Instruction handbook

UniCarriers Europe AB

SE-435 82 Mölnlycke

Sweden

Phone +46 (0)31 98 40 00

info@unicarriers.com

www.unicarriers.com

P/N: 159147, Rev. A

Subsidiary/Dealer

GB

PLL • PLE • PSD • PSL • PS • PSH • PLP • TS

The content of this manual is protected by copyright law and may not be copied,

fully or in part, without written permission.

The material has undergone careful examination with regard to correctness. We

reserve the right to make changes.

©Copyright UniCarriers Europe AB, 2015

TABLE OF CONTENTS

01 INTRODUCTION................................................................................................... 6

Instruction Handbook ...................................................................................... 6

02 TRUCK MODIFICATION................................................................................. 7

Truck modification.............................................................................................. 7

03 ENVIRONMENTAL CONSIDERATIONS............................................ 8

We respect the environment...................................................................... 8

04 THE SUPERVISOR............................................................................................. 9

Foreman’s responsibility............................................................................... 9

05 TRUCK DRIVER................................................................................................. 10

Authorization to drive a truck.................................................................. 10

Driver requirements....................................................................................... 10

Inspection of the truck ................................................................................. 10

06 MACHINE PLATES.......................................................................................... 11

Explanation of machine plates .............................................................. 11

Location of machine plates...................................................................... 13

07 DESCRIPTION OF THE TRUCK........................................................... 14

Powered trucks PLL, PLE, PSL, PSD, PS,

PSH .................................................................................................................... 14

PLL, PLE, PSL, PSD, PS, PSH driver

environment.................................................................................................. 15

PLP pedestrian truck .................................................................................... 16

PLP driver environment.............................................................................. 16

TS pedestrian truck ....................................................................................... 17

TS driver environment ................................................................................. 18

Trucks equipped with folding platform............................................. 20

Options.................................................................................................................... 21

08 BATTERY................................................................................................................. 22

Specifications..................................................................................................... 22

Battery changing.............................................................................................. 22

Maintaining and changing the battery.............................................. 25

Battery servicing .............................................................................................. 27

09 TRUCK COMPUTER (ATC)...................................................................... 28

Introduction.......................................................................................................... 28

General................................................................................................................... 28

Symbols and characters on the display.......................................... 28

TABLE OF CONTENTS

Display of battery status............................................................................. 29

Error messages ................................................................................................ 29

Change language............................................................................................ 29

Warnings................................................................................................................ 30

Menus...................................................................................................................... 31

Navigation in menus ..................................................................................... 31

10 DRIVING INSTRUCTIONS......................................................................... 33

Driving instructions PLL, PLE, PSL, PSD, PS, PSH,

PLP ..................................................................................................................... 33

Driving instructions TS ................................................................................ 36

11 GENERAL LOADING AND UNLOADING

INFORMATION.................................................................................................... 38

Responsibility for the load ........................................................................ 38

Responsibility for others............................................................................. 38

Maximal load ...................................................................................................... 38

Picking up a load ............................................................................................. 38

2-pallet handling............................................................................................... 38

12 GENERAL INFORMATION CONCERNING

STACKING.............................................................................................................. 39

Stacking.................................................................................................................. 39

13 MAINTENANCE OF THE TRUCK........................................................ 40

Daily maintenance (before each shift)............................................. 40

Daily Service (after each shift) .............................................................. 40

Weekly inspection .........................................................................................41

Preventive maintenance ............................................................................ 41

14 SERVICING AND MAINTENANCE ..................................................... 42

Service technician .......................................................................................... 42

Safety instructions for maintenance..................................................42

Maintenance intervals.................................................................................. 42

Maintenance instructions........................................................................... 55

15 SAFETY REGULATIONS............................................................................ 60

The authority and obligations of the truck

driver.................................................................................................................. 60

Getting in and out............................................................................................ 60

Driving the truck ............................................................................................... 60

Transportation security................................................................................ 64

TABLE OF CONTENTS

Lifting the forks.................................................................................................. 65

Normal operating conditions................................................................... 65

Exceptional operating conditions......................................................... 65

Work in hazardous environments ....................................................... 65

Parking.................................................................................................................... 65

When lifting the truck....................................................................................66

Assembling and putting into service ................................................. 68

Temporarily taking the truck out of service................................... 68

Taking the truck out of service............................................................... 69

Swinging loads.................................................................................................. 69

Installing the fire extinguisher ................................................................ 69

In the event of accidents............................................................................ 70

Noise/Sound levels........................................................................................ 70

Vibrations .............................................................................................................. 70

Climatic conditions ......................................................................................... 70

Work platforms.................................................................................................. 70

Overhead guard ............................................................................................... 70

Protective shoes .............................................................................................. 70

Lighting ................................................................................................................... 70

Additional units/Trailers .............................................................................. 70

Safety and warning signs.......................................................................... 71

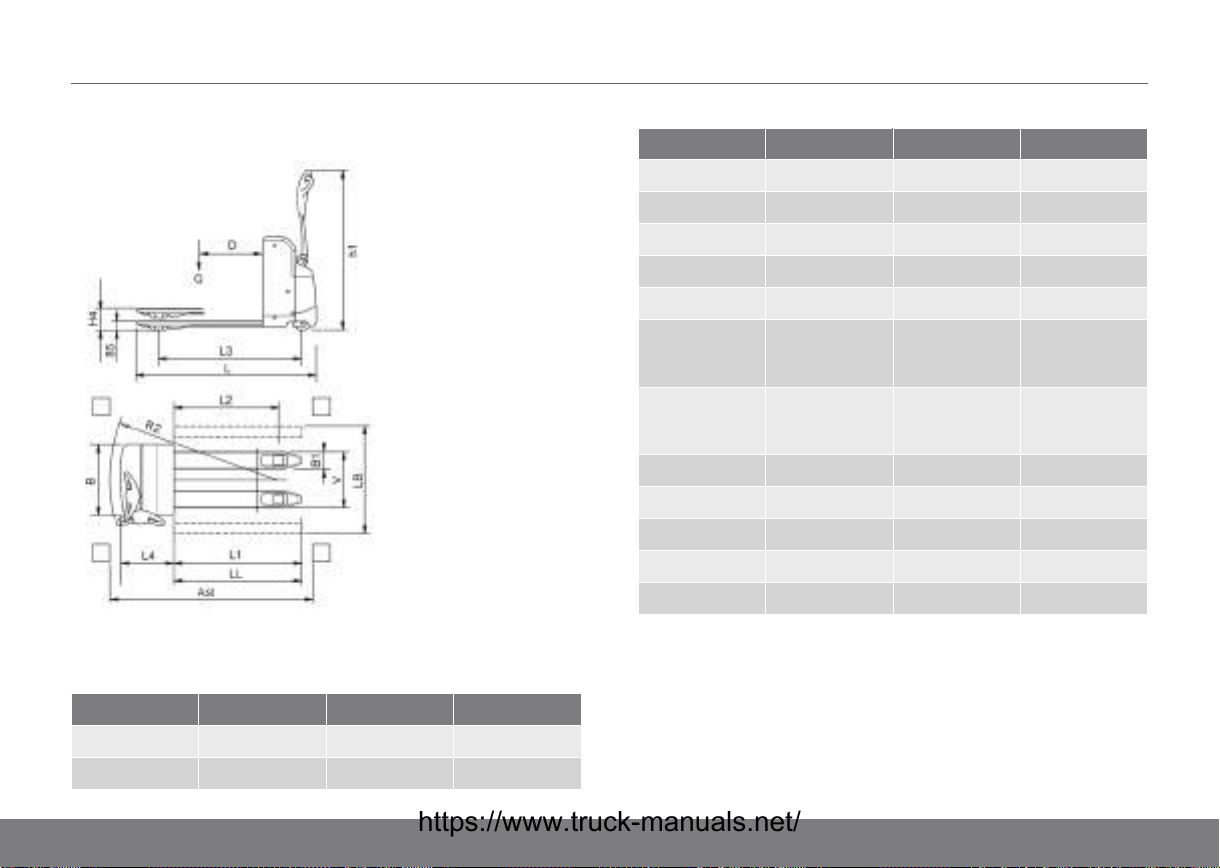

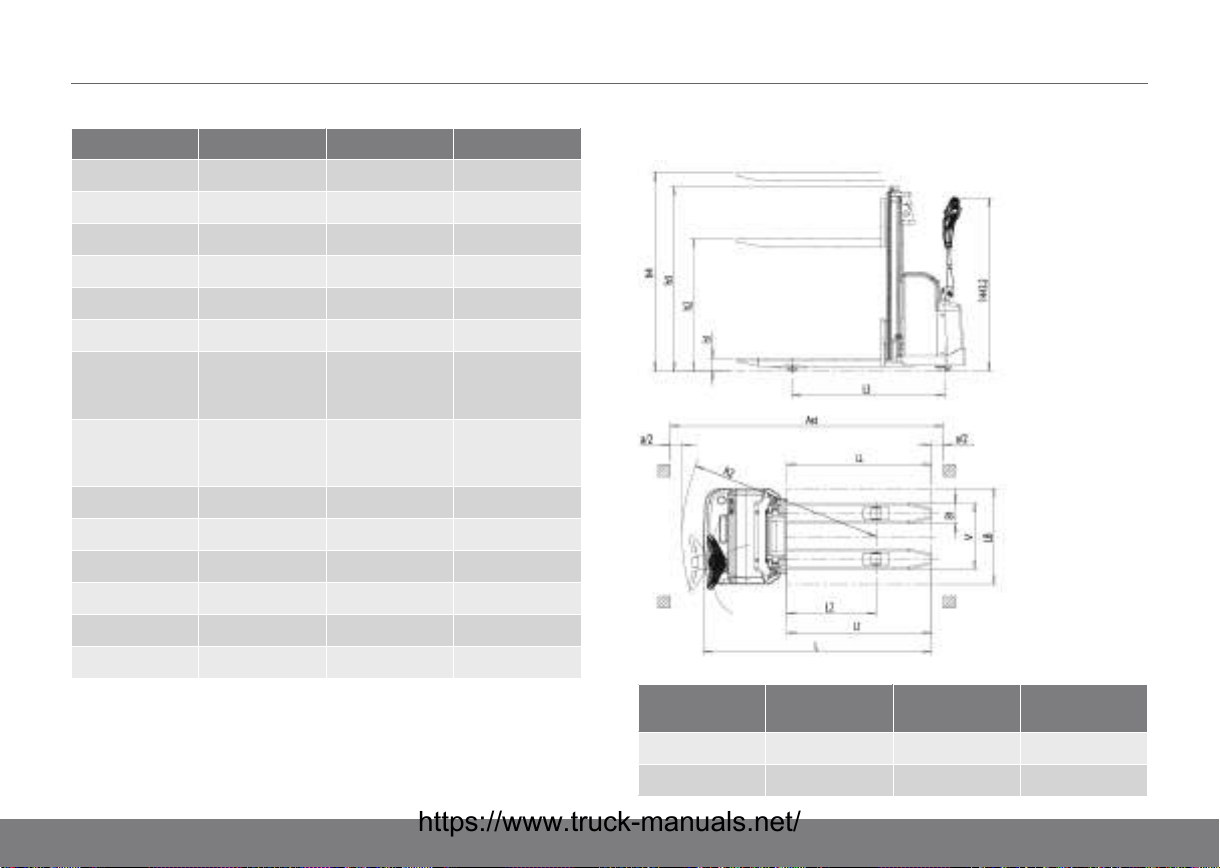

16 DIMENSIONS ....................................................................................................... 75

Dimensions PL*/PS*..................................................................................... 75

Dimensions PS, PSH ................................................................................... 77

Dimensions PLP .............................................................................................. 79

Dimensions TS.................................................................................................. 80

17 WEIGHT.................................................................................................................... 82

Weight PLL, PLE, PSL, PSD, PS, PSH.......................................... 82

Weight PS, PSH............................................................................................... 82

Weight PLP.......................................................................................................... 82

Weight TS............................................................................................................. 82

18 ORDERING HANDBOOKS AND MANUALS.............................. 84

Ordering a Spare Parts Manual............................................................ 84

01INTRODUCTION

Instruction Handbook

This Instruction Handbook contains information that you, as

user of the truck, must be aware of in order to avoid/minimise

the risk of injury/damage to yourself or the truck. You are also

responsible to the company management, other people and

objects in your environment. You should therefore carefully read

all the way through this handbook before starting the truck for

the first time.

The Instruction manual describes a truck with standard

equipment, customer modifications may have been fitted.

It is not obvious that the options that are described in the

Instruction Handbook are suitable for all truck models. Contact

your truck supplier for information.

Our products are constantly being developed and renewed, we

therefore reserve the right to make alterations without prior

notice.

We have been manufacturing trucks since 1958. Quality,

operational safety and innovation have made us a leading

worldwide truck supplier.

Thank you for choosing us as your truck supplier.

Service

As the owner of one of our products, you are also welcome to

contact our service department.

We offer support and advice for any problems that may arise

and assistance with servicing and ordering of replacement

parts. Refer to the nearest authorised sales agent or service

workshop for assistance.

Genuine Parts

The reliability that we promise is contingent upon using our

original spare parts. Only our genuine replacement parts

guarantee correct operation, long life and the right to a

warranty.

Our truck driving courses

The importance of goods handling to companies and society in

general increases every year. At the same time, trucks are

being equipped with ever more advanced technical solutions. It

is therefore important that the operator, who has a key role to

play in goods handling, is given the correct conditions to

operate as safely and efficiently as possible. Statistics show

that the number of incidents decreases significantly when a

truck operator has been properly trained. To receive information

on current training offers, please contact your local authorised

representative, preferably, or, if necessary, another authorised

dealer.

Declaration of conformity

UniCarriers Europe AB, SE-435 82 Mölnlycke, Sweden,

guarantees under its own liability that the product delivered

meets relevant safety requirements in Directives 2006/42/EC

and 2004/108/EC. Risk analysis is based on ISO 3691 and EN

1726. The Declaration of conformity certificate accompanies

every machine, and it is important that it remains with the truck.

6

TRUCK MODIFICATION02

Truck modification

NOTE!

Unauthorized truck modification is not permitted.

No modifications or changes to powered industrial trucks that

can affect areas such as capacity, stability or safety

requirements for the truck may be made without advance

written authorisation from the manufacturer, its authorised

representatives or a successor to these. Contact your local

authorised dealer before any modification or change is made to

your industrial truck that may affect, for example, braking,

steering, visibility and connection of separate load aggregates.

Once permission has been granted by the manufacturer,

authorised representative thereof or successor to these, the

plate indicating the truck's capacity, decals, labels and

operating and instruction handbooks must also be changed

accordingly.

Only in the event that the manufacturer is no longer in business

and there is no successor to the company's stakeholders may

the user implement a modification or alteration to a powered

industrial truck. This applies on the condition that the user:

• arranges for the modification or alteration to be designed,

tested and implemented by one or more engineers who

are experts in industrial trucks and their safety

• maintains a permanent record of the design, test(s) and

implementation of the modification or alteration

• approves and makes appropriate changes to the capacity

plate(s), decals, tags and Instruction Handbook

• affixes a permanent and readily visible label to the truck

stating the manner in which the truck has been modified or

altered, together with the date of the modification or

alteration, and the name and address of the organization

which performed the task.

7

03ENVIRONMENTAL CONSIDERATIONS

We respect the environment

The majority of our products consist of steel, and can be

completely recycled.

Environmental impact

All products have an impact on the environment throughout

their entire life cycle.

The consumption of energy when in use is one of the most

important factors that influences the environment.

Through correct care, maintenance and use the consumption of

energy can be reduced, thereby reducing the environmental

impact.

Waste

Waste material in conjunction with repairs, maintenance,

cleaning, or scrapping, must be collected and disposed of in an

environment-friendly way and in accordance with the directives

of respective countries.

Such work should only be carried out in areas intended for this

purpose.

Recyclable material should be taken care of by specialised

authorities.

