Page 1

Operating instructions

Hydraulic workshop press

WPP 15 E

WPP 15 E

WPP 15 E

Page 2

Publication details

Contents

Product identification

Hydraulic workshop press Item number

WPP 15 E 630 0016

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Germany

Hotline: 0049 (0) 900 19 68 220

(0.49 Euro from German landlines)

Fax: 0049 (0) 951 - 96555-55

email: info@unicraft.de

URL: www.unicraft.de

Publication details..................................................... 2

1 Introduction .............................................................3

1.1 Copyright............................................................ 3

1.2 Customer service................................................ 3

1.3 Disclaimer........................................................... 3

2 Safety....................................................................... 3

2.1 Legend of symbols............................................. 3

2.2 Operator responsibility ....................................... 4

2.3 Operating staff qualification ............................... 4

2.4 Personal protective equipment........................... 5

2.5 Safety identifications on the workshop press ..... 5

3 Intended use ............................................................6

3.1 Foreseeable misuse ........................................... 6

3.2 Remaining risks .................................................. 6

4 Technical data .........................................................6

4.1 Table................................................................... 6

4.2 Environmental conditions ................................... 6

4.3 Type plate........................................................... 7

4.4 Pressure gauge .................................................. 7

5 Transport, packaging, storage...............................7

6 Machine description................................................8

7 Setup ........................................................................8

8 Installation ...............................................................8

8.1 Installing the crossbeam feet and press table ... 9

8.2 Installing the pump unit ...................................... 9

8.3 Installing the pressure gauge............................. 9

Information about the operating instructions

Genuine operating instructions

Edition: 24 March 2016

Version: 1.02

Language: English

Author: DM

Copyright information

Copyright © 2016 Stürmer Maschinen GmbH, Hallstadt,

Germany.

Stürmer is the sole owner of the content of these operating instructions.

Forwarding and reproduction of this document as well

as use and notification of its content is not permitted

without explicit consent. Infringements shall oblige to

payment of compensation.

9 Before commissioning..........................................10

10 Operation .............................................................10

10.1 Adjusting the table height............................... 10

10.2 Setting up the work area................................. 11

10.3 Adjusting the horizontal working position....... 11

10.4 Aligning hydraulic cylinders ........................... 11

10.5 Building up pump pressure............................ 11

10.6 Marking the cylinder limit position.................. 11

10.7 Retracting hydraulic cylinders........................ 12

10.8 Processing the workpiece .............................. 12

11

Maintenance and repairs

11.1 Cleaning maintenance.................................... 13

11.2 Maintenance and repairs................................ 13

12

Disposal, reusing used machines

12.1 Decommissioning........................................... 15

12.2 Lubricant disposal.......................................... 15

.....................................13

.......................15

13 Liability for defects (warranty)...........................16

14 Spare parts...........................................................17

14.1 Spare parts orders.......................................... 17

14.2 Spare parts drawings ..................................... 18

14.3 Hydraulics circuit diagram ............................. 20

15 EU Declaration of Conformity ............................21

Subject to technical modifications and changes.

2 WPP 15 E | Version 1.02

Page 3

Introduction

1Introduction

You have made an excellent choice in purchasing a Unicraft hydraulic workshop press.

Carefully read the operating instructions prior to commissioning.

They describe correct commissioning, intended use

and safe as well as efficient operation and maintenance

of your hydraulic workshop press.

The operating instructions form part of the hydraulic

workshop press. Keep these operating instructions at

the installation location of your hydraulic workshop

press. Please also note the locally applicable accident

prevention regulations and general safety regulations

for the use of hydraulic workshop presses.

1.1 Copyright

The contents of these operating instructions are protected by copyright. Their application is permitted within

the context of the use of the hydraulic workshop press.

Any further use shall not be permitted without written

consent by the manufacturer.

1.2 Customer service

1.3 Disclaimer

All data in these operating instructions has been compiled on the basis of the state-of-the-art, valid standards

and guidelines as well as our many years of expertise

and experience.

The manufacturer shall not be liable for damage in the

following cases:

- Non-observance of these operating instructions

- Unintended use

- Deployment of untrained staff

- Conversions at one's own responsibility

- Technical modifications

- Use of unauthorised spare parts

The actual scope of delivery may deviate from the descriptions and illustrations in this document as a result of

special variants, optional extras or recent, technical

modifications.

The obligations defined in the supply contract shall apply in addition to the general terms and conditions and

the manufacturer's general terms and conditions as well

as the statutory regulations valid at the time of the conclusion of the contract.

Please contact your specialist retailer if you have any

questions regarding your workshop press or require any

technical information. Your specialist retailer will be

happy to support you with specialist advice and information.

Germany:

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Germany

Repair service:

Hotline: 0049 (0) 900 19 68 220

(?0.49 from German landlines)

Fax: 0049 (0) 951 96555-111

Email: service@stuermer-maschinen.de

Spare parts orders:

Fax: 0049 (0) 951 96555-119

Email: ersatzteile@stuermer-maschinen.de

Please submit any information and experiences you

make during application of the machine as these may

be valuable for product improvements.

2 Safety

This section provides an overview of all important safety

packages for personal protection as well as safe and reliable operation. The sections on individual service life

phases contain additional, specifically applicable safety

information.

2.1 Legend of symbols

Safety instructions

Safety instructions in these operating instructions have

been highlighted with symbols. Safety instructions are

indicated by signal terms that express the degree of risk

involved.

DANGER!

This combination of symbol and signal term indicates a directly dangerous situation which may

cause death or serious injury if not averted.

