Unigreen Mistblowers EXPO, Mistblowers DEVIL, Mistblowers SIRIO, Mistblowers EOLO, Mistblowers AP APC User Manual

GB

USE AND MAINTENANCE MANUAL

MISTBLOWERS

MOUNTED MISTBLOWERS

serie EOLO - SIRIO - DEVIL - EXPO - AP APC

Read this manual carefully

before use.

ISO

Color code

01/2007

Summary

1 USING AND KEEPING THE USE AND MAINTENANCE MANUAL .................... 4

1.1 COMPOSITION OF THE MANUAL ....................................................................................... 4

1.2 GUARANTEE ....................................................................................................................... 4

1.3 PRODUCT RESPONSIBILITY .............................................................................................. 4

1.4 WARNING SIGNS IN THE MANUAL AND ON THE MACHINE ............................................. 4

2 SAFETY REGULATIONS AND RESIDUAL RISKS .............................................. 5

2.1 INTENDED USE ................................................................................................................... 6

2.2 PROHIBITED USE ...............................................................................................................6

2.3 USING CHEMICAL PRODUCTS .......................................................................................... 6

2.3.1 REGULATIONS FOR THE USE OF CHEMICAL PRODUCTS ............................................... 6

2.4 RECOMMENDATIONS ......................................................................................................... 6

2.4.1 TAKING PRECAUTIONS AGAINST FIRE HAZARDS ........................................................... 7

2.5 WEATHER CONDITIONS ..................................................................................................... 7

2.6 MACHINES DESIGNED TO BE USED ONLY WITH CLEAN WATER .................................... 7

2.7 DRIVING ON THE ROAD ..................................................................................................... 7

3 CHARACTERISTICS AND SPECIFICATIONS ..................................................... 7

3.1 TABLES OF FITTINGS ALLOWED....................................................................................... 7

3.2 NOISE LEVEL OF THE MACHINE ....................................................................................... 8

3.3 STANDARDS OF REFERENCE: ........................................................................................... 8

4 USER’S INSTRUCTIONS ....................................................................................... 8

4.1 DESCRIPTION OF THE MACHINE ...................................................................................... 8

4.1.1 HAND WASHING TANKS ...................................................................................................... 8

4.2 PRELIMINARY CHECKS...................................................................................................... 8

4.3 TRANSPORTING AND MOVING THE MACHINE ................................................................. 9

4.3.1 TOWED ATOMISERS ........................................................................................................... 9

4.4 TRACTOR COUPLING ........................................................................................................10

4.4.1 THREE-POINT COUPLING ................................................................................................. 10

4.4.2 HYDRAULIC CONNECTION TO THE DISTRIBUTORS ........................................................ 10

4.5 CARDAN SHAFT ................................................................................................................. 11

4.6 PUMP .................................................................................................................................. 11

4.7 SUCTION FILTER ...............................................................................................................11

4.8 PRESSURE REGULATOR ...................................................................................................12

4.8.1 COMPONENTS OF THE PRESSURE REGULATOR ........................................................... 12

4.8.2 GENERAL INSTRUCTIONS ................................................................................................ 12

4.9 DELIVERY FILTERS (ONLY EQUIPPED MODELS) ............................................................ 13

4.10 FILLING THE TANK ............................................................................................................. 14

4.11 TEST WITH CLEAN WATER ................................................................................................ 14

4.12 MIXING ............................................................................................................................... 14

4.12.1 MANUAL PREMIXING.........................................................................................................15

4.12.2 PREMIXER ON COVER (OPTIONAL): ................................................................................15

4.13 WASHING THE ATOMISER ................................................................................................. 15

4.13.1 CIRCUIT WASHER AND TANK WASHER ............................................................................ 15

5 BLOWER GROUP ................................................................................................ 16

5.1 AXIAL BLOWER GROUP WITH PULLEY ............................................................................16

5.2 AXIAL BLOWER GROUP WITH MULTIPLIER ..................................................................... 16

5.3 BLOWER GROUP WITH FRONT SUCTION ........................................................................ 17

5.3.1 SINGLE-SIDE BLOWER GROUP ........................................................................................17

5.4 AXIAL ROTOR ..................................................................................................................... 17

5.5 CLUTCH .............................................................................................................................. 18

5.6 OPTIONAL DEFLECTORS AND ACCESSORIES ...............................................................18

5.7 CANNON BLOWER GROUP ...............................................................................................18

5.7.1 MANUALLY INCLINABILE HEAD.........................................................................................18

5.7.2 HYDRAULIC DRIVEN HEADS .............................................................................................18

5.7.3 HYDRAULIC DRIVES .......................................................................................................... 18

5.7.4 OIL FEED FROM TRACTOR ............................................................................................... 18

6 SPRAYING ............................................................................................................ 19

6.1 DESCRIPTION OF TYPE OF JETS ....................................................................................19

6.2 DESCRIPTION OF TYPE OF NOZZLES ............................................................................. 19

6.2.1 NORMAL VOLUME CONICAL NOZZLES (OVER 500L/HA) ................................................. 19

6.2.2 LOW VOLUME CONICAL NOZZLES (150-500L/HA) ............................................................ 19

2 unigreen

6.2.3 ANTI-DRIFT NOZZLES ....................................................................................................... 19

6.3 CALIBRATING AXIAL FAN ATOMISERS .............................................................................20

6.4 CALIBRATING CANNON ATOMISERS ................................................................................ 20

6.4.1 TREATMENTS ON TALL PLANTS .......................................................................................20

6.4.2 TREATMENTS ON HERBACEOUS CULTIVATIONS ........................................................... 21

7 HAND LANCES .................................................................................................... 21

8 MAINTENANCE .................................................................................................... 22

8.1 PROGRAMMED MAINTENANCE ........................................................................................ 22

8.2 ROUTINE MAINTENANCE ..................................................................................................22

8.2.1 CLEANING THE NOZZLES ................................................................................................. 22

8.2.2 LUBRICATION .....................................................................................................................22

8.2.3 MULTIPLIER LUBRICATION ................................................................................................22

8.3 EXTRAORDINARY MAINTENANCE ...................................................................................22

8.4 REPAIRS .............................................................................................................................22

8.5 STORAGE IN A WAREHOUSE AND TRANSPORTATION ................................................... 23

8.6 PUTTING BACK INTO SERVICE AFTER WINTER LAYUP ................................................. 23

8.7 DEMOLITION AND DISPOSAL ........................................................................................... 23

