Page 1

No. OMFBE-N44140

OPERATOR’S MANUAL

FORKLIFT TRUCK

MODELS 1F1/1F2

It is the responsibility of the Operator and Supervisor to read and understand this manual.

•

Protect the earth and be kind to your lift truck.

•

Page 2

TO OPERATORS

A Word to UniCarriers FORKLIFT Operators

This ORIGINAL OPERATORS MANUAL describes operating procedures,

daily checks and simple maintenance for safe usage of your UniCarriers

FORKLIFT. We urge you to read this ORIGINAL OPERATORS MANUAL carefully before operating a UniCarriers FORKLIFT to familiarize

yourself with the safety instructions. An operator of any industrial truck

should maintain safety as the number one priority at all times. These instructions will not only reduce mechanical issues with a forklift, but may

also save a life.

If you encounter any problems with a UniCarriers FORKLIFT, contact an

authorized UniCarriers FORKLIFT dealer in your area and request a

complete checkup. The dealership will ensure that your forklift is serviced in accordance with the latest factory approved methods. This

ORIGINAL OPERATORS MANUAL is not a training manual, it is a guide

to help trained and authorized operators safely operate this forklift.

Please consult your employer for proper training on the appropriate use

of this forklift while performing your job. Illustrations in this ORIGINAL

OPERATORS MANUAL will show the operator the correct procedures

for checking, starting, operating and stopping this forklift.

UniCarriers Corporation

1-2, Shin-Ogura, Saiwai-ku,

Kawasaki, Kanagawa,

212-0031, Japan

All information, specifications and illustrations in this ORIGINAL OPERATORS MANUAL are based on the latest data obtainable at the

time of publication. UniCarriers Corporation reserves the right to

make changes or improvements at any time without notice.

This ORIGINAL OPERATORS MANUAL has been prepared on the assumption that your forklift is fully equipped (including all optional equipment). Thus, if you have any questions regarding equipment, please

contact an authorized UniCarriers FORKLIFT dealer.

©2015 UniCarriers Corporation

1

Page 3

Dear Owner of a UniCarriers Truck:

Original Instruction Manual

The Original Instruction Manual contains information that You, as user of the truck, must be aware of in order to avoid/minimise the risk of injury/

damage to yourself and the truck. You are also responsible to the company management, other people and objects in your environment. You should

therefore read through this manual before starting the truck for the first time.

Our products are constantly being developed and renewed, we therefore reserve the right to make alterations without prior notice.

Thank you for choosing UniCarriers Corporation as your truck supplier.

UniCarriers Corporation service

As the owner of a UniCarriers truck, we also welcome you to our service organisation.

We offer support and advice for any problems that may arise and assistance with servicing and ordering of replacement parts. Refer to the nearest

authorised sales agent or service workshop for assistance.

Truck driving courses

The importance of goods handling for the company and the environment increases every year, at the same time ever more technical solutions are

developed and introduced on our trucks. It is therefore important that the driver, who has a key role to play in goods handling, is given the correct

conditions to operate as safely and efficiently as possible. Statistics show that the number of incidents decreases significantly when a truck driver

has been properly trained. Please contact us for information about the training package.

Throughout this manual we have used the symbol:

- followed by the word WARNING. This is used to indicate the presence of a hazard which may cause the possibility of a personal injury or

- CAUTION.

other damage and must be followed precisely.

This is also used throughout the manual to indicate the presence of a hazard that could cause possible injury to yourself or components

and the procedures must be followed carefully.

It should be kept in mind that this ORIGINAL OPERATORS MANUAL deals with both standard and optional equipment, and so you may come

across issues that are not applicable to your model in particular.

2

Page 4

TRUCK MODIFICATION

NOTE:

Unauthorized forklift modification is not

permitted.

No modifications or alterations to a powered industrial forklift, which may affect,

for example, capacity, stability or safety requirements of the forklift shall be made

without the prior written approval of

UniCarriers FORKLIFT, its authorized representative or a successor thereof.

Contact an authorized UniCarriers FORKLIFT dealer before making any modification

or alteration to your industrial forklift that

may affect, for example, braking, steering,

visibility and the addition of removable attachments.

After receiving the approval of UniCarriers

FORKLIFT, its authorized representative or

a successor thereof, the capacity plate, decals tags, operation and maintenance

handbooks shall also be changed appropriately.

Only in the event that UniCarriers FORKLIFT is no longer in business and there is

no successor in the interest to the business, the user may arrange for a modification or alteration to a powered industrial

forklift, provided however, that the user

shall:

A. Arrange for the modification or altera-

tion to be designed, tested and implemented by an engineer(s) expert in

industrial forklifts for their safety;

B. Maintain a permanent record of the de-

sign, test(s) and implementation of the

modification or alteration;

C. Approve and make appropriate chang-

es to the capacity plate(s), decals, tags

and instruction handbook;

D. Affix a permanent and easily visible la-

bel to the forklift stating the manner in

which the forklift has been modified or

altered together with the date of the

modification or alteration, and the name

and address of the organization that

performed the alterations.

3

Page 5

Contents

To Operators ...............................................................................................1

TRUCK modification ....................................................................................3

Name of components ..................................................................................5

Operator’s qualifications and protective equipment for operating forklift .....5

Safety rules..................................................................................................6

Traveling on gradients, gangways and in elevators ..................................10

Transporting forklift....................................................................................12

Approach angle, departure angle and gangway ........................................12

Special operating conditions......................................................................14

Installation of attachments.........................................................................14

Position of labels .......................................................................................14

Instruments and controls ...........................................................................20

Changing meter display.............................................................................21

Selector lever position ...............................................................................24

Setting the time..........................................................................................25

Setting the date .........................................................................................26

Explanation of warning lamps....................................................................28

LCD warning symbols................................................................................29

Inspection timing display ...........................................................................30

Displays when malfunction occurs ............................................................30

LPG remaining time management.............................................................34

Switches and controls ...............................................................................37

Starting and operating ...............................................................................47

Loading and unloading .............................................................................. 61

Function tests ............................................................................................63

SEAT (except for EU region)..................................................................... 65

Seat (for EU region) ..................................................................................68

Top panel lock ...........................................................................................72

Daily care and inspection ..........................................................................80

Maintenance.............................................................................................. 91

Maintenance schedule ............................................................................105

Putting forklift in storage.......................................................................... 108

Daily checks ............................................................................................110

UniCarriers FORKLIFT genuine parts .....................................................110

Disposal of parts and materials ...............................................................111

Precautions for using LPG model............................................................ 111

Periodic maintenance schedule ..............................................................125

Identification numbers .............................................................................129

Diesel particle filter [DPF] (option for diesel forklift only) ......................... 131

Specifications ..........................................................................................139

Noise level............................................................................................... 153

Index........................................................................................................ 156

4

Page 6

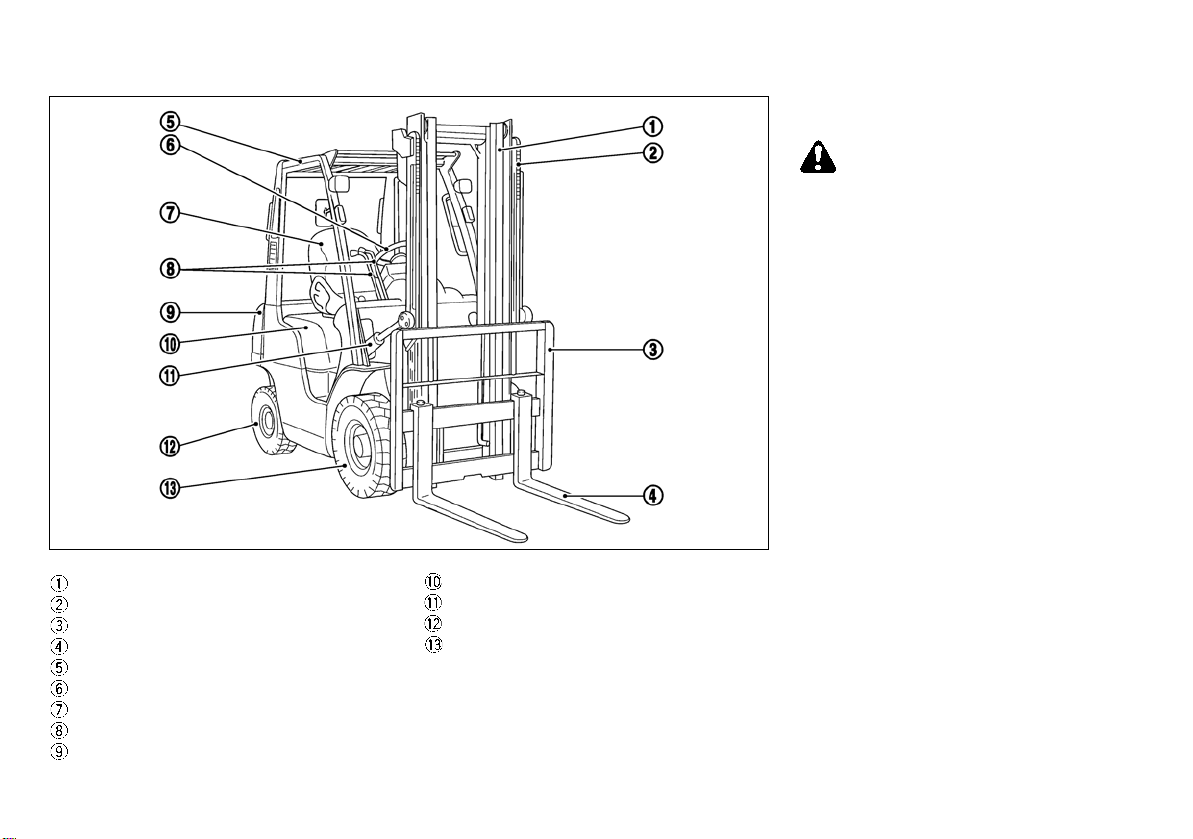

NAME OF COMPONENTS OPERATOR’S QUALIFICATIONS

WARNING:

MOM1872

AND PROTECTIVE EQUIPMENT

FOR OPERATING FORKLIFT

OPERATOR’S QUALIFICATIONS

The forklift shall be operated in accordance

with the operations of the operator’s license and the applicable provisions of the

local laws and regulations.

Mast

Lift chain

Backrest

Fork

Overhead guard

Steering wheel

Operator’s seat

Control lever

Counterweight

Top panel

Tilt cylinder

Rear tire

Front tire

5

Page 7

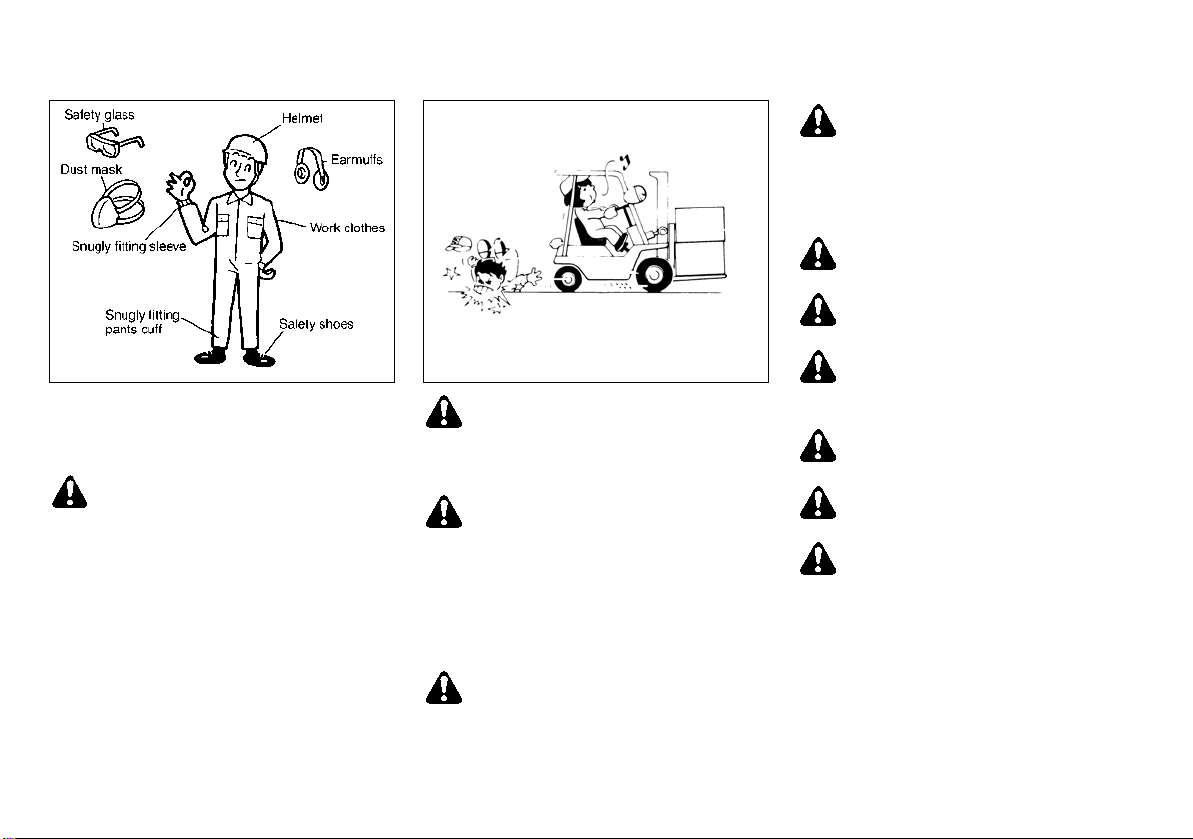

PERSONAL PROTECTIVE

WARNING:

MOM0015

MOM0128

EQUIPMENT FOR OPERATING

FORKLIFT

For operation of the forklift, the protec-

tive equipment for the operator shall be

dependent upon the conditions of use

and the applicable provisions of the local

laws and regulations.

The working clothes worn by the opera-

tor shall be such that sleeves and cuffs fit

snugly so as to prevent them from getting caught on forklift levers, etc., and

safety glasses, earmuffs, dust mask and

safety shoes should also be worn, as required by the work environment or employer.

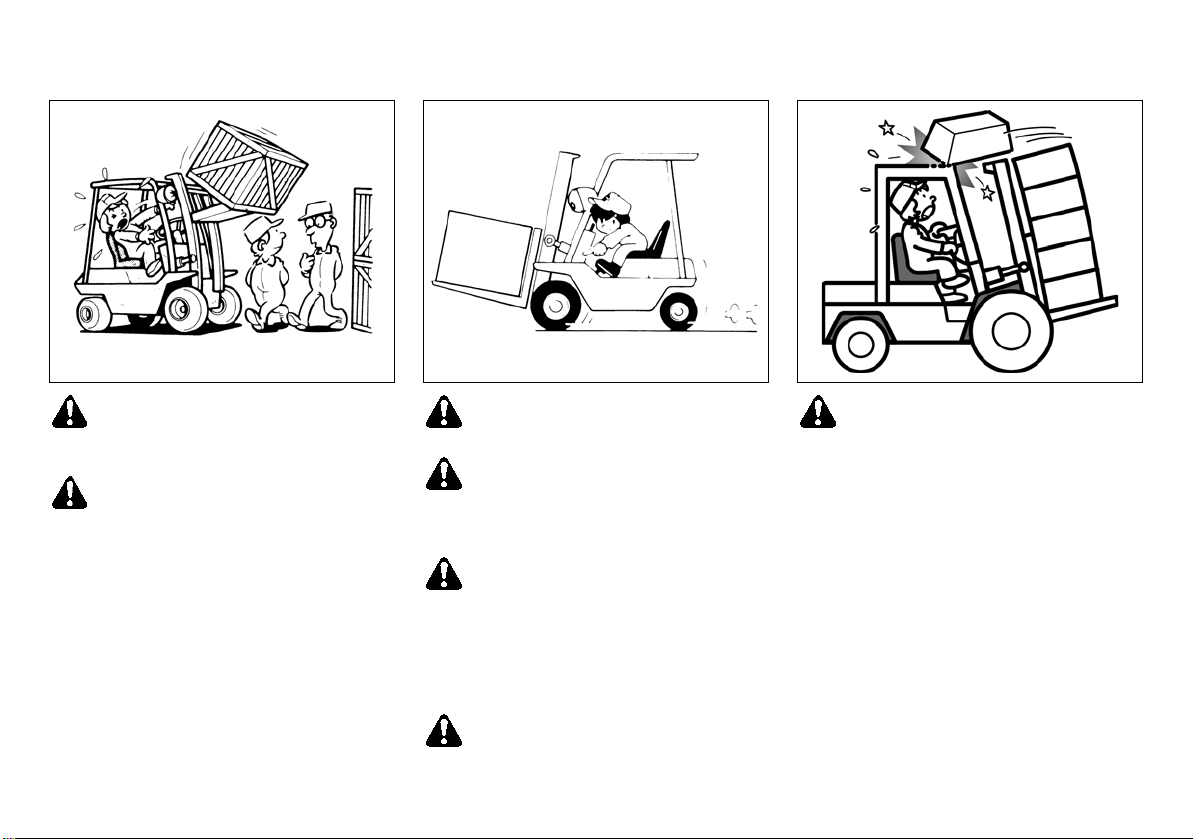

SAFETY RULES

Operator must be trained and authorized to drive the forklift and must understand safety techniques and rules

for forklift operation.

