Uni-max MX5110 User Manual

???

??????

WARRANTY CARD

Product: MILLING MACHINE WITH ADJUSTABLE SPINDLE MX5110

Type:

MX5110

Date of manufacture:

Date of sale, stamp, signature:

Serial number (product series):

Repair centre notes:

Without the correctly filled warranty card or without proof of purchase receipt, including

the product type (invoice, purchase receipt) no warranty claim will be processed.

1. KH Trading machines and tools are covered by 6/24 months warranty, starting on the date of

purchase, as described in the Civil Code (proof of purchase or invoice receipt must be

enclosed with the warranty card when making a claim).

2. This warranty does not cover defects caused by unprofessional handling, machine overloads, not

complying with instructions contained in this manual, using accessories that are not approved,

unauthorized repair, regular wear and tear and damages occurred during transport. Further, this

warranty does not cover parts and accessories such as the motor, carbon brushes, seals and

hot-air operated parts and parts that need to be changed regularly.

3. If the repair is to be found as not covered by the warranty policy, all costs including the repair and shipping to and from the repair centre will be paid by the customer, according to valid price list. See www.

4. When making a claim, you must present the warranty card, showing the date of the purchase, the

serial number of the machine, vendor stamp and signature of sales clerk, as well as the proof of

purchase receipt.

5. Warranty claim shall be made at the vendor shop where you bought your machine or you may mail

it to a service centre. The vendor is obligated to fill out the warranty card (date of sale, serial

number, vendor stamp and signature). All these information must be filled in at the time of sale.

6. The warranty period will be extended for the period of time for which the machine has been in the

service centre possession. If the repair or defect is not covered by the warranty policy, all costs including

the repair and shipping will be paid by the owner of the machine / tool. We recommend sending the

machine in its original packaging. Please, also enclose brief description of the defect with the packaging.

7. Before sending the machine for repair, clean it thoroughly. If the received machine is dirty, it may

be rejected by the service shop or you may be charged a cleaning fee.

