Page 1

GB

USE AND MAINTENANCE MANUAL

UMP - MASTER

serie MASTER 20/40/50/55

09/2010

Read this manual carefully before use

1

Page 2

2

Page 3

Summary

1 USING AND KEEPING THE USE AND MAINTENANCE MANUAL .................... 4

1.1 COMPOSITION OF THE MANUAL ....................................................................................... 4

1.2 GUARANTEE ....................................................................................................................... 4

1.3 PRODUCT RESPONSIBILITY .............................................................................................. 4

1.4 WARNING SIGNS IN THE MANUAL AND ON THE MACHINE ............................................. 4

2 SAFETY REGULATIONS AND RESIDUAL RISKS .............................................. 5

2.1 INTENDED USE ................................................................................................................... 5

2.2 PROHIBITED USE ...............................................................................................................6

2.3 USING CHEMICAL PRODUCTS .......................................................................................... 6

2.3.1 REGULATIONS FOR THE USE OF CHEMICAL PRODUCTS ............................................... 6

2.4 RECOMMENDATIONS ......................................................................................................... 6

2.4.1 TAKING PRECAUTIONS AGAINST FIRE HAZARDS ........................................................... 7

2.5 MACHINES DESIGNED TO BE USED ONLY WITH CLEAN WATER .................................... 7

2.7 WEATHER CONDITIONS ..................................................................................................... 7

2.8 ROAD CIRCULATION ........................................................................................................... 7

3 CHARACTERISTICS AND SPECIFICATIONS ..................................................... 7

3.1 MACHINE IDENTIFICATION ................................................................................................ 7

3.2 TABLES OF FITTINGS ALLOWED....................................................................................... 7

3.3 NOISE LEVEL OF THE MACHINE ....................................................................................... 7

3.3 STANDARDS OF REFERENCE: ........................................................................................... 8

4 USER’S INSTRUCTIONS ....................................................................................... 8

4.1 TRANSPORTING AND MOVING THE MACHINE ................................................................. 8

4.2 DESCRIPTION OF THE MACHINE ..................................................................................... 8

4.2.1 HAND WASHING TANKS ...................................................................................................... 8

4.3 PRELIMINARY CHECKS...................................................................................................... 9

4.4 APPLICATIONS .................................................................................................................... 9

4.5 MOTORS .............................................................................................................................. 9

4.5.1 ELECTRIC MOTORS ............................................................................................................ 9

4.5.2 INTERNAL COMBUSTION ENGINES (TWO STROKE-PETROL-DIESEL) ........................... 9

4.6 PUMP ..................................................................................................................................10

4.7 SUCTION FILTER ...............................................................................................................10

4.8 PRESSURE REGULATOR ...................................................................................................10

4.8.1 COMPONENTS OF THE PRESSURE REGULATOR ...........................................................10

4.8.2 GENERAL INSTRUCTIONS ................................................................................................11

4.9 DELIVERY FILTERS (ONLY EQUIPPED MODELS) ............................................................ 11

4.10 FILLING THE TANK ............................................................................................................. 12

4.10.1 FILLING WITH THE ANTIPOLLUTION EJECTOR (FIG. 6) ................................................12

4.11 TEST TREATMENT WITH CLEAN WATER ..........................................................................12

4.12 MIXING ............................................................................................................................... 12

4.12.1 MANUAL PREMIXING......................................................................................................... 12

4.12.2 PREMIXER ON COVER (OPTIONAL): ................................................................................12

4.13 WASHING THE SPRAYER ..................................................................................................13

5 HAND LANCES .................................................................................................... 13

6 HOSE REEL .......................................................................................................... 13

8 MAINTENANCE .................................................................................................... 14

8.1 PROGRAMMED MAINTENANCE ........................................................................................14

8.2 EMPTYING TANK................................................................................................................14

8.3 ROUTINE MAINTENANCE ..................................................................................................14

8.4 EXTRAORDINARY MAINTENANCE ................................................................................... 14

8.5 REPAIRS .............................................................................................................................14

8.6 STORAGE IN A WAREHOUSE AND TRANSPORTATION ................................................... 15

8.7 PUTTING BACK INTO SERVICE AFTER WINTER LAYUP ................................................. 15

8.7.1 MATERIALS FOR DEMOLITION ......................................................................................... 15

8.7.2 INDICATIONS FOR A SUITABLE TREATMENT OF WASTE ................................................ 15

8.7.3 ELECTRICAL AND ELECTRONIC APPARATUS WASTE (EEAW) ....................................... 15

FIG. 9 CIRCUIT DIAGRAM .............................................................................................. 16

TABLE 4-5 TABLES OF DELIVERY OF NOZZLES FOR HAND LANCES ...................... 17

TABLE 8 PROBLEMS, CAUSES AND SOLUTIONS .......................................................... 18

TABLE 7 TABLE OF PROGRAMMED MAINTENANCE .................................................... 18

TAB.10 ALLOWED FITTINGS ........................................................................................... 19

3

Page 4

Thank you for having chosen UNIGREEN.

The product you purchased has been designed and built with the greatest

attention to the safety of the operator and the environment, nevertheless

there are still some residual risks due to the nature of the product used.

For this reason we recommend reading all of this manual to avoid making

mistakes in the first period of use and to get the most out of the working life of

the sprayer in time, doing the programmed maintenance at regular intervals.

1 USING AND KEEPING THE USE AND MAINTENANCE MANUAL

The manual is an integral part of the machine and should be kept in a safe

place where it can be reached easily for consultation.

1.1 COMPOSITION OF THE MANUAL

This manual consists of various parts to make it easier to consult by subject

and to avoid repetitions; the following are part of the manual:

a) pump handbook

b) pressure regulator handbook (manual or electric)

c) spraying computer handbook (if fitted)

d) optional accessories handbooks (marker, premix, cardan shaft, etc.)

UNIGREEN reserves the right to make changes to the manual without prior

warning and the normal printing cycles may vary slightly.

1.2 GUARANTEE

The enclosed card indicates the conditions of the UNIGREEN guarantee. The

UNIGREEN guarantee covers the repair or replacement of parts considered

manufacturing flaws, according to the unquestionable judgement of

UNIGREEN, only after the authorised agent for that zone has verified the

fault.

Ambit of the guarantee

The guarantee doesn’t cover cases of normal wear, negligent use, poor

maintenance and/or improper use.

The following materials subject to normal wear are not covered by the

guarantee: gaskets and seals, diaphragms, seal rings, tubes and pipes,

nozzles, pressure gauges, oil, tyres, friction material of the clutches.

Evident cases of negligence include: work speed over that indicated in the

spraying tables in the handbook (or too high for the conditions of the terrain),

use of herbicide booms without an auto-levelling system or with the autolevelling system blocked, power-takeoff speed over 540 rpm.

Mounted sprayers: activation of the three-point elevator with cardan shaft

engaged and power-takeoff operational.

And anything else indicated in the present Use and Maintenance Manual.

Maintenance:

The guarantee is void if the maintenance indicated in the tables in this manual

isn’t respected, regarding the period and deadline of the interventions, washing

the machine and the circuit at the end of the treatment.

Improper use:

The use the UNIGREEN machines are designed for is indicated in this

manual, any other use is forbidden and makes the guarantee void.

