UniCarriers FG20 Series, FD20T4C, FD20T3CZ, FG25T3C, FG30 Series Operation & Maintenance Manual

...

OPER. & MAINT. MANUAL No. OMFBE-CK9140

FG20 - FD30

No. OMFBE-CK9140

OPERATION &

MAINTENANCE MANUAL

FORKLIFT TRUCK

FG20 - FG30

FD20 - FD30

It is the responsibility of the operator and supervisor to read and understand this

manual.

Protect the earth and be kind to your lift truck.

Thank you very much for your purchase of UniCarriers’ product.

This original Operation & Maintenance Manual was written to provide the owner/

operator with information about the safe operation and maintenance of the

UniCarriers forklift truck. Read this original manual thoroughly and become

completely familiar with the lift truck before using it. If you have any questions,

see your dealer.

Due to improvements in design, it is possible that the description contained

herein may not completely apply to the truck delivered to you.

CAUTION

If the truck is to be leased, loaned or sold to anyone, this manual must

be with the truck.

Rated load Truck model Engine model

2 tons FG20T3C K21

FD20T4C V2403

FD20T3CZ C240

2.5 tons

FG25T3C K21

FD25T4C V2403

FD25T3CZ C240

3 tons

FG30T3C K21

FD30T4C V2403

FD30T3CZ C240

CONTENTS

1. SAFETY

FOR SUPERVISORS ..........................................1-2

QUALIFIED OPERATORS ..............................1-3

PLANNING AND WORKING AREA .................1-4

PROPER AND IMPROPER USES ..................1-7

TYPES OF VEHICLES AND LOADS ..............1-8

INSPECTION .................................................1-11

TRANSPORTING THE LIFT TRUCK ............1-12

TRAVELING ON PUBLIC ROADS ................1-13

MODIFICATIONS ..........................................1-14

HOW THE LIFT TRUCK WORKS? ...................1-15

TRAVELING ......................................................1-18

LOAD HANDLING .............................................1-24

PARKING ...........................................................1-28

INSPECTION AND SERVICE ...........................1-30

PREVENTING VEHICLE FIRES .......................1-39

CAUTION PLATES ............................................1-41

2. OPERATING CONTROLS

PICTORIAL NOMENCLATURE ...........................2-2

INSTRUMENTS AND CONTROLS .....................2-3

SWITCHES ......................................................2-5

METERS AND WARNING LIGHTS .................2-7

LEVERS AND PEDALS .................................2-10

TRUCK BODY ..............................................2-14

OPTIONAL EQUIPMENT ..............................2-25

3. OPERATION

PROPER OPERATION .......................................3-2

DURING BREAK-IN ........................................3-2

RELATIONSHIP BETWEEN LOAD AND

STABILITY OF TRUCK ....................................3-2

BASIC LOAD CENTER AND RATED

LOAD ...............................................................3-3

STABILITY OF LIFT TRUCK ...........................3-3

USING INCHING PEDAL ................................3-3

TRAVELING AND STARTING ON

A SLOPE .........................................................3-4

TRANSPORTING LIFT TRUCK ......................3-4

MOVING LIFT TRUCK

(IN AN EMERGENCY) .....................................3-5

OPERATING LIFT TRUCK ..............................3-6

MEASURES AGAINST COLD OR

HOT WEATHER ................................................3-10

IN COLD WEATHER .....................................3-10

IN HOT WEATHER ........................................ 3-11

LOAD HANDLING ...........................................3-12

PICK-UP ........................................................3-12

STACKING.....................................................3-12

UNSTACKING ...............................................3-12

STORING ..........................................................3-13

BEFORE STORING; DAILY STORAGE ........3-13

LONG-TERM STORAGE;

OPERATING AFTER

LONG-TERM STORAGE...............................3-13

4. MAINTENANCE

PREOPERATIONAL CHECKS ............................4-2

GENERAL RULES ON INSPECTION .............4-2

ITEMS TO BE CHECKED ...............................4-3

PREVENTIVE MAINTENANCE .........................4-18

ENGINE ROOM .............................................4-18

REPLACING TIRES AND REPAIRING

FLAT TIRE .....................................................4-26

REPLACING LAMP BULBS .........................4-28

STARTING THE ENGINE WITH

AUXILIARY BATTERY ...................................4-28

ADJUSTING OPERATING FORCE OF

PARKING BRAKE LEVER .............................4-29

PERIODIC INSPECTION ..................................4-30

PERIODICAL REPLACEMENT OF

SAFETY PARTS ............................................4-30

MONTHLY (200 HOURS) CHECKS ..............4-31

3 MONTHS (600 HOURS) CHECKS .............4-37

6 MONTHS (1200 HOURS) CHECKS ...........4-39

ANNUAL (2400 HOURS) CHECKS ...............4-40

PREVENTIVE MAINTENANCE

SCHEDULE ..................................................4-41

CONTENTS

5. SPECIFICATIONS & SERVICE DATA

SPECIFICATIONS ...............................................5-2

EQUIPMENT .......................................................5-6

LOAD CHART .....................................................5-7

SERVICE DATA ...................................................5-8

SERVICE DATA ...............................................5-8

BOLT AND NUT TORQUE ...............................5-9

AFTER-THE-SALE SERVICE ...........................5-13

TRUCK SERIAL NUMBER ............................5-13

SERIAL NUMBERS OF MAJOR

COMPONENTS .............................................5-13

NAME PLATE ................................................5-13

ENGINE SERIAL NUMBER ...........................5-14

GENUINE UniCarriers PARTS ......................5-15

GENUINE UniCarriers LUBRICANTS ...........5-15

TRUCK DATA ................................................5-16

6. INDEX

1. SAFETY

CONTENTS

FOR SUPERVISORS .......................................... 1-2

QUALIFIED OPERATORS ............................. 1-3

PLANNING AND WORKING AREA ................ 1-4

PROPER AND IMPROPER USES ................. 1-7

TYPES OF VEHICLES AND LOADS ............. 1-8

INSPECTION .................................................1-11

TRANSPORTING THE LIFT TRUCK ........... 1-12

TRAVELING ON PUBLIC ROADS ............... 1-13

MODIFICATIONS ......................................... 1-14

HOW THE LIFT TRUCK WORKS? ................... 1-15

TRAVELING ...................................................... 1-18

LOAD HANDLING ............................................. 1-24

PARKING ........................................................... 1-28

INSPECTION AND SERVICE ........................... 1-30

PREVENTING VEHICLE FIRES ....................... 1-39

CAUTION PLATES ............................................ 1-41

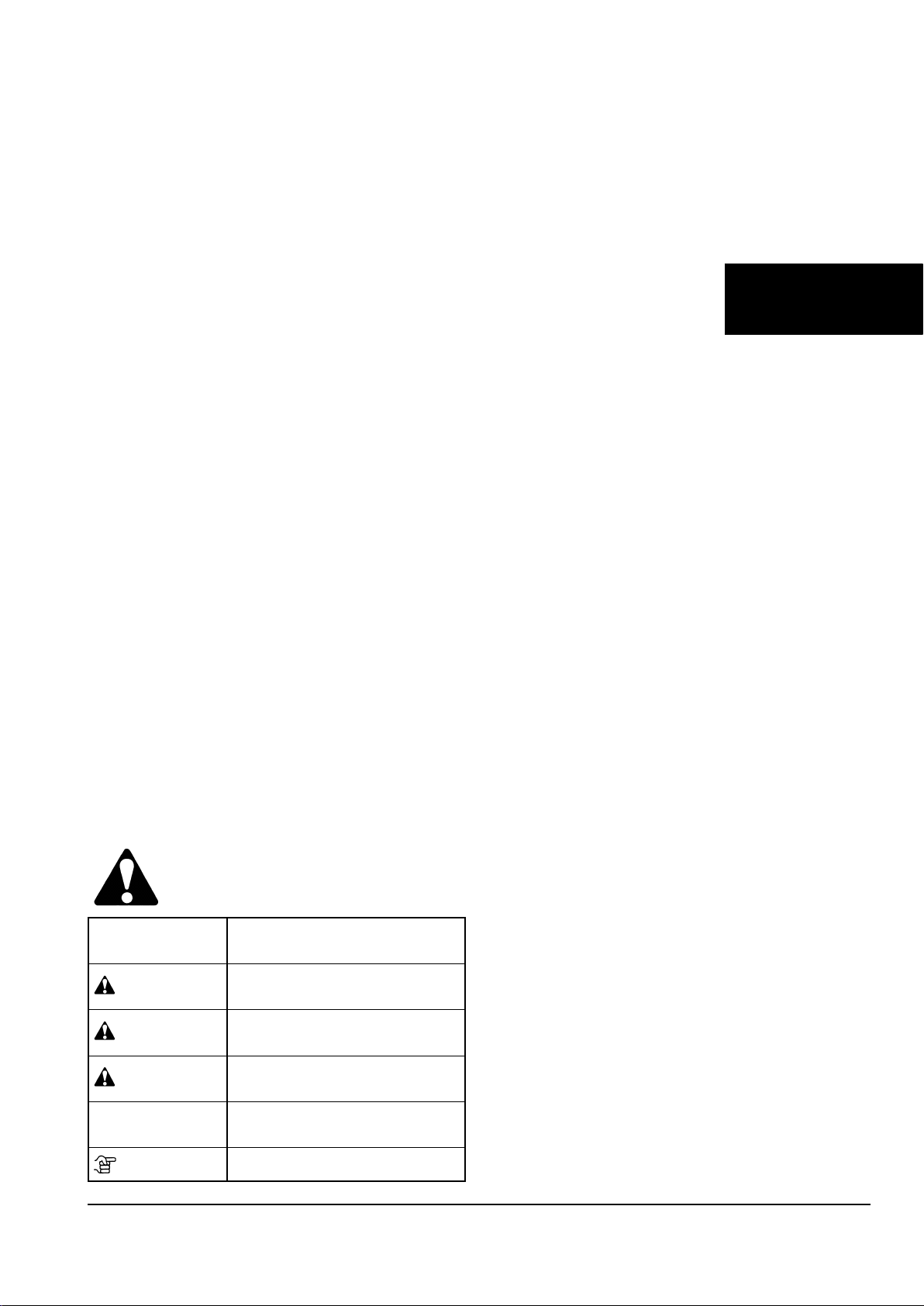

This is the safety alert symbol. It is used to warn the

reader about a potential source of human injury. To

prevent injury or death, make sure you understand

and follow all the safety messages following this safety

alert symbol.

Signal word

(designates the

degree of hazard)

DANGER

WARNING

CAUTION

CAUTION

NOTE

Denition

Indica te s a n imm in en tly h az ardous

situation which, if not avoided, wi ll

result in death or serious injury.

Ind i c ates a poten t i ally h azar d o us

situation which, if not avoided, could

result in death or serious injury.

Ind i c ates a poten t i ally h azar d o us

situation which , if not avoided, may

result in minor or moderate injury.

Indicates a hazardous situation which,

if not avoided, may result in damage to

the truck or other property.

Indicates information which will help

extend the service life of the truck.

1-1

1-2

FOR SUPERVISORS

Right

Forward

Left

The diagram above indicates the meanings of the

terms “forward”, “backward”, “right” and “left” used

in this manual.

Backward

FOR SUPERVISORS

Lift truck accidents cause dozens or hundreds of

deaths every year, and even greater numbers of

personal injuries.

UniCarriers has steadily improved the design and

fabrication of our lift trucks so they may be used

more safely and efciently, but many accidents still

occur due to improper use. Accidents are often

the result of more than just “bad driving”. The use

of inappropriate types of equipment, the selection

of inap p ropriat e attachm ents or acces sories,

inappropriate operating environments, careless

designation of operators, and failure to properly

train the operator are other common causes of

accidents.

It i s no t pos s i b le t o de s c ribe a ll p o t e ntiall y

hazar d o u s s i tuations which may occur while

operating, inspecting or servicing a forklift truck.

The warnings and cautions in this manual, including

the decals attached to the forklift, are not intended

to cover all possible working hazards.

If you operate, inspect or service the forklift in a

manner not described in this manual, please be

careful because you do so at your own risk.

Thi s chapt er cover s the meth ods of acci dent

prevention which are primarily the responsibility of

supervisory personnel.

Pages 1-3 through 1-14 contain instructions

•

which should be enforced by the personnel

supervising the operation of the lift truck. Please

make sure the operators also read these pages.

Pa ge 1-15 and the f ollowing pages cont ain

•

spe c i fic precaut i o ns directly relate d t o t he

operation of the lift truck.

1-3

FOR SUPERVISORS

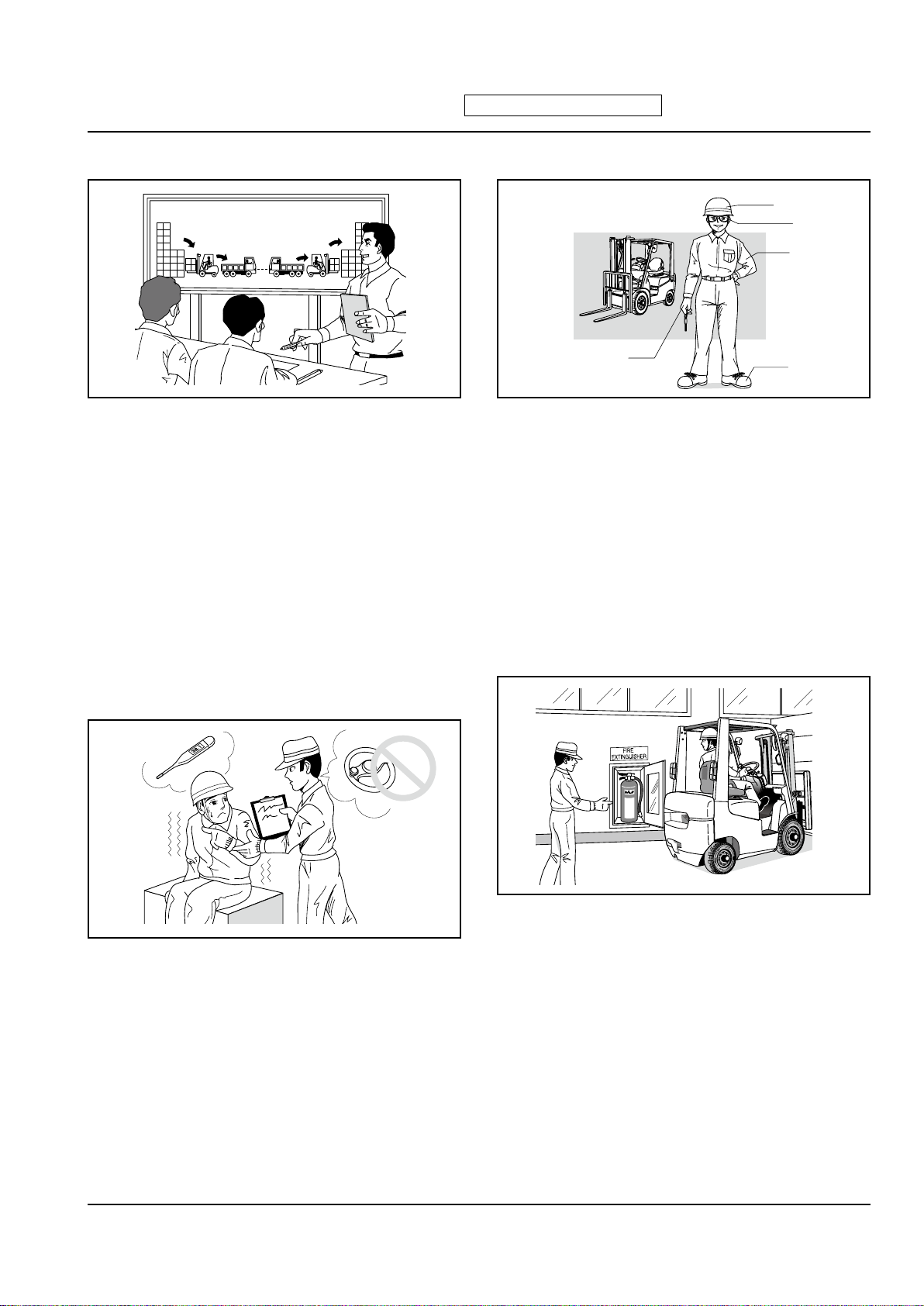

QUALIFIED OPERATORS

TRAIN OPERATOR TO STACK SAFELY

■

Unstacking

Stacking

“Stacking” means piling up a palleted load or

material directly on top of each other, without using

racks or shelves to separate them. If stacking work

is not done properly, the loads may slip or fall,

endangering the operator as well as fellow workers

in the area.