8.7.1 MATERIALS FOR DEMOLITION ......................................................................................... 23

8.7.2 INDICATIONS FOR A SUITABLE TREATMENT OF WASTE................................................ 23

8.7.3 ELECTRICAL AND ELECTRONIC APPARATUS WASTE (EEAW) .......................................23

TABLES FOR CALIBRATING ATOMISERS Ø500-600 ..................................... 25

TABLES FOR CALIBRATING ATOMISERS Ø600-650 ..................................... 26

TABLES FOR CALIBRATING ATOMISERS Ø700-750 ..................................... 27

TABLES FOR CALIBRATING ATOMISERS Ø800 ............................................. 28

TABLES FOR CALIBRATING ATOMISERS Ø900 ............................................. 29

TABLES FOR CALIBRATING ATOMISERS Ø650 TGZ .................................... 30

TABLES FOR CALIBRATING ATOMISERS Ø800 TGZ .................................... 30

TABLES FOR CALIBRATING CANNONS Ø450 ................................................ 31

TABLES FOR CALIBRATING CANNONS Ø400-455 ......................................... 32

TABLES FOR CALIBRATING CANNONS Ø400-455 TILTING HEAD............... 33

TABLE 1-3 TABLES OF DELIVERY OF NOZZLES FOR ATOMISERS ............................ 34

TABLE 4-5 TABLES OF DELIVERY OF NOZZLES FOR HAND LANCES ...................... 35

TABLE 8 PROBLEMS, CAUSES AND SOLUTIONS .......................................................... 36

TABLE 7 TABLE OF PROGRAMMED MAINTENANCE .................................................... 36

TAB.14A ALLOWED FITTINGS ........................................................................................... 37

TAB.15A ALLOWED FITTINGS ........................................................................................... 38

TAB.16A ALLOWED FITTINGS ........................................................................................... 39

unigreen 3

Thank you for having chosen UNIGREEN.

The product you purchased has been designed and built with the greatest attention to the safety of the operator and the environment, nevertheless there are

still some residual risks due to the nature of the product used.

For this reason we recommend reading all of this manual to avoid making mistakes in the first period of use and to get the most out of the working life of the

atomiser in time, doing the programmed maintenance at regular intervals.

1 USING AND KEEPING THE USE AND MAINTENANCE MANUAL

The manual is an integral part of the machine and should be kept in a safe

place where it can be reached easily for consultation.

1.1 COMPOSITION OF THE MANUAL

This manual consists of various parts to make it easier to consult by subject

and to avoid repetitions; the following are part of the manual:

a) pump handbook

b) pressure regulator handbook (manual or electric)

c) spraying computer handbook (if fitted)

d) optional accessories handbooks (marker, premix, cardan shaft, etc.)

UNIGREEN reserves the right to make changes to the manual without prior

warning and the normal printing cycles may vary slightly.

1.2 GUARANTEE

The enclosed card indicates the conditions of the UNIGREEN guarantee. The

UNIGREEN guarantee covers the repair or replacement of parts considered manufacturing flaws, according to the unquestionable judgement of UNIGREEN, only

after the authorised agent for that zone has verified the fault.

Ambit of the guarantee

The guarantee doesn’t cover cases of normal wear, negligent use, poor maintenance and/or improper use.

The following materials subject to normal wear are not covered by the

guarantee: gaskets and seals, diaphragms, seal rings, tubes and pipes, noz-

zles, pressure gauges, oil, tyres, friction material of the clutches.

Evident cases of negligence include:

work speed over that indicated in the spraying tables in the handbook (or too

high for the conditions of the terrain), power-takeoff speed over 540 rpm and

anything else indicated in the Use and Maintenance Manual.

Maintenance:

The guarantee is void if the maintenance indicated in the tables in this manual

isn’t respected, regarding the period and deadline of the interventions, washing

the machine and the circuit at the end of the treatment.

Improper use:

The use the UNIGREEN machines are designed for is indicated in this manual,

any other use is forbidden and makes the guarantee void.

4 unigreen

Composite handbook, consult

the specific files on the various

components

1.3 PRODUCT RESPONSIBILITY

UNIGREEN spa is not responsible if:

a) During the working life of the machine the normal maintenance operations

aren’t performed and documented as indicated in this handbook, in the enclosed handbooks of the pumps-motors-regulators-etc. and in any case as is

customary for the normal maintenance of mechanical machinery.

b) The machine is equipped with non original accessories or components or

parts that aren’t acknowledged by UNIGREEN as their own.

c) The machine is equipped with original accessories or components that are

unsuitable in the measurements, weight or version for the same.

Please consult the page of available and recommended fittings.

d) Not following the instructions in the manual whether totally or partially.

e) Modifications made to the machine that haven’t been authorised by

UNIGREEN.

