iCOLOR 700

And

User Guide

EDGE2Print Software Installation Guide

Please ensure you foll ow ev ery step in order.

Overview of the Installation

System Requirements

- Optimal Requirement ( CPU, Memory, HHD and SO)

- Minimum Requirement for software WITHOUT variable data ( CPU, Memory, HHD and SO)

- Power 120v and 220v

- Network

o Processor: i7 3.5GHz 4770K or better

o Hard Drive: SSDs with 500MBs or greater

o Memory: 12 GB DDR3 1666MHz or greater.

o Motherboard: x79 Chip

o Windows 7 pro 64 bit only

o Processor: Intel i5

o Hard Drive: 7200 RPM

o Memory: 8 GB

o Windows 7 Pro 64 bit only

o Minimum outlet (5)

o (2) IP Addresses for the Feeder and Printer

o (3) Network Cables

Before starting the software installation, you need to ensure that you have

a clean version of Windows 7 with nothing installed. In order to do so, you

will need to make sure of the following:

□ There are no applications ins t a lled or currently running.

□ There are no antivirus programs installed.

□ The computer you’re planning to install the software on has the

printer and feeder on the same ne twork.

□ Ensure your user account has Admini s t rator privileges on the

local computer.

2

Contents

Contents ............................................................................................................................... 3

1. General Information ....................................................................................................... 5

Limitation of Liability ................................................................................................................................ 5

ICOLOR 700 Warranty ............................................................................................................................... 5

Safety Information .................................................................................................................................... 6

Specifications ............................................................................................................................................ 7

ICOLOR 700 Front View ............................................................................................................................. 7

ICOLOR 700 Rear View .............................................................................................................................. 8

ICOLOR 700 Internal Feeder View............................................................................................................. 9

ICOLOR 700 Rewinder View .................................................................................................................... 11

Feeder Display Menu Functions .............................................................................................................. 12

Printer Operator Panel ............................................................................................................................ 14

2. First Time Setup ............................................................................................................ 15

Unpacking and Setting Up the Printer .................................................................................................... 15

Change User Account Control Settings ................................................................................................... 18

Change Region ........................................................................................................................................ 20

Installing the EDGE2Print Software ........................................................................................................ 21

Setting up the IP Addresses .................................................................................................................... 30

Input IP Addresses into EDGE2Print........................................................................................................ 31

Selecting a Media ID ............................................................................................................................... 32

Setting up the Cost Calculator ................................................................................................................ 33

Changing Units of Measurement ............................................................................................................ 34

Changing the Color Registration ............................................................................................................. 35

Saving and Loading Page Information .................................................................................................... 37

3. Before Printing ............................................................................................................. 38

EDGE2Print User Interface ...................................................................................................................... 38

Measuring Your Media ............................................................................................................................ 39

Loading Media for Continuous Printing .................................................................................................. 41

Loading Media/Sensor Calibration for Die-cut Label Printing ................................................................ 46

3

How to Set Up the Rewinder .................................................................................................................. 48

4. Printing ........................................................................................................................ 51

Adding a Label Image .............................................................................................................................. 51

Selecting the Amount of Labels .............................................................................................................. 52

Adjusting the Print Alignment ................................................................................................................. 52

Printing .................................................................................................................................................... 54

5. Software Features & How To’s ...................................................................................... 55

How To Print a Full Bleed Die Cut Label .................................................................................................. 55

How to Create a New Media ID/Custom Media ID ................................................................................. 57

Editing a Newly Created Media ID .......................................................................................................... 59

Install Your Own ICC Profile .................................................................................................................... 60

Installing the Fonts in the RIP ................................................................................................................. 63

Nesting .................................................................................................................................................... 67

Rip Rotate Options .................................................................................................................................. 69

Rip Scaling Options ................................................................................................................................. 70

How to View Cost Report ........................................................................................................................ 71

How to Purchase Variable Data Software (iVDP) ....................................... Error! Bookmark not defined.

How to Install Variable Data Software (iVDP) ......................................................................................... 73

How to Print Using Banner Mode ........................................................................................................... 76

6. Trouble Shooting & Maintenance.................................................................................. 79

Toner Cartridge Replacement ................................................................................................................. 79

Image Drum Replacement ...................................................................................................................... 81

Replacing the Transfer Belt Unit ............................................................................................................. 83

Fuser Replacement ................................................................................................................................. 85

Clearing Paper Jams ................................................................................................................................ 86

Manual Sensor Calibration Using the Feeder (For Die Cut Labels Only)................................................. 90

How to Access the Settings as an Administrator .................................................................................... 94

Paper Sensor Error Codes ....................................................................................................................... 95

4

1. General Information

Limitation of Liability

Uninet’s total liability to the purchaser, or to any third party, for damages from any and all causes whatsoever,

regardless of the form of actio n, w hether in contract or in t ort, incl uding ne gligen ce, and any infringe ment of propriet ary

rights or any misappropriation or unlawful use of any proprietary rights or property of any third party shall, in the

aggregate, be limited to purchase price actually paid by the purchaser for the product relating to the damages. The

limitation of liability provisions of this agreement reflect an informed voluntary allocation of the risks (known and

unknown) that may ex ist in con nect ion w ith the provi sions of t he g oods a nd serv ices provi ded her eund er by Uninet and

that such voluntary risk allocation represents a fundamental part of the agreement reached between Uninet with the

purchaser.

Uninet shall not be li abl e f or a ny spec ial , direct or indirect, incidental, consequential, exemplar y , pu nitiv e or any s im ilar

or other damages of any nature suffered by the purchaser whatsoever including, without limitation, loss of use or lack

of availability of the purch aser facilities, i ncluding its co mputer resource s and any stored dat a, loss of prof its or revenue ,

or other commercial loss, or any claim for contribution or indemnity in respect of any claims against the purchaser,

regardless of whether Uninet has been advised of the possibility of such damag es.

ICOLOR 700 Warranty

Uninet (Uninet) warrants the ICOLOR 700 (Product) to be free from defects in materials and workmanship and will

remedy any such defect according to the terms of this Lim ite d Warra nty.

Uninet warrants the Product t o be free fro m defect s in mater ial and w orkm anship o ccurrin g under n ormal us age, w ithin

the normal operating range and duty cycles specified. If the Uninet Customer Service Representative Department

receives notice of su ch defe cts durin g the w arr anty perio d, Uninet at its option, an d w ithin a reaso nable ti me, w ill repa ir

or replace the defective Product. A certified Uninet service representative shall perform repairs, and such repairs, at

the option of Uninet, may be p erform ed at the custo mer site, a dealer site, a serv ice dep ot or the factory . Re place ment

Product, at the option of Uninet, may be either new or equiv alent in perfor mance to new. D elivery is defined by a signed

and dated receipt from the original carrier or Uninet dealer delivering the Product, or down time for repair and

replacement.

Uninet does not warrant the operation of the Product to be uninterrupted or error free. Uninet assumes no liability for

and holds itself harmless against any claims of consequential costs or damages which may arise from interruption or

error in the operation of the Product.

Uninet does not warrant defects, malfunctions and/or failures, which in its opinion, result from conditions of improper

use, abuse, neglect, operation outside the published environmental specifications, improper site preparation and

maintenance, the use of unqualified or unauthorized media (papers, films, toners, inks, fusers or belts), inadequate

preventative maintena nce, unaut horized modi ficati ons or un authoriz ed maintena nce. Su ch cond itions shal l render th is

warranty void and otherwise release Uninet from its liability under this Product warranty. Consumables are nonwarranty items.

All product returned to factory must be accompanied by an RMA number, obtained by calling the Uninet Service

Department at 403-204-5200 or as otherwise instructed. Shipping and handling charges to vendor for repair are the

sole responsibility of the customer. Uninet will cover shipping charges on the return of the repaired unit for the term of

the warranty as sta ted ab ov e. Shippi ng will consist of Standa r d Shi pm ent level or Best Effor t . Ac cel erated or Premium

Shipping Service is available but costs will be fully born by customer. Any international duties and taxes payable on

transporting the repaired unit across international borders will be the responsibility of the customer. The ICOLOR 700

Printer is a Canadian made product and therefore falls under the import/export laws of NAFTA.

A written receipt for the Product, showing the date of purchase, dealer’s name, and both the model and serial

number/PID’s of the Product must accompany any request or claim for work to be performed under this Limited

Warranty. Additional information on obtaining service under this Limited Warranty or for obtaining Extended Warranty

coverage contact Uninet directly at 866-415-Uninet (4797) or at 403-204-5200.

Uninet or its authorized service partner will repair, or at its option replace, at no charge, any defective

component(s) of the Product for a period of one (1) year from the date of purchase. This Limited Warranty

extends to the original purchaser only. This Limited Warranty does not extend to consumable items.

5

Safety Information

Your Uninet product has been carefully designed to give you years of safe, reliable performance. As with all electrical

equipment, there are a few basic precautions you should take to avoid hurting yourself or damaging the product.

Warning - Here are some of the things to look for:

• Save all provided documentation for future reference. Ensure all warning and instruction labels on the product are

read, understood and followed in order to prevent any risk of injury.

• This product may be heavy. Please check the weight of the product and take all necessary precautions to prevent

the risk of personal injury. Place your product on a firm, solid surface. If placed on something unsteady, it may fall

and be damaged. If placed on a soft surface, the vents may be blocked, causing the product to overheat.

• If the product is installed on a cabi net or h igh capa city fee der, ensure wheel locks are applied onc e pla ced in f ina l

position for use, to prevent risk of movement or injury.

