Uni-Mig PRO-CRAFT240 MIG, PRO-CRAFT210 MIG User Manual

PRO-CRAFT SERIES

210/240 MIG Manual

Standard

MIG / MAG

240 Volt

Machine Model

Description Part Number

MIG Inverter KPC210 / 240

CONTENTS PAGE No:

Safety 3

Main Parameter. 4

Machine Features 4

Installation & Operation 4

Caution 11

Maintenance 12

Troubleshooting 12

Machine Model

This welding equipment for industrial and professional use

conforms to IEC 60974 International Safety Standard.

We hereby state that we provide three year of guarantee for this

welding Power Source from the date of purchase.

Refer to Unimig for further details.

Please read and understand this instruction manual carefully before

the installation and operation of this equipment.

The contents of this manual may be revised without prior notice

and without obligation.

This instruction manual is issued on 1st April 2008.

UNIMIG pursue a policy of continuous research and development, and therefore

reserve the right to change the specifications, or design, without prior notice. * 2 year warranty power source.

YEARS Warranty

*

3

•

Do not switch the function modes while the machine is operating.

Switching of the function modes during welding can damage the machine.

Damage caused in this manner will not be covered under warranty.

•

Disconnect the electrode-holder cable from the machine before switching on the

machine, to avoid arcing should the electrode be in contact with the work piece.

•

A safety switch is necessary to prevent the equipment from electric leakage.

•

Welding tools and accessories should be of high quality and in good working order.

•

Operators should be trained and or qualified. Electric shock: It can kill.

•

Connect the primary input cable according to Australian standard regulation.

•

Avoid all contact with live electrical parts of the welding circuit, electrodes and wires with

bare hands. The operator must wear dry welding gloves while he/she performs the

welding task.

•

The operator should keep the work piece insulated from

himself/herself. Smoke and gas generated whilst welding

or cutting can be harmful to people’s health.

•

Avoid breathing the smoke and gas generated whilst

welding or cutting. Keep the working area well ventilated.

•

Arc rays are harmful to people’s eyes and skin. Always

wear a welding helmet and suitable protective

clothing including welding gloves whilst the welding

operation is performed.

•

Measures should be taken to protect people in or near

the surrounding working area, from all hazards

associated with welding.

Fire hazard

•

The welding sparks may cause fire, therfore remove

flammable material away from the working area.

•

Have a fire extinguisher nearby, and have a trained

person ready to use it.

Noise: possibly harmful to people’s hearing.

•

Noise is generated while welding/cutting, wear approved

hearing protection when noise levels are high.

Machine fault:

•

Consult this instruction manual.

•

Contact your local dealer or supplier for further advice.

