Page 1

Page 2

Page 3

CATALOG

NO.

49

Instructions

Installing,

11500

11500

11500

A

F

G

Operating

With

TJNION

General

Representatives

BRANCHES

Hosiim,

T.yiin.

iliivorhill,

New

York,

Ulien,

Koi'hester,

Newark,

Baltimore,

Detroit,

BELGIUM,

CANADA,

CANADA.

DhlNMARK,

ENGLAND,

FRANCE.

PRANCE.

GERMANY,

ARGENTINE

Buenos

AUSTRIA

Vienna

AUSTRALIA

Meliiourne

Sydney

BRAZIL

Rio

De

Santos

CANADA

Winnipeg

CHINA

Hong

Shanghai

CUBA

Havana

DUTCH

Batavia

Mass.

Mass,

N.

Y.

SERVICE

N.

Mich,

Foreign

Aires

Janeiro

Kong

EAST

AND

Miiss,

N.

Y.

N.

Y.

REPRESENTATIVES,

J.

Md.

Brussels

Toronto

Montreal

Copenhagen

Leicester

Paris

Lyons

Stuttgart

Distributors

REPUBLIC

INDIES

Copyright,

Styles

11500

11700

11700

List

SPECIAL

Office:

SERVICE

BRANCHES,

Union

Union

Union

Comiiagnio

Compagiiie

Union

ECUADOR

ENGLAND

PRKNCH

HAWAIIAN

INDIA

IRELAND

ITALY

JAPAN

1923,

MACHINE

400

North

Chicago,

in

all

STATIONS,

Jolitison

Ainsierdiim.

Triiy,

I'liiiiidelphia,

Reiuiing,

Toledo,

Union

Union

City,

N.

Y.

Pii.

Ohio

Nashville,

Atlanta,

Ga.

Milwaukee,

Special

Special

Special

Special

Special

Special

and

Service

Guayaquil

Leeds

London

Manchester

Norwich

INDO

Saigon

Honolulu

Bombay

Belfast

Milan

Osaka

Tokyo

by

Union

Printed

in

for

and

H

C

F

of

Parts

COMPANY

Franklin

Illinois

Manufacturing

N.

N.

Y.

I'li.

Tenn.

Wis.

FOREIGN

Machine

Machine

Machine

Machine

Machine

des

Machines

de.s

Machines

Machiiienfabrik,

CHINA

ISLANDS

Special

U.

S,

UNITED

Y.

UNITED

Corporation

Company

Company

Corporation

Corporation

Stations

Machine

A.

Union

Union

Adjusting

11700

Street

Centers

STATES

Cleveland,

Ciiieinnati,

Miiineitiiolis,

St.

Kiiiisiis

Sun

Ohio

Louis,

Mo.

City,

Francisco,

STATES

Dallas,

Tex.

Seattle,

'Wash.

Los

Angeles,

of

America.

of

Canada,

of

Canada,

of

America.

of

America.

Special

Special

G.

m.

h.

H.

are

found

MEXICO

Mexico

NEW

PHILIPPINE

PORTUGAL

SCOTLAND

RIAM

SOUTH

SPAIN

URUGUAY

City

ZEALAND

All

ckiand

Ohristchurch

Wellington

Manila

Porto

Glasgow

Durulee

Bangkok

AFRICA

Johannesburg

Barcelona

Montevideo

Co.

11700

11700

Ohio

Minn.

Mo.

Cal.

de

de

in;

ISLANDS

Cal.

Ltd.

Ltd.

France,

Prance.

G

L

M

J

Page 4

IMPORTANT

Tlie

parts

furnished

Attention

that

many

patents,

tions,

at

repairing

their

and

list

prices,

original

or

machines

CUSTOMERS

listed

at

list

prices

is

hereby

of

said

enter

that

in

we

license

condition.

NOTICE

in

tliis

for

called

parts

are

into

i)atented

furnishing

tlielr

of

our

own

TO

catalog

repairs

to

only.

the

subjects

combina

tiiese

parts

use

only

make,

are

fact

of

for

in

Notice

such

thereof

one

than

fringement,

will

is

hereby

parts

by

for

ciiaiiging

style

to

bona fide

for

be

liable

giveii

the

purchaser,

over

another,

repair

to

purposes,

which

the

prosecution.

that

machines

or

for

seller

the

or

any

is

sale

the

from

other

an

or

user

of

use

in

Page 5

CONTENTS

Important

Notice

Foreword

Application

Identification

Illustration

of

of

of

Machines,

Installing

Operating

Oiling

Threading

Adjusting

Formation

Regulating

Tensions

Thread

Repairing

Assembling

Needles

Ordering

Plates

List

of

Repair

Parts

of

Stitch

Length

to

Customers

Catalog

Machines

Ready

of

Stitch

Parts

to

Operate

Page

2

4

5

6

8

H

I7

17

Ig

22

22

27

28

28

31

32

33

35

36

52

Page 6

It

is

Union

that

this

tions

machines

and

Special

will

book

for

definitions.

the

aim

of

tlie

Sewing

secure

is

installing,

in

the

maximum

dedicated.

operating,

Classes

11500

FOREWORD

manaj^ement

Machines

quality

On

the

pages

adjusting

and

11700

to

place

carefully

and

which

witii

prepared

production.

follow

and

repairing

illustrations

before

are

given

the

u.sers

of

information

To

this

end

instruc

the

styles

of

of

the

parts

Detailed

in

Catalog

Catalog

No.

There

mation

which

outs,

efficient

the

users

of

those

relating

sewing

correct

equipment,

Conij)any

of

its

In

all

the

Union

who

information

No.

29.

45.

These

is

also

available a comprehensive

to

the

machines

sejiuence

relating

Needles

books

manufacture

can

of

production

])laces

machines

manufacturing

Special

desire

at

alike

Machine

in

planning

UNION

the

centers

to

the

are

listed

will

be

furnished

of

every

be

used.

operations,

disposal

without

It

specifications

and

all

of

restriction.

can

now

Company,

and

estimating

SPECIAU

MACPIINE

Department

transmitter

and

fully

gratis

fund

of

kind

of

merchandise

embodies

sewing

as

details.

customers

be

who

This

and

found

representatives

Avill

co-operate

their

requirements.

COMPANY

of

Sales

will

be

found

described

on

request.

valuable

infor

room

to

the

information

prospective

Engineering

in

on

lay

most

with

Page 7

This

catalog

widths

specified

as

specified

for

11500

11500

11500

11500

11500

11500

11700

It

can

the

A

F—I

F—^

G—t

G—i

H

C—4

only

APPLICATION

api)lies

tor

tlie

styles

in

inch

"

"

gauge

be

applied

only

to

styles

Class

11700:

hem

with

styles

of

machines

in

Class

11500

11700

11700

11700

11700

11700

11700

11700

11700

discretion

to

and

C-4i

C—5

C—82

F—5

G—5

L—4J

L—5

M—2

otlier

fitted

in

the

gauge

styles.

for

hem

gauges

Page 8

IDENTIFICATION

A

macliiiie

operation

evenly

11700

given a class

divisible

with

made

The

■l\r

inch,

is

given a style

divisible

C.