Inspect the forklift before operating.

Do not operate the forklift if it is in

need of repair. If it is in need of repair, tag the forklift, remove the key

and report the condition to the proper authority. Do not attempt repair

unless you are trained and authorized to perform repairs.

Do not remove the overhead guard or

backrest.

6

Make sure that the selector lever is

set in neutral and the parking brake

is applied before turning the ignition

switch. Do not start or operate the

forklift if you are not in the designated operator’s position.

Do not allow anyone on any part of

the forklift while moving or lifting.

Do not sit on the fork (when loaded

or not) or get under the fork.

Before operation, make sure that the

seat belt is secure and the top panel

latch is in the locked position.

Before starting the engine, make

sure that the seat belt is secure.

1F1/1F2 models do not have the

creeping phenomena.

The forklift will not move if the selector lever is in the F (forward) or R (reverse) position unless you depress

the accelerator pedal. When depressing the accelerator pedal, be sure to

visually confirm the position of the

selector lever. When starting on

slopes, be sure to apply the parking

brake to hold the forklift and then

start, even if the slopes are gentle.

Avoid rapid acceleration (especially

when carrying a high load).

Page 8

Keep hands, feet and other parts of

MOM0129

MOM0130

MOM1677

your body inside the operator’s compartment at all times.

Do not allow anyone to stand or walk

under the elevated portion of the

forklift whether it is empty or loaded.

Space forks as far apart as the load

will permit.

Always carry loads low with the mast

tilted to the backmost position, never

forward. Do not elevate loads except

during stacking.

Maintain a careful lookout for people

and obstructions, and watch the path

of travel. Watch clearances, especially overhead and tail swing. When

visibility is obstructed, use extreme

caution. Yield the right of way to pedestrians.

If the load obstructs the front view,

drive the forklift in reverse.

7

Do not place a load higher than the

backrest of the forklift. A load placed

higher than the backrest may drop

towards the operator and is very dangerous. If such a load must be handled, securely fasten the load using

suitable ropes or hold-down bands.

Page 9

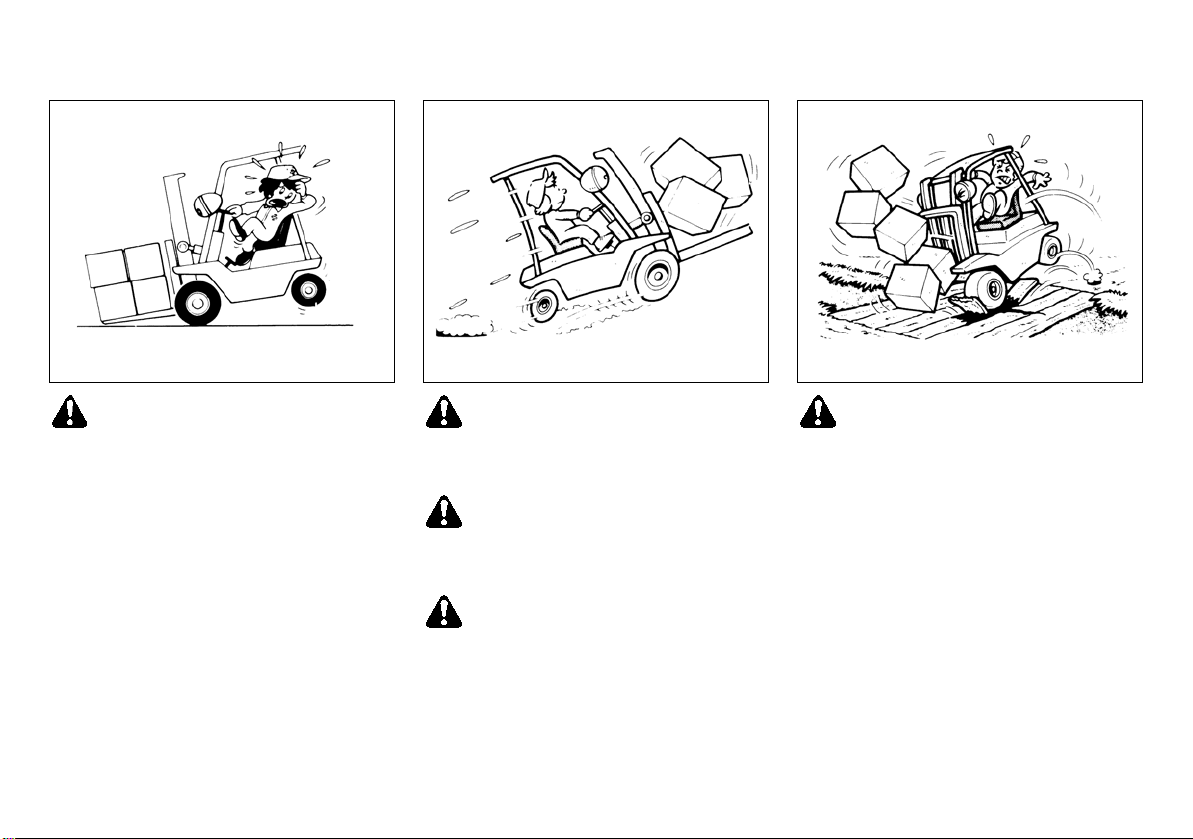

Do not overload the forklift. Check the

MOM0131

MOM0132

MOM0133

load chart for load weight and load

center information. Always pick up

loads as close to the center of the

weight as possible to avoid off-center

loading.

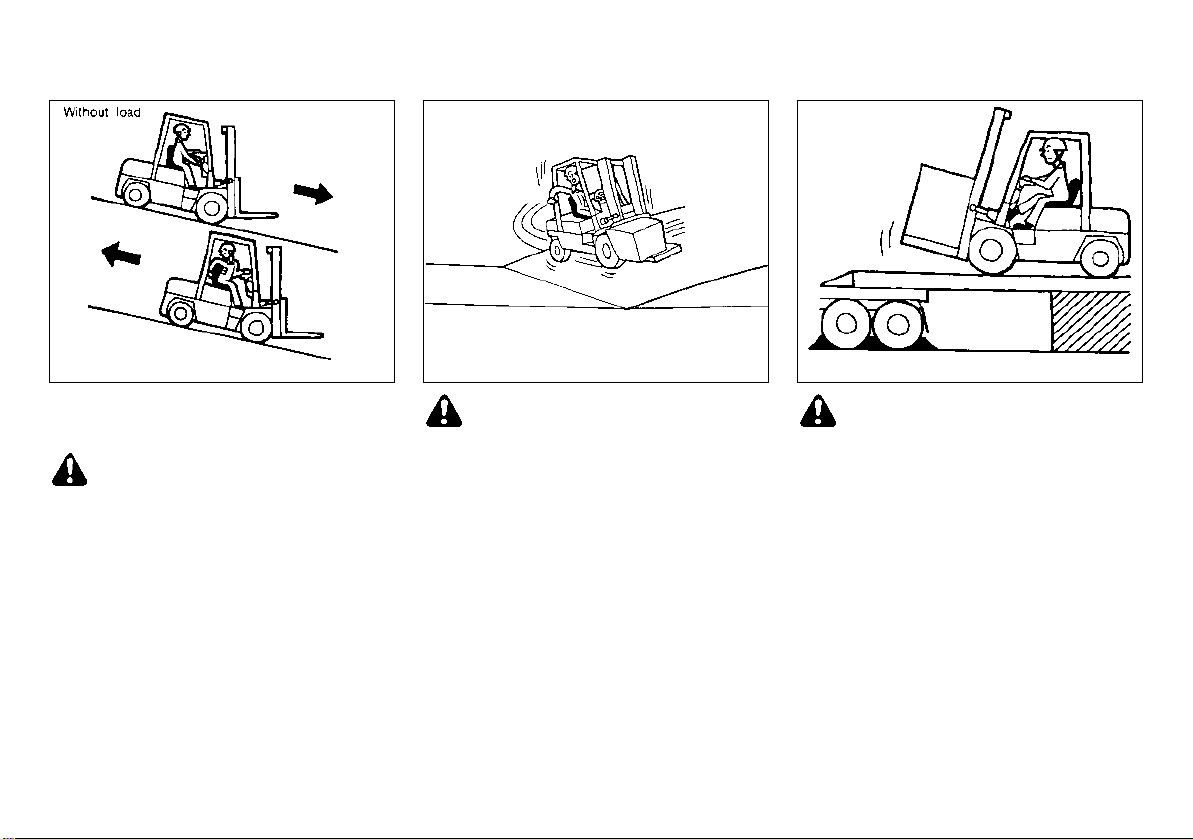

Avoid sudden starts, stops or turns.

Slow down for turns and on uneven

or slippery surfaces that could cause

the forklift to overturn or slide.

Use special care when traveling without a load as the risk of lateral overturn may be greater than when

traveling with a load.

Before entering forklifts or trailers,

be certain that the brakes on the forklift or trailer are applied and the

wheel chocks are in place or that the

trailer is locked to the loading dock.

8

Before driving over a dockboard or

bridge plate, be certain that it is properly secured. Drive carefully and

slowly across the dockboard or

bridge plate. Never exceed its rated

capacity.

Page 10

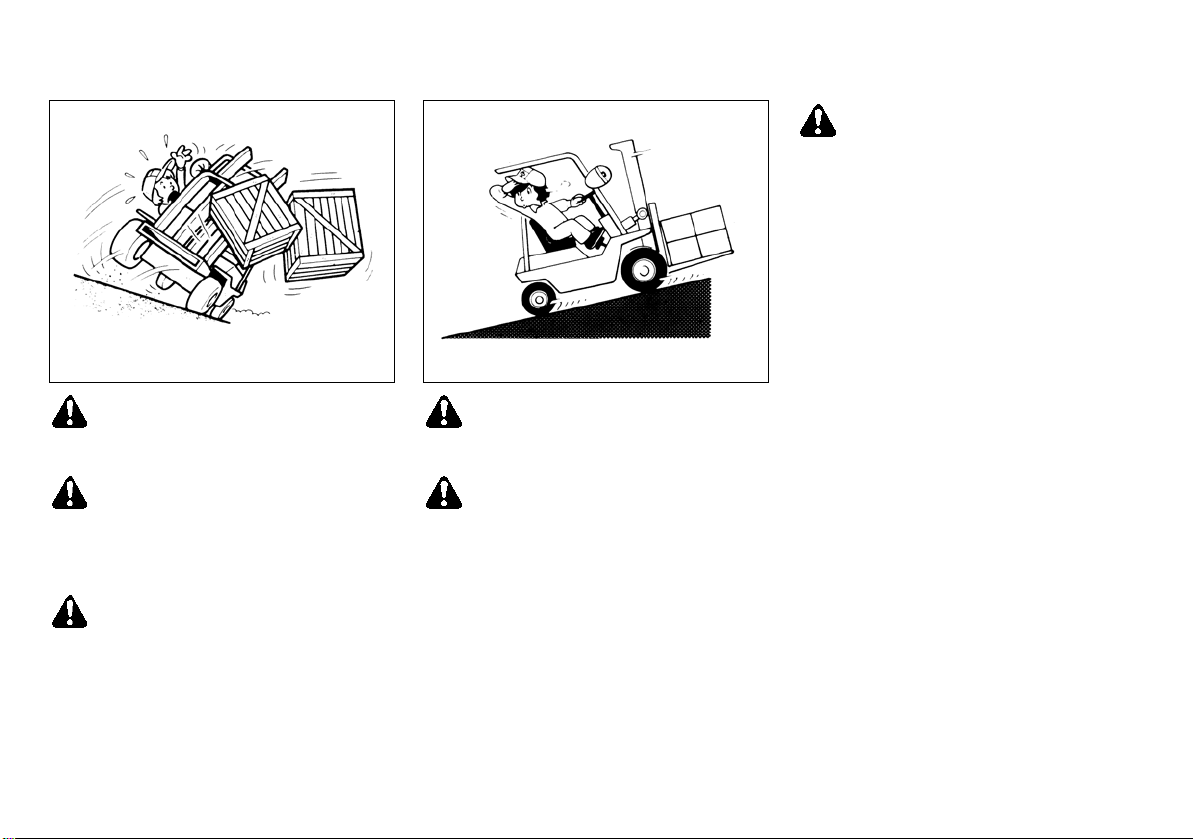

Use special care when operating on

MOM0134

MOM0135

slopes. Travel slowly and do not angle across or turn.

When ascending or descending

slopes, drive the forklift with the load

facing upgrade.

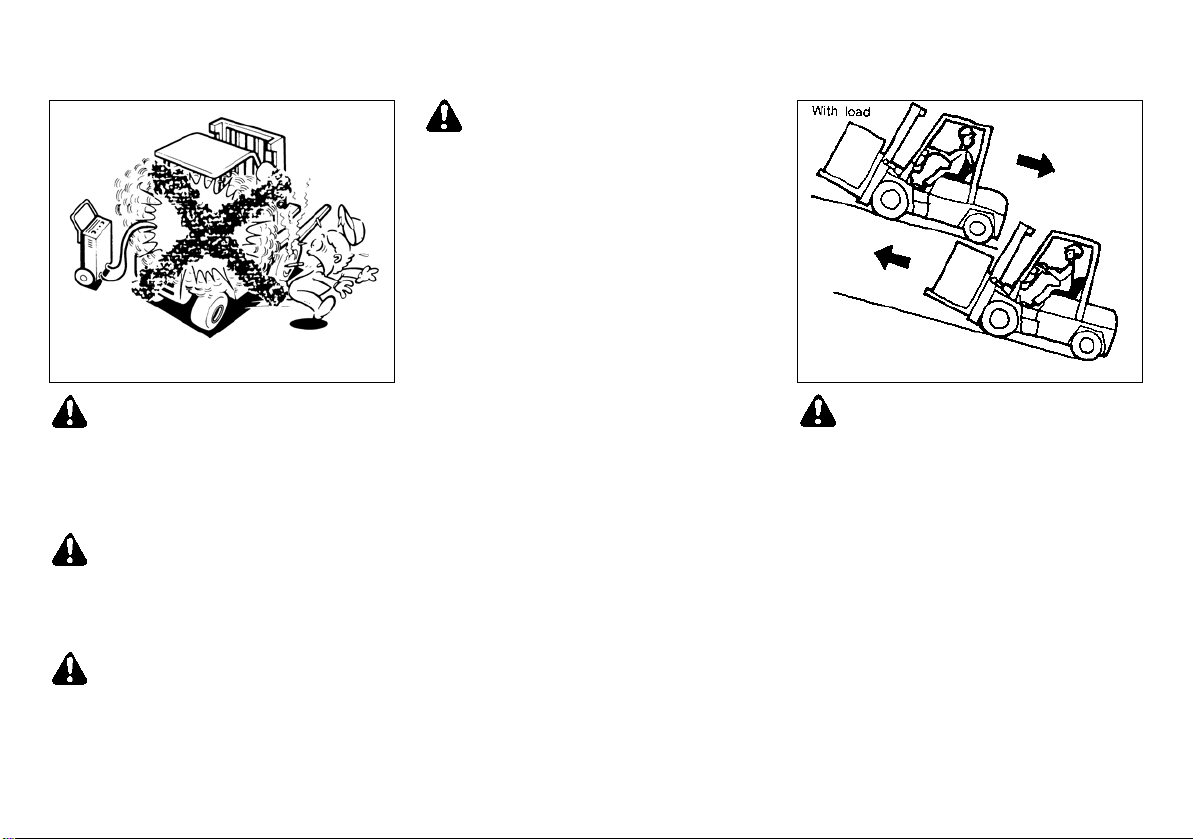

Fuel is highly flammable.

It must be handled with the utmost

care, in accordance with the safe

handling requirements of fuels and

the applicable safety provisions of

the local laws and regulations.

When filling the tank with fuel, make

sure that the forklift is properly

parked. Turn off the ignition switch

and remove the key.

When fuel is spilled, wipe the area

clean with a cloth. The cloth shall be

disposed of in accordance with the

requirements of safe handling of fuels, environmental requirements and

the applicable provisions of the local

laws and regulations.

Do not handle unstable or loosely

stacked loads. When handling long,

high or wide loads, use special care

to ensure stability and carefully

watch the surrounding conditions.

When approaching cross aisles,

slow down and sound the horn if visibility is obstructed.

