S 24

S 28

S 35

ENGLISH

+ TOUCH CONTROL Uy BOX integrate

INSTALLATION AND SERVICING MANUAL

http://www.unicalag.it/prodotti/domestico-50/condensazione-gas/osa/1635/osa-s

Provisions for proper disposal of the product in accordance with Directive 2002/96/EC

At the end of its life cycle the product must not be disposed of as urban waste. It can be taken to

a special recycling centre managed by the local authorities, or to a dealer who offers this service.

Separate disposal of a domestic appliance avoids possible negative consequences for the

environment and human health deriving from inappropriate waste handling and allows the recovery

of the materials of which it is made, in order to obtain signicant energy and resource savings.

2

Attention: this manual contains instructions for the exclusive use of the professionally qualied installer

and/or maintenance technician in compliance with current legislation.

The user is NOT qualied to intervene on the boiler.

The manufacturer will not be held liable in case of damage to persons, animals or objects resulting from

failure to comply with the instructions contained in the manuals supplied with the boiler.

1 GENERAL INFORMATION ...............................................................................................................................4

1.1 General warnings .................................................................................................................................... 4

1.2 Symbols used in the manual ................................................................................................................... 5

1.3 Appropriate use of appliance ...................................................................................................................5

1.4 Information for system manager ..............................................................................................................5

1.5 Safety warnings ....................................................................................................................................... 6

1.6 Technical data plate ................................................................................................................................7

1.7 Water treatment .......................................................................................................................................8

1.8 Boiler antifreeze protection ......................................................................................................................8

2 TECHNICAL FEATURES AND DIMENSIONS ..................................................................................................9

2.1 Technical features ................................................................................................................................... 9

2.2 Main components view and dimensions ..................................................................................................9

2.3 Available ow rate / pressure diagram .................................................................................................. 14

2.4 Operation data .......................................................................................................................................15

2.4.1 Data according to directive ErP ....................................................................................................15

2.4.2 Caratteristiche del controllo integrato Uy BOX ........................................................................... 15

2.5 General features ............................................................................................................................. 15

General information

ENGLISH

3 INSTALLATION INSTRUCTIONS ...................................................................................................................16

3.1 General warnings .................................................................................................................................. 16

3.2 Installation standards ............................................................................................................................16

3.3 Preventive system verication and adjustment operations ...................................................................16

3.4 Packaging ..............................................................................................................................................17

3.4 Positioning the boiler ............................................................................................................................. 18

3.6 Flue gas exhaust pipe connection ......................................................................................................... 19

3.7 Connections ..........................................................................................................................................22

3.8 Filling the system ...................................................................................................................................23

3.9 Electrical connections ............................................................................................................................24

3.10 Commissioning ................................................................................................................................... 26

3.11 Measurement of combustion efciency during installation .................................................................... 27

3.11.1 Calibration function activation ................................................................................................... 27

3.11.2 Probes positioning ....................................................................................................................28

3.12 Burner adjustment ................................................................................................................................. 29

3.12.1 Combustion adjustment function activation ..............................................................................30

3.12.3 Adaptation of the power to the heating system .........................................................................31

4 MAINTENANCE INSTRUCTIONS .................................................................................................................. 32

4.1 Inspection and maintenance instructions .............................................................................................. 32

4.1.1 Pannello comandi Uy BOX ......................................................................................................... 33

4.2 Parameters that can be edited from the control panel ..........................................................................35

4.3 Adaptation of the power to the heating system ..................................................................................... 38

4.3.1 GAC adjustment .......................................................................................................................... 39

4.4 Wiring diagram ................................................................................................................................43

4.5 Error Code .............................................................................................................................................44

4.5.1 Filling system ................................................................................................................................47

4.6 Important Note ....................................................................................................................................... 48

4.6.1 Service panel ................................................................................................................................49

Technical Features

Installation Instructions

Maintenance instructions

3

1

GENERAL INFORMATION

1.1 - GENERAL WARNINGS

The instruction booklet is an integral and essential

part of the product and must be kept by the user.

Read the warnings contained in this instruction

booklet carefully as they provide important guidelines

regarding installation, use and maintenance safety.

Keep the booklet with care for further consultation.

Installation and maintenance must be performed

in compliance with the standards in force according to the instructions of the manufacturer,

up to standard and by personnel qualied and

certied in compliance with law.

Systems for the production of domestic hot water MUST be constructed entirely with compliant

materials.

By professionally qualied personnel we mean:

personnel with specic technical skill in the eld

of heating system components for civil use, domestic hot water production and maintenance.

Personnel must have the qualications provided

for by current legislation.

Incorrect installation or improper maintenance

can cause damage to persons, animals or objects

for which the manufacturer is not responsible.

Before performing any cleaning or maintenance,

disconnect the appliance from the energy mains by

acting on the switch of the system and/or through

the specic cut-off devices.

Do not obstruct the terminals of the intake/exhaust

ducts.

In the event of failure and/or malfunctioning of the

appliance, switch it off and do not try to repair it or

intervene on it directly. Contact only personnel qualied in compliance with law.

Any repairs must be performed solely by personnel

authorised by Unical AG S.p.A., using original spare

parts only. Failure to comply with the above can compromise the safety of the boiler and void the warranty.

To guarantee appliance efciency and its correct

operation, yearly maintenance must be performed

by qualied personnel.

Should you decide not to use the appliance, parts

entailing potential sources of hazard must be made

safe.

Before commissioning an appliance that has not

been used, wash the domestic hot water production

system, making the water ow until it has been fully

replaced.

Should the appliance be sold or transferred to a new

owner or if you move and leave the appliance, always

make sure that the instruction booklet accompanies

it in order to be consulted by the new owner and/or

installer.

Only original accessories must be used for all appliances with optionals or kits (including electric).

This boiler is intended solely for the use for which it

was expressly designed.

Any other use is to be considered improper and

therefore dangerous (*).

4

1.2 - SYMBOLS USED IN THE MANUAL

Pay special attention when reading this manual to the parts marked by the symbols:

DANGER!

Serious danger

to safety

and health

situation for the product

ATTENTION!

Possible dangerous

for the user

and the environment

1.3 - APPROPRIATE USE OF APPLIANCE

The boiler has been built according to the current level of engineering and acknowledged

technical safety rules.

Nonetheless, if improperly used, dangers could arise for the safety and life of the user

and other persons or damage to the equipment or other objects.

The appliance is designed to work in heating systems, with hot water circulation, for

the production of domestic hot water.

Any other use is considered improper.

Unical AG S.p.A. will not be held liable for any damage resulting from improper use.

Use according to the intended purposes also includes strict compliance with the instructions in this manual.

NOTE!

Tips

NOTE!

For more information

See Technical Info:

from site indicated at pag. 2

1.4 - INFORMATION PROVIDED TO THE USER

The user must be instructed concerning the use and operation of his heating system, in particular:

• Deliver these instructions to the user, as well as other documents concerning the appliance

inserted in the envelope inside the packaging. The user must keep this documentation

safe for future consultation.

• Inform the user about the importance of the air vents and the ue gas exhaust system, highlighting their essential features and the absolute prohibition of modifying them.

• Inform the user concerning controlling the system's water pressure as well as operations to

restore it.

• Inform the user concerning correct temperature control, control units/thermostats and radiators

for saving energy.

• Please note that, in compliance with the standards in force, the inspection and maintenance of

the appliance must be carried out in compliance with the regulations and frequency indicated

by the manufacturer.

• Should the appliance be sold or transferred to a new owner or if you move and leave the appliance, always make sure that the instruction booklet accompanies it in order to be consulted

by the new owner and/or installer.

The manufacturer will not be held liable in the event of damage to persons, animals or

objects resulting from failure to comply with the instructions contained in this manual.

5

1.5 - SAFETY WARNINGS

ATTENTION!

The boiler cannot be used by children.

The boiler can be used by adults and only after having carefully read the user’s manual. Children should be supervised to ensure that they do not play or tamper with

the device.

ATTENTION!

The appliance must be installed, adjusted and maintained by professionally qualied

personnel, in compliance with the standards and provisions in force. Incorrect installation can cause damage to persons, animals and objects for which the manufacturer

cannot be held responsible.

DANGER!

NEVER attempt performing maintenance or repairs on the boiler on your own initiative.

Any work must be done by professionally qualied personnel. We recommend stipulating a maintenance contract.

Insufcient or irregular maintenance can jeopardise the operating safety of the appliance and cause damage to persons, animals and objects for which the manufacturer

cannot be held responsible.

Changes to the parts connected to the appliance (once the appliance installation is complete)

Do not modify the following parts:

- the boiler

- the gas, air, water and electricity supply lines

- the ue gas pipe, the safety valve and the exhaust pipe

- the construction parts which affect the operating safety of the appliance

Attention!

To tighten or loosen the screwed ttings, use only appropriate xed spanners.

Incompliant use and/or inappropriate tools can cause damage (e.g. water or gas leakage).

ATTENTION!

Indications for propane gas-red appliances

Make sure that the gas tank has been deaerated before installing the appliance.

For state-of-the-art tank venting, contact the LPG supplier or person qualied in compliance

with the law requirement.

If the tank has not been professionally deaerated, ignition problems could arise.

In that case, contact the supplier of the LPG tank.

Smell of gas

Should a smell of gas be perceived, follow these safety guidelines:

- do not turn electric switches on or off

- do not smoke

- do not use the telephone

- close the gas shut-off valve

- air out the area where the gas leakage has occurred

- inform the gas supplier or a company specialised in installation and maintenance of heating

systems.

Explosive and easily ammable substances

Do not use or store explosive or easily ammable materials (e.g. petrol, paints, paper) in the

room where the appliance is installed.

DANGER!

Do not use the appliance as a supporting base for objects.

In particular, do not place receptacles containing liquids (Bottles, Glasses, Jars or Detergents)

on top of the appliance.

If the appliance is installed inside a housing, do not insert or rest other objects inside this housing.

6

1.6 - TECHNICAL DATA PLATE

The CE marking

certies the compliance of the equipment with the

essential safety requirements dened in the directives and applicable European regulations and that

its functioning satisfy applicable technical standards.

