Page 1

STARLOG

PROLOGGER

Hardware

Model 7001

Revision 33 Firmware

User Manual Revision A

6261 May, 1999

Page 2

Copyright Notice

Copyright ©Unidata Australia 1999. All rights reserved. No part of this

publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language or computer language, in any form or

by any means, electronic, mechanical, magnetic, optical, chemical, manual or

otherwise, without prior written permission of UNIDATA Australia, 40

Ladner St, O'Connor, Western Australia, 6163, Australia.

Printed in Australia.

IBM is a registered trademark of International Business Machines Corp.

Page 3

Contents

1 INTRODUCTION......................................1

1.1 How to Use this Supplement...........................1

2 PROLOGGER OVERVIEW .............................3

2.1 Programming Overview...............................4

2.2 How the PROLOGGER Operates .......................5

2.3 Input Signals........................................6

2.3.1 Instruments....................................6

2.4 Outputs ............................................6

2.5 Memory Capacity ....................................7

2.5.1 Log Size ......................................7

2.6 Status Indicators ....................................7

2.6.1 Battery Status LEDs.............................8

2.6.2 Scheme Status LEDs............................8

2.7 The Display and Keyboard ............................8

2.7.1 Keys Definition .................................9

2.8 Using the Keyboard and Display .......................9

2.8.1 Selecting a Display List and List Entry...............9

2.8.2 Auto Key Repeat ..............................10

2.8.3 Adjusting a Config Entry.........................10

2.8.4 Commands in the Config List .....................10

2.8.5 Using a PIN# (Password)........................10

2.8.6 Displaying the Scheme List ......................11

2.9 Differences with Model 7000 Macro Data logger..........12

2.9.1 Input Signals..................................12

3 SPECIFICATIONS ...................................14

4 POWER SUPPLY ....................................16

4.1 Internal Battery Pack ................................16

4.1.1 Battery Life ...................................16

4.1.2 Battery Pack Connections .......................17

4.1.3 Replacing a Battery Pack ........................18

4.1.4 Recharging NiCad Battery Pack...................18

4.2 External Power Supply ..............................19

4.2.1 Connecting an External Power Supply..............19

4.2.2 Recharging Batteries ...........................19

PROLOGGER Hardware

i

Page 4

4.3 Battery Status Indicators.............................20

4.4 Monitoring Battery Voltage ...........................20

4.5 Flat Battery Shutdown ...............................20

4.5.1 Saving Memory ...............................21

4.5.2 Auxiliary Memory Back-up Battery .................21

4.6 Internal Battery Charger .............................21

4.7 Automatic Battery Type Detection .....................22

4.8 The Input Signals Connector Pin-out...................22

5 INSTALLATION & CONNECTION .......................23

5.1 Locating the logger .................................23

5.2 Instrument Connection ..............................23

5.2.1 Log Start Sense ...............................27

5.2.2 Analog Inputs .................................27

5.2.3 Counters and Digital Inputs ......................28

5.2.4 User Power Sources (UPS) ......................28

5.2.5 High Speed Serial Ports .........................28

5.3 SDI-12 Serial Digital Interface (optional) ................30

5.4 PROLOGGER Initialisation ...........................30

6 INTERNAL CHANNELS ...............................32

6.1 Battery Voltage Monitor (I2, Batt) ....................32

7 COMPUTER COMMUNICATION ........................33

7.1 Computer Connector Pin Designations.................34

7.2 Baud Rates ........................................34

7.3 Communications (STARLOG) Protocol .................35

7.3.1 Scan Synchronised RS-232 Communication.........35

7.3.2 Non-Synchronised RS-232 Communication (default) . . 36

7.3.3 PROLOGGER Requests (Commands) .............36

7.4 Sample Program....................................38

7.4.1 Simple Interrogation Example ....................38

8 PROGRAMMING THE PROLOGGER ....................40

8.1 Memory Layout.....................................40

8.2 Hardware Register Information........................41

8.2.1 PROLOGGER Memory Assignments...............41

8.2.2 Logger Scan Counter ...........................43

8.3 PROLOGGER - Program .............................43

8.3.1 PROLOGGER - Operation Sequence ..............43

8.3.2 PROLOGGER - Program Instructions ..............43

8.4 Typical instructions .................................44

UNIDATA

ii

Page 5

8.5 Buffer Control Table.................................44

8.5.1 Buffer Format Convention .......................45

9 PROLOGGER CONFIGURATION TABLE.................47

9.1 Default Configuration Table ..........................47

9.2 Memory Layout and Protected Memory.................48

9.3 Configuration Table Layout...........................48

9.4 PROLOGGER Linear Calibration Correction .............49

9.5 Initialisation via the RS-232...........................50

9.6 Read/Write Protected Memory ........................50

10 TEST DIAGNOSTICS .................................51

10.1 Diagnostic.........................................51

10.1.1 Task Command List ............................52

A - OPERATING ERRORS ................................1

B - PROLOGGER REVISIONS .............................1

C - STARLOG PROTOCOL COMMAND LIST .................1

D - USING THE SDI-12 INTERFACE.........................1

PROLOGGER Hardware

iii

Page 6

Page 7

1 INTRODUCTION

The PROLOGGER is a battery powered data collection system manufactured

by UNIDATA. It is ideal for automatic data collection at remote, unmanned

locations. The PROLOGGER incorporates the latest advanced CMOS

technology and intelligent auto calibration techniques to provide a very

accurate, low cost, programmable data collection system.

Like other STARLOG products the PROLOGGER has a simple robust

construction, is battery-powered, is available at a low cost, and can be

universally applied.

The main features of the PROLOGGER are:

•

Large 512k battery protected storage area.

•

16 bit conversion resolution on all channels - analog and digital.

•

High impedance input channels with large 26 bit dynamic range down to

microvolt resolution.

•

GSM/Cellular and PSTN telemetry support.

•

SDI-12 communications bus.

•

Large four line LCD display.

The PROLOGGER provides an upgrade path for the Model 7000 Macro

logger. It supports all existing applications. The signal pin-out is the same and

existing field terminations can be used.

The PROLOGGER is designed to be operated with the Version 3 STARLOG

Software Support Package (Model 6301).

1.1 How to Use this Supplement

This supplement provides technical details for users of the PROLOGGER. It

is divided into several chapters. Each describes a different aspect of the

device. The appendices include information for advanced users.

PROLOGGER Hardware

INTRODUCTION 1

Page 8

The chapters are:

PROLOGGER

Overview

Introduces the PROLOGGER and gives a brief summary of

its features and operation.

Specifications

Lists physical and performance specifications and explains

battery and memory capacity options.

Power Supply

Describes how to change battery packs, use an external

power supply and how to test and monitor the power

supply.

Installation &

Connection

Describes how to connect instruments to the logger and

initialising the logger.

Internal Channels

A listing and explanation of two special channels.

Computer

Communication

Lists the specifications for communication with a computer

and explains in detail the most common method of

interface.

PROLOGGER

Programming

Describes PROLOGGER programming techniques if you

intend to program your own logger.

PROLOGGER

Configuration Table

Describes how a PROLOGGER is configured - it identifies

and explains that particular part of memory and how it is

used.

Test Diagnostics

Explains how to use in-built diagnostic firmware to test and

calibrate the PROLOGGER.

UNIDATA

2 INTRODUCTION

Page 9

2 PROLOGGER OVERVIEW

This chapter provides an overview of the PROLOGGER’s features, including

its programming and operation.

The PROLOGGER is a major design development in the STARLOG product

range. It has an expanded signal capacity and range, and is easier to program.

It offers 22 input channels, two high speed serial input/output busses and two

outputs. It also provides two power sources for external instruments. The

range of scan rates extends from 125 milliseconds to 5 minutes. See page 14

for a list of operational specifications.

PROLOGGER Hardware

PROLOGGER OVERVIEW 3

DB37 connector

for input signals

Four line sixteen

character display

Keypad

Battery LEDs

Scheme status

LEDs

Model and serial

number

DB25 RS232

comms connector

Front Panel Layout

Page 10

Data and commands are transferred between the PROLOGGER and an IBM

or compatible computer using asynchronous RS-232 serial communications.

All set-up and adjustments associated with range and calibration are

performed in firmware. The PROLOGGER is fully programmable.

The PROLOGGER has a very low power consumption. It is supplied with an

internal battery with a typical life of one year. Data is stored in 512k of low

power CMOS RAM. An internal crystal-based clock provides accurate time

referencing of all recorded data and also controls the adjustable scan rate. The

logger’s only external connections are:

•

A connector (labelled INPUT SIGNALS) for instrument inputs, user

power supplies and controls.

•

A connector (labelled COMPUTER) used for communication with a

computer.

The PROLOGGER and its battery are housed in a small, robust, dustproof

enclosure. Exact hardware specifications are listed in Chapter 3.

2.1 Programming Overview

The PROLOGGER is a microprocessor based device designed to be

programmed using Unidata’s STARLOG Software Package (Version 3).

This package, designed to run on IBM PC or compatible computers, creates

and implements instructions that control the logger.

Through a series of windows , the STARLOG Software Package allows you

to define how and when the PROLOGGER records, what channels to record

and what signal types to measure. These definitions are compiled by the

package into a list of instructions to be interpreted by the PROLOGGER.

The PROLOGGER must be programmed before it will record/log or display

readings.

The STARLOG Software generates a set of instructions to program the

PROLOGGER. These instructions are explained in the STARLOG

Programmer’s Supplement (6201).

UNIDATA

4 PROLOGGER OVERVIEW

Page 11

2.2 How the PROLOGGER Operates

The PROLOGGER must be “initialised” before it can be used. This is done

automatically when you load a scheme. Alternatively, you can manually

initialise the device (see PROLOGGER Initialisation on page 30). Note that

when delivered, the PROLOGGER is shutdown to conserve batteries. It must

be initialised before use.

The PROLOGGER switches on once per scan. You must specify the scan

rate. It performs three operations each time it is switched on: scanning,

inter-log analysis, and RS-232 comms check. It then switches off. This

sequence occurs every scan interval. It performs a fourth operation, logging,

at an interval you specify. These operations are described below.

n

Scanning

Scan rates, which can be from 125 milliseconds to 5 minutes, determine how

frequently the logger switches on. When it switches on, the logger scans its

input signals. These signals, called the hardware values, are recorded in the

PROLOGGER memory. The hardware values are updated in the logger

memory every scan.

n

Interlog Analysis

After scanning the input signals the logger program performs an inter-log

analysis of the hardware values, storing the analysed values in a different part

of the logger’s memory referred to as the Register. The inter-log analysis

includes: averaging and storing maximum, minimum and raw values. For

example, if a certain channel is programmed to store maximum values of its

input, the logger will check to see if the hardware value is higher than the

value already stored in the Register. If so, it will update the Register. If not,

then it changes nothing and goes to the next instruction. The Register is used

to store data between log intervals.

n

RS232 Comms

When the scan occurs at a log interval, the logger program records data found

in the Register into another part of its memory. Here, the data remains until

the logger is unloaded (or until the entire memory storage space is filled, then

earlier stored data may be overwritten when recent data is logged).