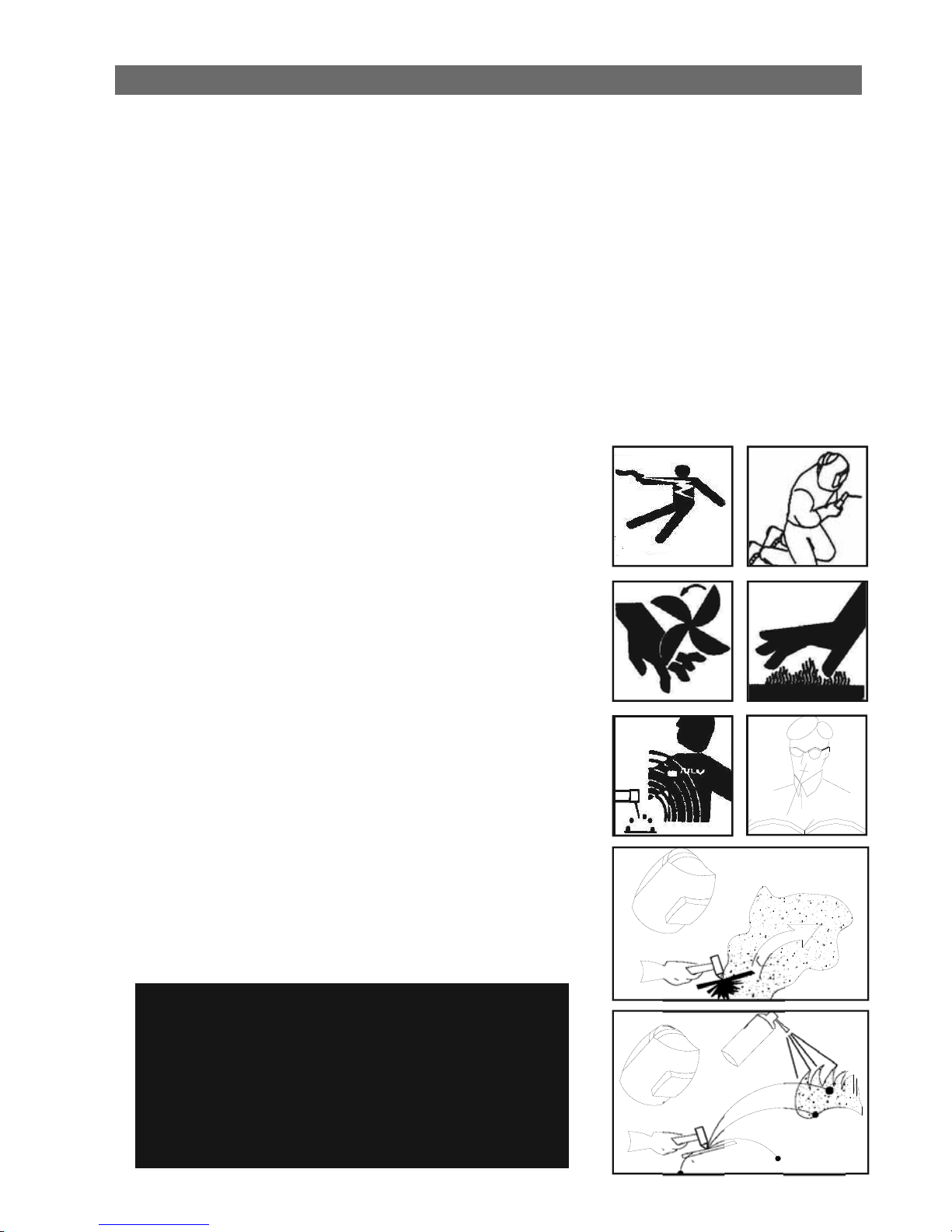

SAFETY

Welding and cutting equipment can be dangerous to both the operator and people in or near the

surrounding working area, if the equipment is not correctly operated. Equipment must only be

used under the strict and comprehensive observance of all relevant safety regulations. Please

read and understand this instruction manual carefully before the installation and use/operation

of this equipment.

*** CAUTION ***

Do not heat, cut or weld tanks, drums or containers

until the proper steps have been taken to insure that

such procedures will not cause flammable or toxic

vapours from substance inside. These can cause

an explosion even though the vessel has been

“cleaned”.Vent hollow castings or containers before

heating, cutting or welding. They may explode.

1.INTRODUCTION

The MIG welding machines of the UNIMIG series are of advanced technical specification which makes them highly reliable. The

240V single phase series consitis of a generator made of a fan cooled and single-phase transformer with double primary,

The power commutations are made on the primary, which is activated by a contactor.

The DC current is obtained through a multi-diodes fan-cooled rectifier bridge. The machine is protected from overload through

a thermic control on the transformer. The PCBs are protected in order to make up for the lack of the ambient characteristics of

the rooms in which the weldings are carried out.

8 welding current settings (Unimig 210 - 240)

The generator can run eight power regulations through a commutator for the power combinations on the primary.

2. HOW TO PUT THE MACHINE ON

Input cable connectionA.Connect the machine to 240V 1 Phase, ensure that the machine is fitted with a plug that is equal to or lar

g

than the Ieff. The input cable should be connected well with the corresponding power supply connection plug or socket, to avoid ox

Single-phase machine is preset by the building factory for a single-phase 50/60 hertz 220÷240 V feeding.

To put the machine on, it has to be equipped with the accessories which it is dispatched with and it has to be completed by a

current plug adequate to the electrical system of the workshop. The operations to carry out are:

Opening, lift and wheel assembly - Plug assembly - Trolley assembly - Gas bottle installation - Torch installation - Wire spool

housing

2.1 OPENING , LIFT AND WHEEL ASSEMBLY

Open the box from the up side, take out the accessories from the box, take the screw-hook and scewit on the top of the machine.

Lifting it by manual or mechanical elevator.

The cart is designed for the mounting of two rotating front wheels and for the insertion of an axle for the fastening of the two

fixed rear wheels.

It is supplied with a kit comprising:

Rotating front wheels, axle for the fixed rear wheels, rear wheels, bolts, split pins and cage nuts.

Insert the cage nuts in the apposite slots as illustrated in pic. A and B.

Mount the two front wheels as illustrated in pic. C.

Insert the axle to fasten the rear wheels and block them with the split pins as illustrated in pic. D.

PART NUMBER KPC210 KPC240

PRIMARY INPUT VOLTAGE 240V 1 Phase 240V 1 Phase

Ieff 16Amps 20Amps

WELDING CURRENT 30-210 Amps 30-240 Amps

VOLTAGE STEPS 8 8

DUTY CYCLE 40°C 18% @ 210 Amps 24.5V 15% @ 240 Amps 26V

60% @ 110 Amps 19.5V 60% @ 150 Amps 21.5V

100% @ 95 Amps 18.75V 100% @ 120 Amps 20V

WELDING VOLTAGE RANGE DC 15.5V – 24.5V 15.5V – 26.5V

WIRE SIZE (mm) 0.6 – 0.9mm Ferrous 0.6 – 0.9mm Ferrous

0.8 – 0.9mm Stainless Steel 0.8 – 0.9mm Stainless Steel

0.8 – 1.0mm Aluminium 0.8 – 1.2mm Aluminium

0.8 – 1.0mm Flux Cored 0.8 – 1.2mm Flux Cored

DIMENSIONS (mm) 920 x 460 x 820mm 920 x 460 x 820mm

WEIGHT (Kgs) 78 Kgs 81 Kgs

Loading...

Loading...