• Protect your product fr om overheating. Make sure no obstr uct ions bl ock th e openi ngs of the produ ct. Do not pu t th e

product on or near a heat so ur ce (suc h as a radiator or heat regis ter). K eep t he prod uct out of direct sunli ght. Allow

enough room around the product for adequate ventilation and easy access to the paper paths. If the product is

placed in any kind of enclosure, make sure the enclosure is well ventilated to prevent a fire.

• When the product cover is open, do not touch the fus er u nit o r print head as you may receive burn s. Allow it to cool

before touching.

• If the product casing gets ex tremely h ot or s moke, u nusual smell s or ab nor mal noi ses ar e emitte d fr om the product ,

there is a risk of fire. Unplug the mains connector and contact Uninet service.

• Do not use the product near water. D o not spil l liquid of any kind on it. D o not con nect or disconnect t he pow er plu g

with a wet hand as this may cause electric shock. Unplug the product before you clean it. Use only a damp cloth;

do not use liquid or aerosol cleaners. Do not use an extremely flammable spray near the product as the product

contains high temperature parts that may cause a fire.

• Be certain that your power source matches the rating listed on the back of the product. If you are not sure, check

with your dealer or local power company before connecting the product.

• Do not connect this product to an uninterruptible power supply (UPS).

• Your product has a grounded, three-prong plug as a safety feature. This plug only fits into a grounded outlet. If the

plug does not fit, the outlet may be an older, non-gr ou nded ty pe. C ont act an electrician to have the o utle t r ep lac ed .

Do not use an adapter to defeat the grounding.

• Install the product near an easily accessible power outlet and avoid damaging the power cord. Do not put anything

on it or place it where it will be walked on. If the cord becomes damaged or frayed, replace it immediately.

• If you are using an extension cord or power bar with the product, make sure the total amperes required by all the

equipment on the extension is less than the extension’s rating. The total ratings of all equipment plugged into the

outlet should not exceed 15 amperes.

• Do not poke anything in the ventilation slots of the product. You could get an electrical shock or cause hazardous

electrical arcing, which could cause a fire.

• The acoustic noise of this product is less than 70 dB (A) as measured in accordance with EN ISO 7779.

• The operating condition range for your product is: 10 to 32°C and 20 to 80% RH. Operation of the product outside

this range could result in damage to the product.

• Do not throw toner cartridges or image drum cartridges into a fire as you may receive burns from a dust explosion.

• Ensure loose clothing and hair is kept clear of moving parts when the product is in operation to prevent possible

risk of injury.

• Ensure both the product and main s p ower switches are in the OFF po sit ion before connecting the AC power ca ble.

• Always hold the power plug to connect/ di sconne ct the pow er cabl e to/fr om the ma ins socket . Unplug ging by pulling

on the cable can cause fraying and may lead to fire or electric shock.

• Use only the power cable supplied. Using a power cable not intended for this product may lead to fire or electric

shock. Do not use the power cable supplied with this product for any other electri cal equ ip ment.

• Aside from the routine maintenance described in the documentation, do not try to service the product yourself.

Removing the cover may expose you to shocks or other hazards.

• Do not make any adjustments other than those outlined in the documentation. You may cause damage that will

require extensive repair work. The provided documentation explains how to get your product serviced by qualified

Uninet technicians. If anything happens that indicating your product is not working properly or has been damaged,

unplug it immediately and follow the procedures in the provided documentation for having your product serviced.

6

Specifications

Print Speed

Up to 9.14 meters/min (30 ft/min)

Technology

Single Pass 4 Color LED (CMYK)

Printer Processor1

533 MHz

Media Width

Minimum: 6.0 inches (152.4 mm)

Maximum: 8.5 inches (216 mm)

Print Width

Minimum: 6.0 inches (152.4 mm)

Maximum: 8.24 inches (209.3 mm)

Print Length

Up to 420 meters (1378 ft)

Substrate Types2

Die Cut Label Stock

Tag Stock

Print Quality

1200 x 600 dpi

Toner Supplies3

CMY - 11,500 pages @ 5%

(Rated according to ISO/IEC 19798 guidelines)

Drum Supplies4

CMYK - 30,000 pages @ 5%

(Rated according to ISO/IEC 19798 guidelines)

Feeder System

Input roll maximum outside diameter: 8 inches (203 mm)

Auto adjusting form synchronization

Rewinder System

Output roll maximum diameter: 8 inches (203 mm)

Maximum output roll weight: 14 lbs (6.35 kg)

Dimensions (H X W X D)

Printer & Feeder: 26" x 17.1 "x 21.5" (660 mm x 434 mm x

Rewinder: 16" x 19.75" x 19" (406 mm x 502 mm x 483 mm)

Weight

Printer & Feeder: 110 lbs (49.9 kg)

Rewinder: 27.65 lbs (12.54 kg)

Operating Environment

Temperature: 10°C to 20°C (50 to 89.6°F)

Humidity: 20 to 60% RH

Power

110 - 127 VAC, 50/60 Hz @ 1150W

220 - 240 VAC, 50/60 Hz @ 1150W

Certifications

FCC Class A, CE, cTUVus, CCC

Warranty

1 year – Parts & Labour

1. Published performance results based on laboratory testing. Individual results may vary.

respective manufacturers. ©2014 Copyright, Uninet. All Rights Reserved. All content is subject to change without notice.

ICOLOR 700: System Specifi cat io ns

Kiss Cut Label Stock

Non Die Cut Label Stock

K - 11,000 pages @ 5%

Core inside diameter: 3 inches (76.2 mm)

Maximum input roll weight: 14 lbs (6.35 kg)

Cut on the fly, auto cut

Auto page width registration

Front Panel LCD interface

Web management system torque

Core inside diameter: 3.0 inches (76.2 mm)

546 mm)

2. This product is designed and engineered to operate only with genuine Uninet consumables and certified media

substrates. Please contact Uninet for the most current Certified Media List of substrates available.

3. Letter-size sheets at 5% coverage. Printer ships with a 7,500 page set of starter toners.

4. Based on 500 cut-sheet pages/job.

Uninet reserves the right to change product specifications without notice. Trademarks are the property of their

ICOLOR 700 Front View

7

1. LED Heads

2. Toner Cartridges (C, M, Y, K)

3. Front Cover Release Lever (Blue Handle

Behind Cover)

4. Cut On The Fly Module

5. Feeder Display Menu

6. Spindle Pin

7. Left and Right Media Guides

8. Static Bar

9. Front Cover

10. Black Tray Latches

11. Width Adjustment Wheel

12. Extension Arms

13. Feeder

14. Top Cover Release Button

15. Drum Units (C, M, Y, K)

16. Rewinder

17. Fuser Release Levers

ICOLOR 700 Rear View

8

Note: USB port is not available

ICOLOR 700 Internal Feeder View

1. Printer Network Connection

2. Printer Power Outlet

3. Feeder Network Connection

4. Feeder Power Outlet

5. Paper Exit Path

6. Rewinder Plate (Rewinder Not Shown

Attached)

9

1. Drive Roller

2. Left and Right Media Guides

3. Tension Roller

4. Pinch Roller

5. Static Bar

6. Black Tray Latches

7. Width Adjustment Wheel

8. Extension Arms

9. Spindle Pin

10

ICOLOR 700 Rewinder View

1. Left End Disk

2. Switch Panel

3. DC Power In

4. Spindle

5. Core Adjustment Knob

6. Right End Disk

7. Dancer Arm

8. Lockdown Knob

9. Width Adjustment

11

Feeder Display Menu Functions

feeder back online.

This item configures the parameters for the top load sensor. To access the I2: Top Load Sensor menu,

feeder back online.

3

4

5

1. Display – Displays the feeder status and any error messages

2. On Line/UP – Toggles between Online and Offline, and also serv es as an “UP” sele cti on bu tton

3. DOWN – Serves as an “DOWN” selection button

4. Load Button – Press to complete loading paper

5. Menu/Select - Accesses the three menus: Feeder Configuration, Feeder Calibration and Network Settings

To access the feeder menu items, press the On Line button to toggle online or offline and gain access to your Menu

system. There are three main menu items: Feeder Configurations, Feeder Calibrations and Network Settings.

M1: Feeder Configurations – NOT AVAILABLE

To access the feeder configuration menu, select On Line to turn the feeder offline. Press the Menu key once for

the M1: Feeder Config menu to appear. The following item is under Feeder Config:

To access the I1: Media Type menu, select the On Line button to take the feeder offline.

I1:

Media

Type

To change the media type, hold down the Menu key until the * disappears. Use the UP and DOWN

arrow keys to select the required media. To save the selection, hold down the Menu key again until

the * appears. The media type is now set. To exit press the Menu button. Select On Line button to

take the feeder back online.

M2: Calibrations

Under the Calibrations menu items, it is possible to configure both the Top and Bottom Load Sensors, the Sensor

Gap, Cut on the Fly parameters and Auto Calibration menus.

To access the M2: Calibrations menu, select On Line to turn the feeder offline. Press the Menu key twice for the M2:

Calibrations menu to appear. The following ite ms are under Calibrations:

This item configures the parameters for the bottom load sensor. To access the I1: Bot Load Sensor

menu, select the UP arrow until I1: Bot Load Sensor is shown on the display.

I1: Bot

Load

Sensor

I2: Top

Load

Sensor

To change the settings, hold down the Menu key for about one full second until the * disappears. Use

the UP and DOWN arrow keys to set the required values. To save the values, press Menu. When all

values have been set, press and hold the Menu key for about one full second, until the * appears. The

bottom load sensor values are now set. To exit press the Menu button. Select On Line button to take the

select the UP arrow until I2: Top Load Sensor is shown on the display.