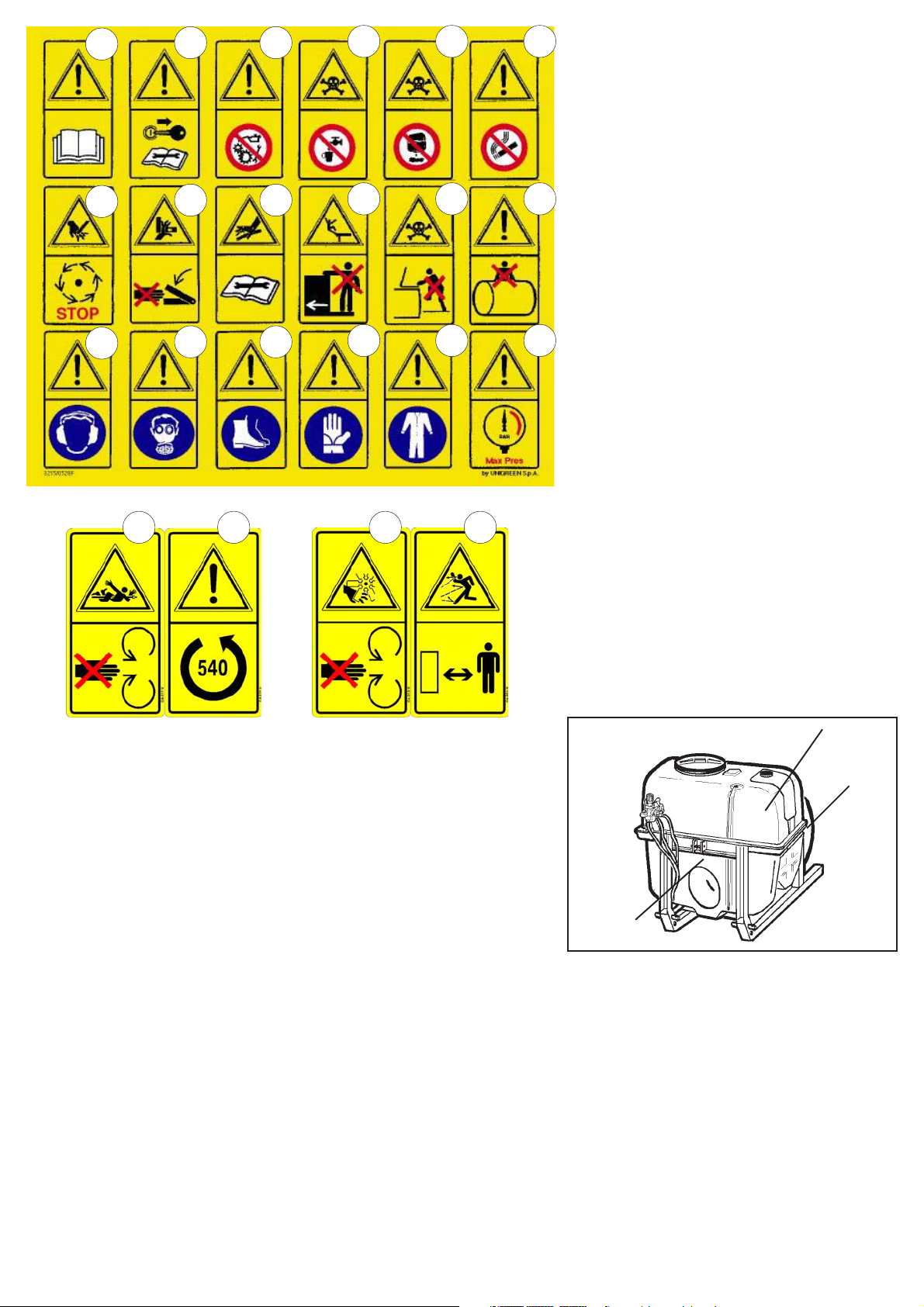

1.4 WARNING SIGNS IN THE MANUAL AND ON THE MACHINE

Below you will find all of the pictograms on the machine (see FIG.1 for their position), in order to illustrate the warnings, the prohibitions and the correct

method of use.

The operations that require particular attention are shown in the images beside

the text.

1

7

13

2

8

14

3

9

15

2019 2221

4 5

10 11

16 17

Key to the symbols

6

1- Read the Use and Maintenance manual

2- Stop the machine and read the manual before

every intervention

3- Don’t lubricate while running

4- Don’t drink

5- Don’t dispose of residue liquids in the

environment

6- No smoking

7- Danger, risk or injury, don’t get near the

12

machine until the moving machine members

have stopped

8- Danger of crushing, don’t get your hands near

the moving mechanical machine members

9- Danger, risk or injury caused by fluids under

pressure

10- Don’t climb on the machine during work or

transfers

18

11- Don’t climb on the tank

12- Don’t enter in the tank

13- Wearing earmuffs is obligatory

14- Wearing a face mask is obligatory

15- Wearing safety footwear is obligatory

16- Wearing protective gloves is obligatory

17- Wearing protective overalls is obligatory

18- Use a working pressure under that indicated

in red on the manometer.

19- Don’t get your hands near the moving cardan

shaft

20- Make sure power-takeoff of the tractor turns

in the right direction and runs at the right speed.

21- Don’t remove the protecting device with fan

moving.

22- Material shooting off the machine, stand at a

safe distance.

2 SAFETY REGULATIONS AND RESIDUAL RISKS

In relation to safety, the following terms will be used:

Dangerous zones: any zone inside and/or near the machine where the presence of a person exposed constitutes a risk for the safety and health of the

same person.

Person exposed: any person who has their body or any part of their body in a

dangerous zone.

Before starting the machine, the operator must check for any visible faults in

the safety devices and the machine itself.

Never start the machine until you have told anyone in the range of action of the

machine to move away and they have done so.

The protective devices must not be removed or disabled when the machine is

running.

It is obligatory to keep all the plates with danger and safety signs in perfect

conditions. If they get damaged or deteriorate, replace them in good time.

Replace parts believed to be faulty with others indicated by UNIGREEN.

NEVER try makeshift or hazardous solutions.

Don’t wear clothes, jewellery, accessories, or anything else that can get

caught in the moving machine members.

Pay the greatest attention to all the warning and danger signs on the machine.

Don’t use the machine for any other purpose other than that indicated in the

manual.

The machine has been designed and built with the appropriate devices to guarantee the safety of the user.

In any case there are some residual risks associated with the improper use of

the machine by the operator; for this purpose danger signs and symbols and

prohibitions are applied near some parts of the machine (see previous

pictograms).

FIG.1

19+20

INDICATIVE POSITION

OF THE WARNING SIGNS ON THE ATOMISER

NB: the position may vary on the basis of the

characteristics of the model.

da1 a 18

unigreen 5

21+22

2.1 INTENDED USE

The sprayer in this series is built for agricultural use. The materials used are

resistant to normal chemical products used in agricultural spraying (or

herbicides) at the time of construction.

Any other use is not allowed and the manufacturer is not responsible for any

damage caused by aggressive, dense or sticky chemicals.

THE USE OF THE MACHINE BY PERSONS UNDER 18 YEARS OF AGE IS

STRICTLY FORBIDDEN

The use of liquid fertilizers in suspension is not allowed, while the use of the

same in a solution is possible if requested when the machine is ordered from

Unigreen and in any case changing some of the parts described in the

handbooks of the regulator, such as the manometer (stainless steel), the

nozzles (large diameter ceramic) and eliminating the fine mesh filters to prevent

blockages.

2.2 PROHIBITED USE

Using the machine with the following products is strictly forbidden:

= Paints of any kind and type

= Solvents or thinners for paints of any kind and type

= Combustibles or lubricants of any kind and type

= LPG or gas of any kind and type

= Flammable liquids of any kind and type

= Liquid foodstuffs, whether for animals or humans

= Liquids containing granules or consistent solids

= Mixtures of various incompatible chemical products

= Liquid fertilizer or manure in suspension with lumps and/or that is

particularly dense

= Liquids with a temperature of over 40°C

= Any products that aren’t suitable for the specific use of the machine.