Before leaving the forklift, be sure

that forks or attachments are lowered, the selector lever is in neutral,

the hand brake is applied and the ignition switch is turned off. Avoid

parking the forklift on a slope.

9

Page 11

WARNING:

WARNING:

When filling the tank with fuel or re-

MOM0136

MOM0016

charging the battery, stop the engine

and place the forklift only in a designated area with good ventilation.

Keep away from arcs, sparks, flames

or lit cigarettes.

Do not breathe exhaust gases: they

contain colorless and odorless carbon monoxide. Carbon monoxide is

a dangerous gas and can cause unconsciousness or death.

TRAVELING ON GRADIENTS, GANGWAYS AND IN ELEVATORS

When moving the forklift in elevators,

check to make sure that the elevator is

capable of withstanding the forklift

weight or the forklift weight plus the load

weight.

Be sure to apply chocks under the tires

to prevent the forklift from moving while

it is parked in the elevator.

Do not perform work in the elevator.

Use care when traveling on gradients.

When traveling on gradients with a load,

always drive forward on upward slopes

and in reverse on downward slopes.

Drive slowly on slopes. Drive in the re-

verse direction on upward slopes when

without a load, and drive forward on

downward slopes.

Do not run the engine in closed spaces or poorly ventilated rooms such

as a garage or refrigerator, etc.

10

Page 12

Use the brake pedal when driving down-

WARNING:

WARNING:

MOM0017

MOM0018

MOM0019

hill to sufficiently reduce the speed.

Use the brake pedal and engine

brake together when driving downhill so as to maximize the effectiveness of the engine brake.

Do not traverse and turn around on slopes.

Because driving on slopes causes the

center of gravity to shift towards the lowest point, the forklift is likely become unbalanced.

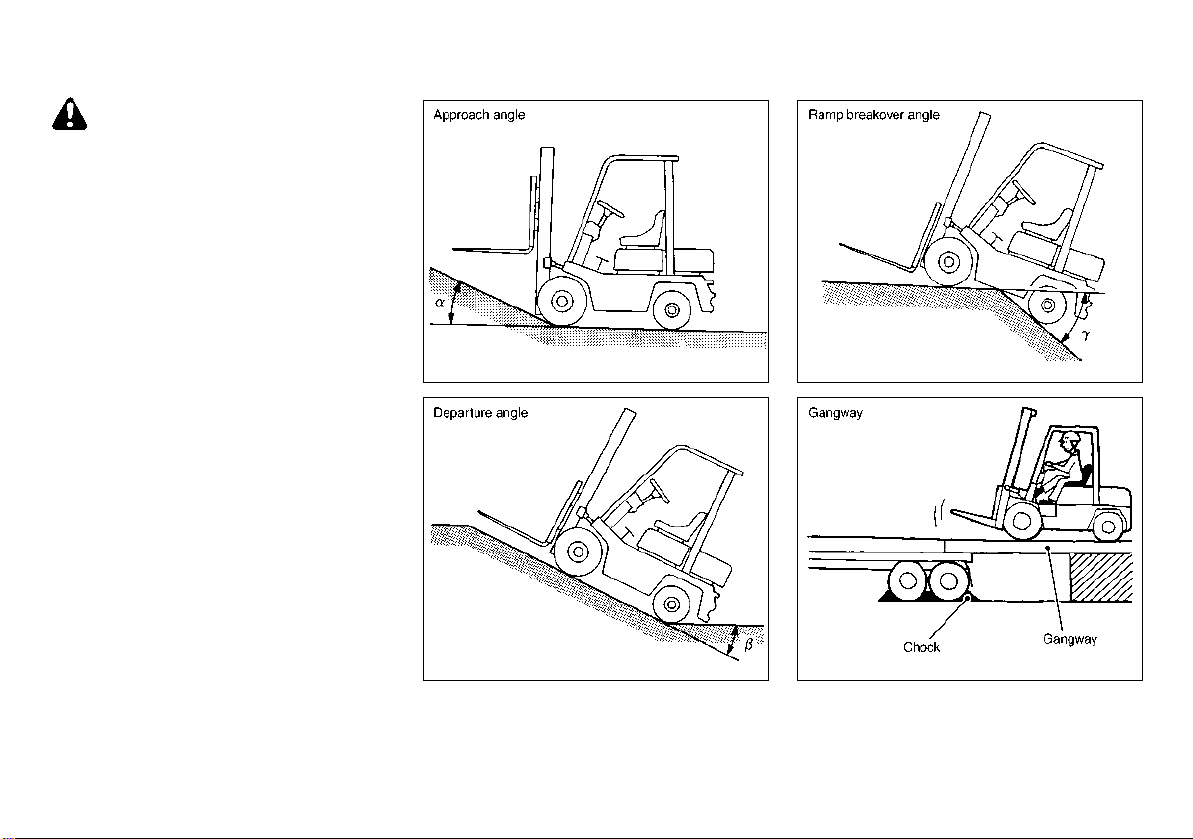

Following are precautions relating to driving onto freight cars and trailers.

Check freight cars and trailers to make

sure that they will not move.

The ramp for driving the forklift onto a

freight car or trailer shall have sufficient

strength to withstand the weight of the

forklift and its load, as well as the forces

exerted by the bouncing of the forklift.

The ramp shall be anchored so that it

does not shift.

Use the utmost care when driving on and

off a freight car or trailer.

11

Page 13

TRANSPORTING FORKLIFT APPROACH ANGLE, DEPARTURE

WARNING:

MOM0020

MOM0021

MOM0022

MOM0023

ANGLE AND GANGWAY

1. Tilt the mast back to the maximum without load.

2. Check the approach and departure angles to make sure that the underside of

the forklift does not come into contact

with the load carrying platform or the

ground.

3. When using a load bridge, make sure

that the planks are capable of withstanding the deadweight of the forklift.

4. When winching the forklift onto a load

carrying platform, be sure to attach the

cable to the traction pin. Do not ride on

the forklift while it is being winched.

5. Be sure to use lashing points and firmly

secure the forklift to the load carrying

platform.

6. When hoisting the forklift, be sure to

use the lifting points.

7. Turn off the ignition switch and remove

the key.

8. Make sure that the battery connector is

disconnected.

12

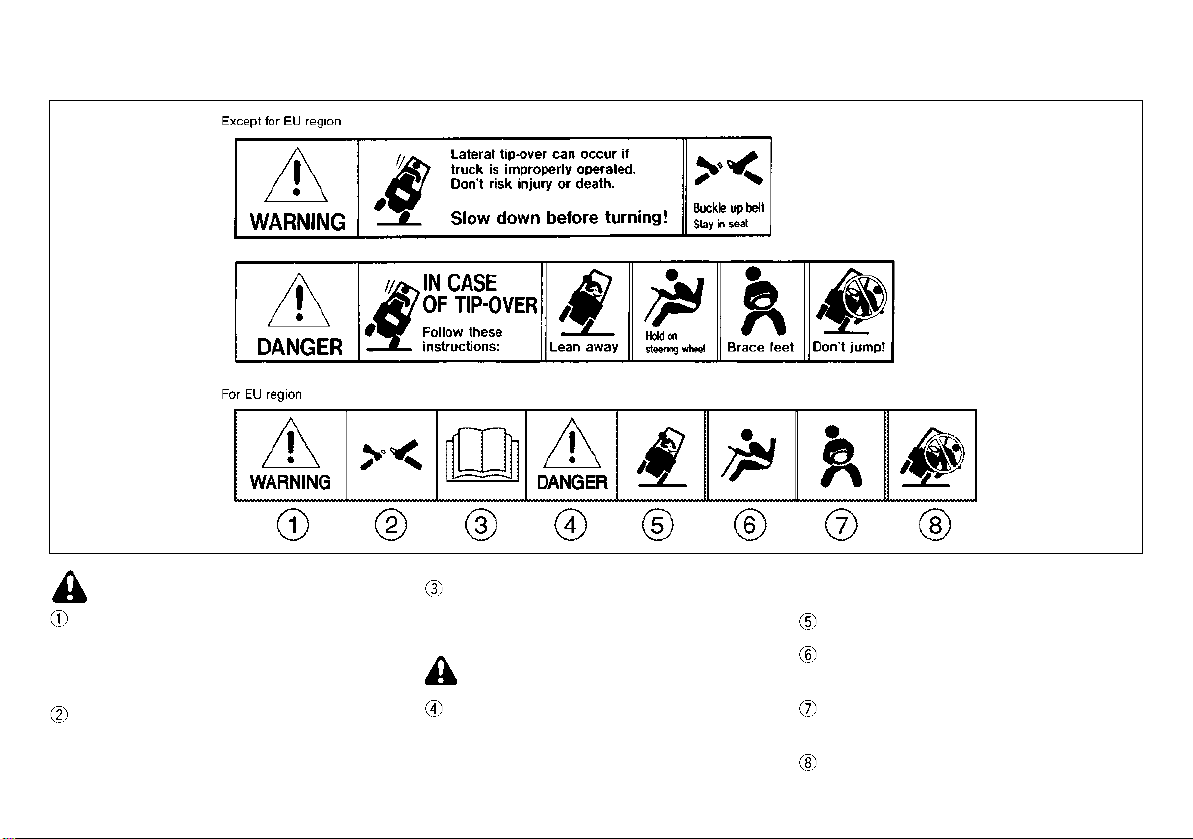

Page 14

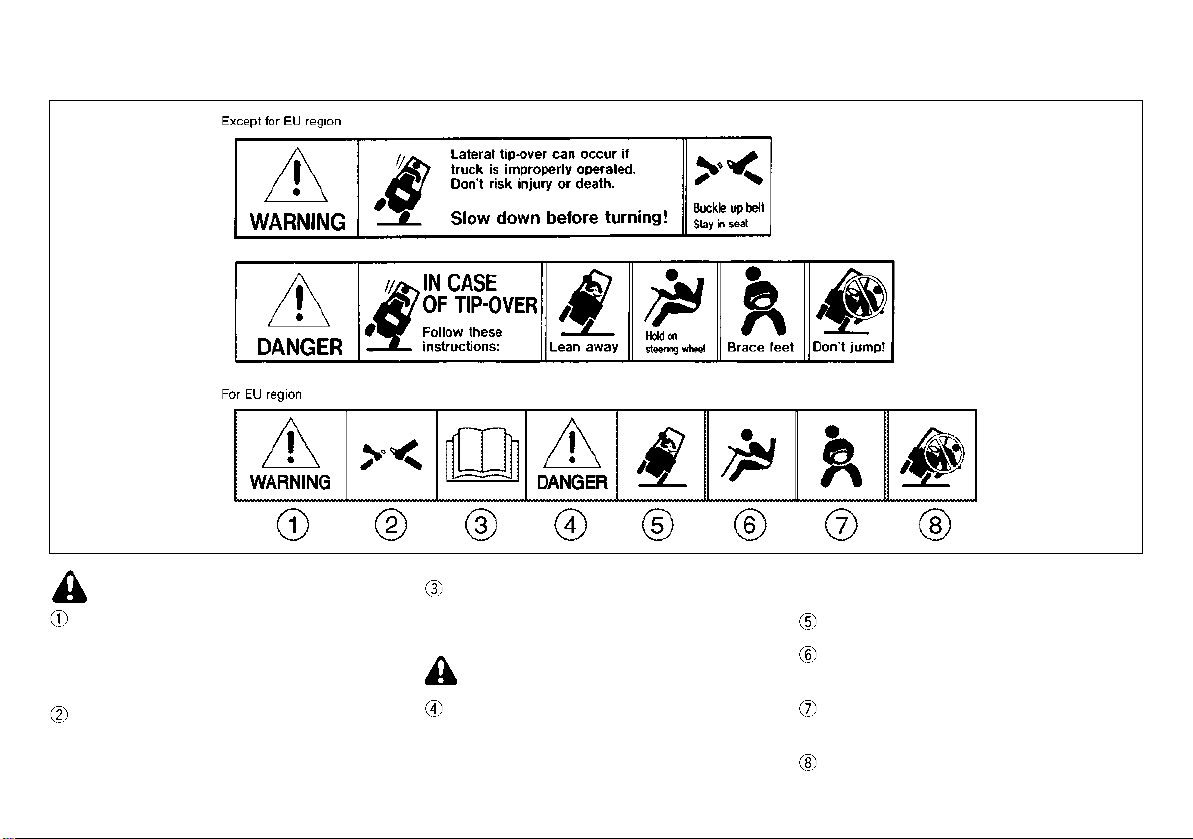

WARNING:

The following precautions should be

MOM2796

closely observed to ensure safe operation of the forklift as well as to prevent

personal injury.

Always make sure your seatbelt is securely fastened, and stay seated while

driving.

Read the manual carefully before operating the truck to familiarize yourself

with the safety instructions.

DANGER:

The operator should stay inside the

forklift if the forklift starts to tip or falls

off a dock or ramp.

The operator should:

Lean away from the point of impact.

Hold on firmly to the steering wheel

with both hands.

Brace your feet and keep yourself inside the operator compartment.

Do not jump outside of the forklift.

13

Page 15

SPECIAL OPERATING CONDITIONS

WARNING:

WARNING:

When operating the forklift under severe climatic conditions such as high temperatures,

high altitudes, in cold storages, and when handling explosives and combustibles, and in areas where the forklift is apt to cause radio

interference, make sure that the forklift is manufactured and approved as conforming to the

local specifications, laws and regulations.

INSTALLATION OF ATTACHMENTS

Before installing hook-on attachments, be

sure to read the installation manual issued

by the attachment manufacturer to assure

correct and proper installation. Contact an

authorized UniCarriers FORKLIFT dealer

for the revised load capacity figures.

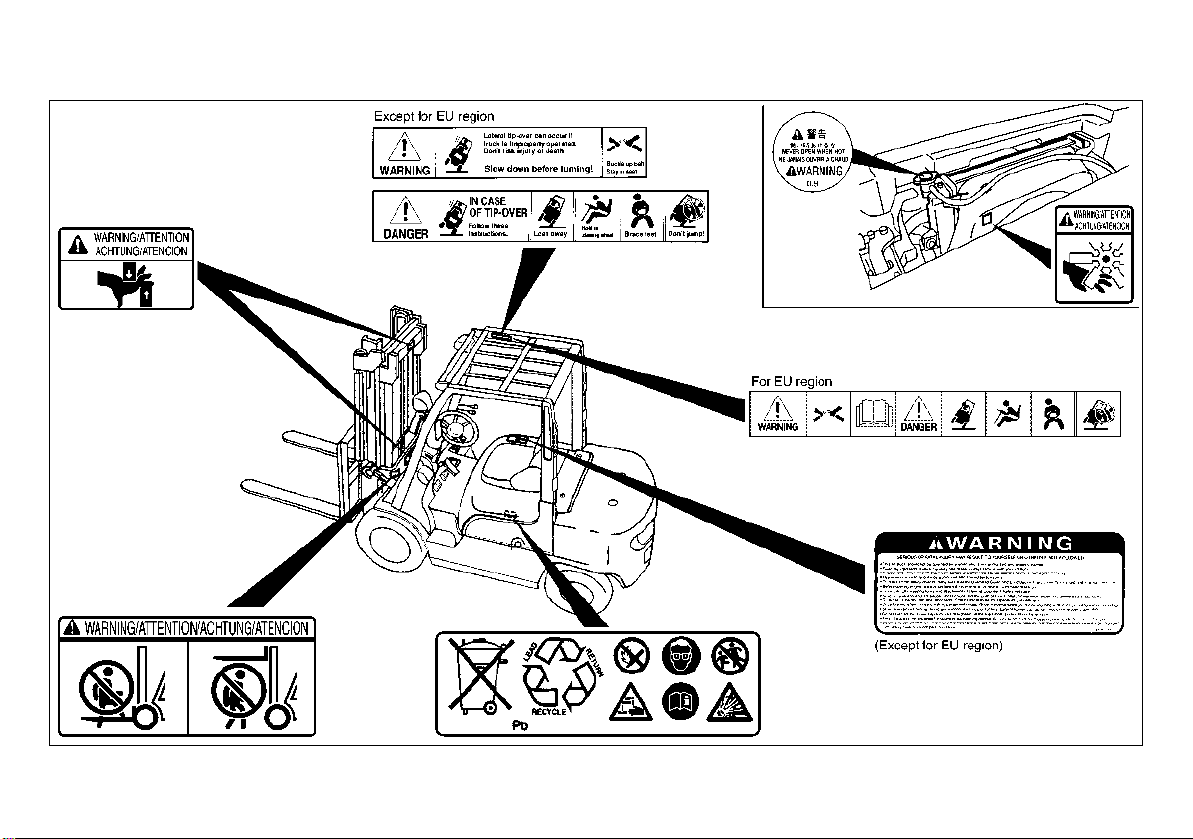

POSITION OF LABELS

When warning and caution labels are damaged such that they cannot be read or have

peeled off, they should be immediately replaced with new labels to ensure that they

are constantly maintained in a legible condition. The warning and caution labels are

available at an authorized UniCarriers

FORKLIFT dealer.