1.3 PRODUCT RESPONSIBILITY

UNIGREEN spa is not responsible if:

a) During the working life of the machine the normal maintenance

operations aren’t performed and documented as indicated in this handbook, in

the enclosed handbooks of the pumps-motors-regulators-etc. and in any case

as is customary for the normal maintenance of mechanical machinery.

b) The machine is equipped with non original accessories or components or

parts that aren’t acknowledged by UNIGREEN as their own.

c) The machine is equipped with original accessories or components that

are unsuitable in the measurements, weight or version for the same.

Please consult the page of available and recommended fittings.

d) Not following the instructions in the manual whether totally or partially.

e) Modifications made to the machine that haven’t been authorised by

UNIGREEN.

Composite handbook, consult the

specific files on the various

components

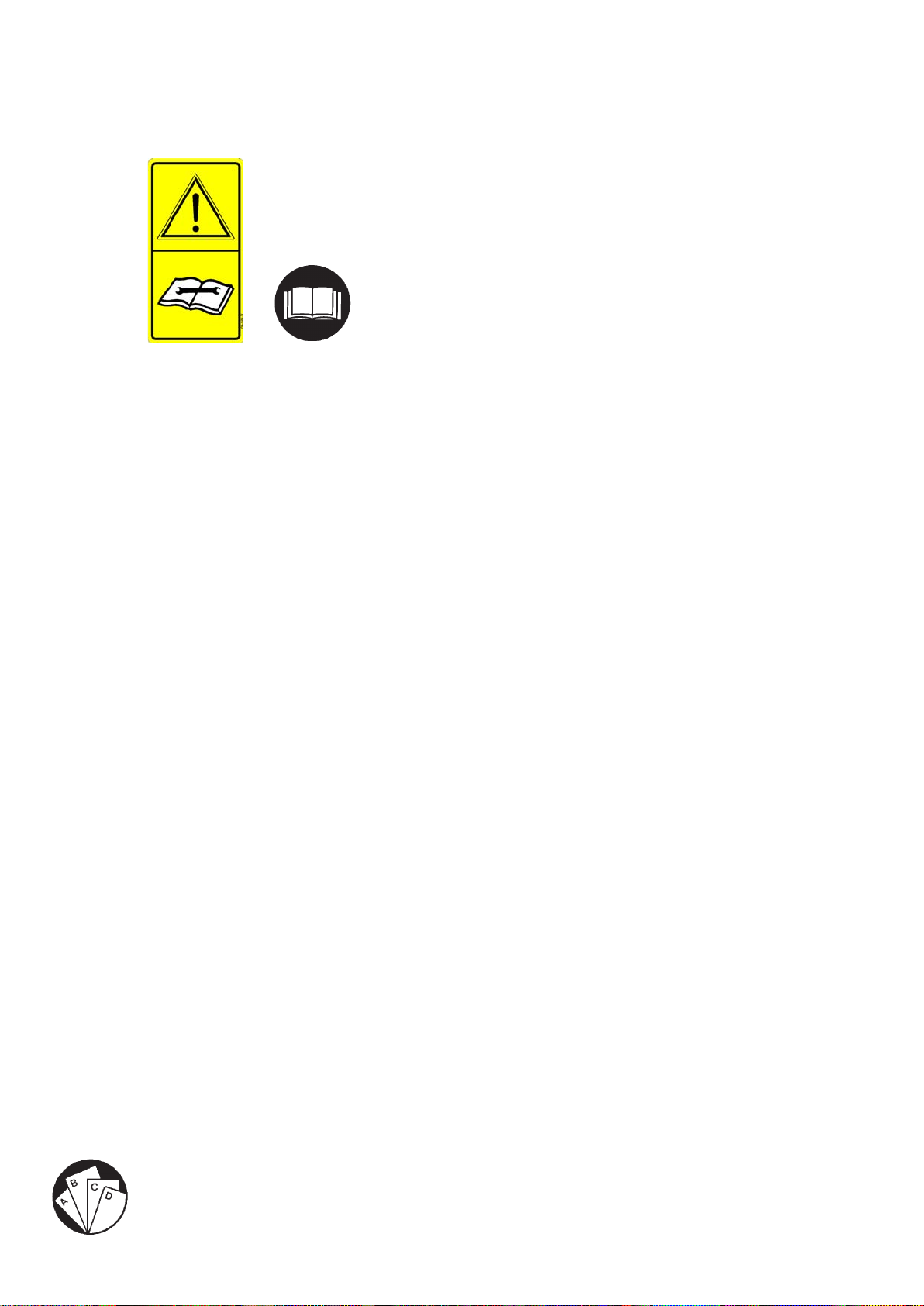

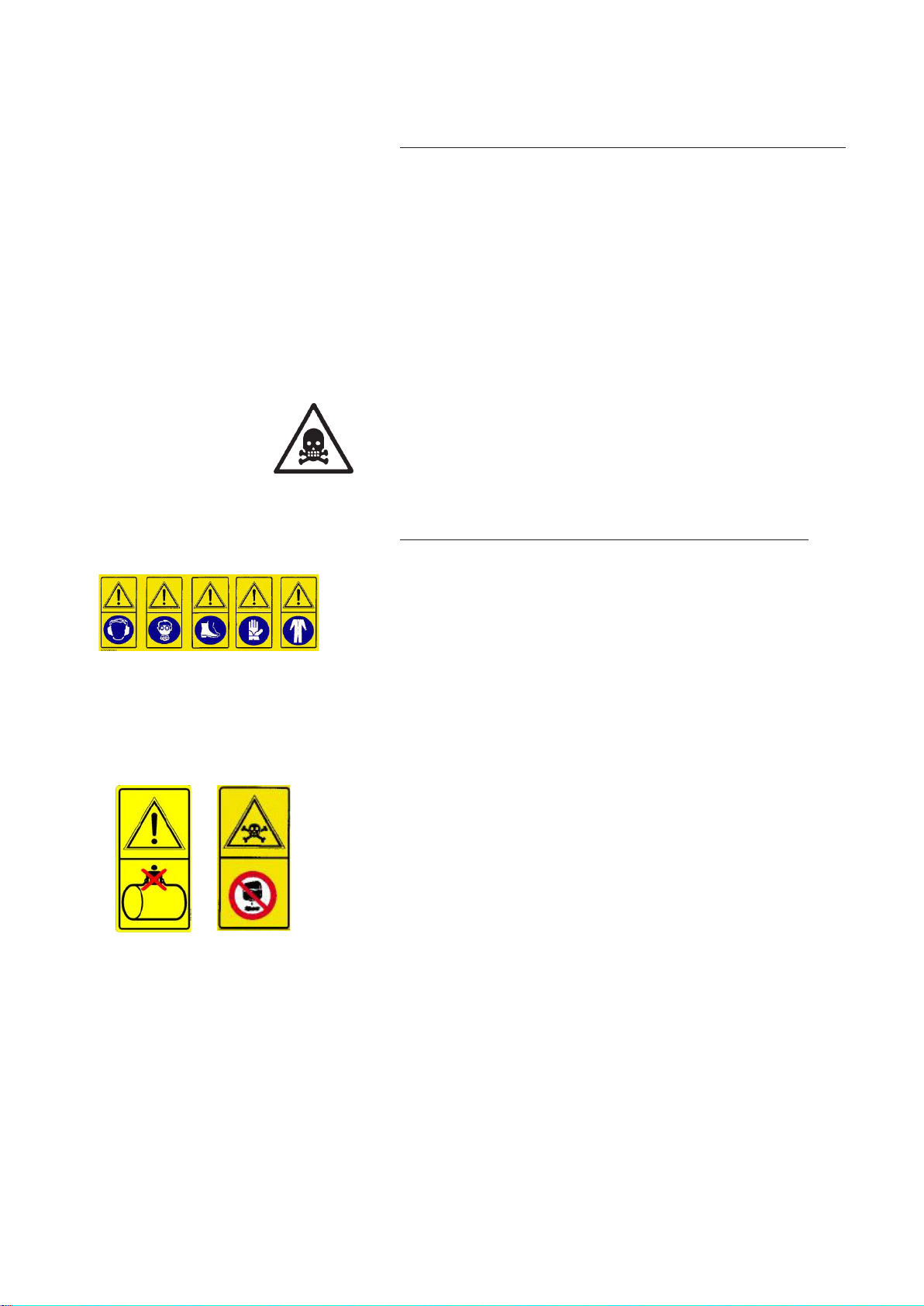

1.4 WARNING SIGNS IN THE MANUAL AND ON THE MACHINE

Below you will find all of the pictograms on the machine, in order to illustrate

the warnings, the prohibitions and the correct method of use.