To change the settings, hold down the Menu key for about one full second until the * disappears. Use

the UP and DOWN arrow keys to set the required values. To save the values, press Menu. When all

values have been set, press and hold the Menu key for about one full second, until the * appears. The

top load sensor values are now set. To exit press the Menu button. Select On Line button to take the

12

This item configures the gap between back sensors. To access the I3: Reg Sensor Back menu, select the

UP arrow until I3: Reg Sensor Back is shown on the display.

feeder back online.

I4:

The Network Settings menu items allow configuration of the IP Address, the Subnet Mask and the Default

times for the M3: Network Settings menu to appear. The following items are under Network Settings:

This item sets the IP Address. To access the I1: IP Address menu, select the UP arrow until I1: IP

online.

I3: Reg

Sensor

Back

RSEN

Autocal

COTF

Paramet

M3: Network Settings

To change the settings, hold down the Menu key for about one full second until the * disappears. Use

the UP and DOWN arrow keys to set the required values. To save the values, press Menu. When all

values have been set, press and hold the Menu key for about one full second, until the * appears. The

back sensor or gap values are now set. To exit press the Menu button. Select On Line button to take the

This item configures the auto calibration values. To access the I4: RSEN Autocal menu, select the UP

arrow until I4: RSEN Autocal is shown on the display.

To change the settings, hold down the Menu key for about one full second until the * disappears. Use

the UP and DOWN arrow keys to set the required values. To save the values, press Menu. When all

values have been set, press and hold the Menu key for about one full second, until the * appears. The

autocalibration values are now set. To exit press the Menu button. Select On Line button to take the

feeder back online.

This item configures the parameters for Cut on the Fly. To access the I5: COTF Parameters menu, select

the UP arrow until I5: COTF Parameters is shown on the display.

I5:

To change the settings, hold down the Menu key for about one full second until the * disappears. Use

the UP and DOWN arrow keys to set the required values. To save the values, press Menu. When all

ers

values have been set, press and hold the Menu key for about one full second, until the * appears. The

COTF parameter values are now set. To exit press the Menu button. Select On Line button to take the

feeder back online.

Gateway.

To access the M3: Network Settings menu, select On Line to turn the feeder offline. Press the Menu key three

Address is shown on the display.

I1: IP

Address

Subnet

Mask

Gateway

To change the settings, hold down the Menu key for about one full second until the * disappears. Use

the UP and DOWN arrow keys to set the required values. To save the values, press Menu. When all

values have been set, press and hold the Menu key for about one full second, until the * appears. The

IP Address now set. To exit press the Menu button. Select On Line button to take the feeder back

This item sets the Subnet Mask. To access the I2: Subnet Mask menu, select the UP arrow until I2:

Subnet Mask is shown on the display.

I2:

To change the settings, hold down the Menu key for about one full second until the * disappears. Use

the UP and DOWN arrow keys to set the required values. To save the values, press Menu. When all

values have been set, press and hold the Menu key for about one full second, until the * appears. The

Subnet Mask is now set. To exit press the Menu button. Select On Line button to take the feeder back

online.

This item sets the Default Gateway. To access the I3: Gateway menu, select the UP arrow until I3:

Gateway is shown on the display.

I3:

To change the settings, hold down the Menu key for about one full second until the * disappears. Use

the UP and DOWN arrow keys to set the required values. To save the values, press Menu. When all

values have been set, press and hold the Menu key for about one full second, until the * appears. The

default Gateway now set. To exit press the Menu button. Select On Line button to take the feeder

back online.

13

Printer Operator Panel

ON: A warning occurs. Printing

OFF: Normal Condition

Enters the Menu mode. In Menu

jump from top to bottom

ON: Ready to receive data

1.Ready LED

2. Display

3. Menu Scroll

Buttons

4. On Line

Button

5. Help Button

BLINKING: Processing data

OFF: Offline

Displays the printer status and any

error messages.

mode, forwards or reverses the

menu item displayed.

Press for 2 seconds or longer to

Switches between ONLINE and

OFFLINE

Scrolls the HELP screen

Provides advice when an error

occurs

6. Attention LED

7. Back Button

8. Enter Button

9. Cancel Button

10.Power Save/

Wake up Button

may be possible (e.g. low toner)

BLINKING: An error occurs.

Printing not possible (e.g. toner

empty)

Returns to the previous menu

In the ONLINE or OFFLINE mode:

enters the Menu mode.

In the Menu mode: determines the

setting selected.

Deletes the data being printed or

received when pressed for two

seconds or longer.

Exits the menu and goes ONLINE

when pressed in the Menu mode.

Pressing this button switches the

machine into sleep or wake- up

mode.

14

2. First Time Setup

With two people lift the top (feeder) box off of the

door.

Unpacking and Setting Up the Printer

STEP 1 of 10 STEP 2 of 10

bottom (printer) box. Open the feeder box and

remove the feeder.

Remove the wing nut on the bottom of the feeder

before placing upright on any surface. Position the

feeder on a level surface. Open the feeder and

remove all packaging material. Close the feeder

Lift the lid off of the printer box. With two people,

remove the printer from the box. Remove all of the

packaging tape from the outside of the printer.

STEP 3 of 10 STEP 4 of 10

Press the button to open the top lid. Remove the fuser shipping lock.

15

STEP 5 of 10 STEP 6 of 10

Pull the drums/toners out of the printer. Remove

all consumables

Unpack the rewinder, removing all of the

install on the printer.

Attach the rewinder plate to the feeder using the

moving it slightly left or right. Adjust accordingly.

the protective film. Place the drums and toners

back into the printer. Ensure all four toners are

locked into the four drums by checking the blue

lever. Close the printer lid.

IMPORTANT: Once the drums/toners are

removed, they must not be exposed to light for

more than 5 minutes. To prevent damage, cover

them with a dark sheet or reinstall.

NOTE: All consumables are print ready and do not

need to be replaced upon opening. Once the

consumables have reached their lifespan, please

refer to the appendix on how to replace and install

Align the printer with the pins located on the top of the

feeder. Keep the printer level and flush to the front

while lowering it onto the feeder.

STEP 7 of 10 STEP 8 of 10

packaging tape.

Unwrap the rewinder attachment and prepare to

screws located on the back of the feeder. Make sure it

is in line with the paper output feeder. You can adjust

the rewinder plate once it is loosely secured by

16

Step 9 of 10

Attach the rewinder mechanism to the plate using the black thumb screws. Make sure that the rewinder

The rewinder attachment has been successfully installed.

Once the rewinder is installed, you need to connect the network and power cables to the correct outlets.

All of the outlets are located on the back side of the ICOLOR 700, con nec t accor dingly.

mechanism is fully supported so it does not bend or break the rewinder plate.

STEP 10 of 10

17

Change User Account Control Settings

STEP 1 of 5

Start

Control Panel

STEP 2 of 5

Click

from Windows toolbar, and then click

Click User Account and Family Safety.

.

18

STEP 3 of 5

Click User Accounts.

STEP 4 of 5

STEP 5 of 5

Click Change User Account Control settings.

Move the left bar all the way down to the bottom and click OK.

