

sliding

The

way

on

clamp

loosening

forward

the

treadle

the

switch

to

lower

the

machine

The

switch

the

switch

or

entire

as

treadle

on

standard

BOX

rod,

is a two

to

the

on

to

can

the

pipe

assembly

backward

rod

tabling).

CONTROL

POWER

SWITCH

position

first

switch

the

material.

lock

into

be

adjusted

clamp

on

to

adjustment

In

desired

its

the

the

(7)

Start

is

actuated

interlock

the

clamp

the

machine

START

interlock

by

the

presser

to

ensure

that

Is

up

and

that

starts

automatic

INTERLOCK

clamp

lift

the

the

LIFT

CYLINDER

switch,

on

cylinder.

machine

clamp

will

mode.

CLAMP

side

It

will

not

bedown

SWITCH

of

machine,

is

used

sew

before

INTERLOCK

SWITCH

as

when

an

Page 18

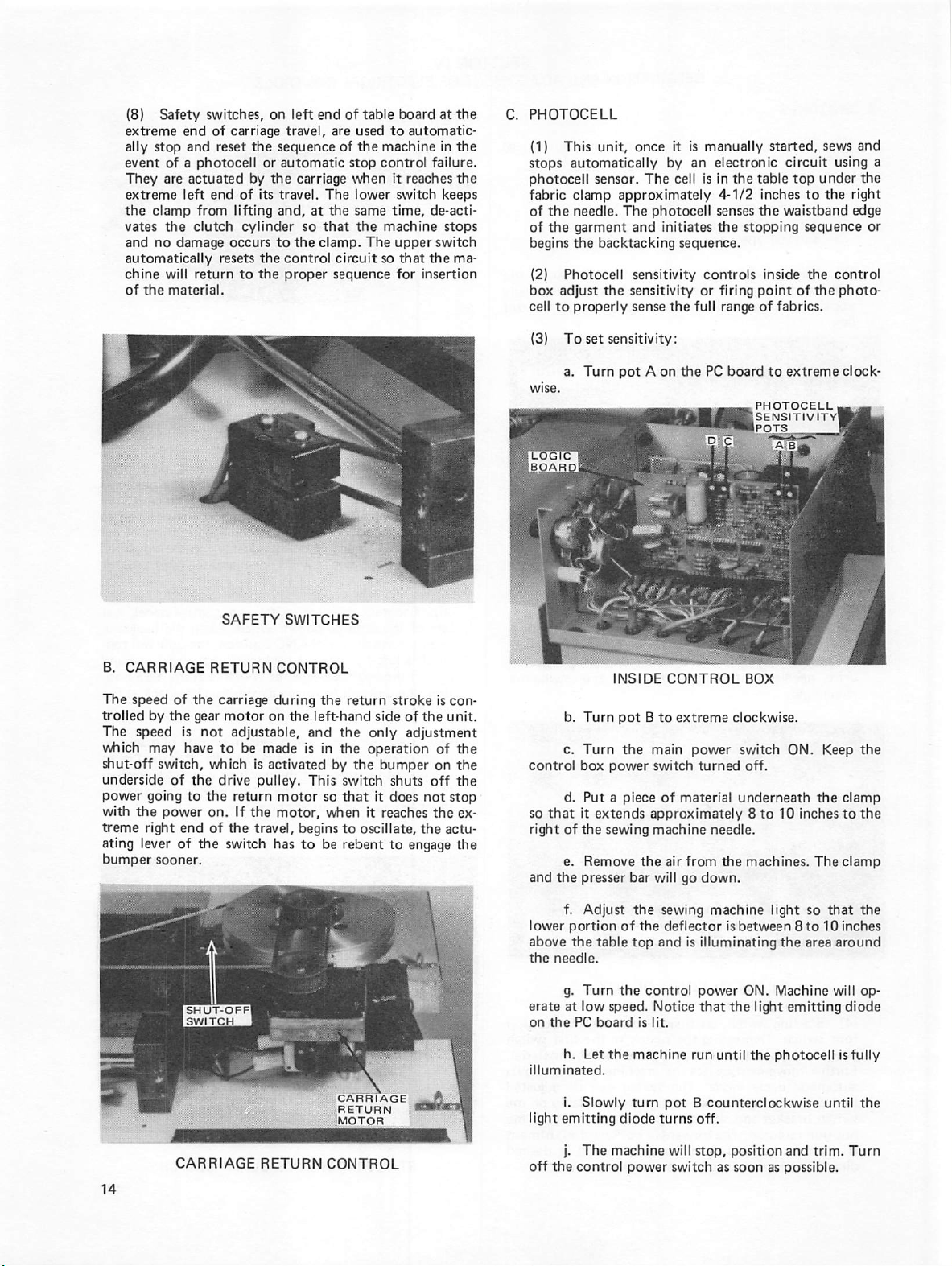

(8)

Safety

switches,

extreme

ally

event

They

extreme

the

vates

and

automatically

chine

of

end

stop

clamp

no

the

of

and

reset

of a photocell

are

actuated

left

end

from

the

clutch

damage

resets

will

return

material.

on

carriage

lifting

occurs

travel,

the

sequence

or

automatic

by

the

of

its

travel.

and,

cylinder

to

the

control

to

the

proper

left

end

of

are

of

carriage

The

at

the

so

that

the

clamp.

circuit

sequence

table

used

the

stop

when

lower

same

the

The

board

to

automatic

machine

control

so

failure.