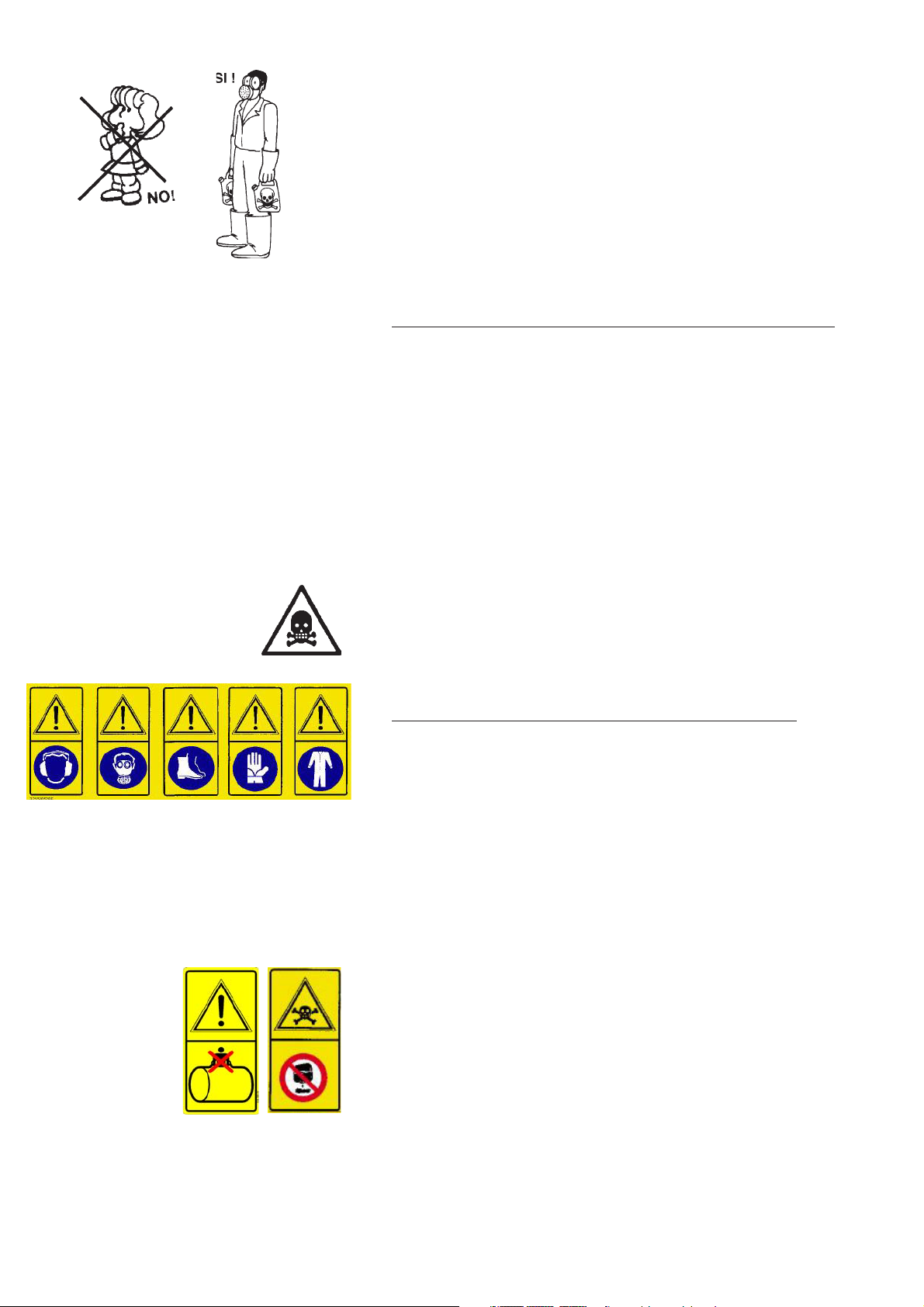

2.3 USING CHEMICAL PRODUCTS

All pesticides or herbicides can be dangerous to humans and the environment if

used erroneously or inadvertently.

Therefore we recommend that only suitably trained persons should use these

products (license) and in any case only after having carefully read the

instructions on the container.

2.3.1 REGULATIONS FOR THE USE OF CHEMICAL PRODUCTS

Some recommendations for avoiding damage and accidents:

= Keep the machine in a suitable, protected place with no access for children

or strangers

= Handle the products with care, wearing rubber acid-proof gloves, gogglesface masks or filtering helmets, overalls made of water-repellent fabrics or

TIVEK and boots made of rubber or similar materials.

= If chemical products or mixtures of product come into contact with the

eyes or are swallowed consult a doctor immediately, taking the label of the

product with you.

= Wash all clothes that come into contact with the chemical, whether diluted

or undiluted, thoroughly before using them again.

= Don’t smoke, drink or eat when preparing or spraying the mix or near or in

the fields treated.

= DON’T ENTER THE TANK: the residues of a chemical product can cause

poisoning and suffocation.

= When spraying, respect safe distances from residential areas, water

courses, roads, sports centres and public parks or paths.

= Thoroughly wash the containers of plant protection products using the

relevant accessories, rinsing several times with clean water. The liquids used for

washing can be used for treatment.

= Collect the washed containers and send them to the relevant collection

centres. Never dispose of them in the environment and don’t use them again for

any other purpose. It is good practice to knock a hole in the bottom of the tins

so they can’t be used again.

= When you have finished spraying, wash the sprayer thoroughly, diluting the

residues with a quantity of water at least 10 times that of the residues, spraying

the resulting mix over the treated field.

6 unigreen

2.4 RECOMMENDATIONS a) Follow the instructions in this manual for the use and maintenance of the

frame, tank, multiplier, blower groups and cannon.

Refer to the enclosed handbooks for the use and maintenance of the pump

and pressure regulator and any accessories or motors.

b) Please contact the agent in your zone, the nearest authorised workshop

or UNIGREEN S.p.A. directly for any repairs the user feels they aren’t capable

of performing alone. (see point 10.4)

c) Due to the complexity of the equipment and the variety of technologies

used (mechanical, hydraulic, oil-pressure and electrotechnical) operators must

not dismantle or modify the equipment. All of the relevant operations must be

performed by specialised personnel, authorised by UNIGREEN S.p.A.