19

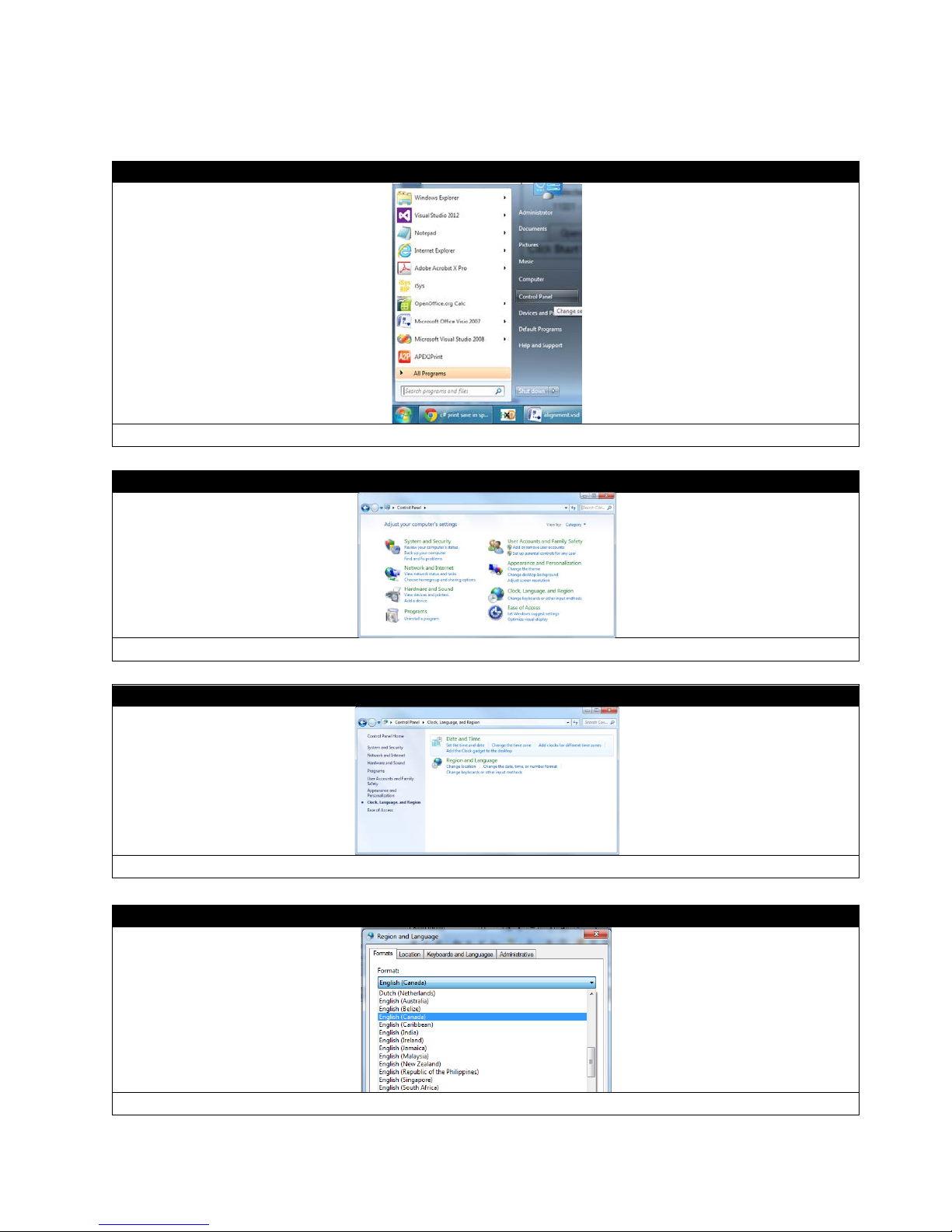

Change Region

STEP 1 of 4

STEP 2 of 4

Clock, Language, and Region

STEP 3 of 4

STEP 4 of 4

Click Start from Windows toolbar then click Control Panel.

Click

Click Region and Language.

.

From the Format list, select English (Canada) and then click OK.

20

Installing the EDGE2Print Software

Installing the RIP - STEP 1 of 18

Uninet utilizes Dropbox for sending the software files. Please send Uninet an email for sharing folders. After this

in the required information and select Sign Up again to register. If it is not your first time using Dropbox, log in.

Installing the RIP - STEP 2 of 18

email confirmation, Uninet will share the software files to your email address. To begin the installation you will

need to log on to the internet and go to

www.dropbox.com. Click Sign Up if it is your first time using Dropbox. Fill

Select one option according to your requirement.

21

Installing the RIP - STEP 3 of 18

Click Sharing on the left side. For example, you have 1 new sharing from Uninet, 1 new shared folder

Installing the RIP - STEP 4 of 18

invitations will show in the middle of the webpage. Click that link.

The window above will pop up. Please click Verify it now, then cl ick Send email to verify your email address.

22

Installing the RIP - STEP 5 of 18

Installing the RIP - STEP 6 of 18

Then click on the EDGE2Print folder from the list. If you cannot see this list, please contact our customer service to

Click Verify your email from your email, then you will see the pop-up window above. Click Accept.

get the sharing capabilities.

23

Installing the RIP - STEP 7 of 18

Installing the RIP - STEP 8 of 18

Click 1st Re-Install RIP.zip fr om the list and cl ic k Download to save your file.

Unzip and open the folder you just downloaded, click Prepare_iSys_RIP_v2.4.exe to install.

24

Installing the RIP - STEP 9 of 18

The KEYLOK and Sentinel Drivers will start to install automatically. Wait until the Install Dongles then Click to

Continue button becomes available before proceeding to the next step.

Installing the RIP - STEP 10 of 18

Insert the two dongles and then click Install Dongles then Click to Continue.

25

Installing the RIP - STEP 11 of 18

The screen above will pop up.

Installing the RIP - STEP 12 of 18

Wait until the window disappears and the window above shows like this. Click Done. The RIP is now installed.

26

Installing the EDGE2Print Software - STEP 13 of 18

Return to the Dropbox folder. Click EDGE2Print Installation from the list.

Installing the EDGE2Print Software - STEP 14 of 18

Select EDGE2Print_Install.msi, and click Download to save your file.

27

Installing the EDGE2Print Software - STEP 15 of 18

Installing the EDGE2Print Software - STEP 16 of 18

Click on the file you just downloaded to install.

The window above will be shown. Click Next to continue.

28

Installing the EDGE2Print Software - STEP 17 of 18

Click Next to continue.

Installing the EDGE2Print Software - STEP 18 of 18

Wait until the process is finished, then c lick Close. Your software is now fully installed.

29

Setting up the IP Addresses

*For any inquiries regarding setting the IP address please contact your support team

*For any inquiries regarding setting the IP address please contact your support team

In order to connect to the ICOLOR 700, you need two predetermined static IP Addresses and two network

cables, one for the printer and one for the feeder.

STEP 1 of 2: Setting the IP Address on the Printer

1. Select Menu>Using DOWN arrow, scroll to Admin Setup> Select Enter

2. At the “Enter Password” prompt, enter the 6 digit Admin password by using the UP arrow, then Enter. The

default password is: aaaaaa(6 x a). Select Enter.

3. Select Network Setup

4. Hit the DOWN key until you can select IPv4 Address Set then Enter. Use the UP/DOWN arrow keys to set

the value you need. Press Enter to move across the address. Press Back to Network Setup.

5. Hit the DOWN arrow key until you can select Subnet Mask. Use the UP/DOWN arrow keys to set the value

you need. Press Enter to move across the address. Press Back to Network Setup. (The default subnet

mask is 255.255.255.0. If that needs to be changed, follow the same procedure as for the IP Address.)

6. Press Back until you have exited the menu

7. Write this IP address down as you will need to input it into the software

STEP 2 of 2: Setting the IP Address on the Feeder

The Network Settings menu items allow configuration of the IP Address, the Subnet Mas k and the Default

Gateway.

1. Press Online to turn the feeder Offline.

2. Press the Menu button three times until M3: Network Settings is shown

3. Press the UP arrow key to I1: IP Address

4. Hold down the Menu key until the * disappears (about 1 full second). Use the UP and DOWN arrow keys to

set the required values.

5. When the address is set, hold down the Menu key again for about 1 full second, until the * reappears. The IP

address is now set/saved.

6. Press the UP arrow key again to set the subnet mask. The default subnet mask is 255.255.255.0. If that

needs to be changed, follow the same procedure as for the IP Address.

7. Select the UP arrow key again to get to I3: Gateway. Use the same procedure to set the Gateway as used to

set the IP Address.

8. Write this IP address down as you will need to input it into the software.

30

Input IP Addresses into EDGE2Print

STEP 1 of 2

Launch the software. T he f ol lo wing window will pop up auto mati cal ly . I np ut t he proper IP address for the printer and

feeder, then click Save.

STEP 2 of 2

If you need to change the IP address, you can click Setup OptionsPrinterIP Address from the toolbar.

31

Selecting a Media ID

STEP 1 of 2

STEP 2 of 2

The following media list will open. This list contains medias that have been certified by Uninet. You can select one

from the list (by double click).

Open the EDGE2Print software, click Media from the toolbar.

32

Setting up the Cost Calculator

STEP 1 of 2

STEP 2 of 2

In the following window, input the price paid for each consumable. This will calculate the cost per label. This value will

appear in the Image List.

Click Setup OptionsSoftwareCost Calculator from the toolbar.

33

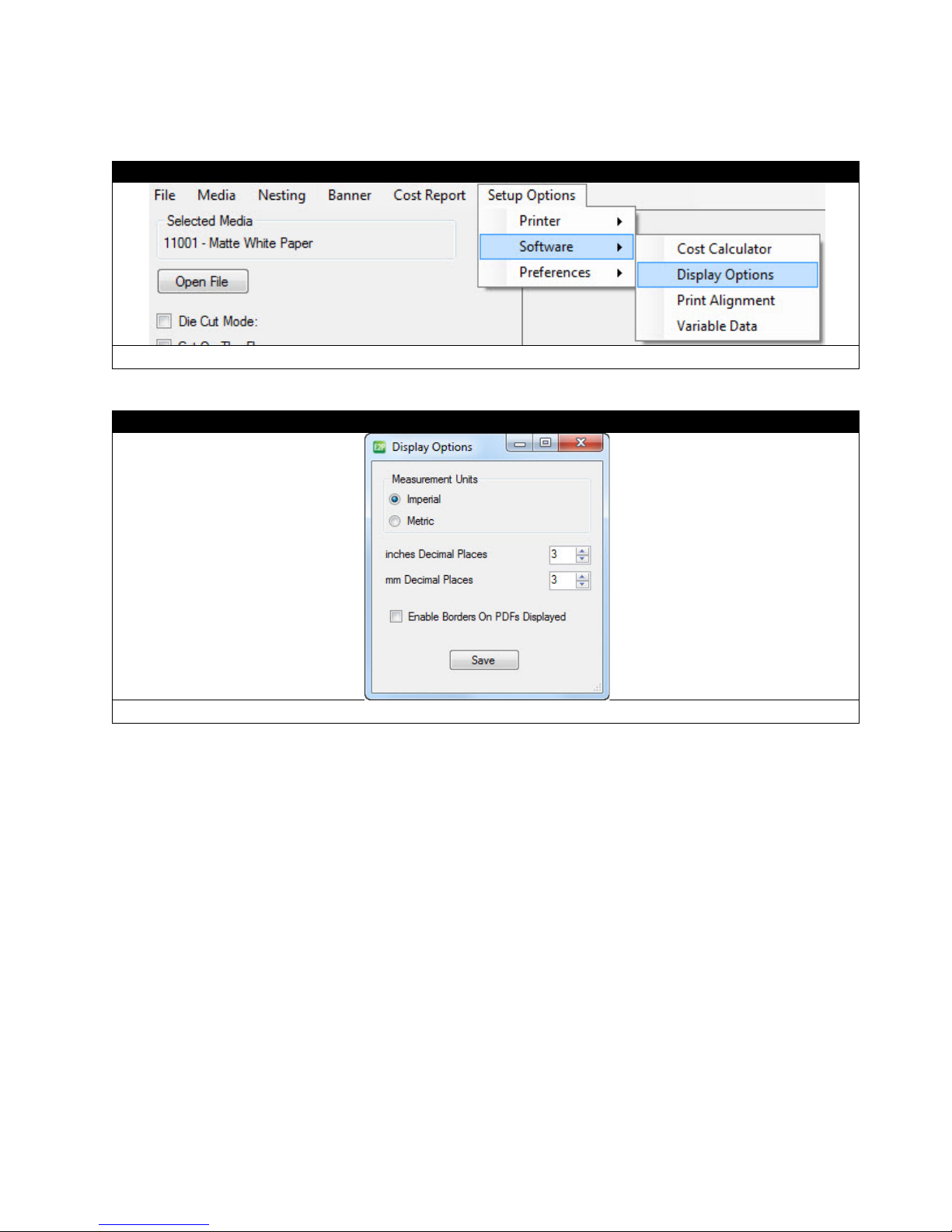

Changing Units of Measurement

STEP 1 of 2

STEP 2 of 2

Save.