PROLOGGER Hardware

PROLOGGER OVERVIEW 5

Page 12

2.3 Input Signals

The PROLOGGER has 22 channels for input signals. These are divided into:

•

Sixteen analog channels with 16-bit resolution. These can be in any

combination of up to 16 single-ended or 8 differential voltage inputs ,

These channels accept signals from ±5 millivolts full-scale to ±5.00 volts

full-scale.

•

Two high speed serial ports (bi-directional synchronous, eight 16 bit

channels on each).

•

Four counter input channels (16-bit resolution).

•

Two sense input channels (used for LOG START and SDI-12 signals).

The PROLOGGER has a number of operating modes for its analog inputs.

Analog inputs are available as low resolution (8 bit, a0 – a15) or high

resolution (16 bit, A0 – A15) all with programmable gain settings. (See

PROLOGGER Configuration Table on page 47.)

For more about inputs see Installation and Connection on page 23.

Note:

To save power the PROLOGGER only measures signals on channels

specified in the scheme. If you load a scheme that only specifies a single

channel, the remaining channels are not scanned. If you want to scan signals

on all channels, you must load a scheme that specifies all channels.

2.3.1 Instruments

To complement the PROLOGGER, a range of low power instruments and

sensors is available. They are designed for direct connection to the

PROLOGGER and can use the PROLOGGER’s battery or their own power

supply.

The PROLOGGER has a broad input range. This means that instruments such

as thermocouples, pyrometers, RTDs (like the PT100), strain gauge pressure

transducers, precision thermistors and frequency derived signals can generally

be connected without amplification or signal conditioning.

2.4 Outputs

The PROLOGGER has two outputs and two power sources for external

instruments. The outputs have a wide range of uses, for example they can be

used to set off an alarm or switch on an external device.

UNIDATA

6 PROLOGGER OVERVIEW

Page 13

The four user power sources described in the PROLOGGER Configuration

Table are:

•

+12 Volts DC unregulated.

•

-12 Volts DC unregulated.

•

+10 Volts regulated (reference).

•

+5 Volts DC regulated, scan synchronised.

2.5 Memory Capacity

The logging duration of the logger depends on the scheme. It is calculated by

the software once the scheme is created (see Scheme Information menu).

The calculation includes the following:

Number of Days = (512 - 8) * 1024 * LI/1440 * 1/LS

LI = Logging Interval (in minutes).

LS = Log Size in bytes.

1024 = The number of bytes in a kilobyte.

1440 = The number of minutes in a day.

2.5.1 Log Size

The Log Size is the sum of bytes used per channel. The bytes used per

channel varies depending on the Log Action (raw reading, totalise to 1 or 2

bytes, etc.) and the capacity of the channel. A counter channel may use from

1 to 4 bytes, a serial channel is usually 2 bytes, and an analog channel may

use 2 bytes (high resolution) or 1 byte (low resolution).

For example: A typical weather station logging raw readings for wind speed

(1 byte), temperature (1 byte), solar radiation (1 byte) and relative humidity

(1 byte) every five minutes in a 512k PROLOGGER would theoretically

record for:

Number of Days = (512 - 8)* 1024 * 5/1440 * 1/4 = 448

2.6 Status Indicators

The PROLOGGER has four LED indicators which flash briefly each scan (5

seconds) to show the status of the battery and logging scheme.

PROLOGGER Hardware

PROLOGGER OVERVIEW 7

Page 14

2.6.1 Battery Status LEDs

The top two indicators (labelled BATTERY) show the internal battery status

(see Battery Status Indicators on page 20).

2.6.2 Scheme Status LEDs

When the PROLOGGER has been programmed with a Scheme (using

Version 2 Software) the lower two indicators show the status of the Scheme

operation.

LED On Description State

None

Waiting to be unloaded. Stopped

Waiting for input signals to be connected. Primed

Green

Connected to signals and waiting to begin

logging.

Primed

Green & Red Actively recording. Logging

Red (No Scheme loaded.) (Invalid)

2.7 The Display and Keyboard

The PROLOGGER has a 64 character Liquid Crystal Display (LCD) and an

eight key operator keyboard.

The Display may be activated by pressing the ON key. The Display will turn

OFF automatically after a delay of 20 seconds (when no further keys have

been pressed).

While the Display is active, the PROLOGGER is in high power mode and

uses about 100 times more battery power than in normal scanning mode.

UNIDATA

8 PROLOGGER OVERVIEW

Page 15

2.7.1 Keys Definition

ON Activate display and display the first entry of the STATUS LIST

.

SCHEME Displays the first entry of the SCHEME LIST

.

CONFIG Displays the first entry of the CONFIG LIST.

ENTER

Used only in the CONFIG LIST to save the current SETUP entry or

perform the current SETUP action.

Up/Down Ar-

rows

Scroll UP

5

or DOWN6the current list entries.

Left/Right

Arrows

Adjust the current CONFIG entry UP in value

4

or DOWN in

value

3

. Used only in CONFIG LIST

.

2.8 Using the Keyboard and Display

The display shows three lists of useful information.

STATUS LIST Lists information about the status of battery and channel readings

(unscaled).

SCHEME LIST Lists details of the current Scheme composed using the

STARLOG Software V3. This is normally blank unless a Scheme

has been loaded.

CONFIG LIST Lets you adjust some logger configuration parameters (change the

scan rate) and execute some useful commands (such as, setting the

logger to the sleep mode).

Warning:

Saving altered Setup Entries using the Enter key will cause data

stored in memory above 64K to be lost.

2.8.1 Selecting a Display List and List Entry

Whenever the ON, SCHEME or CONFIG keys are pressed, the first entry in

the Status, Scheme or Config list is displayed. The ON key will also turn the

Display ON if not already on.

By pressing the scroll keys, you display the next Entry in the list (

6 DOWN

key) or the previous Entry

(5 UP key).

PROLOGGER Hardware

PROLOGGER OVERVIEW 9

Page 16

Entries may be one or two lines, therefore the scroll keys will move the

display UP or DOWN one or two lines, depending on whether the Entry is

two lines or not.

2.8.2 Auto Key Repeat

When a key is held down, it automatically repeats. This is a quick way to scan

up or down a list of display entries. Releasing the key stops the repeat mode.

2.8.3 Adjusting a Config Entry

To alter a logger Config Entry, scroll to the desired Entry in the Config List

and use the Adjust keys

34 to adjust the Config Entry to the required

settings, then press ENTER to save the new setting permanently. If you do

not want to save the Config Entry, press any other key (or no keys at all).

Warning:

Pressing the Enter key while displaying a Config Entry with the

message ...use & ENTER on Line 2 will cause data stored in memory

above 64K to be lost.

2.8.4 Commands in the Config List

Some entries in the Config List are simple commands, they do not use the

Adjust keys

34 and they do not cause loss of memory when executed

(when ENTER is pressed). A useful command “TURN DISPLAY OFF” is

the first entry in the Setup List. Therefore, whenever you have finished

viewing the display, press CONFIG, and then ENTER keys.

The display will automaticallyturn OFF anyway after 20 seconds if no keys

are pressed.

2.8.5 Using a PIN# (Password)

The PROLOGGER is fitted with a keyboard and display. This enables you to

configure various functions of the logger without a computer. To ensure that

only authorised users alter the operation of the logger, an optional 4-digit

PIN# (personal identification number) may be entered. The factory default for

the PIN# is 0.

UNIDATA

10 PROLOGGER OVERVIEW

Page 17

To change this PIN#, turn the display ON and then press CONFIG. Press the

down arrow until CHANGE PIN# appears in the display. Press the left arrow

key to select the digit and then the up or down arrow to alter the digit. Once

you have selected a suitable 4 digit number, press ENTER. It is now

impossible to change important configuration settings until the PIN# is

re-entered.

Once a PROLOGGER has been protected by a non-zero PIN#, you must

re-enter the correct PIN# before altering a configuration via the keyboard.

1.

Press ON to switch the display on.

2.

Press CONFIG.

3.

Press the down arrow until ENTER PIN# appears.

4.

Select the correct 4-digit code (using the arrow keys) and press ENTER.

5.

You can now alter the logger’s configuration.

To change the PIN#, you must enter the old PIN# first. A PIN# of 0 means

that all settings may be changed without PIN# validation (default).

If you forget the PIN#, the PROLOGGER will operate normally but you will

not be able to use the keyboard configuration facility until the PROLOGGER

is returned to UNIDATA for service.

2.8.6 Displaying the Scheme List

The Model 7001 PROLOGGER has a four line liquid crystal display (LCD)

and eight key keyboard.

Using the Version 3 Software you can set-up the PROLOGGER to display

the actual values being recorded by connected transducers. This Scheme

Display List contains information similar to the Scheme Test Mode screen. A

one-line display entry is provided for each Scheme Test Mode entry. Four

entries (lines) are shown on the display at one time.

When you press the up/down scroll keys the display moves up/down this list

one line at a time.

PROLOGGER Hardware

PROLOGGER OVERVIEW 11

Page 18

To view the readings of each transducer:

The display turns OFF after 20 seconds, if no keys are pressed.

If the instrument being displayed uses a non-linear correction formula (such

as a thermistor or wind direction) then the uncorrected (raw) mV reading will

be displayed without units.

2.9 Differences with Model 7000 Macro Data logger

2.9.1 Input Signals

The following inputs are different from the Portable Data logger:

UNIDATA

12 PROLOGGER OVERVIEW

Press the ON key and

this will be displayed

Press the SCHEME key

Press the down key

6

Press the down key6

Continue pressing the down key until you reach the

end of the display list

Press CONFIG and then ENTER to turn the display off

6

Page 19

Pin Model 7001 Model 7000

17 Continuous Battery Unused

19 Sense 1/SDI Unused

PROLOGGER Hardware

PROLOGGER OVERVIEW 13

Page 20

3 SPECIFICATIONS

This chapter lists the physical and performance specifications of the

PROLOGGER.

Material: Grey, high impact rigid PVC.

Size: 211 x 108 x 81mm (H x W x D).

Weight: 2 kg including battery.

Operating Temp: -20°C to 60°C, not affected by humidity.

Scan Rate: 0.125 second to 5 minutes - programmable.

Log Interval: 0.125 second to 1 week - programmable.

Memory: Low power CMOS RAM 512k (standard).

Time Clock:

Crystal regulated,±10 seconds per month.

Analog Inputs: 16 channels, 16-bit resolution.