2.4.1 TAKING PRECAUTIONS AGAINST FIRE HAZARDS

Don’t use naked flames or heat sources near the machines.

The atomisers are made with many materials that derive from petroleum:

tanks, tubes, pipes and hoses, wheels and plastic parts; furthermore the

presence of oils of various nature and residues of chemical products make

them potentially flammable.

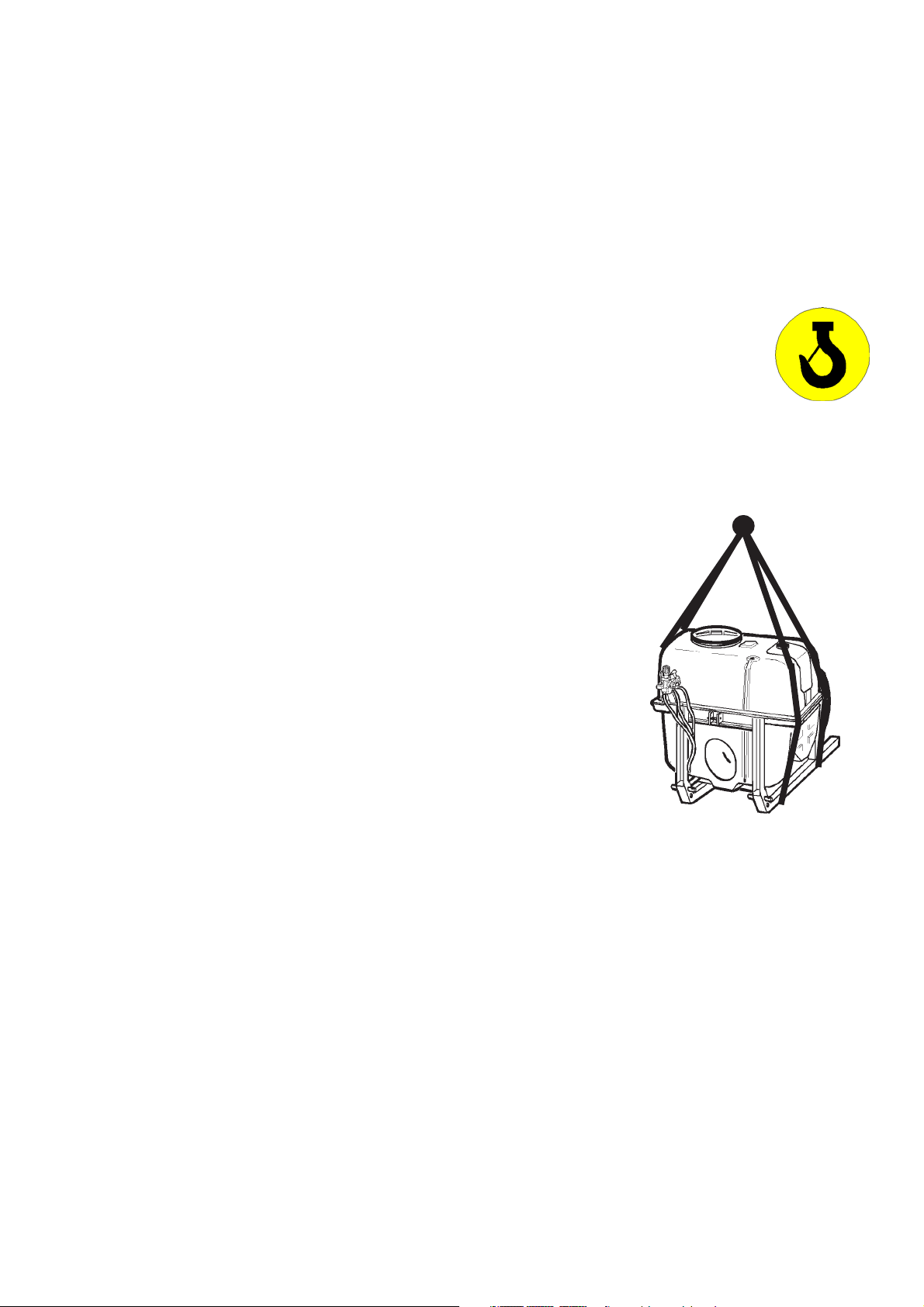

2.5 WEATHER CONDITIONS

We recommend spraying in the early hours of the morning or late in the

afternoon, avoiding the hottest time of day.

Never do any spraying if it’s raining or rain is forecast.

Don’t spray in strong wind or in any case, in winds above 3/5 m/second.

If you have to spray in windy conditions, use relatively low pressures to obtain

quite large drops that are less sensitive to drifting (being heavier the wind has

less effect). There are also special anti-drift nozzles available from UNIGREEN

S.p.A.; for information, please contact our offices.

2.6 MACHINES DESIGNED TO BE USED ONLY WITH CLEAN WATER

There are versions of the machines designed only to be used with a hose reel

for washing with cold clean water.

These machines cannot be used with chemical products as they don’t have some

of the devices or accessories that are needed to use these products safely.

These machines are identified by the word “washing” on the CE plate.

2.7 DRIVING ON THE ROAD

The towed atomisers are not specifically designed for road use. Nevertheless,

many models are also available in the version homologated for road traffic with

the tank empty.

You should check with your local reseller on the correct couplings to use and

use tractors that meet the regulations in force.

3 CHARACTERISTICS AND SPECIFICATIONS

This handbook is valid for mounted atomisers with axial fans for phytosanitary

treatment in orchards and vineyards, in any case for arboreal cultivation in

rows of varying nature and type.

It is also valid for cannon atomisers for the phytosanitary treatment of tall

plants and forest trees such as poplars or similar.

The axial atomisers produce a mixed spray, breaking the drops with the

pressure and the speed of the air produced by the fan.

These atomisers produced by UNIGREEN SPA are identified by the CE plate

(FIG. 2) bearing one of the marks indicated in the tables of the allowed fittings

(see the following paragraph).

TYPE : .......................................................................

code: ........................................ N˚ ...........................

massa a vuoto: ..........................Kg. max press. : ........... bar

net mass

massa totale ammessa: .............................. Kg.

total mass

via Rinaldi, 105 - Reggio Emilia ITALIA

ANNO

YEAR

20 .......

made in

Italy

FIG. 2

3.1 TABLES OF FITTINGS ALLOWED

Tables N° 14A-15A-16A let you identify the version of your machine indicating

the basic equipment and all the possible fittings available (optional).