Environmentally hazardous waste, such as oil filters, hydraulic

oil, batteries and electronic equipment, can, if handled

incorrectly, have a negative effect on the environment and

human health.

8

THE SUPERVISOR04

Foreman’s responsibility

1. It is the responsibility of the supervisor, on behalf of the

company management, to ensure that the truck is driven

and used correctly.

2. The supervisor is responsible for compliance with the

requirements placed on the driver, refer to Driver

requirements page 10.

3. It is the duty of the supervisor to instruct and to ensure that

driver instructions are followed.

4. The supervisor must supply, and the truck operator must

sign for, the following relevant instruction handbooks.

The supervisor must also read and be familiar with the

appropriate instruction handbooks.

The fork lift truck must be insured with at least third party

insurance if this is a national authority requirement.

Maintenance personnel

NOTE!

Daily inspection and certain servicing shall be

carried out by the operator once he or she has

received sufficient training in the truck's construction

and care. Ongoing routine servicing should be

performed by an authorised service organisation. In

order to maintain effective and adequate servicing

for the truck, contact an authorised dealer, who can

offer a service agreement for routine inspection.

Conditions of use

The truck may be driven under the following conditions:

• indoors

• on a flat, hard and smooth surface

• with the maximum floor loading checked and not exceeded

• normal operating temperature, refer to Climatic conditions

page 70

• good visibility, adequate lighting and approved routes.

• driving with the load lowered

WARNING!

A truck operating in an area where there is a risk of

fire or explosion, or in any other high-risk area, must

be specially equipped for the purpose. The truck is

normally not equipped for these environments.

9

05TRUCK DRIVER

Authorization to drive a truck

The employer must ensure that the employee has the required

training and knows what must be observed in order to avoid

risks while working. The employer must take into consideration

an employee's suitability for the work in question. It is therefore

necessary that a person engaged as a driver completes the

appropriate truck driver training, both theoretical and practical,

that corresponds to the work assignments the driver is expected

to undertake after training. Further training may be required in

the event of major changes in work assignments. The employer

should give the employee written authorization to drive the truck

- as well as a written outline of the extent of his/her duties.

Driver requirements

The truck driver shall have the mental and physical capacity

required for the job. The driver shall also be aware of everything

that is relevant to the handling and manoeuvring of the truck,

traffic regulations and any other relevant instructions. The driver

shall have the permission of the supervisor to drive the type of

truck in question and be specially trained for the work and the

traffic conditions involved.

The responsibilities of the driver in specific markets

The following apply in respect of the driver's responsibilities

concerning the use of fork lift trucks:

• Australia: Users shall follow the requirements of AS

2359.2.

• North America: Users shall follow the requirements of the

applicable part of ANSI/ITSDF B56.

Inspection of the truck

• The driver of the truck is responsible to the supervisor, for

ensuring that the truck is kept in good working order.

• Daily maintenance shall be carried out carefully before the

start of each shift. See section Maintenance of the truck

page 40.

• Any faults must be reported to the supervisor immediately.

• The truck must be kept clean and maintained so that it is

always in good working order. It must be checked at

regular intervals in accordance with the service

instructions.

• Check that no safety equipment has been modified or put

out of service.

For optimum performance and so as not to invalidate the

warranty, use only genuine replacement parts!

10

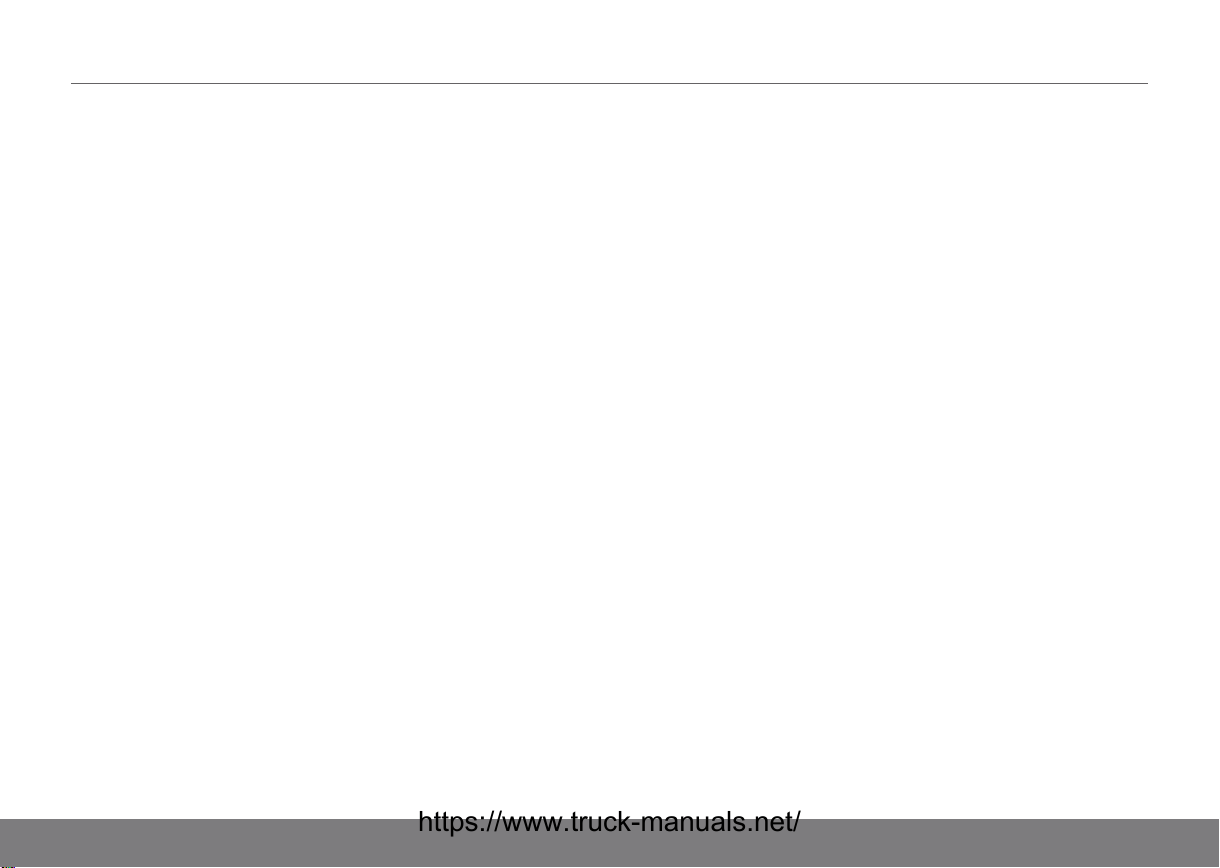

Explanation of machine plates

European machine plates

The Machine plate contains important information. Read it

carefully! The permitted load shall not be exceeded. The stated

load limit assumes that the load is evenly distributed on the

forks.

Figure 1. Machine plates

1. Model designation

2. Type Serial No./Version

(S=Special version)

3. Year of manufacture

4. Weight without battery

5. Minimum battery weight

6. Maximum battery weight

7. Battery voltage

8. Permitted load

9. Distance to centre of

gravity

10. Reference number (year and

nonth of manufacture)

Figure 2. Load limit plates

1. Actual capacity, Q

2. Load centre distance, D

3. Lift height for fork lift, H

4. Lift height for straddle lift

WARNING!

For the truck to fulfil stability requirements, the

instructions on the load limit plate must be

respected.

MACHINE PLATES06

5. Load limit for straddle lift,

Q1

6. Load limit for fork lift with load

on straddle lift, Q2

7. Load limit for fork lift without

load on straddle lift

8. Maximum lifting height for

fork lift with load on straddle

legs

11

06MACHINE PLATES

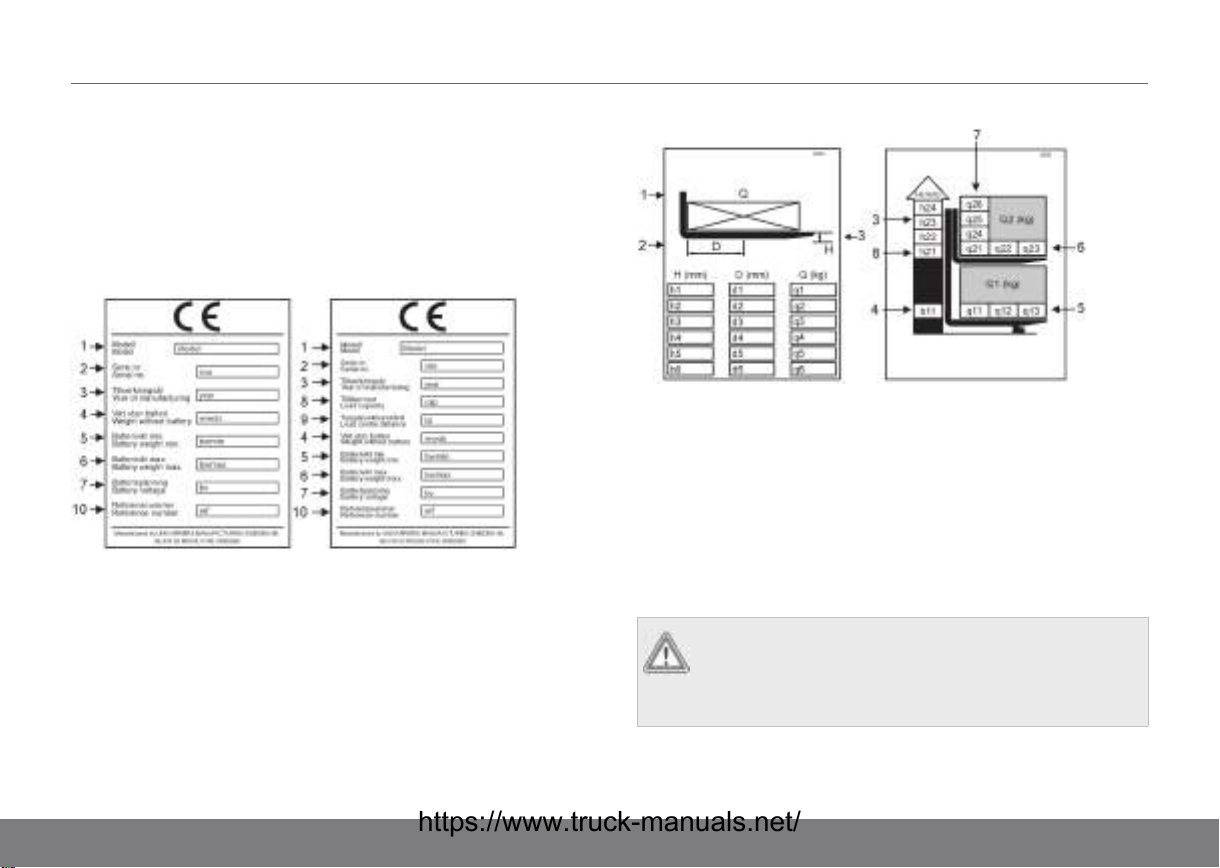

USA machine plates

The machine plate contains important information. Read it

carefully! Permitted loads may not be exceeded. The stated

load limit assumes that the load is evenly distributed over the

forks.

Figure 3. Machine plates

1. Model designation

2. Type Serial No./Version

(S=Special version)

3. Truck Type

4. Year of manufacture, week

and guarantee limit in

months

5. Weight without battery

6. Weight with battery

7. Minimum battery weight

8. Maximum battery weight

9. Battery voltage

10. Battery type maximum

capacity

11. Actual capacity, Q

12. Load centre distance, D

Figure 4. Load limit plates

1. Actual capacity, Q

2. Load centre distance, D

3. Lift height for fork lift, H

4. Lift height for straddle lift

5. Load limit for straddle lift,

Q1

WARNING!

To ensure the machine meets the stability

requirements always ensure the the lift capacity

shown on the machine plate is observed.