The warning and caution labels are affixed

to the designated locations of the forklift as

shown in the figure on the following page.

Before operating the forklift, be sure to take

note of the details given in the labels so as

to ensure proper and safe operation.

14

Page 16

POSITION OF WARNING AND CAUTION LABELS

MOM3254

15

Page 17

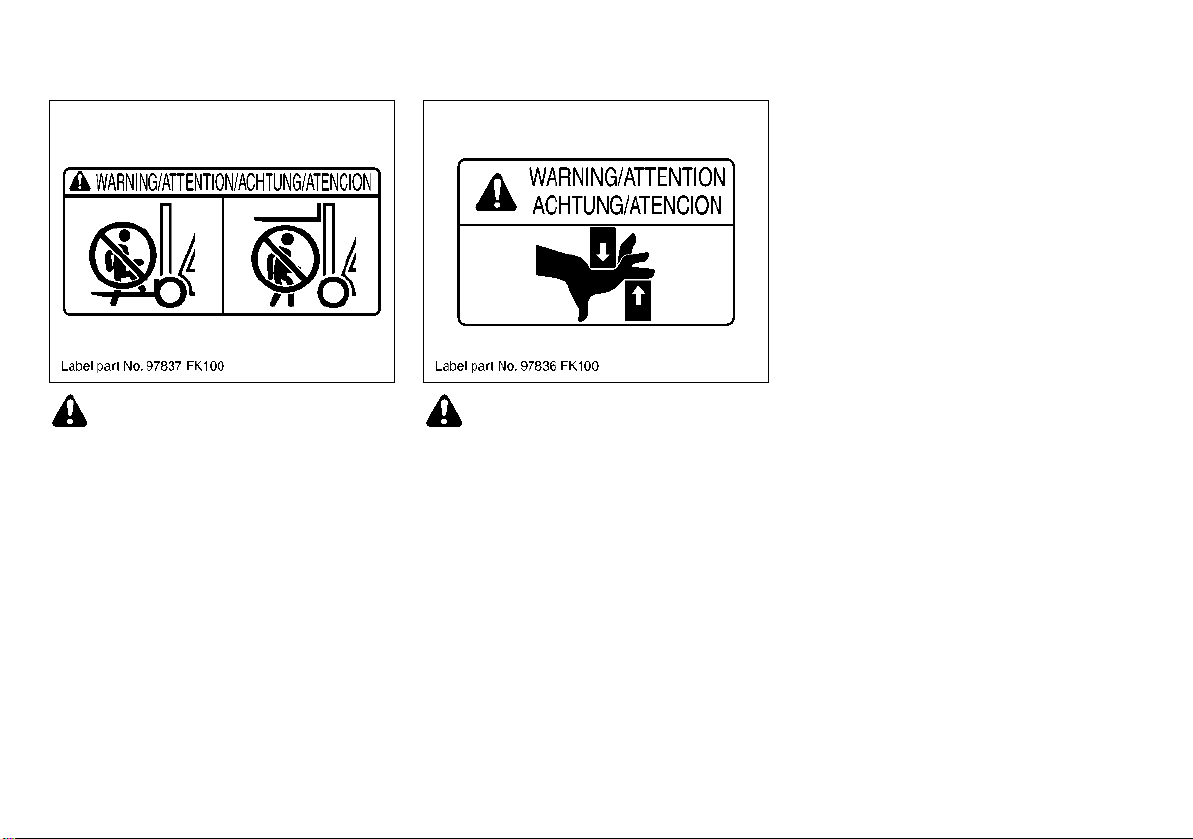

WARNING:

Do not stand on or below forks.

WARNING:

MOM2675

MOM2676

Riding on the forks is strictly prohibited.

Furthermore, do not stand immediately

below the forks. Otherwise, serious accidents can occur if the forks should move

abruptly and the load placed on the forks

unexpectedly falls down. In the worst

cases, these accidents can be fatal.

Be sure to keep your hands, feet and body

away from the masts. Otherwise, parts of

the body are liable to become caught between the moving and fixed sections of the

masts and injury may occur.

16

Page 18

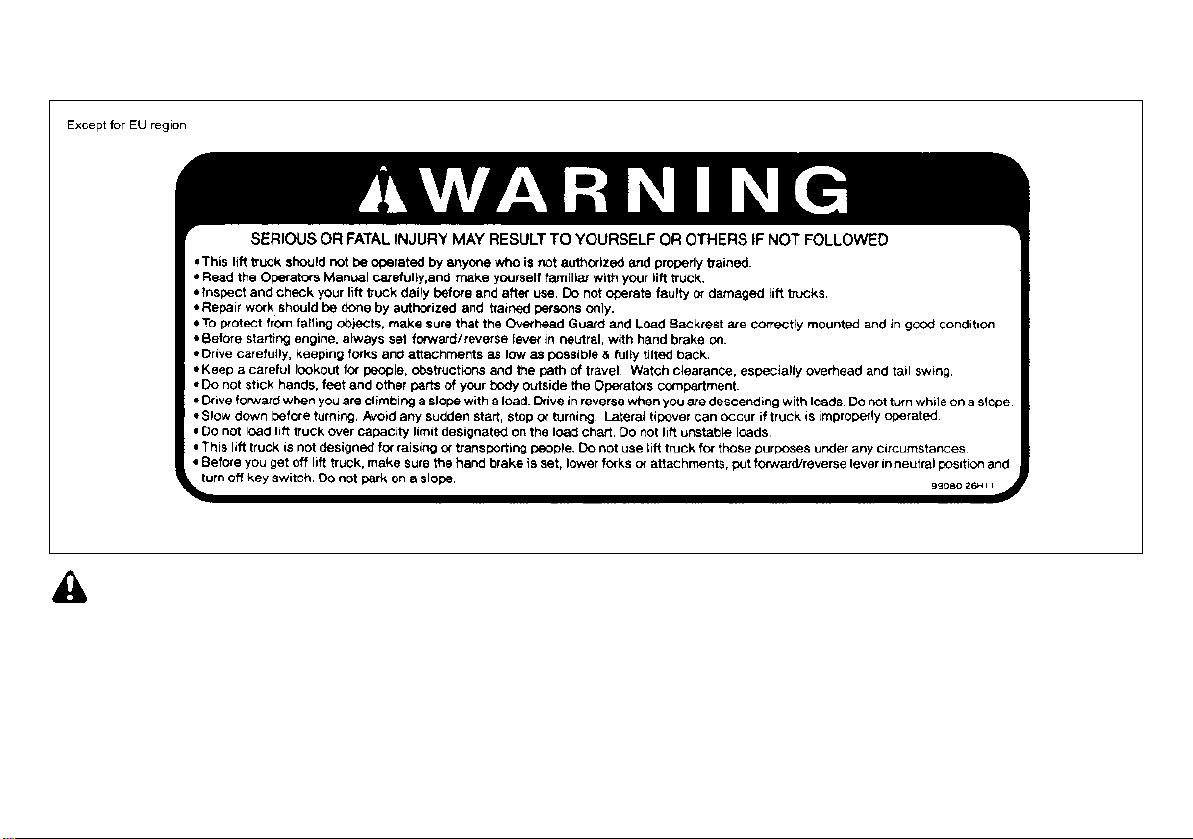

WARNING:

Operation precautions

MOM2807

This label contains instructions on how

to operate the forklift safely and avoid accidents. Therefore, be sure to take careful note of the instructions before

operating the forklift.

17

Page 19

WARNING:

The following precautions should be

MOM2796

closely observed to ensure safe operation of the forklift as well as to prevent

personal injury.

Always make sure your seatbelt is securely fastened, and stay seated while

driving.

Read the manual carefully before operating the truck to familiarize yourself

with the safety instructions.

DANGER:

The operator should stay inside the

forklift if the forklift starts to tip or falls

off a dock or ramp.

The operator should:

Lean away from the point of impact.

Hold on firmly to the steering wheel

with both hands.

Brace your feet and keep yourself inside the operator compartment.

Do not jump outside of the forklift.

18

Page 20

WARNING:

Never open the radiator cap while it is hot.

WARNING:

WARNING:

MOM2748

MOM2808

MOM2346

Touching the radiator cap while it is hot may

result in injury to your hand.

Never touch the cooling fan while it is turning.

Touching the cooling fan while it is turning may

result in injury to your fingers, and in the worst

case, may sever the fingers.

Diluted sulfuric acid and lead are used in

the battery.

Used battery fluid and batteries shall be

disposed of according to the applicable

provisions of the local laws and regulations.

Consult with an authorized UniCarriers

FORKLIFT dealer about the disposal of

the used battery fluid and batteries.

19

Page 21

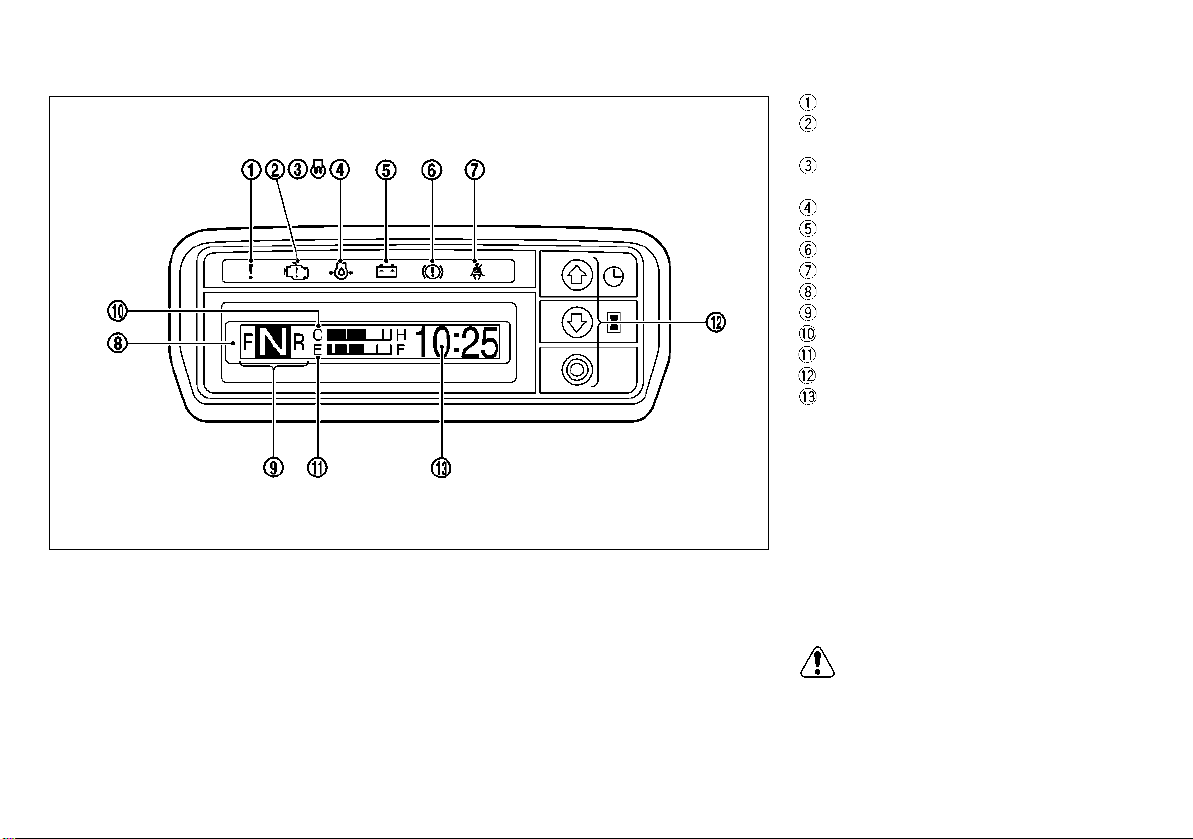

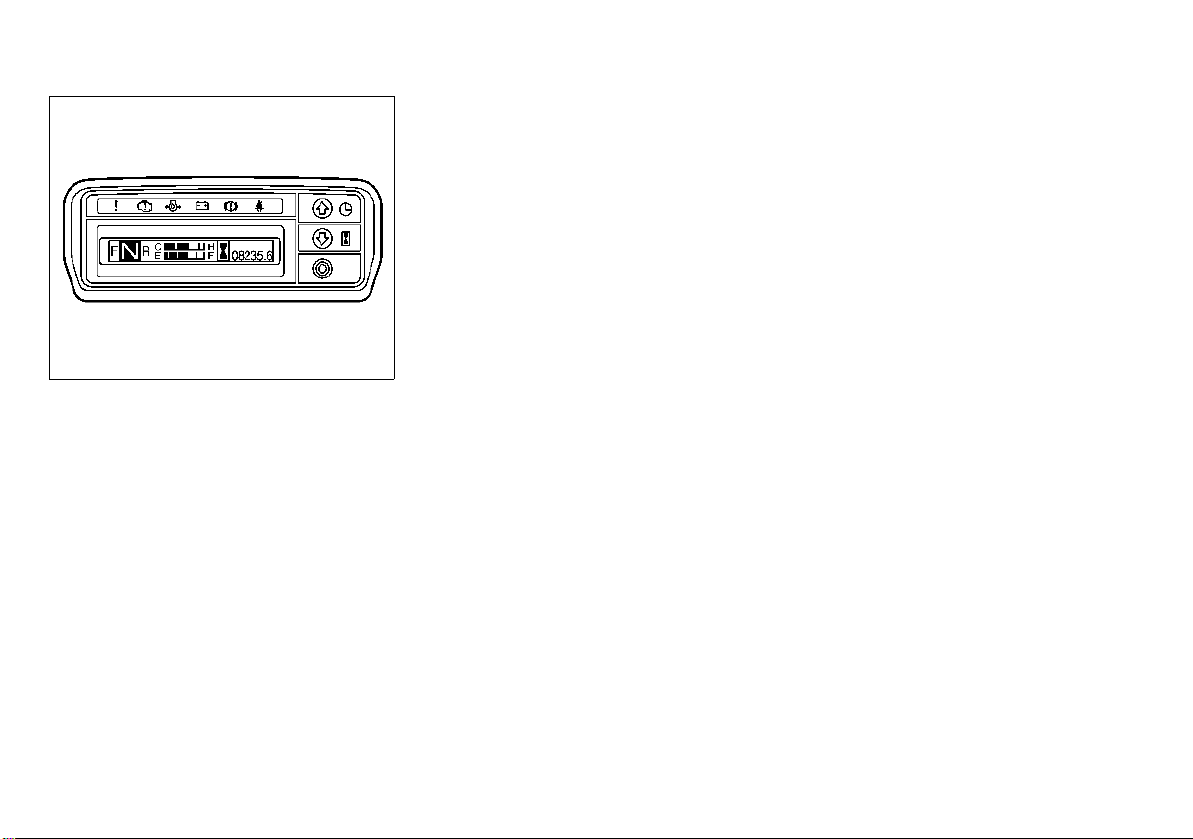

INSTRUMENTS AND CONTROLS

CAUTION:

MOM2196

Multipurpose warning lamp

Engine check lamp

(gasoline/LPG engine forklifts only)

Glow pilot lamp

(diesel engine forklifts only)

Oil pressure warning lamp

Charge warning lamp

Parking brake warning lamp

Seat belt warning lamp

Liquid Crystal Display (LCD)

Selector lever position (left side of LCD)

Water temp. gauge (top center of LCD)

Fuel gauge (bottom center of LCD)

Operation buttons

Time (right side of LCD)

NOTE:

In place of the time, the date or hour me-

ter may be displayed.

While driving, this display changes to

the speedometer when the vehicle speed

is 4.0 km/h (2.5 MPH) or higher.

This display also indicates the inspec-

tion/service timing, malfunctions and

warnings.

The display time and date will be reset if the

battery cable is disconnected or the battery

is replaced. If the display has been reset,

set the time and date again.