Select Setup OptionsSoftwareDisplay Options from the toolbar.

Select your preferred measurement units to display and click

34

Changing the Color Registration

STEP 1 of 4

Select Setup OptionsPrinterColor Registratio n from the toolbar.

selected in the softw are libr ary. Y ou will want to ensure that yo ur front p anel setti ngs and softw are settings ar e the s ame

the exact results that are to be expected. If you do not have an exact match with the front panel and

media library settings, there is potential for an error on the front panel.

STEP 2 of 4

Print Registration Plot.

Go to the front panel of the printer and select the Media Type and Media Weight, based on the media settings you

so you receive

Click

35

STEP 3 of 4

The printer will print a similar page that will aid in determining the proper registration values across CMY.

C:6 M:4 Y:0; this is because the pixels are perfectly filled within the boxes.

STEP 4 of 4

With the values determined i n the previou s step, the f ollowing adjustment s can be made t o the Color Reg istratio n Form.

Note: If there are troubles with the color density, select Printer Density Adjust Before Every Job.

IMPORTANT: Use the third page printed to determine the values.

Using a printer's loupe or best judgment, determine the best values. In this case, the correct values are as follows:

Click Apply to set.

36

Saving and Loading Page Information

STEP 1 of 2

STEP 2 of 2

To load the saved page information, click FileLoad Page Information. Select the page information file you saved

before, and then click Open.

Click FileSave Page Information from the toolbar. The current page information in the software will be saved.

37

3. Before Printing

STEP 1

EDGE2Print User Interface

The following shows the interface of the EDGE2Print software.

38

Measuring Your Media

Gutter: Measures the distance between labels

by using the horizontal gap

Alley: Measures the distance between labels

by using the vertical gap

Measure Width of Paper, Horizontal and Vertical Gaps between labels (if applicable), and input these values into

EDGE2Print. Input the values into Page Information in the EDGE2Print Software.

STEP 1 of 4 STEP 2 of 4

Measure the total width of paper. Input the value

into Media Width.

Measure the distance of horizontal gap. Input the

value into Gutter.

STEP 3 of 4 STEP 4 of 4

Measure the distance of vertical gap. Put the value

into Alley.

You also should measure the width and height of

the label. Save the values for later.

39

Measuring Tip

way! Measure as least one meter of the media, and

measure the height of one label. Then calculate the distance of the gap. The longer you measure the media, the more

precise value you will get.

Ex. For the left picture, we measure 9 label lengths plus 9 gutter lengths; the total length is 1171.58 mm (46.125

In order to get more precise value of Gutter, there is a better

inches).

Then measure one label length, which is 127mm (5 inches).

Therefore, the gutter value should be (1171.58/9)-127= 3.177 mm

40

Loading Media for Continuous Printing

STEP 1 of 11

IMPORTANT: Only use with Media with a width ranging from 6” to 8.5” wide

Note: Maximum Printable Width is 8.24”

Make sure the sides of the roll are straight and flush with the core.

STEP 2 of 11 STEP 3 of 11

41

STEP 4 of 11

STEP 5 of 11

Open the feeder tray by pushing the black tray

latches inward and pulling the tray outwards.

Pu ll out the feeder tray and open the front tray.

Cut a small piece of the media and to use to adjust the width of the guides.

Open the left and right media guides.

Place the paper between the left and right media guides.

Use the rewinder to adjust the width, making sure there is no space on both sides and the paper can pass through

with no tension.

42

Remove the plastic spindle and insert it into the core of the media roll, ensuring that you keep the edges of the roll

completely flush with the core.

STEP 6 of 11

Feed the media through, ensuring it is between the tension and pinch rollers.

STEP 7 of 11

Place the roll in the feeder between the extension arms, with the leading edge of the material at the bottom of the tray.

Adjust the width of the extension arms to fit the paper roll’s width, if necessary.

43

Power on the printer. When the feeder displays

leaving a clean leading edge for printing.

With the media flush against the back plate in the feeder, ensure that there is no extra space on each side of the

media and the left/right med ia guide s.

Feed the media underneath the drive roller and ensure that the paper is at the same level as the top of the rollers.

Back wind the roll if necessary.

Close the red left/right media guides. Ensure that the media is not buckling or too snug against the guides before

proceeding to the next step.

STEP 8 of 11 STEP 9 of 11

Close the front tray cover and push the tray in.

Note: DO NOT press the Load butto n at this

stage.

“Status: Require Load,” press the Load button on

the feeder.

The media will be fed upwards and cut the substrate,

44

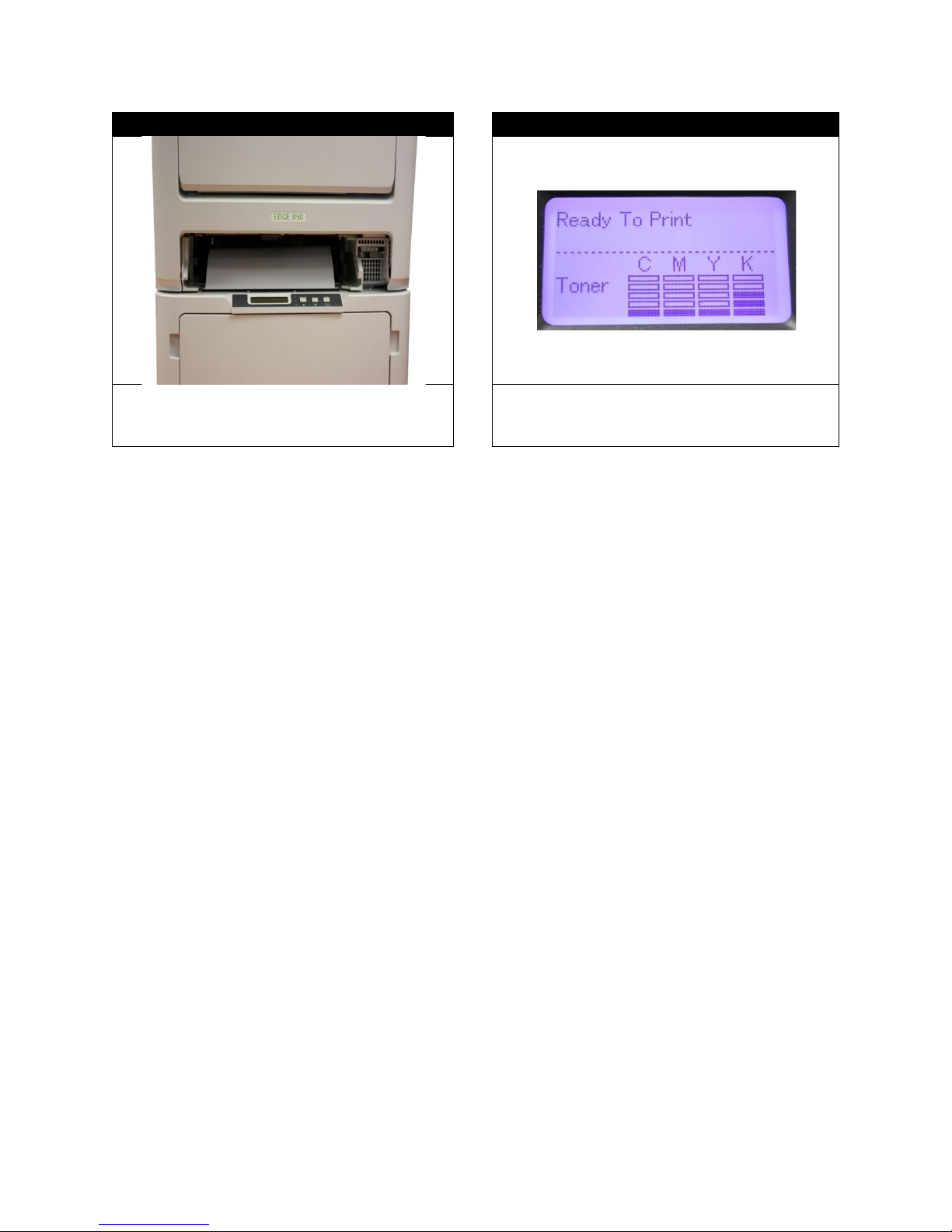

STEP 10 of 11 STEP 11 of 11

After the feeder cuts the paper, remove the Cut on

the Fly module and scrap material. Put the Cut on

the Fly Module back in its position.