Unipolar or Bi-Polar, differential or single ended.

Counters: 4 channels, 16-bit resolution.

STARBUS: 2 high speed serial lines with eight channels on each,

16 bits, bi-directional, synchronous data & clock.

SDI-12: Optional 1200 Baud instrument channel.

Controls: 2 channels, 1 CMOS output.

1 uncommitted open collector output.

Computer I/O: Full duplex, serial, RS-232C, baud rates:

300/1200/2400/4800/9600/19200/38400/76800.

Processor: 8 bit, 80C31 micro controller, 14.7456 MHz.

Battery Life: Alkaline 1 year (typical), or rechargeable NiCad.

Flat Battery Shutdown: 5.6 Volts.

Instrument Power: +5V DC regulated 100mA.

+6.5V DC unregulated, 1mA continuous.

+10V DC regulated, 100mA programmable duty cycle

(PDC).

+12V DC unregulated, 200mA, PDC.

-12V DC unregulated, 50mA, PDC.

Signal Specifications

Counter Channels: DC to 20 kHz potential free contact or

05 V DC digital input.

UNIDATA

14 SPECIFICATIONS

Page 21

Analog Channels: Voltage input in four programmableranges:

-5.00 to +5.00 V, 155mV resolution.

-500 to +500 mV, 15.5mV resolution.

-50 to +50 mV, 1.55mV resolution.

-5 to +5 mV, 155nV resolution.

Input Impedance:

>1 M

W.

Recommended Source

Drive Impedance:

<10 k

W.

PROLOGGER Hardware

SPECIFICATIONS 15

Page 22

4 POWER SUPPLY

This chapter describes the uses of internal and external power supplies for the

PROLOGGER. It also describes the low battery shutdown feature. The

PROLOGGER is powered by an internal battery. External power sources can

be used as an alternative supplies or to recharge batteries (NiCad and Sealed

Lead Acid only).

A battery must remain connected at all times to protect data stored in

memory. Provision is made for fitting a Lithium back-up battery to protect

memory storage if the main battery is removed or fails.

4.1 Internal Battery Pack

The PROLOGGER is powered by its own internal power supply in the form

of a battery pack (usually supplied with each logger). Alkaline (Model

6910A) and NiCad (Model 6910B) battery packs are available. The battery

pack is located in the base of the logger housing and connected via a

three-way socket to the logger.

The PROLOGGER requires a single battery voltage of 6.5 to 10 V DC.

Battery life varies anywhere from a few weeks up to 2 years depending on the

logging project (see below).

This section covers:

•

Battery life.

•

Battery connections.

•

Battery replacement.

•

Recharging a NiCad battery pack.

4.1.1 Battery Life

The PROLOGGER battery life is influenced by five factors:

•

logger scan rate.

•

logger program run time.

•

External instrument power requirements.

•

Display usage.

UNIDATA

16 POWER SUPPLY

Page 23

•

Computer communication (RS-232).

n

Formula for Determining Battery Life

The following calculation will determine the battery life for UNIDATA

battery packs (Model 6910A):

Life (days) = [ST/(RT+35)] * 3300

ST = Scan Time (seconds)

RT = Run Time (milliseconds)

… where external instrument load does not exceed 20mA.

The run time is determined by examining Address 1 of the PROLOGGER

(Block 0, locations 1 and 2), where the program run time is saved.

6910A battery packs have a maximum life of 3 years.

n

Battery Life Estimation Tables

The following table details the estimated battery life from loggers with

various scan rates and battery types. This table assumes a program run time of

12 milliseconds (approximately 40 instructions).

Scan Rate

Model 6910B Model6910A

Life (days) Life (days)

0.25 12 16

130 66

5 40 330

10 40 660

Model 6910A – 10 Ah Alkaline Battery Pack.

Model 6910B–4AhNickel Cadmium Battery Pack.

4.1.2 Battery Pack Connections

The Model 6910 battery packs are manufactured with a 3-way socket

connector that plugs into the Model 7001 PROLOGGER.

PROLOGGER Hardware

POWER SUPPLY 17

Page 24

Users who manufacture their own replacement battery packs may purchase

connectors from a Molex dealer or simply re-use the wire & connector from

the old battery pack. The connector type is Molex brand 050-57-9403

70066-0177 shell with type 016-02-1125 71851-0224 crimp terminals.

4.1.3 Replacing a Battery Pack

All recorded data will be lost when the battery pack is disconnected (unless

the auxiliary battery is installed (see page 21). Ensure the PROLOGGER has

been unloaded before replacing the battery.

To replace a battery pack:

1.

Remove the PROLOGGER lid by unscrewing the six lid screws.

2.

Depress the small retaining clip securing the battery plug and disconnect

the battery cable.

3.

Lift out the black metal battery retaining plate and remove the used

battery pack.

4.

Insert a new battery pack and replace the metal retaining plate making

certain not to crush the battery wires.

5.

Reconnect the new battery and the PROLOGGER will begin operating.

6.

Replace the lid into PROLOGGER base and tighten the six lid screws.

The PROLOGGER will not be damaged if battery wires are accidentally

reversed.

ENVIRONMENT FRIENDLY - UNIDATA uses only mercury-free alkaline cells

in battery packs. UNIDATA or your battery manufacturer will accept battery

packs returned for recycling.

4.1.4 Recharging NiCad Battery Pack

The NiCad Battery Pack can be recharged by a mains power pack or a solar

powered recharge system. You can also recharge a battery pack on site using

an external power source. (See the next section.)

UNIDATA

18 POWER SUPPLY

Page 25

4.2 External Power Supply

An external power source can be connected to the PROLOGGER. External

power can be used with an Alkaline or NiCad battery pack as a backup power

source or simply on its own.

A mains power pack and a solar power pack are available from UNIDATA.

The supply voltage to the PROLOGGER must be maintained at all times to

ensure correct logger operation and data integrity. (See optional Auxiliary

Memory Back-up Battery on page 21.)

The voltage to the logger must be in the range of9Vto20Vandable to

supply a load of 100 mA peak (increasing to 500 mA when recharging a

battery).

4.2.1 Connecting an External Power Supply

To install an external power supply:

1.

Connect +ve to pin 16 of the INPUT SIGNALS socket (terminal 1 of the

Field Termination Strip).

2.

Connect -ve (common) to pin 34 of the INPUT SIGNALS socket

(terminal 2 of the Field Termination Strip).

Pins 50 - EXT Power and 51 - GND on the 7001C Field termination Strip are

generally used for charging external batteries using a solar panel.

4.2.2 Recharging Batteries

With a NiCad battery pack installed a PROLOGGER can be recharged from a

solar panel, mains power pack or other DC power source. The input voltage

should be between 11V and 20V.

NiCad Battery Packs require several charge/discharge cycles before their full

charge is retained. Therefore ensure the PROLOGGER has been fully

charged (connected to solar recharge or mains power pack) then left to

discharge at a high scan rate.

PROLOGGER Hardware

POWER SUPPLY 19

Page 26

4.3 Battery Status Indicators

The PROLOGGER measures its internal battery voltage every scan. If the

battery voltage falls below certain preset levels, the Battery Status LEDs on

the front panel will change state.

GREEN RED BATTERY STATUS ALKN NiCAD LCD DISPLAY

ON OFF Battery OK >7.2V >7.2V OK

ON ON Battery Low (Replace soon) <7.2V <7.2V Low

OFF ON

Battery Flat (Replace

immediately)

<6.6V <7.1V Chg

OFF OFF

Not Operating (Sleep or

Shutdown Mode)

<6.2V <7.0V Bad

Whenever an external power source greater than 11V DC is connected to the

logger, the internal battery is bypassed (and/or recharged). The logger

operates from the external power, but will automatically use the internal

battery if external power falls below 11V DC or fails altogether.

4.4 Monitoring Battery Voltage

The most recent battery voltage measurement is stored in the logger memory

and can be displayed or logged.

The PROLOGGER saves the voltage measurement at Address 236 (Internal

Channel I2, also called, “Batt”, see page 32). Use Test Mode to display the

internal channels.

4.5 Flat Battery Shutdown

The logger also monitors the battery voltage when in sleep mode.Ifthe

voltage falls to a level that could cause faulty operation, the logger enters

shutdown state and will not scan, communicate with a computer or activate

the display. In addition, all equipment power loads are disconnected (counter

channels and pin 18 continuous power) to preserve memory.

The Flat Battery Shutdown voltage limit is 5.6V.

UNIDATA

20 POWER SUPPLY

Page 27

4.5.1 Saving Memory

A logger in “Shutdown” or “Sleep” mode will preserve its memory for many

weeks. To recover information stored in the logger:

Connect a computer to the logger and attempt to “Unload” it.

If the logger was in sleep mode, it will wake-up and unload normally. If it

was in shutdown mode, connect an external power source to the logger (such

as a new battery pack, see page 18 for details). The logger will wake-up and

unload normally.

b. Shutdown, connect an external power source to the logger (such

as a new battery pack, see section 4.3). The logger will then

wake-up and normally.

The external power must be connected without disconnecting the internal

Flat battery (unless the optional memory back-up battery is installed).

Follow the procedurein

Connecting an External Power Supply

on page 19.

4.5.2 Auxiliary Memory Back-up Battery

An optional Lithium battery (Model 6909A) can be installed to provide

memory back-up power when the main battery pack is removed or fails

completely. The battery type is a 3.4VAA lithium cell with wire leads (SAFT

LS14250 or similar).

The status of the auxiliary battery is monitored by the logger. If the battery

requires replacement (or is not installed) an asterisk (*) is displayed adjacent

to the main battery status.

To check auxiliary memory back-up battery:

1.

Press the ON key firmly. The following is displayed:

PROLOGGER 900

V033.00 BAT=OK *

2.

This indicates the auxiliary battery is either not installed or needs

replacement.

In all loggers the auxiliary memory back-up battery status is indicated in Bit 6

of Register 33 (see section 8.2.1).

4.6 Internal Battery Charger

The PROLOGGER has an inbuilt battery charging circuit designed for

continuous recharging of NiCad and Sealed Lead Acid batteries as well as

providing regulated power to the logger when operating from external power.

PROLOGGER Hardware

POWER SUPPLY 21

Page 28

4.7 Automatic Battery Type Detection

The PROLOGGER automatically detects which type of battery is installed

and sets the voltage thresholds accordingly. The logger also enables the

battery charging circuit when a NiCad battery is installed.

ALKLN or NiCad will be displayed on the LCD according to which type of

battery is installed.

If external power is used and no battery pack is installed, the LCD will

indicate ALKLN.