Safety classes should be held to train all operators

in the proper method of stacking and unstacking

loads.

(Your UniCarriers dealer can provide information

about safety stacking training.)

TIRED OR UNWELL? SEND THEM

■

HOME!

WEAR PROTECTIVE GEAR

■

Hard Hat

Goggles

Work

Clothes

Gloves

Always wear proper work clothes for driving.

•

Safety

Shoes

Work clothes should be designed to prevent any

part from accidentally catching on knobs or other

parts of the truck or equipment. For example,

shirts and trousers should have tight cuffs.

Always wear a hard hat and safety shoes.

•

Wear other protective gear as appropriate to

•

the conditions of the work site, i.e., goggles or

gloves.

PROVIDE AND MAINTAIN EMERGENCY

■

EQUIPMENT

Do not let people take chances. An operator who is

overworked or fatigued, an operator who is feeling

unwell, or an operator who is intoxicated must not

be allowed in the driver’s seat.

Fire extinguishers and first aid kits should be

provided and maintained for use in case of a fire

or accident. All personnel should understand the

location and use of emergency equipment.

1-4

FOR SUPERVISORS

PLANNING AND WORKING AREA

KNOW WHO TO CALL IN AN

■

EMERGENCY

Contacts in emergency

....................................

....................................

.............................

...........................

Keep i nformation on hand to allow immediate

calls for help in case of a fire, accident or other

emergency.

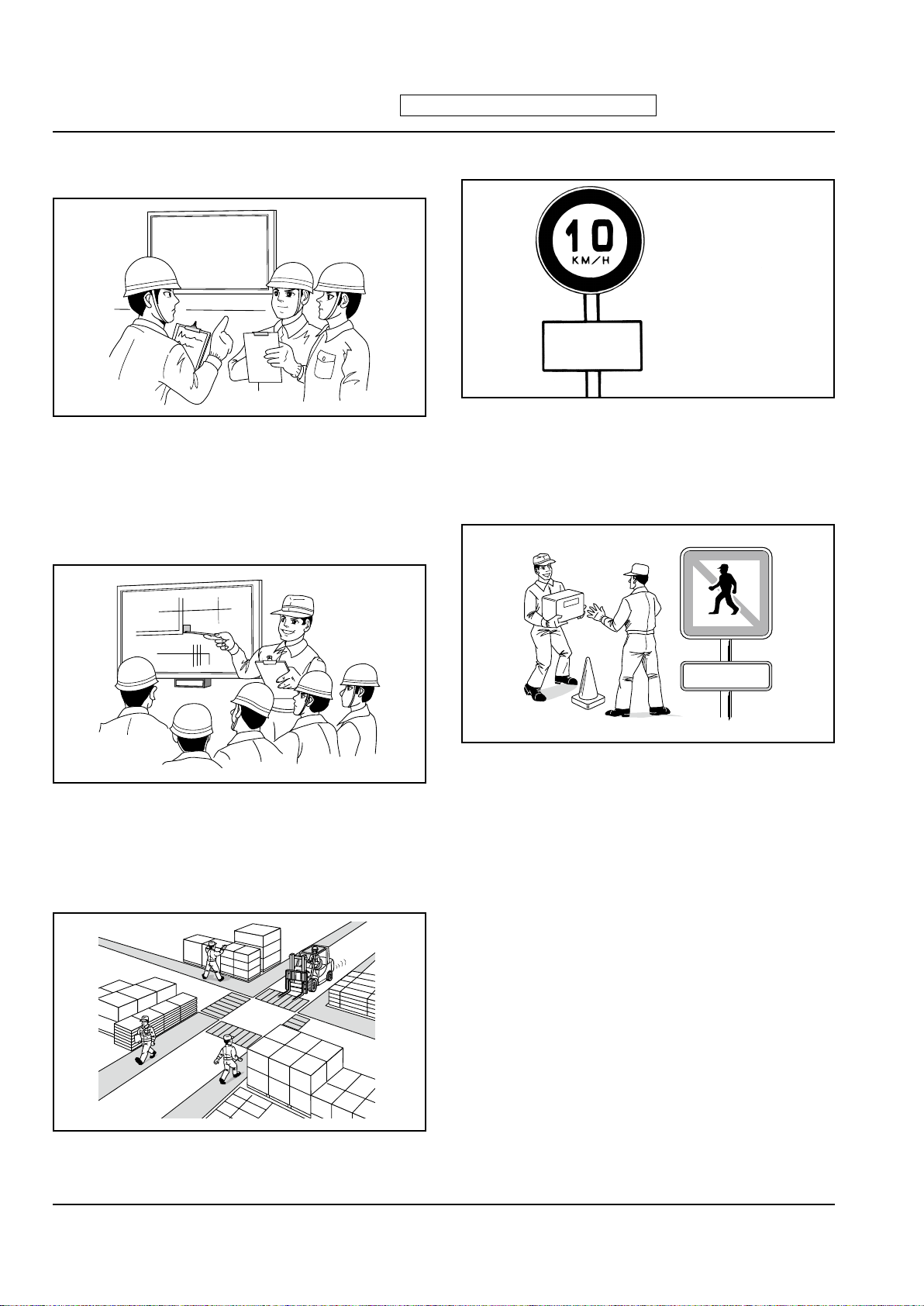

MAKE AN OPERATING PLAN AND

■

DISCUSS IT

SET SPEED LIMITS

■

(Example)

Yard Speed

Limit

Set appropriate speed limits on your company

grounds, and post signs that are clearly visible.

KEEP PEOPLE OUT OF THE

■

OPERATING AREA

Before using the lift truck, plan out the travel routes

and operating procedures, and thoroughly discuss

the details with all involved personnel.

MARK THE TRAVEL LANES

■

Closed to Pedestrians

No Pedestrians

No other personnel should be allowed in areas

where the lift truck is used.

Where other people must be present, post a guide

whose job is to make sure people stay clear of

moving vehicles.

Designate the travel lanes for the lift truck and mark

them clearly, so they will be kept free of obstruction.

1-5

FOR SUPERVISORS

PLANNING AND WORKING AREA

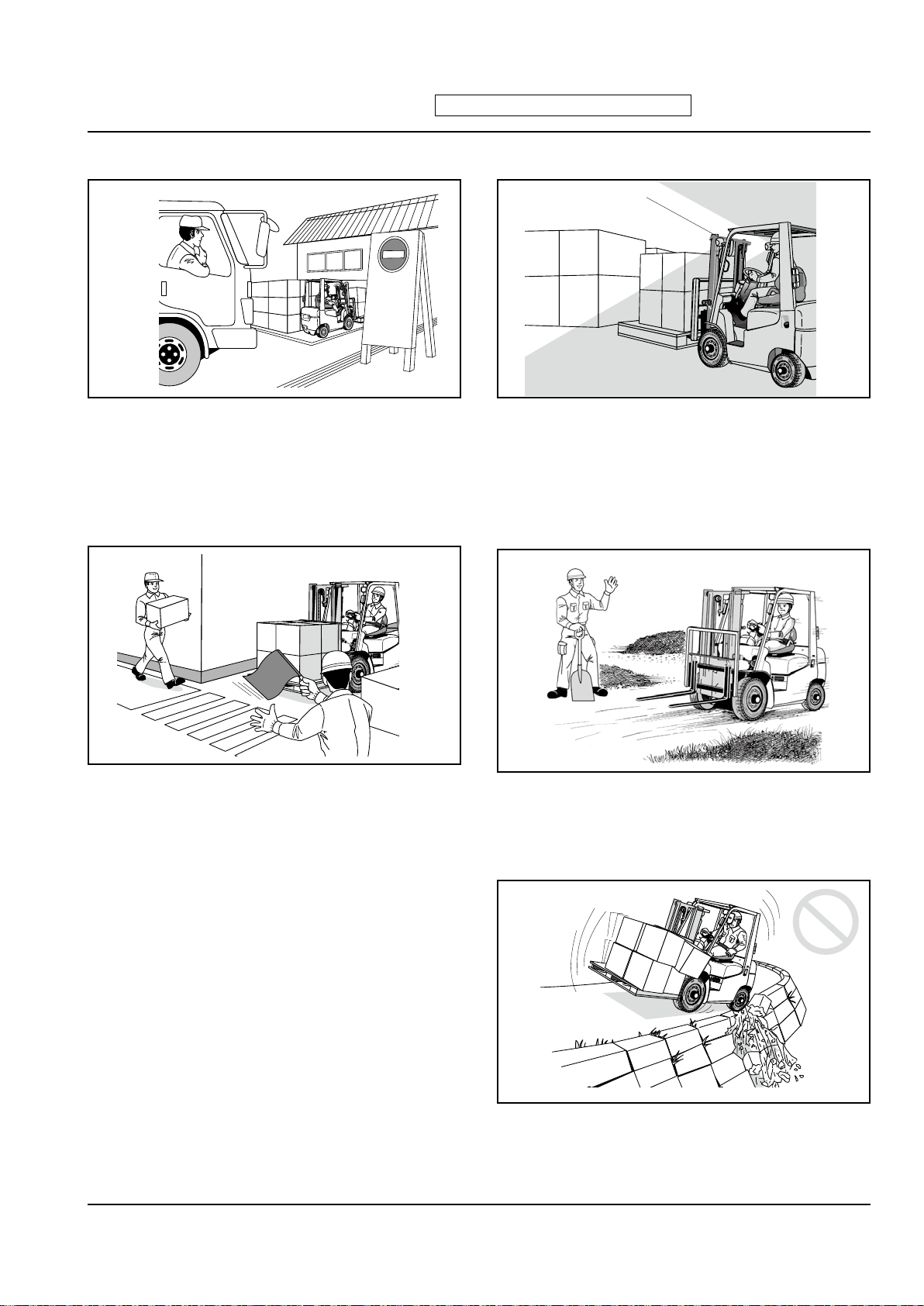

KEEP UNAUTHORIZED VEHICLES OUT

■

vehicles

No entry of

unauthorized

Unauthorized vehicles must be kept out of the

load handling areas. Post signs or give signals as

required.

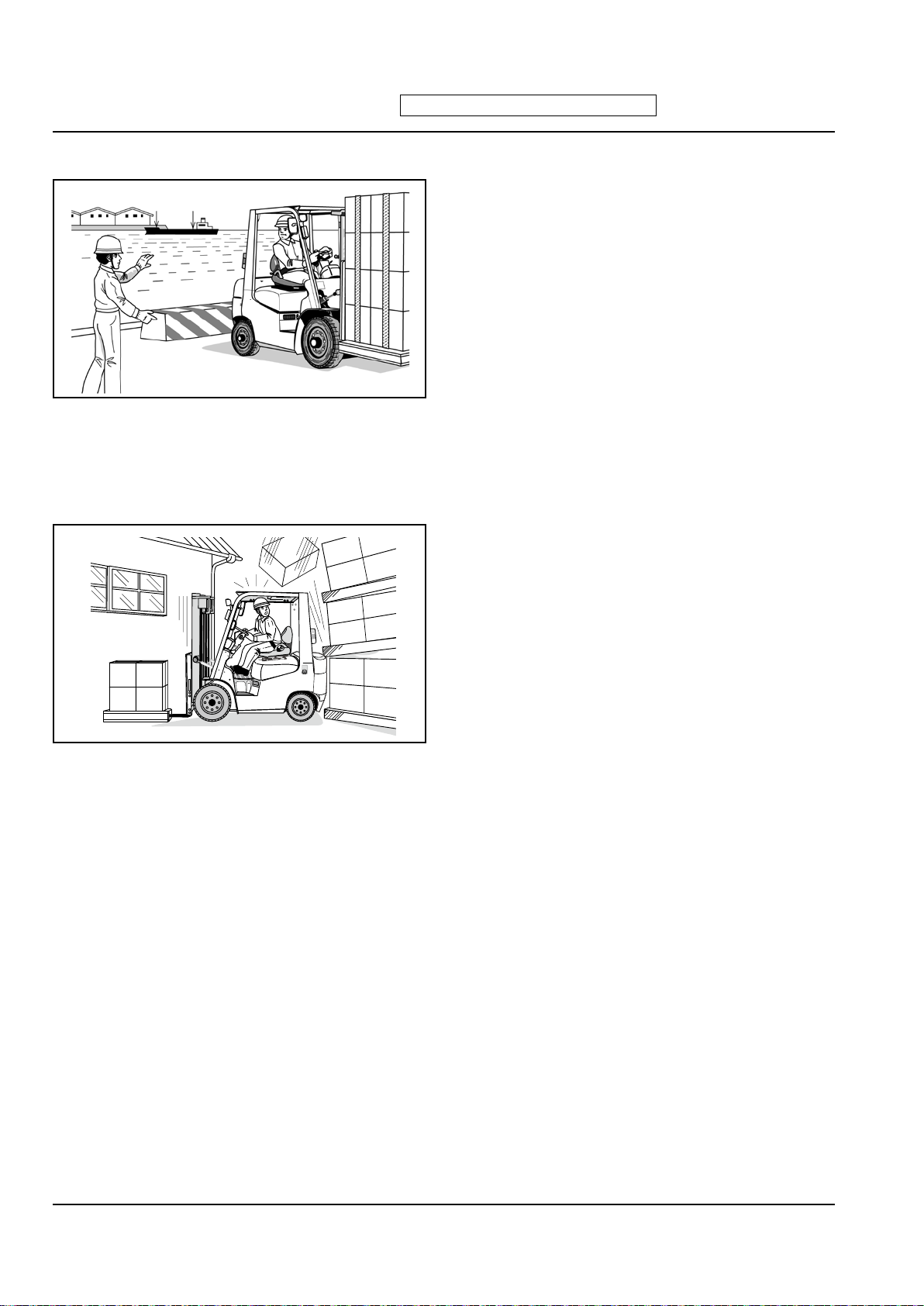

ASSIGN TRAFFIC GUIDES TO

■

CONGESTED AREAS

PROVIDE ADEQUATE LIGHTING

■

Safe operation requires well-lit traveling routes, so

pedestrians and obstacles can be easily seen. Use

headlights, taillights, helmet lamps or other lights as

appropriate.