Styles

of

number,

by

100,

Attached

either

The

by

spacing

to

the

measurement

styles

of

4i

gauge ^ inch, 5 gauge

macliine.s,

e(iuippe<l

witli

specified

nnmber,

by

100

with a letter

similar

tiie

symbol

witlnmt a letter

each

style

niimi)er

in

Class

the

gauges

machine

of

will

or

the

space

11700

is

as

is

OF

MACHINES

parts

and fitted

the

symbol

for

affixed.

in

construction,

for

which

affixed.

be

class

Examples:

found a name

number.

between

the

represented

Examples:

is a number

by a gauge

for a specific

which

is a number

are

grouped

11500,

plate

rows

of

11500

G,

and

evenly

11700.

stamped

stitching

number.

follows: 2 gauge ^ inch, 4 gauge

inch,

32

gauge 4 inch.

STYLES

Right

11500 A For

Hand

open

11500 F For

fabric,

Type

11500 G For

ments;

locked

11500 H For

locked

same

11500 Z A

not

more

ard

operation.

OF

Cylinder

stitching

front

hemming

double

124.

hemming

hem

stitch,

stitching

stitch,

length

special

specifically

parts

styles

MACHINES

Cylinder,

yarn

pi-esser

bags;

locked

<tveralls,

turned

needle

gauntlets

presser

as

Type

style,

similar

defined.

differing

in

tiie

class,

Bed,

rolls

foot,

hem

on

same

foot

021.

from

One

21

Inches

to

mittens;

needle

turned

stitch,

jackets,

under

length

to

canvas

has

to

the

It

is

the

and

is

()

IN

CLASS

Needle,

double

same

length

on

needle

trousers

surface

as

Type

gloves;

yielding

styles

always

fitting

often fitted

of

11500

Diameter

locked

as

upper

same

and

of

fabric,

128.

lap

seam,

left

in

Class

fitted

with

any

of

for a different

Type

surface

length

similar

side,

11500,

the

of

stitch,

121.

gar

double

double

needle

but

one

stand

of

as

or

Page 9

IDENTIFICATION

OF

MACHINES

STYLES

Right

Hand

Left

11700 C For

one

is

fastened

11700 F For

garment

stitch,

11700 G For

garment

stitch,

11700 L For

one

of

11700 M For

locked

same

11700 Z A

special

not

more

ard

operation.

OF

MACHINES

Cylinder

Hand

Needle

Cylinder 2i

sottinjr

operation,

setting

setting

setting

operation

goods

stitching

specifically

styles

jacket

to

passes

needles

i)asses

needles

jacket

is

suspended,

stitch,

length

style,

parts

differing

in

double

cloth

mackitiaw

to

same

mackhunv

to

same

double

gauntlets

presser

as

Type

defined.

the

Bed,

similar

Two

in

Front,

sleeves:

locked

plate,

sleeves;

the

right

length

sleeves;

the

left

length

.sleeves:

locked

needles

to

foot

021.

to

from

class,

and

IN

CLASS

Needles,

Diameter

Inches

double

stitch,

needles

canvas

It

same

one

of

the

as

Type

one

of

the

as

Type

double

stitch,

same

gloves;

has

yielding

the

styles

is

always fitted

tiie fitting

is

often fitted

11700

Two

of

stitch

felled

folder

needles,

128.

needles,

128.

stitch

folder

for

length

operation,

double

operation,

double

felled

for

length

lap

left

in

Class

of

any

for a different

Loopers,

lap

seam,

both

as

Type

body

locked

body

locked

lap

seam,

upper

as

Type

seam,

double

side,

needles

11700,

with

one

of

the

stand

plies

128.

of

of

ply

128.

but

or

Page 10

¥

i^m

style

11700

C—^Ready

to

operate.

y

Page 11

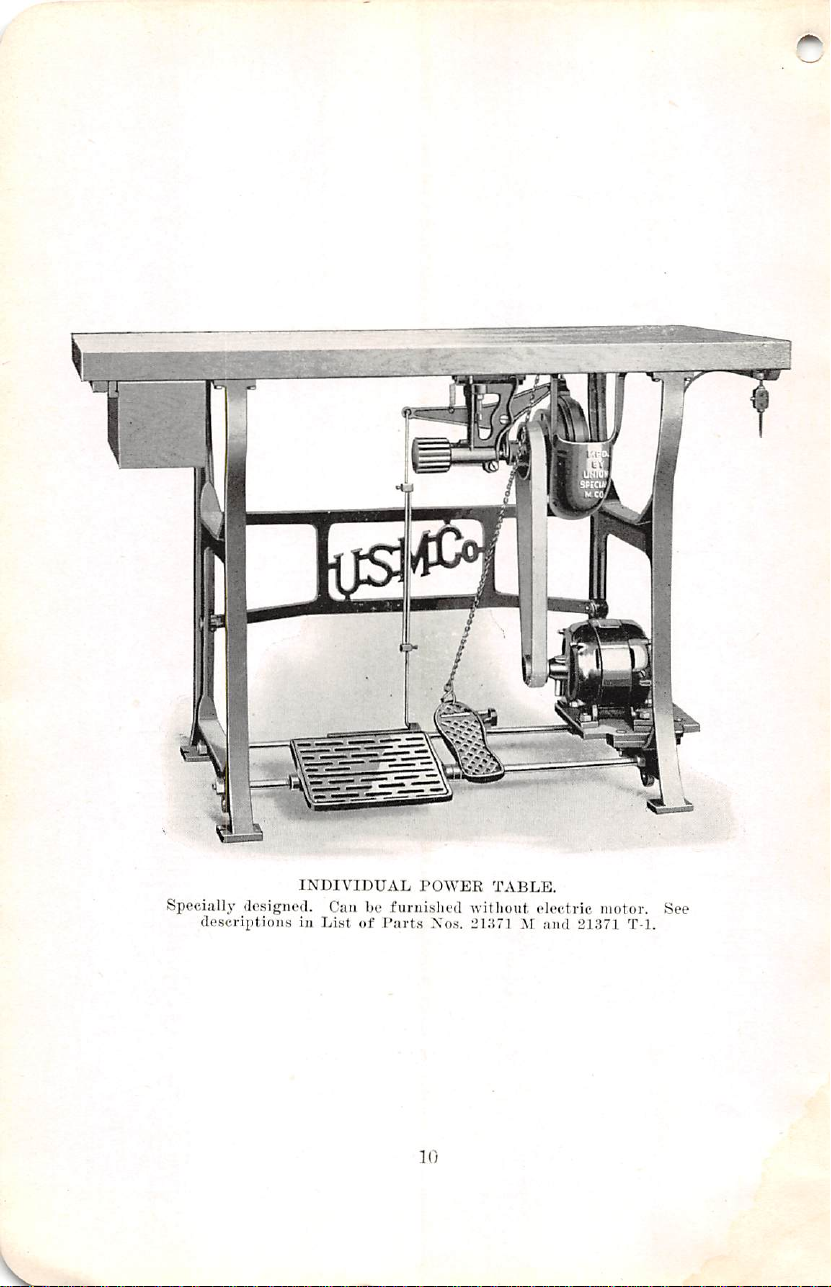

Specially

(lesigned.

(lescriptiojiH

INDIVIDUAL

Can

in

Li.st

be

furnislied

of

P;irts

rOWER

.Vos.