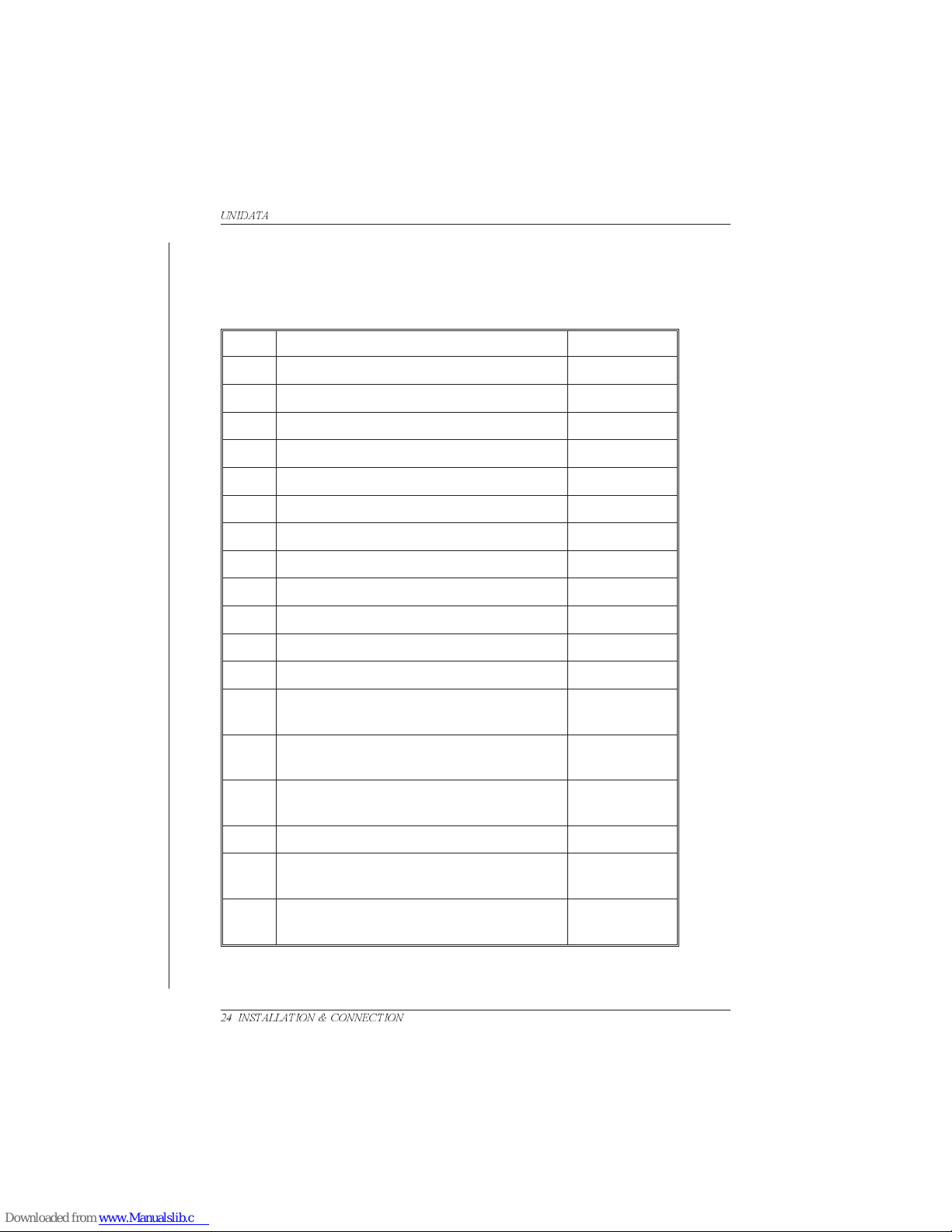

4.8 The Input Signals Connector Pin-out

The table on page 24 lists each pin in the INPUT SIGNALS connector by

number. Next to the pin number is a description of the signal for which this

connection is designed. The last column lists the high resolution channel

mnemonic used by STARLOG to refer to this connection.

UNIDATA

22 POWER SUPPLY

Page 29

5 INSTALLATION & CONNECTION

This chapter provides information necessary to install a PROLOGGER. It

includes:

•

A list of the connections of the INPUT SIGNALS connector.

•

Signal specifications for each connection.

•

How to initialise a PROLOGGER.

5.1 Locating the logger

The PROLOGGER may be installed in nearly any environment with the

following provisos:

•

It should not be exposed directly to the weather. If it is to be used

externally, it should be housed in a weatherproof enclosure.

•

It should be mounted away from electrical noise sources (such as electrical

contactors and radio transmitters). In all cases signal leads should be

shielded and kept as short as possible.

Wherever possible, install the PROLOGGER in a protected location exposed

to the least temperature extremes. This will increase the battery life, and

improve clock and signal measurement accuracy.

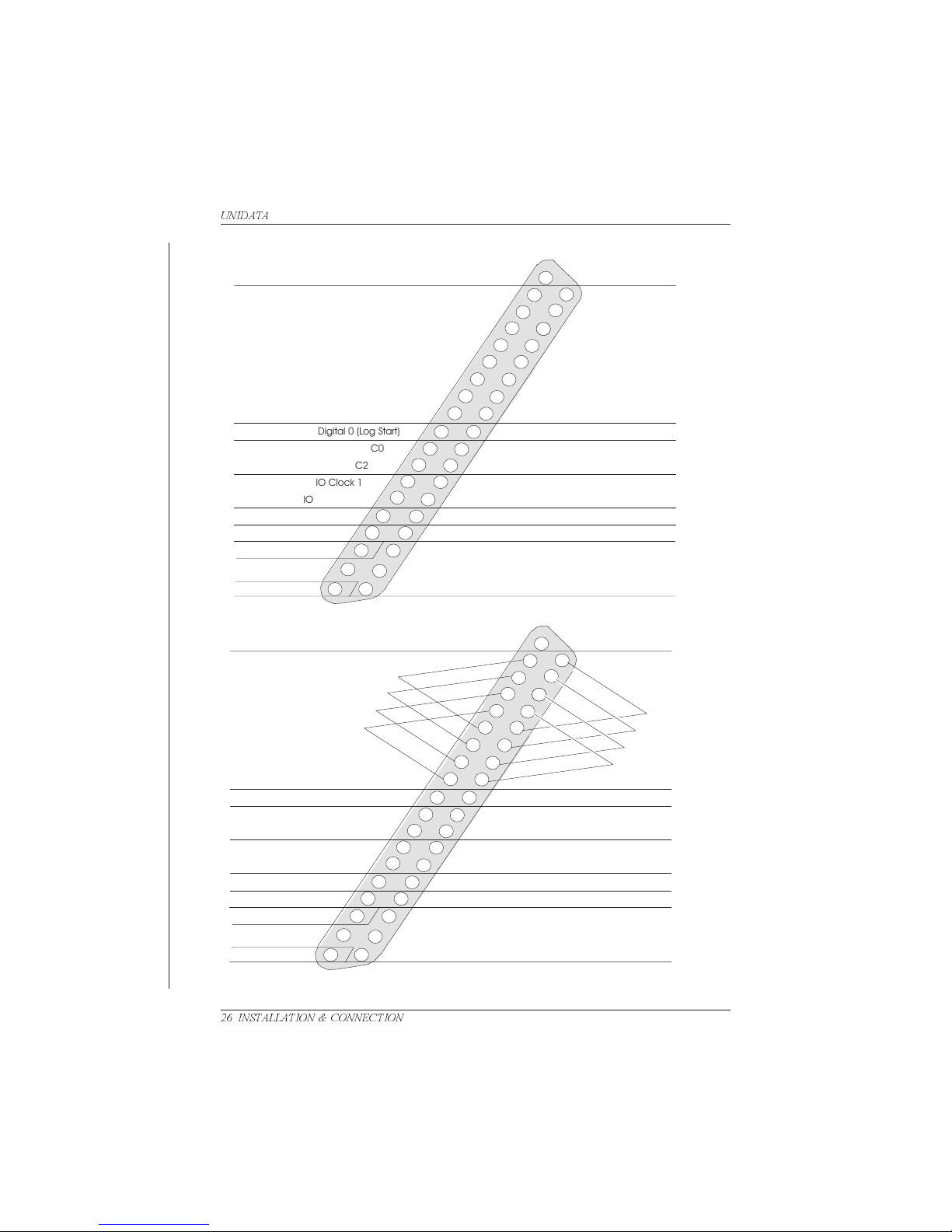

5.2 Instrument Connection

You connect instruments to the PROLOGGER via the 37-pin socket located

on the logger’s front panel and labelled INPUT SIGNALS. For ease of use

you can plug a Field Termination Strip into this connector. Each input is

referred to as a channel in the STARLOG Software Package.

n

Field Termination Strip

This extends the INPUT SIGNALS connector to a row of numbered screw

terminals. The Field Termination Strip (Model 7100C) and its manual

(supplement 7012) are available from UNIDATA.

The pinouts of the INPUT SIGNALS CONNECTOR is shown below.

PROLOGGER Hardware

INSTALLATION & CONNECTION 23

Page 30

The following table lists each pin in the INPUT SIGNALS connector by

number. Next to the pin number is a description of the signal for which this

connection is designed. The last column lists the high resolution channel

mnemonic used by the STARLOG Software to refer to this connection.

Pin Signal Description Channel

1 Analog ground

2 Analog input A1 (A1+ve)*

3 Analog input A3 (A3+ve)

4 Analog input A5 (A5+ve)

5 Analog input A7 (A7+ve)

6 Analog input A9 (A1-ve)

7 Analog input A11 (A3-ve)

8 Analog input A13 (A5-ve)

9 Analog input A15 (A7-ve)

10 Sense input BIT 3 (Log Start, MASK 8) SENSE 0

11 16 bit counter input (20kHz) C0

12 16 bit counter input (20kHz) C2

13

High Speed Synchronous Serial Port Clock

(TTL level input and output)

HSIO Clock 1

14

High Speed Synchronous Serial Port Clock

(TTL level input and output)

HSIO Clock 0

15

Control, Open collector output, 30V, 100mA

drive, 20ms pulse width

OUT 1

16 External power +12V (or recharge) Power Input

17

+6V continuous power for external

instruments (1mA maximum)

Micro Power

18

Scan synchronised +5V regulated UPS or

HSIO Sync (@30mA max)

Sync Power or

HSIO Sync

UNIDATA

24 INSTALLATION & CONNECTION

Page 31

Pin Signal Description Channel

19 Sense input BIT 1 (MASK 2)

SENSE 1

/SDI-12

20 Analog input A0 (A0+ve)

21 Analog input A2 (A2+ve)

22 Analog input A4 (A4+ve)

23 Analog input A6 (A6+ve)

24 Analog input A8 (A0-ve)

25 Analog input A10 (A2-ve)

26 Analog input A12 (A4-ve)

27 Analog input A14 (A6-ve)

28 Digital ground Digital ground

29 16bit counter with prescale (20kHz) C1

30 16bit counter with prescale (20kHz) C3

31

High Speed Synchronous Serial Data Port

(TTL level input and output)

HSIO data 1

32

High Speed Synchronous Serial Data Port

(TTL level input and output)

HSIO data 0

33

Control, Open collector output, 30V, 100mA

drive, 20ms pulse width

34 Power ground Power ground

35 +10V regulated user power source User power

36 -12V, 5mA unregulated user power supply User power

37 +12V, 200mA unregulated user power supply User power

*The channel assignments for inputs in brackets refer to differential signals.