KEEP THE GROUND LEVEL AND DRY

■

Post a trafc guide in conned or congested areas

wh ere other people or vehicles may pass . All

personnel must obey the guide’s signals.

Be sure that all areas where the lift truck travels are

level and regular. Clear away pools of oil or water.

SAFETY MEASURES FOR DANGER SPOTS

■

Post warn ing sig ns or tak e other approp riate

measures to ensure that lift truck operators keep

away from danger spots as they travel.

1-6

FOR SUPERVISORS

INSTALL CURBS OR RAILINGS

■

If the truck is to be used on a loading dock, shore

wall or other raised surface, install curbs or railings.

DO NOT RELY ON THE OVERHEAD

■

PLANNING AND WORKING AREA

GUARD

The overhead guard is a protective device that

will moderate the impact of an object falling from

overhead, but it cannot withstand every impact. If a

heavy object seems likely to fall on the truck, make

every effort to prevent it from doing so.

1-7

FOR SUPERVISORS

PROPER AND IMPROPER USES

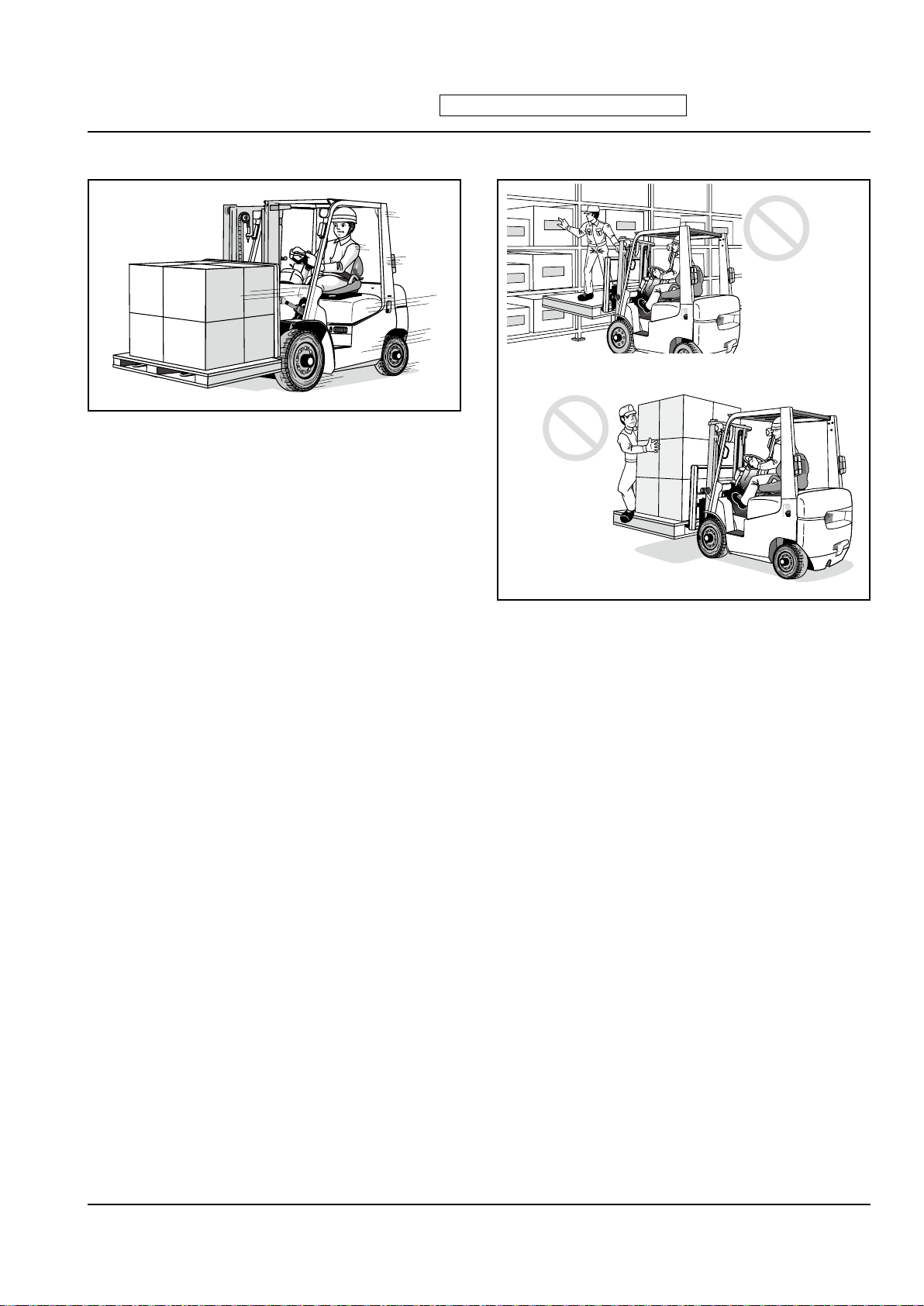

PROPER USE OF THE LIFT TRUCK

■

The proper use of a lift truck is to transport a load

which is placed on the pallet and stacked within the

prescribed height limit.

With a proper attachment, a lift truck may be used

to transport a load which is stacked elsewhere than

on the pallet.

■

IMPROPER USE

Transporting a person, elevating a person, and

towing a n o t her veh i c l e ar e examp l e s of t h e

improper use of a lift truck. Uses which this manual

species as improper must never be requested or

permitted, under any circumstances.

(Examples of Improper Use)

Transporting or elevating a person on the forks or

•

pallet.

Carrying a person on the pallet to control the

•

load.

Hanging wire ropes from forks to lift a load.

•

Towing another vehicle.

•

Pushing a load or another vehicle with the forks.

•

Using the forks or truck body to close or open the

•

door of a freight vehicle.

1-8

FOR SUPERVISORS

TYPES OF VEHICLES AND LOADS

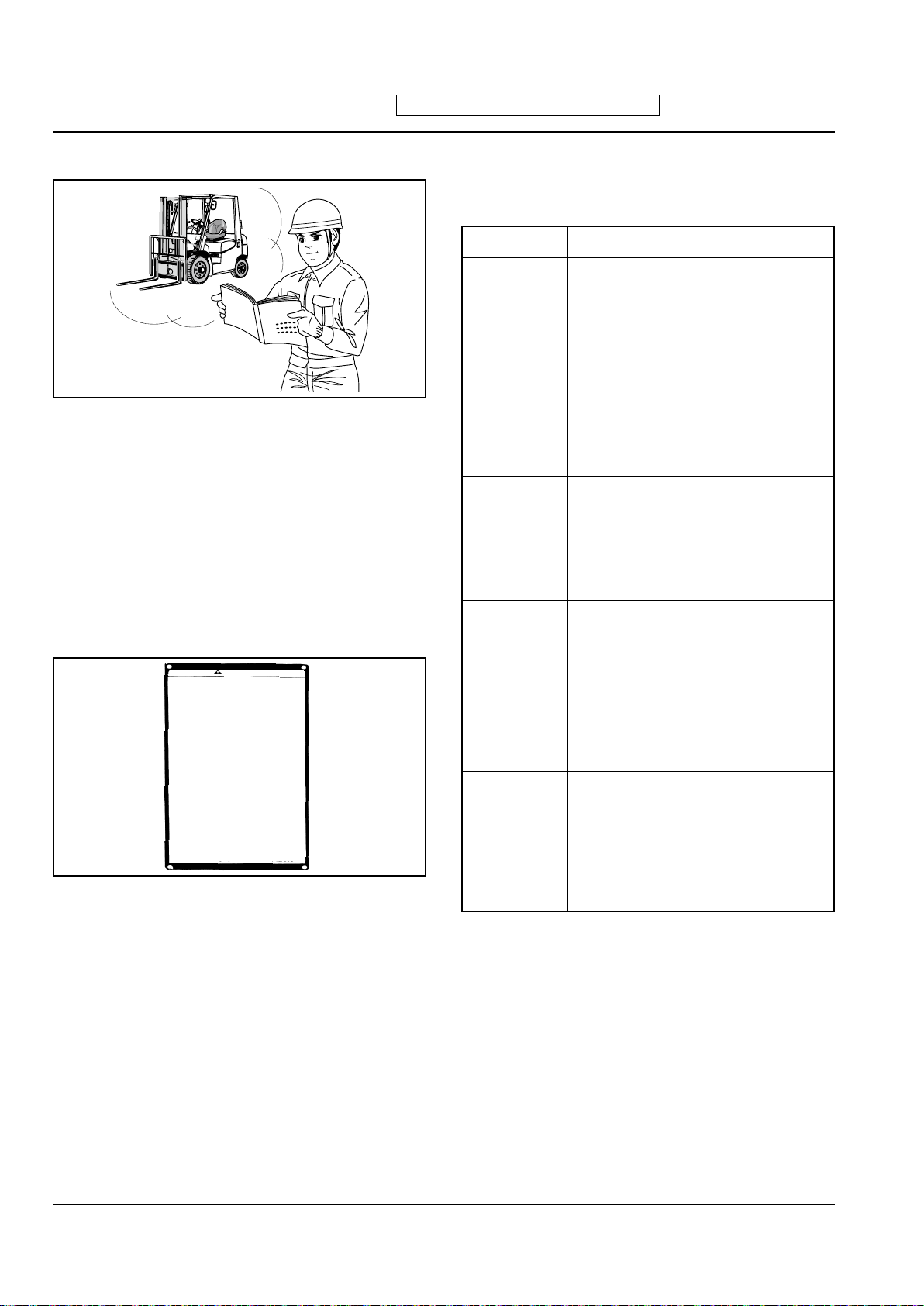

READ MANUAL AND DECALS

■

Read t h e Op e r a tion & Ma i n t enance man u a l

an d caution plates on the tr uck, a nd bec ome

familiar with your truck and operating procedures.

Re membe r that individual lift truck s migh t be

di fferent i n design an d construc tion from o ne

another. Observe the caution decals on the truck.

Keep this Operation and Maintenance manual on

the truck as a ready reference for anyone who may

drive or service it.

KEEP DECALS LEGIBLE

■

YOU MUST FOLLOW THESE RULES TO AVOID SEVERE INJURY OR

DEATH TO YOURSELF AND OTHERS.

1. Operate truck only if trained and authorized by your employer. Know

2. Safety check truck every day. Do not start if damaged or faulty; stop if

Repair allowed only by trained, authorized mechanics.

3. Turn, start, stop, and handle loads smoothly and slowly.

Carry loads low and tilted back; stack only on level using minimum tilt.

4. Look where you are going. Watch out for people, hazards on oors

5. Truck overturn can kill you. Slow for turns even when empty. Never

6. Do not lift overweight or loose loads.

Move slowly with wide, high, or long loads.

Keep forks wide and fully under loads.

Travel in reverse if loads block view.

Attachments require special training, ask your employer.

7. Keep loads upgrade on all inclines. Stay clear of ramp and dock

8. Overhead guard and load backrest must be on truck.

Always keep yourself completely inside guard.

9. Stop engine when refueling. Follow Operation & Maintenance Manual

10. Forks can fall rapidly even with light loads.

Do not raise people or allow them under forks.

No passengers allowed on truck.

11. Park only in authorized areas, never on inclines.

Lower forks to bottom, put direction control in neutral, turn off key and

12. Fasten the seat belt, when operating the lift truck.

WARNING

Operation & Maintenance Manual and all work rules.

problems start.

and overhead, drop-offs and tail swing clearance.

turn on inclines.

edges. Make sure dockboards and trailers are secure before going on

them.

and employer’s work rules about fuel, battery and tire maintenance

hazards.

make sure parking brake is set.

The decals on the truck describe safety precautions

and operating instructions. Replace any damaged

or missing decals. Check that the decals are legible

during regular inspections.

USE THE RIGHT TRUCK FOR THE JOB

■

Be sure the type and capacity of the lift truck is

suitable for the work environment.

Check Point Choice

Capacity Load capacities range from 0.5 to 42

Power Source G a soline , natur a l gas, di esel, and

Balance On co u nt e r b ala n c e d mo d els , the

Tires For indoor use, there are models with

Flammable

Materials

tons. Pay particular attention to the load

center.

(UniCarriers Lift Truck Capacities: 0.5,

0.7, 0.9, 1, 1.35, 1.5, 2, 2.25, 2.5, 2.75, 3,

3.5, 4, 4.5, 5, 6, 7, 8, 10, 10.5, 11.5, 12,

13.5, 15, 18, 20, 22, 23, 24, 25, 30, 37,

or 42 tons.)

battery- powered models are available.

Fuel costs and exhaust composition will

vary.

counterweight at the rear makes the

vehicle longer than reach trucks. A reach

truck performs loading and unloading

by extending the front part of the mast

outward, which gives it the advantage of

compactness.

solid tires (best for reach trucks) and

cushion tires (engine type or battery

type). Both are compact.

For outdoor use, pneumatic tires work

well. Solid cushion tires, with the same

dimensions as pneumatic tires, may be

the best choice in cases where the load

materials or surface conditions could

puncture pneumatic tires.

For handling fl a m m a b l e ma t e r i als

such as petrochemicals, a combustion

engine is too dangerous. An electric

vehicle with explosion-proof or safetyreinforced construction is required. (A

ba tte ry pow er sou rce always offe rs

bett er protectio n again st fi re th an a

combustion engine.)

1-9

FOR SUPERVISORS

TYPES OF VEHICLES AND LOADS

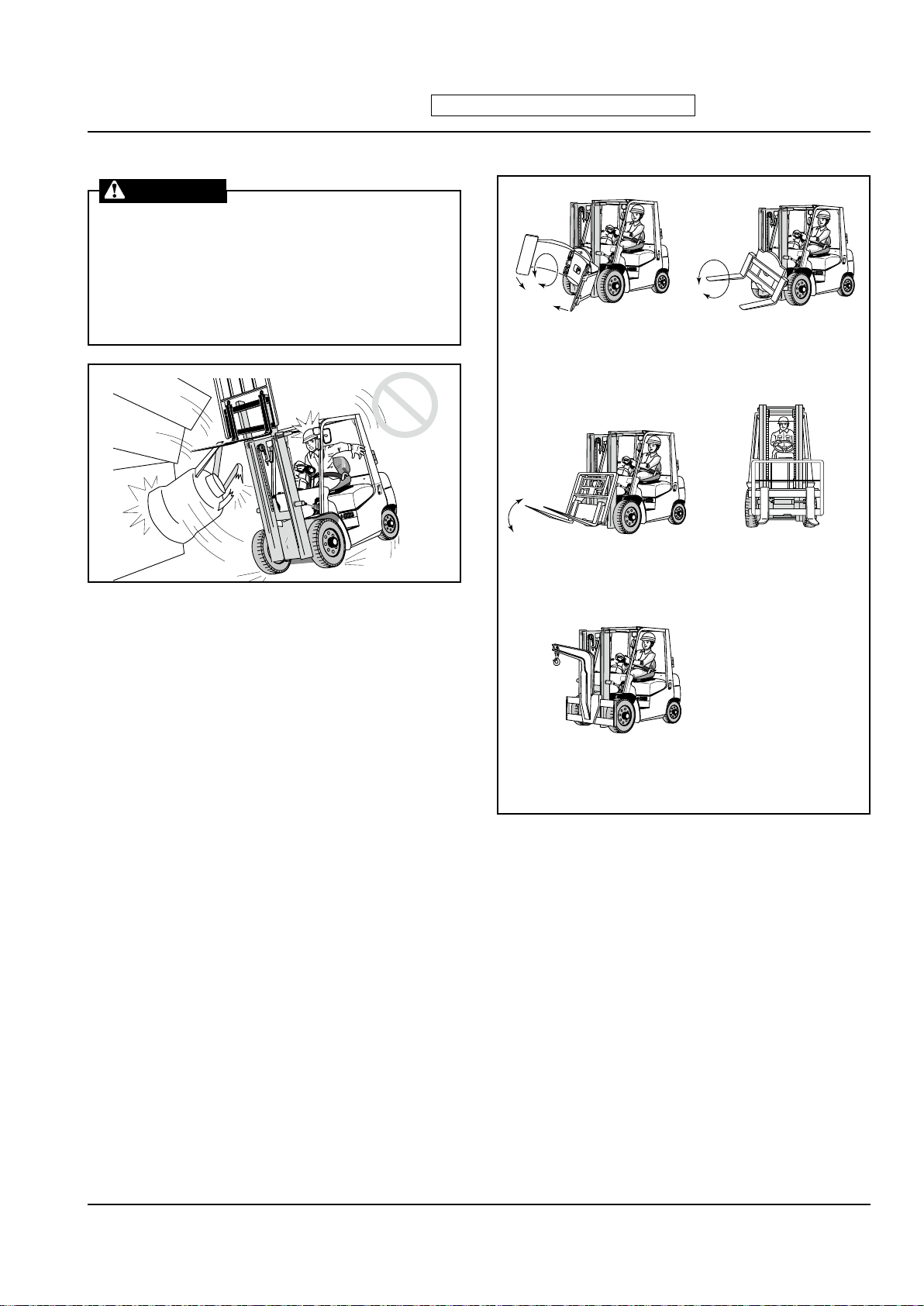

USE THE PROPER ATTACHMENT

■

WARNING

Avoid hoisting a load with wire rope hung

from the forks or an attachment, or avoid

lifting a freight container with forks, because

ther e is da n ger o f t h e tr u ck t i pping . If

necessary, have a qualified operator use a

hook or crane arm attachment.

