UnicalAir UND A 12H, UND A 18H User Manual [nl]

UND A 9H - UND A 12H

UND A 18H - UND A 24H

ver. 2

MANUALE DI INSTALLAZIONE

●

FOR THE AIR CONDITIONER TO OPERATE SATISFACTORILY, INSTALL IT

AS OUTLINED IN THIS MANUAL

●

BE CAREFUL NOT TO SCRATCH THE AIR CONDITIONER UNITS WHEN

HANDLING THEM.

●

CONNECT THE INDOOR UNIT AND THE OUTDOOR UNIT WITH PROPER

CORDS AND AIR CONDITIONER PIPING

●

MOVING A SPLIT AIR CONDITIONER TO ANOTHER LOCATION REQUIRES

SPECIAL TECHNIQUE. IF NECESSARY, CONSULT WITH THE SELLER.

wall type air conditioners

INSTALLATION

MANUAL

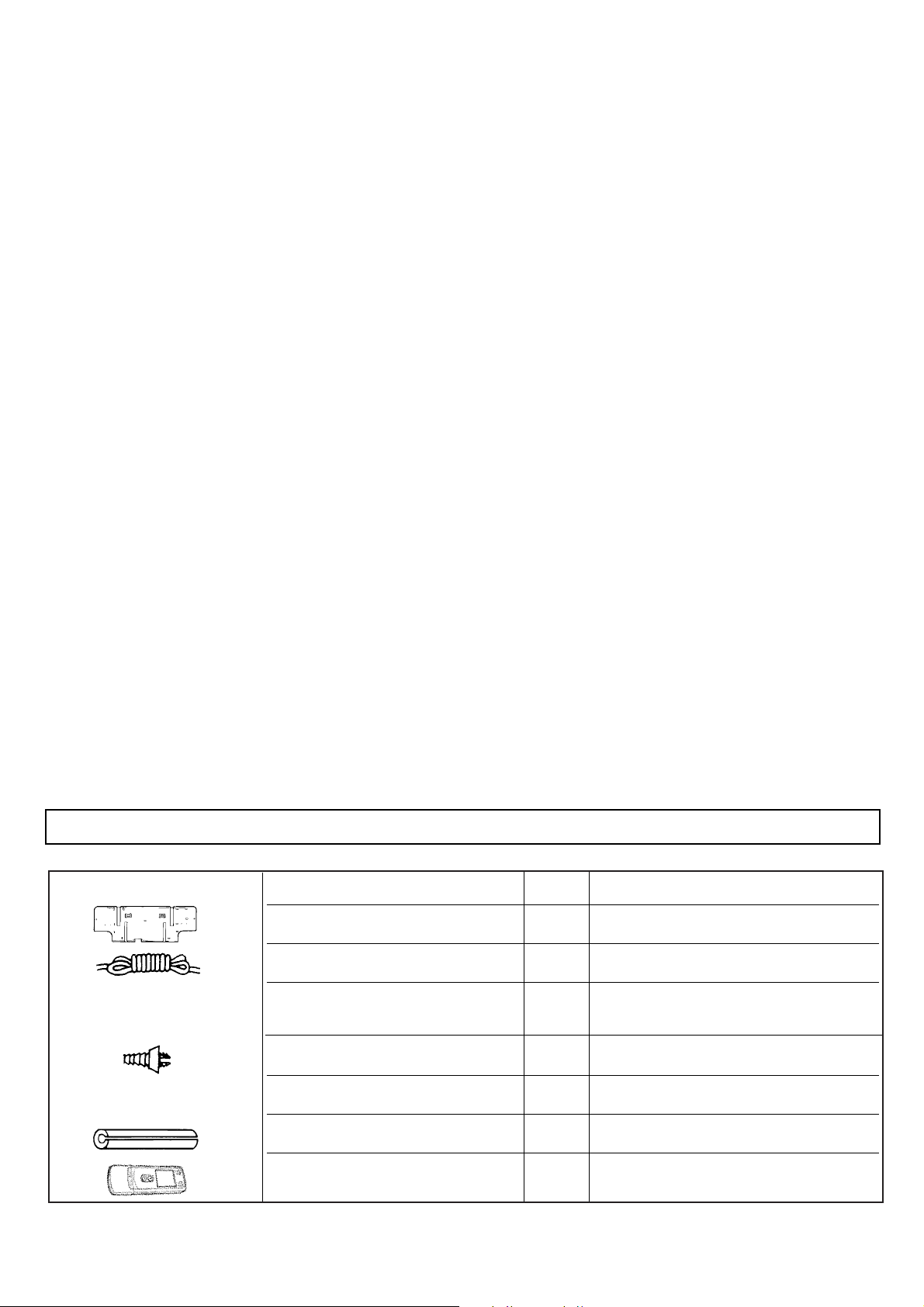

INSTALLATION ACCESSORIES

Name and drawing Quantity Application

Wall hook bracket for the indoor unit 01 To mount the indoor unit

Pipette for condensed water drainage 01 For the outdoor unit drainage

Pipe insulation sleeve 01 To insulate the joints of the indoor unit

Remote control 01

Power cable 01 For interconnecting the indoor and outdoor units

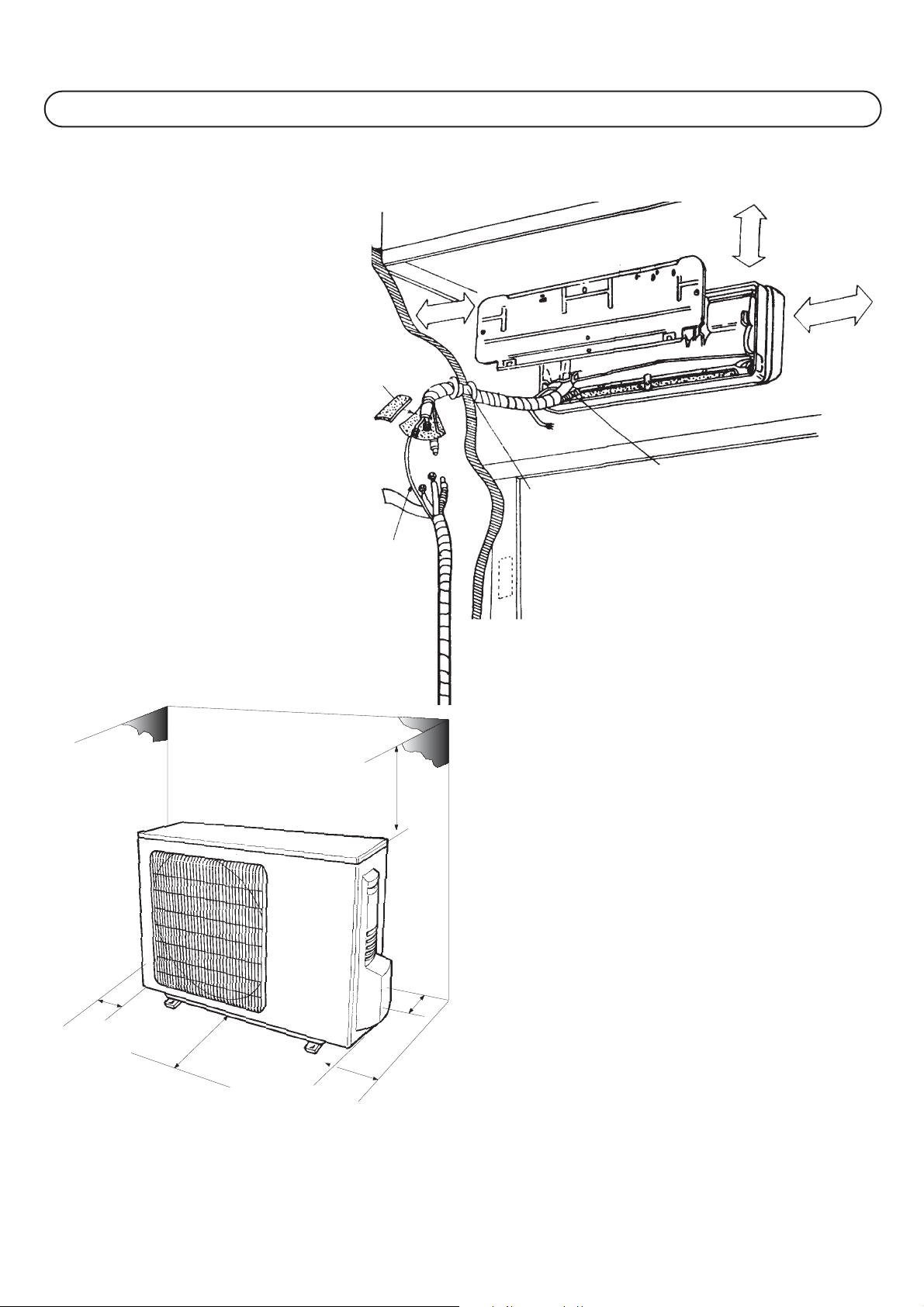

40

70

50

600

600

100

200

100

Install the indoor unit level on a strong wall

that is not subject to vibrations.

The inlet and outlet ports should not be obstructed: the air should be able to blow all over the

room.

Do not install the unit near a source of heat,

steam, or flammable gas..

Install the unit near an electric socket or private circuit.

Do not install the unit where it will be exposed

to direct sunlight.

Install the unit where connection between

indoor and outdoor unit is as easy as possible.

Install the unit where it is easy to drain the condensed water.

Check the machine operation regularly and

leave the necessary spaces as shown in the picture.

Install the indoor unit where the filter can be

easily accessible.

●

●

●

●

●

●

●

●

●

SELECTING THE INSTALLATION PLACE

1

insulating

covering

sleeve

condensed water drain pipe

electrical

connections

Do not install the outdoor unit near sources of heat,

steam or flammable gases.

Do not install the unit in too windy or dusty places.

Do not install the unit where people often pass.

Select a place where the air discharge and operating

sound level will not disturb the neighbours.

Avoid installing the unit where it will be exposed

to direct sunlight (otherwise use a protection, if

necessary, that should not interfere with the air

flow).

Leave the spaces as shown in the picture for the air

to circulate freely.

Install the outdoor unit in a safe and solid place.

If the outdoor unit is subject to vibration, fix rubber

gaskets onto it.

●

●

●

●

●

●

●

●

minimum spaces to be left (mm)

INDOOR UNIT

OUTDOOR UNIT

WORKING LIMITS: cooling mode - unit operatives up to 43° outdoor temperature

heating mode - unit operatives down to - 5°C outdoor temperature

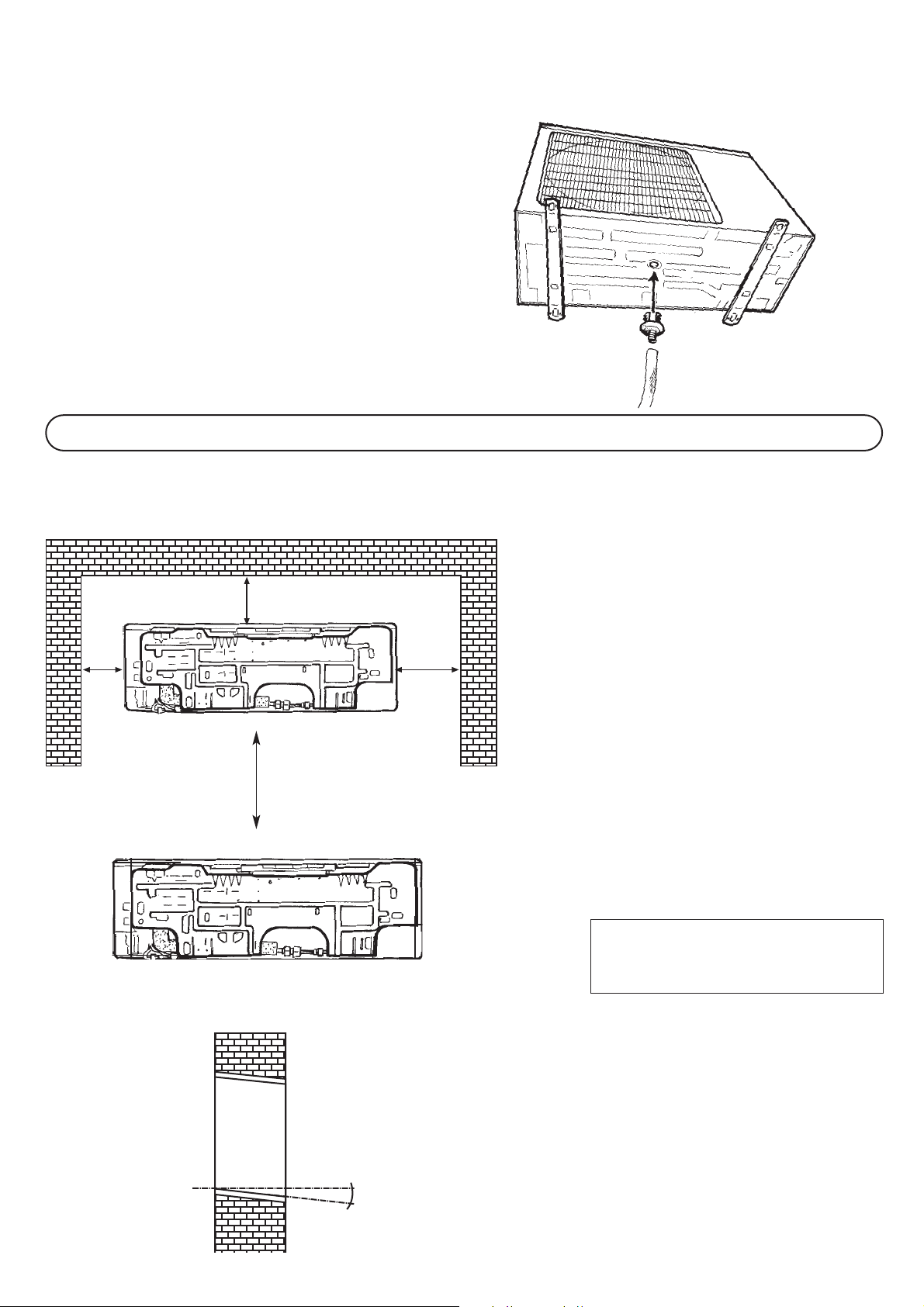

The condensed water and the ice formed in the outdoor

unit during heating operation can be drained away

through the drain pipette.

Installation: fasten the drain pipette in the 25 mm hole

placed in the lower part of the unit as shown in the picture.

Connect the condensed water hose and the pipette. Pay

attention that water is drained in a suitable place.

OUTDOOR UNIT CONDENSED WATER DRAINAGE

(only for heat pump models)

OUTDOOR UNIT

WALL HOOK BRACKET

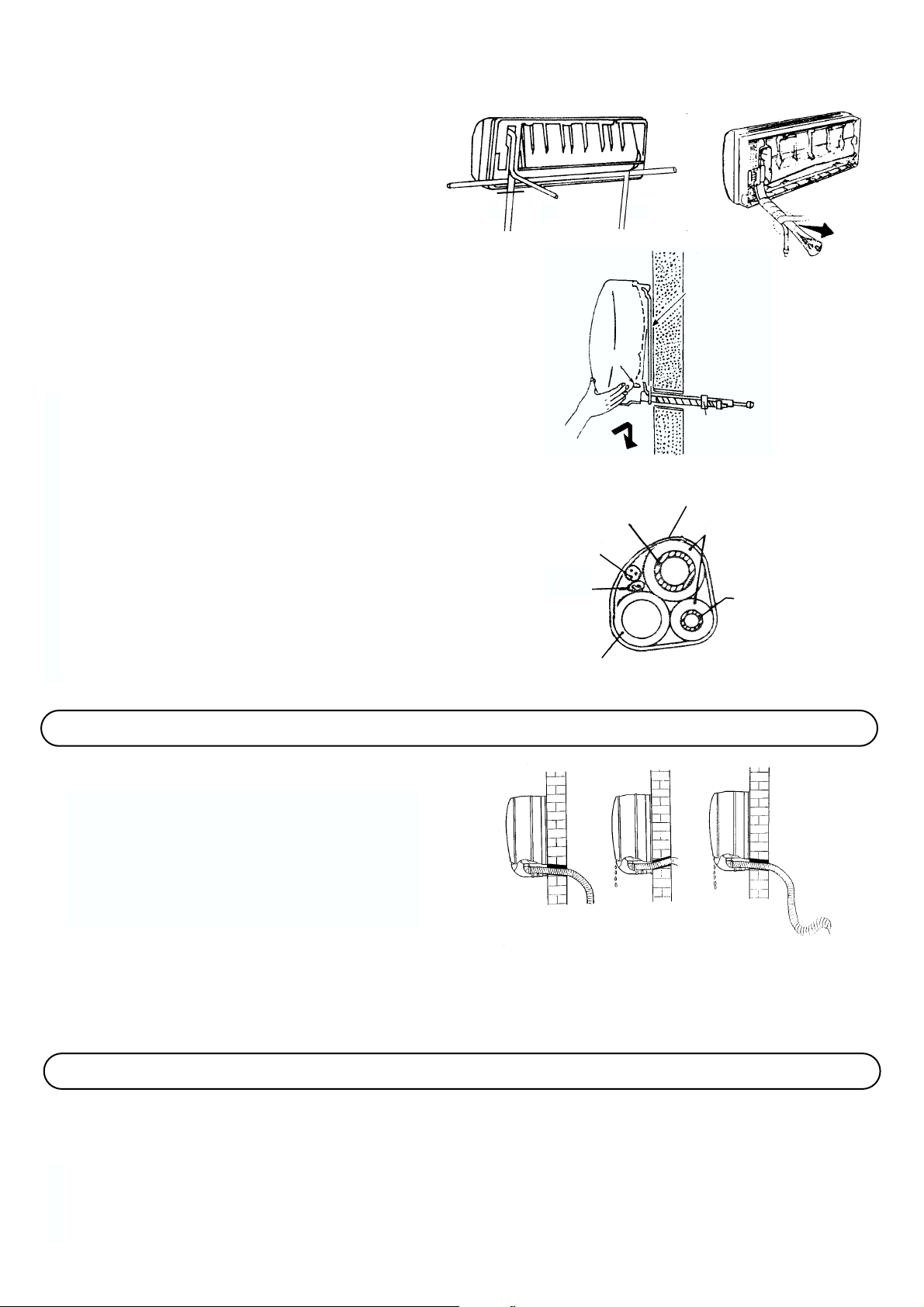

Installation of the wall hook

bracket

1. By using a level, put the wall hook

bracket in a perfect square position, both

vertically and horizontally

2. Fix the bracket first with 5 screws.

3. Use several more tapping screws to secure

the bracket onto the wall with even pressure on

the screws.

4. Cut a hole in the wall for the piping and

electric connection.

N.B.

Drill a hole in the wall with the outdoor side

5-10 mm lower than the inner side, in order

to have a good drain flow.

Note: The shape and dimensions of the wall

hook bracket could be modified without

prior notice.

NOTE : Maintain the drain pipe in the lower part of the

wall hole, or leakage may occur.

indoor

outdoor

5 mm

INSTALLATION OF THE INDOOR UNIT

2

70

50

40

The piping run towards the right

Refrigerant piping connection

The piping can be run in the 5 directions indicated by

numbers 1, 2, 3, 4, 5 in the figure. When the piping is

run in direction 1, 2, 4 or 5, cut a notch along the groove on the side of the indoor unit with a cutter.

Run the piping in the direction of the wall hole and bind

the copper pipes, the drain pipe and the power cables

together with the tape with the drain pipe at the bottom,

so that water can flow freely.

Indoor unit installation

Run the bound pipe and cables through the wall hole

and mount the indoor unit onto the upper part of the

wall hook bracket securely

Arrange the pipes and cables well.

Push the lower part of the indoor unit tight against the

wall hook bracket.

NOTE:

Do not bend or crush the indoor unit piping. Avoid

sharp bends with radius of curvature of less than 10 cm.

Do not bend the same part of the pipe too often, after

three times it could be throttled.

Do not remove the flare nut from the indoor unit piping

until immediately before connecting the connection

pipe.

wa ll hook

bracket

insulation sleeve

refrigerant pipe

condensed water drain pipe

signal

cable

insulation pipes

refrigerant

pipe

power

cable

1.

2.

3.

l

l

l

1.

2.

l

l

l

l

INDOOR UNIT CONDENSED WATER DRAINAGE

3

YES NO NO

The indoor unit condensed water drainage is

fundamental for the success of the installation.

Install the drain hose at the bottom of the wall hole.

The insulator of the copper pipes should be at least 6

mm thick.

Check that:

The top and bottom hooks of the indoor unit are hooked firmly on the wall hook bracket.

The unit is positioned horizontally. If the unit is not installed properly, water will drip onto the floor.

The drain hose has the correct gradient (at least 3 cm for every meter in length).

The drain hose remains at the bottom of the wall hole.

OUTDOOR UNIT INSTALLATION

4

The outdoor unit should be installed on a solid wall and fastened securely

The following procedure must be observed before connecting the pipes and electric cables:

decide which is the best position on the wall and leave enough space to be able to carry out maintenance easily.

fasten the support to the wall using screw anchors which are particularly suited to the type of wall;

use a larger quantity of screw anchors than normally required for the weight they have to bear: during operation the machine

vibrates and has to remain fastened in the same position for years without the screws becoming loose.