The operations that require particular attention are shown in the images

4

beside the text.

Page 5

21

21 63 4 5

87 129 10 11

1413 1815 16 17

Key to the symbols

1- Read the Use and Maintenance manual

2- Stop the machine and read the manual before

every intervention

3- Don’t lubricate while running

4- Don’t drink

5- Don’t dispose of residue liquids in the environment

6- No smoking

7- Danger, risk or injury, don’t get near the machine

until the moving machine members have stopped

8- Danger of crushing, don’t get your hands near the

moving mechanical machine members

9- Danger, risk or injury caused by fluids under

pressure

10- Don’t climb on the machine during work or

transfers

11- Don’t climb on the tank

12- Don’t enter in the tank

13- Wearing earmuffs is obligatory

14- Wearing a face mask is obligatory

15- Wearing safety footwear is obligatory

16- Wearing protective gloves is obligatory

17- Wearing protective overalls is obligatory

18- Use a working pressure under that indicated in

red on the manometer.

19- Don’t get your hands near the moving cardan

shaft

20- Make sure power-takeoff of the tractor turns in the

right direction and runs at the right speed.

2 SAFETY REGULATIONS AND RESIDUAL RISKS

In relation to safety, the following terms will be used:

Dangerous zones: any zone inside and/or near the machine where the

presence of a person exposed constitutes a risk for the safety and health of

the same person.

Person exposed: any person who has their body or any part of their body in a

dangerous zone.

Before starting the machine, the operator must check for any visible faults in

the safety devices and the machine itself.

Never start the machine until you have told anyone in the range of action of

the machine to move away and they have done so.

The protective devices must not be removed or disabled when the machine is

running.

It is obligatory to keep all the plates with danger and safety signs in perfect

conditions. If they get damaged or deteriorate, replace them in good time.

Replace parts believed to be faulty with others indicated by UNIGREEN.

NEVER try makeshift or hazardous solutions.

Don’t wear clothes, jewellery, accessories, or anything else that can get

caught in the moving machine members.

Pay the greatest attention to all the warning and danger signs on the machine.

Don’t use the machine for any other purpose other than that indicated in the

manual.

The machine has been designed and built with the appropriate devices to

guarantee the safety of the user.

In any case there are some residual risks associated with the improper use of

the machine by the operator; for this purpose danger signs and symbols and

prohibitions are applied near some parts of the machine (see previous

pictograms).

21- Danger of surfaces at high temperatures (internal

combustion engine)

9 11+12

1

INDICATIVE POSITION OF THE WARNING SIGNS

ON THE SPRAYERS

NB: the position may vary on the basis of the

characteristics of the model.

da 1 a 18

21

2.1 INTENDED USE

The sprayer in this series is built for agricultural use. The materials used are

resistant to normal chemical products used in agricultural spraying (or

herbicides) at the time of construction.

Any other use is not allowed and the manufacturer is not responsible for any

damage caused by aggressive, dense or sticky chemicals.

THE USE OF THE MACHINE BY PERSONS UNDER 18 YEARS OF AGE IS

STRICTLY FORBIDDEN

The use of liquid fertilizers in suspension is not allowed, while the use of the

same in a solution is possible if requested when the machine is ordered from

5

Page 6

Unigreen and in any case changing some of the parts described in the

handbooks of the regulator, such as the manometer (stainless steel), the

nozzles (large diameter ceramic) and eliminating the fine mesh filters to

prevent blockages.

2.2 PROHIBITED USE

Using the machine with the following products is strictly forbidden:

= Paints of any kind and type

= Solvents or thinners for paints of any kind and type

= Combustibles or lubricants of any kind and type

= LPG or gas of any kind and type

= Flammable liquids of any kind and type

= Liquid foodstuffs, whether for animals or humans

= Liquids containing granules or consistent solids

= Mixtures of various incompatible chemical products

= Liquid fertilizer or manure in suspension with lumps and/or that is

particularly dense

= Liquids with a temperature of over 40°C

= Any products that aren’t suitable for the specific use of the machine.

2.3 USING CHEMICAL PRODUCTS

All pesticides or herbicides can be dangerous to humans and the environment

if used erroneously or inadvertently.

Therefore we recommend that only suitably trained persons should use these

products (license) and in any case only after having carefully read the

instructions on the container.

2.3.1 REGULATIONS FOR THE USE OF CHEMICAL PRODUCTS

Some recommendations for avoiding damage and accidents:

= Keep the machine in a suitable, protected place with no access for

children or strangers

= Handle the products with care, wearing rubber acid-proof gloves, gogglesface masks or filtering helmets, overalls made of water-repellent fabrics or

TIVEK and boots made of rubber or similar materials.

= If chemical products or mixtures of product come into contact with the

eyes or are swallowed consult a doctor immediately, taking the label of the

product with you.

= Wash all clothes that come into contact with the chemical, whether

diluted or undiluted, thoroughly before using them again.

= Don’t smoke, drink or eat when preparing or spraying the mix or near or in

the fields treated.

= DON’T ENTER THE TANK: the residues of a chemical product can cause

poisoning and suffocation.

= When spraying, respect safe distances from residential areas, water

courses, roads, sports centres and public parks or paths.

= Thoroughly wash the containers of plant protection products using the

relevant accessories, rinsing several times with clean water. The liquids used

for washing can be used for treatment.

= Collect the washed containers and send them to the relevant collection

centres. Never dispose of them in the environment and don’t use them again

for any other purpose. It is good practice to knock a hole in the bottom of the

tins so they can’t be used again.

= When you have finished spraying, wash the sprayer thoroughly, diluting

the residues with a quantity of water at least 10 times that of the residues,

spraying the resulting mix over the treated field.

2.4 RECOMMENDATIONS a) Refer to the present handbook for the use and maintenance of the frame,

tank, auto-levelling systems, elevators, mechanical and hydraulic herbicide

booms, spray booms and hose reels.

Refer to the enclosed handbooks for the use and maintenance of the pump

and pressure regulator and any accessories or motors.

b) Please contact the agent in your zone, the nearest authorised workshop

or UNIGREEN S.p.A. directly for any repairs the user feels they aren’t capable

of performing alone. (see point 10.4)

c) Due to the complexity of the equipment and the variety of technologies used

(mechanical, hydraulic, oil-pressure and electrotechnical) operators must not

dismantle or modify the equipment. All of the relevant operations must be

6

performed by specialised personnel, authorised by UNIGREEN S.p.A.