The CMYK colors will adjust, and the printer will

display “Ready To Print” when it is ready.

45

Loading Media/Sensor Calibration for Die-cut Label Printing

STEP 1 of 4

STEP 2 of 4

Refer to steps 1-8 of “Loading Media for Continuous Printing” for how to load the roll of media. After the die cut

Close the front tray cover and push the tray in.

Launch the EDGE2Print software. If your media is die cut, select Die Cut Mode. Then select the Sensor Type. (We

will use the Gap Sensor as the example in the following instructions.)

Note: If the Calibrate button is red, it means the sensor needs calibration before printing.

roll is loaded into the tray, line up the gap of the labels about one inch below the sensor.

Close the left/right media guides. Backwind the roll to ensure there is no tension when the sensor is calibrating. If the

roll is fully wound and has tension on it, it will skew the calibration.

46

STEP 3 of 4

After the media is properly loaded, click Calibrate in the software. The following dialogue will pop up. Select Run

Calibration. The printer will run the paper upwards about 6 inches to the nearest gap mark.

Copy Media Library Settings To Media Library

STEP 4 of 4

If the calibration did not work, an error screen will pop up and you will have to adjust the roll before performing another

You are now ready to add a label image and print a die-cut label.

Note:

1) You can use previously stored values in the feeder from the last use by clicking Copy Feeder Settings To

Media Library.

2) You can also manually input the values for Sensor Gain and Sensor Window under the Media Library Settings,

and then click

calibration.

After calibration is done. Turn the feeder Offline and hold the DOWN arrow on the feeder display to cut extra paper.

Remove the excess paper, then turn the feeder On Line and press Load to finish the loadin g pro cess.

to update the values in the feeder.

47

How to Set Up the Rewinder

STEP 1 of 6

Loosen the Core Adjustment Knob. Place a core on the Rewinder Spindle. Make sure the core is the same width of

flush against the left end disk. If the core is slightly smaller, place it in the center using your best judgme nt.

STEP 2 of 6

Cut a section of the media you’ll be using to print. Place that piece of media flush against the Left End Disk and

core, it will cause the roll to wind haphazardly, not wind tightly and create bubbles in the roll.

the media you’re printing on or slightly smaller. If the core is the exact same width as the media, ensure it is placed

adjust the Right End Disk to fit the media. Ensure that the paper is flat against the core and there is no excess space

on each side of the End Dis k s. Tighten the Core Adjustment Knob.

NOTE: If there is excess space between the core and the Left/Right End Disks OR the media is not flat against the

48

STEP 3 of 6

Loosen the Lockdown Knob for positioning. When you are ready to print, send a small section of labels to the printer.

While the section is printing, adjust the rewinder left/right using the Width Adjustment Knob, aligning the rewinder

Lockdown Knob.

STEP 4 of 6

Plug the DC Power In, and then plug the end of the power cord into a socket. Turn the rewinder on by turning the

switch to REV.

with the paper path as the labels exit the machine. Once the paper path and rewinder are aligned, tighten the

49

STEP 5 of 6

Press Print in the software when your job is ready. As the paper exits the printer, lift the Dancer Arm and bring the

media underneath the Dancer Arm and up onto the core. Secure it to the core using a section of media or excess

or create bubbles between the reams.

STEP 6 of 6

When the roll is done, turn off the rewinder. Unscrew the Core Adjustment Knob on the Spindle. Remove the roll

from the Spindle and return the Right End Disk to its initial position.

label.

Lower the Dancer Arm downwards to begin winding the material onto the core. Place your hand gently on top of the

core to create some initial tension at the beginning of the roll. Once the media is winding, release the Dancer Arm

gently downwards onto the paper. The roll will continue to wind.

NOTE: Winding speed is determined by the position of the Dancer Arm. Lowering the arm will speed up the winding

and lifting upwards will slow it down.

NOTE: If the roll seems to be winding too loosely, place your hand on the top of the roll while it’s winding. This will

increase the tension momentarily. Be careful when doing this as too much tension will cause the roll to wind unevenly

50

4. Printing

STEP 1 of 3

The EDGE2Print uses PDF files only. To open a file, choose FileOpen, click O pe n F i le button to select your PDF

file, or you can simply drag and drop your PDF file to the Preview Screen.

STEP 2 of 3

You can load multiple PDF files as long as they have the same dimensions, but the number of PDF files shouldn't

aligned in columns.

STEP 3 of 3

Image List

Adding a Label Image

exceed the column numbers on the die cut media. The images will show in the Preview Screen, and multiple files are

The information of the images will show in the

on the left.

51

Selecting the Amount of Labels

STEP 1 of 1

Enter how many labels you want to be printed and press Add. The EDGE2Print software will automatically round the

amount of labels up to complete a full row. Then click Print to start printing labels.

STEP 1 of 3

Note: For the first print, you need to adjust vertically where the printer starts printing the label images.

more than 20 inches of labels for the first print. Make sure the proper values for paper width, gutter and alley

set to 0 without affecting the color registration.

Adjusting the Print Alignment

Select Setup OptionsSoftwarePrint Alignment from the toolbar. Set the proper Pattern Header Length. Print

measurements are inserted into the EDGE2Print software.

Recommendation: The header NEEDS to be 22 inche s l on g in or d er t o ad ju st t he color registration. T he f oot er c an be

52

STEP 2 of 3

Check the start position. The 2 0 inches of header colo r patter ns are used f or calibrat ion. The gap betw een labels should

gap on the label line. If the labels are not aligned after the third copy, adjust the start position value

according to how far the label is from the gap.

STEP 3 of 3

be in line with the

Start Position

Positive Value (+): Move print down

Negative Value (-): Move print up

53

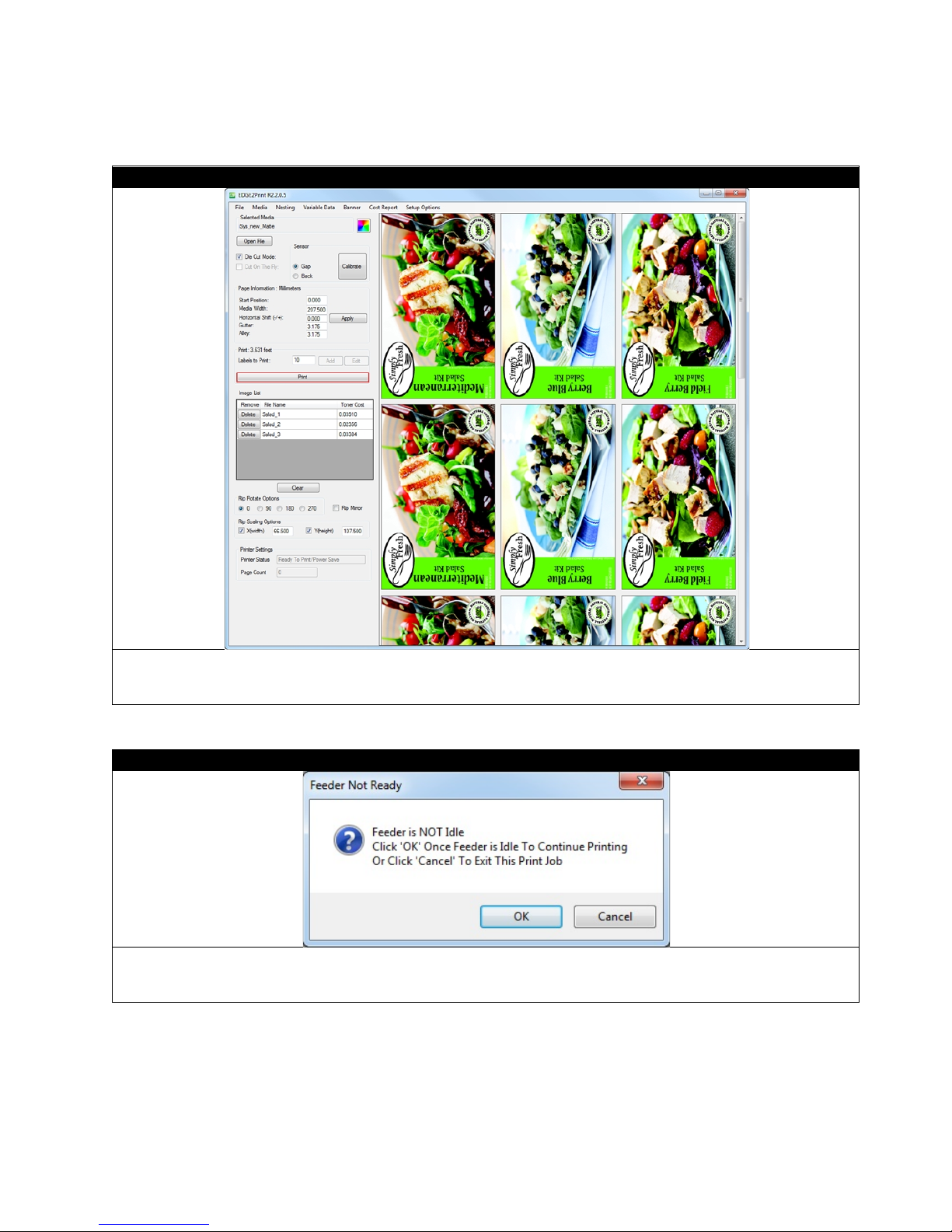

Printing

STEP 1 of 2

STEP 2 of 2

Once all PDF files have been added a nd the Page Information adjustments have been made, click Print button to st ar t

printing.