it

reaches

switch

time,

de-acti

machine

upper

that

the

for

insertion

at

the

in

the

the

keeps

stops

switch

ma

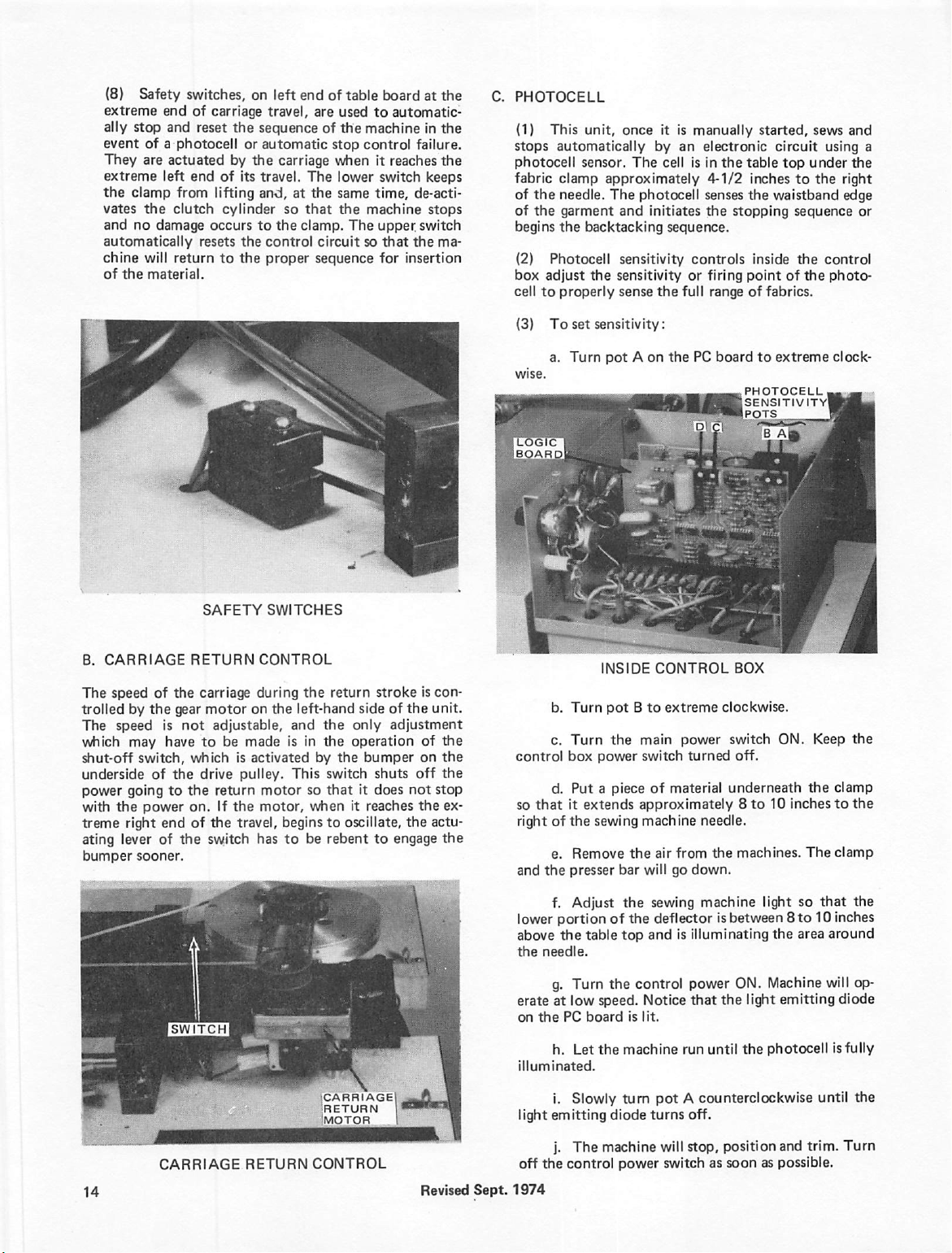

C.

PHOTOCELL

(1)

stops

photocell

fabric

of

the

of

the

begins

(2)

box

cell

to

(3)

This

unit,

once

automatically

sensor.

clamp

needle.

garment

the

Photocell

adjust

properly

To

set

a.

Turn

The

approximately

The

photocell

and

backtacking

sensitivity

the

sensitivity

sense

sensitivity:

pot A on

it

is

manually

by

an

electronic

cell

is

in

4-1/2

initiates

senses

the

sequence.

controls

or

firing

the

full

the

PC

range

board

started,

the

table

inches

the

stopping

inside

point

of

fabrics.

to

PHOTOCELL

SENSITIVITY

POTS

sews

circuit

waistband

extreme

using

top

under

to

the

sequence

the

control

of

the

photo

clock-

right

edge

and

a

the

or

B.

CARRIAGE

The

speed

trolled

by

The

which

shut-off

underside

power

witii

treme

ating

bumper

the

speed

may

switch,

going

the

power

right

lever

sooner.

of

is

have

of

to

end

of

SHUT-OFF

SWITCH

SAFETY

RETURN

the

carriage

gear

motor

not

adjustable,

to

be

which

the

drive

the

return

on.

If

of

the

the

switch

SWITCHES

CONTROL

during

on

the

made

is

is

activated

pulley.

motor

the

motor,

travel,

begins

has

to

the

return

left-hand

and

the

only

in

the

operation

by

the

This

switch

so

that

when

it

to

oscillate,

be

rebent

CARRIAGE

RETURN

MOTOR

stroke

side

of

the

adjustment

bumper

shuts

it

does

reaches

the

to

engage

is

of

on

off

not

the

con

unit.

the

the

the

stop

ex

actu

the

b.

Turn

c.

Turn

control

so

right

and

lower

above

the

erate

on

illuminated.

light

box

d.

Put a piece

that

it

of

the

e.

Remove

the

presser

f.

Adjust

portion

the

needle.

g.

Turn

at

low

the

PC

h.

Let

i.

Slowly

emitting

INSIDE

pot B to

the

power

extends

sewing

the

bar

the

of

the

table

top

the

control

speed.

board

is

the

machine

turn

diode

CONTROL

extreme

main

power

switch

of

material

approximately 8 to

machine

air

from

will

go

sewing

deflector

and

is

Notice

lit.

run

pot B counterclockwise

turns

BOX

clockwise.

switch

turned

underneath

needle.

the

down.

machine

is

between 8 to

illuminating

power

that

the

until

off.

ON.

off.

10

machines.

light

the

ON.

Machine

light

emitting

the

photocell

inches

Keep

the

The

so

that

10

area

around

will

until

the

clamp

to

the

clamp

the

inches

op

diode

is

fully

the

j.

CARRIAGE

RETURN

CONTROL

off

the

control

The

machine

power

will

stop,

switch

position

as

soon

and

as

possible.

trim.

Turn

Page 19

(8)

Safety

switches,

extreme

ally

event

They

extreme

the

vates

and

automatically

chine

of

end

of

stop

and

reset

of a photocell

are

actuated

left

end

clamp

from

the

clutch

no

damage

resets

will

return

the

material.

on

carriage

of

lifting

occurs

to

travel,

the

sequence

or

automatic

by

the

its

travel.

and,

cylinder

to

the

control

the

proper

left

end

of

are

of tiie

stop

carriage

so

the

The

at

the

that

clamp.

circuit

sequence

when

lower

same

table

used

to

machine

control

the

machine

The

so

board

automatic

failure.

it

reaches

switch

time,

de-acti

upper

switch

that

the

for

insertion

at

the

in

the

the

keeps

stops

ma

C.

PHOTOCELL

(1)

stops

photocell

fabric

of

the

of

the

begins

(2)

box

cell

(3)

This

unit,

once

automatically

sensor.

clamp

approximately

needle.

garment

the

Photocell

adjust

to

properly

To

a.