6. Load limit for fork lift with load

on straddle lift, Q2

7. Load limit for fork lift without

load on straddle lift

8. Maximum lifting height for

fork lift with load on straddle

legs

9. Serial number of the

attachment

12

MACHINE PLATES06

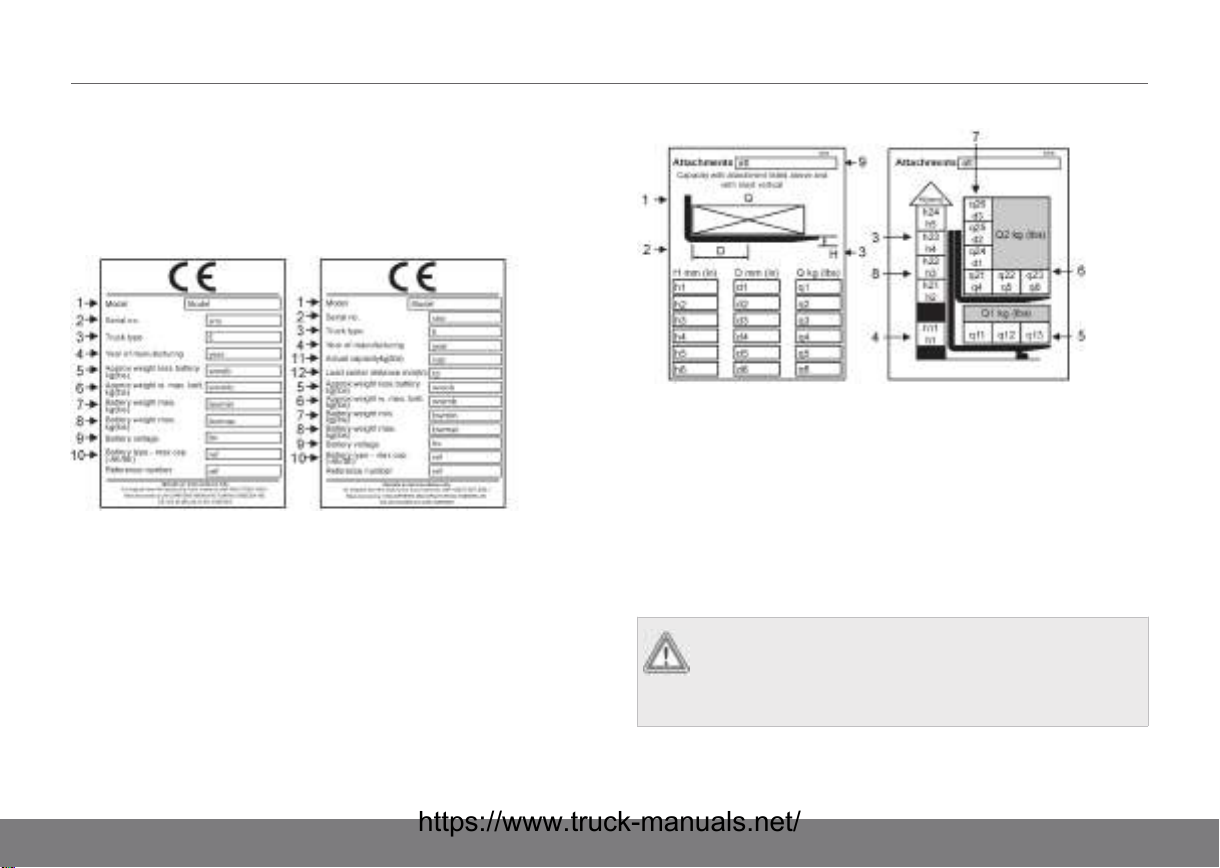

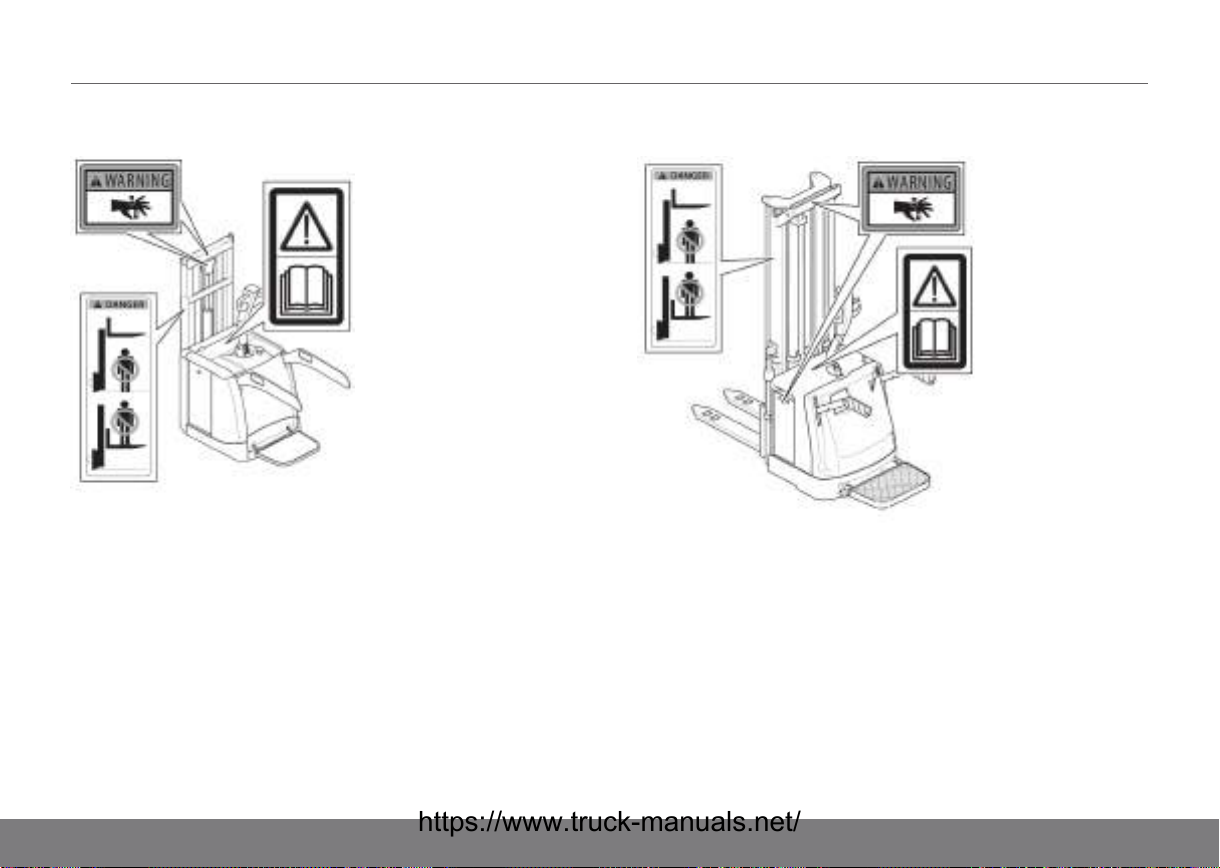

Location of machine plates

Location of machine plates

PSD, PSL PS, PSH

TS PLE

PLP

A. Machine plate

B. Load limit plate

13

07DESCRIPTION OF THE TRUCK

Powered trucks PLL, PLE, PSL, PSD, PS,

PSH

PL* is an electric truck for walking operators, specially adapted

for low level transportation, picking and handling at loading

bays. The truck can be equipped with a low mast for ergonomic

picking height or long forks for the transport of several load

carrier types. Usual loads are pallets or roller containers. The

trucks are intended for use indoors on hard level surfaces.

equipped with straddle lift for the transport of double load

carriers. Usual loads are pallets or roller containers.

PS* is an electric truck for walking operators, specially adapted

for stacking, short to medium distance internal transportation,

order picking and handling at loading bays. Certain trucks are

14

DESCRIPTION OF THE TRUCK07

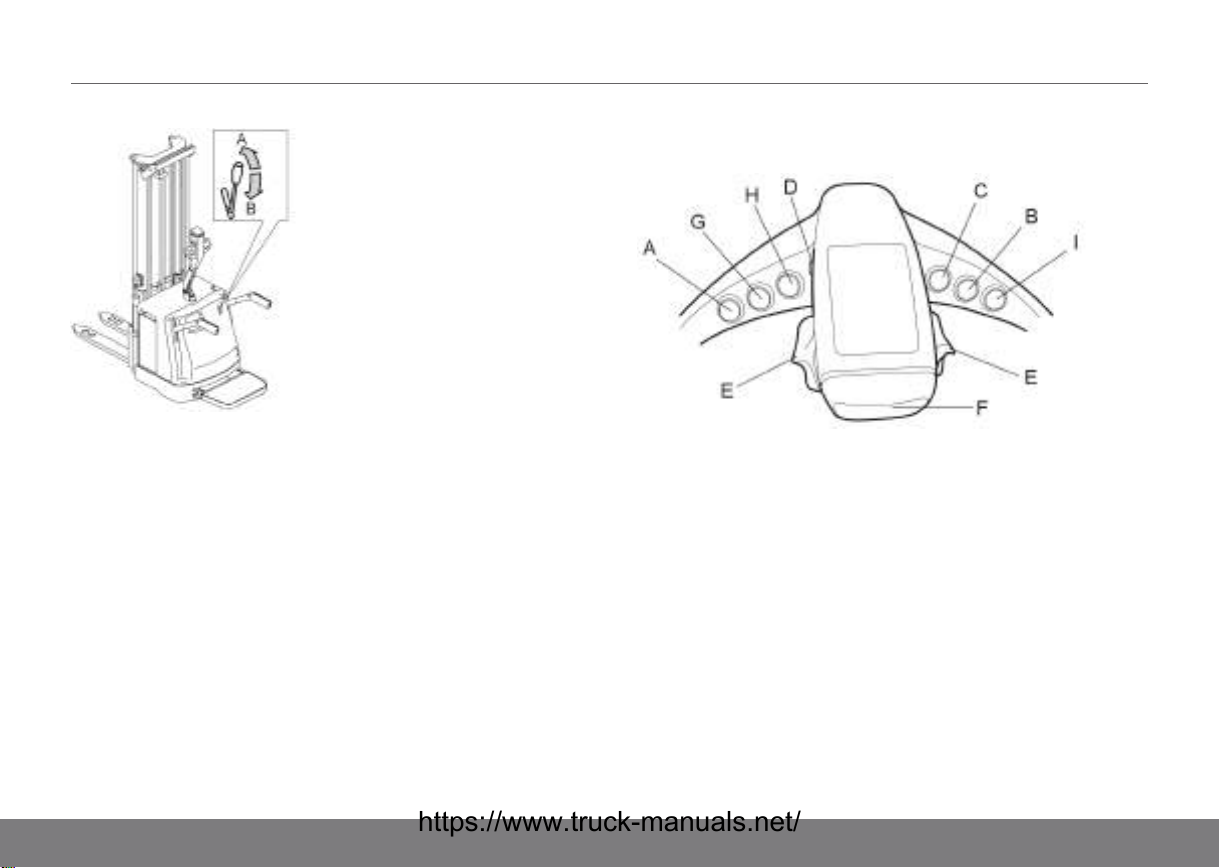

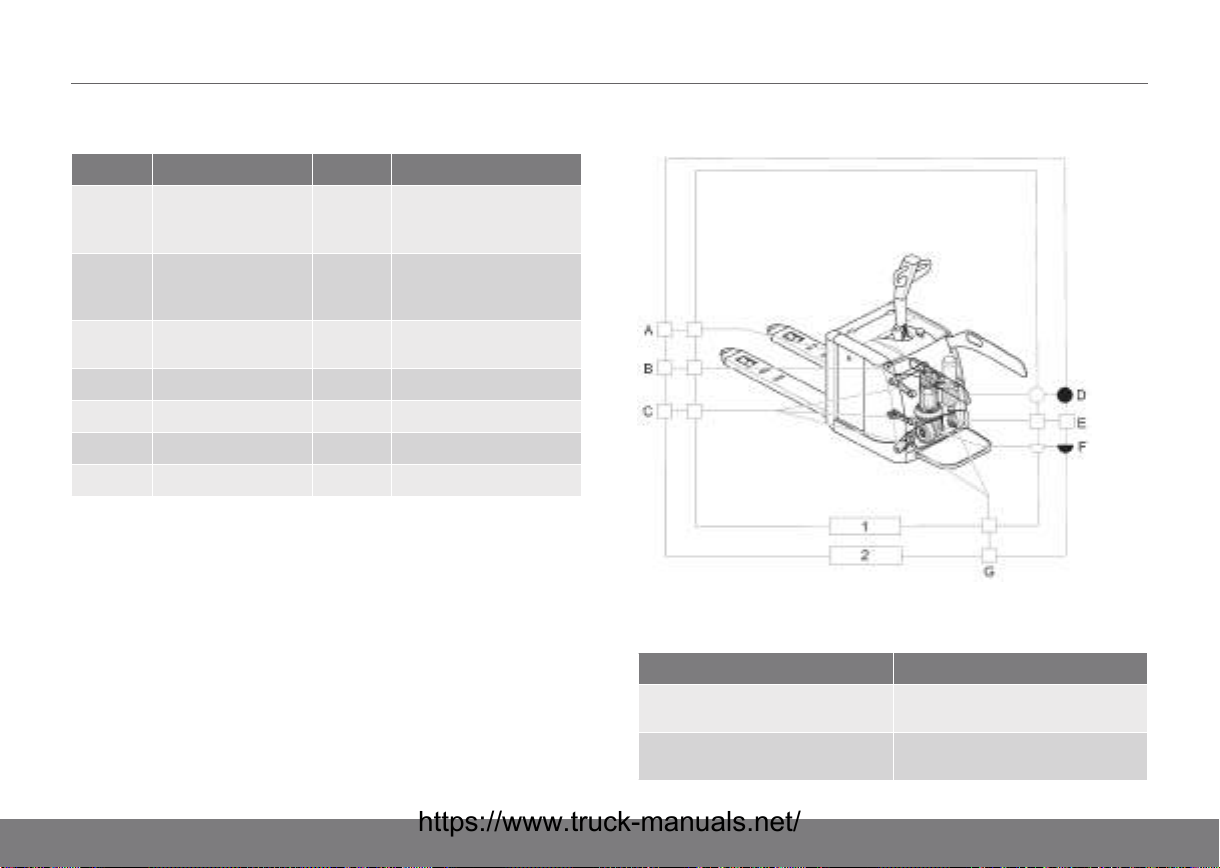

PLL, PLE, PSL, PSD, PS, PSH driver

environment

Functions

Controls PLL, PLE, PSL, PSD, PS

A. “Tiller up drive” driving at

slow speed with the tiller in its

end position (option)

B. Lower

C. Lift

D. Horn

E. Display

F. Keyboard (the keys may be

hidden by a cover)

G. Speed Controller

H. Belly safety switch

I. Lift vertically adjustable

straddle leg (option) (PSD,

PLE)

J. Lower vertically adjustable

straddle leg (option) (PSD,

PLE)

Controls PSH

A. “Tiller up drive” driving at

slow speed with the tiller in its

end position (option)

B. Lower vertically adjustable

straddle leg (option) (PSH)

C. Lift vertically adjustable

straddle leg (option) (PSH)

D. Horn

E. Display

F. Keyboard (the keys may be

hidden by a cover)

G. Speed Controller

H. Belly safety switch

I. Lift

J. Lower

Safety functions

The truck is equipped with a number of safety functions to

minimise the risk of accidents.

15

07DESCRIPTION OF THE TRUCK

• Automatic reversing if the driver becomes trapped between

the tiller arm and an obstacle (belly safety switch).

• Automatic stop when a fault occurs in the electrical

system.

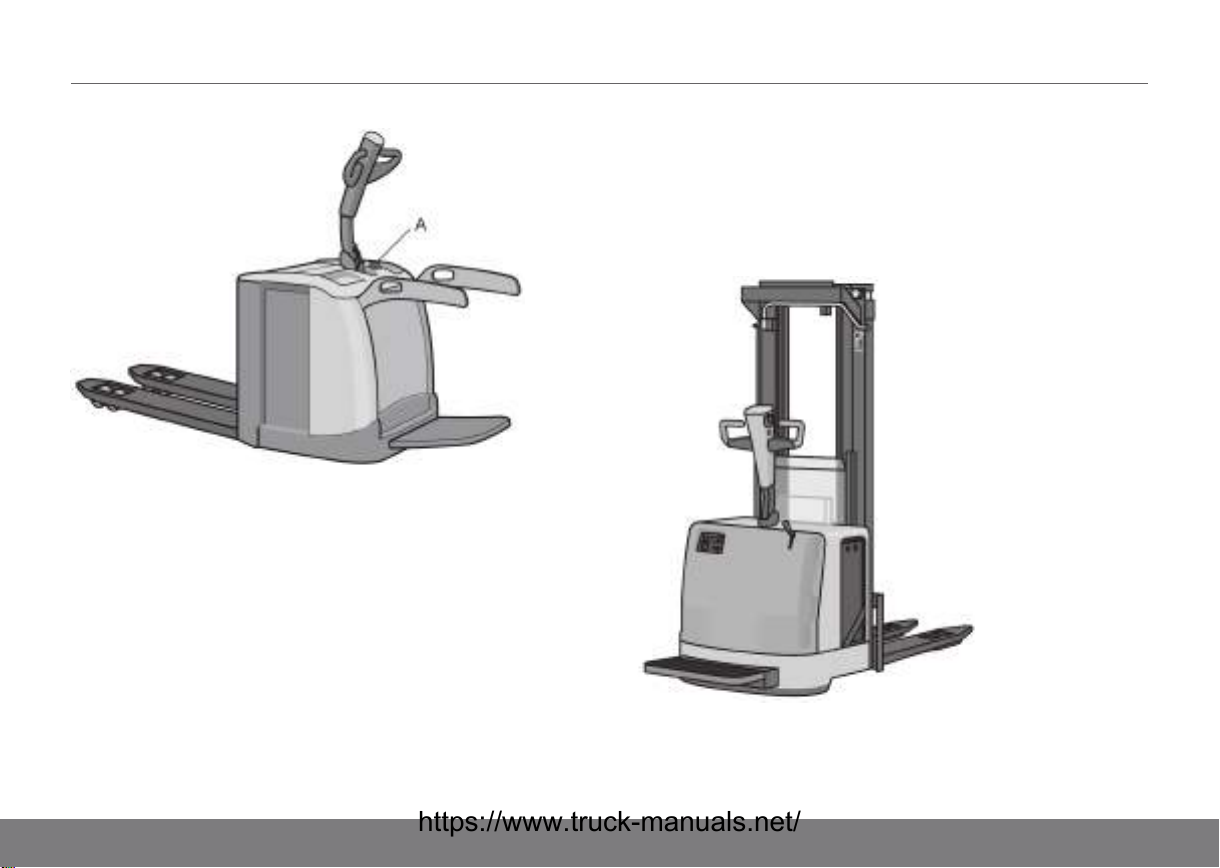

PLP pedestrian truck

The PLP Presto is an electric low lifter for ride-on drivers,

specially adapted for transportation and handling at loading

bays. The truck can be equipped with a mast for stacking and

the transport of double load carriers, or with long forks for the

transport of several load carriers. Usual loads are pallets or

roller containers.

PLP driver environment

Functions

Controls

A. “Tiller up drive” driving at

slow speed with the lever in

its end position (option)

B. Lower

C. Lift

D. Horn

E. Display

F. Keyboard

G. Speed Controller

H. Belly safety switch

I. Forwards/backwards

adjustment (option)

16

A. Emergency stop

Safety functions

The truck is equipped with a number of safety functions to

minimise the risk of accidents.

• Driving is prevented if the platform is down and there is no

operator standing on it.

• In the case of a fixed platform (option), lifting and lowering

of the forks are also prevented if there is no operator

standing on the platform.

DESCRIPTION OF THE TRUCK07

• Automatic reversing if the driver becomes trapped between

the tiller arm and an obstacle (belly safety switch).