]0

TABLE.

witlioiit

I'lHTl

ele<'tric

ami

motor.

21371

T-1.

See

Page 12

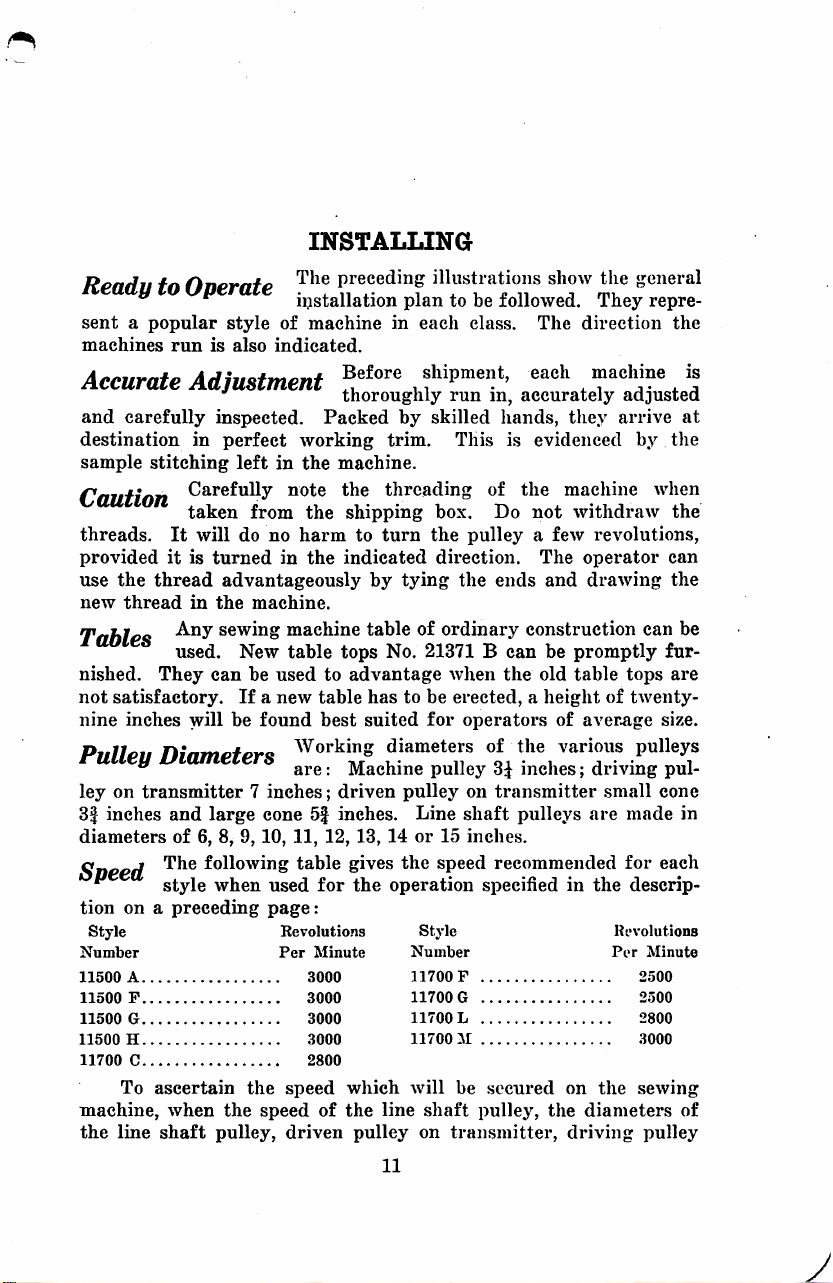

INSTALLING

Ready

sent a popular

machines

Accurate

and

destination

sample

Caution

threads.

provided

use

new

m

to

Operate

"

run

is

Adjustment

'

carefully

inspected.

in

stitching

taken

It

will

it

is

turned

the

thread

thread

in

Any

the

style

also

perfect

left

advantageously

sewing

used.

nished.

not

nine

Pulley

ley

3f

diameters

«

tion

Style

Number

11500

11500

11500

11500

11700

machine,

the

They

can

satisfactory.

inches

"

on

inches

on a preceding

A

P

G

H

To

line

will

be

Diameters

transmitter 7 inches;

and

large

of

6,

8,

» The

C

following

style

when

ascertain

when

the

shaft

pulley,

installation

of

indicated.

working

in

the

from

the

do

no

harm

in

the

machine.

machine

New

table

be

used

If a new

found

are:

cone

9,

10,

11,

table

used

page:

Revolutions

Per

3000

3000

the

speed

speed

driven

P^eding

machine

fjfore

thoroughly

Packed

plan

in

by

trim.

machine.

threading

shipping

to

turn

indicated

by

tying

table

tops

No.

to

advantage

table

has

to

best

suited

diameters

Machine

driven

5|

inches.

12,

for

Minute

3000

3000

2800

of

13,

14

gives

the

operation

which

the

line

pulley

11

pulley

the

illustrations

to

be

each

class.

shipmetit,

run

in,

skilled

This

of

box.

the

pulley a few

direction.

the

of

ordinary

21371 B can

when

be

erected, a height

for

operators

orthc

pulley

on

Line

shaft

or

15

inches.

speed

specified

Style

Number

11700

F

11700

G

11700

L

11700

M

will

be

secured

shaft

pulley,

on

transmitter,

show

followed.

The

each

accurately

hands,

is

evidenced

the

Do

not

the

They

direction

machine

they

machine

withdraw

revolutions,

The

operator

ends

and

drawing

construction

be

promptly

the

old

table

of

of

aver.age

3i

transmitter

recommended

various

inches;

pulleys

driving

small

are

in

the

on

the

the

diameters

driving

adjusted

arrive

for

lifvolutions

Per

general

repre

the

is

at

by

the

when

the

can

the

can

be

fur

tops

are

twenty-

size.

pulleys

pul

cone

made

in

each

descrip

Minute

2500

2500

2800

3000

sewing

of

pulley

Page 13

on

transmitter,

make

an

allowance

the

product

diameter

efficiency

the

transmitter

pulley.

450

revolutions

the

driving

efficiency

on

transmitter

pulley

of

of

the

by

Example:

is

94%

"D"

and

sewing

of

the

speed

transmitter

the

product

pulley,

If

per

minute,

pulley

is

the

is

3f

3^

inches,

"C"

diameter

inches,

INSTALLING

6%

for

of

driving

of

the

and

the

speed

its

on

and

then

machine

the

inevitable

the

line

pulley

diameter

the

diameter

of

diameter

the

transmitter

of

the

the

diameter

the

speed

pulley

shaft

pulley,

and

of

the

of

the

line

is

12

driven

of

are

known,

belt

slippage;

its

diameter,

the

per

cent

driven

the

shaft

inches,

is 7 inches,

cone

of

the

the

cone

sewing

pulley

the

diameter

pulley

sewing

sewing

and

also

divide

the

of

belt

used

on

machine

"A"

the

belt

"B"

used

machine

machine

is

of

is

450 X 12" X 7" X 94%

-or

2915

R.P.M.