The

and

backtacking

sensitivity

the

sensitivity

sense

set

sensitivity:

Turn

pot A on

it

is

manually

by

an

The

cell

is

photocell

initiates

sequence.

controls

or

the

full

the

PC

started,

electronic

in

the

4-1/2

senses

the

circuit

table

inches

the

waistband

stopping

inside

firing

point

range

of

fabrics.

board

to

extreme

PHOTOCELL

SENSITIVITY

POTS

sews

using

top

under

to

the

sequence

the

control

of

the

photo

clock-

and

a

the

right

edge

or

B.

CARRIAGE

The

speed

of

trolled

by

the

The

speed

which

may

shut-off

underside

power

with

treme

ating

bumper

switch,

of

going

the

power

right

lever

sooner.

the

gear

is

not

have

the

to

end

of

the

SWITCH

SAFETY

RETURN

carriage

motor

adjustable,

to

be

made

which

is

drive

pulley.

the

return

on.

If

the

of

the

travel,

switch

SWITCHES

CONTROL

during

the

on

the

left-hand

and

is

in

activated

by

This

motor

so

motor,

when

begins

has

to

be

return

stroke

side

the

only

the

operation

the

bumper

switch

shuts

that

it

does

it

reaches

to

oscillate,

rebent

to

is

con

of

the

unit.

adjustment

of tiie

on

the

off

the

not

stop

the

ex

the

actu

engage

the

b.

Turn

c.

Turn

control

so

right

and

lower

above

the

erate

on

illuminated.

box

d.

Put a piece

that

it

of

the

e.

Remove

the

presser

f.

Adjust

portion

the

needle.

g.

Turn

at

low

the

PC

h.

Let

INSIDE

pot B to

the

main

power

extends

approximately 8 to

sewing

the

bar

the

of

the

table

top

the

control

speed.

board

is

the

machine

CONTROL

extreme

power

switch

turned

of

material

machine

will

sewing

air

from

go

needle.

down.

machine

deflector

and

is

illuminating

power

Notice

that

lit.

run

until

BOX

clockwise.

switch

ON.

off.

underneath

10

the

machines.

light

is

between 8 to

the

ON.

Machine

the

light

the

photocell

Keep

the

clamp

inches

to

The

clamp

so

that

10

inches

area

around

will

emitting

diode

is

fully

the

the

the

op

CARRIAGE

RETURN

CARRIAGE

RETURN

MOTOR

CONTROL

Revised

Sept.

light

off

the

1974

i.

Slowly

emitting

j.

The

control

turn

pot A counterclockwise

diode

turns

machine

will

power

off.

stop,

switch

as

position

soon

and

as

possible.

until

trim.

Turn

the

Page 20

k.

control

starting

a

function

wise

(k).

quencing,

properly

tion.

D.

STOP

(1)

Attach

power

position.

I.

Operate

single

layer

properly;

by

15°

After

calibrated,

POSITION

The

the

the

control

photo-electric

tentiometers

used

to

or

the

position

ing

edge.

(2)

TION.

through

stop

adjust

the

beginning

position

control

machine

The

fine

The

the

position

coarse

the

air

to

switch.

the

of

thin

and

increments,

machine

electric

CONTROL

is

sensing

on

the

the

of

of

the

the

The

machine

pants

if

not,

repeating

goes

eye

and

the

part

of

system

face

of

position

the

backtack

backtack

adjustment

will

stop

in

adjustment

adjustment

small

hole

just

control

knob.

system

clamp

in a normal

material.

turn

and

will

Machine

pot B counterclock

steps

through

circuit

machine

the

and

the

of

the

cycle,

selection

determines

relation

pot

is

pot

to

the

can

put

delay

function

consists

control

final

stop-trim

depending

switch.

where

to

the

labeled

screw

the

lower

turn

on

return

to

manner,

should

(b)

through

proper

be

considered

into

opera

in

of

two

box.

They

The

the

waistband

STOP

POSI

is

accessible

right

of

the

the

using

se

the

po

are

cycle

upon

stop

sew

the

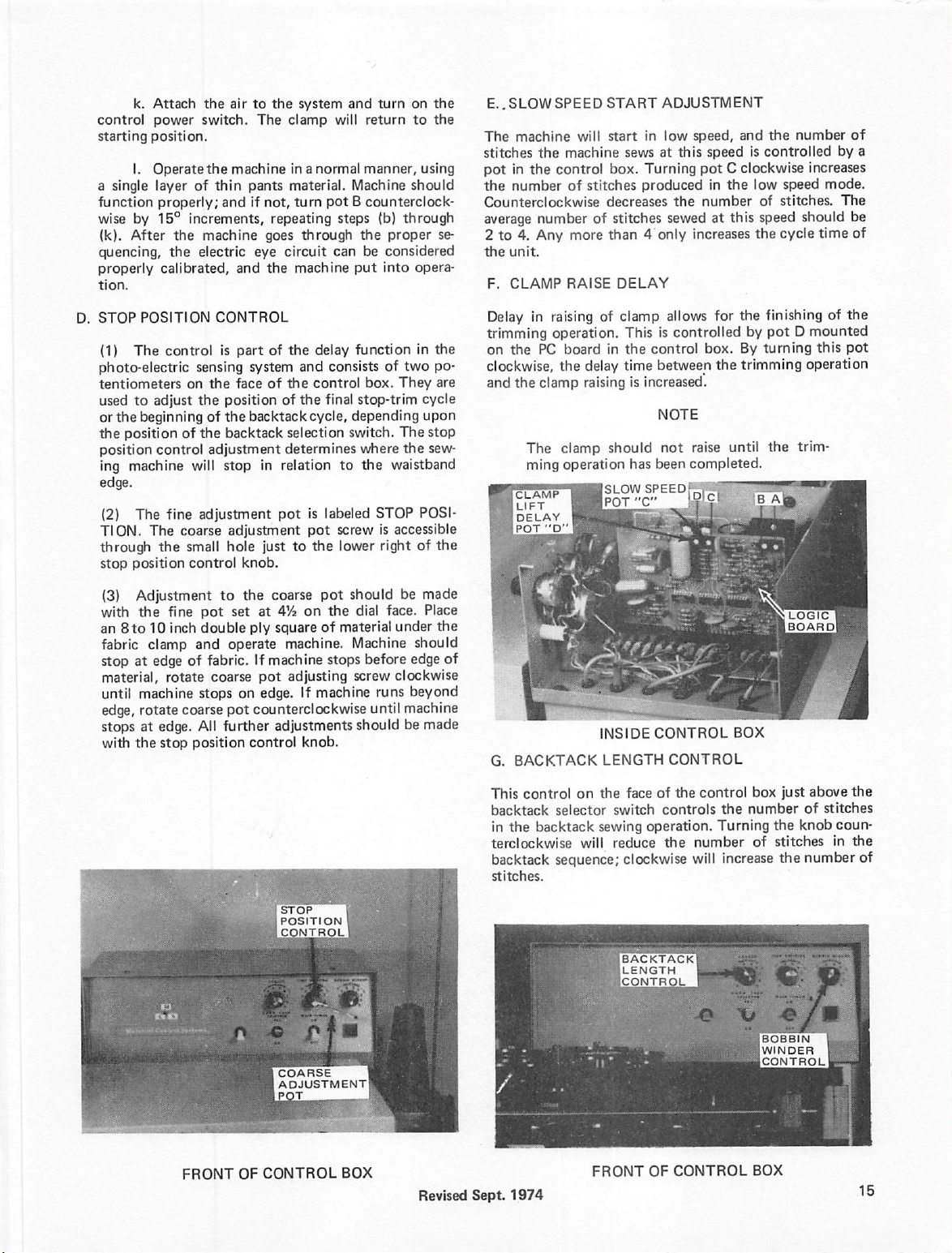

E..