Popular Attachment Examples

① : Roll Clamp

(For paper roll or

drum handling)

③ : Hinged Fork

(for lumber handling)

② : Rotating Fork

(For damping work

or charging work)

④ : Side Shift

(For precise stacking

in containers or other

narrow spaces)

⑤ : Crane Arm

(For slinging work)

1-10

FOR SUPERVISORS

TYPES OF VEHICLES AND LOADS

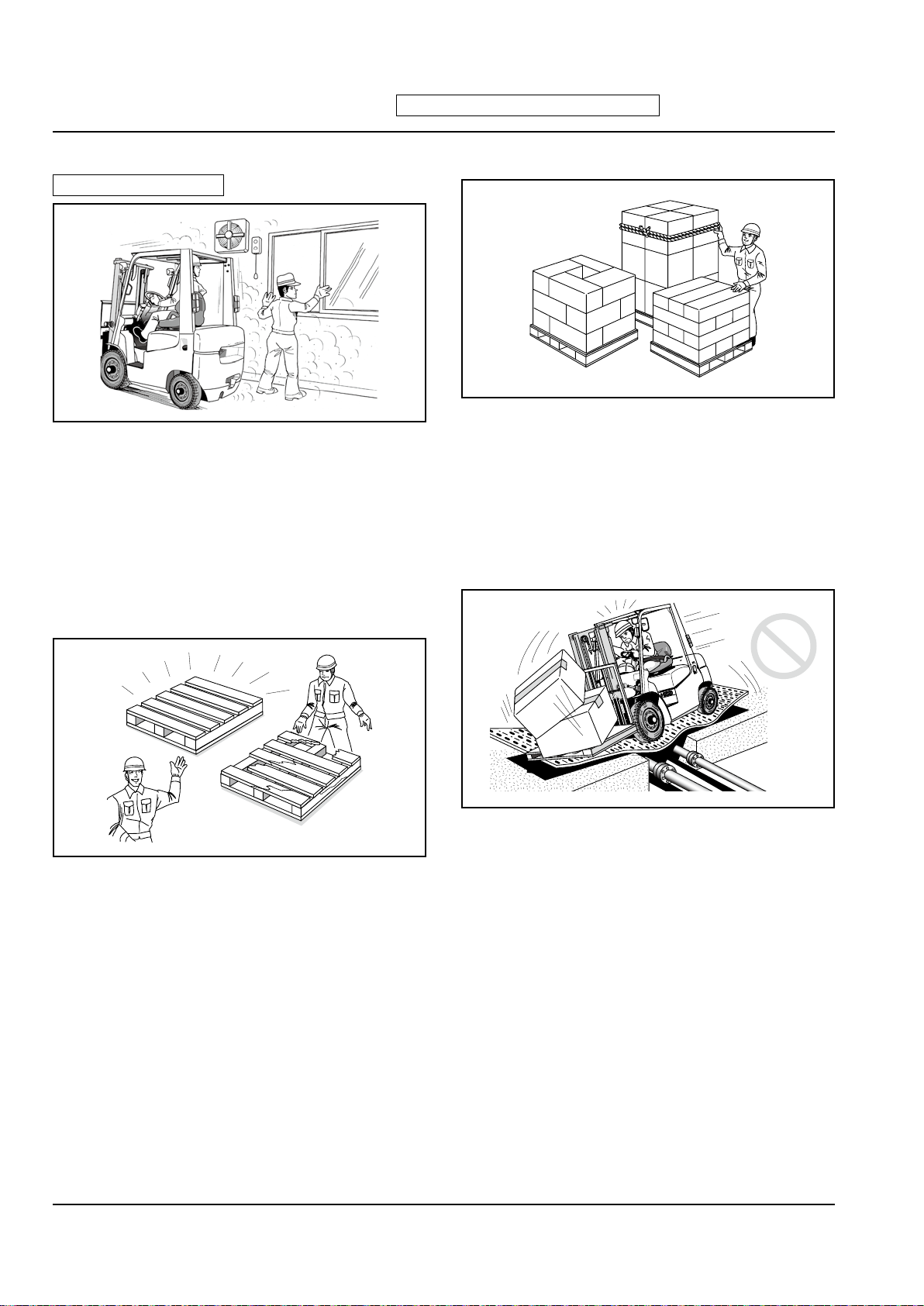

HAVE A GOOD VENTILATION

■

Engine-powered trucks

When the engine is run indoors such as in an

enclosed warehouse, have a fresh-air ventilation.

Exhaust fumes can cause chemical poisoning, and

in the worst case exhaust fumes can kill. When

warming up or operating the truck indoors, open the

windows and doors or use a fan to make sure there

is a good ventilation.

STACK LOADS SECURELY

■

Whe n stacki ng loads , place them i n a stable

manner that they will not easily come apart, and be

sure the weight is evenly distributed. Secure the top

layer with a cord wrapped like a headband or in a

similar fashion.

KNOW THE WITHSTAND LOAD OF

■

YOUR FLOOR

USE STURDY PALLET MATERIALS

■

Pallets and skids m u s t b e strong enough t o

withstand t h e heavy w e i ghts of l o a d i n g and

unloading. Remove or repair any damaged pallet.

The lift truck is heavier than it appears . F o r

example, a 2-ton truck weighs almost 3.5 tons

even when empty. Furthermore, when loaded, 80

to 90% of the total weight is concentrated on the

front wheels. Check the strength of your oors and

roadways, and if necessary reinforce them.

1-11

FOR SUPERVISORS

INSPECTION

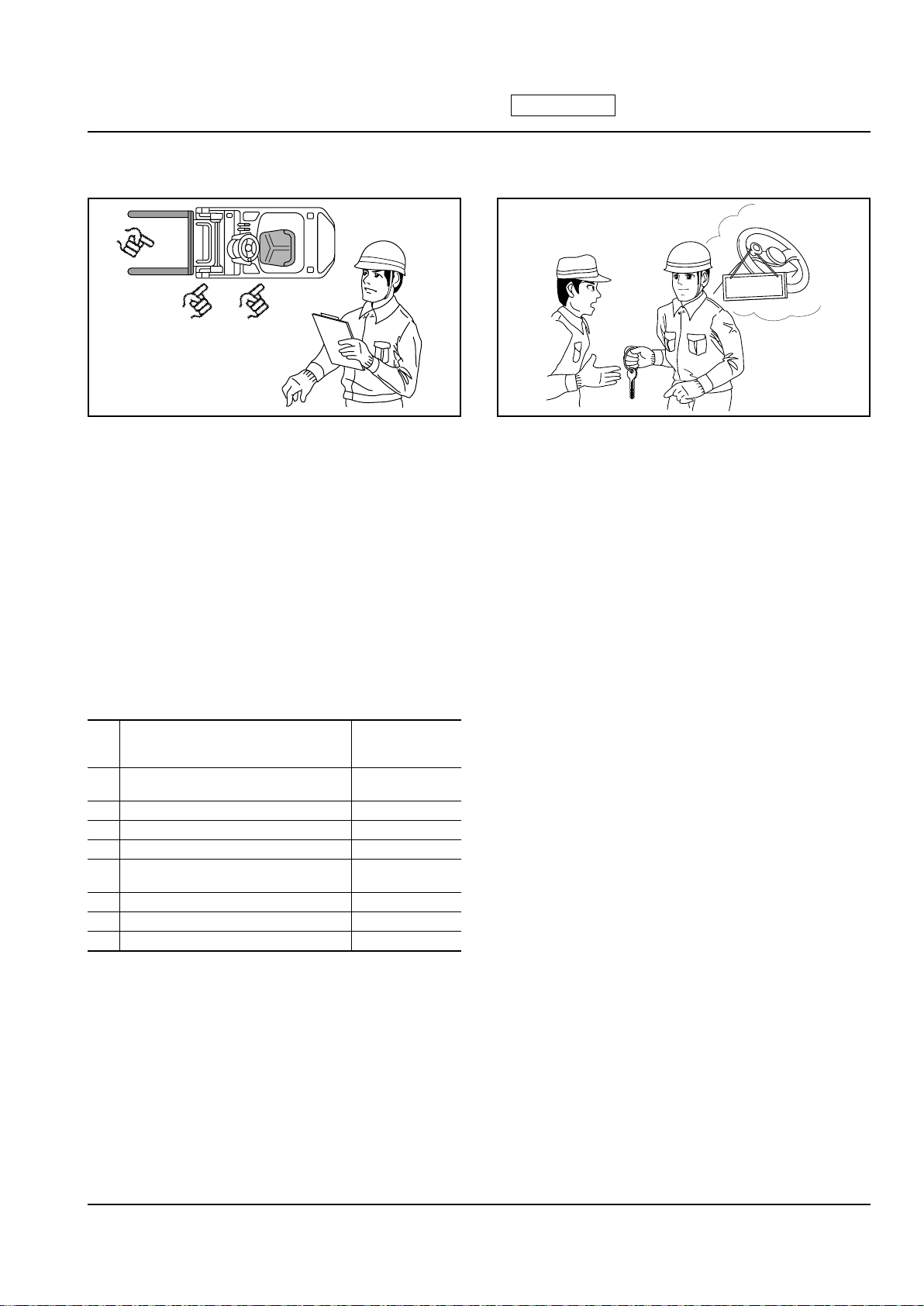

ALWAYS INSPECT BEFORE

■

OPERATING

The operator should always inspect the truck before

each use to verify that all essential safety features

are working. Any abnormality is to be reported to

the supervisor, who is responsible for correcting it.

PERIODIC INSPECTIONS ARE

■

MANDATORY

Monthly and annual inspections must be performed

thoroughly, and any abnormality promptly repaired.

Only a certied expert who has the advanced skills

and equipment is allowed to conduct inspections.

NEVER USE AN UN-MAINTAINED

■

TRUCK

Out of

Service

A truck that has not passed an inspection must

never be operated. Hang a sign on the truck and

remove the ignition switch, to make sure no one

uses it. Then report the problem to the supervisor

and wait for the repair to be completed.

REPLACE SAFETY PARTS REGULARLY

■

Name of safety parts

Master cylinder and wheel cylinder cups

1

and dust seals

2 Power steering hose 2

3 Reserve tank tubing 2 – 4

4 Fuel hose (Engine-powered trucks) 2 – 4

Torque converter rubber hose

5

(Engine-powered trucks)

6 Rubber parts inside power steering unit 2

7 Lift chain 2 – 4

8 Load handling means hoses 1 – 2

Recommended

replacement interval

(year)

1

2

Certain critical parts must be replaced at regular

intervals. Since it is difficult to detect wear on the

above parts by visual inspection, they must be

replaced at the intervals specied, because a failure

would result in a falling load or runaway truck.

1-12

FOR SUPERVISORS

TRANSPORTING THE LIFT TRUCK

DESIGNATE A REPAIR AND ASSEMBLY

■

SUPERVISOR

Repairs and the mounting and dismounting of

attachments must be performed under the direction

of a designated supervisor. The body and major

parts of the lift truck are quite heavy and under very

high pressure. Repair or assembly work undertaken

without careful and thorough preparation can lead

to serious injury.

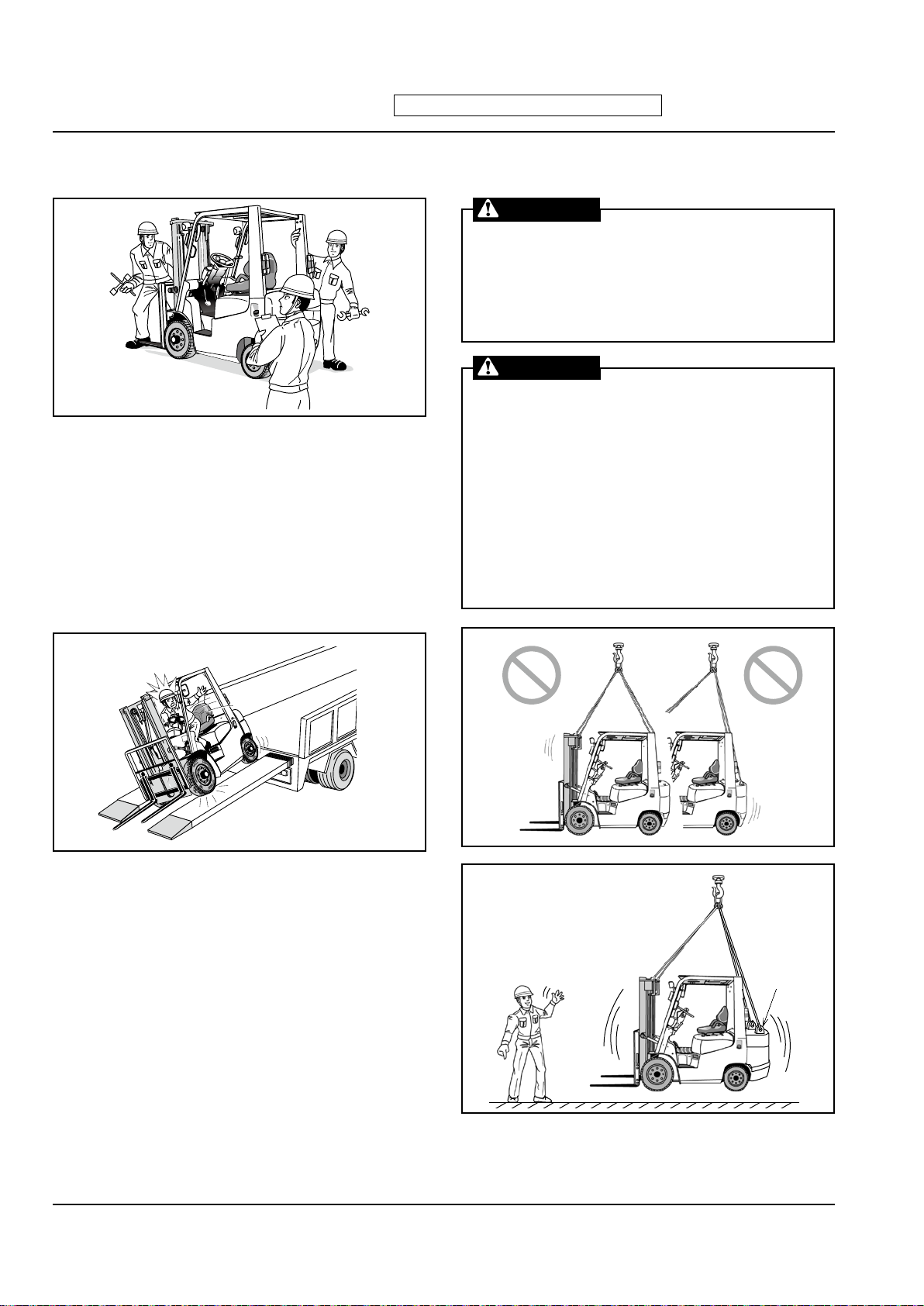

TRANSPORTING THE LIFT TRUCK

■

USE OPTIONAL “LIFTING EYES” FOR

■

LIFTING YOUR LIFT TRUCK

WARNING

Never hoist your lift truck at its overhead

guard or counterweight; otherwise there is a

danger of the truck falling.