3f' X 3i"

The

order

diameter

factor

pulley

two

given

accordingly.

the

line

is

on

different

diameter

cone

to

Fcistening

chine

near

department

shaft

the

speed

the

transmitter

speeds

of

The

formulae

use

to

secure

Machine

the

right-hand

pulley

of

the

is

can

be

line

shaft

the

and

endeavors

with

each

customer's

designed

secured

pulley

furnished

desired

to

machine, A possible

line

with a fast

on

the

by

will

speed.

Transmitter

end

of

the

section.

12

send

the

most

shaft.

sewing

arranging

be

to

As

and a slow

machine

helpful

Table

The

suitable

missing

the

driven

with

the flat

in

deciding

Locate

the

front

cone,

belt

ma

edge

a

Page 14

of

the

base

should

the

table.

machine

in

position.

Mark

base

Do

If a table

its

normal

furnished

and

table.

The

table

the

lifter

is

fastened

pulley

alignment

Invert

the

machine.

with

front

from

Remove

bolt

from

over

to

hold

The

ing

the

swing

shaft

the

front

justment.

Place

bind,

of flat

transmitter

ample

the

belt

in

the

conforms

Turn

Should

by

turning

tion

mitter

position

are

Suitable

transmitter

that

it

lever

with

must

with

the

the

groove

right-hand

tlie

front

the

transmitter

the

the

bolt

it

temporarily.

transmitter

tension

the

frame ^ inch

by

loosening

one.

the

allowing

belt

required

pulley.

tension

around

malleable

to

the

the

pulleys

it

fail

the

with

both

should

be

set

the

table

and

bore

^-inch

not

put

block

is

fiirnished

on

the

of

sufficient

holes

should

will

clear

the

be

the

chain,

in

one

line

line

knee

bolt

with

transmitter

See

that

in

the

hole

in

edge

of

the

top

of

the

and

tighten

is

equipped

on

the flat

tlie

Fasten

pulley

for

the

on

susceptibility

to

Cut

without

the

line

shaft

iron

belt

curvatue

by

hand

to

ride

the

transmitter

the

line

be

permanently

INSTALLING

back

two

inches

under

the

holes.

on

nuts.

to

raise

table,

follow

length

will

be

be

to

found

so

located

pass

operator's

lifter

and

and

three

the

machine

shaft.

and

place

the

groove

machine

the

table.

and

table.

the

in

pulley

transmitter

Mark

bore a ^-inch

Place

nut

securely.

with a pivoted

belt.

To

secure

out

of

the

rear

belt

adjusting

lock

nuts

the

line

shaft.

of

movement.

go

around

the

belt

readjusting

and

lacing

of

the

to

crowns

as

shaft

the

the

abut

No.

cone

and

note

evenly,

required.

and

the

secured

13

from

four

countersunk

Place

the

the

machine

the

same

througli

in

the

block.

on

the

clothing,

knee

press

wood

screws.

pulley,

it

on

top

its

driving

and

that

plate

the

table

hole.

tlie

front

the

benefit

vertical

and

screw,

securely

Tighten

line

shaft,

inches

short.

transmitter

the

ends

21350.

the

teeth

whether

the

error

Once

sewing

to

the

the

front

holes

machine

higher

plan.

the

machine,

under

avoid

contact

mechanism.

The

and

the

of

tlie

table

pulley

the

center

is

twelve

under

Insert

right-hand

This

will

frame

of

for

this

toward

and

to

maintain

sufficiently

Measure

pulley

This

frame.

on

the

cone.

See

that

are

well

the

belt

may

set

in

proper

machine,

table

edge

of

in

the

and

bolts

than

The

bolts

block

side

of

the

with

It

driving

shaft

in

behind

is

in

line

of

the

inches

this

hole.

the

J-inch

hole

be

ample

regulat

feature

the

line

tightening

the

ad

to

the

length

and

the

will

give

Place

Drive

the

lacing

clinched.

runs

true.

be

rectified

rela

the

trans

by

placing

Page 15

INSTALLING

sci'ews

to

belt.

through

is

right.

runs,

holes

By

resting

The

by

to

inch.

positions.

the

of

mitter

ends

in

them

its

be

The

which

The

The

treadle,

treadle

hang

tomary

inch

ciiair

Floor

the

treadle

illustration

in

the

remaining

the

shaft.

Locate

The

the

the

former

hole

furnislied.

If

the

line

cross

the

is

to

use a pointed

placing

angles

cutting

tlie

Kemove

machine

roiuid

on

the

slant

They

bell:

it

at

two

of

slioiild

the

to

i'e<iuire(l

driving

witii

belt

Fasten

front

The

center

tlie

of

the

is

desirable.

transmitter

is

directly

approximately

latter

distance

the

machine

treadle

pitman

in a vei'lical

lumber,

leg

rest

rod

and

may

will

suit

to

increase

and

extensions.

Treadle

rear

of

the

fastened

Two

kinds

of

holes.

holes

for

the

is

easily

in

the

machine

Bore a Linch

sliaft

rotates

round

belt. A convenient

rod.

in

the

gi-oove

tal)le

top,

an

wliicli

they

pieces

the

of

rod.

be

machine,

the

table,

to

pulley.

hook

No.

dress

guard

should

heavy

The

bored ^ inch

bore

using

go

Cut

21351.

transmitter

treadle

under

one

inch

back

may

be

is

used

should

should

the

be

set

lie

attached

be

ad,justed

operator's

position.

the

height

the

lieiglit

Lifter

machine,

to

the floor.

of

floor

Style

connected

treadles

11700

("—Ready

Tighten

lifter

accomplished

hole.

reversely

the

of

the

accurate

diameter

the

lever

base

and

Slant

to

same

machine

location

be

bored

paper

line

chain,

by

the

the

the

direction

plan

diameter

pulley

can

or

card

of

the

forward

the

holes,

and

all

four

bolts.

around

the

to

belt

the

the

under

machine

inches

side

pulleys. A space

should

varied

and

With

presser

be

so

located

the

needles.

from

the

front

according

the

coiiveuienee

witli

the

enclosed

to

the

in

length

so

convenience;

some

stjdes

of

the

treadles

of

the

operator's

furnished

toot,

are

14

by

means

made

to

it

operate

Its

right-hand

that

it

consists

for

shaft

pulley

also

for

the

marking

wood

auger

the

block,

slightly

the

for

locating

as

the

round

with

the

is a simple

also

be

determined

board

holes

from

to

should

their

permanently

Measure

pulley

short.

of

the

of

one

on

front

edge

to

the

end

the

and

Fasten

table

inch

the floor

edge

of

the

operation

of

the

opei'ator.

to

tlie

side

the

incline

need

not

necessarily

of

machines

it

with a piece

chair

with

for

raising

of a lever

of a chain,

this

purpose.

shows

the

securely

round

table

if

one

to

the

machine

the

belt

belt.

point

mattei'.

conform

l)e

(Jiic

normal

fasten

length

trans

tlie

directly

between

that

should

taiile.

for

right.

of

the

of

tlie

is

cus

of

two-

tubular

the

on

with

a

The

kind

Page 16

INSTALLING

generally

taken

treadle.

kiiul

should

the

with

Knpp

As

showji

the

the

connecting

tachment.

over a point

middle

hack

niitter

be

in

ment

between

tional.

geously

under

through

Adjust

Knee

It

is

raising

ing

a

chain

attached

device

table.

rectly

transmitter

transmitter

the

with

of

the

for

formation.

funiisiied.

to

iiave

The

illustration

furnished

be

taken

transmitter

it.