20

Page 22

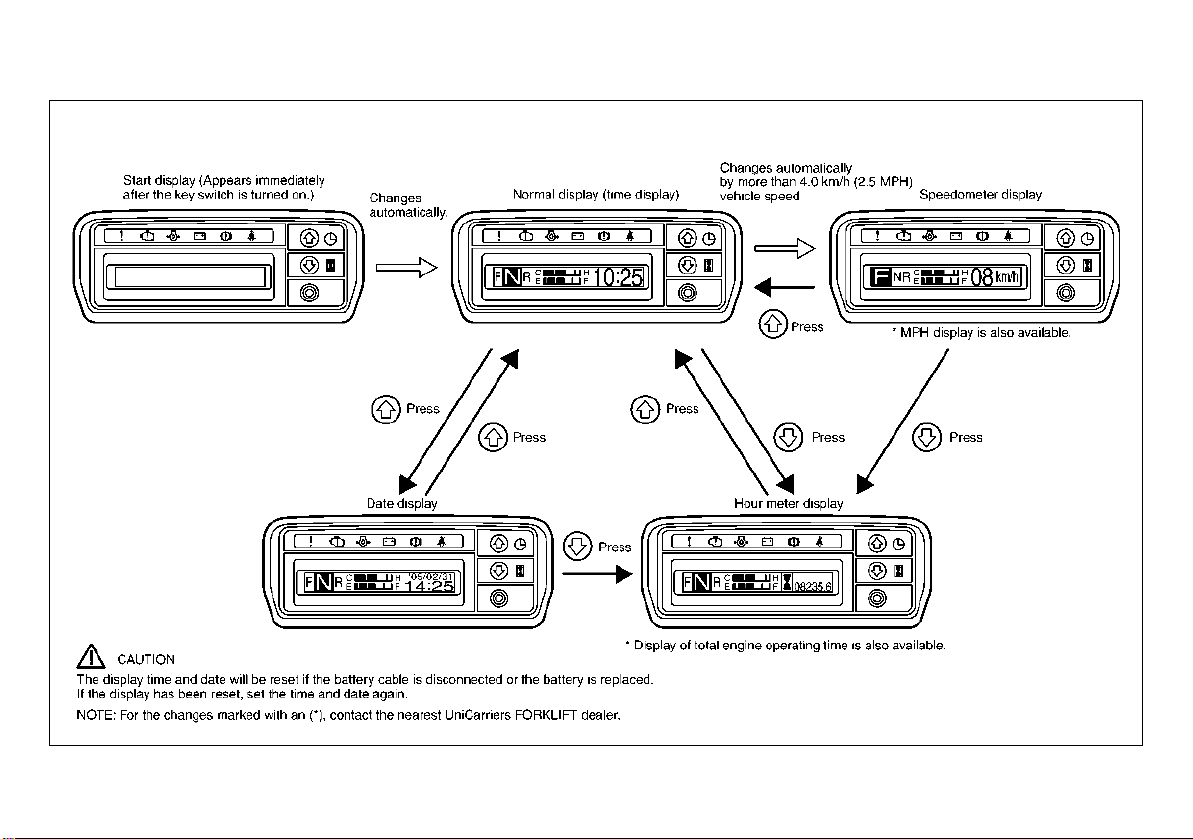

CHANGING METER DISPLAY

MOM2978

21

Page 23

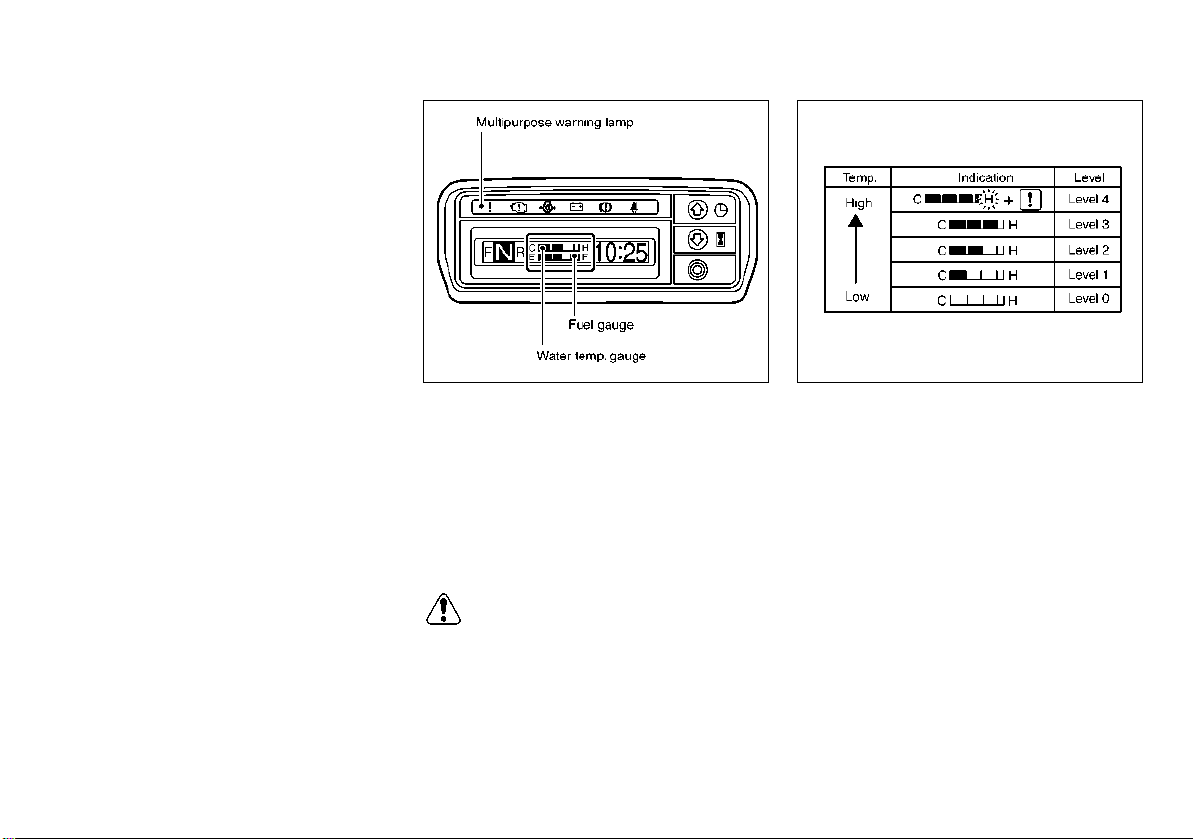

METER ILLUMINATION

CAUTION:

MOM2198

MOM2199

An illumination lamp is provided for meters to

ensure visibility at night.

OPERATION BUTTONS

Use these buttons to change the display, make

settings (time and date) and enter the password.

WATER TEMP. GAUGE

Indicates the current water temperature in levels 0 - 4. When level 2 is indicated, the coolant

temperature is correct. When the indication

reaches level 4, the display begins to blink,

and the multipurpose warning lamp illuminates

to inform the operator of the high water temperature.

If level 4 is indicated, stop the forklift and

allow the engine to cool while idling. After

the engine has sufficiently cooled down,

turn the engine off, and check the coolant

level and fan belt deflection.

22

Note to the operator:

All ECCS forklifts in North America have a

creep home feature that will reduce engine

RPMs if the coolant temperature remains

near the “H” position. This indicates that

the unit should be serviced by an authorized UniCarriers FORKLIFT dealer.

Page 24

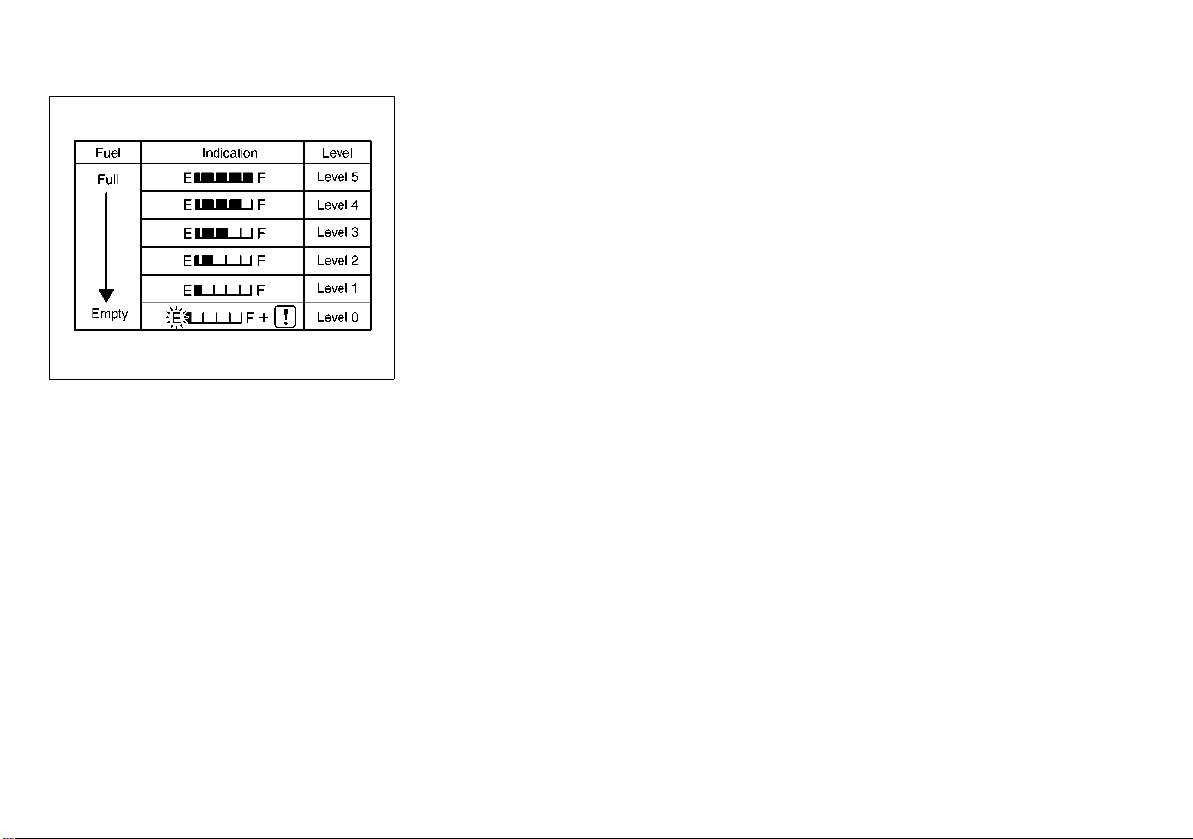

FUEL GAUGE

MOM2200

Indicates the current fuel level in levels 0 - 5.

When level 5 is indicated, the fuel tank is full.

When the indication reaches level 0, the display begins to blink, and the multipurpose

warning lamp illuminates to inform the operator of the nearly empty fuel tank. The fuel tank

is nearly empty. Add fuel immediately.

NOTE:

If the forklift is an LPG - gasoline dual

fuel vehicle, the fuel meter will not work

when the forklift is operated with LPG.

When operating the forklift with LPG,

check from time to time to be sure that

the LPG level warning lamp is not lit and

that the LPG level alarm is not on.

To check the remaining amount of LPG,

use the fuel gauge on the LPG cylinder.

23

Page 25

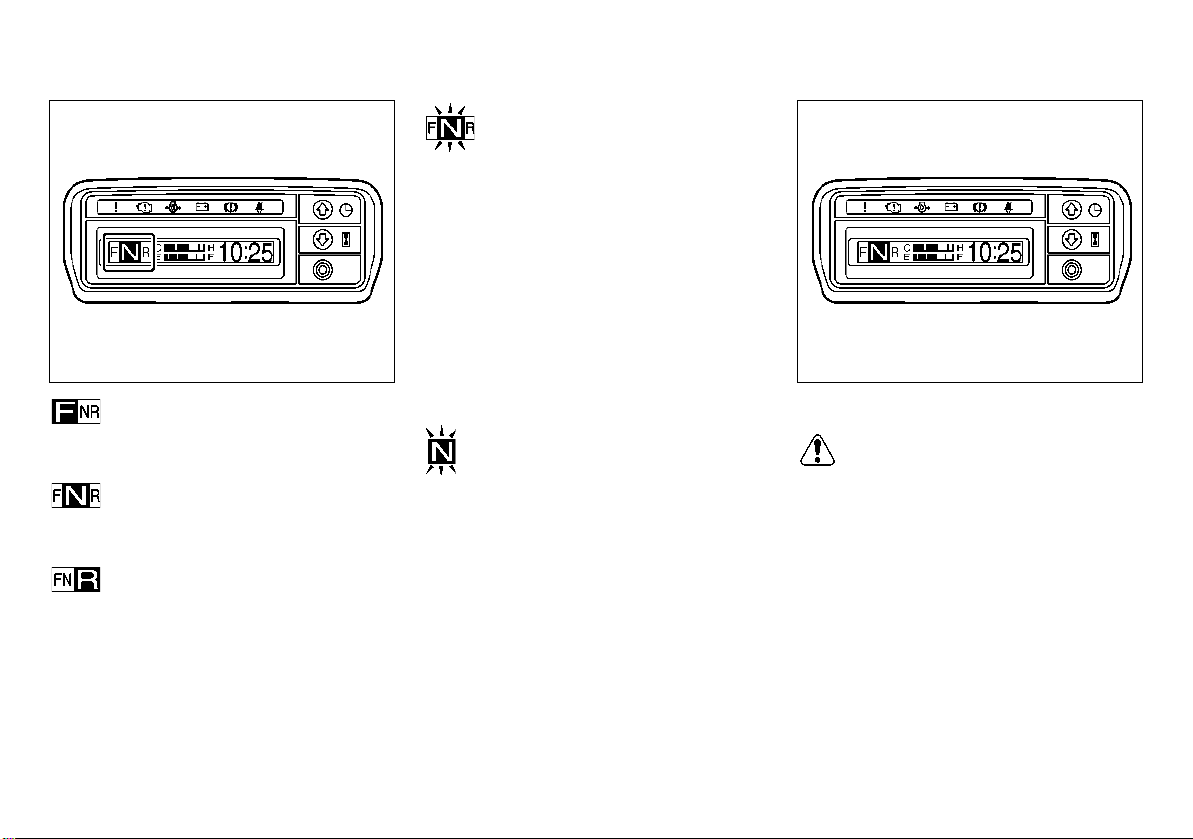

SELECTOR LEVER POSITION

CAUTION:

MOM2201

MOM2202

When the selector lever is in the “F” position,

the display appears as shown here.

When the selector lever is in the “N” position,

the display appears as shown here.

When the selector lever is in the “R” position,

the display appears as shown here.

When the selector lever is in the “F” or “R”

position and the operator is not seated on

the operator’s seat, the display blinks.

Sit on the operator’s seat and shift the

selector lever to Neutral (N), then shift it

again to Forward (F) or Reverse (R) in order

to drive.

When there is an error in the selector lever

signal, the display blinks.

Contact an authorized UniCarriers FORKLIFT dealer and request an inspection.

MTM

[N] illuminates only when the selector lever is

in the “N” position.

When there is an error in the selector lever

signal, the display blinks.

Contact an authorized UniCarriers FORKLIFT dealer and request an inspection.

CLOCK

The time and date will be reset if the battery

cable is disconnected (for example, when

the battery is replaced). Set the time and

date again.

When the ignition switch is turned on, the start

display appears, followed by the normal display (clock display).

NOTE:

Press the buttons to change the display to

the date or hour meter.

24

Page 26

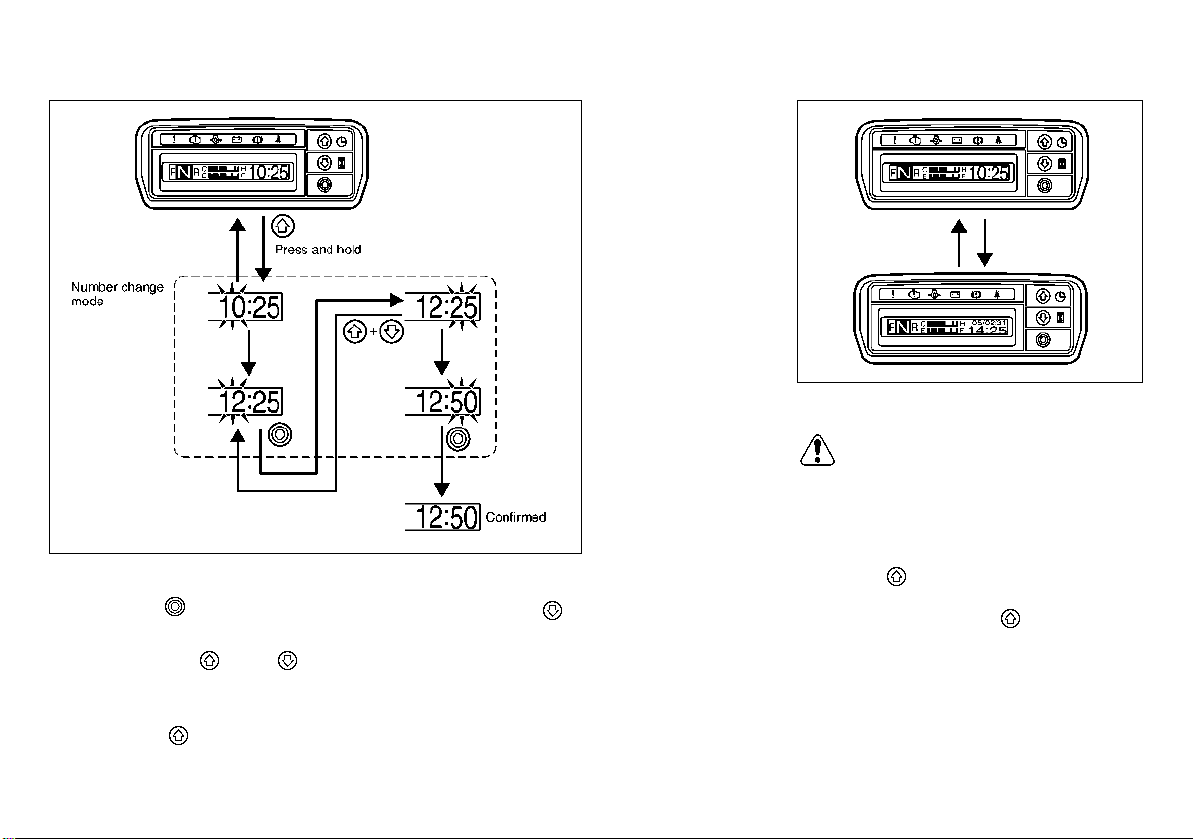

SETTING THE TIME

CAUTION:

MOM2384

MOM2385

NOTE:

Press the button to change from

hours minutes confirmed.