PROLOGGER Hardware

INSTALLATION & CONNECTION 25

Page 32

UNIDATA

26 INSTALLATION & CONNECTION

Digital 0 (Log Start)

C0

C2

IO Clock 1

IO Clock 0

OUT 1

External Power Input

Scan sychronised

Analog Ground

Analog

Digital Ground

OUT 0

C1

C3

IO Data 1

IO Data 0

Power Ground

Continuous Battery +10 V regulated

+12 V unregulated

-12 V unregulated

SDI/Sense1

A0

A2

A4

A6

A8

A10

A12

A14

single ended (normal)

7

8

9

5

4

2

27

26

25

24

20

21

23

6

22

A1

A3

A5

A7

A9

A11

A13

A15

High Speed Synchronous

Counters

User's Power Sources

Outputs

Serial I/O Port

External Power Input

36

35

31

32

33

34

30

29

28

17

18

13

14

15

16

12

11

10

+5V regulated

3

1

3719

Digital 0 (Log Start)

C0

C2

IO Clock 1

IO Clock 0

OUT 1

External Power Input

Scan sychronised

Analog Ground

Analog

Digital Ground

OUT 0

C1

C3

IO Data 1

IO Data 0

Power Ground

Continuous Battery +10 V regulated

+12 V unregulated

-12 V unregulated

SDI/Sense1

7

8

9

5

4

2

27

26

25

24

20

21

23

6

22

High Speed Synchronous

Counters

User's Power Sources

Outputs

Serial I/O Port

External Power Input

36

35

31

32

33

34

30

29

28

17

18

13

14

15

16

12

11

10

+5V regulated

3

1

3719

A1

A3

A5

A7

differential

+

-

+

-

+

-

+

-

A0

A2

A4

A6

+

+

+

+

-

-

-

-

Page 33

5.2.1 Log Start Sense

Normally, the PROLOGGER only begins to record when an instrument is

connected via the INPUT SIGNALS input. To sense this condition, Pin 10

(Log Start Sense 0) of the INPUT SIGNALS socket is grounded (connected

to Pin 28). The PROLOGGER program may then sense this condition by the

BJMPN 32,#8,Branch Label

instruction which branches when the INPUT

SIGNALS are not connected. See the description of the startup.INCLUDE

file in the Programmer’s Supplement (No. 6201) for further information.

Warning:

The STARLOGGER will not begin recording unless the LOG

START Sense is connected to ground (Pin 28). LOG START is automatically

connected to ground when the Model 7100 Field TerminationStrip is used.

5.2.2 Analog Inputs

Analog inputs can be used as low resolution (8 bit) or high resolution

channels (16 bit). Their usage depends how you refer to the input in the

STARLOG software. The software interprets analog inputs as low resolution

channels when you refer to them as a0 – A15 and high resolution channels

when you refer to them as A0 – A15.

All analog channels are programmable to carry a signal in one of four ranges:

-5.00 to 5.00V 155µV resolution

-500 to 500mV 15.5µV resolution

-50 to 50mV 1.55µV resolution

-5 to 5mV 155nV resolution

Input impedance (when the logger is active) is greater than 1MΩ. Load

impedance (when the logger is inactive) for signals less than 500 mV is

greater than 1MΩ. For signals greater than 500mV it is 10kΩ. The

recommended source drive impedance is <10kΩ.

Analog channel calibration coefficients are stored in the configuration table

(see page 47 for details).

PROLOGGER Hardware

INSTALLATION & CONNECTION 27

Page 34

5.2.3 Counters and Digital Inputs

Counter and Digital inputs are DC

inputs suitable for 20 kHz potential

free contacts or 0–5V to 0–12V DC

digital input.

Maximum pulse rate to the counters is

20 kHz. Pulse rates must also be

related to scan rate, to ensure counters

do not overflow before being scanned

by the PROLOGGER.

5.2.4 User Power Sources (UPS)

The User Power Sources (Pins 18, 35, 36, 37) are intended to power

instruments associated with the PROLOGGER. The full load output

capability is 350mA in pulsed mode and 175mA (50% duty cycle) in

continuous operation. The standing battery drain with the UPS switched ON

(and no external UPS load) is 15mA.

The Scan Synchronised UPS (Pin 18) switches on and off in sync with the

logger scan. Any loads connected to these outputs will contribute to the drain

on the PROLOGGER battery (and reduce battery life).

The other User Power Sources (Pins 35, 36, 37) are programmmed to switch

on and off by setting three variables (Prescan, Ontime and Offtime) in the

PROLOGGER Configuration Table. See PROLOGGER Configuration Tables

on page 47 details.

5.2.5 High Speed Serial Ports

There are two serial ports:

Port 0 Pin 13 (Clock 1)

Pin 31 (Data 1)

Port 1 Pin 14 (Clock 0)

Pin 32 (Data 0)

Pin 18 +5V sync signal

UNIDATA

28 INSTALLATION & CONNECTION

10k

Standby = 4.5V

100k

Counter

input

0.001uF (C0/C2)

0.01uF (C1/C3)

Page 35

These ports are read each logger scan. The Sync signal (Pin 18) is used to

indicate to the remote equipment that a logger read scan is about to begin.

This signal is used to load the serial shift register(s) in the remote equipment

in preparation of being read.

The first data bit LSB must be present on the Data (0/1) signal within 7ms

after the Sync signal.

Serial transfer rate is 50 microseconds per bit with a 30 microsecond gap

between each byte. See the timing diagrams for Serial In and Serial Out

below.

Every 1mS a logger interrupt sequence adds a 50 microsecond delay to the

serial transfer sequence. Transfer starts with the least significant bit of the

least significant byte and each clock reads the next most significant bit.

PROLOGGER Hardware

INSTALLATION & CONNECTION 29

Pin 18

SYNC

Pin 14/13

CLOCK 0/1

Pin 32/31

DATA 0/1

LOGGER SCAN

20us

30us

Read Bit 0 Bit 1 Bit 2

50 us

10ms

Bit 0

Bit 1 Bit 2

Bit 7 0 (BYTE 1)

SERIAL IN

Bit 0Bit 7

30us

Serial In Timing Diagram.

Page 36

5.3 SDI-12 Serial Digital Interface (optional)

The PROLOGGERs support the U.S.G.S. SDI-12 standard for serial data

interchange between the logger and intelligent instruments.

SDI-12 is implemented as an alternate use of Sense 1 (Pin 19). Up to ten

SDI-12 compatible instruments may be connected to this bus. Programming

the SDI-12 interface is supported in the STARLOG Version 3 Software.

See Appendix D - Using the SDI-12 Interface details on how to use the

SDI-12 Interface.

5.4 PROLOGGER Initialisation

The STARLOGGER is normally stored and delivered to you in sleep mode to

conserve batteries. You must load a scheme into the logger before it can be

used.

In normal use, the PROLOGGER will not require initialisation. If however,

the logger does not appear to scan at the correct rate, it may need

re-initialization.

Any of the following actions will (re)initialise the logger:

•

Loading a Scheme into the logger.

•

Executing the “RESET LOGGER” command in the Config List.

•

Using the ALT-I command in Diagnostics. (See the STARLOG Software

Package.)

•

Disconnecting, then re-connect the battery after a ten second delay.

WARNING: data stored in memory will be lost.

•

Adjusting and saving any of the Config Entries.

UNIDATA

30 INSTALLATION & CONNECTION

Pin 18

SYNC

Pin 14/13

CLOCK 0/1

Pin 32/31

DATA 0/1

LOGGER SCAN

20us

30us

Write Bit 0 Bit 1 Bit 2

50 us

10ms

Bit 0

Bit 1 Bit 2

Bit 7 0 (BYTE 1)

SERIAL OUT

Bit 0

Bit 7

30us

Serial Out Timing Diagram

Page 37

During initialization, the logger’s firmware and Configuration Table is

check-summed to confirm its integrity. The Scan Counter is set to the logger

Scan Rate and other housekeeping functions performed.

See the STARLOG User’s Manual for more information.

PROLOGGER Hardware

INSTALLATION & CONNECTION 31

Page 38

6 INTERNAL CHANNELS

The PROLOGGER has four internal channels. These are presented as high

resolution values (signed 16 bit) in Register Addresses 232 to 239 as detailed

below:

Name Description Register Address

I0 (Temp) logger Temperature (0.1221°C per bit) 232

I1 (10V) 10V reference (1.221 mV per bit) 234

I2 (Batt) logger battery (or supply) voltage

(1.221 mV per bit)

236

I3 (5V) 5V scan synchronised reference voltage

(1.221 mV per bit)

238

The values of these internal channels are available for recording (logging) or

use in computations in the User Log Program. Typical uses may be to provide

high accuracy corrections to bridge measurements (strain gauge/PT100 etc.)

referenced to the 10V or 5V supplies.

The temperature (which is in thermal contact with the Analog ground point

adjacent to the Input Signal connector) can be used to provide cold junction

compensation for thermocouples connected to the Input connector.

6.1 Battery Voltage Monitor (I2, “Batt”)

Battery voltage is automatically monitored by the logger and recording will

cease if the battery falls below a defined threshold (the logger goes into sleep

mode). The threshold is defined in the Configuration Table (see page 47). The

battery state is also displayed on the Battery Status LEDs while the logger is

operating (see page 20 for details).

UNIDATA

32 INTERNAL CHANNELS

Page 39

7 COMPUTER COMMUNICATION

The PROLOGGER uses standard asynchronous, RS-232 serial

communications to connect to IBM PC or compatible computers.

You can load and unload schemes and data using the RS232 connection .

About half of the pins in this plug are allocated a function. The rest are

reserved for future use. This chapter:

•

Explains how to set the baud rate.

•

Describes the communications protocol.

•

Includes a sample communication program.

•

Includes a table listing pin allocations.

The communication format is:

•

RS-232C compatible.

•

300 to 76800 baud (9600 baud is default - see page34 for details).

•

8 data bits.

•

1 stop/start bit.

•

No parity.

You can connect a computer to the PROLOGGER via the 25-pin socket

(labelled COMPUTER) located on the logger’s front panel. Model 6602A

25-25 pin and Model 6602I 25-9 pin cables are available from UNIDATA.