If Done is not selected on the feeder unit, the printer will remain in a busy state and display a Feeder Not Ready

window. Press Done on the feeder unit and click OK.

54

5. Software Features & How To’s

How To Print a Full Bleed Die Cut Label

The following is a detailed guide to create an oversized label image on top of a die cut label. The term over bleed

means that there is a small portion outside of the actual label known as the “overprint area”. Excess toner of the label

is printed on to this area so that the actual dimensions of the label are met with clear, clean cut edges. The cutting is

done after we print.

55

STEP 1 of 3

Measure the label length, label width, gutter and alley.

STEP 2 of 3

Input the number into proper place. For example, the label width(X) is 50.5mm, label height(Y) is 127mm, gutter is

3.175mm, alley is 3.175mm.

STEP 3 of 3

If you want to print 1mm bleed outside of the label size on both direction, just minus gutter and alley by 2mm, and add

2mm to width and height. So width becomes 52.5mm, height becomes 129mm, gutter becomes 1.175mm and alley

becomes 1.175mm.

56

How to Create a New Media ID/Custom Media ID

STEP 1 of 5

STEP 2 of 5

Media ID

right click

Media ID.

STEP 3 of 5

To create a new media, click the Media tab on the toolbar.

In the pop-up window above, select the correct

The dialogue above will pop u p.

and

on the

57

STEP 4 of 5

Fill in the Media ID, Media Description and Media Vendor, select Media Type and Media Weight from the list, then

provides a variety of substr ates that have b een rigoro usly te sted f or optimal pri nt quality , ease of us e and

responsible for damage or consequences arising from the use of non-certified media or con sum able s.

STEP 5 of 5

There is an option that allows for only the new media to be displayed. Check the Show Only User Media box to view

only new/custom media IDs.

click Create. Your new media will be display in the list.

Note:

Uninet

consistency from the beginning of t he jo b until t he e nd. The I CO LOR 700 was designed and engineer ed to op erate w ith

approved consumables and certified media which ensure superior quality and resolution every time. Uninet is not

58

Editing a Newly Created Media ID

STEP 1 of 3

STEP 2 of 3

The following pop-up window will allow you to edit. After editing, click Update This Media button to update the

Notice: You can only delete the media you created. The Certified Media’s in the library can't be deleted.

STEP 3 of 3

To delete a new Media ID, that same media cannot be loaded, o r an Er r or D eletin g Active Media window w ill disp la y .

ID for Deletion-> click Delete This Media.

If the new media entry needs to be edited, right click on the new Media ID.

information. If you want to delete it, click Delete This Media button.

You should click OK Click MediaSelect Another Media ID to LoadClick MediaRight click on the new Media

59

Install Your Own ICC Profile

STEP 1 of 8

When you are using the created media, you can install your own ICC profile. Click the colourful square button on the

right side of your media's name.

STEP 2 of 8

This dialogue allows you to setup your own color information. Make sure you checked Apply ICC Profile with RIP

Setup Options.

STEP 3 of 8

Install Output ICC Profile

Click

.

60

STEP 4 of 8

Select the ICC profile, click Open.

STEP 5 of 8

Change the ICC name and ICC comment if you need, then click Save.

STEP 6 of 8

Then your ICC profile appears in the list.

61

STEP 7 of 8

STEP 6 of 8

Notice that only CMYK ICC profile can be installed. If it is a RGB ICC profile, this window will pop up.

After making changes, click Save to save and close the dialogue.

62

Installing the Fonts in the RIP

STEP 1 of 9

STEP 2 of 9

Go to ComputerDisk(C:)Windows, double click Fonts.

Press Ctrl+A to select all of the fonts within the folder, and press Ctrl+C to copy all of the fonts.

63

STEP 3 of 9

Create a new folder in a convenient location (e.g. a folder named myFonts on the Desktop), then press Ctrl+V to paste

all of the fonts into this folder.

STEP 4 of 9

Open Windows Start and find iSys RIP, click to open the software.

64

STEP 5 of 9

Click the Red Stop Light Icon to pause the program.

STEP 6 of 9

FontsInstall Fonts

STEP 7 of 9

Find the new folder you just created which has all of the fonts. Double click to open.

Click

from the toolbar.

65

STEP 8 of 9

STEP 9 of 9

The fonts wi ll start t o instal l to the RIP. Once the job has been completed all of the fonts will be available in the Print

Software.

Press Ctrl+A to select all of the fonts, and click Install.

66

Nesting

STEP 1 of 4

Click Nesting on the Toolbar. Notice that the Add and Edit b utton s have become availabl e and the Print butt on is now

labeled Print Nesting.

STEP 2 of 4

Load the PDF file/files and ent er the nu mber you w ant to pr int. T hen click Add and job w ill be saved f or printi ng and t he

images will disappear from the Preview Screen. The Print Nesting button will now display Print Nesting: 1

STEP 3 of 4

Nesting is a feature where user s can print multipl e graphics of the same size and lay out in a sequence w ithout stopping.

Ex. You have wine labels of the same size and need 32 Cabernet, 20 Merlot and 10 Malbec for one run. Rather than

printing these individually, you can print them all in the same run, one after another without stopping. By using the

nesting feature you will save time by setting up the job and running it once rather than three times individually.

67

Repeat the above step until all the printing jobs are loaded. For example, we have 3 jobs loaded, Print Nesting: 3 will

be display. Click that, and the printing process will start right away.

STEP 4 of 4

If you need to edit the ne sting j ob, clic k Edit button and the fol low ing dialogu e w ill pop up. Y o u can change the distance

by adding to the length of the label. Ex. If your label is 6 inches (152.4 mm) high, you will add 6

Label quantity can also be adjusted across each nested job. Once the necessary changes have been made, click

Update then click Exit to return.

between nested jobs

inches (152.4 mm) to create that white space between jobs.

68

Rip Rotate Options

STEP 1 of 1

When the Rip Rotate Option is set to 0 all PDF files will preview in their original orientation. The Rip Rotate Options

For example, if you check 90 in the RIP Rotation Option, the image will rotate 90

Note: If the graphic does not fit the width of the media when rotated, a red error will show on the Image List.

will allow for the desired orientation.

degrees clockwise.

To rotate the graphic, first you will need to clear it from the EDGE2Print software, select the desired rotation, then reimport the graphic.

Adjustments can now be made in the Page Information Section for correct placement on the selected media.

69

Rip Scaling Options

STEP 1 of 1

If the size of your image is not the same as the label size, you can use the RIP Scaling Option to adjust it. Input the

graphic designer and have them properly scale the image rather than using the Scaling feature.

width of label into X(width) and put the height of label into Y(height).

Select the desired scaling values, then select Clear in the Image List section. Re-import the graphic into the

EDGE2Print software. The Preview Screen will now show the graphic scaled according to your specifications.

Note: When scaling an image, some resolution may be lost and result in pixilation. If this is the case, consult your

70

How to View Cost Report

STEP 1 of 3

Cost Report

STEP 2 of 3

The following window will pop up. This is the cost report for the last printing job.

= This takes into account the wear and tear done on the drums, transfer belt and fuser. It also

= This is the total cost for the amount of labels you selected to be printed, including the toner,

drums, transfer belt, fuser and media.

From the EDGE2Print toolbar click Cost Report. The Cost Report will be displayed within a text file. Notice that the 3

PDF files are in the job and each are separately calculated. The TOTAL COST of all jobs is calculated at the bottom

of the page along with the TOTAL LENGTH.

To view cost report, click

from the toolbar

There are three different types of job costing given:

Total Toner Cost = This is the cost of toner ONLY

Total Cost Per Label

adds in the cost of the media based on the length of material used.

Total Cost Per Job

71

STEP 3 of 3

For variable data printing, you can select the above to generate cost report after printing.

72

How to Install Variable Data Software (iVDP)

STEP 1 of 9

STEP 2 of 9

The following window will pop up. Enter the correct Dongle ID and click Import.

STEP 3 of 9

Open the folder that holds the Key and select Variable_Data_Enabled.dat, then select Open.

Open the EDGE2Print software, select Setup OptionsSoftwareVariable Data

73

STEP 4 of 9

Then, close the software and reopen it. The Variable Data tab is now on the toolbar.

STEP 5 of 9

Variable Data

Labels to Print

STEP 6 of 9

Open the PDF file that contains your variable data, which was created using Bartender. Once loaded, click the Print

If only the first ima ge of your variable data is visible on t he preview screen, then yo u did not clic k the Variab le

separate jobs of 1.9GB each.

Select

from the Toolbar. The

option now becomes unavailable.

button.

Important:

Data tab before you opened the file. You should clear the file and redo the two previous steps.

Limitations: Variable Data has a 1.9GB limitation. If the file is larger than 1.9GB, the software will divide the data into

74

STEP 7 of 9

Once the Print button is clicked, the following window will pop up. The RIP and Separations Procession will take a few

seconds to fully process depending on your hardware. Once they have processed, their screens will turn green and a

Printing Job #1 will appear.

STEP 8 of 9

If the print job is larger than 1.9GB, and you selected Pause between 1.9GB print jobs option, this window will appear

to start printing the next job. If you did not select Pause

between 1.9GB print jobs, then job #2 will automatically start printing. Please refer to Step 9 for printing options.

STEP 9 of 9

after the first job is printed and you must click Print Job #2

The following shows the Options of variable data printing.

75

How to Print Using Banner Mode

STEP 1 of 5

EDGE2Print has a feature which can print a long PDF file using the banner mode.