WPP 15 E | Version 1.02 3

Page 4

Safety

WARNING!

This combination of symbol and signal term indicates potentially hazardous situations which may

cause death or serious injury if not averted.

ATTENTION!

This combination of symbol and signal term indicates a potentially hazardous situation which may

cause minor or light injuries if it is not averted.

IMPORTANT!

This combination of symbol and signal term indicates a potentially dangerous situation which may

cause material damage or harm the environment if it

is not averted.

NOTE!

This combination of symbol and signal term indicates

a potentially dangerous situation which may cause

material damage or harm the environment if it is not

averted.

Tips and recommendations

Obligations of the operator:

If the machine is used for commercial purposes, operators are subject to the legal stipulations in terms of occupational safety. For this reason, the safety instructions in

these operating instructions as well as the safety, accident prevention and environmental protection regulations valid at the installation location must be complied

with. In this process, the following shall apply in particular:

- Operators shall obtain information about valid occupational safety regulations and determine additional hazards as part of a risk assessment which

result from the specific operating conditions at the

machine's installation location. Said risk assessment shall be reflected in operating instructions for

machine operation.

- During the entire machine operating time operators must check whether the operating instructions

they created meet current standards and adapt

the operating instructions where necessary.

- Operators shall clearly manage and specify the responsibilities for installation, operation, troubleshooting, maintenance and cleaning.

- Operators must make sure that all persons handling the machine have read and understood

these operating instructions. Operators must also

regularly train staff and notify of the hazards.

- Operators shall provide staff with the required protective equipment and wearing the required protective equipment shall be mandatory.

Tips and recommendations

This symbol highlights useful tips and recommendations as well as information for efficient and reliable

operation.

Observe the safety information in these operating instructions to minimise the risk of personal injury as well

as material damage and prevent hazardous situations.

2.2 Operator responsibility

Operators are defined as the persons who operate the

machine for commercial or profit-based purposes or

provide the machine to third parties for use or application and bear the legal product responsibility in terms of

the protection of users, staff or third parties during operation.

Operators shall also be responsible for maintaining the

machine in a technically perfect condition. For this reason, the following shall apply:

- Operators shall make sure that the maintenance

intervals described in these operating instructions

are complied with.

- Operators shall regularly check that the safety

equipment is fully functional and complete.

4 WPP 15 E | Version 1.02

Page 5

Safety

1

2

2.3 Operating staff qualification

The different tasks described in these operating instructions require different levels of skills in terms of the qualifications of operating staff working with the machine.

WARNING!

Risk from inadequately qualified persons!

Inadequately qualified persons are unable to assess

the risks when handling the workshop press, thus

putting themselves and others at risk of severe or

fatal injuries.

- All work must be carried out by qualified persons

only.

- Keep inadequately qualified persons away from the

work area.

Exclusively persons of whom it can be expected that

they reliably complete assigned tasks shall be authorised to carry out any tasks. Persons whose reactions

have been impaired shall not be authorized, e.g. drug

users, users under the influence of alcohol or medication.

These operating instructions specify the following personal qualifications for the different tasks:

Operating staff:

The personal protective equipment is described in the

following section:

Protective goggles

Protective goggles are intended to protect the eyes

from flying parts.

Protective gloves

Protective gloves are intended to protect the hands

from components with sharp objects as well as friction, abrasion, and deep-cut injuries.

Safety shoes

Safety shoes protect feet from pinching, falling parts

and slipping on slippery surfaces.

Protective clothing

Protective clothing is tight-fitting work clothing without protruding parts, usually with a low tear resistance.

Operating staff has undergone an induction by the operator about the entrusted tasks and potential hazards resulting from improper behaviour. Operating staff shall

exclusively be permitted to carry out any tasks beyond

operation in normal mode if this has been specified in

the operating instructions and operators have explicitly

entrusted operating staff with the task.

Specialist staff:

As a result of specialist training, expertise, experience

and skills in terms of the relevant standards and regulations, specialist staff is able to complete the tasks they

are entrusted with and independently identify hazards

and avert risks.

Manufacturer:

Certain work must be carried out by manufacturer specialist staff only. Other staff is not permitted to carry out

this work. Contact our customer service to have the work

carried out.

2.4 Personal protective equipment

Personal protective equipment is intended to protect the

health and safety of persons at work. Staff must wear the

personal protective equipment indicated in individual

sections of these operating instructions when carrying

out the different tasks on the machine.

2.5 Safety identifications on the workshop press

The following safety identifications have been attached

to the workshop press (Fig. 1) which must be observed.

Fig. 1: Safety identifications

1 Pinching hazard for the upper limbs |

2 Safety information: read operating instructions, wear eye protection,

wear protective clothing and safety shoes

Safety identifications attached to the machine must not

be removed. Damaged or missing safety identifications

may cause errors, personal injury and material damage.

They must be replaced immediately.

If the safety identifications are not visible and comprehensible at first glance, the machine must be stopped

until new safety identifications have been attached.

WPP 15 E | Version 1.02 5

Page 6

Intended use

3 Intended use

The hydraulic workshop press is intended for use in the

automotive and mechanical engineering industry only. It

is suitable for pressing in/out bearings, bushes, embossing, deformation and stamping. The capacity

stated in the technical data must not be exceeded. Do

not apply excessive force to workpieces. Check pressure loads on the pressure gauge.

The hydraulic workshop press must be operated by persons who have been instructed on the use of the machine only.