SLOW

SPEED

The

machine

stitches

pot

the

Counterclockwise

average

2

the

F.

Delay

trimming

on

in

the

number

to

4.

unit.

CLAMP

in

the

the

control

number

Any

raising

operation.

PC

clockwise,

and

the

clamp

The

ming

CLAMP

LIFT

DELAY

POT

"D"

START

will

start

machine

box.

of

stitches

decreases

of

more

than 4 only

RAISE

of

board

in

the

delay

raising

clamp

should

operation

SLOW

POT

ADJUSTMENT

in

low

sews

at

this

Turning

produced

the

stitches

DELAY

clamp

This

is

the

control

time

between

is

increased.

NOTE

sewed

allows

controlled

not

has

been

SPEED'

"C"

speed,

and

the

speed

is

controlled

pot C clockwise

in

the

low

number

at

this

increases

for

box.

the

raise

until

speed

of

stitches.

speed

the

cycle

the

finishing

by

pot D mounted

By

turning

trimming

the

completed.

number

of

by

increases

mode.

The

should

time

of

the

this

pot

be

of

operation

trim

a

(3)

Adjustment

with

the

fine

an

8to

10

inch

fabric

clamp

stop

at

material,

until

edge,

stops

with

edge

rotate

machine

rotate

at

edge.

the

stop

to

pot

set

double

and

operate

of

fabric.

coarse

stops

coarse

pot

Ail

further

position

the

coarse

at

ply

If

machine

pot

on

edge.

counterclockwise

control

pot

on

the

of

material

stops

machine

should

dial

Machine

before

screw

472

square

machine.

adjusting

If

until

adjustments

knob.

should

runs

be

made

face.

Place

under

the

should

edge

of

clockwise

beyond

machine

be

made

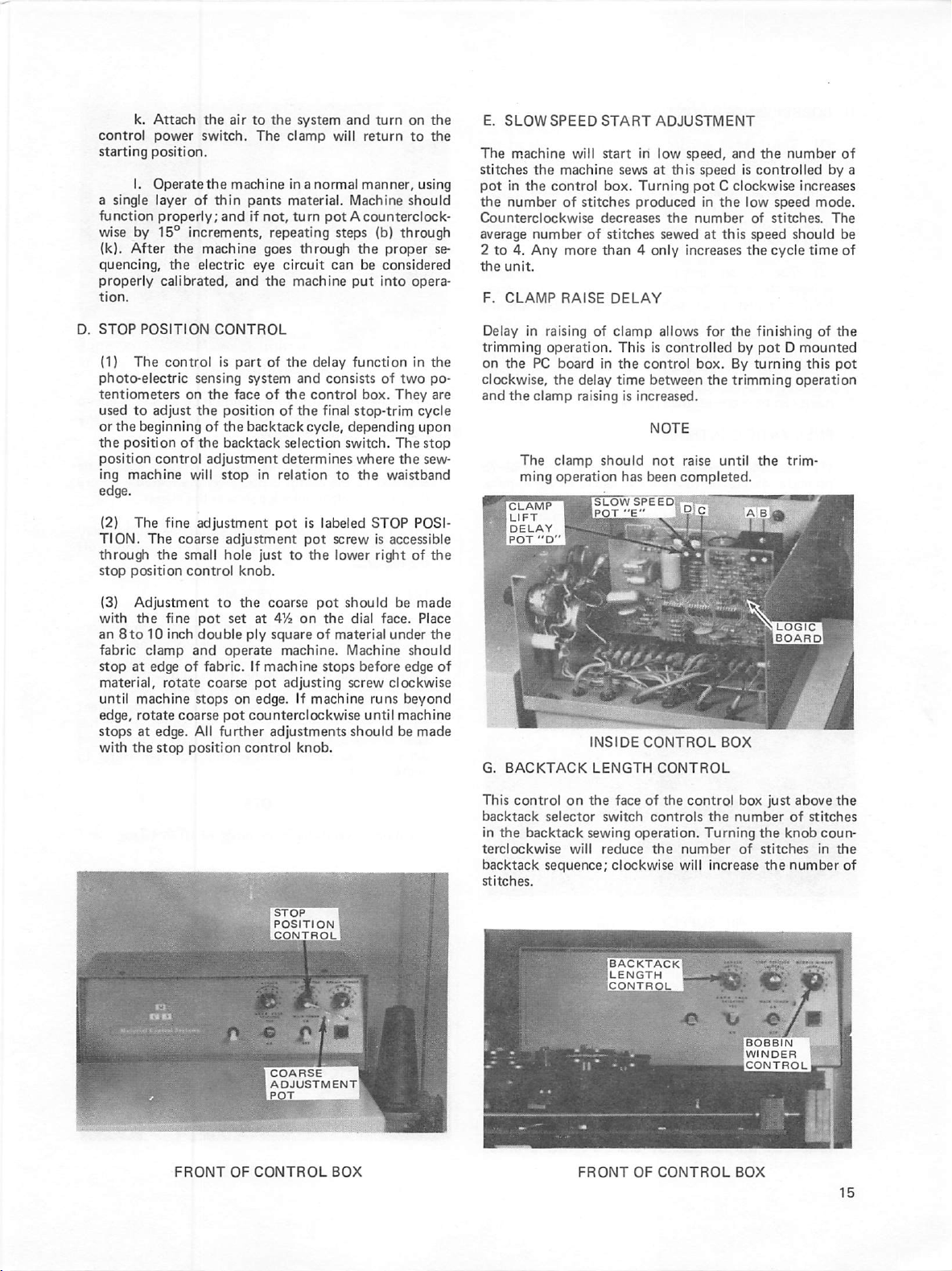

G.

BACKTACK

This

control

backtack

in

the

terclockwise

backtack

stitches.

on

selector

backtack

will

sequence;

INSIDE

LENGTH

the

face

switch

sewing

operation.

reduce

clockwise

CONTROL

CONTROL

of

the

control

controls

the

number

will

BOX

box

just

the

number

Turning

increase

the

of

stitches

the

BOBBIN

WINDER

CONTROL

]

LOGIC

1

board!

above

of

knob

number

I

the

stitches

coun

in

the

of

FRONT

OF

CONTROL

BOX

Revised

Sept.