Page 7

2.4.1 TAKING PRECAUTIONS AGAINST FIRE HAZARDS

Don’t use naked flames or heat sources near the machines.

The sprayers are made with many materials that derive from petroleum: tanks,

tubes, pipes and hoses, wheels and plastic parts; furthermore the presence of

oils of various nature and residues of chemical products make them potentially

flammable.

2.5 MACHINES DESIGNED TO BE USED ONLY WITH CLEAN WATER

There are versions of the machines designed only to be used with a hose reel

for washing with cold clean water.

These machines cannot be used with chemical products as they don’t have

some of the devices or accessories that are needed to use these products

safely. These machines are identified by the word “washing” on the CE plate.

2.7 WEATHER CONDITIONS

We recommend spraying in the early hours of the morning or late in the

afternoon, avoiding the hottest time of day.

Never do any spraying if it’s raining or rain is forecast.

Don’t spray in strong wind or in any case, in winds above 3/5 m/second.

If you have to spray in windy conditions, use relatively low pressures to obtain

quite large drops that are less sensitive to drifting (being heavier the wind has

less effect). There are also special anti-drift nozzles available from UNIGREEN

S.p.A.; for information, please contact our offices.

2.8 ROAD CIRCULATION

The admissible capacity of the vehicle (pickup or truck) or the trailer upon which

the equipment is positioned should be checked.

The equipment is supplied for application to the floor. In the case of fixed rigging

the vehicle needs to be registered.

You need to check the correct couplings with your area dealer.

3 CHARACTERISTICS AND SPECIFICATIONS

3.1 MACHINE IDENTIFICATION

This handbook is valid for UMP-MASTER sprayers to be used for:

a) treatments with hand lances with or without a hose reel

b) hand lances for washing with or without a hose reel

The UNIGREEN S.p.A. sprayers are identified by the CE plate (FIG. 1 ) bearing

one of the marks indicated in the tables of the allowed fittings (TABLE N° 10 ,

page 19).

3.2 TABLES OF FITTINGS ALLOWED

Table N° 10 let you identify the version of your machine indicating the basic

equipment and all the possible fittings available (optional).

You can also find the other fittings allowed or other versions to meet your

requirements in the future.

THE FITTING DEFINED IN TABLE N° 10 (PAGES 19) SHOULD BE

CONSIDERED BINDING FOR THE VALIDITY OF THE DECLARATION OF

CONFORMITY.

Other fittings or setups of basic components and optionals should be

considered unsafe and therefore are not covered by the guarantee and aren’t

UNIGREEN’s responsibility.

The same goes for fittings realised with components or accessories that aren’t

original UNIGREEN parts.

UNIGREEN accessories can easily be identified by the label with the yellow

background “ORIGINAL UNIGREEN ACCESSORY”

TYPE : .......................................................................

code: ........................................ N˚ ...........................

massa a vuoto: ..........................Kg. max press. : ........... bar

net mass

massa totale ammessa: .............................. Kg.

total mass

via Rinaldi, 105 - Reggio Emilia ITALIA

ANNO

YEAR

20 .......

made in

Italy

FIG. 1

3.3 NOISE LEVEL OF THE MACHINE

Use earmuffs to protect your ears when using the machine, the multi-purpose

Units produce a maximum level of sound pressure inferior to 89 dB (A) and a

level of power inferior to 107Db (A).

Readings taken in accordance with the following standards:

Machines Directive 2006/42/CE

Legislative Decree D.Lgs. n°292 of the 4th of September 2002 concerning the

environmental acoustic emission of machines and equipment for use outdoors.

UNI EN ISO 4254-1:2006.

7

Page 8

3.3 STANDARDS OF REFERENCE:

- MACHINES DIRECTIVE 2006/42/CE.

- D.Lgs. 81/08 Unique text for safety and hygiene in working places.

-UNI EN ISO 12100-1/Apr.2005 : Machinery safety - Fundamental concepts,

general design principles - Part 1: basic terminology, methodology

-UNI EN ISO 12100-2/Apr.2005 : Machinery safety - Fundamental concepts,

general design principles - Part 2: Technical principles

-UNI EN ISO 13857: May 2008 Machinery safety, safe distances to avoid

reaching hazardous areas with upper limbs.

-UNI EN 349/November 2008: Machinery safety, minimum spaces to prevent

crushing of body parts

-UNI EN 907/Nov.1998: Agricultural and forestry machinery - Sprayers and

spreaders of liquid fertilizers - Safety.

-UNI EN ISO 13849-1: February 2007: Machinery safety - Fundamental

concepts, general design principles

-UNI EN 982/January 2009: Machinery safety. Safety requisites relevant to

systems and their components for hydraulic and pneumatic transmissions.

Hydraulics.

-UNI EN ISO 4254-1/June 2006: Agricultural machines - Safety - Part 1:

General requisites

-ISO 11684/1995: Pictograms - general principles.

This symbol

identifies the

coupling points

of the machine

FIG . 2

4 USER’S INSTRUCTIONS

4.1 TRANSPORTING AND MOVING THE MACHINE

If the machine has to be lifted, use suitable slinging and tackle, crane or

bridge crane, with capacity suitable for the use. The dry weight of the machine

at the maximum level of fitting and with all the accessories allowed is

stamped on the nameplate; use slings and lifting gear with a adequate loadbearing capacity.

Don’t stand the sprayer on soft ground or steep slopes.

Never lift or move the sprayers by hand if there is liquid in the tank. The

machine will weigh more and the movement of the liquid can change the

centre of gravity causing uncontrolled movements.

It is opportune to apply the slinging as in FIG.2 for the MASTER 55 model or

those equipped with eyebolts. It is necessary to use forklift trucks or transpallets

with an adequate capacity for other models. The forks should be placed as

indicated in the specific pictograms.

Don’t pass or stand under the machine when it is being lifted.

4.2 DESCRIPTION OF THE MACHINE

The UMP and MASTER machines are made to be mounted on the floor of the

pickup vehicle. Some models can be equipped with wheels and handlebar for

towing by hand or by small tractors.

The frame is in hot galvanised steel, the cisterns are in easy-to-empty organic

glass reinforced with glass fibre. Versions are available with the cistern in

galvanised or stainless steel.

The pumps are generally membrane and in some cases piston and are coaxially

mounted with an electric or internal combustion engine reducer.

They are equipped with an external suction filter that allows easy inspection.

All the machines are equipped with a hose nozzle for watering and/or washing

with a length of tubing.

4.2.1 HAND WASHING TANKS

The sprayers are supplied with an auxiliary hand-washing tank with clean

water and a hand tap.

This tank must always be supplied with water and the inside must be clean so

you can wash any parts of the body that come into contact with the chemical

product used.

Never drink the liquid inside.

8

Page 9

4.3 PRELIMINARY CHECKS

When you receive the machine, check that it is complete and no parts are

missing.

If there are any damaged parts, inform your local reseller or UNIGREEN

directly in good time.

When the machine is delivered, make sure you ask:

a) that the machine is delivered with all of its parts fitted and that the fitting

meets the requisites in table N° 10 (page 19). (This procedure is necessary

because for reasons of space during transportation the machine is often

delivered partially dismantled).

b) that it is tested in your presence in particular checking:

= that the suction filter and the inside of the tank are clean and free of work

residues.

= that the connections are made correctly following the basic layout (FIG.