Press both the and buttons at

the same time to return to the previous

display.

Press the button to change the

number up.

Press the button to change the

number down.

DATE

The time and date will be reset if the battery

cable is disconnected (for example, when

the battery is replaced). Set the time and

date again.

Press the button on the normal display

(clock display) to change from the time display

to the date display. Press again to return

to the normal display.

25

Page 27

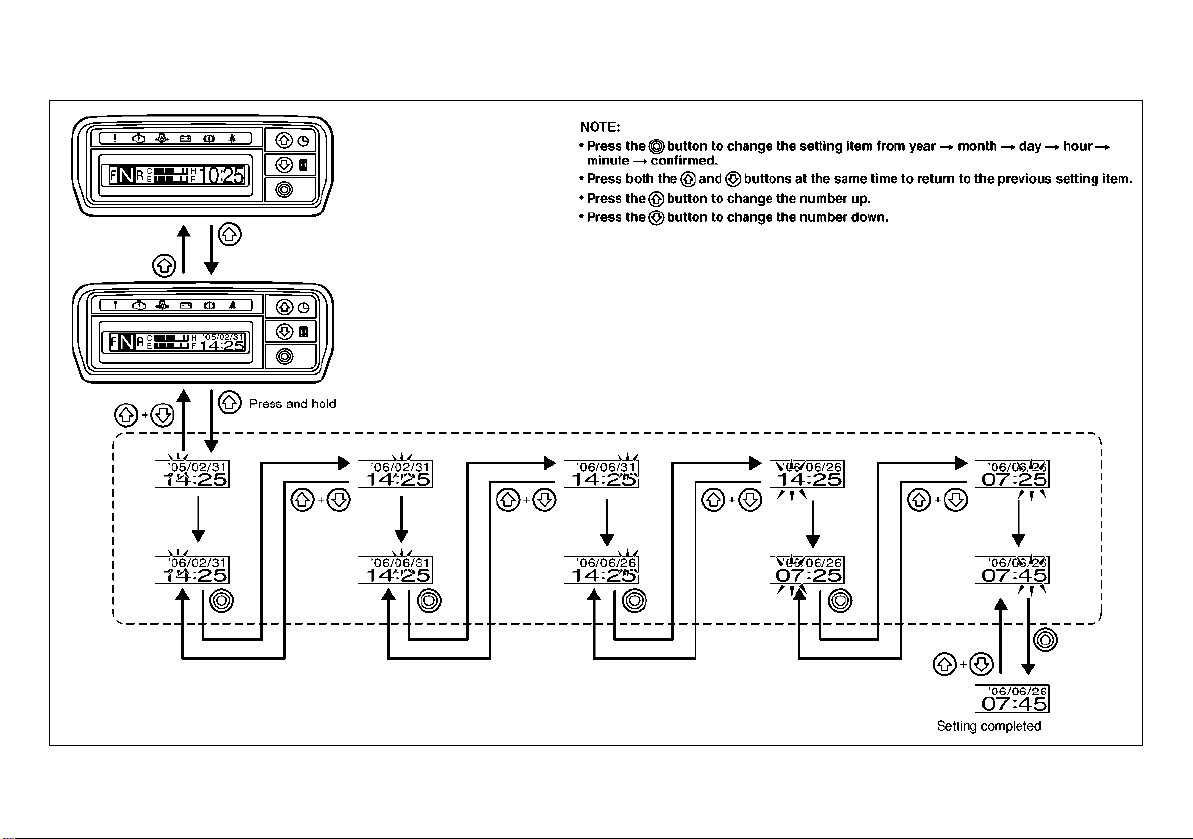

SETTING THE DATE

MOM2205

26

Page 28

HOUR METER

MOM2206

The buttons can be used to change from the

normal display (clock display) to the hour meter display.

The hour meter ordinarily displays the total ignition time that the ignition is on, however it is

possible to change the display to the total engine operating time.

To change the hour meter totaling pattern,

contact an authorized UniCarriers FORKLIFT

dealer.

27

Page 29

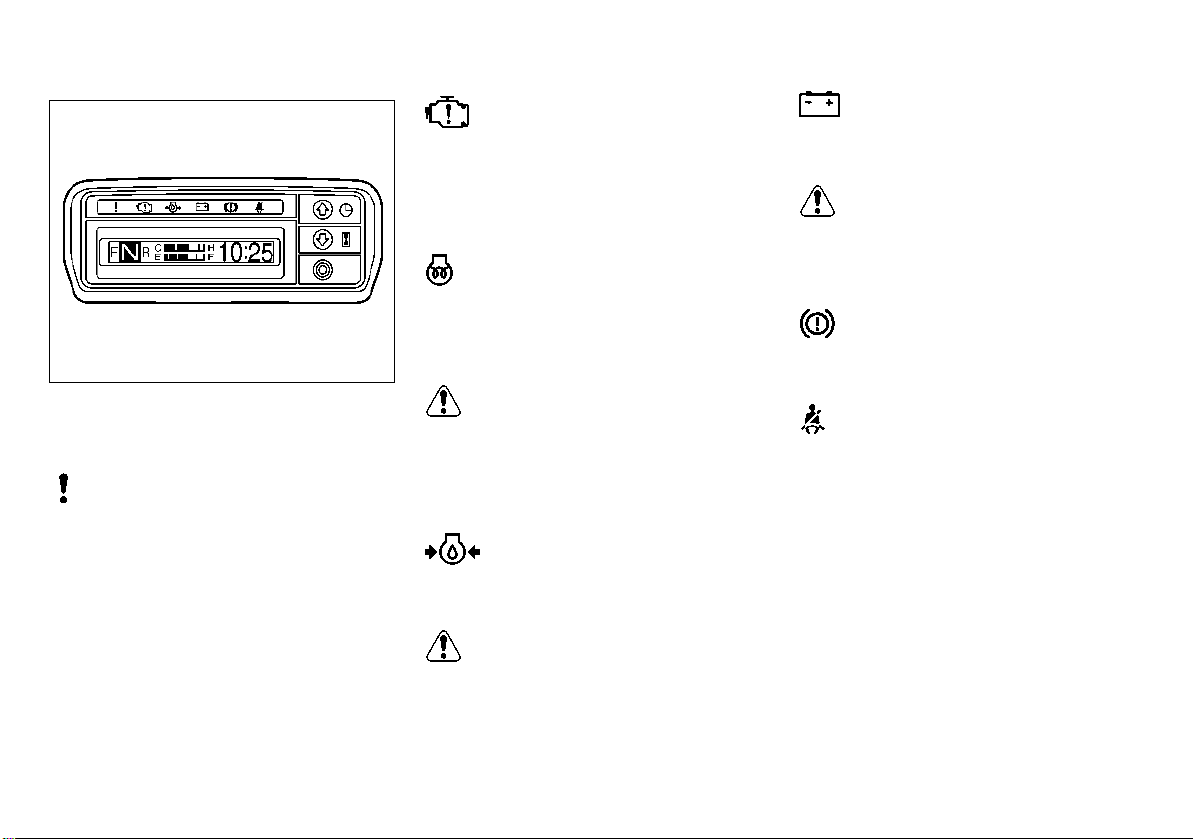

EXPLANATION OF WARNING

CAUTION:

CAUTION:

CAUTION:

MOM2207

LAMPS

Following is an explanation of the meaning

and method of correction when a warning lamp

illuminates.

Multipurpose warning lamp

This warning illuminates when one of the LCD

warning symbols illuminates. It also illuminates

when the water temperature is high or the fuel

level is low. If this lamp illuminates during operation, stop operation immediately, report to

the person having management duties and

take necessary measures.

Malfunction indicator lamp

(gasoline/LPG engine forklifts

only)

This warning illuminates when there is malfunction with an engine sensor or air-fuel ratio

control.

Glow plug indicator lamp

(diesel engine forklifts only)

This warning illuminates when the ignition

switch is turned on, and it turns off when glow

plug preheating is completed.

If the lamp remains illuminated after the

glow plugs are preheated, this indicates

a malfunction in the glow system.

Have the system checked at your nearest

authorized UniCarriers FORKLIFT dealer.

Oil pressure warning lamp

This warning illuminates when the oil pressure

is low.

If the lamp illuminates under ordinary operating conditions, stop the engine immediately

and check the engine lubrication system.

Charge warning lamp

This warning illuminates when there is a malfunction with the charge system.

If the lamp illuminates or flickers occasionally during normal operating conditions,

the alternator and electrical system should

be checked.

Parking brake warning lamp

This warning illuminates when the parking

brake lever has been pulled.

Seat belt warning lamp

This warning illuminates when the seat belt is

not fastened.

28

Page 30

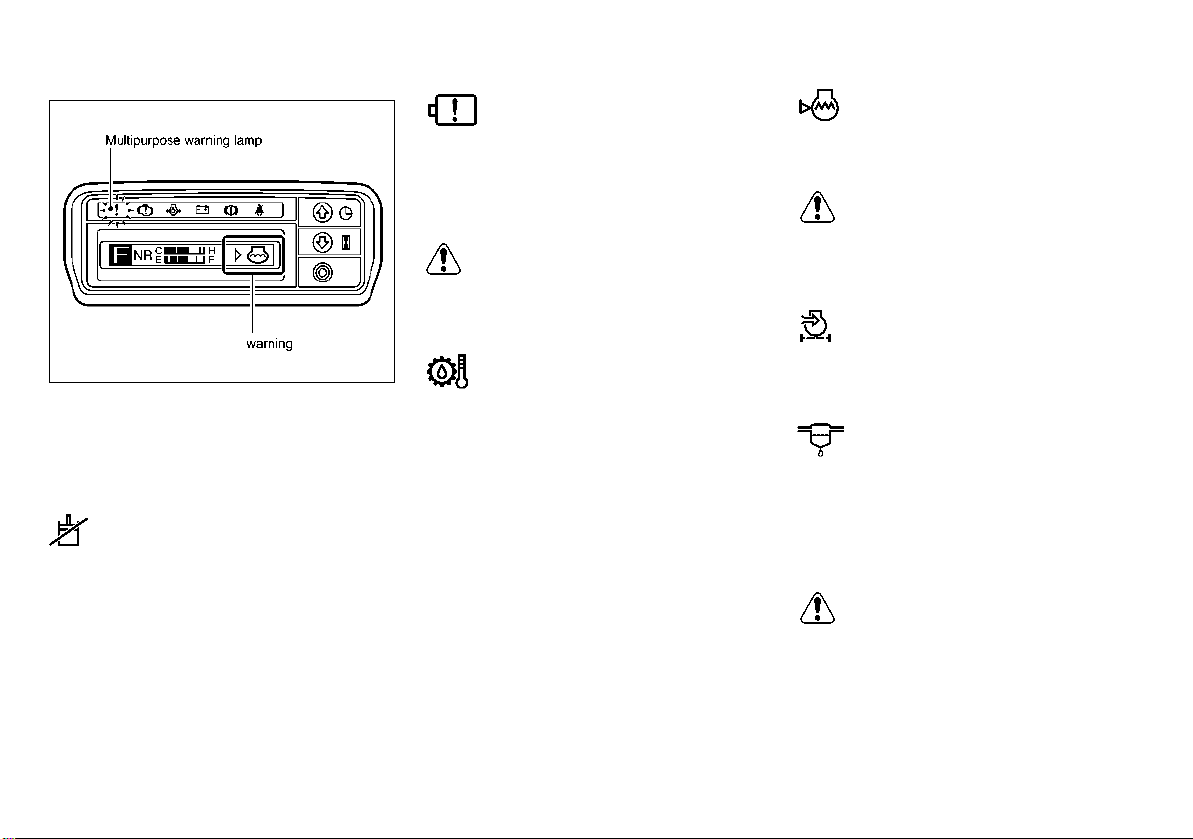

LCD WARNING SYMBOLS

CAUTION:

CAUTION:

CAUTION:

MOM2208

When a forklift warning occurs, a warning symbol and the multipurpose warning lamp illuminate. Following is an explanation of the

meaning and method of correction when a

warning symbol illuminates.

Mast interlock warning

This warning illuminates when the ignition

switch is turned on and the operator is not

seated on the seat. Loading operation is prohibited at this time. Loading becomes possible

when the operator is seated on the seat.

LPG level warning/LPG rack

lock warning (LPG and DUAL

forklifts only)

This warning illuminates when the LPG level is

low. Replace the LPG fuel cylinder before the fuel

(LPG) runs out.

The LPG tank is out of or nearly out of fuel.

Have LPG cylinder tank replaced immediately.

Torque converter fluid temp.

warning

This warning illuminates when the transmission fluid temperature is high. If this warning

symbol illuminates, move the vehicle to a safe

location and allow it to idle in order to lower the

fluid temperature. When the fluid temperature

has returned to normal, the warning turns off.

NOTE:

Check the level of automatic transmis-

sion fluid. (For more information, refer to

“Automatic transmission fluid level” on

page 87.)

If the warning lamp illuminates even

though the transmission fluid is at a normal level, ask your nearest authorized

UniCarriers FORKLIFT dealer to perform

an inspection.

Radiator level warning

This warning illuminates when the engine coolant level is low. Add coolant.

Continuing to drive while the lamp is illuminated may lead to overheating of the engine.

Air cleaner warning

This warning illuminates when the air cleaner has

become clogged. If this warning symbol

nates

, promptly clean or replace the air cleaner.

illumi-

Fuel filter warning

(for diesel engine forklifts)

This warning illuminates when the fuel filter

has become full with water. If this warning

symbol illuminates, promptly drain the water

from the fuel filter.

Continuing to drive while the lamp is illuminated may lead to a reduction in the engine

output or engine damage.

29

Page 31

INSPECTION TIMING DISPLAY DISPLAYS WHEN MALFUNCTION

MOM2209

MOM2210

OCCURS

When the time for regular inspection approaches, this warning illuminates for 15 seconds after the ignition switch is turned on. This

does not affect driving.

When the display shown above appears, contact an authorized UniCarriers FORKLIFT

dealer. It is recommended that regular inspection be performed.

When controller malfunction occurs, an error

code is displayed.

Press a button while the error code is displayed in order to display the cause of the malfunction.

If the display above appears, contact an authorized UniCarriers FORKLIFT dealer.

30

Page 32

DRIVER RECOGNITION MODE

MOM2211

Registering a password can restrict the drivers

of the forklift.

You can register a password for up to 5 persons

(A to E).

Contact an authorized UniCarriers FORKLIFT

dealer for information about the registration of

the password.

31

Page 33

MANAGER MODE

MOM2212

Manager mode can be used by the manager to

check and reset the operating time for each

operator, and to change passwords.

The manager must not disclose to the

operators the password required to enter

manager mode.

If the manager has forgotten the password,

contact an authorized UniCarriers FORKLIFT

dealer.

32

Page 34

The items that can be changed and viewed in manager mode are the following.

CAUTION:

Indication Explanation

PASS ENTRY Enable/disable the operator password entry function.

ENTRY TIME After an operator has entered the password, then it will not be necessary for the same operator to enter the password again for the amount

PASS A Change password “A” for the operator password entry function.

PASS B Change password “B” for the operator password entry function.

PASS C Change password “C” for the operator password entry function.

PASS D Change password “D” for the operator password entry function.

PASS E Change password “E” for the operator password entry function.

PASS MANAGER Change the manager mode password.

A*****.* C*****.*

B*****.* D*****.*

E*****.* Display the vehicle operating time when password “E” is used for the operator password entry function.

MANAGE RESET Reset the vehicle operating times when passwords “A” - “E” are used for the operator password entry function.

of time set here.

Display each of the vehicle operating times when passwords “A” - “D” are used for the operator password entry function.