Prp<t^

in

undei'

assembly

side

The

of

the

as

possible

with

frame.

line

with

of

the

tlie

two

Tiiis

to

overcome

side

of

the

table

the

sheave

Lifter

occasionally

the

presser

illustration

connecting

to

the

is

located

The

knee

fiver

the

treadle

tVame

rear

hanger

the

shaft

parts.

installing

In

this

treadle

of

Style

with

this

machine.

to

have

the

treadle

11500 G for

tlie

of

of

the

knee

four

transmitter

The

the

parts.

feature

the

when

device

illustration

the

table.

the

parts,

lever

plate

inches

without

rear

hanger

shaft

The

sections

can

any

table.

directly

on

the

This

device

illustrations

furnished

foot.

The

shows

the

assembly,

with

roar

of

the

on

the

under

i)late

should

right-hand

and

as

will

j^ermit.

bearing

to

See

knee

should

insure

preceding

pres,s

making

set

of

should

to

treadle,

touching

the

at

the

same

11500

treadle

No.

except

G—Ready

In

as

depressed

21693 M is

operating

"ready

The

illustration

the

the

hemming

hang

the

right

and,

the

installation,

making

high

siiould

the

to

operate,"

directly

of

as

trans-

bearing

to

secure

use

of

the

be

irregularities

Bore a 1-ineh

under

shaft

instead

the

machine.

edge

far

easy

ea.sy

move-

of

the

washers

hanger

utilized

the

and

No.

of

the

accompany

lifter-lever

side

hang

back

Obviously,

be

is

advanta-

on

left

connect

21693 A is

machines

of

the

except

The

of

the

di-

of

the

as

the

in

line

movement

instructions

for

further

in-

15

care

incline

chain

as

the

to

operate

the

installation,

as

possible.

not

come

fiirnisited

hemming

it

to

the

at-

the

far

must

op-

the

hole

end

of

the

the

chain.

not

"ready

door

treadle

wr.-fefcT-l

should

transmitter

shows

However,

in

contact

with

Style

attachment.

is

located

right

shows

«

I

I

MmI

WK

hemmer

shown

lever.

in

to

operate."

lifter

^

A

r

f]|r

^

be

the

care

on

the

for

Page 17

INSTALLING

Tnhlif

1

directly

fl

at

top

Thrpnti

of

pulley.

extensions

to

fiw'n/*£>

aoie

israce

behind

head

will

be

the

table

Styles

increase

screws.

drawn

^fnnH

11500 A and

and

the

the

The

downward.

its

and five

couplings

lieight

^

middle

column

center

inches

11500 F are

Nos.

of

the

furnished

of

the

should

is

to

the

thread

with

transmitter

should

eighteen

21113 A and

be

be

right

of

wires.

so

equipped

Styles

turned

located

inches

the

11700

treadle.

from

groove

21113 B respectively,

so

that

on

the

the

in

with

C,

11700

Use

the

table

front

the

thread

F,

located

1^

inch

table

that

edge

machine

wire

16

Page 18

oPEBATma

SimDlicitu

proficiency

the

work.

Oilina

^ is

The

points

I"experienced

^ Union

iii

oiling

friction.

designated

Specials.

and

plain

Sectional

should

operators

threading

that

oil

be

quickly

Obviously,

the

should

diagram

oiled

practice

machine,

be

applied

"A"

in

the

adapt

tliemselves

will

and

in

handling

wherever

shows

order

these

given.

to

increase

there

places.

Once

Oiling

Styles

memorized,

possibility

Special

and

needle

it

of

attention

lever

11500

A,

11700

can

be

missing

any

is

connection

Diaobam

11500

F,

G,

11700 L and

done

in a surprisingly

place.

directed

lower

a.

11500

G,

to

the

bearing,

17

11500

11700

left

points

H,

11700

M.

end

C,

short

of

the

Nos.

11700

P,

time

without

needle

6, 7 and

lever

27,

Page 19

OPERATING

which

oil-can

are

valves.

spout.

Frequent

It

is

recommended

four

times a day.

The

power

hollow

up

cup

oftener

di>nninn

it

wear

main

about

once a week.

.should

be

than

" carefully

necessary

in

the

They

are

oiling

shaft

screwed

once a month.

to

bearings.

is

necessary,

that

the

transmitter

from a compression

If

up

immediately.

tbne

an

wiped.

keep

the

maciiine

oiled

by

as

machine

is

lubricated

the

bearings

pressing

lint

be

cup,

the

quickly

given a thorough

with

solid

which

run

hot,

Refilling

operator

Accumulations

oils a machine,

as

clean

of

as

possible,

valves

absorbs

oil

should

the

will

not

lint

and

with

the

the

oil.

oiling

through

be

screwed

compression

be

required

it

should

dirt

to

a

be

make

prevent

mm

Twice a week,

machine

for

and

given a thorough

removing

looper

Threading

the

lint

grooves.

Styles

the

and

Diaouam

11500

throat

cleaning, A pin

dirt

B.

A,

11500 F and

plate

should

from

the

.18

or

oil

11500

G.

be

removed

needle

holes,

can

feed

and

be

dog

the

used

slots

Page 20

Setting

point

out

to

the

they

the

tighten

furnished

the

about ^ inch

just

above

eye.

will

go,

needles

the

for

Needles

the

Place

with

will

be

set

screw

that

The

groove

above

eye,

and a long

the

needles

the

long

in

line

with

with

purpose.

OPERATING

needles

the

eye,

as

grooves

the

the

screw

have

two

extending

or

terminating

groove

far

in

up

front,

extending

into

direction

driver,

or

grooves: A short

from

the

shank

in a spot

from

the

needle

so

that

the

of

the

stitcliing.

the

wrench,

the

bar

eyes

No.

to

a

milled

shank

as

of

Then

116.

Threading

Threading

eyelet

Each

is

it

adjacent

venience.

thread

drawn

be

against

turned

The

Styles

11700

A

thread

the

parts

to

the

looper

threads

must

the

completely

should

be

passed

tension

around

Diagram

C,

tweezer

difficult

thread

through

post,

11700

No.

of

not

but

the

.10

C.

F,

11700 G and

118 B is

access.

take-up

be

allowed

the

under

post.