If hoisting the lift truck is necessary for any

reason, use optional “Lifting Eyes.”

WARNING

Observe the following conditions when lifting

the lift truck:

Use optional “Lifting Eyes”.

•

Use ropes strong enough to withstand the

•

weight of the truck.

Do not use any wire rope which is kinked,

•

deformed or frayed.

Lifting the truck should be performed only

•

by qualied personnel.

Do not enter under a lifted truck.

•

Use a level, hard road surface when loading the

truck onto or unloading from a trailer and when

unl o ading it. Be certai n t hat the ramps h a ve

sufficient length and width as well as strength.

Do not load or unload the truck when it is raining,

unless the ramps are fitted with an anti-slipping

surfaces.

It is safe s t to use a self- loading trail e r truck

equipped with a jack and winch. For loading, tilt

the truck bed with the jack, attach the winch to

the towing pin of the lift truck, and pull it up. The

operator must not ride on the l ift truck during

loading or unloading.

LIFTING

EYES

1-13

FOR SUPERVISORS

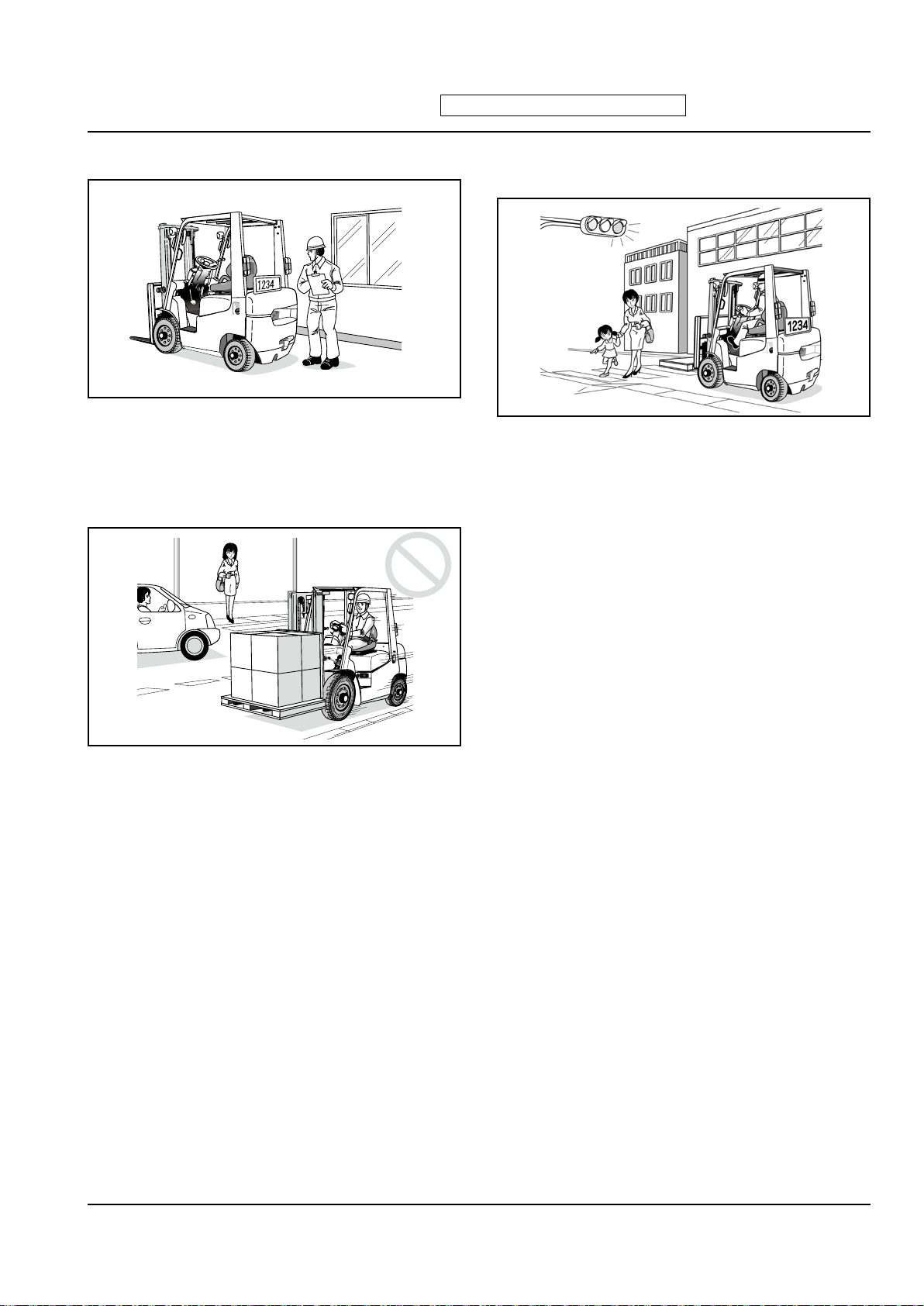

TRAVELING ON PUBLIC ROADS

GOT A LICENSE?

■

Before traveling on a public road, be sure that the

truck has been licensed and inspected as required

by local laws.

NO LOAD, NO TOWING

■

OBEY TRAFFIC LAWS, AND TURN OFF

■

YOUR LIGHTS

On a public road, the lift truck must obey the same

laws as any other vehicle. Do not use rear working

light.

It is usually illegal to carry a load on a public road. It

is also not allowed to make a sideways travel or tow

another vehicle on a public road (with the possible

exception of a disabled vehicle). Never tow another

vehicle, even on company property.

1-14

FOR SUPERVISORS

MODIFICATIONS

NO OPERATION WITHOUT LIGHTS,

■

OVERHEAD GUARD, OR BACKREST

Load

backrest

Lamps

The lift truck cannot be used if the headlights,

taillights, overhead guard, backrest, horn or turn

signals have been removed. Any parts that have

been temporarily removed for some reason must be

reattached immediately.

OBTAIN APPROVAL FOR ANY

■

Overhead

guard

MODIFICATION

IMPLEMENTATION OF MODIFICATIONS

■

Only in the event that the truck manufacturer is no

longer in business and there is no successor in the

interest to the business, the user may arrange for

a modication or alteration to a powered industrial

truck, provided, however, that the user shall:

a) arrange for the modification or alteration to

be designed, tested and implemented by an

engineer(s) expert in industrial trucks and their

safety;

b) maintain a permanent record of the design,

test(s) and implementation of the modication or

alteration;

c) approve and make appropriate changes to the

capacity plate(s), decals, tags and instruction

handbook;

d) affix a permanent and readily visible label to

the truck stating the manner in which the truck

has been modified or altered together with the

date of the modification or alteration, and the

name and addres s of the o rganization that

accomplished the tasks.

Modifications or additions that affect the capacity,

construction or strength of the truck must not be

performed by the user without the manufacturer’s

or his authorized representative’s prior permission.

For example, don’t add a counterweight.

1-15

HOW THE LIFT TRUCK WORKS?

KEEPING THE TRUCK BALANCED

■

Lift trucks are equipped with load handling means

including a mast and forks at its front part. The front

wheels of the truck work as a fulcrum to balance

the center of gravity of the truck and the center of

gravity of the load. The relationship between the

locations of those two centers of gravity is vitally

important for safety.

KNOW THE CENTER OF GRAVITY OF

■

YOUR LOAD

HOW THE CENTER OF GRAVITY

■

SHIFTS

Truck’s center of gravity

with high mast raised

Truck’s center of gravity

with standard mast raised

The higher the load,

the higher the truck’s

center of gravity

Truck’s center of

gravity with truck tilted

Load’s

center

gravity

Distance

Allowable load (kg)

Weight x distance = moment (constant)

Basic load center

Load center (from fork root) mm

Materials of various shapes such as boxes or flat

or cylindrical items may be loaded on the lift truck.

In order to accurately judge the stability of the

truck, it is vitally important for the operator to know

the location of the center of gravity for each type of

load.

Lift truck viewed from front

The stability of the lift truck is determined by the

overall center of gravity, which is the product of the

centers of gravity of the truck and the load. When

the truck is empty, this point is the same as the

center of gravity for the truck, and when it is loaded

it shifts according to the center of gravity of the

load. Since the center of gravity of the load changes

whenever the mast is tilted forward or backward or

the fork is raised or lowered, the overall center of

gravity also changes. The center of gravity is also

governed by the following factors:

Size, weight and shape of the load

•

Unloading height

•

Tilt angle of the fork

•

Tire material

•

Acceleration, deceleration and turning

•

Surface condition and gradient of the road

•

Type of attachment

•

1-16

HOW THE LIFT TRUCK WORKS?

OUTSIDE THE TRIANGLE OF

■

BALANCE, THE TRUCK TIPS

Rear

Lift truck Viewed from Above

RATED LOAD (LOAD WEIGHT AND LOAD CENTER)

■

wheels

Front

wheels

Axis of lateral stability

If the center of gra vity W 1 moves

ou tw ar d pas t the axis of lat er al

stability, the truck will roll.

(A s the cen te r of gravit y com es

closer to the rear axle, the space

between the centerline of the truck

an d th e ax is of late ra l st abi li ty

narrows, and the truck will roll more

easily.)

For a lift truck to remain stable, the overall center

of gravity must be inside the triangle formed by the

contact points of the left and right front tires and

the center point between the steering wheels. The

triangle denes the area of stability for the center of

gravity.

If the overall center of gravity moves further forward

than the front wheels, the truck will tip forward with

the front wheels as the fulcrum. If the overall center

of gravity moves outside the triangle to the right or

the left, the truck will fall over in that direction.

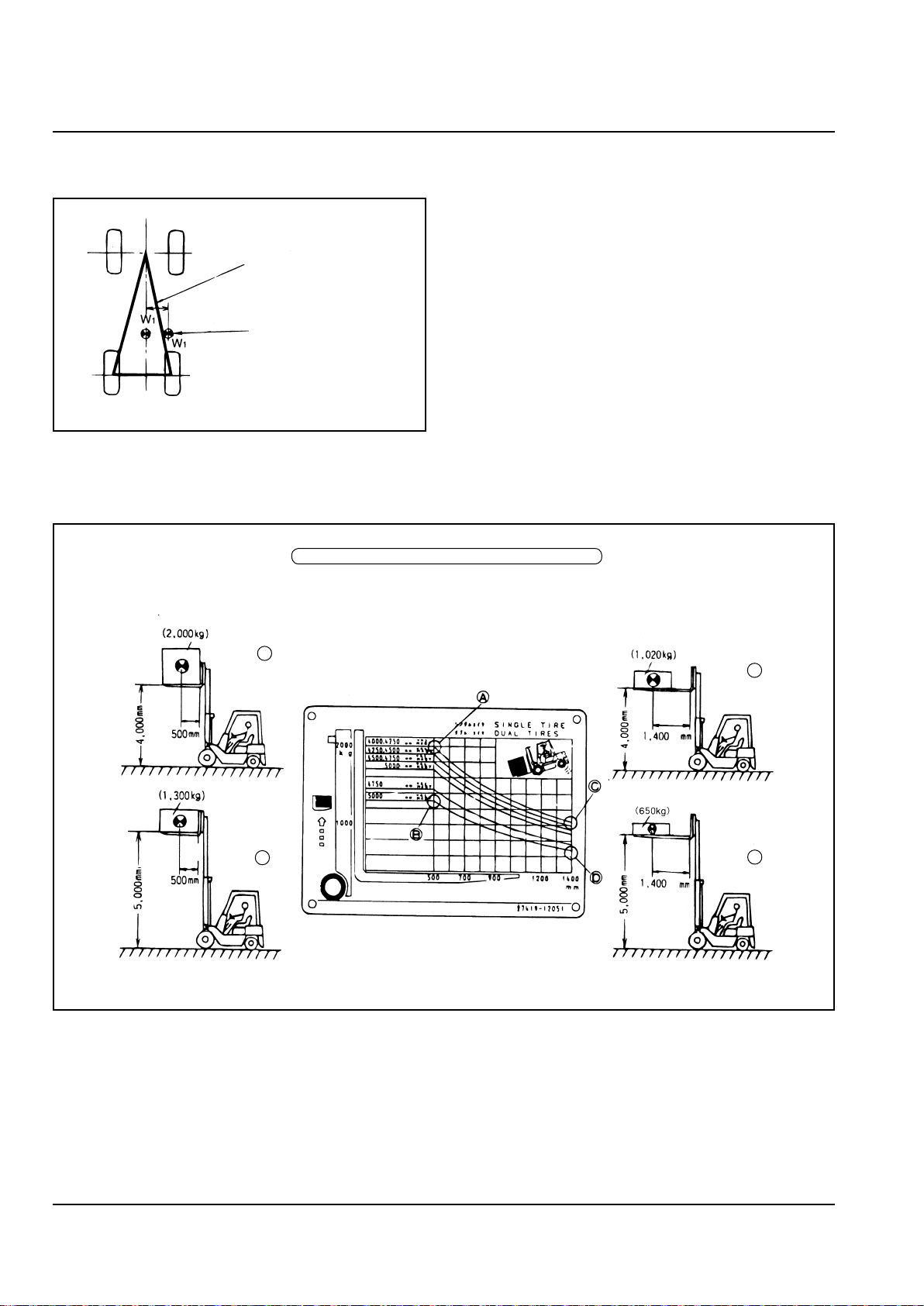

HOW TO READ THE LOAD CHART

The higher the load is raised, and the further forward

from the front wheels the load is moved, the more the

weight of the load increases.

(Slightly heavier loads can be carried with dual tires)

A

Point

Point

B

Point

Point

C

D

The load center is the distance from the front face of the forks to the center of gravity of the load. The rated

load is the maximum weight allowable with the nominal load center.