You can also find the other fittings allowed or other versions to meet your

requirements in the future.

THE EQUIPMENT DEFINED IN THE TABLES OF THIS HANDBOOK (TAB:

14A-15A-16A, pages 37, 38, 39) SHOULD BE CONSIDERED BINDING FOR

THE VALIDITY OF THE DECLARATION OF CONFORMITY.

Other fittings or setups of basic components and/or optionals should be

considered unsafe and therefore are not covered by the guarantee and aren’t

UNIGREEN’s responsibility.

The same goes for fittings realised with components or accessories that aren’t

original UNIGREEN parts.

UNIGREEN accessories can easily be identified by the label with the yellow

background “ORIGINAL UNIGREEN ACCESSORY”

unigreen 7

3.2 NOISE LEVEL OF THE MACHINE

Use earmuffs to protect your ears when using the machine, below you will find

the data on the maximum noise levels during work.

Atomisers with axial fan rotor

ACOUSTIC POWER LEVEL emitted by the machine with axial fan rotor: 113.5

and 118.5 dBA respectively in 1st and 2nd gear

ACOUSTIC POWER LEVEL AT THE OPERATOR’S POSITION emitted by the

machine with axial fan rotor: 89.0 and 89.5 dBA respectively in 1st and 2nd

gear

Atomisers with centrifugal fan rotor (cannon)

ACOUSTIC POWER LEVEL emitted by the machine with axial fan rotor: 111.5

and 117.0 dBA respectively in 1st and 2nd gear

ACOUSTIC POWER LEVEL AT THE OPERATOR’S POSITION emitted by the

machine with axial fan rotor: 94.0 and 97.0 dBA respectively in 1st and 2nd gear

Readings taken in accordance with the following standards:

Machines Directive 98/37/CE (89/392 CE Dir. re-codified).

Legislative Decree D.Lgs. n°292 of the 4th of September 2002 concerning the

environmental acoustic emission of machines and equipment for use outdoors.

Legislative Decree D.Lgs. 277/91 on the subject of the protection of workers

against the risks deriving from exposure to chemical, physical and biological

agents.

3.3 STANDARDS OF REFERENCE:

- MACHINES DIRECTIVE 98/37/CEE (89/392 CE Dir. re-codified).

- Directive 86/188/CEE: risks deriving from exposure to noise (implemented in

Italy by Legislative Decree D.L 277/1991)

- DPR 547/1955: Regulations for the prevention of accidents and hygiene at work.

- Legislative Decree D.Lgs. n°292 of the 4th of September 2002 concerning the

environmental acoustic emission of machines and equipment for use outdoors.

-UNI EN ISO 12100-1/Apr.2005 : Machinery safety - Fundamental concepts,

general design principles - Part 1: basic terminology, methodology

-UNI EN ISO 12100-2/Apr.2005 : Machinery safety - Fundamental concepts,

general design principles - Part 2: Technical principles

-UNI EN 294/July 1993: Machinery safety, safe distances to avoid reaching

hazardous areas with upper limbs.

-UNI EN 349/June 1994: Machinery safety, minimum spaces to prevent crushing

of body parts

-UNI EN 907/Nov.1998: Agricultural and forestry machinery - Sprayers and

spreaders of liquid fertilizers - Safety.

-UNI EN 954-1/Dec. 1998 : Machinery safety - Fundamental concepts, general

design principles

-UNI EN 982/July 1997: Machinery safety. Safety requisites relevant to systems

and their components for hydraulic and pneumatic transmissions. Hydraulics.

-UNI EN ISO 4254-1/June 2006: Agricultural machines - Safety - Part 1:

General requisites

-ISO 11684/1995: Pictograms - general principles.

8 unigreen

This symbol identifies

the clean water tank on

the machine used to

wash your hands

4 USER’S INSTRUCTIONS

4.1 DESCRIPTION OF THE MACHINE

The atomisers consist of a structural steel frame and a polyester tank

reinforced with fibreglass or high-density polyethylene. The frame is hotgalvanised. The tank is easy to empty and this makes it possible to use the

machine even on hillsides.

The pumps are generally diaphragm pumps but in some cases they are fitted

with pistons.

The accessories for completing the fitting, non-drip jets and ceramic nozzles

make the UNIGREEN atomiser a highly qualified and efficient piece of

equipment.

4.1.1 HAND WASHING TANKS

The atomisers are supplied with an auxiliary hand-washing tank with clean

water and a hand tap.

This tank must always be supplied with water and the inside must be clean so

you can wash any parts of the body that come into contact with the chemical

product used.

Never drink the liquid inside.

4.2 PRELIMINARY CHECKS

When you receive the machine, check that it is complete and no parts are

missing.

If there are any damaged parts, inform your local reseller or UNIGREEN

directly in good time.

When the machine is delivered, make sure you ask:

a) that the machine is delivered with all of its parts fitted and that the fitting

meets the requisites in table N° 14b-15b-16b (pages 37, 38, 39).

This procedure is necessary because for reasons of space during

transportation the machine is often delivered partially dismantled.

b) that it is tested in your presence in particular checking:

= that the suction filter and the inside of the tank are clean and free of work

residues.

= that the connections are made correctly following the basic layout (FIG.

N° 16, page 15).

= that the hose clips and all the unions and connections are tightened

properly.

= that all of the protective covers are fitted solidly to the machine, in

particular the protective cover of the power-takeoff of the pump.

= that the multiplier is sufficiently supplied with lubricant oil.

= that the zone where the fan turns hasn’t been bent by knocks during

transportation.

4.3 TRANSPORTING AND MOVING THE MACHINE

Every time you have to lift the machine, before starting the operation, always

make sure the lifting gear and the relevant tools and equipment (cables,

hooks, etc..) are suitable for lifting the load and check the stability of the

same.

It is forbidden to unhook and move the machine with the tank full.

The dry weight of the machine at the maximum level of fitting and with all the

accessories allowed is stamped on the nameplate; use slings and lifting gear

with a adequate load-bearing capacity (FIG.3).

Never lift or move the atomisers by hand if there is liquid in the tank. The

machine will weigh more and the movement of the liquid can change the

centre of gravity causing uncontrolled movements.

We recommend using slings as shown in the figure, the lifting points to use on

the machine are indicated with the relevant symbol.