1974

FRONT

OF

CONTROL

BOX

Page 21

k.

Attach

control

starting

a

function

wise

(k).

power

position.

I.

Operate

single

layer

by

After

properly;

15°

quencing,

properly

tion.

D.

STOP

(1)

calibrated,

POSITION

The

control

photo-electric

tentiometers

used

to

or

the

position

ing

adjust

the

beginning

position

control

machine

edge.

(2)

The

fine

TION.

The

through

stop

the

position

the

air

switch.

the

machine

of

thin

and

increments,

the

machine

the

electric

and

CONTROL

is

part

sensing

on

the

face

the

position

of

the

of

the

backtack

adjustment

will

stop

adjustment

coarse

adjustment

small

hole

control

knob.

to

the

system

The

clamp

in a normal

pants

material.

if

not,

turn

repeating

goes

through

eye

circuit

the

machine

of

the

system

backtack

and

of

the

of

the

cycle,

selection

determines

in

relation

pot

is

pot

just

to

and

turn

on

will

return

to

manner,

Machine

should

pot A counterclock

steps

(b)

through

the

proper

can

be

considered

put

into

opera

delay

function

consists

control

final

stop-trim

box.

of

They

in

two

depending

switch.

to

labeled

screw

the

lower

where

the

waistband

STOP

is

accessible

right

The

the

POSI

of

the

the

using

se

the

po

are

cycle

upon

stop

sew

the

E.

SLOW

SPEED

The

machine

stitches

pot

in

the

number

Counterclockwise

average

2

to

4.

the

unit.

F.

CLAMP

Delay

trimming

on

the

clockwise,

and

the

The

ming

CLAMP

LIFT

DELAY

POT

will

the

machine

the

control

of

number

Any

more

RAISE

in

raising

operation.

PC

board

the

delay

clamp

raising

clamp

operation

"D"

stitches

START

start

in

sews

box.

Turning

produced

decreases

of

stitches

than 4 only

DELAY

of

clamp

This

in

is

the

control

time

between

Is

increased.

NOTE

should

has

been

SLOW

SPEI

POT

"E"

ADJUSTMENT

low

speed,

at

this

speed

pot C clockwise

in

the

the

number

sewed

at

increases

allows

for

controlled

box.

the

not

raise

completed.

and

the

is

controlled

low

of

this

speed

the

the

finishing

by

pot D mounted

By

turning

trimming

until

the

number

increases

speed

mode.

stitches.

should

cycle

time

of

this

operation

trim

by

The

the

pot

of

a

be

of

(3)

Adjustment

with

the

an

8to

10

fabric

clamp

stop

at

material,

until

edge,

stops

witii

edge

rotate

machine

rotate

at

edge.

the

stop

fine

pot

inch

double

and

of

stops

coarse

All

position

to

the

coarse

set

at

472

ply

square

operate

fabric.

coarse

pot

^rther

machine.

If

machine

pot

adjusting

on

edge.

counterclockwise

adjustments

control

pot

on

the

of

stops

If

machine

knob.

should

material

dial

be

face.

under

Machine

before

screw

clockwise

runs

until

should

made

Place

the

should

edge

of

beyond

machine

be

made

G.

BACKTACK

This

control

backtack

in

terclockwise

backtack

stitches.

the

backtack

selector

sequence;

on

sewing

will

INSIDE

the

LENGTH

face

switch

operation.

reduce

clockwise

CONTROL

CONTROL

of

the

controls

the

number

will

BOX

control

the

box

number

Turning

of

increase

;

LOGIC

board!

just

above

of

the

knob

stitches

the

number

I

the

stitches

coun

in

the

of

FRONT

OF

CONTROL

BOX

FRONT

OF

CONTROL

BOX

Page 22

H.

BOBBIN

(1)

unit.

The

fullness

bin

be

put

on

the

(2)

winder

bobbin

stud

Then

button,

cycle.

will

ment

PNEUMATIC

(1)

psi

and

(2)

entire

leg

and

WINDER

The

bobbin

It

is

controlled

CONTROL

winder

potentiometer

of

the

filling.

on

bobbin.

The

starts

and

bobbin

If

turned

the

bobbin,

button

the

winder,

place

wind a few

under

bobbin

momentarily

and

the

bobbin

After

the

pre-selected

stop

and

the

bobbin

can

be

made

on

CONTROLS

The

unit

requires a minimum

consumes

The

main

system.

should

up

regulator

It

is

be

set

is

on

the

by

an

on

the

control

by

controlling

electronic

right

box

the

face

counterclockwise,

while

clockwise

the

winding

bobbin

turns

of

thread

depress

the

winder

time,

will

be

the

control

to

2-72

cubic

controlsthe

mounted

at

45—55

puts

table

near

cycle.

on

the

bobbin

counterclockwise.

bobbin

will

start

the

full.

If

not,

knob.

air

supply

feet

of

air

on

the

right-hand

psi.

side

timing

of

circuit.

adjusts

time

of

less

thread

more

thread

the

bobbin

To

operate

winding

winder

the

winding

bobbin

winder

the

adjust

of

65-75

air

per

minute.