• Automatic stop when a fault occurs in the electrical

system.

TS pedestrian truck

The TS is a versatile electric pedestrian stacker for a walking,

or, if the truck is equipped with a fold-up platform, a ride-on

operator. The truck is designed for stacking, internal

17

07DESCRIPTION OF THE TRUCK

transportation, and order picking. Certain trucks are equipped

with straddle lift for the transport of double load carriers,

ordinary pallets or handling at loading bays.

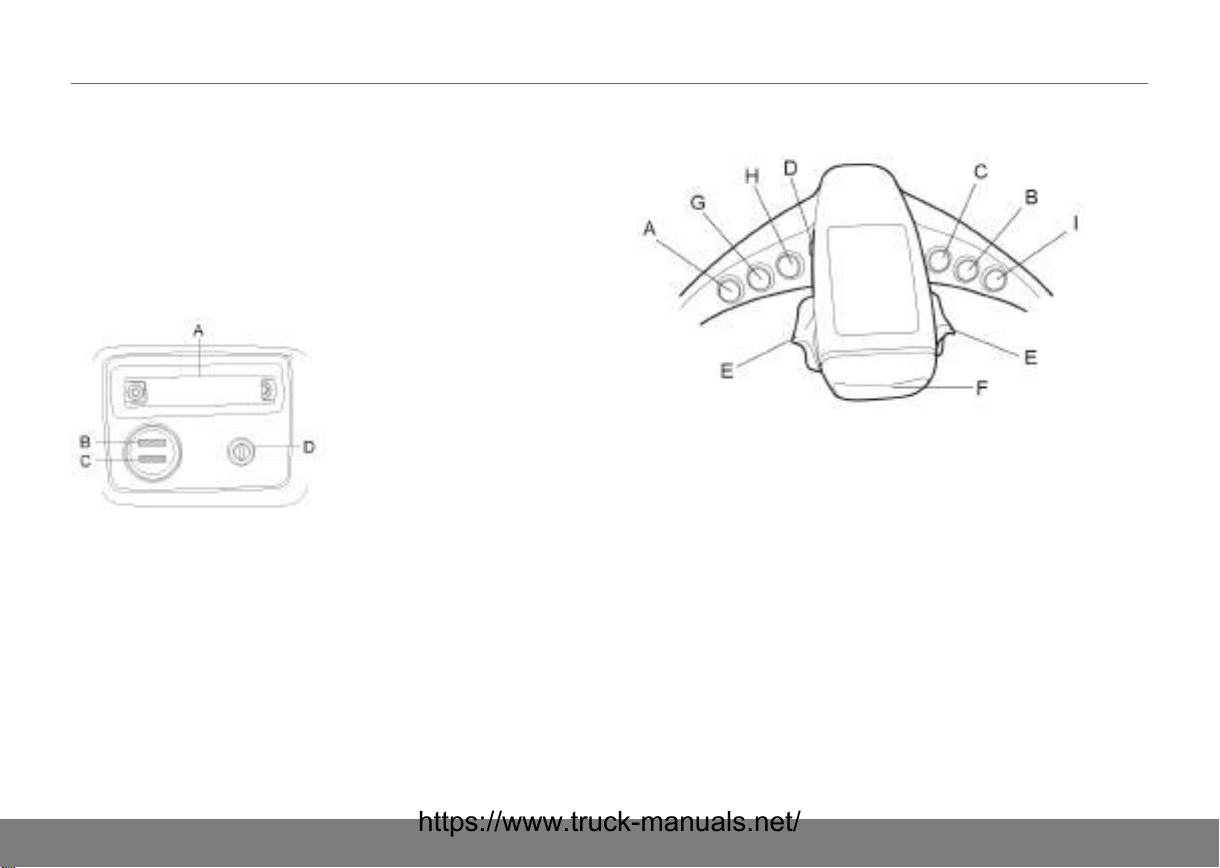

TS driver environment

Functions

Common controls

A. Battery plug (emergency

stop)

B. Battery indicator

C. Hour meter

D. Key switch

Controls for manual operation of lifting/lowering forks

A. Not used

B. Not used

C. Not used

D. Horn

E. Speed Controller

F. Belly safety switch

G. Lowering of the adjustable

height straddle legs (option),

otherwise not used

H. Lifting of the adjustable

height straddle legs (option),

otherwise not used

I. Not used

18

DESCRIPTION OF THE TRUCK07

Controls for proportional operation of lifting/lowering forks

(option)

A. Lower forks B. Lift forks

A. Not used

B. Lower

C. Lift

D. Horn

E. Speed Controller

Safety functions

The truck is equipped with a number of safety functions to

minimise the risk of accidents.

F. Belly safety switch

G. Lowering of the adjustable

height straddle legs (option),

otherwise the same function

as button B

H. Lifting of the adjustable

height straddle legs (option),

otherwise the same function

as button C

I. Not used

19

07DESCRIPTION OF THE TRUCK

• Driving is prevented if the platform is down and there is no

operator standing on it.

• Automatic reversing if the driver becomes trapped between

the tiller arm and an obstacle (belly safety switch).

• Lift stop at 1.8 m forks height and folded up gates. To

continue lifting, the gates must be folded down.

• Automatic stop when a fault occurs in the electrical

system.

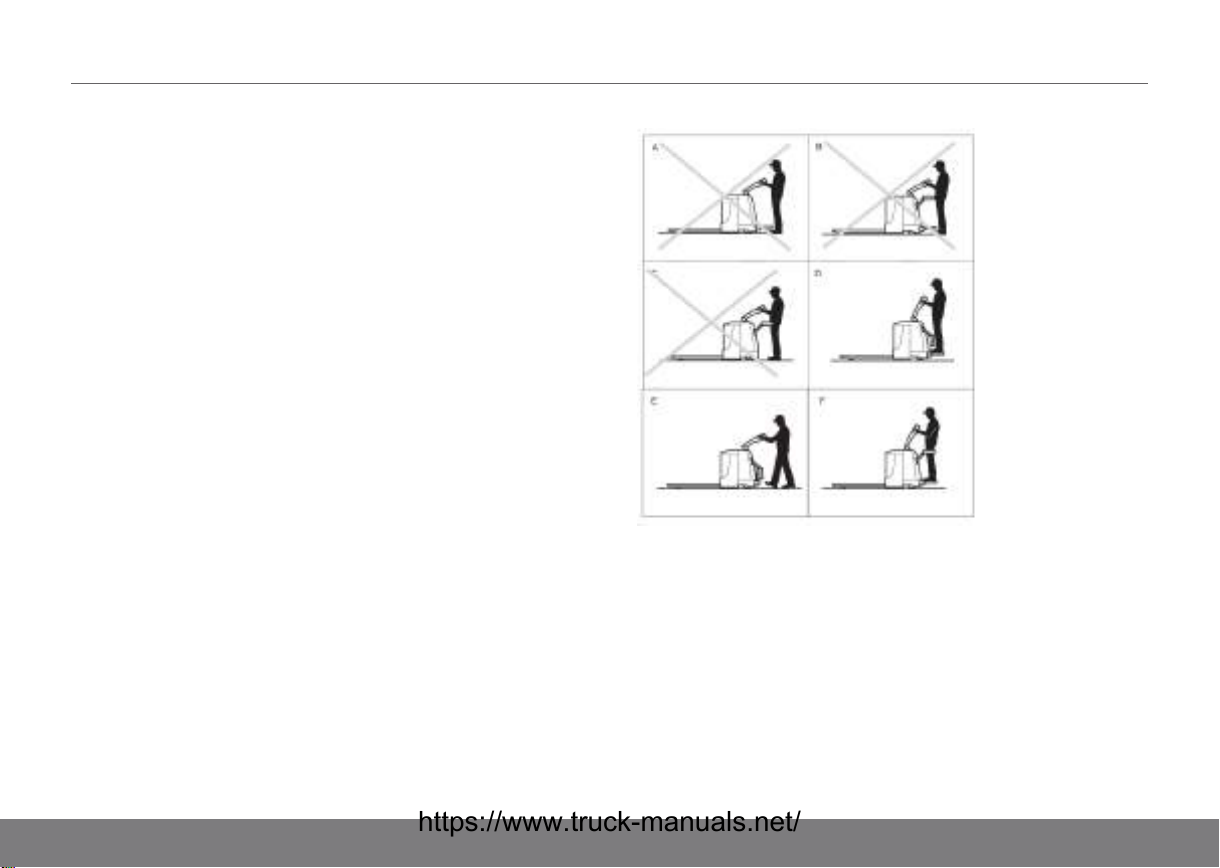

Trucks equipped with folding platform

If the machine is to be used as a pedestrian truck, the platform

must be folded up manually.

A number of safety functions have been built into the truck to

avoid accidents:

20

A. Platform folded down without

operator standing on it: The

truck cannot be driven.

B. Platform folded down and

gates up without operator

standing on it: The truck

cannot be driven.

C. Platform folded up and gates

up: The truck cannot be

driven.

D. Platform folded down with

operator standing on it and

gates down: The truck can be

driven at reduced speed.

E. Platform folded up and gates

down: The truck can be

driven at reduced speed.

F. Platform folded down with

operator standing on it and

gates up: The truck can be

driven at normal speed.

DESCRIPTION OF THE TRUCK07

Options

Additional equipment

The truck may be equipped with additional equipment. Among

other things, there are the following possibilities:

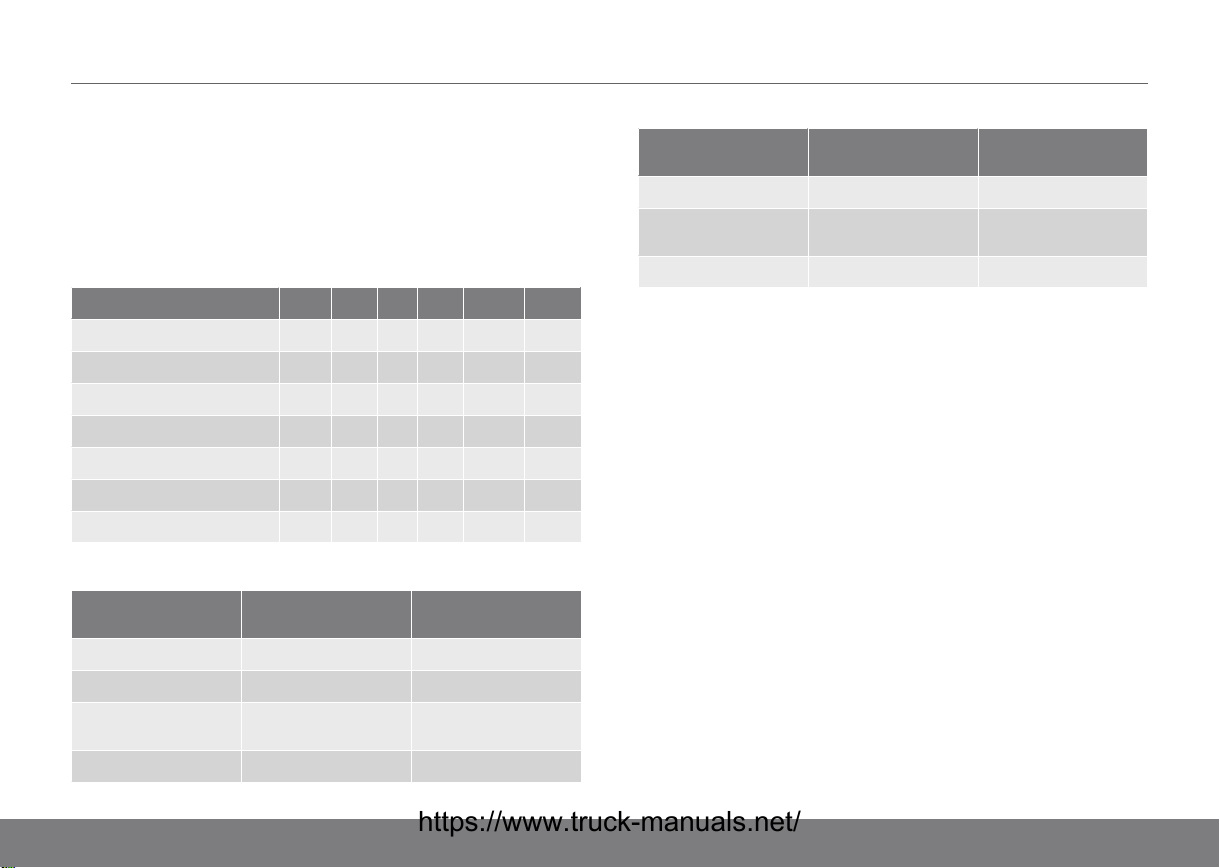

Table 1. PLL, PLE, PS, PSL, PSD, PSH

Additional equipment PLL PLE PS PSL PSD PSH

Writing desk

Earthing strap x x x x x

Rubber foot protection x x

Stretch film holder x

Pen holder x

AC/12 V DC converter x

Fire extinguisher x

Table 2. PLP, TS

Additional

equipment

Writing desk x

Earthing strap

Rubber foot

protection

Stretch film holder

PLP TS

Additional

equipment

Pen holder

AC/12 V DC

converter

Fire extinguisher

PLP TS

21

08BATTERY

Specifications

Specifications PLL, PSD, PSL, PLE, PS, PSH

Table 3. Battery as standard

Truck model Battery voltage

and capacity

(V/Ah)

PLL 24/160-230 3,8-5,5 140/215

PLE 24/150 3,6 140/190

PSD/PSL/PS 24/160-230 3,8-5,5 140/215

PSH 24/240 5,8 240/300

PSH 24/345 6,5 330/360

Specifications PLP

Table 4. Battery as standard

Truck model Battery voltage

and capacity

(V/Ah)

PLP 200 24/220-400 5,3-9,6 250/370

PLP 250 24/330-600 7,9-14,4 350/500

Capacity

(kWh)

Capacity

(kWh)

Weight

min/max (kg)

Weight

min/max (kg)

Specifications TS

Table 5. Battery as standard

Truck model Battery voltage

and capacity

(V/Ah)

TS 24/240 5,8 215/290

TS 24/270 6,5 250/290

Capacity

(kWh)

Weight

min/max (kg)

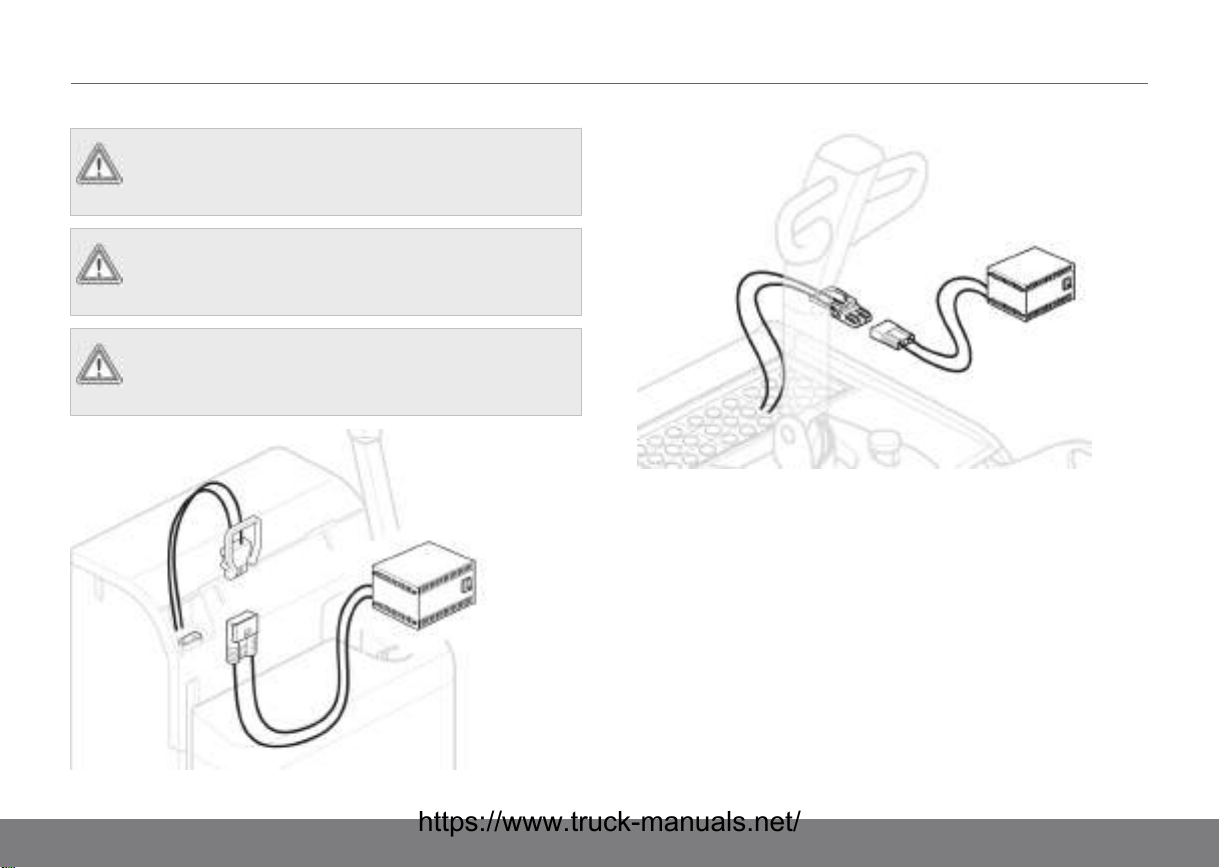

Battery changing

Battery servicing may only be performed by specially trained

personnel. The battery may, however, be charged by other

personnel on the condition that a battery connector is used to

connect the battery to the charging unit. The battery is charged

in accordance with recommendations from the battery

manufacturer, using a charger adapted for the battery. The truck

is intended to be used with lead/acid batteries. Only fully

automatic charging systems should be used.