SERVICE

Logistic centre Klecany

Topolová 483

250 67 Klecany

Czech Republic

Claim department phone number: 266 190 156 T-mobile: 603 414 975

266 190 111 O2: 601 218 255

Fax: 260 190 100 Vodafone: 608 227 255

http://www.KHnet.cz

Email: servis@KHnet.cz

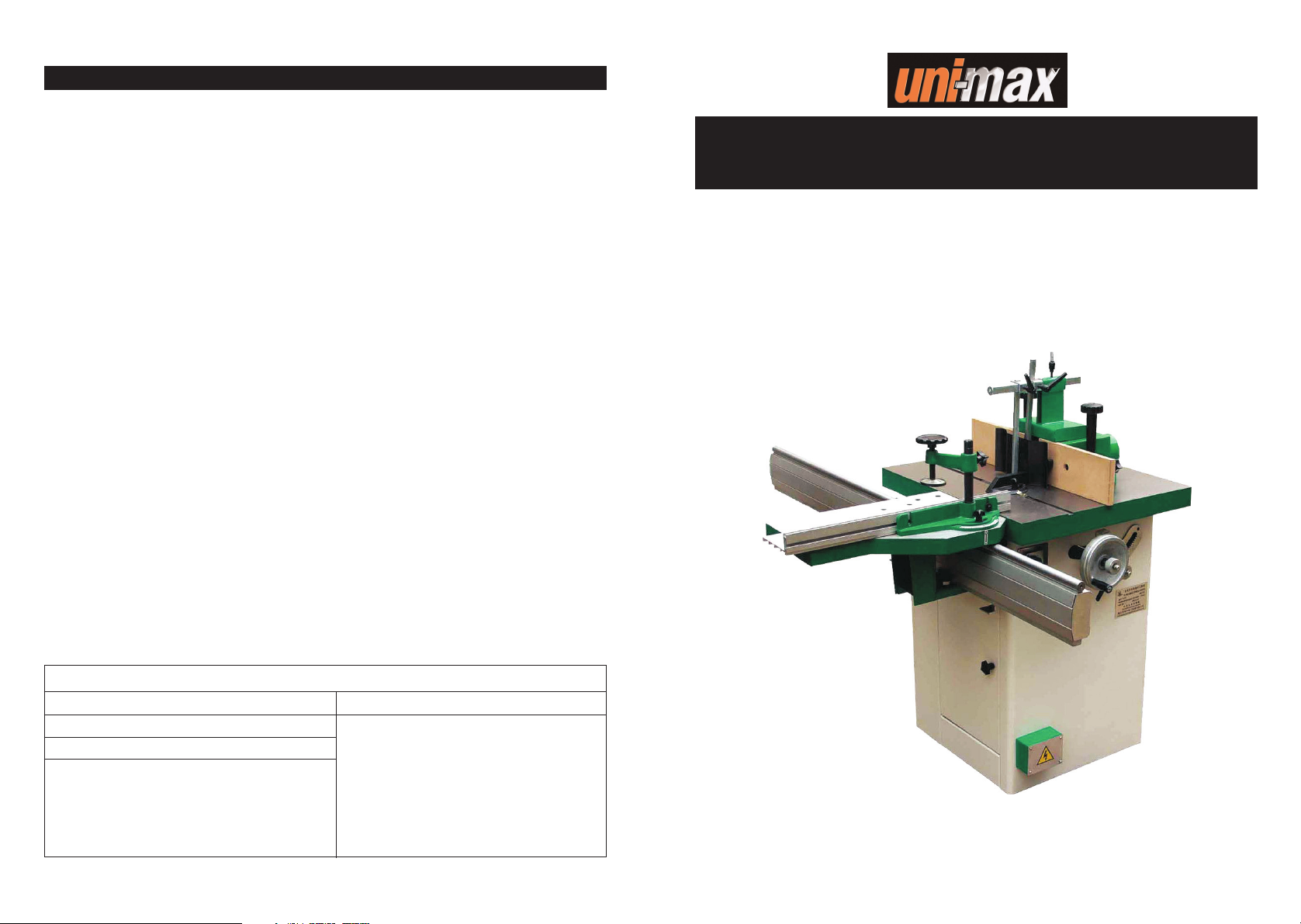

MM II LL LL II NN GG MM AA CC HH II NN EE WW II TTHH

AA DD JJ UU SS TT AA BB LL EE SS PP II NN DD LL EE

MM XX 5511 11 00

USER'S MANUAL

MX5110

2

Dear customer. Thank you for purchasing equipment from KH Trading, s.r.o.

Our company is ready to offer you our services - before, during and after you buy our product.

If you have any question, comment or idea, please contact our business centre. We will do our best to address

your comment or question in timely matter.

Before first use, please read this manual carefully. It is your responsibility to study all instructions,

necessary for safe use and operation and to understand all risks that may be involved during the use

of power machines.

WARNING! Do not try to use this machine before reading this entire manual and before you know

how to handle it. Keep this manual for future reference.

Pay special attention to safety instructions. Not complying with safety rules may cause injury to the

operating person or to people standing by or it may cause damage to the machine or to the work

piece.

Pay special attention to safety notes and safety labels on the machine.

Never remove or damage them.

Please, write information such as the invoice number

and the number of the sale receipt here in this box.

This machine may be used for curved surface milling/ finishing, flat sur face milling and stud and dowel joint

types production, shape cutting and so on. The construction of this machine is very simple, as well as its use

and control.

This machine is widely used in various industries, for wooden structure construction, furniture, art and craft

production etc.

Machine is equipped with variable protective cover system, press/support elements, robust stand, cart with

easy travel support and angle ruler.

The main advantage is angle adjustable spindle in range 0° - 30°.

DESCRIPTION

REPAIR AND MAINTENANCE REPORT

Report and maintenance report:

DATE

SERVICE SHOP

REPAIR AND MAINTENANCE REPORT

Noise level

Prolong exposure to noise levels greater than 85 dB(A) may

cause health problems of the operating personnel. Therefore, it

is recommended to use personal protection such as ear protection

gear.

Testing based on ISO 3746/1995 standard. The operational noise

level during feed is 97.6 dB(A).

The maximum noise value is less than 130 dB(A).

The noise level varies at different part of the machine.

Operating

person position 1 2 3 4 5 6

dB(A) 86 87 84 83 85 86

The accuracy of instructions, graphs and information contained

herein, depends on the printing date.

Due to continuous product improvement, the manufacturer reserves

the right to change technical parameters of the product, without prior

customer notification.