PROLOGGER Hardware

COMPUTER COMMUNICATION 33

Page 40

7.1 Computer Connector Pin Designations

The following table lists each pin in the COMPUTER connector by number.

Next to the pin number is a signal description. The last column explains how

the pin is used.

Pin Signal Description Usage

1 Signaland logic ground Ground

2 Serialdata signal to logger RxD

3 Serialdata signal from logger TxD

4 RTSfrom computer RTS

6 DSRfrom logger DSR to CPU

7 SignalGround GND

10 Mode

15 Baud Rate Select (See section 7.2.)

16 Baud Rate Select

17 Baud Rate Select

20 from computer (not used) DTR

25 Remote Telemetry Control from logger OUT 0

All other pins are not connected and reserved for future use.

Notes

1.

The RTS signal from the computer will activate the logger even between

scans. The logger may respond with a prompt (CR) immediately the RTS

becomes true or wait until the next scan (depending on communication

mode settings).

2.

CTS signal is not used to synchronise communications between the

logger and computer, this is achieved by the logger prompt (CR). The

DSR is true whenever the logger scan is active.

7.2 Baud Rates

The communication baud rate is selected on the COMPUTER connector on

the face of the logger. Note that PC/XT and slow PC/AT computers can only

communicate up to 9600 baud. Fast PC/AT and 386 machines can

communicate at 19200.

UNIDATA

34 COMPUTER COMMUNICATION

Page 41

To select the RS-232 baud rate (other than the default 9600* baud) you must

link one (or more) of the COMPUTER connector pins 15, 16 and 17 to

ground (pin 7).

Pin 15 Pin 16 Pin 17 Baud Rate

GND NC GND 300

NC GND NC 1200

NC GND GND 2400

GND GND NC 4800

NC NC NC 9600*

NC NC GND 19200

GND NC NC 38400

GND GND GND 76800

NC = Not connected.

GND = connected to ground.

Note that pin 14 is reserved.

7.3 Communications (STARLOG) Protocol

This section describes the communications protocol common to all

STARLOG products. See Appendix B Starlog Protocol Command List for a

complete list of STARLOG protocol commands.

7.3.1 Scan Synchronised RS-232 Communication

At the end of every scan (5 seconds usually) the logger will check to see if the

computer interface is connected. If the interface is connected, the logger

sends a prompt to the interface (host computer). This prompt is an ASCII

asterisk followed by a carriage return (CR).

The logger then waits 0.5 second for a request from the host computer. If no

request is received by the logger, the logger powers down (switches off) until

the next scan (5 seconds usually).

While the logger is communicating with the computer, it will remain active

(in high power mode). However, any logger scans that are due will be

processed simultaneously with ongoing communications.

PROLOGGER Hardware

COMPUTER COMMUNICATION 35

Page 42

7.3.2 Non-Synchronised RS-232 Communication (default)

If the PROLOGGER is set to operate in non-synchronised mode the RS-232

communication protocol timing is slightly different.

The logger will immediately enter communications state (and send a prompt)

whenever the Request To Send (RTS) line becomes true (ON/HIGH). It does

not wait until the end of the next logger scan.

If a logger Scan occurs during RS-232 communications, the scan will be

processed.

7.3.3 PROLOGGER Requests (Commands)

A PROLOGGER has three basic commands - GET, PUT and KILL. The

(G)ET and (P)UT commands only access the first 64K of memory.

For memory sizes greater than 64K, lowercase equivalents of these

commands serve as an extended protocol commands. That is,

g

performs an

extended GET command. All extended protocol commands require a

checksum following the message.

If the logger receives an invalid command it will be ignored. Other

commands are used to maintain and initialise the Configuration Table (see

page 47 for details).

See Appendix 7.3C - Starlog Protocol Command List for a complete list of

STARLOG Protocol commands.

n

GET (and (g)et) Commands

GAAAASS where G is the GET command, AAAA is the 16 bit address

(MSB/LSB) and SS is the number of bytes required. A zero in the SS

command corresponds to 256 bytes. AAAA is the command for a 16 bit

address in the first 64K memory storage of the logger.

Gaaaaaaaasssscccc

Where: g is the get command

aaaaaaaa is the 32 bit start memory address (MSB...LSB).

ssss is the 16 bit number of bytes to transfer.

cccc is the 16 bit checksum.

UNIDATA

36 COMPUTER COMMUNICATION

Page 43

To read 256 bytes from address 768 into the host computer the command is:

G030000

n

PUT {and (p)ut} Commands

PAAAASS

paaaaaaaassss...put data...cccc similar to the GET command except that data

is sent to the logger immediately following the command string.

cccc the 16 bit checksum for the (p)ut command includes the address, size

and data fields (i.e., everything except the “p” command and the checksum

itself) and is sent MSB/LSB.

For example, to reset the logger timer to zero, you will want to put zero into

addresses 0004, 0005, 0006 and 0007. The command is:

P00040400000000

Where: P is the put command

0004 is the offset address (in the registers)

04 is the put data count

00000000 is the data to put

The data format for the GET or PUT is a continuous string of hexadecimal

characters. The first two characters correspond to the first byte requested or to

be sent, the next two characters is the second byte, and so on. The data string

is terminated by a carriage return. A command to retrieve 16 bytes may

appear as:

G000010

the returned data may appear as:

00112233445566778899AABBCCDDEEFFmmllCR

Where mmll = Get data checksum consisting of a 16 bit binary addition of all

binary data (not HEX representation) within the retrieved information

(excluding the checksum and CR). The checksum is sent as four HEX

characters - mm = Most Significant Byte and ll = Least Significant Byte.

Two hex characters are always received or transmitted(most significant digit

then least significant digit) even though the number is smaller then 16. For

example, 10 decimal is sent or received as 0A.

PROLOGGER Hardware

COMPUTER COMMUNICATION 37

Page 44

GET or PUT may address any continuous segment of the memory.

n

(K)ILL command

K is the KILL command that directs the logger to switch OFF until the next

scan cycle (usually 5 seconds).

a command to load location 2 with 0 then exit, would be:

P00020100K

Note: After a GET command, the computer must wait until the logger has

sent the GET data before a KILL is issued.

7.4 Sample Program

The following program written in Microsoft QBASIC communicates between

the PROLOGGER and an IBM PC or compatible computer.

7.4.1 Simple Interrogation Example

This sample program will issue a command to the logger and display the

response from the logger. The commands must be valid commands (see

above).

The “ON ERROR GOTO 140" statement is needed to trap (and ignore via

RESUME statement) any I/O errors that may occur as the logger powers up

and the RS-232 signal lines change state.

Statement 70, sends the command to the logger. Notice that a K command

(kill) is appended to the operator request. This shuts the logger down,

immediately after the request has been completed to save logger battery

power.

Try entering these commands:

G000008 (get 8 bytes from location 0)

G000502 (get 2 bytes from location 5)

G010010 (get 16 bytes (10 hex) from location

256 (Block 1, Location 0)

P00020188G000201 (put 88 into location 2 and

UNIDATA

38 COMPUTER COMMUNICATION

Page 45

immediately gets the data)

The maximum G (get) size is 127 (7F hex). This is limited by BASIC string

length maximum of 255 characters.

10 REM PROLOGGER - data transfer example

20 INPUT “Enter data logger command-”,A$

‘Get Command from

operator

30 IF A$="" THEN END ‘Finish on c/r

40 OPEN “COM1:9600,N,8,1,CS0,DS0,CD0” FOR RANDOM AS #1

‘Open RS-232 to logger

50 ON ERROR GOTO 140 ‘Trap I/O errors

60 INPUT #1,L$:IF INSTR(L$"*")=0 THEN 60

‘Wait for logger prompt

70 PRINT #1,A$; ‘Send command to logger

80 INPUT #1,L$ ‘Get response from logger

90 PRINT #1,"K"; ‘Send KILL to save battery

100 ON ERROR GOTO 0 ‘Reset error trapping

110 CLOSE #1 ‘Close RS-232 file (channel)

120 PRINT “Data logger Response =”;L$ ‘Print result on terminal

130 GOTO 20 ‘Go back to beginning

140 RESUME ‘Ignore I/O error

PROLOGGER Hardware

COMPUTER COMMUNICATION 39

Page 46

8 PROGRAMMING THE PROLOGGER

This chapter describes programming techniques of and memory layout for the

PROLOGGER. The contents of this chapter will be useful to those who

program and test the logger using the test mode screens provided with the

STARLOG Software Package.

For those who use the STARLOG software, this chapter provides important

details on the PROLOGGER instructions used by the assembler. For

complete programming information consult the STARLOG Programmer’s

Manual (No. 6201) included with the STARLOG Software Package (Model

6300).