11700

furnished

The

front

can

be

raised

to

cro.ss

tension

no

discs

circumstances

L

to

end

for

each

so

thread

of

the

con

other.

that

it

should

Page 21

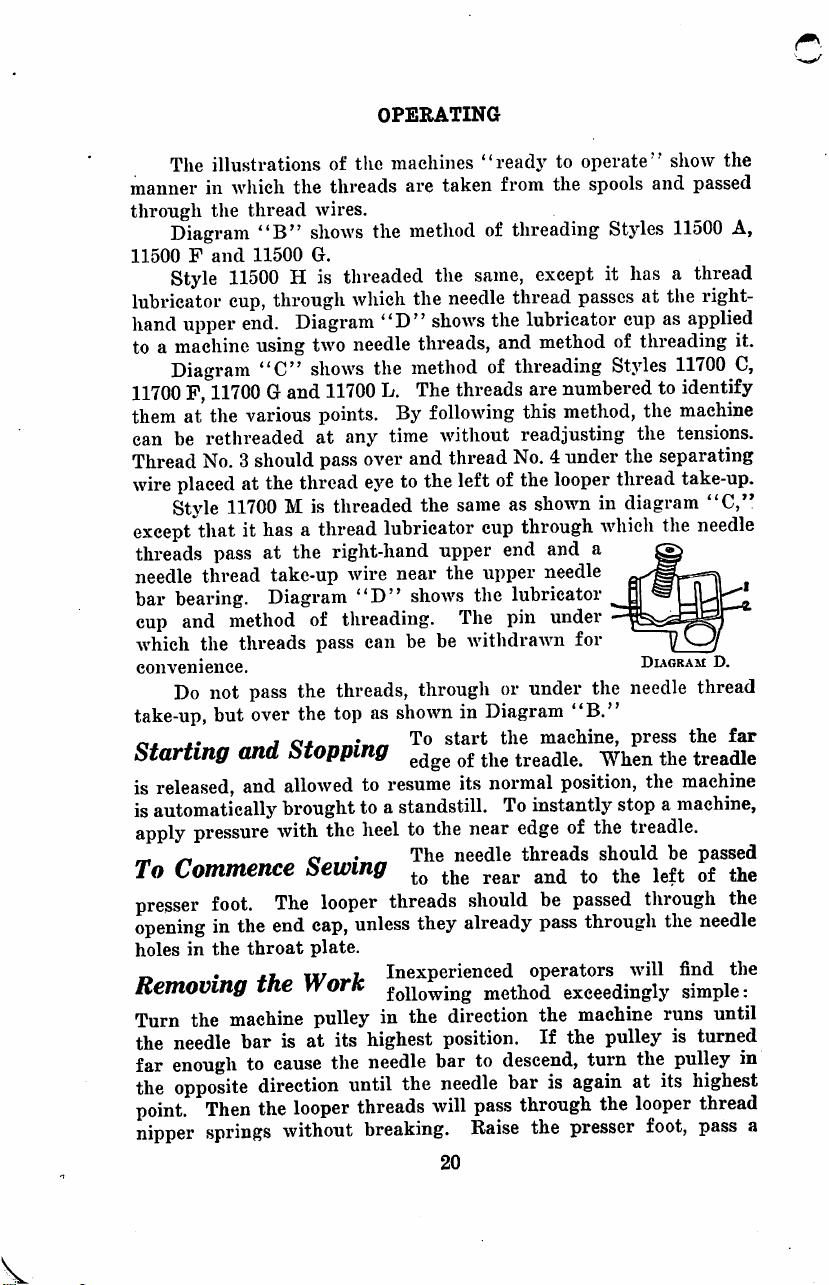

The

illustrations

manner

through

11500 F and

lubricator

hand

to a machine

11700

them

can

Thread

wire

except

threads

needle

bar

cup

which

convenience.

take-up,

ci.t

Starting

in

which

the

thread

Diagram

Style

"B"

11500

11500 H is

cup,

upper

end.

using

Diagram

F,

at

be

placed

Style

bearing.

and

Do

"C"

11700 G and

the

various

rethreaded

No. 3 should

at

the

11700 M is

that

it

has a thread

pass

at

thread

the

take-up

Diagram

method

threads

not

pass

but

over

JO*

and

of

the

the

threads

wires.

shows

G.

threaded

through

which

Diagram

two

needle

shows

11700

points.

at

any

pass

over

thread

eye

threaded

the

right-hand

wire

"D"

of

threading.

pass

can

the

threads,

the

top

Stopping

•

OPERATING

machines

are

the

method

the

"D"

threads,

the

method

L.

The

By

time

and

to

the

lubricator

near

shows

be be

through

as

shown

To

"readj^

taken

from

of

threading

the

same,

needle

shows

thread

the

and

of

threading

threads

following

without

thread

the

No. 4 under

left

of

same

as

cup

upper

end

the

upper

the

lubricator

The

pin

withdrawn

or

in

Diagram

start

the

to

operate"

the

spools

and

Styles

except

lubricator

method

it

has a thread

passes

at

cup

of

threading

Styles

are

numbered

this

method,

readjusting

the

looper

shown

through

and

needle

under

for

under

the

the

the

thread

in

diagram

which

a

Diagram

the

needle

"B."

machine,

treadle.

press

When

show

the

passed

11500

A,

the

right-

as

applied

it.

11700

C,

to

identify

machine

tensions.

separating

take-up.

''C,"

the

needle

D.

thread

the

the

far

treadle

is

released,

is

automatically

apply

_ _

To

Commence

presser

opening

holes

o

Removing

Turn

the

needle

far

enough

the

opposite

point.

nipper

and

allowed

brought

pressure

foot.

in

in

the

* *1,

the

with

The

the

end

throat

tne

machine

bar

is

to

cause

direction

Then

the

looper

springs

without

to

resume

to a standstill.

the

heel

ft

•

to

the

The

its

normal

To

near

edge

needle

threads

position,

instantly

of

Sewing

looper

cap,

plate.

U/ h Inexperienced

rVOrK

pulley

at

threads

unless

its

the

until

they

in

the

highest

needle

the

threads

will

breaking.

should

already

direction

position.

bar

to

needle

pass

Raise

20

be

pass

operators

method

the

If

descend,

bar

through

the

exceedingly

the

is

presser

the

machine

stop a machine,

the

treadle.

should

passed

through

machine

pulley

turn

again

the

be

through

the

will find

simple:

runs

is

the

pulley

at

its

looper

foot,

passed

needle

until

turned

highest

thread

pass

^j^g

the

the

in

a

Page 22

pair

of

scissors

Cut

them

by

passing

threads,

The

needle

work

short

jerk

bar

to

distance,

and

under

as

close

it

to

the

whichever

method

the

break

up

to

to

its

rear

break

the

it

to

the

rear

is

the

follow

highest

and

to

the

needle

looper

OPERATING

and

carry

fabric

and

as

to

the

more

convenient.

after a few

position,

the

left,

threads

threads

the

needle

convenient.

left.

Cut

days

raise

the

allow

the

by

giving

close

to

the

threads

Remove

or

break

operation

presser

presser

is

foot,

foot

the

work a quick

fabric.

to

the

to

the

the

looper

run

pass

to

fall

rear.

work

the

the

a

21

y

Page 23

General

convenient

use

two

than

Plan

for

needles

the

styles

The

check

the

adjuster

and

two

in

Class

ADJUSTING

steps

necessary

its

adjustment

to

follow.

loopers,

11500,

whicli

they

to

readjust a maehine

are

given

in

the

As

the

stjdes

in

are

slightly

use

only

more

one

needle

or

order

most

Class

11700

complicated

and

one

2

looper.

the

the

employed

but

front

result

For

stjdes

in

styles

In

one

While

in

are

describing

point

of

the

many

will

be

Formation

show

the

three

this

reason,

Class

11700.