The CE marking is afxed to each piece of equipment with an appropriate label.

KEY:

1 = CE monitoring body

2 = Type of boiler

3 = Boiler model

4 = Number of stars (directive 92/42 EEC)

5 = (S.N°) Serial Number

6 = P.I.N.ProductIdenticationNumber

7 = Typesofapproveduegasexhaustcongurations

8 = (NOx)NOxClass

The CE declaration of conformity issued in accordance with international standards by the manufacturer, is placed in documentation envelope supplied with the product.

The rating plate is placed inside the

boiler,

The rating plate DUPLICATE is placed

under the front casing (lower-right).

A = Heatingcircuitcharacteristics

9 = (Pn) Effective nominal output

10 = (Pcond) Effective output in condensation

11= (Qn)Maximumheatoutput

12= (AdjustedQn)Adjustedforratedheatoutput

13= (PMS)Max.heatingoperatingpressure

14= (Tmax)Max.heatingtemperature

B = Domestichotwatercircuitcharacteristics

15= (Qnw)Ratedheatoutputindomestichotwaterfunction

(if different to Qn)

16= (D)SpecicD.H.W.owrateaccordingtoEN625-EN

13203-1

19= (PMW)Max.domestichotwateroperatingpressure

20= (Tmax)Max.domestichotwatertemperature

C = Electricalcharacteristics

21= Electricalpowersupply

22 = Consumption

23 = Protection rating

General information

ENGLISH

D = Countries of destination

24 = Direct and indirect countries of destination

25 = Gas category

26 = Supply pressure

E = Factory settings

27 = Adjusted for gas type X

28 = Space for national brands

G = ErP

29=Seasonalspaceheatingenergyefciency

30 =EnergyefciencyinDHWproductionmode

7

1.7 - WATER TREATMENT

The treatment of the supply water

allows to prevent inconveniences

and maintain the functionality and

efciency of the generator over time.

The ideal water pH in heating systems

must be within:

VALUE MIN MAX

PH 6.5 8

Hardness [°fr] 9 15

To minimise corrosion, it is crucial to

use a corrosion inhibitor; in order for

it to work properly, the metal surfaces must be clean.

(see system protection ACCESSORIES sect. in domestic price list)

ATTENTION!

ANY DAMAGE TO THE BOILER

CAUSED BY THE FORMATION OF

FOULING OR BY CORROSIVE WATER

WILL NOT BE COVERED BY THE

WARRANTY.

ATTENTION (*) see general warnings 1.1

The heating only models are NOT

suitable for the production of water

for human consumption according

to Ministerial Decree D.M. 174/2004.

1.8 - BOILER ANTIFREEZE

PROTECTION (*)

(*) The frost protection is always active.

Even disabling the CH and DHW services.

P

O

S

1

2

(*) Sensor 11 par. 2.2

Power supplies 11 - SR (*) Status

Electric Gas

ON ON < 6 °C ON - Burner and Pump ON until T > 14°C

ON OFF

OFF ON

OFF OFF

< 2 °C ON

This protection can intervene only

i f the electricity and gas supplies are

connected.

I f one of the two is not available and

upon reset 11 (SR) a temperature of

< 2 °C is detected, the appliance will

behave as described in tab. pos 2.

The heating system can be protected

effectively from frost by using

antifreeze products with inhibitor

for heating systems (specific for

multidmetal).

Do not use car engine antifreeze

products as they could damage the

water gaskets.

ANTIFREEZE FUNCTION

Actions

function

antifreeze

Only when both the power supplies are ON:

- Burner and Pump OFF until T > 5°C

- When T > 5°C then Burner and Pump

ON until T > 14°C.

8

2

TECHNICAL FEATURES

AND DIMENSIONS

For more information

2.1 - TECHNICAL FEATURES

2.2 - VIEW WITH THE INDICATION OF THE MAIN COMPONENTS AND DIMENSIONS

OSA S 24

See Technical Info

from site indicated at pag. 2

NOTE!

ENGLISH

Technical Features

9

OSA S 28 - OSA S 35

10

OSA S 24 - OSA S 28 - OSA S 35

View from below

View from above

11

KEY

N° C.E. S.E. Description

1 db SS Domestic hot water temperature

sensor

2 FLS Flow switch with cold water lter

3 VG Gas valve

4 Fd E.

Ignition/detection electrode

ACC

/RIL

5 Burner

8 Expansion vessel

10 HL TL Safety thermostat

11 Hb SR Heating temperature sensor

12 Ht P Pump

13 Lp DK Water deciency pressure switch

16 Diverter valve

17 Plate heat exchanger

18 FL

VM

Fan

FH

20 Safety valve

22 rb SRR Return temperature sensor

23 tf TLC Flue gas collector safety ther-

mostat

24 Aluminium Heat Exchanger/Ca-

pacitor

25 Vent valve

26 Condensation drain trap

33 Uy BOX (retractable)

34 Gateway (external links)

35 Emergency panel

Aves Connection for additional

expansion vessel

C Domestic hot water outlet G ½

G Gas inlet G ¾

F Cold water inlet G ½

M Heating system ow G ¾

R Heating system return G ¾

Rc Filling valve

Sc Boiler drain

Svs Safety valve drain

Scond

Condensation drain

Ufp Smoke rear output optional

C.E. = ERROR CODES see

par. 4.6

S.E. = WIRING DIAGRAM

KEY see par. 4.5

12

2.3 - DIAGRAM OF FLOW RATE/PRESSURE AVAILABLE FOR

INSTALLATION

MODULATING PUMP

DIAGRAM OF FLOW RATE/PRESSURE AVAILABLE FOR INSTALLATION

OSA S 24

ENGLISH

Avaible Head (m.c.a.) metres of waterAvaible Head (m.c.a.) metres of water

OSA S 28 - OSA S 35

Technical Features

Flow rate (l/h)

Flow rate (l/h)

13

2.4 - OPERATING DATA ACCORDING TO UNI 10348

Fortheadjustmentdata:NOZZLES-PRESSURES-DIAPHRAGMS-FLOWRATES-CONSUMPTIONSrefertotheparagraphADAPTATIONTOOTHERTYPESOFGAS.

OSA S 24 OSA S 28 OSA S 35

Nominal heat input in CH / DHW mode kW 23,4 28,0 / 33,0 33,0

Minimum heat input with Nat. Gas / Propane kW 3,0 / 3,0 4,4 / 4,4 4,4 / 4,4

Nominal heat output kW 23,02 27,3 32,2

Minimum heat output kW 2,96 4,3 4,3

Nominal output in condensation 50/30 °C kW 23,7 28,9 33,8

Minimum heat output in condensation 50/30 °C kW 3,22 4,68 4,68

Combustion efciency at full load % 97,2 97,8 97,3

Combustion efciency at part load % 98,6 98,2 98,1

Heat losses through the casing (min.-max.) % 1,4 - 1,0 1,1 - 0,2 1,1 - 0,2

(*) Net ue gas temperature tf-ta (max.) °C 56,8 45,1 54,8

Flue gas mass ow rate (min.-max) g/s 1,35 - 10,5 2,0 - 12,5 2,0 - 14,7

Air excess λ % 24,3 23,0 23,0

CO

2

CO at 0% of O

Maximum production of condensate kg/h 3,8 4,5 5,3

NOx class 5 5 5

Chimney heat losses with burner ON (min. - max.) % 1,4 - 2,8 1,8 - 2,2 1,9 - 2,7

Chimney heat losses with burner OFF % 0,35 0,34 0,34

Max. available pressure at the chimney base min. / max.

Notes: (*) Room Temperature = 20°C Data obtained with appliance operated with Nat Gas (G20)

(min. - max) ppm 22 - 114 14 - 88 14 - 94

2

% 9,2 - 9,2 9,2 - 9,3 9,2 - 9,3

Pa 2 / 70 2 / 70 2 / 70

2.4.1 - DATA ACCORDING TO ErP DIRECTIVE

Description Symbol Unit OSA S 24 OSA S 28 OSA S 35

Nominal Heat Output Pnominale kW 23 27 32

Seasonal space heating energy

efciency

Seasonal efciency class in

heating mode

Integrated Weather compensator and

room sensor

Seasonal space heating energy

efciency of package

Seasonal space heating energy

efciency class of package

For CH only and combination boilers: useful heat output

Useful Heat Output in high-temperature regime

(Tr 60 °C / Tm 80 °C)

Useful efciency at nom. heat output

in high-temperature regime

(Tr 60 °C / Tm 80 °C

Useful heat output at 30% of nom.

heat output in low-temperature

regime (Tr 30 °C)

Useful efciency at 30% of nom. heat

output in low-temperature regime

(Tr 30 °C)

Range-rated boiler: YES / NO YES YES YES

Auxiliary electricity consumption

At full load elmax kW 0,085 0,093 0,093

At part load elmin kW 0,012 0,015 0,015

In stand-by mode P

Other items

Stand-by heat loss P

Emissions of nitrogen oxides NOx Mg/kWh 41 36 39

For CH & DHW production boilers

Declared load prole L XL XL

Energy efciency in DHW production

mode

Daily electricity consumption Qelec kWh 0,0644 0,0813 0,0813

Daily fuel consumptionl Qfuel kWh 14,41 22,97 22,97

Inside sound power level Lwa dB (A) 53 54 54

Seasonal efciency class

in DHW production mode

14

ƞ

s % 94 94 94

A A A

Classe VI % 4 4 4

ƞ

s

Packaging

% 98 98 98

A+ A+ A+

4 kW 13 16 18,4

P

ƞ

4 % 88,7 88,9 88,7

1 kW 4,3 5,3 6,1

P

ƞ

1 % 99,2 98,1 98,2

SB kW 0,003 0,001 0,001

stb kW 0,0824 0,113 0,113

wh % 84 86 86

ƞ

A A A

2.4.2 - FEATURES OF INTEGRATED Uy BOX

Uy BOX control panel, togheter with room sensor temperature and outer sensor temperature

provided as standard, performs the environmental thermoregulation work as described in the document

2014/C 207/02, section 6.1.