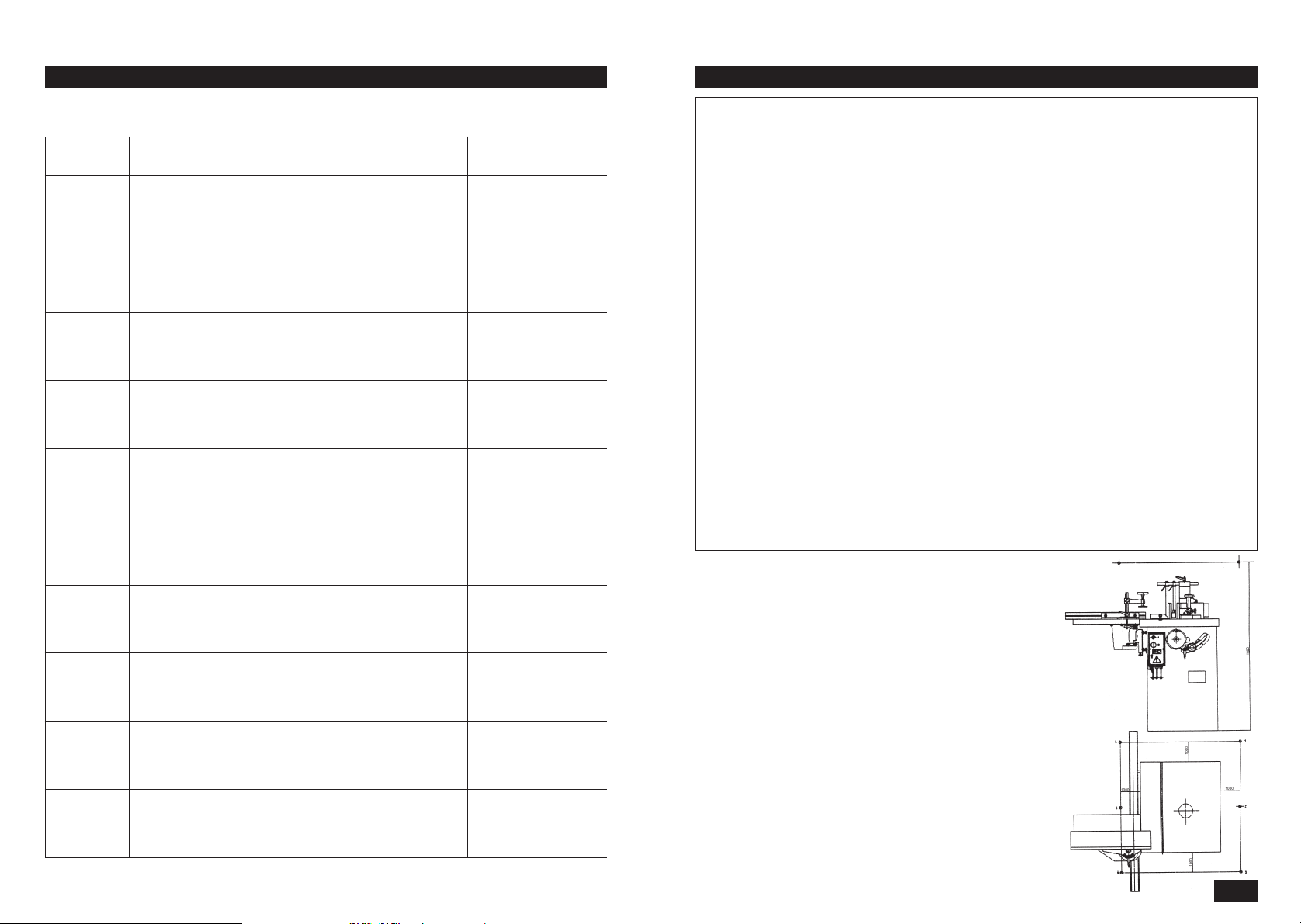

Power input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.2 kW

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .~400 ± 5%. V

Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 Hz

Spindle speed/rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3,250, 6,500, 7,500 min.

-1

Spindle diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 mm

Maximum diameter of milling tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180 mm

Maximum diameter of cutting tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140 mm

Spindle tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0° - 30°

Maximum spindle height above the working table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150 mm

Operational spindle height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 mm

Length of tool travel (slide distance underneath the table) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 mm

Maximum height of sliding tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 mm

Worktable dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .680 × 590 mm

Diameter of sawdust vacuum inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 mm

Spindle stop time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .< 9 s

Overall dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1,620 × 1,200 × 1,200 mm

Machine weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160 kg

Packaging 1

Packaging dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1,000 × 770 × 1,150 mm

Net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160 kg

Gross weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200 kg

Packaging 2

Packaging dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1,650 × 180 × 120 mm

Net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 kg

Gross weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 kg

Maximum amount of emission particles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.34 mg/m

3

TECHNICAL SPECIFICATION

3

4

???

• This device may be used by a qualified person, 18 years or older who has been

trained in work and environmental safety procedures.

• Any person using this equipment must possess a medical certificate

demonstrating his eligibility to operate this equipment.

• "Prevent most common injuries" - MILLING MACHINES

• "Prevent injuries" - WOOD PROCESSING AND CUTTING MACHINES.

We recommend placing work safety regulations notices at your workshop:

Self-adhesive safety symbols labels used with your machine:

Place the self-adhesive stickers on noticeable spots on your machine.

Symbols used in this manual

Warning!

This symbol informs you about the risk of personal injury or damage to the machine

or materials.

Caution! You are using electrically powered machine!!

Electrical hazard.

Risk of being caught by spinning machine parts!

Caution! Loose clothing or body parts may get caught by moving machine parts.

Warning!

Danger of damage.

Note:

Additional information.

Use personal safety gear.

SAFETY PRECAUTIONS

In case of fire do not use water or foam

fire extinguishers

Use respiratory passageways protection

Use ear protection

Use eye protection

Caution! Electrical equipment

Harmful or irritable substances

Caution! Danger of being caught by machine moving parts

Read manual before use

Danger of having fingers cut

REVISION REPORT

The user is obligated to perform tests and revisions of electrical equipment of the machine

in accordance with valid rules and regulations. Result report:

DATE

REVISION TECHNICIAN

Number / SIGNATURE

REVISION REPORT

Loading...

Loading...