For the methods used to view and change the above items, contact an authorized UniCarriers FORKLIFT dealer.

33

Page 35

LPG REMAINING TIME

CAUTION:

MOM2213

MANAGEMENT

With this function, the operator sets the time interval between LPG fuel cylinder replacements. Then, when this time reaches zero, this

function illuminates the LPG level warning

symbol and multipurpose warning lamp to

warn the operator of the need to replace the

LPG fuel cylinder. For the method used to

change the LPG level warning pattern to the

method above, contact an authorized

UniCarriers FORKLIFT dealer.

LPG remaining time management is recommended for the following types of situations.

The timing for replacement of the LPG fuel

cylinder is predetermined.

The LPG level warning appears too early (or

too late) on the forklift that is currently being

used.

Set a time with a sufficient amount of lee-

way.

After replacing the LPG fuel cylinder, be

sure to set the time setting again. Otherwise, the time setting continues after

LPG fuel cylinder replacement, and this

may result in the LPG level warning symbol turning on at an unintended time.

When driving a dual fuel forklift using

gasoline after using LPG without the time

setting, be careful that the time setting

continues to count the time.

LPG remaining time setting

When the time setting is set to [ ], the

meter panel shows the LPG level warning

[].

When the time setting is reset, move to

the setting display by pushing ( ),

( ) and ( ) while the LPG level

warning ( ) is displayed. After resetting the setting time, the LPG level warning turns off.

34

Page 36

Following is an explanation of how to set the time setting for the first time.

MOM2214

Example: Setting the time to 12.3 hours

35

Page 37

Following is an explanation of how to set the time setting for the second and later times.

MOM2215

Example 1: Changing the time from 12.3 hours (previous setting) to 6.5 hours

Example 2: Using the same 12.3 hours setting (previous setting) again

36

Page 38

SWITCHES AND CONTROLS

MOM2343

AUTO STOP/START FUNCTION

(option)

This function automatically stops the engine

when the forklift has not been operated for the

set length of time if the following conditions are

also met: the vehicle is idling (the accelerator

pedal is not depressed), the selector lever is in

the neutral position, the vehicle is stopped and

no malfunctions have occurred. When this

function stops the engine, “AUTO STOP” is

displayed on the LCD panel.

Horn switch

Ignition switch

Lighting switch and turn signal switch

NOTE:

In forklifts with the optional joystick control, this switch is located on the left side.

Throttle sensitivity adjust switch (option)

Maximum speed change switch (option)

Fuel-change switch

(LPG - gasoline dual fuel forklift)

Accelerator pedal

Brake pedal

Inching brake pedal

Parking brake lever

Selector lever

NOTE:

Operation is the same for the optional

right-side selector lever.

For forklifts with the optional joystick

control, this switch is located on the joystick control unit.

37

Page 39

Setting at the time of shipment from facto-

MOM2476

MOM2564

ry: 60 seconds

Adjustable range: 0 - 200 seconds

A setting of 0 seconds disables the auto

stop function.

The status when auto stop is activated is

the same as when the ignition switch is

turned OFF. (The headlamps can be

turned ON, however the turn signal

lamps will not operate.)

To restart the engine from the auto stop status,

leave the selector lever in the neutral position

and sit in the seat, then depress the inching

brake pedal or brake pedal and at the same

time depress the accelerator pedal. This will

restart the engine.

The engine can also be restarted by turning

the ignition switch to the START position.

To change the setting for this function, please

contact the nearest UniCarriers FORKLIFT

dealer.

NOTE:

The set time before auto stop activates can

be adjusted within the range of 0 - 200 seconds.

IGNITION KEY

Insert the ignition key in the ignition switch to

start or stop the engine.

NOTE:

Two ignition keys are provided with eve-

ry UniCarriers FORKLIFT. Use one key

for operation and store the other in a safe

place as a spare.

Be sure to take a note of the key number

in case the key is lost. You need to specify the key number when placing an order

for additional spare keys to an authorized UniCarriers FORKLIFT dealer.

38

Page 40

ON position

MOM2355

Gasoline engine forklift

IGNITION SWITCH

OFF position

The position that allows the ignition key to be

inserted into or removed from the ignition

switch. When the ignition switch is in this position, all electric circuits are open but the following can be turned on and off.

Horn

Lamps by operating the lighting switch

Rear operating lights (option)

Braking lamps by the application of the

brake

The position in which the ignition switch is

placed when the engine is running. When the

ignition switch is in this position, all electric circuits are closed.

START position

To start the engine, turn the ignition switch to

the ON position, then to START. When you

take your hand off the ignition key after starting

the engine, the key returns to this ON position

automatically.

NOTE:

If you leave the ignition switch in the ON

position while the engine is stopped, the

battery may run down, and this may make

it impossible to start the engine. To avoid

this situation, always return the ignition

switch to the OFF position after stopping

the engine.

During operation, the ignition switch is in

the ON position. Never turn it to the OFF

or START position.

Do not operate the starter for a long time

when starting the engine.

If the engine does not start even though

you operate the starter repeatedly, return

the ignition switch to the OFF position,

wait for a short period of time until the battery is restored to a normal voltage level,

and then try to start the engine again.

Do not operate the starter for more than 10

consecutive seconds. If the engine does not

start, wait for at least 10 seconds and then try

to start it again.

Diesel engine forklift

Do not operate the starter for more than 30

consecutive seconds. If the engine does not

start, wait for at least 30 seconds and then try

to start it again, starting with preheating.

39

Page 41

LIGHTING SWITCH

CAUTION:

MOM1898

MOM1899

To turn on one of the lamps listed in the table,

turn this switch to align the position bar (–) on

the switch knob with the corresponding mark

on the switch main unit.

Switch

mark

OFF Off Off

Headlamp Tail lamp

Off On

On On

Do not touch the headlamp lens when the

headlamp is lit or immediately after the

headlamp is turned off, because it is very

hot.

NOTE:

You can turn lamps on and off by turning

the lighting switch, regardless of the position of the ignition switch.

Do not forget to turn off all lamps when

leaving the forklift, otherwise the battery

may run down.

TURN SIGNAL SWITCH

Push the switch lever forward when turning

left, and pull it backward when turning right.

The appropriate turn signal will blink. Upon

completion of the turn, be sure to return the lever to its original position.

HORN SWITCH

Pushing the switch in the center of the steering

wheel will sound the horn, regardless of the

key position.

NOTE:

For forklifts with the optional joystick control, a horn switch is also located on the

joystick control unit.

40

Page 42

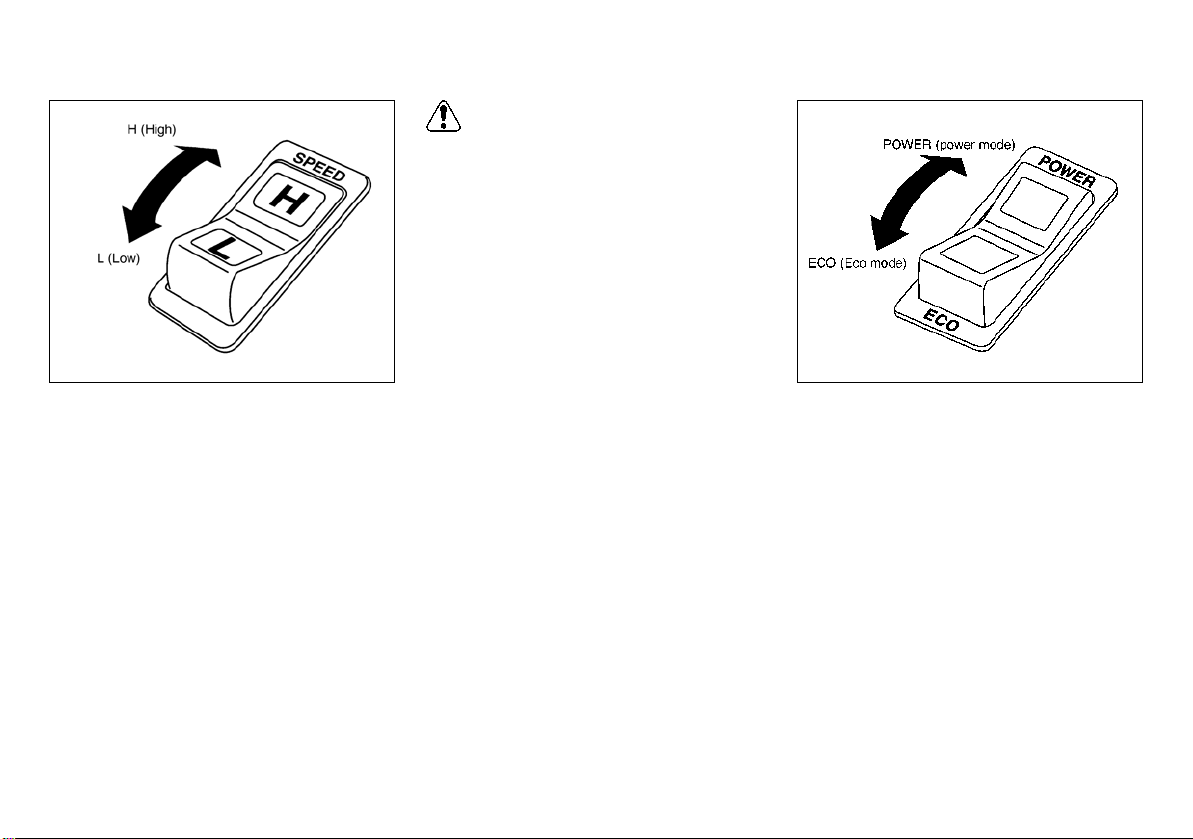

CAUTION:

Do not change the maximum speed when

MOM1900

MOM2217

the forklift is running. Doing so could

cause the load to shift.

Only authorized UniCarriers FORKLIFT

dealers are allowed to change the running speed settings. So, if necessary,

ask an authorized UniCarriers FORKLIFT

dealer to perform this change.

MAXIMUM SPEED CHANGE

SWITCH (option)

This switch is an optional setting switch for

electronic control gasoline vehicle and gasoline-LPG vehicle or diesel speed control vehicle. It allows you to switch the maximum speed

between H (high speed mode) and L (low

speed mode). Press the H (high) side of the

switch if there is no need to limit the maximum

speed to a low level, or press the L (Low) side

to limit the maximum speed to a low level.

The lamp on the side you pressed illuminates,

indicating the speed mode that is currently selected.

THROTTLE SENSITIVITY ADJUST

SWITCH

This switch is an optional setting switch for

electronic control gasoline vehicle and gasoline-LPG vehicle. It allows you to switch the

starting acceleration between POWER (power

mode) and ECO (economy mode). Press the

POWER side of the switch to accelerate the

forklift at a normal rate, or press the ECO side

to accelerate the forklift slowly.

The lamp on the side you depressed illuminates, indicating the power mode that is currently selected. You can switch from one mode

to the other, as described in the table.

41

Page 43

CAUTION:

WARNING:

Switching

MOM1903

operation

From POWER

to ECO

From ECO

to POWER

During

driving

Not

possible

Not

possible

During a halt

and ignition

switch OFF

Possible

Possible

NOTE:

Switching from the ECO mode to the POWER mode can be done only when the accelerator is released.

Turn the ignition switch off before changing the POWER/ECONOMY SWITCH.

FUEL-CHANGE SWITCH

(LPG - gasoline dual fuel forklift)

This switch is used to switch fuel from LPG to

gasoline or from gasoline to LPG.

LPG position: Turn to this position to use LPG.

Neutral position: Turn to this position to exhaust fuel from the fuel pipe.

Gasoline position: Turn to this position to use

gasoline.

The lamp illuminates for the fuel that is currently being used.

Do not manipulate the LPG cylinder charge

valve (green or gray), otherwise LPG may

leak out into atmosphere.

NOTE:

When the engine is running, you can

switch between fuels by operating the

switch.

To switch from one fuel to the other,

strictly follow the specified procedure after warming up the engine.

To prevent deterioration of gasoline,

drive the forklift with gasoline several kilometers about once every two weeks.

The engine does not start when the se-

lector switch is in the neutral position.

Do not forget to turn the switch to the

LPG or gasoline position before starting

the engine.

42

Page 44

CAUTION:

Do not operate the forward-reverse lever

MOM1904

MOM1905

before the forklift comes to a full stop.

When operating the lever, do it correctly

while pressing the clutch pedal flat.

Depending on the model used, the gear

shift lever may be placed on the right

side of the forward-reverse lever (optional). Before use, therefore, make sure of

the position of each lever to avoid operating the wrong lever.

FORWARD-REVERSE LEVER

(MT vehicle)

This lever is used to change the running direction of the forklift (forward or reverse). Push the

lever forward to drive forward, or pull it towards

you to back up. The neutral position is at the

midpoint.

When starting the engine, always return

the forward-reverse lever to the neutral

position.

When operating the lever while the en-

gine is running, be sure to depress the

clutch pedal flat.

GEAR SHIFT LEVER (MT vehicle)

This lever is used to shift gears between low

speed (1st speed) and high speed (2nd

speed). Push the lever forward to shift to low

gears, or pull the lever towards you to shift to

high gears. The neutral position is at the midpoint.

43

Page 45

SELECTOR LEVER (AT vehicle)

WARNING:

MOM2036

MOM1907

This lever is used to change the running direction of the forklift (forward or reverse). Push the

lever forward to drive forward, or pull the lever

towards you to back up. The neutral position is

at the midpoint.

The same operating method applies to the selector lever positioned on the right side of the

forward-reverse lever (option).

NOTE:

The engine cannot be started when the selector lever is in any position other than the

neutral position.

PARKING BRAKE LEVER

When parking the forklift, fully pull the lever towards you. To release the parking brake, push

down the button on top of the lever and then

push the lever forward.

When parking the forklift on a slope, fully pull

the lever towards you and set a chock behind

each wheel.

Always depress the brake or inching

pedal before releasing the parking brake

to avoid movement of the forklift before

selecting a direction.

Driving the forklift with the parking brake

applied could cause the brakes to fail

due to overheating. Also, it hastens

brake pad wear.

NOTE:

To remind the operator to apply the parking

brake, an alarm will sound if:

The operator leaves the operator’s seat

without applying the parking brake while

the ignition switch is in the ON position.

The operator turns off the ignition switch

without applying the parking brake,

whether or not the operator is sitting on

the operator’s seat.

44

Page 46

ACCELERATOR PEDAL

CAUTION:

WARNING:

MOM1908

MOM1909

MOM1910

This pedal allows you to adjust the rotational

speed of the engine. The engine speed changes according to the degree to which the accelerator pedal is depressed.

Do not depress the accelerator pedal

quickly. Depress it slowly to prevent a sudden or rapid start or a shift or falling of cargo.

BRAKE PEDAL

This pedal allows you to bring the forklift to a

stop or slow it down.

Do not brake the forklift too hard. Doing

so may cause the forklift to become unbalanced and could result in a serious

accident.

Adjust the braking effort according to the

cargo weight.

Do not leave your foot on the brake pedal

while driving. Doing so may cause the

brakes to fail because of overheating. Also, it hastens brake pad wear.

INCHING BRAKE PEDAL

(AT vehicle)

The inching brake pedal allows you to finely

adjust the forward and reverse running speed.

The clutch begins to slip when you slightly depress this pedal, and the clutch is completely

disengaged and the brakes are applied when

you further depress the pedal, in which case

the inching brake pedal acts in the same way

as a brake pedal.

45

Page 47

WARNING:

Do not leave your foot on the inching

CAUTION:

MOM1911

brake pedal when driving the forklift.

Doing so may cause the clutch to slip

and prevent engine braking from taking

effect. Moreover, it could cause the

brakes to fail because of overheating.

Also, doing so may cause the hydraulic

clutch in the transmission to slip and

give off a large amount of heat, causing

the clutch to overheat, wear down in a

short time or seize up in the worst case.

CLUTCH PEDAL (MT vehicle)

This pedal is used along with the forward-reverse lever or the gearshift lever.

When operating the forward-reverse lever or

the gearshift lever, depress the clutch pedal

flat, shift the forward-reverse lever or the gearshift lever from one position to another, and

then slowly take your foot off the clutch pedal.

Do not leave your foot on the clutch ped-

al when driving the forklift.

Doing so may cause the clutch to slip

and hastens the wearing away of the

clutch discs.

46

Page 48

STARTING AND OPERATING

WARNING:

WARNING:

MOM1912

GASOLINE ENGINE STARTING

(Including LPG - gasoline dual fuel

forklift)

Do not breathe exhaust gases. They con-

tain colorless and odorless carbon monoxide. Carbon monoxide is a dangerous

gas and can cause unconsciousness or

death.

Do not run the engine in closed spaces or

poorly ventilated rooms such as a garage

or refrigerator, etc.

Follow the procedure outlined below to start

the engine.