N° 9, page 16).

= that the hose clips and all the unions and connections are tightened

properly.

= that all of the protective covers are fitted solidly to the machine, in

particular the protective cover of the power-takeoff of the pump.

4.4 APPLICATIONS

The UMP and MASTER machines are made to be mounted on the floors of vans

or similar vehicles. They can also be mounted on automobile type trolleys or

pickup vehicles with sufficient capacity. Always made sure before mounting that

the capacity of the trolley or the vehicle is sufficient. A tow-hook wheel kit NOT

approved for circulation on the road and suitable for small movements within

private areas is supplied on request.

4.5 MOTORS

4.5.1 ELECTRIC MOTORS

The electric motors of the motor-pumps correspond to the regulations in force

envisaged by the low-tension regulation and are guaranteed by the specific plate

of the constructor. The 20 Volt single-phase version is usually supplied with plug

and switch while the 380 Volt three-phase version is usually supplied with a

terminal board and the plug must be installed by an authorised and competent

installer. The plant to which the motor-pump is applied must correspond to the

regulations in force and be served by an automatic differential lifesaver switch.

Never, for whatever reason, direct the spray of the nozzle towards the motor.

Consult the specific use manual attached.

4.5.2 INTERNAL COMBUSTION ENGINES (TWO STROKE-PETROLDIESEL)

Use the motor keeping scrupulously to the use and maintenance booklet and in

case of need apply to the producer's assistance network.

Nevertheless, we list summarily a number of instructions to observe:

Petrol mixture motors (two stroke): respect the percentage of oil present in the

petrol and avoid the motor losing revs if the liquid contained in the cistern

unexpectedly finishes.

Petrol and diesel motors with electric starters: check the level of efficiency of

the battery and carry out normal maintenance.

B

C

A

Before starting check that the command lever of the pressure adjustor (lever A

page 10) is in the discharge position; starting is difficult in the pressure position

and might not take place.

To start an internal combustion engine proceed as follows:

= Open the fuel supply, putting valve A onto the ON position

= Put air lever B onto the closed position

= Select ON on the main switch of the motor (C)

= Pull start handle D or press the START switch (motors with electric starter)

= Gradually re-open the air (lever B) and adjust the speed.

ATTENTION: normally the parts that heat up (silencer, heads, etc) are protected.

However pay maximum attention to avoiding contact.

D

9

Page 10

FIG . 3

Valve

4.6 PUMP

When using the pump scrupulously observe the instructions in the enclosed

handbook supplied by the manufacturer.

The pump can be identified by the ratings plate on the same; the main data on

the pressure and delivery are easy to find on this plate.

Normally the pumps mustn’t exceed 550 RPM; a higher speed won’t improve

performance but there is a risk of compromising the life and safety of the pump.

There is a safety valve on the pump, calibrated to prevent overpressure. Don’t

tamper with this valve for any reason and don’t block or obstruct the pipes

connected to it in any way.

4.7 SUCTION FILTER

The sprayer is fitted with a suction filter with filter cartridges that have roughly a

50-gauge mesh, which is equivalent to a hole of 0.4 at 0.35 mm.

An efficient filter lets the sprayer work properly.

You should periodically check that the filter cartridge is clean, this check should

be done more often if there are impurities in the liquid.

To inspect the filter cartridge wear rubber acid-proof gloves as the liquid in the

filter can come into contact with your hands when you open the filter.

Don’t perform this operation with the pump running as the depression produced

blocks the cover preventing the removal.

Before removing the cover of the filter, make sure that the same is isolated from

the tubing by unscrewing the relevant rear valve (FIG. N° 3).

After washing the cartridge, reassemble the cover making sure you connect the

same to the circuit again, using the valves described above in the opposite order.

WARNING!: Don’t disperse the washing residues in the environment!!

4.8 PRESSURE REGULATOR

To use the pressure regulator, follow the instructions in the enclosed handbook

scrupulously. The pressure regulator controls all of the most important spraying

functions, the thorough knowledge of its functions makes work easier and more

precise.

The working pressure and the maximum pressure of the sprayer are determined

by the pressure regulator which also protects the circuit from overpressure in any

work conditions. (In serious but very rare cases, if the connecting pipes get

blocked the pressure relief valve lets the pressure off)

In some setups there may be a pump that can reach a pressure of 50 bar

controlled by a regulator designed for 20 bar. In this case the maximum pressure

that can be reached is 20 bar.

The regulators can be manual, mounted on the sprayer or at a distance to make

the controls easier to use; or electrical with a control panel in the cabin.

There are also regulator versions with mechanical remote controls with a cable. If

the tractor has a waterproof cabin the use of electrical controls is obligatory.

4.8.1 COMPONENTS OF THE PRESSURE REGULATOR

Below you will find the indications for the main models fitted on Unigreen

products.

A main ON-OFF command: “open” lets the fluid flow into the circuit in use;

“closed” empties the tank.

B maximum pressure valve: adjusted by hand with the relevant knob (drains the

excess liquid when the set pressure is reached).

C boom section tap: opens the corresponding boom or drains to the

compensation regulator (G).

D auxiliary tap: can be used for various accessories (it is always manual).

E volumetric pressure valve (proportional):

(when present) it regulates the spraying pressure. The valve automatically

compensates variations in speed (within the scope of the same gear ratio),

keeping the quantity of liquid supplied per surface unit (litres/hectare) unchanged.

F self-cleaning filter: filters the delivery liquid.

G compensation regulators: suitably regulated, these make it possible to keep

the pressure constant when one or more sections of jets is closed, they don’t

influence treatments with the boom fully open.

H manometer: indicates the working pressure.

10

Connections:

R1 supply union

R2 drain union

R3 volumetric drain union

R4 boom section delivery union

Page 11

R5 auxiliary delivery union

4.8.2 GENERAL INSTRUCTIONS

When using the pressure regulator, scrupulously observe the instructions in the

enclosed handbook, below you will find generic indications for the major models

fitted by Unigreen.

All the regulation and adjustment tests must be carried out with clean water.

Pressure regulators without a volumetric valve (GCP3-way - RPN - RVA)

Adjusting the maximum pressure valve

= put main control A in the drain position (“OFF”).

= loosen the hand wheel of maximum pressure valve B completely

(anticlockwise).

= start the pump by activating the power-takeoff of the tractor at 540rpm

= open main control A (position “ON”), the manometer will be activated

= open all of the section valves C (position “ON”)

= adjust maximum pressure valve B to the working value (in any case less than

the safe maximum pressure the system can reach).

Pressure regulators with a volumetric valve (RPN-DPR-ERGO-REMO)

Adjusting the maximum pressure valve

= put main control A in the drain position (“OFF”).

= loosen the hand wheel of maximum pressure valve B completely

(anticlockwise).

= open volumetric valve E completely.

= start the pump by activating the power-takeoff of the tractor at 540rpm

= open main control A (position “ON”), the manometer will be activated

= open the drain tap on filter F slightly (only ERGO and REMO)..

= close volumetric valve E completely. If the pressure rises over the maximum

limit of the system, make sure maximum pressure valve B is open (see previous

indications)

= open all of the section valves C (position “ON”)

= adjust maximum pressure valve B to a value over that of the working

pressure (generally 10-14 bar) and in any case lower than the safe maximum

pressure that the system can reach.

Adjusting the volumetric pressure.

= with the volumetric pressure valve E adjust the pressure to the value the

treatment will be done at (the pressure is indicated on the nozzles tables on the

basis of the tractor speed and litres/hectare to spray)

Warning! The working pressure must be adjusted with the volumetric valve

and not with the maximum pressure valve. In the case the working pressure

is too near to the calibrated pressure of the maximum pressure valve, the

proportional valve may not be able to compensate the speed variations

correctly.

Adjusting the compensated returns

= close only one tap of section C (position “OFF”).

= adjust the corresponding compensator G until you return to the pressure set

previously (displayed on the manometer).

= open and close the tap of section C and check that the pressure remains

constant.

= repeat the above operations for all the section taps.

If the types of nozzles aren’t changed the regulations carried out will guarantee a

constant spraying of the liquid also per treatments that are done at different

working pressures.

NB: if the type of nozzle is changed then the calibrating will have to be done

again.

4.9 DELIVERY FILTERS (ONLY EQUIPPED MODELS)

Particularly useful when using small (low volume) nozzles.

In a central position with a manometer after the filter that shows any blockages in

the cartridge. On the RVA version there is also a manometer before the cartridge

to make it easier to find the problem.

For cleaning the cartridge in the model RVA you should open the drain with the

relevant lever (Fig. N° 4) for 2-3 minutes during the washing operations, as in the

enclosed instructions.

You should clean the cartridge by hand periodically, on the basis of the product

used. To clean, stop the pump. Wear rubber gloves and the other personal

protective equipment when cleaning.

FIG . 4

11

Page 12

FIG . 6

4.10 FILLING THE TANK

The machines for defensive crop treatments, in consideration of the safety of

persons, animals and the protection of the environment, must only be filled

indirectly from open water courses and only by free-falling water from the

waterworks.

The pipe used for filling must never come into contact with the liquid inside

the tank and therefore the water must always fall over the upper edge of the

filling inlet and through the filter installed on it.

The tank is fitted with a transparent graduated band that shows the exact

quantity of liquid inside. This reading is precise if the tank is on flat ground;

the actual total capacity coincides with the highest number. All the filling

systems fitted by Unigreen on their production machines or on request are

antipollution and stop the liquid overflowing out of the tank.

4.10.1 FILLING WITH THE ANTIPOLLUTION EJECTOR (FIG. 6)

If you are filling with an antipollution hydroejector (mounted as standard on

some models) then you should proceed as follows:

= put roughly 20-30 L of water in the tank and start the pump.

= remove the cap of ejector P and insert filling pipe S.

= place the other end of the hose, on which you fitted filter Q, in the

watering point.

= open the tap R that supplies the ejector (on pump or pressure regulator ).

= increase the pressure until it reaches a value which is sufficient to suck

up the liquid.

= visually check the level of the liquid inside the tank and after filling

disconnect pipe S from the ejector, close the tap R and replace the cap P.

FIG. 7

FIG. 8

FIG. 9

4.11 TEST TREATMENT WITH CLEAN WATER

We recommend doing a test treatment with clean water to get to know the

system and check the settings.

4.12 MIXING

The active principle can be mixed using the relevant stirrers before and during

the treatment. Correct mixing and stirring is the basis of the correct

distribution on the crops. We recommend some useful accessories such as

the premixer for powders and liquids (see the following paragraph).

To mix the product in the tank proceed as follows:

a) high-pressure machines from 30 to 60 bar (FIG. N° 7): run the stirrer (or

ejector) for roughly 10-15 minutes at the maximum pressure available

b) low pressure machines, max 20 bar

= with a drilled pipe on the drain, run the pump at roughly 540 RPM with the

pressure regulator on drain for at least 10-15 minutes. (FIG. N° 8)

= with the stirrer on a delivery, run the pump supplying the stirrer (or ejector)

at the maximum pressure available for at least 10-15 minutes. (FIG. N° 7)

Some models with very small tanks aren’t equipped with mixers, you should

use the drain of the pressure regulator: run the pump at roughly 540 RPM with

the pressure regulator in the drain position for at least 10-15 minutes. (FIG.

N° 9).

WARNING: using the taps on the pump or in

any case on the front of the machine puts the

operator near the cardan shaft. Despite the

presence of CE standard protective covers

you should take great care.

12

4.12.1 MANUAL PREMIXING

Dilute the active principle by hand before introducing it into the tank, (you

must wear suitable protective clothing such as rubber gloves, a mask or

goggles, overalls, etc.).

4.12.2 PREMIXER ON COVER (OPTIONAL):

Open the cover and pour all of the chemical powder into the filter, close the

cover and open the supply tap until all of the powder has dissolved.

Page 13

4.13 WASHING THE SPRAYER

Thoroughly wash the machine after each treatment pumping clean water

through the circuit and clean the suction and delivery filters.

Dirty equipment is very dangerous for the people and environment.

Discharging the residues of washing in the environment without taking

precautions is forbidden as this pollutes watercourses. Distribute the residues

on the treated field.

5 HAND LANCES

When using hand lances bear in mind the following notes:

= Don’t direct the jet of liquid towards electric power lines or zones where

there is electrical current, houses or where people might pass.

= Don’t point the jet at people or animals.

The jet can cause serious injuries simply due to the mechanical force of the

liquid under pressure.

= Never block the spraying lever of the lance in an open position because if

the lance falls it will be uncontrollable.

= At the end of work after you have stopped the pump, make sure that any

residual pressure in the pipes under pressure has been drained to avoid

unexpected jets when putting the lance away.

There are various types of lances; with a lever, mitra spray gun and pistol grip.

For further information please refer to the handbook in the package.

The lever lance is controlled by opening lever A which, depending on how

much it’s pressed, produces a conical spray or direct jet. The standard nozzle

is Ø 1.5

The mitra spray gun can produce a direct jet or a conical spray and the type

of spray is selected by pushing lever B forwards or backwards. Use lever C to

open the jet. The standard nozzle is Ø 2.5

Replacement nozzles are available for all of the lances and the capacities are

indicated in the tables N° 4 e N° 5 ( 5bis for Master 55).

A

B

C

6 HOSE REEL

Available in the following sizes 20-50-100 , with mechanical, electrical and

hydraulic rotation.

To use the system, consult the enclosed handbook as there are significant

differences between each.

After work it is important to block the winding roller to stop the hose unwinding

while you are moving the sprayer.

Anti-unwinding blocking knob.

13

Page 14

8 MAINTENANCE

(to carry out with the internal combustion engine stopped or the

plug detached for electric motors).

The maintenance of the sprayer is essential for maintaining a

high level of safety. Also consult the single handbooks of the

main components of the sprayer.

All of the maintenance operations and repairs must be carried out

with the machine and cardan shaft stopped and the tank and

circuit clean of any residues of chemical products.

8.1 PROGRAMMED MAINTENANCE

( TAB. N° 7, page 18 )

We recommend using a table of programmed maintenance to

follow in time to keep the sprayer in an efficient working

condition.

For major and important maintenance jobs we recommend using

the normal UNIGREEN assistance service available from your

reseller, using original UNIGREEN spare parts.

8.2 EMPTYING TANK

The MULTI-purpose unit is equipped with a tap for emptying the

tank completely.

When cleaning the interior of the cistern, all the washing liquids

can be conveyed toward the tap indicated to the side.

We advise connecting the supplied tube in order to avoid

discharging the liquid directly onto the unit and its structure.

Rubinetto di svuotamento cisterna

Smontaggio Filtro di Aspirazione

8.3 ROUTINE MAINTENANCE = After every treatment, wash the inside of the tank and the

entire circuit as indicated in paragraph 4.13

= Periodically check that the suction and delivery filters are

clean (see figure)

= Check the oil level in the volumetric compensator of the

pump

= The use of chemical products that are particularly damaging

for a nitrile rubber mix (ex.. herbicides and products for rice

fields) can cause the diaphragm to break before time.

In these conditions check the state of the components more

often.

8.4 EXTRAORDINARY MAINTENANCE

At the end of a season of intense use, or every two years of

normal use, it is a good idea to have a specialised service

technician perform a general check on the machine.

8.5 REPAIRS

We recommend having the normal UNIGREEN assistance

service available from our reseller perform any repairs or contact

a specialised workshop. During all of the repairs, in particular

when welding, the machine and the circuit must be clean of any

residues of chemical product.

If the machine has to be lifted (for example to change a wheel)

follow the instructions in point 4.1 of the present handbook.

Also make sure the machine is stopped, connected to the

tractor, and use the relevant chocks to block the wheel still on

the ground.

If you use a jack (manual or hydraulic) make sure you use a jack

that is suitable for the frame so it can’t slip and put it in the right

position. The jack must be placed under the main frame of the

machine near the wheel to change. Make sure the ground is

compact: if necessary use wooden beams or other sufficiently

resistant material to broaden the supporting base of the jack.

14

Page 15

8.6 STORAGE IN A WAREHOUSE AND TRANSPORTATION

The sprayer must be kept in a closed place away from excessive humidity and protected from

frost. Especially if electrical pressure regulators, electrical motors, a spraying computer or

similar components are fitted.

Before storing the machine, after you have washed it, apply a light coat of oil.

If the temperature might drop to below zero, drain any residual liquid or add roughly 0.5 L of

normal antifreeze for auto vehicles.

To transport the machine follow the instructions in point 4.1 of the present handbook.

8.7 PUTTING BACK INTO SERVICE AFTER WINTER LAYUP

Before using the machine again after a long period of inactivity you should perform some

general checks, following the instructions in point 4.4 and drain any antifreeze.

ATTENTION: It is necessary to adopt appropriate Individual Protection Devices in manipulating

waste.

The disposal of waste deriving from the demolition of the machine must be carried out

respecting the environment, avoiding soil, air and water pollution.

Local legislation in force in the matter must be respected in any case.

Remember that waste is understood as any substance or object that enters into the categories

shown in attachment A in part IV of Legislative Decree 152/2006, that the holder has destroyed,

has decided or is obliged to destroy.

Waste deriving from the demolition of the machine is classifiable as special waste.

8.7.1 MATERIALS FOR DEMOLITION

Non-dangerous special waste is that which can be recovered, according to the February 1998

Ministerial Decree:

· Iron, aluminium, stainless steel and copper materials

· Plastic materials

· Electronic cards

· Hydraulic oil

· Electrical plant

8.7.2 INDICATIONS FOR A SUITABLE TREATMENT OF WASTE

The Correct management of special waste envisages:

- stocking in suitable places, avoiding mixing dangerous waste with the non-dangerous.

- ensuring that authorised carriers and receivers carry out its transport and disposal/recovery.

Transport of one's waste to authorised collection centres is allowed exclusively if you are

enrolled in the Environmental Management Register.

8.7.3 ELECTRICAL AND ELECTRONIC APPARATUS WASTE (EEAW)

The Italian government has adopted the European Parliament directives in the matter of the

disposal of electrical and electronic waste (EEAW) (2002/95/CE and 2003/108/CE Directives)

with Legislative Decree n° 151,July 25 2005).

The measures: in particular, the decree established measures and procedures aimed at:

a) forestalling the production of EEAW;

b) promoting the re-use, recycling and other forms of EEAW recovery, in order to reduce the

quantity to send for disposal;

c) improving, in terms of the environment, the actions of the subjects who participate in the lifecycle of these apparatuses (producers, distributors, consumers and operators directly involved

in the treatment of EEAW);

d) reducing the use of dangerous substances in electrical and electronic apparatus.

The decree imposes the limitation and elimination of several substances present in EEAW:

lead, mercury, cadmium, chrome, hexavalent chrome, polybrominated biphenyl, polybrominated

diphenyl and polybrominated diphenyl ethers.

The machine has been designed and created in conformity with this directive. Follow the

indications shown below.

The symbol to the side, showing a barred garbage can on wheels, indicates the separate

collection of the electrical and electronic apparatuses of the machine.

The user of the present machine can contact the collection centres instituted by the Local

Authorities or the UNIGREEN Company directly, or request withdrawal by the dealer, in order to

carry out correct disposal of the waste.

15

Page 16

FIG. 9 CIRCUIT DIAGRAM

A: MUTORPUMPE

B: SUCTION FILTER

FIG . 9UMP with MOTORPUMPE

C: EJECTOR

D: FLOATING FILTER

16

Page 17

TABLE 4-5 TABLES OF DELIVERY OF NOZZLES FOR HAND LANCES

T ABLE OF DELIVERY IN LITRES / MIN. OF THE CONICAL NOZZLES FOR LEVER LANCE

note: standard Ø1,5 nozzle

NOZZLE DIAMETER Ø 1,0 Ø 1,2 Ø 1,5 Ø 1,75 Ø 2,0 Ø 2,2 Ø 2,5

PRESSURE (BAR) JE T CAPACITY ( Lt / min )

5 cone 1,16 1,40 1,90 2,25 2,65 2,90 3,50

direct jet 1,40 1,70 2,50 3,95 4,7 6,00 7,70

8 cone 1,40 1,80 2,60 2,80 3,40 3,65 4,45

direct jet 1,70 2,20 3,40 4,85 6,00 7,60 9,80

10 cone 1,50 1,96 2,90 3,10 3,90 4,10 5,00

direct jet 1,90 2,40 3,75 5,40 6,95 8,55 11,0

12 cone 1,60 2,20 3,20 3,40 4,30 4,50 5,50

direct jet 2,00 2,70 4,20 5,95 7,70 9,40 12,1

15 cone 1,88 2,40 3,40 3,80 4,50 5,00 6,10

direct jet 2,30 3,00 4,50 6,65 8,30 10,4 13,4

30 cone 2,60 3,40 4,80 5,40 6,30 7,10 8,70

direct jet 3,20 4,20 6,40 9,40 11,7 14,7 19,1

50 cone 3,40 4,40 6,20 6,80 8,10 9,20 11,2

T AB. 4

direct jet 4,10 5,40 8,30 11,8 15,1 19,1 24,6

T ABLE OF DELIVERY IN LITRES / MIN. OF THE CONICAL NOZZLES FOR "MITRA" SPRA Y GUN

note: standard Ø2,5 nozzle

NOZZLE DIAMETER Ø 1,0 Ø 1,2 Ø 1,5 Ø 1,8 Ø 2,0 Ø 2,3 Ø 2,5 Ø 3,0

PRESSURE (BAR) JE T CAPACITY ( Lt / min )