Don’t lift the machine with the forks of a forklift truck because the machine can

tip over due to the overhanging weight of the blower group.

Don’t pass or stand under the machine when it is being lifted.

This symbol

identifies the

coupling points

of the machine

FIG.3

4.3.1 TOWED ATOMISERS

PARKING

Don’t stand the atomiser on unstable ground or steep slopes, the machine is

designed to be parked safely on compact ground with a slope of up to 8.5°

MOVING

To lift the machine, follow the instructions above.

Only move and lift the machine

with the tank empty

unigreen 9

Tractor coupling

4.4 TRACTOR COUPLING

The tractor must have 1”3/8 ASAE DIN 9611/A power-takeoff that runs at 550

rpm. It must have a 3-point elevator suitable for safely supporting the weight of

the atomiser.

Check this by consulting the table of allowed fittings N° 14A-15A-16A (pages

37, 38, 39).

WARNING: make sure there are no persons or things near the atomiser

before starting the machine and while you are using it.

FIG. 4

4.4.1 THREE-POINT COUPLING

a) We recommend carefully checking that the tractor is suitable for supporting

the weight of the fully loaded sprayer safely.

The total weight of the sprayer with all of its accessories and fittings is indicated

on the nameplate in FIG. 2 and also (in the version with the maximum fittings

allowed) in tables N° 14A-15A-16A (pages 37, 38, 39).

For verification use the formula shown here.

M x s < 0,2 T x i + Z x (d + i)

i = tractor wheelbase

d = distance from the front axis and the ballast

s = overhang from the rear axle of the

operating machine

T = mass of the tractor + operator (75kg)

Z = ballast mass

M = sprayer mass

Non-observance can result in a very dangerous situation as the tractor will lose

steering sensitivity and can tip over when driving uphill or over bumps.

b) Check the diameter of the elevator coupling pins. If necessary position the

double diameter pins correctly; there are also appropriate adapter bushes

available.

c) Adjust the length of the third point tie-rod correctly so the sprayer is

perfectly vertical in normal working position.

d) Check for the presence of the safety pins that stop the arms of the tractor

jumping off the connecting pins.

4.4.2 HYDRAULIC CONNECTION TO THE DISTRIBUTORS

Machines that need a hydraulic connection to drive the movements of the

cannon are equipped with 1/2", “Push-Pull”, quick-fit male couplings. You can

connect the pipes by simply pushing them in, making sure you:

- do so only with the engine turned off;

- lower any tools connected to the elevator of the tractor;

- carefully clean the two parts that will be coupled

10 unigreen

Warning: the hydraulic cylinders used are the “Double Effect” type.

Consult the use and maintenance manual of the tractor.

FIG. 5

4.5 CARDAN SHAFT

In some models this is supplied on request.

The cardan shaft must bear the CE mark.

It must always have its own instructions that must be followed scrupulously

and it should come with a cover bearing the mark, integrated in every part.

You should have previously checked the length to avoid:

= if it is too long, DANGEROUS THRUST ON THE PUMP SHAFT

= if too short, the POSSIBILITY OF DANGEROUS BREAKAGES

FIG. 6

THE MINIMUM OVERLAP OF

THE TWO TELESCOPIC

TUBES MUST NEVER BE

LESS THAN 1/3 OF THE

LENGTH OF THE TUBES.

The power that can be transmitted by the cardan shaft must be at least equal

to that required to run the atomiser.

These power ratings are indicated in tables N° 14A-15A-16A (pages 37-38-39).

a) Hook any safety chains to solid anchor points

b) Check that the button or ringnut “E” (FIG. 6) is correctly engaged and

blocked both on the pump side and on the tractor side.

c) Don’t exceed an inclination of 30° in any direction for any reason

d) With the machine stopped, periodically grease the spiders and the pipes,

keeping the connecting zone particularly clean.

e) Avoid letting the end of the cardan shaft come into contact with the

ground with the machine stopped; use the relevant support on some versions

for this, if your machine has no support, hook the external safety chain to a

part of the frame of the machine (ex. control unit support).

FIG. 7

NEVER USE THE CARDAN TRANSMISSION IF THE FOLLOWING

PROTECTIVE COVERS ARE MISSING:

- TRACTOR POWER-TAKEOFF PROTECTIVE COVER

- CARDAN SHAFT PROTECTIVE COVER

- FIXED PROTECTIVE COVER ON THE PUMP SHAFT

4.6 PUMP

When using the pump scrupulously observe the instructions in the enclosed

handbook supplied by the manufacturer.

The pump can be identified by the ratings plate on the same; the main data on

the pressure and delivery are easy to find on this plate.

Normally the pumps mustn’t exceed 550 RPM; a higher speed won’t improve

performance but there is a risk of compromising the life and safety of the

pump.

There is a safety valve on the pump, calibrated to prevent overpressure. Don’t

tamper with this valve for any reason and don’t block or obstruct the pipes

connected to it in any way.

4.7 SUCTION FILTER

The sprayer is fitted with a suction filter with filter cartridges that have roughly

a 50-gauge mesh, which is equivalent to a hole of 0.4 at 0.35 mm.

An efficient filter lets the sprayer work properly.

You should periodically check that the filter cartridge is clean, this check

should be done more often if there are impurities in the liquid.

To inspect the filter cartridge wear rubber acid-proof gloves as the liquid in the

filter can come into contact with your hands when you open the filter.

Don’t perform this operation with the pump running as the depression

produced blocks the cover preventing the removal.

Before removing the cover of the filter, make sure that the same is isolated

from the tubing by unscrewing the relevant rear valve (FIG. N°8).

After washing the cartridge, reassemble the cover making sure you connect

the same to the circuit again, using the valves described above in the

opposite order.

WARNING!: Don’t disperse the washing residues in the environment!!

Don’t use the sprayer

without having consulted

the enclosed handbook.

FIG. 8

Valve

Filter

unigreen 11

Don’t use the sprayer

without having consulted

the enclosed handbook.

way

4.8 PRESSURE REGULATOR

To use the pressure regulator, follow the instructions in the enclosed handbook

scrupulously. The pressure regulator controls all of the most important spraying

functions, the thorough knowledge of its functions makes work easier and more

precise.

The working pressure and the maximum pressure of the sprayer are determined

by the pressure regulator which also protects the circuit from overpressure in

any work conditions. (In serious but very rare cases, if the connecting pipes get

blocked the pressure relief valve lets the pressure off)

In some setups there may be a pump that can reach a pressure of 50 bar controlled by a regulator designed for 20 bar. In this case the maximum pressure

that can be reached is 20 bar.