The Load Chart, showing the relationship between the load center and the rated load, is attached to the truck

as a decal. The rated load decreases as the load center moves toward the tip of the forks, and as the overall

center of gravity moves forward.

1-17

HOW THE LIFT TRUCK WORKS?

ACCELERATING, DECELERATING AND

■

TURNING

The principle of inertia provides that a stationary

object will remain stationary as long as there is no

external force acting on it, and that a moving object

will continue moving at a constant speed as long as

there is no external force acting on it.

Due to inertia, when the lift truck starts to move

there is a momentary backward force, and when

it stops there is a momentary forward force. As a

result, if the brakes are applied suddenly, there

is a very strong hazard that the forward force will

become strong enough for the truck to tip forward.

Likewise, when the truck is turning there is a

centrifugal force that pulls it outward from the

turning center. This force can cause the truck to

fall sideways. Since the zone of lateral stability is

especially narrow, it is necessary to slow down

substantially when turning in order to prevent the

truck from tipping.

When the load is elevated the overall center of

gravity is raised, increasing the danger of the truck

tipping over to the front or side.

1-18

TRAVELING

Do not operate the lift truck until

preoperational checks are nished

If any defect is found during checking, report it to

the supervisor and have it repaired.

Do not operate the truck until the malfunction or

damage is properly repaired.

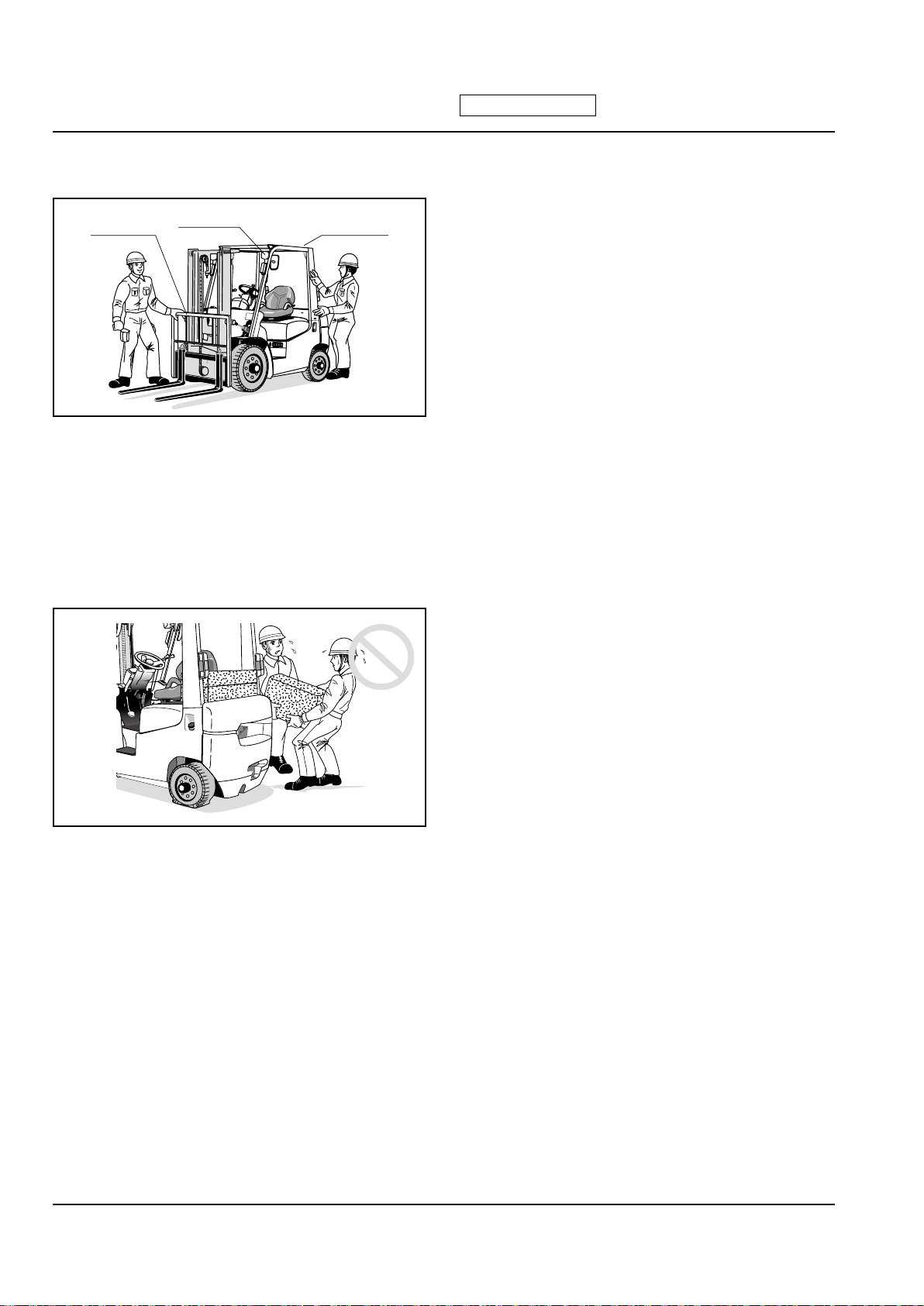

Mount properly

Never mount or dismount a moving truck. When

getting on and off the truck, make sure the truck is

at a complete stop and use the recommended hand

holds and steps with at least three points of support

(for example, put your left foot on a step, and hold

a hand hold with your left hand and the backrest

of the seat with your right hand). Keep the steps,

hand holds and the seat always clean. Repair if

damaged.

Caution to be taken when starting the

electric truck

Electric trucks

Before trying to start the truck (before turning the

key switch to ON), follow the procedure given

below:

1) Apply the parking brake.

2) Place the direction shift lever in neutral.

3) Adjust the steering wheel and operator’s seat

before turning the key switch ON. Do not try

to adjust them during operation; otherwise a

serious accident might occur.

After adjustment, make sure they are securely

locked.

4) Seat yourself in the operator’s seat and fasten

the seat belt.

5) Press the brake pedal.

6) Make sure there is no one under or around the

truck, and turn the key switch to ON.

Do not move controls unless properly

seated

When starting the engine

Engine-powered trucks

When starting the engine, make sure to:

1) Apply the parking brake securely.

2) Place the direction shift lever and speed range

shift lever into neutral.

3) Adjust the steering column angle and driver’s

seat position before starting the engine.

Do not try to adjust them during operation;

otherwise a serious accident might occur.

After adjustment, make sure they are securely

locked.

4) Seat yourself in the operator’s seat and fasten

the seat belt.

5) Press the clutch pedal (trucks with clutch) or

brake pedal (trucks with torque converter).

6) Make sure there is no one under or around the

truck, and start the engine.

Do not operate the controls (levers and pedals)

unless you are properly seated.

1-19

TRAVELING

Sound horn when starting

Before starting, make sure no one is near the truck.

Let other workmen and bystanders know you are

starting up by sounding horn.

Keep your hands clean

It is dangerous to operate the steering wheel and

levers with greasy hands. If grease, oil or soil is

sticking to your hands, clean if off.

Never use man as an additional

counterweight

Do not use man as an additional counterweight. Do

not offer rides to others.

Avoid sharp starts, stops and turns

Keep the truck’s center of gravity

low during traveling (when loaded in

particular)

About 20 cm above ground

When traveling (when loaded in particular), keep

the forks 20 cm above the oor or ground and tilted

back, so as to lower the truck’s center of gravity as

far as possible.

Start, stop and turn slowly. Before turning, slow

down the t r u ck sufficiently. I n pa r t i c u l a r, an

unloaded truck might tip over when it is turned

sharply, because the rear of the truck is heavy.

Before reversing the direction of travel,

bring the truck to a complete stop

It is dangerous to reverse the direction of travel

abruptly.

Carry the load low

It is dangerous to travel with forks lifted higher than

is appropriate, regardless of whether loaded or not.

Keep the load as low as possible while traveling. Do

not turn the truck with the load raised high.

1-20

TRAVELING

Stay away from the edge of road

Ther e i s a f e ar of the edge of a soft grou n d

breaking. Stay away from such a place. Keep

appropriate distance from the edge of a narrow

road or a platform.

Do not travel over a oor or ground

surface covered with water

Do not travel over a oor or ground surface covered

with water. Go round any pothole in the road.

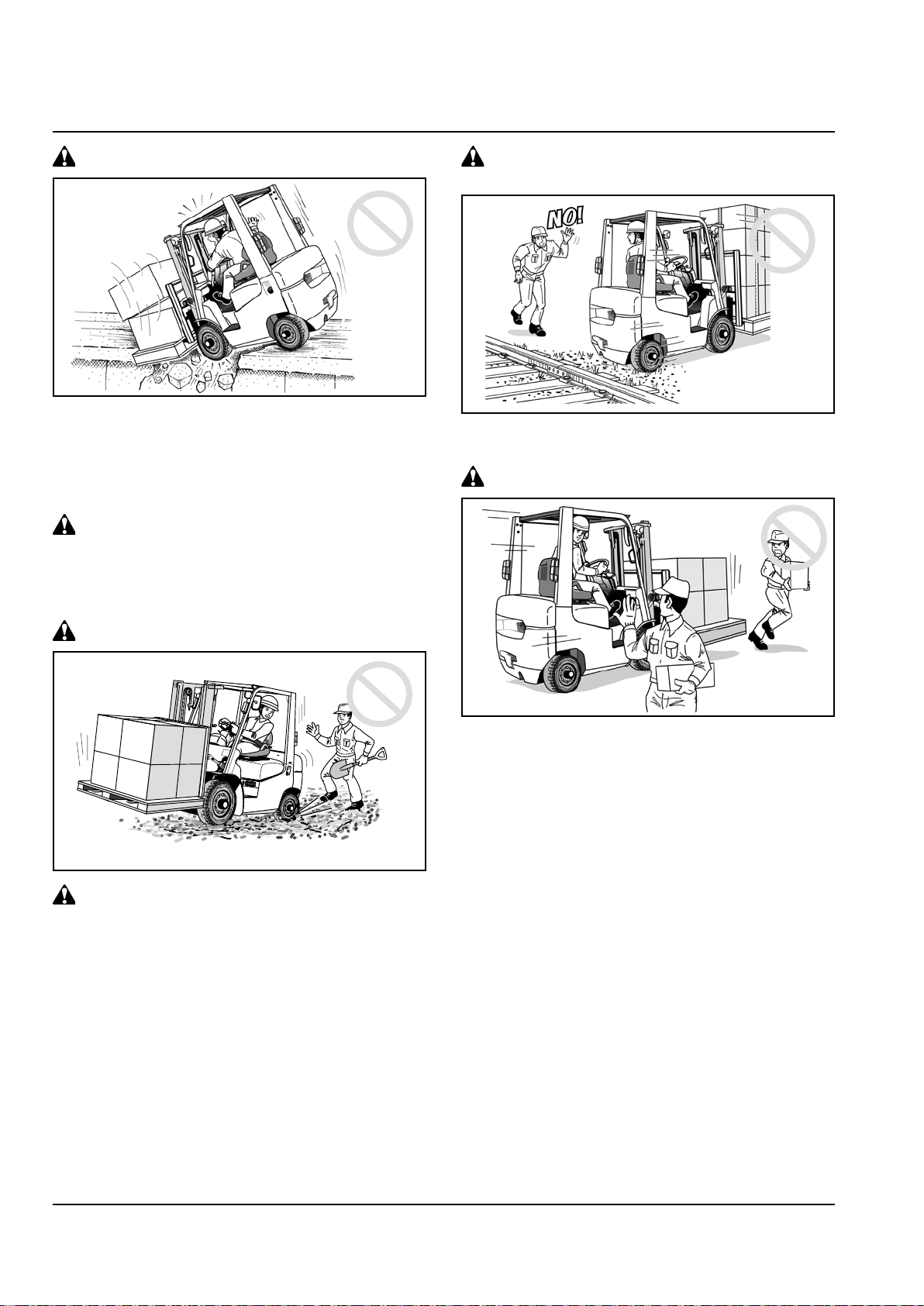

Do not ride on obstacles (curb, railroad

tracks, ditches)

If unavoidable, be careful.

Safe traveling:

Do not get into a soft ground area

Avoid running on a slippery surface

Always look in the direction of travel

•

Always look in the direction of travel; failure to

do so will lead to an accident. When passing

an oncoming truck each other, slow down and

use caution to have a safe distance. Moreover,

maintain a safe distance from the truck ahead of

you at all times.

Observe speed limits

•

Observe the specied speed limits.

Make sure there is no one or obstacle around

•

the truck and in the direction of travel or turning

Do not go past other trucks where vision is

•

restricted

Do not go past other trucks at intersections,

corners, narrow aisles and other locations where

your vision is restricted.

Slow down at corners

•

Slow down and sound horn at intersections and

other locations where your vision is restricted.

Come to a complete stop before crossing

•

roads or at corners

1-21

TRAVELING

When going into areas where there

are limits in height and width, use the

following cautions:

Make sure there is enough height and width for

•

the truck to pass.

Do not put your hands and feet outside the truck.

•

Make sure there is no one around the truck.

•

Watch out for outdoor electric cables and other

•

obstacles.

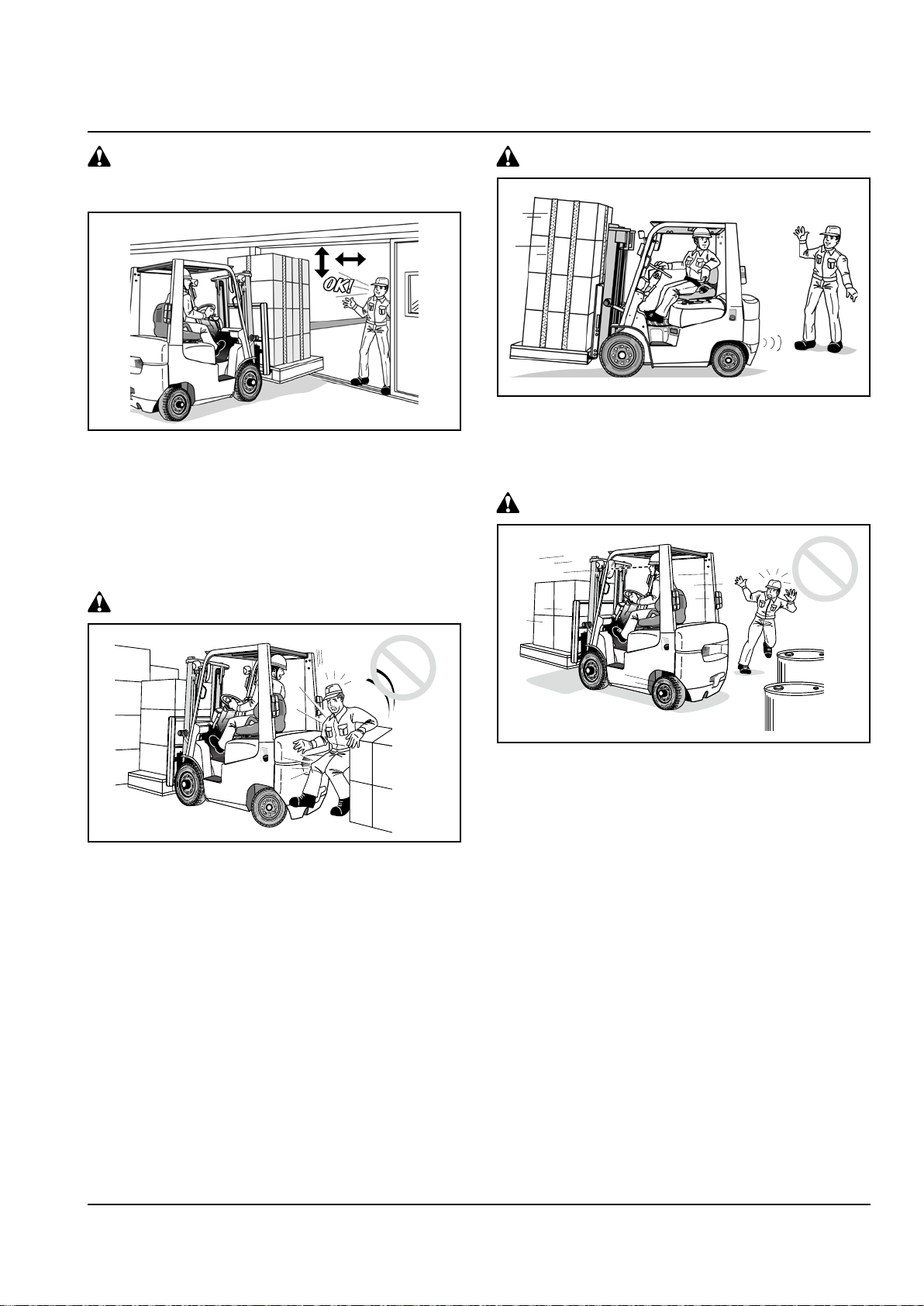

Rear steer, rear swing

Have a guide when handling bulky loads

When handling bulky loads which restrict your

vision, operate the truck in reverse and have a

guide.