Follow local laws and safety regulations when charging the

battery. The area where batteries are charged should be

marked out and have proper ventilation. An eyewash station,

cleaning equipment, fire extinguisher and safety glasses must

be available.

WARNING!

Specific gravity checks should only be performed by

an authorised service technician.

22

WARNING!

Always use safety glasses. Acid can cause serious

corrosive injuries.

WARNING!

Explosive gas is generated during charging!

Smoking or a naked flame can cause an explosion!

WARNING!

Remove all rings, bracelets, necklaces and similar

items before handling batteries.

BATTERY08

23

08BATTERY

Before charging

1. Switch off the truck.

2. Remove any battery covers, to gain access to the battery

plug and to permit the heat generated during charging to

be ventilated away.

3. Remove the battery connector from the truck using the

battery charger handle. This procedure will vary depending

on truck model.

CAUTION!

Do not pull out the battery plug by pulling on its

cables.

4. Check that the battery electrolyte level is not above or

below the cell plates.

The battery can be damaged if the cell plates become dry

during charging. There is a risk that the acid will spill over

during charging if the acid level is too high.

5. Connect the battery plug to the charger's connector.

6. Set the charging switch on the battery charger to on.

7. Check that the ammeter shows a normal indication.

After charging

1. Check that charging is completed.

2. Set the charging switch to off.

3. Disconnect the battery charger connector.

4. Top up to the correct level with distilled water.

5. Dry off the battery to prevent leakage current and self

discharging.

6. Connect the battery plug.

7. If there is a battery cover, close it.

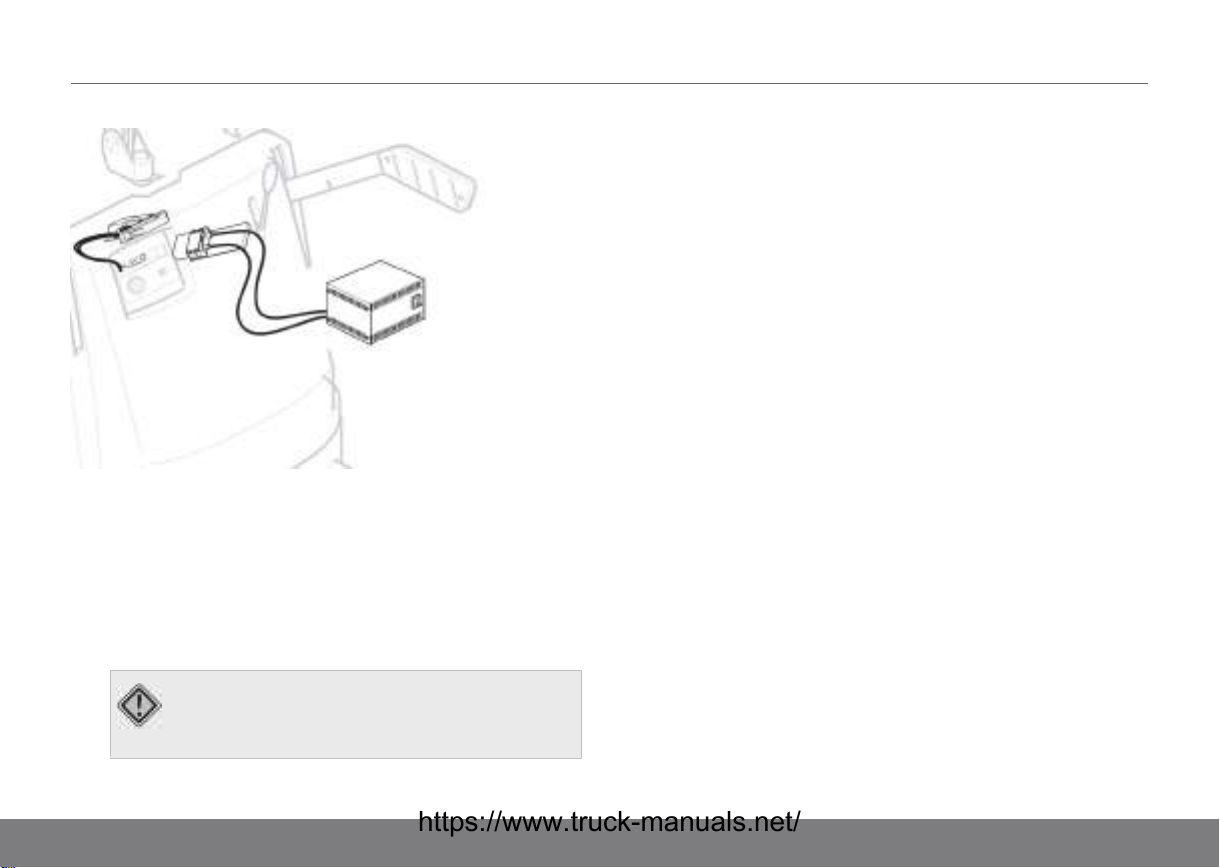

Charging with a built-in charger (option)

1. Switch off the truck.

2. Open the battery cover and pick up the mains power

connector.

3. Check that there is no visible damage to the cable or

connector.

24

BATTERY08

4. Plug the connector into a mains power outlet. Charging will

start.

NOTE!

For safety reasons the truck cannot be driven

while the mains power connector is connected

to an outlet.

When the battery is fully charged the LED lights green.

5. Pull the connector out of the mains power outlet.

6. Dry off the battery to prevent leakage current and self

discharging.

7. Return the mains power connected to the truck and closes

the battery cover.

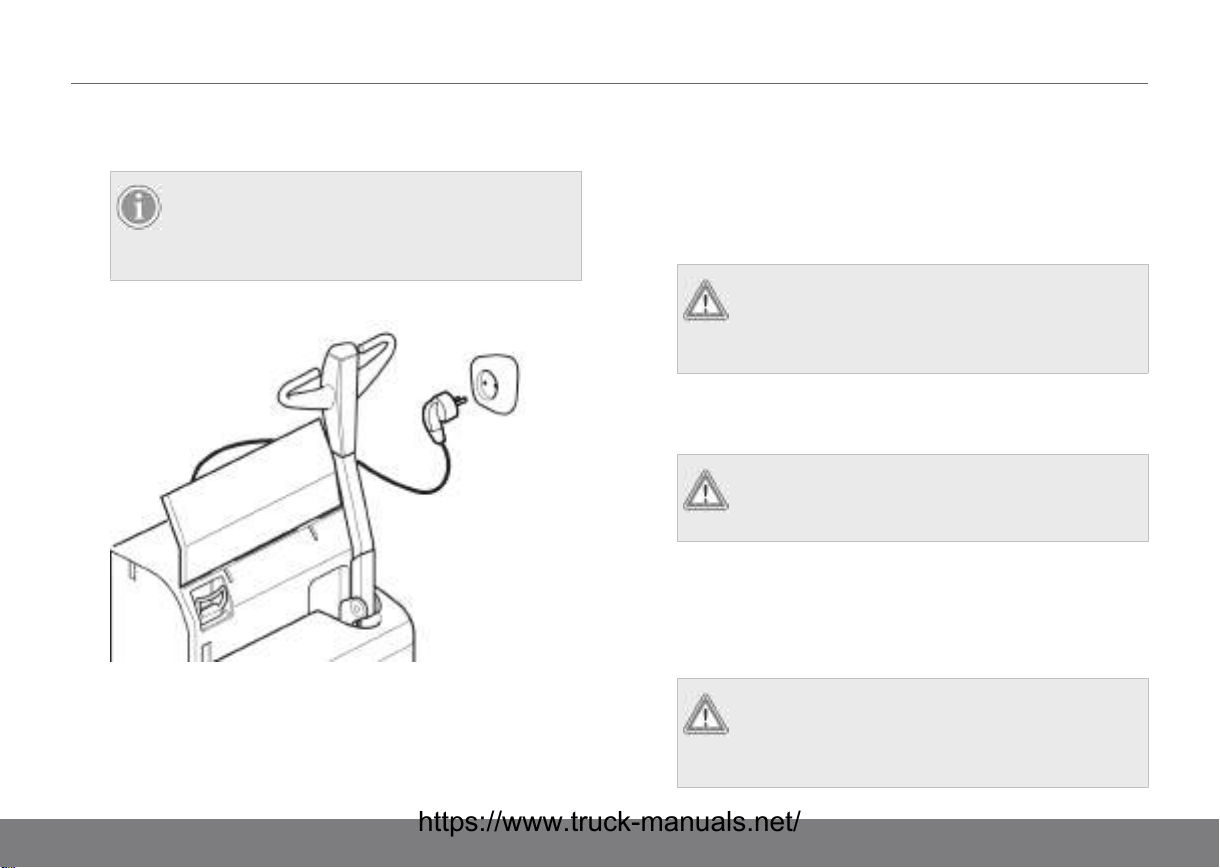

Maintaining and changing the battery

Maintaining and changing the battery PL*/PS*, PS

1) Pull out the battery plug.

2) Open the battery cover.

WARNING!

There is a risk of crushing injury. Do not insert a

hand between the battery cover and the

chassis.

3) Attach the lifting device in the lifting eyes.

4) Lift the battery and set it to one side.

WARNING!

Observe care to avoid splashing waste acid or

oxide from the battery.

5) Perform a battery inspection in accordance with

Maintenance of the truck page 40.

6) Lift the battery in.

7) Carefully close the battery cover.

WARNING!

There is a risk of crushing injury. Do not insert a

hand between the battery cover and the

chassis.

25

08BATTERY

8) Connect the battery plug.

9) Check the battery voltage on the battery indicator.

Maintaining and changing the battery PSH

1)

Pull out the battery plug.

2) Open the battery cover.

3) Open the battery door using the battery key.

4) Roll out the battery on the battery carriage.

5) Perform a battery inspection in accordance with

Maintenance of the truck page 40.

6) Roll the battery back.

7) Close the battery cover.

8) Connect the battery plug.

9) Check the battery voltage on the battery indicator.

NOTE!

A battery carriage must be used when changing

battery.

WARNING!

Observe care to avoid splashing waste acid or

oxide from the battery.

Maintaining and changing the battery PLP

1)

Pull out the battery plug.

2) Release the battery lock.

3) Roll out the battery on the battery carriage.

4) Perform a battery inspection in accordance with

Maintenance of the truck page 40.

5) Roll in the battery after completed service.

6) Lock the battery in place with the battery lock and replace

the battery plug.

7) Check the battery voltage on the battery indicator.

NOTE!

A battery carriage must be used when changing

battery.

WARNING!

Observe care to avoid splashing waste acid or

oxide from the battery.

Maintaining and changing the battery TS

1) Pull out the battery plug.

2) Remove the battery locks (one on each side of the truck).

3) Roll the battery out to one side. Note that a safety stop is

activated when the battery has reached halfway out. When

26

BATTERY08

changing the battery on a truck with vertically adjustable

straddle legs, raise the straddle legs to their highest

position in order to remove the battery stop.

CAUTION!

There is a risk of pinching while rolling the

battery out or in.

NOTE!

A battery carriage must be used when changing

battery. Unscrew and remove the safety stop.

4) Perform a battery inspection in accordance with

Maintenance of the truck page 40.

5) Roll the battery in.

6) Refit the battery locks.

7) Refit the battery plug.

8) Check the battery voltage on the battery indicator.

Battery servicing

WARNING!

Battery and battery charger servicing may only be

carried out by specially trained personnel.

WARNING!

Avoid short circuits, which can cause explosion or

fire.

27

09TRUCK COMPUTER (ATC)

Introduction

The truck is equipped with an ATC system; a control and

monitoring system consisting of a display, a keyboard and a

control unit. The system is also equipped with a buzzer in order

to catch the driver’s attention in various situations.

NOTE!

Not available on TS trucks

General

In order to start the truck, the driver must enter Operator ID and

PIN code or use the keylock (option). Using the display, the

driver may find a lot of information after turning on the truck,

e.g.: date, time, battery status, as well as any error codes and

warnings. The Operator ID and PIN code are supplied along

with the delivery of the truck. The code should be changed after

delivery.

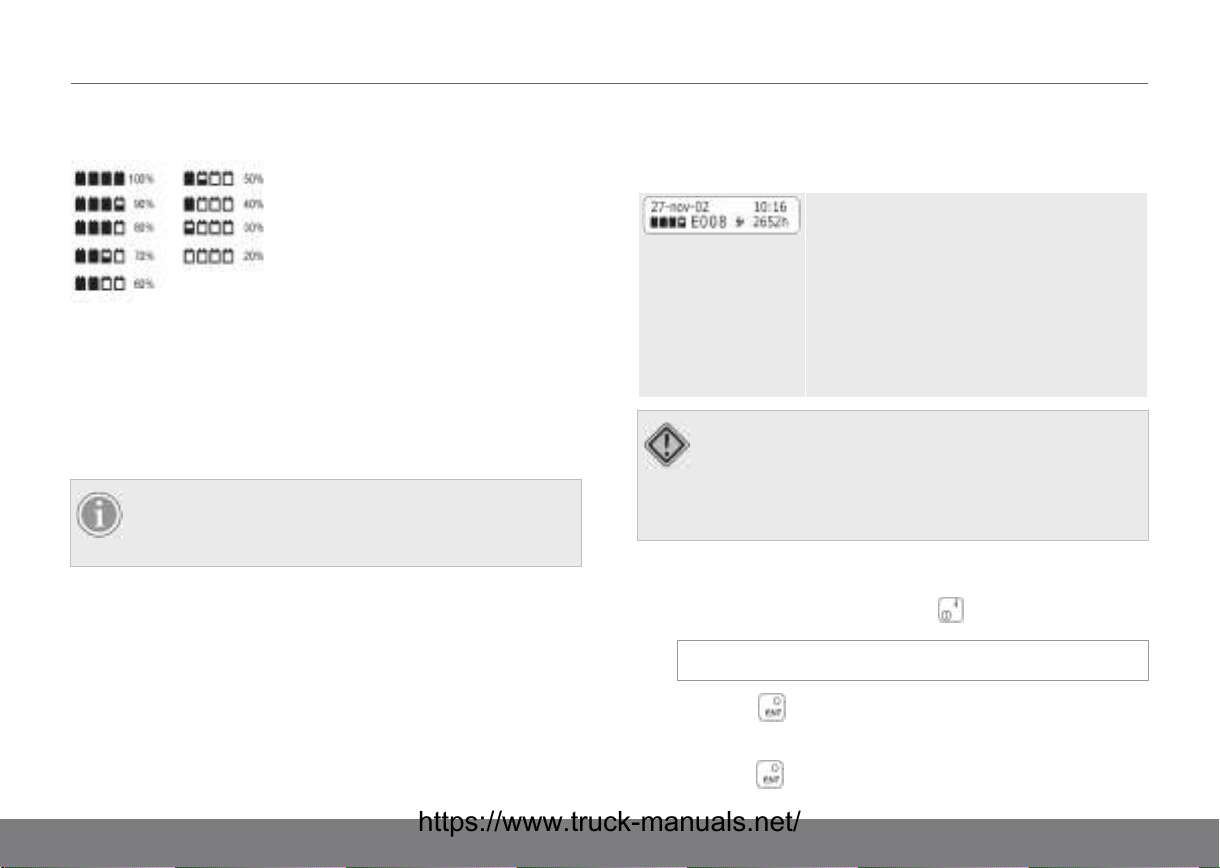

Symbols and characters on the display

A. Date: Day-month-year.

B. Time: Hours-minutes

C. Hour meter: Shows active

time or logon time. Normally,

total active time is

displayed.