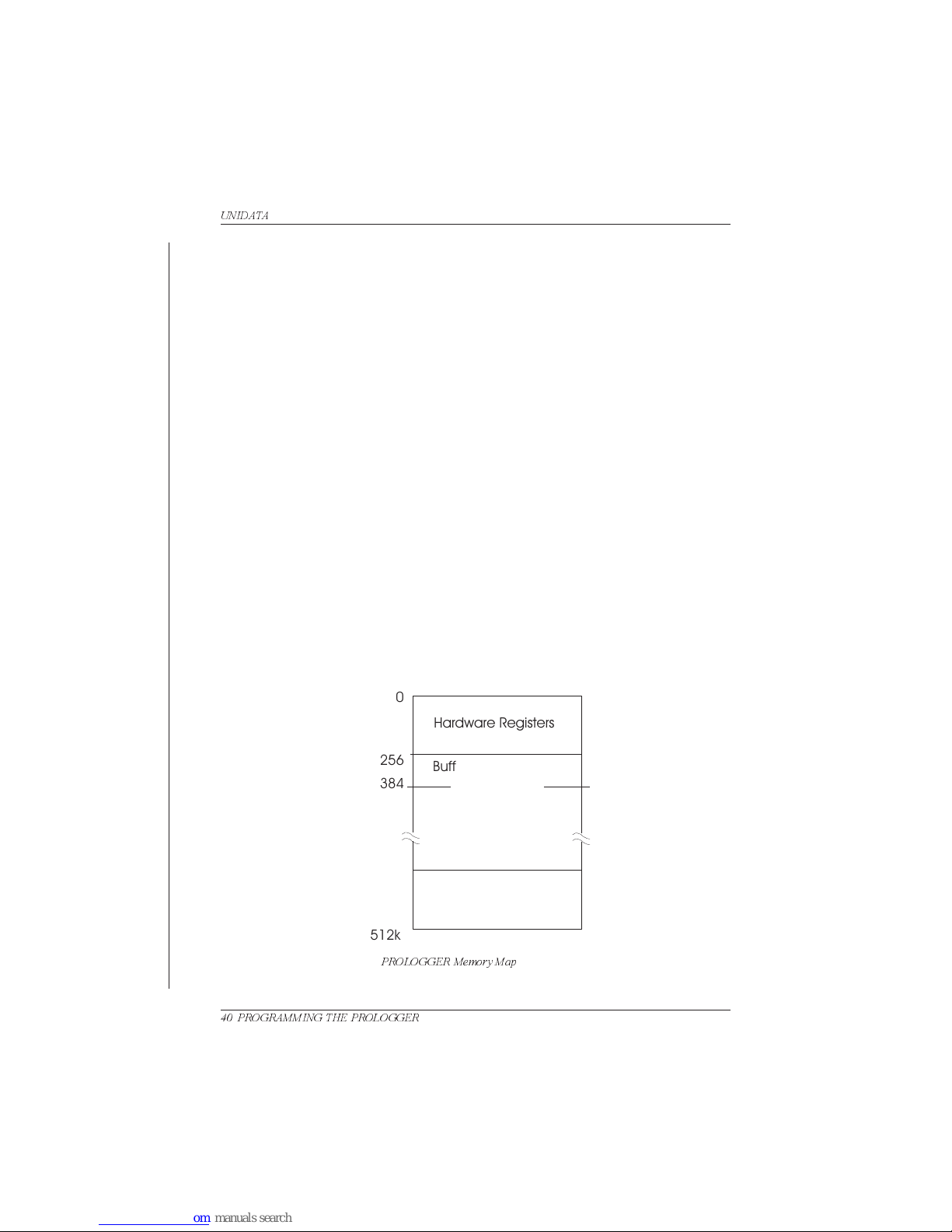

8.1 Memory Layout

The PROLOGGER uses CMOS memory for the:

•

Logger Program - the scheme definition.

•

Buffer Control Table - Storage of pointers controlling the Log Buffer.

•

Hardware Registers - Storage of housekeeping registers.

•

Log Buffer - from the end of the logger program to the end of memory for

recording measured data.

UNIDATA

40 PROGRAMMING THE PROLOGGER

0

256

384

512k

Hardware Registers

Buffer Control Table

Start Log Program

Log Buffer

end of memory

Address

Log Program

PROLOGGER Memory Map

Page 47

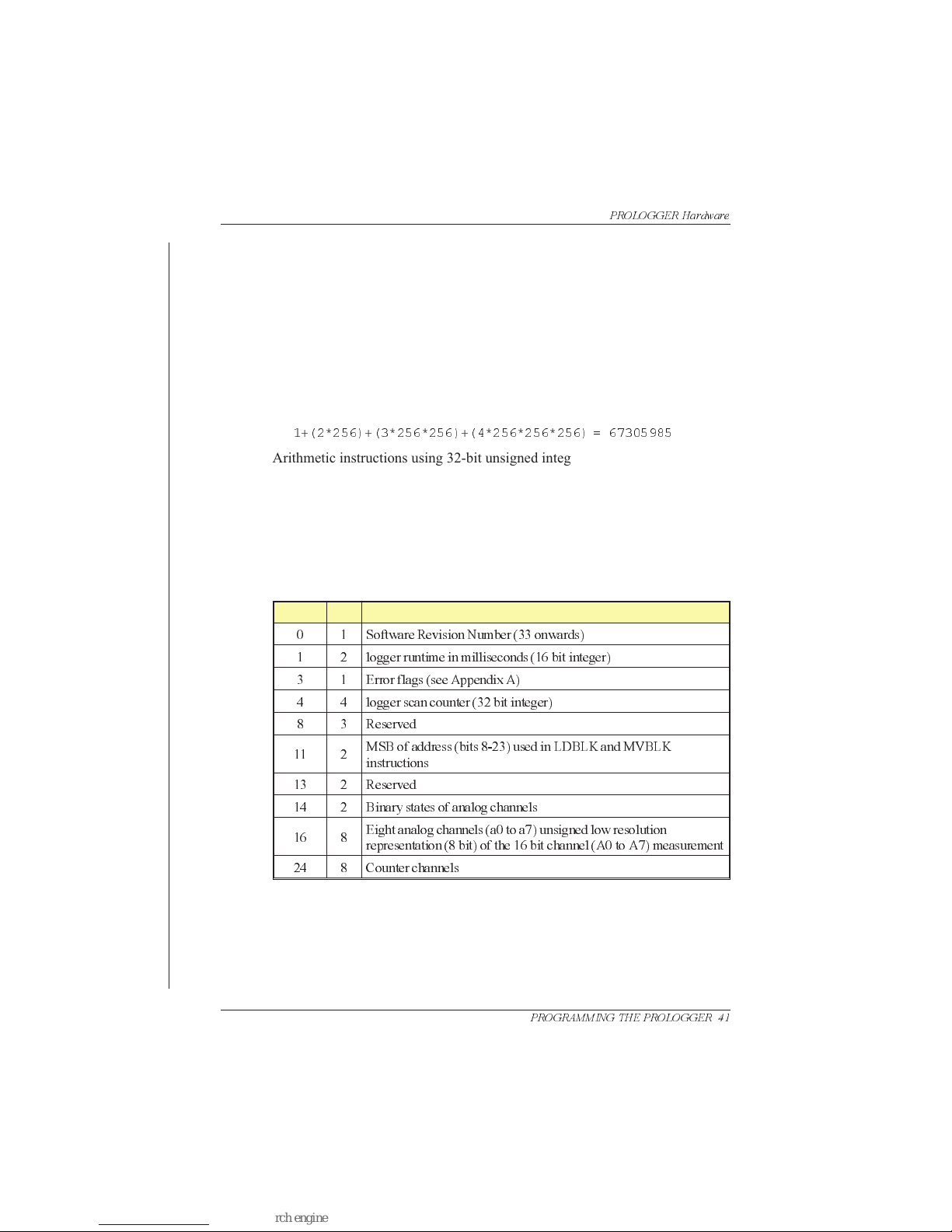

8.2 Hardware Register Information

The hardware register information can be viewed in Test Mode or used by

programmers wishing to write their own unload and analysis programs. The

table below gives a description of each register numbered 0 to 255. For

multiple byte registers the convention used is – least significant byte to most

significant byte. A byte may contain a number from 0 to 255 (8 bits) and for

calculating multiple byte numbers the first byte is added to the second byte

times 256 plus the third byte times 256 times 256, etc.

eg. The four byte number 1234 would give:

1+(2*256)+(3*256*256)+(4*256*256*256) = 67305985

Arithmetic instructions using 32-bit unsigned integers can represent values

from 0 to 4294967295.

8.2.1 PROLOGGER Memory Assignments

The PROLOGGER operating the standard instruction set, has the following

fixed memory assignments in the Hardware Register:

(Pin xx) refers to a pin of the INPUT SIGNALS connector.

Address Size Description

0 1 Software Revision Number (33 onwards)

1 2 logger runtime in milliseconds (16 bit integer)

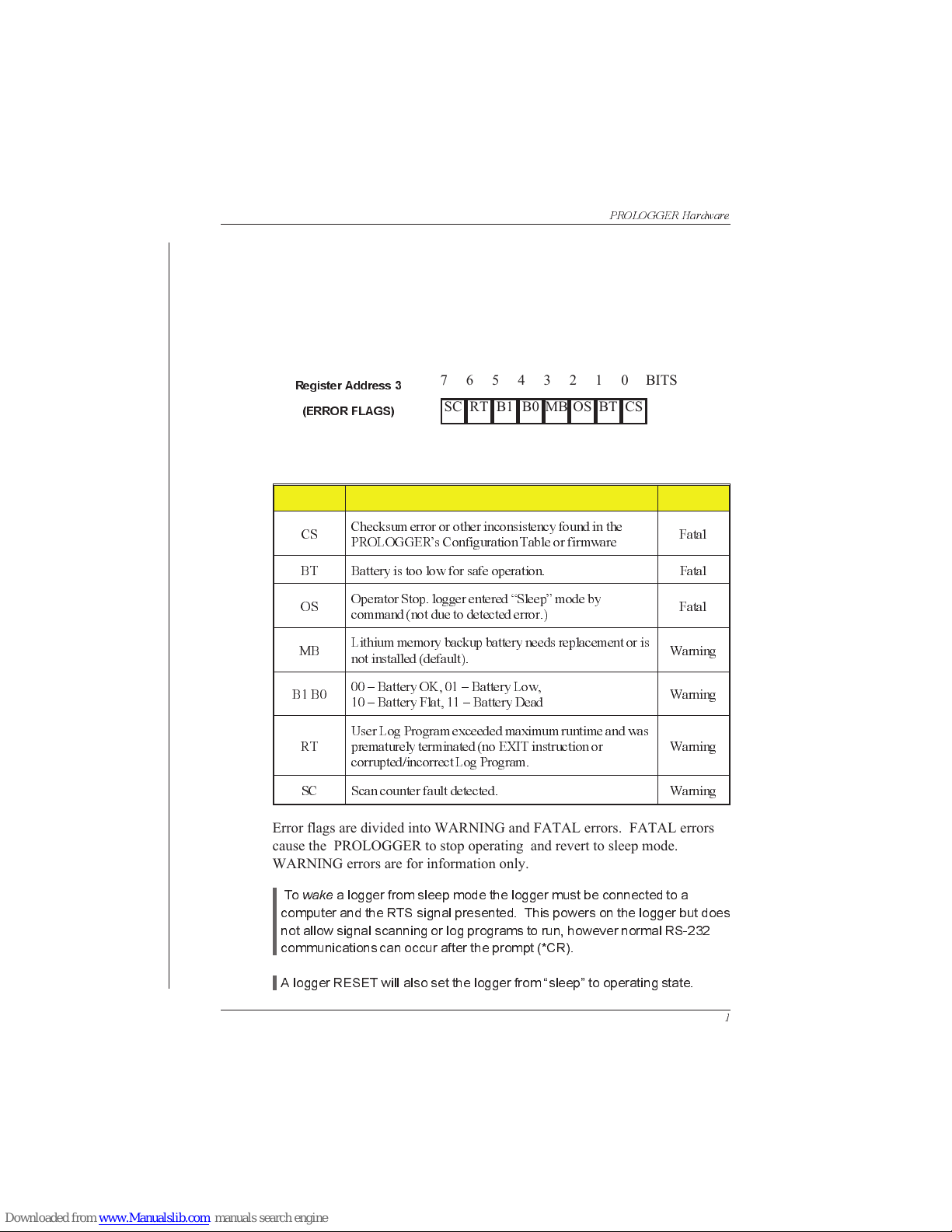

3 1 Error flags (see Appendix A)

4 4 logger scan counter (32 bit integer)

8 3 Reserved

11 2

MSB of address (bits 8-23) used in LDBLK and MVBLK

instructions

13 2 Reserved

14 2 Binary states of analog channels

16 8

Eight analog channels (a0 to a7) unsigned low resolution

representation (8 bit) of the 16 bit channel (A0 to A7) measurement

24 8 Counter channels

PROLOGGER Hardware

PROGRAMMING THE PROLOGGER 41

Page 48

Address Size Description

32 1

Digital input values (normally high)

Bit 0...2 Baud Rate: 000=9600; 101=300; 010=1200

011=2400; 110=4800; 001=19200;

100=38400; 111=76800

Bit 3=0 Log Start (SENSE 0) connected to GND

Bit 4=0 Reserved

Bit 5=0 SDI-12 (SENSE 1) not active

Bit 6 High speed serial DATA 1

Bit 7 High speed serial DATA 0

33 1

User Power Supply status register

Bit 0 = 1 UPS will be ON next scan

Bit 1 = 1 UPS was ON this scan

Bit 2 = 1 UPS is currently ON

Bit 3 unused

Bit 4 = 1 RTS is not active

Bit 5 = DTR not active

Bit 6 = 1 Memory Backup Battery OK

Bit 7 = 1 unused

34 1

Arithmetic status register set by ADD, SUB, MUL,DIV

instructions.