The regulators can be manual, mounted on the sprayer or at a distance to make

the controls easier to use; or electrical with a control panel in the cabin.

There are also regulator versions with mechanical remote controls with a cable.

If the tractor has a waterproof cabin the use of electrical controls is obligatory.

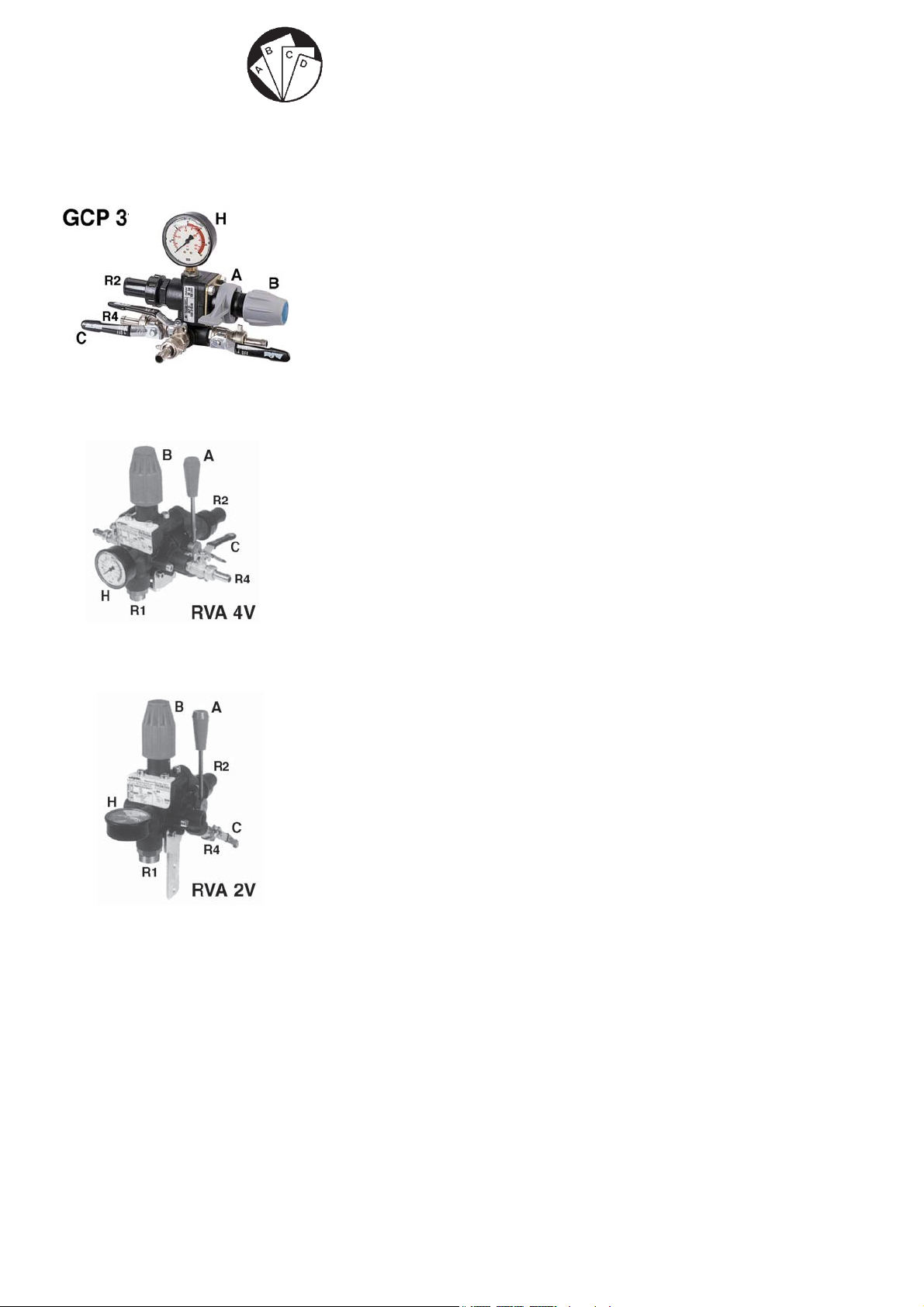

4.8.1 COMPONENTS OF THE PRESSURE REGULATOR

Below you will find the indications for the main models fitted on Unigreen

products.

A main ON-OFF command: “open” lets the fluid flow into the circuit in use;

“closed” empties the tank.

B maximum pressure valve: adjusted by hand with the relevant knob (drains

the excess liquid when the set pressure is reached).

C jets section tap: opens the corresponding jet boom or drains to the

compensation regulator (G).

D auxiliary tap: can be used for various accessories (it is always manual).

E volumetric pressure valve (proportional):

(when present) it regulates the spraying pressure. The valve automatically

compensates variations in speed (within the scope of the same gear ratio),

keeping the quantity of liquid supplied per surface unit (litres/hectare)

unchanged.

F self-cleaning filter: filters the delivery liquid.

G compensation regulators: suitably regulated, these make it possible to

keep the pressure constant when one or more sections of jets is closed, they

don’t influence treatments with the boom fully open.

H manometer: indicates the working pressure.

Connections:

R1 supply union

R2 drain union

R3 volumetric drain union

R4 jets section delivery union

R5 auxiliary delivery union

Control box for GCP ELETTRICO electrical regulators

I1 main control valve switch

I2 volumetric pressure valve switch (proportional)

I3 jets section valves switches

4.8.2 GENERAL INSTRUCTIONS

When using the pressure regulator, scrupulously observe the instructions in the

enclosed handbook, below you will find generic indications for the major models

fitted by Unigreen.

All the regulation and adjustment tests must be carried out with clean

water.

Pressure regulators without a volumetric valve (GCP3-way - GRH-RVA)

Adjusting the maximum pressure valve

= put main control A in the drain position (“OFF”).

= loosen the hand wheel of maximum pressure valve B completely

(anticlockwise).

= start the pump by activating the power-takeoff of the tractor at 540rpm

= open main control A (position “ON”), the manometer will be activated

= open all of the section valves C (position “ON”)

= adjust maximum pressure valve B to the working value (in any case less

than the safe maximum pressure the system can reach).

12 unigreen

Loading...

Loading...