Reverse travel

When the truck is turned in forward driving, the rear

of the truck swings outwards. Before turning, make

sure there is enough clearance from the wall and

other obstacles.

When t raveling in reverse, always look in the

direction of travel. Do not rely too much on the

si devi ew mi rrors (if so equipped) a nd backup

buzzer.

1-22

TRAVELING

Back down and drive up:

Do not make turns on a gradient. There is danger

•

of the truck upsetting.

Keep the forks and pallet at an appropriate

•

ground clearance height.

When operating an unloaded truck on grades,

•

have the rear end of your truck pointed up-hill.

When operating a loaded truck on grades, have

•

the rear end of your truck pointed down-hill.

When descending a grade, use engine braking.

•

Engine-powered trucks

If the truck goes faster than you want, press the

foot brake pedal from time to time. While using

engine braking, do not operate the shift lever(s)

nor press the inching pedal.

When descending a grade, use the brake pedal.

•

Electric trucks

If the truck goes faster than you want, use the

foot and regenerative brakes from time to time to

slow down the truck.

Brake the truck in good time

The truck takes a little longer to come to a stop on a

slippery surface than on a usual surface. Brake the

truck in good time.

In addition, the stopping distance of the truck is

longer on a downhill. Keep the traveling speed

under your control.

Do not shut off the engine during

traveling (trucks with power steering and

power brake)

Engine-powered trucks

If the engine stops during traveling, both the power

steering unit and the power brake goes inoperative.

Do not turning off key switch during

traveling

Electric trucks

If the key switch is turned off during traveling, power

steering becomes disabled to make steering hard.

Engine braking is not available when the

inching pedal is pressed

Engine-powered trucks

When the inching pedal is pressed to the bottom,

the brake i s a pplied to the t r uck, but engi n e

braking is not available because the clutch unit is

disengaged.

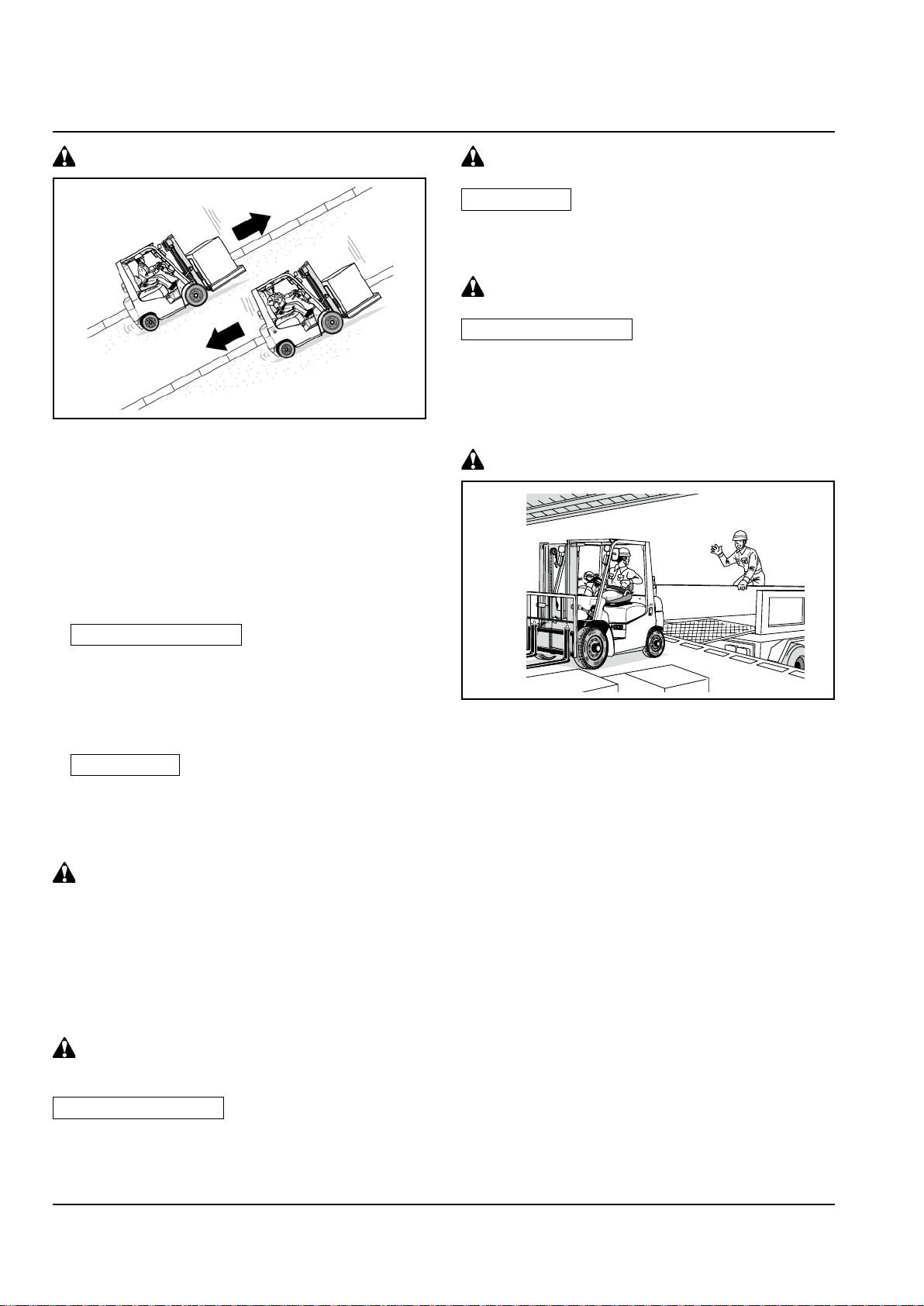

When driving over a dockboard:

Do not ride on the edge of the dockboard or

•

bridgeplates; otherwise the truck might fall down,

leading to personal injury or even death.

Before driving over a dockboard or bridgeplate,

•

make sure it is properly secured. Never exceed

its rated c a p a c i t y. Do not u s e a dama g e d

dockboard or bridgeplate.

Have the brakes set and wheels blocked in place

•

to prevent the trailer from moving.

Jacks must be installed to support the trailer

•

when the truck goes into the trailer.

Drive carefully and slowly across the dockboard

•

or bridgeplate.

Watch for bystanders.

•

Give instructions to the trailer driver not to move

•

the trailer until load handling is nished.

Mak e sure the dock board or bri dgepla te is

•

secured.

1-23

TRAVELING

Know the load bearing capacity of the

oor

Before entering a building or going into an elevator,

make sure the floor is strong enough to withstand

the weights of the truck and the loads.

Practice safe driving and load handling

techniques

Before using the l ift tru ck, you must pr actice

safe driving and load handling techniques. Even

after getting familiar with the operation of the

truck, operate the truck carefully; reckless driving

and operation will cause a personal injury or an

accident.

When using multiple trucks

When operating multiple trucks, remember that their

operating controls have their own characteristics

even if the trucks are of the same specification. If

you change the trucks, keep this point in mind. In

particular, pay attention to the brake system.

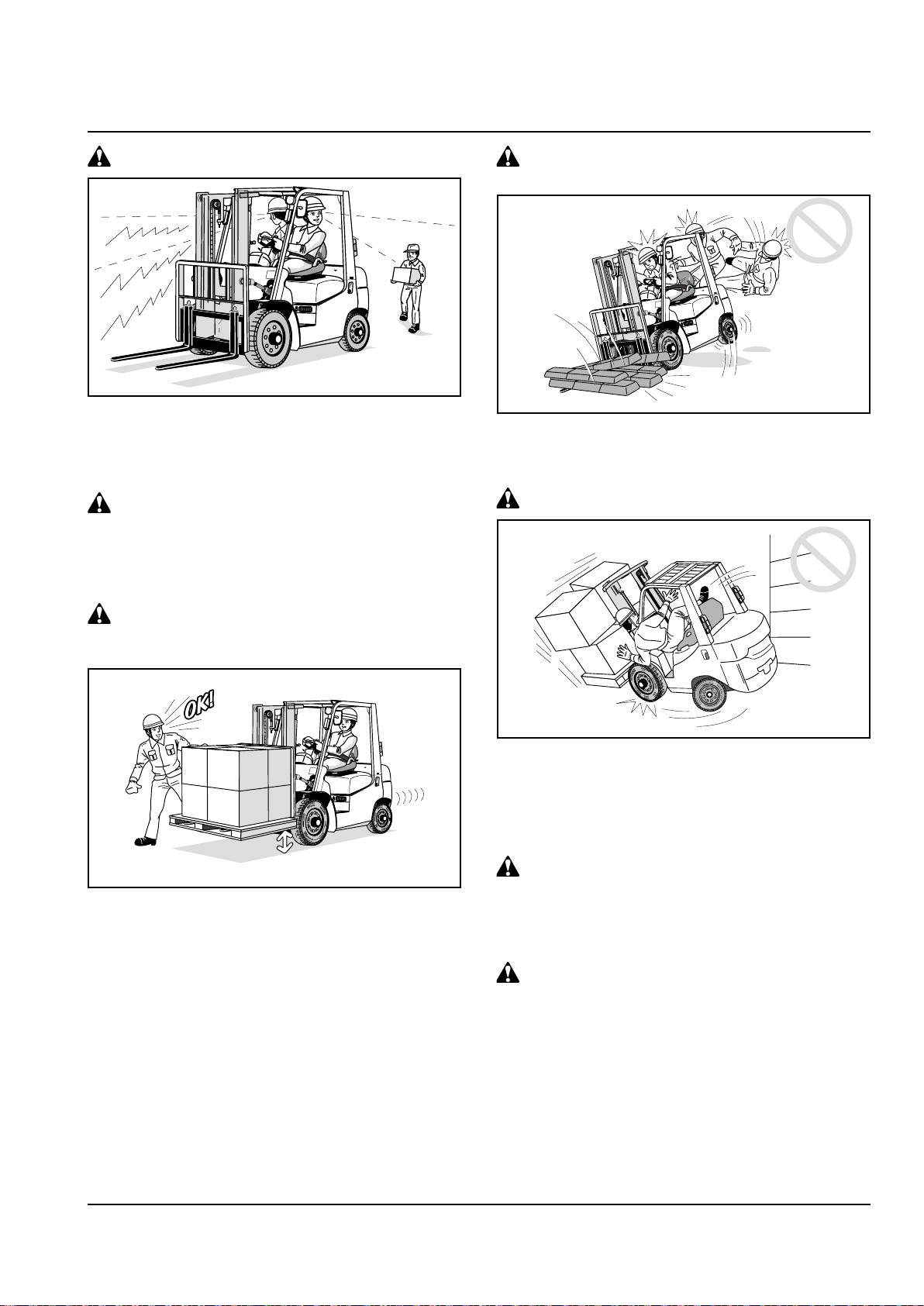

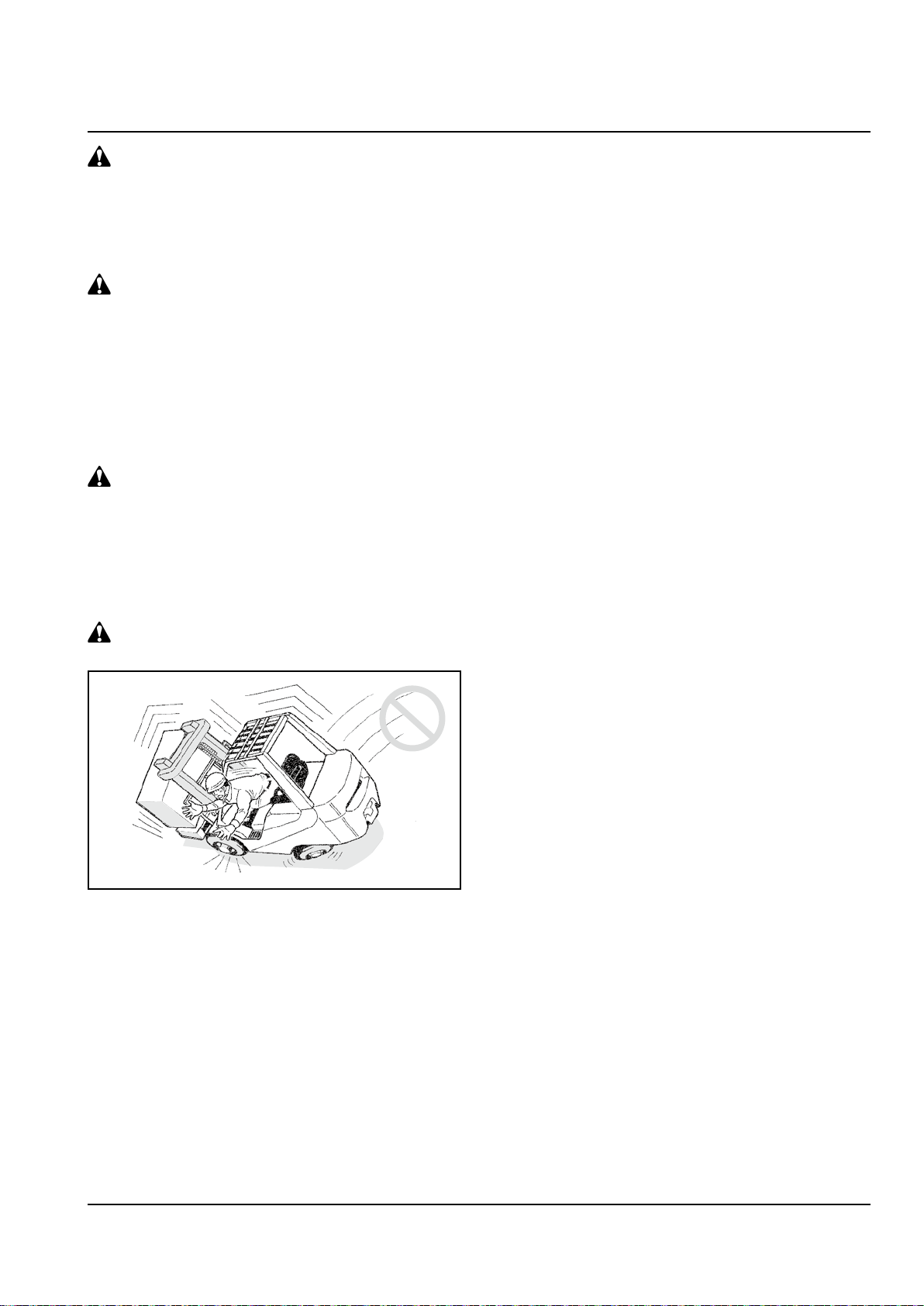

Stay inside if the truck seems like it is

about to turn over

The operator must always fasten his seat belt. If the

truck turns over, the operator might be thrown out

and, in the worst case, the operator can be crushed

under the truck causing severe injury or even death.