Select Banner from the toolbar. The Die Cut Mode now becomes unavailable.

STEP 2 of 5

Load the PDF file into EDGE2Print.

76

STEP 3 of 5

If the following dialogue pops up, it means you did not click the Banner tab before you loaded your PDF file. Please

redo the two previous steps.

STEP 4 of 5

If the media width is large enough to take up multiple columns of the banner, it will show in multiple columns. You can

set a value to the Alley to separate each column.

77

STEP 5 of 5

You can set a value to Gutter if you want a gap between multiple banners. The output of your banner will look like the

. If your graphic is larger than this, you will need to have

now be imported into the software and printed in sequence.

layout above.

Note: The limitation of PDF size is 200 inches (5080 mm) long

your graphic designer crea t e a mult i-pa ge PD F with 199 inches (5054.6 mm) se cti ons or less. The multi-page PDF can

78

6. Trouble Shooting & Maintenance

(a) Pull the colored toner release lever on the

cartridge out of the printer.

Toner Cartridge Replacement

STEP 1 of 8 STEP 2 of 8

cartridge to be replaced fully towards the front of

Press the cover release and open the printer’s top

cover fully. Note the position of the four cartridges.

the printer.

(b) Lift the right hand end of the cartridge and then

draw the cartridge to the right to release the left

hand end as shown, and withdraw the toner

STEP 3 of 8 STEP 4 of 8

Clean the top of the ID unit with a clean, lint free

cloth. Remove the new cartridge from its box but

leave its wrapping material in place.

Gently shake the new cartridge from end to end

several times to loosen and distribute the toner

evenly inside the cartridge.

79

STEP 5 of 8 STEP 6 of 8

Pressing gently down on the cartridge to ensure that

free cloth.

Insert the left end of the cartridge into the top of the

Remove the wrapping material and peel off the

adhesive tape from the underside of the cartridge.

image drum unit first; pushing it against the spring on

the drum unit, then lower the right end of the

cartridge down onto the image drum unit.

STEP 7 of 8 STEP 8 of 8

it is firmly seated, push the colored lever towards

the rear of the printer. This will lock the cartridge

into place and release toner into the image drum

unit.

Gently wipe the LED head surface with a clean, lint

Finally close the top cover and press down firmly at

both sides so that the cover latches closed.

80

Image Drum Replacement

CAUTION! Static sensitive devices, handle with care.

WARNING! If the printer has been powered on, the fuser will be hot. Do not touch.

CAUTION! The green image drum surface at the base of the ID unit is very delicate and light sensitive. Do

The printer contains four image drums: cyan, magenta, yellow and black.

STEP 1 of 8 STEP 2 of 8

Press the cover release and open the printer’s top

cover fully.

Note the position of the four toner cartridges (a) and

image drums (b) it is essential that they go back in

the same order.

not touch it and do not expose it to normal room light for more than 5 minutes. If the drum unit needs to be

out of the printer for longer than this, please wrap the cartridge inside a black plastic bag to keep it away

from light. Never expose the drum to direct sunlight or very bright room lighting.

STEP 3 of 8 STEP 4 of 8

Holding it by its top centre, lift the image drum,

complete with its toner cartridge, up and out of the

printer.

With the colored toner release lever (1) to the right,

pull the lever towards you. This will release the toner

cartridge from the drum.

81

STEP 5 of 8 STEP 6 of 8

STEP 7 of 8

STEP 8 of 8

Lift the right hand end of the toner cartridge (1) and

then draw the cartridge to the right to release the

left- hand end as shown (2) and withdraw the toner

cartridge out of the image drum cartridge. Place the

cartridge on a piece of paper to avoid marking your

furniture.

Push the colored release lever away from you to

lock the toner cartridge onto the new image drum

unit and release toner into it.

Place the toner cartridge onto the new image drum

cartridge as shown. Push the left end in first and then

lower the right end in. (It is not necessary to fit a new

toner cartridge at this time unless the remaining toner

level is very low.)

Holding the complete assembly by its top center,

lower it into place in the printer, locating the pins at

each end into their slots in the sides of the printer.

82

Replacing the Transfer Belt Unit

and withdraw the belt unit (c) from the printer.

CAUTION! The green image drum surface at the base of the ID unit is very delicate and light sensitive. Do

The transfer belt unit is located under the four image drums. Switch off the printer and allow the fuser to cool for about

10 minutes before opening the cover.

STEP 1 of 6 STEP 2 of 6

Press the cover release and open the printer’s top

cover fully.

Note the positions of the four toner cartridges (a) and

image drums (b) it is essential that they go back in

the same order.

STEP 3 of 6 STEP 4 of 6

Locate the two fasteners (a) at each side of the belt

Lift each of the image drum units out of the printer

and place them in a safe place away from direct

sources of heat and light.

and the lifting bar (b) at the front end. Turn the two

fasteners 90˚ to the left. This will release the belt

from the printer chassis. Pull the lifting bar (b)

upwards so that the belt tilts up towards the front,

not touch it and do not expose it to normal room light for more than 5 minutes. If the drum unit needs to be

out of the printer for longer than this, please wrap the cartridge inside a black plastic bag to keep it away

from light. Never expose the drum to direct sunlight or very bright room lighting.

83

STEP 5 of 6 STEP 6 of 6

Turn the two fasteners (a) 90˚ to the right until they

Lower the new belt unit into place, with the lifting

bar at the front and the drive gear towards the rear

of the printer. Locate the drive gear into the gear

inside the printer by the rear left corner of the unit,

and lower the belt unit flat inside the printer.

lock. This will secure the belt unit into place. Replace

the four image drums, complete with their toner

cartridges, into the printer in the same sequence as

they came out.

Close the top cover and press down firmly at both

sides so that the cover latches closed.

84

Fuser Replacement

Identify the fuser handle (a). Pull the two fuser

from its packaging and remove the transit material.

Place the drums back into the printer and replace

WARNING! If the printer has recently been powered on, some fuser components will be very hot. Handle the

cool before opening the printer cover.

The fuser is located inside the printer just behind the four image drum units.

fuser with extreme care, holding it only by its handle, which will only be mildly warm to touch. A warning

label clearly indicates the area. If in doubt, switch the printer off and wait at least 10 minutes for the fuser to

STEP 1 of 5 STEP 2 of 5

Press the cover release and open the printer’s top

cover fully.

retaining levers (b) towards the front of the printer so

that they are fully upright. Remove the new fuser

STEP 3 of 5 STEP 4 of 5

Holding the new fuser by its handle, make sure that it

is the correct way round. The retaining levers (b)

should be fully upright, and the two locating lugs (c)

should be towards you.

Lower the fuser into the printer, locating the two

lugs in the slots in the metal partition which

separates the fuser from the image drums .Push

the two retaining levers (b) towards the rear of the

printer to lock the fuser in place.

STEP 5 of 5

the lid.

85

Clearing Paper Jams

CAUTION: The green image drum surface at the base of the Image Drum is very delicate and light sensitive.

light. Never expose the drum to direct sunlight or very bright room lighting.

STEP 1 of 17 STEP 2 of 17

Note the position of the four toners cartridges (a) and

Press the cover release and open the top cover.

STEP 3 of 17 STEP 4 of 17

image drums (b). It is essential that they go back in

the same order.

Lift the image drum, complete with its toner

cartridge, up and out of the printer

Put the assembly down gently onto a piece of paper to

prevent toner from staining surrounding areas and to

avoid damaging the green drum surface and cover.

Do not touch it and do not expose it to normal room light for more than 5 minutes. If the drum unit needs to

be out of the printer for longer than this, wrap the cartridge inside a black plastic bag to keep it away from

86

STEP 5 of 17 STEP 6 of 17

To remove a sheet in the fuser; push the two

handle (f).

Check if any sheets of paper are visible on any part

of the belt unit (a. release handle, b. belt, c. fuser or

d. fuser pressure release lever).

To remove sheet from the front, lift the sheet from the

belt and pull it forward into the internal drum cavity to

withdraw the sheet.

STEP 7 of 17 STEP 8 of 17

To remove a sheet from the central area, separate

the sheet from the belt surface and withdraw the

sheet.

retaining levers (e) towards the rear of the printer to

release the fuser. Withdraw the fuser unit using the

STEP 9 of 17 STEP 10 of 17

Press release lever (g) and pull trapped paper from

the fuser.

Replace fuser unit into the machine and move

locking levers (e) toward the rear of the machine.

87

STEP 11 of 17 STEP 12 of 17

Starting with the cyan image drum unit nearest the

cavity, making sure to place in the correct order.

Open the rear exit tray (h) and check for sheets of

found in this area.

If the sheet is low down in this area and difficult to

press down on the fuser pressure release lever (d).

Pull out the paper tray and ensure all paper is stacked

cover and press down firmly so the cover latch closes.

fuser, replace the four image drums into the drum

paper in the rear path area (i), pull out any sheets

STEP 13 of 17 STEP 14 of 17

remove, it is probably still gripped by the fuser. In

this case raise the top cover, reach around and

Pull down the MP tray using the depressions. Lift the

front cover release lever and lower the front cover.

STEP 15 of 17 STEP 16 of 17

Check inside the cover for sheets in this area and

remove any that you find, and then close the cover.

properly, is undamaged, and that the paper guides

are properly positioned against the edge of the paper

stack. When satisfied replace the tray. Close the top

STEP 17 of 17

Pull out the paper guide tray, clear out any paper

jams. Reload fan fold paper and close the paper

guide tray.

88