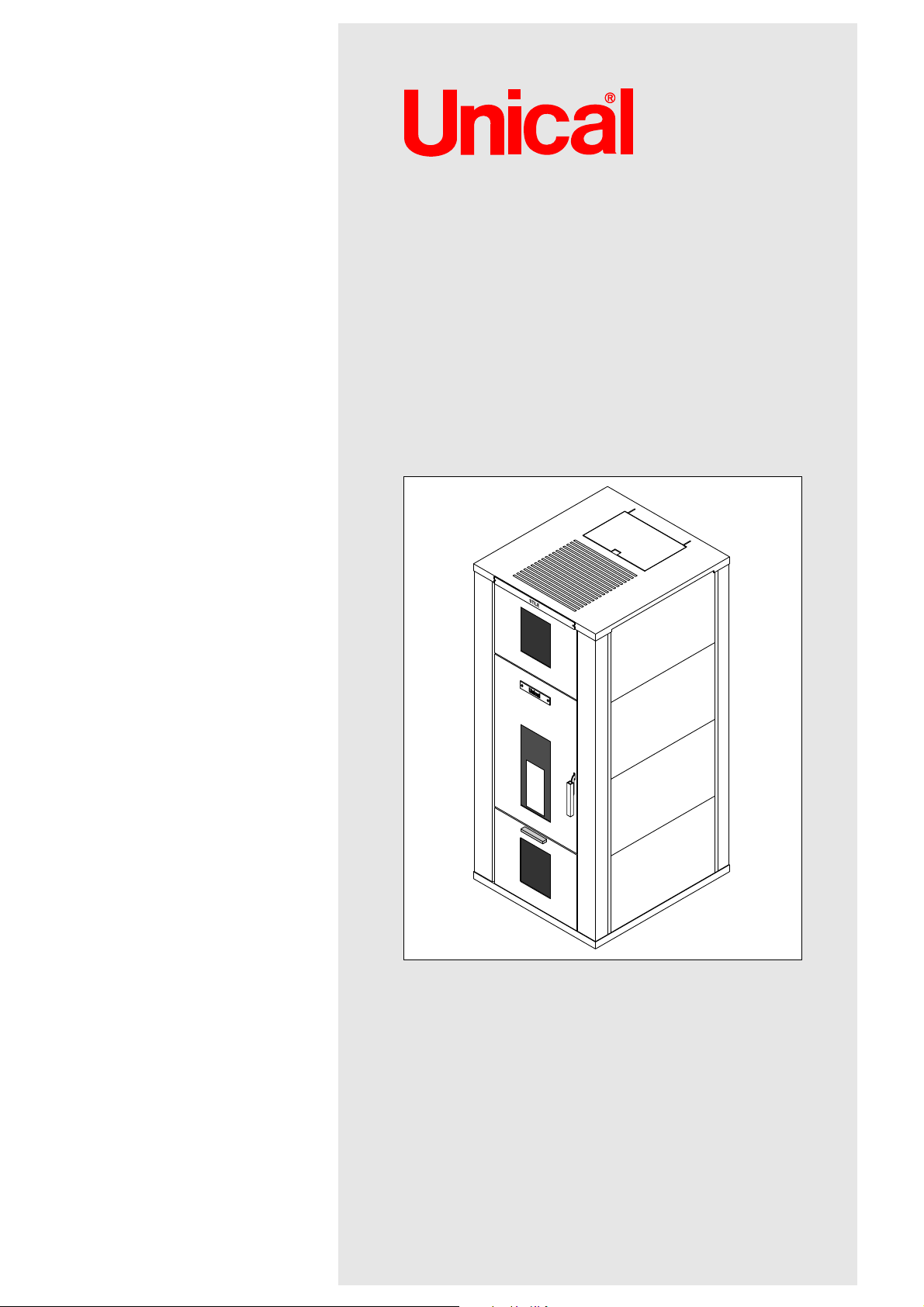

STILE 27

00334578 - 05/13

rev. 0

INSTRUCTIONS

FOR INSTALLATION,

MAINTENANCE

AND USE

General information

TABLE OF CONTENTS

1 GENERAL INFORMATION ............................................................................................................................................................................ 4

1.1 Symbols used in the manual ........................................................................................................................................................................ 4

1.2 Appropriate use of appliance ....................................................................................................................................................................... 4

1.3 Water treatment ............................................................................................................................................................................................ 4

1.4 Information for user ...................................................................................................................................................................................... 4

1.5 Safety warnings ............................................................................................................................................................................................ 5

1.6 Technical data plate ...................................................................................................................................................................................... 5

1.7 General warnings ......................................................................................................................................................................................... 6

2 TECHNICAL FEATURES AND DIMENSIONS ........................................................................................................................................... 7

2.1 Technical features ........................................................................................................................................................................................ 7

2.2 Dimensions and hydraulic connections ...................................................................................................................................................... 7

2.3 Technical data ............................................................................................................................................................................................. 11

2.4 Supply..........................................................................................................................................................................................................11

2.5 Main components ....................................................................................................................................................................................... 12

2.6 General Information .................................................................................................................................................................................... 12

3 INSTALLATION INSTRUCTIONS ............................................................................................................................................................... 14

3.1 General warnings ...................................................................................................................................................................................... 14

3.2 Installation standards ................................................................................................................................................................................ 15

3.3 Packaging .................................................................................................................................................................................................. 16

3.4 Installation .................................................................................................................................................................................................. 16

3.5 Flue connection ......................................................................................................................................................................................... 17

3.5.1 Exhaust through external wall........................................................................................................................................................ 18

3.5.2 Exhaust through roof by means of traditional flue ........................................................................................................................ 19

3.6 Connecting heat stove to system ............................................................................................................................................................ 20

3.7 Filling the system....................................................................................................................................................................................... 20

4 ELECTRICAL CONNECTIONS .................................................................................................................................................................... 21

5 HEAT STOVE START-UP .............................................................................................................................................................................. 24

5.1 Commissioning .......................................................................................................................................................................................... 24

5.2 Initial lighting checks ................................................................................................................................................................................. 24

6 INSPECTION AND MAINTENANCE ........................................................................................................................................................... 25

6.1 Troubleshooting ......................................................................................................................................................................................... 28

7 PROGRAMMING SETTING ........................................................................................................................................................................... 29

7.1 Using the product ...................................................................................................................................................................................... 29

7.2 Remote control .......................................................................................................................................................................................... 30

7.3 Function of buttons ................................................................................................................................................................................... 32

7.4 Menu ........................................................................................................................................................................................................... 33

7.4.1 User menu ........................................................................................................................................................................................ 33

7.4.2 Menu 01 - set clock ........................................................................................................................................................................ 35

7.4.3 Menu 02 - set chrono ..................................................................................................................................................................... 35

7.4.4 Menu 03 - choose language........................................................................................................................................................... 39

7.4.5 Menu 04 - standby mode ............................................................................................................................................................... 39

7.4.6 Menu 05 - buzzer mode ................................................................................................................................................................. 39

7.4.7 Menu 06 - initial load ....................................................................................................................................................................... 39

7.4.8 Menu 07 - heat stove status .......................................................................................................................................................... 40

7.5 User operating mode ................................................................................................................................................................................ 41

7.5.1 Lighting STILE 27 ............................................................................................................................................................................. 41

7.5.2 Start-up............................................................................................................................................................................................ 41

7.5.3 Failed ignition ................................................................................................................................................................................... 41

7.5.4 Heat stove working......................................................................................................................................................................... 42

7.5.5 Changing room temperature setting .............................................................................................................................................. 42

7.5.6 Using external thermostat / chronothermostat............................................................................................................................. 42

7.5.7 Changing water temperature setting ............................................................................................................................................. 43

7.5.8 The room temperature reaches the set temperature (SET temperature) .................................................................................. 43

7.5.9 The water temperature reaches the set temperature (SET water temperature) ....................................................................... 44

7.5.10 Restarting after extinction having reached set room and/or water temperature ..................................................................... 44

7.5.11 Cleaning the brazier ..................................................................................................................................................................... 45

7.5.12 Heat stove extinction .................................................................................................................................................................... 45

7.5.13 Heat stove off ................................................................................................................................................................................ 46

7.5.14 Heat stove re-ignition ................................................................................................................................................................... 46

7.6 What happens if......................................................................................................................................................................................... 47

7.6.1 The pellet does not light ..................................................................................................................................................................47

7.6.2 Electric power is missing ................................................................................................................................................................ 47

7.7 Alarms ........................................................................................................................................................................................................ 48

7.7.1 Flue gas temperature probe alarm ................................................................................................................................................ 48

7.7.2 Flue gas overtemperature alarm ................................................................................................................................................... 48

2

General information

7.7.3 Failed ignition alarm......................................................................................................................................................................... 49

7.7.4 Extinction during working phase alarm ......................................................................................................................................... 49

7.7.5 Screw safety pressure switch alarm............................................................................................................................................. 49

7.7.6 General thermostat alarm .............................................................................................................................................................. 50

7.7.7 Flue gas intake fan fault alarm ....................................................................................................................................................... 50

7.8 Operational mode (technical menu)......................................................................................................................................................... 51

7.8.1 Submenu 08 - 01 - 01 ..................................................................................................................................................................... 53

7.8.2 Submenu 08 - 02 - 01 chimney type ............................................................................................................................................. 53

7.8.3 Submenu 08 - 03 database ............................................................................................................................................................ 53

7.8.4 Submenu 08 - 04 various settings ................................................................................................................................................. 53

7.8.5 Submenu 08 - 05 outputs test........................................................................................................................................................ 53

7.8.6 Submenu 08 - 06 factory settings ................................................................................................................................................. 53

7.8.7 Submenu 08 - 07 reset partial hours............................................................................................................................................. 53

7.8.8 Submenu 08 - 08 alarm reset ........................................................................................................................................................ 54

7.8.9 Submenu 08 - 09 counter memories ............................................................................................................................................. 54

7.8.10 Flue gas probe calibration ............................................................................................................................................................. 54

3

General information

Attention: this manual contains instructions for the exclusive use of the professionally qualified installer and/or

maintenance technician in compliance with current legislation.

The user is NOT qualified to intervene on the heat stove.

The manufacturer will not be held liable in case of damage to persons, animals or objects resulting from failure to

comply with the instructions contained in the manuals supplied with the heat stove.

1

GENERAL INFORMATION

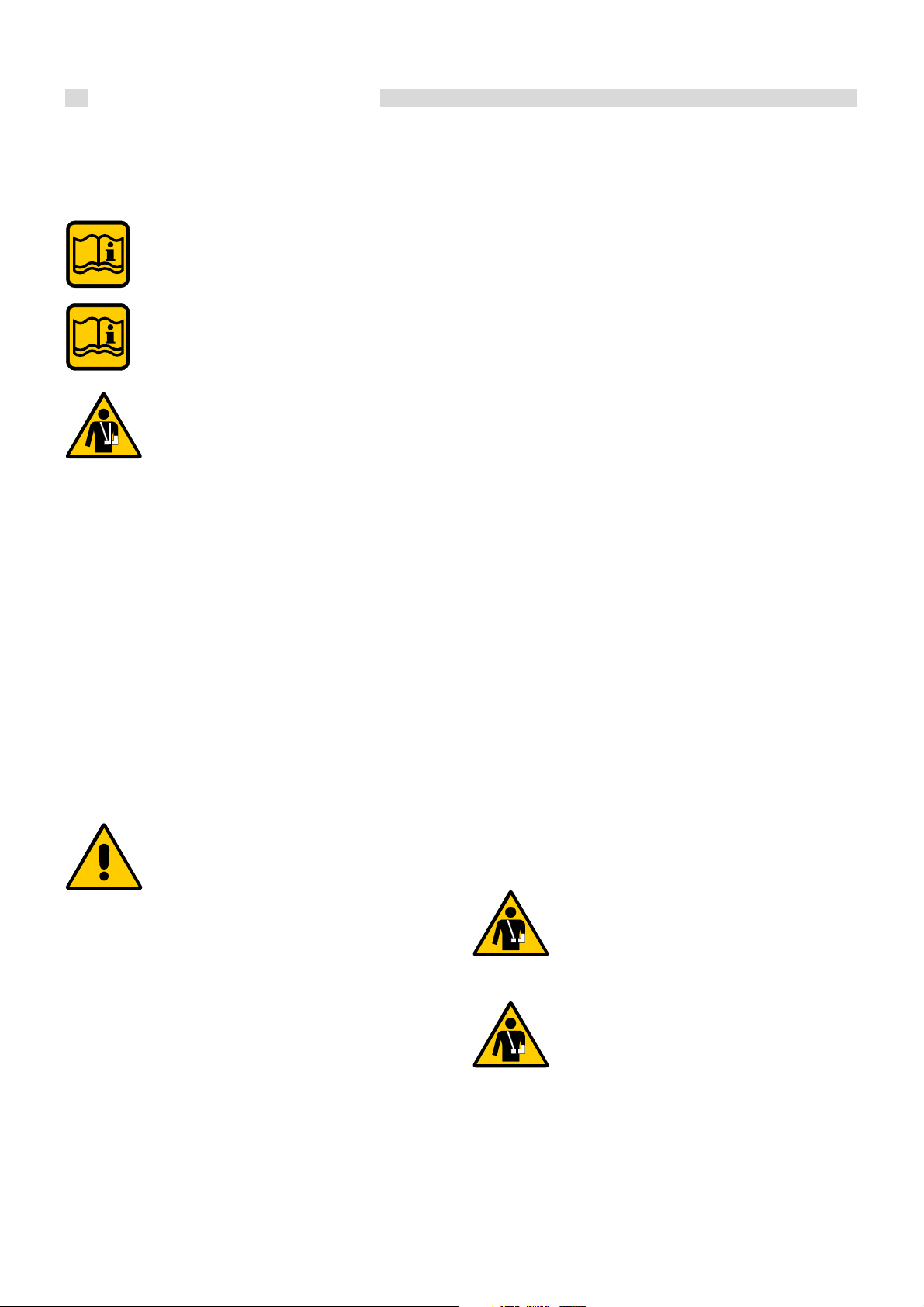

1.1 - SYMBOLS USED IN THE MANUAL

Pay special attention when reading this manual to the parts marked by the symbols:

DANGER!

Serious danger for

personal safety and life

ATTENTION!

Possible hazardous situation

for the product and the environment

1.2 - APPROPRIATE USE OF APPLIANCE

The STILE 27 appliance has been built according to the current level of engineering and acknowledged

technical safety rules.

Nonetheless, if improperly used, dangers could arise for the safety and the very life of the user and other

persons or damage to the equipment or other objects.

The appliance is intended to operate in hot air circulation heating systems. Any other use must be

considered improper.

UNICAL shall not be held liable for any damage resulting from improper use; in this case the user is fully

responsible for the risk.

Use according to the intended purposes also includes careful compliance with the instructions in this

manual.

NOTE!