If it seems like the truck is about turn over, stay in

the operator’s seat. Hold on to the steering wheel

rmly, brace your feet rmly on the oor, lean your

body away the direction in which the truck seems

like it is going to turn over. Never jump out of the

truck!

1-24

LOAD HANDLING

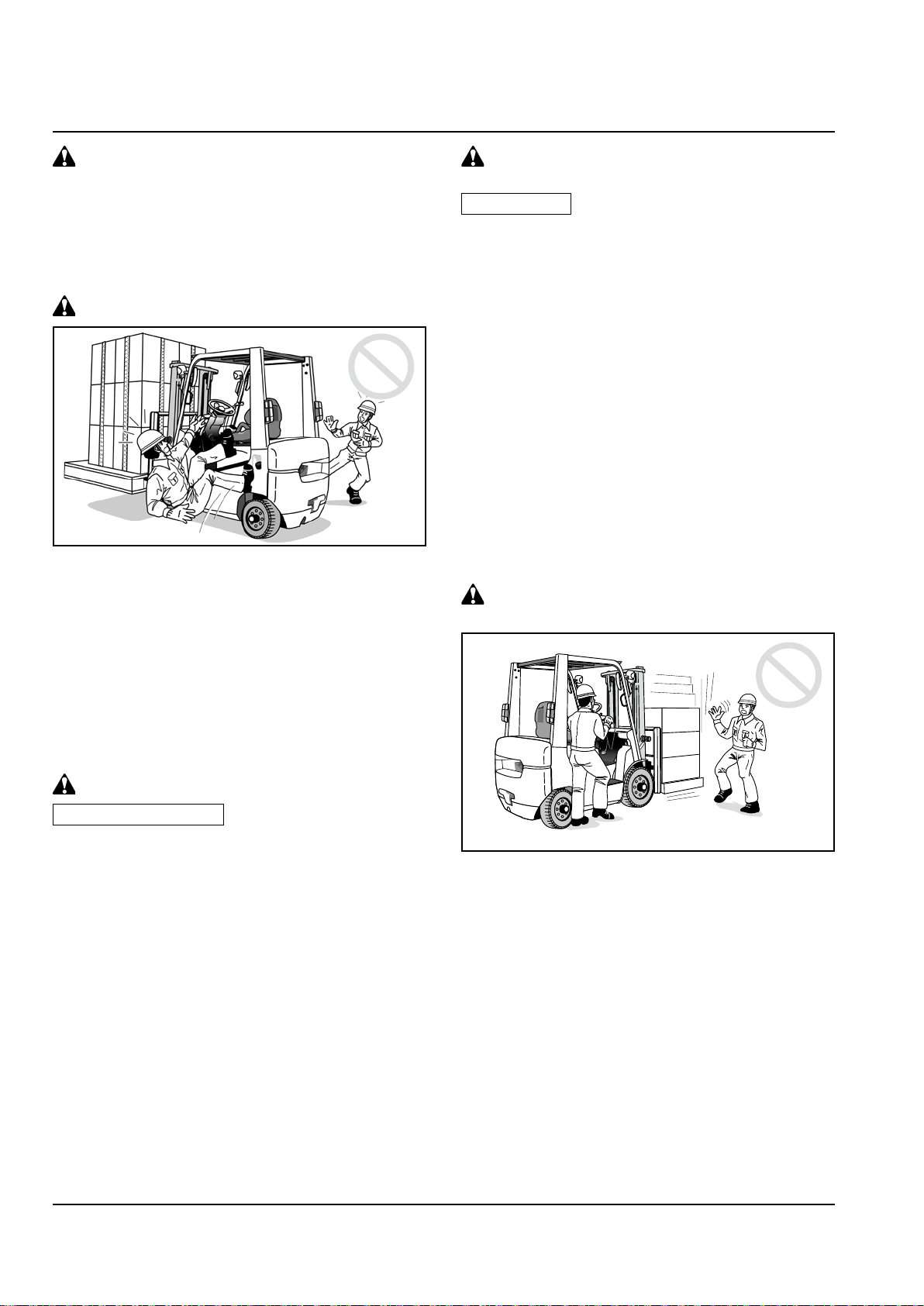

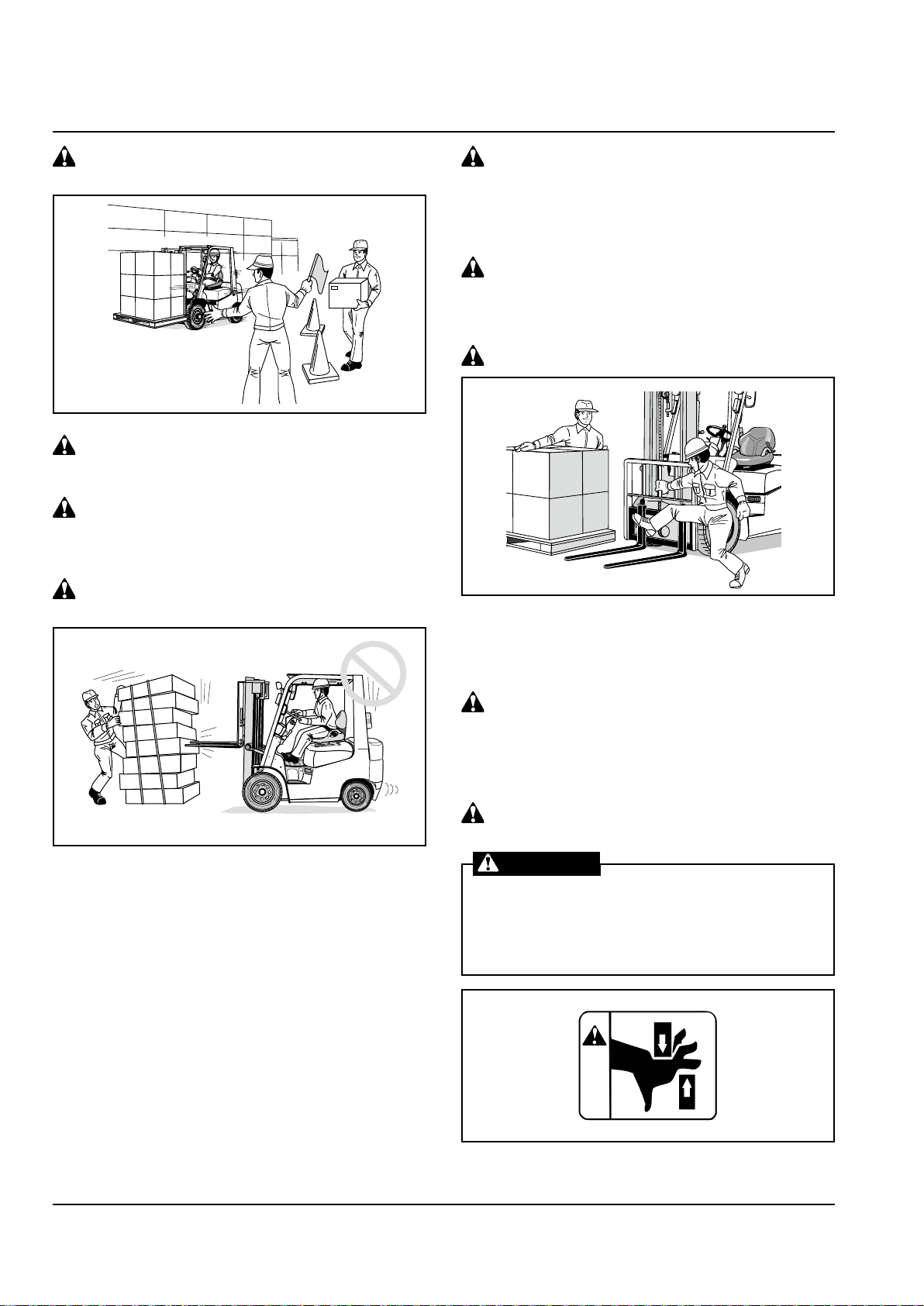

Keep anyone but a guide away from the

working area

Do not let other persons or truck

approach your lift truck during operation

When working in a group, have a person

present to give guidance and follow his

instructions

Do not use your truck for purposes other

than specied:

Pay attention to the fork tips

The fork tips are sharp and could cause personal

injury. In addition, if they catch on obstructions, the

truck might lose control, leading to an accident.

Adjust fork spacing properly

Adjust the fork spacing suitable according to the

size of the load.

Adjust fork spacing with your feet

Adjust the fork spacing with your feet. Do not use

your hands. You hands might get pinched between

the forks and carriage.

Do not use the truck to open or close the doors of

•

freight cars or warehouses.

Do not push other trucks.

•

Do not hoist loads, using ropes hung on the

•

forks.

Do not tow another vehicle using the draw bar.

•

Do not push or pull loads with forks; otherwise,

•

the load might fall off or get damaged. In

particular, the truck with the max. lift height of

more than 150 cm might tip over, if you try to do

that.

Make sure forks are securely locked

After adjusting the fork spacing, lock the forks

with fork stoppers. Unlocked forks will slide during

traveling, causing the load to fall off.

Do not put your hands or feet into the

load handling system

WARNING

Never put your hands or feet on the mast or

mast connecting members; otherwise your

hands or feet might be cut if the mast moves

unexpectedly.

WARNING

1-25

LOAD HANDLING

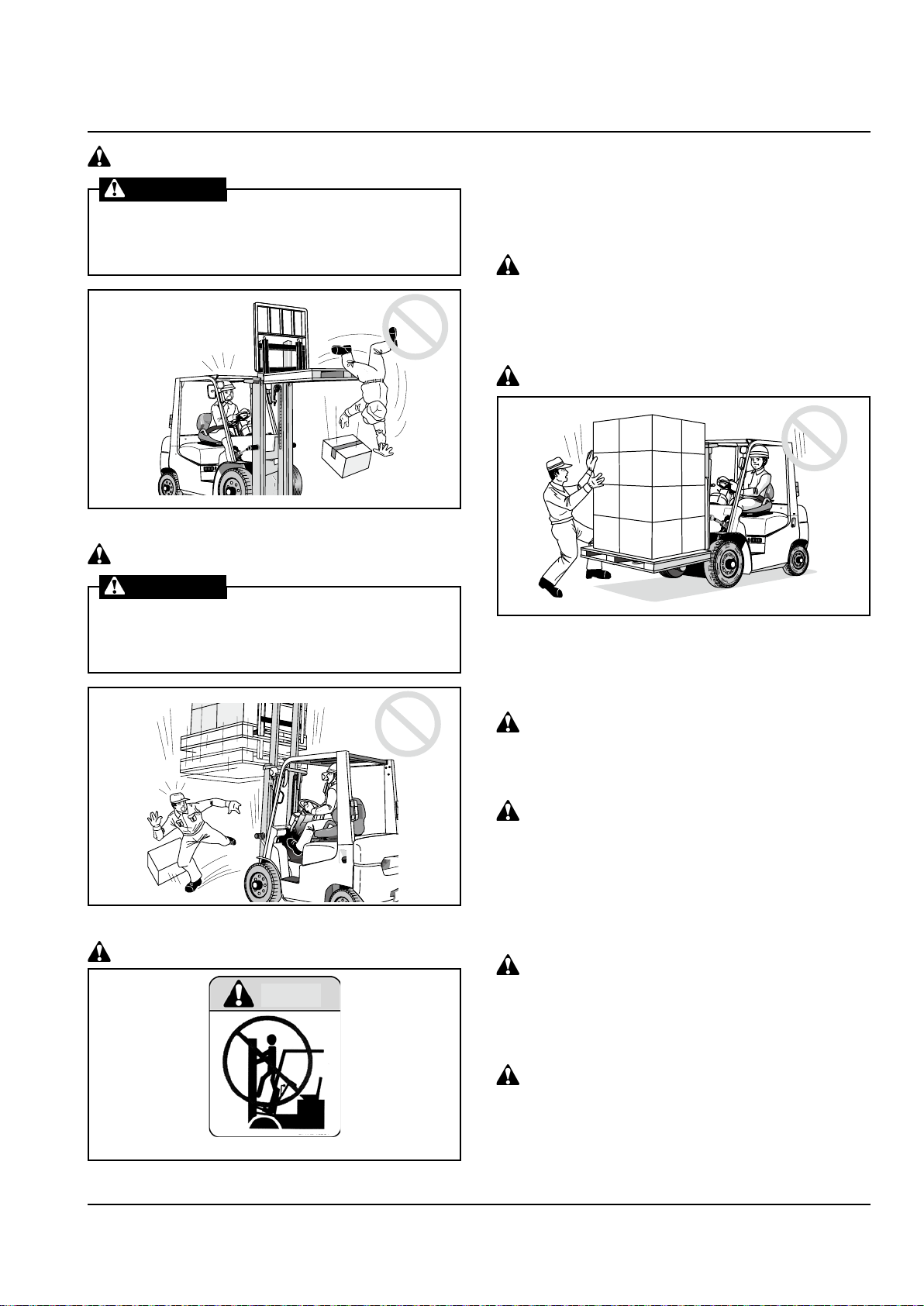

Never elevate a man

WARNING

Never allow other person(s) to ride on the

forks. He might fall off the forks, getting

injured.

Never lift a load over anyone

WARNING

It is dangerous to use the truck body or mast as a

ladder to ride on a high place.

You might be caught between the mast and truck

body, resulting in a serious accident.

Do not pick up loads from other truck

Do not pick up loads from raised forks of other

truck. This might cause an off-centered load or the

load to fall off.

Do not hold loads on the forks by hand

Never permit anyone to stand under raised

forks. The forks might fall down unexpectedly,

thus causing a personal injury.

Do not ride on front guard

WARNING

Do not hold loads on the forks by hand. If the truck

moves unexpectedly, the load might fall off, getting

the person caught under it.

Make loads in contact with load backrest

Insert the forks into the pallet as far as possible to

make the loads in contact with the load backrest.

Do not stack loads too high on forks

Do not stack loads on forks in such a way that the

top of loads exceeds the load backrest height;

otherwis e, loads migh t fall o n the pa rt of t he

operator, and in the worst case lead to a serious

injury or death.

Do not lift unstable loads

Do not handle unstable loads. When handling loose

loads, make sure they are stable enough before

lifting.

Use special caution when stacking or

unstacking loads

When stacking or unstacking loads, stabilize them

with ropes or others, to prevent from falling off.

Loading...

Loading...