Unical PK 150 X 2S, PK 230 X 2S, PK 300 X 2S, PK 348 X 2S Installation And Servicing Instructions

PK 150 X 2S

PK 230 X 2S

PK 300 X 2S

PK 348 X 2S

00334158 - 1st edition - 05/2012

INSTALLATION

AND SERVICING

INSTRUCTIONS

2

General Information

CONTENTS

1 GENERAL INFORMATIONI .................................................................................................................................................................................. 3

1.1 Symbols used in this manual ....................................................................................................................................................................... 3

1.2 Correct use of the appliance ....................................................................................................................................................................... 3

1.3 Water treatment ............................................................................................................................................................................................ 3

1.4 Information to be handed over to the user or the person in charge of the appliance ............................................................................. 3

1.5 Safety warnings ............................................................................................................................................................................................ 4

1.6 Data plate ...................................................................................................................................................................................................... 5

1.7 General warnings ......................................................................................................................................................................................... 6

2 TECNICAL FEATURES AND MACHINES ........................................................................................................................................................... 7

2.1 Tecnical featuers .......................................................................................................................................................................................... 7

2.2 Dimensions ................................................................................................................................................................................................... 8

2.3 Performance data ....................................................................................................................................................................................... 10

2.4 Main components ....................................................................................................................................................................................... 11

3 INSTRUCTIONS FOR THE INSTALLER ............................................................................................................................................................ 12

3.1 General warnings ...................................................................................................................................................................................... 12

3.2 Standard codes of installation .................................................................................................................................................................. 13

3.3 Packaging .................................................................................................................................................................................................. 14

3.4 Handling and lifting .................................................................................................................................................................................... 15

3.5 Installation on existing heating system .................................................................................................................................................... 15

3.6 Boiler location ............................................................................................................................................................................................ 16

3.7 Chimney conection ................................................................................................................................................................................... 16

3.8 Condensaet drainage ................................................................................................................................................................................ 18

3.9 Boiler connection ....................................................................................................................................................................................... 19

3.10 Gas conection ........................................................................................................................................................................................... 20

3.11 System connection .................................................................................................................................................................................... 21

3.12 Determination of primary circuit pump or boiler system pump .............................................................................................................. 22

3.13 Frost protection ......................................................................................................................................................................................... 23

3.14 Mixing header and plate heat exchanger ................................................................................................................................................ 26

3.15 Water treatment ......................................................................................................................................................................................... 27

3.16 Casing assembly ....................................................................................................................................................................................... 28

3.17 Filling the system ....................................................................................................................................................................................... 28

3.18 Electrical connections ............................................................................................................................................................................... 29

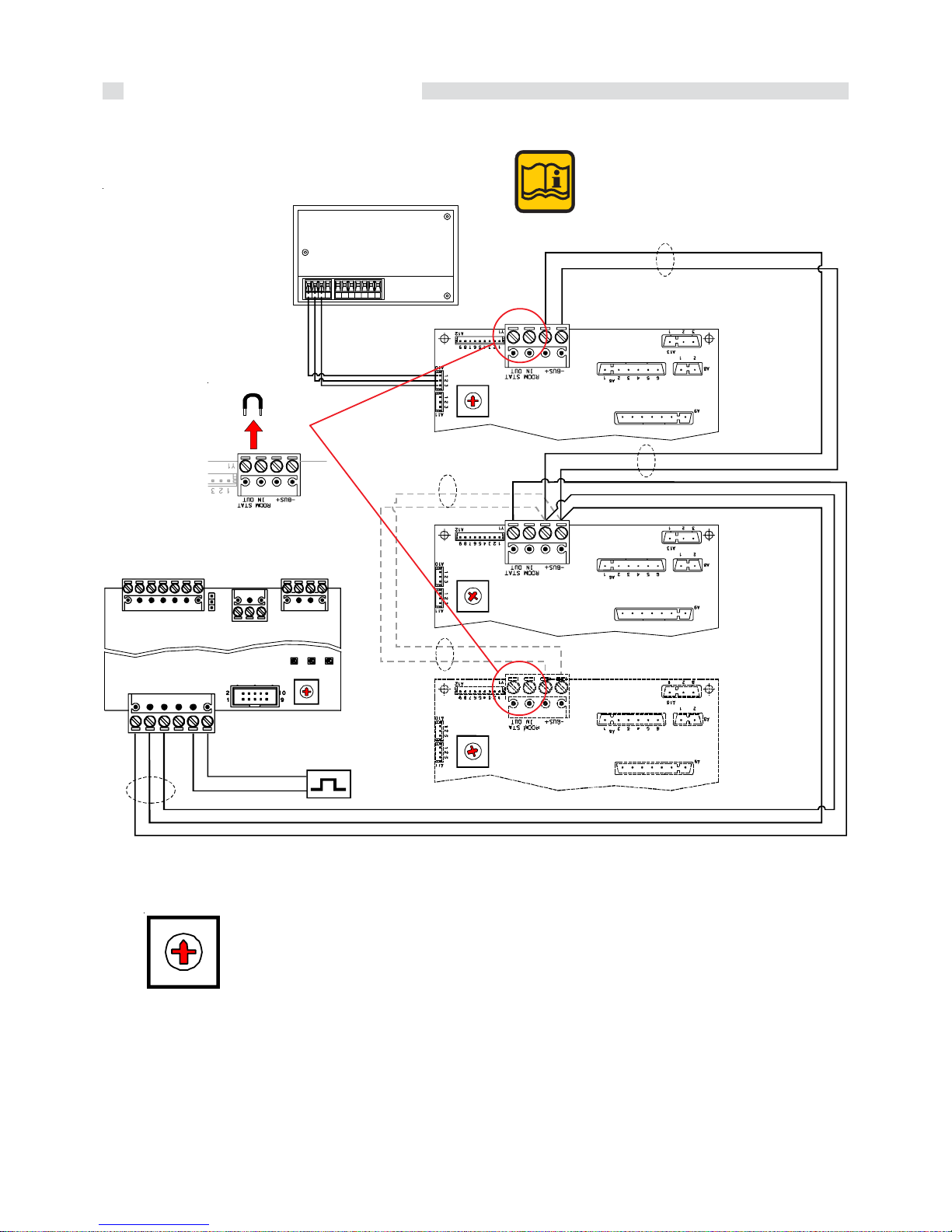

3.19 Functional low wiring diagram .................................................................................................................................................................. 31

3.20 Types of installation ................................................................................................................................................................................... 32

3.21 Electrical panel .......................................................................................................................................................................................... 34

3.22 Wiring connection for electrical panel ...................................................................................................................................................... 35

3.23 Wiring connection panel within multiinox Master + Slave ....................................................................................................................... 35

3.24 Table positioning selector and cards ........................................................................................................................................................ 37

3.25 Installation examples ................................................................................................................................................................................. 38

3.26 Initial lighting ............................................................................................................................................................................................... 41

3.27 Burner pressure adjustment .................................................................................................................................................................... 42

3.28 Test mode .................................................................................................................................................................................................. 44

3.29 Programming of the operating modes ..................................................................................................................................................... 46

3.30 Operatività di emergenza e sicurezze .................................................................................................................................................... 48

4 INSPECTION AND MAINTENANCE .................................................................................................................................................................. 49

6 CE CERTIFICAT ................................................................................................................................................................................................. 52

Warning: this manual contains instructions to be used exclusively by the

installer and/or a competent person in accordance with the current laws in

force.

The end user MUST not make any alterations to the boiler.

Failure to follow the instructions indicated in this manual, which is supplied

with the boiler, could cause injury to persons, animals or damage to property.

UNICAL shall not be held liable for any injury and/or damage.

3

General Information

1.1 -SYMBOLS USED IN THIS GUIDE

When reading this guide particular care has to be given to the parts marked with the followings symbols:

1.2 - CORRECT USE OF THE APPLIANCE

The PKX appliance has been designed utilizing today’s heating technology and in compliance with the

current safety regulations.However, following an improper use, dangers could arise for the safety and life

of the user or of other people, or damage could be caused to the appliance or other objects.The appliance

is designed to be used in pumped hot water central heating systems. Any other use of this appliance will be

considered improper. UNICAL declines any responsibility for any damages or injuries caused by an improper

use; in this case the risk is completely at the user’s responsibility . In order to use the appliance according

to the scopes it was designed for it is essential to carefully follow the instructions indicated in this guide.

1.3 - WATER TREATMENT (refer to specific guide)

1

GENERAL INFORMATION

NOTE!

Suggestions for the

user

WARNING!

Indicates a potentially dangerous

situation for the product and the

environment

DANGER!

Indicates serious danger

for your personal safety

and for your life

• The hardness of the mains water supply conditions the frequency with which the heat exchanger is

cleaned.

• In hard water areas where the main water can exceed 15°f total hardness, a scale reducing device is

recommended. The choice of this device has to be made taking into consideration the characteristics

of the water.

• We recommend you to check the state of cleanliness of the domestic hot water heat exchanger at the

end of the first year and subsequently every two years; in this occasion check the state of wear of the

anode.

1.4 - INFORMATION TO BE HANDED OVER TO THE USER

The user has to be instructed on the use and operation of his heating system, in particular:

• Hand over these instructions to the end user, together with any other literature regarding this appliance,

placed inside the envelope contained in the packaging. The user has to keep these documents in a safe

place in order to always have them at hand for future reference.

• Inform the user on the importance of air vents and of the flue outlet system, stressing the fact that is absolutely

forbidden to make any alterations to the boiler.

• Inform the user how to check the system’s water pressure as well as informing him how to restore the correct

pressure.

• Explain the function of time and temperature controls, thermostats, heating controls and radiators, to ensure

the greatest possible fuel economy.

• Remind the user that it is obligatory to carry out a comprehensive service annually and a combustion analysis

every two years (in compliance with the national law).

• If the appliance is sold or transferred to another owner or if the present user moves home and leaves the

appliance installed, ensure yourself that the manual always follows the appliance so that it can be consulted

by the new owner and/or installer.

Failure to follow the instructions indicated in this guide, which is supplied with the boiler, could cause injury

to persons, animals or damage to property. The manufacturer shall not be held liable for any such injury and/

or damage.

4

General Information

WARNING!

The device should not be used by people with reduced physical, mental and sensory , experience and

knowledge. These people must be well-informed and supervised during the work. Children must be

supervised so they do not play with the appliance.

WARNING!

The installation, adjustment, and servicing of this appliance must be carried out by a competent person and

installed in accordance with the current standards and regulations. Failure to correctly install this appliance

could cause injury to persons, animals or damage to property . The manufacturer shall not be held liable for

any injury and/or damage.

DANGER!

Servicing or repairs of the appliance must be carried out by UNICAL authorised service technicians; UNICAL

recommends drawing up a service contract. Bad or irregular servicing could compromise the safe operation

of the appliance, and could cause injury to persons, animals or damage to property for which UNICAL shall not

be held liable.

Modifications to parts connected to the appliance

Do not carry out any modifications to the following parts:

- the boiler

- to the gas, air, water supply pipes and electrical current

- to the flue pipe, safety relief valve and its drainage pipe

- to the constructive components which influence the appliance’s safe operation

WARNING!

When tightening or loosening the screw pipe connections, use only adequate fork spanners.

The improper use and/or the use of inadequate equipment can cause damages (for example water or gas

leakages).

WARNING!

Indications for appliances operating with propane gas

Ensure yourself that before installing the appliance the gas tank has been purged.

For a correct purging of the tank contact the liquid gas supplier or a competent person who has been legally

authorized.

If the tank has not been correctly purged problems could occur during ignition.

If this occurs contact the liquid gas tank’s supplier.

Smell of gas

If you smell gas follow these safety indications:

- Do not turn on or off electrical switches

- Do no smoke

- Do not use the telephone

- Close the main gas tap

- Open all windows and doors where the gas leakage has occurred

- Inform the gas society or a company specialized in installing and servicing heating systems

Explosive and easily inflammable substances

Do not use or leave explosive or easily inflammable material (as for example: petrol, paint, paper) in the room

where the appliance has been installed.

1.4 -SAFETY W ARNINGS

5

General Information

®

1

2

3

5

7 8

6

4

9

11

13

10

12

14

15

17

19

16

18

20

28

A

B

21 22

23

24

25

26

27

C D

E

The data plate can be found underneath the casing above

the first module's electrical box, a duplicate of the same

data plate can be found on the control instrument's inside

door.

CE Marking

The CE marking documents that the boilers satisfy:

LEGEND:

1 = Y ear of CE certification issue

2=

Boiler type

3=Boiler model

4=Number of stars (Directive 92/42/CEE)

5=(S.N°) Serial number

6=P.I.N. code

7=Approved fluing configurations

8=(N0x) N0x class

A = Central Heating circuit features

9=

(Pn) Nominal output

10 = (Pcond) Condensing nominal output

11 = (Qmax) Nominal heat input

12 = (Adjusted Qn) Adjusted for nominal Heat input

13 =

(PMS) Max. pressure C.H. system

14 = (T max) Max. C.H. temperature

B = Domestic Hot Water circuit features

15 = (Qnw) Nominal heat input in D.H.W. mode (if different from Qn)

16 = (D) Specific D.H.W. flow rate according to EN 625 - EN 13203-1

17 = (R factor) N° taps based on the quantity of water declared EN

13203-1

18 = (F factor) N°stars based on the quality of water declared

EN 13203-1

19 = (PMW) Max. pressure D.H.W. system

20 = (T max) Max. temperature D.H.W system

C = Electrical features

21 = Electrical power supply

22 = Consumption

23 = Protection grade

D = Countries of destination

24 = Direct and indirect country of destination

25 = Gas family

26 = Supply pressure

E = Factory setting

27 = Adjusted for gas type X

28 = Space for national brands

- The essential requirements of the Directive regarding gas

appliances (Directive

2009-142 EC)

- The essential requirements of the Directive regarding

electromagnetic compatibility (Directive 2004/108 EC)

- The essential requirements of the Efficiency Directive

(Directive 92/42/EEC)

- The essential requirements of the low voltage Directive

(Directive

2006/95EC).

1.7 - DATA PLATE

6

General Information

1.7 - GENERAL WARNING

This instruction manual is an integral and indispensable part

of the product and must be retained by the person in charge of

the appliance.

Please read carefully the instructions contained in this manual as they provide important indications regarding the safe

installation, use and servicing of this appliance.

Keep this manual in a safe place for future reference.

The installation and servicing must be carried out in accordance with the regulations in force according to the manufacturer's instructions and by registered engineers or installers.

By a competent person, we imply a person who has a specific

technical qualification in the field of components for central

heating systems for domestic use, domestic hot water production and servicing. The person must have the qualifications foreseen by the current laws in force.

Bad or irregular servicing could compromise the safe operation of the appliance, and could cause injury to persons, animals or damage to property. The manufacturer shall not be

held liable for any such injury and/or damage.

Before carrying out any cleaning or servicing turn off the electrical supply to the boiler by means of the ON/OFF switch and/or

by means of the appropriate shutdown devices.

Do not obstruct the intake/outlet terminal ducts.

In the event of failure and/or faulty functioning of the appliance, switch off the boiler. Do not attempt to make any repairs:

contact qualified technicians.

Any repairs must be carried out by Unical authorized service

engineers and using only original spare parts. Non-observance of the above requirement may jeopardize the safety of

the appliance.

To guarantee the efficiency and correct functioning of the appliance it is indispensable to have the boiler serviced annually by a qualified person.

If the boiler remains unused for long periods, ensure that any

dangerous parts are rendered innocuous.

If the appliance is sold or transferred to another owner or if the

present user moves home and leaves the appliance installed, ensure yourself that the manual always follows the appliance so that it can be consulted by the new owner and/or

installer.

Only original accessories must be used for all appliances

supplied with optionals or kits (including electrical ones).

This appliance must be used only for the purposes for which

it has been expressively designed. Any other use shall be

considered incorrect and therefore dangerous

WARNING

If the boiler operates with a forced draught gas burner, the appliance, not appertaining to any category contemplated in the

annexe II of the legislative decree n°93 dated 25/02/2000 (implementation of the PED Directive 97/23/EC), and moreover

also being contemplated in the Gas Appliances Directive 90/396/EEC), to which the art. 1, comma 3 paragraph "f.5" refers

to, results as being excluded from the scope of the same decree.

7

Technical features and dimensions

2.1 - TECHNICAL FEATURES

The PK series ... X is made up of gas heating units and very

low condensing temperature according to dir. 92/42, made

??entirely of stainless steel, high water content, complete with

modulating burner premix.

Efficiency class:

(4) stars

Power supplye 150 to 348 kW

Performance in condensation, more than 107% to 100% and

109% load at 30% load, thanks to the special pipes patented

progressive.

The components of the parts under pressure, such as steel

plates and pipes, are built in stainless steel 316L, according

to the tables EURONORM 25 and EURONORM 28.

The welders and the welding processes have been approved

by TUV (GE) - UDT (PL) - SD (S) and ISPESL (IT).

2

Optional kits:

Neutral Kit NH300 - part number: 00262827 for appliances

up to 300 kW

Neutral Kit NH1500-P part number: 00262829 for appliances upto 300 kW

MODULE MANAGER CASCADE BCM - code 00361602

MODULE SHC (slave heating controller) - code 00362317

TECHNICAL FEATURES

AND DIMENSIONS

- Horizontal direct-fired hearth;

- Tube bundle consisting of armored tubes patented progressive 316L stainless steel exterior with aluminum inner blades, placed in vertical tube bundle 1: functional drainage of

condensate, the absence of acid deposition wet cleaning

severity of heat transfer surfaces;

- Double return for medium and low temperature in the lower

back;

- Smoke chamber with stainless steel condensate drain

connection and condensate level sensor;

- Opening the door to the left with the possibility of change of

rotation;

- Control panel and electronic HSCP Master (Heating

System Control Panel), external to the mantle, with tempe

rature control unit eBus placed vertically at the side door,

single boiler code:

00362322 for PK150X 2S

00362321 for PK230X 2S

00362320 for PK300X 2S

00362318 for PK348X 2S

- For boilers in battery (up to 7), control panel and electronic

slave, external to the mantle, placed vertically at the side

door code:

00362326 for PK150X 2S

00362325 for PK230X 2S

00362324 for PK300X 2S

00362323 for PK348X 2S

- External shell covered with a layer of mineral wool 80 mm

thick in turn protected by a tissue mineral fiber;

- Attack 2 ½ "conduit with an inner diameter of 15 mm

(suitable for housing 3 bulbs each);

- Sides of the coat fitted with holes for cable glands for power

cables and any other assistive device;

- Total premix burner built in AISI 441 and coated with

special fiber:

- Mixing air / gas ratio of 1:1 range of modulation

(modulation ratio greater than 1:4);

- mixing system upstream of the fan, which ensures proper

operation even with low gas supply pressures

(up to 13 mbar);

- reduced power consumption compared to a

conventional forced draft burner;

- Very low emission combustion.

8

Technical features and dimensions

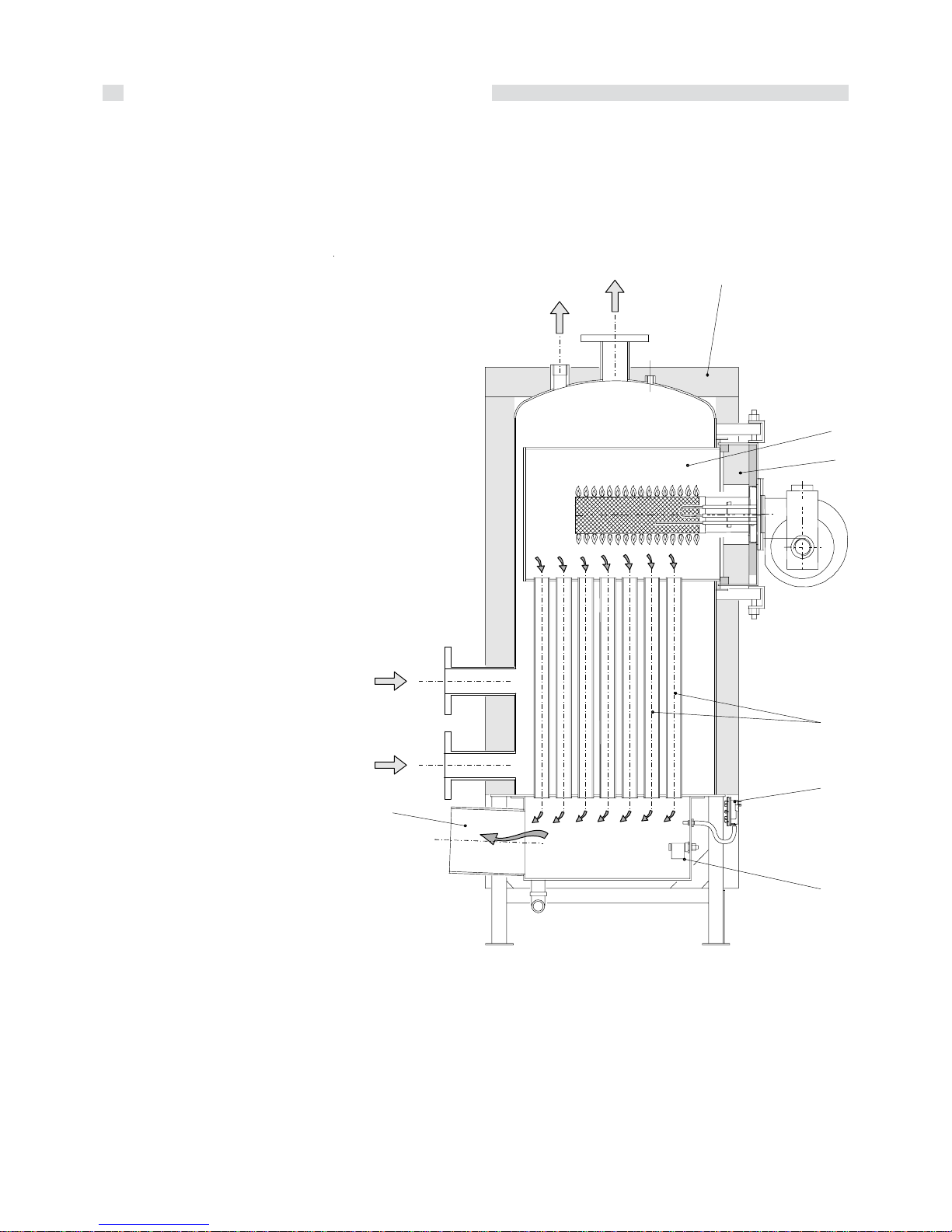

2.2 - MAIN COMPONENTS AND

FUNCTIONING

The PKX boilers are built with a blind furnace, in which the

burner's central flame travels towards the bottom and then is

distributed in the flue pipes; at the terminal part of the pipes

the combustion gas is collected in the flue chamber and then

sent to the chimney. During burner operation, within the boiler's output range, the combustion chamber is always under

positive pressure.

For this pressure value refer to the table on page 8, to the

column "Heating losses flue side".

2

4

5

M

Rmt

Ve

Rbt

1

3

6

7

1. Furnace

2. Flue pipes with flue deflectors

3. Door complete with flame control light

4. Smoke chamber

5. Body insultation

-- Control panel (not visible)

M System flow

Rbt Low temperature system return

Rmt Average temperature system return

Ve Expansion vessel

9

Technical features and dimensions

150

230

300

348

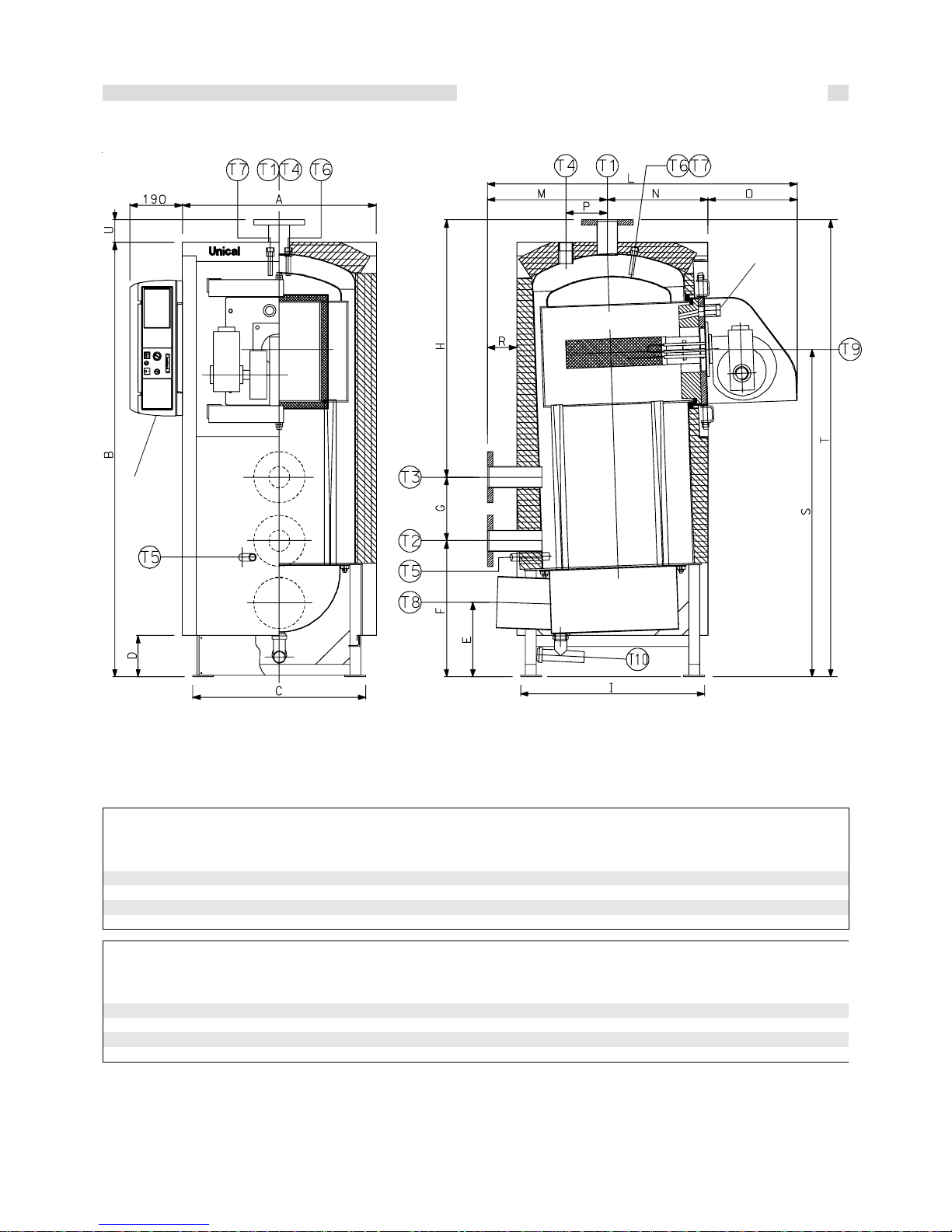

2.3 - DIMENSIONS

1 Control box

2 Flame control sight glass

T1 C.H flow

T2 Average temperature system return

T3 Low temperature system return

T4 Expansion vessel connection

T5 Boiler drainage

T6 Cable sheathing leads bulbs

T7 Cable sheathing leads bulbs

T8 Chimney connection

T9 Burner connection

T10 Condensate drain

Heat

output

(50°-30°C)

kW

150

230

300

348

CONNECTIONS

T 1,T2 ,T3

UNI 2278 PN16T4ISO 7/1

T5

ISO 7/1

T8

Øi

mm

65

65

80

80

1½

1½

2

2

¾

¾

¾

¾

180

180

200

200

150

230

300

348

PKX

2S

Model

Furnace

Output

kW

140

215

279,3

5324

Boiler

Volume

l

151

257

317

389

Water

side

losses (**)

m c.a.

0,27

0,32

0,55

0,60

35

40

45

50

Flue

side

losses

mm c.a.

Max

boiler

working

pressure

bar

5

5

5

5

Weight

without

burner

kg

310

447

540

661

PKX

2S

Model

DIMENSIONS

A

mm

700

830

880

960

(

*) Minimum dimensions for boiler room access requirements.

(**) Hydraulic resistance for delta T 15K.

(***) Minimum pressure gas train entrance (natural gas - G20)

T9

Øi

mm

163

163

163

163

Heat

output

(80°-60°C)

kW

136,5

209,2

273,6

317,7

T10

Øe

mm

40

40

40

40

B

mm

1570

1670

1830

1860

C (*)

mm

625

755

795

785

D

mm

150

150

160

160

E

mm

270

270

305

332

F

mm

491

491

556

586

G

mm

230

230

250

250

H

mm

929

1044

1024

1114

I

mm

685

815

855

965

L

mm

1147

1277

1329

1429

M

mm

433

503

526

576

N

mm

364

454

483

533

O

mm

350

320

320

320

P

mm

150

170

170

170

R

mm

107

107

109

109

S

mm

1183

1209

1300

1333

T (*)

mm

1650

1765

1920

1950

U

mm

80

95

90

90

Gas

pressure

(***)

mbar

20

20

20

20

T6,T7

Øi

mm

163

163

163

163

2

1

10

Technical features and dimensions

PK348X 2S

324

70

317,7

68,5

348

76,1

98,0

97,8

107,4

108,7

109

4

98,20

96,81

98,0

98,5

0,6

0,1

30

50

11,4

529,5

25,53

9,1

9,1

83,8

4

1,5

2

0,1

13660

0,5

5

389

34,26

7,40

39,85

8,61

25,15

5,43

100

52,16

10

58

230/50

6,3

370

20

18

PK300X 2S

280

70

273,6

68,4

300

76,1

97,9

97,7

107,4

108,7

109

4

98,20

96,81

97,5

98,5

0,7

0,1

30

50

114,4

457,6

25,53

9,1

9,1

89,7

4

1,5

2,5

0,1

11781

0,5

5

317

29,61

7,40

34,43

8,61

21,73

5,43

100

45,08

10

61

230/50

6,3

315

20

18

PK150X 2S

140

35

136,5

34,3

150

38,1

97,5

98,0

107,1

108,8

109

4

97,27

95,41

97,5

98,5

0,5

0,1

30

50

57,2

228,8

25,53

9,1

9,1

47,83

5

1,5

2,5

0,1

5870

0,5

5

151

14,8

3,70

17,22

4,30

10,87

2,72

100

22,54

19

45

230/50

6,3

280

20

18

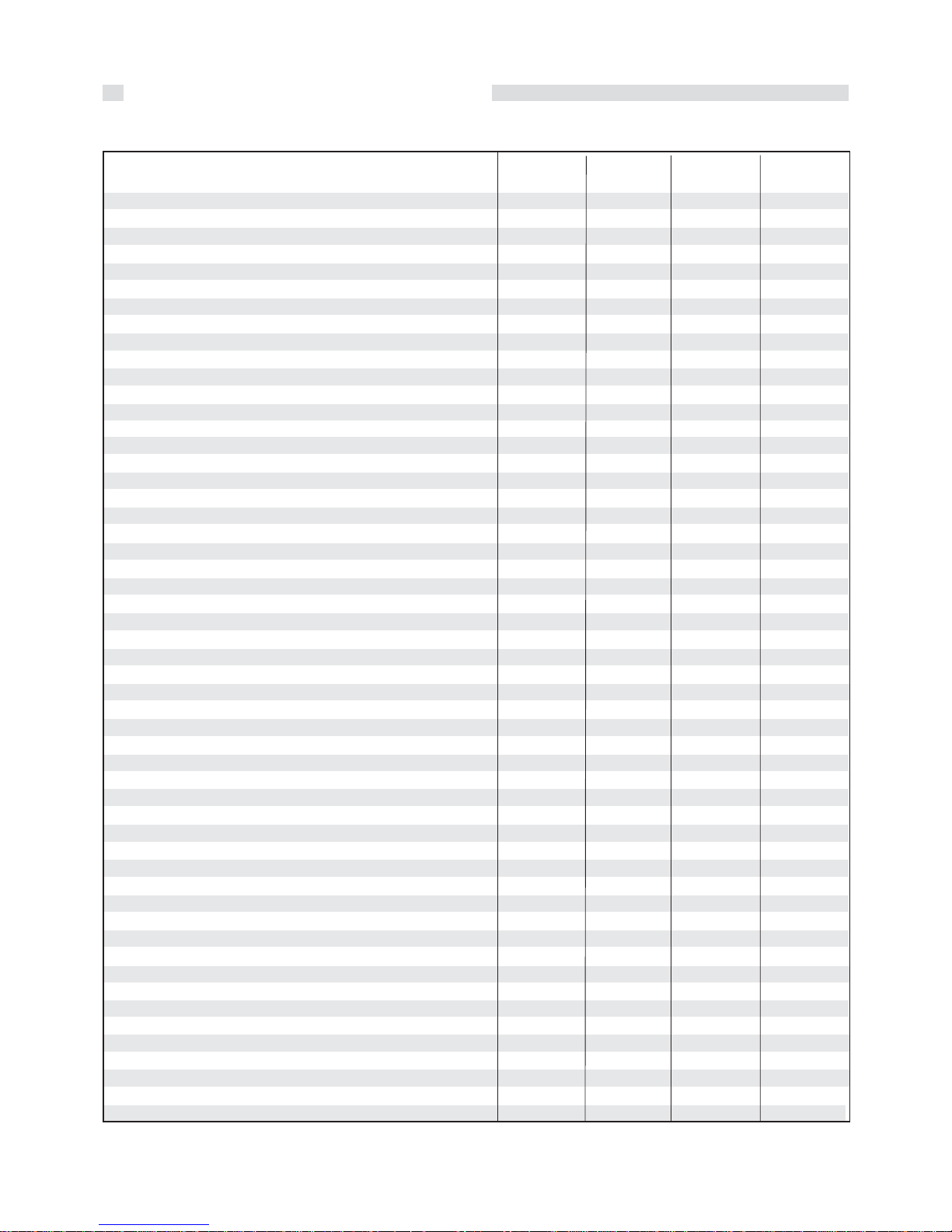

BOILER TYPE

Boiler family gas category II 2H3P I

2H

Nominal heat input on LCV Qn kW

Minimum heat input on LCV Qmin kW

Nominal heat output (Tr 60/Tm 80°C) Pn kW

Minimum heat output (Tr 60/Tm 80°C) Pn min kW

Nominal heat output (Tr30/Tm 50°C) Pcond kW

Minimum heat output (Tr 630/Tm 50°C) Pcond minkW

Efficiency at nominal output (Tr 60/Tm 80°C) %

Efficiency at minimum output (Tr 60/Tm 80°C) %

Efficiency at nominal output (Tr30/Tm 50°C) %

Efficiency at minimum output (Tr30/Tm 50°C) %

Efficiency at partial load 30% (Tr 30°C) %

Efficiency Class

Efficiency at 100% %

Efficiency at partial load 100% (30%) %

Combustion efficiency at nominal load %

Combustion efficiency at reduced load %

Flue losses with burner On %

Flue losses with burner Off %

Flue gas temperature tf-ta (min) °C

Flue gas temperature tf-ta (max) °C

Flue gas mass flow rate (min) kg/h

Flue gas mass flow rate (max) kg/h

Air excess %

CO2 (min) %

CO2 (max) %

N0x (value according to EN 297/A3)

mg/kWh

N0x class

Heat loss at chimney with burner on (min) %

Perdite al camino con bruciatore funzionante (max) %

Heat loss at chimney with running burner (max) %

Water flow rate at nominal output (delta T 20°C) l/h

Minimum pressure CH circuit bar

Maximum pressure CH circuit bar

Water content l

Natural gas consumption G20 (20mbar) at Qn m3/h

Natural gas consumption G20 (20mbar) at Qmin m3/h

G25 gas consumption (20/25 mbar) at Qn m3/h

G25 gas consumption (20/25 mbar) at Qmin m3/h

Propane gas consumption (37/50 mbar) at Qn kg/h

Propane gas consumption (37/50 mbar) at Qmin kg/h

Max. available pressure at chimney base Pa

Max. condensate production (15°C) kg/h

Emissions

C0 at 0% of 02 in the flue gasses ppm

NOx with 0% of 02 in the flue gasses ppm

Electrical data

Electrical supply V/Hz

Fuse rating A (F)

Maximum/Minimum absorbed power W

Electrical protection IP

Stand-by consumption W

PK230X 2S

214

50

209,2

49

230

54,5

97,7

98,0

107,4

109

109

4

98,20

96,81

97,9

98,5

0,5

0,1

30

50

80,97

346,5

24,25

9,2

9,2

68,65

5

1,48

2,1

0,1

8994

0,5

5

257

22,63

5,29

26,32

6,15

16,61

3,88

100

34,45

19

76

230/50

6,3

300

20

18

(*) Room temperature = 20°C

(**) See table "INJECTORS-PRESSURES"

2.4 - PERFORMANCE DATA

11

Instructions for the installer

3

INSTRUCTIONS FOR

THE INSTALLER

3.1 - GENERAL WARNINGS

AThis boiler has to be destined for the use for

which it has been expressively designed for.

Any other use shall be considered improper

and therefore dangerous.

This boiler is designed to heat water at a

temperature inferior to boiling point at an

atmospheric pressure.

WARNING!

These appliances are exclusively designed

to be installed inside adequate boiler rooms.

Before installing the boiler the following

points have to be carried out by a competent

engineer:

a) The whole system should be thoroughly

flushed in order to remove any residual

dirt or grime which could compromise the

good operation of the boiler, even from a

hygienical point of view.

b) Check that the boiler has been preset for

operating with the gas type available.

This is verifiable via the indication on the

packaging and on the data badge;

c) Check that the chimney/flue pipe has an

adequate draught, does not have any

constrictions, and that no other applian

ce's flue outlets have been fitted, unless

the chimney is serving more than one

heating appliance, according to the spe

cific standards and regulations in force.

The connection between the boiler and chimney/flue outlet can be made only after this verification has been carried out.

WARNING!

In rooms where aggressive vapours or dust

is present, the appliance must operate

independently from the air present in the

boiler's location room!

WARNING!

The appliance must be installed by a registered engineer or gas installer.

The boiler must be connected to a heating

system which is compatible to its performance

and output.

12

Instructions for the installer

3.2 - STANDARD CODES FOR

INSTALLATION

This appliance must be installed in compliance to the manufacturer's instructions and

the national regulations in force. Read the instructions fully

before installing or using the appliance

In the interests of safety, a competent installer should be employed to effect the installation of the appliance.

Moreover, the installation of the boiler MUST be in accordance with the latest wiring regulations local buildings regulations and any relevant requirements regarding central heating plants in force in the country the boiler is installed.

The MULTIINOX boilers are a range of heating units in stainless steel foreseen for the II2H3P family gas category.

3

INSTRUCTIONS FOR

THE INSTALLER

3.1 - GENERAL WARNINGS

AThis boiler has to be destined for the use for

which it has been expressively designed for.

Any other use shall be considered improper

and therefore dangerous.

This boiler is designed to heat water at a

temperature inferior to boiling point at an

atmospheric pressure.

WARNING!

These appliances are exclusively designed

to be installed inside adequate boiler rooms.

Before installing the boiler the following

points have to be carried out by a competent

engineer:

a) The whole system should be thoroughly

flushed in order to remove any residual

dirt or grime which could compromise the

good operation of the boiler, even from a

hygienical point of view.

b) Check that the boiler has been preset for

operating with the gas type available.

This is verifiable via the indication on the

packaging and on the data badge;

c) Check that the chimney/flue pipe has an

adequate draught, does not have any

constrictions, and that no other applian

ce's flue outlets have been fitted, unless

the chimney is serving more than one

heating appliance, according to the spe

cific standards and regulations in force.

The connection between the boiler and chimney/flue outlet can be made only after this verification has been carried out.

WARNING!

In rooms where aggressive vapours or dust

is present, the appliance must operate

independently from the air present in the

boiler's location room!

WARNING!

The appliance must be installed by a registe-

red engineer or gas installer.

The boiler must be connected to a heating

system which is compatible to its performance

and output.

13

Instructions for the installer

3.3 - PACKAGING

The PKX boilers are delivered fully complete with door and

smoke chamber already

fitted, whilst the casing with the insulation mattress is contained in separate cardboard

packaging(s). The control panel and accessories are inside

the combustion chamber.

Before starting the installation make sure that the length and

the width of the boiler body received, indicated in the table on

page 8, correspond to the dimensions of the ordered boiler,

and that the cartons, containing the casing, or part of it, are

marked as indicated below.

The casing of the boilers PK X complete with the insulation

mattress, is contained in n°2 cartons.

(1 carton for the PK 150 X S2).

In addition to the above indicated control panel, packaged in

its own carton, in the combustion chamber as accessories,

there are also:

- a carton containing the flanges for flow, return and safety

connections (if applicable) with relevant gaskets and bolts;

- ceramic fibre rope for the insulation between the door and

burner blast tube;

- 1 bag containing the condensate drain kit

After having unpacked the boiler check that it is

intact and undamaged.

Keep the packaging material (cardboard box,

plastic bags, polyester protection etc.) out of

the reach of children as they can be dangerous.

UNICAL refuses all liability for injury to persons, animals or damage to property deriving

from not having respected the above mentioned recommendations.

In the packaging, in addition to the boiler, you can also find

the following contents:

- Hydraulic test certificate

- Service logbook

- Instruction manual for the person in charge of the

appliance

- Instruction manual for the installer and servicing

personnel

- Warranty certificate

- Adhesive sticker indicating local venting regulations

ISOLATION AND CASING

N.B. For the model PK150X 2S, mantle and isolation are

contained in 1 package marked:

38353 (casing insulation PK150X + 2S)

N.B. For models PK230X 2S, PK300X 2S PK348X 2S the

casing and insulation are contained in 2 packages

marked:

37462 (casing side + isolation PK230X 2S)

37463 (casing front. + back + cover PK230X 2S)

38355 (casing side + isolation PK300X 2S)

38354 (casing front. + back + cover PK300X 2S)

37464 (casing side + isolation PK348X 2S)

37465 (casing front. + back + cover PK348X 2S)

CONTROL PANEL

N.B. For the model PK150X 2S the control panel is contai-

ned in a package marked:

00362322 (control panel with control unit + exter

nal probe EBUS)

00362326 (PK150X 2S control panel "Slave")

N.B. For models PK230X 2S the control panel is contained

in a package marked:

00362321 (control panel with control unit EBUS + ex

ternal probe)

00362325 (control panel "Slave")

N.B. For models PK300X 2S the control panel is contained

in a package marked:

00362320 (control panel with control unit + exter-

nal probe EBUS)

00362324 (control panel "Slave")

N.B. For models PK230X 2S the control panel is contained

in a package marked:

00362318 (control panel with control unit EBUS +

external probe )

00362323 (control panel "Slave")

ACCESSORIES

N.B. The hydraulic connection flanges with gaskets and bolts

are contained in a package marked:

36372 (accessories PK150X S2 PK230X S2)

36373 (accessories PK300X S2 PK348X S2)

N.B. The condensate drain kit is contained in a package

labeled: 27982

14

Instructions for the installer

When the appliance is installed on existing systems, ensure

yourself that:

- The flue outlet pipe is suitable for condensing boilers, for

the temperature of the products of combustion, calculated

and manufactured according to the regulations in force. It

must be installed as much as possible in a straight line,

tested for soundness, insulated and must not have any

occlusions or restrictions.

- The flue outlet pipe has a connection for the discharge of

condensate.

- The boiler room has a suitable outlet for the discharge of

condensate produced by the boiler.

- The electrical system has been fitted in compliance to the

specific standards and the work has been carried out by a

competent person.

- The circulation pump's output, the head and flow direction are suitable.

- The gas feed supply pipe and eventual tank are constructed according to the regulations in force.

- The expansion vessels assure the total absorption of the

expansion of the fluid contained in the system.

- The system has been cleaned of impurities and lime scale.

3.5 - INSTALLATION ON EXISTING

HEATING SYSTEMS

3.4 - HANDLING AND LIFTING

The boiler can be moved by lifting, via the holes

or upper hooks.

If necessary, due to the dimensions of the boiler,

it is possible to remove the front door to facilitate

the introduction in the boiler house.

A

A

15

Instructions for the installer

3.7 - CHIMNEY FLUE CONNECTION

In condensing boilers the flue gases are evacuated at a very

low temperature (max about 84°C). Therefore the chimney

must be perfectly impermeable to the condensate of products

of combustion and built with suitable materials which are resistant to corrosion.

The different spigot joints must be well sealed and equipped

with suitable gaskets, in order to prevent the outlet of condensate and the inlet of air.

Furthermore ensure that the possible condensate or rain water coming from the chimney does not

enter the boiler's flue chamber.

Refer to applicable regulations while determining the size

and height of the flue.

In order to prevent the formation of ice during normal boiler

operation, the temperature of the internal wall of the combustion product evacuation system, in all its length, has not to be

below 0°C.

The flue must be installed in accordance with the recommendations of local and national codes of practice.

The flue pipe must be built using materials resistant to products of combustion, in Class W1, in accordance to EN 1443,

in stainless steel or certified plastic. This can be PVDF

(polyvinylidene fluoride) or PPS (Polyphenylene sulfide) or

otherwise aluminium or different materials but with equivalent characteristics which comply to the regulations in force.

3.6 - BOILER LOCATION

The boiler must be installed in accordance with the relevant

requirements of the Gas Safety Regulations, current I.E.E.

Regulations, local water authority by e-laws and it should also

comply with any relevant requirements of the local gas supplier, local authority and the relevant Standard Codes of Practice and building regulations.

The boiler house must be ventilated via permanent openings

having a total surface not inferior to 1/30th of the floor area of

the boiler house, with a minimum of 0.5 m

2

It is advisable to install the boiler as close as possible to the

chimney connection on a non combustible floor (i.e. concrete

or brick).

To facilitate cleaning of the flue circuit the boiler must have

sufficient clearance space in front, not less then the length of

the boiler body and, in any case, never less then 1300 mm.

When the door is open 90° the distance between the door

and the adjacent wall must be at least equal to the burner

length.

The surface must be flat, level, and of a suitable load bearing

capacity to support the weight of the boiler (when filled with

water - see general data table).

If the boiler is mounted on a plinth then the dimensions (see

Frame 2) of the plinth must be at least CxZ (refer to the table

dimensions).

Once the boiler has been installed it must be perfectly horizontal and stable (to avoid vibrations and noise).

1000

X

XX

XX

600

600

X = not less then the length of the boiler body (dimensions

given in millimetres); in any case never less than 1300 mm.

XX = see instructions.

16

Instructions for the installer

Esemple:

PK 230X 2S

Flue gas mass flow rate = 349,6 Kg/h

Chimney height = 25 m

Chimney connect. diam. = 200 mm

Note: The diagram shows indicative values

Co level

2

d125

a

d400

a

d315

a

d 250

a

d200

a

d160

a

d110

a

d75

a

6

7

8

9

10

12

14

16

18

20

30

40

50

60

70

80

90

100

120

140

160

180

200

300

400

500

600

700

800

900

1000

1200

1400

4,4

5,9

6,6

7,4

8

9

10

12

22

30

37

44

52

59

66

74

89

104

119

133

148

222

296

370

444

519

593

668

741

889

1037

3,4

3,9

4,4

5,0

5,6

7

8

9

11

17

22

28

34

39

44

50

56

67

78

89

100

111

167

222

277

333

389

445

555

667

778

0,001

0,002

0,003

0,004

0,005

0,006

0,007

0,008

0,009

0,010

0,015

0,020

0,030

0,035

0,040

0,050

0,060

0,070

0,080

0,090

0,100

0,150

0,200

0,250

0,300

0,350

0,400

0,500

0,600

5

0,700

9,0

10,8

12,0

14,4

22

25

29

32

36

54

72

90

108

126

144

180

216

252

288

324

360

540

720

900

1080

1260

1440

1800

2160

2520

6

7

8

9

10

12

14

16

18

20

30

40

50

60

70

80

90

100

120

140

160

180

200

300

400

500

600

700

800

900

1000

1200

1400

8%

6%

kg/skg/h 10%

10 15 20 25 30

51015202530

Flue gas

mass rate

40°C

396

240

40 Pa

Chimney dimension

DIN 4705

Pressure avaible

Flue Gas Temperature

Nominal Heat input (kW)

Nominal Heat input (kW) with CO level at 10%

2

PK ... X 2S

150

230

300

348

Flue gas mass

flow rate (max)

kg/h

228,8

349,6

457,7

529,6

Flue gas mass flow rate

17

Instructions for the installer

The condensate drain system must be:

- built in order to prevent the products of combustion discharging in the ambient or in the sewage(siphon);

- sized and built so as to permit the correct flow of the liquid

discharges preventing any eventual leakages;

- installed in such a way to prevent the liquid contained

inside freezing in cold weather

- The condensate, before being evacuated to the sewer,

has to be neutralized, neutralisation which can be obtained by mixing the drain water coming from washing machines, dish washers etc., which normally have a base

pH.

To maintain proper flow of condensate the drain pipe must

have an inclination toward the drain of at least 30 mm/m

(3/8 in./ft). The liquid column inside the condensate siphon

needs to be filled with water after installation. Its minimum

height when all the fans are in operation must be at least

25 mm (1 in).

Given the acidity degree (pH 3 to 5 ) only plastic material

can be used for the condensation evacuation pipes (special optional neutralization kits are available on request).

* Minimum height safety siphon required by the Standard

** Minimum height with boiler running at maximum output

If the boiler is not installed on a plinth then it can be fitted

directly onto the boiler floor and than a deep well of at

least 100 mm will be required to house the siphon.

3.8 - CONDENSARE DRAIN

Any neutralization devices can be connected to the condensate after the trap.

For the calculation of the neutralization of the charge must be

assessed the state of wear of the neutralizer after a year of

operation.

Based on this information you can extrapolate the total duration of the charge.

For the neutralization of the condensate neutralizer kits are

available NH 300 and NH 1500-P.

KIT NEUTRALIZATION NH 300 - code 00262827

L 'NH neutralization unit 300 is designed to:

- Appliances with power up to 300 kW

- Works well with condensate drain the boiler placed lower

down the condensate drain the boiler.

This unit does not require neutralization of the electrical connections.

KIT NEUTRALIZATION NH 1500-P - code 00262829

The 'unit of neutralizing NH 1500-P is designed to:

- Appliances with power up to 1500 kW

- Works well with condensate drain the boiler placed higher

condensate drain the boiler.

This unit requires the neutralization of electrical connections.

Flue chamber

Base (H min 100 mm)

To the condensate

drain

The upper part of the drain pipe

must not be higher then the tray bottom

Boiler room floor

Initial trap

filling-up plug

18

Instructions for the installer

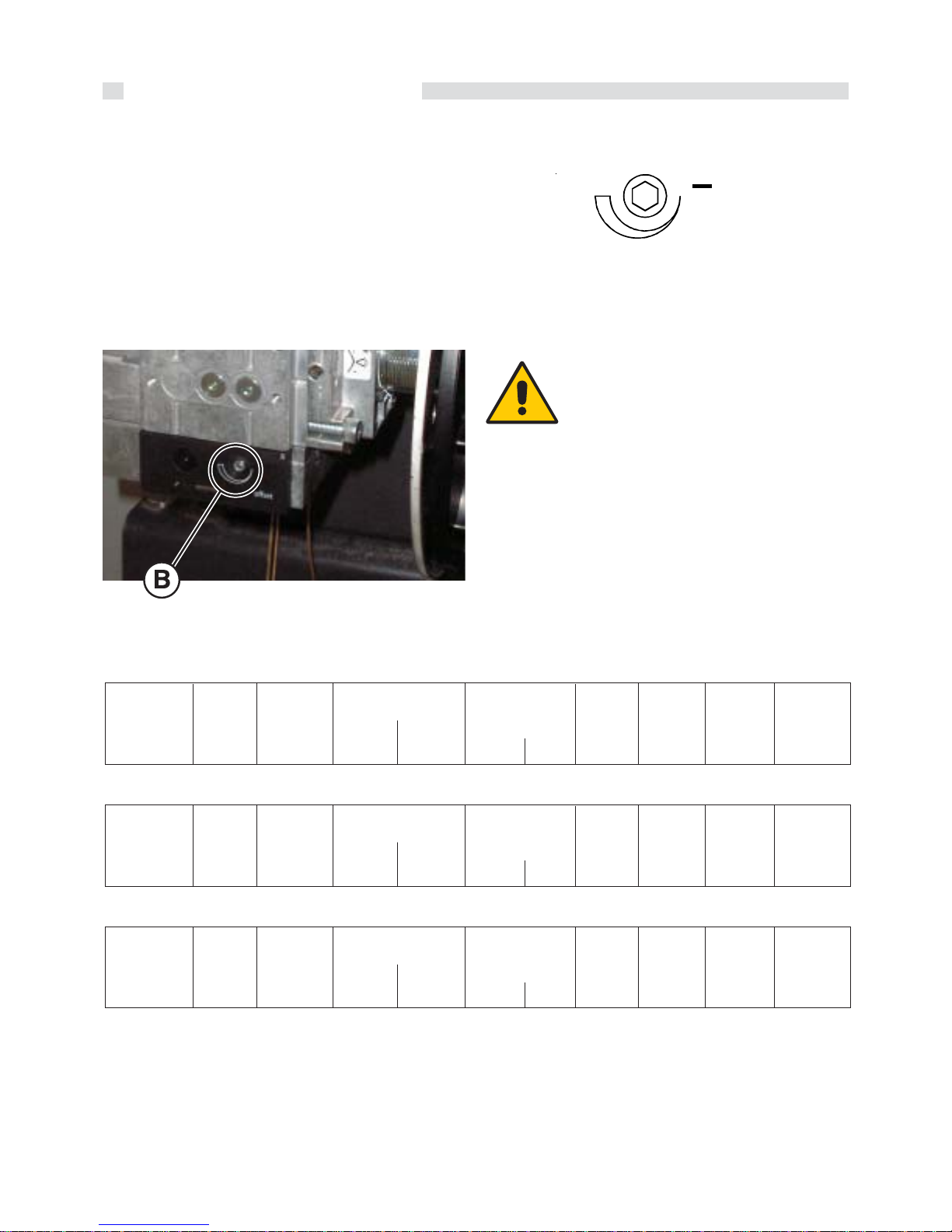

3.9 - FIRE DOOR: ADJUSTMENT,OPENING &

CLOSING

IMPORTANT

- The door must be opened only when the boiler

is cold to avoid causing damages to the fibre

lining due to thermal stress.

- The door's fibre lining can crack after a brief

period of boiler operation; this however does

not reduce it's insulating capacity or it's life

span.

- The door's fibre lining is easily replaceable

and is covered by a 2 years guarantee.

For these models the door is assembled according to fig. 6.

The door is therefore installed with two rotating hinges on the

left hand side; the door is shut via 4 screws (position C).

The door mounting can be reversed so that it hinges from left

to right.

Door adjustment:

A) Axial door adjustment: further adjustment to the position of

the door in relation to the chamber can be achieved through adjustment o the screws.

WARNING

Before opening the furnace door it is necessary to adopt the following precautions:

- Close the fuel cock (oil or gas) to the

burner.

- Cool down the boiler by keeping the

water circulating through it, and only then

switch off the power.

- Place a Warning sign on the boiler with

the following text: DO NOT USE , BOILER OUT OF ORDER, TO BE SERVICED.

19

Instructions for the installer

3.10 - GAS CONENCTION

DANGER!

The gas connection must be carried out only

by a qualified registered engineer who will

have to respect and comply to the regulations

in force and to the requirements indicated by

the local gas supplier. An incorrect installation could cause injury to persons, animals or

damage to property. The manufacturer shall

not be held liable for any injury and/or

damage.

Before installing the boiler it is recommended

to thoroughly clean all the supply piping in

order to remove any eventual residual grime

which could compromise the boiler's correct

functioning.

If you smell gas:

a. Do not turn on or off electrical switches,

use the telephone or any other object which

can provoke sparks;

b. Open all doors and windows in order to

allow fresh air to enter and purify the room;

c. Close all gas cocks

d. Contact a service engineer, qualified

installer or your gas supplier.

As a safety measure against gas leaks,

Unical recommends installing a surveillance

and protective system composed of a gas

leakage detector combined with an on-off

selenoid valve fitted on the gas supply line.

The gas supply pipe must have a section which is adequate

to the burner's output.

It is however important to comply with the specific standards

and requirements in force.

Before commissioning an internal gas distribution system

and therefore before connecting it to the gas meter, the

complete installation must be tested for gas soundness.

If any part of the system is concealed from view the gas

soundness test must be carried out before covering the

pipes.

Before connecting the pipework the system must be tested

with air or inert gas at a pressure of at least 100mbar.

Before commissioning the boiler ensure that the following

operations are carried out:

- Open the gas meter cock and vent the air contained in

the piping and subsequently proceed to vent device by

device.

- Check, with the gas cock turned off, that there are no gas

leaks. During the 2nd quarter of the hour from the start of

the test, no pressure drop should be detected by the

pressure gauge. Any gas leaks must be found by using

only water soap solutions, or an equivalent product, and

eliminated.

- Never look for gas leaks using a naked flame.

1 2 3 4 5 66

1 On-off gas supply valve

2 Double membrane regulator

3 Gas Filter

EXAMPLE OF A GAS SUPPLY SYSTEM

4 Anti-vibrating joint

5 Selenoid valve

6 On-off cock

20

Instructions for the installer

WARNING!

IT IS ABSOLUTELY FORBIDDEN TO FIT ONOFF VALVES ON THE BOILER BEFORE THE

SAFTEY DEVICES

CH pressure relief valve drainage

In correspondence to the CH pressure relief valve, provision should be made to install a discharge pipe with a

funnel and a siphon which lead to an adequate drainage.

The drainage has to be controllable by sight.

WARNING!

If this precaution is not taken it could lead to

injury to persons, animals or damage to

property. The manufacturer shall not be held

liable for any such injury and/or damage

Expansion vessel connection

The PK...X 2S boilers are suitable for operating with a forced water circulation with an

open or closed water tank.

An expansion vessel is always needed

because it compensates the increase in

water volume caused by heating.

Filling /drainage connection

The boiler can be filled and drained by providing an appropriate external cock on the system's return pipe T5.

3.11 - SYSTEM CONNECTION

WARNING!

Before connecting the boiler to the heating

system we recommend that the system is

flushed out with a suitable product in order to

eliminate any metallic tooling or welding

residues, oil and grime which could reach

the boiler and affect the proper running of the

boiler.

Do not use any solvents for flushing out the

system as they could damage the system

and/or its components.

Non-observance of these instructions could

cause injury to persons, animals or damage

to property. The manufacturer shall not be

held liable for any such injury and/or damage.

The CH flow and return circuits have to be connected to the

boiler via the respective connections as indicated on page

8.

When determining the size of the CH circuit pipes it is

essential to bear in mind the pressure losses induced by

any of the system's components and by the configuration of

the system.

The route of the piping has to be conceived taking all the

necessary precautions in order to avoid air locks and to

facilitate the continuous purging of the system

Ensure yourself that the system's piping is

not used as the earth clamps for the electrical

or telephonic system. They are absolutely

unsuitable for this use. In a short time this

could cause serious damage to the piping,

boiler and radiators.

21

Instructions for the installer

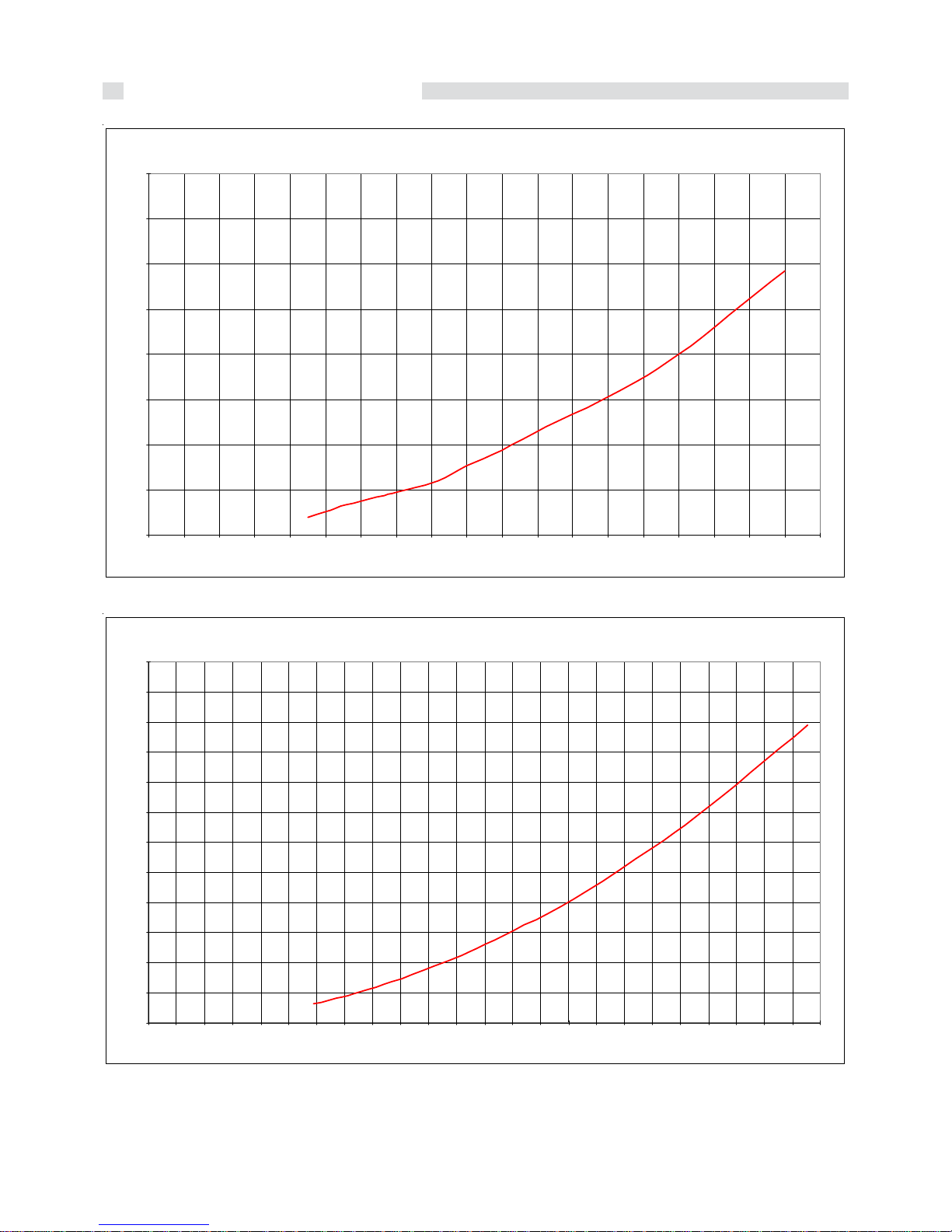

Perdita di carico lato acqua

0

0,5

1

1,5

2

2,5

3

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 13000 14000 15000 16000 17000 18000 19000 20000 21000 22000 23000 24000

Q : portata acqua (l/h)

perdita di carico (mmh2O)

PK150X 2S

230 300 348

8994

11781

13660

11992 15708

18213

150

5870

7826

Power supply in kW

Max flow rate

demanded in l/h

( t=15 K)

Δ

Nominal flow rate

requested in l/h ( t=20 K)

Δ

3.12 - DETERMINATION OF PRIMARY CIRCUIT PUMP OR BOILER SYSTEM PUMP

The boiler pump must have a delivery head which can

ensure the water flow rate as shown in the graph "Water

pressure losses".

The following table gives an indication of the pump's flow

rate in function of the ?t of the primary circuit.

The size of the pumps must be determined

by installers or technical engineers according to boiler data and system design.

The water side resistance curve of the boiler

is shown in the following graph.

The pump is not an integral part of the boiler.

We recommend you choose a pump with the

rate and discharge head at about 2/3 of its

characteristic curve.

Q: water flow rate (l/h)

WA TER SIDE PRESSURE LOSSES

Pressure losses (mmH2O)

22

Instructions for the installer

Perdita di carico lato acqua

0

0,5

1

1,5

2

2,5

3

3,5

4

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000 22000 24000 26000 28000 30000 32000 34000 36000 38000

Q : portata acqua (l/h)

perdita di carico (mmh2O)

PK230X 2S

Perdita di carico lato acqua

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

5,5

6

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000 22000 24000 26000 28000 30000 32000 34000 36000 38000 40000 42000 44000 46000 48000

Q : portata acqua (l/h)

perdita di carico (mmh2O)

PK300X 2S

Q: water flow rate (l/h)

Pressure losses (mmH2O)

WA TER SIDE PRESSURE LOSSES

Q: water flow rate (l/h)

Pressure losses (mmH2O)

WA TER SIDE PRESSURE LOSSES

23

Instructions for the installer

3.14 - MIXING HEADER AND PLATE HEAT EXCHANGER

In order to ensure correct boiler operation it is necessary to

use a mixing header which guarantees:

- the separation and collection of circuit dirt

- optimal air venting

- hydraulic de-coupling of the two hydraulic circulation

circuits

- balancing of the circuits

A suitably sized plate heat exchanger has the advantage of

separating the two circuits (primary and secondary), permitting the installation of the boiler in an industrial design.

Perdita di carico lato acqua

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

5,5

6

0 5000 10000 15000 20000 25000 30000 35000 40000 45000 50000 55000

Q : portata acqua (l/h)

perdita di carico (mmh2O)

PK348X 2S

Q: water flow rate (l/h)

Pressure losses (mmH2O)

WA TER SIDE PRESSURE LOSSES

3.13 - FROST PROTECTION

If the flow temperature (measured at global flow NTC) falls

below 7°C, the system pump circulates water around the

water circuit and all the heat modules will operate at

minimum output.

Note: The anti-freeze solution must be compatible with the

materials used on the entire heating system and tolerable

with aluminium alloys.

WARNING:

If the boiler has remained unused for a long

period, and you notice the presence of

frost (temperatures of < 3°C), do NOT fire

the boiler. Fire the boiler only of you know

that an anti-freeze solution has been

added in the proper percentage to the

primary circuit.

24

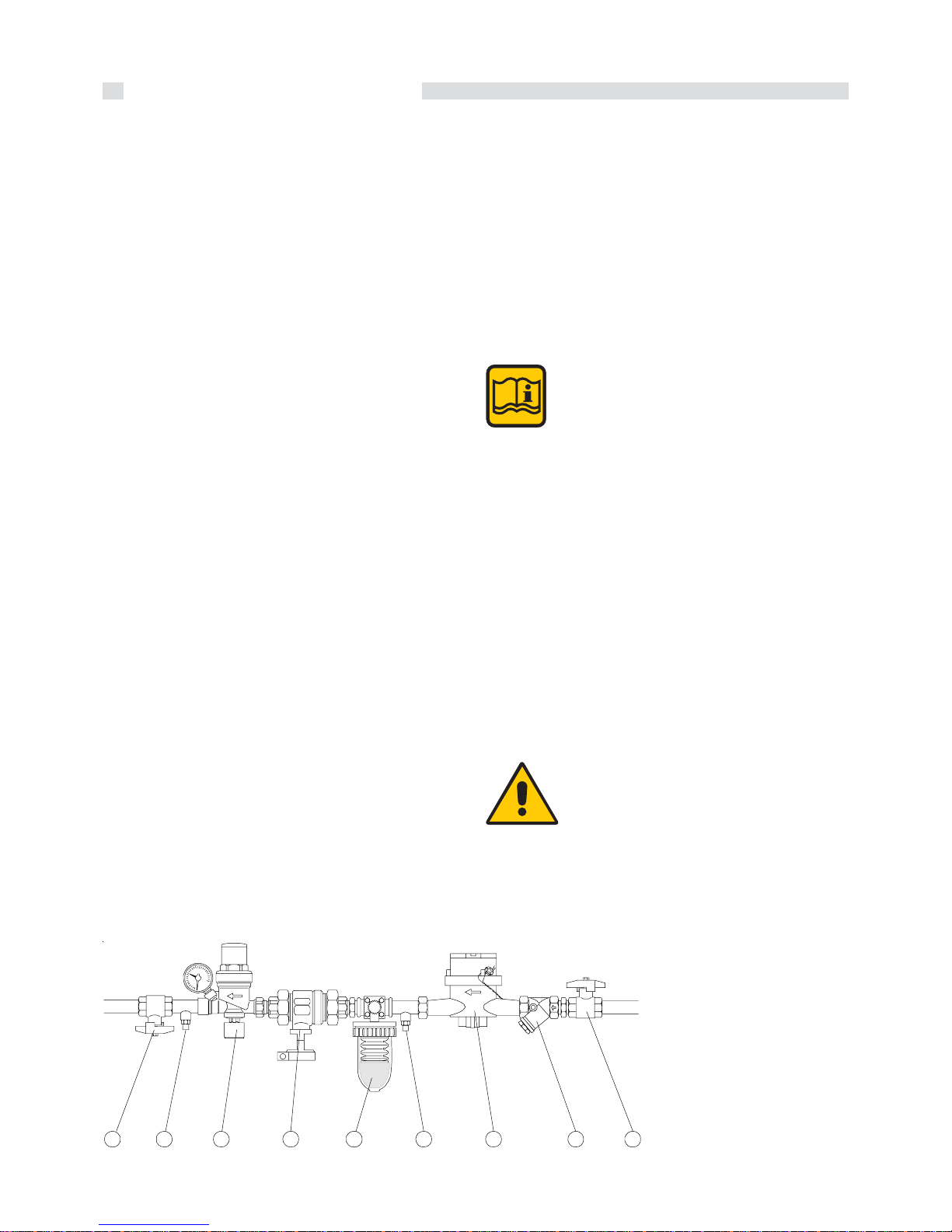

Instructions for the installer

1 2 3 4 5 2 7 16

3.15 - WATER TREATMENT

The chemical-physical characteristics of the filling water and

reinstatement water in heating systems are of fundamental

importance for guaranteeing correct and safe boiler operation.

Before filling the CH circuit with water, it is necessary to analyse

the water and decide for a proper treatment.

The purpose of this treatment is finalized to eliminate or

substantially reduce the following problems:

- lime scale deposit

- corrosions

- deposits

- biological growths (moulds, bacteria, algae, fungi, etc)

The chemical treatment of the network water enables the

prevention of these problems and guarantees safe boiler

operation and economical advantages, in terms of

maintenance and global thermal efficiency.

The chemical analysis of the water enables us to obtain a lot

of information on the system’s condition and state of “health”.

It is essential to avoid any problems with the boiler.

The pH is a measure of the acidity or alkalinity of a solution.

The pH scale has a range of 0-14, where 7 is neutral.

Values inferior to 7 indicate acidity, values above 7 indicate

alkalinity.

The ideal pH value for water in heating systems fitted with

aluminium boilers is between 6,5 and 8, with a hardness of

15°F.

In heating systems where the water has a value outside this

range, this considerably accelerates the destruction of the

protective oxidized layer which naturally develops inside the

aluminium bodies: if the pH is below 6, acidity is present, if it is

above 8, the water is alkaline or it is caused by an alkaline

treatment (for example phosphate or glycol used as an

antifreeze) or in several cases it is due to the natural formation

of alkaline in the system.

Vice versa, if the pH value is between 6,5 and 8, the aluminium

surfaces of the boiler body are passivated and protected from

further corrosive attacks.

To minimize corrosion it is essential to use a scale inhibitor,

however in order for this to function correctly, the metallic

surfaces have to be clean.

The best corrosion inhibitors on sale also contain a

protective system for aluminium which acts by stabilizing

the water’s pH value, preventing unforeseen variations.

We recommend that the heating system’s water pH value

is systematically controlled (minimum twice a year). In order

to do this, it is not necessary to run a chemical analysis in

a laboratory, but it is sufficient to use a simple analytical

‘kit’ contained in portable cases, easily found on sale.

Therefore, prior to filling the heating system with

water it will be necessary to fit the devices

indicated in the figure below.

THE CONNECTION MUST BE FITTED ON THE PRIMARY

CIRCUIT’S RETURN PIPE DOWNSTREAM OF THE

CIRCULATING PUMP

All the necessary precautions must be taken in order to avoid

the formation and localization of oxygen in the system’s water.

For this reason, the plastic pipes used in underfloor heating

systems must be impermeable to oxygen.

If any antifreeze solutions are used ensure yourself that they

are compatible with aluminium and with any other components

and materials fitted on the system.

WARNING!

ANY DAMAGE CAUSED BY THE BOILER, DUE

TO THE FORMATION OF LIME SCALE OR DUE

TO CORROSIVE WATER WILL INVALIDATE THE

APPLIANCE WARRANTY.

1. Ball valve

2. Inspection pocket

3. Filling-up group

4. Disconnector

5. Scale reducing device

6. Litrecounter

(recommended)