Suggestions for the user

1.3 - WATER TREATMENT (see specific booklet)

• The hardness of the feed water conditions the frequency at which the domestic hot water exchanger must be

cleaned.

• If the water has a hardness greater than 15°f, we recommend using water softeners, chosen according to the

characteristics of the water.

• We recommend checking and cleaning the eventual domestic hot water exchanger at the end of the first year

of use and every two years thereafter.

1.4 - INFORMATION FOR USER

• The user must be instructed concerning the use and operation of his heating system, in particular:

• Deliver these instructions to the user, as well as other documents concerning the appliance inserted in the

envelope contained in the packaging. The user must keep this documentation so that it is available

for further consultation.

• Inform the user about the importance of the air vents and the flue gas exhaust system, highlighting

their essential features and the absolute prohibition of modifying them.

• Inform the user concerning controlling the system’s water pressure as well as operations to restore it.

• Inform the user concerning correct temperature control, control units/thermostats and radiators for saving

energy.

• Remember that the system must receive regular maintenance once a year and a combustion analysis

must be performed in the timetable foreseen by standards in force.

• Should the appliance be sold or transferred to a new owner or if you move and

leave the appliance, always make sure that the instruction booklet accompanies it in order to be

consulted by the new owner and/or installer.

4

1.5 - SAFETY WARNINGS

ATTENTION!

The appliance must be installed, adjusted and maintained by professionally qualified personnel, in

compliance with standards and provisions in force. Incorrect installation can cause damage to persons,

animals and objects for which the manufacturer cannot be held responsible.

DANGER!

NEVER attempt performing maintenance or repairs on the heat stove on your own initiative.

Any work must be done by professionally qualified personnel.

We recommend stipulating a maintenance contract.

Insufficient or irregular maintenance can jeopardise the operating safety of the appliance and cause

damage to persons, animals and objects for which the manufacturer cannot be held responsible.

Modifying parts connected to appliance

Do not modify the following parts:

- the heat stove

- the air, water and electricity lines

- the flue gas pipe, safety valve and heating water drain pipe

- construction parts which affect the operating safety of the appliance

General information

Attention!

To tighten or loosen the screwed fittings, use only appropriate fixed spanners.

Incompliant use and/or inappropriate tools can cause damage (e.g. water leakage).

Explosive and easily flammable substances

Do not use or store explosive or easily flammable materials (e.g. petrol, paints, paper) in the room where the

appliance is installed.

1.6 - TECHNICAL DATA PLATE

The technical data plate is adhesive and is applied on the back of the heat stove body.

The serial number of the heat stove is on the riveted plaque on the body (upper left side), visible by removing the top.

5

General information

1.7 - GENERAL WARNINGS

The instruction booklet is an integral and essential part of the

product and must be kept by the user or system manager.

Read the warnings contained in this instruction booklet

carefully as they provide important guidelines regarding

installation, use and maintenance safety.

Keep the booklet with care for further consultation.

Installation and maintenance must be performed in compliance

with standards in force according to the instructions of the

manufacturer and by qualified and certified personnel in

compliance with law.

By professionally qualified personnel we mean: personnel

with specific technical skill in the field of heating system

components for civil use, domestic hot water production and

maintenance. Personnel must have the qualifications provided

for by current legislation.

Incorrect installation or improper maintenance can cause

damage to persons, animals or objects for which the

manufacturer is not responsible.

Before performing any cleaning or maintenance, disconnect

the appliance from the energy mains by acting on the switch

of the system or by unplugging it.

In case of failure and/or malfunctioning of the appliance, switch

it off and do not try to repair it or intervene on it directly. Contact

only personnel qualified in compliance with law.

Any repairs must be performed solely by personnel

authorised by Unical using original spare parts only. Failure to

comply with the above can jeopardise the safety of the

appliance.

To guarantee appliance efficiency and its correct operation,

yearly maintenance must be performed by qualified

personnel.

Should you decide not to use the appliance, parts entailing

potential sources of hazard must be made safe.

Should the appliance be sold or transferred to a new owner or

if you move and leave the appliance, always make sure that

the instruction booklet accompanies it in order to be consulted

by the new owner and/or installer.

Only original accessories must be used for all appliances with

optionals or kits (including electric).

This appliance is intended solely for the use for which it was

expressly designed. Any other use is to be considered

improper and therefore dangerous.

Do not obstruct the terminals of the intake/exhaust ducts.

6

Technical features and dimensions

2

TECHNICAL FEATURES

AND DIMENSIONS

2.1 - TECHNICAL FEATURES

The heat generator mod. STILE 27 is a steel heating stove

operating with wood pellets with the combustion chamber

under negative pressure.

DESCRIPTION OF COMPONENTS:

• Steel heat stove body

• Refractory steel burner

• Front cleaning door equipped with ceramic glass

• Bottom cleaning door

• Automatic combustion air regulator

• Flue gas passage zone that can be inspected

• Powder painted sheet steel casing

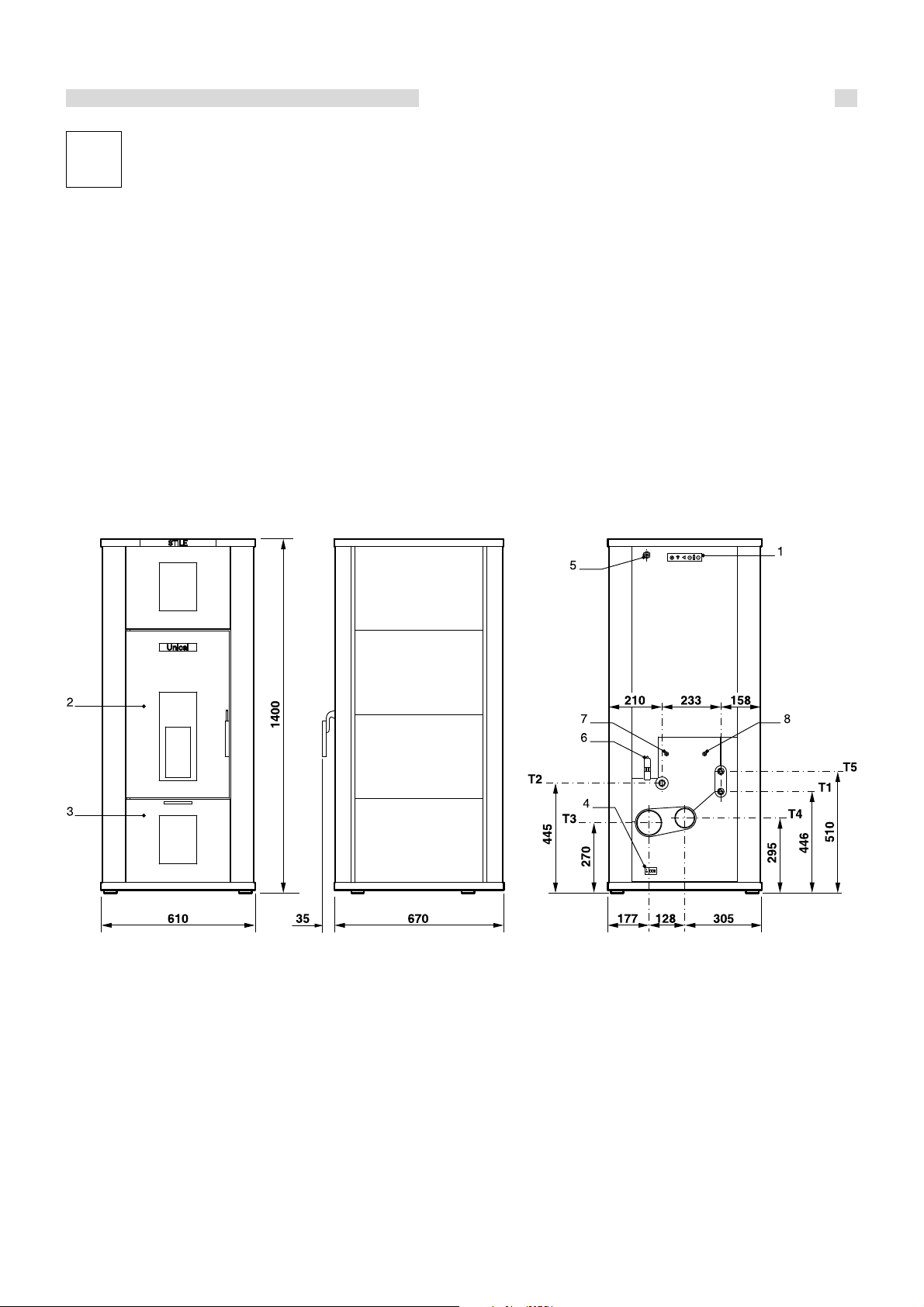

2.2 - HYDRAULIC DIMENSIONS

AND CONNECTIONS

1. Emergency console *

2. Front cleaning door equipped with ceramic glass

3. Bottom cleaning cover

4. Main switch with plug

5. Remote control reception antenna

6. Room thermostat electric connection

7. Manually reset water safety thermostat

8. Manually reset pellet safety thermostat

T1. CH flow (R 3/4)

T2 CH return (R 1)

T3 Chimney connection (ø100)

T4 Air intake connection (ø80)

T5 Safety valve discharge connection (R 3/4)

* Only switches ON/OFF and performs OUTPUT CHANGE, aside from an LED which signals a generic error.

fig. 1

7

Technical features and dimensions

Indicative hydraulic diagram

M Heating system flow

R Heating system return

1 Heating system overpressure valve (2.5 bar) (supplied)

2 Automatic release valve (supplied)

3 Heating system expansion vessel (preloaded at 1 bar) (supplied)

4 System filling tap (not supplied)

5 System shut-off valves (not supplied)

6 Main pump (supplied)

7 System drain tap (not supplied)

Attention!

The diagram above is indicative and can be customised.

For special requirements, please contact our After-Sales Service.

When installing, check the correct direction of the water flow.

fig. 2

8

Technical features and dimensions

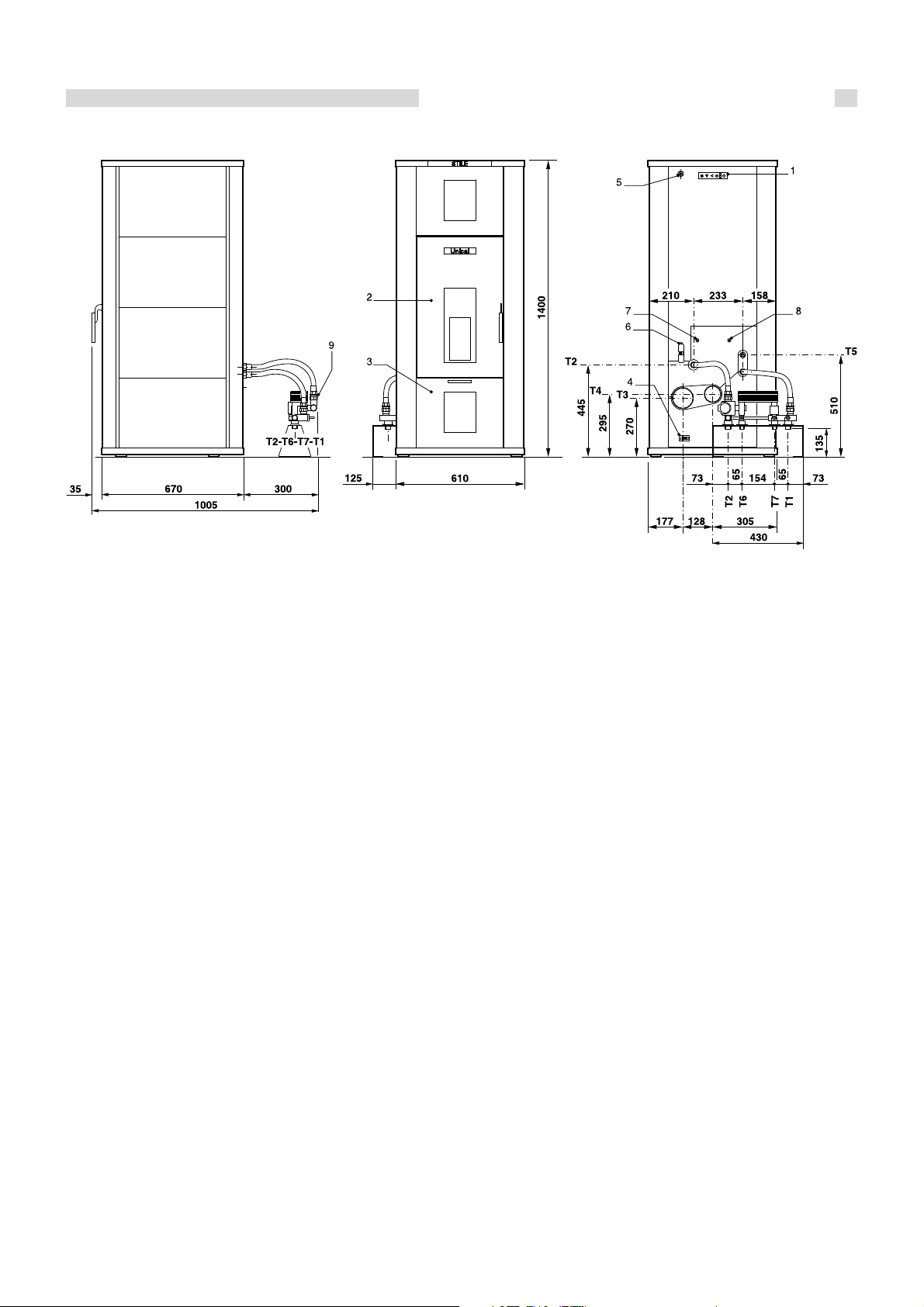

Hydraulic dimensions and connections with DOMESTIC HOT WATER PRODUCTION KIT

1. Emergency console *

2. Front cleaning door equipped with ceramic glass

3. Bottom cleaning cover

4. Main switch with plug

5. Remote control reception antenna

6. Room thermostat electric connection

7. Manually reset water safety thermostat

8. Manually reset pellet safety thermostat

9. Domestic hot water production unit

T1 CH flow (R 3/4)

T2 CH return (R 3/4)

T3 Chimney connection (ø100)

T4 Air intake connection (ø80)

T5 Safety valve discharge connection (R 3/4)

T6 Domestic hot water outlet connection

T7. Domestic cold water inlet connection

fig. 3

* Only switches ON/OFF and performs OUTPUT CHANGE, aside from an LED which signals a generic error.

Note: the support bracket of the domestic hot water production unit can be fastened to the ground with plugs.

The maximum clearance of the domestic hot water production unit from the back of the boiler is indicative as it depends on the

length of the flexible hoses.

9

Technical features and dimensions

Indicative hydraulic diagram

M Heating system flow

F Domestic cold water inlet

C Domestic hot water outlet

R Heating system return

1 Heating system overpressure valve (2.5 bar) (supplied)

2 Automatic release valve (supplied)

3 Heating system expansion vessel (preloaded at 1 bar) (supplied)

4 System filling tap (not supplied)

5 System shut-off valves (not supplied)

6 Main pump (supplied)

7 DHW system shut-off valve (not supplied)

8 Domestic cold water inlet filter (not supplied)

9 Differential flow switch (supplied)

10 Plate heat exchanger (supplied)

11 Diverter valve (supplied)

12 Water hammer prevention system (not supplied)

13 System drain tap (not supplied)

Attention!

The diagram above is indicative and can be customised.

For special requirements, please contact our After-Sales Service.

When installing, check the correct direction of the water flow.

fig. 4

10

Technical features and dimensions

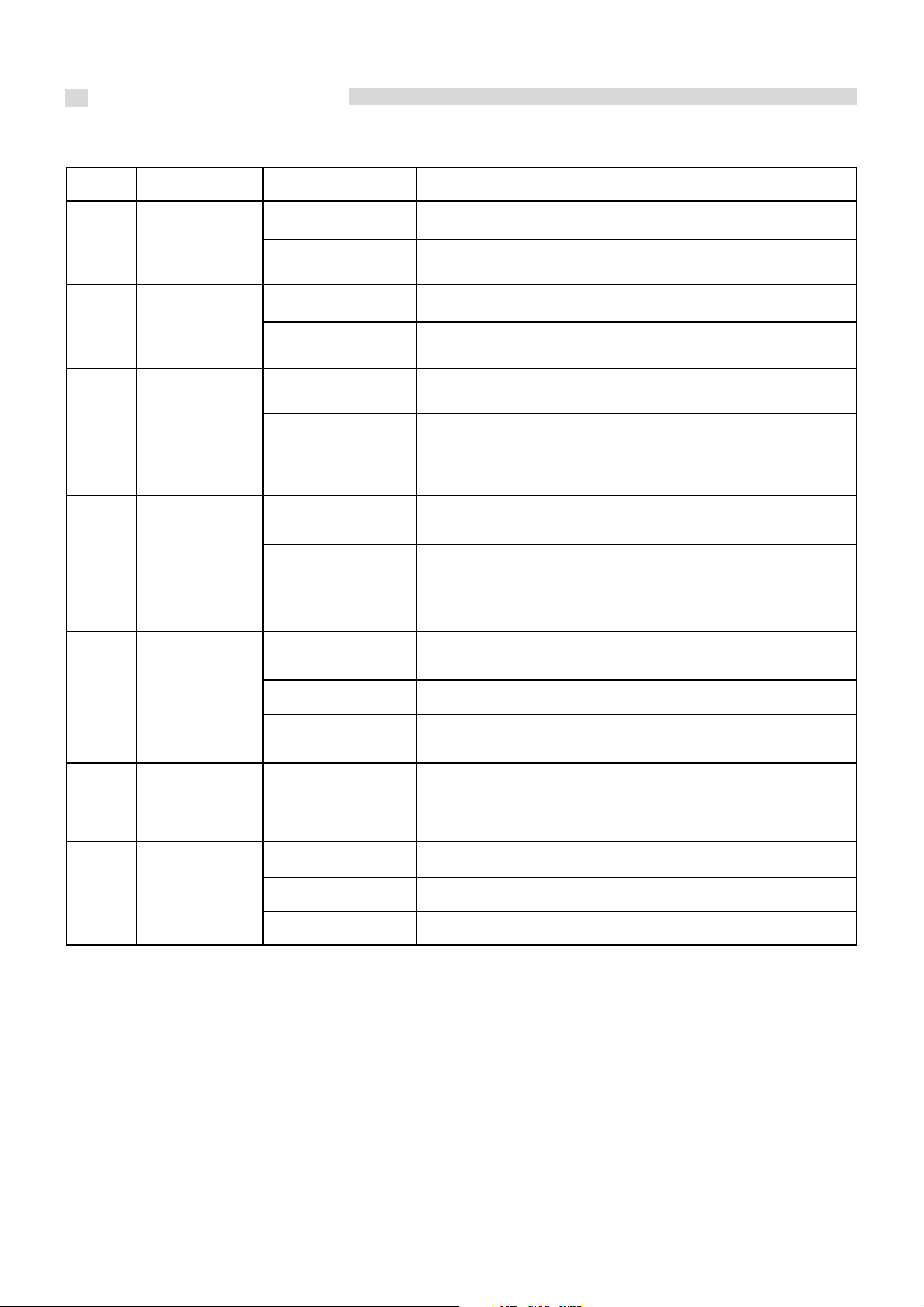

2.3 - TECHNICAL DATA

OVERALL OUTPUT

NOMINAL OUTPUT

THERMOCHEMICAL OUTPUT

ELECTRIC ABSORPTION

MAX. WORKING PRESSURE

PELLET TANK CAPACITY

FLUE GAS TEMPERATURE

FLUE GAS MASS FLOW RATE

MINIMUM DRAUGHT

CO VALUE 13%

TOTAL EFFICIENCY

PELLET CONSUMPTION

AUTONOMY

HEAT STOVE CAPACITY

WATER SIDE PRESSURE DROPSA (standard version)*

MAX HEATABLE VOLUME**

DHW PRODUCTION (see note)***

* Pressure drops for flow rate corresponding to a thermal drop of 15K.

** Values calculated based on the Law 10/91 for residential homes with a heat requirement of 30 kcal/hm³. The data is indicative.

*** NOTE: DHW production is subordinated to operation of the system pump. This cannot start up until the water temperature in the heat stove reaches 40°C. Beyond

this threshold it is necessary to consider the time required for the water temperature in the heat stove to reach a degree which allows thermal exchange through

the plate heat exchanger. A pressure drop caused by the thermal exchange is also considered. Therefore, with the heat stove at full capacity and water

temperature of 80°C, with a continuous withdrawal of 10 litres a minute, the outlet temperature from the DHW exchanger will be approximately 40°C with cold water

inlet at approximately 10°C.

The results in the table have been obtained using certified pellets based on the standards DIN 51731, DINplus and ÖNORM M 7135.

(kW) 6,8÷22

(kW) 5,2÷20

(kW)

starting

(W)

full capacity(W)

(bar)

(kg)

(°C)

(g/s)

(Pa)

(%)

(%)

min.

max.

(kg/h)

min.

max.

(h)

at nominal flow rate

at minimum

(l)

(m.w.c.)

(m³)

(l/min.)

8÷27

395

250

2

60

max. 180°C - min. 80°C

10,20

10

< 0,04

81,48

85

1,65

5,62

10,7

36,4

35

0,3

573

10

Emissions: according to UNI EN 14785

Efficiency: according to UNI EN 14785

2.4 - SUPPLY

Controlled combustion system with flue gas

temperature recovery

Flue gas draught control pressure switch

Dual combustion system

Ceramic glass

Two-way remote control

Automatic re-ignition in case of blackout (within 60 seconds)

5-speed forced ventilation

Possibility of setting heat outputs (5 levels)

Weekly programming

standard

standard

standard

standard

standard

standard

standard

standard

standard

11

Technical features and dimensions

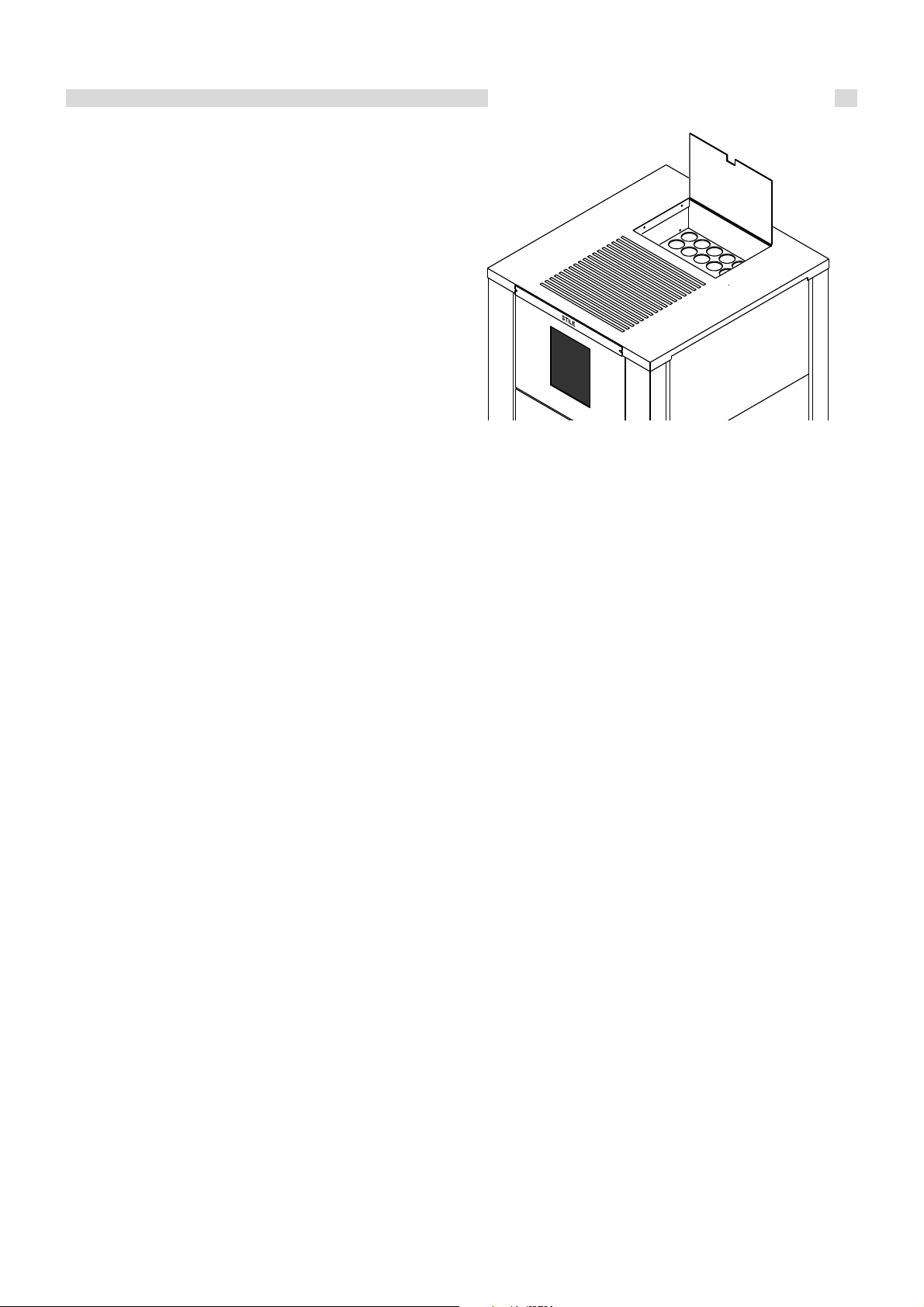

2.5 - MAIN COMPONENTS

1. Removable top with pellet loading cover

2. Panel board

3. Front door with ceramic glass

4. Pellet combustion crucible

5. Pellet igniter

6. Upper ash cleaning pan

7. Lower ash cleaning pan

8. Heat exchange pipe scraper system

9. Pellet tank

10. Pellet feeding screw

11. Feeding screw motor

12. System pump

13. Combustion flue gas intake/exhaust unit

M C.H. flow

R C.H. return

A Combustion air intake

F Combustion flue gas exhaust

N.B.: The smoke side of the thermal exchange pipes becomes dirty; it is therefore

advised, every time you load pellets, to activate the scraper system (pos. 8) in the

opposite vertical direction for a few seconds to keep them clear.

2.6 - GENERAL INFORMATION

The main feature of the STILE 27 heat stove is that of burning

natural fuel (pellets) obtained in an environmentally-friendly

way from wood industry waste (sawdust, powders). The

sawdust and powders coming from wood processing, after

having been appropriately cleaned and dried, are compacted

at high pressure giving way to pure wood cylinders: the pellet.

Each cylinder can have variable length and thickness,

respectively, between 1÷3 cm long and 6÷8 mm in diameter.

The main features of the pellet are its low moisture content

(lower than 12%), its high density (about 600 kg/m3) as well

as its regularity and compactness providing this type of fuel a

Net Calorific Value (NCV) of 4100÷5000 kcal/kg.

In order to provide STILE 27 with a long lifespan, Unical advises

using good quality pellets.

The pellets used to feed the heating stove must have high

quality features such as, for example, those determined by

standards DIN 51731 and ÖNORM M 7135. The following a

some of their fundamental data.

fig. 5

12

Technical features and dimensions

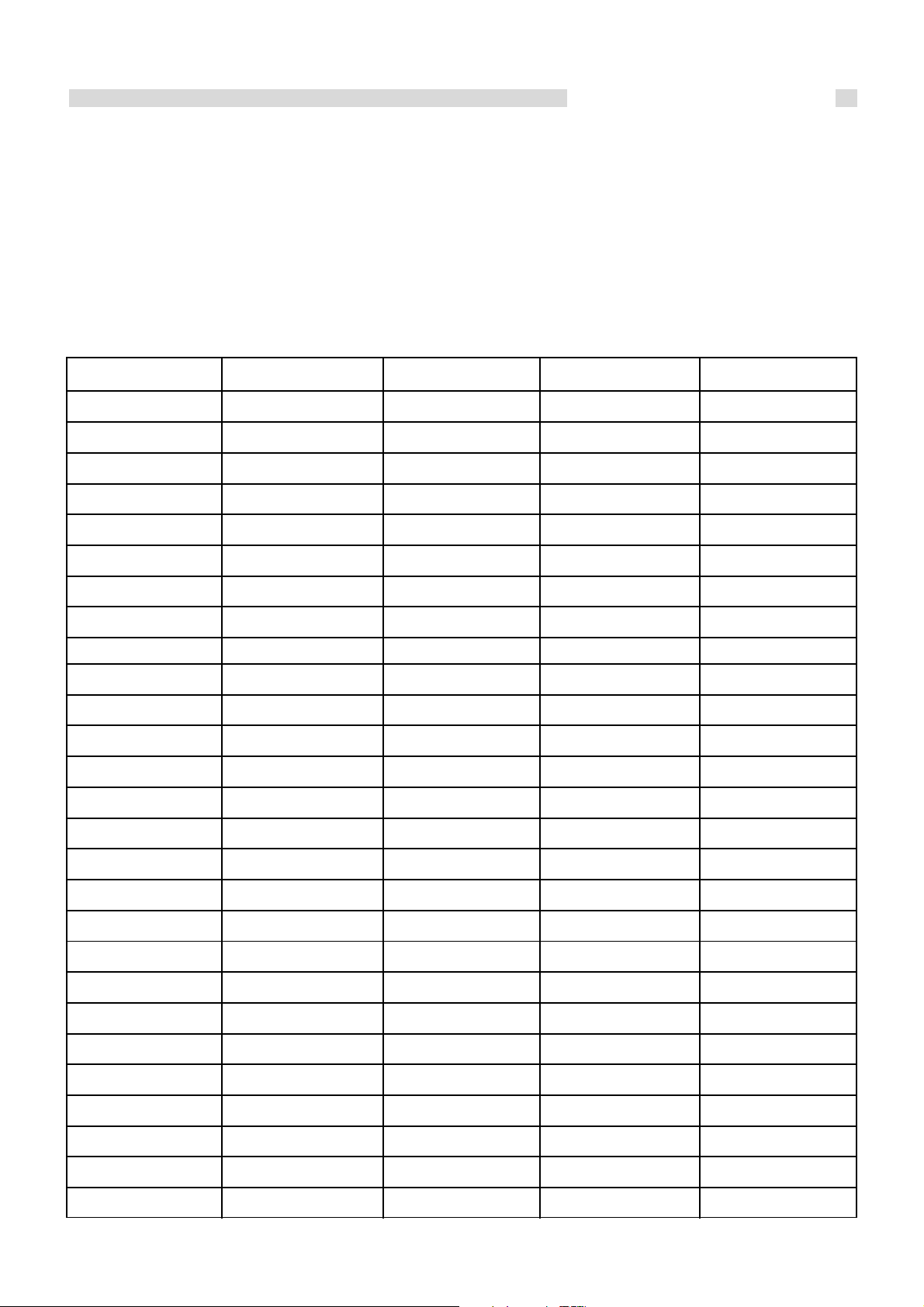

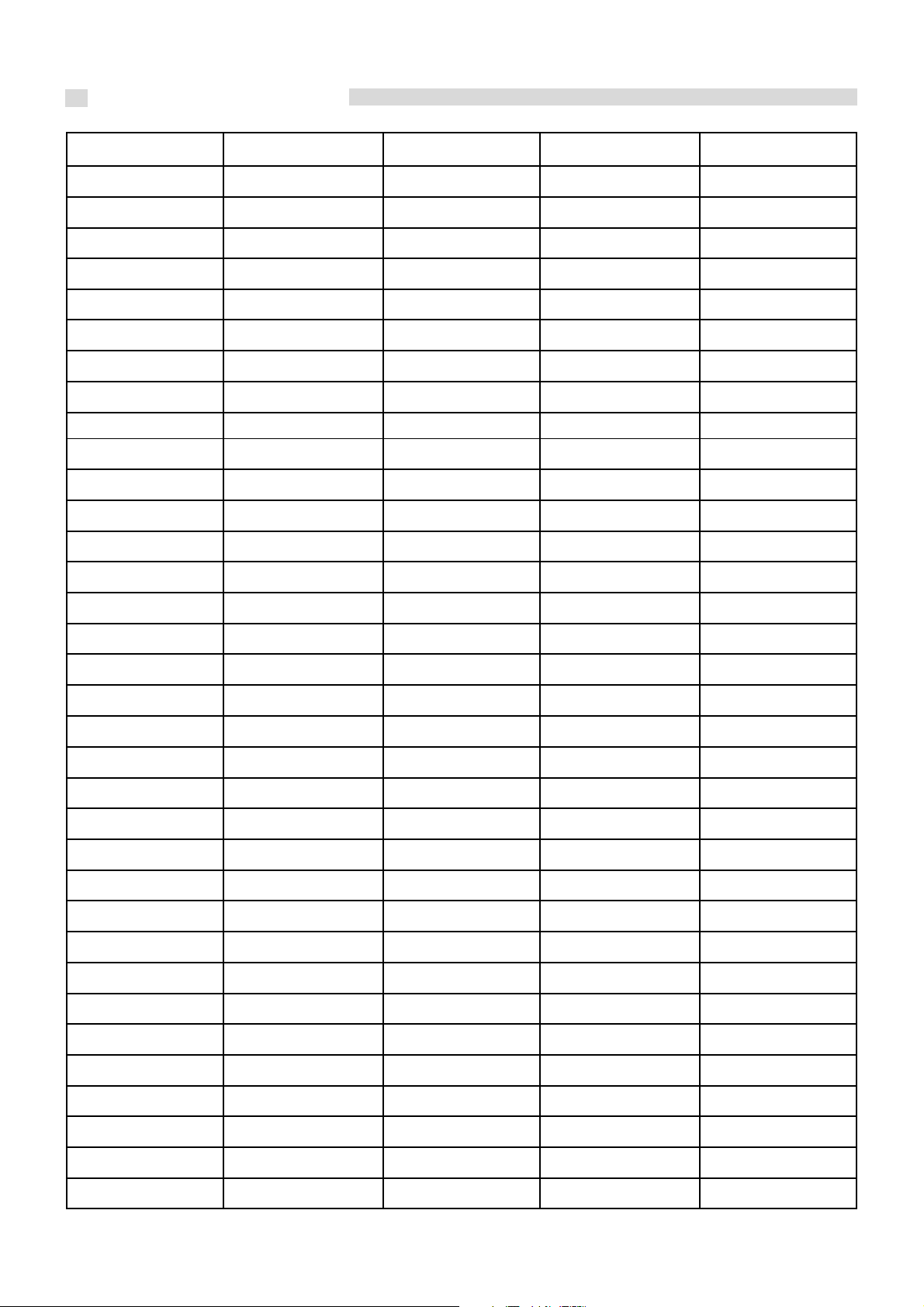

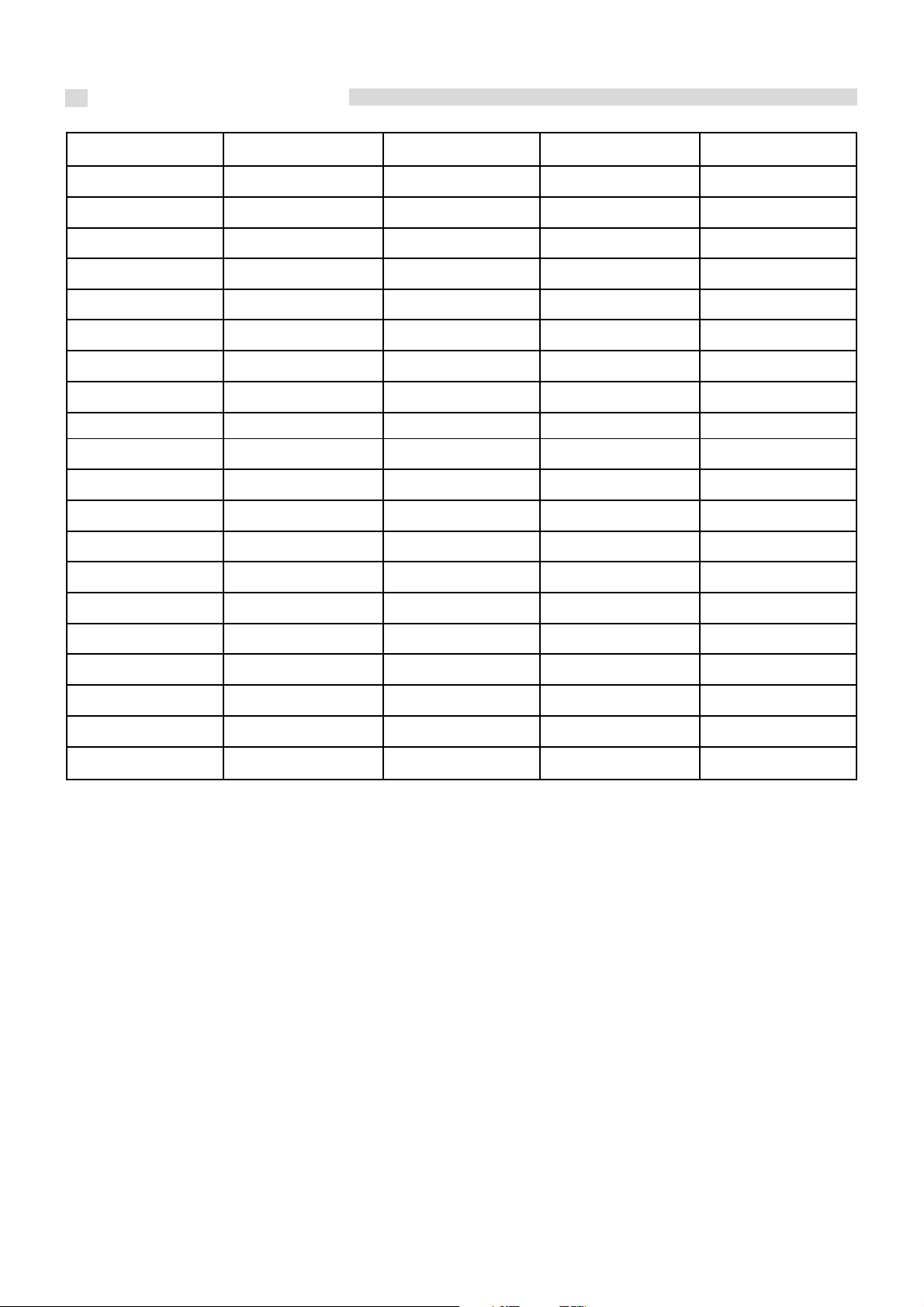

Quality standards for Unit of measurement ÖNORM M 7135 DIN 51731 DIN plus

wood Pellet

Diameter mm from 4 to 10 from 4 to 10 from 4 to 10

Length mm 5 x D

Density Kg/dm

3

1

< 50 5 x D

> 1,12 1,0 – 1,4 >1,12

1

Humidity % < 10 < 12 < 10

Ash % < 0,50 < 1,50 < 0,50

Calorific value kWh/kg > 5 4.86 – 5.42 > 5

Sulphur % < 0,04 < 0,08 < 0,04

Nitrogen % < 0,3 < 0,3 < 0,3

Chlorine % < 0,02 < 0,03 < 0,02

Dusts % weight < 2,3 - < 2,3

Bonding agents % of pressed mass < 2

1

No more than 20% of the pellets can be 7.5 times longer than the diameter D.

2

DIN prohibits use of any added substance. However this prohibition is not valid for small heating systems.

2

< 2

The standard DINplus proposes the combination of quality parameters proposed by the standard DIN 51731 and by the

Austrian standard ÖNorm M 7135.

The pellet, as foreseen by current Italian

legislation governing commodity features of

fuels (DPCM 2.10.1995), must be produced

exclusively with untreated wood sawdust

without other materials added.

It is absolutely forbidden to use any solid or

liquid fuel other than pellets to feed STILE

27.

For best operation of STILE 27, it is

recommended to use pellets the quality of which

is certified by an authorised body. The use of poor

quality pellets can cause STILE 27

malfunctioning and shall terminate the warranty.

Storage and handling of pellets are important operations to

be performed with care:

- The fuel must be stored in a dry place which is not cold;

- Pellets must be moved in such a way to avoid breaking

them up into small powder.

Compliance with these two simple rules provides better

combustion efficiency and conserves the moving mechanical

parts of the appliance.

If STILE 27 remains unlit for long periods

(more than seven days), the tank must be

emptied from residual fuel to keep it from

becoming excessively moist which could

cause the appliance to malfunction.

A high moisture content in the pellet can cause

it to break up into powder generating greater

accumulation of residue in the brazier and

blocking the fuel feed system (screw).

13

Installation instructions

3

INSTALLATION

INSTRUCTIONS

3.1 - GENERAL WARNINGS

ATTENTION!

This heat stove is intended solely for the

use for which it was expressly designed.

Any other use is to be considered improper

and therefore dangerous.

This heat stove heats water to a

temperature lower than the atmospheric

pressure boiling temperature.

ATTENTION!

The appliances are designed to be installed

inside suitable rooms or technical spaces

only. The appliances cannot be installed or

operate outdoors. Outdoor installation can

cause malfunctioning and be dangerous.

Choose specifically designed appliances for

outdoor installation.

Before connecting the heat stove, have

professionally qualified personnel:

a) Thoroughly wash all the piping of the system

to remove any residue or impurities which

could jeopardise proper operation of the

heat stove;

b) Check that the chimney/flue has an

appropriate draught, without any

bottlenecks, and that no exhausts from other

appliances are inserted, unless the flue has

been implemented to accommodate several

utilities according to specific standards and

prescriptions in force. Only after this check

can the fitting between the heat stove and

chimney/flue be mounted;

ATTENTION!

The appliance must be installed by a

qualified technician with the technicalprofessional requirements according to law

46/90 who, under his own responsibility,

guarantees compliance with standards

according to good practice rules.

The heat stove must be connected to a central

heating system and/or domestic hot water

production network compatible with its efficiency

and output.

14

3.2 - INSTALLATION STANDARDS

STILE 27 is a heat stove designed to operate with wood

pellets.

It must be installed according to the following standards:

Standard UNI 10683 of 09/2005

Wood or other solid biofuel fed systems.

Installation requirements.

FIELD OF APPLICATION: wood or other solid biofuel fed

systems with a thermochemical input less than 35 kW.

Standard UNI 11263 of 11/2007

Solid biofuels - Characterization of pellet for energy purposes.

Standard UNI 11264 of 11/2007

Solid biofuels - Characterization of wood logs, briquettes and

chips.

LAW March 5,1990 N° 46 and relative applicative regulation

D.P.R. 447 December 6, 1991 (and subsequent amendments).

Safety standards for systems

FIELD OF APPLICATION: without thermal potential limits.

Installation instructions

Standard UNI 10847 of March 2000.

Single flue systems for generators fed by solid and liquid fuels.

Maintenance and control. Guidelines and procedures.

FIELD OF APPLICATION: systems fed with solid and liquid

fuels.

LAW January 9,1991 N°10 and relative applicative regulation

D.P.R. 412 26/08/93 (and subsequent amendments), D.P.R.

n°551 of 21.12.1999.

Regulation with amendments to Italian Presidential Decree.

n° 412 concerning design, installation, operation and

maintenance of thermal systems in buildings, in order to reduce

energy consumption.

FIELD OF APPLICATION: without thermal potential limits.

Law n°186 of 01.03.1968

Installation standard IEC 64-8 / II ed.

Electric systems using rated voltage no greater than 1000 V

AC and 1500 V DC.

Installation standard IEC 64-8 / I ed.

Electric systems in buildings intended for residential and

similar use.

This appliance must be installed according to that

indicated by the standards in force in the country where

the heat stove is installed.

15

Installation instructions

3.3 - PACKAGING

The STILE 27 heat stove is delivered encased on a pallet

and protected by cardboard packaging.

After having removed packaging, make sure that

the supply is complete and undamaged.

If in doubt, do not use the appliance and contact

the supplier.

To handle the heat stove and to remove the pallet

below, remove the top and, using appropriate

lifting systems, fasten the upper hook intended

for this purpose.

Keep the packaging material (cardboard boxes,

straps, plastic bags, etc.) out of the reach of

children as they are potential sources of

danger.

3.4 - INSTALLATION

STILE 27 is a heat generator which withdraws the combustion

air required for the combustion process directly from the

environment in which it is installed.

For this reason, and above all for the safety of the persons

using STILE 27, it must be installed in a sufficiently ventilated

area so that a continuous flow of combustion air is guaranteed.

It is therefore essential to make air vents linked with the outside

which, in compliance with that indicated by Standard UNI

10683, have the following features:

1. Have a free cross-section no less than 80 cm2;

2. Be made close to the floor;

3. Be appropriately protected by metallic mesh or grille so

that the minimum air passage cross-section is not reduced;

4. Be positioned in such a way that it cannot be obstructed.

The correct air influx can also be guaranteed

by using openings towards an adjacent

room as long as that room is provided with

direct ventilation and it has no fire risks such

as depots, garages or storerooms as

regulated by standard UNI 10683.

STILE 27 should be installed in rooms without appliances

which do not operate in an airtight fashion respect to the room

or appliances which can create a vacuum in the room respect

to the outside environment and therefore hinder the draught

of the flue gas exhaust system (UNI 10683).

To make it easier to clean, there must be a clearance space in

front of the heat stove no less than the length of the stove itself.

You must at least make sure that the door can open 90°

unobstructed

Unical will not be held liable for damage to persons, animals

or objects due to failure to comply with the above instruction.

The document envelope, inserted in the combustion chamber,

contains:

- Heating system booklet

- The installation, maintenance and operating instruction

booklet

- Warranty

- Local ventilation requirements adhesive label

If the heat stove is stored for long periods, it should be

adequately protected.

The heat stove can be placed directly on the floor as it is

equipped with a self-supporting frame.

When inspecting compatibility of the heating system, you

should make sure that the support surface (floor) has a support

capacity (kg) suitable to bear the weight of the product. If it is

not adequate, suitable safety measures should be taken (e.g.

load distribution plate).

Furthermore, should the floor be made of combustible material

(such as parquet) it should be protected by using a sheet of

fireproof material underneath STILE 27 sufficiently wider than

the base.

When installation has been performed, the heat stove must

be horizontal and stable, in order to reduce vibrations and

noise.

However clearance space must be left behind the heat stove

and on both sides to allow the casing to be opened to service

the fan and the pellet feeding screw.

During installation, place the outermost

clearance point of STILE 27 at least 80 cm

from combustible and/or flammable

material. If this distance cannot be

maintained, a thermal protection should be

arranged (UNI 7129, UNI 10683).

Do not approach or touch the outer surfaces

of the combustion chamber with flammable

material as it can reach high temperatures

following continuous use.

16

Installation instructions

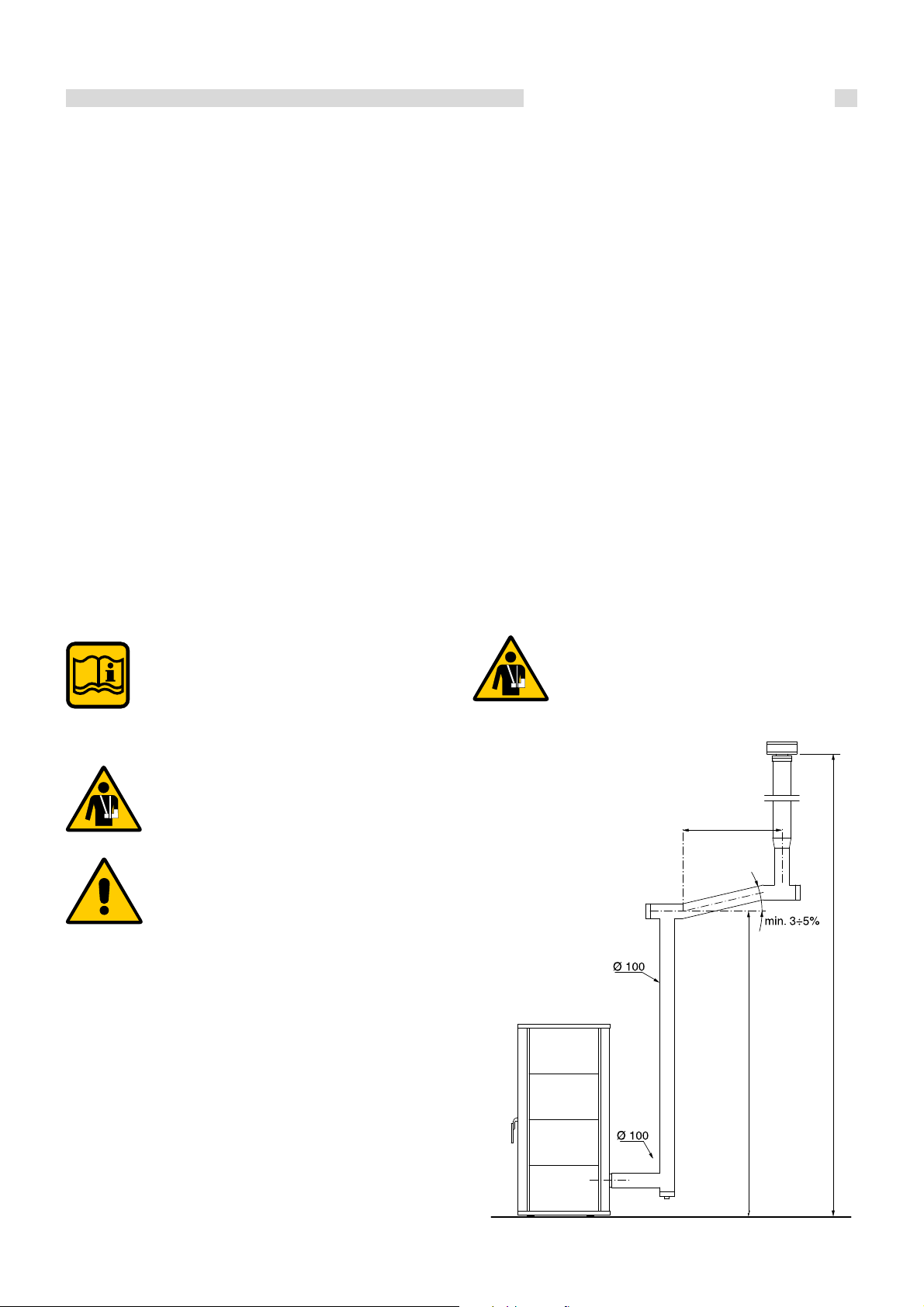

3.5 - FLUECONNECTION

To connect the flue gas exhaust pipe, local and national

standards must be respected (see Standards UNI 7129 and

UNI 10683).

The chimney is of the utmost importance for correct heat stove

operation: it is therefore necessary that the chimney be

waterproof and properly insulated.

Old or new chimneys, built without respecting the specific

requirements, can be recovered by “piping” the chimney itself.

It will be necessary to introduce a metallic pipe inside the

existing chimney and insulate the space between the metallic

pipe and the chimney.

Chimneys made of prefabricated blocks must have perfectly

sealed joints to avoid that flue condensate smudge the walls

due to permeation.

The entrance to the chimney should be at a 45° angle.

At the base of the chimney a flue inspection opening has to be

made.

It is recommended to insulate the pipe connecting to the

chimney to reduce heat loss and noise.

The dimensions of the chimney must guarantee the necessary

draught required to properly operate the heat stove.

An insufficient draught, besides causing smoke leakage,

considerably reduces the heat output. On the contrary, an

excessive draught causes an abnormal heat output increase,

a higher flue gas temperature in the chimney and too much

fuel consumption.

- The flue gas exhaust must be equipped with inspection

plugs;

- The minimum height of the pipe connected directly to the

flue gas exhaust of STILE 27 is between 2÷3 m;

- If a horizontal section is inevitable, it is recommended that

it be no longer than 1.5 m at most and sloping 3÷5% to

favour the escape of the flue gas;

- Use of a weatherproof terminal to avoid altering the

slight state of overpressure found in the flue (do not fit a

horizontal section at the end of the pipe);

- The exhaust ducts must be made with material resistant to

combustion products and condensation (the inspection

plug can drain any condensation which may be formed);

- Pipes must be built in such a way to guarantee maximum

smoke tightness (UNI 10683);

- It is recommended to insulate the exhaust pipe, especially

the outside part exposed to foul weather.

Do not make sections fully horizontal.

There must be no flue gas exhaust hoods installed or

already existing in the room where the heat generator is

installed to avoid creating a vacuum in the environment.

It is prohibited to close the air vents.

It is forbidden to exhaust flue gas through the wall.

Have the flue cleaned at least once a year; we therefore

recommend having both the chimney and the flue gas

fitting thoroughly cleaned.

Use only exhaust pipes suitable for the type

of fuel used.

The supplier will have no contractual or extracontractual liability for damage caused due

to incorrect installation and use and anyway

failure to comply with the instructions

provided by the manufacturer.

It is prohibited to exhaust STILE 27

combustion products in shared smoke

pipes.

The flue must comply with standards in

force.

The flue gas chimney must be made properly

to favour the normal flow of flue gas from

the combustion chamber towards the

outside in the case of a power outage.

Remember that the elimination of excess heat is managed

optimally by the electronic control unit (modulation,

extinction phase etc.).

The following are the main features of the flue gas exhaust

pipe according to that established by standards UNI 7129

and UNI 10683:

Should the flue or piping catch fire,

immediately switch STILE 27 off and

disconnect it from the household electrical

mains.

Weatherproof

terminal

1.5 metres

fig. 6

H > 4 metres

2-3 metres min

Soot container

with

condensation

drain

17

Installation instructions

3.5.1 - EXHAUST THROUGH EXTERNAL WALL

Weatherproof

terminal

One of the installation solutions which can be adopted is that

of positioning STILE 27 near a perimeter wall of the home so

that flue gas is discharged directly outside. Here are some

guidelines from the standard UNI 7129 for this particular type

of configuration:

- Always provide an inspection plug which allows you to

perform efficient and periodical cleaning as well as draining

any condensation formed;

- The chimney must be strictly wind and rain proof;

Soot container with

condensation drain

fig. 7

- Appropriately insulate the flue gas exhaust pipe in the

section passing through the wall.

The flue gas exhaust pipe, if completely outside, should be

made in double wall stainless steel to guarantee both greater

resistance to atmospheric agents and a sufficient flue gas

temperature.

18

Installation instructions

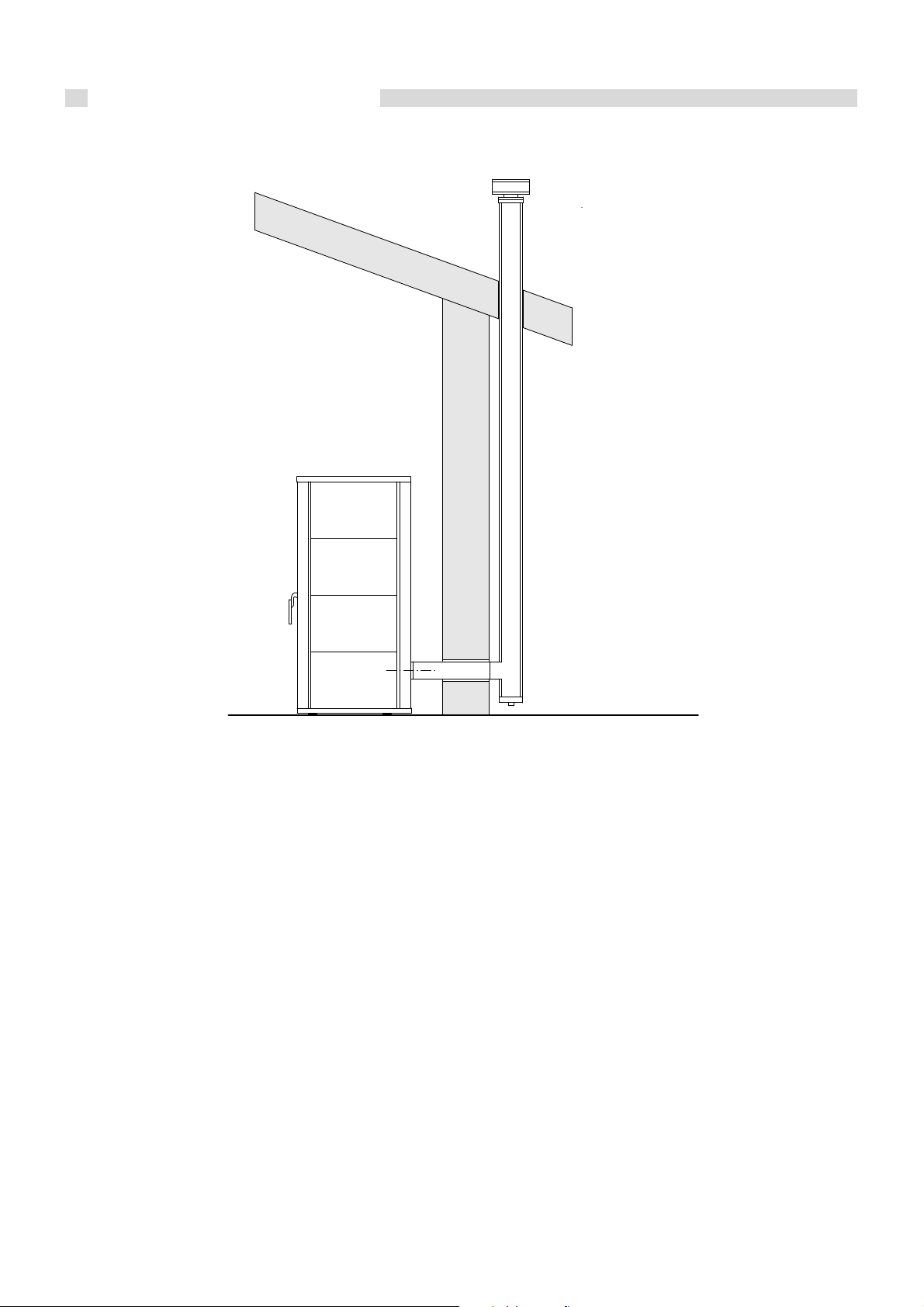

3.5.2 - EXHAUST THROUGH ROOF BY MEANS OF TRADITIONAL FLUE

The pellet combustion flue gas can also be discharged using

a traditional pre-existing flue as long it is made up to standard

(see UNI 10683).

We will briefly list some of the main features highlighted by

the standard which characterise a good chimney:

- Adequate insulation especially in the outside section

exposed to the atmosphere;

- Constant internal cross-section (there must be no crosssection constrictions);

- Made with material resistant to high temperatures, to the

action of combustion products and to the corrosive action

of condensation which could be formed;

- Predominately vertical with deviations no greater than 45°;

Inspectionable soot

container with possible

condensation drain

It is recommended to provide a solid material and/or

condensation collection chamber which can be inspected

through an airtight door.

It is recommended to abide by that established by standards

UNI 9615 and 9731 for the dimensioning of the chimney crosssection and anyhow not to make pipes with a diameter less

than 100 mm.

If there are larger cross-sections, a steel pipe must be inserted

inside the masonry duct.

The steel pipe must be sufficiently insulated

with high temperature resistant material and

sealed from the outer chimney.

fig. 8

19

Installation instructions

3.6 - CONNECTING HEAT STOVE

TO SYSTEM

Attention!

Make sure that there are no mechanical

tension points while connecting the pipes to

avoid the risk of leakage!

Heating flow and return pipes must be connected to the heat

stove at the respective fittings as indicated on page 8.

For the STILE 27 heat stove equipped with the domestic hot

water production kit, see the diagram on page 10.

For the dimensioning of the heating circuit pipes, you must

take into account pressure drops caused by radiators,

3.7 - FILLING THE SYSTEM

Attention!

Do not mix the heating water with incorrect

concentrations of antifreeze or anticorrosion substances! This could damage

the gaskets and cause noise during

operation.

Unical will not be held liable for damage to

persons, animals or objects due to failure

to comply with the instruction above.

After completion of all the hydraulic connections, fill the

heat stove and proceed with the inspection of soundness

of all the connections.

This operation must be performed carefully, respecting the

following phases:

- open the radiator air release valves;

- open the filling tap gradually, making sure that the

automatic air release valves installed on the system work

properly;

- close the radiator air release valves as soon as water

comes out;

- by means of the pressure gauge inserted on the system,

check that pressure reaches approximately 1 bar;

- close the filling tap of the system and bleed air once again

through the radiator air release valves;

-make sure that all the connections are watertight;

-after commissioning the heat stove and bringing

the system to the operating temperature, stop the

pumps and repeat the air bleed operations;

-let the system cool off and, if necessary, return

the water pressure to 1 bar.

NOTE

In systems equipped with closed expansion

vessel, the water pressure in the heating system

- with the system cold - must not drop below 1

bar; open the filling tap when pressure is too low.

This operation must be performed with the system

cool.

thermostatic valves, radiator stopping valves and by the

configuration of the system.

The laying of the pipes must be designed taking every

necessary precaution to avoid air pockets and to facilitate

continuous degassing of the system.

Make sure that the pipes of the water and

heating system are not used as earthing

electrodes of the electric or telephone system.

They are absolutely not suitable for this type of

use. Serious damage could result for the piping,

heat stove and radiators in a short amount of

time.

The pressure gauge fitted on the system allows

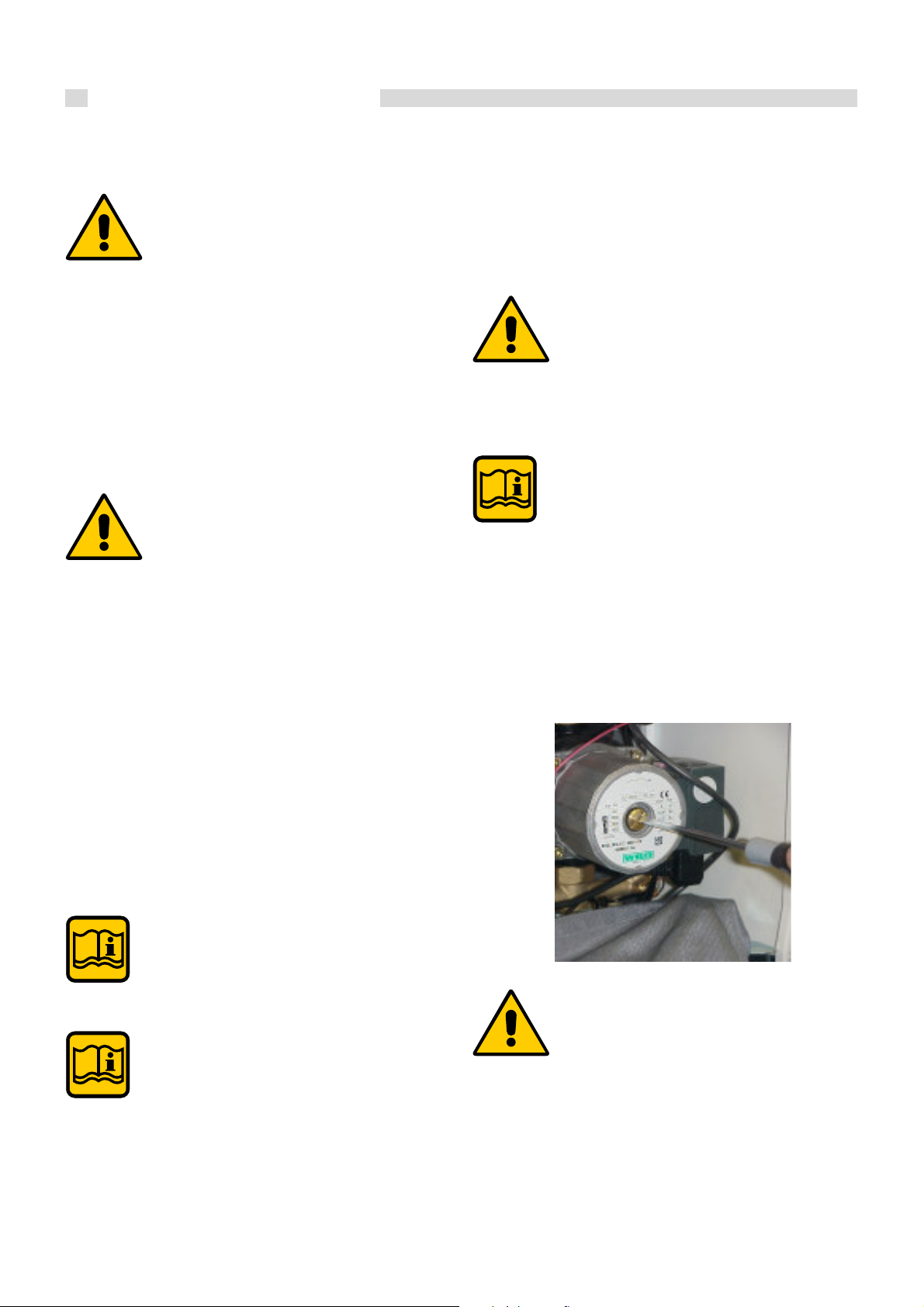

you to read circuit pressure.

NOTE

If the system was without electric power, after a

certain idle period, the pump/s could be blocked.

Before turning on the main switch, the pump must

be unblocked by operating as follows:

Introduce a screwdriver in the hole below the

protective screw in the centre of the pump

intended for this purpose and turn the pump shaft

clockwise.

After having unblocked the pump, tighten the

protective screw and make sure there is no water

leakage.

fig. 9

ATTENTION!

After removing the protective screw, a small

amount of water could leak out. Dry off all wet

surfaces before powering the boiler.

20

4

Installation instructions

ELECTRIC

CONNECTIONS

General warnings

The electrical safety of the system is guaranteed only when it

has been properly connected to an efficient earthing system

carried out as intended by safety standards in force: pipes of

the gas, water and heating systems are absolutely unsuitable

as earthing electrodes.

It is necessary to verify this fundamental safety requirement. If

in doubt, have the electric system carefully checked by

professionally qualified personnel as the manufacturer of the

heat stove is not liable for damage caused by failure to provide

an earthing system.

Have professionally qualified personnel check that the electric

system is adequate for the maximum power absorbed by the

system. Make sure in particular that the cross-section of the

cables is suitable for the power absorbed by the loads.

Adapters, multiple sockets and/or extension cords cannot be

used to power the pumps or other loads from the electric mains.

Use of any type of component using electric energy requires

the observance of some fundamental rules, such as:

• do not touch the appliance with wet and/or moist parts of

the body and/or in bare feet;

• do not pull the electric cables;

• do not leave the appliance exposed to atmospheric agents

(rain, sun, etc.) unless expressly designed;

• do not allow children or unskilled persons to use the

appliance.

Remember that a bipolar switch must be

installed on the heat stove power line with over

3 mm between contacts, easy to access, making

maintenance quick and safe.

The power cable must be replaced by authorised technical

personnel. Failure to comply with the above can jeopardise

the safety of the appliance.

230V electric power supply connection

The general electrical connections are illustrated on page 22

and 23.

Installation of the electrical accessories of the heat stove

requires connection to a 230 V - 50 Hz electric mains: This

connection must performed up to standard as intended by

current IEC regulations.

Danger!

Only a qualified technician may perform the

electrical installation.

Before performing connections or any type

of operation on electrical parts, always

disconnect electrical power and make sure

that it cannot be reconnected accidentally.

21

Installation instructions

CRONO

RELE

AUX

FUS

CN8

TRASFORMATORE

SERIALE

CN13

DISPLAY

FUM

CN2

COD. I023_3

CN5

CN1

PE

CN14

N FSCA

COCACCAL1 AL2NV2/PO

CN4

CN6

CN7

CN9

CN15

CN11

JTAG

ENC +5V GND

BLU N.PEL N.H2O N.AMB TERM -TC1+

BUZZER

Terra

Rete 230V 50Hz

M

M

Ventilatore

Fumi

Encoder

ventilatore fumi

ALC = Depressimetro

ALP = Termostato sicurezza vano pellet

ALM = Termostato sicurezza acqua

Candeletta

Coclea

Spina

Wieland

Sonda

acqua

Sonda

fumi

ALC

ALP

blu

blu

blu

grigio

grigio

blu

marrone

marrone

azzurro

rosso

bianco

Ter most.

ambiente

verde

marrone

FILTRO

DI RETE

230V

* posizionata sul posteriore della caldaia

T.A.

(esterno)

*

PI

ALM

Trasduttore

di pressione

OUT giallo

- marrone

+ verde

PRACTICAL WIRING DIAGRAM

Earth

MAINS

FILTER

TRANSFORMER

RELAY

Grey

blue

blue

brown

light blue

brown

blue

230V 50Hz mains

Flue gas

fan

brown

green

Pressure

transducer

Yellow

SERIAL

White

brown

green

Flue gas fan

encoder

probe

Water

CHRONO

probe

Room

temperature

Red

Blue

Screw

Grey

Igniter

probe

Flue gas

ALC = Depression thermostat

ALP = Pellet compartment safety thermostat

ALM = Water safety thermostat

* positioned at back of boiler

Wieland

Plug

Room

thermostat

(external)

fig. 10

22

Installation instructions

estate

inverno

Spina

Wieland

T.A.

caldaia

T1

Presa

Wieland

Spina

Wieland

giallo/verde

Spina

Wieland

N (azzurro) neutro

L1 (nero) riscaldamento

L2 (marrone) sanitario

T1 (azzurro)

T2 (marrone)

T2

Presa

Wieland

Presa

Wieland

valvola

deviatrice

termostato

ambiente

flussostato

230V ~ 50Hz

alimentazione

E/I

N

Fase (230V~ 50Hz)

I

Relé

12V

E

Flussostato

Trasformatore

12V

C

NA

NC

r

r

Valvola

deviatrice

a 3 vie

azzurro

nero

riscaldamento

marrone

sanitario

Termostato

ambiente *

T1 T2

* NOTA: in caso di montaggio del TERMOSTATO AMBIENTE,

togliere il ponte sulla presa Wieland; vedere figura sopra.

C

NA

PRACTICAL WIRING DIAGRAM (with DHW production kit)

summer

winter

power supply

room

diverter

valve

thermostat

flow switch

Wieland

socket

Wieland

plug

yellow/green

L2 (brown)DHW

N (light blue) Neutral

Phase (230V ~50Hz)

L1 (black) heating

Flow switch

Relay

Transformer

* NOTE: when mounting the ROOM THERMOSTAT, remove the

bridge on the Wieland socket; see figure below.

Wieland

socket

Wieland

plug

boiler

T.A.

black

heating

Wieland

plug

Wieland

socket

T1 (light blue)

3-way

diverter

valve

light blue

T2 (brown)

brown

(DHW)

Room

thermostat

fig. 11

23

Installation instructions

HEAT STOVE

5

START-UP

5.1 - COMMISSIONING

Preliminary checks

Commissioning must be done by

professionally qualified personnel. Unical

will not be held liable for damage to persons,

animals or objects due to failure to comply

with the instruction above.

Before commissioning the heat stove check that:

- the adduction of combustion air and flue gas evacuation

are performed correctly according to that laid down by

standards in force;

- the heat stove is provided with all safety and control devices

prescribed by current standards;

- the power supply of the electrical accessories of the heat

stove is 230V - 50Hz;

- the system is filled with water;

- any system shut-off gate valves are open;

- the external main switch is connected;

- the system safety valve is not blocked and is connected to

the sewer system drainage;

Switching boiler on and off

To switch the heat stove on and off, see chapter 7.1.

Information for user

The user must be instructed concerning the use and operation

of his heating system, in particular:

• Deliver these instructions to the user, as well as other

documents concerning the appliance inserted in the

envelope inside the packaging. The user must keep this

documentation for future consultation.

• Inform the user about the importance of the air vents and

the flue gas exhaust system, highlighting their essential

features and the absolute prohibition of modifying them.

• Inform the user concerning controlling the system’s water

pressure as well as operations to restore it.

• Inform the user concerning correct temperature control,

control units/thermostats and radiators for saving energy.

• Remember that the system must receive regular

maintenance at least once a year and a combustion

analysis must be performed if foreseen by standards in

force.

• Should the appliance be sold or transferred to a new owner

or if you move and leave the appliance, always make sure

that the instruction booklets accompany it in order to be

consulted by the new owner and/or installer.

- there is no water leakage;

- ventilation conditions and minimum distances are

guaranteed to perform maintenance.

5.2 - CHECKS AT

COMMISSIONING

GENERAL CONTROLS

Upon commissioning: check that the C.H. system

is full of water and is properly purged, that the

chimney has a sufficient draught, that the electrical

connections have been made correctly (chap. 4)

and that the system’s service pump is not blocked.

24

Inspections and maintenance

6

INSPECTIONS AND

MAINTENANCE

Inspections and maintenance performed

professionally and according to a regular

schedule as well as the use of original spare

parts are of the utmost importance for faultfree operation of the heat stove and to

guarantee its long life.

Maintenance of the appliance is mandatory

in compliance with Laws in force, at the

frequency laid down by D.P.R 412 of August

26, 1993 and subsequent amendments,

concerning the type of fuel used and the heat

stove output.

Failure to perform Inspections and

Maintenance can entail material and

personal damage.

We therefore recommend stipulating an inspection or

maintenance contract.

Inspections help to determine the actual status of the appliance

and to compare it with the nominal status. This is done through

measuring, controls and observation.

Maintenance is required to eliminate any differences between

the actual status and the nominal status. This is normally done

by cleaning, setting and replacing individual components

subject to wear.

Inspection and maintenance instructions

To assure long-term functioning of your

appliance and to avoid altering its approved

status, only original Unical spare parts must

be used.

Before proceeding with maintenance, always perform the

following operations:

• Disconnect the electric mains switch.

• Isolate the appliance from the electric mains by means of

an isolated device with a contact opening of at least 3 mm

(e.g. safety devices or power switches) and make sure that

it cannot be re-connected accidentally.

• Close any shut-off valves on the heating flow and return

pipes, as well as the cold water inlet valve.

After having completed all maintenance work, always perform

the following operations:

• Open the heating flow and return pipes, as well as the

cold water inlet valve.

• If necessary, restore the heating system pressure.

• Reconnect the appliance to the electric mains and engage

the switch.

• Make sure the appliance is flue gas tight and watertight.

• Vent the heating system and restore pressure if necessary.

Maintenance intervals and their extent are determined by a

specialist based on the status of the appliance ascertained

through inspection.

Inspection and maintenance jobs must be performed in the

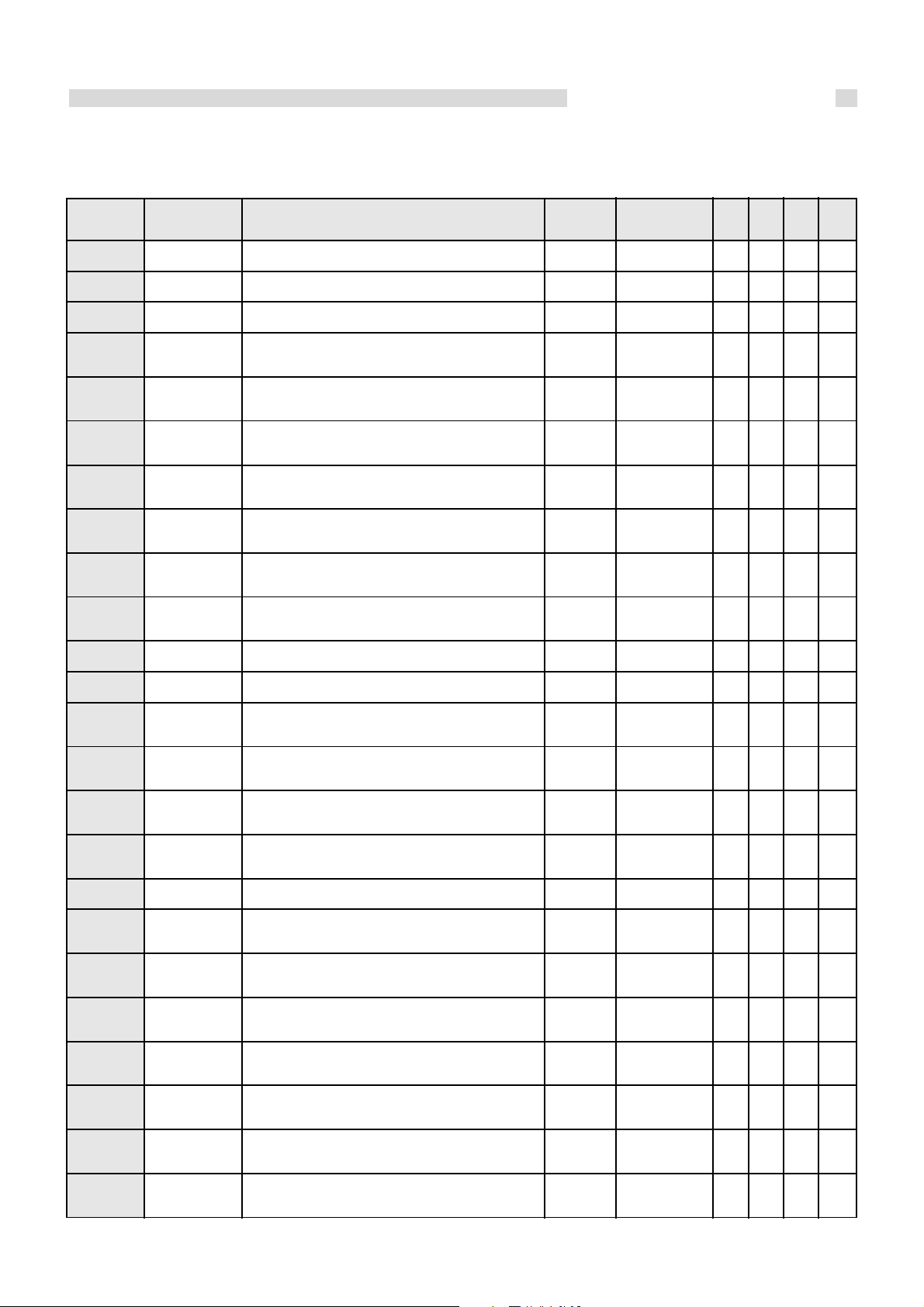

order shown on page 26.

25

Inspections and maintenance

Boiler body maintenance

Danger!

Before performing any maintenance, make

sure the heat stove and its components

have cooled down.

Warnings

Never drain water from the system, even partially, unless

absolutely necessary.

Periodically check the proper operation and integrity of the

flue gas exhaust pipe and/or device.

If work or maintenance is performed on the structures near

the flue gas pipes and/or flue gas exhaust devices and their

accessories, switch the appliance off and, when the work is

over, check their efficiency.

Do not clean the heat stove and/or its parts with easily

flammable substances (e.g. petrol, alcohol, etc.).

Do not leave flammable substances in the room where the

heat stove is installed.

Do not clean the boiler room while the heat stove is running.

- Remove the bottom panel with the furnace door open,

pulling it by the top part to release it from the blockage

system.

Extract the two ash pans and empty them. To extract the

pans, turn the front pins until they release from the blockage

system.

- IMPORTANT! STILE 27 is equipped with an internal heat

exchanger unit cleaning system which is controlled by

repeatedly pushing the lever in the inner top part of the

pellet combustion chamber.

This operation must be repeated until it slides without any

resistance.

Cleaning the surface of the heat exchanger pipes

guarantees the most efficient thermal exchange possible.

- It could also be necessary to clean the glass as it inevitably

gets dirty.

The frequency of this cleaning depends on use and the

quality of the pellets.

Clean the glass when it is completely cooled off, using

specific nonabrasive cleansers.

When cleaning is finished, put all pieces back in place

acting in the opposite order.

The frequency with which the glass is cleaned is

linked to how much the heat stove is used.

At the end of each heating period, inspect the heat stove to

keep the system in perfect efficiency.

Thorough maintenance always enhances energy saving and

safety.

IMPORTANT

Use brushes and a vacuum cleaner to clean

the heat stove; if rags are used, make sure they

are all recovered.

CLEANING AND ROUTINE MAINTENANCE STILE 27

STILE 27 must receive regular maintenance to guarantee its

correct and efficient operation.

The following cleaning operations must be performed only

when the heat stove is completely cold and disconnected

from the household electric mains.

Daily

- Remove the ashes from the combustion chamber using a

vacuum cleaner intended for recovery of combustion

products.

- This operation will be easier by removing the crucible from

the combustion chamber, as shown in the following figure.

Check the integrity of the bottom grate of the crucible and

in case of doubt, have it replaced.

Eliminate incrustations which obstruct the air passage

vents.

Remove any slag deposited around the crucible support.

fig. 12

26

LOADING THE PELLET

Access the pellet tank by lifting the top cover.

We recommend using only guaranteed quality pellets: this

will allow STILE 27 to work with high efficiency, to save on

maintenance and to make your heat stove last longer.

EXTRAORDINARY MAINTENANCE STILE 27

Inspections and maintenance

fig. 13

At the end of each heating season, perform a general cleaning

of the heat stove acting as follows. During summer, keep the

heat stove door closed.

- Clean the combustion chamber using a vacuum cleaner

intended for recovery of combustion products after having

removed the crucible.

- Remove the top cover by pulling it upwards.

- Disassemble the top cover and clean the heat exchanger

pipe unit with a vacuum cleaner.

- Remove the bottom front panel (pulling the top) and empty

the pans.

Vacuum the combustion residue.

- Check the integrity of the glass door sealing gasket and

the air tightness of the combustion chamber.

Replace the gasket if necessary.

- We recommend emptying the pellet tank completely at the

end of the heating season to prevent it from deteriorating

due to moisture, causing possible malfunctioning the next

time it is lit.

- We also recommend thoroughly cleaning both the chimney

and the flue gas fitting to avoid the risk of a fire.

- Put all the components back in place, sealing the required

parts with high temperature resistant silicon.

Every two years, clean the steel impeller of the flue gas intake

fan and its housing.

It can be reached after having pulled off the top and side

panels and having removed the 4 screws.

It can be cleaned conveniently with a vacuum cleaner.

Check the integrity of the pellet feeding system (screw, control

motor, thrust bearing) and have it overhauled if necessary.

Check the correct positioning of the pellet ignition resistance.

Check the preload of the expansion vessel which must be

approximately 1 bar with the system cool.

27

Inspections and maintenance

6.1 - TROUBLESHOOTING

This paragraph provides the purchaser of our product with a quick and efficient guide to understand problems which could

arise while using STILE 27.

Problem found

The remote control display does

not switch on.

The remote control display

indicates NO FIELD.

The fan does not work.

Repeated failed ignitions,

the flame is weak, the crucible

fills up with fuel.

Possible cause

1 Batteries missing / discharged.

2 The remote control is faulty.

1 The heat stove is disconnected from the

electric mains.

Possible temporary power cut.

2 Protective fuse blown.

3 Main switch at rear of heat stove could

be OFF.

1 Possible obstruction of tangential fan

inlets.

2 The fan could be burnt or blocked.

3 Malfunctioning of sensors or circuit

board.

1 Possible obstruction of combustion air

inlet of crucible or its holes.

2 The pellet could be too moist.

3 Electric or electronic problem in board.

4 The ignition resistance or thermal probe

could be faulty.

5 The door could be closed improperly.

6 Improper functioning of combustion air

exhaust system (flue gas fan).

Remedy

1 Insert/replace the batteries.

2 Contact technical assistance.

1 Make sure power is present and that the

power cable is connected.

2 Contact technical assistance.

3 Place the switch at ON.

1 Contact technical assistance.

2 Contact technical assistance.

3 Contact technical assistance.

1 Empty the pellet crucible.

Clean the crucible and make sure the

combustion air passage holes are not

obstructed.

2 Change the type of pellet (see

specifications on page 10).

3 Contact technical assistance.

4 Contact technical assistance.

5 Contact technical assistance to replace

the gaskets.

6 Contact technical assistance.

The pellet does not drop into the

brazier.

Low level of hot water in

radiators.

Heat stove blockage due to fuel

gas overtemperature.

Heat stove blockage due to

water overtemperature.

Faulty control unit watch.

Should these possible solutions fail to resolve the problem you detected, please contact the customer assistance service for

further information.

28

1 Pellet tank empty.

2 The pellet feeding gearmotor is faulty.

3 Faulty electronic control unit.

1 Air in system.

2 Possible pump malfunctioning.

3 Faulty water temperature probe.

4 Faulty electronic control unit.

1 Flue gas exchanger obstructed.

2 Faulty fuel gas temperature probe.

1 Safety thermostat needs to be reset.

2 Safety thermostat faulty.

3 Faulty electronic control unit.

1 Watch buffer battery flat.

1 Fill pellet tank.

2 Contact technical assistance.

3 Contact technical assistance.

1 Bleed the system.

2 Contact technical assistance.

3 Contact technical assistance.

4 Contact technical assistance.

1 Contact technical assistance to clean the

flue gas circuit.

2 Contact technical assistance.

1 Reset the safety thermostat in the rear of

the heat stove.

2 Contact technical assistance.

3 Contact technical assistance.

1 Contact technical assistance.

Programming setting

PROGRAMMING

7

SETTING

7.1 - USING THE PRODUCT

Before describing in detail how to operate the product, we remind you that it is mandatory to respect the relevant national and

local provisions, rules and laws in force.

To better understand how to operate the product, we have provided diagrams accompanied by an in-depth description of the

remote control and the programming modes of the product, as well as operations to be performed to commission STILE 27.

STILE 27 is lit very easily. After having connected it to the household electric mains, press the ON/OFF key only after having

properly connected the product to an adequate water system (see our installation guidelines).

It is strictly forbidden to operate STILE 27 without having properly connected it to an adequate water

system, or else the warranty shall be terminated.

The first few times that the heat stove is lit, there could be vapours and bad smells of the painted parts.

These problems are intrinsic to the chemical stabilising process of the special paint used. Therefore the

room must be well ventilated during this phase.

Remember that the appliance must always operate with the combustion chamber door closed.

Though the surface temperatures which our appliance reaches are not extremely high, we recommend

the utmost attention and caution when touching it. The outer surfaces of the combustion chamber in

particular can become red-hot ensuing intensive use.

Place the outermost clearance point of the heat stove 80 cm from combustible and/or flammable material.

If this distance cannot be maintained, a thermal protection should be arranged (UNI 7129, UNI 10683).

To avoid the onset of malfunctioning which could in turn be a source of damage to persons or objects,

we recommend avoiding switching the appliance on and off suddenly and continuously, but to follow

the timetables foreseen by the manufacturer for these operations.

We also recommend thoroughly cleaning both the chimney and the flue gas fitting (at least once during the

whole season of operation) to avoid the risk of a fire.

The appliance must operate with the ash pan hermetically shut.

We recommend to avoid operating the heat stove with an instable electric power supply; continuous

blackouts could cause malfunctioning.

29

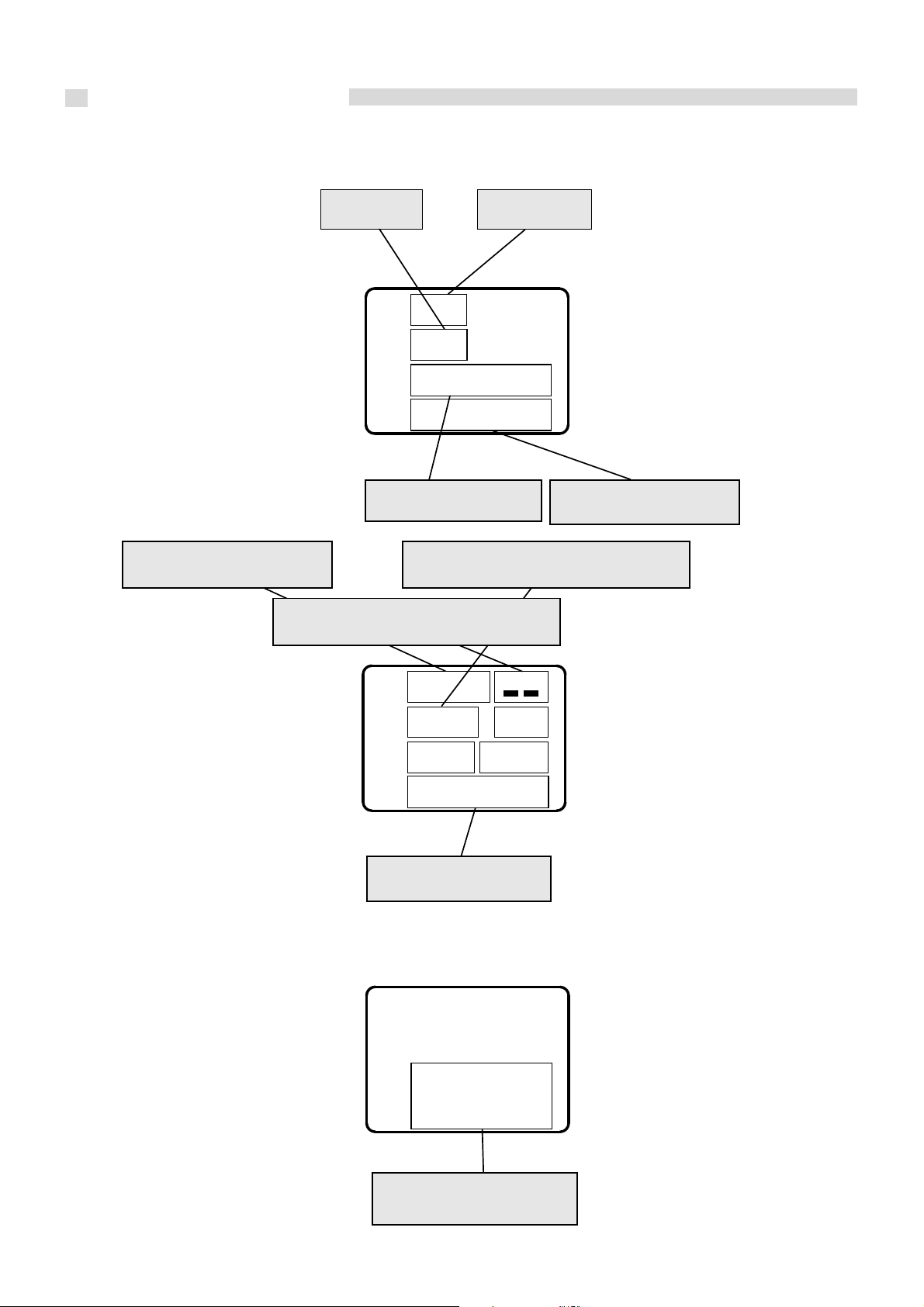

Programming setting

08 : 10

M-2-3-01

PROG-1

START

input livello di menù

dialogo

14 : 24

21°C

SPENTO

orologio temperatura ambiente

dialogo temperatura acqua

45°C

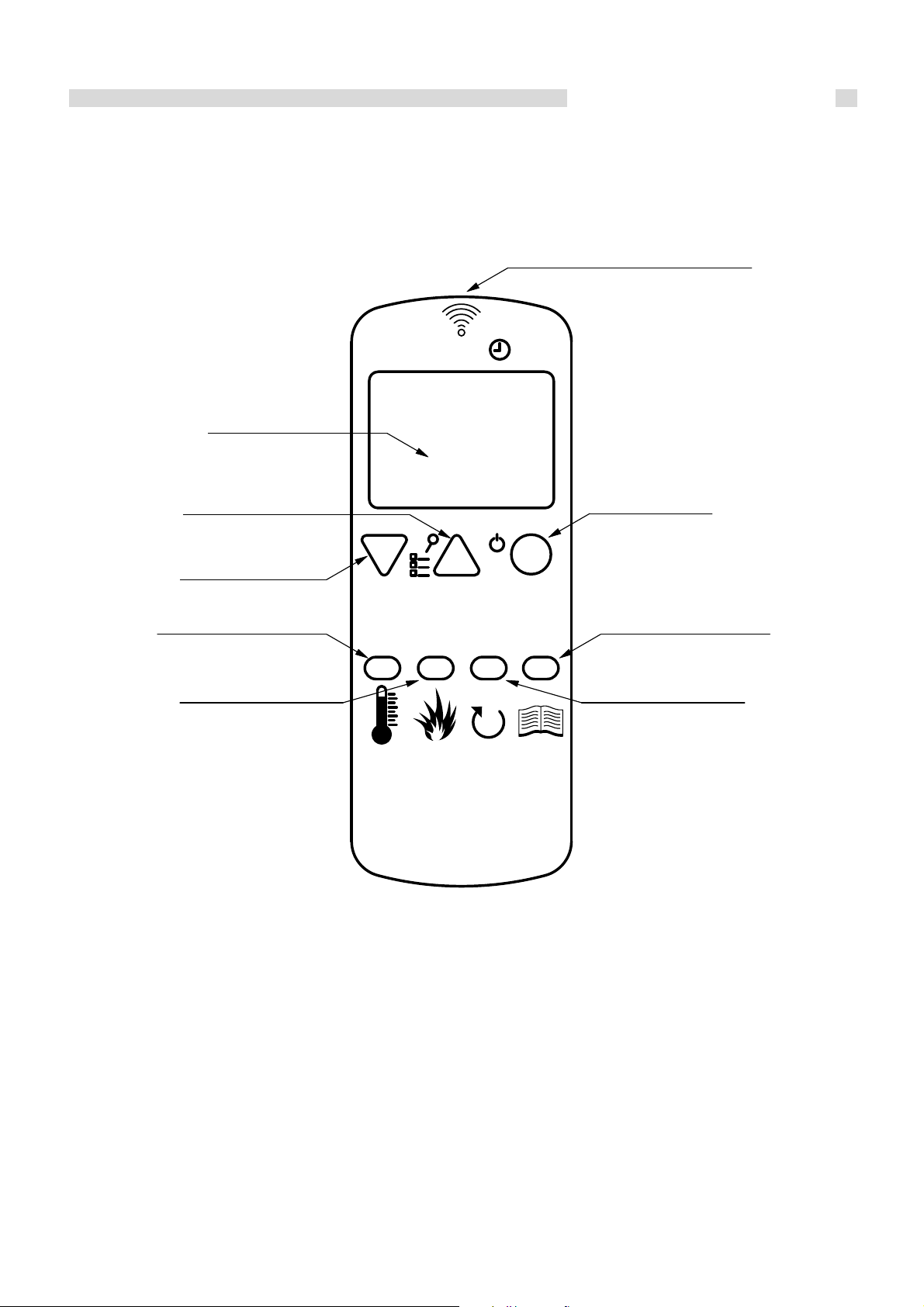

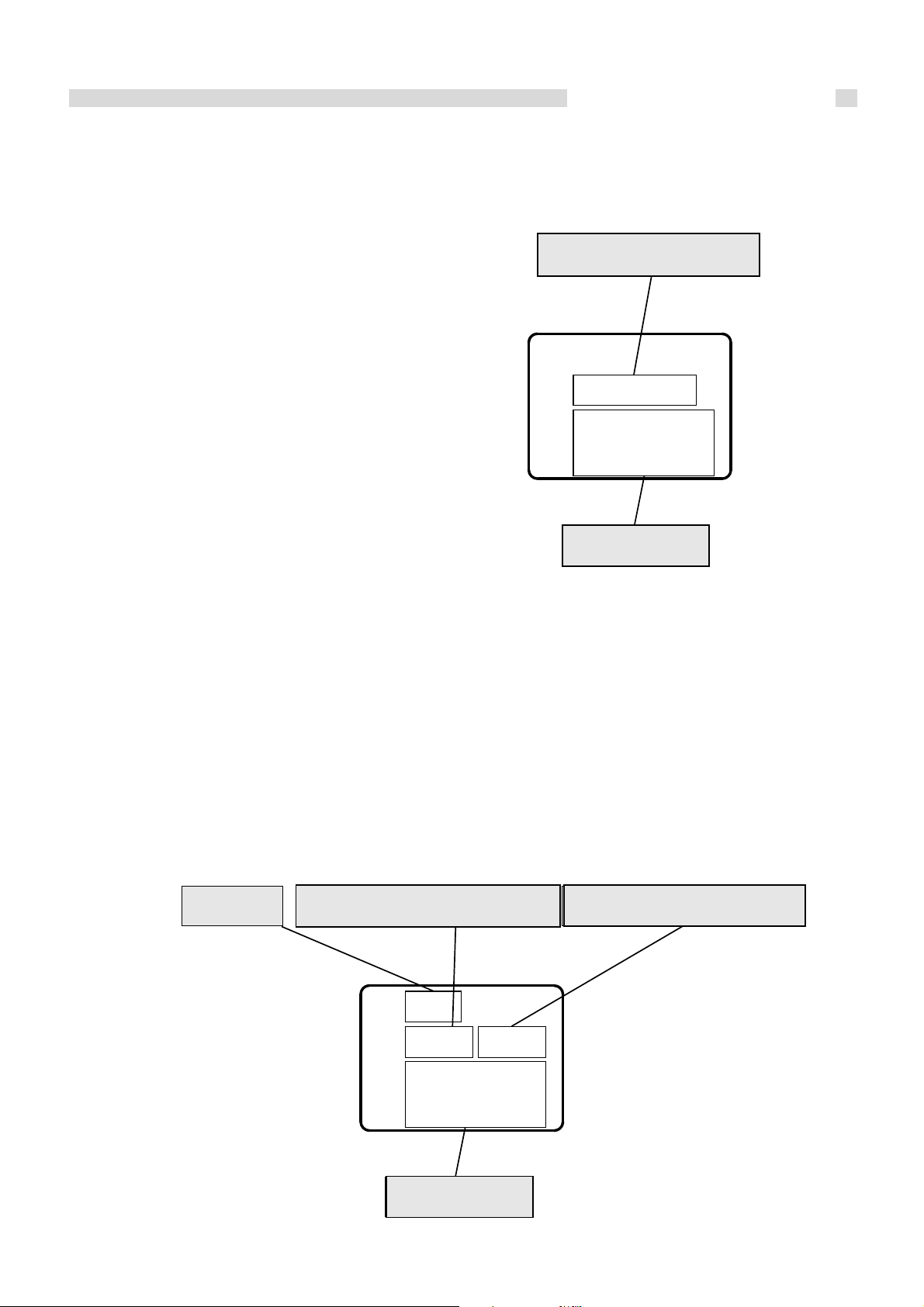

7.2 - REMOTE CONTROL

The remote control displays information concerning the

operating status of STILE 27.

By accessing the menu, you can obtain various types of

displays and perform the settings available depending on the

access level.

Depending on the operating mode, the displays can take on

different meanings according to the position on the screen.

Example with STILE 27 off.

clock

The following figure shows the arrangement of the

messages during programming or operating parameter

setting. In particular:

- The input area displays the entered programming values.

- The menu level area displays the current menu level. See

the menu chapter further on.

room temperature

water temperaturedialogue

fig. 14

input

30

menu level

dialogue

fig. 15

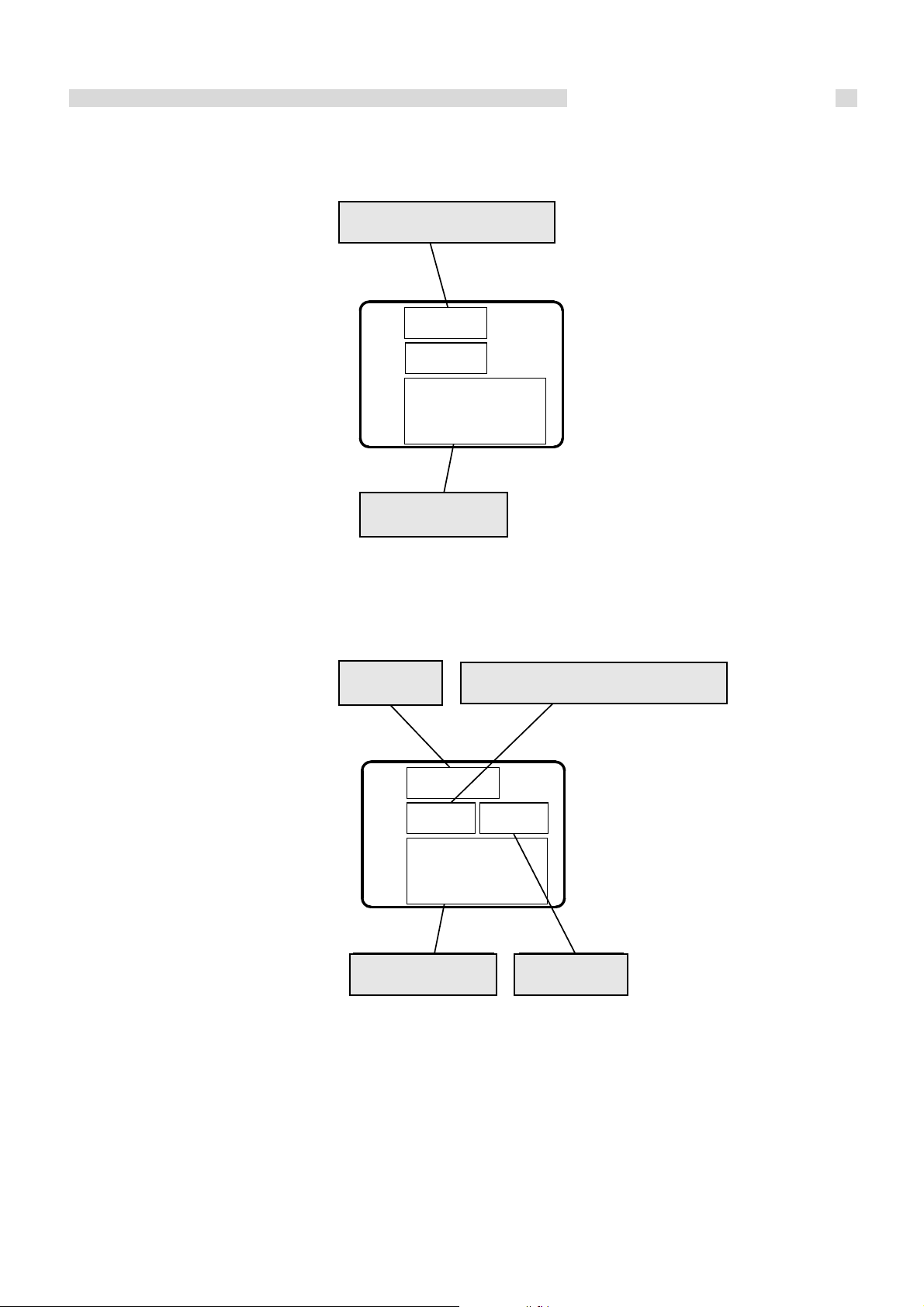

1 2 3

4 5 6 7

DISPLAY

INCREMENTO

DECREMENTO

SET TEMPERATURA

AMBIENTE

Scorri menù

ON / OFF

ESCI DA MENÙ

ACCESSO AL MENÙ/

CONFERMA DATO

SET TEMPERATURA

ACQUA DI CALDAIA

SENSORE TEMPERATURA

AMBIENTE

SET POTENZA

Scorri menù

The figure below, describes the keys of the remote control

and the functions linked to them.

The set operations are viewed on the display.

DISPLAY

INCREASE

Programming setting

SET ROOM

TEMPERATURE

ON/OFF

EXIT MENU

DECREASE

SET ROOM

TEMPERATURE

Scroll menu

SET OUTPUT

Scroll menu