Class VI – Weather compensator and room sensor, for use with modulating heaters: A heater ow temperature control that varies the ow temperature of water leaving the heater dependant upon prevailing

outside temperature and selected weather compensation curve. A room temperature sensor monitors

room temperature and adjusts the compensation curve parallel displacement to improve room comfort.

Control is achieved by modulating the output of the heater.

2.5 - GENERAL FEATURES

ENGLISH

Appliance category

Minimum heat. circuit output (∆t 20 °C) l/min

Minimum heating circuit pressure bar

Maximum heating circuit pressure bar

Primary circuit content l

Maximum operating temperature in heat. °C

Minimum operating temperature in heat. °C

Expansion vessel total capacity l

Expansion vessel pre-load bar

Maximum system capacity (max temp. calc.) l

Minimum domestic hot water circuit ow rate l/min.

Minimum domestic hot water circuit pressure bar

Maximum domestic hot water circuit pressure bar

Domestic hot water specic ow rate (∆t 30 °C) ‘‘D’’ l/min.

Domestic hot water ow rate limiter l/min.

Production of D.H.W. in continuous operation with ∆t 45 K

Production of D.H.W. in continuous operation with ∆t 40 K

Production of D.H.W. in continuous operation with ∆t 35 K

Production of D.H.W. in continuous operation with ∆t 30 K

Production of D.H.W. in continuous operation with ∆t 25 K (*)

l/min.

l/min.

l/min.

l/min.

l/min.

Voltage/Frequency electric power supply °C

Fuse on the power supply V-Hz

Maximum absorbed output A (F)

Protection rating IP

Net weight boiler kg

Gross weight boiler kg

Net weight front case (shell) kg

Gross weight front case (shell) kg

OSA S 24 OSA S 28 OSA S 35

2H3P

II

2,1 3,06 3,08

0,5 0,5 0,5

3 3 3

2,2 2,2 2,2

85 85 85

30 30 30

9 (6+3) 6 6

1 1 1

185 123 123

2 2 2

0,5 0,5 0,5

6 6 6

11,2 16 16

10 15 15

7,3 10,3 10,3

8,3 11,6 11,6

9,4 13,3 13,3

11,0 15,5 15,5

13,2 18,6 18,6

35-60 35-60 35-60

230/50 230/50 230/50

3,15 3,15 3,15

X4D X4D X4D

41 41 41

45,7 45,7 45,7

3 3 3

4,9 4,9 4,9

2H3P

II

II

F factor 1 2 2

R factor

(*) mixed

2H3P

Technical Features

15

3

INSTALLATION INSTRUCTIONS

3.1 - GENERAL WARNINGS

ATTENTION!

This boiler is intended solely for

the use for which it was expressly

designed. Any other use is to be

considered improper and therefore

dangerous.

This boiler heats water at a temperature lower than the atmospheric

pressure boiling temperature.

Before connecting the boiler, have professionally qualied personnel:

a) Thoroughly wash all the piping of

the system to remove any residues

or impurities which could jeopardise proper operation of the boiler,

even from a hygienic point of view.

b) Check that boiler is set up to oper-

ate with the available type of fuel.

This can be seen written on the

package and on the technical feature

plate;

c) Check that the chimney/ue has an

appropriate draught, without any

bottlenecks, and that no exhausts

from other appliances are inserted,

unless the ue has been implemented to accommodate several utilities

according to specic standards and

regulations in force. Only after this

check can the fitting between the

boiler and chimney/ue be mounted;

ATTENTION!

If there is dust and/or if there are

aggressive/corrosive vapours

present in the installation room,

the appliance must be protected

suitably and must be able to

operate independently from the air

in the room.

ATTENTION!

Only mount the appliance on a closed

wall, made of non-ammable materi-

al, at, vertical so that the minimum

distances required for installation and

maintenance can be observed.

The boiler must be connected to a central heating system and/or domestic hot

water supply network compatible with its

efciency and output.

NOTE!

For more information

See Technical Info

from site indicated at pag. 2

3.2 - INSTALLATION STANDARDS

It must be installed by a professionally qualied

technician, who shall take the responsibility of

observing all local and/or national laws published

in the ofcial journal, as well as the applicable

technical standards.

3.3 - PREVENTIVE VERIFICATION

AND VERIFICATION AND ADJUSTMENT OPERATIONS

16

NOTE!

For further details relating to the

standards, rules and regulations

for safe installation of the thermal

unit, refer to the section "Technical

Information" on the boiler page of

the www.unicalag.it website

NOTE!

For more information

See Technical Info

from site indicated at pag. 2

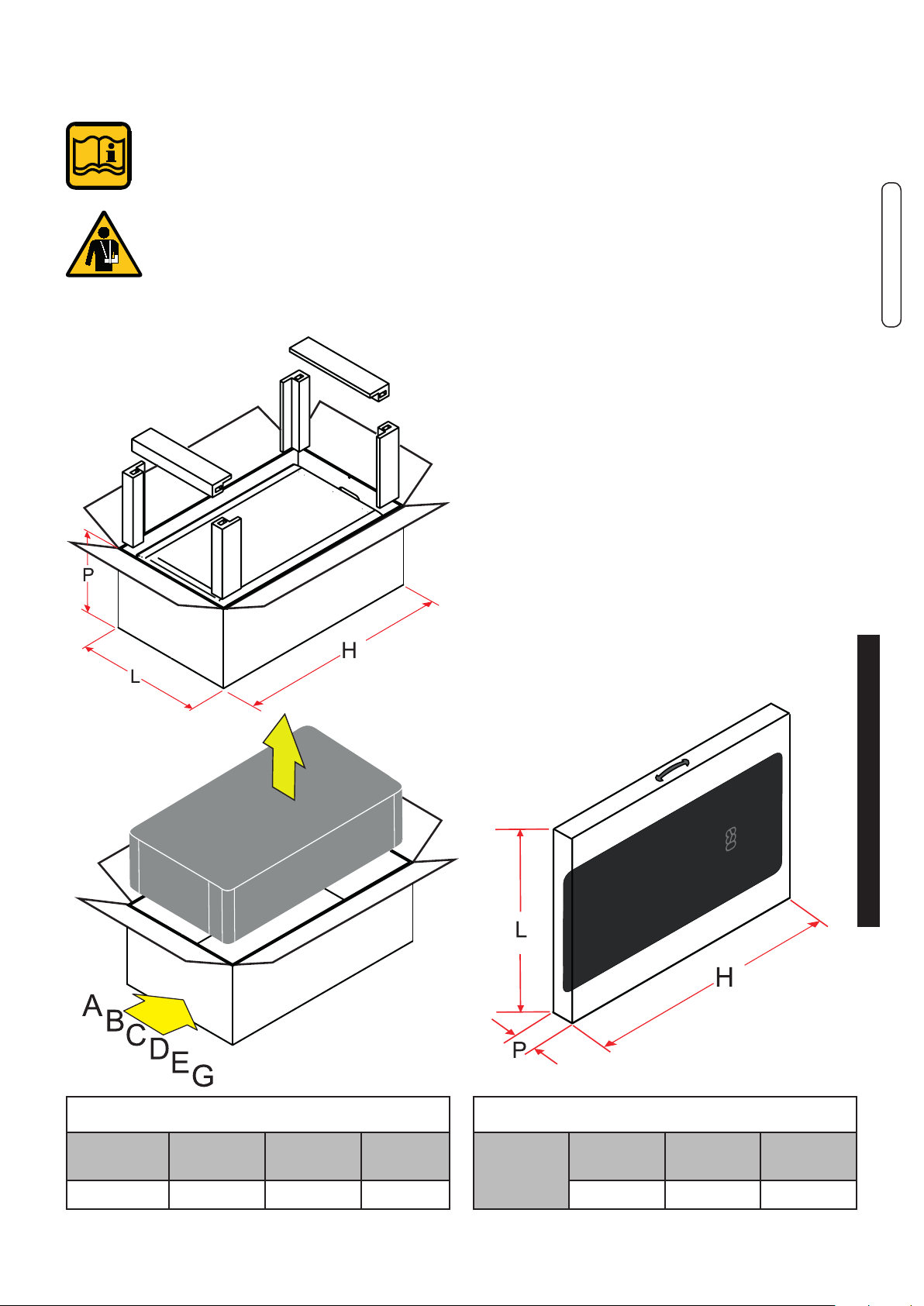

3.4 - PACKAGING

The OSA boiler is supplied completely assembled

in a sturdy cardboard box.

After having removed the appliance from

the packaging, make sure that the supply

is complete and undamaged.

The packaging elements (cardboard

box, straps, plastic bags, etc.) must be

kept out of the reach of children as

they are potential sources of danger.

Unical AG S.p.A. will not be held liable

1

for damage to persons, animals or objects due to

failure to comply with the instruction above.

As well as the appliance, the packaging contains:

A DOCUMENTATION ENVELOPE

- User operating instructions booklet

- Instruction booklet for the installer and

maintenance engineer

- Warranty

- 2 Spare parts form

- Certicate of conformity

- Gas conversion label

B - Connection predisposition paper template

D - Chimney spacer

E - Bracket for xing

F - Uy BOX

G - Outer sensor + Remote temperature sensor

ENGLISH

2

BOILER

OSA S P

Depth

200 mm 540 mm 1010 mm

L

Width

H

Height

3

SHELL

OSA S P

L

Depth

62 mm 592 mm 1000 mm

Width

H

Height

Installation Instructions

17

3.5 - POSITIONING THE BOILER

When choosing the place of the installation of the

appliance, follow the safety instructions below:

- Place the appliance in rooms protected from frost.

- Avoid installation in rooms with a corrosive or very

dusty atmosphere.

- The appliance must only be installed on a vertical

and solid wall which can support its weight.

- The wall must not be made of ammable material.

Since the temperature of the wall on which the boiler is installed and the temperature of the coaxial

exhaust pipe do not exceed, in normal operating

conditions, a room temperature beyond 60 K, it is

not necessary to observe the minimum distances

from ammable walls.

For boilers with double intake and exhaust pipes, in

the event of crossing ammable walls, insert insulation between the wall and the ue gas exhaust pipe.