Class

11500

identical.

the

of

view

macliine.

variations

secured

of

the

"Double

steps

in

r/quRC

the

It

as

positions

used.

can

by

following

the

formation

3

instructions

is a simple

the

stitches

or

movements

It

is

tliat

be

made

them.

Locked

of

22

given

matter

made

of

the

from

Stitch"

the

"Double

F'tquR^

apply

to

and

of

the

operator

these

ing

Locked

3

directly

apply

them

mechanism

parts,

there

sitting

rules,

the

accompany

illustrations

Stitch."

best

to

to

is

in

Page 24

A

careful

considerable

ences

In

with

back

and

Each

it

ascends,

as

shown

the

feed

the

front

right,

looper,

right—into

in

Figure

leaves

again

the

fabric

The

of

the

study

assistance

to

the

illustrations

the

formation

the

front

needle,

needle.

its

looper

The

is

needle

carries

throws

in

Figure

dog

moves

across

forming a triangular

the

looper

which

2.

The

the

stitch

on

ascending,

by

the

tension

stitches.

applied

ADJUSTING

of

tliem

and

in

making

are

of

the

and

formation

the

same.

its

thread

out a loop

1.

While

the

fabric

the

path

of

thread

the

looper,

recedes

action

needle

the

needle,

of

to

on

continuing

from

the

the

the

explanatory

an

adjustment.

made

in

this

chapter.

stitches,

the

of

at

the

the

the

back

looper

the

.stitch

down

the

rear,

needle

to

the

needle

front

made

through

which

is

above

rear,

and

space—bounded

the

left

and

the

needle

descends

as

the

looper

needle

with

to

shown

stitch,

as

it

thread

its

return

in

Figure

Avhich

forms

controls

matter

looper

co-operates

the

the

the

returns

by

the

thread,

toAvard

the

will

Frequent

co-operates

with

by

each

needle

fabric

the

looper

thread

3.

is

next

and,

looper

enters

throat

rocks

toward

back

of

on

as

shown

the

right,

The

needle,

tightened

stitch.

the

tightness

be

refer

plate,

of

tJie

as

to

the

the

the

in

Caution

bearing

structed,

any

consistent

thread

a

the

.straight

possible.

best

whether

rethread,

the

set

in

(1)

especially'

lint

which

(2)

See

tensions

slight

tension,

machine.

(3)

Examine

with

(4)

Remove

possible

the

(5)

Remove

as

(6)

Clean

loopers

of

needles.

mind

Note

with

points

shown

and

^

apparently

carefully

may

that

the

test

the

machine

in

the

following

at

the

have

the

needle

the

strength

are

quite

barely

is

take-up.

enough

the

needles

long

grooves

the

needles

to

roll

roll

true.

all

the

in

the

machine

fails

good

whether

tensions

accumulated.

loose.

and

them

threads

threading

thoroughly,

Oil

the

to

repair,

suggestions:

the

and

thread

of

the

thread.

The

to

steady

and

in

front,

note

on a perfectly

from

diagram.

machine

23

work

satisfactorily,

delay

machine

nipper

tensions

looper

note

and

whether

the

particularly

will

is

threaded

springs,

are

See

that

threads

them

in

passing

whether

inserted

they

flat

surface

machine,

thoroughly.

be

avoided

and

as

tight

the

require

through

they

are

as

far

are

bent.

and

and

carefully

the

grooves

Try a new

though

by

as

in

remove

as

is

looper

only

set

up

as

The

note

in

Page 25

(7)

The

and

needle

which

can

be

(8)

injured.

the

under

(9)

instructed

(10)

made

be

sure

interfere

If

checked

In

thread

Avill

cause

remedied

Unravel

The

surface

See

in

the

Before

in

the

Avorking

that

Avith

the

foregoing

Avith

Adjusting

throat

plate

take-up

breaking

by

smoothing

the

stitching

teeth

of

of

the

that

the

chapter

operating

parts,

it

runs

freely

the

frame

suggestions

the

folloAving

Machines,

ADJUSTING

needle

may

of

lioles,

have

both

the

the

surfaces

and

the

feed

dog

fabric.

pulley

is

as.sembled

on

"Repairing,"

by

poAver,

ahvays

and

that

or

Avith

each

fail,

instructions:

NOTE:

Always

Use A New

thread

become

needle

Avith

note

if

the

may

be

subject

after

turn

the

the

other.

the

eyelets,

roughened

and

cutting

on

tension

or

looper

emery

threads

threads.

cloth.

are

the

the

main

"Assembling."

any

change

machine

Avorking

adjustment

Set

by

parts

should

Of

discs

grooved,

It

cut

or

stitch

has

on

shaft

as

been

hand,

to

do

not

be

Needles

Needle

of

is

the

machine

used

Rear

on

each

The first

in

the

under

position

the

It

the

correctly

needles.

As

time

NeedUs

rect

vertical

by

dog

rear

needles

loAvest

can

guard

is

needles.

in

set

correctly

The

second

Avhen

The

it

moves

the

length

and

First

Adjustment:

Avhen

faces

turning

and

the

guard

Second

and

position

be

Avith

it

the

needle

Avill

Adjustment:

Guard

in

passing

machine,

style

side

secured

the

desired

Avhen

style

its

screAv

the

of

the

Loopers

corresponds

of

the

needle

be

points

should

through

tAVo

is

stationary,

of

the

throat

by

slightly

direction

its

is

fastened

A'crtical

hole

is

feed

dog,

stitch

"i™''

The

needle

bar

front

guard,

.secured.

of

the

be \ incli.

should

styles

they

the

fabric.

are

furnished.

and

is

fastened

plate. A slight

loosening

Avhile

the

A'ertical

faces

elongated

is

oblique

Avith

rear

in

The

loopers

faces

barely

to

the

feed

barely

to

permit

the

guard

altered.

«d.iustments

the

guard.

its

liearings.

an

unobstructed

space

24

must

proper

position

oblique

The

betAveen

Avhen

the

This

distance

'T

glance

While

the

scrcAv

scrcAV

dog.

touch

of

be

are

necessary

time.

of

the

position

adjustment

By

removing

vicAv

the

needles

toward

in a seat

A'ariation

touch

It

the

this

re-adjusted

the

only

one

milled

in

and

forcing

is

retightened.

the

rear

is

likeAvise

rear

of

adjustment.

to

needles

center

controls

of

of

the

are

is

the

is

the

needle

of

at

the

rear

style

its

of

set

the

each

bring

cor

tAVO

made

feed

the

their

size

Page 26

and

form

of

the

an

accurate

gauge

lowest

even

with

connecting

loosen

tightening

see

that

the

right-hand

ley

in

farthest

ball

joint

securely.

has

not

With

from

the

should

adjustment

No.