D. Symbol normal speed/slow

speed: Shows whether the

truck is in normal speed or

crawler mode

(hare/tortoise).

E. Field for error codes: An error

code consisting of an

E+digits is shown if a fault

occurs (if a warning is

displayed, it covers the entire

upper row).

F. Battery indicator: Shows

battery status.

G. Symbol for lift stop. If the

truck is equipped with a

restart function, press push

button to continue

lifting.

28

TRUCK COMPUTER (ATC)09

Display of battery status

If the battery is discharged, the battery indicator will start

blinking and a buzzer will sound at regular intervals. If the

battery is not recharged or replaced, the lift function will shortly

be deactivated in order to avoid harming the battery or

preventing the truck from functioning normally. A deactivated lift

function is indicated by a lit ^ symbol to the left of the

hare/tortoise symbol.

NOTE!

When the battery status display indicates that the

battery is discharged, it must be recharged/replaced.

Error messages

Error codes

All error messages are shown on the bottom

row of the display. An error message is

presented in the form of a code, consisting of

the letter E and a code number, e.g. 008.

When an error code is shown, the truck will

go into a failsafe mode, which may mean that

the truck's functions will stop. Certain error

conditions are corrected automatically or by

turning the truck on and off. The error code

will then be turned off.

CAUTION!

The error code will persist in the event of a serious

error. If this occurs, an authorised service technician

should be contacted and given the error message

code.

Change language

1)

Navigate to “Settings”, using the button.

Settings

2)

Press the button.

3) Navigate with the arrow keys to select a language, then

press the button to confirm the selection.

29

09TRUCK COMPUTER (ATC)

SELECT LANGUAGE:

English

4) You will now enter the logon mode automatically with the

new language setting.

Operator ID:

?

Warnings

There are a number of different warnings used to catch the

driver’s attention in the case of, for example, an operational

error. Certain of the truck’s systems will also not be operable

until the driver has followed the command on the display.

•

Release throttle

The driver is asked to position the speed lever in neutral.

•

Release controls

The driver is asked to set all hydraulic levers to their

neutral positions.

•

Release tiller

The driver is instructed to place the steering arm to its

uppermost and lowermost positions.

disappear even though the driver has followed the instructions

on the display, contact and authorised service technician.

Other warning messages are shown if, for example. a system in

the truck is beginning to overheat. If the warnings do not

30

TRUCK COMPUTER (ATC)09

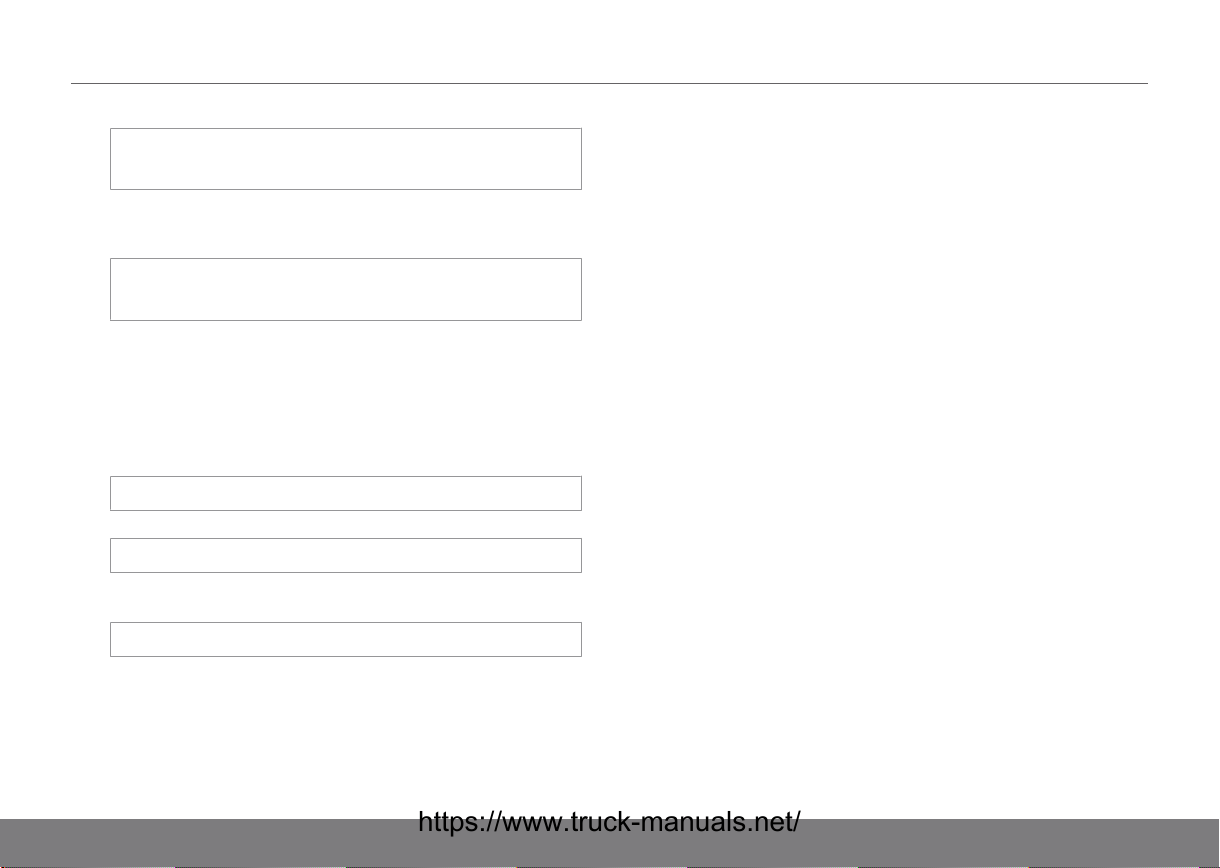

Menus

ATC has a number of functions available in a menu system.

There are five basic menus with multiple submenus. The button

is used to navigate between menus. Certain basic menus

require a password to be able to access them.

• Operator ID: Menu to start the truck.

• Local: Intended for local supervisor.

• Service: Intended for authorised service technician.

• Settings: Here, it is possible to set the language to be

shown in the display. ATC supports Swedish, English,

German and French. It is also possible to install one

additional language using special software.

• Trac: Intended for authorised service technician.

Navigation in menus

The arrow keys (buttons 4, 6, 2, 8 on the keyboard) are used for

navigating in the menus. You may navigate either vertically or

horizontally. The availability of these alternatives is shown on

the display.

31

09TRUCK COMPUTER (ATC)

•

To enter into a menu: Press the button.

•

To exit a selected menu: Press . The horn button

serves as an "Esc button". Press the button when

"Exit" is shown in the display.

32

DRIVING INSTRUCTIONS10

Driving instructions PLL, PLE, PSL, PSD,

PS, PSH, PLP

Starting the truck

1) Connect the battery plug and check that the emergency

stop function is disengaged.

2) If the truck is equipped with an electric lock, turn the key.

The display briefly shows a start image.

3) A request to state the operator identification will be

displayed. You will be asked to enter an Operator ID. Note

that there must be as many digits as question marks.

Operator ID:

?

4) Enter your PIN code.

Operator code

????

5) When the valid Operator ID and PIN code have been

entered, the truck will be ready to drive.

NOTE!

If a lever is activated when the truck is started,

you will see a message on the display asking

you to reposition the lever to neutral position.

Then the truck may be operated. This means

that sudden movements are avoided when

starting.

Driving instructions

1) Start the truck in accordance with Starting the truck page

33. Release the parking brake by moving the tiller arm

backwards-downwards (but not to the bottom position).

2) The truck begins to move when the tiller arm speed control

is pushed forwards/backwards. The further the speed

control is moved the faster the truck will move.

3) There are several ways to brake the truck:

• Brake the truck by reversing, i.e. changing the

direction of travel.

NOTE!

The further the speed control is moved the

greater the braking capacity.

33

10DRIVING INSTRUCTIONS

• Brake by moving the speed control back to its neutral

position and moving the tiller arm up or down to its

end position.

NOTE!

The brakes function whether the lever is

released or not.

4) If the main power needs to be disconnected in an

emergency, press the emergency stop button or pull out

the battery plug. The emergency stop buttons are on the

left and right hand sides of the driver cab facing the forks.

5) In order to avoid crushing injuries during driving, there is a

belly switch at the end of the tiller arm. When the belly

switch (H) is pressed in, the truck will move in the direction

the forks are pointing.

6) It is possible to manually activate crawl speed during

operations. Select crawl speed by pressing the button

(F). (Button (F) to go directly to normal speed.)

7) Switch off the truck in accordance with Switching off the

truck page 34.

Switching off the truck

1)

To turn off the truck: Keep the button pressed in for

approx. two seconds. The display will show “shutting

down” and then show the log-on text.

shutting down...

Operator ID:

?

NOTE!

Always turn off the truck in accordance with the

above instructions before the battery plug is

disconnected to avoid locking the program or

damaging the ATC system.

2) In the case of a lengthy stop, pull out the battery plug.

NOTE!

Emergency stop shall not be used to turn off the

truck.

Normal or crawler mode

Normal speed mode

A symbol for normal speed (hare) or crawler (tortoise) is always

shown on the display, depending on which is currently active.

34

DRIVING INSTRUCTIONS10

Crawler mode

It is possible to manually activate crawl speed during

operations. Button alternates between the two speed

selections. (Button to go directly to normal speed.) Various

safety systems in the truck may automatically reduce the speed

in certain situations. For example, driving with forks lifted high

and/or folded out side stabilizers results in reduced speed. The

symbols for normal speed or crawler mode are not changed by

reducing the speed.

Standby position

Standby mode is only used for shorter stops during the work

shift. At the end of the work shift or when the truck is going to

be left unattended, it should always be turned off.

1)

To enter standby mode: Keep the button pressed until

the text “standing by” is shown on the display.

2)

To return to operating mode: Briefly press the button

again.

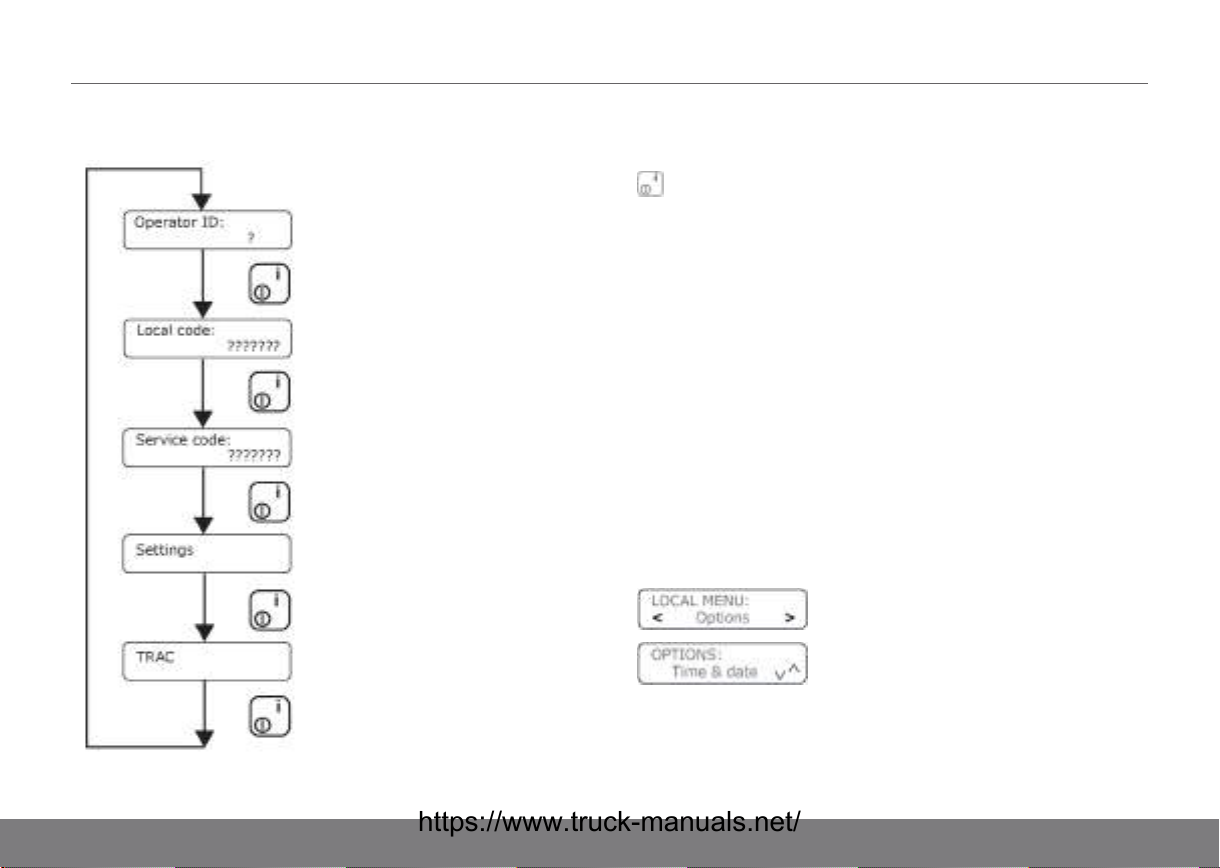

Manual release of the brake PLL, PSD, PLE, PSL, PS

The brake can be released in order to move a truck without

power by turning the handle at the top of the brake clockwise

(A). The truck cannot be driven in this position. To return to

normal operation, turn the handle anticlockwise back to normal

position (B).

35

10DRIVING INSTRUCTIONS

WARNING!

The brake may only be released when the truck is

standing still on clean, level and solid ground.

2) Turn the key.

Driving instructions

1) Start the truck in accordance with Starting the truck page

36.

2) Release the parking brake by moving the tiller arm

downwards (but not to the bottom position).

NOTE!

For trucks with fixed/protected platforms, the

driver must stand on the platform to be able to

use any of the hydraulic functions.

3) The truck begins to move when the lever on the operating

handle is pushed forwards/backwards. The further the

speed control is moved the faster the truck will move.

Driving instructions TS

Starting the truck

1) Connect the battery plug.

36

4) There are several ways to brake the truck:

• Brake the truck by reversing, i.e. changing the

direction of travel.

DRIVING INSTRUCTIONS10

NOTE!

The further the speed controller is moved the

greater the braking capacity.

• Brake by moving the lever on the operating handle

back to its neutral position and moving the operating

handle up or down to its end position.

NOTE!

The brakes function whether the speed control

is released or not.