LPG - gasoline dual fuel forklifts have a fuelchange switch. Use this switch to select the

desired fuel.

When using LPG, slowly open the (red) discharge valve on LPG cylinder (tank) to start the

engine.

1. Pull the parking brake lever up as far as

possible. Move the selector lever to the

neutral position.

2. Depress the inching brake pedal as far as

it can go.

3. Remove your foot from the accelerator

pedal. Turn the starter to start the engine.

NOTE:

Do not operate the starter for more than 10

seconds. If the engine fails to start within

10 seconds, release the starter and wait for

10 seconds before attempting to start the

engine again. This allows the battery time

to recover.

4. After starting the engine, give it time to

warm up. Allow the engine to idle for 1

minute after starting. Then, press the

accelerator pedal lightly and release it. If

the surrounding temperature is high, lightly

pressing and releasing the accelerator

pedal will reduce engine speed and permit

quiet warming up. This also results in fuel

savings.

47

NOTE:

The engine is cold immediately after

starting. Do not intermittently race the

engine or run the engine at high speeds

immediately after starting.

Do not move the key to the START posi-

tion when the engine is running. Damage

to the starter motor will result.

After operation, always close the LPG

(red) discharge valve on LPG cylinder

(tank) after shutting the engine off

(down).

After operation, if the forklift is not used

for several hours or more, or during cold

weather seasons, park the forklift with

the fuel-change switch positioned on the

gasoline side. This helps to start the engine more easily the next time (LPG gasoline dual fuel forklift).

The engine speed becomes high immediately after starting. Exercise caution when

moving the forklift or handling cargo.

Inspect the condition of the LPG hose

connections and check for gas leaks

from LPG hoses and pipes before starting the engine.

In the event of LPG leakage or some other

malfunction, close the discharge valve immediately. Have the LPG system checked

at an authorized UniCarriers FORKLIFT

dealer.

Page 49

FUEL-CHANGE SWITCH

WARNING:

CAUTION:

CAUTION:

MOM1903

(LPG - gasoline dual fuel forklift)

Do not operate (turn on or open) the LPG

cylinder (tank) change (refill) valve. Opening the valve may cause LPG to leak into

the atmosphere and could cause a dangerous fire hazard.

TO CHANGE FROM LPG OPERATION

TO GASOLINE OPERATION

1. Press the fuel-change switch and change

the switch position from the LPG to the

neutral position.

2. Shut off the red or discharge valve on the

LPG cylinder side.

3. Let the engine run at idle until it stops.

4. After the engine has completely stopped,

move the fuel-change switch to the GAS

position. Restart the engine.

Directly changing over LPG to GAS without

the fuel-change switch first being positioned at the neutral position causes the remaining fuel (LPG) and gasoline to be

mixed, resulting in a poorly operating engine. Before changing over the switch position, always exhaust the remaining fuel

(LPG) by setting the switch to the neutral

position.

To change from gasoline operation to LPG operation

1. Press the fuel-change switch and change

the switch position from GAS to the neutral

position. Slightly depress the accelerator

pedal and hold it to allow the engine to

race. Continue pressing the accelerator

pedal until the engine stops.

48

2. After the engine has completely stopped,

open the red discharge valve on the

cylinder side and move the fuel-change

switch to the LPG position. Restart the

engine.

Directly changing over GAS to LPG without

the fuel-change switch first being positioned at neutral causes the remaining fuel

(gasoline) and LPG to be mixed, resulting

in a poorly operating engine. Before changing over the switch position, always exhaust the remaining fuel (gasoline) by

setting the switch to the neutral position.

NOTE:

Change over the fuel-change switch po-

sition according to the operating procedure of this switch. Otherwise, the air/

fuel ratio of fuel (mixture) is negatively

affected, making it difficult to start the

engine.

When driving an LPG-gasoline dual fuel

vehicle using LPG during the cold weather seasons, first start the engine using

gasoline and then change over to LPG

with the fuel-change switch after warming up the engine.

Page 50

Do not use the fuel-change switch to

WARNING:

MOM1915

change fuels when the engine is running.

Change fuels only after the engine has

completely stopped.

Operate the vehicle with gasoline for sev-

eral kilometers at least once every two

weeks. This will prevent gasoline deterioration.

Do not change fuels immediately after

starting the engine. Allow the engine to

warm up before changing fuels.

With the fuel-change switch set to the

neutral position, the engine cannot be

started. Before starting the engine, always change over the switch position to

LPG or gas.

Carefully follow the procedures below when

turning the engine off after LPG operation.

1. Move the fuel-change switch to the neutral

position.

2. Let the engine idle until it stops.

3. Make sure that all of the remaining LPG (in

the piping and other receptacles) has been

used. After the engine stops, turn the

ignition switch to the OFF position.

4. After completion of operation and before

storing the vehicle for an extended period,

completely close the (red) discharge valve.

Check the engine for gas leakage. Refer to

“LPG cylinder replacement” on page 112.

In the event of gas leakage, an accident,

or some other malfunctions, immediately

and completely close the discharge valve

(colored red). Have the LPG system

checked at an authorized UniCarriers

FORKLIFT dealer.

If the forklift is not used for several hours

or more after operation, park the forklift

with the fuel-change switch in the GAS

position. This helps to start the engine

more easily the next time.

DIESEL ENGINE

Starting

1. Set the parking brake lever and move the

selector lever to the neutral position.

2. Depress the inching brake pedal as far as

it can go.

3. When the ignition key is set to the ON

position, the glow plug indicator lamp on

the instrument panel illuminates, indicating

that engine preheating has started.

Keep the ignition key in the ON position until

the glow plug indicator lamp turns off (indicates completion of preheating).

49

Page 51

NOTE (QD32 engine):

Engine preheating is controlled automatically corresponding to the engine coolant

temperature, atmospheric air temperature,

etc., and the glow plug indicator lamp turns

off when the engine is preheated to the

specified temperature.

4. When the glow plug indicator lamp has

turned off, turn the ignition key to the

START position while fully depressing the

accelerator pedal, until the engine starts.

NOTE (for diesel engines only):

Do not operate the starter for more than

30 consecutive seconds.

If the engine does not start even after op-

erating the starter 3 times for approximately 5 seconds, turn the ignition key to

the OFF position and then wait for about

30 seconds. Subsequently, try to start it

again from the preheating process.

5. After the engine has started, release the

accelerator pedal gradually and then

perform warm-up of engine.

NOTE:

When restarting, return the ignition key

to the OFF position once, and then turn it

to the START position.

Regardless of the atmospheric tempera-

ture, always perform warm-up for approximately 5 minutes. During warm-up,

check for any malfunction of meters,

warning lights or indicator lamps.

Failure to properly warm up the engine

can cause degradation and shortened

life of engine.

When it is not necessary to preheat the

engine because of high engine coolant

temperature immediately after it stops or

for some other reasons, the engine can

be started by turning the ignition switch

to the START position before the glow

plug indicator lamp turns off.

If the glow plug indicator lamp is not illu-

minated, malfunction may exist. In this

case, promptly contact your supervisor

for measures or contact an authorized

UniCarriers FORKLIFT dealer to inspect

the forklift.

Stopping

To stop the engine, turn the ignition key to the

OFF position.

50

Page 52

CAUTION:

3. When the gear shift is positioned in the

CAUTION:

MOM1916

MOM1917

desired place, foot the accelerator pedal

while gradually releasing the clutch pedal.

Positioning the gear shift in 1st without decelerating the forklift may cause a gear

shift shock, resulting in dropped loads or

damaged transmission.

GEARSHIFT LEVER

MT vehicle

FORWARD-REVERSE

lever and GEARSHIFT lever

The “FORWARD-REVERSE” lever is used to

make a directional change.

1. Release the accelerator pedal.

2. Foot the brake pedal, to fully depress the

clutch pedal immediately before the forklift

stops.

3. Further depress the brake pedal, to

completely stop the forklift.

4. When the forklift completely stops, position

the forward-reverse lever in forward or

reverse.

While the forklift is moving, do not change

over the forward-reverse lever positions.

Otherwise, the transmission may be damaged.

The “GEARSHIFT” lever permits selection of

different transmission gear ratios.

1. Simultaneously with the release of

accelerator pedal, fully depress the clutch

pedal.

2. Change the gear shift from 1st to 2nd or

from 2nd to 1st.

51

Page 53

AUTOMATIC TRANSMISSION

WARNING:

CAUTION:

MOM1918

MODELS

Automatic transmission models do not

have the creeping phenomena.

The forklift does not move regardless of

whether accelerator is depressed or not.

When the selector lever is in the F

(forward) or R (reverse) position:

The forklift starts moving when the

accelerator pedal is depressed.

The forklift does not move if the

accelerator pedal is not depressed.

2. While driving the forklift

When the selector lever is in the F or R

position:

The forklift continues accelerating by

depressing the accelerator pedal.

When the accelerator pedal is released.

The engine brake is applied with the

clutch engaged if the forklift speed is

above 6.5 km/h (4.5 MPH) for 3 seconds.

3. Inhibitor function

When the selector lever is in the F

(forward) or R (reverse) position, it is not

possible to start the engine.

4. Precautions

This forklift has no creeping

phenomena.

The forklift will not move if the selector

lever is in the F or R position unless you

depress the accelerator pedal. When

depressing the accelerator pedal, be

sure to visually confirm the position of

the selector lever.

When starting on slopes, be sure to

apply the parking brake to hold the

forklift and then start, even if the slopes

are gentle.

Avoid rapid acceleration (especially

when carrying a high load).

While the forklift is moving, do not change

over the selector lever positions. Otherwise, the transmission may be damaged.

1. When starting the forklift from the stopped

condition

When the selector lever is in the neutral

position:

The clutch disengages to the neutral position if the forklift speed is below 6.5 km/h

(4.5 MPH) for 3 seconds.

When the selector lever is in the neutral

position:

The lever is in the neutral position

independent of the forklift speed.

52

Page 54

PARKING BRAKE LEVER

WARNING:

WARNING:

MOM1919

MOM1920

To set the brake, pull the parking brake lever

backward. To release the brake, press the button and then push the parking brake lever forward. Before leaving the forklift, be sure to

apply the parking brake securely.

Always depress the brake or inching pedal

before releasing the parking brake to avoid

movement of the forklift before selecting a

direction.

INCHING BRAKE PEDAL

1. Fully depress the inching brake pedal.

2. Move the selector lever to the forward or

reverse position.

3. Depress the accelerator pedal little by little.

At the same time, gradually releasing the

inching brake pedal moves the forklift bit

by bit.

When the inching/brake pedal is fully de-

pressed the service brake will be applied.

However the inching/brake pedal should

not be used as the method for stopping

the forklift. In normal traveling operations, the inching/brake pedal should

only be used during loading, or unloading, which requires short, controlled

movement of the forklift.

During deceleration on any grade, only

use the brake pedal or an increase or decrease in speed by using the accelerator.

Do not use or depress the inching pedal

because this would put the transmission

in the neutral mode.

53

Page 55

LOAD CONTROL LEVERS

WARNING:

WARNING:

MOM1921

To control the loading mechanism for moving

the fork up and down and tilting the mast forward and backward, there are two operating

methods: 2-lever type or 1-lever type.

Before using the forklift, make sure which operating lever type is adopted in controlling the

loading mechanism and thoroughly read the

related instruction manual.

Always sit in the operator’s seat when

operating the lever.

Operating the control lever without prop-

erly sitting on the operator’s seat causes

the loading interlock warning lamp to

blink and the loading mechanism to be

inactive.

Before operating the lever, make certain

that the surrounding area is clear and it is

safe to proceed.

If the engine is stopped, operation of the

lever to the downside or lowering direction may cause the fork and mast to go

down due to its own weight or the cargo

that may be on the forks. This may result

in serious damage or injury.

Always avoid any abrupt or sudden lever

operation that may cause loads to shift

or fall off fork or cause the forklift to become unbalanced and tip over.

2-lever type

This method uses 2 levers: a lift lever for moving the fork up and down and a tilt lever for tilting the mast forward and backward:

Lift lever:

Lift: Pull the lever to the operator side.

Lower: Push the lever forward.

54

Tilt lever:

Forward: Push the lever forward.

Backward: Pull the lever to the operator side.

Do not perform forward tilt while raising

the forks, as this may cause loads to shift

or fall, which could affect the stability of

the forklift.

Do not perform forward tilt while lifting

loads in higher positions. This may

cause loads to shift or fall, which could

affect the stability of the forklift.

NOTE:

Control of lifting speed:

Can be changed by controlling the tilt angle of the lever and by how much the operator depresses the accelerator pedal.

Control of lowering speed:

Can be changed only by controlling the

tilt angle of lever. Do not depress the accelerator pedal.

Control of forward and backward tilting

speeds:

For both forward and backward tilts, the

speed can be changed by controlling the

tilt angle of the lever and by how much

the operator depresses the accelerator

pedal.

Page 56

1-lever type

WARNING:

MOM1922

Forward: Push the lever in the left

forward direction.

Backward: Diagonally pull the lever to the

right side of the operator.

Simultaneous operations are also allowed by

combining up and down movements and forward and backward tilts.

This may be done by moving the lever into the

a, b or c position.

a: Backward tilt while lifting:

Pull the lever to the center of the operator

side.

b: Backward tilt while lowering:

Turn over the lever to the right side of the

center.

c: Forward tilt while lowering:

Push the lever in the center forward

direction.

NOTE:

Control of lifting, forward tilting and

backward tilting speeds:

Can be changed by controlling the tilt angle of the lever and by how much the operator depresses the accelerator pedal.

Control of lowering speed:

Can be changed only by controlling the

tilt angle of the lever. Do not depress the

accelerator pedal.

This method performs up and down movements of the fork and forward and backward

tilting of mast using 1 lever:

Lift: Diagonally pull the lever to the

left side of the operator.

Lower: Push the lever in the right

forward direction.

Do not perform forward tilt while raising the

forks, because this may cause loads to shift

or fall, which could affect the stability of the

forklift.

55

Page 57

CAUTION:

MOM1923

Loading

condition

Without load

With load

Forward tilt operation of mast

Automatically stops in the

horizontal fork position.

• No automatic forward stop to

horizontal

• No movement when turning

on the tilt-horizontal switch

NOTE:

In case of 2-lever method, the tilt-hori-

zontal switch is attached to the tilt lever.

The tilt-horizontal switch is kept on while

pressed and turned off when released.

Unless the tilt-horizontal switch is

pressed, normal forward and backward

tilt operations are performed.

TILT-HORIZONTAL SWITCH

(option)

When forward tilt is performed with the mast

tilted backward, the forward tilt operation can

automatically be stopped in the position where

the fork is level.

Performing forward tilt while pressing the tilthorizontal switch moves the mast as shown in

the following list, depending on the loading

condition.

With load: Turning on the tilt-horizontal switch

during operation will not automatically stop tilt

in the horizontal direction (no movement).

56

The horizontal fork position allowing automatic stops requires a position parallel to

the road surface. Do not use this function if

the road surface is not level.

Page 58

JOYSTICK CONTROL LEVER TYPE

WARNING:

MOM2040

MOM2041

MOM2377

(option) (2 ton, 2W MAST only)

The joystick lever is an electrically controlled type.

The cargo handling operation can be performed

only when the ignition switch is turned on.

Do not perform forward tilt while raising the

forks. Otherwise, dropped loads or an unbalanced forklift may cause the forklift to

fall down.

NOTE:

Before the ignition switch is turned on,

make sure that the joystick lever is set to

the neutral position. If the lever is placed

in any position other than the neutral position, cargo handling or fork operation

cannot be performed.

When the ignition switch is turned off,

the fork does not lower even under its

own weight.

The joystick lever is used to tilt the mast

forward or backward and to lift or lower

the forks. Cargo handling speed (lift, lower, forward and backward) can be adjusted by the distance that the lever is

moved.

For detailed joystick lever operation, re-

fer to the illustration above.

57

Page 59

WARNING:

The warning mark and a malfunction

WARNING:

MOM2378

MOM2218

MOM2043

message will appear on the meter when the

joystick control system malfunctions. When

this occurs, immediately stop cargo handling

operations and have the forklift checked and

repaired by an authorized UniCarriers FORKLIFT dealer.

If an erroneous cargo handling operation is

noticed regardless of the joystick lever position, press the emergency stop button on

the console box, stop cargo handling operations and have the forklift checked and repaired by an authorized UniCarriers

FORKLIFT dealer. (To release the emergency stop button, turn it in the direction indicated by the arrow.)

58

Page 60

TRAVELING

WARNING:

WARNING:

CLIMBING

While traveling, the mast should be tilted back

and the forks lowered to approximately 200 mm

(8 in) above the ground.

1F1/1F2 models do not have the creeping

phenomena.

The forklift will not move if the selector

lever is in the F or R position unless the