21225-^,

position,

the

rod,

nuts,

use

the

the

left

the

direction

position

in a vertical

Again

been

the

point

be

approximately

needle

loops. A very

will

having a "V"

the

point

of

right-hand

which

wrencli

looper

ball

nut

is

provided

No.

connecting

joint

has

slightlj%

the

machine

to

the

left,

position

apply

the

altered.

foregoing

of

adjustment

the

front

the

ADJUSTING

be

found

from

dicated

In

using

"V"

Avith

right.

the

back

edge

of

115

and

side

then

loosen

gauge

looper

same.

convenient

by

slot,

the

the

edge

by

the

this

slot

enclo.sing

the

wider

Then,

looper

the

gauge

with

right

turn

rod

nuts,

play

in

all

the

left

nut

runs

till

the

right-hand

and

tighten

to

make

of

the

to

the

manner

using a looper

center

gauge,

the

them

sure

back

center

of

which

of

the

wider

dotted

side

should

care

positions.

securely;

the

line

hold

the

of

the

needle

be

by

turning

and

left

toward

should

loopers

nut,

the

right-hand

that

the

being

made

threads.

the

First

turn

hold

looper,

of

the

back

gauge

are

the

front

of

securing

adjusting

is ^ inch

side,

as

in-

in

the

cut.

it

with

the

needle

to

the

at

its

to

come

the

looper

To

rear.

In

be

taken

to

tighten

the

pul

at

their

the

left

nut

adjustment

distance

needle

Third

Adjustment:

with

respect

the

machine

right

to

the

upper

below

to

have

with

the

1

and 2 respectively

made

by

turning

adjustment

the fingers

and

press

With

the

turn

the

upward

opposite

to

runs

left,

is

edge

the

under

the

upper

functions

moving

the

needle

of

of

the

the

right

pulley

if

the

direction

the

even

of

side

edge ^ inch

the

bar

the

left

thumb firmly

hand,

so

needle

till

the

of

needles.

if

To

set

loopers,

the

with

turn

point

the

needle

of

the

looper.

the

loopers

of

the

needle

in

its

bearings,

An

hand

back

loosen

that

the

bar

is

to

the

needle

the

needles

the

machine

of

the

left

side

eye

should

below

and

stitch

formation.

bar.

Care

excellent

of

the

against

the

two

needle

bar

be

lowered;

bar

25

front

of

the

be

Enough

the

looper,

needles,

should

as

that

will

plan

presser

the

front

needle

connection

is

to

be

at

their

proper

pulley

in

the

looper,

front

moving

needle.

direction

approximately

variation

without

as

The

destroy

is

guide

of

bar

turn

raised.

is

shown

adjustment

be

taken

as

follows:

bar

the

set

screws,

Avill

the

pulley

allowable

interfering

in

Figures

to

the

oblique

bearings,

needle

be

height

from

Then,

iiich

is

avoid

Place

bar.

and

moved

in

the

Page 27

ADJUSTING

Fourth

enter

the

needle

pass

back

the

left

of

in

making

loosen

the

to

slightly

point

possible

spot

position

in

that

the

Whenever

its

position

through

passes

to

Looper

main

It

purpose

needle

Fig. 2 of

tlie

then

the

looper

the

required

altered,

in

tlie

to

on

the

of

proper

position

permit

relation

the

oblique

looper

n

d e Front

should

the

tlie

this

Thread

shaft

consists

is

points

eyes

of

release

Adjustment:

loops,

of

the

needles. A small

the

needles

this

adjustment.

two

screws

rock

shaft.

position.

by

required

alter

the

looper

the

point

adjustment

has

become

either

needle

looper

Avith

respect

j.

Guard

it

glance

fabric.

Avithout

adjustment.

they

as a background,

which

This

loosening

direction,

position

shank,

has

to

with

the

bent

is

I A guard

toAvard

The

Take-up

is

located a device

of a take-up,

to

hold

the

liaA'e

passed

the

stitch

the

them.

formation,

loopers

are

When

the

should

To

change

fasten

permits

The

position

the

looper

while

of

either

but

it

is

be

altered

back';

of

of

the

or

is

designed

replaced

to

the

back

force

the

guard

striking

and

for

cast-off

looper

treads

beloAV

and

to

the

left

loopers

have ^ inch

piece

the

the

the

of

re-tightening

looper

not

advisable

more

the

needle

in

the

of

is

attached

the

front

front

is

set

it.

The

Cast-off

controlling

Avire

the

looper

continue

of

move

of

white

will

be

position

looper

looper

rocker

either

looper

set

screw

point

than ^ inch,

needles,

bar

is

for a different

machine,

the

needle.

to

needle

of

the

correctly

scrcAV

Wire

the

and

thread

taut

until

threads

to

the

middle

to

the

left

space,

paper,

of

great

of

eccentric

and

the

by filing

to

do

it

will

incorrect,

the

into

machine

Avhen

hole

looper

as

placed

assistance

the

loopers,

fork

to

be

point

may

forcing

screw.

the flat

this.

to

bring

be

evident

or,

machine.

carefully

front

its

in

passing

it

is

elongated

threads.

eyelet.

the

descending

as

shoAA'n

hold

them

of

the

needles,

to

they

to

to

moved

be

the

It

is

If

the

it

that

note

looper

proper

barely

Their

in

until

A

simple

be

made

side

of

and

Avhile

machine

of

the

take-up

points

is

looper.

should

alloAvable

test

as

folloAA\s:

the

thread

so

doing,

runs,

until

to

be

to

liaA'e

to

determine

Take

eyelet,

turn

the

the

circular

beloAv

the

the

Avhether

hold

draAV

the

machine

threads

points

move

edge.

middle

even

26

of

the

them

Stop

of

the

they

are

looper

sloAvly

pulley

from

the

at

this

looper.

A\dth

the

in

adjustment

threads

through

in

the

direction

long

straight

point.

Enough

loAA^er

edge

on

the

the

eyelet,

edge

The

needle

A'ariation

of

can

left

the

the

Page 28

The

are

set

correctly

change

ing

the

screw

arras

of

height

in

the

the

thread

when

they

of

the

cast-olf

ADJUSTING

eyelet,

just

arras,

wire

change

frame.

which

clear

the

project

the

over

main

shaft

height

the

main

sleeves.

of

the

shaft,

To

support

Intermittent

^

right-hand

clarap

Their

thread

where

holes

to

their

operation

the

leave

adjustment

PpfiH

the

right-hand

the

teeth

ing

it

rocker

rocker

of

venient

one

located

the

purpose

through

they

as

shown

tighten

movement

regular

some

Finn

^

feed

crank

two

set

The

height

project

on

the

is

necessary

No.

No.

the

feed

hole

of

the

under

Looper

end

of

the

looper

can

threads

is

to

prevent

the

tensions

pass

from

in

Fig.

on

the

threads

toward

readily

manner

slack

is

end.

screws

from ^ inch

kind

11742,

11743

dog

will

screws

and

between

made

by

locate

equidistant

link

pin

Before

whicli

of

the

of

work

to

loosen

also

to

the

can

be

found

in

the

throat

Thread

cylinder

when

the

2.

the

be

drawing

the

bending

the

No.

making

feed

being

the

the

feed

be

altered

the

plate.

is a pair

the

the

instead

looper

They

as

soon

left

and

observed

tensions

the

feed

from

the

305 A is

any

fasten

dog

to

inch

sewed.

two

two

screws

rock

in

the

left

feed

Nipper

of

loopers

take-up

eyes

are

the

its

is

screws

shaft

by

rear

from

of

holding

to

set

correctly

as

the

returned

by

threading

threads,

and

the

outer

spring.

bar

so

ends

of

eccentric,

change,

left

end

correct

above

the

Before

which

which

No.

moving

of

the

rocker.

Springs

nipper

are