OSA S 24 - OSA S 28 - OSA S 35

Clearance

18

3.6 - FLUE GAS EXHAUST PIPE CONNECTION

FOR BOILERS WITH FORCED DRAUGHT

To connect the ue gas exhaust pipe, local and national standards must be observed

In the event the boiler is replaced, ALWAYS re-

C13x C13

% Slope towards inlet = 3%

TOTAL LENGTH (LA intake + L Exhaust)

COAXIAL Ø60/100 DOUBLE Ø80

FROM [m] TO [m] FROM [m] TO [m]

1 5,5 1 + 1

COAXIAL Ø80/125 DOUBLE Ø60

FROM [m] TO [m] FROM [m] TO [m]

1 8 1 + 1

Distance between air

inlet pipe and ue gas

exhaust pipe: min 250

mm - max 500

Horizontal exhaust and intake terminals directed

outside via coaxial or double pipes..

40

(20A+20S)

20

(10A+10S)

place the ue gas pipe as well.

The boiler is type approved for the exhaust congurations listed below:

C43x C43

ENGLISH

Collective chimney ue system, consisting of two

pipes, one for combustion air intake and the other

one for combustion products evacuation, coaxial

or double.

C53x C53

C33x C33

TOTAL LENGTH (LA intake + L Exhaust)

COAXIAL Ø60/100 DOUBLE Ø80

FROM [m] TO [m] FROM [m] TO [m]

1 7 0,5 + 0,5

COAXIAL Ø80/125 DOUBLE Ø60

FROM [m] TO [m] FROM [m] TO [m]

1 9 1 + 1

ertical exhaust and intake terminals directed out-

side via coaxial or double pipes.

40

(20A+20S)

20

(10A+10S)

C53

NOT ALLOWED C53

TOTAL LENGTH (LA intake + L Exhaust)

DOUBLE Ø80 DOUBLE Ø60

FROM [m] TO [m] FROM [m] TOA [m]

1 + 1

40

(max 30 S)

1 + 1

(max 15 S)

20

Separate combustion air intake and combustion

products evacuation pipes.

These pipes can discharge into areas with different

pressure.

Installation Instructions

19

C63x C63

Boiler intended for connection to a combustion air

intake and combustion products evacuation system,

approved and sold separately

ATTENTION:

The ue must comply with standards

in force.

C83x C83

B23P

TOTAL LENGTH (LS)

DOUBLE Ø80

FROM [m] TO [m]

1 30

Connection to a combustion products evacuation

pipe outside the room; the combustion air is taken directly from the room where the appliance is

installed.

Connection to a terminal for combustion air intake

and ue gas exhaust via a single or collective

chimney.

C93x C93

Air / ue gas through concentric pipes in the boiler

room and single pipes in the chimney (combustion

air with counterlow in the chimney)

ATTENTION:

(*) Values in the MT018 available on the website.

For the type of connection B23P the

room follows the same installation rules

for boilers with natural draught.

CAUTION

LT total length is a reference value

for the dimensioning of the ducts of A

(intake) and S (Exhaust). Subtracting

the values of LT reported, at values of

bends* / terminals* / extensions* you

get the value:

if > 0 = OK - POSSIBLE conguration

if < 0 = NO - WRONG conguration

Please note:

These values relate to exhausts/

made by means of rigid pipes and

smooth original UNICAL.

20

NOTE!

For more information

See Technical Info

from site indicated at pag. 2

GENERAL INFORMATION ON THE FLUE GAS EXHAUST SYSTEM

Rear smoke

outlet

not possible

ENGLISH

Rubber sealing caps

(Remove according to the type

Exhaust used:

HIGHER

- Split (remove both)

- Coaxial (leave only one shown)

REAR NOT VISIBLE

(rear in the boiler)

installation instructions in the kit.

it is possible only with coax

(Leave 2 above).

(+) Adapter for double systems

Departure Coaxial

It is recommended to only use original

Unical exhaust pipes.

The supplier will have no contractual

or extra-contractual liability for damage

caused due to incorrect installation and

use and in any case failure to comply

with the instructions provided by the

manufacturer.

NOTE!

For further details relating to pressure drops of

the individual components, for information on

standards, rules and regulations for proper ue

gas exhaust, refer to the "Technical Information"

section on the boiler page of the www.unicalag.

it website

Installation Instructions

21

3.7 - CONNECTION

G GAS 3/4’’

Danger!

The gas connection must be carried out

only by a qualied installer who must respect and apply that foreseen by relevant

laws in force in the local prescriptions of

the supply company. Incorrect installation

can cause damage to persons, animals

and objects for which the manufacturer

cannot be held responsible.

If you smell gas:

a) Do not operate electric switches,

the telephone or any other object that

may cause sparks;

b) Immediately open doors and

windows to create air current

to purify the room;

c) Shut the gas cocks.

M FLOW 3/4’’

R RETURN 3/4’’

Condensation drain

The boiler, during the combustion process, produces condensation that, through pipe “A”, ows

into the trap.

The condensation that forms inside the boiler ows

into a suitable drain via pipe “B”.

Danger!

Before commissioning the appliance:

- check that the trap is assembled

properly

- ll the trap and check that

the condensation is drained properly

If the appliance is used with an empty

condensation drain trap, there is an

intoxication hazard due to the release

of exhaust gasses.

C HOT 1/2’’

F COLD 1/2’’

Sc BOILER DRAIN

S.cond CONDENSATION DRAIN

Rc FILLING VALVE

Svs SAFETY VALVE DRAIN

Provide a drain pipe with funnel and a

trap that lead to a suitable drain, in correspondence of Svs.

This drainage must be controlled on

sight.

If this precaution is not taken, triggering of the safety valve can cause damage to persons, animals and objects,

for which the manufacturer cannot be

held responsible.

Aves

Connection for additional expansion

vessel.

22

The mains pressure must be within 1 and 3

bar (in the event of greater pressure install

a pressure reducer).

Condensation outlet, pipe to be connected to

the drainage system

The connection between the appliance

and the domestic waste system must

be made in compliance with the specic

reference standards.

3.8 - FILLING THE SYSTEM

Attention!

Do not mix the heating water with incorrect concentrations of antifreeze

or anti-corrosion substances! This

could damage the gaskets and cause

noise during operation.

When the system connections have been completed,

the circuit can be lled.

This operation must be performed carefully, respecting the following phases:

- open the radiator vent valves and make sure the

automatic valve is working properly in the boiler.

- ONLY FOR FIRST FILL - normally the lling is

automatic - open the lling tap gradually Rc (mediante cacciavite) making sure that the automatic

air release valves installed on the system work

properly.

- close the radiator air release valves as soon as

water comes out.

- check the pressure gauge U-y until pressure

reaches approximately 0.8/1 bar.

- close the lling tap Rc and bleed air once again

through the radiator air release valves.

- make sure that all the connections are watertight.

- after commissioning the boiler (see par. 3.10) and

bringing the system to the operating temperature,

stop the boiler and repeat the air bleed operations.

- let the system cool down and, if necessary, return

the water pressure to 0.8/1 bar.

(See par. 4.5).

NOTE!

For more information

See Technical Info

from site indicated at pag. 2

ENGLISH

Note: The rst ll of the boiler must

be made manually.

FILLING VALVE

Screw in load position

LOAD

FILLING VALVE

Screw in position of

NORMAL OPERATION.

Unical will not be held liable for damage to persons, animals or objects

due to failure to comply with the above

instruction.

Installation Instructions

Rc

The lling valve RC is positioned

behind the siphon.

23

3.9 - ELECTRICAL CONNECTIONS

Danger!

Only a qualied technician may perform the electrical installation.

Before performing connections or

any type of operation on electrical parts, always

disconnect electrical power and make sure that

it cannot be reconnected accidentally.

The external connections have to be made on the

GATEWAY (connector Y3), the cable exits wil be

made in groves on cover A.

OT/TA = ON-OFF room thermostat (*)

OT (OpenTherm) is not enabled

- Arranged on GATEWAY connector, Y 3 5-6.

Remove the jumper and connect the wires of

the room thermostat between terminals.

(*) Optional

SA = Room sensor supplied

- Arranged on GATEWAY connector, Y3 9-10,

Remove the bridge between terminals 5-6.

24

SE = Outside sensor supplied

SHC = Multifunction module (*)

ENGLISH

- Arranged on GATEWAY connector, Y3 7-8.

Electric power supply connection

Modulation

Board

INSIDE

BOILER

- Arranged on GATEWAY connector, Y3 4-3.

The boiler is equipped with a power

cable, boiler installation requires electric al connection to the mains power

supply. This connection must be made

up to standard, as required the regulations in force.

Remember that a bipolar switch must

be installed on the boiler power line

with over 3 mm between contacts, easy

to access, making maintenance quick

and safe.

The power cable must be replaced

by technical personnel authorised by

UNICAL AG S.p.A., using original spare

parts only. Failure to comply with the

above can jeopardise the safety of the

appliance.

Installation Instructions

If necessary the shield of the sensor

cable, can be connected to the terminal. (Ground connections - modulation

board).

See par. 4.5 positioning on the board

(*) Optional

25

3.10 - COMMISSIONING

Commissioning must be done by professionally qualied personnel. Unical AG

S.p.A. will not be held liable for damage

to persons, animals or objects due to

does the installation meet the specic standards and regulations in force, both relating to the

gas part as well as the electrical part?

do the combustion air intake and ue gas exhaust take place properly according to what is

dened by the specic rules and regulations in force?

is the fuel supply system sized according to the capacity required by the boiler?

Is it equipped with all safety and control devices required by the standards in force?

is the power supply of the boiler 230V - 50Hz?

has the system been lled with water (approximately 0.8/1 bar pressure on the pressure gauge

with the pump stopped)?

Has the condensation drain trap been lled with water as indicated in chapter 3.7?

are any system shut-off gate valves open?

does the gas to be used correspond to the boiler calibration gas?: otherwise, perform the boiler

conversion in order to use the gas available (see section: 4.3”);

this operation must be carried out by technical staff qualied in compliance with the standards in force;

is the gas supply valve open?

failure to comply with the above instruction.