5) If the main power needs to be disconnected in an

emergency, pull out the battery plug.

6) In order to avoid crushing injuries during driving, there is a

belly switch at the end of the tiller arm. When the belly

switch is pressed in, the truck will move in the direction the

forks are pointing.

7) Switch off the truck in accordance with Switching off the

truck page 37.

Switching off the truck

1) Switch off the truck by turning the key counterclockwise.

2) In the case of a lengthy stop, pull out the battery plug.

NOTE!

Emergency stop shall not be used to turn off the

truck.

37

11GENERAL LOADING AND UNLOADING INFORMATION

Responsibility for the load

The driver of the truck is responsible for the load that is being

carried during transport. There must not be any risk of the load

tipping or sliding off during transport. The driver of the truck has

the right and duty to refuse to carry any load that is a clear

safety hazard. Refer to the load limit plate to see the permitted

maximum load for the truck.

Responsibility for others

Operate the truck so that there is no risk of an accident. No one

may pass or stand under the raised forks, whether they are

carrying a load or not. The driver has the right and duty to see

that these directives are followed.

Maximal load

The maximum lifting capacity of the truck must not be exceeded

(refer to the fork lift truck load limit plate). Note the effect of the

centre of gravity on the lifting capacity.

Picking up a load

Always pick up a load so that it comes to rest as close to the

mast as possible.

CAUTION!

Check the location of the centre of gravity of the

load.

CAUTION!

Do not drive with the load lifted, except during

2-pallet handling.

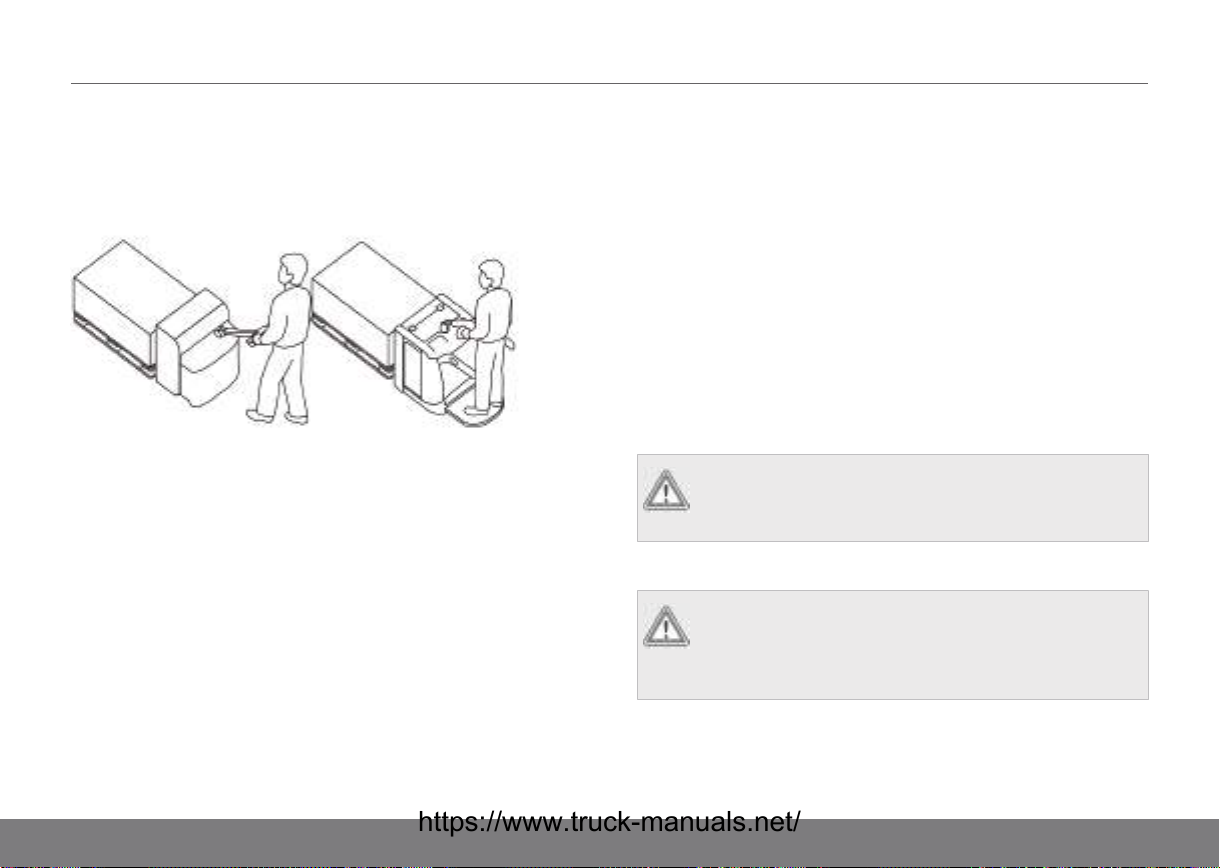

2-pallet handling

The following applies to trucks with adjustable outriggers which

make 2 pallet handling possible:

• Adjust the speed in accordance with floor conditions, load

distribution and when cornering.

• Remember that a higher centre of gravity makes the truck

less stable. Try to have the load as low as possible, with

the heaviest load always lowermost.

• Whilst loading with only the forks, the straddle legs must

be completely lowered.

• Refer to the load limit plate to see the permitted load

combinations for a particular truck.

38

GENERAL INFORMATION CONCERNING STACKING12

Stacking

1) Approach the stack with the load in the lowered position.

2) Lift the load sufficiently high that it clears the stack or shelf

and then drive towards the stack.

3) When the load is in a suitable position, lower it onto the

stack.

4) Lower the forks so that they release the load/pallet, and

check that no-one is behind the truck before reversing

away from the stack.

5) Lower the forks into their transport positions.

6) When fetching a load from a stack, carry out these

movements in reverse order.

39

13MAINTENANCE OF THE TRUCK

Daily maintenance (before each shift)

Responsibility: Fork lift truck driver

CAUTION!

Naked flames or smoking are prohibited when

working on or near to the battery.

CAUTION!

Loading ergonomics must be observed during

battery change or battery check.

1) Check that the battery cables, connections and plugs are

connected correctly and not damaged.

2) Check that the battery is properly secured in its

compartment.

3) Check that the truck is not leaking oil.

4) Check the horn by activating the controls while the truck is

running.

5) Check the braking capacity on the main brake and parking

brake.

6) Check for external damage or excessive wear on the

wheels.

7) Check that there are no error messages or warnings on

the truck computer display.

8) Check that the securing arrangements for the finger

protection are intact and that there is a good view through

the protection.

WARNING!

There is the danger of personal injury if the

truck is operated without having the finger

protection in place.

WARNING!

There is a danger to life if the truck is driven

with insufficient visibility through the finger

protection.

CAUTION!

Errors detected during daily inspection must be

reported to a foreman/supervisor. See section

Truck Driver page 10.

9) Check the height measuring system reflector surface.

10) Trucks with gates: check the gate switches.

Daily Service (after each shift)

Responsibility: Fork lift truck driver

40

MAINTENANCE OF THE TRUCK13

Battery changing

1. Check the battery voltage on the battery indicator.

2. Charge the battery as necessary. The battery is charged in

accordance with the recommendation from the battery

manufacturer. Only fully automatic charging units should

be used.

Refer to Battery changing page 22 for the charging

procedure.

If there is damage

Any damage that has occurred must be reported to the

supervisor.

Weekly inspection

Responsibility: Truck operator

1) Clean the battery; see the battery manufacturer's

maintenance instructions.

2) Check the oil level in the hydraulic system by pushing all

the hydraulic cylinders to their fully extended positions.

Then, check that the fork truck raise all the way up to

maximum lift height without the pump sucking air.

3) Check that the wheels have not separated – tread/hub and

tread/cord.

4) The outside of the truck must be cleaned. Vacuum clean

and wipe with moist cloth in the operator cab. Electrical

panels and circuit boards must always be protected from

fluids. Damage to the truck caused by fluids in electrical

components is not covered by the manufacturer's warranty.

Preventive maintenance

NOTE!

Preventive maintenance must be carried out by

specially appointed and trained personnel with a

good working knowledge of the function and

maintenance of the truck.

To obtain the best results from your truck investment, we advise

you to contact an authorised service technician and take out a

service agreement for preventive maintenance.

41

14SERVICING AND MAINTENANCE

Service technician

NOTE!

Servicing and maintenance must be carried out by a

specially appointed and trained technician with a

good working knowledge of the truck's function and

maintenance.

To obtain the best results from your truck investment, we advise

you to contact an authorised service technician and take out a

service agreement for routine maintenance.

Safety instructions for maintenance

Working at height

Comply with local safety instructions when working at height.

Precautionary measures during repair

Extreme importance must be placed on precautionary

measures to avoid accidents during all work on the truck.

•

• Ensure that the drive wheel is off the ground before trouble

shooting. Secure the truck with blocks.

WARNING!

The battery plug should be pulled out before

working on the truck.

• To prevent injuries caused by crushing the battery plug

should always be removed when working on and around

the mast and hydraulic unit.

• When dismantling parts of the hydraulic system the system

must not be pressurised, e.g. the pump motor is shut off

and the forks are down.

• The battery should always be protected during grinding

work.

• When changing a fuse the controllers must be thoroughly

discharged. (Remove the battery plug and wait for two

minutes before fuses are changed, otherwise there a risk

of arcing.)

• Great caution must be observed when removing gas

springs.

Maintenance intervals

Recommended replacements

NOTE!

To ensure correct operation, use only original spare

parts.

42

SERVICING AND MAINTENANCE14

• The hydraulic oil filter and air filter for the hydraulic oil tank

must be changed after every 500 hours of operation. For

TS, this should happen every 1,000 hours of operation.

NOTE!

Only TS trucks have replaceable hydraulic

filters.

• The hydraulic oil must be changed annually or every 1,000

hours of operation.

CAUTION!

If the hydraulic oil has been heated to over

60°C the oil and the filter must be replaced

immediately, since the technical properties of

the oil may have changed.

• Hoses should be replaced after 5 years, since they are

perishable.

Servicing, type and frequency

General

A complete operations test must be performed before the

inspection. Faulty functions must be rectified before the

inspection.

First service (200 hours)

This service has the purpose of securing the operation of the

truck and its component parts. The gearbox oil and hydraulic oil

filter must be changed and a functional test carried out in

accordance with the following list.

• Check for external damage on chassis.

• Check of weld joints at vital points.

• Check of lifting devices.

• Check of component attachments.

• Functional test, lever, lever bolts, 195 Nm.

• Check of the horn.

• Test drive backwards and forwards, and turning.

• Check of the drive unit.

• Check of all the wheels.

• Test of the brake function.

• Change the oils and filter in accordance with instructions.

• Check for oil leakage.

• Check of the hydraulic unit, pipes and hoses.

• Check of the cylinders.

• Function test, lifting and lowering.

• Lubrication in accordance with lubrication chart.

• Measurement and check of the battery and charging

function.

Service intervals

Service must be carried out regularly, once a year or after 500

hours of operation with normal use of the truck. The planned

43

14SERVICING AND MAINTENANCE

servicing includes operations such as test driving, functional

tests, and the changing of filters and oils, etc.

NOTE!

In the case of demanding and/or dusty environments

with humid or corrosive air, it is advisable to perform

maintenance more often. Reduce the periods

between maintenance by one half (or one third).

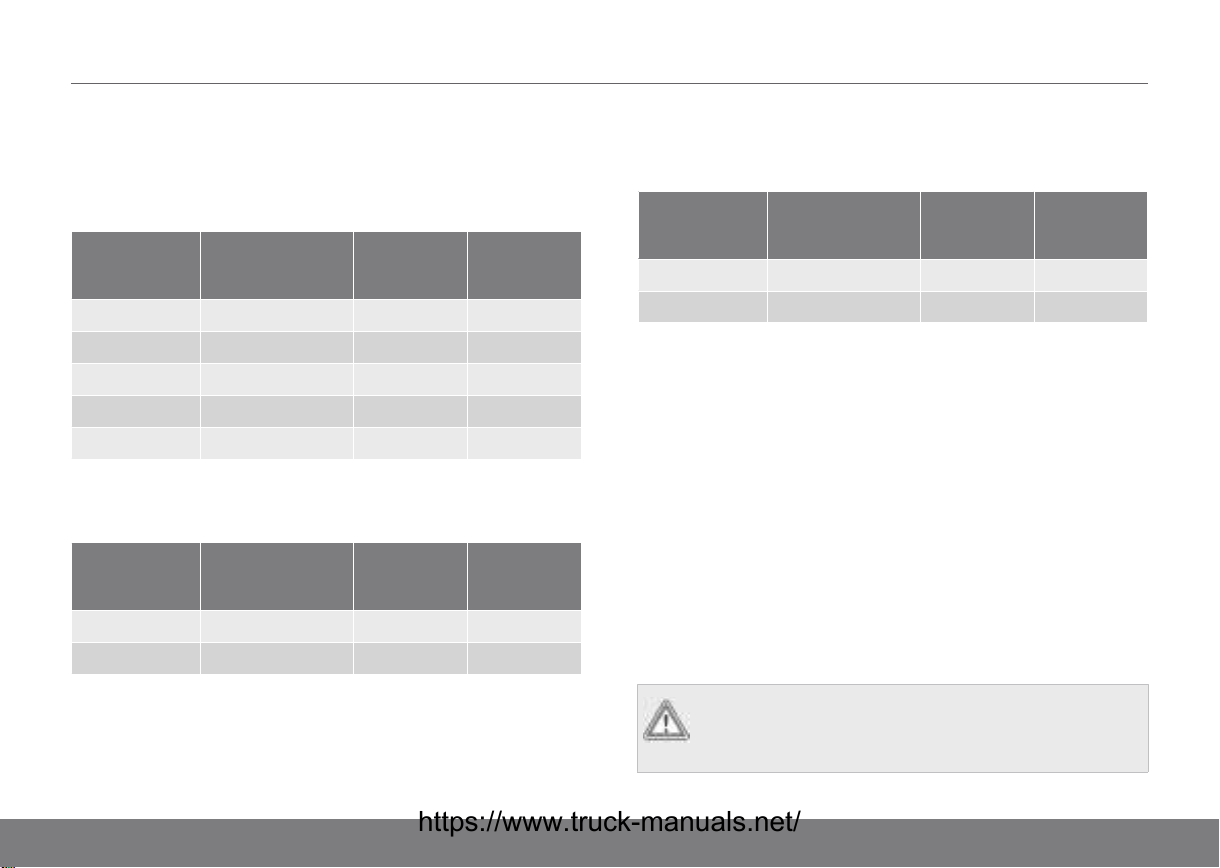

Service points PLP, PS, PSH, TS

Planned service inspections are implemented in accordance

with the following points:

X Obligatory

O Not obligatory

Chassis

Descriptions PLP PS/PSH TS

Signs/Decals X X

Covers and panels X X X

Overhead guard X

Rail wheel X X O

Battery stop, Lock, Rollers X X X

Rubber mat X X

Chassis X X X

Chassis

Descriptions PLP PS/PSH TS

Lubrication X X X

Link system X X O

Stabilizers X O

Castor wheel X X X

Microswitch X X X

Pivot points X

Driver’s platform X X

Gates X X

Colour X X X

Finger protection X X

Machine plate X X X

Drive unit

Descriptions PLP PS/PSH TS

Gearbox X X X

Traction motor X X X

Drive wheel X X X

Drive shaft X X X

Gearbox oil level X X X

44

SERVICING AND MAINTENANCE14

Mast system

Descriptions PLP PS/PSH TS

Lift chains X X X

Forks, fork carriage X X X

Bearings/Rollers X X X

Lubrication X X X

Mast profile X X X

Pull rods X X O

Steering

Descriptions PLP PS/PSH TS

Servo motor X O

Steering servo unit X O

Sliding bearing X X

Tiller foot X X X

Steering Bearing X X

Steering belt/Steering chain X X

Hydraulic system

Descriptions PLP PS/PSH TS

Hydraulic oil level X X X

Hoses X X X

Hydraulic system

Descriptions PLP PS/PSH TS

Couplings X X X

Pump motor X X X

Hydraulic pump X X X

On/off valve proportional

valve

Friction force system X

Descriptions PLP PS/PSH TS

Cylinders X X X

Electrical system

Descriptions PLP PS/PSH TS

Cables, Switches X X X

Contactors X X X

Battery X X X

Traction motor controllers X X X

Horn X X X

Speed Controller X X X

Mast sensor/switch X X

X X X

Lift cylinders

45

14SERVICING AND MAINTENANCE

Electrical system

Descriptions PLP PS/PSH TS

Fuses X X X

Battery plug X X X

Cooling fan X X

Truck computer X X

Belly switch button X X X

Emergency stop X X X

Lift switch X

Hour meter X X X

Driver presence sensor X X

Battery indicator X X X

Key switch O O X

Brake-System

Descriptions PLP PS/PSH TS

Brake function X X X

Parking brake X X X

Brake disc X X X

Service points PLL, PLE, PSD, PSL

Planned service inspections are implemented in accordance

with the following points:

X Obligatory

X Not obligatory

Chassis

Descriptions PLL PLE PSD/PSL

Signs/Decals X X X

Covers and panels X X X

Rail wheel X X X

Battery stop, Lock, Rollers O O O

Chassis X X X

Lubrication X X X

Link system X X X

Stabilizers X

Castor wheel X X X

Microswitch X X X

Colour X X X

Finger protection X

Machine plate X X X

46

SERVICING AND MAINTENANCE14

Drive unit

Descriptions PLL PLE PSD/PSL

Gearbox X X X

Traction motor X X X

Drive wheel X X X

Drive shaft X X X

Gearbox oil level X X X

Mast system

Descriptions PLL PLE PSD/PSL

Lift chains X X

Forks, fork carriage X X X

Bearings/Rollers X X X

Lubrication X X X

Mast profile X X

Pull rods X X X

Steering

Descriptions PLL PLE PSD/PSL

Sliding bearing X X X

Tiller foot X X X

Steering Bearing X X X

Hydraulic system

Descriptions PLL PLE PSD/PSL

Hydraulic oil level X X X

Hoses X X X

Couplings X X X

Pump motor X X X

Hydraulic pump X X X

On/off valve proportional

valve

Descriptions PLL PLE PSD/PSL

Cylinders X X X

Electrical system

Descriptions PLL PLE PSD/PSL

Cables, Switches X X X

Contactors X X X

Battery X X X

Traction motor controllers X X X

Horn X X X

Speed Controller X X X

X X X

Lift cylinders

47

14SERVICING AND MAINTENANCE

Electrical system

Descriptions PLL PLE PSD/PSL

Fuses X X X

Battery plug X X X

Truck computer X X X

Belly switch button X X X

Emergency stop X X X

Hour meter X X X

Battery indicator X X X

Key switch O O O

Brake-System

Descriptions PLL PLE PSD/PSL

Brake function X X X

Parking brake X X X

Brake disc X X X

Consumable materials

Only supplies (oils, grease, lubricants etc.) that have been

approved by our genuine spare parts department may be used

for servicing and maintenance of the truck. See Genuine Parts.

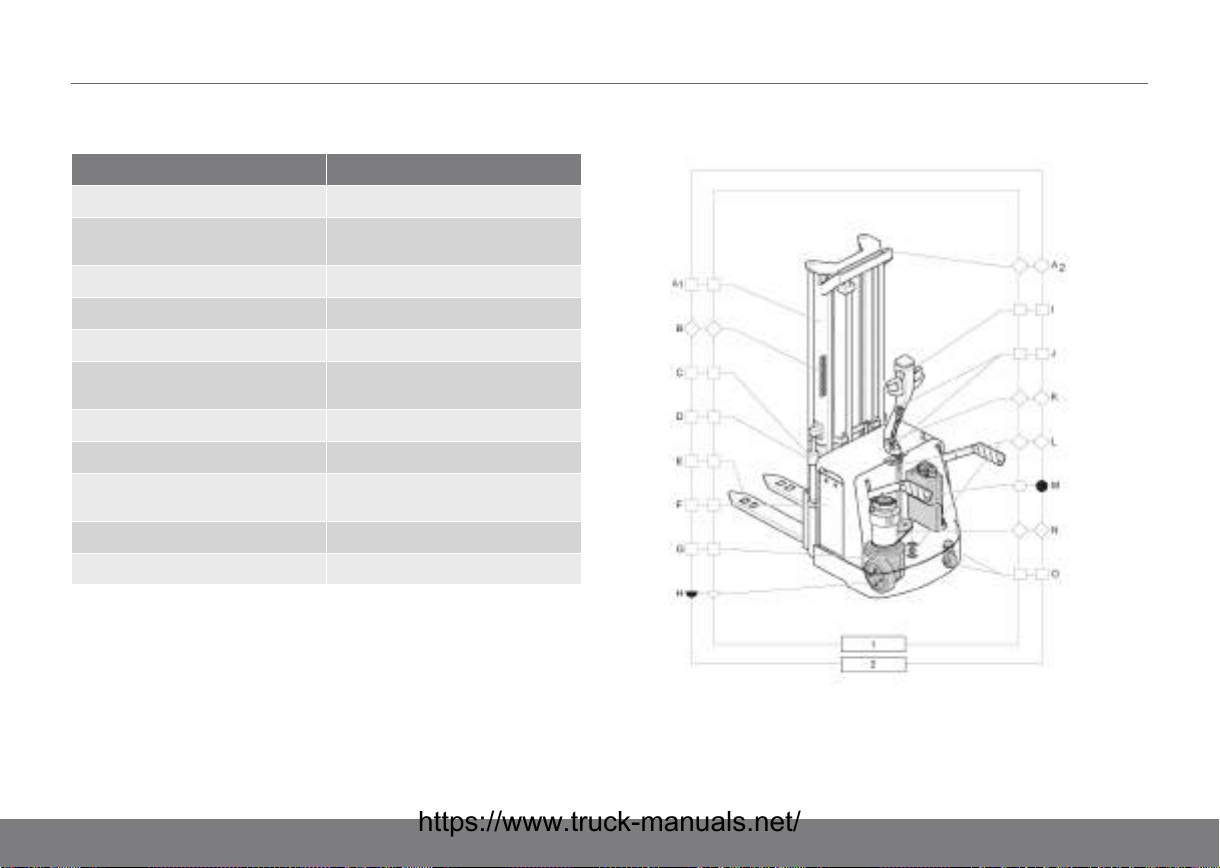

Lubrication chart PL*/PS*

Figure 5. PSL, PSD

1. 500 hr service 2. Annual service

48

SERVICING AND MAINTENANCE14

PL*/PS* components requiring lubrication

Location Explanation

A1 Mast profile roller surfaces and slide surfaces

A2 Thrust rollers

B Lift chains

C Straddle legs

D Fork carriage

E Bogie wheel

F Battery rollers

G Castor wheel - sliding bearing, grease nipple

H Speed and brake controls - slide surfaces and springs

I Steering arm - gas spring

J Steering arm housing

K Hydraulic tank

L Guide ring

M Gearbox

Figure 6. PLE, PLL

1. 500 hr service 2. Annual service

49

14SERVICING AND MAINTENANCE

Lubrication chart PS/PSH

Figure 7. PS

1. 500 hr service 2. Annual service

50

Figure 8. PSH

1. 500 hr service 2. Annual service

SERVICING AND MAINTENANCE14

PS/PSH components requiring lubrication

Location Explanation Location Explanation

A1 Mast profile roller

surfaces and slide

surfaces

A2 Thrust rollers H Speed and brake

B Lift chains I Steering arm - gas

C Straddle legs J Steering arm housing

D Fork carriage K Hydraulic tank

E Bogie wheel L Guide ring

F Battery rollers M Gearbox

G Castor wheel - sliding

bearing, grease nipple

controls - slide surfaces

and springs

spring

Lubrication chart PLP

1. 500 hr service 2. Annual service

Components to lubricate, PLP

Location Explanation

A Mast section - roller surfaces and

slide surfaces

B Gates – bearing surfaces

lubricated

51

14SERVICING AND MAINTENANCE

Location Explanation

C Spring-mounted drive unit – link

bearings, 12 grease nipples

D Hydraulic oil

E Castor wheel - sliding bearings, 2

grease nipples

F Gearbox oil

G Platform, 2 grease nipples

Lubrication chart PLP CD

1. 500 hr service 2. Annual service

52

SERVICING AND MAINTENANCE14

PLP CD components requiring lubrication

Location Explanation

A Thrust rollers

B Mast profile roller surfaces and

slide surfaces

C Bogie wheel

D Gates, bearing surfaces

E Fork carriage

F Spring-mounted drive unit, link

bearings, 12 grease nipples

G Lift chains

H Hydraulic oil

I Castor wheel, sliding bearings, 2

grease nipples

J Gearbox oil

K Platform, 2 grease nipples

Lubrication chart TS

1. 500 hr service 2. Annual service

53

14SERVICING AND MAINTENANCE

TS components requiring lubrication

Location Explanation

A1 Mast section - roller surfaces and slide surfaces

A2 Thrust rollers - all

B Lift chains - all

C Fork carriage - support rollers

D Fork carriage – slide surfaces

E Bogie – axle (unloaded)

F Battery rollers

G Guide ring

H Gearbox

I Speed and brake controls – slide surfaces and springs

lubricated

J Attachment gas spring steering arm

K Steering arm housing

L Upper/lower guide bearings lubricated

M Hydraulic tank

N Steering chain

O Castor wheel, sliding bearings, wheel bearings

Symbol key lubrication chart

Symbol Explanation Symbol Explanation

Oil filter and air filter,

change

Gearbox oil, check Gearbox oil, change

Grease Only cold store

Chain spray Chain spray/oil

Hydraulic oil, oil filter

and air filter, change

version

Applicable in general for the symbols:

Unfilled symbol, check lubrication.

Filled symbol – Change.

Fuses

General

WARNING!

Fuses should be changed by an authorised service

technician.

WARNING!

Always switch off the current by pulling out the

battery plug when changing fuses.

54

SERVICING AND MAINTENANCE14

PL*/PS* fuses

Table 6. PL*/PS* fuses

Designations Heavy current (A) Use

F1 100 Traction motor

F2 80 Pump motor

F3 7,5 Manoeuvring

PS, PSH fuses

Table 7. PS, PSH fuses

Designations Heavy current (A) Use

F1 100 Traction motor

F2 125 Pump motor (PS)

160 Pump motor (PSH)

F3 7,5 Manoeuvring

PLP fuses

Table 8. Fuses

Designations Heavy current (A) Use

F1 250 Traction motor

F2 250 Pump motor

F3 7,5 Manoeuvring

Designations Heavy current (A) Use

F4 5 For additional

equipment. Max. 120

W

F5 25 Servo steering

TS fuses

Table 9. TS fuses

Model Heavy current (A) Use

TS 1.1 kW, TS 2 kW 3 Manoeuvring

TS 1.1 kW, TS 2 kW 7,5 Manoeuvring

TS 1.1 kW, TS 2 kW 250 Pump motor

TS 1.1 kW 100 Traction motor

TS 2 kW 160 Traction motor

Maintenance instructions

Genuine replacement parts

Genuine Parts

The reliability that we promise is contingent upon using original

spare parts. Only our genuine replacement parts guarantee

correct operation, long life and the right to a warranty.

55

14SERVICING AND MAINTENANCE

Basic trouble shooting

If the truck does not work after action has been taken in

accordance with the following table, contact an authorised

service technician. Further action should only be carried out by

specially assigned and trained servicing technicians. If an error

code is shown on the diver's display, this must be reported to an

authorised service technician.

Truck condition Possible cause Procedure

The truck does not

start

The battery plug has

not been inserted

The emergency stop

switch/battery

connector is not

connected

The battery capacity

is too low

Fuse defective Change the defective

The key switch is set

to "0" or the truck is

not logged on

Insert the battery plug

Connect the

emergency stop

switch/battery

connector

Charge the battery

fuse

Turn the key switch to

position "I" or enter

the appropriate

Operator ID and

password

Truck condition Possible cause Procedure

The truck cannot be

driven

The truck will not lift

the load

The truck is not ready

for use

The driving seat

switch is not activated

Drive fuse defective

The truck is not ready

for use

The driving seat

switch is not activated

The hydraulic oil level

is too low

The battery capacity

is below 20%

Pump fuse defective Change the defective

The load is too heavy Reduce the load

Carry out all the

actions under the

heading "The truck

does not work"

Sit in the driving seat

P**/TS: Pull down the

tiller arm and stand

on the platform

Change the defective

drive fuse

Carry out all the

actions under the

heading "The truck

will not start"

PLP/TS: Stand on the

platform

Check the level and

top up the hydraulic

oil

Charge the battery

pump fuse

Refer to the maximum

permitted weight on

the machine plate

56

SERVICING AND MAINTENANCE14

Dismantling and assembling the panels

General

WARNING!

The removal and refitting of panels and covers

should be carried out by an authorised service

technician.

WARNING!

Disconnect the main power circuit by pulling out the

battery plug before the covers are removed.

WARNING!

It is not permitted to use the truck with covers and

panels removed.

Removal and installation of the machine housing cover,

PL*/PS*

1) Remove the securing bolts.

2) Hold the cover by the holes in the sides and lift it off.

3) Install in the reverse order.

Removal and installation of the machine housing cover,

PLP

1) Press the emergency stop button.

3) Insert a round rod or similar into the emergency stop

button. Turn the emergency stop button until the hole in

the shaft is found. Then remove the emergency stop

button shank by turning it counterclockwise.

4) Remove the securing bolts.

5) Fold out the gates and remove the panel by working it over

the gates.

6) Install in the reverse order.

Removal and installation of the machine housing cover, TS

1) Remove the securing bolts.

2) Lift off the cover.

3) Install in the reverse order.

Dismantling and assembling wheels

Safety regulations concerning wheel change

WARNING!

For safety reasons, we recommend that wheel

changes only be carried out by an authorised service

technician.

2) Take out the plastic plug from the plastic cover over the

battery.

57

14SERVICING AND MAINTENANCE

WARNING!

For optimum performance and so as not to invalidate

the warranty, use only our genuine replacement

parts! Otherwise, we are unable to guarantee

stability and brake function.

WARNING!

Take care while lifting and securing the truck with a

block, as there is a risk of crushing injury.

Dismantling and assembling the castor wheel, PLL, PLE,

PSL, PSD, PS, PSH

Lift the load wheel off the ground and secure the truck with

blocks.

WARNING!

Ensure that the truck is unable to move while work is

in progress.

1) Remove the plastic cover from the machine housing.

2) Remove the bolts.

3) Take out the castor wheel assembly and support the fork in

a vice.

4) Undo the bolt and drive out the wheel axle. Now the wheel

can be taken out of the fork.

Torque

The bolts must be tightened to a torque of 47

Nm.

Dismantling and assembling the castor wheel, PLP

Lift the load wheel off the ground and secure the truck with

blocks.

WARNING!

Ensure that the truck is unable to move while work is

in progress.

1) Remove the plastic cover from the machine housing.

2) Remove the securing bolts.

3) Take out the castor wheel assembly and support the fork in

a vice.

4) Tap out the retaining pin, drive out the wheel axle and

remove the wheel from the fork.

NOTE!

In connection with a wheel change, the

retaining pin should also be replaced.

5) Install in the reverse order.

5) Install in the reverse order.

58

SERVICING AND MAINTENANCE14

Torque

The bolts must be tightened to a torque of 47

Nm.

Dismantling and assembling the castor wheel, TS

Lift the wheel off the ground and secure the truck with blocks.

WARNING!

Ensure that the truck is unable to move while work is

in progress.

1) Remove the plastic cover from the machine housing.

2) Remove the securing bolts.