The intended use shall also include adherence to all information in these operating instructions. Any other use

or use beyond the intended use shall be deemed misuse.

WARNING!

Risk of misuse!

Misuse of the machine may cause hazardous situations.

- Operate the machine within the performance range

stated in the technical data only.

- Do not bypass or disarm safety equipment.

- The workshop press must be operated in technically perfect condition only.

All persons working with the workshop press must be

aware of the remaining risks and observe the instructions to prevent these remaining risks from causing accidents or damage:

- Risk of pinching upper limbs during operation

- It may be necessary to remove installed protective

equipment to configure and equip the machine.

This causes various remaining risks and potential

hazards each user must be aware of.

4 Technical data

4.1 Table

Model WPP 15 E

Compression force 15 t

Foot width x depth 700 x 540 mm

Total height 1616 mm

Inside width 500 mm

Work area 173 - 985 mm

Piston stroke 160 mm

Piston travel 169 mm

Conversions at one's own responsibility or modifications

to the workshop press may invalidate the CE conformity

of the workshop press and this shall not be permitted.

Stürmer Maschinen GmbH shall not assume any liability

for design-based or technical modifications to the workshop press.

Unintended use of the workshop press as well as nonobservance of the safety instructions or operating instructions shall exclude the manufacturer's liability for

any resulting damage or injury and this shall void any

warranty claims!

Any claims resulting from damage due to unintended

use shall be excluded.

3.1 Foreseeable misuse

If the intended purpose of the workshop press is observed, there is no actually foreseeable misuse that may

cause hazardous situations involving personal injury.

3.2 Remaining risks

Weight 91.5 kg

4.2 Environmental conditions

Model WPP 15 E

Operating temperature -5°C to 40°C

Storage temperature -25°C to 55°C

Transport temperatures -25°C to 70°C (< 24 h)

Altitude range max. 1,000 m

Humidity max. 85% relative hu-

midity

Working environment Non-flammable, dry and

free from dust

Even when observing all safety instructions, operation of

the workshop press involves the remaining risks described in the following.

6 WPP 15 E | Version 1.02

Page 7

Transport, packaging, storage

4.3 Type plate

Fig. 2: Type plate of the WPP 15 E hydraulic workshop press

4.4 Pressure gauge

The pressure gauge used features two scales:

- Outer scale [1] shows US tons [1tn. sh.=907.18 kg]

- Inner scale [2] shows metric tons

[1 t = 1000 kg], usual throughout Europe

The hydraulic workshop press must be transported upright only. Do not stack hydraulic workshop presses on

top of each other. Do not place any other objects onto

workshop presses.

Secure the upright hydraulic workshop press on a pallet

using bolts. Said pallet must be correctly secured in the

cargo area. Any loose parts must be securely fastened

to the hydraulic workshop press, secured separately or

safely stored in a separate container.

Blank metal parts have been greased to protect them

from humidity and dirt.

Tips and recommendations

Make sure the corrosion protection is active or

replaced (if necessary) in the event of prolonged

transport.

Transport using industrial trucks/pallet trucks:

The hydraulic workshop press must be positioned on an

even, stable surface (e.g. a pallet) and be secured with

bolts in the event of transport using a suitably dimensioned pallet truck or industrial truck.

Fig. 3: Pressure gauge

5 Transport, packaging, storage

Delivery

Check the hydraulic workshop press for visible transport

damage upon delivery. Immediately notify the haulage

company or retailer if you identify damage on the hydraulic workshop press.

Transport

NOTE!

Take into account the weight of the machine when

transporting and lifting it. Transport and hoisting

equipment must be able to carry the load.

Packaging

All packaging materials and packing aids used for the

hydraulic workshop press are suitable for recycling and

must always be disposed of using material-based recycling systems.

Packaging materials made of cardboard must be shredded and disposed of as part of waste paper recycling.

The foils are made of polyethylene (PE), padding is

made of polystyrene (PS). Dispose of these substances

at a recycling centre or hand them over to the relevant

waste disposal company.

Storage

As a rule, the hydraulic workshop press must be stored

in a clean condition and a dry, clean and frost-free environment. The pistons must be fully retracted.

NOTE!

Protect the machine from humidity.

WPP 15 E | Version 1.02 7

Page 8

Machine description

1

2

3

4

5

13

9

12

11

10

8

7

6

6 Machine description

Figures in these operating instructions may deviate from the

original.

7Setup

The hydraulic workshop press must be set up and operated in dry, well-ventilated indoor areas only.

It must be positioned securely and set up on an even,

stable surface that is free from vibrations and be secured using suitable ground anchors.

Make sure there is a sufficient amount of clearance, approximately 1 m clearance on each side (see Fig. 6) and

the work area is adequately lit.

Fig. 4: WPP 15 E hydraulic workshop press

1 Hydraulic cylinder

2 Pressure gauge

3 Manual hydraulic pump

4 Pump lever for the manual hydraulic pump

5 Switching valve to move the hydraulic cylinder up/

down

6 Trigger valve

7 Pedal

8 Crossbeam feet

9 Frame

10 Press table support bolt

11 Press table

12 Support blocks

13 Stamp

6.1 Optional accessories

- Protective grille

- Pressure barb set

Fig. 5: Correctly set up the hydraulic workshop press

8Installation

Wear head protection!

Wear protective gloves!

Wear safety shoes!

Wear protective clothing!

Do not exceed the maximum pressure of 15 tons

when using the pressure barb set.

8 WPP 15 E | Version 1.02

IMPORTANT!

Page 9

Installation

ATTENTION!

Risk of pinching!

Risk of injury to fingers and hands caused by incorrect installation work on the workshop press.

- Keep in mind the workshop press' weight. Ensure

stable supports and support equipment.

The following parts of the hydraulic workshop press are

provided in disassembled condition in the cardboard

box:

- Crossbeam feet

- Press table

- Pump unit

- Pressure gauge

These parts must be assembled or converted and secured with screws.

8.1 Installing crossbeam feet and press table

8.2 Installing the pump unit

Fig. 7: Installing the pump unit

Step 1: screw the pump unit onto the outside of the

frame using the screws and shims (see Fig. 7).

Step 2: install the pressure lines.

Fig. 6: Installing crossbeam feet

Step 1: secure the crossbeam feet and the two cross-

beams to both sides of the frame using the

screws, shims, spring washers and nuts (see

Fig. 6).

Step 2: insert the support bolts into the frame at the de-

sired height and secure them using the safety

splints. The position the press table onto the

support bolts in the frame.

8.3 Installing the pressure gauge

The machine is delivered with a seal plug instead of the

pressure gauge to prevent escaping oil. Replace it with

the pressure gauge.

Step 1: remove the sealing plug and seal.

Step 2: securely fasten the pressure gauge and seal to

the distributor (see Fig. 8). The connection

must not leak to prevent escaping oil.

Fig. 8: Installing the pressure gauge

WPP 15 E | Version 1.02 9

Page 10

Before commissioning

9 Before commissioning

Step 1: bleed the hydraulic system; for this purpose,

turn the switching valve in anti-clockwise direction. Operate the pump lever several times to remove the air from the hydraulic system. Then

once again close the switching valve.

Wear safety shoes!

Wear protective clothing!

Step 2: check all lines and connections are not leaking.

Check all machine parts are undamaged and

operate as intended.

10 Operation

WARNING!

Risk of death!

Non-observance of these instructions causes a risk

of death.

- Do not work on the hydraulic workshop press under

the influence of alcohol, drugs or medication and/

or if you are very tired or suffer from conditions impairing your concentration.

- The hydraulic workshop press must be operated by

one person only. Additional persons must keep out

of the work area during operation.

ATTENTION!

Risk of pinching!

Incorrectly working on the hydraulic workshop press

causes a risk of injury to fingers and hands.

- Securely position the workpiece for processing on

the support blocks and/or secure it to the support

blocks.

- Do not reach into the operating range of the hydraulic workshop press during operation.

- Do not reach into the press and keep away from

moving parts!

Wear head protection!

NOTE!

Carry out the following before operating the hydraulic workshop press for the first time.

- Check all screw connections on the installed, hydraulic workshop press and retighten if necessary.

- Fill the pump with hydraulic oil or top it up and seal

the filler neck using the yellow, plastic vent plug.

- Remove any air from the hydraulic system.

10.1 Adjusting the table height

ATTENTION!

Risk of pinching!

Pinching may result from the press table not having

been fully supported on the support bolts.

- Check the table is fully supported on the support

bolts before adjusting the table height.

- Make sure the safety splints have been attached

correctly!

Adjust the correct table working height using the support bolts to safely work on the hydraulic workshop

press.

Step 1: lift the press table on one side and keep it in this

position.

Step 2: pull the support bolt from the frame bore on the

side the table was lifted.

Step 3: lift the press table to the desired height or

slightly above the corresponding frame bore.

Step 4: insert the support bolt into the corresponding

frame bore.

Wear hearing protection!

Step 5: lower the press table onto the support bolt.

Step 6: also carry out these steps on the second side so

the table is positioned horizontally.

Wear protective goggles!

10.2 Setting up the work area

Wear protective gloves!

10 WPP 15 E | Version 1.02

The work area must have been set up properly to be

able to safely process the workpiece.

Page 11

Operation

Step 1: position the support blocks on the press table.

Step 2: press the four pins in the support blocks down

on each side so they are fully inserted in the

press table.

This prevents the support blocks from slipping or tilting

during processing.

10.3 Adjusting the horizontal working position

Step 1: align the workpiece so that it is horizontal to the

hydraulic cylinder.

As a result, it cannot tilt during hydraulic cylinder processing.

10.4 Aligning hydraulic cylinders

The hydraulic cylinder can be manually moved to the

desired position over the workpiece. For this purpose, it

can be moved towards the left or right.

For this purpose, operate the pneumatic foot-operated

pump and proceed as described for the pump lever until the required pressure has been built up.

10.6 Marking the cylinder limit position

NOTE!

Monitor both the work area and the piston rod during

the pressing process for the purpose of marking the

limit position to prevent potential damage to the cylinders caused by overloads.

IMPORTANT!

Make sure the workpiece has been centred under

the piston!

10.5 Building up pump pressure

NOTE!

Monitor both the working area and the pressure

gauge during pressing to exclude potential damage

to the press or workpiece caused by overloads.

Step 1: move the switching valve to the right-hand posi-

tion to access the hydraulic cylinder for filling.

Step 2: move the pump lever and the pedal up and

down until the stamp comes into contact with the

workpiece. Fill the hydraulic cylinder with oil.

Step 3: continue to pump until the required pump pres-

sure has built up. For this purpose, monitor the

pressure gauge.

Fig. 9: Cylinder limit position mark on the piston rod

1 - Cylinder

2 - Limit position mark on the piston rod

3 - Piston rod

If the marking on the piston rod [2] becomes visible during the pressing process, the pressing process must be

terminated to prevent potential damage to the cylinder.

In the event of non-observance and continued pumping

the cylinder will be damaged with the result that the cylinder may no longer retract correctly.

Retract the cylinder if the pressing process was insufficient up to the mark (see section 10.7). In this case, elevate the press table and repeat the pressing process

(from section 10.2).

10.7 Retracting hydraulic cylinders

IMPORTANT!

- Do not exceed the press capacity!

- Do not use extensions for the pressure lever

The pump pressure can also be built up using the pneumatic

foot-operated pump.

WPP 15 E | Version 1.02 11

The manufacturer has already configured the

retracting speed of the hydraulic cylinder. Modifications are required or permitted following maintenance work or repairs only. For this reason, the

adjusting screw has been covered.

Tips and recommendations

Page 12

Maintenance and repairs

Step 1: move the rotary button of the switching valve to

the left-hand position.

The hydraulic oil returns from the cylinder back into the

pump oil tank. The hydraulic cylinder returns to its base

position/standby position.

10.8 Processing the workpiece

IMPORTANT!

- Make sure the securing bolts have been installed

correctly!

- Make sure the workpiece has been centred under

the piston!

- Do not exceed the press capacity!

- Do not use extensions for the pressure lever

- Do not reach into the press and keep away from

moving parts!

Step 1: lock the support blocks on the press table.

Step 2: position and/or secure the workpiece on the

support blocks.

Step 3: turn the hydraulic pump control valve in clock-

wise direction until it has been closed completely.

Step 4: operate the hand/foot-operated pump. The

pump is activated and the hydraulic cylinder

lowers.

11 Maintenance and repairs

11.1 Cleaning maintenance

Keep the hydraulic workshop press clean.

IMPORTANT!

- Do not use solvent to clean plastic parts or painted

surfaces. This may cause the surface to disintegrate and cause consequential damage.

Wear protective gloves!

NOTE!

Do not use sharp cleaning tools for any cleaning. This

may cause damage or destroy the machine.

Clean all plastic parts and painted surfaces with a soft,

moist close and some neutral cleaning agent.

Remove any excess lubricant or escaped oil using a

clean and lint-free cloth.

We recommend to have specialist staff clean and check

the hydraulic workshop press at minimum once a year.

Step 5: release the hand/foot-operated pump once the

hydraulic cylinder is over the workpiece.

Step 6: align the workpiece and hydraulic cylinder.

Step 7: operate the foot-operated/hand pump to press

the stamp onto the workpiece. Monitor the pressure gauge display.

Step 8: turn the control valve in anti-clockwise direction

after having processed the workpiece. The hydraulic cylinder returns to its base position/

standby position.

Step 9: remove the workpiece.

11.2 Maintenance and repairs

Maintenance and repairs must be carried out by specialist staff only.

If the hydraulic workshop press is not operating correctly, contact a specialist retailer or our customer service. The contact details are listed in section 1.2 Customer service.

All protective and safety equipment must be immediately reinstalled after having completed repair and

maintenance work.

An authorised person must check the hydraulic pipes

and connections once a year. In the event of increased

usage periods, frequent or increased pressure pulses

or severe external influences the machine must be

checked once every six months.

The hydraulic pipes must be replaced after an operating

period of six years. In the event of increased usage periods and stricter requirements pipes must be replaced

every two years.

12 WPP 15 E | Version 1.02

Page 13

11.2.1Visual inspection

Maintenance and repairs

Maintenance intervals

and operating hours

Daily Visual inspection of the hydraulic workshop press for dirt, clean if necessary

Weekly Visual inspection of the hydraulic workshop press, in particular the press table and support

Weekly Visual inspection of the hydraulic workshop press, in particular the functions of the hydrau-

200 Functional inspection of the entire hydraulic workshop press to verify the machine com-

Annually Have the hydraulic pipes and connections checked by an authorised person. In the event

Maintenance point

bolts:

if necessary, replace damaged components or request repairs

lic components and checking for oil leaks (pump, hoses, cylinders, pressure gauge, etc.):

If necessary, replace damaged components

pletes all steps and operates correctly and safely:

If necessary, request repairs

of increased usage periods, frequent or increased pressure pulses or severe external influences the machine must be checked once every six months.

If necessary, have damaged pipes replaced.

11.2.2 Maintenance tasks

Maintenance intervals

and operating hours

Maintenance task

200

300 Change the hydraulic oil.

When necessary Vent the hydraulic system.

When necessary Top up hydraulic oil and then vent the hydraulic system.

6 years Have hydraulic lines replaced. Every two years in the event of increased usage periods.

Lubricate the hydraulic workshop press (all moving parts, bearings and guides).

11.2.3Recommended processing materials

Processing material Specification Manufacturer/type

(non-binding recommendation)

Hydraulic oil ISO 32

Viscosity from 22 to 25 mm²/s

Grease SO XM 2 OMV SIGNUM M 283 As required

OMV HYDRAL 32

Quantity

11.2.4Lubrication

Machine component Lubrication point Lubrication medium

Manual hydraulic

pump

Stamp

Shaft on the switching valve

Grease:

Apply grease to the listed components using a greased

brush. Remove excess lubricant using a dry and lint-free

cloth.

WPP 15 E | Version 1.02 13

Page 14

Disposal, reusing used machines

11.2.5 Oil changes

Draining oil:

Step 1: open the screw connection on the retracted hy-

draulic cylinder.

Step 2: pump out the hydraulic oil and collect it in a suit-

able container using a hose.

NOTE!

Dispose of the removed oil separately.

Consult the lubricant manufacturer for appropriate

information.

Topping up oil:

Step 1: retract the piston so that it is in the base position.

Step 2: top up new oil via the filler neck.

Step 3: vent the hydraulic system. For this purpose, turn

the switching valve in anti-clockwise direction.

Operate the pump lever several times to remove

the air from the hydraulic system. Then once

again close the switching valve.

12 Disposal, reusing used machines

In your own interest and to protect the environment

make sure that all machine components are exclusively

disposed of in as intended and permitted.

12.1 Decommissioning

Disused machines must be decommissioned immediately to prevent misuse at a later point and putting the

environment or persons at risk.

Step 1: remove all environmentally hazardous process-

ing materials from the used machine.

Step 2: if necessary, disassemble the machine into as-

semblies and components that are easy to handle and suitable for recycling.

Step 3: the machine components and processing mate-

rials must be disposed of using the intended disposal methods.

12.2 Disposing of lubricants

Remove escaping, used or excess grease from the lubrication points featuring lubricant.

Lubricant manufacturers provide disposal information

for the lubricants used. If necessary, request productspecific data sheets.

13 Liability for defects (warranty)

Our customers also represent consumers and they are subject

to statutory regulations. Customers must give us the opportunity to audit the defect and transport the goods to our workshops for auditing upon our request and at our expense. The

following applies to our commercial customers:

(1) Customers shall check delivered goods for defects immediately on delivery. In this process, any identified, obvious damage must be immediately indicated in writing. Transport

damage and missing packaging items shall also be reported

to the haulage company immediately. Any defects that were

not identified despite thorough inspections shall be reported in

writing immediately after having been identified. In this case,

our customer must immediately stop processing and using the

ordered goods. Customers must give us the opportunity to

audit the defect and transport the goods to our workshops for

auditing upon our request and at our expense. After having

carried out a mutually agreed approval, any indication of

defects that were identified upon approval shall be excluded.

The statutory period of liability for defects of two years shall not

apply to commercial customers.

(2) The period of liability for defects shall be one year from the

transfer of risk, providing no other periods have been specified

in agreements or statutory regulations. If the manufacturer of

the item subject to delivery grants a longer period of liability for

defects or a warranty, we shall transfer our resulting rights to

the ordering party/purchaser upon making the purchase. We

can provide an up-to-date list of individual periods of liability

for defects and their terms and conditions as well as warranty

periods and their terms and conditions as specified by the

manufacturer.

(3) In the event of a warranty case we shall carry out improvements or provide replacement deliveries following coordination

with the manufacturer. We shall not be obliged to reimburse

any incurred costs, in particular for transport, travelling, labour

and material caused by transporting the item subject to the

purchase to a different location than the place of fulfilment,

unless specified in the statutory regulations. If any improvements or replacement deliveries as a result of defects fail twice

(provide verification) or if the elimination of the defect would

incur unfeasibly high costs, causing improvements to be

denied, customers shall be permitted to demand either a

reduction of the price or annulment of the contract. We hereby

notify customers that there shall be no liability for defects in

particular for damage caused at customer premises as a result

of misuse or unintended use as well as for damage caused by

subjecting products to damaging, external influences at customer premises (in particular extreme temperatures, humidity,

extraordinary physical or electrical loads, voltage fluctuations,

lighting strikes, static electricity, fire).

(4) If audits as part of claims for liability for defects result in that

the claim has been unjustified, we shall be authorised to

charge a conventionally applicable remuneration for the audit

of the goods as well as shipping costs.

(5) Our warranty shall not apply to natural wear, incorrect use

and storage, incorrect installation or damage caused after the

transfer of risk as a result of incorrect or irresponsible handling,

excessive use, unsuitable processing materials or as a result

of other influences that have not been specified in the contract.

(6) Any repairs carried out by ordering parties/purchasers or

third parties without our consent or incorrect repairs by a service partner that has not been authorised by the manufacturer

shall render any claims for liability for defects void.

14 WPP 15 E | Version 1.02

Page 15

Spare parts

(7) In the event of active, contractual infringements, delays,

non-performance, unauthorised actions or any other legal reason (except infringements occurring prior to conclusion of the

contract) we shall be liable in case of intent or gross negligence only. In the event of culpable damage to life, health or

injuries, in case of culpable infringements of major, contractual

obligations (main contractual obligations) or in the event of

malicious actions and claims for replacement as per Article

437, Section 2 of the German Civil Code (BGB), we shall be liable as per the statutory regulations, whereby our liability in the

event of an infringement of major, contractual obligations shall

be restricted to the typical, foreseeable damage. The term

"major, contractual obligations" shall either be used to specify

a specifically described, paramount infringement of obligations that put the objective of the contract at risk or, in abstract

terms, it shall be defined as an obligation as part of which its

compliance guarantees the correct implementation of the contract on which customers can rely on a regular basis. In the

event of delays, customers shall be permitted to demand compensation or alternatively withdraw from the contract.

(8) In the event of a loss of data we shall exclusively be liable if

our customers can verify that they have backed up the data

once a day (at minimum). The liability for data loss shall be

restricted to the recovery costs if there are backups, unless we

caused the data loss intentionally or as a result of gross negligence. In any other case, except in the event of intent or gross

negligence, liability shall be excluded.

(9) The scope of our liability as per product liability legislation

shall remain unaffected.

14.1 Spare parts orders

Spare parts are available from authorised retailers or directly from the manufacturer. The contact details have

been listed in section 1.2 Customer service.

The following key data is required for queries or spare

parts orders:

- Machine type

- Item number

- Spare parts drawing number

- Position number

- Year of manufacture

- Quantity

- Desired shipping type (post, freight, sea, air, express)

- Shipping address

Spare parts orders without the aforementioned data

cannot be taken into account. The supplier shall determine the shipping type if no relevant data was provided.

Data on the machine type, item number and year of

manufacture is listed on the type plate attached to the

workshop press.

14 Spare parts

DANGER!

Risk of injury caused by the use of

incorrect spare parts!

The use of incorrect or faulty spare parts may cause

risks for operating staff and damage as well as malfunctions.

- Exclusively genuine spare parts made by the manufacturer or spare parts authorised by the manufacturer shall be used.

- Always contact the manufacturer if you are unsure.

Tips and recommendations

The manufacturer warranty shall be rendered void in

the event of a use of unauthorised spare parts.

Example

You are required to order the pressure gauge for the

WPP 15 E workshop press. The pressure gauge is defined as number 38 in spare parts drawing 1.

- Machine type: WPP 15 E workshop press

- Item number: 630 0016

- Position number: 38

Order number: 0-630 0016-38

The order number is made up of the item number, spare

parts drawing number, position number and one digit of

the item number.

- The item number must feature a leading 0 (zero).

- Position numbers 1 to 9 shall also feature a leading

zero.

WPP 15 E | Version 1.02 15

Page 16

Spare parts

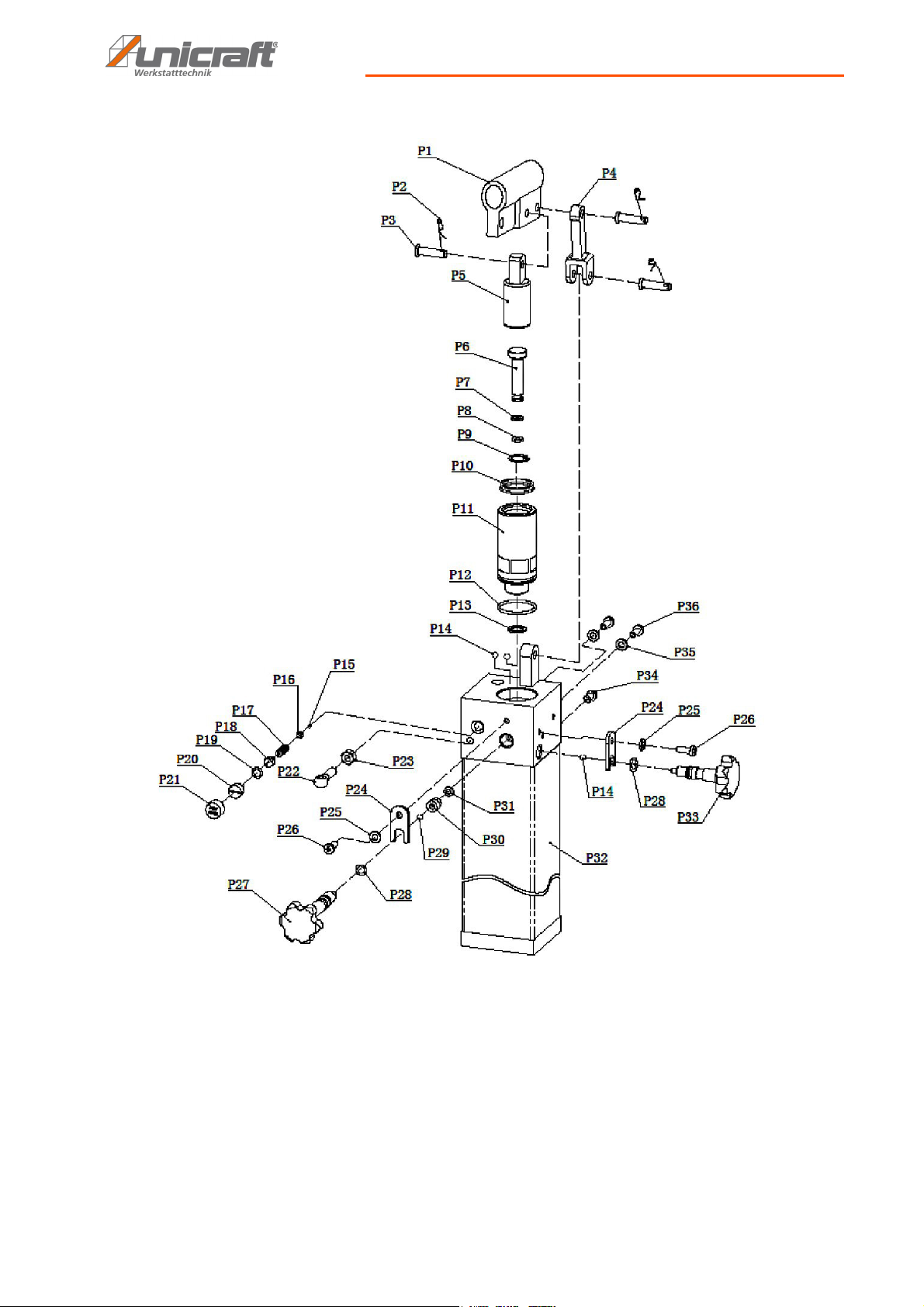

14.2 Spare parts drawings

The following drawings are intended to identify the required spare parts in the event of service. If applicable, submit a

copy of the parts drawing including the highlighted components to your authorised retailer.

Fig. 10: Spare parts drawing 1

16 WPP 15 E | Version 1.02

Page 17

Spare parts

Fig. 11: Spare parts drawing 2

WPP 15 E | Version 1.02 17

Page 18

Spare parts

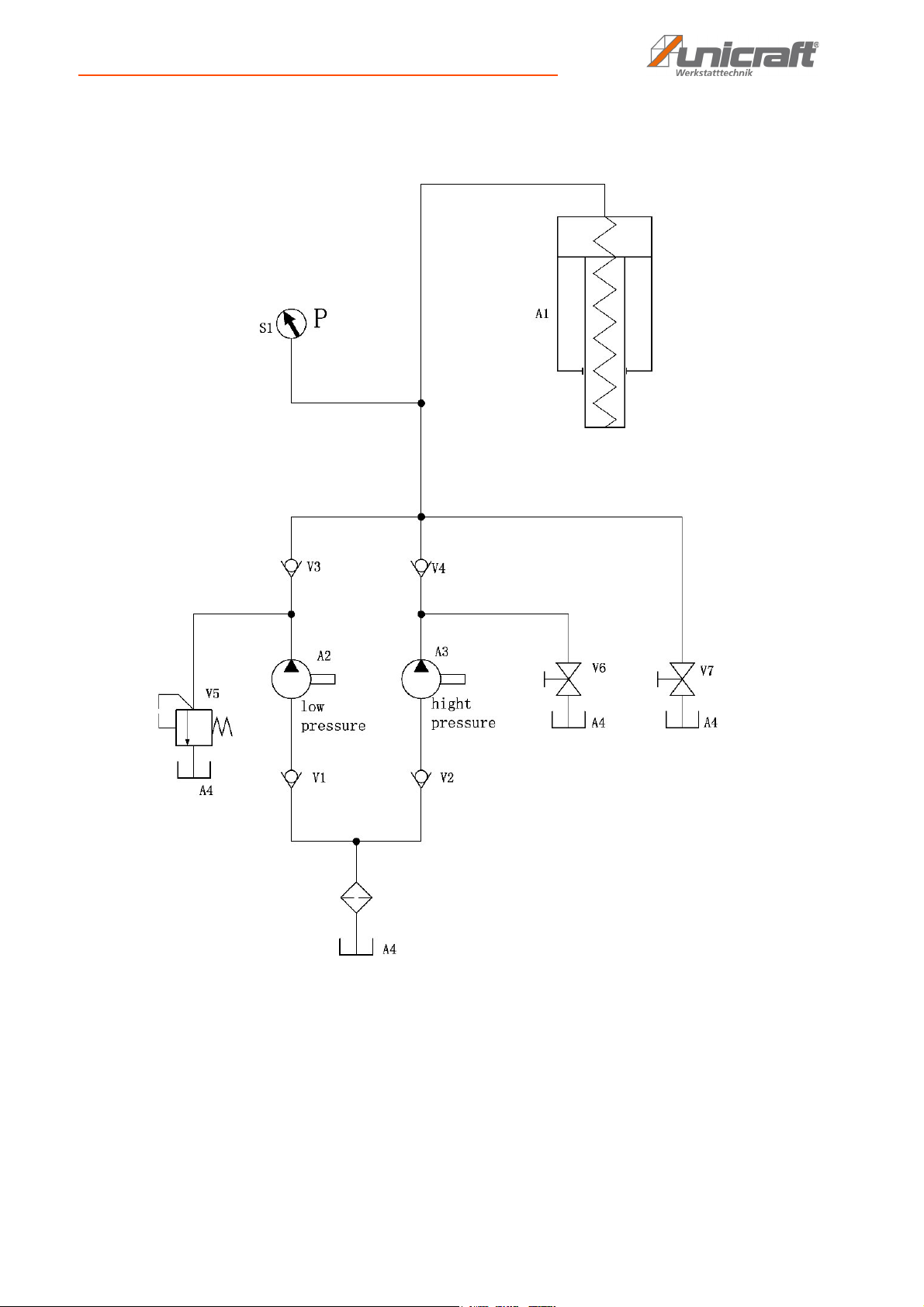

14.3 Hydraulics circuit diagram

Fig. 12: WPP 15 E hydraulics circuit diagram

18 WPP 15 E | Version 1.02

Page 19

15 EU Declaration of Conformity

As per machine directive 2006/42/EC, Annex II 1.A

Manufacturer/seller: Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Germany

hereby declares that the following product

Product group: Unicraft® workshop technology

Machine type: Hydraulic workshop press

Machine designation: WPP 15 E

Item number: 630 0016

EU Declaration of Conformity

Serial number: ____________

Year of manufacture: 20___

complies with all relevant regulations of the aforementioned directive as well as any other, applicable directives (subsequently added) -including the changes applicable at the time the declaration was made.

Relevant EU directive: 1997/23/EC Directive for pressurised devices (until 18.07.2016)

2014/68/EU Directive for pressurised devices (from 19.07.2016)

The following, harmonised standards have been applied:

DIN EN ISO 12100:2010 Safety of machinery - general design principles -

Risk assessment and reduction of risks

DIN EN 693:2009 Tooling machines - safety - hydraulic presses

DIN EN 1494:2009-05 Mobile or movable hoisting devices and related equipment

Responsible for documentation: Technology department, Dr.-Robert-Pfleger-Str. 26, D-96103 Hallstadt

Hallstadt, 30.04.2015

______________________

Kilian Stürmer

General Manager

WPP 15 E | Version 1.02 19

Page 20

www.unicraft.de

Loading...

Loading...