Before commissioning the boiler, check that:

has the system been checked for gas leaks?

is the outside main switch ON?

is the system safety valve efcient and is it connected to the drains?

is the condensation drain trap connected to the drains?

has the system been checked for water leaks?

are the ventilation conditions and minimum distances to perform any maintenance

ensured?

have the GAS, HEATING and DOMESTIC HOT WATER pipes been cleaned thoroughly with

products suitable for each circuit?

has a surveillance and protection system against gas leaks been installed? (Optional)

are the system pipes NOT used as the electrical system earthing?

has the system been sized properly bearing in mind the radiator pressure drops?

thermostatic valves, radiator stop valves

has the operator been trained and has the documentation been supplied?

26

Please tick the operations performed

Switching boiler on and off

NOTE!

For more information

See Technical Info

from site indicated at pag. 2

3.11 - MEASUREMENT OF COMBUSTION EFFICIENCY DURING INSTALLATION

3.11.1- ACTIVATION OF THE CALIBRATION

FUNCTION

ATTENTION!

Function reserved for Authorised

Assistance Centres only.

ENGLISH

3

1 - Inserit psw and select the function

4

4 - Activation

2

2 - Activation

3 - Available choice generator indicated by

es: usually 1 / modulex 1÷8

Installation Instructions

27

5 - Generator active modulation max 100%.

6 - Change the % modulation to minimum

10%, and select the generator

7 - Generator active modulation min.

3.11.2 - POSITIONING THE PROBES

To determine the combustion efciency

one must make the following measurements:

- measurement of the combustion air temperature

taken in the relevant hole 2.

COAXIAL PIPES

A

Air

probe

1

Air

probe

2

Flue gas

probe

SEPARATE PIPES

B

Flue gas

probe

8 - Disable function Chimney sweep

- measurement of the ue gas temperature and

content of CO2 taken in the relevant hole 1.

Take the measurements with the generator in

steady state conditions (see par. 3.11.1).

PIPES Ø 80 TYPE B23

C

1

Air

probe

1

2

2

Flue gas

probe

28

NOTE:

Do not enter immediately the analyzer

probe in the sampling point, to avoid the

saturation analyzer.

It’s important to perform also the

combustion air of combustion analysis,

(Observing that the concentration

of oxygen falls O

tolerance 0.2 - 0.4%).

This is to prevent there being any

recirculation of the fumes.

= 20.8%

2

3.12 - ADJUSTING THE BURNER

Check the levels of CO2 often,

especially with low ow rates. They

refer to the boiler with a closed

combustion chamber.

PRESSURE - FLOW RATES TABLE

OSA S 24

Type of

Gas

Nat. gas (G20) 2,96 - 23,0 3 - 23,4 20 - - - 9,2 (*) 9,2 (*) 0,32 m³/h 2,48 m³/h -

Propane (G31) 2,96 - 23,0 3 - 23,4 37 - - - 10,5(+) 10,5(+) 0,23 kg/h 1,82 kg/h -

(*) 9,0 ± 9,8 Acceptable range for G20 (+) 10,0 ± 11,0 Acceptable range for G31

OSA S 28

Type of

Gas

Gas nat. (G20) 4,3 - 27,3 4,4 - 28,0 20 - - - 9,2 (*) 9,3 (*) 0,47 m³/h 2,96 m³/h -

Propano (G31) 4,3 - 27,3 4,4 - 28,0 37 - - - 10,4(+) 10,5(+) 0,34 kg/h 2,17 kg/h -

(*) 9,0 ± 9,8 Acceptable range for G20 (+) 10,0 ± 11,0 Acceptable range for G31

Effective

Output

[kW]

Effective

Output

[kW]

Heating

Thermal

[kW]

Capacity

Heating

Thermal

[kW]

Capacity

Supply

Press.

[mbar]

Supply

Press.

[mbar]

Fan

speed

[rpm]

min max min max min max

Fan

speed

[rpm]

min max min max min max

Collector

diaphragm

[Ø/n.

holes]

Collector

diaphragm

[Ø/n.

holes]

CO2 levels

[%]

CO2 levels

[%]

Con-

sumption

Con-

sumption

Con-

sumption

Con-

sumption

Start-up

power

IG [%]

Start-up

power

IG [%]

ENGLISH

OSA S 35

Type of

Gas

Gas nat. (G20) 4,3 - 32,2 4,4 - 33,0 20 - - - 9,2 (*) 9,3 (*) 0,47 m³/h 3,49 m³/h -

Propano (G31) 4,3 - 32,2 4,4 - 33,0 37 - - - 10,4(+) 10,5(+) 0,34 kg/h 2,56 kg/h -

(*) 9,0 ± 9,8 Acceptable range for G20 (+) 10,0 ± 11,0 Acceptable range for G31

Effective

Output

[kW]

Heating

Thermal

[kW]

Capacity

Supply

Press.

[mbar]

Fan

speed

[rpm]

min max min max min max

Collector

diaphragm

[Ø/n.

holes]

CO2 levels

[%]

Con-

sumption

Con-

sumption

If the CO2 level detected is out of recommended range, verify the integrity of the electrode.

In case of necessity replace the electrode.

If the problem persists you can use the functions described below.

Start-up

power

IG [%]

Installation Instructions

29

3.12.1 - COMBUSTION ADJUSTMENT FUNCTION ACTIVATION

This function allows a partial adjustment of the

value on the following modulation points:

CO

2

Maximum output 100 %

Start-up output xx %

Minimum output 0 %

After Auto Calibration GAC par. 4.3.1

Perform combustion adjustment calibration

as indicated:

If the CO2 value is not as expected, when

appears box (+/-), you can retouch the value of the

Maximum Power.

If the desired value has been reached, proceed to

the next level by pressing: Ignition

If the CO2 value is not as expected, when

appears box (+/-), you can retouch the value of the

Minimum Power.

If the CO2 value is not as expected, when

appears box (+/-), you can retouch the value of

the Ignition. If the desired value has been reached,

proceed to the next level by pressing: Minimum

The combustion adjustment is nished.

30

3.12.3 - ADAPTATION OF THE POWER TO THE HEATING SYSTEM

ATTENTION!

Function reserved for Authorised

Assistance Centres only.

It is possible to adjust the maximum thermal capacity

in heating mode, by decreasing the burner pressure

value.

E.g.: OSA S 24

to decrease the output of the

boiler to 18 kW, edit parameter

792 on Uy BOX (about 70)

E.g.: OSA S 28

to decrease the output of the

boiler to 20 kW, edit parameter

792 on Uy BOX (about 65)

E.g.: OSA S 35

to decrease the output of the

boiler to 24 kW, edit parameter

792 on Uy BOX (about 68)

.

.

.

The user is NOT authorised to activate the function described below.

Act on parameter 792 (par. 4.2 SE parameters list)

to achieve the value corresponding to the desired

output.

ENGLISH

parameter 792 (HP %)

Installation Instructions

31

4

INSPECTIONS AND MAINTENANCE

Inspections and maintenance performed

professionally and according to a regular

schedule, as well as the use of original

spare parts, are of the utmost importance

for fault-free operation of the boiler and

to guarantee its long life.

Yearly maintenance of the appliance is

mandatory in compliance with Laws in

force.

4.1 - INSPECTION AND MAINTE NANCE INSTRUCTIONS

To assure long-term functioning of your appliance

and to avoid altering its approved status, only original

Unical AG S.p.A. spare parts must be used.

If a component needs to be replaced:

• Disconnect the appliance from the electrical mains

and make sure that it cannot be reconnected

accidentally.

• Close the gas shut-off valve upstream the boiler.

• If needed, and depending on the intervention to

be carried out, close any shut-off valves on the

ow and return line of the heating system, as well

as the cold water inlet valve.

Failure to perform Inspections and Maintenance can entail material and personal

damage.

• Remove the front casing from the appliance.

Once all maintenance operations are complete

resume boiler operation

• Open the heating ow and return pipes, as well

as the cold water inlet valve (if closed previously).

• Vent and, if necessary, restore the heating pressure until reaching a pressure of 0.8/1.0 bar.

• Open the gas shut-off valve.

• Switch the boiler back on.

• Make sure the appliance is gas tight and watertight.

• Remount the front casing of the appliance.

TABLE OF RESISTANCE VALUES, ACCORDING TO THE TEMPERATURE, TO THE HEATING PROBE 11 (SR)

AND TO THE DOMESTIC HOT WATER PROBE 1 (SS) AND ANY HEATING RETURN PROBE 22 (SRR) see par. 4.5.

T°C 0 1 2 3 4 5 6 7 8 9

0 32755 31137 29607 28161 26795 25502 24278 23121 22025 20987

10 20003 19072 18189 17351 16557 15803 15088 14410 13765 13153

20 12571 12019 11493 10994 10519 10067 9636 9227 8837 8466

30 8112 7775 7454 7147 6855 6577 6311 6057 5815 5584

40 5363 5152 4951 4758 4574 4398 4230 4069 3915 3768

50 3627 3491 3362 3238 3119 3006 2897 2792 2692 2596

60 2504 2415 2330 2249 2171 2096 2023 1954 1888 1824

70 1762 1703 1646 1592 1539 1488 1440 1393 1348 1304

80 1263 1222 1183 1146 1110 1075 1042 1010 979 949

90 920 892 865 839 814 790 766 744 722 701

Relation between the temperature (°C) and the nom. resistance (Ohm) of the heating probe SR and of the domestic hot

water probe SS

Example: At 25°C, the nominal resistance is 10067 Ohm At 90°C,the nominal resistance is 920 Ohm

32

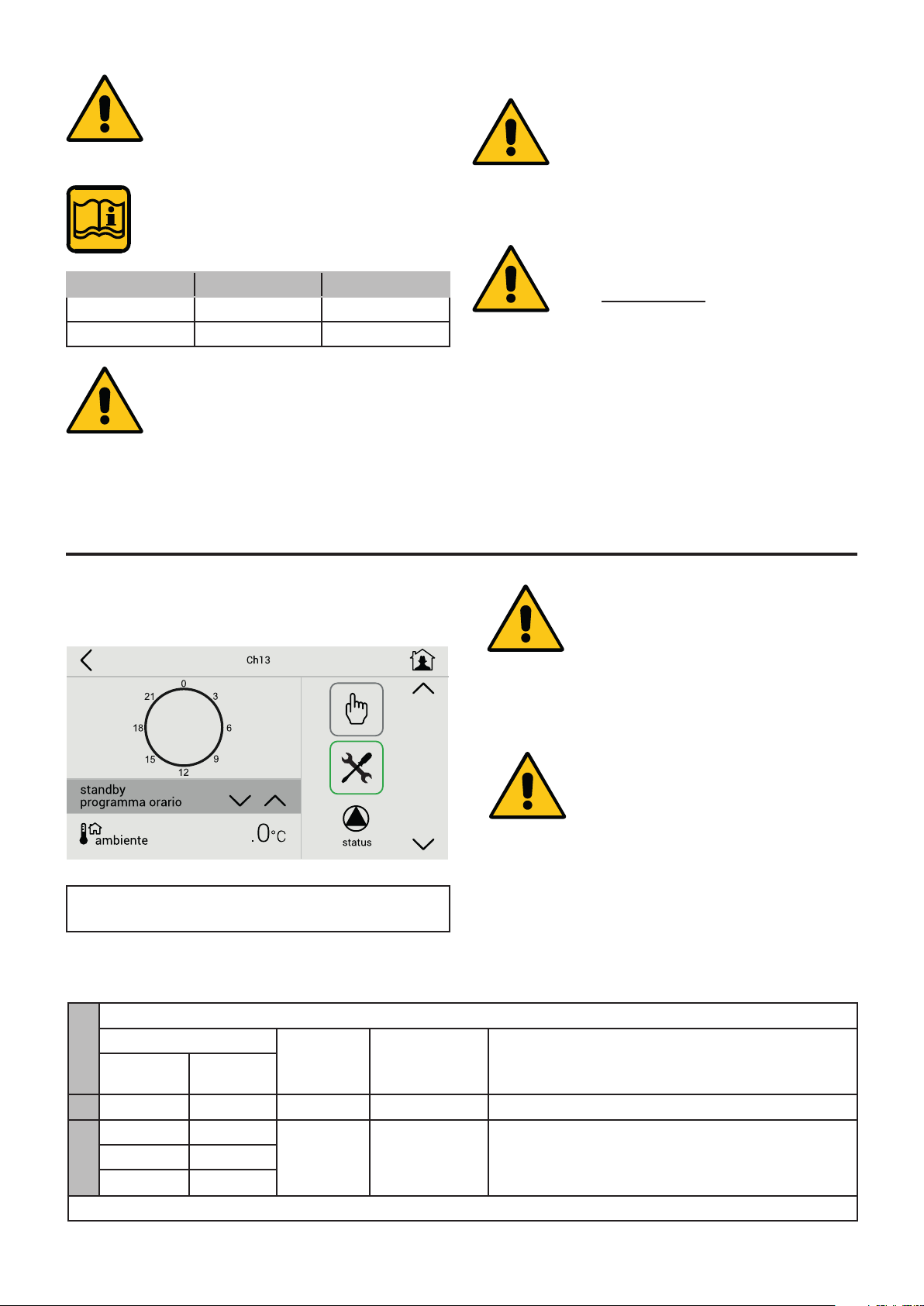

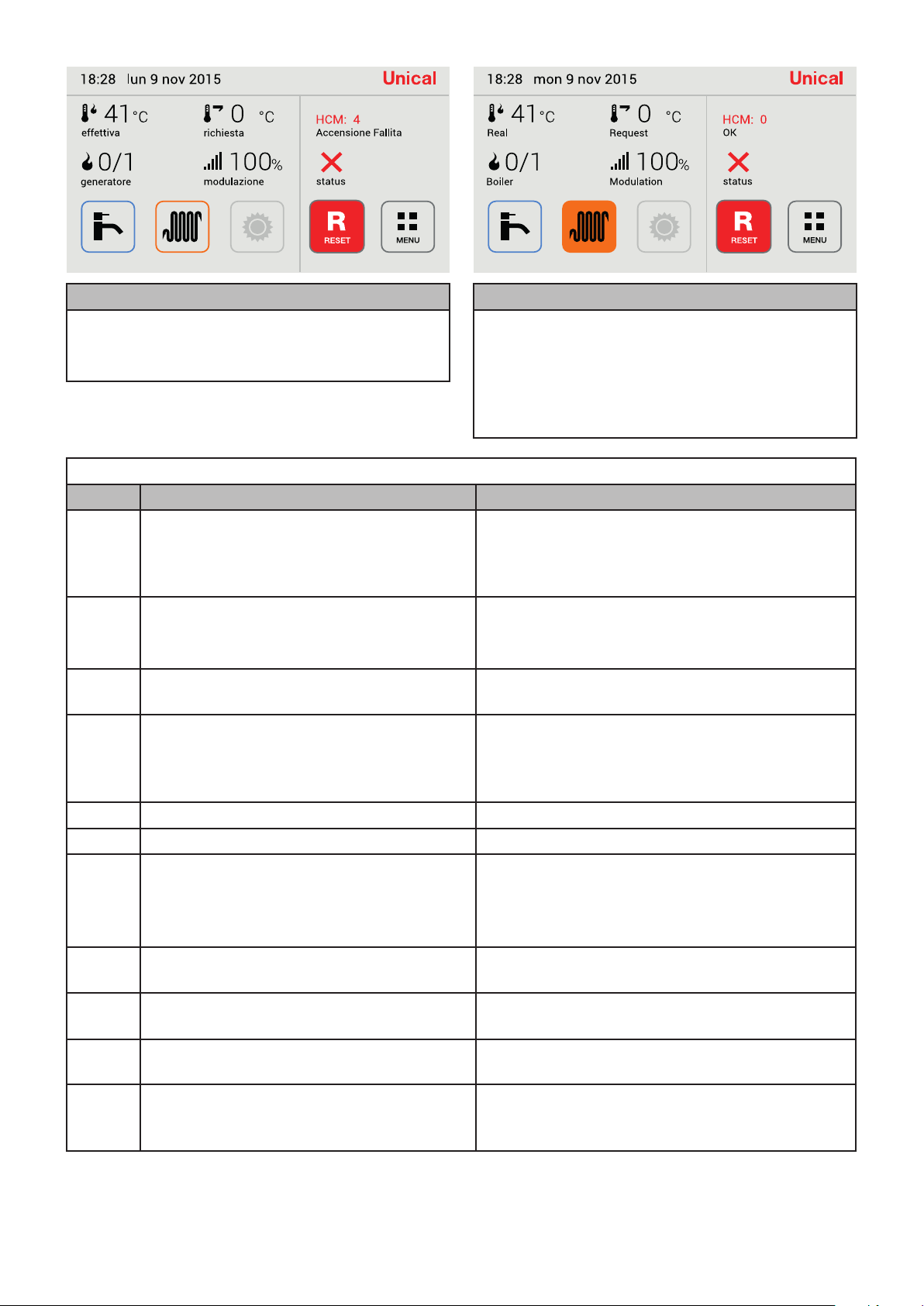

4.1.1- CONTROL PANEL Uy BOX

Uy BOX is hidden inside the boiler, to

access it, rotate as indicated.

General Operating Instructions for UyBOX, are contained in specic manual

provided with the boiler.

This section only lists the steps requi-

red to

Adjustment / maintenance of the boiler:

- Chimney sweep function (Par. 3.11.1)

- Calibration (Par. 3.12.1)

- Edit parameters (Par. 4.2)

- Automatic calibration GAC

Adaptive Calibration Gas (Par. 4.3.1)

ENGLISH

Maintenance instructions

33

ROUTINE YEARLY VERIFICATION OPERATIONS

COMPONENT: VERIFY: CONTROL/INTERVENTION

METHOD:

FL

(domestic hot water

Is the minimum domestic hot water

ow rate 3 l/min.?

The burner must ignite with an

intake above or equal to: 3 l/min.

priority ow switch ( 2 )

VG

(Gas valve) ( 3 )

SR (heating sensor)( 11 )

SS (domestic hot water sensor)

( 1 )

SSR (return sensor) ( 22 )

E ACC/RIV. (ignition/detection

electrode) ( 4 )

TL (anti-overheating

limit thermostat) ( 10 )

DK (safety pressure switch

against water deciency) ( 13 )

Does the valve modulate properly? Open a hot water tap at maxi-

mum ow rate and then at minimum. Make sure that the ame

modulates.

Do the sensors maintain the

original characteristics?

12571 ohm at 20° C / 1762 ohm

at 70° C.

Measurement to be taken with

the wires disconnected (see

table Res/Temp).

Does the discharge of sparks before

putting the boiler in safe conditions last

less than 10 sec.?

Does the TL put the boiler in safety

conditions when overheating?

Detach the electrode ionisation

wire and check the securing

time.

Heat the TL until it intervenes

at 95°C and check that it intervenes at 95°.

Does the pressure switch block the

boiler

if the water pressure is below 0.4 bar?

Without request: close the shutoff valves of the heating circuit,

open the drain valve to make the

water pressure decrease. Before

pressurising again, check the

pressure of the expansion vessel.

Expansion vessel ( 8 ) Does the vessel contain the right

amount

of air?

Check the pressure in expansion

vessel (1 bar when the boiler

is empty). Pressurise the boiler

(open the pump automatic vent

valve). Open the heating circuit

closing valves.

Condensation drain trap (26) Has the trap got deposits on the

Clean the trap with water.

bottom?

Domestic hot water ow rate Filter in cold water inlet ( 2 ) Clean the lter with limescale

remover.

Heat exchanger body ( 24 ) 1) Measure the Thermal Capacity

using a meter and compare the value with that contained in table 3.12.

The data measured indicates if the

exchanger needs cleaning.

It is recommended to use the

products purposely created by

Unical (see system protection

ACCESSORIES sect. in the

domestic price list), being careful to wash the area with most

2) Check that the space between

the rungs of the exchanger are not

clogged

Burner ( 5 ) Check the state of cleanliness of the

burner mesh

rungs rst (lowest part visible

from above) and then the upper

part if necessary.

Remove any deposits using

compressed air, blowing from

the mesh side.

( Num ) = see key Par. 2.2

34

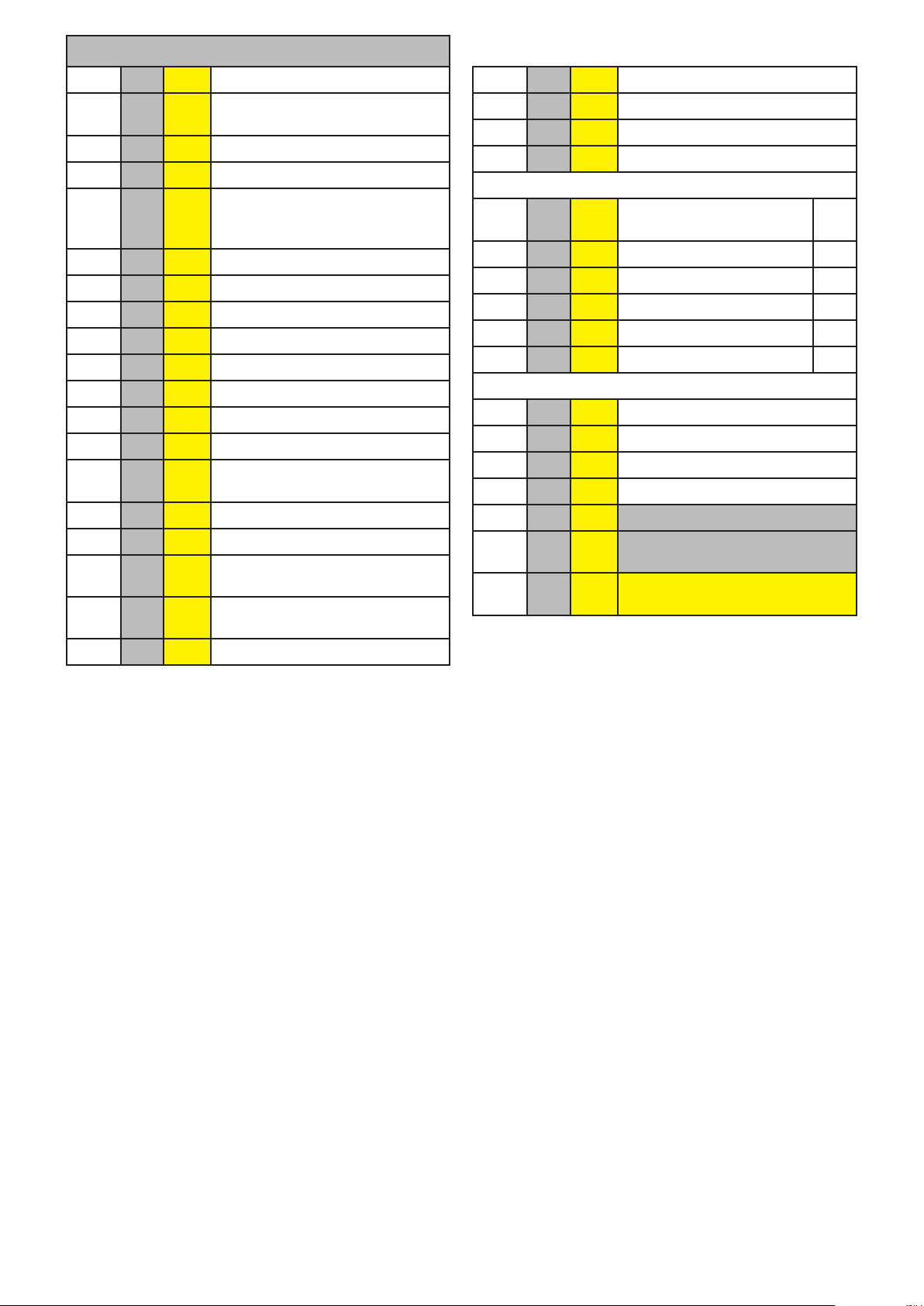

4.2 - PROGRAMMING OF THE OPERATION PARAMETERS

WARNING!

Function reserved exclusively to

authorized service centers.

ENGLISH

At every boiler lighting UFLY scans devices, if new

devices are recognized, such as:

hcm /

bcm

shc

bmm

Heating / Burner Control Manager

Slave Heating Controller

Multifunction module

Burner Modul Manager

They are displayed on the next screen, and is

prompted to save the new conguration.

Icon scanning devices

icon save new conguration

Device detected

Not installed device

previously recognized device, but not detected.

Maintenance instructions

35

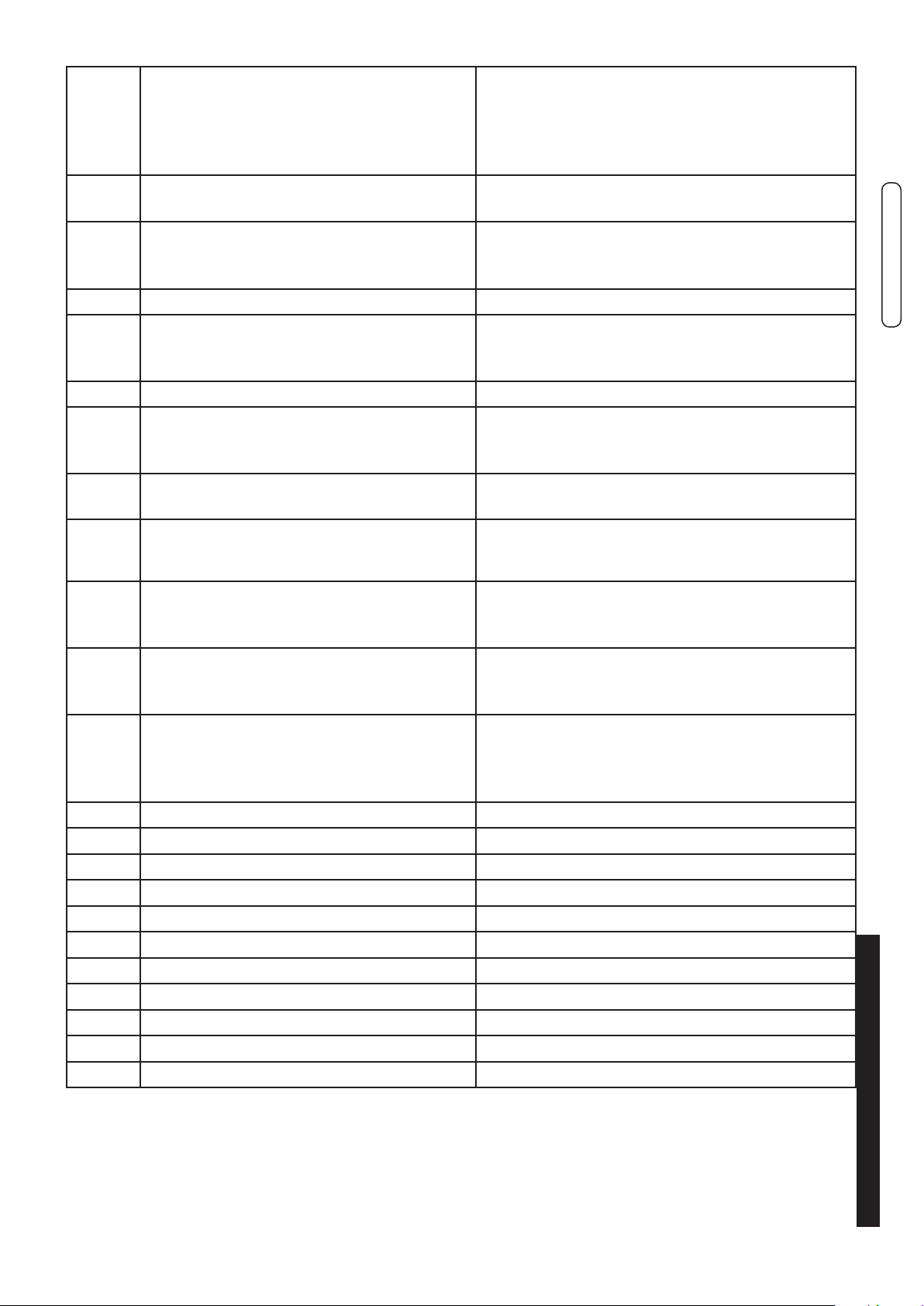

To change the parameters is required password.

Parametri

Code Description

803

322

787

789

807

792

31

36

Enabled Services:

0: CH & DHW disabled

1: CH enabled

2: DHW enabled

3: CH & DHW enabled

Pump: Post-circulation

0: overrun 5 min.

1: continuous

Outdoor minimum

temp °C

Night shift °C

0: T.A.

5÷30: Value night shift

ACS Preheating

CH: Modulation max

CH#1 Minimum Set

point

Set. Min.

3 0 3

0 0 1

10 0 30

0 0/5 30

0 0 1

100 0 100

30 20 45

Max.

39

650

385

48

832

CH#1 Max. Set point

ACS Set point Min.

ACS Set point Max.

CH#1 Set point °C

Access Code (#)

85 50 85

35 25 45

60 50 65

70 20 85

0 0 199

To change the following parameters you must

enable the access code.

778

341

313

312

775

309

771

Burner:

0: G20 - 1 GPL

Pump: Minimum

Control

Pump: Maximum

Control

Pump: temp. diff. °C

Valvola Dev.: Stroke

time sec.

System congurations:

1: W1

2: W2

3: W3

4: W4

Sensore pressione

Acqua

0: assente - 1 presente

0 0 1

-- 0 100

-- 20 100

-- 5 20

-- 0 6

-- 1 4

-- 0 1

896

806

848

483

672

2590

619

Unit:

0 = °C / bar

1 = °Fahrenheit / PSI

Frequency:

0: 50 Hz - 1: 60 Hz

Dis. local setpoint:

0: bidirectional

1: Only by remote

Temp. different. Max

Min modulation

CH/ACS

Burner power

Modulation and ignition

0 0 1

0 0 1

0 0 1

1 0 1

0 0 100

-- 0 9

-- 10 70

346

319

353

354

478

323

324

325

(#) Enable (insert value)

to change parameter

(*) ( x 10 + 750) = rpm x 100

(**) ( x 10 + 5000) = rpm x 100

Fan min speed

fan max speed

Regolation

Proportional

Regolation Integrative

Regolation Derivative

ACS PID:Proportional

ACS PID:Integrative

ACS PID:Derivative

(*) 0 199

(**) 0 199

-- 1 20

-- 1 20

-- 1 20

-- 1 20

-- 1 50

--

1 20

ENGLISH

Historical Error

Clean display Error with CLEAR .

Maintenance instructions

37

4.3 - ADAPTATION

TO THE USE OF OTHER GAS

The boilers are produced for the type of gas specically requested upon ordering.

Gas Conversion

DANGER!

The conversion for the operation of

the boiler with a type of gas other

than that specically required in the

order, must be performed by pro-

fessionally qualied personnel, in

compliance with the standards and

regulations in force.

The manufacturer cannot be held

liable for any damage resulting from

a conversion operation that is incorrect or not performed in compliance

with the laws in force and/or with the

instructions given.

ATTENTION!

After performing the conversion for

the operation of the boiler with a type

of gas (e.g. propane gas) other than

that specically requested when or-

dering, the appliance will only work

with this new type of gas.

ATTENTION!

Indications for propane gas-fired

appliances

Make sure that the gas tank has been

deaerated before installing the appli-

ance.

For state-of-the-art deaeration of the

tank, contact the LPG supplier or a

person qualied in compliance with

law.

If the tank has not been profession-

ally deaerated, ignition problems

could arise.

In that case, contact the supplier of

the LPG tank.

NOTE!

For more information

See Technical Info

from site indicated at pag. 2

In order to change the gas one must change

the Factory parameter:

PARAMETER par 4.2

CODE GAS NAT. PROPANE

778 0 1

Once the 778 parameter has been

edited one must perform the GAC

automatic calibration (Gas Adaptive

Calibration) Chapter 4.3.1

- when the conversion is complete, ll in the

information required on the label supplied in

the documentation envelope and apply it next

to the technical data label of the boiler.

EXAMPLE OF COMPILATION

38

4.3.1 - GAC AUTOMATIC CALIBRATION

One can perform the GAC in domestic hot water

mode as well.

Make sure that there are no heating requests present and that all the valves of the heating system

are open.

If during this stage one wishes to disperse the heat

on the domestic hot water circuit, open at least 2 hot

water taps (ONLY AFTER HAVING ACTIVATED THE

GAC FUNCTION).

WARNING!

Function reserved exclusively to

authorized service centers.

ENGLISH

Start Calibration phase - Wait:

Step 1 = Calibration Maximum Power

Step 2 = Calibration Power Start

Step 3 = Calibration Minimum Power.

Maintenance instructions

39

Step 1: CALIBRATION MAX POWER

Step 3: CALIBRATION MIN POWER

Step 2: CALIBRATION POWER START

The automatic calibration is completed.

To perform the calibration adjustment of combustion, see par. 3.12.1.

40

(This page is intentionally left blank)

ENGLISH

Maintenance instructions

41

KEY

BOARDBMM

A1.....A9 Services connectors

ALIM.P.sup Supply.PumpExtra

CMP Control modulating Pump

E.ACC./RIL Ignition/detection electrode

EVCI (*) Caricamento Impianto (Only OSA S)

FLS Domestichotwaterrequestowswitch

MEMORY

Memory

CARD

42

4.4 - WIRING DIAGRAM

Practical connection board

ENGLISH

MVD Diverter valve motor

MDV (**) Controlpredispositiondiverter(externalwater

heater)onlyHeatingboilers

PM Circolatore Modulante

SPI Pressure Sensor System

SR Flowheatingsensor

SRR Returnheatingsensor

SS

TL Limitthermostat

TLC Fluegascollectorlimitthermostat

Domestichotwaterprobe(Pred.forRmodels)

VG Gas valve

VM (A) Soupply modulating fan

VM(R) Rilev./Reg.ModulatingFun

SchedaGATEWAY

Y1....Y3 Services connectors

230V-50Hz Boiler Supply

EXT DEVICE Externaldevices:SHC(eBUS+/eBUS-)

SA TerminalRoomsensor

SE Terminal Outer sensor

OT/TA TerminalTAon-off/OT disabled)

UFLY

connection

U-yBOXsupply

Maintenance instructions

43

4.5 - ERROR CODES

Failure that causes the stop of the boiler:

- The error code is displayed, the boiler is in lock.

After resolving the fault press Reset to restart the

boiler.

ERROR CODES (FAULT) ( Num ) = see key Par. 2.2

CODE

01

04

06

08

09

10

11

12

13

14

15

DESCRIPTION SOLUTIONS

SAFETY THERMOSTAT

Intervention of the safety thermostat (10)

BLOCK

No gas or failed burner ignition

High Temperature

Boiler temperature too high

Water Decency

Insufcient water pressure and consequent

intervention of the minimum water pressure

- pressure switch ( 13 ).

Outer Sensor Check the wiring, if needed replace outer sensor

Internal failure

Parasite Flame

Flame detected upon ignition

Heating Sensor (11)

Heating sensor fault

Domestic Hot Water Sensor

Domestic hot water sensor fault (1)

Inlet temperature Sensor

(SRR)

Water circulation insufcent

Primary circuit water circulation insufcient

(∆t > 35° C)

Failure that could NOT cause stop of the boiler:

Error code is displayed, the boiler is in CH

-

demand, Icon Reset (note that was detected

a fault even if the fault was temporary.

Is therefore necessary always push reset to

clear the display’ ‘‘error’’

Press Reset and/or check that the thermostat or

its connections are not interrupted.

Check the gas supply or that the ignition/detection

electrode is working properly (4).

Check pump operation and if needed

clean the exchanger (24)

Fill the heating circuit as described in chap. 3.8 and

wait for the values to return within default limits.

If needed, check the electrical connections and

replace the minimum water pressure switch.

Check the wiring of the Ign/Det. electrode and remove any oxidation. Check for humidity between

drain wire and ceramic, if necessary, replace the

electrode, press the unblock key, if the anomaly

persists, replace the electrode (4).

Check the efciency of the sensor (see table Res/

Temp) (Par.4) or its connections.

Check the efciency of the sensor (see table Res/

Temp) (Par.4) or its connections..

Check the efciency of the sensor / and replace it

Check pump operation (12) and speed - remove

any heating system obstructions - clean the scaled

domestic hot water exchanger

44

16

Exchanger Freezing ( 24 )

Exchanger freezing is detected If the heating

sensor detects a temperature below 2° C,

burner ignition is inhibited until the sensor

detects a temperature above 5°C

20 Parasite Flame

Flame detected after swtich-off

24

Speed out of control

Check fan operation (18) and the con-

nections

25

26

28

30

31

32

38

44

45

47

49

50

56

57

58

60

62

66

74

75

Exhaust smoke overheating

Speed out of control

Alteration of the fan speed; the speed is

above that requested

Scambiatore Ostruito

Service Parameter

Service parameters altered due to possible

electromagnetic interferences.

System conguration invalid or

corrupted

Low line voltage Correction: if the line voltage is <190 Vac: the

Factory Parameters

Alteration of the factory parameters due to

possible electromagnetic interferences.

Water sensor pressure

detected if the pressure Transducer is

present

Water Overheater

detected if the H

present with pressure > 2.5 bar; it is reset

automatically when H

Communication error

HCM, SHC: host controller missing

Room1: temperature sensor

Host controller missing

Burners NOT detected

Global ow temperature sensor

Date and Time not valid

Actuators SGV

Missing calibration

Temp. sensors swap

Temperature slope exceeds the limit

O pressure Transducer is

2

O pressure < 2 bar

2

Disconnect the from the power supply, close the

gas valve, defrost the exchanger carefully.

Check the wiring and for any leaks from the

gas valve (3), if needed replace the gas valve.

Check fan operation (18) and the connections

ENGLISH

Check fan operation (18) and the connections

Reset and via Uy restore the altered parameters

line voltage is really below the minimum limit,

otherwise the line monitor error: replace BMM

Press RESET; if the anomaly persists, replace

the board.

Wait for the values to return to default limits / Replace the Transducer

Wait for the values to return to default limits /

Replace the Transducer

Maintenance instructions

45

94

95

99

100

101

102

103

Gas valve wiring

Frequent loss of ame

Internal error

General Lockout not listed

Ignition failure

Short circuit of the iono electrode

Gas valve open delay

46

4.5.1 - FILL THE SYSTEM

By pressing reset icon, start the automatic lling,

up to a pressure of 1.2 bar (60 sec. max).

If the system does not reach 1.2 bar pressure within

60 seconds, activate the ll manually by pressing

LOAD icon.

47

4.6 - IMPORTANT NOTES

REPLACING COMPONENTS

Before replacing components one must follow the

notes of chap. 4 "Inspections and maintenance".

To replace the components:

- GAS VALVE

- FAN

- BURNER,

- IGNITION/DETECTION ELECTRODE,

- MODULATION BOARD (in the event the

memory board CANNOT be reused) (*),

GAC calibration is required

MODULATION BOARD

A universal

board

memory

board (*)

B

(*) In the event the memory board can be reused, there is no need to reprogram parameters, settings and automatic calibration.

The memory board is

programmed by default for METHANE

gas operation.

In the event of LPG

operation the 778 parameter must be edited

(Factory parameters),

see (Chap. 4.2).

A

B

Act carefully, pay attention to the insertion direction of the memory board.

48

4.6.1 - SERVICE PANEL

The boiler can be programmed also by

means of the service inner panel.

Remove the screws indicated to extract the panel and turn.

Indications related to programming

with the emergency panel, can be

found at the address indicated on

page 2, or on the user / installation

manual and maintenance of KONE

model boiler.

49

www.unical.eu

ed. 06/15

st.

00336315 - 1

46033 casteldario - mantova - italia - tel. +39 0376 57001 - fax +39 0376 660556

AG S.p.A.

info@unical-ag.com - export@unical-ag.com - www.unical.eu

Also reserves the right to bring those changes that it will hold necessary to it own products or prots, without jeopardizing its essential characteristics.

Unical declines every responsibility for the possible inaccuracies if owed to errors of transcript or press.

Loading...

Loading...