Bit 2 = Arithmetic overflow

Bit 7 = Arithmetic carry

Logic status register set by CMP (compare) instruct.

Bit 4 set Operand 1 =Operand2

Bit 5 set Operand 1 < Operand 2 (unsigned)

Bit 6 set Operand 1 < Operand 2 (signed)

35 1 Reserved

80 6 Software stores Scheme Name here.

200 32

16 x analog channel A0 (Pin 1) signed 16 bit channel (155mV/bit)

232 2

PROLOGGER internal temperature signal±500°C range (0.1°C

resolution/bit)

234 2 10V reference (0.01V/bit) (Pin 35)

236 2 Supply (Battery) voltage scaled 0.01V/bit

238 2 5V scan synchronised reference voltage (0.01V/bit) (Pin18)

UNIDATA

42 PROGRAMMING THE PROLOGGER

Page 49

8.2.2 Logger Scan Counter

This is incremented every scan and when loaded with a scheme represents the

number of scan intervals past 1/1/1980 at 00:00:00.

8.3 PROLOGGER - Program

The PROLOGGER is a programmable data recording unit. The program

resides in the first part of the logger’s main memory (after the Hardware

Registers and Buffer Control Table). It is defined by a user and loaded into

logger memory from the host computer.

The logger program is executed every logger scan (from 0.125 of a second to

5 minutes). The first instruction in the logger program is at Address 384. The

PROLOGGER executes this program until an EXIT instruction is

encountered (opcode = 0), then the logger proceeds to service the RS232 port

of the computer.

8.3.1 PROLOGGER - Operation Sequence

Every logger scan cycle, the logger hardware performs the following

sequence:

1.

Read all channels and store their values in the Hardware Register area

(Address 0 to 255).

2.

Execute the logger program (until EXIT detected).

3.

If an RS-232 connection is sensed, send

*CR

prompt to the Computer

Port and wait 0.5 second for a response.

4.

Shut down the PROLOGGER and await next scan time.

8.3.2 PROLOGGER - Program Instructions

A logger program starts at Address 384 and consists of one or more

instructions. Each instruction is four bytes long (even though some

instructions do not use all four bytes). An instruction takes about 0.5

millisecond to interpret and execute.

PROLOGGER Hardware

PROGRAMMING THE PROLOGGER 43

Page 50

8.4 Typical instructions

TIMED GOTO Timer controlled logging sequences

CONDITIONALGOTO Event controlled logging sequences

LOAD Flexible data storage command

(BLOCK) MOVE Block, Word and Byte move

ACCUMULATE Block summation for averaging

OUTPUT Control output sequences

BLOCK CLEAR Storageinitialization

ADDITION 2 & 4 byte operands, 4 byte result

SUBTRACTION 2 & 4 byte operands, 4 byte result

MULTIPLICATION 2 & 4 byte operands, 4 byte result

DIVISION 2 & 4 byte operands, 4 byte result or 2 byte

result & remainder

SERIAL INPUT/OUTPUT Bi-directional Data Bus read/write

8.5 Buffer Control Table

Information to be recorded by the PROLOGGER is stored in one of eight

memory areas. Normally only one memory area is used and this occupies all

free external memory, starting at Address 1536 and ending at the limit of the

PROLOGGER’s CMOS memory (512k).

For some log programs requiring lookup tables, the storage starting address

may be different.

The storage of channel data in these memory areas (buffers) is controlled by

pointer registers held in the Buffer Control Table. Both standard 16 bit and

extended 32 bit pointers are supported by Revision #32 firmware. The

PROLOGGER‘s LOG instructions uses one table entry for each buffer

(memory area).

An extended (32 bit, 4 byte pointers) Buffer Control Table, illustrated

overleaf, is indicated by setting bit 7 of the flag byte (BFLO) in the Buffer

Control Table entry for the appropriate buffer(s).

UNIDATA

44 PROGRAMMING THE PROLOGGER

Page 51

Standard and extended buffers can be intermixed, but only extended buffers

can log data past the 64K memory limit.

8.5.1 Buffer Format Convention

Information is stored in the data buffers as a sequence of one or more data

bytes. Each sequence is called a ‘log entry’. There may be many log entries in

each buffer.

There are two log entry types:

•

Fixed TIME and SIZE.

•

Variable TIME and fixed SIZE.

n

Fixed TIME and SIZE

This is the most common form of log entry. Each entry is a fixed number of

bytes long and is stored at a fixed interval. For example, recording the wind

speed and ambient temperature every hour would produce fixed TIME and

SIZE log entries.

PROLOGGER Hardware

PROGRAMMING THE PROLOGGER 45

256

260

264

268

272

Current Buffer Pointer

Buffer Status Flags

Reserved

End Buffer Pointer

Start Buffer Pointer

Current Buffer Pointer

Buffer Status Flags

End Buffer Pointer

Start Buffer Pointer

SmallExtended

(up to 64K)

Buffer 0

Buffer 1

76543 210

XT

OV NC

Extended Addressing

BCT (32 bit pointers)

OV=1

Buffer has overflowed

NC=1 Non-Circular Data Buffer

XT=1

(32 bit)

(16 bit)

(16 bit)

(16 bit)

Buffer overflow counter

(24 bit)

LM MC EV OF

OF=1

Buffer overflow

EV=1

Counter active (event

based logging)

LM=1

Log to memory card

MC=1

Memory card active

R

R

Reserved

Page 52

n

Variable TIME and Fixed SIZE

This form is used with event-initiated log entries. The first 4 bytes of the

entry is the time that the event occurred. The time bytes come from Register

Address 4 to 7 followed by the log entry (if any). For example, if an event

initiated log entry stored the instantaneous value channel 1, the entry would

be:

time (4 bytes), channel 1 (1 byte)

UNIDATA

46 PROGRAMMING THE PROLOGGER

Page 53

9 PROLOGGER CONFIGURATION TABLE

The PROLOGGER has a number of operating modes for its analog inputs.

During factory calibration and testing a standard setup and some calibration

factors are permanently written into the logger’s firmware (in ROM). This

part of the firmware is referred to as the Configuration Table and a copy of it

is also located in protected memory. If a different configuration is required,

you may alter parts of the table.

This chapter describes the Configuration Table and its operation.

9.1 Default Configuration Table

The PROLOGGER has a permanent (default) copy of the Configuration

Table in a ROM (Read Only Memory) chip. This default version instructs the

logger to operate with commonly used settings. A user may alter some (or all)

of these default settings to instruct the logger in another manner.

PROLOGGER Hardware

PROLOGGER CONFIGURATION TABLE 47

0

Hardware Registers

Buffer Control Table

Log Buffers

8192

Real Address Virtual Address

Log Program

end of memory

256

384

0

Virtual Address is the

address used by the

LOG program and other

user communications.

Real Address

is the actual

hardware

protected

memory

memory address.

512k

Memory Map of Real and Virtual Addresses.

Page 54

9.2 Memory Layout and Protected Memory

A small portion of the PROLOGGER memory is set aside for housekeeping

functions such as I/O buffers and the LCD Scheme Display List. This portion

of memory is protected (hidden) from normal logger operations and cannot be

read or written by the Log Program or normal GET/PUT commands.

9.3 Configuration Table Layout

The Configuration Table is stored in ROM and may be read by the computer

using the

S/s

commands. The configuration table contains an array of 16 bit

(LSB/MSB) variables which control many aspects of the PROLOGGER’s

operation (such as scan rate). The (i)nt command is used to permanently alter

settings in the configuration table. Some settings may be viewed and adjusted

from the Display/Keyboard.

A copy of the configuration table is also stored at Real Address 0 and may be

read using the protected

R

(ead) command. This copy is not used for

PROLOGGER control, it is available for reference only.

UNIDATA

48 PROLOGGER CONFIGURATION TABLE

Page 55

9.4 PROLOGGER Linear Calibration Correction

The PROLOGGER uses the following linear correction formula:-

y=gx+o

Where: y = corrected value.

x = raw value (from A/D converter).

g = gain coefficient.

o = offset coefficient.

The gain coefficient (g) is made up of the gain coefficients from the

appropriate Gain Drive Table gain stage entry. The same applies to the offset

coefficient (o).

These coefficients represent decimal numbers (e.g. 0.15) which are stored in

the PROLOGGER in a normalised 16 bit form.

n

GAIN

The decimal gain coefficient is multiplied by 8192 to form the PROLOGGER

gain coefficient entry. That is, each bit is 1/8192 or 1.2207E-4.

g = 0.00610

g = 0.00610 * 8192 = 50 (or 32 HEX)

Gain coefficients must be POSITIVE.

n

OFFSET

The decimal offset coefficient is multiplied by 8 to form the PROLOGGER

offset coefficient entry in bits. This offset must take into account the 16 bit

A/D conversion as each offset bit has a magnitude of 1/64516 of the input

signal range (155µV/bit in the -5V to 5V range).

For example:

Gain stage = 1, input range -5 to 5V

each bit = 10,000,000/64516 = 155mV

therefore, if O (offset)= 1.55mV on a gain of 1

= 1.55/0.155 x8=80(50HEX)

Offset coeffiecients may be POSITIVE or NEGATIVE.

PROLOGGER Hardware

PROLOGGER CONFIGURATION TABLE 49

Page 56

9.5 Initialisation via the RS-232

Before the PROLOGGER can be used it must be initialised. In some cases,

the logger may have stopped scanning to conserve its battery. Normally this

initialisation occurs automatically when the logger is loaded with a Scheme.

The command to initialise (or re-initialise) the logger is: