TERNOx 2S

INSTRUCTIONS ON INSTALLATION, USE AND MAINTENANCE

Attention: this manual contains instructions for the exclusive use of the professionally qualified installer and/or maintenance technician in compliance

with current legislation.

The system manager is NOT authorised to service the boiler.

The manufacturer will not be held liable in case of damage to persons, animals

or objects resulting from failure to comply with the instructions contained in

the manuals supplied with the boiler.

2

1 GENERAL INFORMATION ................................................................................................................................................................................. 5

1.1 General warnings .......................................................................................................................................................................................... 5

1.2 Symbols used in the manual .........................................................................................................................................................................6

1.3 Appropriate use of appliance ........................................................................................................................................................................ 6

1.4 Information for system manager ................................................................................................................................................................... 6

1.5 Safety warnings ............................................................................................................................................................................................7

1.6 Technical data plate ...................................................................................................................................................................................... 8

1.7 Water treatment ............................................................................................................................................................................................8

2 TECHNICAL FEATURES AND DIMENSIONS ...................................................................................................................................................9

2.1 Technical features ......................................................................................................................................................................................... 9

2.2 Operation principle ........................................................................................................................................................................................ 9

2.3 Dimensions ................................................................................................................................................................................................. 10

2.4 Operating data according to UNI 10348 ..................................................................................................................................................... 13

General informationTechnical featuresInstallation instructionsMaintenance instructions

3 INSTALLATION INSTRUCTIONS ...........................................17

3.1 General warnings ............................................................17

3.2 Installation standards.......................................................17

3.3 Installation on old or retrofittable systems .......................17

3.4 Packaging ........................................................................18

3.5 Handling ..........................................................................18

3.6 Positioning in boiler room ................................................19

3.7 Hydraulic connections .....................................................20

3.8 Filling and emptying the system ......................................20

3.9 Gas connection................................................................21

3.10 Connection to the flue......................................................21

3.11 Furnace door: adjustment, opening, closing....................22

3.12 Burner ..............................................................................22

3.13 Electric panel assembly ...................................................24

3.14 Electrical connections ......................................................25

3.15 STANDARD panel board .................................................26

3.16 Hydraulic and electrical system connection.....................25

4 INSPECTION AND MAINTENANCE ................................................................................................................................................................44

Routine and extraordinary maintenance ............................................................................................................................................................ 44

Inspection and maintenance instructions ........................................................................................................................................................... 45

Maintenance of body ......................................................................................................................................................................................... 45

Troubleshooting.................................................................................................................................................................................................. 46

3.17 Optional MASTER panel board ....................................... 29

3.18 Hydraulic and electrical system connection.....................32

3.19 Example of hydraulic and electrical system connection ..35

3.20 CASCADE panel board ...................................................37

3.21 Hydraulic and electrical system connection

with boilers in cascade ....................................................39

3.22 Commissioning ............................................................. 41

3.23 Burner adjustment ...........................................................42

3.24 Checks during and after commissioning ..........................43

3.25 Alkaline or “boiling” wash .................................................43

3.26 Boiler shutdown ...............................................................43

3

(This page has been intentionally left blank)

4

ATTENTION

Wherever the boiler operates with a pressure jet gas burner, the appliance, not belonging to any category among those considered

in Annex II of the Legislative Decree 93 of 25/02/2000 (Implementation of the Directive 97/23/EC regarding pressurised equipment),

and moreover being considered by the Directive 90/396/EEC (Gas-fired appliances - transposed in Italy with Italian Presidential Decree 661 of 15/11/1996) to which art. 1 comma 3 paragraph “f.5” refers, is excluded from the range of application of the decree itself.

1

GENERAL INFORMATION

1.1 - GENERAL WARNINGS

The instruction booklet is an integral and essential part of the

product and must be kept by the system manager.

Read the warnings contained in this instruction booklet carefully

as they provide important guidelines regarding installation, use

and maintenance safety.

Keep the booklet with care for further consultation.

Your appliance must be installed and serviced in compliance

with the standards in force according to the manufacturer

instructions, up to standard and by legally qualified and

certified personnel.

Systems for the production of domestic hot water MUST be

constructed entirely with materials that comply with M.D.

174/2004 (taps, pipes, fittings, etc.).

By professionally qualified personnel we mean: personnel

with specific technical skill in the field of heating system

components for civil use, domestic hot water production

and maintenance. Personnel must have the qualifications

provided for by current legislation.

General information

Any product repairs must be performed solely by personnel

authorised by Unical, using original spare parts only. Failure to

comply with the above can compromise the safety of the appliance and void the warranty.

To guarantee appliance efficiency and its correct operation,

yearly maintenance must be performed by qualified personnel.

Should you decide not to use the appliance, parts entailing

potential sources of hazard must be made safe.

Before commissioning an appliance that has not been used,

wash the domestic hot water production system, making the

water flow until it has been fully replaced.

Should the appliance be sold or transferred to a new owner or

if you move and leave the appliance, always make sure that the

instruction manual accompanies it in order to be consulted by

the new owner and/or installer.

Only original accessories must be used for all appliances with

optionals or kits (including electric).

Incorrect installation or improper maintenance can cause damage to persons, animals or objects for which the manufacturer

is not responsible.

Before performing any cleaning or maintenance, disconnect the

appliance from the energy mains by acting on the switch of the

system and/or through the specific cut-off devices.

Do not obstruct the terminals of the intake/exhaust ducts.

In case of failure and/or malfunctioning of the appliance, switch

it off and do not try to repair it or intervene on it directly. Contact

only personnel qualified in compliance with law.

This appliance is intended solely for the use for which it was

expressly designed.

Any other use is to be considered improper and therefore dangerous.

5

1.2 - SYMBOLS USED IN THE MANUAL

Pay special attention when reading this manual to the parts marked by the symbols:

DANGER!

Serious danger for

personal safety and life

ATTENTION!

Possible dangerous

situation for the product

and the environment

1.3 - APPROPRIATE USE OF THE APPLIANCE

The TERNOX 2S appliance has been built according to the current level of engineering and acknowledged

technical safety rules.

Nonetheless, if improperly used, dangers could arise for the safety and life of the user and other persons

or damage to the equipment or other objects.

The appliance is intended to operate in hot water circulation heating systems.

Any other use must be considered improper.

UNICAL will not be held liable for any damage resulting from improper use.

Use according to the intended purposes also includes strict compliance with the instructions in this manual.

1.4 - INFORMATION FOR SYSTEM MANAGER

The user must be instructed concerning the use and operation of his heating system, in particular:

• Deliver these instructions to the user, as well as other documents concerning the appliance inserted in the envelope

inside the packaging. The user must keep this documentation safe for future consultation.

• Inform the user about the importance of the air vents and the flue gas exhaust system, highlighting their essential

features and the absolute prohibition of modifying them.

• Inform the user concerning controlling the system's water pressure as well as operations to restore it.

• Inform the user concerning correct temperature control, control units/thermostats and radiators for saving energy.

• Remember that the system must receive regular maintenance at least once a year and combustion analysis must

be performed every two years (as per national law).

• Should the appliance be sold or transferred to a new owner or if you move and leave the appliance, always make

sure that the instruction manual accompanies it in order to be consulted by the new owner and/or installer.

NOTE!

Tips

for the user

The manufacturer will not be held liable in the event of damage to persons, animals or objects resulting from

failure to comply with the instructions contained in this manual.

6

1.5 - SAFETY WARNINGS

ATTENTION!

The appliance must not be used by people with reduced physical, sensory and mental abilities, without

experience and knowledge. These people must be previously trained and supervised during manoeuvre

operations. Children must be supervised so that they do not play with the appliance.

ATTENTION!

The appliance must be installed, adjusted and maintained by professionally qualified personnel, in compliance with the standards and provisions in force. Incorrect installation can cause damage to persons,

animals and objects for which the manufacturer cannot be held responsible.

DANGER!

The boiler must be serviced or repaired by professionally qualified personnel, authorised by Unical. We

recommend stipulating a maintenance contract.

Insufficient or irregular maintenance can jeopardise the operating safety of the appliance and cause damage

to persons, animals and objects for which the manufacturer cannot be held responsible.

Modifying parts connected to appliance

Do not modify the following parts:

- the boiler

- the gas, air, water and electricity supply lines

- the flue gas pipe, the safety valve and the exhaust pipe

- the construction parts which affect the operating safety of the appliance.

Attention!

To tighten or loosen the screwed fittings, use only appropriate fixed spanners.

Incompliant use and/or inappropriate tools can cause damage (e.g. water or gas leakage).

ATTENTION!

Indications for propane gas-fired appliances

Make sure that the gas tank has been deaerated before installing the appliance.

For state-of-the-art tank venting, contact the LPG supplier or person qualified in compliance with the law requirement.

If the tank has not been professionally deaerated, ignition problems could arise.

In that case, contact the supplier of the LPG tank.

Smell of gas

Should a smell of gas be perceived, follow these safety guidelines:

- do not turn electric switches on or off

- do not smoke

- do not use the telephone

- close the gas shut-off valve

- air out the area where the gas leakage has occurred

- inform the gas supplier or a company specialised in installation and maintenance of heating systems.

General information

Explosive and easily flammable substances

Do not use or store explosive or easily flammable materials (e.g. petrol, paints, paper) in the room where the appliance is installed.

7

1.6 - TECHNICAL DATA PLATE

The technical data plate is inserted in the document envelope. When installation is finished, it is MANDATORY that the

appliance installer apply it at the front top part.

If lost, ask the Unical Technical Assistance Service for a duplicate.

The serial number of the boiler is on the riveted plaque on the front plate of the body (front right top side).

If the identification plate is tampered with, removed or missing, the product cannot be safely identified, making any

installation and maintenance operation difficult.

CE marking

The CE marking certifies that the boilers meet:

- The essential requirements of the gas appliance directive

(90/396/EEC)

- The essential requirements of the electromagnetic compatibility directive (89/336/EEC)

- The essential requirements of the efficiency directive (92/42/

EEC)

- CE marking compliant to directives governing the use of

gas-fired appliances - Ts < 110°C.

Boiler type

Serial number

Year of manufacture

Mains: 230V~ 50Hz

W:

Fuels

(only those with X)

OUTPUTS

Useful

Furnace

P.I.N. code

Approval

* See serial no. on boiler body

1.7 - WATER TREATMENT

Boiler water capacity

*

Storage tank:

Gas

Category

kW

min. max. min. max.

AG S.P.A.

Max. operating pressure

Max. operating temp. °C

Capacity Max. press. Max. temp.

l °C

Wood

Sup. m²

46033 CASTELDARIO (MN) - Via Roma

tel. 0376 57001 - fax 0376 660556

www.unical.ag info@unical-ag.com

Charcoal

kW

bar

Diesel oil

l

bar

kW

Naphtha

The treatment of the supply water allows to

prevent inconveniences and maintain the

functionality and efficiency of the generator

over time.

The values displayed in the table can be

used as a reference.

TOTAL HARDNESS ppm 10

ALKALINITY mg/l CaCO3 750

PH 8÷9

SILICA ppm 100

CHLORIDES ppm 3500

To minimise corrosion, it is crucial to use

a corrosion inhibitor; in order for it to work

properly, the metal surfaces must be clean.

8

ATTENTION!

ANY DAMAGE TO THE BOILER CAUSED BY

THE FORMATION OF FOULING OR BY CORROSIVE WATER WILL NOT BE COVERED BY

THE WARRANTY.

ATTENTION: These appliances are NOT suitable for the production of water for human

consumption according to Ministerial Decree

D.M. 174/2007.

2

TECHNICAL FEATURES

AND DIMENSIONS

2.1 - TECHNICAL FEATURES

One of the significant aspects taken into account when designing the TERNOx 2S series boilers is the reduction of the formation of pollutants in exhaust gases.

One of these consists of nitrogen oxides (Nox). In Europe, their

emission is governed by several legislative standards and provisions. Welding procedures and devices are approved and

certified according to EN Standards.

The main technical elements of the design are:

- An accurate study of geometries, to achieve an ideal ratio

between combustion volumes and exchange surfaces.

- The selection of the materials used to guarantee the long life

of the boiler.

Welding procedures and devices are approved and certified

according to EN Standards.

The boilers have pressurised combustion, with 3 flue gas passes with passing flame and wet inversion chamber.

The combustion gases produced by the burner, having passed

the combustion chamber of the furnace, enter the pipes in the

second flue gas pass.

2.2 - OPERATION PRINCIPLE

TERNOX 2S boilers have pressurised combustion, with 3 flue

gas passes with passing flame and wet inversion chamber.

The combustion gases produced by the burner, having passed

the inversion chamber of the furnace, enter the pipes in the

second flue gas pass.

After the exhaust gases return to the front of the boiler, they

again change direction and pass through the pipes of the third

flue gas pass towards the flue duct.

After the exhaust gases return to the front of the boiler, they

again change direction and pass through the pipes of the third

flue gas pass towards the flue duct.

This type of boilers achieves a high average yearly performance

and low content of harmful substances in the flue gas. Another

advantage of the three flue gas pass structure consists of the

fact that combustion products remain less time in high temperature areas, thus limiting harmful emissions of nitrogen oxides.

The boiler body is thermally insulated by the application of a

mineral wool mattress with a high insulation level to reduce

heat dispersion to extremely low levels. It is finished by aluminium sheets.

The combustion chamber is always pressurised while the burner is operating.

For the value of this pressure, see the TECHNICAL DATA table,

in the column Flue gas pressure drop.

The flue gas duct and the fitting to the flue must be implemented in compliance with Standards and Legislation in force, with

rigid ducts resistant to heat, condensation, mechanical stress

and airtight.

Technical features

1 Furnace

2 Smoke pipes

3 Door with flame control warning light

(2nd pass) (3rd pass)

4. Smoke chamber

5 Body insulation

9

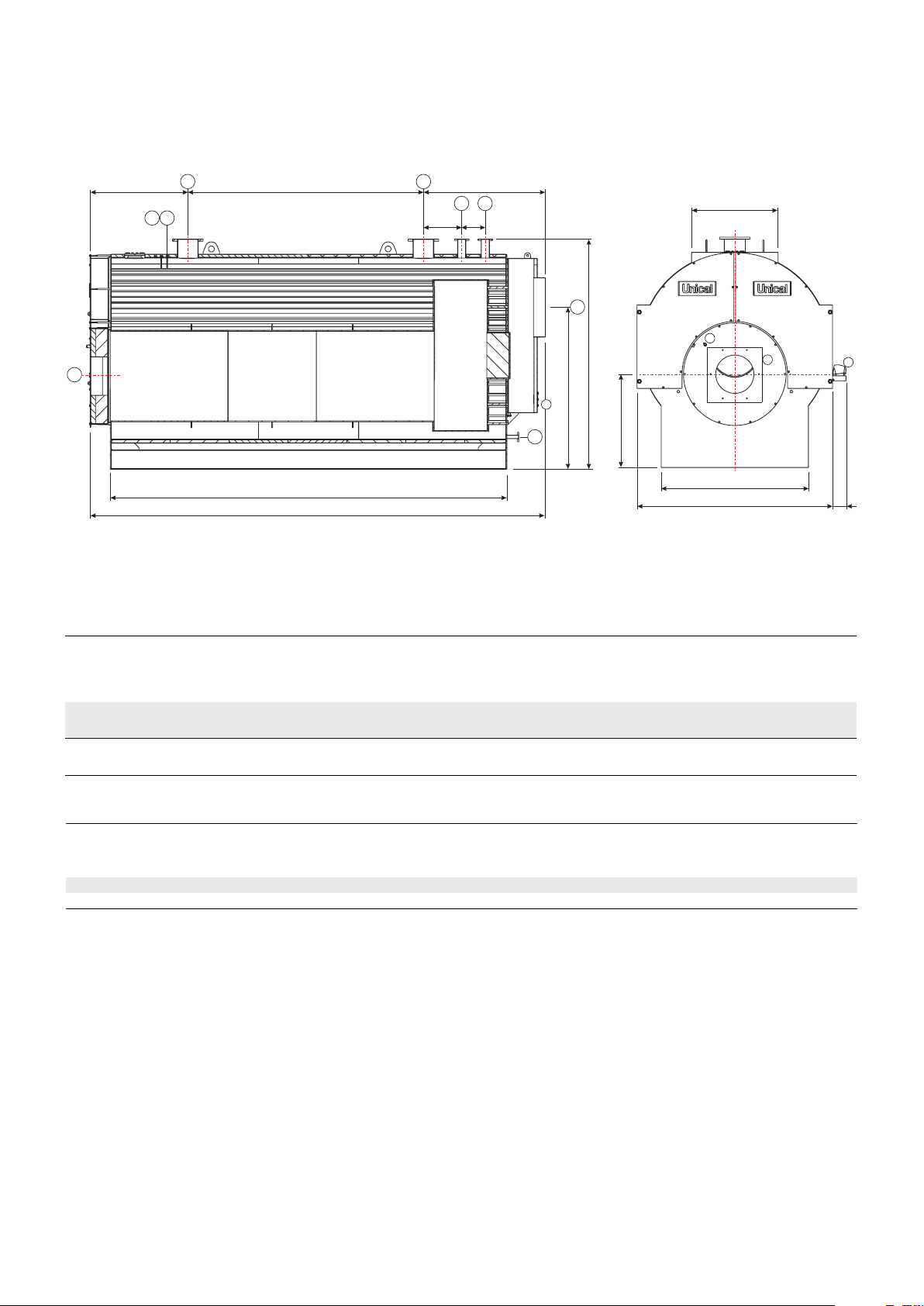

2.3 - DIMENSIONS

BP

TERNOX 2500 2S STD - 2200 2S Low NOx - 1800 2S Low NOx E

TERNOX 3500 2S STD - 3050 2S Low NOx - 2350 2S Low NOx E

E

T8

1 Panel board

2 Burner connection flange

3 Smoke chamber cleaning door

4 Flame control warning light

T6

T7

T1

T2

F

T3

T3

G

M

HQ

T5

4

2

1

C

I

3

T4

D

N

L

A

T1 Heating flow

T2 Heating return

T3 Expansion vessel connection

T4 Boiler drain

T5 Chimney connection

T6 Probe holder conduit connection

T7 Probe holder conduit connection

T8 Burner connection

TERNOx 2S

Model

2500 2S STD

2200 2S Low NOx

1800 2S Low NOx E

3500 2S STD

3050 2S Low NOx

2350 2S Low NOx E

Useful

output

kW

1800 - 2500

1800 - 2200

1800

2350 - 3500

2350 - 3050

2350

Furnace

furnace

kW

1951 - 2753

1951 - 2406

1951

2537 - 3848

2537 - 3329

2537

Boiler

capacity

3790

4750

Water side

pressure

drop(**)

l

m.w.c.

0.26 - 0.50

0.26 - 0.39

0.26

0.43 - 0.95

0.43 - 0.72

0.43

(**) Pressure drops corresponding to a thermal variation of 15K.

TERNOx 2S

Model

2500 2S STD

2200 2S Low NOx

1800 2S Low NOx E

3500 2S STD

3050 2S Low NOx

2350 2S Low NOx E

A

mm

4225

4711

B

mm

1710

1830

C

mm

2010

2120

D

mm

3370

3824

E

mm

1940

1954

Flue gas

pressure

drop

mbar

3.77 - 7.50

3.77 - 5.73

3.77

3.48 - 8.00

3.48 - 5.99

3.48

DIMENSIONS

F

mm

820

1140

M

aximum

W

operating

pressure

boiler

G

mm

1465

1617

bar

eight

T1

T2

UNI 2278 PN16

kg

5500

6

6 7000 DN 65DN 200 Rp 1½ 620

mm

420

570

H

mm

1400

1480

I

CONNECTIONS

T3

UNI 2278 PN16

DN 50DN 200

L

mm

1350

1450

mm

800

800

M

T4

ISO 7/1

Rp 1½

mm

570

N

mm

1030

1080

T5

Øi

T7

T6

Ø

Ø

mm

mm

Rp 1/2

Rp 1/2

Rp 1/2 Rp 1/2

P

mm

245

245

mm

230

250

T8

Ø

mm

400

400

Q

10

TERNOX 4500 2S STD - 3800 2S Low NOx - 3000 2S Low NOx E

TERNOX 5800 2S STD - 5000 2S Low NOx - 4000 2S Low NOx E

TERNOX 7000 2S STD - 6300 2S Low NOx - 5100 2S Low NOx E

TERNOX 8500 2S STD - 7500 2S Low NOx - 5700 2S Low NOx E

TERNOX 10200 2S STD - 9500 2S Low NOx - 8400 2S Low NOx E

E

T8

T1 T2

F

T6 T7

D

A

1 Panel board

2 Burner connection flange

3 Smoke chamber cleaning door

4 Flame control warning light

TERNOx 2S

Model

4500 2S STD

3800 2S Low NOx

3000 2S Low NOx E

5800 2S STD

5000 2S Low NOx

4000 2S Low NOx E

7000 2S STD

6300 2S Low NOx

5100 2S Low NOx E

8500 2S STD

7500 2S Low NOx

5700 2S Low NOx E

10200 2S STD

9500 2S Low NOx

8400 2S Low NOx E

Useful

output

kW

3000 - 4500

3000 - 3800

3000

4000 - 5800

4000 - 5000

4000

5100 - 7000

5100 - 6300

5100

5700 - 8500

5700 - 7500

5700

8400 - 10200

8400 - 9500

8400

3239 - 4951

3239 - 4144

4325 - 6381

4325 - 5457

5529 - 7705

5529 - 6892

6169 - 9377

6169 - 8215

9128 - 11191

9128 - 10377

Furnace

furnace

kW

3239

4325

5529

6169

9128

T1 Heating flow

T2 Heating return

T3 Expansion vessel connection

T4 Boiler drain

Boiler

capacity

6400

8060

9760

11480

14960

Water side

pressure

drop(**)

l

m.w.c.

0.27 - 0.60

0.27 0.43

0.27

0.44 - 0.93

0.44 - 0.69

0.44

0.72 - 1.36

0.72 - 1.10

0.72

0.90 - 2.00

0.90 - 1.56

0.90

0.96 - 1.41

0.96 - 1.22

0.96

(**) Pressure drops corresponding to a thermal variation of 15K.

T3 T3

HQ

Flue gas

pressure

drop

mbar

3.64 - 8.50

3.64 - 5.96

3.64

4.36 - 9.50

4.36 - 6.95

4.36

4.89 - 9.50

4.89 - 7.60

4.89

4.76 - 11.0

4.76 - 8.44

4.76

8.32 - 12.50

8.32 - 10.75

8.32

G

T5

C

I

N

3

T4

T5 Chimney connection

T6 Probe holder conduit connection

T7 Probe holder conduit connection

T8 Burner connection

M

aximum

operating

pressure

boiler

bar

W

eight

T1

kg

6

6 10000 DN 80DN 250 Rp 1½ 660

6 11500 DN 100DN 250 Rp 1½ 720

6 13500 DN 100DN 250 Rp 1½ 820

6 17300 DN 100DN 300 Rp 1½ 820

8200

T2

UNI 2278 PN16

CONNECTIONS

T3

UNI 2278 PN16

DN 80DN 250 Rp 1½ 660

4

T4

ISO 7/1

mm

M

L

B

T5

Øi

2

T6

T7

Ø

Ø

mm

mm

Rp 1/2

Rp 1/2

Rp 1/2 Rp 1/2

Rp 1/2

Rp 1/2

Rp 1/2 Rp 1/2

Rp 1/2

Rp 1/2

P

T8

mm

500

500

500

500

500

1

Technical features

Ø

TERNOx 2S

Model

4500 2S STD

3800 2S Low NOx

3000 2S Low NOx E

5800 2S STD

5000 2S Low NOx

4000 2S Low NOx E

7000 2S STD

6300 2S Low NOx

5100 2S Low NOx E

8500 2S STD

7500 2S Low NOx

5700 2S Low NOx E

10200 2S STD

9500 2S Low NOx

8400 2S Low NOx E

A

mm

5134

5639

5875

6420

6772

B

mm

1980

2180

2320

2400

2650

C

mm

2360

2580

2700

2870

3080

D

mm

4174

4626

4840

5330

5632

E

mm

2017

2451

2505

2035

1406

DIMENSIONS

F

mm

1380

1400

1510

2590

3450

1737

1788

1860

1795

1916

mm

G

mm

550

600

550

480

550

H

mm

1620

1780

1870

1980

2080

I

L

mm

1550

1710

1850

1900

2080

M

mm

800

800

880

880

1000

N

mm

1180

1300

1350

1460

1560

mm

250

250

250

250

250

P

mm

300

300

350

350

350

Q

11

TERNOX 12500 2S STD

TERNOX 15000 2S STD

T1 T2

E

T6 T7

T8

1 Panel board

2 Burner connection flange

3 Smoke chamber cleaning door

4 Flame control warning light

F

T3 T3

G

M

HQ

T5

4

C

I

3

2

1

N

T4

D

A

T1 Heating flow

T2 Heating return

T3 Expansion vessel connection

T4 Boiler drain

T5 Chimney connection

T6 Probe holder conduit connection

T7 Probe holder conduit connection

T8 Burner connection

L

B

P

TERNOX

Model

12500 2S STD

15000 2S STD

Useful

output

kW

12500

15000

Furnace

furnace

kW

13789

16458

Boiler

capacity

24100

27300 1.46 - 2.20 9.72 - 15.0 6 30000 DN 125DN 350 DN 60 1000

Water side

pressure

drop(**)

l

m.w.c.

1.31 - 2.00

(**) Pressure drops corresponding to a thermal variation of 15K.

TERNOx

Model

12500 2S STD

15000 2S STD

A

mm

7211

7761

B

mm

3210

3320

C

mm

3715

3910

D

mm

6236

6736

E

mm

1643

1693

Flue gas

pressure

drop

mbar

8.93 - 14.0

DIMENSIONS

F

mm

3500

4000

M

aximum

operating

pressure

boiler

bar

G

mm

2068

2068

W

eight

T1

T2

UNI 2278 PN16

kg

25500

6

mm

650

650

H

mm

2700

2750

I

CONNECTIONS

T3

UNI 2278 PN16

DN 125DN 300 DN 60 820

L

mm

2400

2500

M

mm

1470

1470

ISO 7/1

T7

Ø

mm

Rp 1/2

mm

400

400

T8

Ø

mm

650

650

Q

mm

N

mm

1480

1583

T5

Øi

T6

Ø

mm

Rp 1/2

Rp 1/2 Rp 1/2

P

mm

230

230

T4

12

2.4 - OPERATING DATA ACCORDING TO UNI 10348

GAS-FIRED

TERNOX 2500

2S STD

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

CO2 content

Flue gas mass flow rate (min.-max)

kW

kW

%

%

%

%

%

%

°C

%

kg/h

1800 - 2500

1951 - 2753

92.25 - 90.80

91.40

92.9 - 91.5

0.60 - 0.71

7.15 - 8.49

0.10

146.46 - 174

9.80

2932.8 - 4138.6

DIESEL OIL-FIRED TERNOX 2500

2S STD

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

CO

content

2

Flue gas mass flow rate (min.-max)

kW

kW

%

%

%

%

%

%

°C

%

kg/h

1800 - 2500

1951 - 2753

92.25 - 90.80

91.40

92.9 - 91.5

0.60 - 0.71

7.15 - 8.49

0.10

156.73 - 186.20

12.80

2987.9 - 4216.3

TERNOX 2200

2S LOW NOx

1800 - 2200

1951 - 2406

92.25 - 91.45

91.40

92.9 - 92.1

0.60 - 0.65

7.15 - 7.90

0.10

146.46 - 161.92

9.80

2932.8 - 3616.1

TERNOX 2200

2S LOW NOx

1800 - 2200

1951 - 2406

92.25 - 91.45

91.40

92.9 - 92.1

0.60 - 0.65

7.15 - 7.90

0.10

156.73 - 173.27

12.80

2987.9 - 3684.0

TERNOX 1800

2S LOW NOx E

1800

1951

92.25

91.40

92.9

0.60

7.15

0.10

146.46

9.80

2932.8

TERNOX 1800

2S LOW NOx E

1800

1951

92.25

91.40

92.9

0.60

7.15

0.10

156.73

12.80

2987.9

Technical features

GAS-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

content

CO

2

Flue gas mass flow rate (min.-max)

DIESEL OIL-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

CO

content

2

Flue gas mass flow rate (min.-max)

kW

kW

%

%

%

%

%

%

°C

%

kg/h

kW

kW

%

%

%

%

%

%

°C

%

kg/h

TERNOX 3500

2S STD

2350 - 3500

2537 - 3848

92.64 - 90.95

91.40

93.2 - 91.7

0.58 - 071

6.78 - 8.34

0.10

139.00 - 171.00

9.80

3813.1 - 5784.7

TERNOX 3500

2S STD

2350 - 3500

2537 - 3848

92.64 - 90.95

91.40

93.2 - 91.7

0.58 - 071

6.78 - 8.34

0.10

148.67 - 182.90

12.80

3884.6 - 5893.1

TERNOX 3050

2S LOW NOx

2350 - 3050

2537 - 3329

92.64 - 91.62

91.40

93.2 - 92.3

0.58 - 0.65

6.78 - 7.73

0.10

139.0 - 158.35

9.80

3913.1 - 5003.7

TERNOX 3050

2S LOW NOx

2350 - 3050

2537 - 3329

92.64 - 91.62

91.40

93.2 - 92.3

0.58 - 0.65

6.78 - 7.73

0.10

148.67 - 169.37

12.80

3884.6 - 5097.5

TERNOX 2350

2S LOW NOx E

2350

2537

92.64

91.40

93.2

0.58

6.78

0.10

139

9.80

3813.1

TERNOX 2350

2S LOW NOx E

2350

2537

92.64

91.40

93.2

0.58

6.78

0.10

148.67

12.80

3884.6

13

GAS-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

content

CO

2

Flue gas mass flow rate (min.-max)

kW

kW

%

%

%

%

%

%

°C

%

kg/h

TERNOX 4500

2S STD

3000 - 4500

3239 - 4951

92.62 - 90.90

91.40

93.2 - 91.6

0.58 - 0.71

6.80 - 8.39

0.10

139.31 - 172.00

9.80

4868.5 - 7441.4

TERNOX 3800

2S LOW NOx

3000 - 3800

3239 - 4144

92.62 - 91.70

91.40

93.2 - 92.4

0.58 - 0.65

6.80 - 7.65

0.10

139.31 - 156.79

9.80

4868.5 - 6228.9

TERNOX 3000

2S LOW NOx E

3000

3239

92.62

91.40

93.2

0.58

6.80

0.10

139.31

9.80

4868.5

DIESEL OIL-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

CO

content

2

Flue gas mass flow rate (min.-max)

GAS-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

CO

content

2

Flue gas mass flow rate (min.-max)

kW

kW

%

%

%

%

%

%

°C

%

kg/h

kW

kW

%

%

%

%

%

%

°C

%

kg/h

TERNOX 4500

2S STD

3000 - 4500

3239 - 4951

92.62 - 90.90

91.40

93.2 - 91.6

0.58 - 0.71

6.80 - 8.39

0.10

149.03 - 184.00

12.80

4959.9 - 7581.0

TERNOX 5800

2S STD

4000 - 5800

4324 - 6381

92.50 - 90.90

91.40

93.1 - 91.6

0.59 - 0.71

6.91 - 8.39

0.10

141.70 - 172.00

9.80

6500.2 - 9591.1

TERNOX 3800

2S LOW NOx

3000 - 3800

3239 - 4144

92.62 - 91.70

91.40

93.2 - 92.3 0.58 -

0.65

6.80 - 7.65

0.10

149.03 - 167.73

12.80

4959.9 - 6345.8

TERNOX 5000

2S LOW NOx

4000 - 5000

4324 - 5457

92.50 - 91.62

91.40

93.1 - 92.3

0.59 - 0.65

6.91 - 7.73

0.10

141.70 - 158.42

9.80

6500.2 - 8203.0

TERNOX 3000

2S LOW NOx E

3000

3239

92.62

91.40

93.2

0.58

6.80

0.10

149.03

12.80

4959.9

TERNOX 4000

2S LOW NOx E

4000

4324

92.50

91.40

93.1

0.59

6.91

0.10

141.70

9.80

6500.2

DIESEL OIL-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

CO

content

2

Flue gas mass flow rate (min.-max)

14

kW

kW

%

%

%

%

%

%

°C

%

kg/h

TERNOX 5800

2S STD

4000 - 5800

4324 - 6381

92.50 - 90.90

91.40

93.1 - 91.6

0.59 - 0.71

6.91 - 8.39

0.10

151.58 - 184.00

12.80

6622.2 - 9771.1

TERNOX 5000

2S LOW NOx

4000 - 5000

4325 - 5457

92.50 - 91.62

91.40

93.1 - 92.3

0.59 - 0.65

6.91 - 7.73

0.10

151.58 - 169.47

12.80

6622.2 - 8356.9

TERNOX 4000

2S LOW NOx E

4000

4324

92.50

91.40

93.1

0.59

6.91

0.10

151.58

12.80

6622.2

GAS-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

content

CO

2

Flue gas mass flow rate (min.-max)

kW

kW

%

%

%

%

%

%

°C

%

kg/h

TERNOX 7000

2S STD

5100 - 7000

5529 - 7705

92.25 - 90.85

91.40

92.9 - 91.6

0.61 - 0.71

7.15 - 8.44

0.10

146.49 - 173.00

9.80

8310.3 - 11581.7

TERNOX 6300

2S LOW NOx

5100 - 6300

5529 - 6892

92.25 - 91.41

91.40

92.9 - 92.1

0.61 - 0.65

7.15 - 7.94

0.10

146.49 - 162.81

9.80

8310.3 - 10360.0

TERNOX 5100

2S LOW NOx E

5100

5529

92.25

91.40

92.9

0.61

7.15

0.10

146.48

9.80

8310.3

DIESEL OIL-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

CO

content

2

Flue gas mass flow rate (min.-max)

GAS-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

CO

content

2

Flue gas mass flow rate (min.-max)

kW

kW

%

%

%

%

%

%

°C

%

kg/h

kW

kW

%

%

%

%

%

%

°C

%

kg/h

TERNOX 7000

2S STD

5100 - 7000

5529 - 7705

92.25 - 90.85

91.40

92.9 - 91.6

0.61 - 0.71

7.15 - 8.44

0.10

156.65 - 185.00

12.80

8465.9 - 11798.7

TERNOX 8500

2S STD

5700 - 8500

6169 - 9376

92.40 - 90.65

91.40

93.0 - 91.4

0.58 - 0.71

7.01 - 8.64

0.10

143.78 - 177.00

9.80

9272.2 - 14093.8

TERNOX 6300

2S LOW NOx

5100 - 6300

5529 - 6892

92.25 - 91.41

91.40

92.9 - 92.1

0.61 - 0.65

7.15 - 7.94

0.10

156.65 - 174.10

12.80

8465.9 - 10554.1

TERNOX 7500

2S LOW NOx

5700 - 7500

6169 - 8214

92,40 - 91,30

91.40

93.0 - 92.0

0.58 - 0.65

7.01 - 8.04

0.10

143.78 - 164.93

9.80

9272.2 - 12347.4

TERNOX 5100

2S LOW NOx E

5100

5529

92.25

91.40

92.9

0.61

7.15

0.10

156.65

12.80

8465.9

Technical features

TERNOX 5700

2S LOW NOx E

5700

6169

92.40

91.40

93.0

0.58

7.01

0.10

143.78

9.80

9272.2

DIESEL OIL-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

CO

content

2

Flue gas mass flow rate (min.-max)

kW

kW

%

%

%

%

%

%

°C

%

kg/h

TERNOX 8500

2S STD

5700 - 8500

6169 - 9377

92.40 - 90.65

91.40

93.0 - 91.4

0.58 - 0.71

7.02 - 8.64

0.10

153.94 - 189.50

12.80

9446.8 - 14359.4

TERNOX 7500

2S LOW NOx

5700 - 7500

6169 - 8215

92.40 - 91.29

91.40

93.0 - 91.9

0.58 - 0.65

7.02 - 8.06

0.10

153.94 - 176.58

12.80

9446.8 - 12579.9

TERNOX 5700

2S LOW NOx E

5700

6169

92.40

91.40

93.0

0.58

7.02

0.10

153.94

12.80

9446.8

15

GAS-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

CO

content

2

Flue gas mass flow rate (min.-max)

kW

kW

%

%

%

%

%

%

°C

%

kg/h

TERNOX 10200

2S STD

8400 - 10200

9128 - 11191

92.02 - 91.14

91.40

92.7 - 91.9

0.64 - 0.71

7.33 - 8.15

0.10

150.34 - 167.00

9.80

13721.2 - 16822.0

TERNOX 9500

2S LOW NOx

8400 - 9500

9128 - 10377

92.02 - 91.55

91.40

92.7 - 92.2

0.64 - 0.65

7.33 - 7.80

0.10

150.34 - 159.88

9.80

13721.2 - 15579.9

TERNOX 8400

2S LOW NOx E

8400

9128

92.03

91.40

92.7

0.64

7.33

0.10

150.34

9.80

13720.5

DIESEL OIL-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

CO

content

2

Flue gas mass flow rate (min.-max)

GAS-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

CO

content

2

Flue gas mass flow rate (min.-max)

kW

kW

%

%

%

%

%

%

°C

%

kg/h

kW

kW

%

%

%

%

%

%

°C

%

kg/h

TERNOX 10200

2S STD

8400 - 10200

9128 - 11191

92.02 - 91.14

91.40

92.7 - 91.9

0.64 - 0.71

7.33 - 8.15

0.10

160.78 - 178.60

12.80

13978.3 - 17137.3

TERNOX 12500

2S STD

10100 - 12500

11012 - 13789

91.72 - 90.65

91.40

92.3 - 91.4

0.58 - 0.71

7.70 - 8.64

0.10

157.83 - 177.00

9.80

16552,5 - 20726,2

TERNOX 9500

2S LOW NOx

8400 - 9500

9128 - 10377

92.02 - 91.55

91.40

92.7 - 92.2

0.64 - 0.65

7.33 - 7.80

0.10

160.78 - 170.98

12.80

13978.3 - 15890.1

TERNOX 15000

2S STD

12200 - 15000

13251 - 16458

92.07 - 91.14

91.40

92.7 - 91.9

0.64 - 0.71

7.29 - 8.15

0.10

149.40 - 167.00

9.80

19918.5 - 24738.3

TERNOX 8400

2S LOW NOx E

8400

9128

92.03

91.40

92.7

0.64

7.33

0.10

160.78

12.80

13977.6

DIESEL OIL-FIRED

Nominal heat output

Thermal output of furnace

Heat efficiency at nominal load (100%)

Heat efficiency at 30% load

Combustion efficiency at nominal load (100%)

Heat loss at casing (min.-max.)

Heat loss at chimney with burner on (min.-max.)

Heat loss at chimney with burner off (min.-max.)

Flue gas temperature tf-ta (min.-max.)

CO

content

2

Flue gas mass flow rate (min.-max)

16

kW

kW

%

%

%

%

%

%

°C

%

kg/h

TERNOX 12500

2S STD

10100 - 12500

11012 - 13789

91.71 - 90.65

91.40

92.3 - 91.4

0.58 - 0.71

7.70 - 8.64

0.10

168.89 - 189.40

12.80

16863.5 - 21115.7

TERNOX 15000

2S STD

12200 - 15000

13251 - 16458

92.07 - 91.14

91.40

92.7 - 91.9

0.64 - 0.71

7.29 - 8.15

0.10

159.78 - 178.60

12.80

20291.8 - 25201.8

3

INSTRUCTIONS FOR

INSTALLATION

3.1 - GENERAL WARNINGS

ATTENTION!

This boiler is intended solely for the use for

which it was expressly designed. Any other

use is to be considered improper and therefore dangerous.

This boiler heats water at a temperature

lower than the atmospheric pressure boiling

temperature.

Before connecting the boiler, have professionally

qualified personnel:

a) Thoroughly wash all the piping of the system

to remove any residues or impurities which

could jeopardise proper operation of the

boiler, even from a hygienic point of view.

b) Check that boiler is set up to operate with the

available type of fuel.

The type of fuel can be seen written on the

package and on the technical feature plate.

c) Check that the chimney/flue has an appropri-

ate draught, without any bottlenecks, and that

no exhausts from other appliances are inserted, unless the flue has been implemented to

accommodate several utilities according to

specific standards and prescriptions in force.

Only after this check can the fitting between

the boiler and chimney/flue be mounted.

ATTENTION!

In rooms with the presence of aggressive

vapours or dust, the appliance must operate

independently from the air inside the installation room!

ATTENTION!

The appliance must be installed by a qualified

technician with the technical-professional

requirements according to law 46/90 which,

under his own responsibility, guarantees

compliance with standards according to

good practice rules.

ATTENTION!

Mount the appliance respecting the minimum

distances required for installation and maintenance.

The boiler must be connected to a heating

system compatible with its performance and

output.

3.2 - INSTALLATION STANDARDS

It must be installed by a professionally qualified technician, who

shall take the responsibility of observing all local and/or

national laws published in the official journal, as well as

applicable technical standards.

3.3 - INSTALLATION ON

OLD OR RETROFITTABLE SYSTEMS

Before installing this appliance on old systems, check that:

- The flue is able to withstand the temperature generated by

the combustion products, has been measured and designed

according to the regulations in force, is airtight and insulated,

and does not feature obstructions or constrictions.

- The flue has a device for releasing condensation.

- The electrical system has been set up by a qualified technician in compliance with the rules in force.

- The rate, head and direction of the flow of the circulation

pumps are appropriate.

- The expansion vessel(s) can fully absorb dilation of the fluid in the system.

- The fuel adduction line and the tank, if any, are made ac-

cording to relevant standards in force.

- The expansion vessels can fully absorb dilation of the fluid

in the system.

- The system has been cleaned and cleared of all sludge

and scale, has been vented, and all its seals have been

checked.

- There is a treatment system for feed/recirculation water

(see reference values).

Technical features and dimensions

17

3.4 - PACKAGING

TERNOX 2S boilers are supplied with casing and with the door

and smoke chamber assembled.

The panel and accessories are inside the combustion chamber.

Upon reception, make sure that the supply is complete and

undamaged.

The document envelope, besides the appliance, contains:

- Hydraulic test certificate

- Heating system booklet

- System manager operating instructions

- Installation and maintenance instruction booklet

- Warranty

- Local ventilation requirements label.

3.5 - HANDLING

TERNOX 2S boilers are equipped with lifting eyebolts.

Pay attention when handling the boiler and use equipment suitable for its weight.

18

3.6 - POSITIONING IN BOILER ROOM

TERNOX 2S boilers must be installed in rooms for exclusive

use complying with Technical Standards and Legislation in

force and with sufficiently sized air vents.

The ventilation openings must be permanent, communicating

directly with the outside and must be positioned high or low

according to standards in force.

The location of the ventilation openings, the fuel supply trains,

electric energy supply and lighting must comply with current

legal provisions in relation to the type of fuel used.

To make it easier to clean the smoke circuit, a free space must

be left in front of the boiler no less than the length of the boiler

body and, in any case, never less than 1300 mm. It must be

checked that with the door/s open 90°, the distance between

the door and the adjacent wall X is at least equal to the length

of the burner.

The boiler must rest on a perfectly level surface.

It is advisable to provide a flat, level cement basement capable

of bearing the weight of the boiler full of water. For the dimensions of the basement, see the dimensions R x B (dimensions

table).

If the burner is fed with fuel gas weighing more than air, the

electrical parts must be placed higher than 500 mm above the

ground.

The appliance cannot be installed outdoors as it was not so

designed and does not have automatic antifreeze systems.

Technical features and dimensions

19

3.7 - HYDRAULIC CONNECTIONS

ATTENTION!

Before connecting the boiler to the heating

system, thoroughly clean the piping with an

appropriate product compliant with UNI-CTI

8065, in order to eliminate metallic residue

from processing and welding, oil and grease

which could be present and which, reaching

the boiler, could alter its functioning.

Attention!

The fittings of the boiler must not take the

weight of the connecting pipes of the system; suitable supporting devices should be

installed to do this.

The dimensions of the supply and return pipes for each boiler

model are given in the DIMENSIONS table.

The connection pipes of the expansion vessel will start from the

T3 attachment (see DIMENSIONS TABLES) and must have no

shut-off valve.

Safety valve drain

Install a safety pressure valve on the flow pipe within 0.5 m of

the starting flange, sized according to the capacity of the boiler

and in compliance with local standards in force.

It is prohibited to place any type of shut-off valve between the

boiler and expansion vessel or between the boiler and safety

pressure valves. The valves used must be adjusted to trigger

not beyond the maximum allowed operating pressure.

3.9.1 - RECIRCULATION PUMP

Check that the system is fitted with a sufficient number of air

release valves.

Connection of expansion vessel

TERNOX 2S boilers are suitable for operating with forced water

circulation both with the expansion vessel opened or closed.

An expansion vessel is always necessary to compensate the

increase in water volume due to heating.

In the first case, the hydrostatic column must be

at least 3 m above the casing of the boiler and

sufficient to contain the volume increase of all

the water of the system between the exposed

surface of the water in the tank and the overflow

pipe.

3.8 - FILLING AND EMPTYING

THE SYSTEM

Attention!

Do not mix the heating water with incorrect

concentrations of antifreeze or anti-corrosion

substances! This could damage the gaskets

and cause noise during operation.

Unical will not be held liable for damage to

persons, animals or objects due to failure to

comply with the above instruction.

TERNOX 2S boilers must always operate with forced water

circulation and a minimum return temperature of 55°C.

It is therefore recommended to use a recirculation pump, which

also has an anti-condensation function, installed between the

flow and return connections upstream the mixing valve.

This pump is dimensioned according to the formula:

Q = P x 22

where Q = Flow rate in l/hr

P = Nominal output of boiler in kW

and head 1÷2 m H2O

The values displayed in the table can be used

as a reference.

TOTAL HARDNESS ppm 10

ALKALINITY mg/l CaCO3 750

PH 8÷9

SILICA ppm 100

CHLORIDES ppm 3500

When all system connections have been completed, the circuit

can be filled.

A specific tap can be connected to the T4 attachment at the rear of the boiler for filling and draining.

20

ATTENTION!

ANY DAMAGE TO THE BOILER CAUSED BY

THE FORMATION OF FOULING OR BY CORROSIVE WATER WILL NOT BE COVERED BY

THE WARRANTY.

3.9 - GAS CONNECTION

Connecting Gas

Danger!

The gas connection must be carried out only

by a qualified installer who must respect and

apply that foreseen by relevant laws in force

in the local prescriptions of the supply company. Incorrect installation can cause damage

to persons, animals and objects for which the

manufacturer cannot be held responsible.

Before installation, we recommend a thorough inner cleaning of all fuel adduction

piping to remove any residue which could

jeopardise proper operation of the boiler.

If you smell gas:

a) Do not turn electric switches on or off, use

a telephone or any other object which can

create sparks;

b) Immediately open doors and windows to

create an air current to air out the room;

c) Shut the gas cocks;

d) Request the intervention of professionally

qualified personnel.

3.10 - CONNECTION TO THE FLUE

The TERNOX 2S boiler can be attached to the chimney in different ways; straight pipes or elbows can be used to exit from

the rear, on the left, on the right, or else vertically to enter the

flue at a higher level.

It is recommended to insulate the pipe connecting to the chimney

to reduce heat loss and noise.

Along the section connecting the boiler to the flue there

must be suitable points for measuring flue gas temperature and analysing combustion products.

The flue gas duct and the fitting to the flue must be implemented in compliance with Standards and Legislation in force, with

rigid ducts resistant to heat, condensation, mechanical stress

and airtight.

The flue must guarantee the minimum negative pressure foreseen by Standards in force, considering “zero” pressure at the

flue duct fitting.

Inadequate or improperly sized flues and flue ducts can amplify

combustion noise, generate condensation problems and negatively affect combustion parameters.

Non-insulated exhaust pipes are a potential source of risk.

The seals of the junctions must be made with materials resistant to temperatures of at least 250°C.

Along the section connecting the boiler to the flue there must

be suitable points for measuring flue gas temperature and analysing combustion products.

Refer to national and local regulations in force for that which

regards the cross-section and height of the chimney.

Technical features and dimensions

21

3.11 - FURNACE DOOR: ADJUSTMENT,

OPENING AND CLOSING

IMPORTANT

- The door of the boiler must be opened when it is cooled off

to avoid thermal shocks.

- The rear factory material of the door can show cracks after

a short time of operation; this however does not reduce its

insulation capacity nor jeopardise its lifespan.

The door is hinged and fixed according to the indicated diagram:

In these cases, the two hinges on the left are normally used as

rotation hinges (from right to left), while the two on the right are

used as closing hinges.

It will be exactly the opposite when the door is opened from

left to right.

To invert rotation, just move the door support lock nut.

The following adjustments can be made on the door:

A) Adjustment in the vertical direction: by acting on the nut

of the upper hinge pin on which the door turns.

B) Adjustment in the transverse direction: loosen the hinges

fixed on the front plate of the boiler and move them sideways.

C) Adjustment in the axial direction: by adjusting the tightening

nuts.

3.12 - BURNERS

The burners operating with the TERNOX 2S boilers must have

the EC certification and comply with:

- Gas appliance directive (90/396/EEC);

- EMC Directive - Electromagnetic Compatibility (89/336/EEC).

They must also be approved according to the specifications:

- UNI EN 267 - test methods for atomizing oil burners of the

monobloc type.

- UNI EN 676 - air-blown burners for gaseous fuel.

- Efficiency Directive (92/42 EEC).

22

3.12.1 - SELECTING THE BURNER

L

Ø A

The correct choice and adjustment of the burner are fundamental

for optimal operation of the boiler and therefore must be done

carefully and not underestimated.

The burner must be chosen verifying that its firing rate (fuel

capacity - combustion chamber pressure) is compatible with the

same features declared for the boiler.

Remember that pressure drops on the flue side of the boiler,

namely combustion chamber counter pressure, refer to zero

pressure at the base of the chimney.

It is also recommended that the burner blast tube be no shorter

than the minimum dimension shown in the following table and

that the flame which must be implemented be suitable for the

characteristics of the combustion chamber.

The manufacturing companies of the burners can supply the

dimensions of the flames which their appliances develop, especially those approved based on the standards indicated above.

DIMENSIONS OF BURNER BLAST TUBE

TERNOx

2500

3500

4500

5800

7000

8500

10200

12500

15000

øA

mmL mm (min)

400

400

500

500

500

500

500

650

650

370

370

410

410

410

450

450

450

450

mm (max)

L

520

520

560

560

560

650

650

650

650

3.12.2 - INSTALLATION OF THE BURNER

The burner must be mounted to the door of the boiler guaranteeing perfect sealing of the combustion products.

The burner is supplied with a piece of ceramic fibre cord which

must be placed on the blast tube of the burner to fully seal

the space between the blast tube and the slot in the door.

Make sure that no gaps remain between the blast tube and the

slot on the refractory material inside the door.

3.12.3 - CONNECTING FLAME CONTROL

WARNING LIGHT TO BURNER

The flame control warning light is supplied with a threaded 1/8”

connection with a 9mm pressure test nipple mounted on it, to

be used with a silicone tube to measure back pressure in the

combustion chamber.

In place of this test nipple, which must be kept, an appropriate

fitting will be mounted to connect the flame control warning light

directly to the pressure chamber downstream the burner fan by

means of a copper tube.

The air blown by the fan will conveniently cool the warning light

glass and keep it from blackening.

If the cooling tube is not connected to the warning light, it could

break.

Should a cone larger than the diameter of the blast tube be

mounted, it must be removed before mounting the burner on

the support plate and put back afterwards.

With the burner mounted, check that the flexible hoses of the

liquid fuel and the electric cables are long enough to allow the

door to open 90°.

For gas-fired burners, flexible hoses cannot be used for connections. Therefore it must be equipped with a threaded or flanged

joint for disconnecting the final section of the gas adduction tube.

Technical features and dimensions

ATTENTION: the flame control warning light

can be very hot; therefore pay the utmost

attention.

23

3.13 - MOUNTING ELECTRIC PANEL

TERNOX 2S boilers are supplied with casing. Therefore to mount

the panel board, proceed as follows:

A) Dismount the right upper walkways (pos. 1 and 2).

B) Fix the support box of the panel board to the bracket on the

right side of the boiler.

C) Remove the lower cover pos. 4 from the support box of the

panel board.

Fasten the panel board (pos. 5) to the support box pos. 3.

D) Rotate the cover of the panel board frontwards after having

removed the two screws on the side and insert the electric

inlet cables and the outlet probe capillaries through the slots

at the base.

Insert the thermostat probe capillaries in the tube designed

for their passage, that is placed under the casing (see detail

“A”).

Pay special attention when unrolling the capillaries and insert

the bulbs in the two holders, inserting the contact springs and

blocking the capillaries with the fixing springs.

E) After having carried out the electric connections, close the

panel board and reposition the lower cover of the support box.

F) Remount the upper walkways.

24

3.14 - ELECTRICAL CONNECTIONS

General warnings

The electrical safety of the appliance is guaranteed only when it has been properly connected

to an efficient earthing system carried out as

intended by safety standards in force: pipes of the

gas, water and heating systems are absolutely

unsuitable as earthing electrodes.

It is necessary to verify this fundamental safety requirement. If

in doubt, have the electric system carefully checked by professionally qualified personnel as the manufacturer is not liable for

damage caused by failure to provide an earthing system.

Have professionally qualified personnel check

that the electric system is adequate for the maximum power absorbed by the appliance, indicated

on the data plate. Make sure in particular that

the cross-section of the cables is suitable for the

power absorbed by the appliance.

Use of any type of component using electric energy requires the

observance of some fundamental rules, such as:

• do not touch the appliance with wet and/or moist parts of the

body and/or in bare feet;

• do not pull the electric cables;

• do not leave the appliance exposed to atmospheric agents

(rain, sun, etc.) unless expressly designed;

• do not allow children or unskilled persons to use the appli-

ance.

230V electric power supply connection

The electrical connections are illustrated in chap. 3.15 .... 3.19.

The boiler installation requires a connection to a 230 V - 50 Hz

electric mains: this connection must be properly carried out as

provided for by current IEC regulations.

Danger!

Only a qualified technician may perform the

electrical installation.

Before performing connections or any type

of operation on electrical parts, always disconnect electrical power and make sure that

it cannot be reconnected accidentally.

Remember that a bipolar switch must be installed on the boiler

power line with over 3 mm between contacts, easy to access,

making maintenance quick and safe.

Technical features and dimensions

25

3.15 - STANDARD PANEL BOARD

The main switch 11 powers the board and the equipment connected to it.

Switches 12 and 13 in turn cut power to the burner and to the

C.H. pump.

Thermostat 32 adjusts the working temperature of the boiler.

The working thermostat is provided with two switching contacts

to control the two-stage burners.

The differential between the two contacts is 6°C (not adjustable).

11 Main switch with indicator light

12 Burner switch

13 System pump switch

31 Safety thermostat

The minimum thermostat, which can only be accessed after

having lifted the cover of the electric control board, stops the

C.H. pump until the boiler reaches the temperature of 50°C.

The electric power line of the boiler's control board must have a

switch with protective fuses.

32 Working thermostat

41 General fuse

42 Boiler thermometer

For use of the panel board, see the system manager instruction manual

If the Room thermostat is mounted,

remove bridge 11-12

7-pole plug

Plug stage 2

(optional)

Ph Phase (230V ~50Hz)

N Neutral

F1 General fuse (max 4A)

Ib Burner switch

IG Main switch with indicator light

Ipi System pump switch

Ta Room thermostat

26

Te1 Working thermostat stage 1

(60°C÷90°C)

Te2 Working thermostat stage 2

(54°C÷84°C)

Tm Minimum thermostat (50°C)

Ts Safety thermostat (100°C)

Pi System pump

A Possible repetition of burner block

B Possible working hour counter stage 1

C Possible working hour counter stage 2

3.16 - HYDRAULIC AND ELECTRICAL

SYSTEM CONNECTION

The following figures show the typical layout of the connection

of the boiler to the heating system with production of domestic

hot water.

Remember that TERNOX boilers operate with forced circulation.

TERNOx BOILER

Key:

Pr = recirculation pump

VM = zone mixing valve

Pi = heating system pump

VE = expansion vessel

IR = heating system distribution

Ps = domestic water recirculation pump

Pc = domestic hot water production charge pump

TA = room thermostat

The standard panel board of the TERNOX boiler automatically

switches the burner off when the temperature in the boiler reaches the value set on the control thermostat.

It also manages the C.H. pump, which will only be activated

when the minimum boiler temperature of 50°C has been reached

(anti-condensation protection temperature).

The pump will switch off when the lower threshold of 50°C (decreasing) is reached.

DOMESTIC HOT WATER

PRODUCER

The panel is set up to manage dual-stage or modulating burners.

With this layout configuration, the DHW storage tank loading

pump will have the priority over the heating C.H. pump.

Technical features and dimensions

27

POWER SUPPLY

TO THE 7-POLE SOCKET

OF THE BURNER

POWER SUPPLY

POWER SUPPLY

TERNOx BOILER

DOMESTIC HOT WATER

PRODUCER

NOTE: With absorption beyond 4A, place adequate contactors between the panel board and the loads

28

3.17 - OPTIONAL MASTER PANEL BOARD

The main switch 14 powers the board and the equipment connected to it.

The switches 18 and 19 control the burner and P1 pump if the

boiler operates in cascade.

The switches 20 and 21 control the Z1 pump (direct) and Z2

pump (mixed).

The thermostat adjusts the working temperature of the boiler:

to achieve this, the thermostat must be placed at maximum

full-scale pos. 33 .

Modulation of the burner will be managed by heat control.

The electric power line of the boiler's control board must have a

switch with protective fuses.

User

System

Service

Visual Inf.

Date/Time/Holiday

Solar/MF

Hot Water

Technician

Time Progr.

Heating circuit I

Heating circuit II

14 Main switch with indicator light

16 General fuse

18 Burner switch

19 P1 C.H. pump switch (cascade)

20 Pz1 direct zone C.H. pump switch

21 Pz2 mixed zone C.H. pump switch

33 Working thermostat

35 Safety thermostat

For use of the panel board, see the system manager instruction manual

The heating controller probes (boiler, storage tank, external,

flow) are included in the supply; the ambient probes 1 and 2

are optional; the mixing valve and relative control motor are not

included in the supply.

The optional panel board of the TERNOX 2S boiler automatically switches the burner off when the temperature in the boiler

reaches the value set on the heating controller.

It also manages the pump to fill a storage tank for DHW production.

The heating systems are managed automatically based on the

data detected by the boiler, external, ambient and flow probes.

The high temperature zone C.H. pump is made ready for operation by the control switch pos. 20, and will only switch off when

the temperature set on the heating controller has been reached.

The low temperature zone C.H. pump is made ready for operation

by the control switch pos. 21, and will only switch off when the

temperature set on the heating controller has been reached.

The storage tank charge pump for DHW production switches on

automatically and will only switch off when the temperature set

on the heating controller has been reached.

Should ambient probes be mounted (optional), the room temperature will only be determined with the boiler curve set by

the program.

The panel is set up to manage the modulating burners.

With this system configuration, the heating controller is capable

of checking:

- direct zone system; the control unit commands the C.H. pump.

The room temperature is controlled by the programming

curves set in the heating controller;

- one zone system with motorised mixing valve: the flow probe

(downstream the mixing valve) must be fitted; the control unit

commands the C.H. pump and the mixing valve. The room

temperature is controlled by the programming curves set in

the heating controller;

- DHW production through storage tank;

- anti-legionella function with increase of water temperature

in storage tank (function not enabled in factory, but can be

enabled by customer).

Technical features and dimensions

29

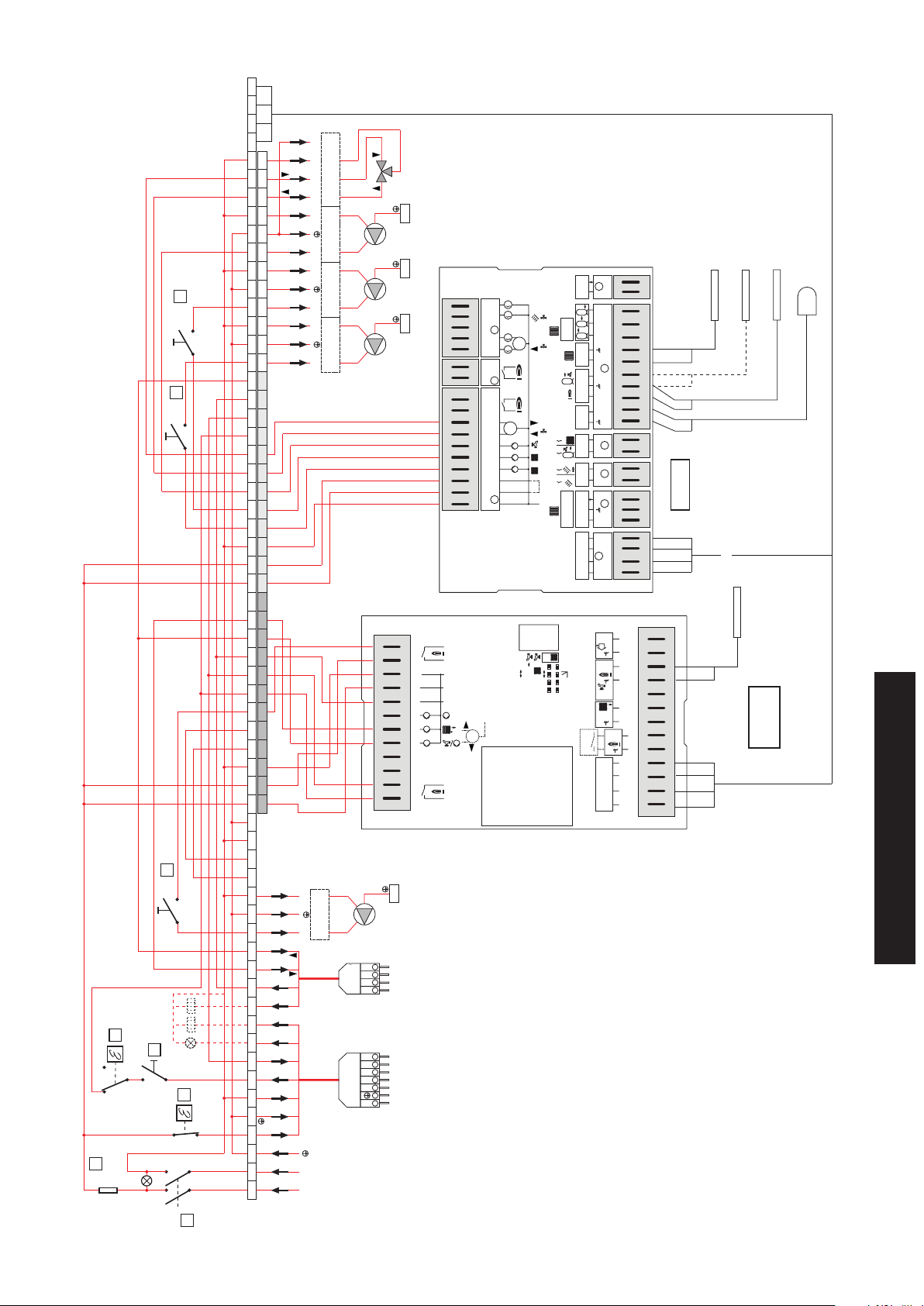

E

L1 T2N S3T1 B4

IG

3

4

Ts

7695810

B

A

28 42

Ib

(0°÷100°C)

(110°C)

Te

14

18

33

35

N

230V~ 50Hz

(max 4A)

2

1

L1

2

C

Spina a 7 poli

16

F1 (max 6 A)

B5 T7 T8

11

13

12

Spina a 4 poli

T6

14 15 16 17 18 19 20 21 46 47 48 49 50 51 52 53 54 55

56

57

C

32 25

30 31 26

3727 38 39 40

41

teleruttore pompa

zona 1

teleruttore

pompa ricircolo

teleruttore pompa

zona 2

teleruttore pompa

boiler

teleruttore valvola

mix. zona 2

L1LLL

L

L2 NNNN

N

Pz1

Pr

Pz2 Pb

Zona mix 2

24 36

Ipz1

Ip1

Ipz2

20

19

21

29 43

c

E

1

2

44 45

34

35

HL-+

22 23

33

Nero

Blu

Marrone

Bianco

Rosso

Grigio

Blu

Marrone

Nero

Bianco

1

2 8

6

10

5

9 11

II

-2

II

-3

II

-4

II

-5

II

-6

II

-7

II

-8

..

MORSETTI DEL TERMOREGOLATORE

Lago Basic 0201 RV1

.....

MORSETTI DEL TERMOREGOLATORE

E8.5064

Can bus

12

II

-1

mix. zone 2

valve contactor

Zone mix 2

HEATING CONTROLLER TERMINALS

E8.5064

HEATING CONTROLLER TERMINALS

Lago Basic 0201 RV1

storage tank

pump contactor

zone 2

pump contactor

zone 1

pump contactor

contactor

recirculation pump

White

Black

Brown

Blue

Grey

Red

White

Brown

Blue

Black

4-pole plug

7-pole plug

Ipz1 System pump zone 2 switch

Pz1 System pump zone 1

Pz2 System pump zone 2

Pb Storage tank pump

Pr Recirculation pump

Ip1 Main ring pump switch

Mix zone 2 Mixing valve zone n° 2

30

Ph Phase (230V ~50Hz)