pressure

to

table

the

the

bob

will

start

the

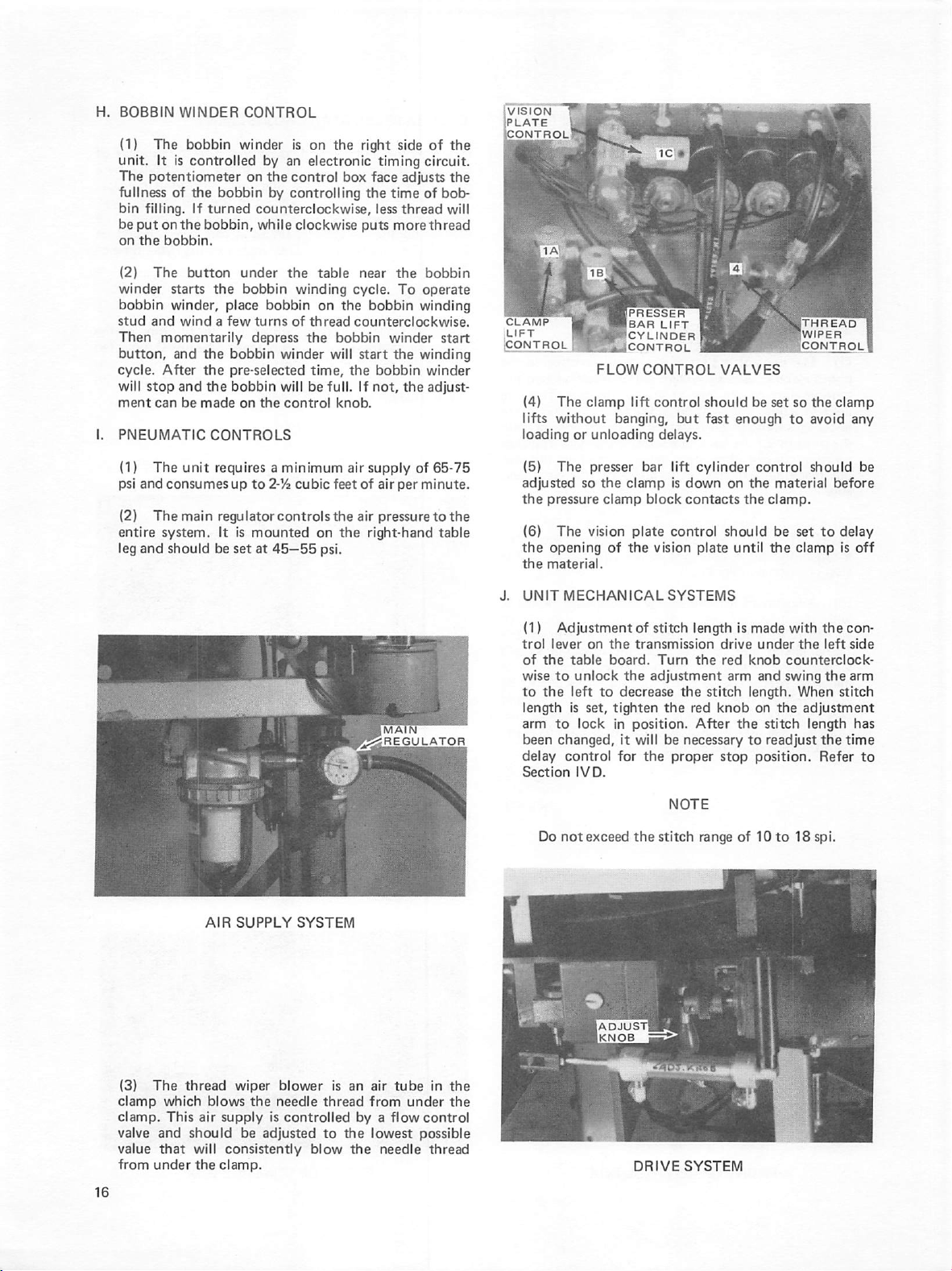

VISION

PLATE

CONTROL

(4)

lifts

loading

(5)

adjusted

the

pressure

(6)

the

opening

the

material.

1

FLOW

The

clamp

without

or

unloading

The

presser

so

the

clamp

The

vision

of

CONTROL

lift

control

banging,

delays.

bar

lift

clamp

is

block

plate

control

the

vision

VALVES

should

but

fast

cylinder

down

on

contacts

should

plate

be

set

enough

control

the

material

the

clamp.

be

until

the

so

the

to

avoid

should

set

clamp

clamp

before

to

delay

is

any

be

off

AIR

SUPPLY

SYSTEM

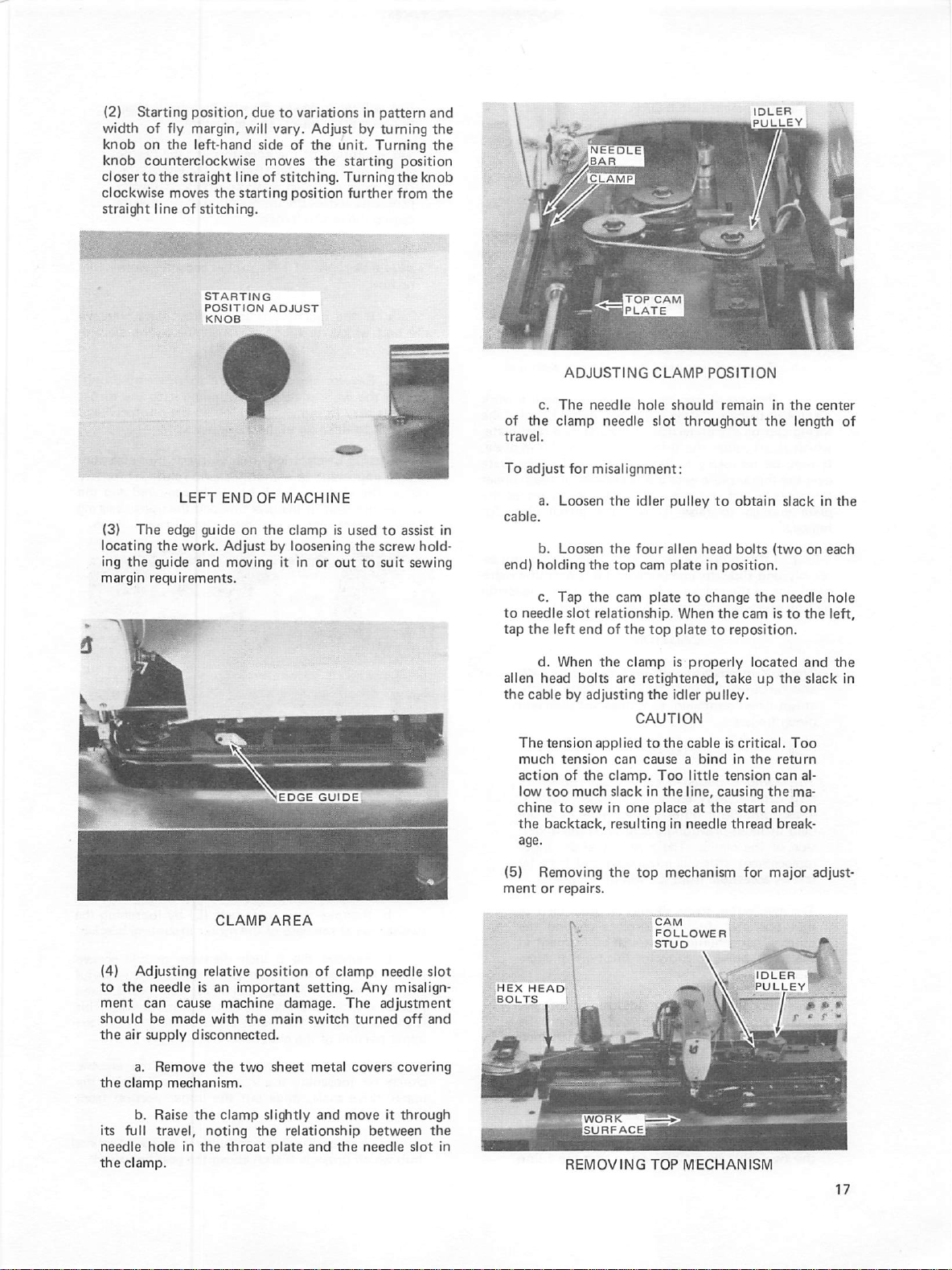

J.