l

l

l

1

2

3

5

4

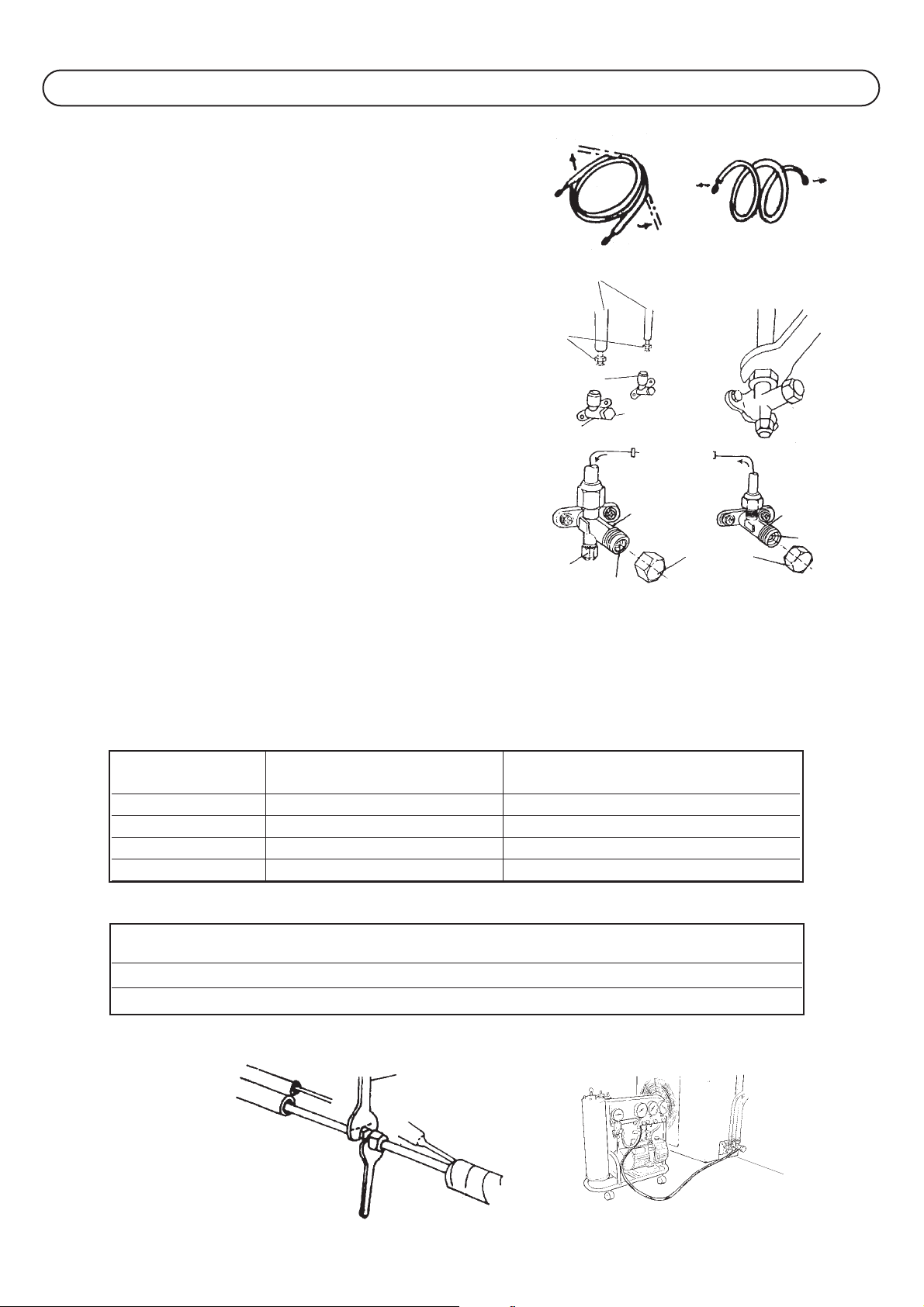

To empty the refrigerant pipe from air and humidity, the use of the vacuum pump is recommended.

PIPING CONNECTION

5

●

●

●

●

●

●

●

●

●

●

ATTENTION: ONLY ACR

copper pipes for air conditioners are allowed

YES

NO

Connecting the pipes

Do not remove the cap from the pipe until connecting

it, to avoid dampness or dirt from entering.

If the pipe is bent or pulled too often, it will become

stiff. Do not bend the pipe more than three times at one

place.

When extending the rolled pipe, straighten the pipe by

unwinding it gently as shown in the figure below

To avoid leakage, pay particular attention to the following points:

Tighten the flare nuts using two wrenches. Pay attention not to damage the pipes.

If the tightening torque is not sufficient, there will probably be some leakage. With excessive tightening torque there will also be

some leakage, as the flange could be damaged.

The surest system consists in tightening the connection by using a fix wrench and a torque wrench: in this case use the following

table.

CONNECTIONS TO THE INDOOR UNIT

Shape the connection pipe following the diagram.

Remove the indoor unit pipe cap (check that there is no

debris inside).

Insert the flare nut and create a flange at the extreme

end of the connection pipe.

Connect the pipes by using two wrenches.

CONNECTIONS TO THE OUTDOOR

UNIT

Screw the flare nuts to the outdoor unit coupling with

the same tightening procedures described for the indoor

unit.

flare nuts

connection pipes

gas tap

liquid tap

indoor unit

protection

caps

service port

nut

tap

tap

gas valve

liquid valve

➡

FLANGE CONNECTION TIGHTENING TORQUE

Pipe Tightening torque Corresponding stress

[N x m] (using a 20 cm wrench)

6,35 mm

(1/4”)

15 - 20 wrist strength

9,52 mm

(3/8”)

31 - 35 arm strength

12,70 mm (1/2”) 50 - 55 arm strength

15,88 mm (5/8”) 65 - 70 arm strength

TIGHTENING TORQUE FOR PROTECTION CAPS

Tightening torque

[N x m]

Service port nut 7 - 9

Protection caps 25 - 30

Service port nut

torque wrench

IMPORTANT ! REFRIGERANT LEAKAGE INSPECTION

After connecting the piping, check the joints for refrigerant leakage with leak detector carefully.

Loading...

Loading...