15 cone 2,45 3,60 4,60 5,90 6,90 8,10 9,20 1 1,5

direct jet 2,50 3,80 5,10 7,30 8,80 10,8 13,0 18,4

25 cone 3,00 4,25 5,70 7,20 8,10 10,2 11,4 14,4

direct jet 3,10 4,60 6,50 9,30 11,7 14,1 16,4 24,1

35 cone 3,40 4,70 6,60 8,50 10,2 12,9 14,0 18,0

direct jet 3,50 5,40 7,40 10,8 13,4 16,8 19,1 28,2

40 cone 3,55 5,20 6,90 9,20 10,9 13,7 14,5 18,8

direct jet 3,65 5,90 7,80 11,7 14,3 17,9 21,0 30,1

45 cone 3,75 5,35 7,30 9,70 1 1,7 14,3 15,4 19,6

direct jet 3,85 6,10 8,20 12,2 15,2 18,8 22,0 31,5

50 cone 4,00 5,60 7,70 10,5 12,5 14,9 16,4 20,9

T AB. 5

T ABLE OF DELIVERY IN LITRES / MIN. OF THE CONICAL NOZZLES FOR "SUPERGETTO" SPRA Y GUN

direct jet 4,10 6,30 8,60 12,7 15,8 19,7 23,0 33,0

note: standard Ø4,5 nozzle

NOZZLE DIAMETER Ø 3,5 Ø 4,0 Ø 4,5 Ø 5,0 Ø 5,5 Ø 6,0 Ø 7,0

PRESSURE (BAR) JE T CAPACITY ( Lt / min )

15 cone 24,0 29,0 33,7 40,3 43,8 47,3 47,3

direct jet 24,8 30,2 36,2 41,8 47,3 52,0 55,8

25 cone 31,0 37,5 43,5 52,0 56,5 61,0 61,0

direct jet 32,0 39,0 47,0 54,0 61,0 67,0 72,0

35 cone 36,7 44,4 51,5 61,5 67,0 72,2 72,2

direct jet 37,9 46,1 55,6 64,0 72,2 79,3 85,2

40 cone 39,2 47,4 55,0 65,8 71,5 77,2 77,2

direct jet 40,5 49,3 59,5 68,3 77,2 84,7 91,1

45 cone 41,6 50,3 58,4 69,8 75,8 81,8 81,8

direct jet 43,0 52,3 63,1 72,5 81,8 90,0 96,6

50 cone 43,8 53,0 61,5 73,5 80,0 86,3 86,3

T AB. 5bis

direct jet 45,3 55,2 66,5 76,4 86,3 94,8 102,0

17

Page 18

TABLE 7 TABLE OF PROGRAMMED MAINTENANCE

OPERATION 8 h 50 h 300 h END

OF SEASON

Check the level and state of the oil 0

Check the accumulator pressure 0

Check the suction (hoses, pipes, unions) 0

Check and clean the suction 0

and delivery filters

Check the pump fixing feet 0

and screws in general

Check the diaphragm and the oil X (1) X (2)

and change if necessary

Check the suction/delivery valves X X

Check the pump screws and bolts are tight X

Check and clean the nozzles and the non-drip diaphragm 0

Check the wear of the nozzles 0

Check the hydraulic oil level 0

Check any failures or cracking of the welds, 0

especially on herbicide booms

Grease the articulated joints and the wheel hubs 0

Check the tyre pressure 0

NOTE: 0 Operation to be carried out by the operator

X Operation to be carried out by a specialised technician or in an authorised workshop

(1) First oil change

(2) Change at the same time a changing the diaphragm

TABLE 8 PROBLEMS, CAUSES AND SOLUTIONS

PROBLEMS CAUSES SOLUTIONS

The pump won’t charge Air suction Check the suction system

Adjustment valve closed Position the lever correctly

(Command group isn’t at

zero pressure)

Valves and/or valve seats Replace or clean ( * )

suction and delivery worn

or dirty

The pump doesn’t reach the set Valve and/or valve seat Replace ( * )

pressure adjustment worn

Valves and/or valve seats suction Replace or clean ( * )

and delivery worn or dirty

Insufficient rpm Bring speed up to correct rpm

The nozzles used are worn or have Replace

holes that are too big

Suction blocked Clean the cartridge of the

Irregular pressure (with impulses) Valves and/or valve seats Replace or clean ( * )

suction and delivery worn

or dirty

Air suction Check the suction system

Excessive vibrations at delivery Pressure accumulator discharged Bring the air pressure back up to the right

or incorrect air pressure value (see pump handbook) ( * )

Noisiness and the level of the oil Blocked suction Check the suction system

has dropped

Water in the oil Breakage of one or more diaphragms Replace ( * ) If the replacement isn’t

No liquid comes out of the nozzles Delivery filter dirty Clean

Non-drip filters dirty

Nozzles blocked

always in the field of 350 ÷ 550 rpm.

filter or remove the blockage

done immediately, drain the water out

of the pump and introduce clean oil

without water (also used) or diesel to

stop rust attacking the internalparts

NOTE: ( * ) Only specialised technician

18

Page 19

TAB.10 ALLOWED FITTINGS

XXX

XXX

XXX

X

XXX

XXX

XXX

XXX

X

XXX

XXX

XXX

X

XXX

X

XXX

XXX

X

XXXXXXX

X

XXXXXXX

X

XXXXXXX

X

XXXXXXX

X

XXXXXXX

X

XXXXXXX

X

XXX

X

XXXXXXX

X

XXXXXXX

X

XXXXXXX

X

XXXXXXX

X

XXXXXXX

X

XXXXXXX

X

XXXXXXX

X

XXXXXXX

X

2005

TYPE OF MACHINE

Mobile Unit Spray er with Fiberglass Tank

TAB. 10

FITTING MASTER 20 MASTER 40 MASTER 40 MASTER 50 MASTER 50 MASTER 55 MASTER 55 MASTER 55

PUMPS PUMP MP40

COMET " " APS 31

" " APS 41

" " APS 51

" " P48

PUMPS PUMP AR 50

ANNOVI " " AR 503

REVERBERI " " AR 813

CLEANING AXD 3020 G

PUMPS ZWD 3530 G

4-STRO KE B & S 6,5 H P

ENGINES B & S 9 HP

B & S 16 HP

HONDA GC160 5 HP

HONDA GX160 5,5 HP

ELECTRIC Battery 12V

STAR T

HOSE R EEL 20 Mt

40 Mt

50 Mt

SPRAY G UN LEVER

MITRA

SUPERGETTO

BOOMS GREEN 2 mt

Herbicide boom 3 mt

NOZZ LES Unijet Antidrip

NOZZLES TIPS FAN NOZZLE TIP ISO

CONE NOZZLE TIP ATR

CONE NOZZLE TIP ISO

ANTIDRIFT NOZZLE TIP

TOWING WHEELS KIT AND TOWBAR

WEIGHT EMPTY MAX FITINGS 155 175 180 165 175 175 200 220

in Kg FULL MAX FITINGS 370 630 640 700 710 740 770 790

Capacity (lt) 200 400 400 500 500 500 500 500

T able of standard riggings supplied by UNIGREEN, special riggings must be agreed with the constructor .

Multi-purpose Mobile Units with a higher capacity (800 - 1000 - 2000 litres) and cistern in organic glass or steel (galvanised or

stainless) are available on request. For information apply to the administration office.

19

Page 20

via Rinaldi, 105 - Loc. Cavazzoli (Reggio Emilia) - ITALY

Tel. +39 0522 369811

Fax. +39 0522 369898

e-mail: info@unigreen-spa.com

internet: www.unigreen-spa.com

member of the group

Descriptions, indicative illustrations, UNIGREEN S.P.A. reserves the right to make variations or modifications without prior warning.

20

UNI 16100008F GB Sett.-10

Loading...

Loading...