(1)

trol

to

Section

UNIT

MECHANICAL

Adjustment

lever

of

the

table

wise

to

the

length

is

arm

to

been

changed,

delay

control

Do

not

on

the

board.

unlock

left

to

set,

lock

IV

D.

exceed

SYSTEMS

of

stitch

transmission

Turn

the

adjustment

decrease

tighten

in

the

position.

it

will

be

for

the

the

stitch

length

drive

the

red

the

stitch

red

knob

After

necessary

proper

stop

NOTE

range

is

made

under

knob

arm

and

length.

on

the

stitch

to

readjust

position.

of

10

with

the

the

left

counterclock

swing

the

When

the

adjustment

length

the

Refer

to

18

spi.

con

side

arm

stitch

has

time

to

(3)

The

clamp

clamp.

valve

and

value

that

from

under

thread

w^ich

This

wiper

blows

air

supply

should

be

will

consistently

the

clamp.

blower

the

needle

is

controlled

adjusted

is

thread

to

blow

an

air

tube

from

by a flow

the

lowest

the

needle

in

under

control

possible

thread

the

the

DRIVE

SYSTEM

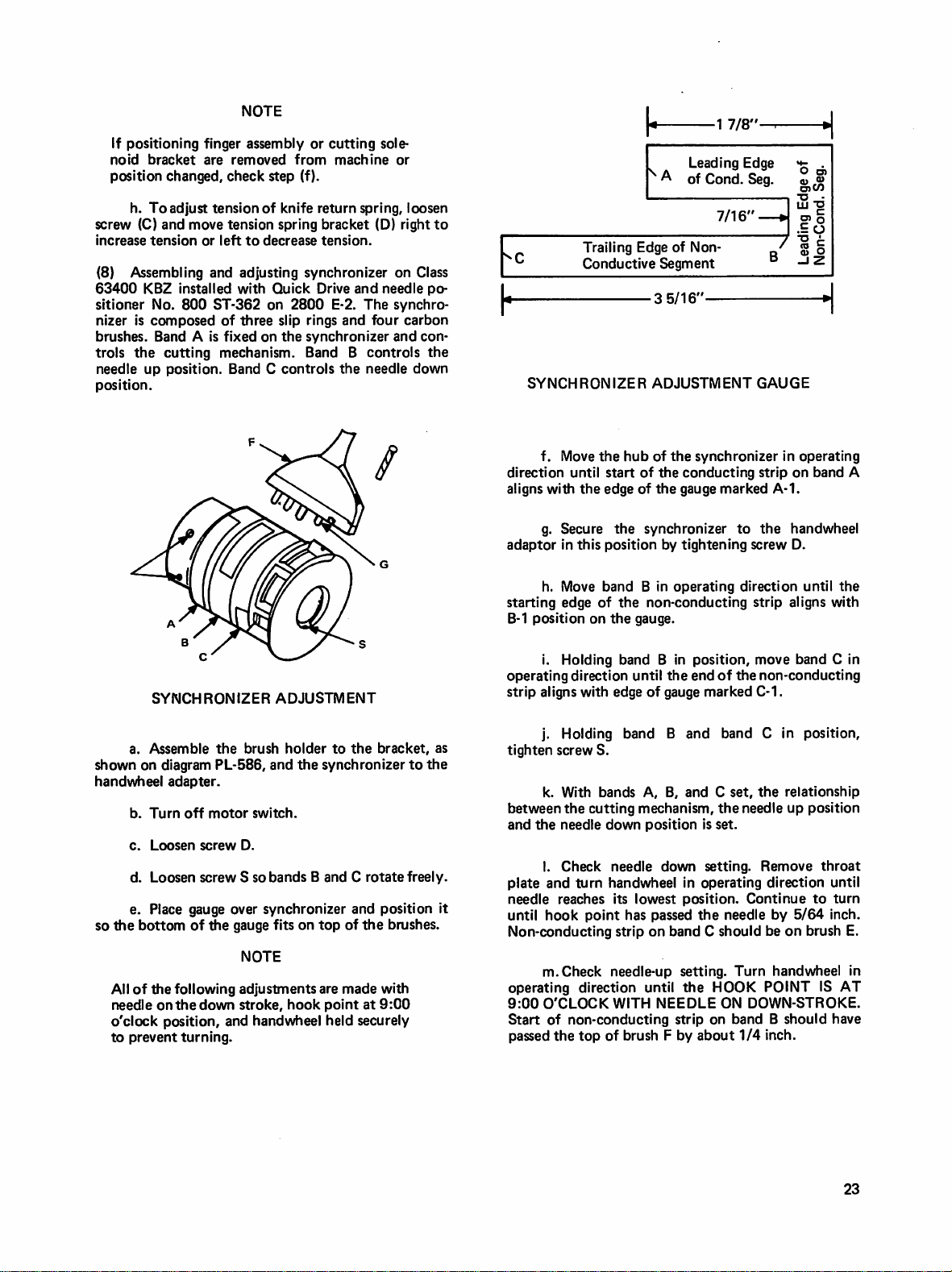

Page 23

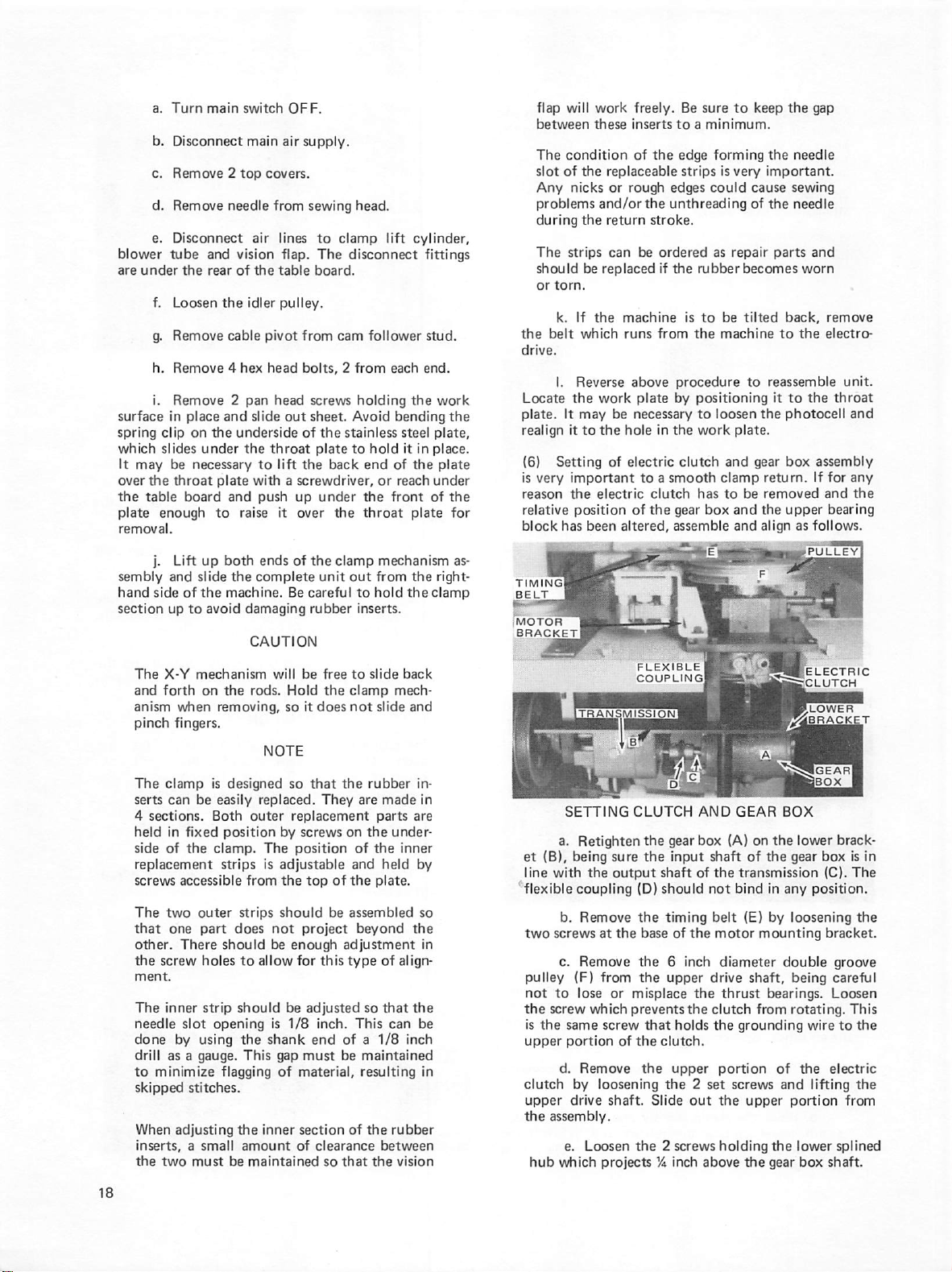

(2)

Starting

width

knob

on

knob

closer

to

clockwise

straight

position,

of

fly

margin,

the

counterclockwise

the

straight

moves

line

of

due

will

left-hand

side

line

the

starting

stitching.

to

variations

vary.

Adjust

of

the

moves

of

the

stitching.

position

in

pattern

by

turning

unit.

Turning

starting

position

Turningthe

further

from

and

the

the

knob

the

TOP

PLATE

CAM

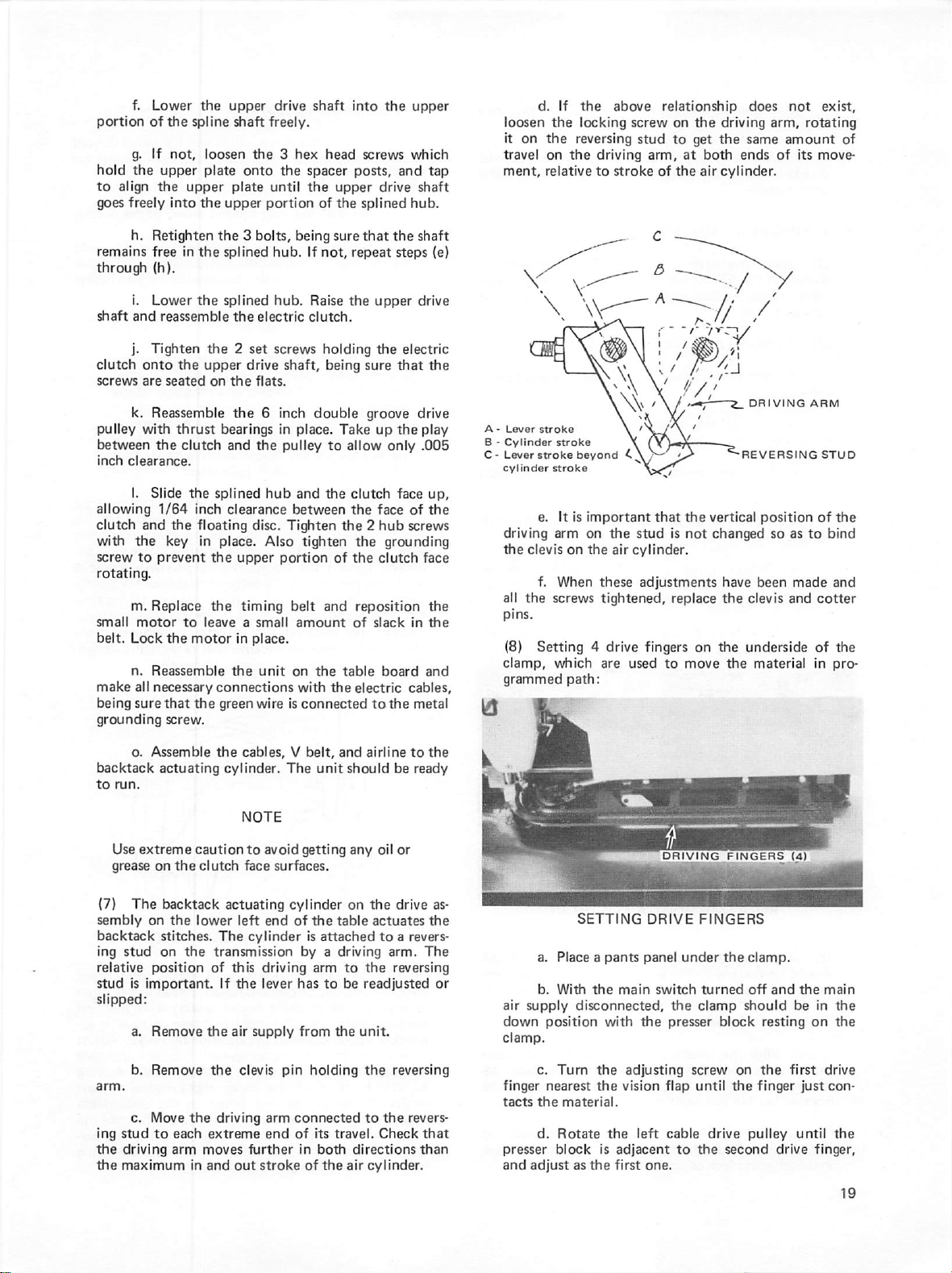

{3}

The

locating

ing

margin

the

the

guide

requirements.