7. “Y” filter

EXAMPLE OF SCALE REDUCING DEVICE CONNECTION FOR WATER TREATMENT

25

Instructions for the installer

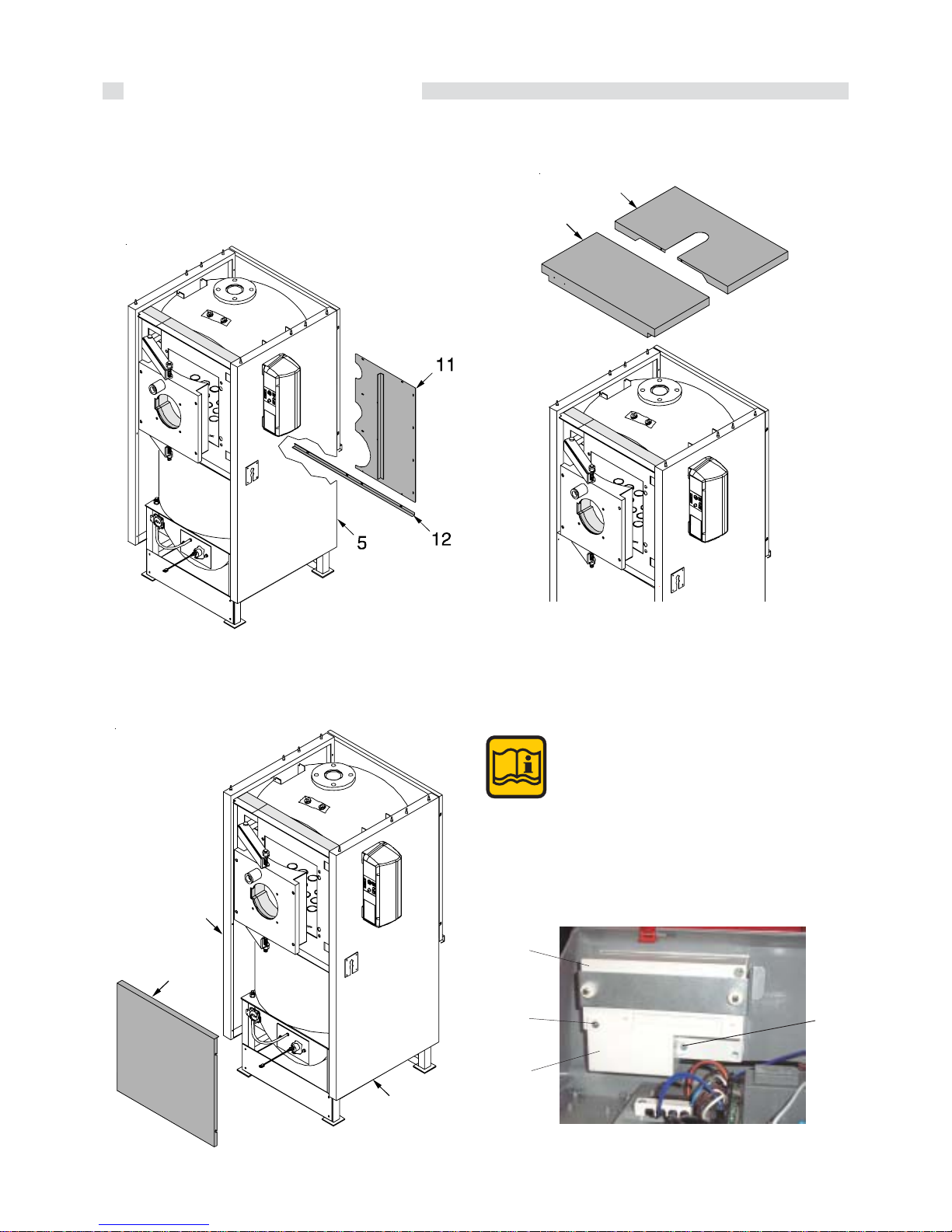

3.16 - CASING ASSEMBLY

(con pannello comandi montato a destra)

2

1

3

A. Fit the insulation blanket (1) onto the boiler shell and secu-

re in to place using the elasticated straps (2) provided,

ensuring that the metal clips grip in to the external surface

of the insulation.

B. Fit the boiler shells top insulation blanket (3) and secure in

to place using the elasticated straps (2) provided, ensuring that the metal clips grip in to the external surface of

the boiler shell's insulation.

Make a convenient cut in the upper part of the insulation blanket to get easy access to the bulb holders

C. Fit the self-tapping screws onto the internal profiles of the 2

side panels (4 and 5 ).

D. Fit the left side panel (4) fixing it on to the front panel and

securing it to the top left squadretta on the boiler shell,

inserting the lower bend inside the bottom L profiles.

26

Instructions for the installer

E. After removal of the two side screws from the control panel

rotate its cover towards the front

and insert the cables and the capillaries of thermometer and thermostats through the slots on its base.

Fit the control panel to the right hand side panel (5).

F. Fit the right hand side panel (5) to the lower panel and fix it

to the upper squadretta on the right hand side of the boiler

body, inserting the lower bend inside the bottom L profiles.

G. Insert the thermometer and thermostat bulbs in the sensor

pockets as shown in Fig. 8

boiler sensor

termometer

sensor

HL thermostat

sensor

and connect the mains, the burner, the pump(s) and

any equipment to the control panel.

PF

SL

27

Instructions for the installer

Guide the burner plug through the side cable clamp plate(6) and clamp the cable using the cable clamp supplied. Fix the side cable clamp plates to the casing side

panels.

Refit the upper shell of the control panel.

H. Fit the top panel (8) and fix it onto the side panels (4 & 5).

I. Fix the retaining strips (9) onto the lower left hand side

rear panel (4) and to the upper panel (8).

10

8

4

8

4

5

L. Fit the right hand side rear panel (10) onto the left hand

side rear panel (4) and to the upper rear panel (8).

10

9

Fix the platelets (pos 6) support the two sides of the conduit and the plate (pos 7) closing the lateral left side.

28

Instructions for the installer

O. Position the top panels (14 and 15) and press them

against the side panels.

M. Fit the lower right hand side rear panel (11) onto the right

hand side rear panel (5), to the left hand side rear panel

(10) and to the upper rear panel (8).

Unite the two rear panels with the retaining strips profile

(12).

N. Fit the lower front panel (13)and fix it on to the side panels

(4 and 5).

13

4

5

14

15

P. Remove the protective paper film from the data plates and

fit them on to the side panel.

The data plates are in the plastic bag containing the documents.

Warning!

In the event that the panel is mounted on the left

side, you must turn the temperature control unit

eBus.

To turn the temperature control unit eBus on the control panel,

you must:

Q) remove the two screws "1" cover fixing "2" access to the

terminal unit of the "3",

Montaggio del pannello comandi sul lato sinistro

3

1

2

1

29

Instructions for the installer

R) after removing the cover disconnect the connector "4", un-

screw the 2 nuts "5" and remove the bracket "6",

4

S) Turn the Unit 180°,

5

6

5

T) to reposition the unit "3", through the bracket "6" and ti-

ghten the 2 nuts "5",

3

5

6

5

U) plug the connector "4" on the unit,

4

V) replace the cover "2" access to the terminal unit, and se-

cure with the two screws "1".

1

2

30

Instructions for the installer

3.17 - SYSTEM FILLING AND DRAINING

Warning!

Do not mix the CH system's water with antifreeze or anti-corrosion solutions using

wrong concentrations! It could cause damage to the washers and could provoke noise

during normal boiler operation.

UNICAL refuses all liability for injury to

persons, animals or damage to property

deriving from not having respected the above

mentioned recommendations.

After completing all the system's service connections the

circuits may be filled.

To fill the system it is necessary to fit a filling cock on the

system's return.

The boiler is equipped with its own drain tap, whose

position is indicated in the figure on page 17.

This tap must NEVER be used for draining of the whole

system as this could lead to system dirt gathering in the

boiler, compromising good boiler operation. Therefore, the

system has to be fitted with its own draining tap, of the right

size for the system's capacity.

GRUPPO DI

CARICAMENTO

EXAMPLE OF FILLING MANIFOLED

FILLING MANIFOLD

31

Instructions for the installer

Mains electrical supply connection 230V

The electric connections of the boiler are shown in the section

named “ACTUAL WIRING DIAGRAM” (paragraph 3.19 page

31)

The boiler installation requires a mains supply of 230 V - 50

Hz. The wiring to the boiler must conform to current CEI regulations.

The supply cable must have the following characteristics: PVC

HT CABLE H05V2V2-F 3x0,75

DANGER!

The electrical connections must be carried out

only by a qualified engineer.

Before carrying out the connections or any

other operation on the electrical parts, always

switch off and disconnect the electricity supply

and ensure yourself that it cannot be accidentally turned on.

It is necessary to fit a double pole switch on the

electrical supply line, having a 3 mm contact

separation in both poles, in an easy accessible

position in order to make quick and safe the servicing operations.

The supply cable must be replaced only by

highly qualified personnel. Failure to do so

could compromise the appliance's safety.

WARNING!

We remind you that upstream of the electrical

connection, it will be necessary to foresee a

service relay (NOT SUPPLIED) which, when

the electrical safety devices (ISPESL) intervene, shuts down the electrical supply to the onoff fuel valve fitted on the gas supply circuit,

but not to the boiler so as to guarantee the

running of the pump and permit the boiler to

cool down.

- Gain access to the Y1 terminal board

- Room thermostat: connect the thermostat's cables to the

terminals 1 and 2.

DANGER!

Switch off and disconnect the electricity supply before carrying out any operations on the

electrical parts.

Room

Thermostat

Room thermostat connection

3.18 - ELECTRICAL CONNECTIONS

General warnings

The elctrical safety of the appliance is assured only when it is

correctly earthed, according to the electrical rules in force.

The gas, D.H.W. and the CH system pipes cannot be used as

ground plates.

Ensure that the above safety electrical requirements subsist;

in case of doubt, ask for a professionally qualified technician

to check the appliance’s electrical system.

UNICAL refuses responsibility for any damages arising from

failure to earth the boiler correctly.

It is necessary that a qualified technician verifies that the

electrical system is adequate to the appliance’s maximum

absorbed power, indicated on the data plate, verifying in

particular that the section of the system’s cables is suitable

to the appliance’s maximum absorbed power.

For the appliance’s general electrical supply the use of

adaptors, multiple sockets and/or extension cords is strictly

forbidden.

The use of any power supplied equipment implies the

observance of several fundamental rules, such as:

- Do not touch the appliance with any wet part of your body

and/or barefooted;

- Do not pull the supply cables

- Do not expose the boiler to sunlight, rain, etc., unless it is

explicitly foreseen;

- Do not permit children or inexpert people to use the

appliance.

32

Instructions for the installer

- Gain access to the rear of the eBus and remove the

terminals numbered from 5 to 11.

- Outdoor sensor connection: insert the cables between

the pins 9 and 10 on the e-Bus terminal board.

DANGER!

Switch off and disconnect the electricity supply before carrying out any operations on the

electrical parts.

Outdoor sensor connection

EBUS UNIT

1234 5678 910

11

OUTDOOR

SENSOR

0

1

2

3

4

5

6

7

8

9

BUS +

Single boiler

DANGER!

Switch off and disconnect the electricity supply before carrying out any operations on the

electrical parts.

- Gain access to the Y2 terminal board on the BCM

Cascade controller

- Outdoor sensor connection: insert the cables between

the pins 6 and 7 on the terminal board.

Boilers installed in a cascade formation

OUTDOOR

SENSOR

123Y24567

Y3

123

Jp1

12

3

Y4

4

DL1 DL2 DL3

1

23

Y1

456

A1

SW1

BCM

eBUS -

eBUS +

+ 24 V

0

1

2

3

4

5

6

7

8

9

BCM

33

Instructions for the installer

The BCM (optional kit) board, elaborates the data concerning the thermal drop (Δt between primary flow and

return) and provided power.

When the provided power is reduced, the number of turns

of the pump reduces as well and therefore also the hourly

flow rate, keeping the thermal drop constant.

.

Boiler battery

IThe 0 - 10 Volt modulation signal is reset at:

- 3 Volt for minimum speed

- 10 Volt for maximum speed.

These values can be modified according to the

pump model used. For further information of

the 0 - 10 Volt signal, also refer to the pump

manual.

FIX RATE PUMP

Modulating Pump

12

3

Y2

45

67

Y3

12

3

Jp1

12

3

Y4

4

DL1 DL2 DL3

123

Y1

45 6

A1

SW1

ALLARM

SIGNAL

BCM

eBUS -